Siemens SINAMICS V10 Operating Instructions Manual

SINAMICS

SINAMICS V10

Operating Instructions

SW version: V 01.63

08/2011

A5E03453178 (this is not an order number)

Introduction

1

Safety notes

2

Description

3

Identification

4

Installation

5

Commissioning

6

Parameter list

7

Troubleshooting

8

Technical data

9

Replacing the fans

A

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the relevant information is not taken into account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be

used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property

damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions. Qualified

personnel are those who, based on their training and experience, are capable of identifying risks and avoiding

potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended or

approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described.

Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in

this publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Siemens AG

Industry Sector

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E03453178 (this is not an order number)

Ⓟ 08/2011

Copyright © Siemens AG 2010.

Technical data subject to change

Table of contents

1 Introduction...................................................................................................................................................5

2 Safety notes..................................................................................................................................................7

3 Description..................................................................................................................................................13

4 Identification...............................................................................................................................................15

5 Installation..................................................................................................................................................21

5.1 Mechanical installation................................................................................................................21

5.1.1 Mounting orientation and clearance............................................................................................21

5.1.2 Wall mounting..............................................................................................................................23

5.1.3 Push-through mounting...............................................................................................................25

5.1.4 Mounting the operator panel to cabinet door...............................................................................31

5.2 Electrical installation....................................................................................................................33

5.2.1 Interface definition.......................................................................................................................33

5.2.2 Connecting power supply to the motor........................................................................................37

6 Commissioning ..........................................................................................................................................39

6.1 Typical connection modes...........................................................................................................39

6.2 Application macros......................................................................................................................56

6.3 Operator panel overview.............................................................................................................58

6.3.1 Function overview of operator panel...........................................................................................59

6.3.2 Various data displays..................................................................................................................60

6.3.3 Displays during inverter initialization stage..................................................................................62

6.4 Quick commissioning...................................................................................................................63

6.5 Inverter status display..................................................................................................................65

6.6 Overview of various operation modes.........................................................................................66

6.6.1 Operation mode ① - Quick motor data setting............................................................................66

6.6.2 Operation mode ② - Connection macro selection.......................................................................67

6.6.3 Operation mode ③ - Application macro selection.......................................................................69

6.6.4 Operation mode ④ - Common application macro specific parameter setting.............................70

6.6.5 Operation mode ⑤ - Access all the parameters..........................................................................71

6.7 Factory reset................................................................................................................................72

6.8 Cloning parameters with the operator panel................................................................................73

7 Parameter list.............................................................................................................................................75

8 Troubleshooting........................................................................................................................................107

9 Technical data..........................................................................................................................................115

A Replacing the fans....................................................................................................................................119

Index.........................................................................................................................................................123

SINAMICS V10

Operating Instructions, 08/2011, A5E03453178 (this is not an order number) 3

Introduction

1

Purpose of this manual

This manual provides customers with information about the proper installation, connecting,

commissioning, operation and maintenance of the SINAMICS V10 inverter.

Internet addresses for SINAMICS V10

You can obtain continually updated information about the product at

SIEMENS Website for the SINAMICS V10 Inverters (http://www.ad.siemens.com.cn/products/

sd)

You can download the SINAMICS V10 user documentation at

SIEMENS Website for the SINAMICS V10 User Documentation (http://

www.ad.siemens.com.cn/download)

Technical support

In case of any questions concerning the product, contact your local distributor.

SINAMICS V10

Operating Instructions, 08/2011, A5E03453178 (this is not an order number) 5

Safety notes

2

This chapter lists safety instructions which apply when handling the SINAMICS V10 inverter.

These instructions are classified as General, Identification, Transport & Storage, Installing,

Connecting, Commissioning, Troubleshooting and Disposal. Please read the information

carefully, since it is provided for your personal safety and will also help prolong the service life

of your inverter and the equipment connected to it.

General

WARNING

This equipment contains dangerous voltage and controls potentially dangerous rotating

mechanical parts. Failure to work on the equipment/system in accordance with the

instructions/procedures contained in this manual can result in death, severe personal injury

or considerable damage to property.

Only appropriately qualified personnel should work on the inverter system, and only after

becoming acquainted with all the safety instructions, installation, connecting, operation and

maintenance procedures contained in this manual.

Any unauthorized modification of the equipment is NOT allowed.

To fulfill the requirements of CE and Low Voltage directives, the equipment must be mounted

in a metal cabinet and accessories like chokes should be used.

The equipment will automatically restart after a mains blackout, brownout or fault if automatic

restart (configured with parameter P1210) is activated, thus please check whether there is

any necessity to set parameter P1200 (flying restart) again.

When setting a connection mode code or resetting (via P0970) the inverter to factory default

parameter values, it is NOT allowed to operate the inverter via external signal source.

If the equipment has been stored for over 1 year before installation, you must recharge

capacitors in the inverter first. For specific recharging requirements, consult your local

distributor or local dealer.

SINAMICS V10

Operating Instructions, 08/2011, A5E03453178 (this is not an order number) 7

CAUTION

Children and the general public must be prevented from accessing or approaching the

equipment!

This equipment may only be used for the purpose specified by the manufacturer. Any

unauthorized modification and the use of accessories that are not sold or recommended by

the manufacturer of the equipment can cause fire, electric shock or injury.

The operator panel of the SINAMICS V10 inverter does NOT support plug and play. When

you are in an attempt to switch between LOC and REM control modes via an external signal

source, make sure that the communication between the operator panel and the inverter body

unit is in good condition.

NOTICE

Keep this manual as a handy reminder and make them available to all users, if necessary.

Identification

WARNING

Make sure that deliverables received are free from damage and in conformity with your

purchase order. Should any damage or inconsistence with the purchase order be found,

contact your local distributor or local dealer.

It's not permissible to put the equipment into use if it's damaged or short delivered.

Transport & Storage

CAUTION

Transport and storage must meet the specified environmental conditions (see topic Technical

data (Page 115) for details).

Installing

WARNING

Risk of fire or electric shock. Do not install the equipment in an area subject to inflammables

or combustibles, water or corrosion hazards.

Safety notes

SINAMICS V10

8 Operating Instructions, 08/2011, A5E03453178 (this is not an order number)

CAUTION

Do not install the equipment in an area where it is likely to be exposed to constant vibrations,

physical shocks or interference from electromagnetic field.

Risk of fire. Make sure that no foreign body (e.g., chips of wood or metal, dust, paper, etc.)

falls into the inverter or lie on the heatsink of the inverter.

Keep sufficient clearance between inverters, one inverter and another device/the inner wall

of the cabinet. (See topic "Mounting orientation and clearance (Page 21)" for clearance

requirements).

The inverter MUST NOT be mounted horizontally.

Connecting

WARNING

The inverter must have been disconnected from the power supply for at least five minutes

before you perform any wiring to the inverter.

Make sure that all connections are correct and reliable. Only permanently-wired input power

connections are allowed and the inverter must be well grounded (IEC 536 Class 1, NEC and

other applicable standards).

According to IEC 61800-5-1, a PDS (Power Drive System) with leakage currents over 3.5

mA requires a secure ground connection (e.g., at least 10 mm2 Cu or multiple connection) or

an automatic shutdown in case of a ground connection fault.

To avoid input power cable wires loosening or dropping from the mains input terminal

connector, use a proper clamp to secure the input power connections.

If you have to install a Residual Current-operated protective Device (RCD), it must be an

RCD type B.

Use of the protection from direct contact by means of SELV/PELV is permitted only in areas

with equipotential bonding and in dry interior spaces. If these conditions are not present, other

protective measures against electric shock must be taken, e.g., protection through protective

impedances or limited voltage or use of protection class I and II.

Only PELV or SELV voltages may be connected at terminals with either PELV or SELV

voltages (refer to EN 60204-1, Section 6.4).

CAUTION

The rated mains input voltage to the inverter must be 3 AC 400 V.

Never connect the mains input cable to the motor terminals U, V, W or connect the motor

cable to the mains input terminals L1, L2, L3.

Route signal cables and power cables separately in different cable conduits. The signal

cables shall be at least 10 cm away from the power cables.

Keep connecting cables away from rotating mechanical parts.

Safety notes

SINAMICS V10

Operating Instructions, 08/2011, A5E03453178 (this is not an order number) 9

Commissioning

WARNING

Before switching the power on, make sure that the inverter system has been reliably installed

and connected, and the mains voltage is within the allowable range.

