Siemens Sinamics S120,Sinumerik 828D Diagnostic Manual

SINUMERIK

SINUMERIK 828D,

SINAMICS S120

Alarms

Diagnostics Manual

Validfor:CNCsystemsoftware

Version4.3SINAMICSS120Booksize/Combi

Version4.3SP2

07/2010

6FC5398-8BP40-0BA0

Preface

Introduction

1

NCK alarms

2

HMI alarms

3

SINAMICS alarms

4

611D drive alarms

5

PLC alarms

6

List of actions

7

System reactions

8

Appendix

A

Legal information- Warning notice system

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be

used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property

damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation for the specific task, in particular its warning notices and safety

instructions. Qualified personnel are those who, based on their training and experience, are capable of identifying

risks and avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

Trademarks

All names identified by ® are registered trademarks of the SiemensAG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described.

Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in this

publication is reviewed regularly and any necessary corrections are included in subsequent editions.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the corresponding information is not taken into account.

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended or

approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be adhered to. The information in the relevant documentation must be observed.

Order number:6FC5398-8BP40-0BA0

Ⓟ 07.2010

Copyright © SiemensAG2010.

Technical data subject to change

Alarms

Diagnostics Manual 07/2010, 6FC5398-8BP40-0BA0

3

Preface

SINUMERIK documentation

The SINUMERIK documentation is organized in three parts:

• General documentation

• User documentation

• Manufacturer/service documentation

Information on the following topics is available at http://www.siemens.com/motioncontrol/

docu:

• Ordering documentation:

Here you can find an up-to-date overview of publications.

• Downloading documentation:

Links to more information for downloading files from Service & Support.

• Researching documentation online

Information on DOConCD and direct access to the publications in DOConWEB.

• Compiling individual documentation on the basis of Siemens contents with the My

Documentation Manager (DM), refer to http://www.siemens.com/mdm.

My Documentation Manager provides you with a range of features for generating your own

machine documentation.

• Training and FAQs

Information on our range of training courses and FAQs (frequently asked questions) is

available via the page navigation.

Target group

This publication is intended for:

• Project engineers

• Commissioning engineers

• Machine operators

• Service and maintenance personnel

Benefits

The Diagnostics Manual enables the intended target group to evaluate fault displays and to

respond accordingly.

With the help of the Diagnostics Manual, the target group has an overview of the various

diagnostic options and diagnostic tools.

Preface

Alarms

4 Diagnostics Manual, 07/2010, 6FC5398-8BP40-0BA0

Standard version

This documentation only describes the functionality of the standard version. Extensions or

changes made by the machine manufacturer are documented by the machine manufacturer.

Other functions not described in this documentation might be executable in the control. This

does not, however, represent an obligation to supply such functions with a new control or

when servicing.

Further, for the sake of simplicity, this documentation does not contain all detailed information

about all types of the product and cannot cover every conceivable case of installation,

operation or maintenance.

Technical Support

If you have any technical questions, please contact our hotline:

Europe / Africa

Phone +49 (0) 911 895 7222

Fax +49 (0) 911 895 7223

Internet http://www.siemens.com/automation/support-request

Americas

Phone +1 423 262 2522

Fax +1 423 262 2200

E-mail mailto:techsupport.sea@siemens.com

Asia / Pacific

Phone +86 1064 757 575

Fax +86 1064 747 474

E-mail mailto:support.asia.automation@siemens.com

Note

National telephone numbers for technical support are provided under the following Internet

address:

http://www.siemens.com/automation/partner.

Preface

Alarms

Diagnostics Manual, 07/2010, 6FC5398-8BP40-0BA0

5

Questions about this documentation

If you have any queries (suggestions, corrections) in relation to this documentation, please

send a fax or e-mail to the following address:

SINUMERIK Internet address

http://www.siemens.com/sinumerik

Fax: +49 9131 98 2176

A fax form is available at the end of this document.

mailto:docu.motioncontrol@siemens.com

Preface

Alarms

6 Diagnostics Manual, 07/2010, 6FC5398-8BP40-0BA0

Alarms

Diagnostics Manual 07/2010, 6FC5398-8BP40-0BA0

7

Table of contents

Preface.........................................................................................................................................................3

1 Introduction .................................................................................................................................................9

1.1 Using the Diagnostics Manual ..................................................................................................... 9

1.2 Structure of the diagnostics manual .......................................................................................... 10

1.3 Alarm number ranges ................................................................................................................ 13

1.4 System error alarms .................................................................................................................. 16

2 NCK alarms ...............................................................................................................................................17

3 HMI alarms ..............................................................................................................................................501

4 SINAMICS alarms ...................................................................................................................................507

5 611D drive alarms ...................................................................................................................................891

6 PLC alarms .............................................................................................................................................903

7 List of actions ..........................................................................................................................................909

8 System reactions ............................................. .......................................................................................931

8.1 System reactions to SINUMERIK alarms ................................................................................ 931

8.2 Cancel criteria for alarms......................................................................................................... 934

8.3 System reactions for SINAMICS alarms.................................................................................. 936

A Appendix .................................................................................................................................................939

A.1 List of abbreviations...................................................................................................... ........... 939

A.2 Feedback on the documentation ............................................................................................. 944

A.3 Documentation overview ......................................................................................................... 946

Table of contents

Alarms

8

Diagnostics Manual, 07/2010, 6FC5398-8BP40-0BA0

Alarms

Diagnostics Manual 07/2010, 6FC5398-8BP40-0BA0

9

1

Introduction

1.1 Using the Diagnostics Manual

The Diagnostic Manual specifies the alarms/messages from the NCK area. It should be used

as a reference manual and allows operators at the machine tool:

• To correctly assess special situations when operating the machine.

• To identify the reaction of the system to the special situation.

• To utilize the possibilities for continued operation following the special situation.

• To follow references to other documentation containing further details.

Introduction

1.2 Structure of the diagnostics manual

Alarms

10 Diagnostics Manual, 07/2010, 6FC5398-8BP40-0BA0

1.2 Structure of the diagnostics manual

NCK / HMI / 611D drive / PLC alarms

The descriptions of the NCK/HMI/611D drive/PLC alarms are provided in the chapters:

• NCK alarms [Page 17]

• HMI alarms [Page 501]

• 611D drive alarms [Page 891]

• PLC alarms [Page 903]

In each chapter, the alarm descriptions are sorted according to ascending alarm number.

There are gaps in the sequence.

Structure of the NCK / HMI / 611D drive / PLC alarm descriptions

The descriptions of the NCK/HMI/611D drive/PLC alarms have the following layout:

Each alarm is uniquely identified using the <Alarm number> and the <Alarm text>.

The description of the NCK/HMI/611D drive/PLC alarms is sub-divided into the following

categories:

•Explanation

• Reaction

See Chapter "System reactions [Page 931]".

•Remedy

• Program continuation

See Chapter "Cancel criteria for alarms [Page 934]"

Action list

The actions described in the NCK alarm texts ("Action %...") are explained in Chapter "List of

actions [Page 909]".

<Alarm No.>

Explanation:

Reaction:

Help:

Continue

program:

<Alarm text>

Introduction

1.2 Structure of the diagnostics manual

Alarms

Diagnostics Manual, 07/2010, 6FC5398-8BP40-0BA0

11

SINAMICS alarms

The faults and states detected by the individual components of the drive system are indicated

by alarms. These SINAMICS alarms are categorized into faults and alarms.

The differences between faults and alarms are as follows:

The descriptions for the SINAMICS alarms are provided Chapter:

• SINAMICS alarms [Page 507]

Structure of SINAMICS alarm descriptions

The descriptions of the SINAMICS alarms have the following layout:

Each alarm is uniquely identified using the <Alarm number> and the <Alarm text>.

The <Location data> is optional display information. Location data can include:

• Axis name and drive number or

• Bus and slave number of the PROFIBUS DP component affected

The place holder <Location data> is kept in the alarm description for this optional information.

The description of the SINAMICS alarms is classified according to the following categories:

Fault • The appropriate fault reaction is initiated when a fault occurs.

