Siemens SINAMICS G130, SINAMICS G150, SINAMICS S120, SINAMICS S120 Chassis, SINAMICS S150 Engineering Manual

SINAMICS - Low Voltage

Engineering Manual

SINAMICS G130, G150, S120 Chassis, S120 Cabinet Modules, S150

Version 4.0 x May 2008

SINAMICS Drives

s

Foreword

SINAMICS

Engineering Manual

May 2008

List of Contents

Fundamental Principles and System Description

EMC Installation Guideline

General Engineering Information for SINAMICS

Converter Chassis Units SINAMICS G130

Converter Cabinet Units SINAMICS G150

Disclaimer

We have checked that the contents of this document

correspond to the hardware and software described.

However, as deviations cannot be totally excluded, we are

unable to guarantee complete consistency. The information

given in this publication is reviewed at regular intervals and

any corrections that might be necessary are made in the

subsequent editions.

Siemens AG 2008

Subject to change without prior notice.

SINAMICS S120,

General Information about Built-in and Cabinet

Units

Modular Cabinet Unit System

SINAMICS S120 Cabinet Modules

Converter Cabinet Units SINAMICS S150

Drive Dimensioning

Motors

Dimension Drawings

SINAMICS Engineering Manual - May 2008

Siemens AG

3/396

Foreword

Engineering Information

To all SINAMICS customers!

This engineering manual is supplementary to the SINAMICS catalog range and is designed to provide additional

support to SINAMICS users. It focuses on drives with units in Chassis and Cabinet format in the output power range

≥ 75 KW operating in vector control mode.

The engineering manual contains a general analysis of the fundam ental pr inciples of vari able-speed dr ives as well as

detailed system descriptions and specific information about the following units in the SINAMICS equipment range:

Converter Chassis Units SINAMICS G130 (Catalog D11)

Converter Cabinet Units SINAMICS G150 (Catalog D11)

Modular Chassis Unit System SINAMICS S120 (Catalog PM21)

Modular Cabinet Unit System SINAMICS S120 Cabinet Modules (Catalog D21.3 Cabinet Modules)

Converter Cabinet Units SINAMICS S150 (Catalog D21.3).

This engineering manual is divided into different chapters.

The first chapter “Fundamental Principles and System Description” focuses on the phys ical fundament als of electrica l

variable-speed drives and provides general system descriptions of products in the SINAMICS range.

The second chapter “EMC Installation Guideline” gives an introduction to the subject of Electro-magnetic

Compatibility (EMC), and provides all information required to install drives with the aforementioned SINAMICS

devices in an EMC-compliant manner.

The chapters that follow, which describe the configuration of SINAMICS G130, G150, S120 chassis units, S120

Cabinet Modules and S150, focus on specific unit types in more detail than the chapter on fundamental principles.

To provide an easy overview of the system varia nts and cabinet design, the dimensions are given at the e nd of the

manual.

This engineering manual can and should on ly be viewed as a supplement to SINAMICS catalo gs D11, PM21, D21.3

and D21.3 Cabinet Modules. The document does not, therefore, contain any ordering data. The manual is availab le

as an electronic document in English and German only.

The information of this manual is aimed at technically qualified and trained personnel. The configuring engine er is

responsible for assessing whether the information provided is sufficiently comprehensive for the application in

question and, therefore, assumes overall responsibility for the whole drive or the whole system.

The information provided in this engineering manual contains descriptions or character istics of performance which in

case of actual use do not always apply as described or which may change as a r esult of further development of the

products.

The desired performance features are only binding if expressly agreed upon in the contra ct.

Availability and technical specifications are subject to change without prior notice.

EMC warning information

The SINAMICS converter systems G130, G150, S120 chassis units, S120 Cabinet Modules and S150 are not

designed to be connected to public networks (first environment). RFI suppression of these converter systems is

designed for industrial networks (second environment) in accordance with the EMC product standard EN 61800-3 for

variable-speed drives. If the converter systems are connected to public networks (first environment) el ectro-magnetic

interference can occur. With additional measures (e.g. EMC-filters) the converter systems can also be connected to

public networks

SINAMICS Engineering Manual – May 2008

4/396

Siemens AG

List of Contents

List of Contents

Engineering Information

Fundamental Principles and System Description

█ Operating principle of SINAMICS converters .......................................................................................................12

General operating principle ..................................................................................................................................12

Pulse modulation method.....................................................................................................................................12

Generation of a variable voltage by pulse width modulation.................................................................................13

Maximum attainable output voltage with space vector modulation SVM..............................................................15

Maximum attainable output voltage with pulse-edge modulation PEM.................................................................15

The pulse frequency and its influence on key system properties ......................................................................... 17

Output power ratings of SINAMICS converters and inverters / Definition of the output power.............................19

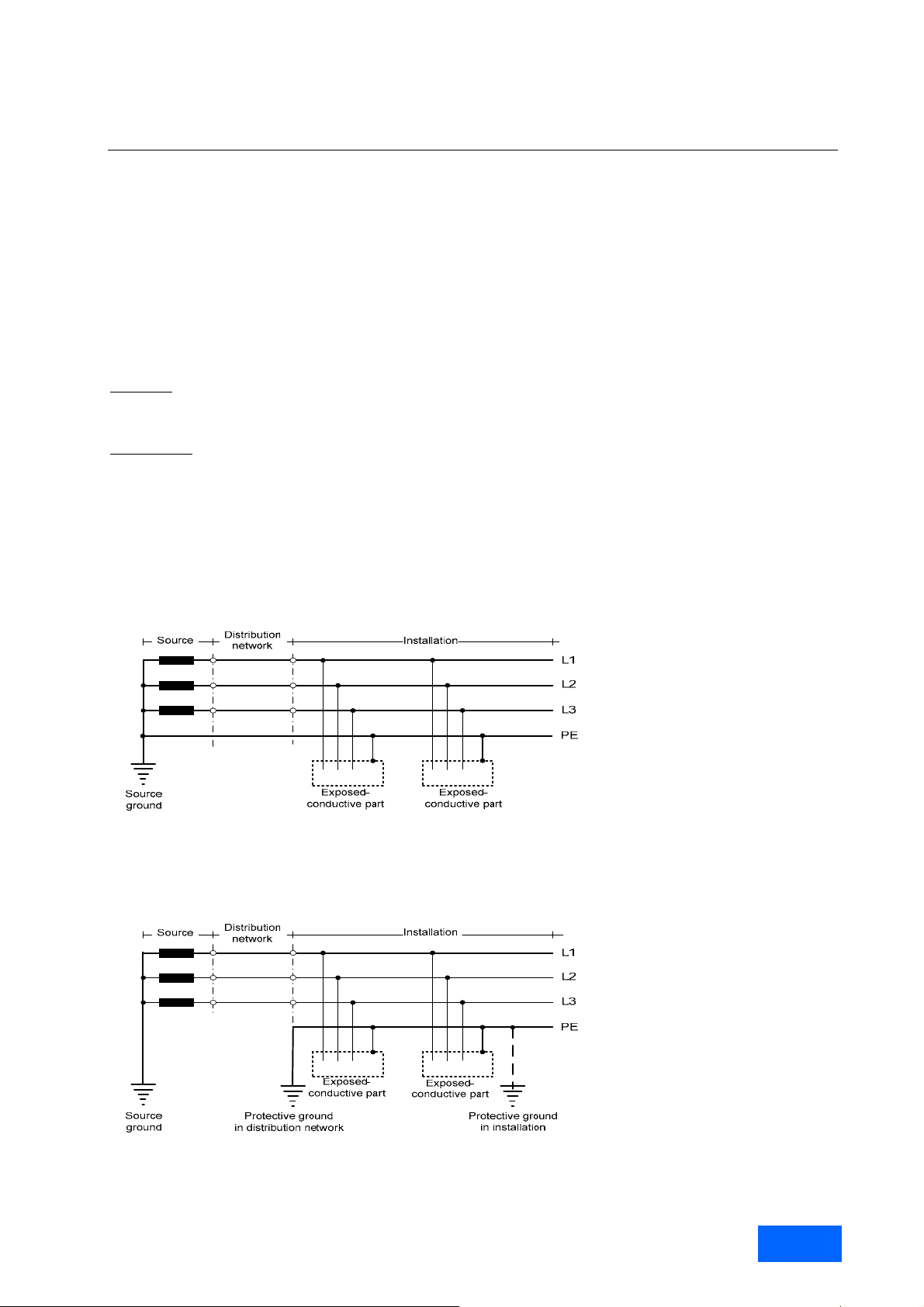

█ Supply systems and supply system types............................................................................................................21

General.................................................................................................................................................................21

Connection of converters to grounded systems (TN or TT)..................................................................................22

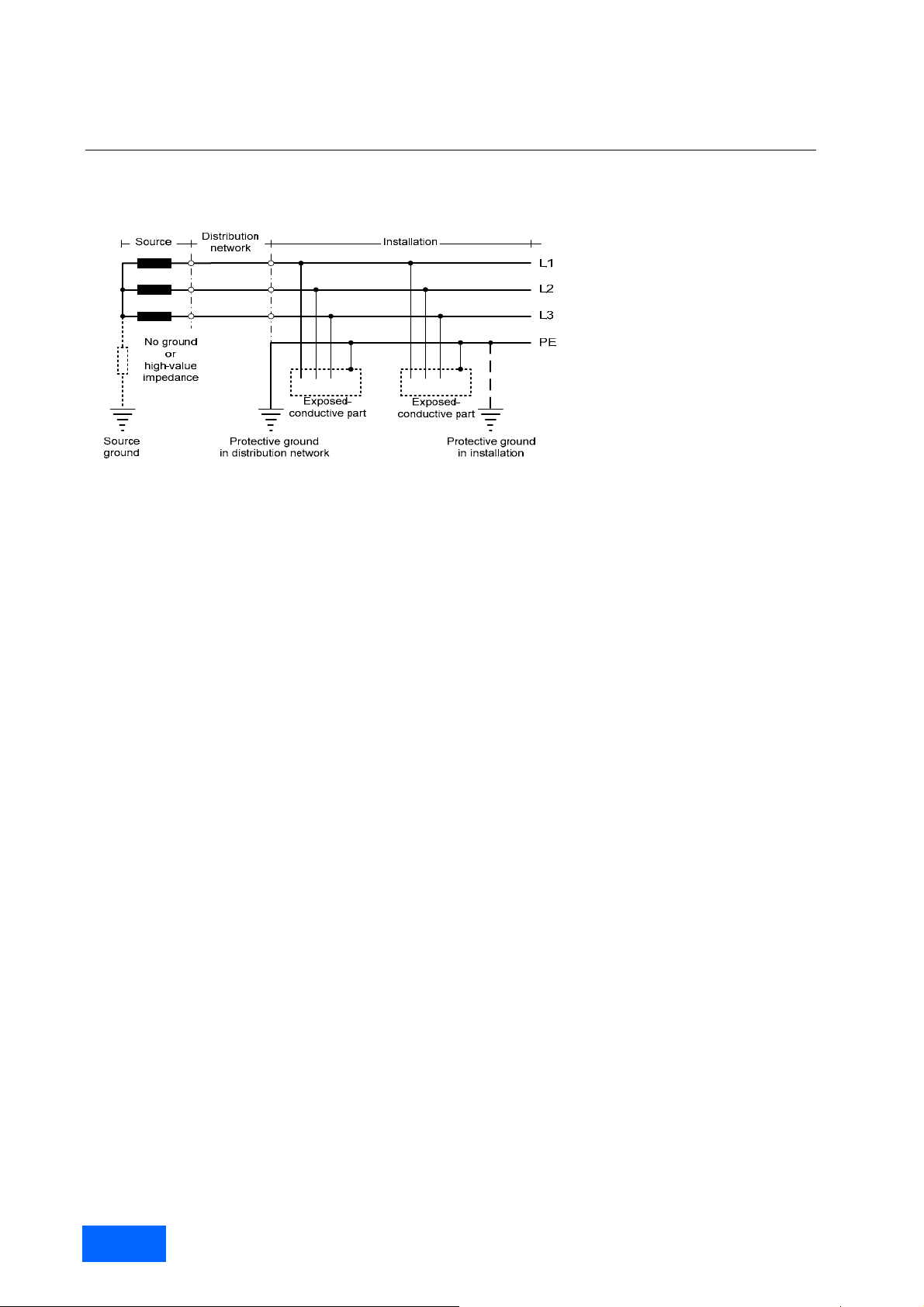

Connection of converters to non-grounded systems (IT)......................................................................................22

