Siemens SINAMICS Series, SINAMICS G130, SINAMICS S120 Cabinet Module, SINAMICS S150, SINAMICS G150 Function Manual

...

Safety Integrated

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SINAMICS

G130, G150, S120 Chassis, S120

Cabinet Modules, S150

Safety Integrated

Function Manual

Firmware version 4.8

07/2016

A5E03264275A

Preface

Safety information

1

Introduction

2

General information about

SINAMICS Safety Integrated

3

Description of Safety

Integrated functions

4

Controlling the safety

functions

5

Commissioning and

acceptance test

6

Siemens AG

Division Process Industries and Drives

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E03264275A

Ⓟ

08/2016 Subject to change

Copyright © Siemens AG 2005 - 2016.

All rights reserved

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by

personnel qualified

for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Safety Integrated

Function Manual, 07/2016, A5E03264275A

5

Preface

Target group

This documentation is intended for machine manufacturers, commissioning engineers, and

service personnel who use the SINAMICS drive system.

Standard version

The scope of the functionality described in this document can differ from that of the actually

supplied drive system.

● Other functions not described in this documentation might be able to be executed in the

drive system. This does not, however, represent an obligation to supply such functions

with a new controller or when servicing.

● The documentation can also contain descriptions of functions that are not available in a

particular product version of the drive system. The functionalities of the supplied drive

system should only be taken from the ordering documentation.

● Extensions or changes made by the machine manufacturer must be documented by the

machine manufacturer.

For reasons of clarity, this documentation does not contain all of the detailed information on

all of the product types. This documentation cannot take into consideration every

conceivable type of installation, operation and service/maintenance.

Technical Support

In case of questions, please contact us through the following hotline:

Time zone Europe / Africa

Phone

+49 911 895 7222

Fax

+49 911 895 7223

Internet

https://support.industry.siemens.com/sc/ww/en/sc/2090

Time zone Americas

Phone

+1 423 262 2522

Fax

+1 423 262 2200

E-mail

techsupport.sea@siemens.com

Time zone Asia/Pacific

Phone

+86 1064 757 575

Fax

+86 1064 747 474

E-mail

support.asia.automation@siemens.com

Preface

Safety Integrated

6 Function Manual, 07/2016, A5E03264275A

Note

Country

-specific telephone numbers for technical support are provided under the following

Internet address:

https://www.automation.siemens.com/aspa_app

Spare parts

You can find spare parts on the Internet at:

https://support.industry.siemens.com/sc/de/en/sc/2110

Internet address for SINAMICS

http://www.siemens.com/sinamics.

Internet address for Safety Integrated

http://www.siemens.com/safety

This address contains detailed application examples for Safety Integrated.

Safety Integrated

Function Manual, 07/2016, A5E03264275A

7

Table of contents

Preface ................................................................................................................................................... 5

1 Safety information ................................................................................................................................... 9

1.1 Industrial security .................................................................................................................... 10

2 Introduction ........................................................................................................................................... 13

3 General information about SINAMICS Safety Integrated ........................................................................ 15

3.1 Supported functions ................................................................................................................ 15

3.1.1 SINAMICS G130 ..................................................................................................................... 18

3.1.1.1 Basic functions ........................................................................................................................ 18

3.1.1.2 Extended Functions ................................................................................................................ 18

3.1.2 SINAMICS G150 ..................................................................................................................... 20

3.1.2.1 Basic functions ........................................................................................................................ 20

3.1.2.2 Extended Functions ................................................................................................................ 20

3.1.3 SINAMICS S120 chassis ........................................................................................................ 22

3.1.3.1 Basic functions ........................................................................................................................ 22

3.1.3.2 Extended Functions ................................................................................................................ 22

3.1.4 SINAMICS S120 Cabinet Modules, booksize format ............................................................. 24

3.1.4.1 Basic functions ........................................................................................................................ 24

3.1.4.2 Extended Functions ................................................................................................................ 24

3.1.5 SINAMICS S120 Cabinet Modules, chassis format ................................................................ 26

3.1.5.1 Basic functions ........................................................................................................................ 26

3.1.5.2 Extended Functions ................................................................................................................ 26

3.1.6 SINAMICS S150 ..................................................................................................................... 28

3.1.6.1 Basic functions ........................................................................................................................ 28

3.1.6.2 Extended Functions ................................................................................................................ 28

3.2 Drive monitoring with or without encoder................................................................................ 29

4 Description of Safety Integrated functions ............................................................................................. 31

4.1 Preconditions for Safety Integrated Basic Functions .............................................................. 31

4.2 Preconditions for Safety Integrated Extended Functions ....................................................... 32

5 Controlling the safety functions.............................................................................................................. 33

5.1 Control possibilities ................................................................................................................. 33

5.2 Control of "STO" and "SS1" via terminal module for option K82 ............................................ 34

5.2.1 Terminal module for control of "STO" and "SS1" for SINAMICS G150 .................................. 34

5.2.2 Terminal module for control of "STO" and "SS1" for SINAMICS S120 Cabinet Modules ...... 39

5.2.2.1 General information ................................................................................................................ 39

5.2.2.2 Use of the K82 option with Control Unit CU320-2 .................................................................. 43

5.2.2.3 Use of the K82 option with Control Unit CU320-2 .................................................................. 44

5.2.2.4 Wiring ...................................................................................................................................... 44

5.2.3 Terminal module for control of "STO" and "SS1" for SINAMICS S150 .................................. 44

5.3 Control of "STO" and "SS1" via terminals on the Control Unit and the Motor/Power

Module .................................................................................................................................... 50

Table of contents

Safety Integrated

8 Function Manual, 07/2016, A5E03264275A

5.3.1 Simultaneity and tolerance time of the two monitoring channels ........................................... 53

5.3.2 Bit pattern test ........................................................................................................................ 55

5.3.3 Control of "STO" and "SS1" for SINAMICS G130 ................................................................. 56

5.3.4 Control of "STO" and "SS1" for SINAMICS G150 ................................................................. 62

5.3.5 Control of "STO" and "SS1" for SINAMICS S120 Chassis .................................................... 68

5.3.6 Control of "STO" and "SS1" for SINAMICS S120 Cabinet Modules ...................................... 74

5.3.7 Control of "STO" and "SS1" for SINAMICS S150 .................................................................. 80

5.4 Activating "SBC" via the Safe Brake Adapter ........................................................................ 86

5.4.1 Activating "SBC" via the Safe Brake Adapter for option K88 (230 V AC) .............................. 86

5.4.2 Safe Brake Adapter SBA 230 V AC for SINAMICS G130/SINAMICS S120 Chassis ........... 90

5.5 Control by way of PROFIsafe ................................................................................................ 95

5.6 Control via TM54F.................................................................................................................. 96

5.6.1 Control via TM54F for SINAMICS G130, S120 Chassis ....................................................... 96

5.6.2 Control via option K87 for SINAMICS S120 Cabinet Modules .............................................. 96

5.6.3 Control via K87 for SINAMICS S150 ..................................................................................... 96

5.7 Motion monitoring without selection ....................................................................................... 97

6 Commissioning and acceptance test ..................................................................................................... 99

Index ................................................................................................................................................... 101

Safety Integrated

Function Manual, 07/2016, A5E03264275A

9

1

Safety notices

WARNING

Risk of death if the safety instructions and remaining risks are not carefully observed

If the safety instructions and residual risks are not observed in the associated

documentation, accidents involving severe injuries or death can occur.

• Observe the safety instructions given in the associated documentation.

• When assessing the risk, take into account residual risks.

WARNING

Danger to life or malfunctions of the machine as a result of incorrect or changed parameter

assignment

Machines can malfunction as a result of incorrect or changed parameter assignment, which

in turn can lead to injuries or death.

• Protect the parameterization (parameter assignments) against unauthorized access.

• Respond to possible malfunctions by applying suitable measures (e.g. EMERGENCY

STOP or EMERGENCY OFF).

Safety information

1.1 Industrial security

Safety Integrated

10 Function Manual, 07/2016, A5E03264275A

1.1

Industrial security

Note

Industrial security

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, solutions, machines, devices, and/or networks. They are

important compon

ents in a holistic industrial security concept. With this in mind, Siemens

products and solutions undergo continuous development. Siemens recommends strongly

that you regularly check for product updates.

For the secure operation of Siemens products and sol

utions, it is necessary to take suitable

preventive action (e.g. cell protection concept) and integrate each component into a holistic,

state

-of-the-art industrial security concept. Any third-party products that may be in use must

also be taken into accoun

t. For more information about industrial security, visit Hotspot-Text

(

http://www.siemens.com/industrialsecurity).

To receive information about product updates on a regular basis, register for ou

r product

newsletter. For more information, visit Hotspot

-Text (https://support.industry.siemens.com).

WARNING

Danger due to unsafe operating states caused by software manipulation

Software manipulations (e.g. viruses, trojans, malware, worms) can cause unsafe operating

states in your system that may lead to death, serious injury, and property damage.

• Update your software regularly.

You will find relevant information and newsletters at this address

(http://www.siemens.com/industrialsecurity).

• Integrate the automation and drive components into a holistic, state-of-the-art industrial

security concept for the plant or machine.

You will find further information at this address (https://support.industry.siemens.com).