• The following measures are required to remove the fault:

– Removing the cause of the fault

– Acknowledging the fault

Alarm • No fault reaction.

• Alarms are self-acknowledging, i.e. if the cause has been removed, the

alarms reset themselves automatically.

<Alarm No.>

Message value:

Drive object:

Reaction:

Acknowledgment:

Cause:

Help:

<Location data> <Alarm text>

Introduction

1.2 Structure of the diagnostics manual

Alarms

12 Diagnostics Manual, 07/2010, 6FC5398-8BP40-0BA0

• Message value

The information provided under the message value tells you about the composition of the

fault/alarm value.

Example:

Message value: Component number: %1, cause: %2

This fault value or alarm value contains information about the component number and

cause. The entries %1 and %2 are place holders, which are filled appropriately in online

operation with the commissioning software.

• Drive object

For each alarm (fault/alarm) it is specified in which drive object this message can be

found. A message can belong to either one, several or all drive objects.

• Reaction

Specifies the default reaction in the event of a fault.

See Chapter "System reactions for SINAMICS alarms [Page 936]".

• Acknowledgment

See Chapter "System reactions for SINAMICS alarms [Page 936]".

• Cause

For the cause of the alarm, the fault/alarm value is essentially prepared in text form.

•Remedy

Introduction

1.3 Alarm number ranges

Alarms

Diagnostics Manual, 07/2010, 6FC5398-8BP40-0BA0

13

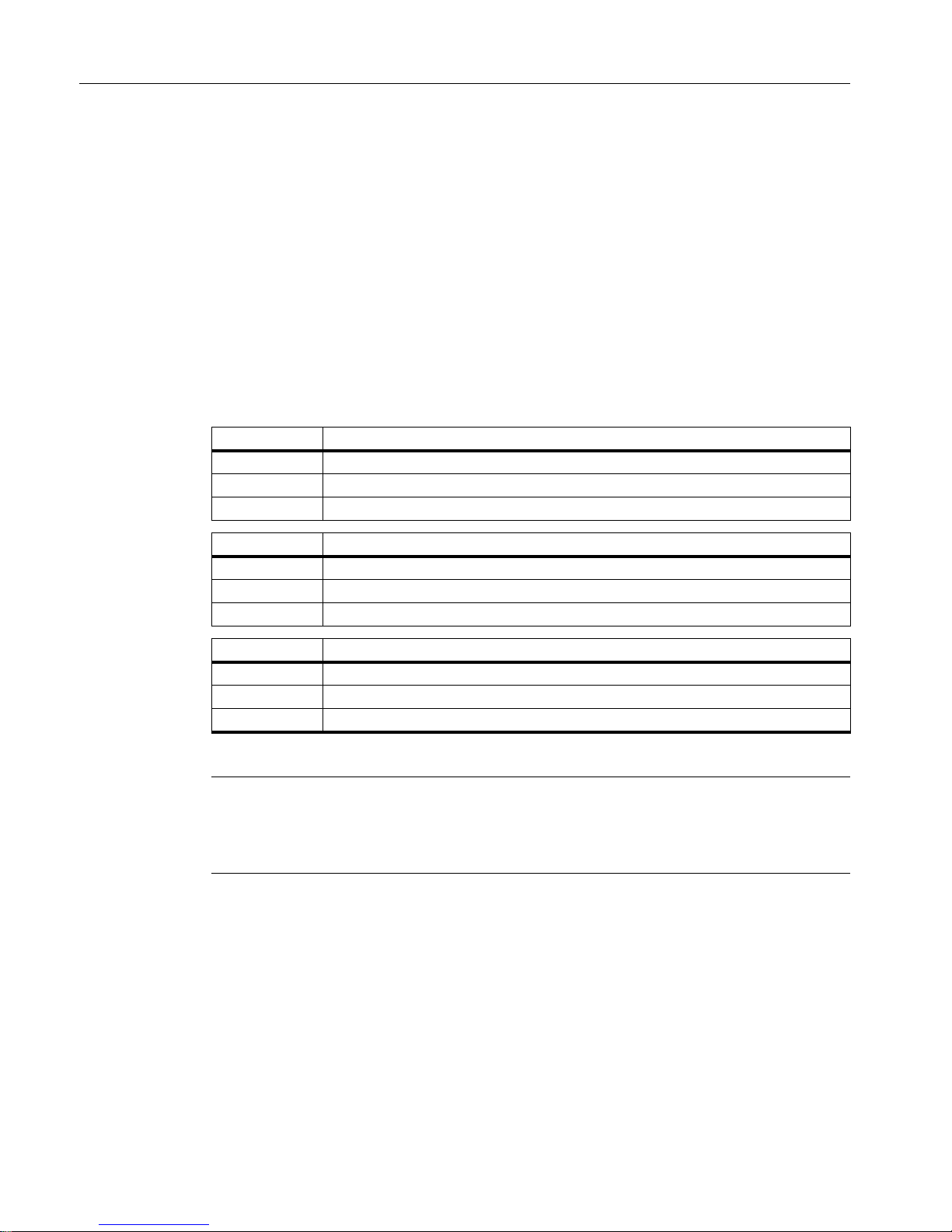

1.3 Alarm number ranges

The following tables show an overview of all of the reserved number ranges for alarms/

messages.

NOTICE

In the alarm lists of this Diagnostics Manual, only those number ranges are represented,

which are valid for the specified product.

