Siemens SINAMICS G110M, SINAMICS G120, SINAMICS G120P, SINAMICS G120C, SINAMICS G120D Function Manual

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SINAMICS

SINAMICS G120, G120P, G120C,

G120D, G110M

Fieldbuses

Function Manual

Edition 04/2018, firmware V4.7 SP10

04/2018, FW V4.7 SP10

A5E34229197B AE

Preface

Fundamental safety

instructions

1

General information

2

Communication via

PROFIBUS and PROFINET

3

Communication via

EtherNet/IP

4

Communication via RS485

5

Communication over

CANopen

6

Communication via AS-i only for G110M

7

Appendix

A

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E34229197B AE

Ⓟ

Copyright © Siemens AG 2014 - 2018.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

04/2018 Subject to change

Preface

About this manual

Fieldbuses for SINAMICS G120

Additional fieldbuses for SINAMICS G120P

Additional fieldbuses for SINAMICS G110M

Changes in this edition

What is the meaning of the symbols in the manual?

This manual describes the settings and preconditions that are required to communicate with

a higher-level control system with the subsequently listed fieldbus systems.

● PROFIBUS DP

● PROFINET

● EtherNet/IP

● USS

● Modbus RTU

● CANopen

● BACnet MS/TP

● P1

● AS-Interface

Inverter settings are described in the context of the Startdrive PC commissioning tool. The

descriptions for settings using STARTER have been removed.

Reference to further information in the manual

Download from the Internet

DVD that can be ordered

End of a handling instruction.

❒

Fieldbuses

Function Manual, 04/2018, FW V4.7 SP10, A5E34229197B AE

3

Preface

Fieldbuses

4 Function Manual, 04/2018, FW V4.7 SP10, A5E34229197B AE

Table of contents

Preface ................................................................................................................................................... 3

1 Fundamental safety instructions .............................................................................................................. 9

2 General information .............................................................................................................................. 13

3 Communication via PROFIBUS and PROFINET ................................................................................... 17

1.1 General safety instructions ....................................................................................................... 9

1.2 Warranty and liability for application examples ........................................................................ 9

1.3 Industrial security .................................................................................................................... 10

2.1 Ethernet and PROFINET protocols that are used .................................................................. 14

3.1 PROFIDRIVE profile - Cyclic communication ......................................................................... 17

3.1.1 Assigning control and status words ........................................................................................ 21

3.1.1.1 Control and status word 1 ....................................................................................................... 21

3.1.1.2 Control and status word 2 ....................................................................................................... 25

3.1.1.3 Control and status word 3 ....................................................................................................... 26

3.1.2 NAMUR message word .......................................................................................................... 28

3.1.3 Control and status word, encoder ........................................................................................... 29

3.1.4 Position actual value of the encoder ....................................................................................... 31

3.1.5 Extend telegrams and change signal interconnection ............................................................ 33

3.1.6 Data structure of the parameter channel ................................................................................ 35

3.1.6.1 Application examples .............................................................................................................. 39

3.1.7 Slave-to-slave communication ................................................................................................ 41

3.2 PROFIDRIVE profile - Acyclic communication ....................................................................... 42

3.3 PROFIdrive profile - Diagnostic channels ............................................................................... 47

3.3.1 Diagnostics with PROFINET ................................................................................................... 48

3.3.2 Diagnostics with PROFIBUS .................................................................................................. 50

3.4 Identification & maintenance data (I&M) ................................................................................. 54

3.5 S7 communication .................................................................................................................. 55

3.5.1 Directly accessing a SINAMICS G120 converter from a SIMATIC panel ............................... 55

3.6 Communication via PROFINET .............................................................................................. 59

3.6.1 Converter with PROFINET interface ....................................................................................... 61

3.6.2 Integrating inverters into PROFINET ...................................................................................... 62

3.6.3 PROFINET IO operation ......................................................................................................... 63

3.6.3.1 What do you have to set for communication via PROFINET?................................................ 63

3.6.3.2 Configuring communication to the control .............................................................................. 63