• Make sure that you include all installed products into the holistic industrial security

concept.

Note

Industrial Security Configuration Manual

You can

find a Configuration Manual on the topic of Industrial Security at this address

(

https://support.industry.siemens.com/cs/ww/en/view/108862708).

Safety information

1.1 Industrial security

Safety Integrated

Function Manual, 07/2016, A5E03264275A

11

Note

Malfunctions as a result of withdrawing and inserting components

Malfunctions can occur by withdrawing and inserting components that are used for Safety

Integrated without having to exit the fail

-safe state. For example, PROFIsafe communication

is not reestablished after this

event.

•

Withdrawing and inserting components used for Safety Integrated (power units, Sensor

Modules, TM54F) in operation

and

in the deactivated state is

not

permissible. Activating

the components always requires a POWER ON.

Note

Approval of option K82

Only circuits that have been manufactured by the OEM or by certified factories or that have

been installed by the authorized service for option K82, possess an approval. Possible plant

-

side reproductions by non

-certified manufacturers do not possess this approval!

An up

-to-date list of authorized factories is available on request from your local Siemens

office.

Safety information

1.1 Industrial security

Safety Integrated

12 Function Manual, 07/2016, A5E03264275A

Safety Integrated

Function Manual, 07/2016, A5E03264275A

13

2

This document is a supplement to the "SINAMICS S120 Safety Integrated Function Manual"

which serves as the basis for the functional scope of the Safety Integrated functions.

The "SINAMICS S120 Safety Integrated Function Manual" is available on the Internet at the

following address (https://support.industry.siemens.com/cs/ww/en/ps/13231/man).

This document contains additional information on the use of the Safety Integrated functions

with the following SINAMICS converters:

● SINAMICS G130

● SINAMICS G150

● SINAMICS S120 Chassis

● SINAMICS S120 Cabinet Modules

● SINAMICS S150

Introduction

Safety Integrated

14 Function Manual, 07/2016, A5E03264275A

Safety Integrated

Function Manual, 07/2016, A5E03264275A

15

Integrated

3

3.1

Supported functions

All of the Safety Integrated functions available under SINAMICS are listed in this section.

SINAMICS makes a distinction between Safety Integrated Basic Functions and Safety

Integrated Extended Functions.

The safety functions listed here are in conformance with:

● Safety Integrity Level (SIL) 2 according to IEC 61508

● Category 3 according to DIN EN ISO 13849-1

● Performance Level (PL) d according to DIN EN ISO 13849-1

The safety functions correspond to the functions according to DIN EN 61800-5-2 (under the

assumption that they are defined there).

The following Safety Integrated functions (SI functions) are available:

●

Safety Integrated Basic Functions

These functions are part of the standard scope of the drive and can be used without

requiring an additional license. These functions are always available, and do not require

an encoder and/or do not place any special requirements on the encoder used.

– Safe Torque Off (STO)

Safe Torque Off is a safety function to avoid unexpected startup in accordance with

EN 60204-1. STO prevents the supply of energy to the motor which can generate a

torque and corresponds to Stop Category 0.

– Safe Stop 1 (SS1, time-controlled)

Safe Stop 1 is based on the "Safe Torque Off" function. This means that a Category 1

stop according to EN 60204-1 can be implemented.

– Safe Brake Control (SBC)

Safe Brake Control safely controls a holding brake.

1)

General information about SINAMICS Safety Integrated

3.1 Supported functions

Safety Integrated

16 Function Manual, 07/2016, A5E03264275A

●

Safety Integrated Extended Functions

These functions require an additional safety license. Extended Functions with encoder

require an encoder with safety capability.

– Safe Torque Off (STO)

Safe Torque Off is a safety function that prevents the drive from restarting

unexpectedly according to EN- 60204-1.

– Safe Stop 1 (SS1, time- and acceleration-controlled)

Safe Stop 1 is based on the "Safe Torque Off" function. This means that a Category 1

stop according to EN 60204-1 can be implemented.

– Safe Brake Control (SBC)

Safe Brake Control safely controls a holding brake.

1)

– Safe Operating Stop (SOS)

Safe Operating Stop protects against unintentional movement. The drive is in closedloop control mode and is not disconnected from the power supply.

– Safe Stop 2 (SS2)

Safe Stop 2 safely brakes the motor with a subsequent transition into the "Safe

Operating Stop" state (SOS). This means that a Category 2 stop according to EN

60204-1 can be implemented.

– Safely-Limited Speed (SLS)

Safely Limited Speed monitors that the drive does not exceed a preset speed/velocity

limit.

– Safe Speed Monitor (SSM)

Safe Speed Monitor safely identifies when a speed limit is undershot in both directions

of motion, e.g. to identify zero speed. A fail-safe output signal is available for further

processing.

– Safe Direction (SDI)

Safe Direction is used to safely monitor the direction of motion.

– Safely-Limited Position (SLP)

Safely-Limited Position ensures that a freely definable traversing range is not left.

– Transferring safe position values (SP)

The "Transfer safe position values (SP)" function enables you to transfer a safe

position to a higher-level controller via PROFIsafe.

– Safe gearbox stage switchover

The "Safe gearbox stage switchover" function facilitates reliable switching between

different gearbox stages. The switchover is only possible via PROFIsafe.

– Safe Brake Test (SBT)

The diagnostic function "Safe Brake Test" function (SBT) checks the required holding

torque of a brake (operating or holding brake).

1)

Note on Power/Motor Modules with chassis format:

For chassis format, SBC is only supported by Power/Motor Modules with article number

...3 or higher. A Safe Brake Adapter is also required for this design.

General information about SINAMICS Safety Integrated

3.1 Supported functions

Safety Integrated

Function Manual, 07/2016, A5E03264275A

17

Note

Parallel use of Safety Integrated Functions

All Safety Integrated Functions can be used simultaneously.

Exce

ption:

If SOS and SLS are activated simultaneously, SOS has higher priority and overrides the SLS

reaction.

Invalid operating modes for Safety Integrated Extended Functions "without encoder"

● Current controller clock cycles 31.25 µs and 62.5 μs (for Double Motor Modules with two

configured safety drives) are not permissible.

● For the independent setting of current controller clock cycle and pulse frequency in

conjunction with Safety Integrated "without encoder", the following system clock cycles

are not permissible:

– Double Motor Modules <125 μs

– All other components: <62.5 μs

– p9589 must be set = 3300 to allow the current controller clock cycle and pulse

frequency to be independently set.

● For chassis format devices, the following also applies:

– For chassis format devices, operation without encoder is only permissible for induction

motors, however

not

for synchronous motors.

– No operation involving parallel connections

– Optimized pulse patterns cannot be selected for SIMOTICS FD

– Only using parameter p1810 = factory setting, this includes:

- No wobbling

- No fine setting of the pulse frequency

● No "shaft generator" functionality

● Induction motors up to a maximum of 1000 kW; for extremely large machines, it is

necessary to adapt parameter p9585

General information about SINAMICS Safety Integrated

3.1 Supported functions

Safety Integrated

18 Function Manual, 07/2016, A5E03264275A

3.1.1

SINAMICS G130

3.1.1.1

Basic functions

Requirements

The Safety Integrated Basic Functions are part of the standard scope of the drive and can be

used without an additional license.

Supported Safety Integrated Basic Functions

Safety function

Abbreviation

Safe Torque Off

STO

Yes

Safe Stop 1

SS1

Yes

Safe Brake Control

SBC

Using Safe Brake Adapter

Control options

● Control Unit and terminal (on the power unit)

● PROFIsafe and terminal (on the power unit)

3.1.1.2

Extended Functions

Requirements

● Option

F01

: Safety license for one axis

Note

The term "axes" should also be interpreted

as "drives".

● For Extended Functions with encoder:

Two SMC30 Sensor Modules (HTL/TTL encoders)