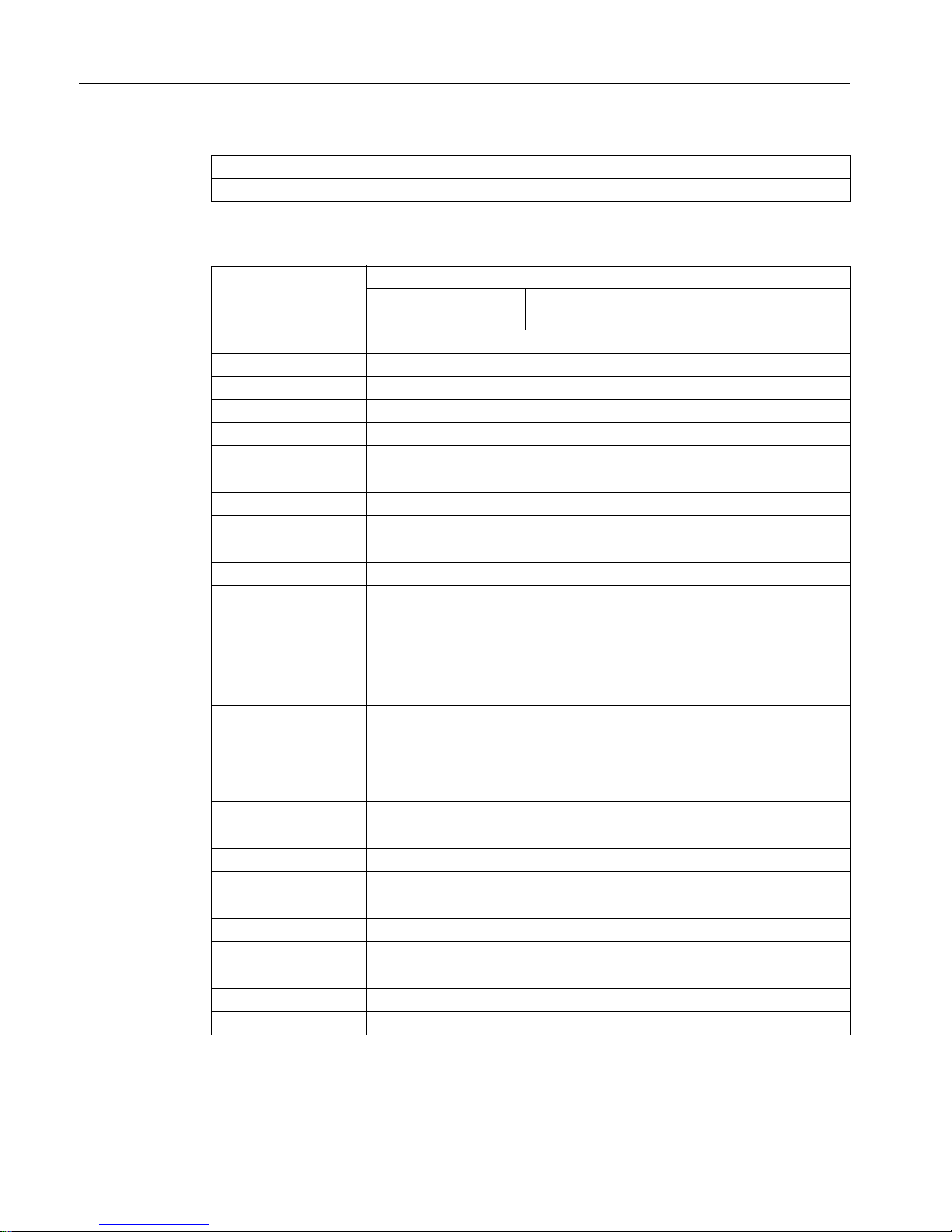

Table 1-1 NCK alarms/messages

000 000 - 009 999 General alarms

010 000 - 019 999 Channel alarms

020 000 - 029 999 Axis/spindle alarms

027 000 - 027 999 Alarms for Safety Integrated

030 000 - 099 999 Functional alarms

060 000 - 064 999 Cycle alarms SIEMENS

065 000 - 069 999 Cycle alarms user

070 000 - 079 999 Compile cycles, manufacturer and OEM

082 000 - 082 999 Messages, SHOPMILL and CMT cycles

083 000 - 084 999 Messages, measurement cycles

085 000 - 089 999 Messages, user cycles

Table 1-2 HMI alarms/messages

100 000 - 119 999 HMI Embedded

100 000 - 100 999 Basic system

101 000 - 101 999 Diagnostics

102 000 - 102 999 Services

103 000 - 103 999 Machine

104 000 - 104 999 Parameter

105 000 - 105 999 Programming

106 000 - 106 999 Reserved

107 000 - 107 999 MCU

108 000 -108 999 HiGraph

109 000 - 109 999 Distributed systems (M : N)

110 000 - 110 999 Cycles

113 000 - 113 999 Wizard (HMI Embedded)

114 000 - 114 999 HT 6

119 000 - 119 999 OEM

120 000 - 129 999 HMI Advanced

130 000 - 139 999 HMI Advanced OEM

142 000 - 142 099 Remote diagnostics, RCS host/viewer

148 500 - 148 999 MCIS

149 000 - 149 999 ePS

Introduction

1.3 Alarm number ranges

Alarms

14 Diagnostics Manual, 07/2010, 6FC5398-8BP40-0BA0

150 000 - 159 999 SINUMERIK Operate

160 000 – 169 999 SINUMERIK Operate OEM

Table 1-3 SINAMICS alarms (faults/alarms)

201 000 - 203 999 Control Unit, closed-loop control

201 600 - 201 799 Messages from the "Safety Integrated" function

integrated in the drive

204 000 - 204 999 Reserved

205 000 -205 999 Power unit

206 000 - 206 899 Infeed

206 900 - 206 999 Braking Module

207 000 - 207 999 Drive

208 000 - 208 999 Option Board

209 000 - 212 999 Reserved

213 000 - 213 010 Licensing

213 011 - 219 999 Reserved

220 000 - 229 999 OEM

230 000 - 230 999 DRIVE-CLiQ component power unit

231 000 - 231 999 DRIVE-CLiQ component encoder 1

232 000 - 232 999 DRIVE-CLiQ component encoder 2

Note:

Faults that occur are automatically output as an alarm if the encoder is

parameterized as a direct measuring system and does not intervene in the

motor control.

233 000 - 233 999 DRIVE-CLiQ component encoder 3

Note:

Faults that occur are automatically output as an alarm if the encoder is

parameterized as a direct measuring system and does not intervene in the

motor control.

234 000 - 234 999 Voltage Sensing Module (VSM)

235 000 - 235 199 Terminal Module 54F (TM54F)

235 200 - 235 999 Terminal Module 31 (TM31)

236 000 - 236 999 DRIVE-CLiQ Hub Module

240 000 - 240 999 Controller Extension

241 000 - 248 999 Reserved

249 000 - 249 999 SINAMICS GM/SM/GL

250 000 - 250 499 Communication Board (COMM BOARD)

250 500 - 259 999 OEM Siemens

260 000 - 265 535 SINAMICS DC MASTER (DC closed-loop control)

Table 1-2 HMI alarms/messages

Introduction

1.3 Alarm number ranges

Alarms

Diagnostics Manual, 07/2010, 6FC5398-8BP40-0BA0

15

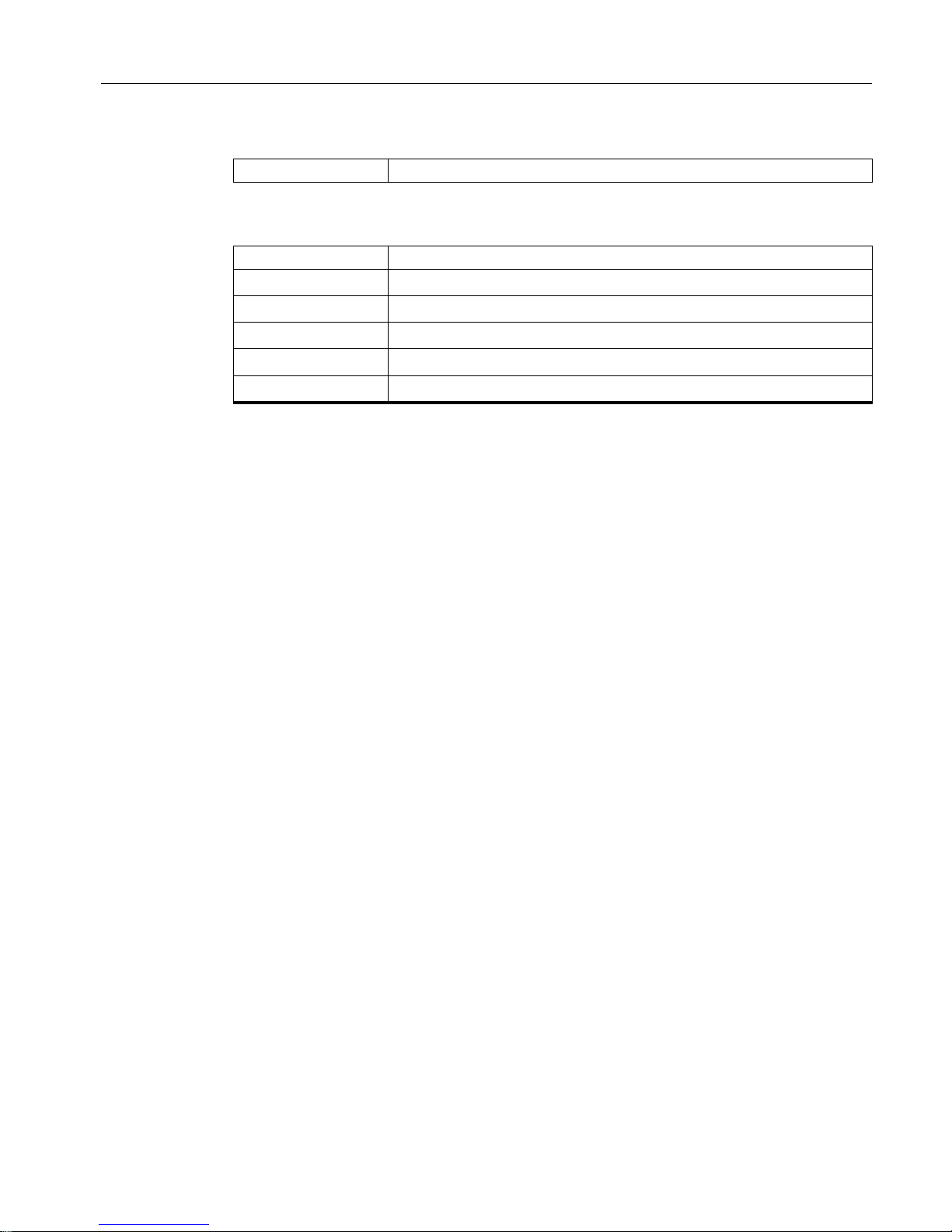

Table 1-4 611D drive alarms

300 000 - 399 999 General drive alarms

Table 1-5 PLC alarms/messages

400 000 - 499 999 General PLC alarms

500 000 - 599 999

Channel alarms

2)

600 000 - 699 999

Axis/spindle alarms

2)

700 000 - 799 999

User area

2)

800 000 - 899 999

Sequencers/graphs

2)

(810 001 - 810 009

System fault messages in the PLC 1))

1)

More detailed information is available via the diagnostic function (diagnostic buffer) in SIMATIC

STEP 7.