Do not touch the motor shaft when the motor is running. Failure to comply may cause personal

injury.

Risk of electric sock. DC link capacitors remain charged for five minutes after power-off. It is

not allowed to open the equipment until five minutes has elapsed since power-off.

The following inverter terminals can carry dangerous voltages even if the inverter is

inoperative:

- Mains input terminals L1, L2, L3

- Motor terminals U, V, W.

This equipment must not be used as an "emergency stop mechanism" (

see EN 60204,

9.2.5.4

).

It's not allowed to open the equipment or connect/disconnect the equipment during its

operation.

When inverter is confirming a selected connection macro, cloning parameters or reset via

P0970, it's NOT allowed to attempt to control the inverter operation via an external digital

input.

CAUTION

Motor commissioning under loaded conditions may only be performed after motor

commissioning under no-load (dry-run) conditions.

Do not touch the inverter heatsink, motor or other high-temperature parts during equipment

operation or within a certain period since power disconnection. Failure to comply may cause

personal injury.

Do not run or stop the inverter by switching on/off the mains supply frequently. This may

cause damage to the equipment/system.

Troubleshooting

WARNING

Even if damage is only suspected (for example, water), don't operate the equipment but

contact your distributor.

Do not touch terminals or disassemble cables until the inverter system has been disconnected

for at least five minutes, because the inverter may remain charged during this period.

Troubleshooting may only be performed by personnel furnished with necessary expertise, or

there is a risk of electric shock or damage to the equipment.

Safety notes

SINAMICS V10

10 Operating Instructions, 08/2011, A5E03453178 (this is not an order number)

CAUTION

Do not approach the machine after an input power failure! Certain parameter settings of the

inverter can cause the machine to restart automatically.

Disposal

WARNING

Disposal of the equipment must be made in accordance with regulations of the competent

environmental protection administration on the disposal of electronic wastes.

Safety notes

SINAMICS V10

Operating Instructions, 08/2011, A5E03453178 (this is not an order number) 11

Description

3

Overview

The SINAMICS V10 inverters are designed for controlling the speed of three phrase AC

asynchronous squirrel cage motors. The available inverter versions range from the 0.55 kW

three phase output power to the 22 kW three phase output power.

The inverters are microprocessor-controlled and use state-of-the-art IGBT technology. A

special pulse-width modulation method with selectable pulse frequency permits quiet motor

operation. Comprehensive protective functions provide excellent inverter and motor protection.

SINAMICS V10 with its default factory settings is ideal for a large range of simple motor control

applications. By configuring relevant parameters, you can use the inverter for some advanced

motor control operations. In addition, the SINAMICS V10 inverters are also suitable for use in

"stand-alone" applications or being integrated into "Automation Systems" via input/output

signals.

SINAMICS V10

Operating Instructions, 08/2011, A5E03453178 (this is not an order number) 13

Features

● Main characteristics

– Easy installation and commissioning, simple cable connection

– Can be operated on TNC, TNS, TT or IT mains systems

– A comprehensive range of parameters enabling configuration for a wide range of simple

applications

– Compact design for fast installation

– High switching frequencies for low-noise motor operation

● Performance characteristics

– Fast Current Limitation (FCL) for normal operation under sudden load changes

– Built-in DC braking mode

– Compound braking to improve braking performance

– V/f control with linear characteristic

– V/f control with Flux Current Control (FCC)

– V/f control with parabolic characteristic

– Acceleration/deceleration times with programmable smoothing

– Integrated PI controller for simple process control

● Protection characteristics

– Short-circuit protection

– Over-current protection

– Inverter and motor over-temperature protection

– Over-voltage and under-voltage protection

– Load-side ground fault protection

– Motor blocking protection

– Parameter interlock

Description

SINAMICS V10

14 Operating Instructions, 08/2011, A5E03453178 (this is not an order number)

Identification

4

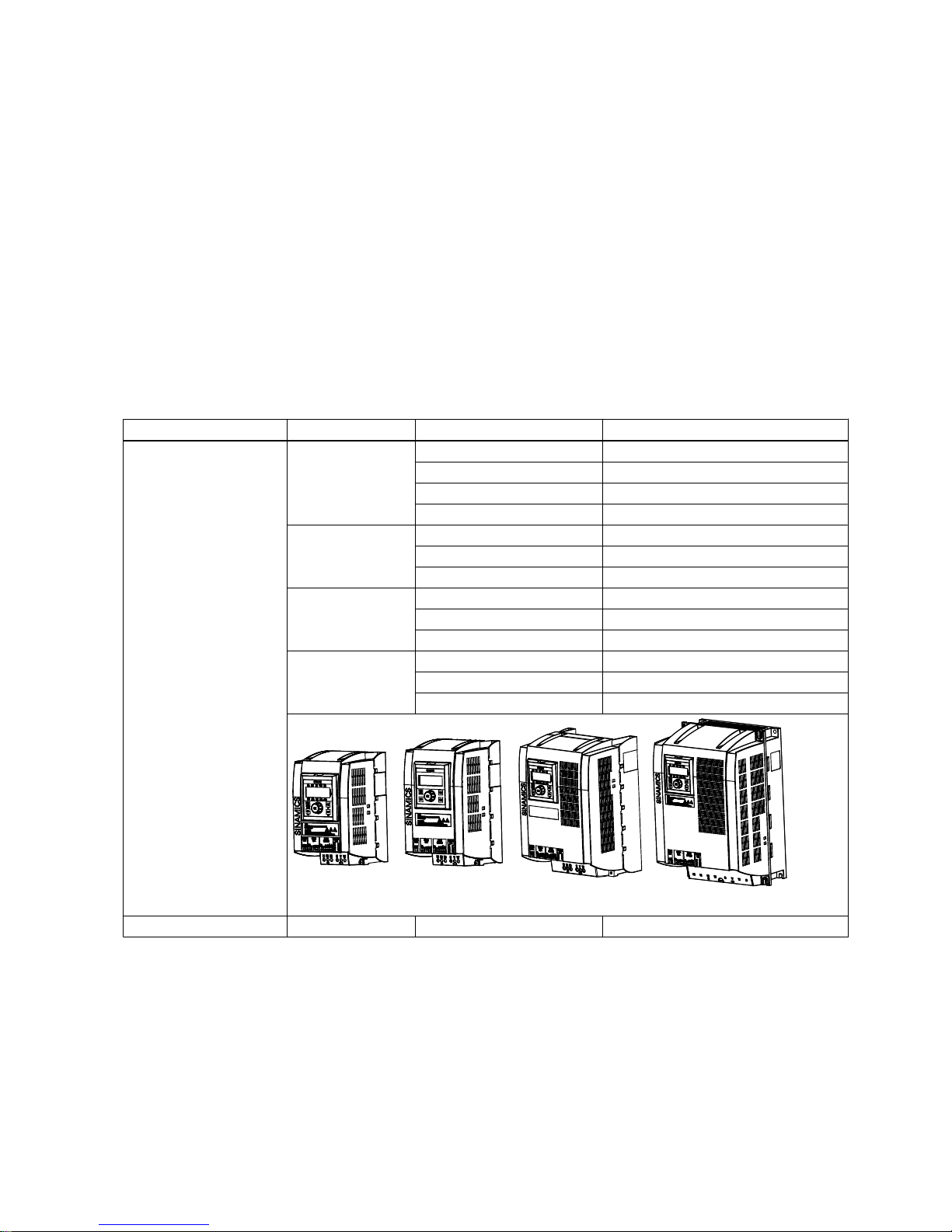

Scope of delivery

When opening the delivered SINAMICS V10 inverter package, check that the following

components are included:

Table 4-1 Scope of delivery (SINAMICS V10 Inverter + Quick Start Guide + Certificate)

Component Variant Rated output power MLFB (order number)

