Page 1

© Siemens 2020

Catalog

D 32

Edition

January

2020

Motion Control Drives

SINAMICS S210

Servo Drive System

siemens.com/drives

Page 2

Related catalogs

Motion Control Drives D 31.1

SINAMICS Inverters for Single-Axis Drives

Built-In Units

© Siemens 2020

Motion Control System PM 21

SIMOTION

Equipment for Production Machines

E86060-K5531-A111-A1-7600

Motion Control Drives D 31.2

SINAMICS Inverters for Single-Axis Drives

Distributed Inverters

E86060-K5531-A121-A1-7600

Motion Control Drives D 31.5

SINAMICS Converters for Single-Axis Drives

SINAMICS G120X infrastructure converters

for HVAC/Water/Wastewater

PDF (E86060-K5531-A151-A3-7600)

SINAMICS S120 D 21.3

Chassis Format Converter Units

Chassis-2 Format Converter Units

Cabinet Modules, Cabinet Modules-2

SINAMICS S150

Converter Cabinet Units

E86060-K5521-A131-A7-7600

Motion Control Drives D 21.4

SINAMICS S120 and SIMOTICS

E86060-K5521-A141-A1-7600

E86060-K4921-A101-A4-7600

Industrial Controls IC 10

SIRIUS

E86060-K1010-A101-B1-7600

Industrial Controls IC 10 AO

SIRIUS Classic

PDF (E86060-K1010-A191-A5-7600)

Low-Voltage Power Distribution and LV 10

Electrical Installation Technology

SENTRON

• SIVACON • ALPHA

Protection, Switching, Measuring and Monitoring

Devices, Switchboards and Distribution Systems

PDF (E86060-K8280-A101-B1-7600)

Print (E86060-K8280-A101-A6-7600)

SIMATIC ST 70

Products for

Totally Integrated Automation

SIMOTICS S-1FG1

D 41

Servo geared motors

Helical, Parallel shaft, Bevel and

Helical worm geared motors

PDF (E86060-K5541-A101-A4-7600)

SIMOTICS GP, SD, XP, DP D 81.1

Low-Voltage Motors

Type series 1FP1, 1LE1, 1LE5, 1MB1, 1MB5, 1PC1

Frame sizes 63 to 450

Power range 0.09 to 1000 kW

PDF (E86060-K5581-A111-B4-7600)

FLENDER Couplings MD 10.1

Standard Couplings

E86060-K5710-A111-A5-7600

SIMOGEAR D 50.1

Geared Motors

Helical, parallel shaft, bevel, helical worm

and worm geared motors

E86060-K5250-A111-A6-7600

PDF (E86060-K4670-A101-B7-7600)

SIMATIC HMI / ST 80/ST PC

PC-based Automation

Human Machine Interface Systems

PC-based Automation

PDF (E86060-K4680-A101-C7-7600)

Industrial Communication IK PI

SIMATIC NET

E86060-K6710-A101-B8-7600

Products for Automation and Drives CA 01

Interactive Catalog

Download

www.siemens.com/automation/ca01

Industry Mall

Information and Ordering Platform

on the Internet:

www.siemens.com/industrymall

Change 07/2020

Page 3

© Siemens 2020

SINAMICS S210

Servo Drive System

Motion Control Drives

Catalog D 32 · January 2020

Dear Customer,

We are pleased to present you with the new Catalog D 32 · January 2020. This edition replaces Catalog D 32 · April 2019. The catalog

provides a comprehensive overview of the new SINAMICS S210 servo drive system consisting of a SINAMICS S210 servo converter,

a SIMOTICS S-1FK2 servomotor and a matching One Cable Connection (OCC).

The single-axis AC/AC servo converter system stands out due to its high performance and dynamic response for mid-range Motion

Control applications. In addition to details of updates and technical modifications, the latest edition of the catalog has also been

supplemented with the 400 V versions.

The products listed in this catalog are also included in the Industry Mall. Please contact your local Siemens office for additional

information.

NEW:

By clicking on the Article No. in the web PDF you can jump directly to the Industry Mall where you can obtain additional

information and order products online.

Up-to-date information about SINAMICS S210 is available on the Internet at:

www.siemens.com/sinamics-s210

You can access our Interactive Catalog and Industry Mall online at:

www.siemens.com/industrymall

Your personal contact will be happy to receive your suggestions and recommendations for improvement.

You can find your representative in our Personal Contact database at:

www.siemens.com/automation-contact

We hope that you will often enjoy using Catalog D 32 · January 2020 as a selection and ordering reference document and wish you

every success with our products and solutions.

With kind regards,

Achim Peltz

Vice President

General Motion Control

Siemens AG, Digital Industries, Motion Control

siemens.com/drives

Page 4

© Siemens 2020

Page 5

© Siemens 2020

SINAMICS S210 Servo Drive System

Motion Control Drives

Catalog D 32 · January 2020

Supersedes:

Catalog D 32 · April 2019

Refer to the Industry Mall for current updates of

this catalog:

www.siemens.com/industrymall

System overview

SINAMICS S210 servo drive

SIMOTICS S-1FK2 servomotors

MOTION-CONNECT connection systems

1

2

3

4

The products contained in this catalog can also be found

in the Interactive Catalog CA 01.

The Catalog CA 01 can be downloaded at:

www.siemens.com/automation/ca01

Please contact your local Siemens branch.

© Siemens 2020

Click on an Article No. in the catalog PDF to call it up in the

Industry Mall and to obtain all the information.

Article No.

6SL3070-0AA00-0AG0

6SL3072-0AA00-0AG0

Or directly on the Internet, e.g.

www.siemens.com/product?6SL3070-0AA00-0AG0

Engineering tools

Services and documentation

Appendix

5

6

7

The products and systems described in

this catalog are manufactured/distributed

under application of a certified quality

management system in accordance with

DIN EN ISO 9001. The certificate is

recognized by all IQNet countries.

Page 6

© Siemens 2020

Digital Enterprise

The building blocks that ensure

everything works together

perfectly in the digital enterprise

Digitalization is already changing all areas of life and existing

business models. It is placing greater pressure on industry

while at the same time creating new business opportunities.

Today, thanks to scalable solutions from Siemens, companies

can already become a digital enterprise and ensure their

competitiveness.

Industry faces tremendous challenges

Reduce

time-to-market

Today manufacturers

have to bring products to

market at an ever-increasing pace despite the

growing complexity of

these products. In the

past, a major manufacturer would push aside a

small one, but now it is a

fast manufacturer that

overtakes a slow one.

Boost

flexibility

Consumers want customized products, but at

a price they would pay

for a mass-produced

item. That only works

if production is more

flexible than ever

before.

Improve

quality

To ensure a high level of

quality while meeting

legal requirements,

companies have to

establish closed quality

loops and enable the

traceability of products.

Boost

efficiency

Today the product itself

needs to be sustainable

and environmentally

friendly, while energy

efficiency in production

has become a competitive advantage.

Increase

security

Increasing networking

escalates the threat to

production facilities

of cyberattacks. Today

more than ever, companies need suitable

security measures.

2

Siemens D 32 · January 2020

Page 7

© Siemens 2020

The digital enterprise has already

become a reality

To fully benefit from all the advantages of

digitalization, companies first have to

achieve complete consistency of their data.

Fully digitally integrated business processes,

including those of suppliers, can help to

create a digital representation of the entire

value chain. This requires

• the integration of industrial software

and automation,

• expansion of the communication networks,

• security in automation,

• and the use of business-specific

industrial services.

MindSphere

The cloud-based open IoT operating

system from Siemens

With MindSphere, Siemens offers a costeffective and scalable cloud platform as a

service (PaaS) for the development of applications. The platform, designed as an open

operating system for the Internet of Things,

makes it possible to improve the efficiency

of plants by collecting and analyzing large

volumes of production data.

Totally Integrated Automation (TIA)

Where digitalization becomes reality

Totally Integrated Automation (TIA) ensures

the seamless transition from the virtual to

the real world. It already encompasses all

the necessary conditions for transforming

the benefits of digitalization into true added

value. The data that will form the digital

twin for actual production is generated from

a common base.

IA/DT Digital Enterprise En 05.03.18

Digital Plant

Learn more about the

digital enterprise for the

process industry

www.siemens.com/

digitalplant

Digital Enterprise Suite

Learn more about the

digital enterprise for the

discrete industry

www.siemens.com/

digital-enterprise-suite

Siemens D 32 · January 2020

3

Page 8

With TIA Portal you can

cut your engineering time

by up to

30 %

© Siemens 2020

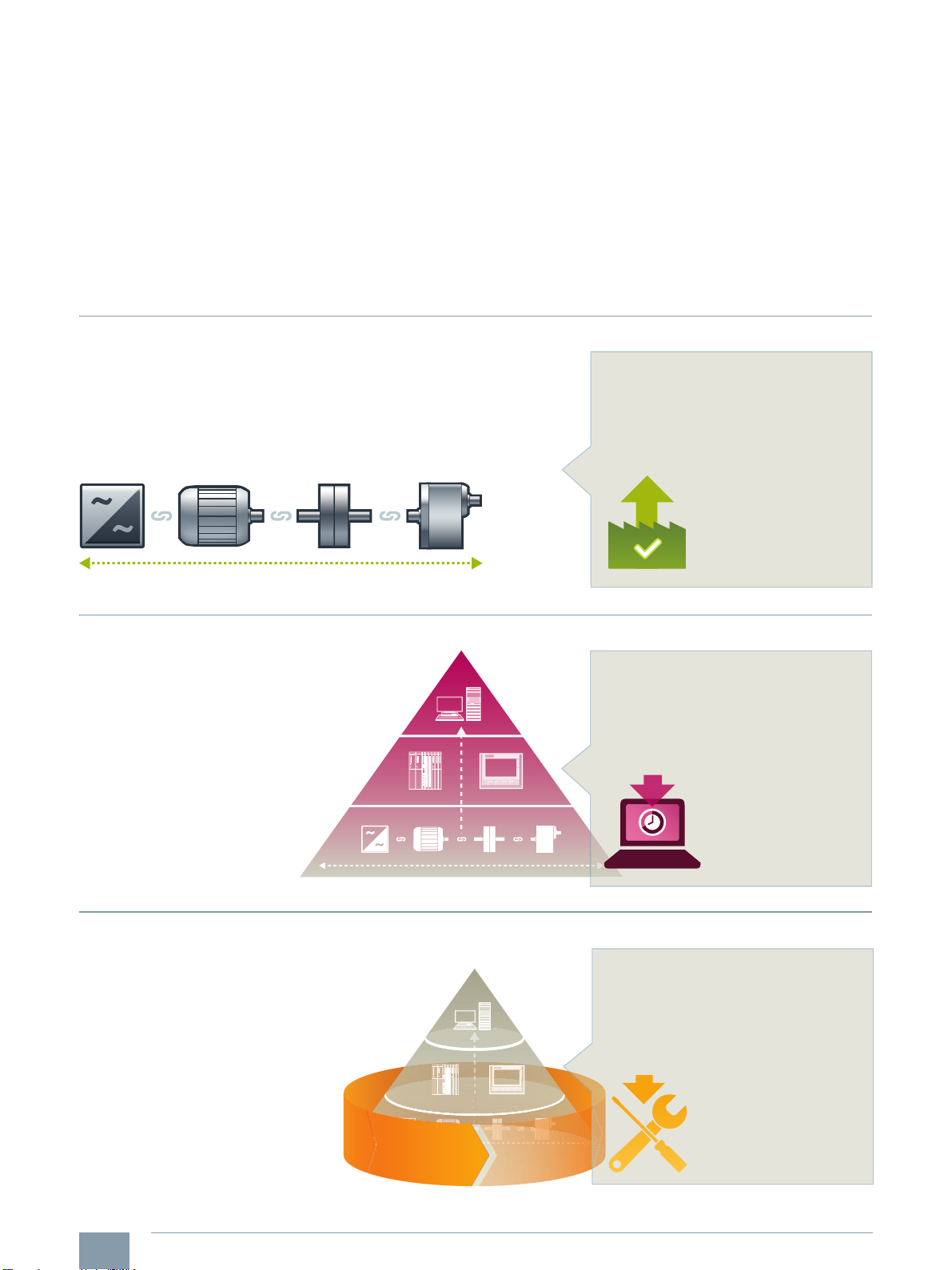

Integrated Drive Systems

Faster on the market and in the black with Integrated Drive Systems

Integrated Drive Systems are Siemens’ trendsetting answer to the high

degree of complexity that characterizes drive and automation technology

today. The world’s only true one-stop solution for entire drive systems is

characterized in particular by its threefold integration: Horizontal, vertical,

and lifecycle integration ensure that every drive system component fits

seamlessly into the whole system, into any automation environment, and

even into the entire lifecycle of a plant.

Horizontal integration

Integrated drive portfolio: The core elements of a fully integrated drive

portfolio are frequency converters, motors, couplings, and gear units.

At Siemens, they‘re all available from a single source. Perfectly integrated,

perfectly interacting. For all power and performance classes. As standard

solutions or fully customized. No other player in the market can offer a

comparable portfolio. Moreover, all Siemens drive components are

perfectly matched, so they are optimally interacting.

The outcome is an optimal workflow – from engineering all the way to

service that entails more productivity, increased efficiency, and better

availability. That’s how Integrated Drive Systems reduce time to market

and time to profit.

You can boost the avail ability

of your application or plant

to up to

*

99 %

*e.g., conveyor application

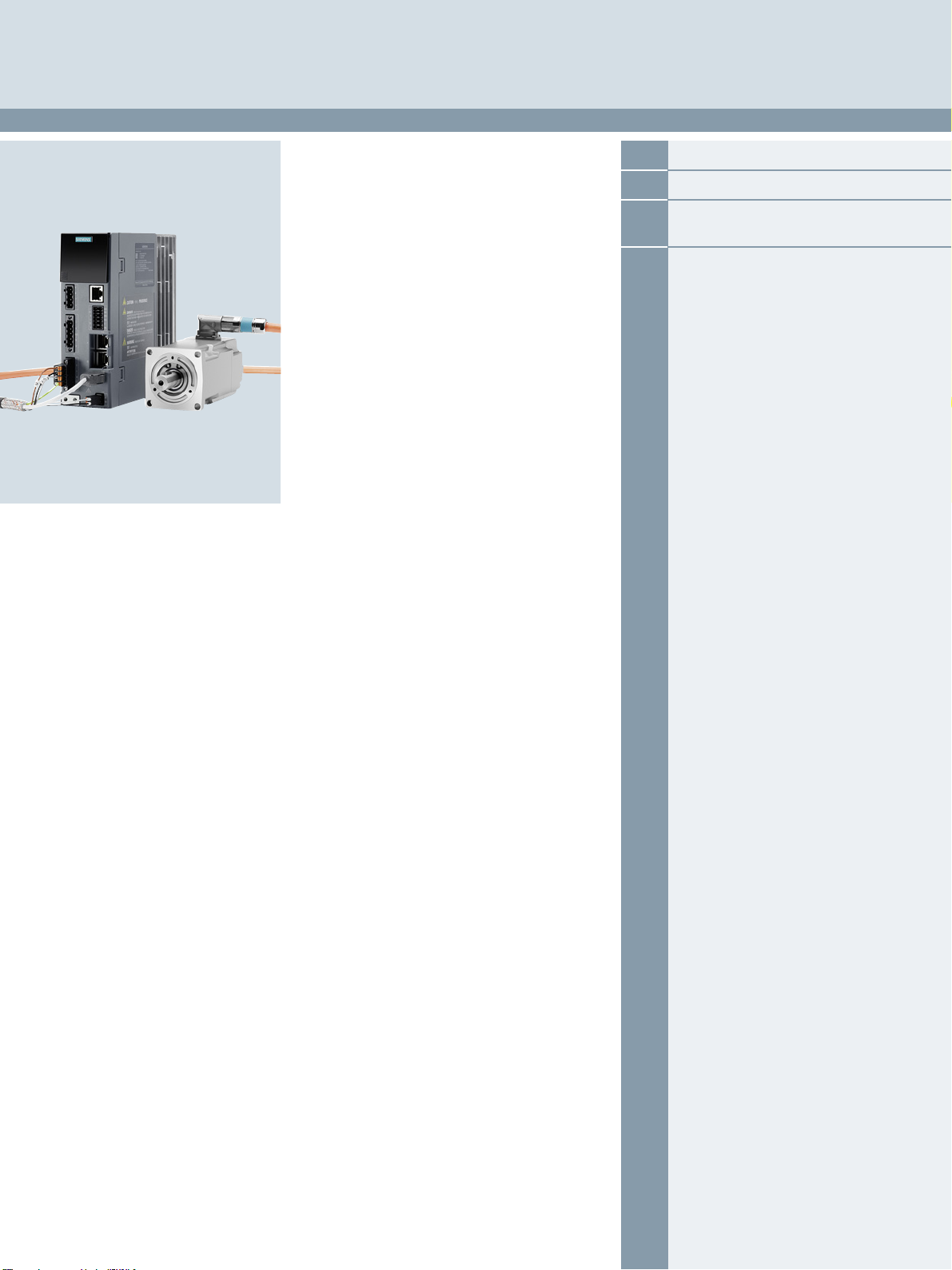

Vertical integration

Thanks to vertical integration, the complete drive train is

seamlessly integrated in the entire automation environment –

an important prerequisite for production with maximum

value added. Integrated Drive Systems are part of Totally

Integrated Automation (TIA), which means that they

are perfectly embedded into the system architecture

of the entire industrial production process. This

enables optimal processes through maximum

communication and control.