3.6.3.3 Installing GSDML .................................................................................................................... 65

3.6.3.4 Activating diagnostics via the control ...................................................................................... 65

3.6.4 PROFIenergy .......................................................................................................................... 65

3.6.4.1 General inverter behavior when in the PROFIenergy energy-saving mode ........................... 66

3.6.4.2 Supported PROFIenergy energy-saving modes ..................................................................... 66

3.6.4.3 Settings and displays for PROFIenergy in the inverter ........................................................... 67

3.6.4.4 Control commands and status queries ................................................................................... 68

Fieldbuses

Function Manual, 04/2018, FW V4.7 SP10, A5E34229197B AE

5

Table of contents

4 Communication via EtherNet/IP ............................................................................................................ 81

5 Communication via RS485 ................................................................................................................... 107

3.6.5 The inverter with PROFINET interface as Ethernet node. ..................................................... 70

3.7 Communication via PROFIBUS ............................................................................................. 72

3.7.1 Inverters with PROFIBUS interface ....................................................................................... 73

3.7.2 What do you have to set for communication via PROFIBUS? .............................................. 75

3.7.3 Integrating inverters into PROFIBUS ..................................................................................... 76

3.7.4 Configuring communication to the control system ................................................................. 76

3.7.4.1 Configuring the communication using SIMATIC S7 control ................................................... 76

3.7.4.2 Configuring the communication with a third-party control system ......................................... 76

3.7.4.3 Installing the GSD .................................................................................................................. 77

3.7.5 Setting the address ................................................................................................................ 78

3.8 Select telegram ...................................................................................................................... 79

4.1 Inverters with Ethernet/IP interface ........................................................................................ 82

4.2 Connect converter to Ethernet/IP........................................................................................... 84

4.3 What do you need for communication via Ethernet/IP?......................................................... 85

4.4 Configuring communication via EtherNet/IP .......................................................................... 86

4.4.1 Communication settings ......................................................................................................... 86

4.4.2 Special issues if you wish to use the ODVA AC/DC Drive profile ......................................... 87

4.5 Supported objects .................................................................................................................. 88

4.5.1 Supported ODVA AC/DC assemblies .................................................................................. 102

4.6 Create generic I/O module ................................................................................................... 103

4.7 The inverter as an Ethernet station ...................................................................................... 104

5.1 Inverter with RS485 interface ............................................................................................... 108

5.2 Integrating inverters into a bus system via the RS485 interface ......................................... 110

5.3 Communication via USS ...................................................................................................... 111

5.3.1 Basic settings for communication ........................................................................................ 111

5.3.1.1 Setting the address .............................................................................................................. 112

5.3.1.2 Parameters to set communication via USS ......................................................................... 113

5.3.2 Telegram structure ............................................................................................................... 114

5.3.3 User data range of the USS telegram .................................................................................. 115

5.3.4 USS parameter channel ....................................................................................................... 116

5.3.4.1 Telegram examples, length of the parameter channel = 4 .................................................. 120

5.3.5 USS process data channel (PZD) ........................................................................................ 122

5.3.6 Time-out and other errors .................................................................................................... 123

5.4 Communication using Modbus RTU .................................................................................... 125

5.4.1 Basic settings for communication ........................................................................................ 126

5.4.1.1 Setting the address .............................................................................................................. 127

5.4.1.2 Parameters for Modbus communication settings ................................................................. 128

5.4.2 Modbus RTU telegram ......................................................................................................... 130

5.4.3 Baud rates and mapping tables ........................................................................................... 131

5.4.4 Mapping tables - inverter data ............................................................................................. 133

5.4.5 Acyclic communication via Modbus RTU ............................................................................. 136

5.4.6 Write and read access using function codes ....................................................................... 137

5.4.7 Acyclically read and write parameter via FC 16 ................................................................... 140

Fieldbuses

6 Function Manual, 04/2018, FW V4.7 SP10, A5E34229197B AE

Table of contents

6 Communication over CANopen ........................................................................................................... 169