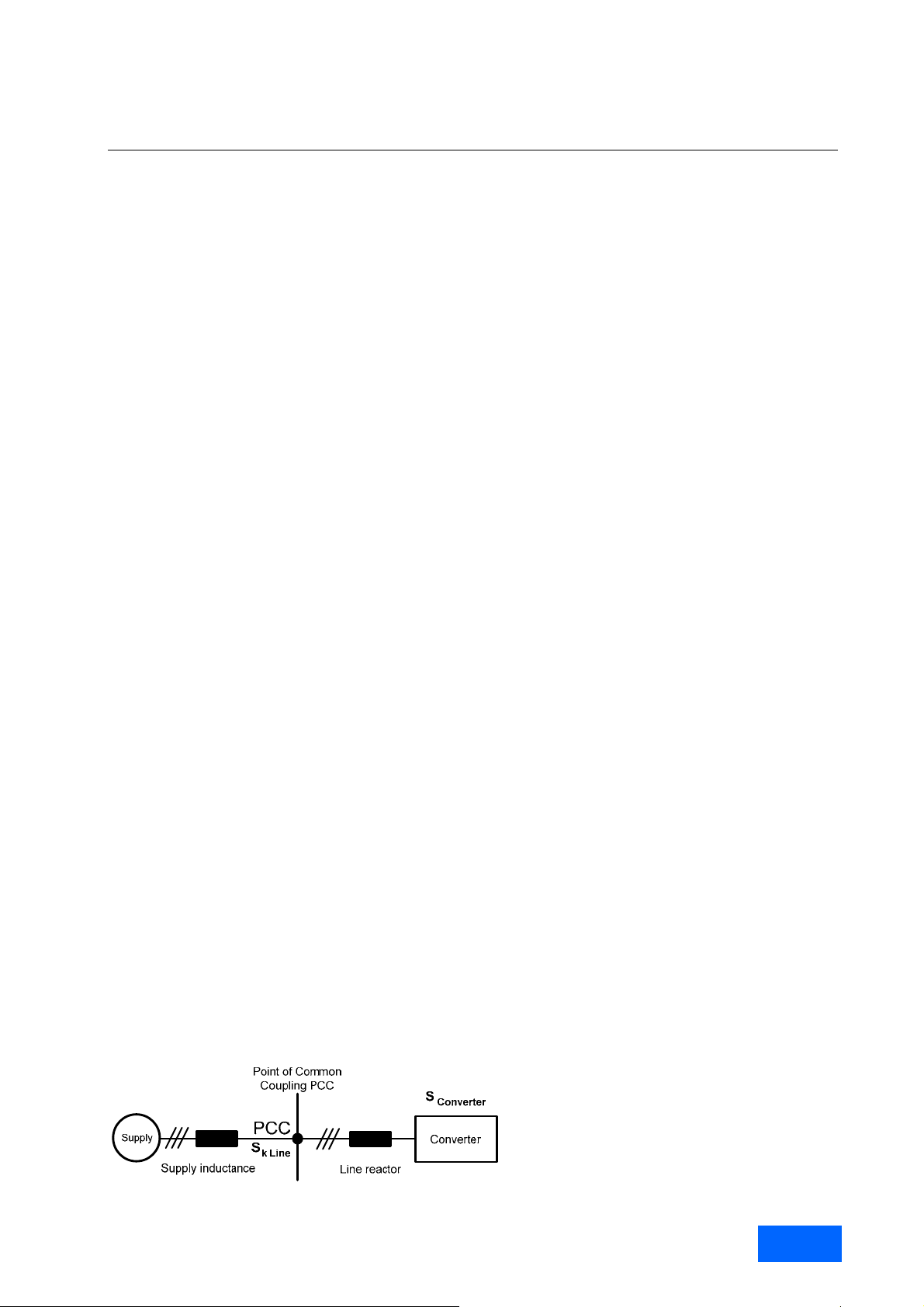

Connection of converters to supply systems with different short-circuit powers...................................................23