Lifecycle integration

Lifecycle integration adds the factor of time: Software and service

are available for the entire lifecycle of an Integrated Drive System.

That way, important optimization potential for maximum

productivity, increased efficiency, and highest availability

can be leveraged throughout the system’s lifecycle –

from planning, design, and engineering to operation,

maintenance, and all the way even to

modernization.

With Integrated Drive Systems, assets

become important success factors. They

ensure shorter time to market, maximum

productivity and efficiency in operation,

and shorter time to profit.

With Integrated Drive

Systems you can reduce

your main tenance costs

by up to

15 %

4

Siemens D 32 · January 2020

www.siemens.com/ids

Page 9

System overview

© Siemens 2020

1

1/2 The SINAMICS converter family

1/6 Drive selection

1/7 SINAMICS S210 servo drive system

1/13 Order overview

1/20 SINAMICS S210 starter kit

Siemens D 32 · January 2020

Page 10

1

System overview

Management level

Process control level Control center / control system:

SIMATIC PCS 7 / WINCC

Automation systems / HMI:

SIMATIC / SIMOTION / SINUMERIK

pumping

ventilating

compressing

moving processing

machining

G_D011_EN_00337d

Office environment: SIMATIC IT / COMOS...

Control level

Fieldbus

SINAMICS V

SINAMICS G

SINAMICS V

SINAMICS G

SINAMICS S

SINAMICS V

SINAMICS G

SINAMICS S

SINAMICS S

The SINAMICS converter family

■

Overview

Integration in automation

© Siemens 2020

Totally Integrated Automation and communication

SINAMICS is an integral component of the Siemens "Totally

Integrated Automation" concept. Integrated SINAMICS systems

covering configuration, data storage, and communication at

automation level ensure low-maintenance solutions with the

SIMATIC, SIMOTION and SINUMERIK control systems.

Depending on the application, the appropriate variable

frequency drives can be selected and incorporated in the automation concept. With this in mind, the drives are clearly subdivided into their different applications. A wide range of communication options (depending on the drive type) are available for

establishing a communication link to the automation system:

•PROFINET

Applications

SINAMICS is the comprehensive converter family from Siemens

designed for machine and plant engineering applications.

SINAMICS offers solutions for all drive tasks:

• Simple pump and fan applications in the process industry

• Demanding single drives in centrifuges, presses, extruders,

elevators, as well as conveyor and transport systems

• Drive line-ups in textile, plastic film, and paper machines as

well as in rolling mill plants

• Highly dynamic servo drives for machine tools, as well as

packaging and printing machines

• PROFIBUS

• EtherNet/IP

• Modbus TCP

•Modbus RTU

•BACnet MS/TP

• AS-Interface

1/2

Siemens D 32 · January 2020

Page 11

1

■

SIMOTICSSIMOGEAR

G_D011_XX_00515b

SIMATICSIMOTION SINUMERIK

SINAMICS

Overview

SINAMICS as part of the Siemens modular automation system

© Siemens 2020

System overview

The SINAMICS converter family

Innovative, energy-efficient and reliable drive systems and

applications as well as services for the entire drive train

The solutions for drive technology place great emphasis on

the highest productivity, energy efficiency and reliability for all

torque ranges, performance and voltage classes.

Siemens offers not only the right innovative variable frequency

drive for every drive application, but also a wide range of

energy-efficient low-voltage motors, geared motors, explosionprotected motors and high-voltage motors for combination with

SINAMICS.

Furthermore, Siemens supports its customers with global

pre-sales and after-sales services, with over 295 service points

in 130 countries – and with special services e.g. application

consulting or motion control solutions.

Energy efficiency

Energy management process

Efficient energy management consultancy identifies the energy

flows, determines the potential for making savings and implements them with focused activities.

Almost two thirds of the industrial power requirement is from

electric motors. This makes it all the more important to use drive

technology permitting energy consumption to be reduced effectively even in the configuration phase, and consequently to

optimize plant availability and process stability. With SINAMICS,

Siemens offers powerful energy efficient solutions which,

depending on the application, enable a significant reduction in

electricity costs.

Siemens D 32 · January 2020

1/3

Page 12

1

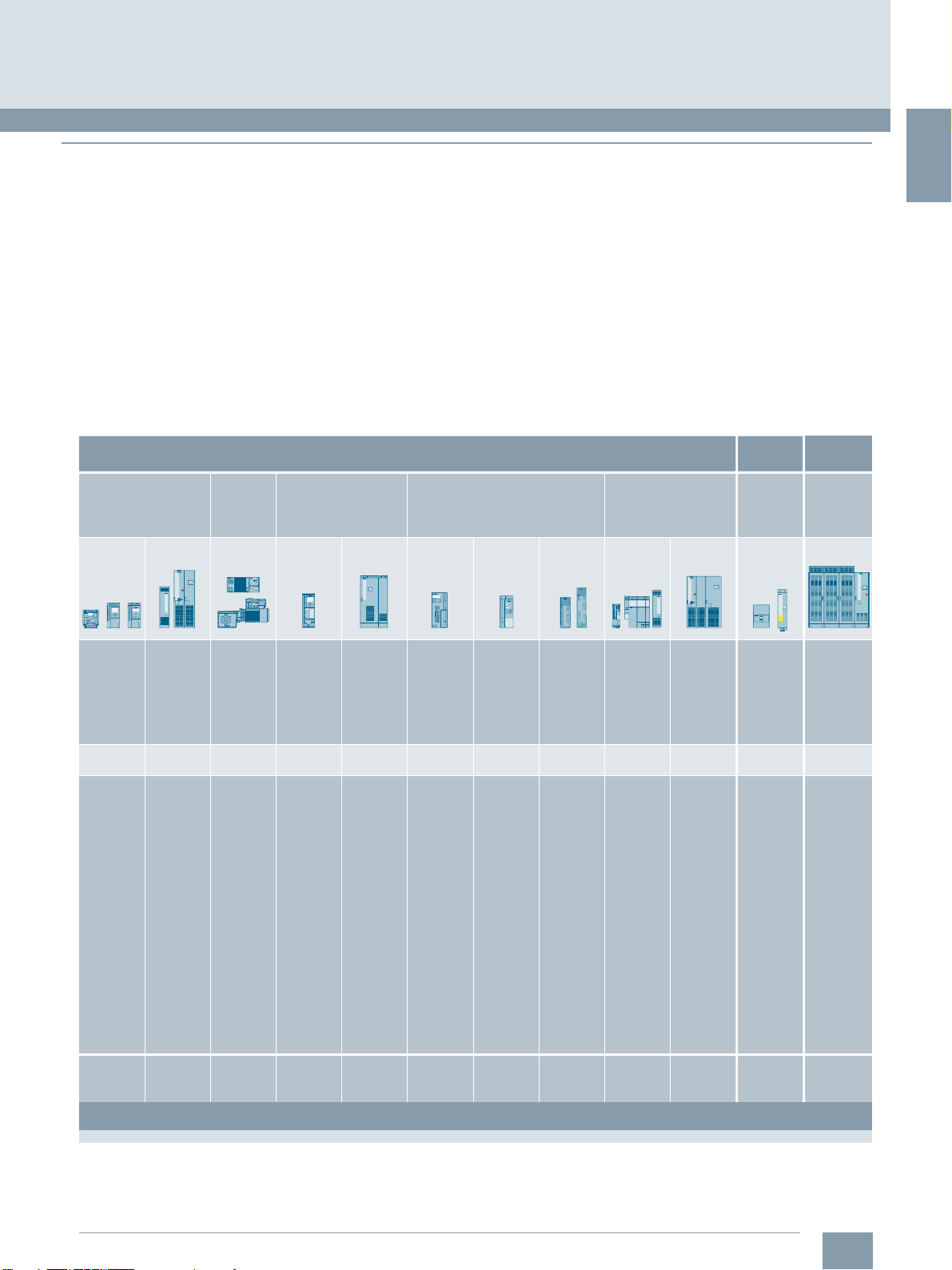

SINAMICS V drives focus on

the essentials both in terms of hardware

and functionality.

This results in a high degree of ruggedness

combined with lower investment costs.

SINAMICS G drives function perfectly for low

and medium demands on the dynamic

response of the control system.

SINAMICS S drives are predestined

for demanding single - and multi-axis

applications in machine and plant engineering

as well as for numerous motion control tasks.

Price

G_D011_EN_00449b

Performance

SINAMICS SSINAMICS GSINAMICS V

© Siemens 2020

System overview

The SINAMICS converter family

■

Overview

Up to 70 % potential for savings using variable-speed operation

SINAMICS enables great potential for savings to be realized by

controlling the motor speed. In particular, huge potential savings

can be recovered from pumps, fans and compressors which are

operated with mechanical throttle and valves. Here, changing to

variable-speed drives brings enormous economic advantages.

In contrast to mechanical control systems, the power consumption at partial load operation is always immediately adjusted to

the demand at that time. So energy is no longer wasted,

permitting savings of up to 60 % – in exceptional cases even up

to 70 %. Variable-speed drives also offer clear advantages over

mechanical control systems when it comes to maintenance and

repair. Current spikes when starting up the motor and strong

torque surges become things of the past – and the same goes

for pressure waves in pipelines, cavitation or vibrations which

cause sustainable damage to the plant. Smooth starting and

ramp-down relieve the load on the mechanical system, ensuring

a significantly longer service life of the entire drive train.

Varia nts

Depending on the application, the SINAMICS converter family offers the ideal variant for any drive task.

Regenerative feedback of braking energy

In conventional drive systems, the energy produced during

braking is converted to heat using braking resistors. Energy

produced during braking is efficiently recovered to the supply

system by versions of SINAMICS G and SINAMICS S drives with

regenerative feedback capability and these devices do not

therefore need a braking resistor. This permits up to 60 % of the

energy requirement to be saved, e.g. in lifting applications.

Energy which can be reused at other locations on a machine.

Furthermore, this reduced power loss simplifies the cooling of

the system, enabling a more compact design.

Energy transparency in all configuration phases

Early on, in the configuration phase, the SIZER for Siemens

Drives engineering tool provides information on the specific

energy requirement. The energy consumption across the entire

drive train is visualized and compared with different plant

concepts.

SINAMICS in combination with energy-saving motors

Engineering integration stretches beyond the SINAMICS

converter family to higher-level automation systems, and to a

broad spectrum of energy-efficient motors with a wide range of

performance classes, which, compared to previous motors, are

able to demonstrate up to 10 % greater efficiency.

1/4

Siemens D 32 · January 2020

Page 13

1

■

Engineering tools (e.g. Drive Technology Configu rato r, SIZER for Siemens Drives, STARTER and SINAMICS Startdrive)

G_D011_EN_00450o

Pumps, fans,

compressors,

conveyor

belts, mixers,

mills, spinning

machines,

textile

machines,

refrigerated

display

counters,

fitness

equipment,

ventilation

systems,

single-axis

positioning

applications in

machine and

plant

engineering

Handling

machines,

packaging

machines,

automatic

assembly

machines,

metal forming

machines,

printing

machines,

winding and

unwinding

units

0.12 kW to

250 kW

0.05 kW to

7 kW

Conveyor

technology,

single-axis

positioning

applications

(G120D)

Pumps,

fans,

compressors,

building

management

systems,

process

industry,

HVAC,

water/waste

water

industries

0.37 kW to

7.5 kW

0.75 kW to

630 kW

D 31.5

Catalog

D 31.1

Catalog

D 33

CatalogCatalog

D 31.2

Pumps,

fans,

compressors,

conveyor

belts,

extruders,

mixers, mills,

kneaders,

centrifuges,

separators

Pumps,

fans,

compressors,

conveyor

belts, mixers,

mills,

extruders

2.2 kW to

6600 kW

75 kW to

2700 kW

Catalog Catalog

D 11

D 18.1

Single-axis

positioning

applications in

machine and

plant

engineering

0.55 kW to

132 kW

Catalog Catalog

D 31.1 D 32

0.55

kW to

5700 kW

0.05 kW to

7 kW

Catalogs

D 21.3, D 21.4

NC 62

Test bays,

cross cutters,

centrifuges

75 kW to

1200 kW

Catalog

D 21.3

Rolling mill

drives,

wire-drawing

machines,

extruders and

kneaders,

cableways

and lifts,

test bay drives

6 kW to

30 MW

Catalog

D 23.1

* Industry Mall

0.15 MW to

85 MW

Catalogs

D 15.1, D 12

Converters for

applications

with high

outputs

High performance

frequency converters

Industry-specific frequency

converters

Distributed

frequency

converters

Standard performance

frequency converters

Servo drives

Medium

voltage

Low voltage

Packaging

machines,

handling

equipment,

feed and

withdrawal

devices,

stacking units,

automatic

assembly

machines,

laboratory

automation,

wood, glass

and ceramics

industry,

digital printing

machines

Production

machines

(packaging,

textil e and

printing

machines,

paper

machines,

plastic

processing

machines),

machine

tools, plants,

process lines

and rolling

mills, marine

drives, test

bays

Pumps,

fans,

compressors,

mixers,

extruders,

mills,

crushers,

rolling mills,

conveyor

technology,

excavator s,

test bays,

marine drives,

blast furnace

fans, retrofit

DC

converters

Direct

voltage

* DC/DC

controllers

GH150

GH180

GM150

SM150

GL150

SL150

SM120CM

V20

G120C

G120

SINAMICS SINAMICSSINAMICSSINAMICS

SIMATIC

ET 200pro FC-2

SINAMICS SINAMICS SINAMICS SINAMICS SINAMICS SINAMICS SINAMICS

V90G110D

G120D

G110M

G180

G130

G150

S110

SINAMICS

S210 S120

S120M

S150 DCM

DCP *

G120X

Overview

Platform concept

All SINAMICS variants are based on a platform concept. Joint

hardware and software components, as well as standardized

tools for dimensioning, configuration, and commissioning tasks

ensure high-level integration across all components. SINAMICS

handles a wide variety of drive tasks with no system gaps. The

different SINAMICS variants can be easily combined with each

other.

Quality management according to EN ISO 9001

SINAMICS conforms to the most exacting quality requirements.

Comprehensive quality assurance measures in all development

and production processes ensure a consistently high level of

quality.

Of course, our quality management system is certified by an

independent authority in accordance with EN ISO 9001.

© Siemens 2020

System overview

The SINAMICS converter family

IDS – Integration at its very best

The Siemens Integrated Drive Systems (IDS) solution offers

perfectly matched drive components with which you can meet

your requirements. The drive components reveal their true

strengths as an Integrated Drive System over the full range

from engineering and commissioning through to operation:

Integrated system configuration is performed using the Drive

Technology Configurator: Just select a motor and a converter

and design them with the SIZER for Siemens Drives engineering

tool. The STARTER and SINAMICS Startdrive commissioning

tools integrate the motor data and at the same time simplify

efficient commissioning. Integrated Drive Systems are incorporated in the TIA Portal – this simplifies engineering, commissioning and diagnostics.

Siemens D 32 · January 2020

1/5

Page 14

1

1)

Industry-specific converters.