7 Communication via AS-i - only for G110M ........................................................................................... 215

5.4.7.1 Read parameter .................................................................................................................... 141

5.4.7.2 Write parameter .................................................................................................................... 142

5.4.8 Communication procedure .................................................................................................... 144

5.4.9 Application example .............................................................................................................. 145

5.5 Communication via BACnet MS/TP - only CU230P-2 HVAC / BT ....................................... 146

5.5.1 Basic settings for communication ......................................................................................... 147

5.5.1.1 Setting the address ............................................................................................................... 148

5.5.1.2 Parameters for setting communication via BACnet .............................................................. 149

5.5.2 Supported services and objects ............................................................................................ 151

5.5.3 Acyclic communication (general parameter access) via BACnet ......................................... 160

5.6 Communication via P1 - only CU230P-2 HVAC, CU230P-2 BT........................................... 162

5.6.1 Basic settings for communication via P1 .............................................................................. 163

5.6.2 Setting the address ............................................................................................................... 164

5.6.3 Point numbers ....................................................................................................................... 165

6.1 Network management (NMT service) ................................................................................... 172

6.2 SDO services ........................................................................................................................ 175

6.2.1 Access to SINAMICS parameters via SDO .......................................................................... 175

6.2.2 Access PZD objects via SDO ............................................................................................... 177

6.3 PDO services ........................................................................................................................ 179

6.3.1 Predefined connection set .................................................................................................... 182

6.3.2 Free PDO mapping ............................................................................................................... 184

6.3.3 Interconnect objects from the receive and transmit buffers .................................................. 187

6.3.4 Free PDO mapping for example of the actual current value and torque limit....................... 189

6.4 CANopen operating modes .................................................................................................. 191

6.5 RAM to ROM via the CANopen object 1010 ........................................................................ 193

6.6 Object directories .................................................................................................................. 194

6.6.1 General objects from the CiA 301 communication profile .................................................... 194

6.6.2 Free objects .......................................................................................................................... 203

6.6.3 Objects from the CiA 402 drive profile .................................................................................. 204

6.7 Integrating the inverter into CANopen .................................................................................. 206

6.7.1 Connecting inverter to CAN bus ........................................................................................... 207

6.7.2 Setting the node ID and baud rate ........................................................................................ 207

6.7.3 Setting the monitoring of the communication ....................................................................... 208

6.8 Error diagnostics ................................................................................................................... 210

6.9 CAN bus sampling time ........................................................................................................ 214

7.1 Setting the address ............................................................................................................... 217

7.2 Single Slave mode ................................................................................................................ 219

7.3 Dual Slave mode ................................................................................................................... 221

7.4 Assignment tables ................................................................................................................. 224

7.5 Cyclic and acyclic communication via CTT2 ........................................................................ 226

7.5.1 Cyclic communication ........................................................................................................... 227

Fieldbuses

Function Manual, 04/2018, FW V4.7 SP10, A5E34229197B AE

7

Table of contents

A Appendix ............................................................................................................................................. 231

Index ................................................................................................................................................... 239

7.5.2 Acyclic communication - standard ....................................................................................... 228

7.5.3 Acyclic communication - manufacturer-specific ................................................................... 228

A.1 Application examples for communication with STEP7......................................................... 231

A.2 Manuals and technical support ............................................................................................ 232

A.2.1 Overview of the manuals ..................................................................................................... 232

A.2.2 Configuring support .............................................................................................................. 236

A.2.3 Product Support ................................................................................................................... 237

Fieldbuses

8 Function Manual, 04/2018, FW V4.7 SP10, A5E34229197B AE

1

1.1

General safety instructions

WARNING

Danger to life if the safety instructions and residual risks are not observed

WARNING

Malfunctions of the machine as a result of incorrect or changed parameter settings

1.2

Warranty and liability for application examples

If the safety instructions and residual risks in the associated hardware documentation are

not observed, accidents involving severe injuries or death can occur.

• Observe the safety instructions given in the hardware documentation.