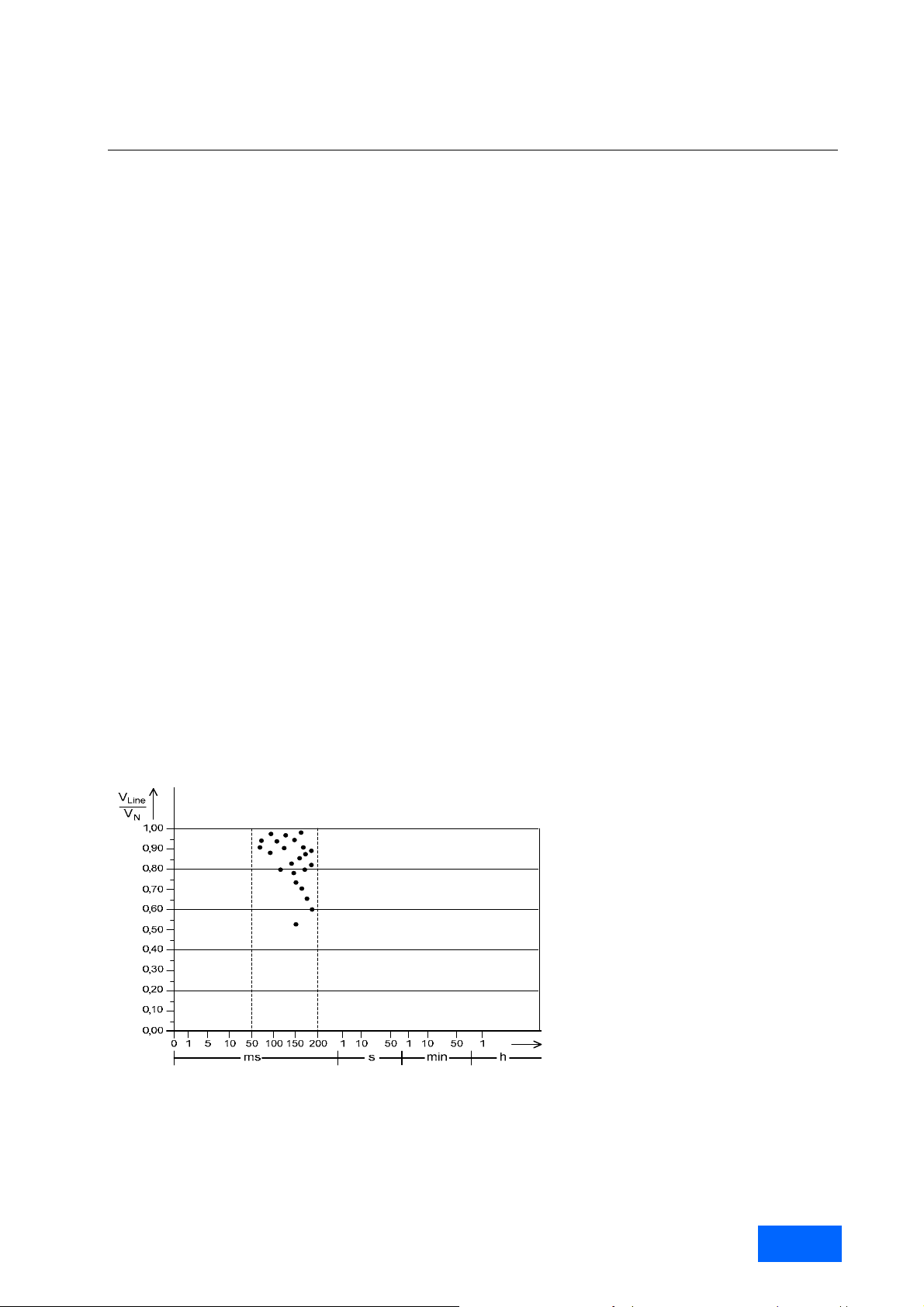

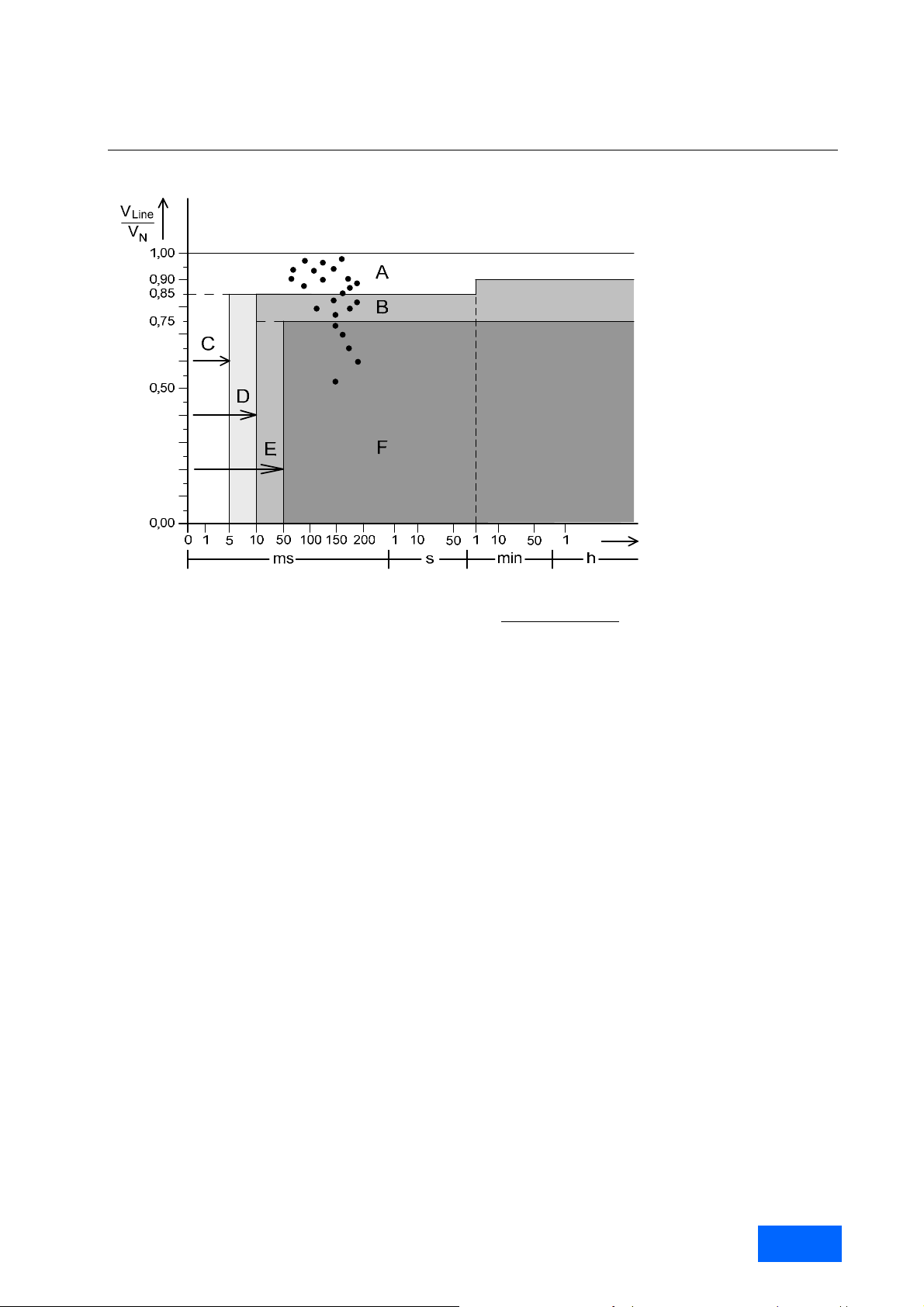

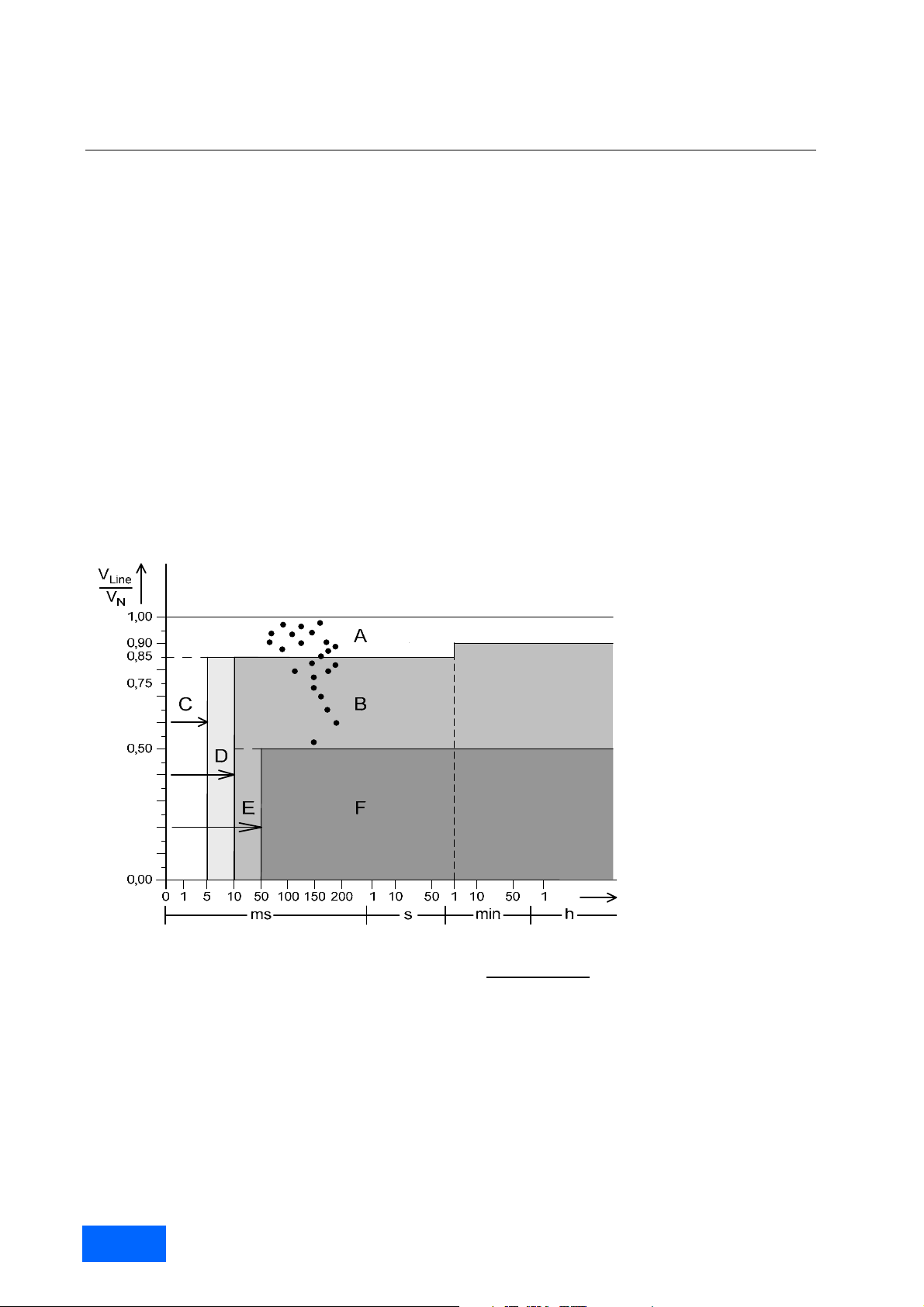

Supply voltage variations and supply voltage dips...............................................................................................25

Behaviour of SINAMICS converters during supply voltage variations and dips....................................................26

Permissible harmonics on the supply voltage.......................................................................................................32

█ Transformers........................................................................................................................................................33

Unit transformers..................................................................................................................................................33

Transformer types................................................................................................................................................34

Features of standard transformers and converter transformers ...........................................................................35

Three-winding transformers..................................................................................................................................36

█ Harmonic effects on the supply system................................................................................................................37

General.................................................................................................................................................................37

Harmonic currents of 6-pulse rectifier circuits......................................................................................................39

Harmonic currents of 6-pulse rectifier circuits with Line Harmonics Filter ...........................................................42

Harmonic currents of 12-pulse rectifier circuits.....................................................................................................44

Harmonic currents and harmonic voltages of Active Infeeds (AFE technology)...................................................45

Standards and permissible harmonics .................................................................................................................47

█ Line reactors (line commutating reactors) ............................................................................................................51

█ Line Harmonics Filter (LHF) .................................................................................................................................52

█ Line filters (radio frequency interference (RFI) suppression filters or EMC filters)................................................54

General information and standards ......................................................................................................................54

Line filters for the "first" environment (residential) and "second" environment (industrial).................................... 56

Operating principle of line filters ...........................................................................................................................57

Magnitude of leakage or interference currents .....................................................................................................57

EMC-compliant installation...................................................................................................................................58

█ SINAMICS Infeeds and their properties ...............................................................................................................60

Basic Infeed..........................................................................................................................................................60

Smart Infeed.........................................................................................................................................................62

Active Infeed.........................................................................................................................................................64

Comparison of the properties of the different SINAMICS Infeeds ........................................................................67

Redundant line supply concepts...........................................................................................................................68

Permissible total cable length for S120 Infeed Modules feeding multi-motor drives.............................................74

................................................................................. 12

SINAMICS Engineering Manual - May 2008

Siemens AG

5/396

List of Contents

Engineering Information

█ Effects of using fast-switching power components (IGBTs)................................................................................. 75

Increased current load on the inverter output as a result of long motor cables.................................................... 75

Increased voltage stress on the motor winding as a result of long motor cables ................................................. 77

Bearing currents caused by steep voltage edges on the motor ........................................................................... 81

Measures for reducing bearing currents............................................................................................................... 82

1. EMC-compliant installation for optimized equipotential bonding in the drive system ....................................... 83

2. Insulated bearing at the non-drive end (NDE end) of the motor....................................................................... 86

3. Other measures ............................................................................................................................................... 86

Brief overview of the different types of bearing currents ...................................................................................... 87

█ Motor reactors...................................................................................................................................................... 89

Reduction of the voltage rate of rise dv/dt at the motor terminals........................................................................ 89

Reduction of additional current peaks when long motor cables are used ............................................................ 89

Permissible motor cable lengths with motor reactor(s) for single-motor and multi-motor drives .......................... 90

Supplementary conditions which apply when motor reactors are used................................................................ 93

█ dv/dt filter plus VPL.............................................................................................................................................. 94

█ Sine-wave filters................................................................................................................................................... 96

█ Load duty cycles.................................................................................................................................................. 98

General................................................................................................................................................................ 98

Standard load duty cycles.................................................................................................................................... 98

Free load duty cycles........................................................................................................................................... 99

Thermal monitoring of the power unit during load duty cycles and continuous operation .................................. 102

█ Efficiency of SINAMICS converters at full load and at partial load..................................................................... 103

Converter efficiency at full load.......................................................................................................................... 103

Converter efficiency at partial load..................................................................................................................... 104

█ Parallel connections of converters..................................................................................................................... 110

General.............................................................................................................................................................. 110

Parallel connections of SINAMICS converters................................................................................................... 110

Parallel connection of S120 Basic Line Modules ............................................................................................... 112

Parallel connection of S120 Smart Line Modules............................................................................................... 114

Parallel connection of S120 Active Line Modules .............................................................................................. 116

Parallel connection of S120 Motor Modules ....................................................................................................... 116

Admissible and inadmissible winding systems for parallel connections of SINAMICS converters ..................... 118

█ SINAMICS S120 Liquid-Cooled units in chassis format..................................................................................... 121

General.............................................................................................................................................................. 121

Design of the SINAMICS S120 Liquid-Cooled units........................................................................................... 121

Requirements concerning coolant and cooling circuit........................................................................................ 122

EMC Installation Guideline .................................................................................................................... 126

█ Introduction........................................................................................................................................................ 126

General.............................................................................................................................................................. 126

EC Directives..................................................................................................................................................... 126

CE marking........................................................................................................................................................ 126

EMC Directive.................................................................................................................................................... 127

EMC product standard EN 61800-3................................................................................................................... 127

█ Fundamental principles of EMC......................................................................................................................... 129

Definition of EMC............................................................................................................................................... 129

Interference emissions and interference immunity............................................................................................. 130

█ The frequency converter and its EMC................................................................................................................ 130

The frequency converter as a source of interference......................................................................................... 130

SINAMICS Engineering Manual – May 2008

6/396

Siemens AG

List of Contents

Engineering Information

The frequency converter as a high-frequency source of inter

The frequency converter as a low-frequency source of interference..................................................................134

The frequency converter as potentially susceptible equipment ..........................................................................135

Methods of influence ..........................................................................................................................................135

Conductive coupling...........................................................................................................................................135

Capacitive coupling............................................................................................................................................136

Inductive coupling...............................................................................................................................................137

Electromagnetic coupling (radiative coupling)....................................................................................................138

█ EMC-compliant installation.................................................................................................................................138

Zone concept within the converter cabinet.........................................................................................................139

Converter cabinet structure................................................................................................................................140

Cables inside the converter cabinet ...................................................................................................................140

Cables outside the converter cabinet .................................................................................................................141

Cable shields......................................................................................................................................................141

Equipotential bonding in the converter cabinet, in the drive system, and in the plant.........................................141

Examples for installation.....................................................................................................................................143

EMC - compliant installation of a SINAMICS G150 converter cabinet unit......................................................... 143

EMC - compliant construction / installation of a cabinet with a SINAMICS G130 chassis unit...........................144

EMC - compliant cable routing on the plant side on cable racks and in cable routes.........................................145

ference.................................................................131

General Engineering Information for SINAMICS................................................................................. 146

█ Overview of documentation................................................................................................................................146

█ Safety-integrated, drive-integrated safety functions ...........................................................................................150

Safe Torque Off (previously known as “Safe Standstill”) and Safe Stop 1 .........................................................150

Safe Brake Control.............................................................................................................................................153

█ Precharging intervals of the DC link ...................................................................................................................155

SINAMICS Booksize units..................................................................................................................................155

SINAMICS chassis units.....................................................................................................................................155

█ Operator Panel................................................................................................................................................... 155

Basic Operator Panel (BOP20) .......................................................................................................................... 155

Advanced Operator Panel (AOP30) ...................................................................................................................155

█ Cabinet construction and air conditioning...........................................................................................................157

Directives and standards.................................................................................................................................... 157

Cabinet air conditioning......................................................................................................................................158

Cooling air requirement and sizes of cabinet openings......................................................................................160

Partitioning .........................................................................................................................................................161

█ Changing the power block on chassis power units............................................................................................. 162

█ Replacement of SIMOVERT P and SIMOVERT A converter ranges by SINAMICS .......................................... 163

General...............................................................................................................................................................163

Replacement of converters in SIMOVERT P 6SE35/36 and 6SC36/37 ranges by SINAMICS ..........................163

Replacement of converters in SIMOVERT A 6SC23 range by SINAMICS........................................................ 165

Converter Chassis Units SINAMICS G130........................................................................................... 167

█ General information............................................................................................................................................167

█ Rated data of converters for drives with low demands on control performance .................................................170

█ Incorporating different loads into the 24 V supply...............................................................................................173

█ Factory settings (defaults) of customer interface on SINAMICS G130...............................................................174

█ Line-side components ........................................................................................................................................180

Line fuses...........................................................................................................................................................180

SINAMICS Engineering Manual - May 2008

Siemens AG

7/396

List of Contents

Engineering Information

Line reactors..................................................................................................................