General information about SINAMICS Safety Integrated

3.1 Supported functions

Safety Integrated

Function Manual, 07/2016, A5E03264275A

19

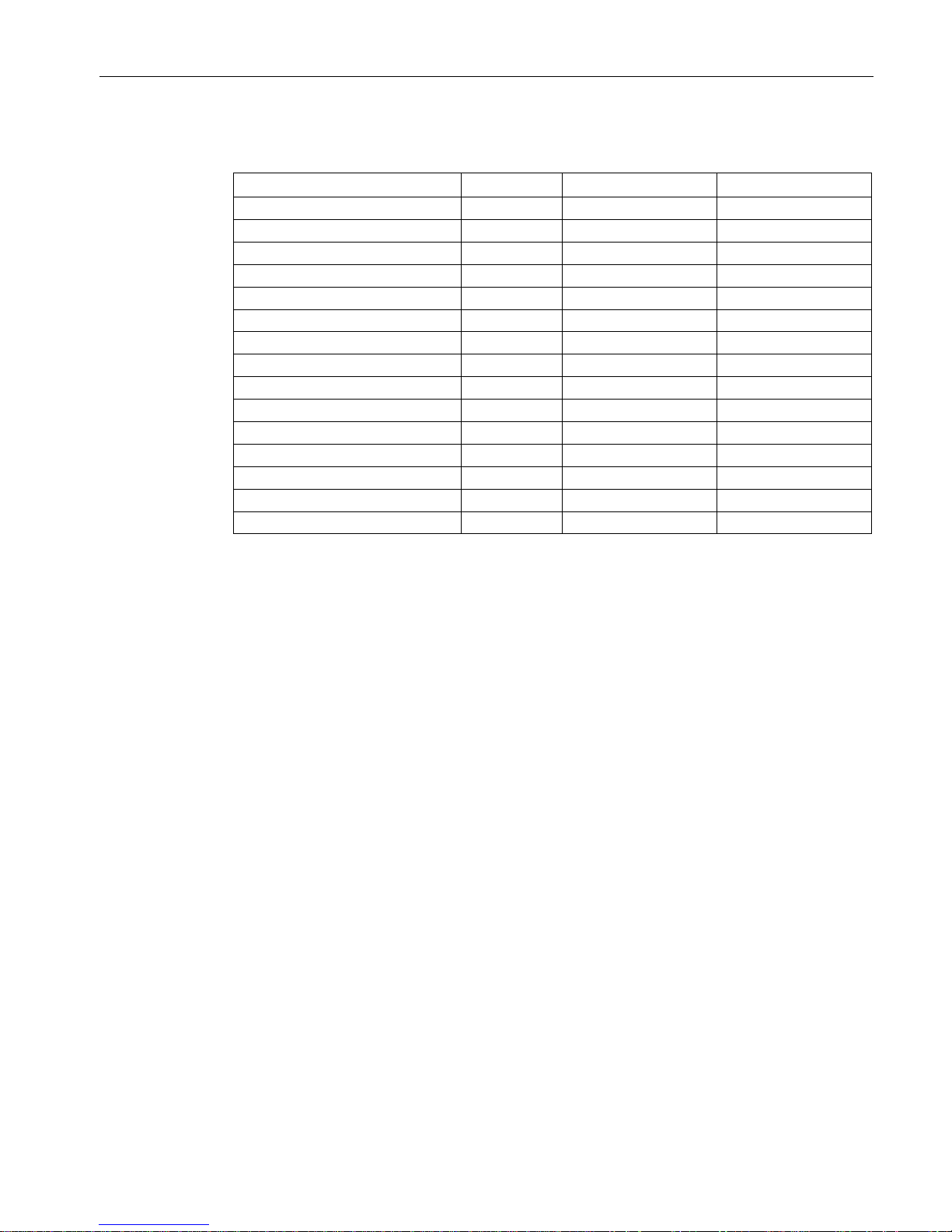

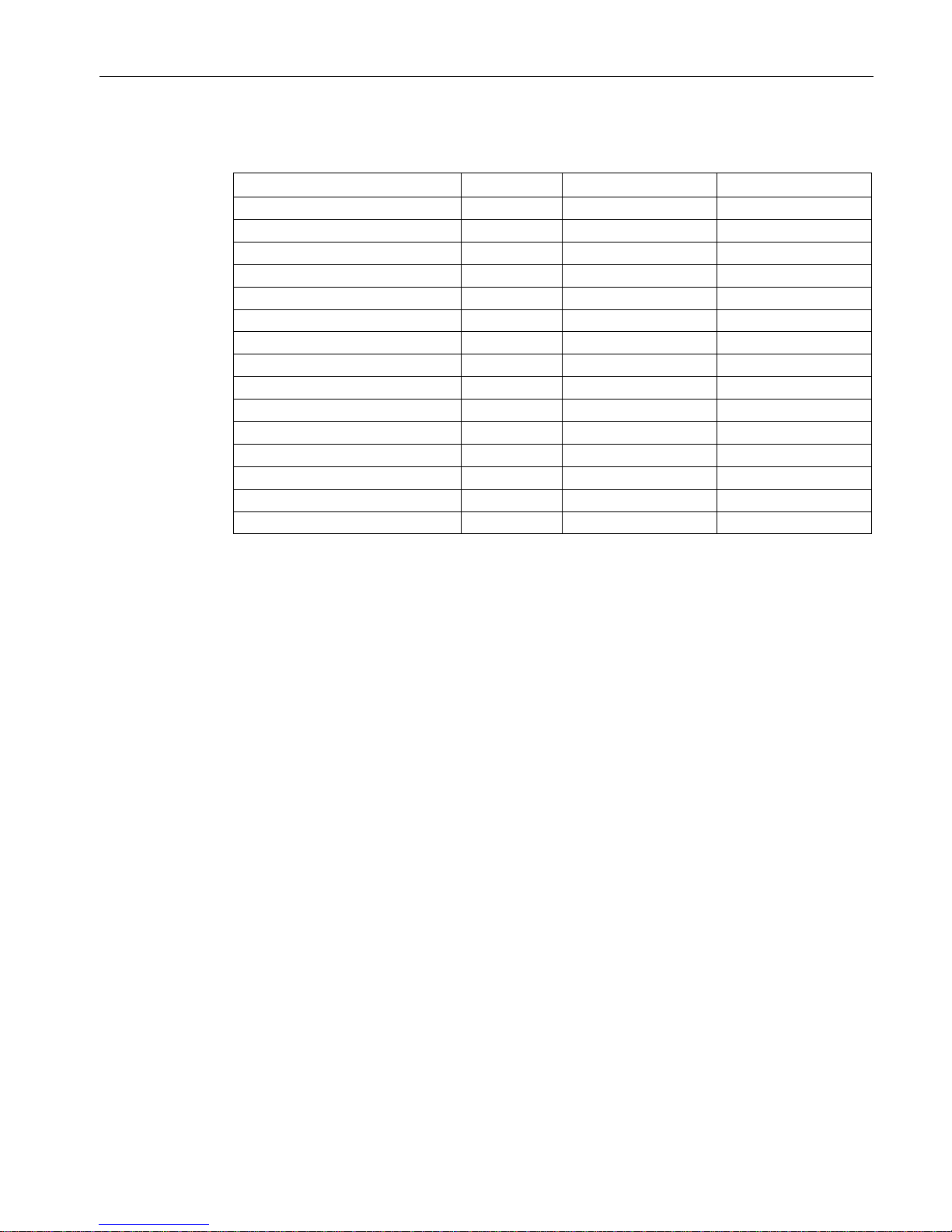

Supported Safety Integrated Extended Functions

Safety function

Abbreviation

With encoder 1)

Without encoder

Safe Torque Off

STO

Yes

Yes 2)

Safe Stop 1

SS1

Yes Yes2)

Safe Brake Control

SBC

Yes

Yes2)

Safe Operating Stop

SOS

Yes

No

Safe Stop 2

SS2

Yes

No

Safely-Limited Speed

SLS

Yes

Yes2)

Safe Speed Monitor

SSM

Yes

Yes2)

Safe Direction

SDI

Yes

Yes2)

Safely-Limited Position

SLP

Yes

No

Safe referencing/homing

SR

Yes

No

Transferring safe position values

SP

Yes

Yes2)

Safe Brake Test

SBT

Yes

No

Safe Acceleration Monitor

SAM

Yes

Yes2)

Safe Brake Ramp

SBR

No

Yes2)

Safe gearbox stage switchover

--

Yes

No

1)

Two SMC30 Sensor Modules (HTL/TTL encoders)

2)

The use of this safety function without an encoder is permitted only for induction motors.

3)

Using Safe Brake Adapter.