2)

Information on the SIMATIC ET 200pro FC-2 frequency converter is

available in Catalog D 31.2 and at: www.siemens.com/et200pro-fc

© Siemens 2020

System overview

Drive selection

■

Overview

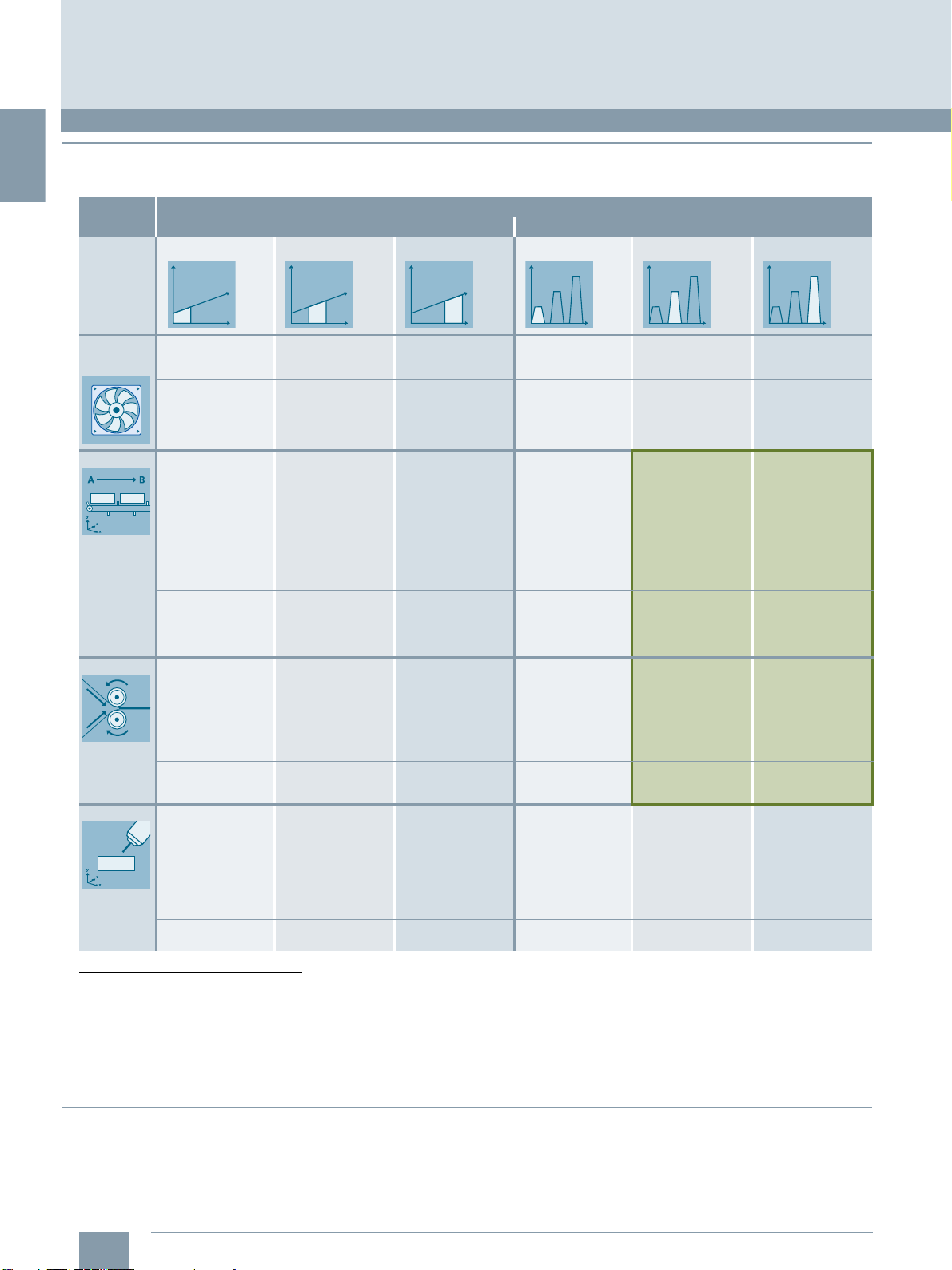

SINAMICS selection guide – typical applications

Use Requirements for torque accuracy/speed accuracy/position accuracy/coordination of axes/functionality

Continuous motion Non-continuous motion

Basic Medium High Basic Medium High

Pumping,

ventilating,

compressing

Moving Conveyor belts

Processing Mills

Machining Main drives for

Centrifugal pumps

Radial / axial fans

Compressors

V20

G120C

G120X

Roller conveyors

Chain conveyors

V20

G110D

G110M

G120C

ET 200pro FC-2

Mixers

Kneaders

Crushers

Agitators

Centrifuges

V20

G120C

• Turning

• Milling

• Drilling

S110 S110

Centrifugal pumps

Radial / axial fans

Compressors

G120X

G130/G150

G180

Conveyor belts

Roller conveyors

Chain conveyors

Lifting/lowering

devices

Elevators

Escalators/moving

walkways

Indoor cranes

Marine drives

Cable railways

G120

G120D

G130/G150

G180

2)

Mills

Mixers

Kneaders

Crushers

Agitators

Centrifuges

Extruders

Rotary furnaces

G120

G130/G150

G180

Main drives for

• Drilling

• Sawing

S120

Eccentric screw

pumps

S120 G120 S110 S120

1)

Elevators

Container cranes

Mining hoists

Excavators for

open-cast mining

Test bays

S120

S150

1)

1)

DCM

Extruders

Winders/unwinders

Lead/follower drives

Calenders

Main press drives

Printing machines

S120

S150

DCM

Main drives for

• Turning

• Milling

• Drilling

• Gear cutting

•Grinding

S120 S110 S110

Using the SINAMICS selection guide

The varying range of demands on modern variable frequency

drives requires a large number of different types. Selecting the

optimum drive has become a significantly more complex process. The application matrix shown simplifies this selection process considerably, by suggesting the ideal SINAMICS drive for

examples of typical applications and requirements.

Hydraulic pumps

Metering pumps

Acceleration

conveyors

Storage and retrieval

machines

V90

G120

G120D

Tubular bagging

machines

Single-axis motion

control

such as

• Position profiles

• Path profiles

V90

G120

Axis drives for

• Turning

• Milling

• Drilling

Hydraulic pumps

Metering pumps

Acceleration

conveyors

Storage and retrieval

machines

Cross cutters

Reel changers

S110

S210

DCM

Tubular bagging

machines

Single-axis motion

control

such as

• Position profiles

• Path profiles

S110

S210

Axis drives for

• Drilling

• Sawing

S120

Descaling pumps

Hydraulic pumps

Storage and retrieval

machines

Robotics

Pick & place

Rotary indexing tables

Cross cutters

Roll feeds

Engagers/disengagers

S120

S210

DCM

Servo presses

Rolling mill drives

Multi-axis motion

control

such as

• Multi-axis positioning

•Cams

• Interpolations

S120

S210

DCM

Axis drives for

• Turning

• Milling

• Drilling

• Lasering

• Gear cutting

•Grinding

• Nibbling and

punching

S120

• The application type is selected from the vertical column

- Pumping, ventilating, compressing

-Moving

- Processing

- Machining

• The quality of the motion type is selected from the horizontal row

-Basic

-Medium

-High

■

More Information

Further information about SINAMICS is available on the

Internet at

www.siemens.com/sinamics

1/6

Siemens D 32 · January 2020

Practical application examples and descriptions are available

on the Internet at

www.siemens.com/sinamics-applications

Page 15

1

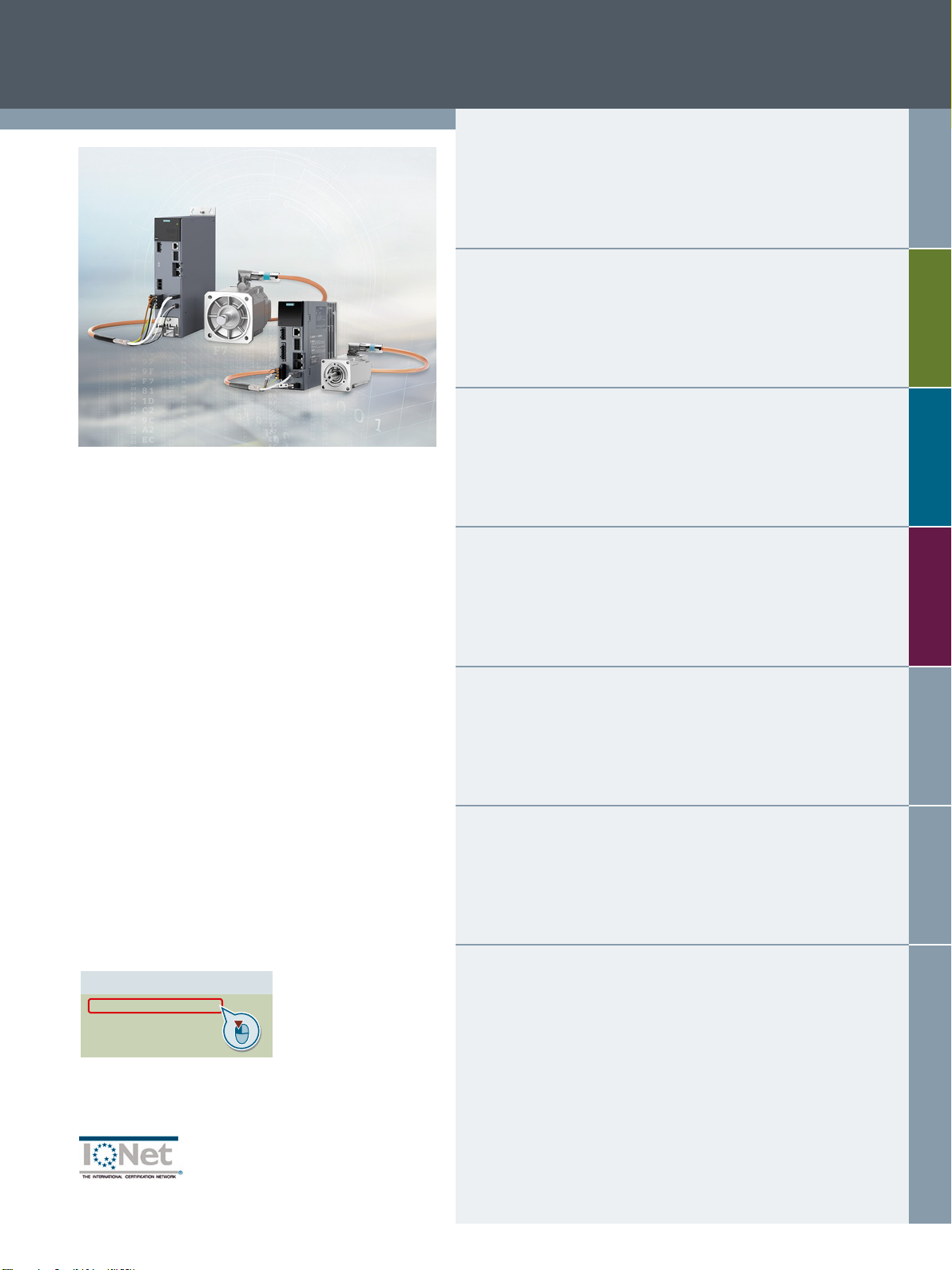

■

Overview

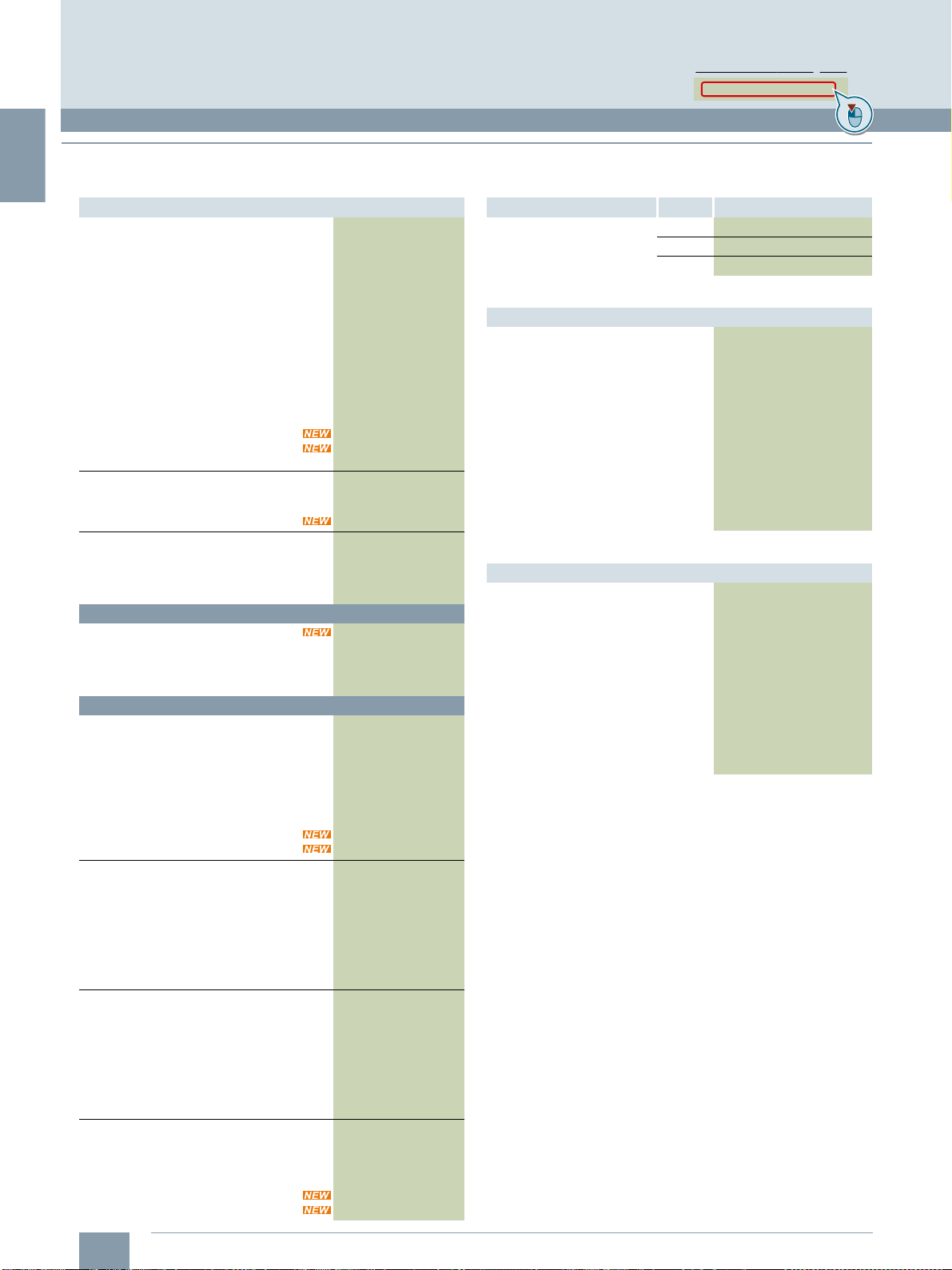

Example: SINAMICS S210 converter frame size FSB, 200 V 1 AC,

with SIMOTICS S-1FK2 servomotor shaft height 30

Example: SINAMICS S210 converter frame size FSB, 400 V 3 AC,

with SIMOTICS S-1FK2 servomotor shaft height 63

The new servo drive system comprises a SINAMICS S210 servo

converter, a SIMOTICS S-1FK2 servomotor and a matching

One Cable Connection (OCC) for connecting the motor to the

converter. The SINAMICS S210 is a single-axis AC/AC servo

converter system with high performance and dynamic response

for mid-range Motion Control applications.

SINAMICS S210 servo converters are available for the following

line voltages:

• 200 V to 240 V 1 AC (1 AC series)

• 200 V to 480 V 3 AC (3 AC series)

Depending on the converter voltage, the SIMOTICS S-1FK2

servomotors are available in the following frame sizes and

torque ranges:

•1AC series

- Up to 240 V: Shaft heights 20 to 48 with 0.16 to 3.6 Nm

•3AC series

- Up to 240 V: Shaft heights 20 to 100 with 0.16 to 40 Nm

- Up to 480 V: Shaft heights 40 to 100 with 1.27 to 40 Nm

The motors are available in the High Dynamic (HD) and

Compact (CT) designs.

© Siemens 2020

System overview

SINAMICS S210 servo drive system

The SINAMICS S210 can be used in numerous applications.

Typical applications are:

• Packaging machines

• Handling equipment

• Feed and withdrawal devices

• Stacking units

• Automatic assembly machines

• Laboratory automation

• Woodworking, glass and ceramic industries

• Digital printing machines

Flexible in application

The SINAMICS S210 is a flexible, versatile system.

SIMOTICS S-1FK2 series synchronous servomotors are installed

in rotary and linear axes. The integrated One Cable Connection

(OCC) interface allows user-friendly connection of a

SIMOTICS S-1FK2 motor with just one cable. The electronic

motor type plate data can be read out, which eliminates the need

to parameterize the converter with the motor data. This significantly simplifies and shortens commissioning.

In conjunction with the technological functions of the higher-level

controller, there are many possibilities of motion – from continuous operation through positioning and synchronous operation,

to coordinated motion of multiple axes via cyclic cams or

interpolation – everything is possible.

The SINAMICS S210 converter has an integrated PROFINET

communications interface for connecting to a control system.

The data exchange with the higher-level controllers takes place

via standardized protocols – the PROFIdrive profile for positioning mode and the PROFIsafe profile for safety-related communication.

Thus, operation is optimally ensured with the SIMATIC S7

automation system. The drive axis is connected via technology

objects and Motion Control blocks in the SIMATIC S7 or a

SIMOTION controller.

High performance for fast and precise control

The high performance of the SINAMICS S210 servo drive

system in conjunction with the SIMOTICS S-1FK2 servomotor

derives from the following features:

• Low moment of inertia and high overload capability of the

motor

• High-resolution encoder with fast scanning

• Current controller clock cycle of 62.5 μs and a pulse

frequency of 8 kHz of the servo converter

This enables short cycle times on the machine even with

complex motion control.

DC link coupling (only 3 AC series)

For devices of the 3 AC series, the DC links of up to six converters can be coupled. Thus, energy balancing between the axes

is possible and energy produced during braking can be used by

other axes for accelerating. This is not only efficient but also

reduces the dissipated heat in the control cabinet, because the

energy that is produced no longer has to be converted to heat in

the braking resistor.

