Page 1

Operating instructions

SINAMICS S210 converter

SIMOTICS S-1FK2 servomotor

12/2017Edition

Servo drive system

SINAMICS S210

www.siemens.com/drives

SINAMICS/SIMOTICS

Page 2

Page 3

SINAMICS/SIMOTICS

SINAMICS S210 servo drive system

Firmware V5.1

Preface

Fundamental safety

instructions

1

Operating Instructions

Description

Configuring

Safety functions integrated in

the drive

Installing

Commissioning and

diagnostics in the Web server

Diagnostics

Technical specifications

2

3

4

5

6

7

8

Dimension drawings

Decommissioning and

disposal

Ordering data

Parameters

Faults and alarms

Appendix

9

10

11

12

13

A

12/2017

A5E41702836B AA

Page 4

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be

used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property

damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions. Qualified

personnel are those who, based on their training and experience, are capable of identifying risks and avoiding

potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended or

approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described.

Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in

this publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E41702836B AA

Ⓟ 12/2017 Subject to change

Copyright © Siemens AG 2017.

All rights reserved

Page 5

Preface

Keeping the documentation safe

This documentation should be kept in a location where it can be easily accessed. Make the

documentation available to the personnel responsible.

Target group

These operating instructions are intended for persons who perform different tasks in the drive

environment, e.g. for:

● Planning engineers

● Project engineers

● Machine manufacturers

● Commissioning engineers

● Electricians

● Installation personnel

More information

My support

● Service technician

● Warehouse personnel

Information on the following topics is available at:

● Ordering documentation / overview of documentation

● Additional links to download documents

● Using documentation online (find and search in manuals / information)

Additional information on drive technology (

13204)

If you have any questions relating to the technical documentation (e.g. suggestions,

corrections) then please email them to the following address: Email

(mailto:docu.motioncontrol@siemens.com)

The following link provides information on how to create your own individual documentation

based on Siemens content, and adapt it for your own machine documentation:

My support (https://support.industry.siemens.com/My/de/en/documentation)

https://support.industry.siemens.com/cs/de/en/ps/

SINAMICS S210 servo drive system

Operating Instructions, 12/2017, A5E41702836B AA 3

Page 6

Preface

Note

If you want to use this function, you must first register.

Later, you can log on with your login data.

Technical Support

Country-specific telephone numbers for technical support are provided on the Internet under

Contact:

Technical Support (

Websites of third parties

This publication contains hyperlinks to websites of third parties. Siemens does not take any

responsibility for the contents of these websites or adopt any of these websites or their contents

as their own, because Siemens does not control the information on these websites and is also

not responsible for the contents and information provided there. Use of these websites is at

the risk of the person doing so.

Use of OpenSSL

This product contains software (https://www.openssl.org/) that has been developed by the

OpenSSL project for use in the OpenSSL toolkit.

This product contains cryptographic software (mailto:eay@cryptsoft.com) created by Eric

Young.

This product contains software (mailto:eay@cryptsoft.com) developed by Eric Young.

https://support.industry.siemens.com)

SINAMICS S210 servo drive system

4 Operating Instructions, 12/2017, A5E41702836B AA

Page 7

Table of contents

Preface.........................................................................................................................................................3

1 Fundamental safety instructions.................................................................................................................11

1.1 General safety instructions.....................................................................................................11

1.2 Equipment damage due to electric fields or electrostatic discharge......................................17

1.3 Warranty and liability for application examples......................................................................18

1.4 Industrial security...................................................................................................................19

1.5 Residual risks of power drive systems...................................................................................20

2 Description..................................................................................................................................................21

2.1 System overview....................................................................................................................22

2.2 The scope of supply for the system components...................................................................24

2.3 Motor......................................................................................................................................25

2.4 Converter...............................................................................................................................28

2.5 Connection systems...............................................................................................................31

2.6 Motor-converter combinations................................................................................................32

2.7 Optional accessories..............................................................................................................33

3 Configuring.................................................................................................................................................35

3.1 EMC-compliant installation of a machine or system..............................................................35

3.1.1 Control cabinet.......................................................................................................................35

3.1.2 Cables....................................................................................................................................36

3.1.3 Electromechanical components.............................................................................................38

3.2 Permissible line supplies and connection options..................................................................39

3.2.1 Connection options, 230 V devices........................................................................................40

3.3 Configuring the motor.............................................................................................................44

3.3.1 Configuration sequence.........................................................................................................44

3.3.1.1 Clarification of type of drive....................................................................................................45

3.3.1.2 Specification of the supplementary conditions and integration into the automation system......46

3.3.1.3 Definition of the load, calculation of the maximum load torque and determination of the

motor......................................................................................................................................46

3.4 Configuring the external braking resistor...............................................................................52

3.5 Establishing communication of the converter with the controller...........................................55

4 Safety functions integrated in the drive......................................................................................................57

4.1 Overview of Safety Integrated Functions...............................................................................57

4.2 Basic Functions......................................................................................................................58

4.2.1 Safe Torque Off (STO)...........................................................................................................58

4.2.2 Safe Brake Control (SBC)......................................................................................................61

SINAMICS S210 servo drive system

Operating Instructions, 12/2017, A5E41702836B AA 5

Page 8

Table of contents

4.2.3 Safe Stop 1 (SS1, time-controlled).........................................................................................63

4.3 Configuring the safety functions.............................................................................................68

4.4 Responses to safety faults.....................................................................................................69

4.4.1 Stop responses......................................................................................................................69

4.4.2 Response to a discrepancy when STO is active....................................................................71

4.5 System properties..................................................................................................................73

4.5.1 Response times of the Basic Functions.................................................................................73

4.5.2 Control of the Basic Functions via terminals..........................................................................73

4.5.3 Control of the Basic Functions via PROFIsafe.......................................................................74

4.5.4 PFH values.............................................................................................................................74

4.6 Acceptance - completion of commissioning...........................................................................75

4.6.1 STO acceptance test..............................................................................................................78

4.6.2 SBC acceptance test..............................................................................................................79

4.6.3 SS1 acceptance test..............................................................................................................80

4.7 Functional safety....................................................................................................................81

4.8 Machinery Directive................................................................................................................82

5 Installing.....................................................................................................................................................83

5.1 Safety instructions..................................................................................................................83

5.2 Installing the motor.................................................................................................................84

5.2.1 Checklists prior to assembly..................................................................................................84

5.2.2 Mounting instructions for the motor........................................................................................85

5.2.3 Fitting output elements...........................................................................................................86

5.3 Installing the converter...........................................................................................................87

5.3.1 Installation conditions.............................................................................................................87

5.3.2 Dimension drawings and drilling dimensions.........................................................................88

5.4 Connecting the converter and the motor................................................................................89

5.4.1 Cable lengths.........................................................................................................................89

5.4.2 Connecting the motor.............................................................................................................90

5.4.3 Connecting the converter.......................................................................................................93

5.4.3.1 Connections at the converter.................................................................................................95

5.4.3.2 Connecting the line supply, motor, motor holding brake and encoder to the converter.........98

5.4.3.3 Connections for open-loop and closed-loop control of the converter...................................101

5.4.3.4 Connection example............................................................................................................103

5.4.3.5 Connection example of the fail-safe digital input..................................................................104

6 Commissioning and diagnostics in the Web server..................................................................................105

6.1 Fundamentals......................................................................................................................106

6.2 First login..............................................................................................................................108

6.3 Structure of the Web browser..............................................................................................111

6.3.1 Changing parameter values in dialog input screens............................................................113

6.4 Login/logout..........................................................................................................................114

6.4.1 Users and access rights.......................................................................................................114

6.4.2 Login/logout..........................................................................................................................116

6.5 Commissioning.....................................................................................................................118

6.5.1 Assigning the drive name.....................................................................................................118