Line filters........................................................................................................................................................... 181

█ Components at the DC link................................................................................................................................ 182

Braking units...................................................................................................................................................... 182

█ Load-side components and cables .................................................................................................................... 185

Motor reactor...................................................................................................................................................... 185

dv/dt filter plus VPL............................................................................................................................................ 185

Sine-wave filter .................................................................................................................................................. 185

Maximum connectable motor cable lengths....................................................................................................... 185

Converter Cabinet Units SINAMICS G150............................................................................................ 187

█ General information............................................................................................................................................ 187

█ Rated data of converters for drives with low demands on control performance................................................. 187

█ Factory settings (defaults) of customer interface on SINAMICS G150 .............................................................. 191

█ Cable cross-sections and connections on SINAMICS G150 Cabinet Units ....................................................... 193

Recommended and maximum possible cable cross-sections for line and motor connections........................... 193

Required cable cross-sections for line and motor connections.......................................................................... 195

Grounding and PE conductor cross-section....................................................................................................... 196

█ Line-side components........................................................................................................................................ 197

Line fuses........................................................................................................................................................... 197

Line reactors...................................................................................................................................................... 197

Line filters........................................................................................................................................................... 198

█ Components at the DC link................................................................................................................................ 199

Braking units...................................................................................................................................................... 199

█ Load-side components and cables .................................................................................................................... 202

Motor reactor...................................................................................................................................................... 202

dv/dt filter plus VPL............................................................................................................................................ 202

Sine-wave filter .................................................................................................................................................. 202

Maximum connectable motor cable lengths....................................................................................................... 202

█ SINAMICS G150 parallel converters (SINAMICS G150 power extension) ........................................................ 203

6-pulse operation of SINAMICS G150 parallel converters................................................................................. 205

12-pulse operation of SINAMICS G150 parallel converters ............................................................................... 207

Operation at motors with electrically isolated winding systems and one common winding system .................... 208

Special features to note when precharging SINAMICS G150 parallel converters.............................................. 209

Brief overview of SINAMICS G150 parallel converters with production date up to autumn 2007....................... 210

Brief overview of SINAMICS G150 parallel converters with production date from autumn 2007 ....................... 211

.................................... 180

SINAMICS S120, General Information about Built-in and Cabinet Units..........................................212

█ General.............................................................................................................................................................. 212

Assignment table ............................................................................................................................................... 212

█ Control properties .............................................................................................................................................. 212

Performance features......................................................................................................................................... 212

Control properties, definitions ............................................................................................................................ 214

Closed-loop control characteristics .................................................................................................................... 214

█ Rating data......................................................................................................................................................... 217

Maximum output frequencies............................................................................................................................. 217

█ DRIVE CLiQ....................................................................................................................................................... 218

Basic informations.............................................................................................................................................. 218

DRIVE-CLiQ cables supplied with the unit......................................................................................................... 218

SINAMICS Engineering Manual – May 2008

8/396

Siemens AG

List of Contents

Engineering Information

Cable installation................................................................................................................................................220

Specification of the required control performance and selection of the Control Unit ..........................................223

Specification of component cabling.................................................................................................................... 225

█ Check of the maximum DC link capacitance......................................................................................................228

Basic informations.............................................................................................................................................. 228

Capacitance values............................................................................................................................................229

█ Braking Module / External braking resistor.........................................................................................................233

Braking Module for power units in chassis format..............................................................................................233

Braking resistors for power units in chassis format ............................................................................................ 235

█ Maximum connectable motor cable lengths .......................................................................................................237

Booksize units....................................................................................................................................................237

Chassis units...................................................................................................................................................... 238

█ Checking the total cable length for multi-motor drives........................................................................................239

Modular Cabinet Unit System SINAMICS S120 Cabinet Modules..................................................... 240

█ General...............................................................................................................................................................240

Design................................................................................................................................................................240

General configuring process...............................................................................................................................240

█ Dimensioning and selection information.............................................................................................................241

Derating data......................................................................................................................................................241

Degrees of protection of S120 Cabinet Modules................................................................................................243

Required cross-sections of DC busbars.............................................................................................................243

Required cable cross-sections for line and motor connections...........................................................................244

Cooling air requirements ....................................................................................................................................245

Auxiliary power requirements.............................................................................................................................247

Line reactors.......................................................................................................................................................254

Parallel configuration..........................................................................................................................................255

Weights of S120 Cabinet Modules.....................................................................................................................256

█ Information about equipment handling ...............................................................................................................259

Customer terminal block -A55............................................................................................................................259

Customer terminal block -X55............................................................................................................................261

Auxiliary voltage distribution...............................................................................................................................262

DRIVE-CLiQ wiring.............................................................................................................................................263

Erection of cabinets............................................................................................................................................264

Examples of Cabinet Module arrangements.......................................................................................................264

Door opening angle............................................................................................................................................265

█ Line Connection Modules...................................................................................................................................266

Design................................................................................................................................................................266

Planning recommendations, special features.....................................................................................................267

Assignment to rectifiers......................................................................................................................................267

Parallel connections...........................................................................................................................................268

DC busbar..........................................................................................................................................................269

Circuit breakers..................................................................................................................................................269

Short-circuit strength ..........................................................................................................................................271

█ Basic Line Modules ............................................................................................................................................272

Design................................................................................................................................................................272

DC link fuses......................................................................................................................................................273

Parallel connections of Basic Line Modules .......................................................................................................273

SINAMICS Engineering Manual - May 2008

Siemens AG

9/396

List of Contents

Engineering Information

█ Smart Line Modules........................................................................................................................................... 274

Design................................................................................................................................................................ 274

DC link fuses...................................................................................................................................................... 275

Parallel connections of Smart Line Modules...................................................................................................... 275

█ Active Line Modules + Active Interface Modules................................................................................................ 276

Design................................................................................................................................................................ 276

DC Link fuses..................................................................................................................................................... 278

Parallel connections of Active Line Modules + Active Interface Modules........................................................... 278

█ Motor Modules................................................................................................................................................... 280

Design................................................................................................................................................................ 280

DC link fuses...................................................................................................................................................... 281

Parallel connections of Motor Modules .............................................................................................................. 281

█ Booksize Base Cabinet / Booksize Cabinet Kits................................................................................................ 283

Design................................................................................................................................................................ 283

Booksize Base Cabinet...................................................................................................................................... 283

Booksize Cabinet Kits........................................................................................................................................ 283

DC link fuses...................................................................................................................................................... 284

Planning recommendations, special features..................................................................................................... 284

█ Central Braking Modules.................................................................................................................................... 288

Design................................................................................................................................................................ 288

Position in the DC link configuration .................................................................................................................. 289

DC Link fuses..................................................................................................................................................... 290

Parallel configuration of Central Braking Modules ............................................................................................. 290

Braking resistor..................................................................................................................................................290

█ Options............................................................................................................................................................... 292

Option G33 (Communication Board CBE20)...................................................................................................... 292

Option K75 (Second auxiliary busbar)................................................................................................................ 292

Option K82 (Terminal module for controlling the “Safe Torque Off” and “Safe Stop1” functions)....................... 292

Option K90 / 91 (Control Unit CU320)................................................................................................................ 296

Option L08 / L09 (Motor reactors)...................................................................................................................... 297

Option L25 (Withdrawable circuit breaker)......................................................................................................... 297

Option L34 (Circuit breaker on the output side) ................................................................................................. 298

Option L37 (DC coupling)................................................................................................................................... 299

Option M59 (Cabinet door closed) ..................................................................................................................... 299

Option Y11 (Factory assembly of Cabinet Modules into transport units)............................................................ 300

Converter Cabinet Units SINAMICS S150............................................................................................ 302

█ General information............................................................................................................................................ 302

█ Rated data and continuous operation of the converters..................................................................................... 303

█ Factory settings (defaults) of customer interface on SINAMICS S150............................................................... 306

█ Cable cross-sections and connections on SINAMICS S150 cabinets................................................................ 308

Recommended and maximum possible cable cross-sections for line and motor connections........................... 308

Required cable cross-sections for line and motor connections.......................................................................... 309

Grounding and PE conductor cross-section....................................................................................................... 309

█ Load-side components and cables .................................................................................................................... 311

Motor reactor...................................................................................................................................................... 311

dv/dt filter plus VPL............................................................................................................................................ 311

Sine-wave filter .................................................................................................................................................. 311

Maximum connectable motor cable lengths....................................................................................................... 311

SINAMICS Engineering Manual – May 2008

10/396

Siemens AG

List of Contents

Engineering Information

Drive Dimensioning................................................................................................................................ 313

Drives with quadratic load torque.......................................................................................................................313

Drives with constant load torque ........................................................................................................................313

Permissible motor-converter combinations.........................................................................................................314

Drives with permanent-magnet three-phase synchronous motors ..................................................................... 314

Motors...................................................................................................................................................... 320

1LG4/1LG6 and 1LA8 self-cooled asynchronous motors...................................................................................320

1PH7/ 1PL6 compact asynchronous motors ......................................................................................................320

1FW3 / 1FW4 three-phase synchronous motors (high-torque motors with permanent magnets).......................320

Special insulation for line supply voltages > 500 V in converter-fed operation...................................................321

Bearing currents.................................................................................................................................................321

Motor protection .................................................................................................................................................322

Operation of explosion proof motors with type of protection "d".........................................................................322

Dimension Drawings.............................................................................................................................. 323

█ SINAMICS G130................................................................................................................................................323

█ SINAMICS Line Harmonics Filter.......................................................................................................................327

█ SINAMICS G150 (type A)................................................................................................................................... 329

█ SINAMICS G150 (type C)...................................................................................................................................345

█ SINAMICS S120 Chassis (Basic Line Modules).................................................................................................347

█ SINAMICS S120 Chassis (Smart Line Modules)................................................................................................349

█ SINAMICS S120 Chassis (Active Interface Modules) ........................................................................................352

█ SINAMICS S120 Chassis (Active Line Modules)................................................................................................356

█ SINAMICS S120 Chassis (Motor Modules)........................................................................................................360

█ SINAMICS S120 Chassis Liquid Cooled (Power Modules)................................................................................364

█ SINAMICS S120 Chassis Liquid Cooled (Basic Line Modules) .......................................................................... 366

█ SINAMICS S120 Chassis Liquid Cooled (Motor Modules).................................................................................368

█ SINAMICS S120 Cabinet Modules (Line Connection Modules).........................................................................371

█ SINAMICS S120 Cabinet Modules (Basic Line Modules)...................................................................................373

█ SINAMICS S120 Cabinet Modules (Smart Line Modules).................................................................................. 374

█ SINAMICS S120 Cabinet Modules (Active Interface Modules + Active Line Modules) ......................................376

█ SINAMICS S120 Cabinet Modules (Motor Modules)..........................................................................................378

█ SINAMICS S120 Cabinet Modules (Booksize Base Cabinet / Booksize Cabinet Kits)....................................... 380

█ SINAMICS S120 Cabinet Modules (Central Braking Modules) .......................................................................... 381

█ SINAMICS S120 Cabinet Modules (Auxiliary Power Supply Modules) ..............................................................382

█ SINAMICS S150.................................................................................................................................................383

Notes.........................................................................................................................................................................393