Siemens D 32 · January 2020

1/7

Page 16

1

System overview

SINAMICS S210 servo drive system

■

Overview

Optimized connection technology with

One Cable Connection (OCC)

© Siemens 2020

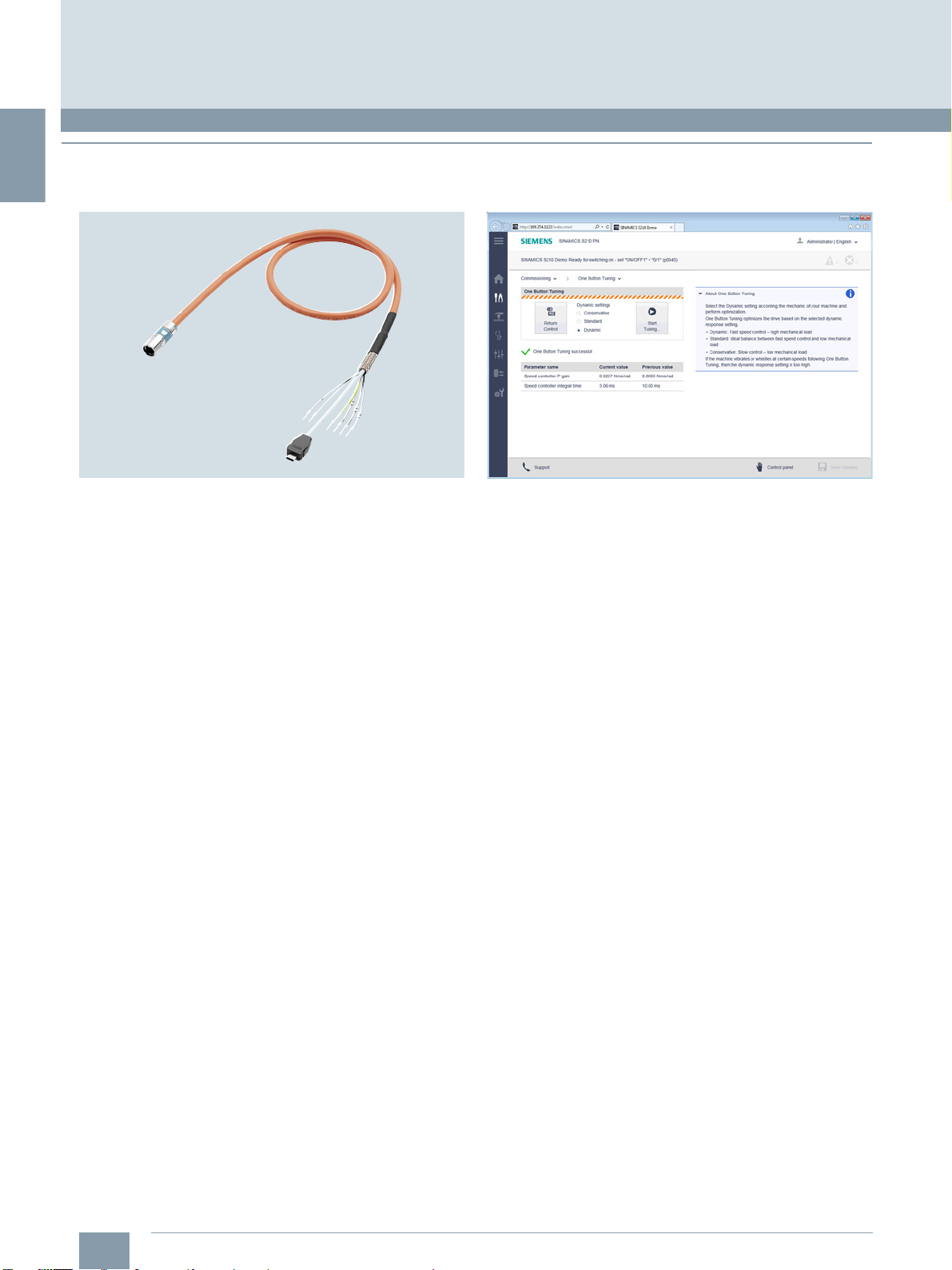

Easy commissioning via web server, One Button Tuning and

SINAMICS Startdrive/TIA Portal (V15.1 or higher)

Example: SINAMICS S210 M12 OCC connecting cable

Motor and converter are simply connected to one another by

one instead of the usual two or three cables. With this One Cable

Technology, energy supply, encoder signals and braking signal

are brought together in a single cable. This results in the following advantages:

• Time-saving by laying only one cable

• Smaller installation space and space requirement in cable

collars, tight bending radii

• Only one cable has to be cleaned. This is advantageous, e.g.

in the pharmaceutical industry and where higher requirements

are placed upon hygiene

• Can be ordered to the decimeter

• Compact connection system

• Rotatable connector on the motor side

• Motor with very low interfering contour for restricted installation space.

Cables are available in two different qualities:

• MOTION-CONNECT 500

• MOTION-CONNECT 800PLUS

In addition to the pre-assembled cable, individual components

(connectors and products sold by the meter) can be ordered for

self-assembly (available soon).

One Button Tuning

The web server of the converter offers a simple means of

parameter assignment. The web server allows commissioning

purely oriented on the functionality of the drive. With the web

server, the SINAMICS S210 servo drive system can be brought

into operation with a few clicks.

As a result of reading the electronic type plate of the connected

SIMOTICS S-1FK2 servomotor, only a few operator actions, such

as automatic controller optimization with One Button Tuning,

are necessary, as the motor and encoder are automatically

detected. The controller parameters are automatically optimized. The three selectable dynamic levels of the controller can

optimally take into account the desired behavior of the

connected mechanics.

A motion of the axis can take place directly via the control panel

during commissioning.

The customer benefits from the web server in many ways:

• Commissioning can also be easily done in places difficult to

access, as the web server in the converter can also be

accessed directly via PROFINET from the controller.

• The web server provides full diagnostic capability without the

need for additional software.

• Commissioning and diagnostics can also be done without a

cable via mobile devices, such as laptops, smart phones and

tablets (an additional WLAN access point is necessary).

• Intuitive user interface

In addition to easy commissioning directly via the web server

of the converter, engineering is also possible with SINAMICS

Startdrive and TIA Portal (V15.1 or higher). The tool for configuration, commissioning and diagnostics has been optimized with

regard to the consistent utilization of the TIA Portal advantages –

one shared work environment for PLC, HMI and drives.

SINAMICS firmware V5.2 or higher is required for

SINAMICS S210 devices.

For more information, see the Engineering tools section.

1/8

Siemens D 32 · January 2020

Page 17

1

■

1)

Available in SINAMICS V5.1 SP1 and higher. The Extended Functions

require a Safety license.

Overview

Diagnostics

Faults and warnings are shown on the display located under the

front cover, and they can be acknowledged with the Acknowledge button. Extensive diagnostics with plain text messages for

cause and remedy information is possible via the web server.

Safety Integrated

The integrated safety functions provide highly effective, application-oriented protection for personnel and machinery (terms as

defined in IEC 61800-5-2).

The following Safety Integrated Basic Functions are included as

standard:

• Safe Torque Off (STO)

• Safe Brake Control (SBC)

• Safe Stop 1 (SS1)

The following Safety Integrated Extended Functions

available as options:

• Safe Stop 2 (SS2)

• Safe Operating Stop (SOS)

• Safely-Limited Speed (SLS)

• Safe Speed Monitor (SSM)

• Safe Direction (SDI)

• Safely-Limited Acceleration (SLA)

• Safe Brake Test (SBT) diagnostic function

The Safety Integrated Functions are fully integrated into the drive

system. They can be activated via fail-safe digital inputs on the

converter (only STO and SS1) or via PROFINET with PROFIsafe.

The Safety Integrated Functions are implemented electronically

and therefore require no additional installation effort or space in

the control cabinet. Furthermore, the costs are considerably

lower than for externally implemented monitoring functions.

The Safety Integrated Functions can be easily commissioned

using the web server of the converter or SINAMICS Startdrive/

TIA Portal V15.1 or higher.

1)

are

© Siemens 2020

System overview

SINAMICS S210 servo drive system

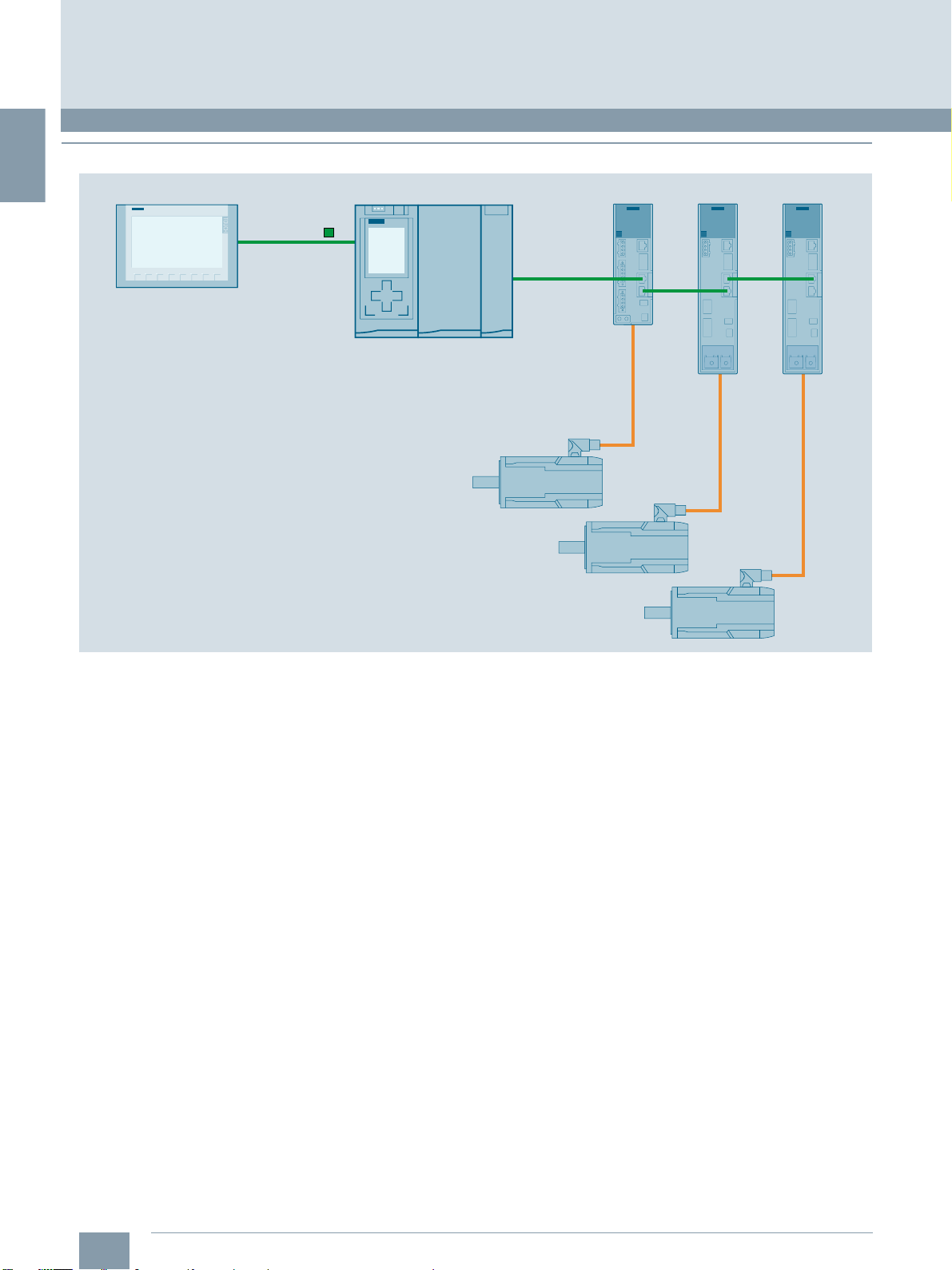

Perfect combination with

SIMATIC S7-1500, SIMATIC S7-1500 T-CPU,

SIMATIC ET 200SP Open Controller, and PROFINET

It communicates with the higher-level control via PROFINET IRT.

For optimal interaction between the controller and the

SINAMICS S210 servo drive system, SIMATIC S7-1500,

SIMATIC S7-1500 T-CPU, SIMATIC ET 200SP Open Controller,

and SIMOTION can be used as the control system.

The SINAMICS S210 servo converter has an integrated

PROFINET communications interface with a cycle of up to

250 μs for connecting to a control system.

Standardized protocols for linking to a higher-level control with

RT and IRT are supported – the PROFIdrive profile with DSC for

positioning mode and the PROFIsafe profile for safety-related

communication. Functions, such as Shared Device, ring redundancy and PROFIenergy, are also possible.

Everything from one source: Through the use of Motion Control

functionalities in the controller, the combination of converter and

SIMATIC S7 automation system or a SIMOTION controller allows

ideally harmonized engineering. As a result, commissioning

times are shortened.

Via technology objects and Motion Control blocks of the higherlevel controller, there are many possibilities of motion, such as

continuous operation, positioning and synchronous operation,

and coordinated motion of multiple axes via cyclic cams or

interpolation.

Siemens offers tested SIMATIC PLC/HMI application examples

for connection of the servo drive system to a SIMATIC controller:

www.siemens.com/sinamics-applications

Further information on the SIMATIC S7-1500,

SIMATIC S7-1500 T-CPU and SIMATIC ET 200SP Open Controller is available in the ST 70 Catalog and on the Internet under