SINAMICS S210 servo drive system

6 Operating Instructions, 12/2017, A5E41702836B AA

Page 9

Table of contents

6.5.2 Performing One Button Tuning............................................................................................119

6.5.3 Using the control panel........................................................................................................122

6.6 Settings................................................................................................................................124

6.6.1 Setting limits.........................................................................................................................124

6.6.2 Setting the brake control......................................................................................................125

6.6.3 Configuring digital inputs......................................................................................................127

6.6.4 Adapt parameter list.............................................................................................................129

6.6.4.1 Configuring the parameter list..............................................................................................130

6.6.4.2 Changing the parameter value.............................................................................................132

6.6.4.3 Filtering the parameter list....................................................................................................132

6.7 Plant-specific settings..........................................................................................................134

6.7.1 Changing the direction of rotation of the motor....................................................................134

6.7.2 Electronic weight counterbalance for a vertical axis............................................................134

6.8 Safety settings......................................................................................................................135

6.8.1 Safety commissioning..........................................................................................................135

6.8.1.1 Overview..............................................................................................................................135

6.8.1.2 Commissioning step 1..........................................................................................................138

6.8.1.3 Commissioning step 2..........................................................................................................140

6.8.1.4 Commissioning step 3..........................................................................................................141

6.8.1.5 Commissioning step 4..........................................................................................................144

6.8.1.6 Commissioning step 5..........................................................................................................145

6.8.1.7 Configuring the safety password..........................................................................................146

6.8.1.8 Checking existing safety settings in the read mode.............................................................148

6.8.2 Safety diagnostics................................................................................................................149

6.9 Diagnostics in the Web server.............................................................................................150

6.9.1 Adapt message list...............................................................................................................150

6.9.1.1 Displaying messages...........................................................................................................150

6.9.1.2 Filtering messages...............................................................................................................151

6.9.2 Displaying communication settings......................................................................................152

6.10 Backup and restore..............................................................................................................153

6.10.1 Backing up the parameter settings externally......................................................................154

6.10.2 Restoring externally backed-up parameter settings.............................................................155

6.10.3 Restoring the factory settings...............................................................................................155

6.11 System settings....................................................................................................................156

6.11.1 Setting or changing user accounts.......................................................................................156

6.11.2 Configuring the IP connection..............................................................................................158

6.11.3 Configuring the system time.................................................................................................160

6.12 Saving permanently.............................................................................................................161

6.13 Calling Support information..................................................................................................162

6.14 Firmware update..................................................................................................................163

7 Diagnostics...............................................................................................................................................165

7.1 Status displays and operating elements on the converter...................................................165

7.1.1 Status display via LEDs.......................................................................................................166

7.2 Message classes in accordance with PROFIdrive...............................................................168

7.3 Correcting faults on the motor..............................................................................................171

SINAMICS S210 servo drive system

Operating Instructions, 12/2017, A5E41702836B AA 7

Page 10

Table of contents

7.4 Alarms..................................................................................................................................173

7.5 Faults...................................................................................................................................174

8 Technical specifications............................................................................................................................175

8.1 Technical data and properties of the motor..........................................................................175

8.1.1 Technical features................................................................................................................175

8.1.2 Permissible environmental conditions for the motor............................................................176

8.1.3 Cooling.................................................................................................................................178

8.1.4 Derating factors....................................................................................................................180

8.1.5 Degree of protection.............................................................................................................180

8.1.6 Balancing.............................................................................................................................181

8.1.7 Vibration response...............................................................................................................182

8.1.8 Shaft extension....................................................................................................................183

8.1.9 Radial eccentricity, concentricity and axial eccentricity........................................................184

8.1.10 Permissible radial and axial forces.......................................................................................185

8.1.11 Available encoders...............................................................................................................185

8.1.12 Brake data............................................................................................................................185

8.1.13 Technical data and characteristics 1FK2 High Dynamic......................................................187

8.1.13.1 1FK2102-0AG......................................................................................................................187

8.1.13.2 1FK2102-1AG......................................................................................................................189

8.1.13.3 1FK2103-2AG......................................................................................................................190

8.1.13.4 1FK2103-4AG......................................................................................................................191

8.1.13.5 1FK2104-4AK.......................................................................................................................192

8.1.13.6 1FK2104-5AK.......................................................................................................................193

8.1.14 Technical data and characteristics 1FK2 Compact..............................................................194

8.1.14.1 1FK2203-2AG......................................................................................................................194

8.1.14.2 1FK2203-4AG......................................................................................................................196

8.2 Technical specifications of the converter.............................................................................197

8.2.1 Electromagnetic compatibility ..............................................................................................199

8.2.2 Converter ambient conditions..............................................................................................200

8.2.3 General data, converter.......................................................................................................202

8.2.4 Specific data, converter........................................................................................................203

8.3 Technical data and properties of the connection system.....................................................204

9 Dimension drawings.................................................................................................................................207

9.1 Dimension drawings of motor...............................................................................................207

9.2 Dimension drawings of converter.........................................................................................210

10 Decommissioning and disposal................................................................................................................213

10.1 Removing and disposing of the motor..................................................................................213

10.2 Disposing of converter.........................................................................................................214

11 Ordering data............................................................................................................................................215

11.1 Ordering data of the motor...................................................................................................215

11.2 Ordering data of the converter.............................................................................................216

11.3 Connection cables between the motor and the converter....................................................217

11.4 Accessories..........................................................................................................................219

11.4.1 Memory cards......................................................................................................................219

SINAMICS S210 servo drive system

8 Operating Instructions, 12/2017, A5E41702836B AA

Page 11

Table of contents

11.4.2 PROFINET patch cable........................................................................................................219

11.4.3 External line filter..................................................................................................................219

11.4.4 Cabinet bushing via mounting flange...................................................................................220

11.4.5 Degree of protection kit IP65 for the motor..........................................................................220

11.5 Spare parts...........................................................................................................................221

12 Parameters...............................................................................................................................................225

12.1 Parameter overview.............................................................................................................225

12.2 List of parameters................................................................................................................228

13 Faults and alarms.....................................................................................................................................291

13.1 Overview of faults and alarms..............................................................................................291

13.2 List of faults and alarms.......................................................................................................292

A Appendix...................................................................................................................................................737

A.1 Communication telegrams...................................................................................................737

A.1.1 Standard telegrams..............................................................................................................737

A.1.2 Supplementary telegrams....................................................................................................739

A.1.3 PROFIsafe telegrams...........................................................................................................740

A.1.4 Bit assignments of the process data....................................................................................740

A.1.4.1 Control word 1 and status word 1........................................................................................741

A.1.4.2 Control word 2 and status word 2........................................................................................741

A.1.4.3 Encoder 1 - control word and status word............................................................................742

A.1.4.4 Safety control word and status word 1.................................................................................742

A.1.4.5 Safety control word and status word 1B ..............................................................................743

A.1.4.6 Safety status word 2B .........................................................................................................743

A.1.4.7 Safety control word and status word 3B...............................................................................744

A.1.4.8 Message word......................................................................................................................744

A.2 What is the difference between the Emergency Off and Emergency Stop functions?.........745

A.3 Directives and standards......................................................................................................746

A.3.1 Directives, standards and certificates for the converter.......................................................746

A.3.2 Directives, standards and certificates for the motor.............................................................747

A.4 Certifications........................................................................................................................749

A.5 Certificates for the secure data transfer...............................................................................750

A.5.1 Overview..............................................................................................................................750

A.5.2 Using the certificate default configuration............................................................................750

A.6 List of abbreviations.............................................................................................................756

Index.........................................................................................................................................................761

SINAMICS S210 servo drive system

Operating Instructions, 12/2017, A5E41702836B AA 9

Page 12

Table of contents

SINAMICS S210 servo drive system

10 Operating Instructions, 12/2017, A5E41702836B AA

Page 13

Fundamental safety instructions

1.1 General safety instructions

WARNING

Electric shock and danger to life due to other energy sources

Touching live components can result in death or severe injury.