SINAMICS Engineering Manual - May 2008

Siemens AG

11/396

Fundamental Principles and System Description

Engineering Information

Fundamental Principles and System Description

█ Operating principle of SINAMICS converters

General operating principle

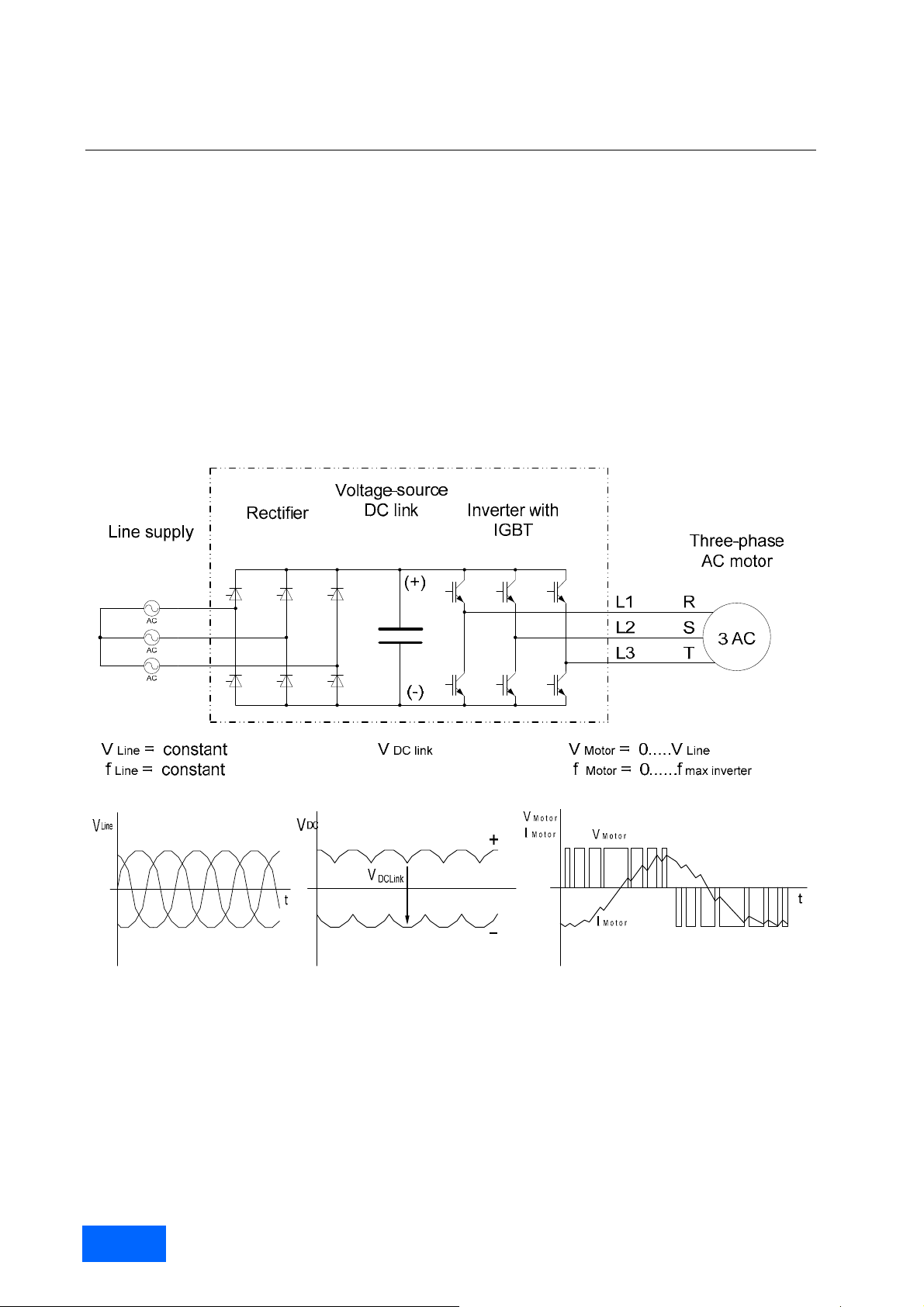

The converters in the SINAMICS product range are PWM converters with a voltage-source DC link. At the input side,

the converter consists of a rectifier (shown in the schematic sketch as a thyristor rectifier) which is supplied with a

constant voltage V

voltage V

DCLink

side converts the DC link voltage to a thr ee-phase s ystem with a variable voltage V

This process operates according to the principle of pulse width modulation PWM. By varying the voltage and the

frequency, it is possible to vary the speed of the connected three-phase motor continuously and virtually without

losses.

and a constant frequency f

Line

from a three-phase supply. The rectifier produces a const ant DC

Line

, i.e. the DC link voltage, which is smoothed by the DC link capacitors. The IGBT inverter on the output

and variable frequency f

Motor

Motor

.

Block diagram of a PWM converter with voltage-source DC link

Pulse modulation method

The power semiconductors of the IGBT inverter (IGBT = Insulated Gate Bipolar Transist or) are hig h-speed, el ectronic

switches which connect the converter outputs to the positive or negative pole of the DC link voltage. The duration of

the gating signals in the individual inverter phases and the magnitude of the DC link voltage thus clearly determi ne

the output voltage and therefore also the voltage at the connected motor.

SINAMICS Engineering Manual – May 2008

12/396

Siemens AG

Fundamental Principles and System Description

Engineering Information

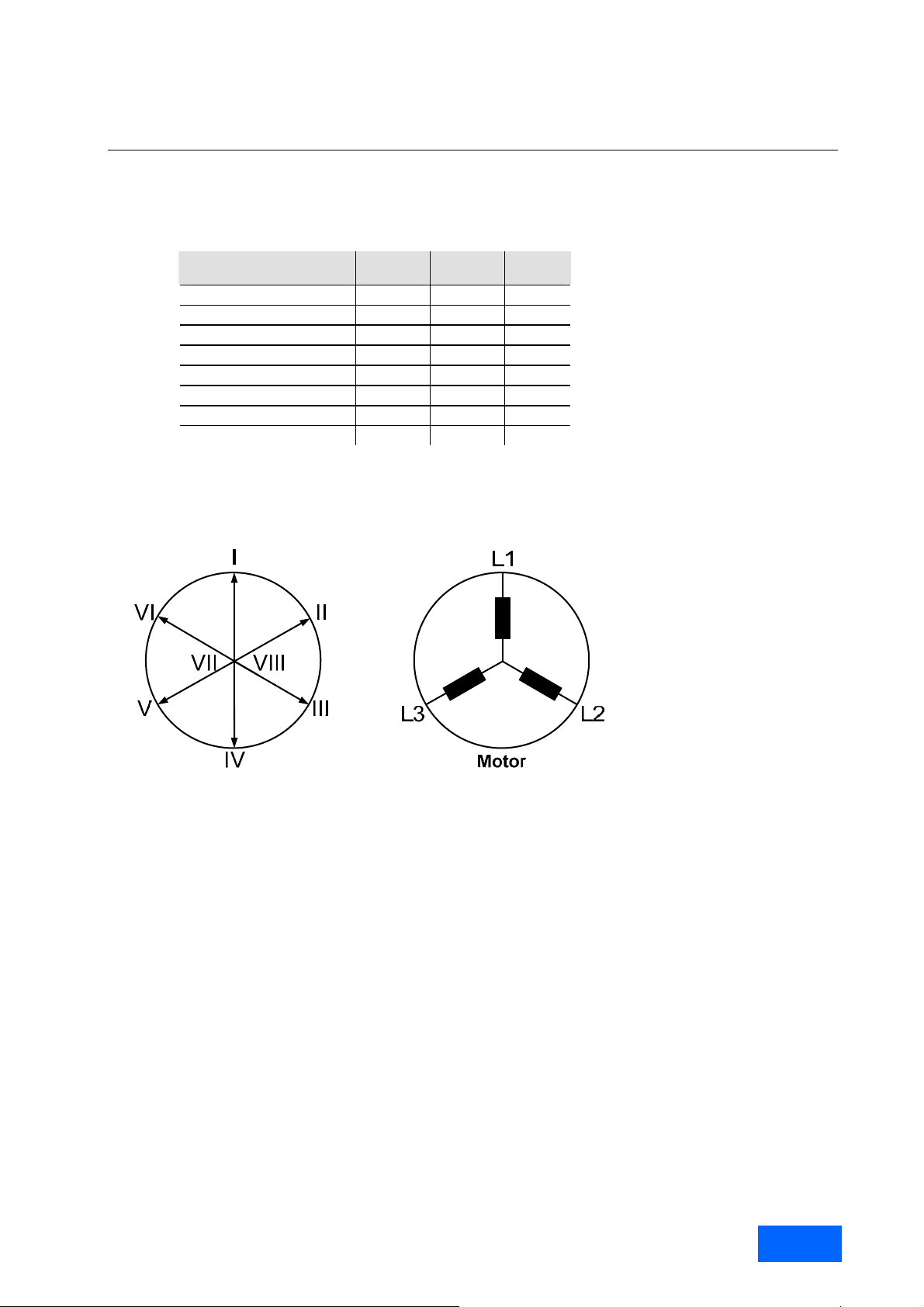

If we consider all three phases, there are a total of 2

states in the motor can be defined by voltage phasors.

Switching states of the

inverter

V

+ - -

1

V

+ + -

2

V

- + -

3

V

- + +

4

V

- - +

5

V

+ - +

6

V

+ + +

7

V

- - -

8

Phase

L1

If, for example, phase L1 is connected to the positive DC link voltage, and phases L2 and L3 to the negative voltage

so as to produce switching state V

, the resultant voltage phasor points in the direction of motor phase L1 and is

1

designated phase I. The length of this phasor is determined by the DC link voltage.

³ = 8 switching states in the inverter, and the effect of these

Phase

L2

Phase

L3

Representation of resultant motor voltages as phasor

If the switching state changes from V

to V2, then the voltage phasor rotates clockwise by an angle of 60°el due to the

1

change in potential at terminal L2. The length of the phasor remains unchanged.

In the same way, the relevant voltage phasors are produced by switching combinations V

combinations V

and V

7

produce the same potential at all motor terminals. These two combinations therefore pr od uc e

8

to V6. Switching

3

voltage phasors of "zero" length (zero voltage phasor).

Generation of a variable voltage by pulse width modulation

Voltage and frequency must be specified in a suitable way for a certain operatin g state of the motor, cha racterized by

speed and torque. Ideally, this corresponds to control of the voltage vector V

rotation t = 2

f and adjusted absolute value. This is achieved th rough modulation of the actual settable voltage

* *

space vectors (pulse width modulation). In this way, t he momentary value V

actual settable voltage space vectors and the voltage zero.

The solid angle is set directly by varying the ratio of the ON dur ations (pulse width) of adjacent voltage vectors, the

desired absolute value by varying the ON duration of the zero voltage vector. This method of generating gating

signals is called space vector modulation SVM. Space vector modulation provides sine-modulated pulse patterns.

on a circular path with the speed of

(t)

is formed by pulses of the adjacent,

(t)