• Consider the residual risks for the risk evaluation.

As a result of incorrect or changed parameterization, machines can malfunction, which in

turn can lead to injuries or death.

• Protect the parameterization (parameter assignments) against unauthorized access.

• Handle possible malfunctions by taking suitable measures, e.g. emergency stop or

emergency off.

Application examples are not binding and do not claim to be complete regarding

configuration, equipment or any eventuality which may arise. Application examples do not

represent specific customer solutions, but are only intended to provide support for typical

tasks.

As the user you yourself are responsible for ensuring that the products described are

operated correctly. Application examples do not relieve you of your responsibility for safe

handling when using, installing, operating and maintaining the equipment.

Fieldbuses

Function Manual, 04/2018, FW V4.7 SP10, A5E34229197B AE

9

Fundamental safety instructions

1.3

Industrial security

Note

Industrial security

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement

security concept. Siemens’ products and solutions constitute one element of

Customers are responsible for preventing unauthorized access to their plants, systems,

machines and networks. Such systems, machines and components should only be

connected to an enterprise network or the Internet if and to the extent such

necessary and only when appropriate security measures (e.g. firewalls and/or network

segmentation) are in place.

For additional information on industrial security measures that may be implemented, please

visit:

Industrial security (

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends that product updates are applied as soon as they are

available and that the latest product versions are used. Use of product versions that are no

longer supported, and failure to apply the latest updates may increase customer’s exposure

to cyber threats.

To stay informed about product updates, subs

Feed at:

Industrial security (

1.3 Industrial security

– and continuously maintain – a holistic, state-of-the-art industrial

such a concept.

a connection is

http://www.siemens.com/industrialsecurity)

cribe to the Siemens Industrial Security RSS

http://www.siemens.com/industrialsecurity)

Further information is provided on the Internet:

Industrial Security Configuration Manual

(https://support.industry.siemens.com/cs/ww/en/view/108862708)

Fieldbuses

10 Function Manual, 04/2018, FW V4.7 SP10, A5E34229197B AE

Fundamental safety instructions

WARNING

Unsafe operating states resulting from software manipulation

1.3 Industrial security

Software manipulations (e.g. viruses, trojans, malware or worms) can cause unsafe

operating states in your system that may lead to death, serious injury, and property

damage.

• Keep the software up to date.

• Incorporate the automation and drive components into a holistic, state-of-the-art

industrial security concept for the installation or machine.

• Make sure that you include all installed products into the holistic industrial security

concept.

• Protect files stored on exchangeable storage media from malicious software by with

suitable protection measures, e.g. virus scanners.

• Protect the drive against unauthorized changes by activating the "know-how protection"

drive function.

Fieldbuses

Function Manual, 04/2018, FW V4.7 SP10, A5E34229197B AE

11

Fundamental safety instructions

1.3 Industrial security

Fieldbuses

12 Function Manual, 04/2018, FW V4.7 SP10, A5E34229197B AE

2

Communication with the control, even when the line voltage is switched off

If, in your plant or system, communication with the control system should continue to function

even when the line voltage is switched off, then you must externally supply the

inverter/Control Unit with 24 V DC. To do this, use terminals 31 and 32 – or connector X01.

You can find additional details in the operating instructions for the inverter or the Control

Unit.