Control options

● Terminal Module TM54F

● PROFIsafe

General information about SINAMICS Safety Integrated

3.1 Supported functions

Safety Integrated

20 Function Manual, 07/2016, A5E03264275A

3.1.2

SINAMICS G150

3.1.2.1

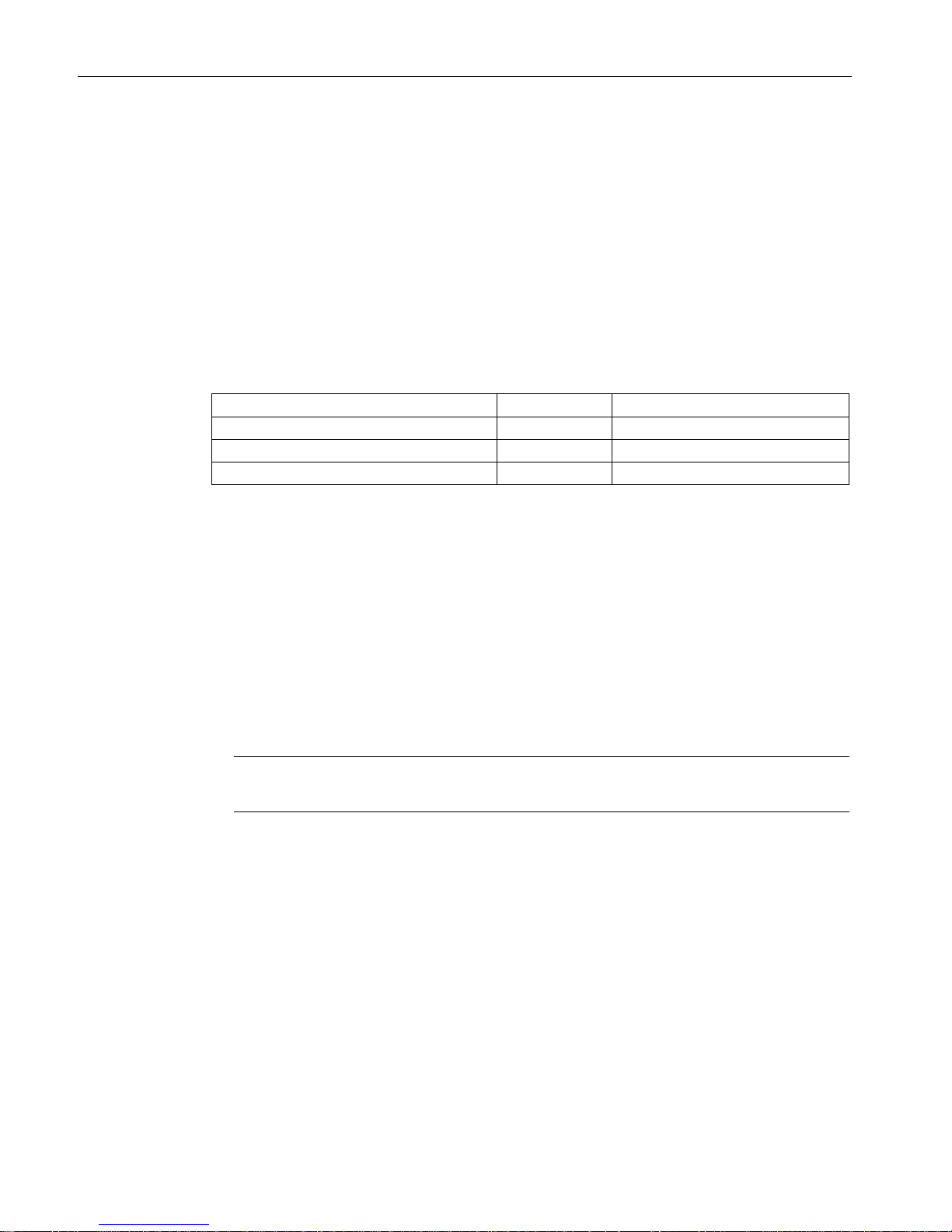

Basic functions

Requirements

The Safety Integrated Basic Functions are part of the standard scope of the drive and can be

used without an additional license.

Supported Safety Integrated Basic Functions

Safety function

Abbreviation

Safe Torque Off

STO

Yes

Safe Stop 1

SS1

Yes

Safe Brake Control

SBC

Via option K88

Control options

● With option

K82

: Terminal Module for controlling safety functions "STO" and "SS1"

● Control Unit and terminal (on the power unit)

● PROFIsafe and terminal (on the power unit)

3.1.2.2

Extended Functions

Requirements

● Option

K01

: Safety license for one axis

Note

The term "axes" should also be interpreted as "drives".

● For Extended Functions with encoder:

Options

K50 and K52

: Two SMC30 Sensor Modules (HTL/TTL encoders)

General information about SINAMICS Safety Integrated

3.1 Supported functions

Safety Integrated

Function Manual, 07/2016, A5E03264275A

21

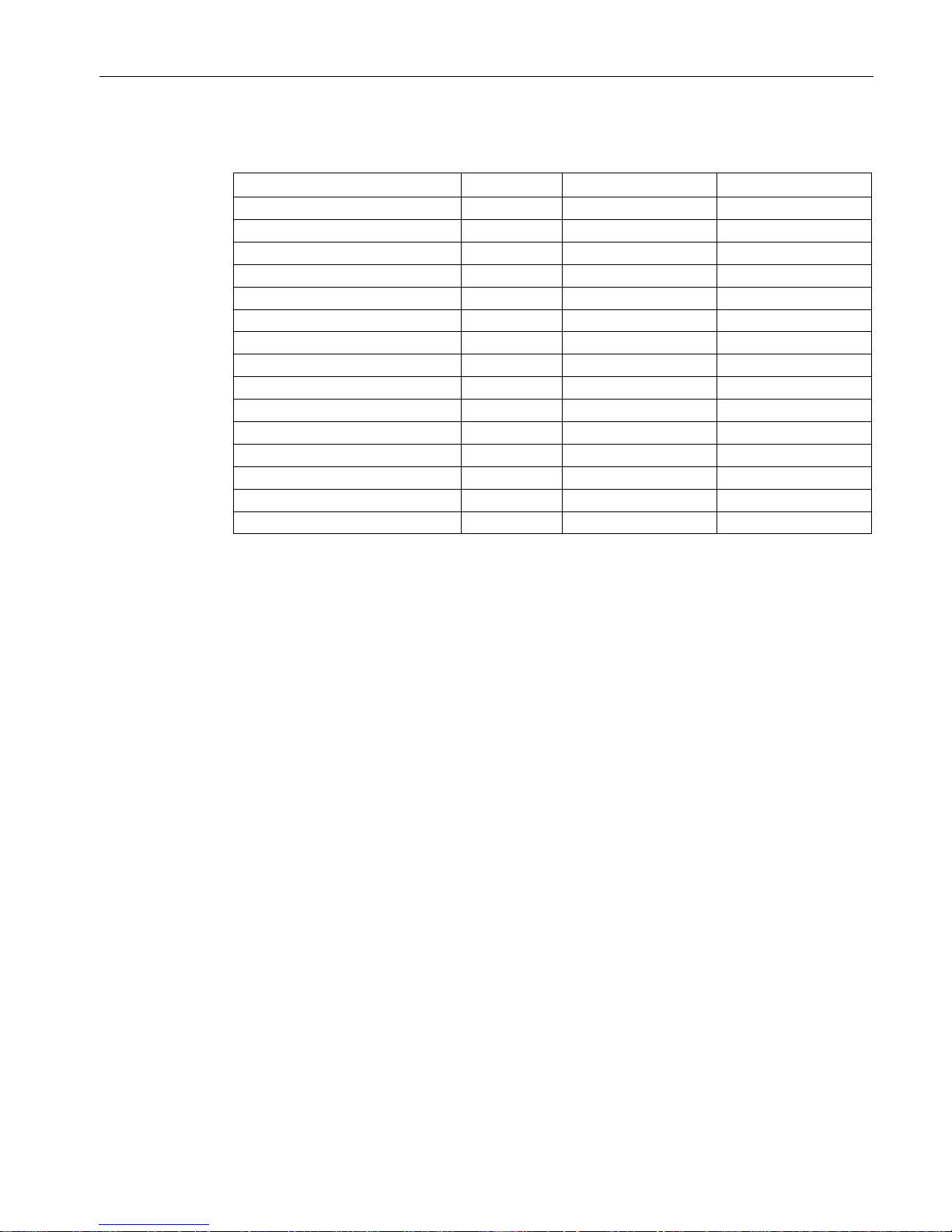

Supported Safety Integrated Extended Functions

Safety function

Abbreviation

With encoder 1)

Without encoder

Safe Torque Off

STO

Yes

Yes2)

Safe Stop 1

SS1

Yes Yes2)

Safe Brake Control

3)

SBC

Yes

Yes2)

Safe Operating Stop

SOS

Yes

No

Safe Stop 2

SS2

Yes

No

Safely-Limited Speed

SLS

Yes

Yes2)

Safe Speed Monitor

SSM

Yes

Yes2)

Safe Direction

SDI

Yes

Yes2)

Safely-Limited Position

SLP

Yes

No

Safe referencing/homing

SR

Yes

No

Transferring safe position values

SP

Yes

Yes2)

Safe Brake Test

SBT

Yes

No

Safe Acceleration Monitor

SAM

Yes

Yes2)

Safe Brake Ramp

SBR

No

Yes2)

Safe gearbox stage switchover

--

Yes

No

1)

Options

K50 and K52

: Two SMC30 Sensor Modules (HTL/TTL encoders)

2)

The use of this safety function without an encoder is permitted only for induction motors.

3)

Using Safe Brake Adapter (option K88).

Control options

● Option

K87

: Terminal Module TM54F

● PROFIsafe

General information about SINAMICS Safety Integrated

3.1 Supported functions

Safety Integrated

22 Function Manual, 07/2016, A5E03264275A

3.1.3

SINAMICS S120 chassis

3.1.3.1

Basic functions

Requirements

The Safety Integrated Basic Functions are part of the standard scope of the drive and can be

used without an additional license.

Supported Safety Integrated Basic Functions

Safety function

Abbreviation

Safe Torque Off

STO

Yes

Safe Stop 1

SS1

Yes

Safe Brake Control

SBC

Using Safe Brake Adapter

Control options

● Control Unit and terminal (on the power unit)

● PROFIsafe and terminal (on the power unit)

3.1.3.2

Extended Functions

Requirements

● Option

F01 to F05

: Safety license for one to five axes

Note

The term "axes" should also be interpreted as "drives".