SINAMICS Engineering Manual - May 2008

Siemens AG

13/396

Fundamental Principles and System Description

Engineering Information

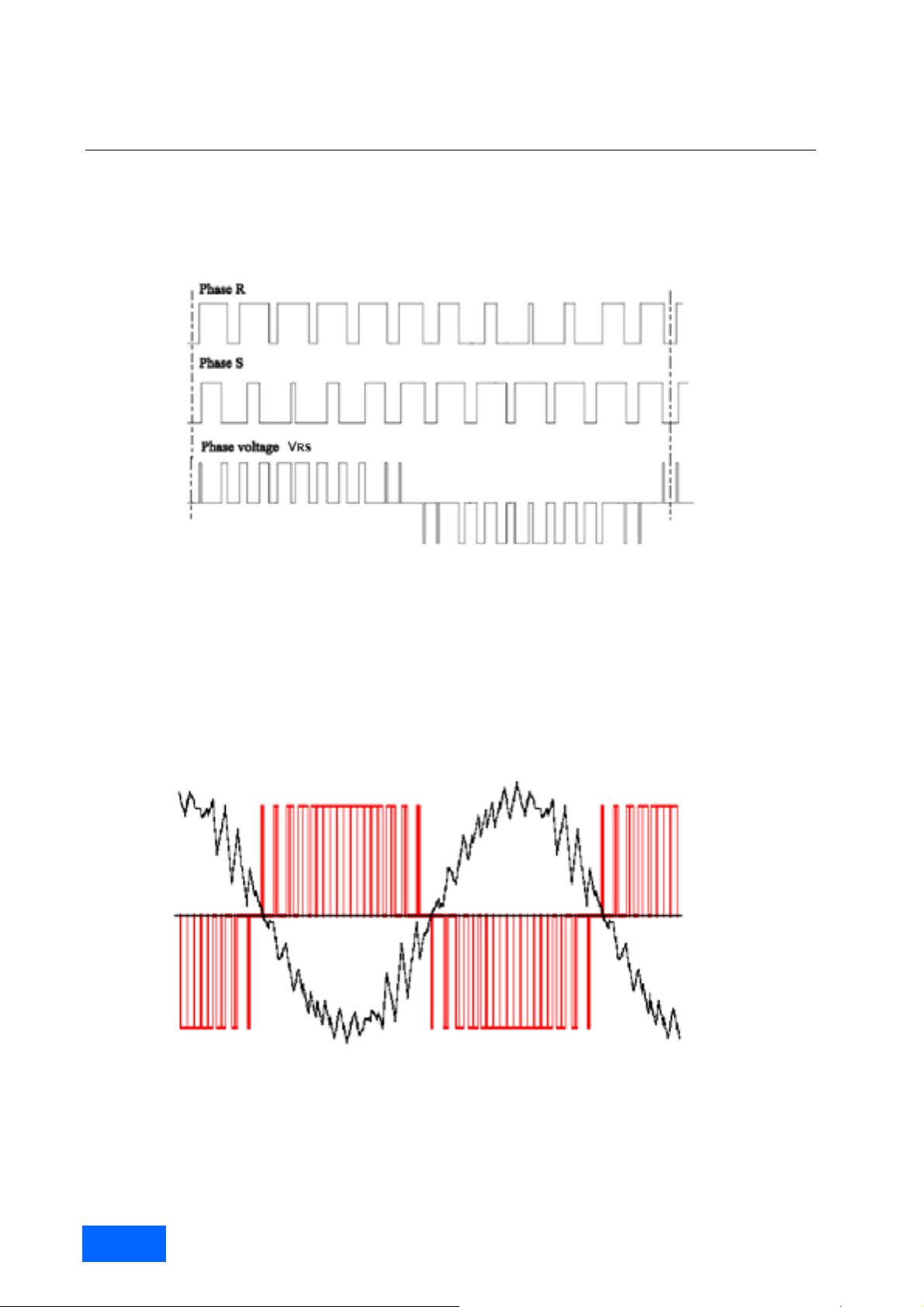

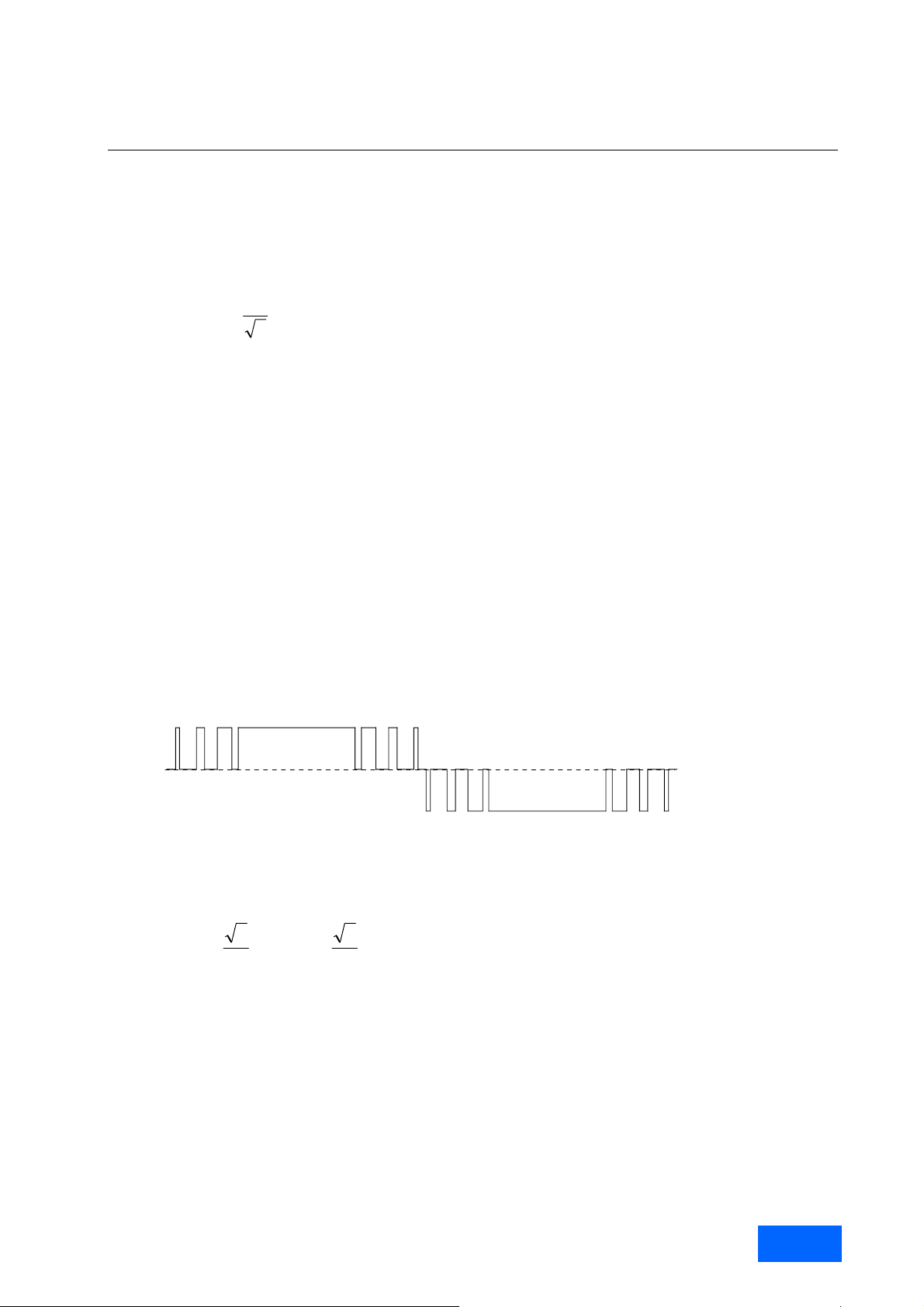

The following diagram illustrates how the voltages in p hases L1 (R) and L2 (S) plus output voltage V

(phase-to-

RS

phase voltage) are produced by the method of pulse width modulation and shows their basic time characteristics. The

frequency with which the IGBTs in the inverter phases are switched on and off is referred to as the pulse frequency or

clock frequency of the inverter.

Timing of the gating signal sequence for the IGBTs of the two inverter phases L1 (R) and L2 (S) plus the associated output

voltage V

(V- phase-to-phase). The amplitude of the voltage pulses corresponds to the DC link voltage.

RS

The diagram below shows the time characteristic (in red) of the invert er output voltage (phase-to-phase voltage) and

the resulting current (in black) generated in the motor when a stan dar d as ynchro nous mot or with a rated freque nc y of

50 Hz or 60 Hz is used and the inverter is operating with a pulse frequency of 1.25 kHz. The diagram shows that the

smoothing effect of the motor inductances causes the motor current to be v irtually sinuso idal, des pite t he fact that th e

motor is supplied with a square-wave pulse pattern.

Motor voltage (phase-to-phase) and motor current with space vector modulation

SINAMICS Engineering Manual – May 2008

14/396

Siemens AG

Fundamental Principles and System Description

Engineering Information

Maximum attainable output voltage with space vector modulation SVM

Space vector modulation SVM generates pulse patterns which approximat e an ideal si nusoid al motor voltage thro ug h

voltage pulses with constant amplitude and corresponding pulse-duty factor. The peak value of the maximum

(fundamental) voltage that can be attained in this way corresponds to the amplitude of the DC link voltage V

Thus the theoretical maximum motor voltage with space vector modulation which results is:

SVM

max

The true amplitude of the DC link voltage V

1

DCLink

VV

2

is determined by the method of line voltage rectification. In the case

DCLink

of rectifiers of the type used with SINAMICS G130 and G150 and also with S120 Basic Line Modules, it averages

1,41

*V

with no load, 1.35*V

Line

amplitude of V

DCLink

≈ 1.32*V

with partial load and 1.32*V

Line

at full load, the motor voltage theoretically attainable with space vector modulatio n

Line

.with full load. Thus with the true DC link voltage

Line

is:

V

SVM max

= 0.935 * V

Line

As a result of voltage drops in the converter and minimum pulse times and interlock times in the gating unit

responsible for generating the IGBT gating pulse pattern, the values in practice are lower. In practice, the values are:

V

SVM max

≈ 0.92 * V

(with pulse frequency of 2.0 kHz or 1.25 kHz according to the factory setting)

Line

For SINAMICS G130 chassis and G150 cabinets that were supplied with firmware versions < V2.3 until the autumn of

2005, this value is the maximum attainable output voltage as devices with this firmware are not capable of utilizing

pulse-edge modulation.

DCLink

.

Maximum attainable output voltage with pulse-edge modulation PEM

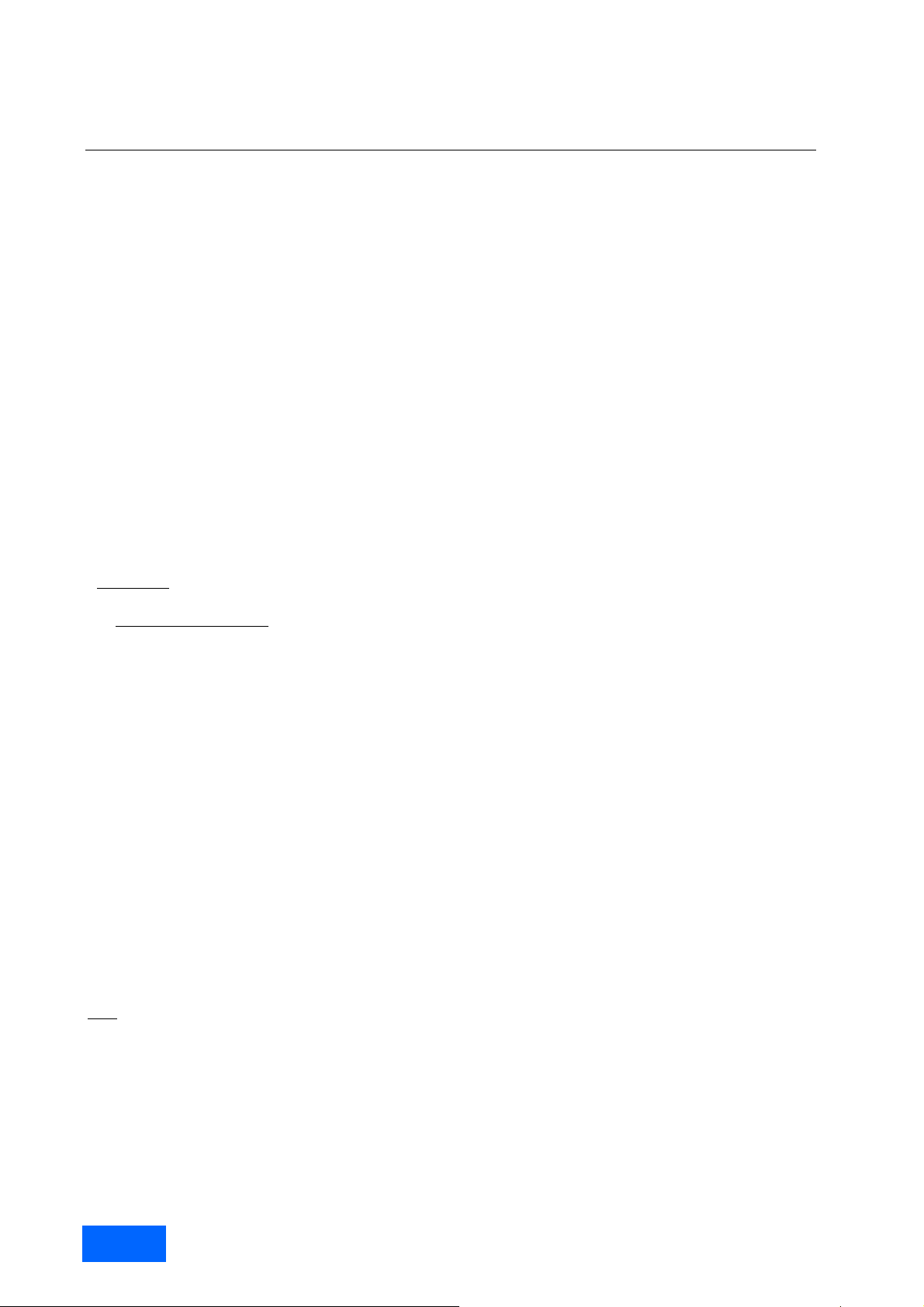

It is possible to increase the inverter output voltage abov e the values attained with space vector modulation by not

pulsing over the entire fundamental-wave period, but only at its edges. This process is referred to as pulse- edge

modulation (PEM). The basic waveform of the motor voltage is then as shown below.