● Only work on electrical devices when you are qualified for this job.

● Always observe the country-specific safety rules.

Generally, the following six steps apply when establishing safety:

1. Prepare for disconnection. Notify all those who will be affected by the procedure.

2. Isolate the drive system from the power supply and take measures to prevent it being

switched back on again.

3. Wait until the discharge time specified on the warning labels has elapsed.

4. Check that there is no voltage between any of the power connections, and between any

of the power connections and the protective conductor connection.

5. Check whether the existing auxiliary supply circuits are de-energized.

6. Ensure that the motors cannot move.

7. Identify all other dangerous energy sources, e.g. compressed air, hydraulic systems, or

water. Switch the energy sources to a safe state.

8. Check that the correct drive system is completely locked.

1

After you have completed the work, restore the operational readiness in the inverse sequence.

WARNING

Electric shock due to connection to an unsuitable power supply

When equipment is connected to an unsuitable power supply, exposed components may

carry a hazardous voltage that might result in serious injury or death.

● Only use power supplies that provide SELV (Safety Extra Low Voltage) or PELV(Protective Extra Low Voltage) output voltages for all connections and terminals of the

electronics modules.

SINAMICS S210 servo drive system

Operating Instructions, 12/2017, A5E41702836B AA 11

Page 14

Fundamental safety instructions

1.1 General safety instructions

WARNING

Electric shock due to damaged motors or devices

Improper handling of motors or devices can damage them.

Hazardous voltages can be present at the enclosure or at exposed components on damaged

motors or devices.

● Ensure compliance with the limit values specified in the technical data during transport,

storage and operation.

● Do not use any damaged motors or devices.

WARNING

Electric shock due to unconnected cable shields

Hazardous touch voltages can occur through capacitive cross-coupling due to unconnected

cable shields.

● As a minimum, connect cable shields and the cores of cables that are not used at one end

at the grounded housing potential.

WARNING

Electric shock if there is no ground connection

For missing or incorrectly implemented protective conductor connection for devices with

protection class I, high voltages can be present at open, exposed parts, which when touched,

can result in death or severe injury.

● Ground the device in compliance with the applicable regulations.

WARNING

Arcing when a plug connection is opened during operation

Opening a plug connection when a system is operation can result in arcing that may cause

serious injury or death.

● Only open plug connections when the equipment is in a voltage-free state, unless it has

been explicitly stated that they can be opened in operation.

WARNING

Electric shock due to residual charges in power components

Because of the capacitors, a hazardous voltage is present for up to 5 minutes after the power

supply has been switched off. Contact with live parts can result in death or serious injury.

● Wait for 5 minutes before you check that the unit really is in a no-voltage condition and

start work.

SINAMICS S210 servo drive system

12 Operating Instructions, 12/2017, A5E41702836B AA

Page 15

Fundamental safety instructions

1.1 General safety instructions

WARNING

Spread of fire from built-in devices

In the event of fire outbreak, the enclosures of built-in devices cannot prevent the escape of

fire and smoke. This can result in serious personal injury or property damage.

● Install built-in units in a suitable metal cabinet in such a way that personnel are protected

against fire and smoke, or take other appropriate measures to protect personnel.

● Ensure that smoke can only escape via controlled and monitored paths.

WARNING

Failure of pacemakers or implant malfunctions due to electromagnetic fields

Electromagnetic fields (EMF) are generated by the operation of electrical power equipment,

such as transformers, converters, or motors. People with pacemakers or implants in the

immediate vicinity of this equipment are at particular risk.

● If you have a heart pacemaker or implant, maintain a minimum distance of 2 m from

electrical power equipment.

WARNING

Failure of pacemakers or implant malfunctions due to permanent magnetic fields

Even when switched off, electric motors with permanent magnets represent a potential risk

for persons with heart pacemakers or implants if they are close to converters/motors.

● If you have a heart pacemaker or implant, maintain the minimum distance specified in the

Chapter "Technical data".

● When transporting or storing permanent-magnet motors always use the original packing

materials with the warning labels attached.

● Clearly mark the storage locations with the appropriate warning labels.

● IATA regulations must be observed when transported by air.

WARNING

Unexpected movement of machines caused by radio devices or mobile phones

When radio devices or mobile phones with a transmission power > 1 W are used in the

immediate vicinity of components, they may cause the equipment to malfunction.

Malfunctions may impair the functional safety of machines and can therefore put people in

danger or lead to property damage.

● If you come closer than around 2 m to such components, switch off any radios or mobile

phones.

● Use the "SIEMENS Industry Online Support App" only on equipment that has already been

switched off.

SINAMICS S210 servo drive system

Operating Instructions, 12/2017, A5E41702836B AA 13

Page 16

Fundamental safety instructions

1.1 General safety instructions

WARNING

Motor fire in the event of insulation overload

There is higher stress on the motor insulation through a ground fault in an IT system. If the

insulation fails, it is possible that death or severe injury can occur as a result of smoke and

fire.

● Use a monitoring device that signals an insulation fault.

● Correct the fault as quickly as possible so the motor insulation is not overloaded.

WARNING

Fire due to inadequate ventilation clearances

Inadequate ventilation clearances can cause overheating of components with subsequent

fire and smoke. This can cause severe injury or even death. This can also result in increased

downtime and reduced service lives for devices/systems.

● Ensure compliance with the specified minimum clearance as ventilation clearance for the

respective component.

WARNING

Unrecognized dangers due to missing or illegible warning labels

Dangers might not be recognized if warning labels are missing or illegible. Unrecognized

dangers may cause accidents resulting in serious injury or death.

● Check that the warning labels are complete based on the documentation.

● Attach any missing warning labels to the components, where necessary in the national

language.

● Replace illegible warning labels.

NOTICE

Device damage caused by incorrect voltage/insulation tests

Incorrect voltage/insulation tests can damage the device.

● Before carrying out a voltage/insulation check of the system/machine, disconnect the

devices as all converters and motors have been subject to a high voltage test by the

manufacturer, and therefore it is not necessary to perform an additional test within the

system/machine.

SINAMICS S210 servo drive system

14 Operating Instructions, 12/2017, A5E41702836B AA

Page 17

Fundamental safety instructions

1.1 General safety instructions

WARNING

Unexpected movement of machines caused by inactive safety functions

Inactive or non-adapted safety functions can trigger unexpected machine movements that

may result in serious injury or death.

● Observe the information in the appropriate product documentation before commissioning.

● Carry out a safety inspection for functions relevant to safety on the entire system, including

all safety-related components.

● Ensure that the safety functions used in your drives and automation tasks are adjusted

and activated through appropriate parameterizing.

● Perform a function test.

● Only put your plant into live operation once you have guaranteed that the functions relevant

to safety are running correctly.

Note

Important safety notices for Safety Integrated functions

If you want to use Safety Integrated functions, you must observe the safety notices in the Safety

Integrated manuals.

WARNING

Malfunctions of the machine as a result of incorrect or changed parameter settings

As a result of incorrect or changed parameterization, machines can malfunction, which in turn

can lead to injuries or death.

● Protect the parameterization (parameter assignments) against unauthorized access.

● Handle possible malfunctions by taking suitable measures, e.g. emergency stop or

emergency off.

WARNING

Injury caused by moving or ejected parts

Contact with moving motor parts or drive output elements and the ejection of loose motor

parts (e.g. feather keys) out of the motor enclosure can result in severe injury or death.

● Remove any loose parts or secure them so that they cannot be flung out.

● Do not touch any moving parts.

● Safeguard all moving parts using the appropriate safety guards.