● For Extended Functions with encoder:

– Sin/cos sensor evaluation (SMC20, SME20/25/120/125, SMI20 Sensor Modules) or

– Two SMC30 Sensor Modules (HTL/TTL encoders)

General information about SINAMICS Safety Integrated

3.1 Supported functions

Safety Integrated

Function Manual, 07/2016, A5E03264275A

23

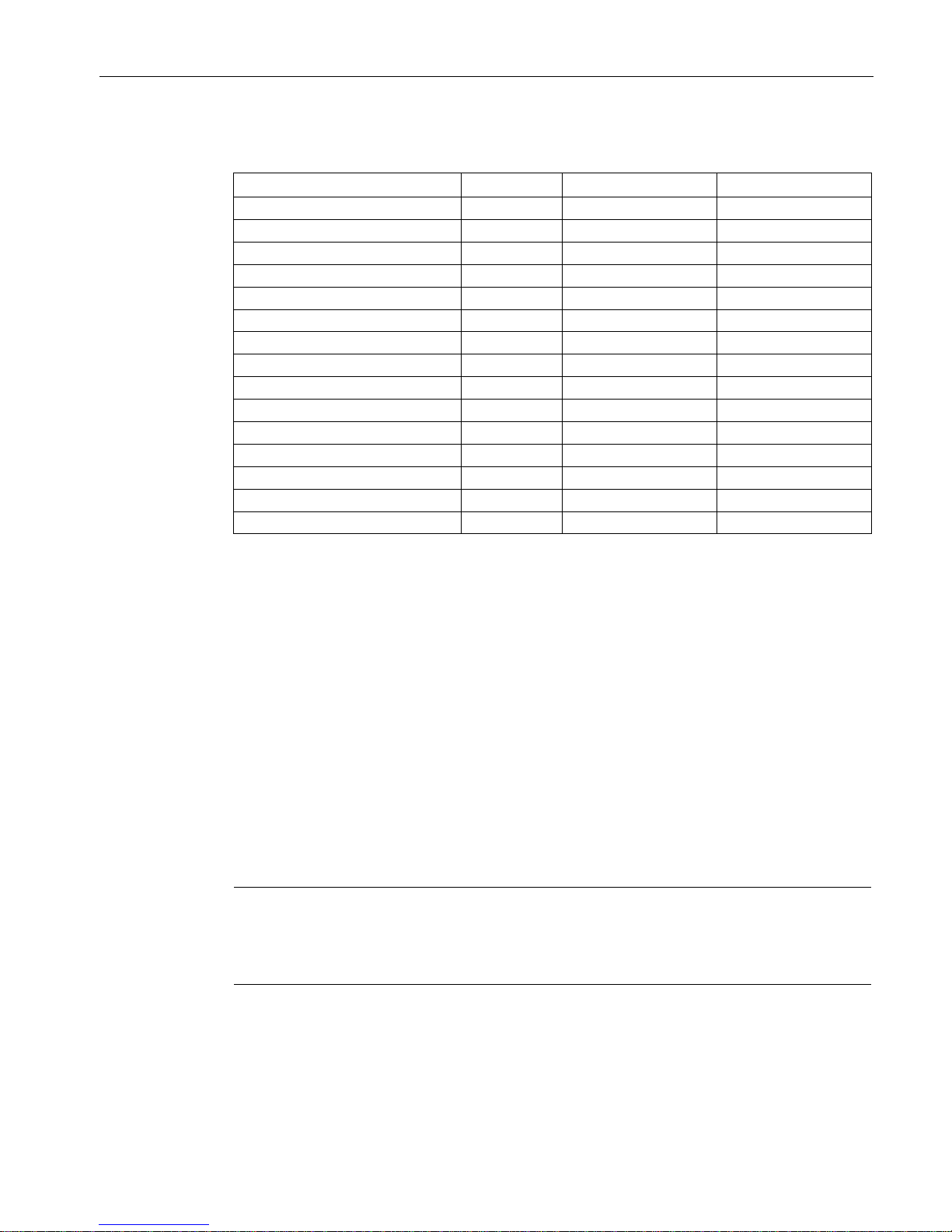

Supported Safety Integrated Extended Functions

Safety function

Abbreviation

With encoder 1)

Without encoder

Safe Torque Off

STO

Yes

Yes2)

Safe Stop 1

SS1

Yes Yes2)

Safe Brake Control

3)

SBC

Yes

Yes2)

Safe Operating Stop

SOS

Yes

No

Safe Stop 2

SS2

Yes

No

Safely-Limited Speed

SLS

Yes

Yes2)

Safe Speed Monitor

SSM

Yes

Yes2)

Safe Direction

SDI

Yes

Yes2)

Safely-Limited Position

SLP

Yes

No

Safe referencing/homing

SR

Yes

No

Transferring safe position values

SP

Yes

Yes2)

Safe Brake Test

SBT

Yes

No

Safe Acceleration Monitor

SAM

Yes

Yes2)

Safe Brake Ramp

SBR

No

Yes2)

Safe gearbox stage switchover

--

Yes

No

1)

Sin/cos sensor evaluation or 2 SMC30 Sensor Modules (HTL/TTL encoders)

2)

The use of this safety function without an encoder is permitted only for induction motors.

3)

Using Safe Brake Adapter.

Control options

● Terminal (TM54F)

● PROFIsafe

General information about SINAMICS Safety Integrated

3.1 Supported functions

Safety Integrated

24 Function Manual, 07/2016, A5E03264275A

3.1.4

SINAMICS S120 Cabinet Modules, booksize format

3.1.4.1

Basic functions

Requirements

The Safety Integrated Basic Functions are part of the standard scope of the drive and can be

used without an additional license.

Supported Safety Integrated Basic Functions

Safety function

Abbreviation

Safe Torque Off

STO

Yes

Safe Stop 1

SS1

Yes

Safe Brake Control

SBC

Using Safe Brake Adapter

Control options

● With option

K82

: Terminal Module for controlling safety functions "STO" and "SS1"

● Control Unit and terminal (on the power unit)

● PROFIsafe and terminal (on the power unit)

3.1.4.2

Extended Functions

Requirements

● Option

K01 to K05

: Safety license for one to five axes

Note

The term "axes" should also be interpreted as "drives".

● For Extended Functions with encoder

– Option

K48

: SMC20 Sensor Module (sin/cos encoder) or

– Options

K50 and K52

: Two SMC30 Sensor Modules (HTL/TTL encoders)

General information about SINAMICS Safety Integrated

3.1 Supported functions

Safety Integrated

Function Manual, 07/2016, A5E03264275A

25

Supported Safety Integrated Extended Functions

Safety function

Abbreviation

With encoder 1)

Without encoder

Safe Torque Off

STO

Yes

Yes2)

Safe Stop 1

SS1

Yes Yes2)

Safe Brake Control

SBC

Yes

Yes2)

Safe Operating Stop

SOS

Yes

No

Safe Stop 2

SS2

Yes

No

Safely-Limited Speed

SLS

Yes

Yes2)

Safe Speed Monitor

SSM

Yes

Yes2)

Safe Direction

SDI

Yes

Yes2)

Safely-Limited Position

SLP

Yes

No

Safe referencing/homing

SR

Yes

No

Transferring safe position values

SP

Yes

Yes2)

Safe Brake Test

SBT

Yes

No

Safe Acceleration Monitor

SAM

Yes

Yes2)

Safe Brake Ramp

SBR

No

Yes2)

Safe gearbox stage switchover

--

Yes

No

1)

Option

K48

: SMC20 Sensor Module (sin/cos encoder) or

options

K50 and K52

: Two SMC30 Sensor Modules (HTL/TTL encoders)

2)

The use of this safety function without encoder is permitted only for induction motors or synchro-

nous motors of the SIEMOSYN series.

Control options

● Option

K87

: Terminal Module TM54F

● PROFIsafe

General information about SINAMICS Safety Integrated

3.1 Supported functions

Safety Integrated

26 Function Manual, 07/2016, A5E03264275A

3.1.5

SINAMICS S120 Cabinet Modules, chassis format

3.1.5.1

Basic functions

Requirements

The Safety Integrated Basic Functions are part of the standard scope of the drive and can be

used without an additional license.

Supported Safety Integrated Basic Functions

Safety function

Abbreviation

Safe Torque Off

STO

Yes

Safe Stop 1

SS1

Yes

Safe Brake Control

SBC

Via option K88

Control options

● With option

K82

: Terminal Module for controlling safety functions "STO" and "SS1"

● Control Unit and terminal (on the power unit)

● PROFIsafe and terminal (on the power unit)

3.1.5.2

Extended Functions

Requirements

● Option

K01 to K05

: Safety license for one to five axes

Note

The term "axes" should also be interpreted as "drives".