2)

The PLC alarms in the range 500000 - 899999 are configured and described by the machine manufacturer.

Introduction

1.4 System error alarms

Alarms

16 Diagnostics Manual, 07/2010, 6FC5398-8BP40-0BA0

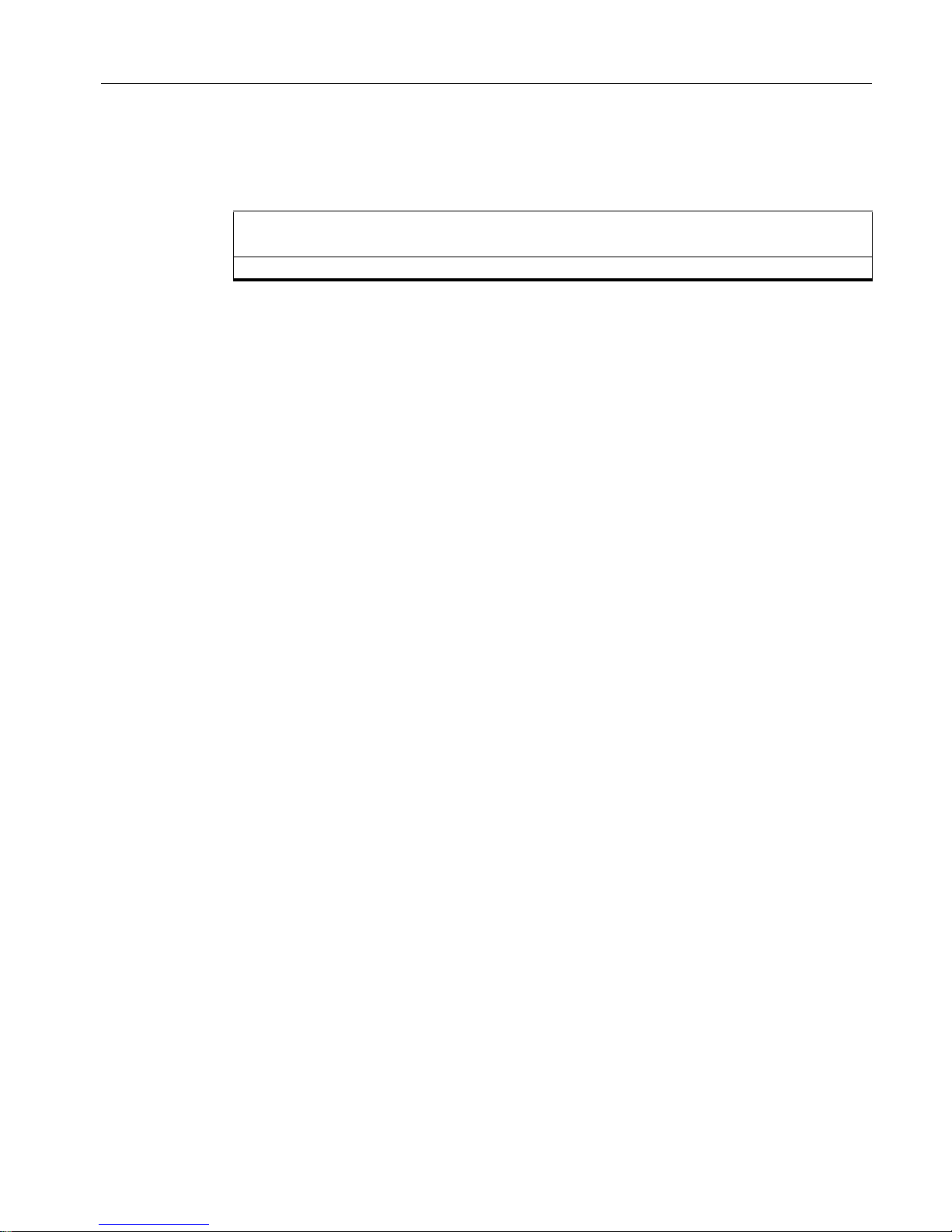

1.4 System error alarms

The following alarms are system errors:

These system error alarms are not described in detail. If such a system error occurs, please

contact the hotline and indicate the following details:

• Alarm number

•Alarm text

• Internal system error number (contained in the alarm text)

1000 1005 1013 1017

1001 1010 1014 1018

1002 1011 1015 1019

1003 1012 1016 1160

Alarms

Diagnostics Manual 07/2010, 6FC5398-8BP40-0BA0

17

2

NCK alarms

Product: Solutionline_828, Version: V12.0, Language: eng,

Objects:

2000 PLC sign-of-life monitoring

Definitions: The PLC must give a sign of life within a defined period of time (MD10100 $MN_PLC_CYCLIC_TIMEOUT). If this does

not occur, the alarm is triggered.

The sign of life is a counter reading on the internal NC/PLC interface which the PLC causes to count up with the 10

ms time alarm. The NCK also tests cyclically whether the counter reading has changed.

The PLC must give a sign of life within a defined period of time. If this does not occur, this alarm is triggered.

Reaction: NC not ready.

Local alarm reaction.

Channel not ready.

NC Start disable in this channel.

Interface signals are set.

Alarm display.

NC Stop on alarm.

Remedy: Please inform the authorized personnel/service department. Check monitoring time frame in MD10100

$MN_PLC_CYCLIC_TIMEOUT (reference value: 100ms).

Establish the cause of the error in the PLC and eliminate it (analysis of the ISTACK. If monitoring has responded with

a loop in the user program rather than with a PLC Stop, there is no ISTACK entry).

This alarm is also caused by PLC stop.

(PLC stop with programming tool,

PLC stop by commissioning switch,

PLC stop by alarm)

If none of these cases applies, please contact the hotline mentioned at the beginning of this document and provide

the operating system error number.

Program

Continuation:

Switch control OFF - ON.

2001 PLC has not started up

Definitions: The PLC must give at least 1 sign of life within a period of time defined in MD10120

$MN_PLC_RUNNINGUP_TIMEOUT (default: 1 sec.).

The PLC must give at least 1 sign of life within the defined period of time after Power ON.

Reaction: NC not ready.

Local alarm reaction.

Channel not ready.

NC Start disable in this channel.

Interface signals are set.

Alarm display.

NC Stop on alarm.

Remedy: - Please inform the authorized personnel/service department. The monitoring time in MD10120

$MN_PLC_RUNNINGUP_TIMEOUT must be checked and adapted to the first OB1 cycle.

- Determine the cause of error in the PLC (loop or stop in the user program) and eliminate it.

Contact the hotline mentioned at the beginning of this documentation.

Program

Continuation:

Switch control OFF - ON.

NCK alarms

Alarms

18 Diagnostics Manual, 07/2010, 6FC5398-8BP40-0BA0

2130 5V/24V encoder or 15V D/A converter undervoltage

Definitions: A failure has occurred in the power supply to the encoder (5V/24V) or D/A converter (+/-15V).

Reaction: NC not ready.

The NC switches to follow-up mode.

Mode group not ready, also effective for single axes.

NC Start disable in this channel.

Axes of this channel must be re-referenced.