SINAMICS V10 Inverter

Frame Size A 0.55 kW 6SL3217-0CE15-5UA1

0.75 kW 6SL3217-0CE17-5UA1

1.1 kW 6SL3217-0CE21-1UA1

1.5 kW 6SL3217-0CE21-5UA1

Frame Size B 2.2 kW 6SL3217-0CE22-2UA1

3.0 kW 6SL3217-0CE23-0UA1

4.0 kW 6SL3217-0CE24-0UA1

Frame Size C 5.5 kW 6SL3217-0CE25-5UA1

7.5 kW 6SL3217-0CE27-5UA1

11 kW 6SL3217-0CE31-1UA1

Frame Size D 15 kW 6SL3217-0CE31-5UA1

18.5 kW 6SL3217-0CE31-8UA1

22 kW 6SL3217-0CE32-2UA1

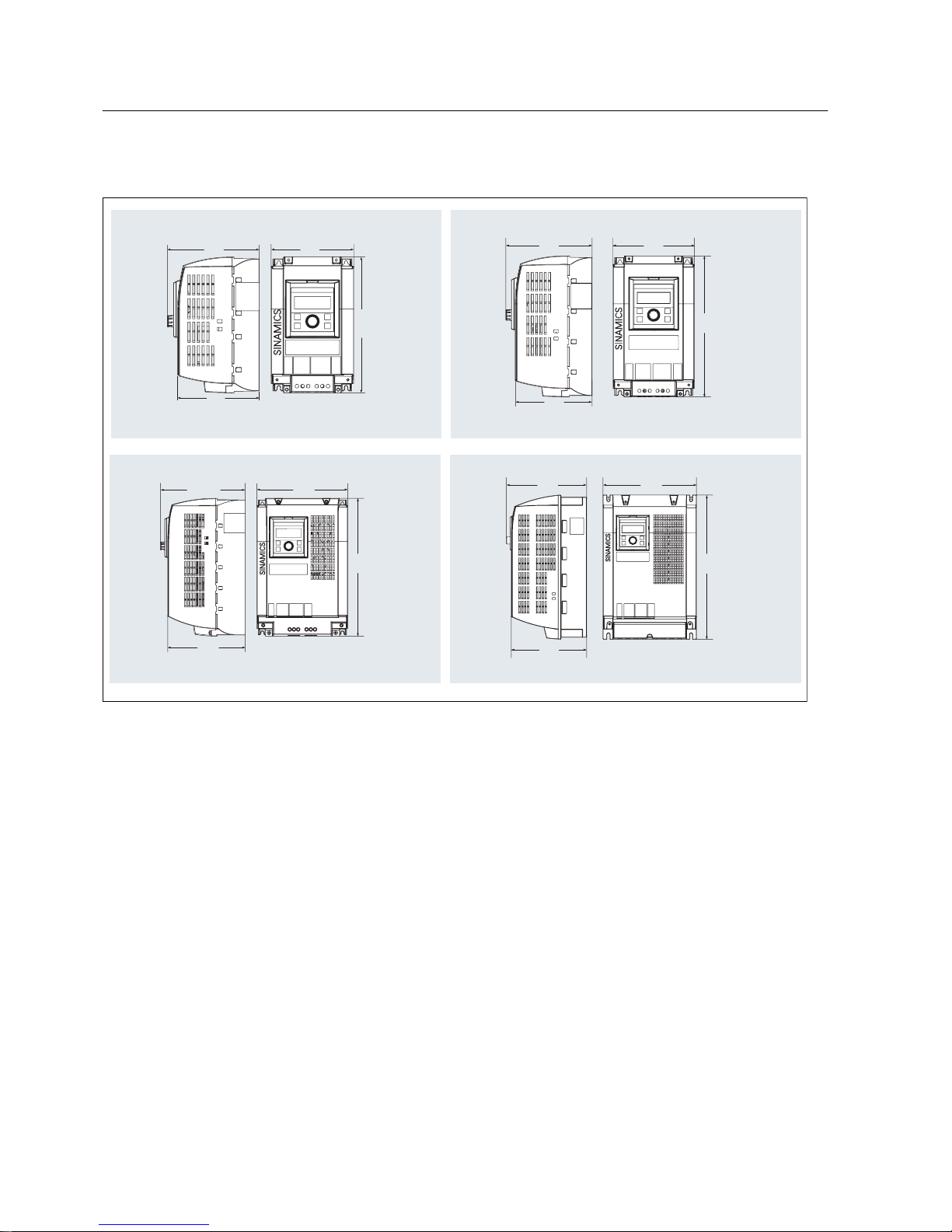

)UDPH6L]H$)UDPH6L]H&)UDPH6L]H')UDPH6L]H%

Quick Start Guide

1)

English version - -

1)

The documentation identification number of the Quick Start Guide is A5E02583918 (this is not an order number).

SINAMICS V10

Operating Instructions, 08/2011, A5E03453178 (this is not an order number) 15

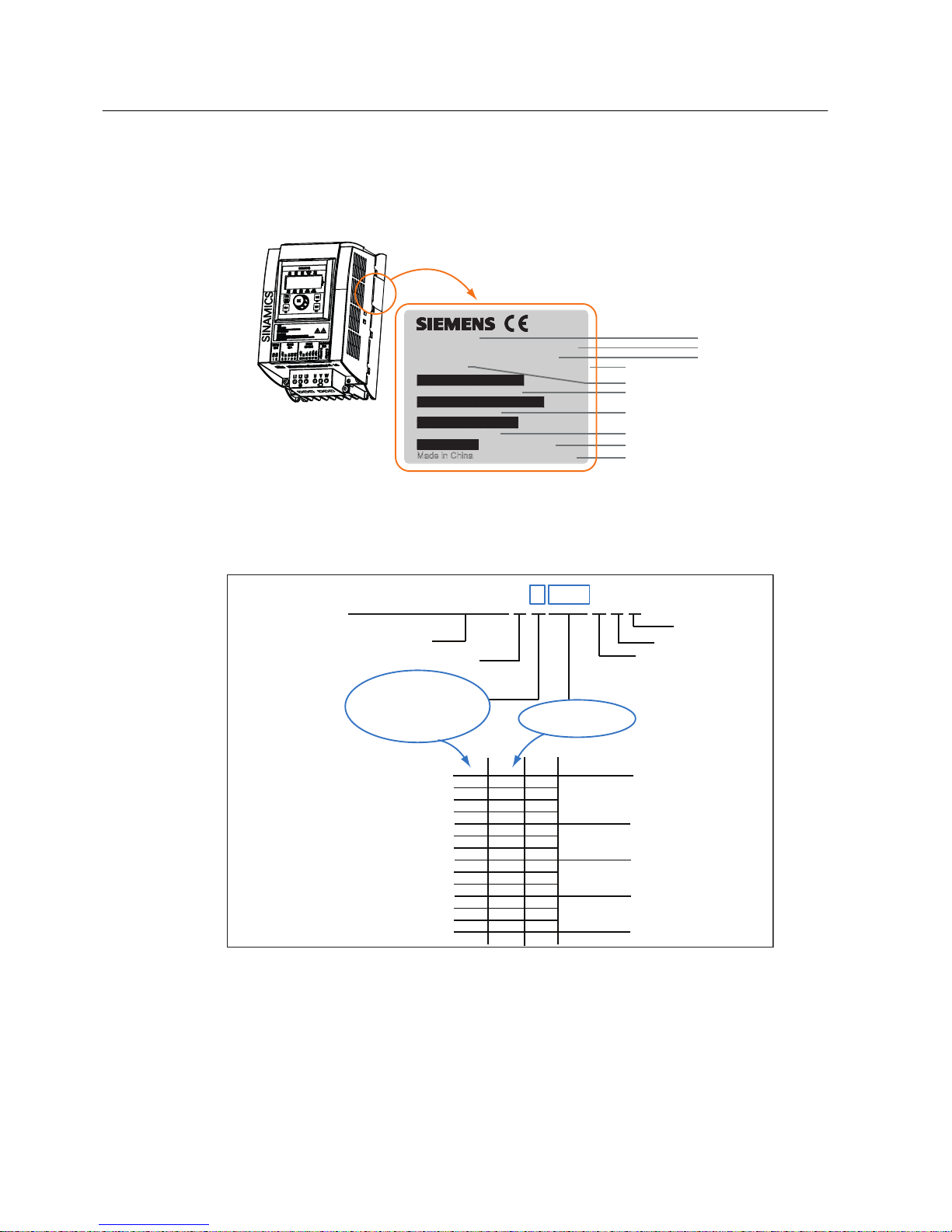

Inverter rating plate

Check the information shown on the inverter rating plate against your purchase order. Viewing

from the inverter front, the rating plating is located on the right side of the inverter housing.