● For Extended Functions with encoder:

– Option

K48

: SMC20 Sensor Module (sin/cos encoder) or

– Options

K50 and K52

: Two SMC30 Sensor Modules (HTL/TTL encoders)

General information about SINAMICS Safety Integrated

3.1 Supported functions

Safety Integrated

Function Manual, 07/2016, A5E03264275A

27

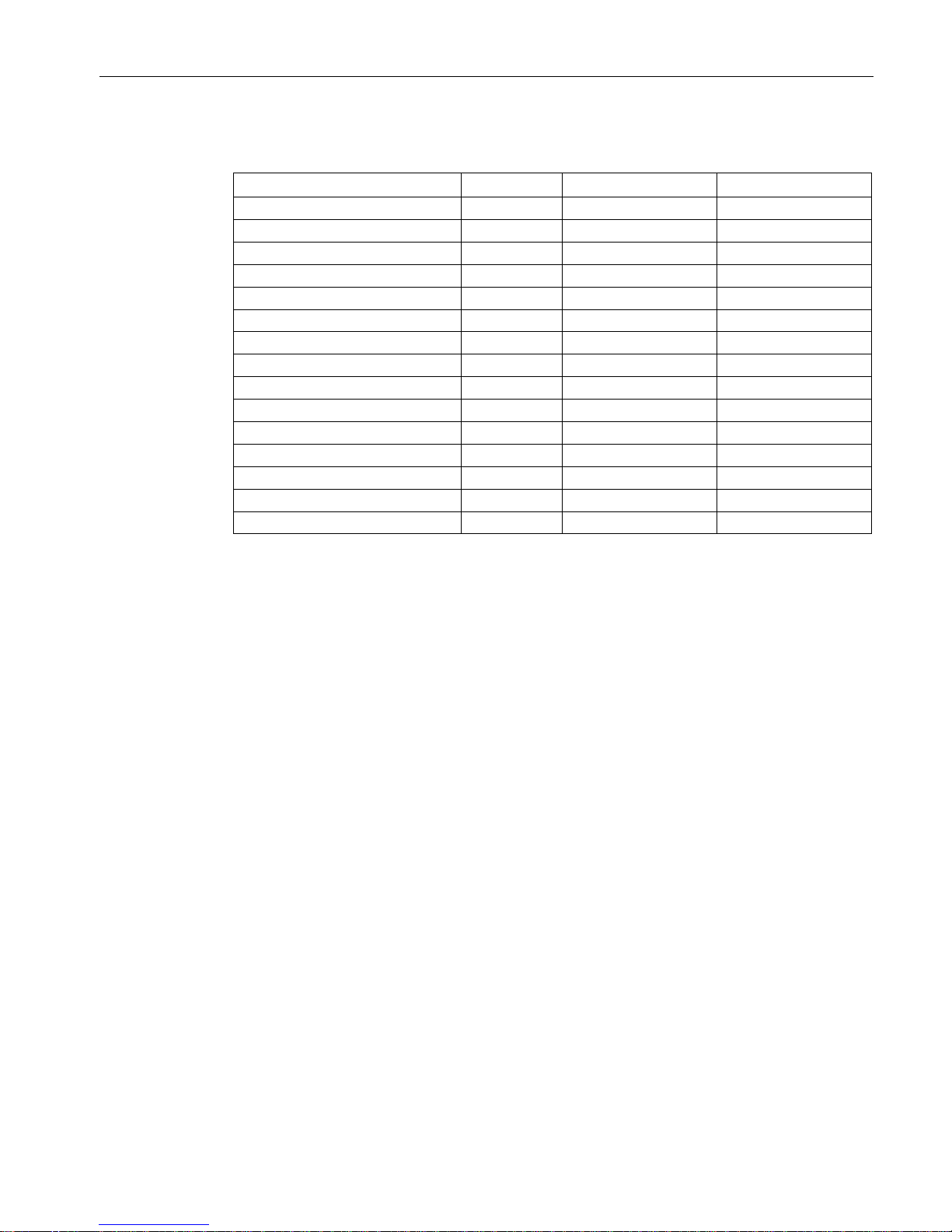

Supported Safety Integrated Extended Functions

Safety function

Abbreviation

With encoder 1)

Without encoder

Safe Torque Off

STO

Yes

Yes2)

Safe Stop 1

SS1

Yes Yes2)

Safe Brake Control

3)

SBC

Yes

Yes2)

Safe Operating Stop

SOS

Yes

No

Safe Stop 2

SS2

Yes

No

Safely-Limited Speed

SLS

Yes

Yes2)

Safe Speed Monitor

SSM

Yes

Yes2)

Safe Direction

SDI

Yes

Yes2)

Safely-Limited Position

SLP

Yes

No

Safe referencing/homing

SR

Yes

No

Transferring safe position values

SP

Yes

Yes2)

Safe Brake Test

SBT

Yes

No

Safe Acceleration Monitor

SAM

Yes

Yes2)

Safe Brake Ramp

SBR

No

Yes2)

Safe gearbox stage switchover

--

Yes

No

1)

Option

K48

: SMC20 Sensor Module (sin/cos encoder) or

options

K50 and K52

: Two SMC30 Sensor Modules (HTL/TTL encoders)

2)

The use of this safety function without an encoder is permitted only for induction motors.

3)

Using Safe Brake Adapter (option K88).

Control options

● Option

K87

: TM54F Terminal Module

● PROFIsafe

General information about SINAMICS Safety Integrated

3.1 Supported functions

Safety Integrated

28 Function Manual, 07/2016, A5E03264275A

3.1.6

SINAMICS S150

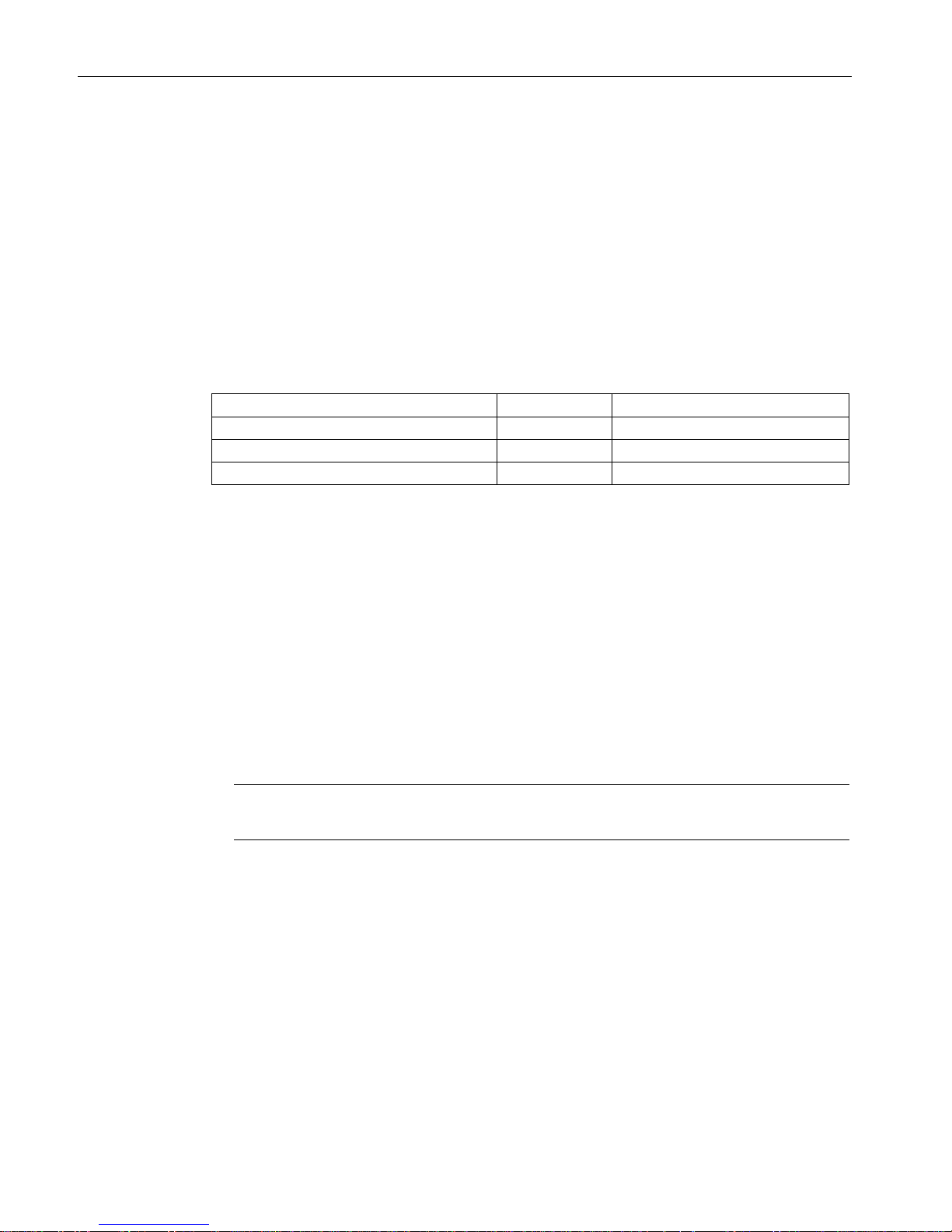

3.1.6.1

Basic functions

Requirements

The Safety Integrated Basic Functions are part of the standard scope of the drive and can be

used without an additional license.