Interface signals are set.

Alarm display.

NC Stop on alarm.

Remedy: Please inform the authorized personnel/service department. Check the encoder and cable for short-circuits (the fault

should not occur when you remove the cable). Check the power feeder line.

Program

Continuation:

Switch control OFF - ON.

2900 Reboot is delayed

Definitions: This alarm indicates a delayed reboot.

This alarm only occurs when reboot was carried out by the HMI and MD10088 $MN_REBOOT_DELAY_TIME was set

greater than zero.

The alarm can be suppressed with MD11410 $MN_SUPPRESS_ALARM_MASK Bit 20.

Reaction: NC not ready.

The NC switches to follow-up mode.

Mode group not ready, also effective for single axes.

Interpreter stop

NC Start disable in this channel.

Interface signals are set.

Alarm display.

NC Stop on alarm.

Alarm reaction delay is cancelled.

Remedy: See MD10088 $MN_REBOOT_DELAY_TIME and MD11410 $MN_SUPPRESS_ALARM_MASK.

Program

Continuation:

Switch control OFF - ON.

3000 Emergency stop

Definitions: The EMERGENCY STOP request is applied to the NCK/PLC interface DB2600 DBX0000.1 (Emergency stop).

Reaction: NC not ready.

Mode group not ready, also effective for single axes.

NC Start disable in this channel.

Interface signals are set.

Alarm display.

NC Stop on alarm.

Alarm reaction delay is cancelled.

Remedy: Please inform the authorized personnel/service department. Remove the cause of the emergency stop and acknowl-

edge the emergency stop via the PLC/NCK interface DB2600 DBX0000.2 (emergency stop acknowledgement).

Program

Continuation:

Teileprogramm neu starten.Clear alarm with the RESET key in all channels of this mode group. Restart part program.

NCK alarms

Alarms

Diagnostics Manual, 07/2010, 6FC5398-8BP40-0BA0

19

4000 [Channel %1: ] Machine data %2[%3] has gap in axis assignment

Parameters: %1 = Channel number

%2 = String: MD identifier

Definitions: The assignment of a machine axis to a channel by the MD20070 $MC_AXCONF_MACHAX_USED must be contigu-

ous. At system power-up (Power On) gaps are detected and displayed as an alarm.

Reaction: NC not ready.

Mode group not ready, also effective for single axes.

NC Start disable in this channel.

Interface signals are set.

Alarm display.

NC Stop on alarm.

Remedy: Please inform the authorized personnel/service department. The entries for the indices for the machine axes used in

the channels must be contiguous in table MD20070 $MC_AXCONF_MACHAX_USED. Channel axis gaps must be

enabled via MD11640$MN_ENABLE_CHAN_AX_GAP.

Program

Continuation:

Switch control OFF - ON.

4002 [Channel %1: ] Machine data %2[%3] assigns an axis not defined in channel

Parameters: %1 = Channel number

%2 = String: MD identifier

%3 = Index: MD array index

Definitions: Only axes that have been activated in the channel by means of MD20070 $MC_AXCONF_MACHAX_USED [kx]=m

may be declared as geometry axes or transformation axes by means of the MD20050

$MC_AXCONF_GEOAX_ASSIGN_TAB [gx]=k. This also applies to MD22420 $MC_FGROUP_DEFAULT_AXES

(gx: Geometry axis index, kx: Channel axis index, k: Channel axis no., m: Machine axis no.).

Assignment of geometry axes to channel axes

MD20050 $MC_AXCONF_GEOAX_ASSIGN_TAB (includes channel axis no. k):

- Geometry axis index: 0, 1st channel: 1, 2nd channel: 1

- Geometry axis index: 1, 1st channel: 2, 2nd channel: 0

- Geometry axis index: 2, 1st channel: 3, 2nd channel: 3

MD20070 $MC_AXCONF_MACHAX_USED (includes machine axis no. m):

- Channel axis index: 0, 1st channel: 1, 2nd channel: 4

- Channel axis index: 1, 1st channel: 2, 2nd channel: 5

- Channel axis index: 2, 1st channel: 3, 2nd channel: 6

- Channel axis index: 3, 1st channel: 7, 2nd channel: 0

- Channel axis index: 4, 1st channel: 8, 2nd channel: 0

- Channel axis index: 5, 1st channel: 0, 2nd channel: 0

- Channel axis index: 6, 1st channel: 0, 2nd channel: 0

- Channel axis index: 7, 1st channel: 0, 2nd channel: 0

Reaction: NC not ready.

Mode group not ready, also effective for single axes.

NC Start disable in this channel.

Interface signals are set.

Alarm display.

NC Stop on alarm.

Remedy: Please inform the authorized personnel/service department.

Correct

- MD20050 $MC_AXCONF_GEOAX_ASSIGN_TAB

- MD24... $MC_TRAFO_AXES_IN_...

- MD24... $MC_TRAFO_GEOAX_ASSIGN_TAB_...

- MD22420 $MC_FGROUP_DEFAULT_AXES

- and/or MD20070 $MC_AXCONF_MACHAX_USED.

Program

Continuation:

Switch control OFF - ON.

NCK alarms

Alarms

20 Diagnostics Manual, 07/2010, 6FC5398-8BP40-0BA0

4004 [Channel %1: ] Machine data %2 axis %3 defined repeatedly as geometry axis

Parameters: %1 = Channel number

%2 = String: MD identifier

%3 = Axis index

Definitions: An axis may only be defined once as a geometry axis.

Reaction: Mode group not ready.

Channel not ready.

NC Start disable in this channel.

Interface signals are set.

Alarm display.

NC Stop on alarm.

Remedy: Correct MD20050 $MC_AXCONF_GEOAX_ASSIGN_TAB.

Program

Continuation:

Switch control OFF - ON.

4005 [Channel %1: ] Maximum number of axes in channel %1 exceeded. Limit %2

Parameters: %1 = Channel number

%2 = Upper limit for the number of axes in the channel

Definitions: MD20070 $MC_AXCONF_MACHAX_USED defines which machine axes can be used in this channel. This simulta-

neously defines the number of active axes in the channel. This upper limit has been exceeded. Note: The channel axis

gaps may cause certain indices of MD20070 $MC_AXCONF_MACHAX_USED to remain unused and therefore do

not count as active channel axes.

Example:

- CHANDATA(2)

- $MC_AXCONF_MACHAX_USED[0] = 7

- $MC_AXCONF_MACHAX_USED[1] = 8

- $MC_AXCONF_MACHAX_USED[2] = 0

- $MC_AXCONF_MACHAX_USED[3] = 3

- $MC_AXCONF_MACHAX_USED[4] = 2

- $MC_AXCONF_MACHAX_USED[5] = 0

- $MC_AXCONF_MACHAX_USED[6] = 1

- $MC_AXCONF_MACHAX_USED[7] = 0

This channel uses the five machine axes 1, 2, 3, 8, 7, i.e. it has 5 active channel axes.

Reaction: NC not ready.

Channel not ready.

NC Start disable in this channel.

Interface signals are set.

Alarm display.

NC Stop on alarm.

Remedy: Modify MD20070 $MC_AXCONF_MACHAX_USED.

Program

Continuation:

Switch control OFF - ON.

4006 The maximum number of activatable axes has been exceeded (limit %1)

Parameters: %1 = Number of axes

Definitions: The sum of the two option data $ON_NUM_AXES_IN_SYSTEM and $ON_NUM_ADD_AXES_IN_SYSTEM must not

exceed the maximum number of axes in the system.

Reaction: NC not ready.

Mode group not ready, also effective for single axes.

NC Start disable in this channel.

Interface signals are set.

Alarm display.

NC Stop on alarm.

NCK alarms

Alarms

Diagnostics Manual, 07/2010, 6FC5398-8BP40-0BA0

21

Remedy: Please inform the authorized personel/service department. The sum of the two option data

$ON_NUM_AXES_IN_SYSTEM and $ON_NUM_ADD_AXES_IN_SYSTEM must not exceed the maximum number

of axes (dependent on configuration).