Inverter rating plate

SINAMICS V10 Frame Size A

Product name

Product serial number

Mains input

Hardware version

Firmware version

Mains output

Protection class

Rated motor output power

Siemens part number

MLFB (order number)

6,1$0,&69

9(56,21

):9

$

36/&(8$

6=9:2<97

61&$(

0RWRUN:

,QSXW$&9$+=

2XWSXW$&9$+=

0DGHLQ&KLQD

3URWHFWLRQ,3VHHPDQXDO

Figure 4-1 Inverter rating plate (example)

Inverter MLFB (order number) explanation

SINAMICS V10 AC inverter, frame size

Rated mains input voltage: 3 AC 380 V

Unfiltered

Rated output power

Standard

Hardware version

Multiplier for output power:

1: x 0.1

2: x 1

3: x 10

6 S L 3 2 1 7 - 0 C E 2 1 - 5 U A 1

Inverter variant

kW

Frame size A

Frame size B

Frame size C

Frame size D

1

1

2

2

5 - 5

7- 5

2 - 2

3 - 0

4 - 0

1 - 1

1 - 5

1 - 8

2 - 2

5 - 5

7 - 5

1 - 1

1 - 5

2

2

2

3

3

3

3

2

2

0.55

0.75

1.1

1.5

2.2

3.0

4.0

11

15

18

22

5.5

7.5

Figure 4-2 Inverter MLFB (Order Number) explanation

Identification

SINAMICS V10

16 Operating Instructions, 08/2011, A5E03453178 (this is not an order number)

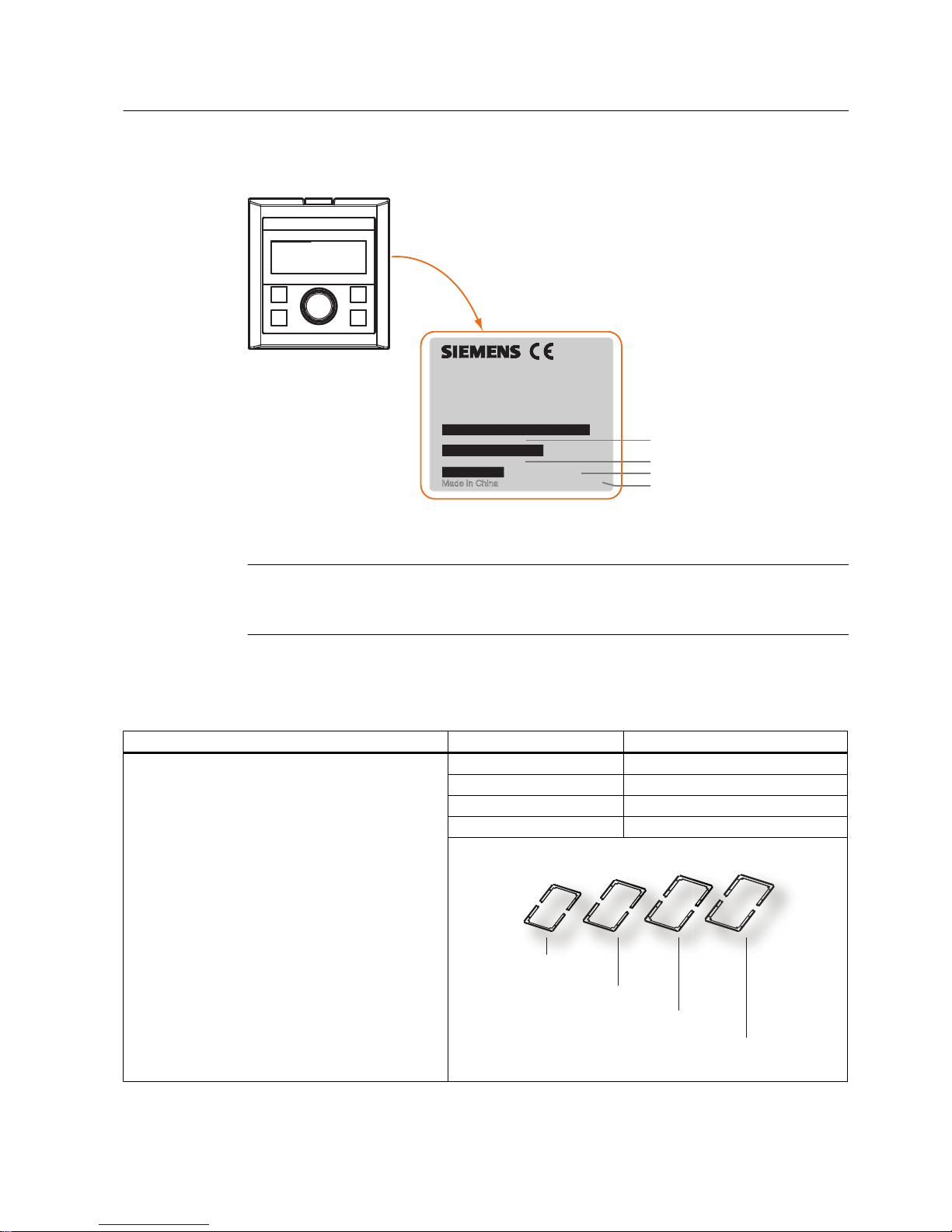

Rating plate on the rear of the operator panel

Rating plate on the rear of the operator panel

Product serial number

Hardware version

Firmware version

Siemens part number

6,1$0,&692SHUDWRU3DQHO

9(56,21$

6=9:2<9&

61&$(

0DGHLQ&KLQD

):9

Figure 4-3 The operator panel rating plate

Note

Beside operator panel rating plate, there is a small label. This label indicates the firmware

version of the operator panel.

Options

Option Variant MLFB (order number)

Push-through mounting components

The push-through mounting components include:

● Push-through mounting kit (1 set)

2)

● Production Information Sheet (1 piece)

● Plastic rivets (2 pieces)

● Metal back cover (1 piece)

3)

● Mounting screws:

– Frame Size A: 4 x M5 screws

– Frame Size B: 4 x M5 screws

– Frame Size C: 8 x M5 screws

– Frame Size D: 8 x M5 screws + 4 x M8 screws

● Mounting nuts

– Frame Size A: 4 x M5 nuts

– Frame Size B: 4 x M5 nuts

– Frame Size C: 8 x M5 nuts

– Frame Size D: 8 x M5 nuts + 4 x M8 nuts

Frame Size A specific 6SL3261-6AA00-0VA0

Frame Size B specific 6SL3261-6AB00-0VA0

Frame Size C specific 6SL3261-6AC00-0VA0

Frame Size D specific 6SL3261-6AD00-0VA0

(6-hole, for Frame Size A)

(6-hole, for Frame Size B)

(10-hole, for Frame Size C)

(14-hole, for Frame Size D)

Push-through mounting kit variants

Identification

SINAMICS V10

Operating Instructions, 08/2011, A5E03453178 (this is not an order number) 17

Option Variant MLFB (order number)

Door mounting components

The door mounting components include:

● Connecting cable, 3-meter long (1 piece)

● Production Information Sheet (1 piece)

● M3 preassembled screw and washer assemblies

(4 pieces)

- 6SL3256-0VP00-0VA0

To: inverter body unit

To: door-mounted operator panel

Connecting cable (inverter body unit to operator panel)

Choke

4)

Line commutating choke: A line commutating choke is

required to smooth spike pulses in power voltage, or

voltage sags generated during the phase change of a

bridge rectifier circuit; besides, a line commutating

choke can also used to lower harmonic interference to

inverter and power supply. If power impedance < 1%,

a line commutating choke is a must to reduce current

spikes.

Output choke: An output choke is necessary for

lowering varying rate of capacity current and voltage

(dv/dt) if the length of motor cable is longer than 50m

(shielded) or 100m (unshielded). For the detailed

information about the length of motor cable, please

refer to Technical data (Page 115)

Frame size Rated out

put power

Line commutating

choke

Output choke

Frame Size A 0.55 kW 6SE6400-3CC00-

2AD3

(6SE6400-3CR00-

2AD3)

6SE6400-3TC0

0-4AD2

0.75 kW 6SE6400-3CC004AD3

(6SE6400-3CR004AD3)

1.1 kW

1.5 kW 6SE6400-3CC006AD3

(6SE6400-3CR006AD3)

Frame Size B 2.2 kW 6SE6400-3CC01-

0BD3

(6SE6400-3CR01-

0BD3)

6SE6400-3TC0

1-0BD3

3.0 kW

4.0 kW 6SE6400-3CC014BD3

(6SE6400-3CR014BD3)

Frame Size C 5.5 kW 6SE6400-3CC02-

2CD3

(6SE6400-3CR02-

2CD3)

6SE6400-3TC0

3-2CD3

7.5 kW

11 kW 6SE6400-3CC03-

5CD3

(6SE6400-3CR03-

5CD3)

Framze Size D15 kW

18.5 kW 6SE6400-3CC044DD0

(6SE6400-3CR044DD0)

6SE6400-3TC0

5-4DD0

22 kW 6SE6400-3TC0

3-8DD0

Operating Instructions

5)

English version -

2)

The mounting kit consists of two mating parts. You can well engage both parts when installing.