www.siemens.com/simatic-s7-1500

Change 07/2020

Siemens D 32 · January 2020

1/9

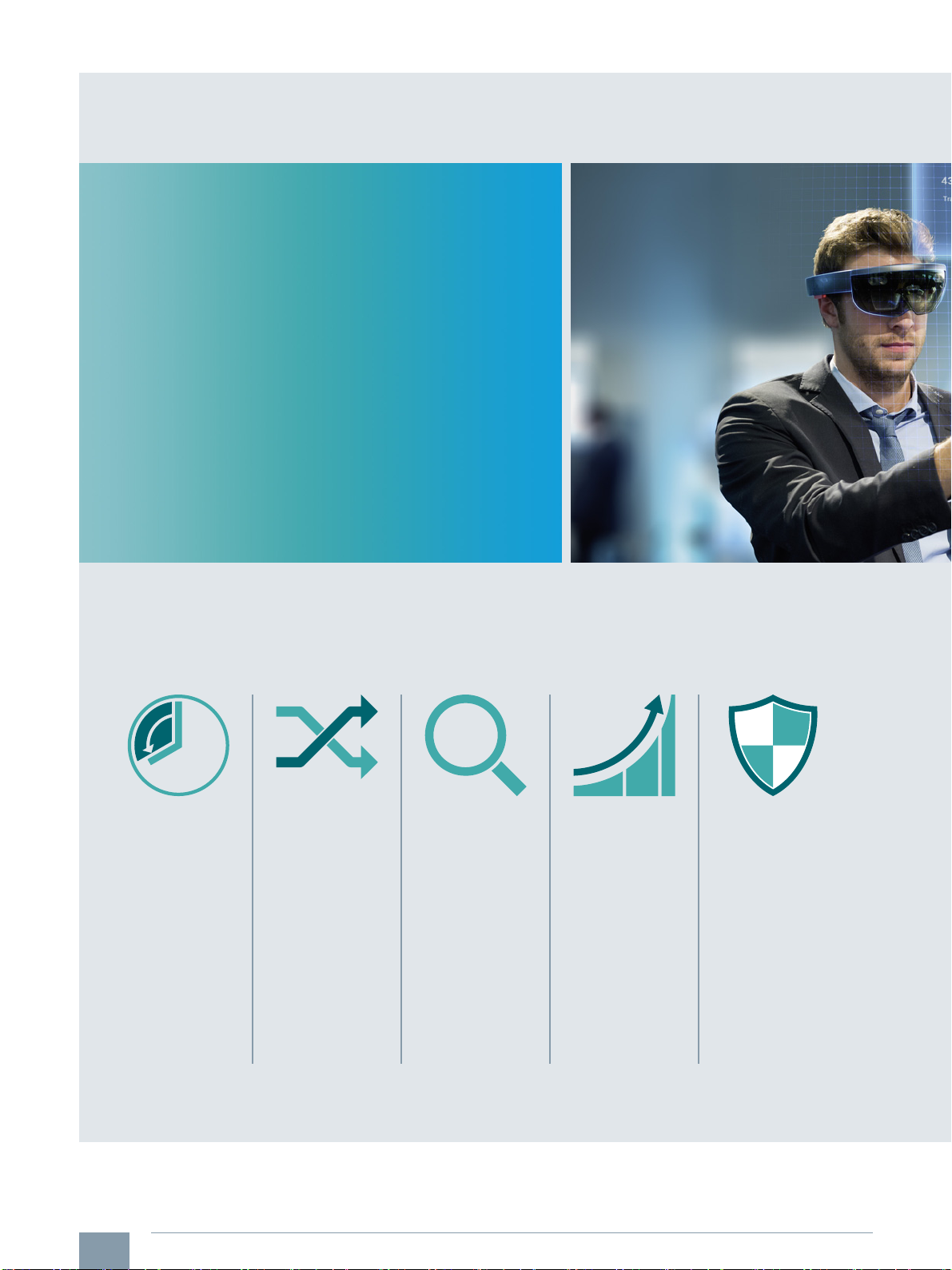

Page 18

1

System overview

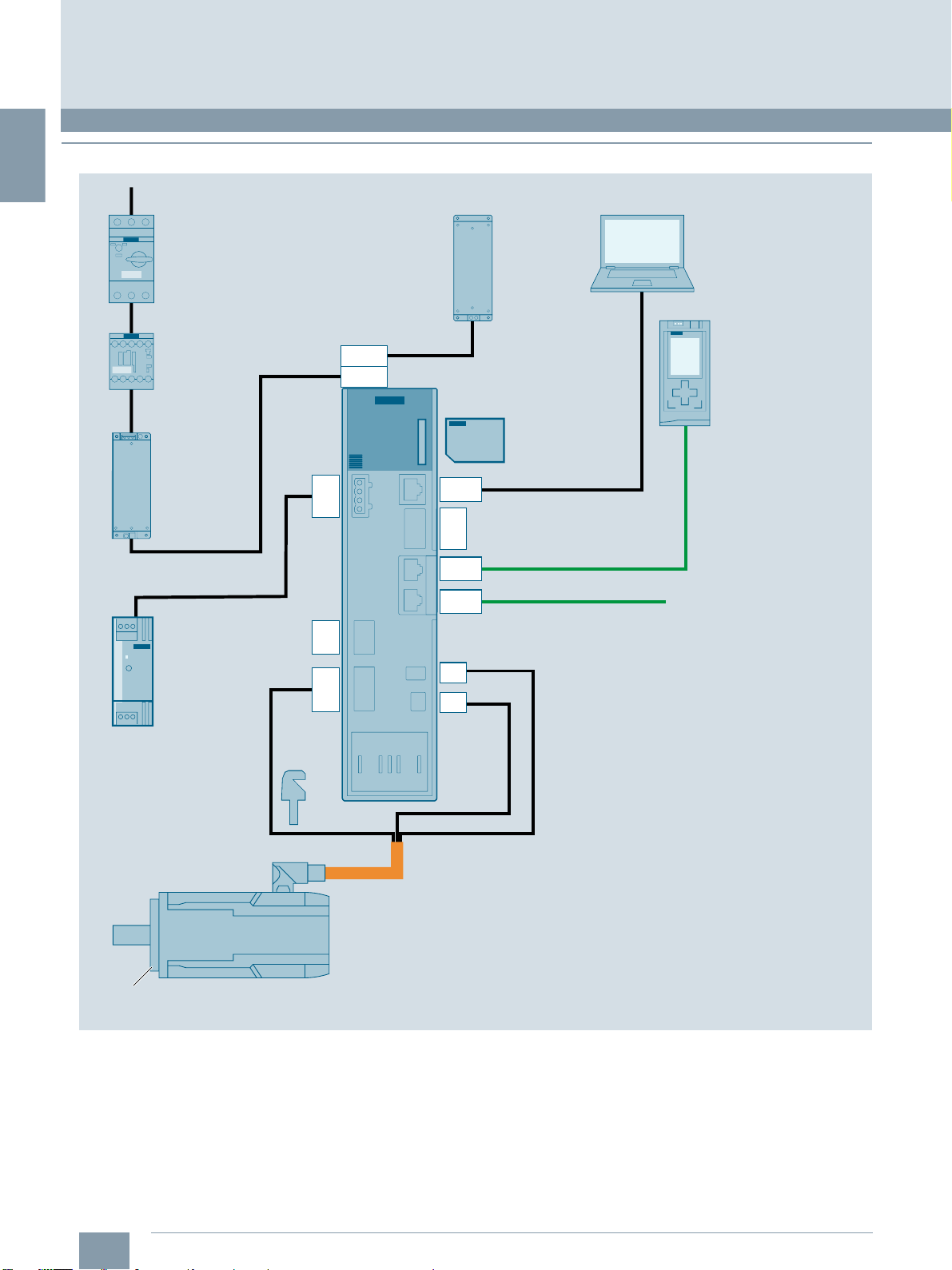

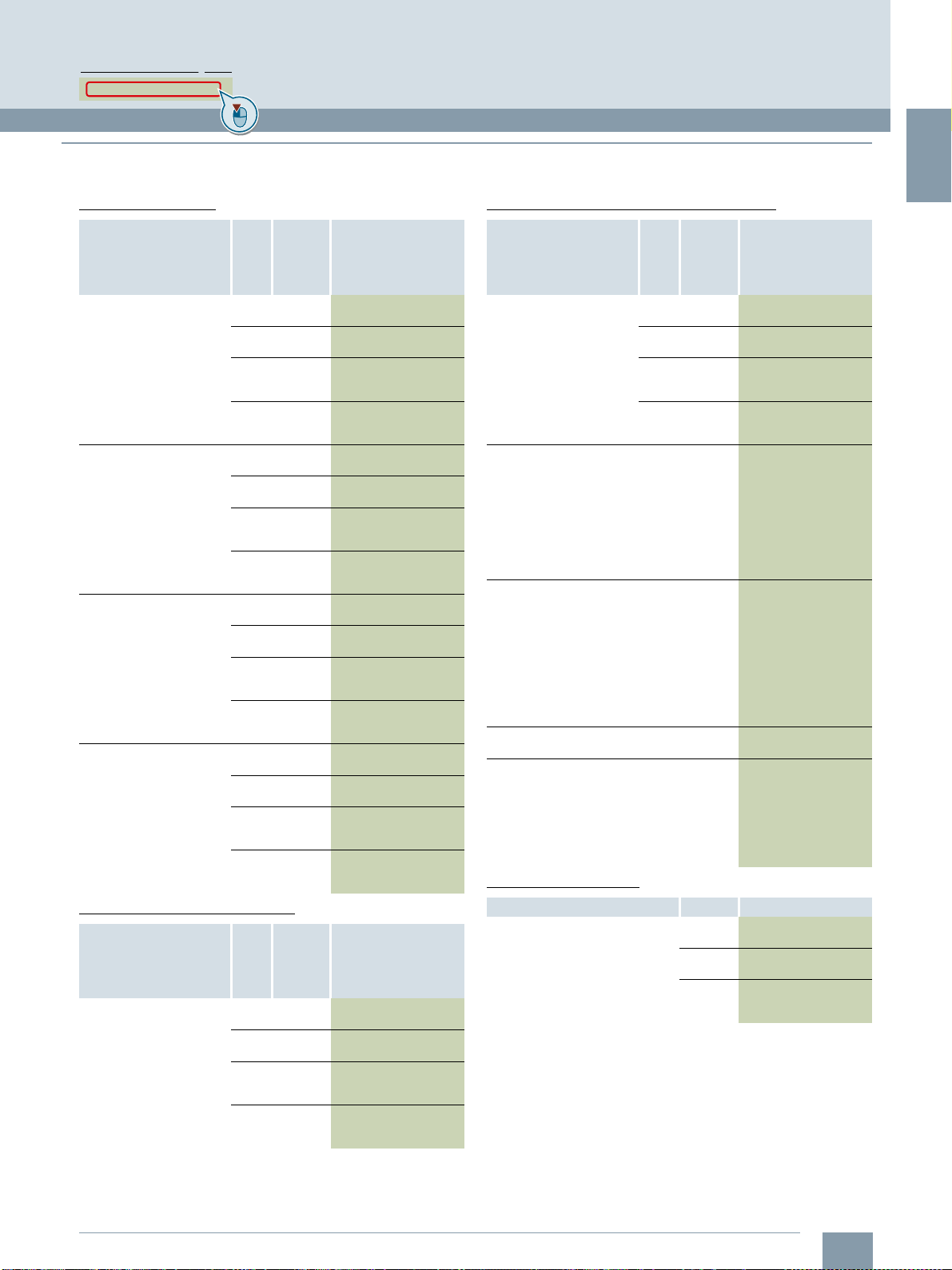

OCC (One Cable Connection for motor,

motor holding brake and encoder)

SIMOTICS S-1FK2 servomotors

G_D211_EN_00392

SINAMICS S210 servo driveSIMATIC S7-1515T PN SIMATIC Basic Panel

PROFINET IRT

PROFINET

SINAMICS S210 servo drive system

■

Overview

© Siemens 2020

Example: Communication via PROFINET

Ruggedness

The SINAMICS S210 is equipped as standard with varnished or

partially varnished modules. The painting on the modules protects the sensitive SMD components against corrosive gases,

chemically active dust and moisture.

Can be used worldwide

In addition to the usual approvals, the SINAMICS S210 drive

system also has UL approval for the North American market.

This means that the drive system, comprising SINAMICS S210

and SIMOTICS S-1FK2, including the One Cable Connection

(OCC), can be used worldwide.

More information

A Quick Installation Guide is supplied in hard copy form in

English with every SINAMICS S210. Further documentation,

such as the operating instructions, is available free on the

Internet at:

www.siemens.com/sinamics-s210/documentation

Detailed information on the SINAMICS S210 drive system,

including the latest technical documentation (brochures,

tutorials, dimensional drawings, certificates, manuals and

operating instructions), is available on the Internet at:

www.siemens.com/sinamics-s210

and is also available via the Drive Technology Configurator

(DT Configurator) on the Internet.

The DT Configurator can be found in the Siemens Industry Mall

at the following address:

www.siemens.com/dt-configurator

1/10

Siemens D 32 · January 2020

Page 19

1

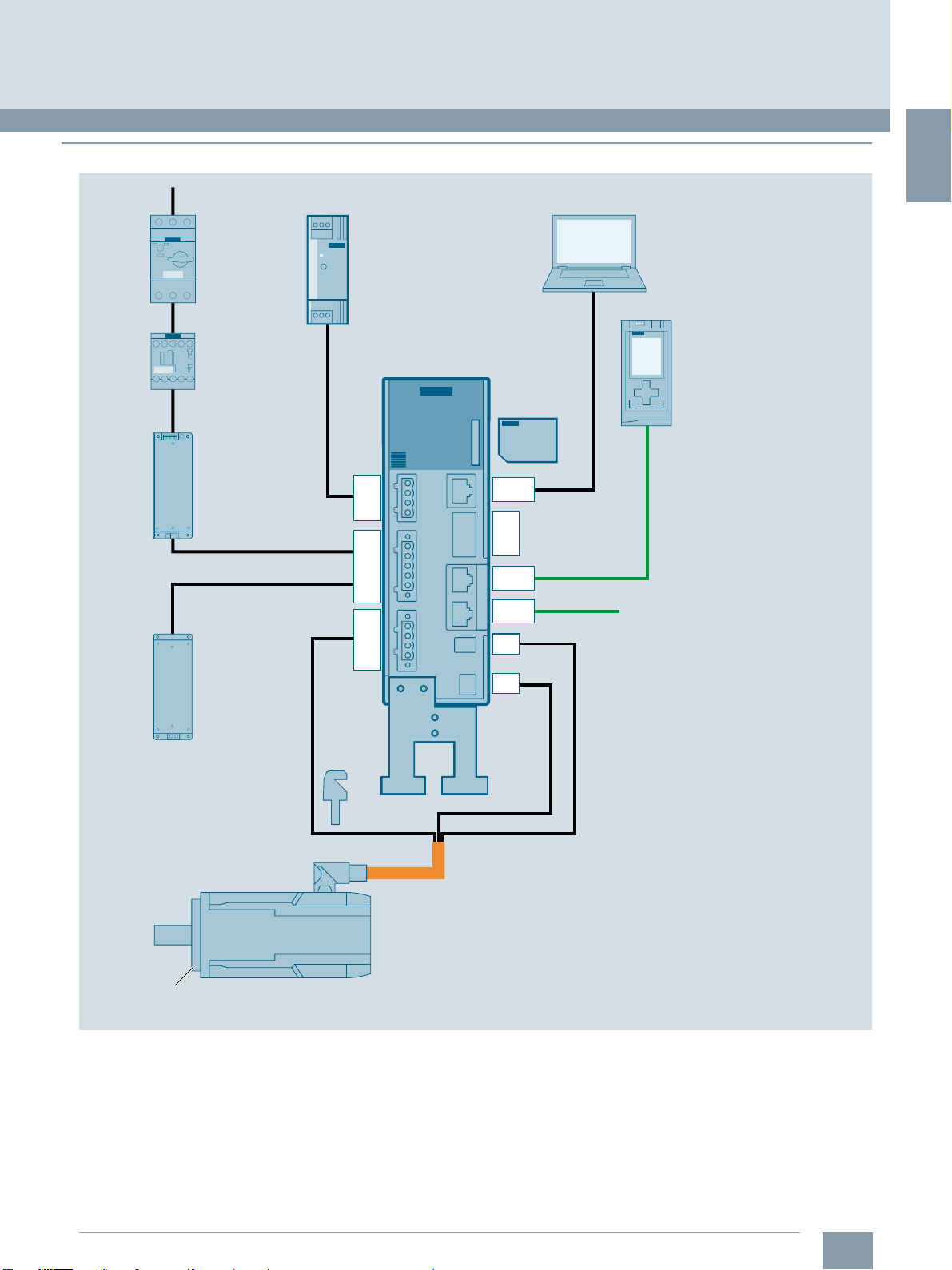

■

Overview

© Siemens 2020

System overview

SINAMICS S210 servo drive system

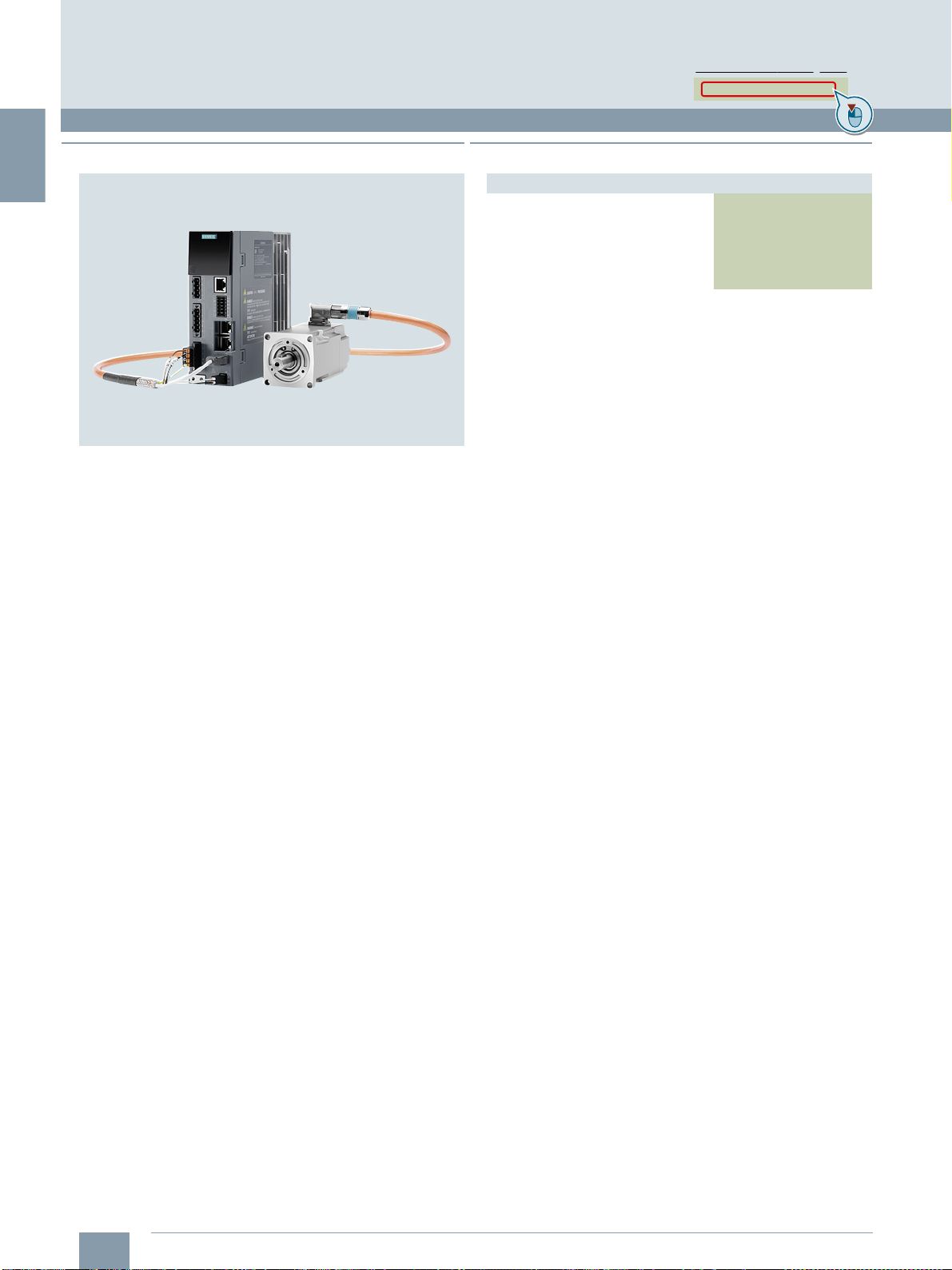

Fuse or

circuit-breaker

Line contactor

(optional)

Line filter

(optional)

External

braking resistor

(optional)

Power supply

24 V DC

SINAMICS S210

converter

1 AC series

X124

X1

X2

SD memory card

(optional)

X127

F-DI

X130

measuring probe

X150 P1

X150 P2

X100

X107

Commissioning device

Controller

(e.g. SIMATIC S7-1500)

To further PROFINET devices

(e.g. further SINAMICS S210)

SIMOTICS S-1FK2

servomotor

Shaft sealing ring

(optional)

Example for the 1 AC series

Shield plate

Shield

connection clamp

OCC (One Cable Connection for motor,

motor holding brake and encoder)