Program

Continuation:

Switch control OFF - ON.

4009 Machine data %1 contains an illegal value.

Parameters: %1 = String: MD identifier

Definitions: A value has been entered which exceeds the value range or a limit value for a variable, a machine data or a function.

Reaction: NC not ready.

Channel not ready.

NC Start disable in this channel.

Interface signals are set.

Alarm display.

NC Stop on alarm.

Remedy: Enter correct values.

Program

Continuation:

Switch control OFF - ON.

4010 Invalid identifier used in machine data %1[%2]

Parameters: %1 = String: MD identifier

%2 = Index: MD array index

Definitions: When determining a name in the NCK tables (arrays) for: machine axes, Euler angles, direction vectors, normal vec-

tors, interpolation parameters and intermediate point coordinates, one of the following syntax rules for the identifier to

be entered has been violated:

- The identifier must be an NC address letter (A, B, C, I, J, K, Q, U, V, W, X, Y, Z), possibly with a numerical extension

(840D: 1-99)

- The identifier must begin with any 2 capital letters but not with $ (reserved for system variables).

- The identifier must not be a keyword of the NC language (e.g. POSA).

Reaction: NC not ready.

Mode group not ready, also effective for single axes.

NC Start disable in this channel.

Interface signals are set.

Alarm display.

NC Stop on alarm.

Remedy: Please inform the authorized personnel/service department. Enter the identifier for user-defined names with correct

syntax in the displayed MD.

- Machine axes: MD10000 $MN_AXCONF_MACHAX_NAME_TAB

- Euler angles: MD10620 $MN_EULER_ANGLE_NAME_TAB

- Normal vectors: MD10630 $MN_NORMAL_VECTOR_NAME_TAB

- Direction vectors: MD10640 $MN_DIR_VECTOR_NAME_TAB

- Interpolation parameters: MD10650 $MN_IPO_PARAM_NAME_TAB

- Intermediate point coordinates: MD10660 $MN_INTERMEDIATE_POINT_NAME_TAB

Program

Continuation:

Switch control OFF - ON.

NCK alarms

Alarms

22 Diagnostics Manual, 07/2010, 6FC5398-8BP40-0BA0

4011 [Channel %1: ] Invalid identifier used in machine data %2[%3]

Parameters: %1 = Channel number

%2 = String: MD identifier

%3 = Index: MD array index

Definitions: When defining names in the channel-specific tables for geometry axes and channel axes, one of the following syntax

rules for the identifier to be entered has been violated:

- The identifier must be an NC address letter (A, B, C, I, J, K, U, V, W, X, Y, Z), possibly with a numerical extension.

- The identifier must begin with any 2 capital letters but not with $ (reserved for system variables).

- The identifier must not be a keyword of the NC language (e.g. SPOS).

Reaction: NC not ready.

Mode group not ready, also effective for single axes.

NC Start disable in this channel.

Interface signals are set.

Alarm display.

NC Stop on alarm.

Remedy: Please inform the authorized personnel/service department.

Enter the identifier for user-defined names with correct syntax in the displayed MD

- Geometry axes: MD20060 $MC_AXCONF_GEOAX_NAME_TAB

- Channel axes: MD20080 $MC_AXCONF_CHANAX_NAME_TAB

Program

Continuation:

Switch control OFF - ON.

4012 Invalid identifier used in machine data %1[%2]

Parameters: %1 = String: MD identifier

%2 = Index: MD array

Definitions: The selected identifier is invalid. Valid identifiers are:

- AX1 - AXn: Machine axis identifiers

Reaction: NC not ready.

Channel not ready.

NC Start disable in this channel.

Interface signals are set.

Alarm display.

NC Stop on alarm.

Remedy: Use the correct identifier.

Program

Continuation:

Switch control OFF - ON.

4020 Identifier %1 used several times in machine data %2

Parameters: %1 = String: Name of identifier

%2 = String: MD identifier

Definitions: When determining a name in the NCK tables (arrays) for: machine axes, Euler angles, direction vectors, normal vec-

tors, interpolation parameters and intermediate point coordinates, an identifier has been used that already exists in

the control.

Reaction: NC not ready.

Mode group not ready, also effective for single axes.

NC Start disable in this channel.

Interface signals are set.

Alarm display.

NC Stop on alarm.

NCK alarms

Alarms

Diagnostics Manual, 07/2010, 6FC5398-8BP40-0BA0

23

Remedy: Please inform the authorized personnel/service department. Select for the identifier to be entered a character string

that is not yet used in the system (max. 32 characters).

Program

Continuation:

Teileprogramm neu starten.Clear alarm with the RESET key in all channels of this mode group. Restart part program.

4021 [Channel %1: ] Identifier %2 used several times in machine data %3

Parameters: %1 = Channel number

%2 = String: Name of identifier

%3 = String: MD identifier

Definitions: To determine the name in the channel-specific tables for geometry axes and channel axes an identifier already existing

in the control has been used.

Reaction: NC not ready.

Mode group not ready, also effective for single axes.

NC Start disable in this channel.

Interface signals are set.

Alarm display.

NC Stop on alarm.

Remedy: Please inform the authorized personnel/service department. Select for the identifier to be entered a character string

that is not yet used in the system (max. 32 characters).

Program

Continuation:

Switch control OFF - ON.

4030 [Channel %1: ] Identifier missing in machine date %2[%3]

Parameters: %1 = Channel number

%2 = String: MD identifier

%3 = Index: MD array index

Definitions: An axis identifier is expected for the displayed MD in accordance with the axis configuration in the MD20070

$MC_AXCONF_MACHAX_USED and MD20050 $MC_AXCONF_GEOAX_ASSIGN_TAB.

Reaction: NC not ready.

Mode group not ready, also effective for single axes.

NC Start disable in this channel.

Interface signals are set.

Alarm display.

NC Stop on alarm.

Remedy: Please inform the authorized personnel/service department.

Check axis configuration and enter the missing identifier into the MD or, should the axis not exist, specify for this channel axis the machine axis 0 in the channel-specific MD20070 $MC_AXCONF_MACHAX_USED. If this concerns a

geometry axis that is not to be used (this applies only for 2-axis machining, e.g. on lathes), then channel axis 0 must

be entered additionally in the channel-specific MD20050 $MC_AXCONF_GEOAX_ASSIGN_TAB.

Program

Continuation:

Switch control OFF - ON.

4032 [Channel %1: ] Wrong identifier for facing axis in %2

Parameters: %1 = Channel number

%2 = String: MD identifier

Definitions: According to the axis configuration in MD20150 $MC_GCODE_RESET_VALUES or MD20100

$MC_DIAMETER_AX_DEF, a facing axis identifier is expected at the specified location.

NCK alarms

Alarms

24 Diagnostics Manual, 07/2010, 6FC5398-8BP40-0BA0

Reaction: Mode group not ready.

Channel not ready.

NC Start disable in this channel.

Interface signals are set.

Alarm display.

NC Stop on alarm.

Remedy: Please inform the authorized personnel/service department. Add the correct identifier.

Program

Continuation:

Switch control OFF - ON.

4040 [Channel %1: ] Axis identifier %2 not consistent with machine data %3

Parameters: %1 = Channel number

%2 = String: Axis identifier

%3 = String: MD identifier

%4 = There are not enough channel axes entered in the MD displayed.

Definitions: The use of the specified axis identifier in the displayed MD is not consistent the channel's axis configuration stated in

the MD20070 $MC_AXCONF_MACHAX_USED and MD20050 $MC_AXCONF_GEOAX_ASSIGN_TAB.

Reaction: NC not ready.

Mode group not ready, also effective for single axes.

NC Start disable in this channel.

Interface signals are set.

Alarm display.

NC Stop on alarm.

Remedy: Please inform the authorized personnel/service department.

Check and correct the identifier used in the MD10000 $MN_AXCONF_MACHAX_NAME_TAB, MD20080

$MC_AXCONF_CHANAX_NAME_TAB and/or MD20060 $MC_AXCONF_GEOAX_NAME_TAB.