Fieldbuses

Function Manual, 04/2018, FW V4.7 SP10, A5E34229197B AE

13

General information

2.1

Ethernet and PROFINET protocols that are used

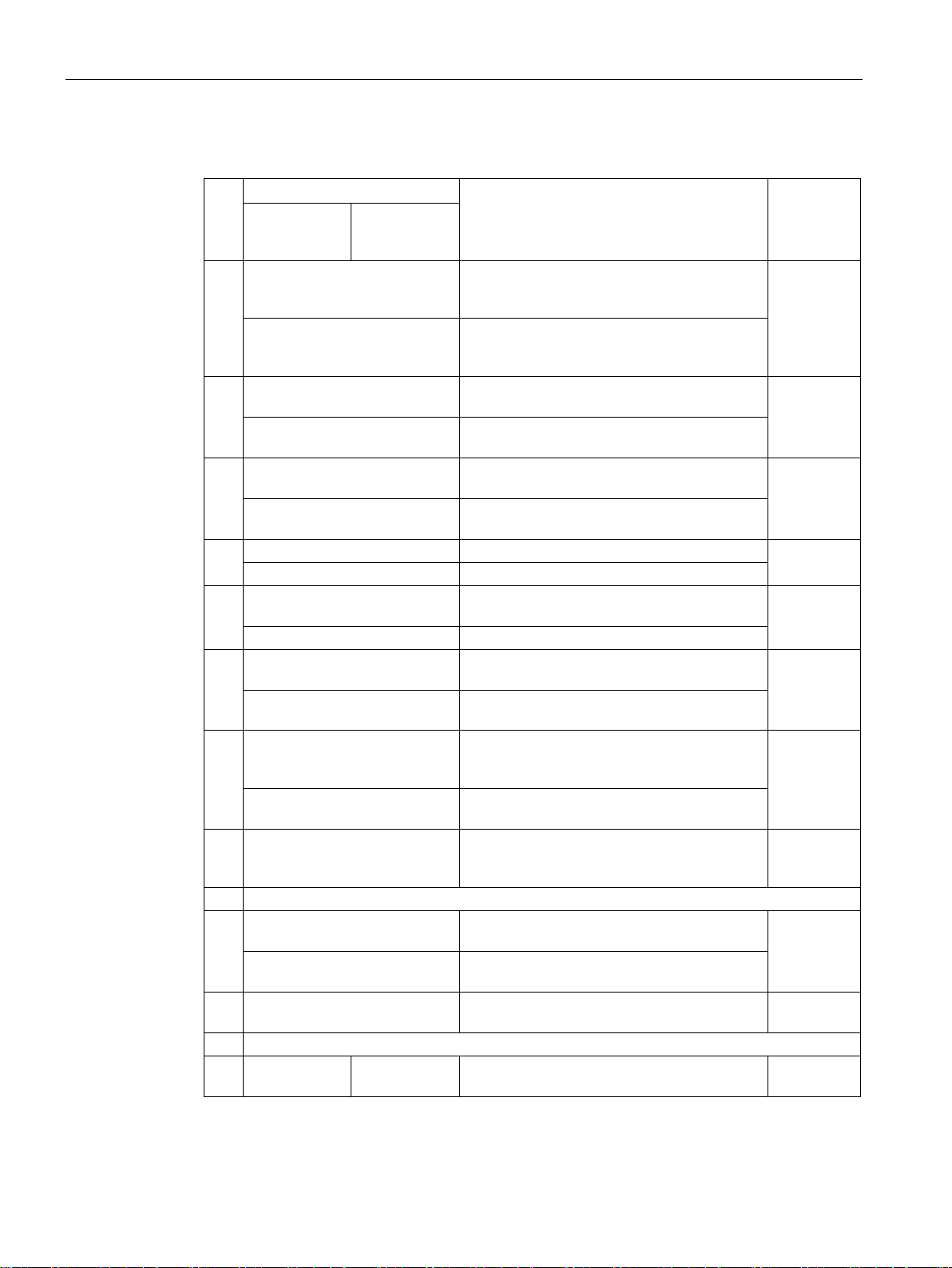

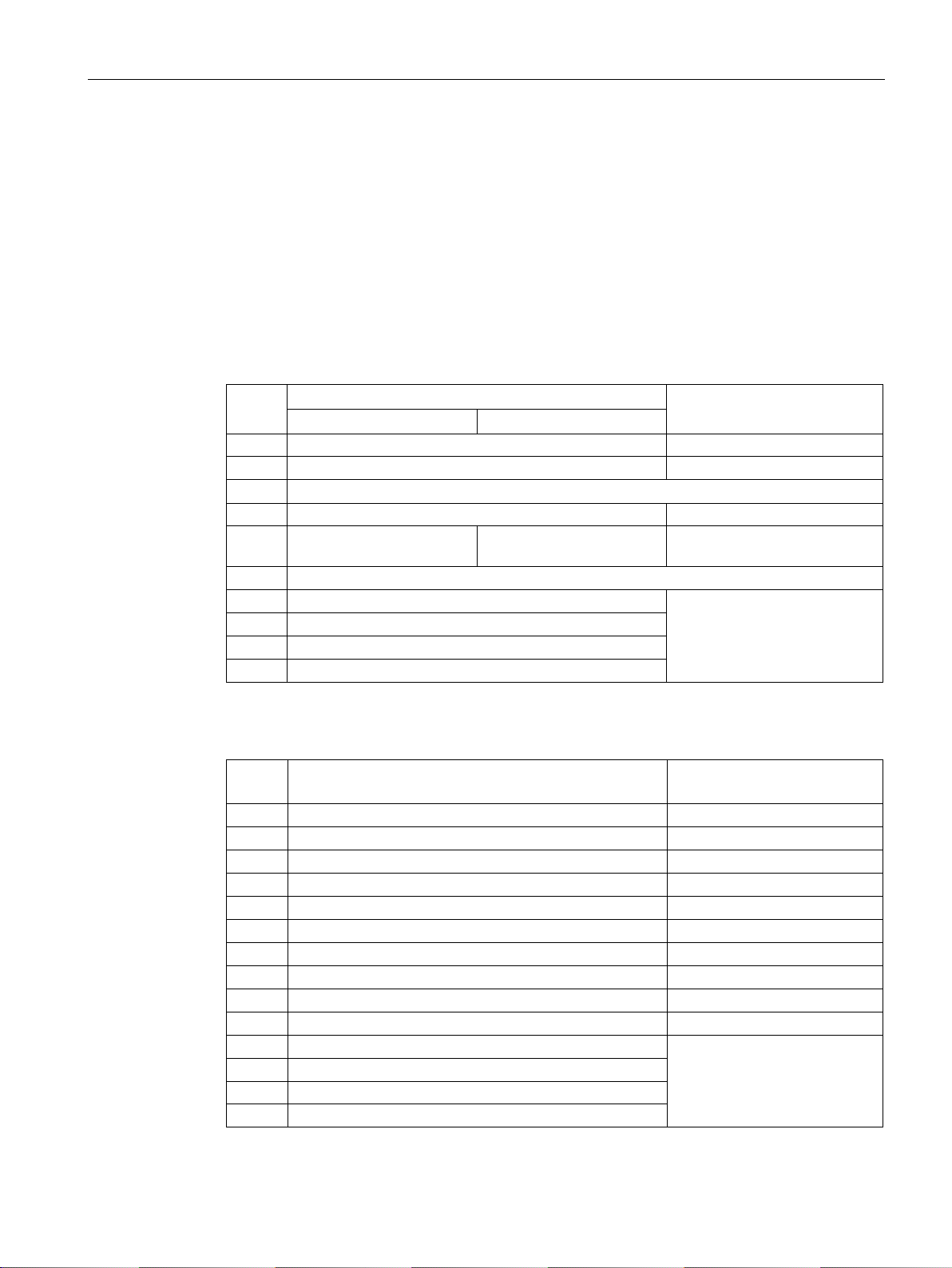

Protocol

Port

number

Layer

(2) Link layer

(4) Transport layer

Function/description

Accessible stations, PROFINET Discovery and configuration

xx-xx-xx = Organizationally Unique Identifier

PROFINET Link Layer Discovery protocol

01-80-C2-00-00-0E

PROFINET medium redundancy

xx-xx-xx = Organizationally Unique Identifier

PROFINET send clock and time synchronization, based on IEEE

1588

xx-xx-xx = Organizationally Unique Identifier

(PROFINET)

PROFINET Cyclic IO data transfer

PROFINET connection less RPC

order to establish an application relationship (PROFINET AR).