G_D211_EN_00368a

Siemens D 32 · January 2020

1/11

Page 20

1

System overview

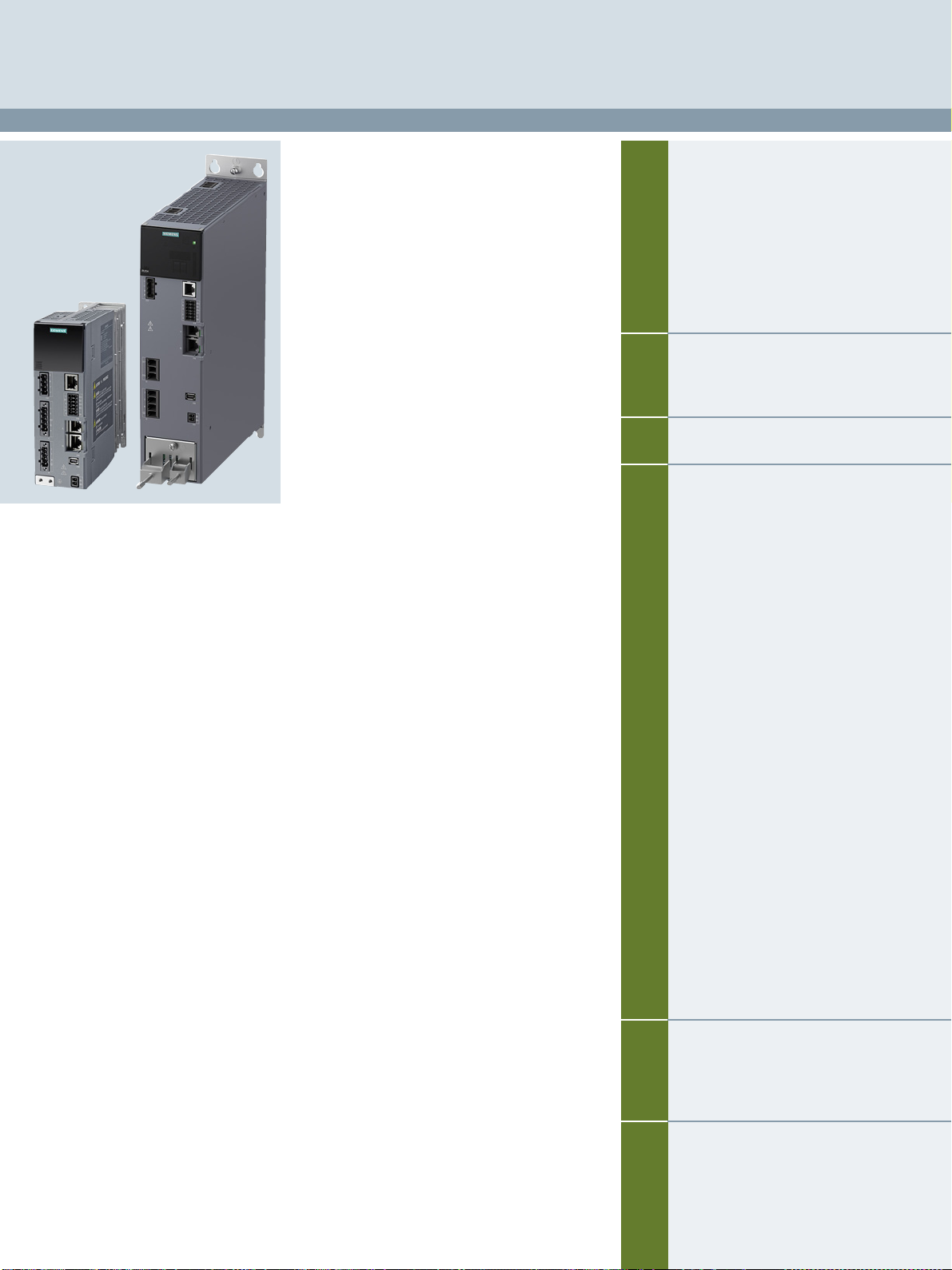

SINAMICS S210 servo drive system

■

Overview

© Siemens 2020

Fuse or

circuit-breaker

Line contactor

(optional)

Line filter

(optional)

DC link

coupling

(optional)

SINAMICS S210

converter

3 AC series

X4

X1

X124

X3

X2

External

braking resistor

(optional)

SD memory card

(optional)

X127

F-DI

X130

measuring probe

X150 P1

X150 P2

X100

X107

Commissioning device

Controller

(e.g. SIMATIC S7-1500)

To further PROFINET devices

(e.g. further SINAMICS S210)

Power supply

24 V DC

SIMOTICS S-1FK2

servomotor

Shaft sealing ring

(optional)

Example for the 3 AC series

Shield connection

clamp

OCC (One Cable Connection for motor,

motor holding brake and encoder)

G_D211_EN_00391

1/12

Siemens D 32 · January 2020

Page 21

1

Clicking to the Industry Mall

6SL3255-0AA00-5AA0

© Siemens 2020

System overview

SINAMICS S210 servo drive system

■

Order overview

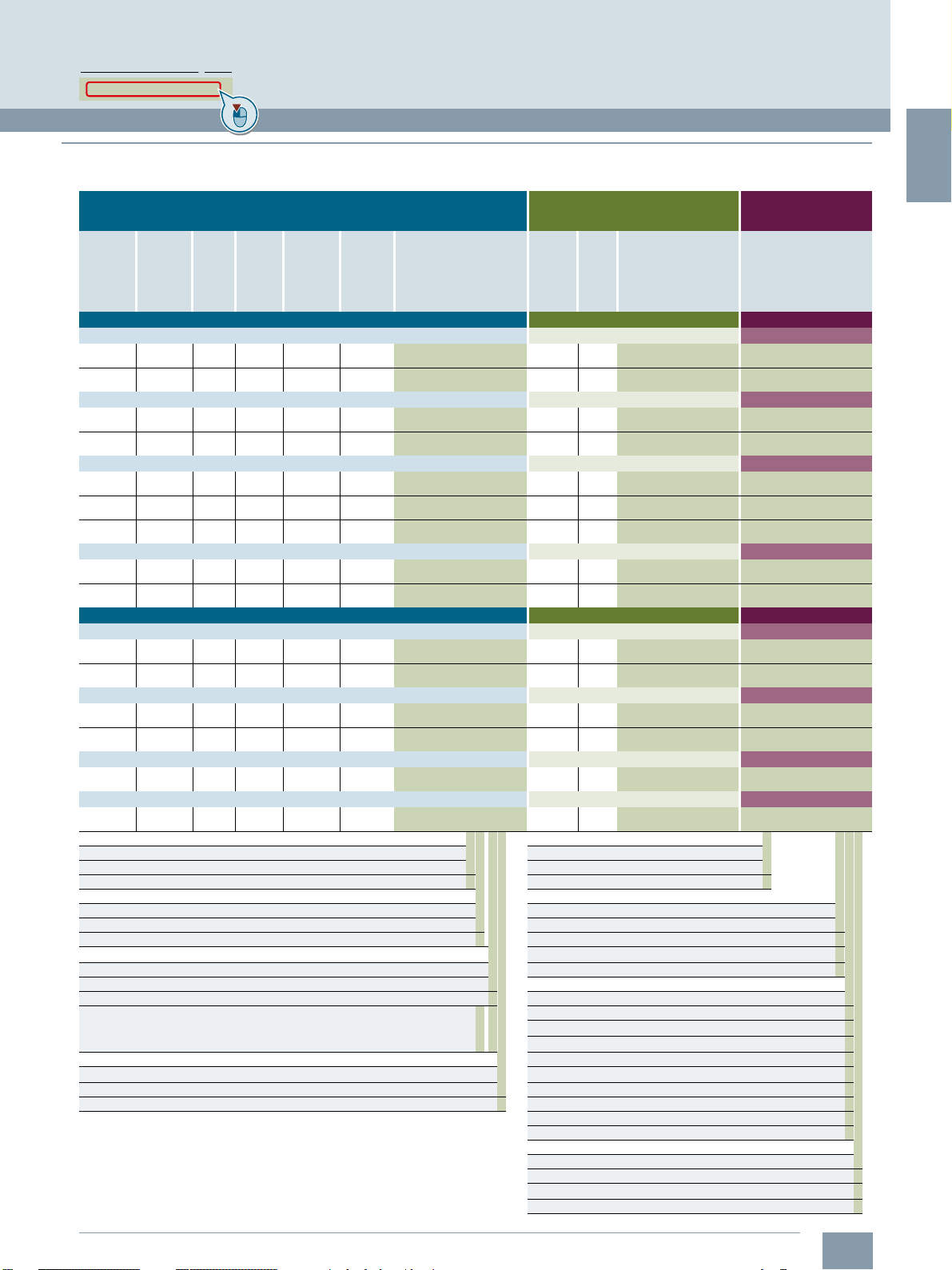

SINAMICS S210 drive system for line connection 200 ... 240 V 1 AC

SIMOTICS S-1FK2 servomotor SINAMICS S210 servo converter

Static

torque

M

0

Nm

(lb

High Dynamic for highly dynamic applications SINAMICS S210 servo converter One Cable Connection

Shaft height 20 – rated speed n

0.16

(0.12)

0.32

(0.24)

Shaft height 30 – rated speed n

0.64

(0.47)

1.27

(0.94)

Shaft height 40 – rated speed n

1.27

(0.94)

2.4

(1.77)

3.2

(2.36)

Shaft height 40 – rated speed n

1.27

(0.94)

2.4

(1.77)

Compact for high precision applications SINAMICS S210 servo converter One Cable Connection

Shaft height 30 – rated speed n

0.64

(0.47)

1.27

(0.94)

Shaft height 40 – rated speed n

2.4

(1.77)

3.2

(2.36)

Shaft height 40 – rated speed n

2.4

(1.77)

Shaft height 48 – rated speed n

3.6

(2.66)

Article No. supplements

Holding brake Pre-assembled MOTION-CONNECT cable

Without brake 0 MOTION-CONNECT 500 5

With brake 1 MOTION-CONNECT 800PLUS 8

Maximum

torque

M

Nm

-ft)

(lb

f

0.56

(0.41)

1.11

(0.82)

1.95

(1.44)

4.05

(2.99)

3.75

(2.77)

7.5

(5.53)

10

(7.38)

3.85

(2.84)

7.6

(5.61)

1.85

(1.36)

3.75

(2.77)

7.1

(5.24)

9.5

(7.01)

7.1

(5.24)

10.8

(7.97)

max

-ft) rpm

f

Maxi-

Rated

power

230 V

kW

(hp)

rated

(0.07)

(0.13)

rated

(0.27)

(0.54)

rated

(0.27)

(0.51)

(0.67)

rated

(0.54)

(1.01)

rated

(0.27)

(0.54)

rated

(0.51)

(0.67)

rated

(1.01)

rated

(0.71)

Rated

torque

Nm

(lb

3000 rpm

0.16

(0.12)

0.32

(0.24)

3000 rpm

0.64

(0.47)

1.27

(0.94)

1500 rpm

1.27

(0.94)

2.4

(1.77)

3.2

(2.36)

3000 rpm

1.27

(0.94)

2.4

(1.77)

3000 rpm

0.64

(0.47)

1.27

(0.94)

1500 rpm

2.4

(1.77)

3.2

(2.36)

3000 rpm

2.4

(1.77)

1500 rpm

3.4

(2.51)

mum

speed

n

maxPratedMrated

8000 0.05

8000 0.1

8000 0.2

7300 0.4

3600 0.2

3300 0.38

3600 0.5

7500 0.4

7100 0.75

8000 0.2

7800 0.4

3700 0.38

3800 0.5

7500 0.75

3200 0.53

Rotor

moment

of inertia

J

Mot

kg cm

-ft)

(lbf-in2) Article No.

f

0.025

(0.009)

0.036

(0.012)

0.093

(0.032)

0.14

(0.048)

0.35

(0.120)

0.56

(0.191)

0.76

(0.260)

0.35

(0.120)

0.56

(0.191)

0.20

(0.068)

0.35

(0.120)

1.2

(0.410)

1.6

(0.547)

1.2

(0.410)

3.2

(1.093)

2

1FK2102-0AG■■-■■A0 0.1 FSA 6SL3210-5HB10-1UF0 6FX■002-8QN04-1■■■

1FK2102-1AG■■-■■A0 0.1 FSA 6SL3210-5HB10-1UF0 6FX■002-8QN04-1■■■

1FK2103-2AG■■-■■A0

1FK2103-4AG■■-■■A0

1FK2104-4AF■■-■■A0 0.2 FSA 6SL3210-5HB10-2UF0 6FX■002-8QN08-1■■■

1FK2104-5AF■■-■■A0 0.4 FSB 6SL3210-5HB10-4UF0 6FX■002-8QN08-1■■■

1FK2104-6AF■■-■■A0 0.75 FSC 6SL3210-5HB10-8UF0 6FX■002-8QN08-1■■■

1FK2104-4AK■■-■■A0 0.4 FSB 6SL3210-5HB10-4UF0 6FX■002-8QN08-1■■■

1FK2104-5AK■■-■■A0 0.75 FSC 6SL3210-5HB10-8UF0 6FX■ 002-8QN08-1■■■

1FK2203-2AG■■-■■A0 0.2 FSA 6SL3210-5HB10-2UF0 6FX■002-8QN04-1■■■

1FK2203-4AG■■-■■A0 0.4 FSB 6SL3210-5HB10-4UF0 6FX■002-8QN04-1■■■

1FK2204-5AF■■-■■A0 0.4 FSB 6SL3210-5HB10-4UF0 6FX■002-8QN08-1■■■

1FK2204-6AF■■-■■A0 0.75 FSC 6SL3210-5HB10-8UF0 6FX■002-8QN08-1■■■

1FK2204-5AK■■-■■A0 0.75 FSC 6SL3210-5HB10-8UF0 6FX■ 002-8QN08-1■■■

1FK2205-2AF■■-■■A0 0.75 FSC 6SL3210-5HB10-8UF0 6FX■002-8QN08-1■■■

(1 AC series)

Supply voltage 200 ... 240 V 1 AC

Rated

power

230 V

P

kW

0.2 FSA

0.4 FSB

rated

Frame

size

Article No. Article No.

6SL3210-5HB10-2UF0 6FX■002-8QN04-1■■■

6SL3210-5HB10-4UF0 6FX■002-8QN04-1■■■

MOTION-CONNECT

motor connection cable

Degree of protection Length code (max. 50 m (164 ft))

IP64 (without shaft sealing ring) 0 0 m (0 ft) A

IP65 (with shaft sealing ring) 1 10 m (32.8 ft) B

Shaft extension / feather key 50 m (164 ft) F

Plain shaft 0

Shaft with feather key 1 0 m (0 ft) A

Plain shaft, reduced shaft diameter 0 2 1 m (3.28 ft) B

• ∅11 × 23 mm (0.43 × 0.91 in) (only for 1FK2.03 and IP64)

• ∅14 × 30 mm (0.55 × 1.18 in) (only for 1FK2.04 and IP64)

Encoder 5 m (16.4 ft) F

AS22DQC (absolute encoder 22-bit singleturn) S 6 m (19.7 ft) G

AM22DQC (absolute encoder 22-bit + 12-bit multiturn) M 7 m (23.0 ft) H

...

2 m (6.56 ft) C

3 m (9.84 ft) D

4 m (13.1 ft) E

8 m (26.2 ft) J

9 m (29.5 ft) K

0 m (0 ft) 0

0.1 m (0.33 ft) 1

...

0.8 m (2.62 ft) 8

Siemens D 32 · January 2020

...

1/13

...