3)

Only used for Frame Size D

4)

An order number without a bracket indicates that this choke is manufactured by a non-Chinese company, while an order

number with a bracket indicates that this choke is supplied by a local Chinese company. You can make your selection

according to your own needs.

Identification

SINAMICS V10

18 Operating Instructions, 08/2011, A5E03453178 (this is not an order number)

5)

The documentation identification number of the Operating Instructions (English version) is A5E02583916 (this is not an

order number).

Spare parts

Spare parts Variant MLFB (order number)

Fan components

The fan components for Frame Size B include:

● Fan (1 piece)

● Production Information Sheet (1 piece)

● M3 Mounting screws (2 pieces)

The fan components for Frame Size C or Frame Size D

include:

● Fan (1 piece)

● Production Information Sheet (1 piece)

● M4 Mounting screws (2 pieces)

● Spacers (2 pieces)

Frame Size B specific 6SL3200-0VF02-0AA0

Frame Size C specific 6SL3200-0VF03-0AA0

Frame Size D specific 6SL3200-0VF04-0AA0

Operator panel - 6SL3200-0VB01-0AA0

Identification

SINAMICS V10

Operating Instructions, 08/2011, A5E03453178 (this is not an order number) 19

Installation

5

5.1 Mechanical installation

5.1.1 Mounting orientation and clearance

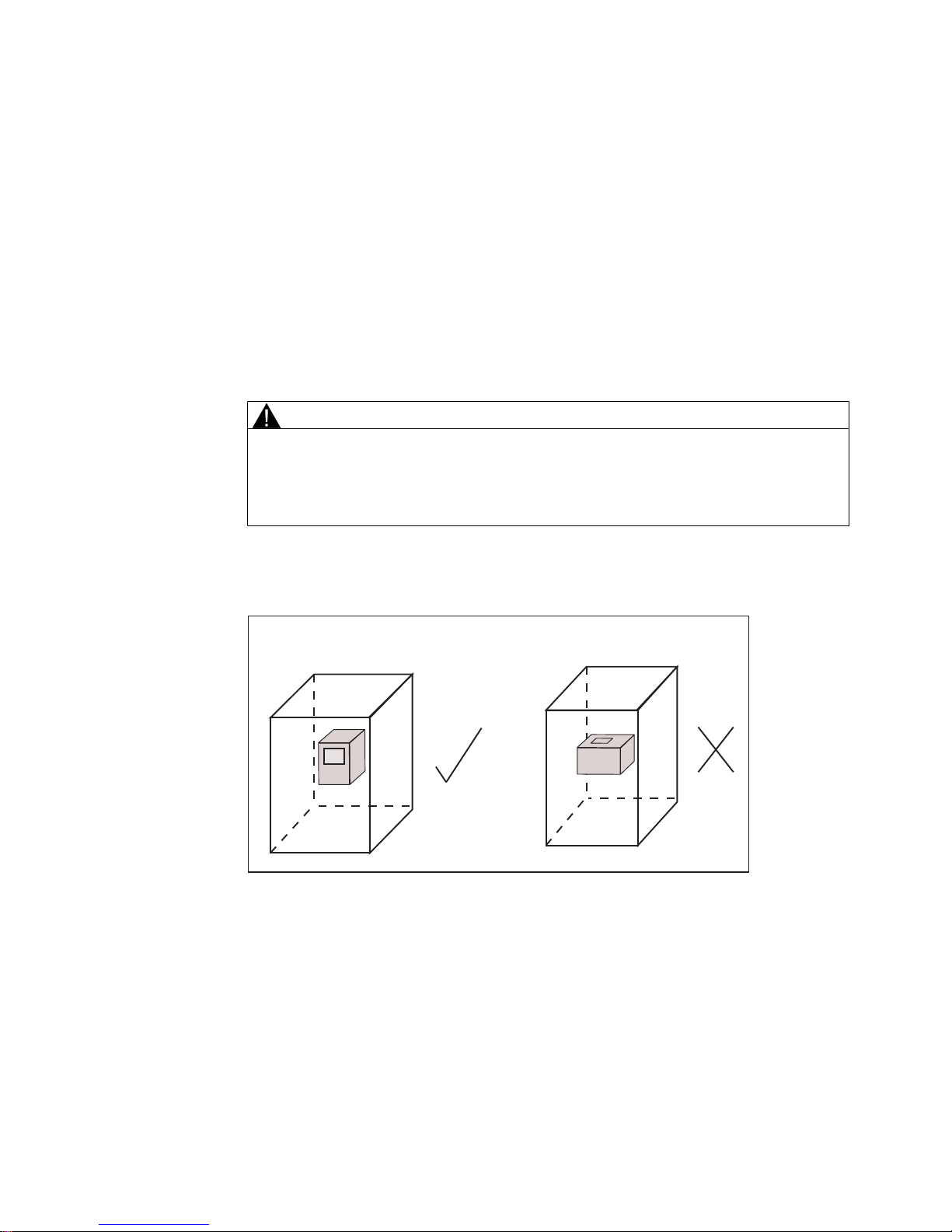

WARNING

Depending on the mounting method selected, you MUST mount the inverter vertically

● in a cabinet or

● in a cabinet, but with the inverter heasink extending outside the cabinet.

Do NOT mount the inverter horizontally in the cabinet.

Mounting orientation

+RUL]RQWDOPRXQWLQJ)RUELGGHQ

9HUWLFDOPRXQWLQJLQFDELQHW0XVW

,QYHUWHU

Figure 5-1 Mounting orientation

When performing vertical mounting, you can mount the inverter with an angle of 87° to 90°

between inverter and horizontal surface. See figure below for details:

SINAMICS V10

Operating Instructions, 08/2011, A5E03453178 (this is not an order number) 21

,QYHUWHUIURQW

PLQLQXP

+RUL]RQWDO

&DELQHWZDOO

Figure 5-2 Allowed mounting angle between inverter and the horizon

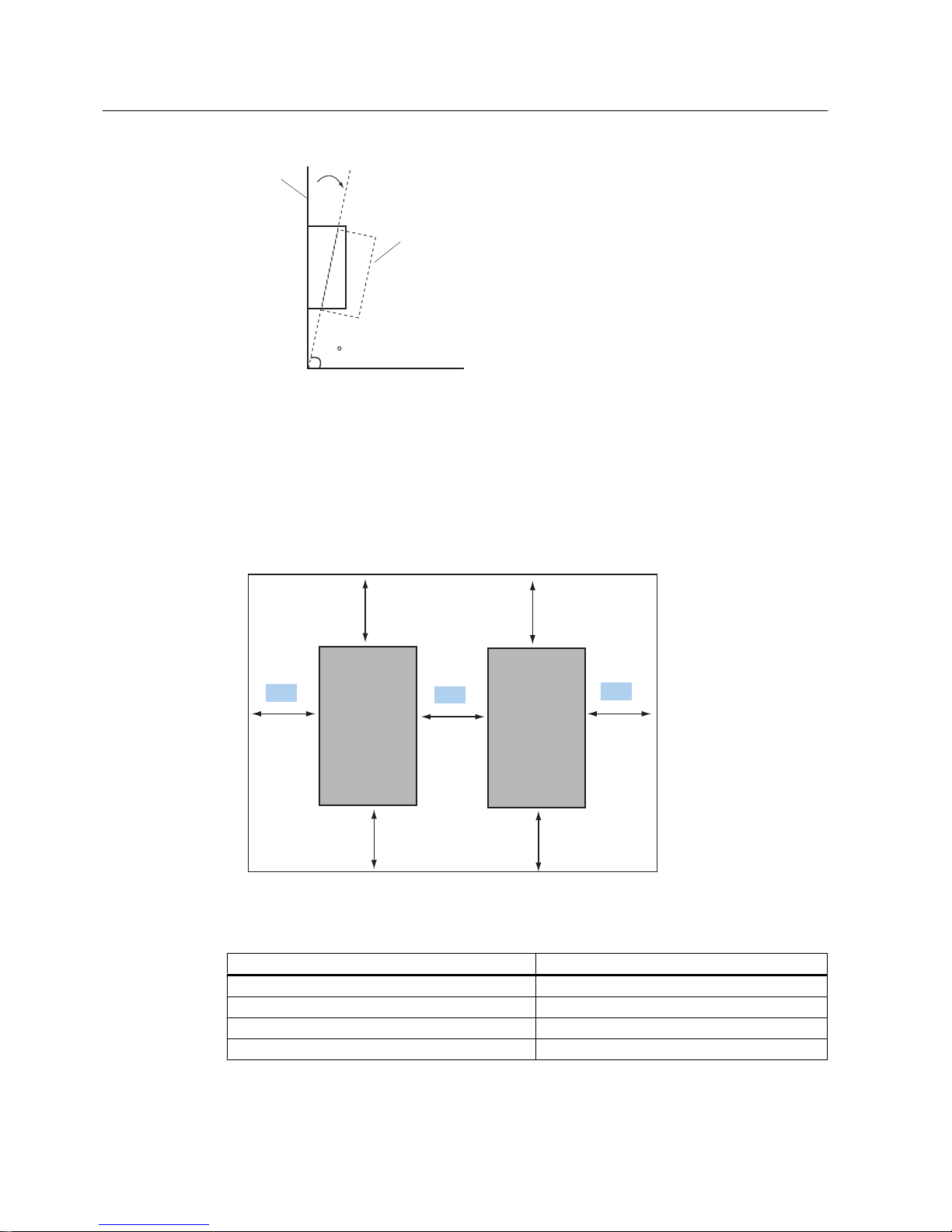

Mounting clearance

You can mount inverters one next to another or one above another with the clearance below:

● Allow at least 100 mm clearance above and below the inverter..

● Allow at least specified clearance A (see Figure 5-3 and Table 5-1 below) between the

inverters.

≥100 mm

≥100 mm

≥100 mm

≥100 mm

A

A

A

SINAMICS V10

SINAMICS V10

SINAMICS V10

SINAMICS V10

Figure 5-3 Inverter mounting clearance

Table 5-1 Requirements for inverter mounting clearance

Inverters positioned side by side Minimum clearance ("A") in mm

Frame Size A ↔ Frame Size A 50

Frame Size B ↔ Frame Size A / B 50

Frame Size C ↔ Frame Size A / B / C 70

Frame Size D ↔ Frame Size A / B / C / D 75

Installation

5.1 Mechanical installation

SINAMICS V10

22 Operating Instructions, 08/2011, A5E03453178 (this is not an order number)

5.1.2 Wall mounting

What does "Wall mounting" mean?

The term "Wall mounting" means:

1. The inverter mounts directly to a cabinet wall, without use of optional mounting kit.

2. The entire inverter including its heatsink mounts inside the cabinet.

3. You don't need an external fan to cool the inverter.

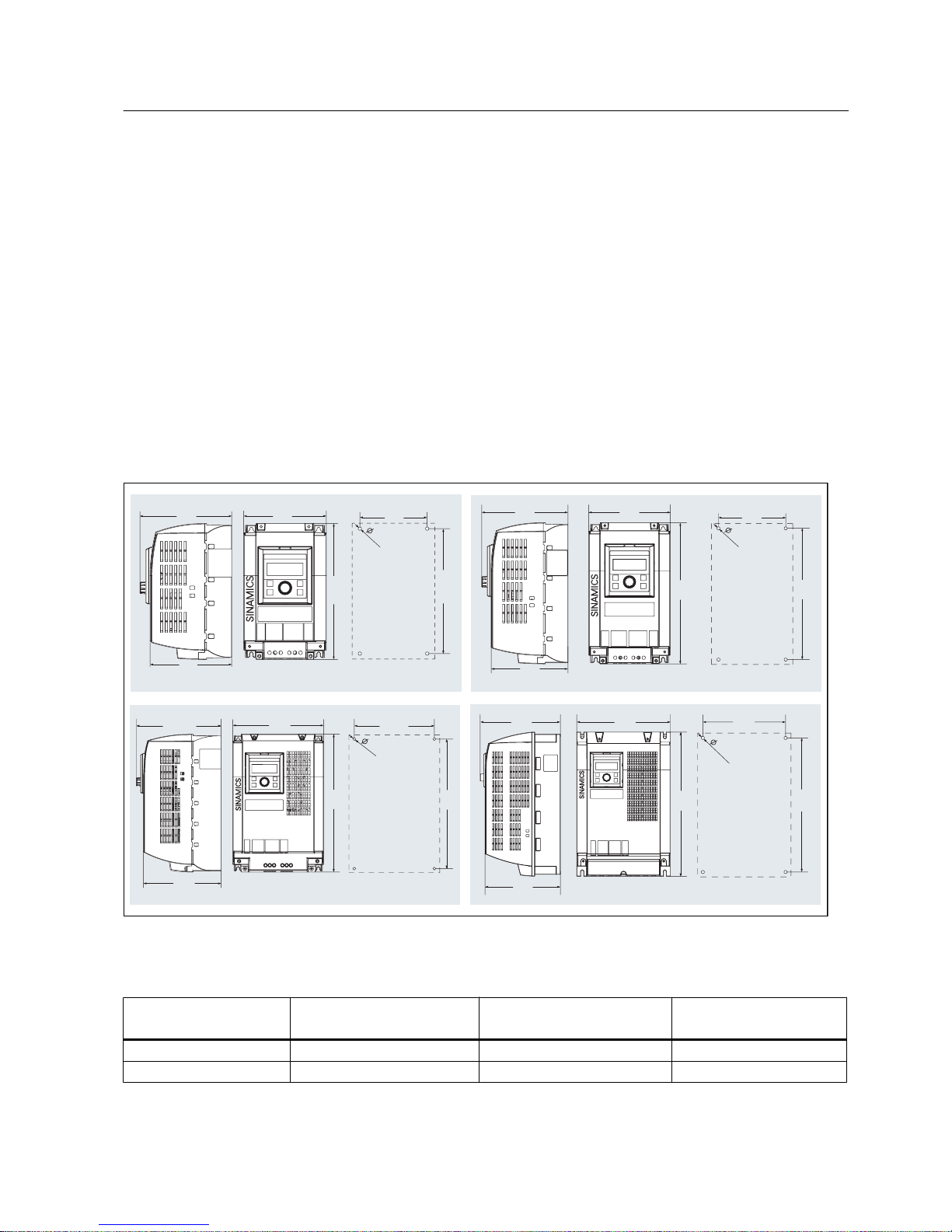

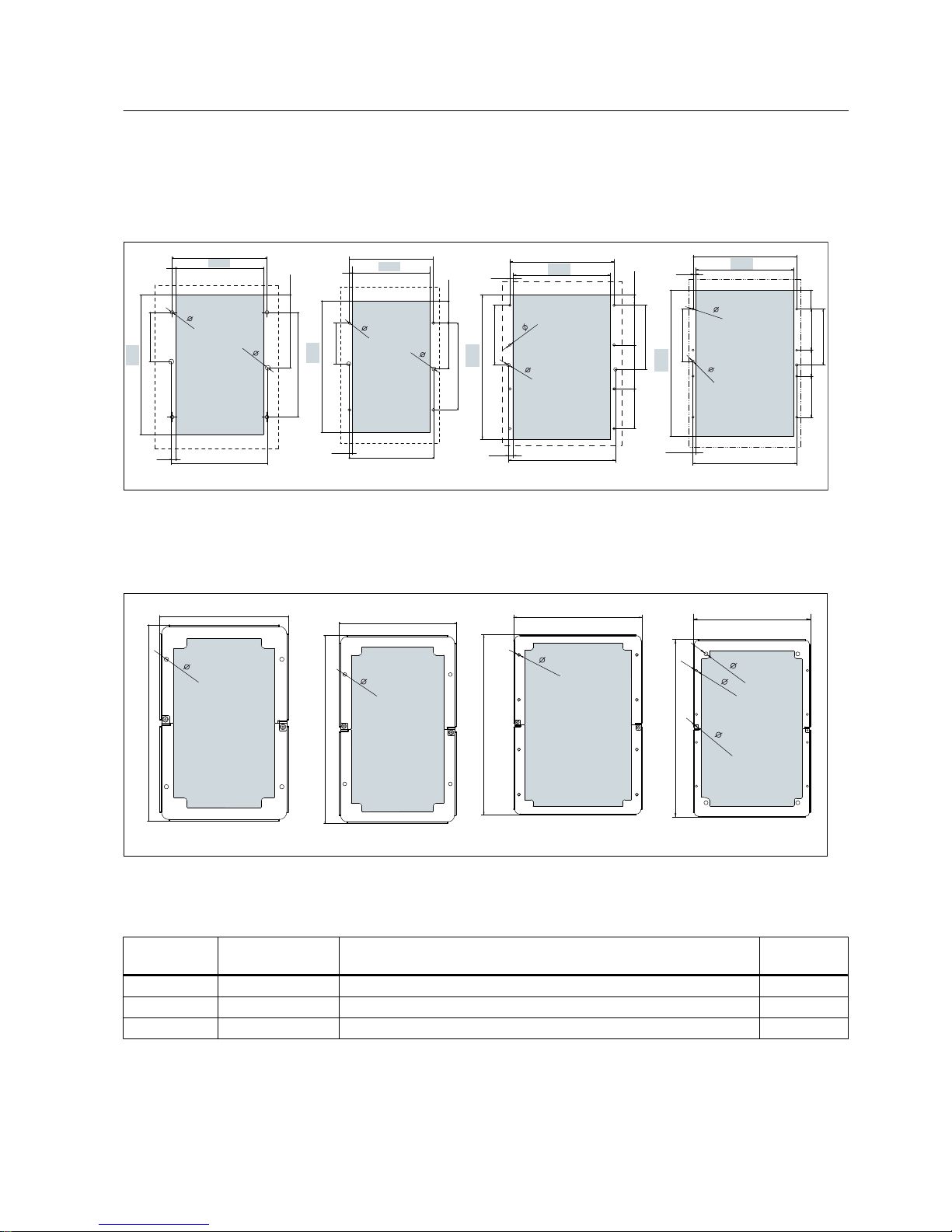

Mounting dimensions (outline dimensions + drill patterns)

You can drill holes in cabinet wall according to the drill patterns shown below. The inverter

outline dimensions are also provided in the figure for your reference:

5.8

155

138

114

211.5

140

230

5.8

142

159

150

124

260

242

7

192.5

218

203.11

186

331

311

230260223

210

401

373

8.

8

)UDPH6L]H$

)UDPH6L]H%

)UDPH6L]H&

)UDPH6L]H'

'ULOOSDWWHUQ

'ULOOSDWWHUQ

'ULOOSDWWHUQ

'ULOOSDWWHUQ

Figure 5-4 Mounting dimensions (in mm)

Table 5-2 Mounting torque requirements

Inverter variant Holes to be drilled in cabinet

wall

Fixing method Tightening torque

(Nm)

Frame Size A 4 4 x M5 screws and nuts 2.5

Frame Size B 4 4 x M5 screws and nuts 2.5

Installation

5.1 Mechanical installation

SINAMICS V10

Operating Instructions, 08/2011, A5E03453178 (this is not an order number) 23

Inverter variant Holes to be drilled in cabinet

wall

Fixing method Tightening torque

(Nm)

Frame Size C 4 4 x M6 screws and nuts 2.5

Frame Size D 4 4 x M8 screws and nuts 2.5

Mounting sequence

Proceed the following procedure to complete your mounting of the inverter directly to cabinet

wall:

Cabinet wall

Mounting holes

1.

Drill 4 holes in cabinet wall

1

Mounting

holes

Mounting screws

Screw

nuts

2.

Mount the inverter to the wall and fix it with supplied

mounting screws and screw nuts.

2

Figure 5-5 Mounting sequence (wall mounting)

Installation

5.1 Mechanical installation

SINAMICS V10

24 Operating Instructions, 08/2011, A5E03453178 (this is not an order number)

Mounting the operator panel to cabinet door

The inverter has a removable operator panel. If necessary, you can remove the operator panel

from the inverter and mount it to the cabinet door. (See topic "Mounting the operator panel to

cabinet door (Page 31)" for details.)

5.1.3 Push-through mounting

What does "Push-through mounting" mean?

The term "Push-through mounting" means:

1. The inverter is mounted through cabinet wall, using an optional push-through mounting kit.

2. The inverter body unit mounts inside cabinet, while the heatsink extends outside the cabinet.

3. If necessary, you can use an external fan to cool the inverter.

Installation

5.1 Mechanical installation

SINAMICS V10

Operating Instructions, 08/2011, A5E03453178 (this is not an order number) 25

Outline dimensions of SINAMICS V10

155

138

140

230

142

159

150

260

218

203.11

186

331

260223

210

401

)UDPH6L]H$

)UDPH6L]H%

)UDPH6L]H&

)UDPH6L]H'

Figure 5-6 Outline dimensions of SINAMICS V10 (in mm)

Installation

5.1 Mechanical installation

SINAMICS V10

26 Operating Instructions, 08/2011, A5E03453178 (this is not an order number)

Drill patterns and cut-out dimensions

Please drill holes and cut out an opening in cabinet wall according to the data specified in the

figure below:

)UDPH6L]H$)UDPH6L]H%)UDPH6L]H&)UDPH6L]H'

154

142

156.8

7.4

6

227

80

90

170

28.5

2- 8

4- 6

&XWRXWDUHD

152

164

257

80

170

43.5

90

&XWRXWDUHD

6

2- 8

4- 6

&XWRXWDUHD

166.8

7.4

8- 6

220

7.9

235.8

327

90 90

99.4

23.8

&XWRXWDUHD

242.3

11.1

135.2

145.2

2- 8

262

8

278

392

51

110

150

110

70

&XWRXWDUHD

278.7

8.3

140

2- 8

8- 6

Figure 5-7 Drill pattern and cut-out dimensions (in mm)

Outline dimensions of optional mounting kits

)UDPH6L]H$VSHFLILF)UDPH6L]H%VSHFLILF)UDPH6L]H&VSHFLILF)UDPH6L]H'VSHFLILF

257.6

361

8- 5.8

2- 4.1

4- 10

294

445

172

262

4- 5.8

182

292

4- 5.8

4- 5.8

Figure 5-8 Outline dimensions of optional mounting kits (in mm)

Table 5-3 Mounting torque requirements

Inverter

variant

Holes to be drilled

in cabinet wall

Fixing method Tightening

torque (Nm)

Frame Size A 6 4 x M5 screws and nuts; 2 x plastic rivets 2.5

Frame Size B 6 4 x M5 screws and nuts; 2 x plastic rivets 2.5

Frame Size C 10 8 x M5 screws and nuts; 2 x plastic rivets 2.5

Installation

5.1 Mechanical installation

SINAMICS V10

Operating Instructions, 08/2011, A5E03453178 (this is not an order number) 27

Inverter

variant

Holes to be drilled

in cabinet wall

Fixing method Tightening

torque (Nm)