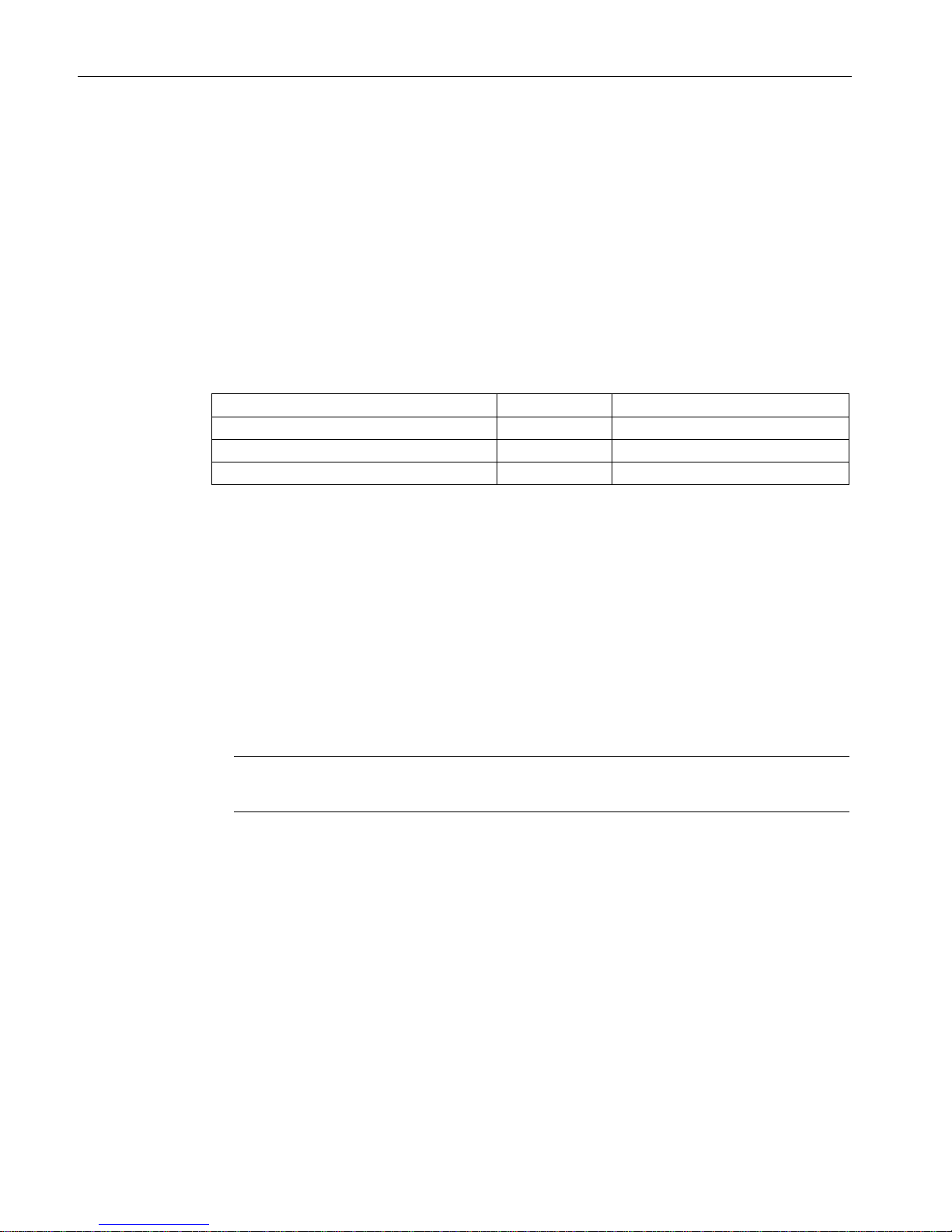

Supported Safety Integrated Basic Functions

Safety function

Abbreviation

Safe Torque Off

STO

Yes

Safe Stop 1

SS1

Yes

Safe Brake Control

SBC

Via option K88

Control options

● With option

K82

: Terminal Module for controlling safety functions "STO" and "SS1"

● Control Unit and terminal (on the power unit)

● PROFIsafe and terminal (on the power unit)

3.1.6.2

Extended Functions

Requirements

● Option

K01

: Safety license for one axis

Note

The term "axes" sh

ould also be interpreted as "drives".

● For Extended Functions with encoder:

– Option

K48

: SMC20 Sensor Module (sin/cos encoder) or

– Options

K50 and K52

: Two SMC30 Sensor Modules (HTL/TTL encoders)

General information about SINAMICS Safety Integrated

3.2 Drive monitoring with or without encoder

Safety Integrated

Function Manual, 07/2016, A5E03264275A

29

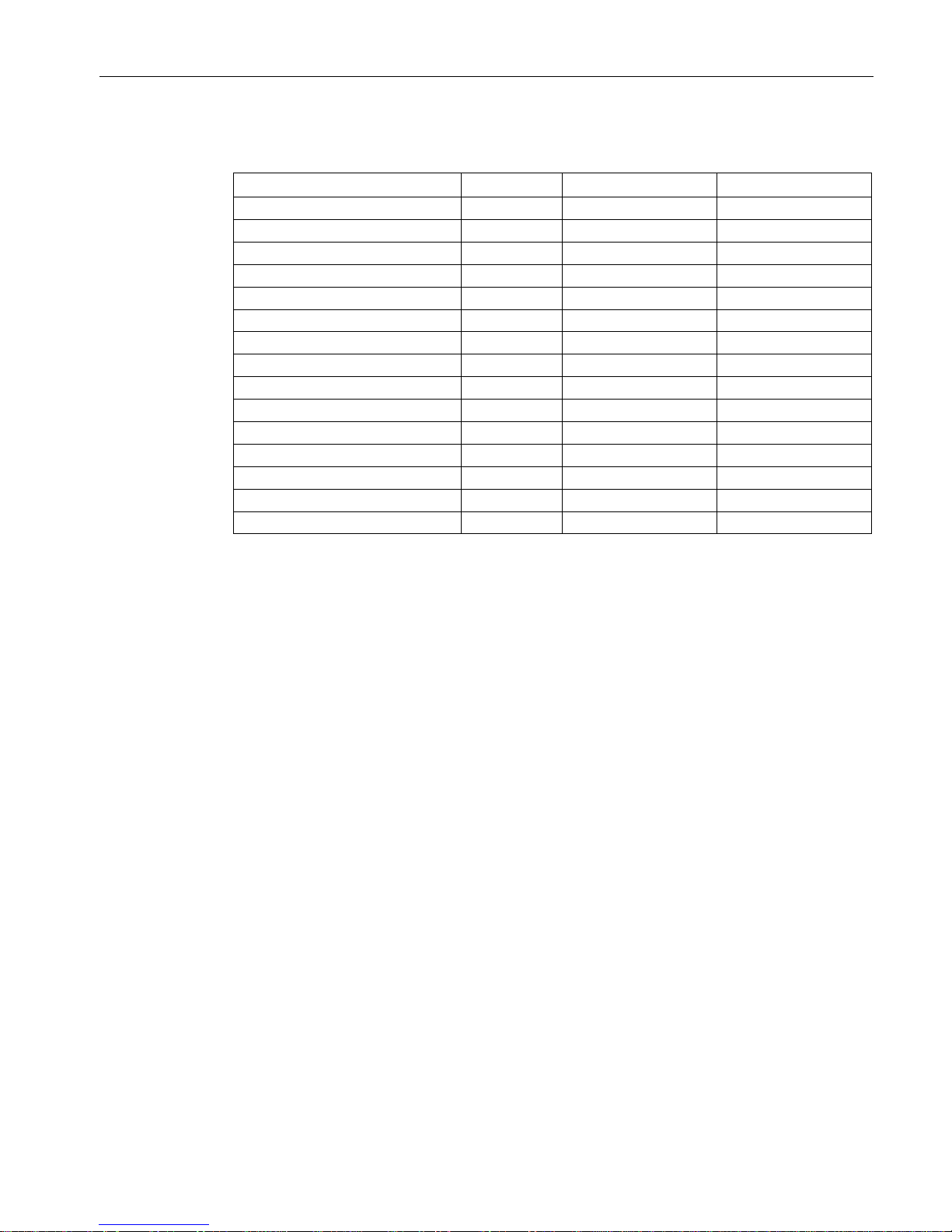

Supported Safety Integrated Extended Functions

Safety function

Abbreviation

With encoder 1)

Without encoder

Safe Torque Off

STO

Yes

Yes2)

Safe Stop 1

SS1

Yes Yes2)

Safe Brake Control

3)

SBC

Yes

Yes2)

Safe Operating Stop

SOS

Yes

No

Safe Stop 2

SS2

Yes

No

Safely-Limited Speed

SLS

Yes

Yes2)

Safe Speed Monitor

SSM

Yes

Yes2)

Safe Direction

SDI

Yes

Yes2)

Safely-Limited Position

SLP

Yes

No

Safe referencing/homing

SR

Yes

No

Transferring safe position values

SP

Yes

Yes2)

Safe Brake Test

SBT

Yes

No

Safe Acceleration Monitor

SAM

Yes

Yes2)

Safe Brake Ramp

SBR

No

Yes2)

Safe gearbox stage switchover

--

Yes

No

1)

Option

K48

: SMC20 Sensor Module (sin/cos encoder) or

options

K50 and K52

: Two SMC30 Sensor Modules (HTL/TTL encoders)

2)

The use of this safety function without an encoder is permitted only for induction motors.

3)

Using Safe Brake Adapter (option K88).

Control options

● Option

K87

: TM54F Terminal Module

● PROFIsafe

3.2

Drive monitoring with or without encoder

If motors without a (safety-capable) encoder are being used, not all Safety Integrated

functions are available.

Note

Definition: "Without encoder"

When "without encoder" is used in this manual, then this always means that either no

encoder or no safety

-capable encoder is being used.

General information about SINAMICS Safety Integrated

3.2 Drive monitoring with or without encoder

Safety Integrated

30 Function Manual, 07/2016, A5E03264275A

In operation without encoder, the actual speed values are calculated from the measured

electrical actual values. Therefore, speed monitoring is also possible during operation

without encoder.