Page 22

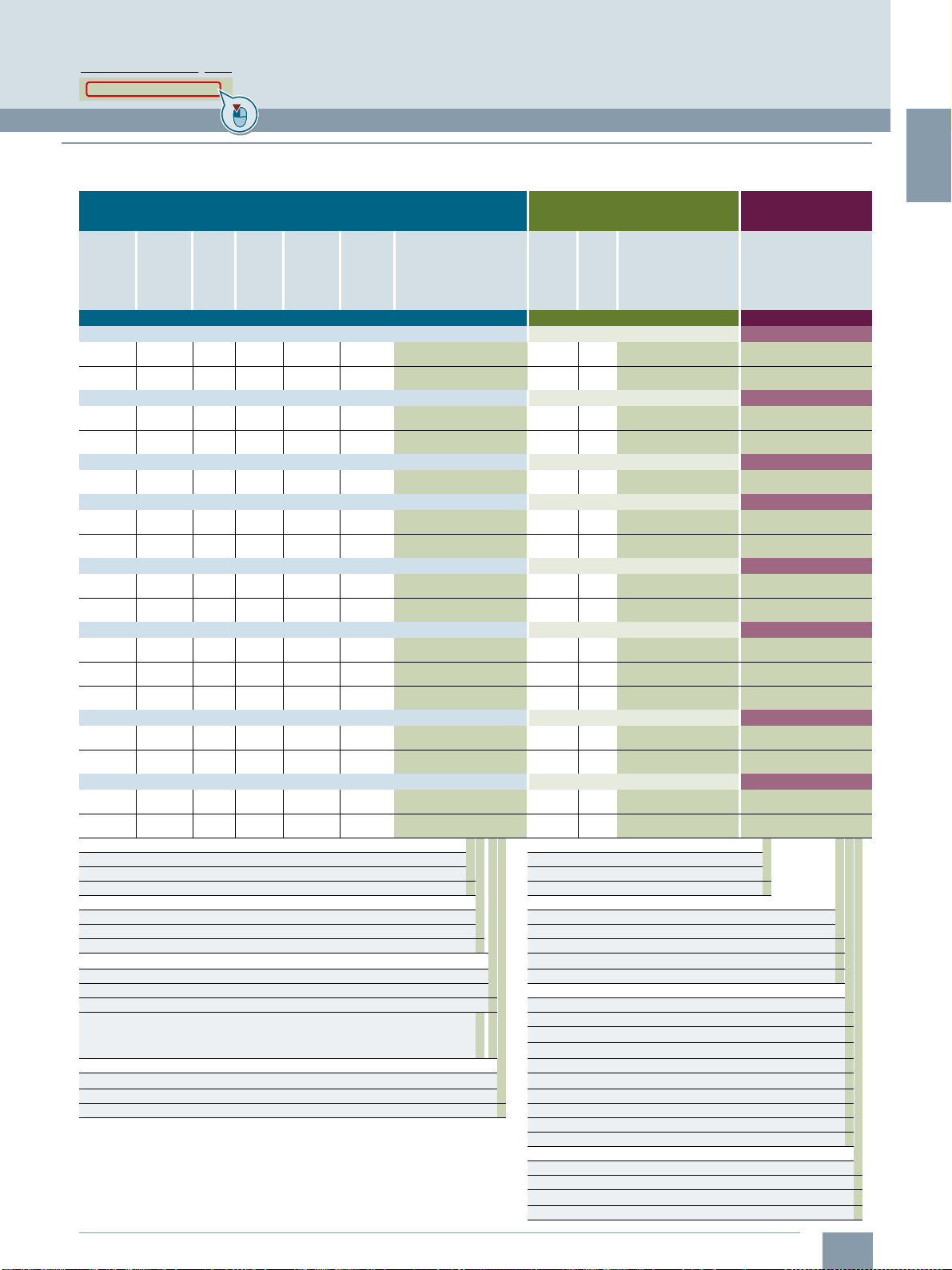

1

© Siemens 2020

System overview

Clicking to the Industry Mall

6SL3255-0AA00-5AA0

SINAMICS S210 servo drive system

■

Order overview

SINAMICS S210 drive system for line connection 200 ... 240 V 3 AC

SIMOTICS S-1FK2 servomotor SINAMICS S210 servo converter

Static

torque

M

0

Nm

(lb

High Dynamic for highly dynamic applications SINAMICS S210 servo converter One Cable Connection

Shaft height 20 – rated speed n

0.16

(0.12)

0.32

(0.24)

Shaft height 30 – rated speed n

0.64

(0.47)

1.27

(0.94)

Shaft height 40 – rated speed n

1.27

(0.94)

2.4

(1.77)

3.2

(2.36)

Shaft height 40 – rated speed n

1.27

(0.94)

2.4

(1.77)

Shaft height 52 – rated speed n

5

(3.69)

8

(5.90)

Shaft height 63 – rated speed n

9

(6.64)

12

(8.85)

16

(11.80)

Article No. supplements

Holding brake Pre-assembled MOTION-CONNECT cable

Without brake 0 MOTION-CONNECT 500 5

With brake 1 MOTION-CONNECT 800PLUS 8

Maximum

torque

M

Nm

-ft)

(lb

f

0.56

(0.41)

1.11

(0.82)

1.95

(1.44)

4.05

(2.99)

3.75

(2.77)

7.5

(5.53)

10

(7.38)

3.85

(2.84)

7.6

(5.61)

15

(11.06)

24

(17.70)

24.5

(18.07)

32.5

(23.97)

42

(30.98)

max

-ft) rpm

f

Maxi-

Rated

mum

speed

n

maxPratedMrated

8000 0.05

8000 0.1

8000 0.2

8000 0.4

7200 0.2

6700 0.38

7200 0.5

8000 0.4

8000 0.75

6000 0.79

6000 1.26

6000 1.3

6000 1.64

6000 2.15

Rated

power

torque

240 V

kW

Nm

(hp)

(lb

3000 rpm

rated

0.16

(0.07)

(0.12)

0.32

(0.13)

(0.24)

3000 rpm

rated

0.64

(0.27)

(0.47)

1.27

(0.54)

(0.94)

1500 rpm

rated

1.27

(0.27)

(0.94)

2.4

(0.51)

(1.77)

3.2

(0.67)

(2.36)

3000 rpm

rated

1.27

(0.54)

(0.94)

2.4

(1.01)

(1.77)

1500 rpm

rated

(1.06)5 (3.69)

(1.69)8 (5.90)

1500 rpm

rated

8.3

(1.74)

(6.12)

10.5

(2.20)

(7.74)

13.8

(2.88)

(10.18)

Rotor

moment

of inertia

J

Mot

kg cm

-ft)

(lbf-in2) Article No.

f

0.025

(0.009)

0.036

(0.012)

0.093

(0.032)

0.14

(0.048)

0.35

(0.120)

0.56

(0.191)

0.76

(0.260)

0.35

(0.120)

0.56

(0.191)

1.7

(0.581)

2.7

(0.923)

4.6

(1.572)

6.0

(2.050)

8.7

(2.973)

2

1FK2102-0AG■■-■■A0 0.24 FSA 6SL3210-5HE10-4UF0 6FX■002-8QN04-1■■■

1FK2102-1AG■■-■■A0 0.24 FSA 6SL3210-5HE10-4UF0 6FX■002-8QN04-1■■■

1FK2103-2AG■■-■■A0 0.45 FSA 6SL3210-5HE10-8UF0 6FX■002-8QN04-1■■■

1FK2103-4AG■■-■■A0 0.6 FSA 6SL3210-5HE11-0UF0 6FX■002-8QN04-1■■■

1FK2104-4AF■■-■■A0 0.24 FSA 6SL3210-5HE10-4UF0 6FX■002-8QN08-1■■■

1FK2104-5AF■■-■■A0 0.45 FSA 6SL3210-5HE10-8UF0 6FX■002-8QN08-1■■■

1FK2104-6AF■■-■■A0 0.6 FSA 6SL3210-5HE11-0UF0 6FX■002-8QN08-1■■■

1FK2104-4AK■■-■■A0 0.6 FSA 6SL3210-5HE11-0UF0 6FX■002-8QN08-1■■■

1FK2104-5AK■■-■■A0 0.9 FSB 6SL3210-5HE11-5UF0 6FX■002-8QN08-1■■■

1FK2105-4AF■■-■■A0 0.9 FSB 6SL3210-5HE11-5UF0 6FX■002-8QN08-1■■■

1FK2105-6AF■■-■■A0 1.2 FSB 6SL3210-5HE12-0UF0 6FX■002-8QN08-1■■■

1FK2106-3AF■■-■■A0 3FSC6SL3210-5HE15-0UF0 6FX■002-8QN11-1■■■

1FK2106-4AF■■-■■A0 3FSC6SL3210-5HE15-0UF0 6FX■002-8QN11-1■■■

1FK2106-6AF■■-■■A0 4.2 FSC 6SL3210-5HE17-0UF0 6FX■002-8QN11-1■■■

(3 AC series)

Supply voltage 200 ... 240 V 3 AC

Rated

power

240 V

P

kW

rated

Frame

size

Article No. Article No.

MOTION-CONNECT

motor connection cable

Degree of protection Length code (max. 50 m (164 ft))

IP64 (without shaft sealing ring) 0 0 m (0 ft) A

IP65 (with shaft sealing ring) 1 10 m (32.8 ft) B

Shaft extension / feather key 50 m (164 ft) F

Plain shaft 0

Shaft with feather key 1 0 m (0 ft) A

Plain shaft, reduced shaft diameter 0 2 1 m (3.28 ft) B

• ∅11 × 23 mm (0.43 × 0.91 in) (only for 1FK2.03 and IP64)

• ∅14 × 30 mm (0.55 × 1.18 in) (only for 1FK2.04 and IP64)

Encoder 5 m (16.4 ft) F

AS22DQC (absolute encoder 22-bit singleturn) S 6 m (19.7 ft) G

AM22DQC (absolute encoder 22-bit + 12-bit multiturn) M 7 m (23.0 ft) H

When operating a SINAMICS S210 servo converter with a supply

voltage of 200 V to 240 V 3 AC, an external, intrinsically safe

braking resistor is always required.

1/14

Siemens D 32 · January 2020

...

2 m (6.56 ft) C

3 m (9.84 ft) D

4 m (13.1 ft) E

8 m (26.2 ft) J

9 m (29.5 ft) K

0 m (0 ft) 0

0.1 m (0.33 ft) 1

...

0.8 m (2.62 ft) 8

...

...

Page 23

1

Clicking to the Industry Mall

6SL3255-0AA00-5AA0

© Siemens 2020

System overview

SINAMICS S210 servo drive system

■

Order overview

SINAMICS S210 drive system for line connection 200 ... 240 V 3 AC (continued)

SIMOTICS S-1FK2 servomotor SINAMICS S210 servo converter

Static

torque

M

0

Nm

(lb

Compact for high precision applications SINAMICS S210 servo converter One Cable Connection

Shaft height 30 – rated speed n

0.64

(0.47)

1.27

(0.94)

Shaft height 40 – rated speed n

2.4

(1.77)

3.2

(2.36)

Shaft height 40 – rated speed n

2.4

(1.77)

Shaft height 48 – rated speed n

3.6

(2.66)

6

(4.43)

Shaft height 63 – rated speed n

6.5

(4.79)

12

(8.85)

Shaft height 80 – rated speed n

18

(13.28)

22

(16.23)

27

(19.92)

Shaft height 100 – rated speed n

30

(22.13)

40

(29.50)

Shaft height 100 – rated speed n

30

(22.13)

40

(29.50)

Article No. supplements

Holding brake Pre-assembled MOTION-CONNECT cable

Without brake 0 MOTION-CONNECT 500 5

With brake 1 MOTION-CONNECT 800PLUS 8

Maximum

torque

M

Nm

-ft)

(lb

f

1.85

(1.36)

3.75

(2.77)

7.1

(5.24)

9.5

(7.01)

7.1

(5.24)

10.8

(7.97)

18

(13.28)

18

(13.28)

36

(26.55)

51

(37.62)

66

(48.68)

80

(59.01)

90

(66.38)

120

(88.51)

90

(66.38)

120

(88.51)

max

-ft) rpm

f

Maxi-

Rated

power

240 V

kW

(hp)

rated

(0.27)

(0.54)

rated

(0.51)

(0.67)

rated

(1.01)

rated

(0.71)

(1.15)

rated

(1.30)

(2.31)

rated

(2.33)

(2.88)

(3.35)

rated

(3.35)

(4.09)

rated

(4.29)

(5.23)

Rated

torque

Nm

(lb

3000 rpm

0.64

(0.47)

1.27

(0.94)

1500 rpm

2.4

(1.77)

3.2

(2.36)

3000 rpm

2.4

(1.77)

1500 rpm

3.4

(2.51)

5.5

(4.06)

1500 rpm

6.1

(4.50)

10.9

(8.04)

1000 rpm

16.6

(12.24)

20

(14.75)

23.5

(17.33)

750 rpm

30

(22.13)

39

(28.77)

1000 rpm

30

(22.13)

37

(27.29)

mum

speed

n

maxPratedMrated

8000 0.2

8000 0.4

7500 0.38

7600 0.5

8000 0.75

6000 0.53

6000 0.86

6000 0.97

5800 1.72

4100 1.74

4600 2.15

4700 2.5

2500 2.5

2500 3.05

4400 3.2

3300 3.9

Rotor

moment

of inertia

J

Mot

kg cm

-ft)

(lbf-in2) Article No.

f

0.20

(0.068)

0.35

(0.120)

1.2

(0.410)

1.6

(0.547)

1.2

(0.410)

3.2

(1.093)

5.1

(1.743)

7.8

(2.665)

15

(5.126)

30

(10.251)

39

(13.326)

48

(16.402)

89

(30.411)

120

(41.004)

89

(30.411)

120

(41.004)

2

1FK2203-2AG■■-■■A0 0.45 FSA 6SL3210-5HE10-8UF0 6FX■002-8QN04-1■■■

1FK2203-4AG■■-■■A0 0.6 FSA 6SL3210-5HE11-0UF0 6FX■002-8QN04-1■■■

1FK2204-5AF■■-■■A0 0.45 FSA 6SL3210-5HE10-8UF0 6FX■002-8QN08-1■■■

1FK2204-6AF■■-■■A0 0.6 FSA 6SL3210-5HE11-0UF0 6FX■002-8QN08-1■■■

1FK2204-5AK■■-■■A0 0.9 FSB 6SL3210-5HE11-5UF0 6FX■002-8QN08-1■■■

1FK2205-2AF■■-■■A0 0.6 FSA 6SL3210-5HE11-0UF0 6FX■002-8QN08-1■■■

1FK2205-4AF■■-■■A0 0.9 FSB 6SL3210-5HE11-5UF0 6FX■002-8QN08-1■■■

1FK2206-2AF■■-■■A0 0.9 FSB 6SL3210-5HE11-5UF0 6FX■002-8QN11-1■■■

1FK2206-4AF■■-■■A0 2.1 FSC 6SL3210-5HE13-5UF0 6FX■002-8QN11-1■■■

1FK2208-3AC■■-■■A0 2.1 FSC 6SL3210-5HE13-5UF0 6FX■002-8QN11-1■■■

1FK2208-4AC■■-■■A0 3FSC6SL3210-5HE15-0UF0 6FX■002-8QN11-1■■■

1FK2208-5AC■■-■■A0 4.2 FSC 6SL3210-5HE17-0UF0 6FX■002-8QN11-1■■■

1FK2210-3AB■■-■■A0 2.1 FSC 6SL3210-5HE13-5UF0 6FX■002-8QN11-1■■■

1FK2210-4AB■■-■■A0 3FSC6SL3210-5HE15-0UF0 6FX■002-8QN11-1■■■

1FK2210-3AC■■-■■A0 4.2 FSC 6SL3210-5HE17-0UF0 6FX■002-8QN11-1■■■

1FK2210-4AC■■-■■A0 4.2 FSC 6SL3210-5HE17-0UF0 6FX■002-8QN11-1■■■

(3 AC series)

Supply voltage 200 ... 240 V 3 AC

Rated

power

240 V

P

kW

rated

Frame

size

Article No. Article No.

MOTION-CONNECT

motor connection cable

Degree of protection Length code (max. 50 m (164 ft))

IP64 (without shaft sealing ring) 0 0 m (0 ft) A

IP65 (with shaft sealing ring) 1 10 m (32.8 ft) B

Shaft extension / feather key 50 m (164 ft) F

Plain shaft 0

Shaft with feather key 1 0 m (0 ft) A

Plain shaft, reduced shaft diameter 0 2 1 m (3.28 ft) B

• ∅11 × 23 mm (0.43 × 0.91 in) (only for 1FK2.03 and IP64)

• ∅14 × 30 mm (0.55 × 1.18 in) (only for 1FK2.04 and IP64)

Encoder 5 m (16.4 ft) F

AS22DQC (absolute encoder 22-bit singleturn) S 6 m (19.7 ft) G

AM22DQC (absolute encoder 22-bit + 12-bit multiturn) M 7 m (23.0 ft) H

When operating a SINAMICS S210 servo converter with a supply

voltage of 200 V to 240 V 3 AC, an external, intrinsically safe

braking resistor is always required.

...

2 m (6.56 ft) C

3 m (9.84 ft) D

4 m (13.1 ft) E

8 m (26.2 ft) J

9 m (29.5 ft) K

0 m (0 ft) 0

0.1 m (0.33 ft) 1

...

0.8 m (2.62 ft) 8

Siemens D 32 · January 2020

...

1/15

...