Motor voltage with pulse-edge modulation PEM

The maximum possible output voltage is attained when clocking is perform ed with the fundamental frequency only,

i.e. when "pulsing" ceases altogether. The output voltage t hen consists of 120° rectang ular blocks with the amplitude

of the DC link voltage. The fundamental frequency RMS value of the output voltage can then be calculated as:

rect

66

So it is possible with pure rectangular modulation to achieve a motor voltage which is slightly higher than the line

voltage. However, the motor voltage then has an unsuitable harmonic spectrum which causes major stray losses in

the motor and utilizes the motor inefficiently. It is for this reason that pure square-wave modu lation is not utilized on

SINAMICS converters.

The pulse-edge modulation method used on SINAMICS converters perm its a maximum output voltage which is only

slightly lower than the line voltage, even when allowance is made for voltage drops in the converter:

V

PEM max

= 0.97 * V

Line

The pulse-edge modulation process uses o ptimized pulse patterns which cause only minor harmonic currents and

therefore utilize the connected motor efficiently. Commercially available standard motors for 50 Hz or 60 Hz and

utilized according to temperature class B in mains operatio n can be partia lly utilized acc ording to temp erature cl ass F

at the nominal working point up to rated torque when operated with pulse-edge modulation.

LineLineDCLink

VVVV 03.132.1

SINAMICS Engineering Manual - May 2008

Siemens AG

15/396

Fundamental Principles and System Description

Engineering Information

With introduction of firmware version V2.3 and simultaneous modification of the CIB board hardware (interface

module between the Control Unit and power unit), pulse-e dge modulation has been available as a stand ard feature

on the following SINAMICS units in vector control mode since autumn 2005:

SINAMICS G130* Chassis

SINAMICS G150* Cabinets

SINAMICS S150* Cabinets

SINAMICS S120* Motor Modules / chassis format

SINAMICS S120* Motor Modules / Cabinet Modules format

At low output frequencies and low depth of modulation, i.e. at low output voltage, these products utilize the sp ace

vector modulation SVM option and switch automatically over to pulse-edge modulation PEM if the depth of

modulation required at higher output frequencies is so high that it can no longer be provided by space vector

modulation (output voltage > 92 % of input voltage).

In principle it would be possible to reach an output voltage of over 92 % through overmodulation of the space vector

modulation (SVM). However, through doing this, the harmonics spectrum in the motor current would increase

considerably, which would lead to higher torque ripples and noticeabley higher motor losses. T herefore, SINAMICS

units operating in the vector control mode use pulse-edge modulation with optimised pulse patterns in order to

achieve optimum drive behaviour with regard to torque ripples and motor losses.

* Exceptions:

Parallel converters on which two or more power units operating in parallel are supplying one motor with a

common winding system. Under these conditions pulse-edge modulation cannot be selected.

If either a Basic or Smart Infeed is used to supply the inverter, the following formulas apply for the DC link

voltage at full load: V

edge modulation is limited to 92 % of the line input voltage.

If an Active Infeed is used to supply the inverter, the following formula applies to the DC link voltage bec ause the

Active Infeed utilizes a step-up converter function: V

This means that the maximum output voltage even without pulse-edge modulation ca n correspond to 100 % of

the line input voltage or higher if the parameters of ratio V

Active Infeed. This is described in the section “SINAMICS Infeeds and their properties”, subsection “Active

Infeed”.

Converters with output-side sine-wave filter. Pulse-edge modulation cannot be selected under these conditions.

If either a Basic or Smart Infeed is used to supply the inverter, the following formulas apply for the DC link

voltage at full load: V

limited to 85 % of the line input voltage for units with a supply v oltage of 380 V to 48 0 V 3AC and to 83 % for

units with a supply voltage of 500 V to 600 V 3AC.

If an Active Infeed is used to supply the inverter, the following formula applies to the DC link voltage bec ause the

Active Infeed utilizes a step-up converter function: V

This means that the maximum output voltage even without pulse-edge modulation ca n correspond to 100 % of

the line input voltage or higher if the parameters of ratio V

Active Infeed. This is described in the section “SINAMICS Infeeds and their properties”, subsection “Active

Infeeds”.

:

Note

Pulse-edge modulation PEM is only available in vector control mode. In servo control mode, the converters

always operate with space vector modulation (SVM). The reason for this is the slig ht lo wer dynamic performance

of the drive when it is operating with pulse- edge modulation. This can be accepted in almost all vector co ntrol

applications, but not in high-dynamic servo control applications.

With the introduction of Firmware version V2.5 SP1 and the simultaneous chan ging of the hard ware, pulse-edge

modulation is available as standard also for Booksize units since autumn 2007.

DCLink

DCLink

≈ 1.32 • V

≈ 1.32 • V

resp. 1.30 • V

Line

resp. V

Line

Line

DCLink

= 1.30 • V

DCLink

DCLink

. Therefore the maximum output voltage without pulse-

> 1.42 • V

/ V

DCLink

. In this case, the maximum output voltage is

Line

> 1.42 • V

/ V

DCLink

(factory setting: V

Line

are set to sufficiently high values on the

Line

(factory setting: V

Line

are set to sufficiently high values on the

Line

DCLink

DCLink

= 1.5 • V

= 1.5 • V

Line

Line

).

).

SINAMICS Engineering Manual – May 2008

16/396

Siemens AG

Fundamental Principles and System Description

Engineering Information

The pulse frequency and its influence on key system properties

The pulse frequency of the inverter is an important param eter which has a crucial influence on various properties of

the drive system. It can be varied within certain given limits. In order to reduce the motor noise, reac h very high

output frequencies or in the event that sinus filters are to be used at the converter output, it is sensible, or rather

necessary, to increase the pulse frequency.

The following aspects of the pulse frequency are described briefly below:

The pulse frequency factory settings

The limits within which the pulse frequency can be adjusted

The effect of the pulse frequency on various properties of the drive system

When it is advisable or even essential to change the pulse frequency

What needs to be noted in connection with motor-side options (motor reactor, motor filter).

Factory settings and pulse frequency setting ranges

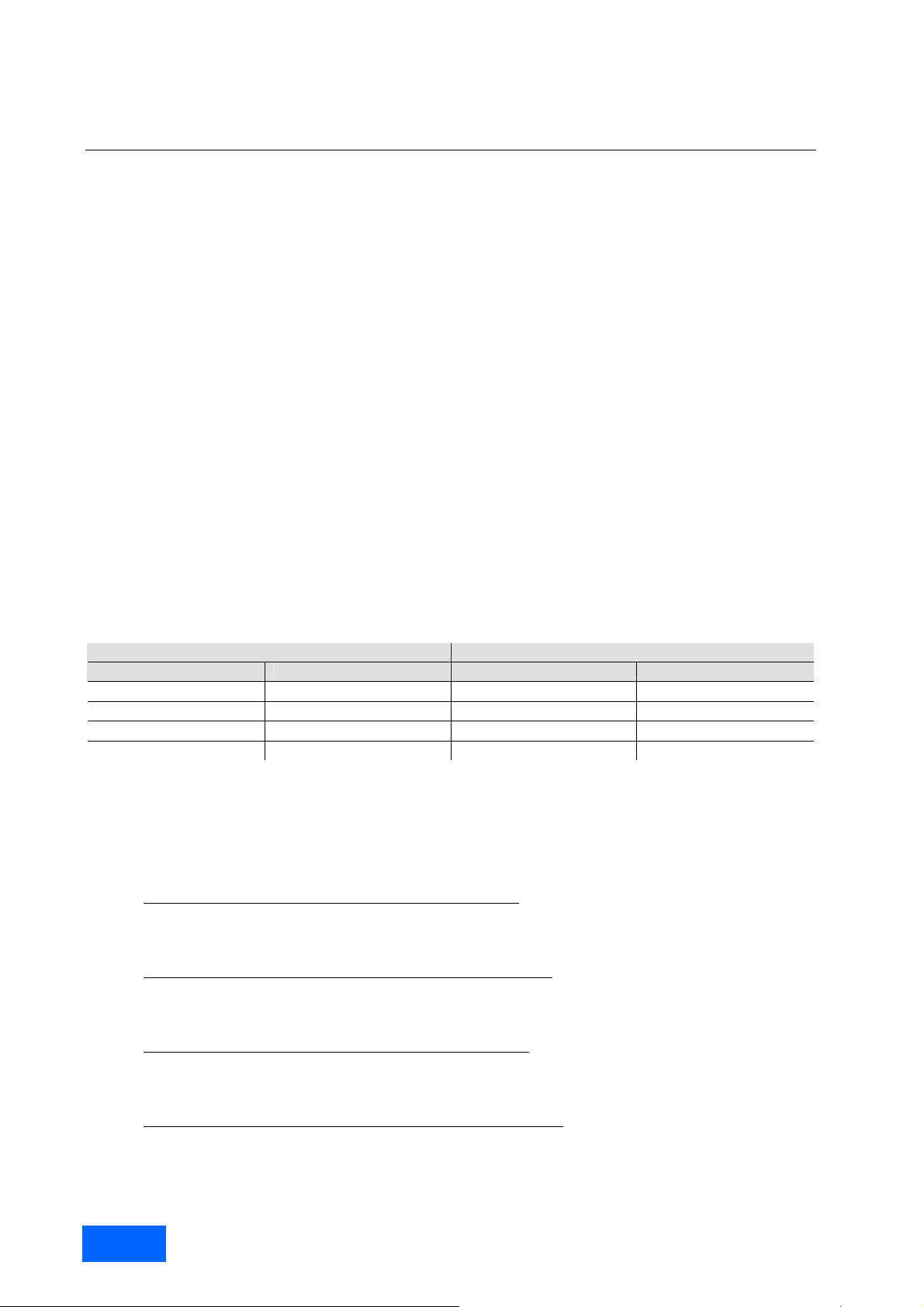

The pulse frequency of the motor-side inverter on SINAMICS G130, G150, S150, S120 (Chassis and Cabinet

Modules) operating in vector control mode is preset at the factory to 2.0 kHz or 1.25 kHz as specified in the table

below.