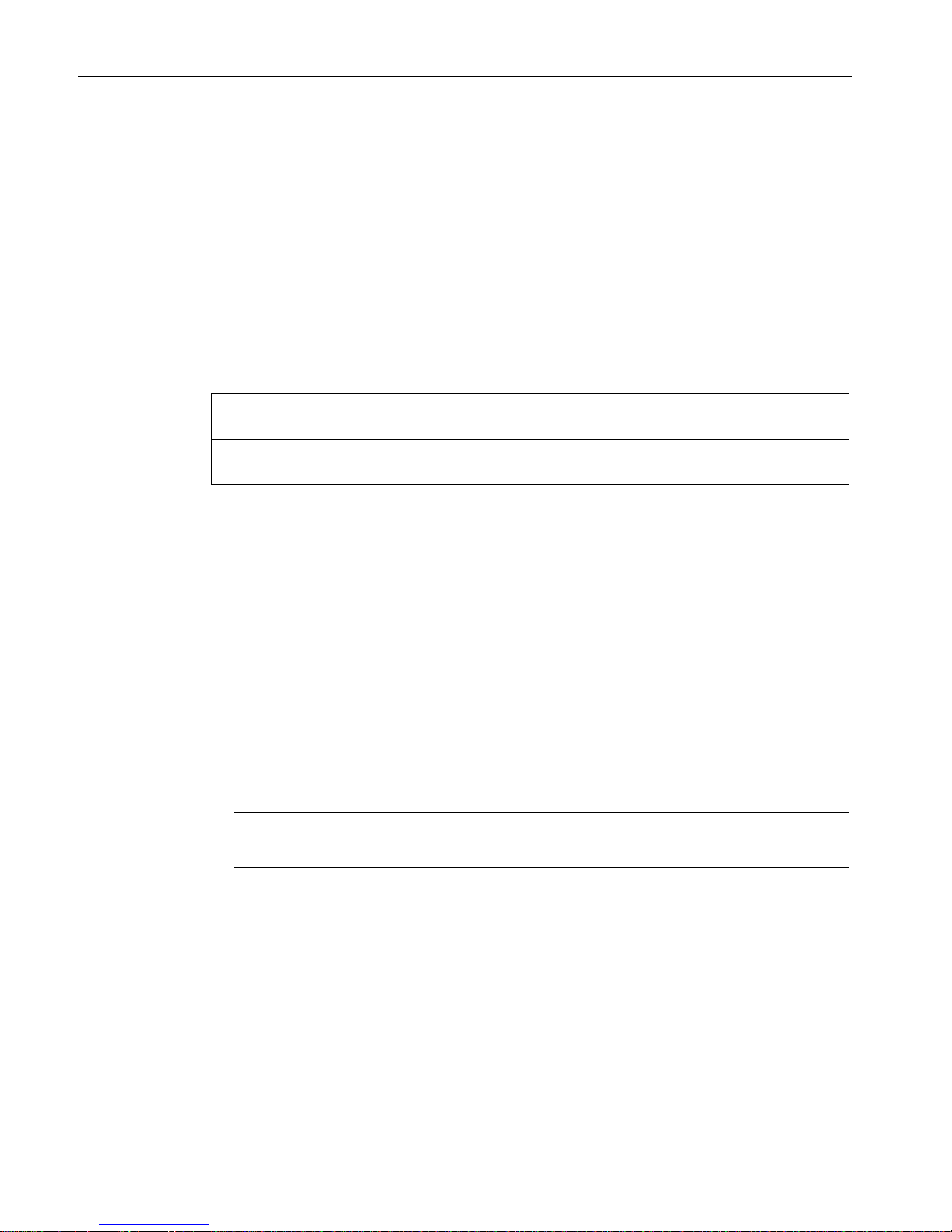

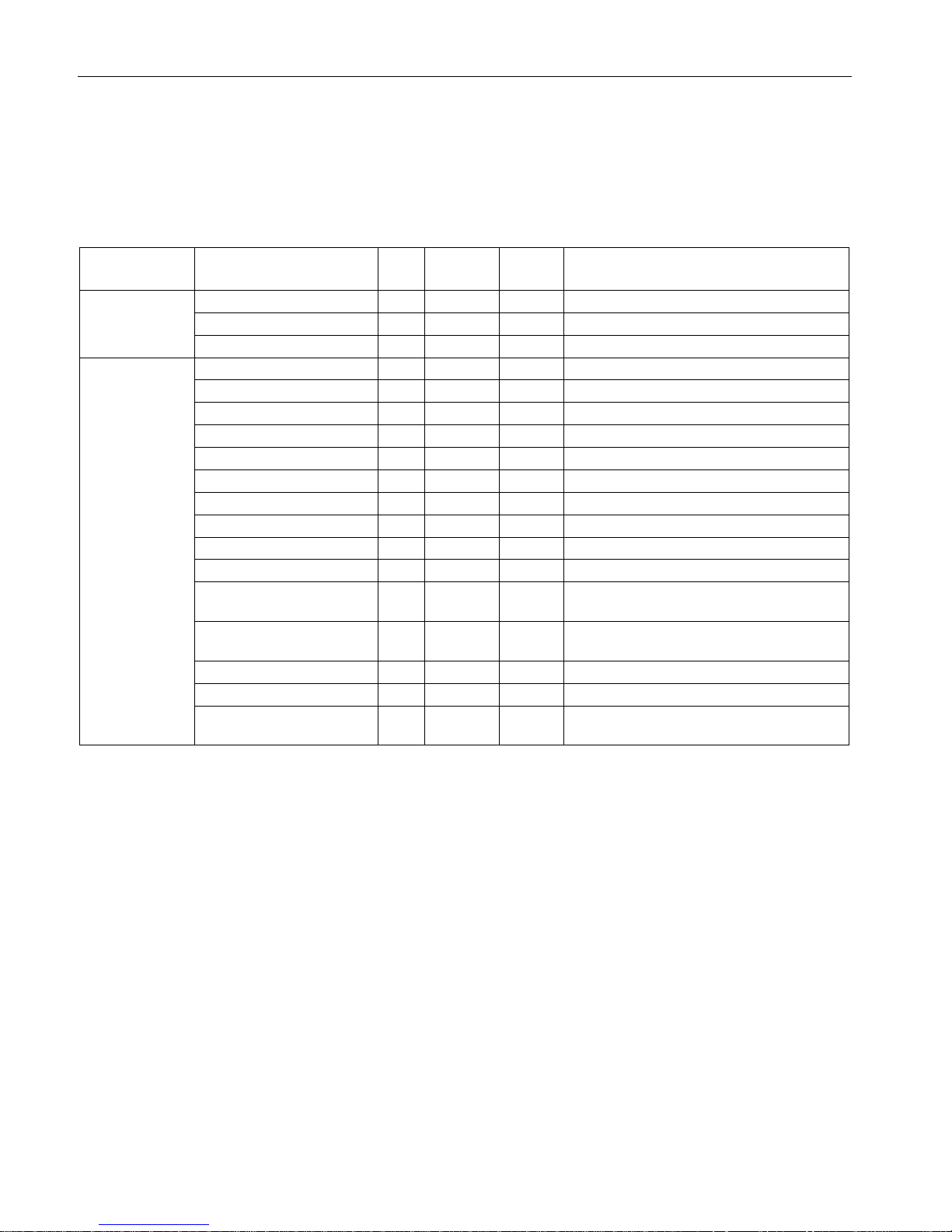

Table 3- 1 Overview of Safety Integrated functions

Functions

Abbr.

With

encoder

Without

encoder

Brief description

Basic Functions

Safe Torque Off

STO

Yes

Yes

Safe Torque Off

Safe Stop 1 SS1 Yes Yes Safe stop according to stop category 1

Safe Brake Control

SBC

Yes

Yes

Safe Brake Control

Extended Func-

tions

Safe Torque Off

STO

Yes

Yes1)

Safe Torque Off

Safe Stop 1

SS1

Yes

Yes1)

Safe stop according to stop category 1

Safe Brake Control

SBC

Yes

Yes1)

Safe Brake Control

Safe Operating Stop

SOS

Yes

No

Safe monitoring of the standstill position

Safe Stop 2

SS2

Yes

No

Safe stop according to stop category 2

Safely-Limited Speed

SLS

Yes

Yes1)

Safe monitoring of the maximum speed

Safe Speed Monitor

SSM

Yes

Yes1)

Safe monitoring of the minimum speed

Safe Direction

SDI

Yes

Yes1)

Safe monitoring of the direction of motion

Safely-Limited Position

SLP

Yes

No

Safely-limited position

Safe referencing/homing

SR

Yes

No

Safe referencing/homing

Transferring safe position

values

SP Yes Yes1) Transferring safe position values

Safe Brake Test SBT Yes No Safe test of the required holding torque of a

brake

Safe Acceleration Monitor

SAM

Yes

Yes1)

Safe monitoring of drive acceleration

Safe Brake Ramp

SBR

No

Yes1)

Safe braking ramp

Safe gearbox stage switch-

over

– Yes No –

1)

The use of this safety function without encoder is permitted only for induction motors or synchronous motors of the

SIEMOSYN series.

The configuration of the Safety Integrated functions and the selection of monitoring with or

without encoder is realized in the Safety screens of the STARTER or SCOUT tools.

Loading...

Loading...