SINAMICS S210 servo drive system

Operating Instructions, 12/2017, A5E41702836B AA 15

Page 18

Fundamental safety instructions

1.1 General safety instructions

WARNING

Fire due to inadequate cooling

Inadequate cooling can cause the motor to overheat, resulting in death or severe injury as a

result of smoke and fire. This can also result in increased failures and reduced service lives

of motors.

● Comply with the specified cooling requirements for the motor.

WARNING

Fire due to incorrect operation of the motor

When incorrectly operated and in the case of a fault, the motor can overheat resulting in fire

and smoke. This can result in severe injury or death. Further, excessively high temperatures

destroy motor components and result in increased failures as well as shorter service lives of

motors.

● Operate the motor according to the relevant specifications.

● Only operate the motors in conjunction with effective temperature monitoring.

● Immediately switch off the motor if excessively high temperatures occur.

CAUTION

Burn injuries caused by hot surfaces

In operation, the motor can reach high temperatures, which can cause burns if touched.

● Mount the motor so that it is not accessible in operation.

Measures when maintenance is required:

● Allow the motor to cool down before starting any work.

● Use the appropriate personnel protection equipment, e.g. gloves.

SINAMICS S210 servo drive system

16 Operating Instructions, 12/2017, A5E41702836B AA

Page 19

Fundamental safety instructions

1.2 Equipment damage due to electric fields or electrostatic discharge

1.2 Equipment damage due to electric fields or electrostatic discharge

Electrostatic sensitive devices (ESD) are individual components, integrated circuits, modules

or devices that may be damaged by either electric fields or electrostatic discharge.

NOTICE

Equipment damage due to electric fields or electrostatic discharge

Electric fields or electrostatic discharge can cause malfunctions through damaged individual

components, integrated circuits, modules or devices.

● Only pack, store, transport and send electronic components, modules or devices in their

original packaging or in other suitable materials, e.g conductive foam rubber of aluminum

foil.

● Only touch components, modules and devices when you are grounded by one of the

following methods:

– Wearing an ESD wrist strap

– Wearing ESD shoes or ESD grounding straps in ESD areas with conductive flooring

● Only place electronic components, modules or devices on conductive surfaces (table with

ESD surface, conductive ESD foam, ESD packaging, ESD transport container).

SINAMICS S210 servo drive system

Operating Instructions, 12/2017, A5E41702836B AA 17

Page 20

Fundamental safety instructions

1.3 Warranty and liability for application examples

1.3 Warranty and liability for application examples

The application examples are not binding and do not claim to be complete regarding

configuration, equipment or any eventuality which may arise. The application examples do not

represent specific customer solutions, but are only intended to provide support for typical tasks.

You are responsible for the proper operation of the described products. These application

examples do not relieve you of your responsibility for safe handling when using, installing,

operating and maintaining the equipment.

SINAMICS S210 servo drive system

18 Operating Instructions, 12/2017, A5E41702836B AA

Page 21

1.4 Industrial security

Note

Industrial security

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens products and solutions only represent one component of such a

concept.

The customer is responsible for preventing unauthorized access to its plants, systems,

machines and networks. Systems, machines and components should only be connected to

the enterprise network or the internet if and to the extent necessary and with appropriate

security measures (e.g. use of firewalls and network segmentation) in place.

Additionally, Siemens’ guidance on appropriate security measures should be taken into

account. For more information about industrial security, please visit:

Industrial security (http://www.siemens.com/industrialsecurity).

Fundamental safety instructions

1.4 Industrial security

Siemens’ products and solutions undergo continuous development to make them more secure.

Siemens strongly recommends to apply product updates as soon as available and to always

use the latest product versions. Use of product versions that are no longer supported, and

failure to apply latest updates may increase customer’s exposure to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed at:

Industrial security (http://www.siemens.com/industrialsecurity).

WARNING

Unsafe operating states resulting from software manipulation

Software manipulations (e.g. viruses, trojans, malware or worms) can cause unsafe operating

states in your system that may lead to death, serious injury, and property damage.

● Keep the software up to date.

● Incorporate the automation and drive components into a holistic, state-of-the-art industrial

security concept for the installation or machine.

● Make sure that you include all installed products into the holistic industrial security concept.

● Protect files stored on exchangeable storage media from malicious software by with

suitable protection measures, e.g. virus scanners.

SINAMICS S210 servo drive system

Operating Instructions, 12/2017, A5E41702836B AA 19

Page 22

Fundamental safety instructions

1.5 Residual risks of power drive systems

1.5 Residual risks of power drive systems

When assessing the machine- or system-related risk in accordance with the respective local

regulations (e.g., EC Machinery Directive), the machine manufacturer or system installer must

take into account the following residual risks emanating from the control and drive components

of a drive system:

1. Unintentional movements of driven machine or system components during commissioning,

operation, maintenance, and repairs caused by, for example,

– Hardware and/or software errors in the sensors, control system, actuators, and cables

and connections

– Response times of the control system and of the drive

– Operation and/or environmental conditions outside the specification

– Condensation/conductive contamination

– Parameterization, programming, cabling, and installation errors

– Use of wireless devices/mobile phones in the immediate vicinity of electronic

components

– External influences/damage

– X-ray, ionizing radiation and cosmic radiation

2. Unusually high temperatures, including open flames, as well as emissions of light, noise,

particles, gases, etc., can occur inside and outside the components under fault conditions

caused by, for example:

– Component failure

– Software errors

– Operation and/or environmental conditions outside the specification

– External influences/damage

3. Hazardous shock voltages caused by, for example:

– Component failure

– Influence during electrostatic charging

– Induction of voltages in moving motors

– Operation and/or environmental conditions outside the specification

– Condensation/conductive contamination

– External influences/damage

4. Electrical, magnetic and electromagnetic fields generated in operation that can pose a risk

to people with a pacemaker, implants or metal replacement joints, etc., if they are too close

5. Release of environmental pollutants or emissions as a result of improper operation of the

system and/or failure to dispose of components safely and correctly

6. Influence of network-connected communication systems, e.g. ripple-control transmitters or

data communication via the network

For more information about the residual risks of the drive system components, see the relevant

sections in the technical user documentation.

SINAMICS S210 servo drive system

20 Operating Instructions, 12/2017, A5E41702836B AA

Page 23

Description

The components described in this manual – motor, converter and associated connection

cables – are optimally tailored to one another and thereby facilitate the installation and

commissioning in a few steps.

The commissioning and diagnostics are performed with a PC or notebook (commissioning

device) via the web server integrated in the converter. A separate commissioning program or

diagnostics tool is not required.

Correct usage

The components are intended for industrial and commercial use in industrial networks.

The motor is only approved for operation with a converter.

For system-specific setting options, refer to the following Chapter:

Typical applications

● Robots and handling systems

2

Commissioning and diagnostics in the Web server (Page 105).