Program

Continuation:

Switch control OFF - ON.

4045 [Channel %1: ] Conflict between machine data %2 and machine data %3

Parameters: %1 = Channel number

%2 = String: MD identifier

%3 = String: MD identifier

Definitions: Using the specified machine data %1 leads to a conflict with machine data %2.

Reaction: NC not ready.

Mode group not ready, also effective for single axes.

NC Start disable in this channel.

Interface signals are set.

Alarm display.

NC Stop on alarm.

Remedy: Correct the specified machine data.

Program

Continuation:

Switch control OFF - ON.

NCK alarms

Alarms

Diagnostics Manual, 07/2010, 6FC5398-8BP40-0BA0

25

4050 NC code identifier %1 cannot be reconfigured to %2

Parameters: %1 = String: Old identifier

%2 = String: New identifier

Definitions: Renaming of an NC code was not possible for one of the following reasons:

- The old identifier does not exist

- The new identifier lies in another type range.

NC codes/keywords can be reconfigured via machine data as long as the type range is not abandoned.

Type 1: "real" G codes: G02, G17, G33, G64, ...

Type 2: named G codes: ASPLINE, BRISK, TRANS, ...

Type 3: settable addresses: X, Y, A1, A2, I, J, K, ALF, MEAS, ...

Reaction: NC not ready.

Mode group not ready, also effective for single axes.

NC Start disable in this channel.

Interface signals are set.

Alarm display.

NC Stop on alarm.

Remedy: Please inform the authorized personnel/service department.

Correct MD10712 $MN_NC_USER_CODE_CONF_NAME_TAB (protection level 1).

The list must be built up as follows:

Even address: Identifier to be modified.

Following odd address: New identifier

e.g.: $MN_NC_USER_CODE_CONF_NAME_TAB [10] = "ROT"

$MN_NC_USER_CODE_CONF_NAME_TAB [11] = " "

clears the ROT function from the control

Program

Continuation:

Switch control OFF - ON.

4060 Standard machine data loaded (%1, %2, %3, %4)

Parameters: %1 = Identifier 1

%2 = Identifier 2

%3 = Identifier 3

%4 = Identifier 4

Definitions: The standard MD were loaded because

- a cold start was requested or

- the MD buffer voltage failed or

- an initialization was requested for loading the standard machine data (MD11200 $MN_INIT_MD).

Reaction: Alarm display.

Remedy: Please inform the authorized personnel/service department. After automatically loading the standard MDs, the individ-

ual MDs must be entered or loaded in the relevant system.

Program

Continuation:

Clear alarm with the RESET key. Restart part program

4062 Backup data loaded

Definitions: The user data saved in the flash memory are loaded to the SRAM.

Reaction: Alarm display.

Remedy: Load specific machine data again.

Program

Continuation:

Clear alarm with the RESET key. Restart part program

NCK alarms

Alarms

26 Diagnostics Manual, 07/2010, 6FC5398-8BP40-0BA0

4065 Buffered memory was restored from backup medium (potential loss of data!)

Definitions: Only occurs with SINUMERIK 840D / 840Di sl / 802D.

!! 840Di sl only

The user data of the NC and the remanent data of the PLC are stored in the static memory area (SRAM) of the MCI

board. The content of the SRAM is backed up as an SRAM image on PCU hard disk at each "NCK POWER ON reset"

and each time Windows XP is closed down normally. The previously valid SRAM image then becomes the SRAM

backup, which is also stored on the PCU hard disk.

The SRAM backup is used and alarm 4065 issued in the following cases:

HW serial no SRAM MCI board SRAM image

MCI board "OK" "OK"

1. Known No No

2. Unknown Yes No

3. Unknown No No

!! Only for 802D

The reason for this alarm is that the backup time is exceeded. Make sure that the required operating time of the control

corresponds to the specifications in your Installation & Start-up Guide. The current backup copy of the buffered memory has been created by the last internal data backup via the "Save data" softkey on the HMI.

Reaction: NC not ready.

NC Start disable in this channel.

Interface signals are set.

Alarm display.

Remedy: Make a POWER ON reset.

!! 840Di / 840Di sl only:

Alarm 4065 also has to be acknowledged on the HMI after a POWER ON reset:

HMI: Operating area switchover > Diagnostics > NC/PLC Diagnostics > Diagnostics > "Acknowledge alarm 4065" button

Note

Press the "ETC" key to change to the secondary softkey bar in order to acknowledge the alarm with a softkey.

Program

Continuation:

Switch control OFF - ON.

4070 Normalizing machine data has been changed

Definitions: The control uses internal physical units (mm, degrees, s, for paths, velocities, acceleration, etc.). During programming

or data storage, some of these values are input and output using different units (rev./min, m/s2, etc.).

The conversion is carried out with the scaling factors that can be entered (system-spefic MD array MD10230

$MN_SCALING_FACTORS_USER_DEF USER_DEF[n] (n ... index number 0 - 10), when the corresponding masking

bit is set to "1".

If the masking bit is set to "0" then scaling takes place with the internal standard factors.

The following machine data influence the scaling of other MDs:

MD10220: $MN_SCALING_USER_DEF_MASK

MD10230: $MN_SCALING_FACTORS_USER_DEF

MD10240: $MN_SCALING_SYSTEM_IS_METRIC

MD10250: $MN_SCALING_VALUE_INCH

MD30300: $MA_IS_ROT_AX

If these data are modified, the NCK must be powered up again. Only then will the input of dependent data be performed

correctly.

Reaction: Alarm display.

Remedy: Please inform the authorized personnel/service department.

If the alarm has been displayed after downloading an MD file which is consistent within itself, then the download operation must be repeated with a new NC power-up. (The file contains scaling-dependent machine data in front of the

scaling factors).

Program

Continuation:

Clear alarm with the Delete key or NC START.

NCK alarms

Alarms

Diagnostics Manual, 07/2010, 6FC5398-8BP40-0BA0

27

4071 Check the position of the encoder

Definitions: A machine data has been changed that affects the value of an absolute encoder position. Please check the postion

values.

For absolute encoders:

Encoder adjustment has been changed, the machine reference of the axis position may have changed, check the

encoder adjustment.

Other encoders:

The reference point of the axis position has been changed, check the referencing procedure.

Reaction: Alarm display.

Remedy: Please inform the authorized personnel/service department.

Program

Continuation:

Clear alarm with the Delete key or NC START.

4075 Machine data %1 (and maybe others) not changed due to missing permission level %2

Parameters: %1 = String: MD identifier

%2 = Write protection level of the MD

Definitions: On executing a TOA file or when writing machine data from the part program, an attempt has been made to write an

item of data with a higher protection level than the access authorization currently set in the control. The item of data

in question has not been written and program execution is continued. This alarm is set only when access violation is

detected for the first time.

Reaction: Alarm display.

Remedy: Please inform the authorized personnel/service department. Set the required access level by means of keyswitch or

password entry or delete the machine data concerned from the MD file/part program.

Program

Continuation:

Clear alarm with the Delete key or NC START.

4076 %1 Machine data could not be changed with permission level %2

Parameters: %1 = Number of MDs

%2 = Preset access authorization

Definitions: On executing a TOA file or when writing data from the part program an attempt has been made to write data with a

higher protection level than the access authorization currently set in the control. The data in question have not been

written and program execution is continued without hindrance. This alarm is issued on acknowledging alarm 4075. It

can be cleared only with Power ON.

Reaction: NC Start disable in this channel.

Alarm display.

Remedy: Please inform the authorized personnel/service department. Set the required access level by means of keyswitch or

password entry or delete the machine data concerned from the MD file/part program.

Program

Continuation:

Switch control OFF - ON.

NCK alarms

Alarms

28 Diagnostics Manual, 07/2010, 6FC5398-8BP40-0BA0

4077 New value %1 of MD %2 not set. Requested %3 bytes too much %4 memory.

Parameters: %1 = New value of machine data

%2 = Machine data number

%3 = Number of bytes requested that exceeded availability

%4 = Type of memory

Definitions: An attempt was made to enter a new value in the specified memory configuration machine data. It was not possible

to modify the value, as this would have cleared the contents of the user memory. This was because the memory

requested exceeded the available capacity.