Frame Size D 10 4 x M8 screws and nuts (for fixing the inverter to the push-through

mounting kit) ; 2 x plastic rivets

2.5

8 x M5 screws and nuts (for fixing the inverter to cabinet wall) 2.5

4 x M4 screws (for fixing the metal back cover to the back of inverter) 0.8

Installation

5.1 Mechanical installation

SINAMICS V10

28 Operating Instructions, 08/2011, A5E03453178 (this is not an order number)

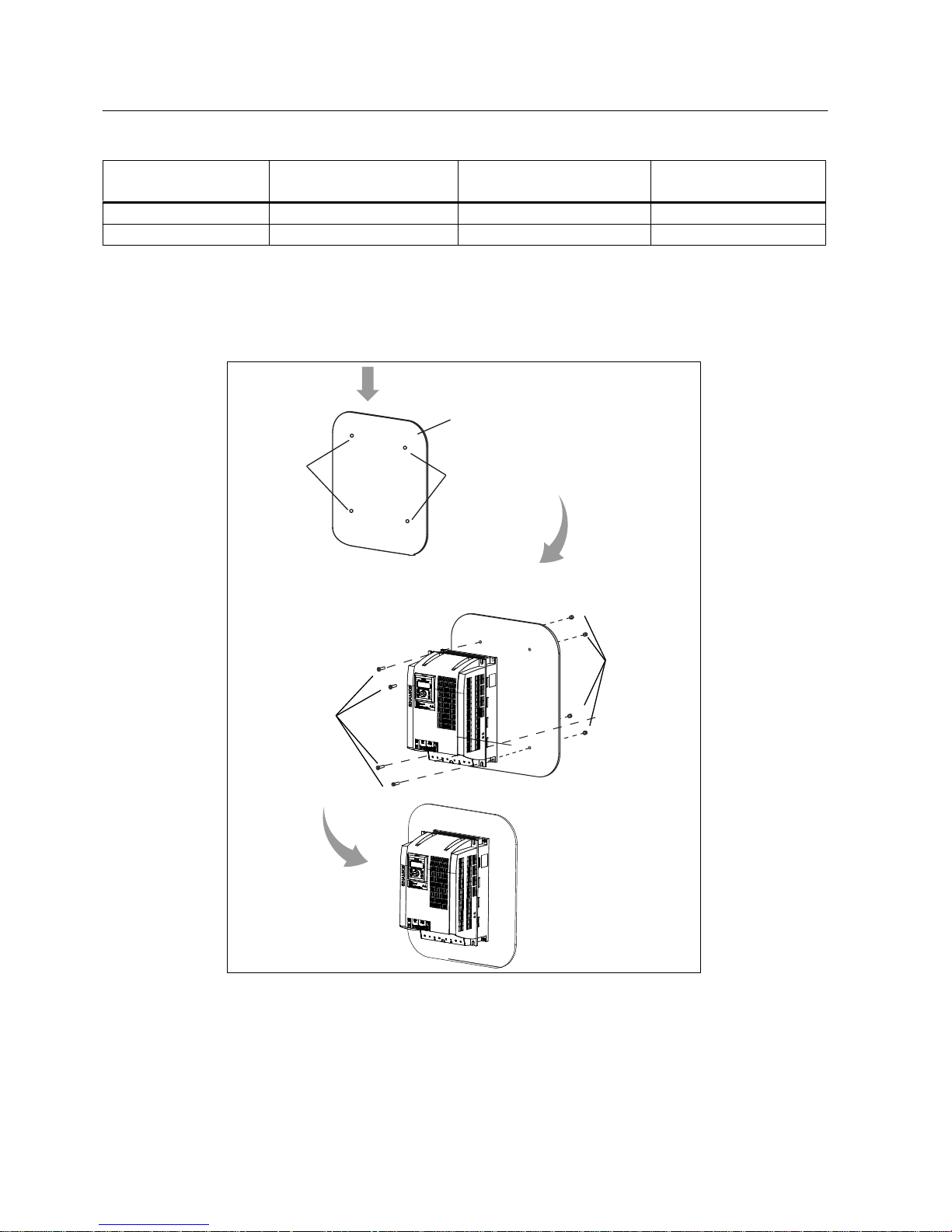

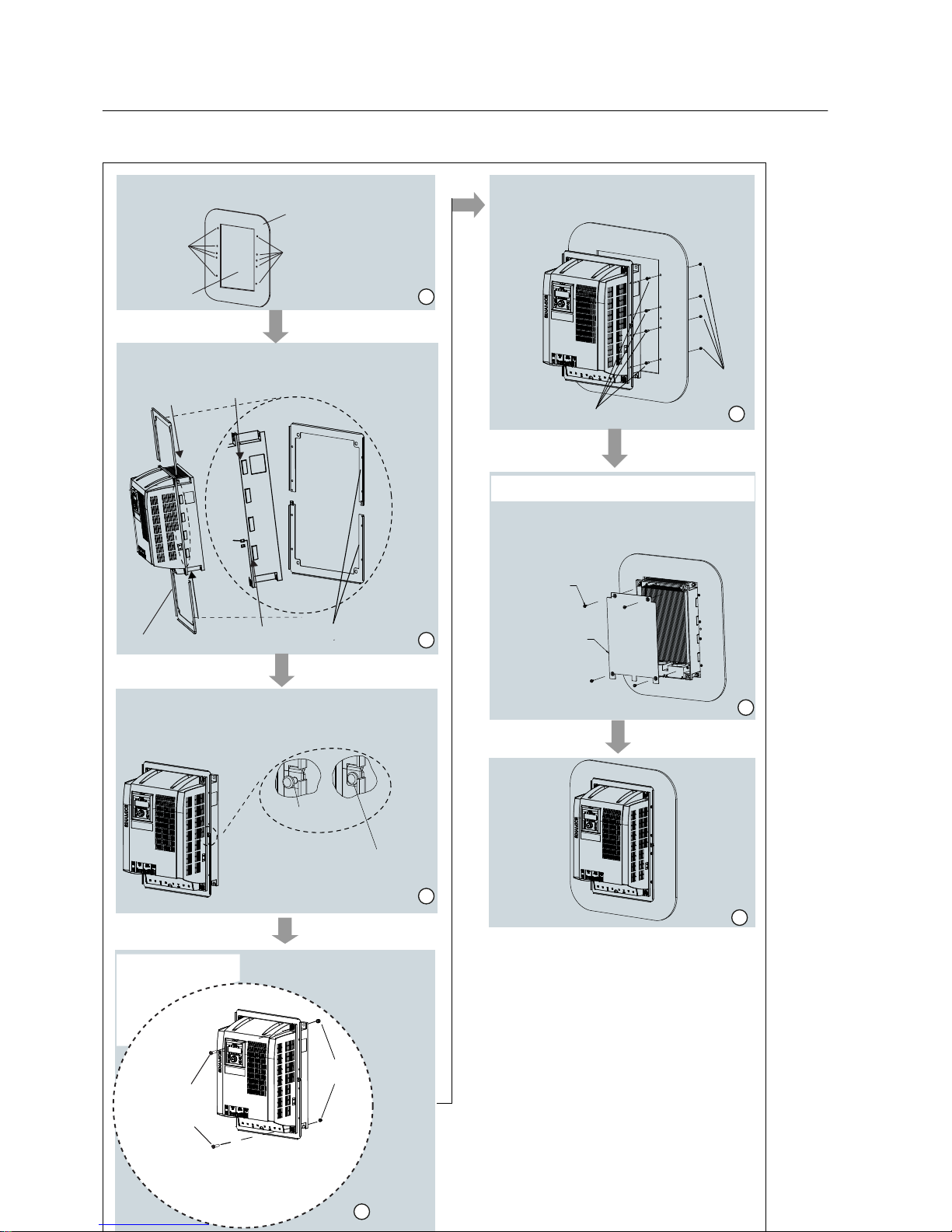

Mounting sequence

Proceed the following procedure to complete your mounting of the inverter with optional

mounting kit through cabinet wall:

Installation

5.1 Mechanical installation

SINAMICS V10

Operating Instructions, 08/2011, A5E03453178 (this is not an order number) 29

Cabinet wall

Wall cut-out

Mounting holes

Mounting

holes

Make a cut-out in the cabinet wall and drill holes in the wall.

Insert the plastic rivets into the fully overlapped holes of the

mating parts of the push-through mounting kit to interlock

both parts in place.

Slide in the direction of the arrow head each part of the

mounting kit into the mounting slot of the inverter housing

until both parts are well engaged.

Push-through mounting kit

Put this side toward

inverter front

View after locking

Plastic rivet

Mount the inverter to the mounting

kit and tighten the 4 x M8 mounting

screws and screw nuts.

4 x M8 mounting

screws (Tightening

torque: 2.5 Nm)

4 x M8

screw nuts

Mounting the inverter to the cabinet wall, then

tighten the mounting screws and screw nuts

delivered with the product.

Screw

nuts

Mounting screws

This step is necessary

only when mounting

Frame Size D.

06FUHZ

0HWDOEDFNFRYHU

,IQHFHVVDU\XVLQJIRXU0VFUHZVPRXQWWKH

PHWDOEDFNFRYHUWRWKHEDFNRILQYHUWHUWRLPSURYH

FRROLQJHIIHFW

This step is also necessary only when mounting

Frame Size D.

Installation

5.1 Mechanical installation

SINAMICS V10

30 Operating Instructions, 08/2011, A5E03453178 (this is not an order number)

Loading...

Loading...