● Packaging, plastics and textile machines

● Wood, glass, ceramics and stone working machines

● Printing machines

SINAMICS S210 servo drive system

Operating Instructions, 12/2017, A5E41702836B AA 21

Page 24

&RQWUROOHU3/&

HJ6,0$7,&6

2&&FRQQHFWLRQFDEOHIRU

SRZHUFRQQHFWLRQVPRWRUKROGLQJEUDNH

DQGHQFRGHUV

6,1$0,&66FRQYHUWHU

(QJLQHHULQJYLD/$1ZLWKWKH

ZHEVHUYHULQWHJUDWHGLQWKH

FRQYHUWHU

&RPPXQLFDWLRQYLD352),1(7

6,027,&66).PRWRUV

Description

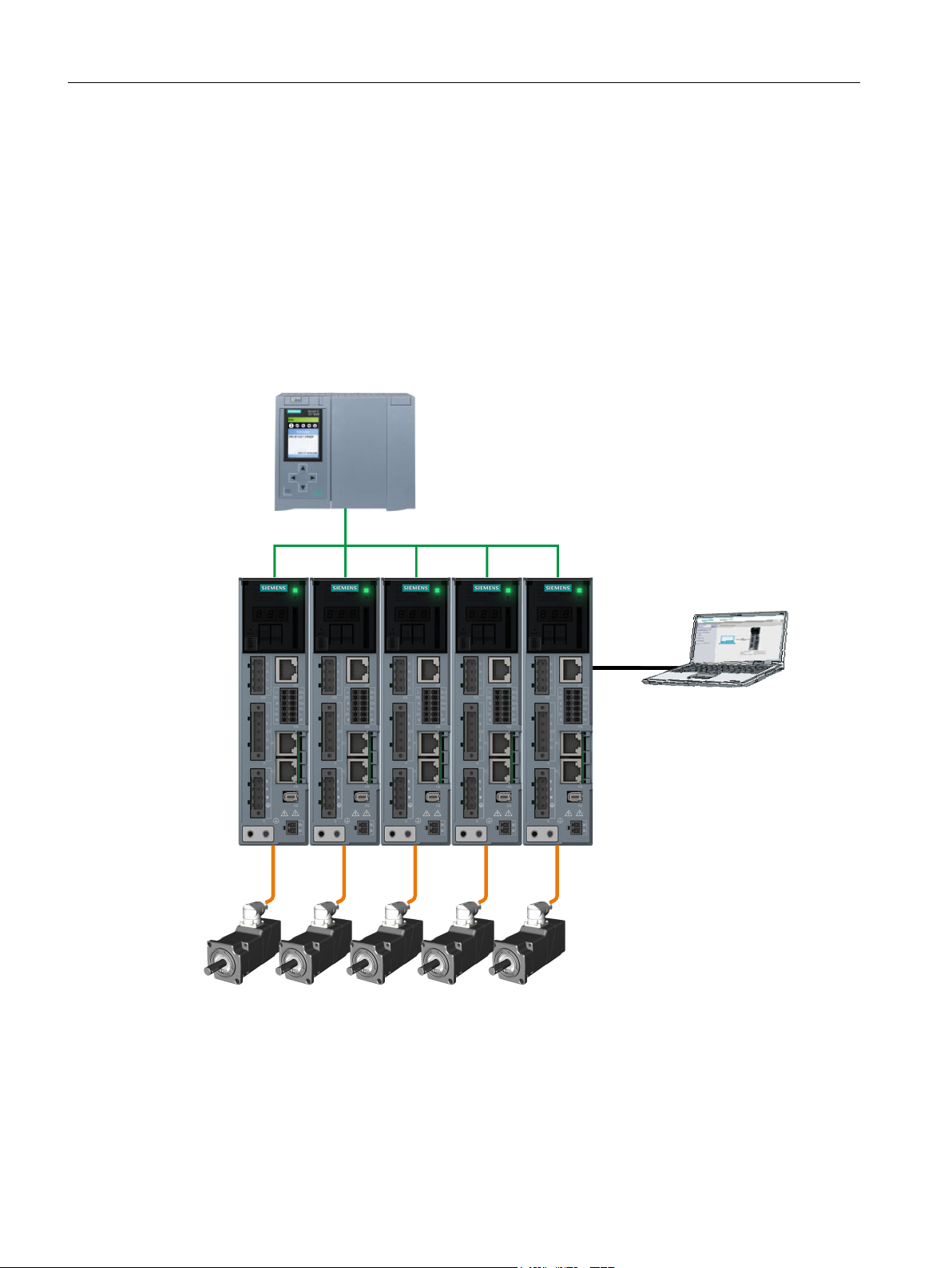

2.1 System overview

2.1 System overview

The drive system comprises the following system components tailored to one another:

● SINAMICS S210 converter

● SIMOTICS S-1FK2 motor

● OCC MOTION-CONNECT cable

The converter and the motor are optimally tailored to one another and are intended for use

with a higher-level controller (PLC). Connection to the controller is via PROFINET:

Prefabricated MOTION-CONNECT cables in various lengths are available to simply connect

the motor to the converter and to ensure safe and reliable operation.

Figure 2-1 System

22 Operating Instructions, 12/2017, A5E41702836B AA

SINAMICS S210 servo drive system

Page 25

9$&

;

;

;

;3

;

;

;

;3

;

352),1(7

352),VDIH

3(

Description

2.1 System overview

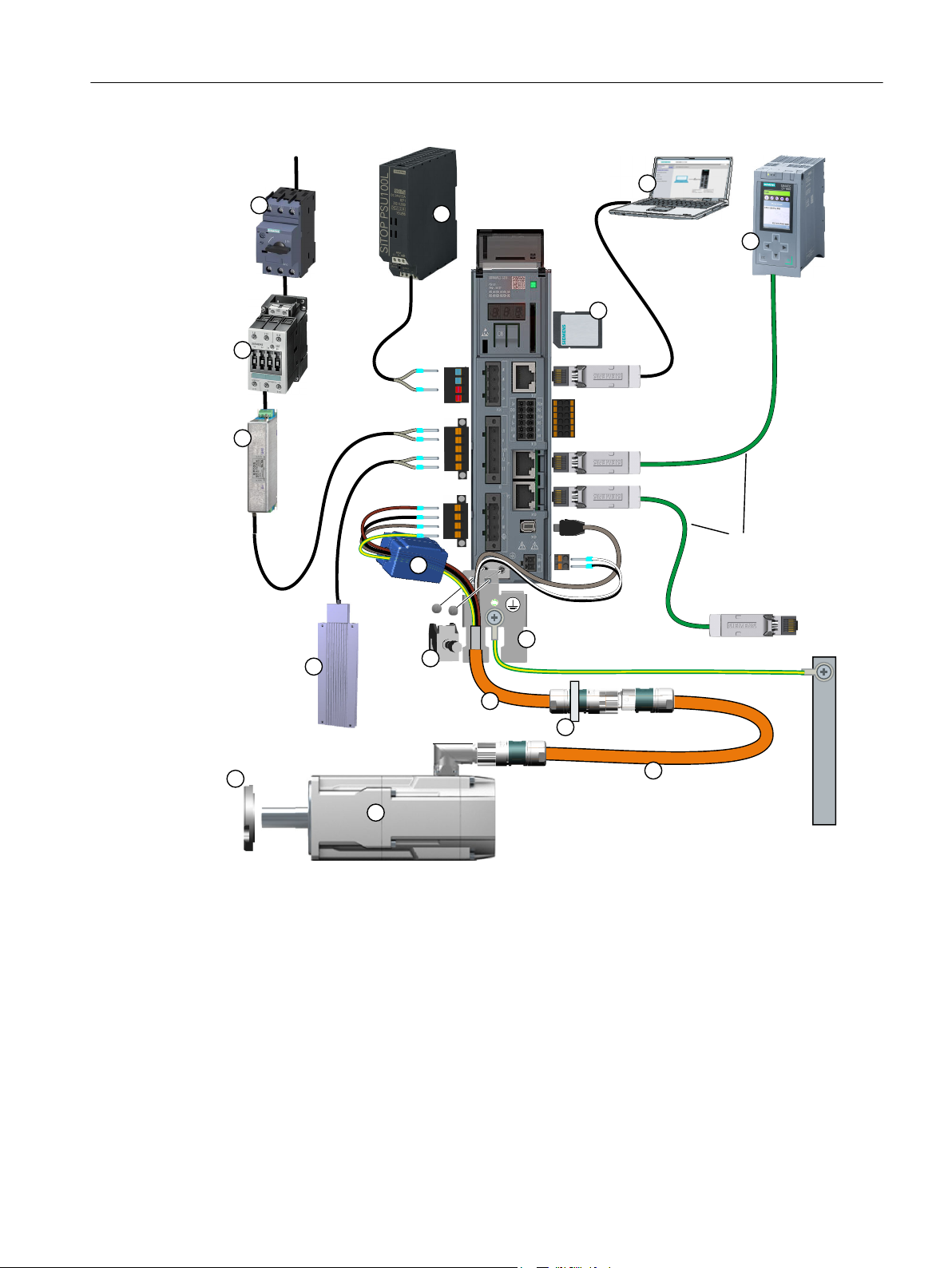

① Fuse or circuit breaker ⑨ OCC connection cable for motor, motor holding

② Line contactor (optional) ⑩ Shield clamp

③ Line filter (optional) ⑪ Shield plate

④ External braking resistor (optional) ⑫ Ferrite core (for frame size FSB)

brake and encoder

⑤ Shaft sealing ring for IP65 (optional) ⑬ 24 V power supply

⑥ 1FK2 servomotor ⑭ SD memory card (optional)