The third parameter specifies the number of bytes by which the maximum user memory was exceeded.

The fourth parameter specifies the type of memory whose limit was exceeded.

- "D" stands for dynamic or non-buffered user memory (this is where, for example, the LUD variables are stored and

the interpolation buffer size is entered). The capacity of this memory type is defined by the current memory configuration and the value in MD18210 $MN_MM_USER_MEM_DYNAMIC.

- "S" stands for static or buffered user memory (this is where part programs, offset data, R parameters, tool data, etc.

are stored). This memory type is defined by the current memory configuration and the value in MD18230

$MN_MM_USER_MEM_BUFFERED.

- "iS" stands for internal static or buffered user memory. This memory type is defined by the current memory configuration (not settable). A few NCK functions use this memory.

Reaction: Alarm display.

Remedy: If the modification was unintentional, ignore the error message and continue. The alarm has no negative effects. The

remedy depends on the access right and the current memory configuration of the NCK:

- The intended change is not possible -> Try again with a smaller value. Observe the change in the number of bytes.

- Is it possible to expand the memory? This option depends on the model in use. (Not possible if parameter 4 equals

"iS").

- The NCK user memory may have been set smaller than it could be. With the appropriate access authorization, the

machine data (see above) can be changed.

- If parameter 4 equals "iS" and no synchronous actions are used, then MD18232

$MN_MM_ACTFILESYS_LOG_FILE_MEM[2] = 0 can be set. Otherwise the desired machine data change cannot be

made.

Program

Continuation:

Clear alarm with the Delete key or NC START.

4080 Incorrect configuration of indexing axis in MD %1

Parameters: %1 = String: MD identifier

Definitions: The assignment of a position table to an indexing axis or the contents of a position table contains an error, or the length

of a position table has been parameterized with 0.

Reaction: NC not ready.

Mode group not ready, also effective for single axes.

NC Start disable in this channel.

Interface signals are set.

Alarm display.

NC Stop on alarm.

Remedy: Please inform the authorized personnel/service department. 3 MD identifiers are output, depending on the type of

error.

1. MD30500 $MA_INDEX_AX_ASSIGN_POS_TAB: the error is due to multiple assignment of a position table

MD10910 $MN_INDEX_AX_POS_TAB_1 or MD10930 $MN_INDEX_AX_POS_TAB_2) to axes with different types

(linear/rotary axis).

2. MD10910 $MN_INDEX_AX_POS_TAB_1 or MD10930 $MN_INDEX_AX_POS_TAB_2: the contents of the displayed tables are incorrect.

- The entered positions must be arranged in increasing size.

- A particular position must not be set more than once.

- If the table is assigned to one or several modulo axes, then the contents must be within the 0 to < 360 degree range.

3. MD10900 $MN_INDEX_AX_LENGTH_POS_TAB_1 or MD10920 $MN_INDEX_AX_LENGTH_POS_TAB_2: the

length of the displayed position table n was specified with 0.

Program

Continuation:

Clear alarm with the RESET key. Restart part program

NCK alarms

Alarms

Diagnostics Manual, 07/2010, 6FC5398-8BP40-0BA0

29

4090 Too many errors during power-up

Definitions: More than <n> errors occurred during control power-up.

Reaction: NC Start disable in this channel.

Alarm display.

Remedy: Set the machine data correctly.

Program

Continuation:

Switch control OFF - ON.

4100 System cycle time/scan time divider corrected for digital drive

Definitions: MD10050 $MN_SYSCLOCK_CYCLE_TIME (system clock cycle) and/or MD10080

$MN_SYSCLOCK_SAMPL_TIME_RATIO (division factor of the position control cycle for actual value acquisition)

have been corrected.

The new value of the system clock cycle can be taken from MD10050 $MN_SYSCLOCK_CYCLE_TIME.

For PROFIdrive:

The sampling cycle to which the digital drive is synchronized (drive clock cycle) is largely determined by the cycle specifications of the STEP 7 project (above all the PROFIBUS and PROFINET cycle grids).

An additional, independent cycle division factor is not required for the actual value acquisition (that means MD10080

$MN_SYSCLOCK_SAMPL_TIME_RATIO = 1 usually applies).

Reaction: Alarm display.

Remedy: No remedial measures are required. The alarm display can be canceled with Reset.

Program

Continuation:

Clear alarm with the Delete key or NC START.

4110 IPO cycle changed to %1 ms

Parameters: %1 = String (new IPO cycle time)

Definitions: The IPO cycle divisor was set to a value which was not an integral multiple of the position control cycle divisor. The

divisor (MD10070 $MN_IPO_SYSCLOCK_TIME_RATIO) was increased.

For PROFIBUS/PROFINET: MD10070 $MN_IPO_SYSCLOCK_TIME_RATIO has been modified because of the

modified DP cycle in the SDB (MD10050 $MN_SYSCLOCK_CYCLE_TIME).

Reaction: Alarm display.

Remedy: MD10070 $MN_IPO_SYSCLOCK_TIME_RATIO has been modified.

Program

Continuation:

Clear alarm with the RESET key. Restart part program

4111 PLC cycle increased to %1 ms

Parameters: %1 = String (new PLC cycle time)

Definitions: The PLC cycle divisor was set to a value which was not an integral multiple of the IPO cycle divisor. The divisor

(MD10074 $PLC_IPO_TIME_RATIO) has been increased.

For PROFIBUS/PROFINET: MD10074 $PLC_IPO_TIME_RATIO has been modified because of the modified DP

cycle in the SDB (MD10050 $SYSCLOCK_CYCLE_TIME).

Reaction: Alarm display.

Remedy: MD10074 $MN_PLC_IPO_TIME_RATIO has been modified.

Program

Continuation:

Clear alarm with the RESET key. Restart part program

NCK alarms

Alarms

30 Diagnostics Manual, 07/2010, 6FC5398-8BP40-0BA0

4112 Servo cycle changed to %1 ms

Parameters: %1 = String (new servo cycle time)

Definitions: For PROFIBUS/PROFINET only:

MD10060 $POSCTRL_SYSCLOCK_TIME_RATIO has been modified because of the modified DP cycle in the SDB

(MD10050 $SYSCLOCK_CYCLE_TIME).

Reaction: Alarm display.

Remedy: MD10060 $MN_POSCTRL_SYSCLOCK_TIME_RATIO RATIO has been modified.

Program

Continuation:

Clear alarm with the RESET key. Restart part program

4113 Sysclock cycle changed to %1 ms

Parameters: %1 = String (new PLC cycle time)

Definitions: For PROFIBUS/PROFINET only:

MD10050 $SYSCLOCK_CYCLE_TIME has been modified because of the modified DP cycle in the SDB.

Reaction: Alarm display.

Remedy: MD10050 $MN_SYSCLOCK_CYCLE_TIME has been modified.

Program

Continuation:

Clear alarm with the RESET key. Restart part program

4114 Error in DP cycle of the SDB

Parameters: %1 = String (new PLC cycle time)

Definitions: For PROFIBUS/PROFINET only:

The DP cycle in the SDB contains an error and cannot be set. The default value of

MD10050$MN_SYSCLOCK_CYCLE_TIME is set.

Reaction: Alarm display.

Remedy: Correct the SDB

Program

Continuation:

Switch control OFF - ON.

4115 Time ratio communication to Ipo changed to %1

Parameters: %1 = String (new PLC cycle time)

Definitions: The value of the MD10072 $MN_COM_IPO_TIME_RATIO has been adapted. This can only occur, if the value of the

machine data is smaller than one and the time thus calculated is no multiple of the position control cycle.

Reaction: Alarm display.

Remedy: The MD10072 $MN_COM_IPO_TIME_RATIO has been adapted. Please check to ensure that the calculated value is

correct.

Program

Continuation:

Clear alarm with the RESET key. Restart part program

Loading...

Loading...