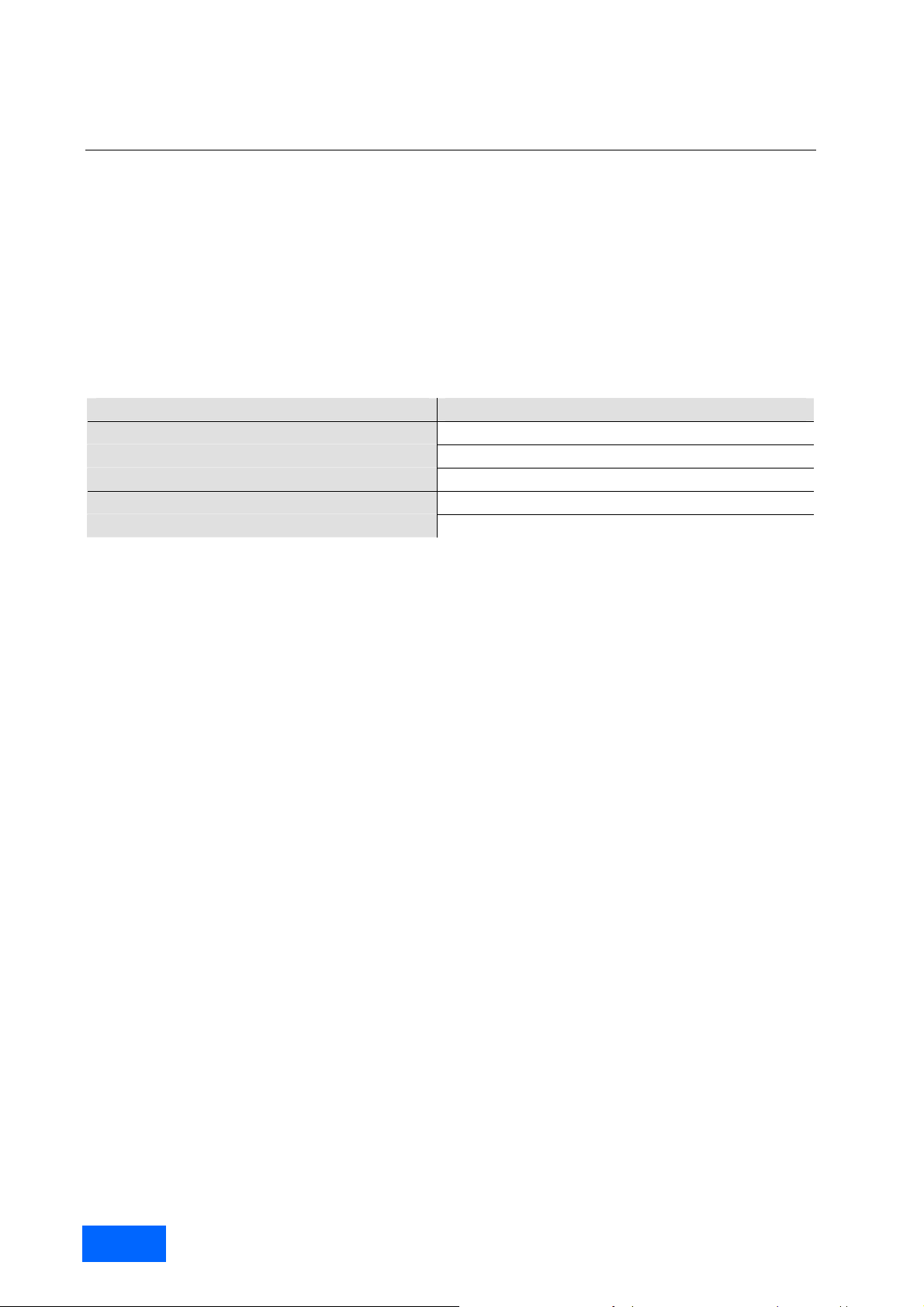

Line supply voltage Power Rated output current Pulse frequency factory

380 V to 480 V 3AC ≤ 250 kW ≤ 490 A 2.00 kHz

≥ 315 kW ≥ 605 A 1.25 kHz

500 V to 600 V 3AC All power ratings All currents 1.25 kHz

660 V to 690 V 3AC All power ratings All currents 1.25 kHz

Converter-dependent factory setting of pulse frequency for SINAMICS G130, G150, S150

and for SINAMICS S120 Motor Modules, Chassis and Cabinet Modules

The pulse frequency can be varied in discret e steps. Possi b le settings corr espo nd to twice the factory setting value in

each case as well as whole multiples thereof. Depending on the unit type, the pulse frequency can therefore be

increased to 8 kHz (when factory setting is 2 kHz) or to 7.5 kHz (when factory setting is 1.25 kHz). Switching between

integer multiples of the pulse frequency is also possible when the drive is in operati on.

With introduction of firmware version V2.4 in the summer of 2006 intermediate values can als o be parameterized,

allowing the pulse frequency to be set in relatively fine increments. This setting of intermediate values is only p ossibl e

when the drive is not in operation.

Influence of the pulse frequency on the inverter output current

The pulse frequency factory setting of eith er 2.0 kHz or 1.25 kHz is relatively low to generate low inverter s witching

losses. If the pulse frequency would be increased, and this can be done at any time by adjustment of the param eter

settings, the switching losses in the inverter and thus the overall losses in the conv erter would increase accordingl y.

The result would be overheating of the power unit if the inverter would operate at full capacity. For this reason, the

conducting losses must be lowered in order to compensate for the increase of the switching losses. T his can be

achieved by reducing the permissible output current (current derating). The pulse-frequency-dependent current

derating is specific to individual units. This has to be taken into account when dimensio ning a c onverter. T he derating

factors for integer multiples of factory settings can be found in the chapters on specific unit types. The derating

factors for intermediate values can be ascertained through linear interpolation between the corresponding table

values.

Influence of the pulse frequency on losses and efficiency of inverter and motor

With the factory set pulse frequency of 2.0 kHz or 1.25 kHz, the motor current is already close to sinusoidal. The

stray losses in the motor caused by harmonic currents are low, but not negligible. Commercially availabl e standard

motors for 50 Hz or 60 Hz and utilized according to temperature class B in mains operation can be partially utilized

according to temperature class F at the nominal working point up to rated torque when operated on a converter. The

winding temperature rise is then between 80 and 100 K.

Raising the pulse frequency on standard mot ors for 50 Hz or 60 Hz reduces the motor stray losses only slightly, but

results in a considerable increase in the converter switching loss es. The efficiency of the overall system (converter

and motor) deteriorates as a result.

setting

SINAMICS Engineering Manual - May 2008

Siemens AG

17/396

Fundamental Principles and System Description

Engineering Information

Influence of the pulse frequency on motor noise

A higher level of magnetic motor noise is excited when three-phase moto rs are operated on PW M converters. This is

caused by the voltage pulsing which results in additional voltage and current harmonics.

According to DIN VDE 0530 or IEC 60034-17 "Rotating electrical machines / Squirrel-cage induction motors fed from

converters - Application guide“, the A-graded noise pressure level i ncreases in the order of magnitude of between

5 dB and 15 dB when three-phas e motors are operated on a PWM converter up to rated frequency as compared to

motors of the same type operating on sinusoidal volta ge at rated frequency. The actual values depend on the PWM

method used, the pulse frequency of the converter and the design and number of poles of the converter-fed motor.

In the case of SINAMICS converters operating at the factory-set pulse frequenc y, the additional noise pr essure level

produced by the motor as a result of the converter supply is in the order of magnitude of between 5 dB(A) and

maximum 10 dB(A).

A reduction of the additional motor noise caused b y the conv erter su pply ca n gener all y b e achi eved by an incre ase in

the pulse frequency. It can therefore be meaningful to raise the pulse frequenc y in ord er to attenuate the motor nois e.

It must be noted that the inverter current may need to be reduced (derated) with an increased pulse frequency and

other limitations may apply with respect to motor-side options such as motor reactors, dv/dt filters plus VPL (Voltage

Peak Limiter) and sine-wave filters.

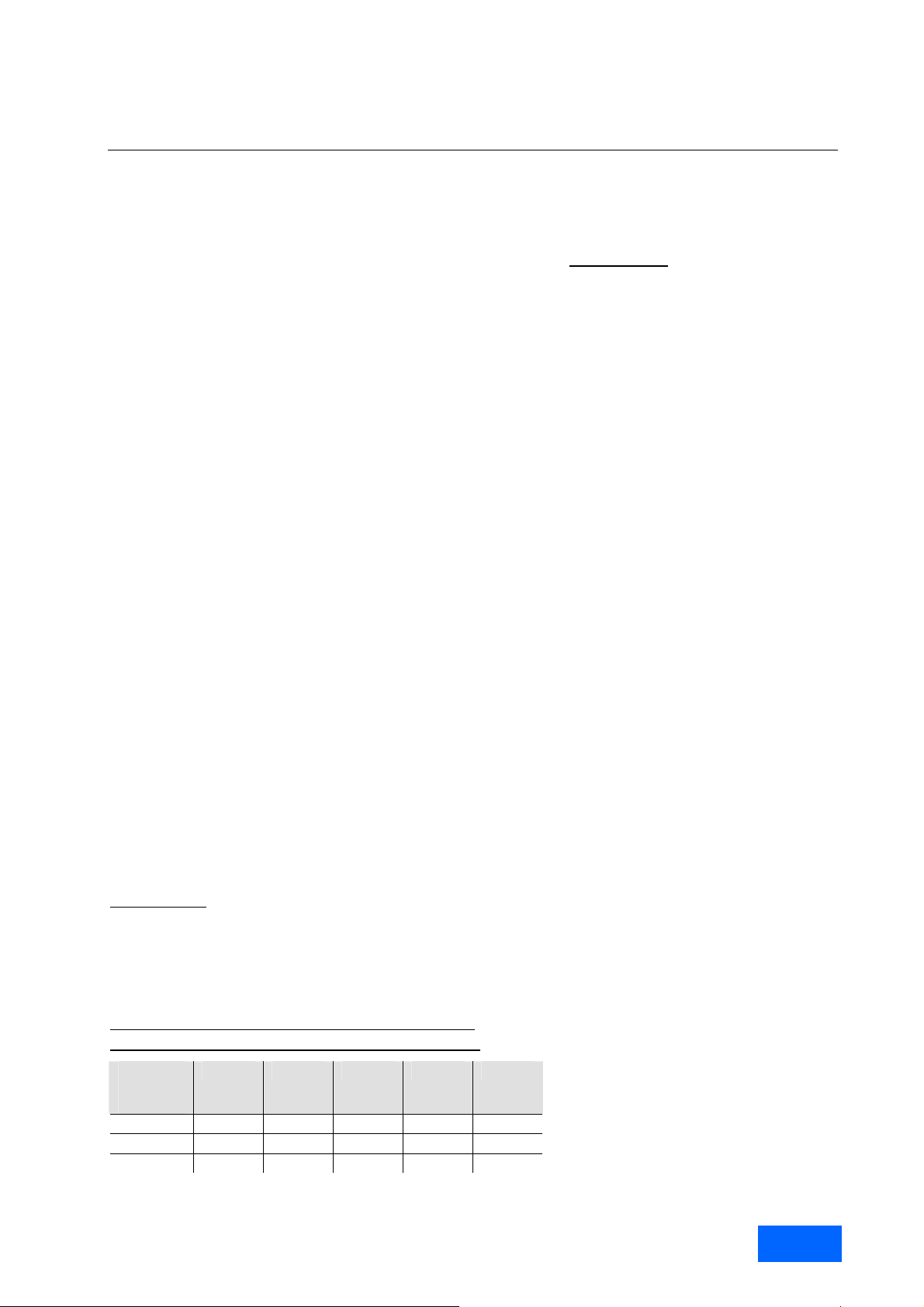

Correlation between pulse frequency and converter output frequency (fundamental wave frequency)

With space vector modulation, there is a fixed correlatio n between the pulse frequency and the m aximum attainable

converter output frequency (fundamental wave frequency) . The pulse frequency must be at least 12.5 times higher

than the required converter output frequency on SINAMICS converters. This means that the maximum achievabl e

output frequency at a given pulse frequency is limited according to the formula

= f

f

Converter max

The table below shows the possible pulse frequency settings and the associated maximum achievable output

frequencies for converters and inverters with the factory set pulse freq uencies f

pulse frequency setting scale is expanded with firmware version V2.4 and higher.

Units with factory setting f

Pulse frequency Max. output frequency Pulse frequency Max. output frequency

2.0 kHz 160 Hz 1.25 kHz 100 Hz

4.0 kHz 300 Hz 2.50 kHz 200 Hz

8.0 kHz 300 Hz 5.00 kHz 300 Hz

- - 7.50 kHz 300 Hz

Settable pulse frequencies and associated maximum attainable output frequencies on SINAMICS converters

Correlation between pulse frequency and motor-side options (motor reactor and motor filter)

If motor reactors, dv/dt filters p

pulse frequency and thus also the maximum output frequency are limited by these options. In some cases, a fixed

pulse frequency is specified:

Permissible pulse frequency with motor reactor (SINAMICS):

The maximum pulse frequency is limited to twice the value of the factory setting, i.e. to 4 kHz on units with

factory setting 2 kHz and to 2.5 kHz on units with factory setting 1.25 kHz. The maximum output frequency is

limited to 150 Hz independent of the selected pulse frequency.

Permissible pulse frequency with dv/dt filter plus VPL (SINAMICS)

The maximum pulse frequency is limited to twice the value of the factory setting, i.e. to 4 kHz on units with

factory setting 2 kHz and to 2.5 kHz on units with factory setting 1.25 kHz. The maximum output frequency is

limited to 150 Hz independent of the selected pulse frequency.

Permissible pulse frequency with sine-wave filter (SINAMICS):

Sine-wave filters are available for voltage levels 38 0 V to 480 V 3AC and 500 V to 600 V 3AC. The pulse

frequency is a mandatory fixed value and equals 4 kHz (380 V to 480 V) or 2.5 kHz (50 0 V to 600 V). The

maximum output frequency is limited to 150 Hz.

Permissible pulse frequency with sine-wave filter (external supplier):