⑦ OCC extension cable (optional) ⑮ Commissioning device

⑧ Mounting flange for control cabinet

Figure 2-2 System components and accessories

bushing (optional)

⑯ Controller, e.g. SIMATIC S7-1500

SINAMICS S210 servo drive system

Operating Instructions, 12/2017, A5E41702836B AA 23

Page 26

Description

2.2 The scope of supply for the system components

2.2 The scope of supply for the system components

You must order the components individually.

Motor

The motor scope of delivery includes:

● A "Safety instructions" sheet

● A sheet referencing links to product information

Converter

The converter scope of delivery includes:

● The Quick Installation Guide (English)

● Shield plate

● A warning label for affixing in the control cabinet

● For FSB a ferrite core for EMC category C2

● The following connectors:

– X1: Line connection and external braking resistor (jumper for internal braking resistor is

enclosed.)

– X2: Motor connection

– X107: Motor holding brake

– X124: 24 V DC supply voltage

– X130: Connector for digital inputs

MOTION-CONNECT cable (OCC cable)

The scope of supply for the prefabricated MOTION-CONNECT cables includes:

● The MOTION-CONNECT cable with assembled connectors for connecting to motors and

encoders

● A shield clamp for the connection of the shield to the shield plate of the converter

● A safety data sheet

Details on the OCC MOTION-CONNECT cables can be found in the following Section:

Connection cables between the motor and the converter (Page 217).

SINAMICS S210 servo drive system

24 Operating Instructions, 12/2017, A5E41702836B AA

Page 27

2.3 Motor

The SIMOTICS S-1FK2, called "1FK2" in the following, is a permanent-magnet compact

synchronous motor with an integrated encoder and a high degree of protection.

The 1FK2 meets the requirements of standards EN 60034 and EN 60204-1 - and complies

with the Low-Voltage Directive 2014/35/EU.

Failure of pacemakers or implant malfunctions due to electromagnetic fields

Electromagnetic fields (EMF) are generated by the operation of electrical power equipment,

such as converters or motors. People with pacemakers or implants in the immediate vicinity

of this equipment are at particular risk.

Deviating from the notes in Section "General safety instructions (Page 11), applies to the

1FK2 motors:

● If you are affected, stay at a minimum distance of 30 cm from the motors.

Description

2.3 Motor

WARNING

Dynamic versions

● 1FK21 "High Dynamic" with low moment of inertia for a maximum acceleration capability

● 1FK22 "Compact" with average moment of inertia and precise positioning and synchronous

Power range

0.05 kW … 0.75 kW for a line supply voltage of 230 V 1 AC

Degree of protection

● IP64

● IP65 with a radial shaft sealing ring to protect against spray water

For additional information on the degree of protection, see Chapter:

Cooling

The 1FK2 is a non-ventilated motor.

The motor thermal losses are dissipated by thermal conduction, thermal radiation and natural

convection.

in applications with low load moments of inertia

operation characteristics for applications with a high and variable load moment of inertia

"Degree of protection (Page 180)"

If the ambient temperature exceeds 40 °C (104 °F) or the installation altitude 1000 meters

above sea level, you must reduce torque and power of the motor (derating).

Information on derating can be found in Chapter:

"Derating factors (Page 180)"

SINAMICS S210 servo drive system

Operating Instructions, 12/2017, A5E41702836B AA 25

Page 28

Description

2.3 Motor

When mounting the motor, carefully observe the specifications in Chapter:

"Cooling (Page 178)"

Bearing version

The motors have deep groove ball bearings with life-long lubrication.

The average bearing service life is designed for 25000 operating hours.

The motors have spring-loaded bearings in the NDE direction. For version with holding brake,

the NDE bearing is a locating bearing.

The permissible axial and radial forces can be found in the technical data in Chapter:

"Permissible radial and axial forces (Page 185)"

Shaft extension (IEC 60072-1)

● Cylindrical shaft without feather key

● Cylindrical shaft with feather key (half-key balancing)

● Optional for SH30 (1FK2❒03): Cylindrical shaft without feather key, diameter x length:

11 mm x 23 mm

Encoder

Holding brake

For additional information, see Chapter:

"Shaft extension (Page 183)"

The motor encoder resolution is 20 bit (1,048,576) per revolution (singleturn). An optional

multiturn encoder is available that is equipped with an additional 12-bit revolution counter

(traversing range of 4096 revolutions).

The names of these two encoders are as follows:

● AS20DQC: Absolute encoder, singleturn, 20 bit

● AM20DQC: Absolute encoder, 20 bit + 12 bit multiturn

For additional information, see Chapter:

"Available encoders (Page 185)"

The 1FK2 servomotor is available with integrated holding brake. The holding brake is used to

clamp the motor shaft when the motor is at a standstill.

The holding brake closes in the current-free state and locks the motor shaft. It opens as soon

as current is flowing.

SINAMICS S210 controls the holding brake without any additional devices.

The torsional backlash of the holding brake is less than 1°.

The holding brake is not a working brake for braking the rotating motor. However, limited

emergency stop operation is permissible.

SINAMICS S210 servo drive system

26 Operating Instructions, 12/2017, A5E41702836B AA

Page 29

Rating plate

+

SIMOTICS 1P 1FK2104-4AK00-0CA0

M0 1,27 Nm

Brake 24 VDC

Siemens AG, DE-97616 Bad Neustadt Made in Germany

Encoder AS22DQ35 G95

3 ~ Mot. S YF JO662 2670 01 002

Z:

M

N

1,27 Nm

I0 2,4 A

IN 2,4 A

n

max

7400 /min

nn 3000 /min

UiN108 V Th.Cl.155 (F)

IP 64 IC410

RN 000

m: 3 kg

EN60034

Description

2.3 Motor

The brake data can be found in Chapter:

"Brake data (Page 185)"

The rating plate contains the Article No. and the technical information of the motor.

Figure 2-3 Rating plate

Position Description / technical specifica‐

Position Description / technical specifications

tions

1 Article number 12 Degree of protection

2 ID No., serial number 13 Rated current

3 Additional options specified as a

supplement to the article number

4 Static torque

M

/ Nm 15 Thermal class of the insulation sys‐

0

14 Cooling mode according to EN

60034-6

I

/ A

rated

tem

5 Rated torque

6 Induced voltage at rated speed

M

/ Nm 16 Revision

rated

V

/ V17 Type of balancing (only for motors

IN

with feather key)

7 Motor weight m / kg 18 Rated speed

8 Marking of encoder type 19 Maximum speed

n

rated

/ rpm

n

/ rpm

max

9 Data of the holding brake 20 Certifications

10 Manufacturer's address 21 Standard for all rotating electrical ma‐

chines

11 Stall current

I

/ A 22 Data matrix code

0

SINAMICS S210 servo drive system

Operating Instructions, 12/2017, A5E41702836B AA 27

Page 30

Description

2.4 Converter

2.4 Converter

The converter is a single-axis device (complete converter with integrated infeed). It is

characterized by a compact design, side-by-side installation and high overload capability.

It is intended for use with 1FK2 motors.