Page 24

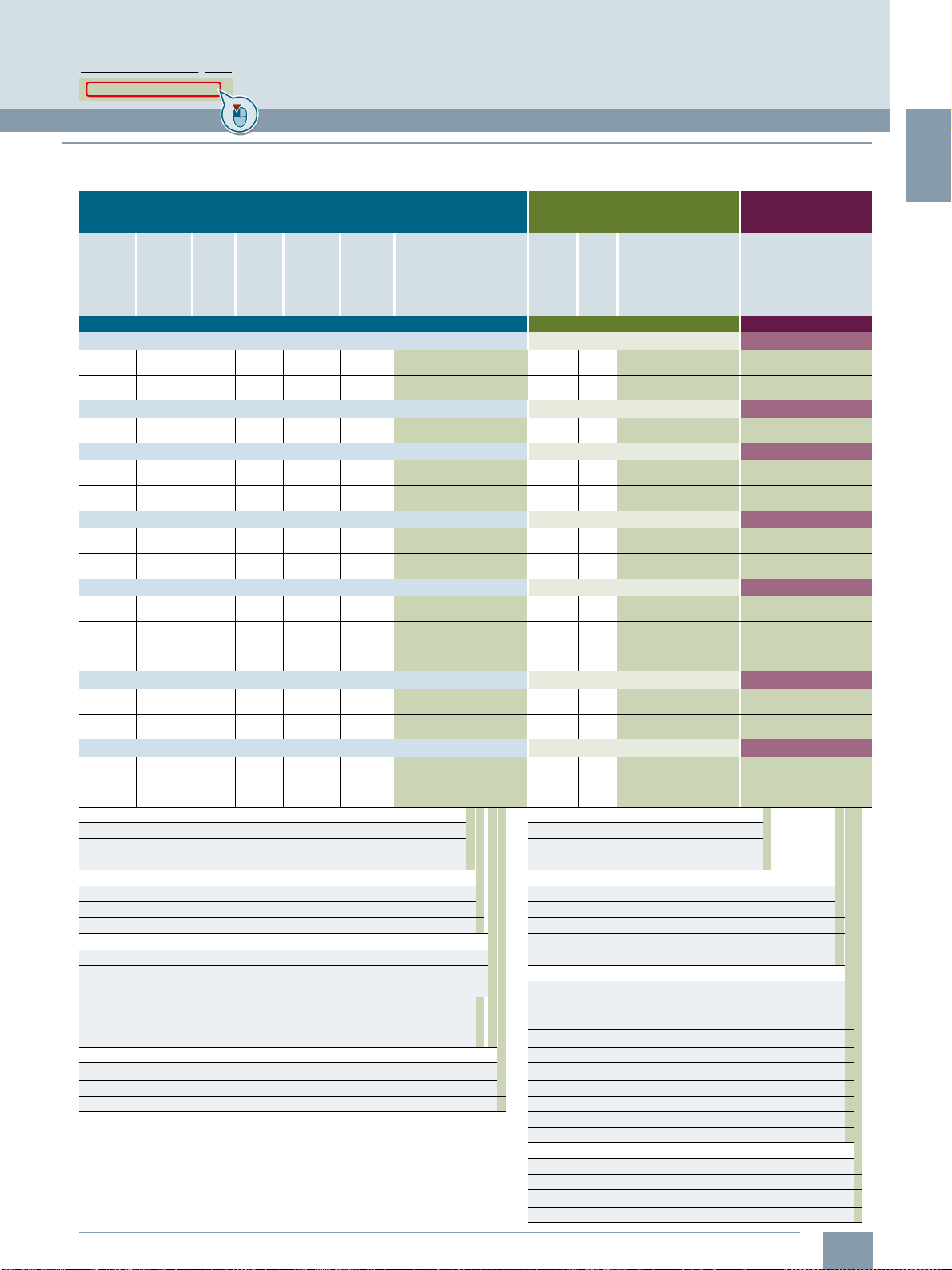

1

© Siemens 2020

System overview

Clicking to the Industry Mall

6SL3255-0AA00-5AA0

SINAMICS S210 servo drive system

■

Order overview

SINAMICS S210 drive system for line connection 380 ... 480 V 3 AC

SIMOTICS S-1FK2 servomotor SINAMICS S210 servo converter

Static

torque

M

0

Nm

(lb

High Dynamic for highly dynamic applications SINAMICS S210 servo converter One Cable Connection

Shaft height 40 – rated speed n

1.27

(0.94)

2.4

(1.77)

3.2

(2.36)

Shaft height 52 – rated speed n

5

(3.69)

8

(5.90)

Shaft height 63 – rated speed n

9

(6.64)

12

(8.85)

16

(11.80)

Article No. supplements

Holding brake Pre-assembled MOTION-CONNECT cable

Without brake 0 MOTION-CONNECT 500 5

With brake 1 MOTION-CONNECT 800PLUS 8

Maximum

torque

M

Nm

-ft)

(lb

f

3.75

(2.77)

7.5

(5.53)

10

(7.38)

15

(11.06)

24

(17.70)

24.5

(18.07)

32.5

(23.97)

42

(30.98)

max

-ft) rpm

f

Maxi-

Rated

power

400 V

kW

(hp)

rated

(0.54)

(1.01)

(1.34)

rated

(1.94)

(2.82)

rated

(3.08)

(3.62)

(4.43)

Rated

torque

Nm

(lb

3000 rpm

1.27

(0.94)

2.4

(1.77)

3.2

(2.36)

3000 rpm

4.6

(3.39)

6.6

(4.87)

3000 rpm

7.3

(5.38)

8.6

(6.34)

10.6

(7.82)

mum

speed

n

maxPratedMrated

7200 0.4

6700 0.75

7200 1

6000 1.45

6000 2.1

6000 2.3

6000 2.7

6000 3.3

Rotor

moment

of inertia

J

Mot

kg cm

-ft)

(lbf-in2) Article No.

f

0.35

(0.120)

0.56

(0.191)

0.76

(0.260)

1.7

(0.581)

2.7

(0.923)

4.6

(1.572)

6.0

(2.050)

8.7

(2.973)

2

1FK2104-4AF■■-■■A0 0.4 FSA 6SL3210-5HE10-4UF0 6FX■002-8QN08-1■■■

1FK2104-5AF■■-■■A0 0.75 FSA 6SL3210-5HE10-8UF0 6FX■002-8QN08-1■■■

1FK2104-6AF■■-■■A0 1FSA6SL3210-5HE11-0UF0 6FX■002-8QN08-1■■■

1FK2105-4AF■■-■■A0 1.5 FSB 6SL3210-5HE11-5UF0 6FX■002-8QN08-1■■■

1FK2105-6AF■■-■■A0 2FSB6SL3210-5HE12-0UF0 6FX■002-8QN08-1■■■

1FK2106-3AF■■-■■A0 5FSC6SL3210-5HE15-0UF0 6FX■002-8QN11-1■■■

1FK2106-4AF■■-■■A0 5FSC6SL3210-5HE15-0UF0 6FX■002-8QN11-1■■■

1FK2106-6AF■■-■■A0 7FSC6SL3210-5HE17-0UF0 6FX■002-8QN11-1■■■

(3 AC series)

Supply voltage 380 ... 480 V 3 AC

Rated

power

400 V

P

kW

rated

Frame

size

Article No. Article No.

MOTION-CONNECT

motor connection cable

Degree of protection Length code (max. 50 m (164 ft))

IP64 (without shaft sealing ring) 0 0 m (0 ft) A

IP65 (with shaft sealing ring) 1 10 m (32.8 ft) B

Shaft extension / feather key 50 m (164 ft) F

Plain shaft 0

Shaft with feather key 1 0 m (0 ft) A

Plain shaft, reduced shaft diameter 0 2 1 m (3.28 ft) B

• ∅11 × 23 mm (0.43 × 0.91 in) (only for 1FK2.03 and IP64)

• ∅14 × 30 mm (0.55 × 1.18 in) (only for 1FK2.04 and IP64)

Encoder 5 m (16.4 ft) F

AS22DQC (absolute encoder 22-bit singleturn) S 6 m (19.7 ft) G

AM22DQC (absolute encoder 22-bit + 12-bit multiturn) M 7 m (23.0 ft) H

...

2 m (6.56 ft) C

3 m (9.84 ft) D

4 m (13.1 ft) E

8 m (26.2 ft) J

9 m (29.5 ft) K

0 m (0 ft) 0

0.1 m (0.33 ft) 1

...

0.8 m (2.62 ft) 8

...

...

1/16

Siemens D 32 · January 2020

Page 25

1

Clicking to the Industry Mall

6SL3255-0AA00-5AA0

© Siemens 2020

System overview

SINAMICS S210 servo drive system

■

Order overview

SINAMICS S210 drive system for line connection 380 ... 480 V 3 AC (continued)

SIMOTICS S-1FK2 servomotor SINAMICS S210 servo converter

Static

torque

M

0

Nm

(lb

Compact for high precision applications SINAMICS S210 servo converter One Cable Connection

Shaft height 40 – rated speed n

2.4

(1.77)

3.2

(2.36)

Shaft height 40 – rated speed n

2.4

(1.77)

Shaft height 48 – rated speed n

3.6

(2.66)

6

(4.43)

Shaft height 63 – rated speed n

6.5

(4.79)

12

(8.85)

Shaft height 80 – rated speed n

18

(13.28)

22

(16.23)

27

(19.92)

Shaft height 100 – rated speed n

30

(22.13)

40

(29.50)

Shaft height 100 – rated speed n

30

(22.13)

40

(29.50)

Article No. supplements

Holding brake Pre-assembled MOTION-CONNECT cable

Without brake 0 MOTION-CONNECT 500 5

With brake 1 MOTION-CONNECT 800PLUS 8

Maximum

torque

M

Nm

-ft)

(lb

f

7.1

(5.24)

9.5

(7.01)

7.1

(5.24)

10.8

(7.97)

18

(13.28)

18

(13.28)

36

(26.55)

51

(37.62)

66

(48.68)

80

(59.01)

90

(66.38)

120

(88.51)

90

(66.38)

120

(88.51)

max

-ft) rpm

f

Maxi-

Rated

mum

speed

n

maxPratedMrated

7500 0.75

7600 1

8000 0.57

6000 0.94

6000 1.45

6000 1.71

5800 2.85

4100 3.05

4600 3.55

4700 4

2500 4.5

2500 5.4

4400 5.5

3300 6.4

Rated

power

torque

400 V

kW

Nm

(hp)

(lb

3000 rpm

rated

2.4

(1.01)

(1.77)

3.2

(1.34)

(2.36)

6000 rpm

rated

0.9

(0.76)

(0.66)

3000 rpm

rated

(1.26)3 (2.21)

4.6

(1.94)

(3.39)

3000 rpm

rated

5.4

(2.29)

(3.98)

9.1

(3.82)

(6.71)

2000 rpm

rated

14.5

(4.09)

(10.70)

17

(4.76)

(12.54)

19.1

(5.36)

(14.09)

1500 rpm

rated

28.5

(6.03)

(21.02)

34.5

(7.24)

(25.45)

2000 rpm

rated

26

(7.38)

(19.18)

30.5

(8.58)

(22.50)

Rotor

moment

of inertia

J

Mot

kg cm

-ft)

(lbf-in2) Article No.

f

1.2

(0.410)

1.6

(0.547)

1.2

(0.410)

3.2

(1.093)

5.1

(1.743)

7.8

(2.665)

15

(5.126)

30

(10.251)

39

(13.326)

48

(16.402)

89

(30.411)

120

(41.004)

89

(30.411)

120

(41.004)

2

1FK2204-5AF■■-■■A0 0.75 FSA 6SL3210-5HE10-8UF0 6FX■002-8QN08-1■■■

1FK2204-6AF■■-■■A0 1FSA6SL3210-5HE11-0UF0 6FX■002-8QN08-1■■■

1FK2204-5AK■■-■■A0 1.5 FSB 6SL3210-5HE11-5UF0 6FX■002-8QN08-1■■■

1FK2205-2AF■■-■■A0 1FSA6SL3210-5HE11-0UF0 6FX■002-8QN08-1■■■

1FK2205-4AF■■-■■A0 1.5 FSB 6SL3210-5HE11-5UF0 6FX■002-8QN08-1■■■

1FK2206-2AF■■-■■A0 1.5 FSB 6SL3210-5HE11-5UF0 6FX■002-8QN11-1■■■

1FK2206-4AF■■-■■A0 3.5 FSC 6SL3210-5HE13-5UF0 6FX■002-8QN11-1■■■

1FK2208-3AC■■-■■A0 3.5 FSC 6SL3210-5HE13-5UF0 6FX■002-8QN11-1■■■

1FK2208-4AC■■-■■A0 5FSC6SL3210-5HE15-0UF0 6FX■002-8QN11-1■■■

1FK2208-5AC■■-■■A0 7FSC6SL3210-5HE17-0UF0 6FX■002-8QN11-1■■■

1FK2210-3AB■■-■■A0 3.5 FSC 6SL3210-5HE13-5UF0 6FX■002-8QN11-1■■■

1FK2210-4AB■■-■■A0 5FSC6SL3210-5HE15-0UF0 6FX■002-8QN11-1■■■

1FK2210-3AC■■-■■A0 7FSC6SL3210-5HE17-0UF0 6FX■002-8QN11-1■■■

1FK2210-4AC■■-■■A0 7FSC6SL3210-5HE17-0UF0 6FX■002-8QN11-1■■■

(3 AC series)

Supply voltage 380 ... 480 V 3 AC

Rated

power

400 V

P

kW

rated

Frame

size

Article No. Article No.

MOTION-CONNECT

motor connection cable

Degree of protection Length code (max. 50 m (164 ft))

IP64 (without shaft sealing ring) 0 0 m (0 ft) A

IP65 (with shaft sealing ring) 1 10 m (32.8 ft) B

Shaft extension / feather key 50 m (164 ft) F

Plain shaft 0

Shaft with feather key 1 0 m (0 ft) A

Plain shaft, reduced shaft diameter 0 2 1 m (3.28 ft) B

• ∅11 × 23 mm (0.43 × 0.91 in) (only for 1FK2.03 and IP64)

• ∅14 × 30 mm (0.55 × 1.18 in) (only for 1FK2.04 and IP64)

Encoder 5 m (16.4 ft) F

AS22DQC (absolute encoder 22-bit singleturn) S 6 m (19.7 ft) G

AM22DQC (absolute encoder 22-bit + 12-bit multiturn) M 7 m (23.0 ft) H

...

2 m (6.56 ft) C

3 m (9.84 ft) D

4 m (13.1 ft) E

8 m (26.2 ft) J

9 m (29.5 ft) K

0 m (0 ft) 0

0.1 m (0.33 ft) 1

...

0.8 m (2.62 ft) 8

Siemens D 32 · January 2020

...

1/17

...

Page 26

1

1)

Extended function for an existing memory card (firmware V5.1 SP1 or

higher). The memory card is not included in the scope of delivery.

The Safety license can also be ordered together with a memory card

(see above). With a CoL in electronic form, the license is supplied as a

PDF file. Notification of this with a download link is received by email.

For further information, see section Supplementary system components >

Memory cards.

2)

The data is applicable for the complete cable length of the motors, whose

associated converters are coupled with one another via an AC coupling or

through the DC link.

The maximum cable length per motor is 25 m using the internal filters or an

external filter to achieve EMC category C2. If an external filter is used to

achieve EMC category C3, the maximum cable length per motor is 50 m.

3)

Permissible cables:

-16mm

2

, Class 5 (finely stranded, PVC-insulated) H07V-K + H07V2-K

according to EN 50525-2-31

- HELUTHERM 145: 16 mm

2

, Class 5 (finely stranded, crosslinked

polyolefin-copolymer, halogen-free)

www.helukabel.com

- External diameter 6.7 mm to 8.1 mm

Permissible cables (UL approval):

- AWG 6, copper cable with PVC insulation, with or without nylon jacket,

19 strands

- Types: MTW, THHW, THW, THW-2, THHN, THWN-2, TW, TWN

- CSA types: TW, TWU, TWN75, TW75, TWU75, T90, no compressed

conductors

© Siemens 2020

System overview

SINAMICS S210 servo drive system

■

Order overview

Accessories for SINAMICS S210 servo converters Accessories for SIMOTICS S-1FK2 servomotors

Description Article No.

SINAMICS SD card (optional)

512 MB

The parameter assignment, firmware and

licenses for a converter can be stored on

this memory card.

Firmware V5.2 or higher is required for the

3 AC series.

•Empty 6SL3054-4AG00-2AA0

• With firmware V5.1

• With firmware V5.1 SP1

• With firmware V5.1 SP1 and

Safety license (Extended Functions)

• With firmware V5.2

• With firmware V5.2 and

Safety license (Extended Functions)

• With firmware V5.2 SP3

• With firmware V5.2 SP3 and

Safety license (Extended Functions)

Safety license

(Extended Functions)

• CoL in paper form 6SL3074-0AA10-0AA0

• CoL in electronic form

PROFINET patch cable

For the networking of concatenated

converters

•0.3m 6XV1870-3QE30

•0.5m

Only for the 1 AC series

Line filter

With this line filter, Category C2 for cable

lengths up to 25 m (82 ft), Category C3 for

cable lengths up to 50 m (164 ft) acc. to

IEC 61800-3 can be achieved.

Only for the 3 AC series

Line filter

With these line filters, Category C2 for cable lengths

up to 25 m (82 ft), Category C3 for cable lengths

up to 50 m (164 ft) acc. to IEC 61800-3 can be

achieved.

When connected via a DC link, a total cable

length of up to 100 m (328 ft) with Category C2

and up to 250 m (820 ft) with Category C3 is

2)

possible

• ≤ 35 A 6SL3203-0BE23-5HA0

• ≤ 65 A

Connector set AC bus and DC link

For coupling the DC link and the line infeed

Scope of delivery: 1 AC bus connector,

1 DC link connector, 2 cover caps

The AC bus connector replaces the push-

in connector included in the scope of delivery of the converter. Wiring is performed

with conventional 16 mm

included in scope of delivery)

Connector set AC bus individual

For coupling the line infeed

Scope of delivery: 1 AC bus connector,

1 cover cap

This connector replaces the push-in

connector included in the scope of delivery

of the converter. Wiring is performed with

conventional 16 mm

in scope of delivery)

External braking resistors

for 200 … 240 V 3 AC

For a supply voltage of 200 V to 240 V 3 AC,

an external, intrinsically safe braking resistor

is always required for each converter

• 100 W, 47 Ω for FSA and FSB GXK:BWG250047TS-190

• 240 W, 14 Ω for FSC

1/18

1)

2

cable (not

3)

2

cable (not included

3)

Siemens D 32 · January 2020

6SL3054-4FB00-2BA0

6SL3054-4FB10-2BA0

6SL3054-4FB10-2BA0-Z