● Supply voltage 200 V … 240 V 1 AC ± 10%

●

Power range 100 W … 750 W

Control mode

Servo control, optimized for 1FK2 motors

Integrated safety functions

With firmware version 5.1, the converter provides the following Safety Integrated Basic

Functions:

● STO - Safe Torque Off

● SS1 - Safe Stop 1, time-controlled

● SBC - Safe Brake Control

Safety functions integrated in the drive (Page 57)

Integrated braking resistor

In order to absorb the regenerative load of the motor, converters have an internal braking

resistor (exception: 100 W device).

If the internal braking resistor is not sufficient, you have the option of connecting an external

braking resistor.

Configuring the external braking resistor (Page 52)

Connections at the converter (Page 95)

Communicating with the controller via PROFINET

The converter supports the following functions:

RT (real time)

●

● IRT (isochronous real time)

● MRP (media redundancy) with RT

● MRPD (seamless media redundancy) with IRT

● Shared device

● PROFIsafe

● PROFIenergy

● Automatic telegram selection

SINAMICS S210 servo drive system

28 Operating Instructions, 12/2017, A5E41702836B AA

Page 31

Commissioning, diagnostics and data backup

SINAMICS S210

1P 6SL3210-5HB10-4UF0

S ZVE4Y7M000141

SNC-A5E37577127

INPUT: 1AC 200-240V 5.8A/0.3A 50/60Hz

INPUT: 24VDC 0.5A OUTPUT: 3AC 0-INPUT V 2.6A 0-550Hz

IP CLASS: IP20 MOTOR: 0.2kW/0.4kW

VERSION: 01 SCCR: 65kA

USE IN PD2 AND OVC III ENVIRONMENT ONLY

USE 75°C COPPER WIRES ONLY | REFER TO MANUAL

KCC-

REM-S49-

S100

Siemens AG, Frauenauracher Str. 80, DE-91056 Erlangen

Made in China

IND.CONT.EQ.

4TR2

s

The commissioning, diagnostics and data backup are performed using a PC or notebook

(commissioning device) via the web server integrated in the converter.

The converter is connected to the commissioning device via the service interface (X127).

Functions of the web server integrated into the converter:

● Commissioning

● Diagnostics of the drive

● Data backup and restore

● Restoring factory settings

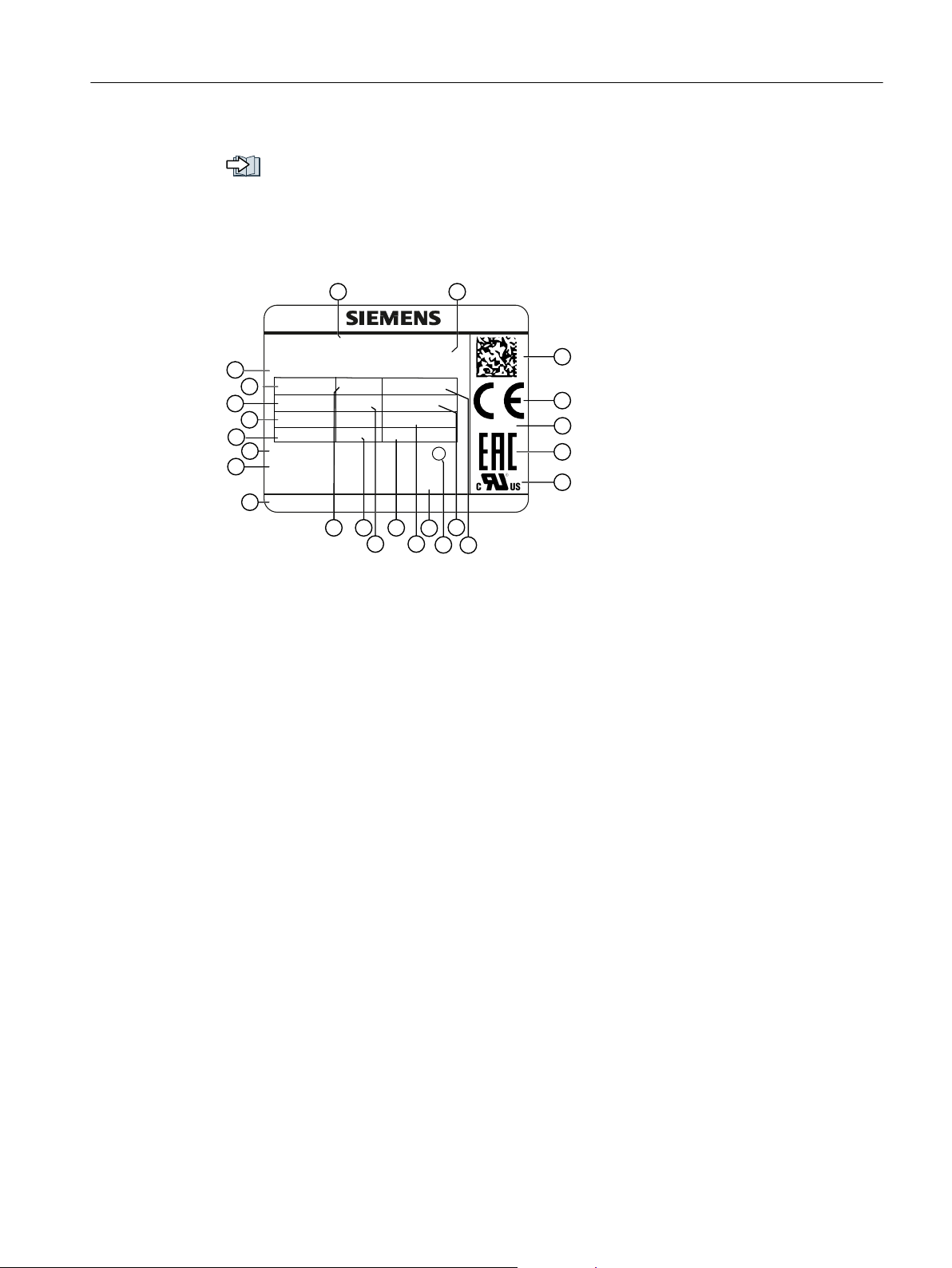

Rating plate and information plate

Description

2.4 Converter

1 Manufacturer 8 Environmental conditions

2 Product designation 9 Reference to the manual

3 Article number 10 Certificates

4 Serial number 11 Manufacturer's address

5 Material number 12 Production location

6 Electrical data and degree of protection 13 Data matrix code

7 Version number

Figure 2-4 Rating plate of the converter

SINAMICS S210 servo drive system

Operating Instructions, 12/2017, A5E41702836B AA 29

Page 32

PN1 / X127

FS: 01

SINAMICS S210

00-0 0-00-00-00-0 0

00-0 0-00-00-00-0 0

Description

2.4 Converter

1 Product designation 4 MAC address of the PROFINET interface

2 Function release 5 MAC address of the service interface

3 PROFINET interface / service interface 6 Data matrix code

Figure 2-5 Information plate of the converter

30 Operating Instructions, 12/2017, A5E41702836B AA

SINAMICS S210 servo drive system

Page 33

2.5 Connection systems

The motor is connected to the converter by a MOTION-CONNECT cable.

The cable is in one cable connection technology and called "OCC cable" in the following.

As a result of its flexibility and low diameter, it permits very tight bending radii.

The OCC cables are available in the following variants:

● MOTION-CONNECT 500

– Cost-effective solution for mainly fixed installation

– Suitable for low mechanical loading

● MOTION-CONNECT 800PLUS

– Meets requirements for use in cable carriers

- tested for horizontal movement distances up to 50 m

- not self-supporting

– Suitable for high mechanical loading

– Oil-resistant

Description

2.5 Connection systems

The OCC cables can be supplied in lengths by the decimeter.

Extensions and cabinet bushings are available for the OCC cables.

For additional information, see Chapter:

"Technical data and properties of the connection system (Page 204)"

SINAMICS S210 servo drive system

Operating Instructions, 12/2017, A5E41702836B AA 31

Page 34

Description

2.6 Motor-converter combinations

2.6 Motor-converter combinations

The following table contains possible combinations of motors, converters and the associated

connecting cables.

Motor Converter OCC cable

Shaft

height

[mm]

High Dynamic

20 1FK2102-0AG… 0.16 x x

20 1FK2102-1AG… 0.32 x x

30 1FK2103-2AG… 0.64 x x

30 1FK2103-4AG… 1.27 x x

40 1FK2104-4AK… 1.27 x x

40 1FK2104-5AK… 2.4 x x

Compact

30 1FK2203-2AG... 0.64 x x

30 1FK2203-4AG... 1.27 x x

Article number

digits 1 … 10

Torque

M

/ Nm 100 W 200 W 400 W 750 W M12 M17

0

Article number

6SL3210-5HB10-...

…1UF0 …2UF0 …4UF0 …8UF0 …8QN04-... …8QN08-...

Article number

6FX . 002-...

SINAMICS S210 servo drive system

32 Operating Instructions, 12/2017, A5E41702836B AA

Page 35

2.7 Optional accessories

The following accessories are optionally available for the drive:

● Memory card for the converter for data backup, series commissioning and for firmware

updates

● Line filter

● Extension cable

● Components for customers to fabricate the connecting cable

– Shield clamp

– Connectors and cut-to-length cables (probably available from spring 2018)

● Mounting flange for control cabinet bushing

● Degree of protection kit: Shaft sealing ring for IP65 degree of protection for the motor

Ordering data (Page 215)

Description

2.7 Optional accessories

SINAMICS S210 servo drive system

Operating Instructions, 12/2017, A5E41702836B AA 33

Page 36

Description

2.7 Optional accessories

SINAMICS S210 servo drive system

34 Operating Instructions, 12/2017, A5E41702836B AA

Page 37

Configuring

3.1 EMC-compliant installation of a machine or system

The converter is designed for operation in industrial environments.

Reliable and disturbance-free operation is only guaranteed for EMC-compliant installation.

Further information

Additional information about EMC-compliant installation is available in the Internet:

EMC installation guideline (http://support.automation.siemens.com/WW/view/en/60612658)

3.1.1 Control cabinet

Control cabinet assembly

● Install a shield support for shielded cables that are routed out of the control cabinet.

3

● Connect the PE bar and the shield support to the control cabinet frame through a large

surface area to establish a good electrical connection.

● Mount the converter, the 24 V DC power supply and the optional line filter on a bare metal

mounting plate.

● Connect the mounting plate to the control cabinet frame and PE bar and shield support

through a large surface area to establish a good electrical connection.

SINAMICS S210 servo drive system

Operating Instructions, 12/2017, A5E41702836B AA 35

Page 38

Configuring

3.1 EMC-compliant installation of a machine or system

3.1.2 Cables

Cables with a high level of interference and cables with a low level of interference are

connected to the converter.

Note

Cables with a high level of interference must be shielded.

● Cables with a high level of interference:

– Cable between the line filter and converter

– Motor cable

– Cable between the converter and external braking resistor

● Cables with a low level of interference:

– Cable between the line and line filter

– Signal and data cables

Cable routing inside the cabinet

● Route the cables with a high level of interference so that there is the largest possible

clearance to cables with a low level of interference.

● Cables with a high level of interference and cables with a low level of interference may only

cross over at right angles:

● Keep all of the cables as short as possible.

● Route all of the cables close to the mounting plates or cabinet frames.

● Route signal and data cables - as well as the associated equipotential bonding cables parallel and close to one another.

● Twist incoming and outgoing unshielded individual conductors.

Alternatively, you can route incoming and outgoing conductors in parallel, but close to one

another.

● Ground any unused conductors of signal and data cables at both ends.

● Signal and data cables must only enter the cabinet from one side, e.g. from below.

● Use shielded cables for the following connections:

– Cable between the converter and line filter

– Cable between the converter and motor

– Cable between the converter and external braking resistor

SINAMICS S210 servo drive system

36 Operating Instructions, 12/2017, A5E41702836B AA

Page 39

0RXQWLQJSODWH

6KLHOGVXSSRUW

)XVHVVZLWFKHVDQG

FRQWDFWRUV

)LOWHURSWLRQDO

&RQYHUWHU

&RQQHFWVKLHOG

(OHFWULFDOO\

FRQGXFWLYH

FRQQHFWLRQV

WKURXJKDODUJH

VXUIDFHDUHD

%UDNLQJUHVLVWRU

RSWLRQDO

&RQWUROFDELQHW

/LQH

&RQQHFWVKLHOG

&RQQHFWVKLHOG

3.1 EMC-compliant installation of a machine or system

Routing converter cables inside and outside a control cabinet

Configuring

Figure 3-1 Routing converter cables inside and outside a control cabinet

Routing cables outside the control cabinet

● Maintain a minimum clearance of 25 cm between cables with a high level of interference

and cables with a low level of interference.

● Use shielded cables for the following connections:

– Converter motor cable

– Cable between the converter and braking resistor

– Signal and data cables

SINAMICS S210 servo drive system

Operating Instructions, 12/2017, A5E41702836B AA 37

Page 40

2&&FRQQHFWLRQFDEOHWRWKH

PRWRU

)HUULWHFRUHUHTXLUHGIRU)6%

IRU(0&&DWHJRU\&

&RQQHFWLRQFDEOHIRUH[WHUQDO

EUDNLQJUHVLVWRU

&RQQHFWLRQFDEOHIRUIDLOVDIHGLJLWDO

LQSXWDQGSUREH

Configuring

3.1 EMC-compliant installation of a machine or system

Requirements relating to shielded cables

● Use cables with finely-stranded, braided shields.

● Connect the shield at both ends of the cable.

Figure 3-2 Shield support with the shield terminal from the scope of supply of the MOTION-

CONNECT OCC cable.

● Connect the shield to the shield support.

● Do not interrupt the shield.

3.1.3 Electromechanical components

Surge voltage protection circuit

● Connect surge voltage protection circuits to the following components:

– Coils of contactors

– Relays

– Solenoid valves

● Connect the surge voltage protection circuit directly at the coil.

● Use RC elements or varistors for AC-operated coils and freewheeling diodes or varistors

for DC-operated coils.

38 Operating Instructions, 12/2017, A5E41702836B AA

SINAMICS S210 servo drive system

Page 41

3.2 Permissible line supplies and connection options

3.2 Permissible line supplies and connection options

The converter is designed for the following line supplies according to IEC 60364-1 (2005).

● TN system

● TT system

● IT system

Converter operated on an IT system

You must move the grounding screw when operating the converter on an IT line system. As

a consequence, you remove the grounding of the integrated EMC filter.

Configuring

Figure 3-3 Screw for grounding at the converter

SINAMICS S210 servo drive system

Operating Instructions, 12/2017, A5E41702836B AA 39

Page 42

1RWUDQVIRUPHUUHTXLUHG

1RWUDQVIRUPHUUHTXLUHG1RWHWKH

IROORZLQJVDIHW\LQVWUXFWLRQV

UHJDUGLQJWKHFXUUHQWVLQWKH

QHXWUDOFRQGXFWRU

7UDQVIRUPHUUHTXLUHG7UDQVIRUPHUUHTXLUHG

1RWUDQVIRUPHUUHTXLUHG

1RWUDQVIRUPHUUHTXLUHG

/

1

$&99

$&99

9

9

9

1

$&99

/

/

/

1

/

1

$&9

/

/

/

1

$&99$&99

/

/

/

Configuring

3.2 Permissible line supplies and connection options

3.2.1 Connection options, 230 V devices

Basic connection options