2.1 Ethernet and PROFINET protocols that are used

The inverter supports the protocols listed in the following tables. The address parameters,

the relevant communication layer as well as the communication role and the communication

direction are specified for each protocol.

You require this information to set the appropriate safety measures to protect the automation

system, e.g. in the firewall.

As the security measures are limited to Ethernet and PROFINET networks, no PROFIBUS

protocols are listed in the table.

Table 2- 1 PROFINET protocols

DCP:

Discovery and

configuration

protocol

LLDP:

Link Layer

Discovery

Protocol

MRP:

Media Redun-

dancy Protocol

PTCP

Precision

Transparent

Clock Protocol

Not

relevant

Not

relevant

Not

relevant

Not

relevant

(2) Ethernet II and

IEEE 802.1Q and

Ethertype 0x8892

(PROFINET)

(2) Ethernet II and

IEEE 802.1Q and

Ethertype 0x88CC

(PROFINET)

(2) Ethernet II and

IEEE 802.1Q and

Ethertype 0x88E3

(PROFINET)

(2) Ethernet II and

IEEE 802.1Q and

Ethertype 0x8892

(PROFINET)

DCP is used by PROFINET to determine PROFINET devices and to

make basic settings.

DCP uses the special multicast MAC address:

xx-xx-xx-01-0E-CF,

LLDP is used by PROFINET to determine and manage neighborhood relationships between PROFINET devices.

LLDP uses the special multicast MAC address:

MRP enables the control of redundant routes through a ring topology.

MRP uses the special multicast MAC address:

xx-xx-xx-01-15-4E,

PTC is used to implement send clock synchronization and time synchronization between RJ45 ports, which are required for IRT operation.

PTCP uses the special multicast MAC address:

xx-xx-xx-01-0E-CF,

PROFINET IO

data

PROFINET

Context Manager

Fieldbuses

14 Function Manual, 04/2018, FW V4.7 SP10, A5E34229197B AE

Not

relevant

34964 (4) UDP

(2) Ethernet II and

IEEE 802.1Q and

Ethertype 0x8892

The PROFINET IO telegrams are used to transfer IO data cyclically

between the PROFINET IO controller and IO devices via Ethernet.

The PROFINET context manager provides an endpoint mapper in

General information

Protocol

Port

number

Layer

(2) Link layer

(4) Transport layer

Function/description

Net/IP.

Net/IP.

Protocol

Port

number

Layer

(2) Link layer

(4) Transport layer

Function/description

ISO-on-TCP protocol

oriented data exchange to a remote CPU, WinAC or devices of other

and is always required.

Simple network management protocol

It is activated in the factory setting, and is always required

(4) UDP

2.1 Ethernet and PROFINET protocols that are used

Table 2- 2 Ethernet/IP protocols

Implicit messaging

Explicit messaging

2222 (4) UDP Used for exchanging I/O data.

This is inactive when delivered. Is activated when selecting Ether-

44818 (4) TCP

(4) UDP

Used for parameter access (writing, reading).

This is inactive when delivered. Is activated when selecting Ether-

Table 2- 3 Connection-oriented communication protocols

ISO on TCP

(according to

RFC 1006)

102 (4) TCP

ISO on TCP (according to RFC 1006) is used for the message-

suppliers.

Communication with ES, HMI, etc. is activated in the factory setting,

SNMP

Simple Net-

work Manage-

161 (4) UDP

SNMP enables network management data to be read out and set

(SNMP managed objects) by the SNMP manager.

ment Protocol

Reserved 49152 ...

(4) TCP

65535

Fieldbuses

Function Manual, 04/2018, FW V4.7 SP10, A5E34229197B AE

Dynamic port area that is used for the active connection endpoint if

the application does not specify the local port.

15

General information

2.1 Ethernet and PROFINET protocols that are used

Fieldbuses

16 Function Manual, 04/2018, FW V4.7 SP10, A5E34229197B AE

3

3.1

PROFIDRIVE profile - Cyclic communication

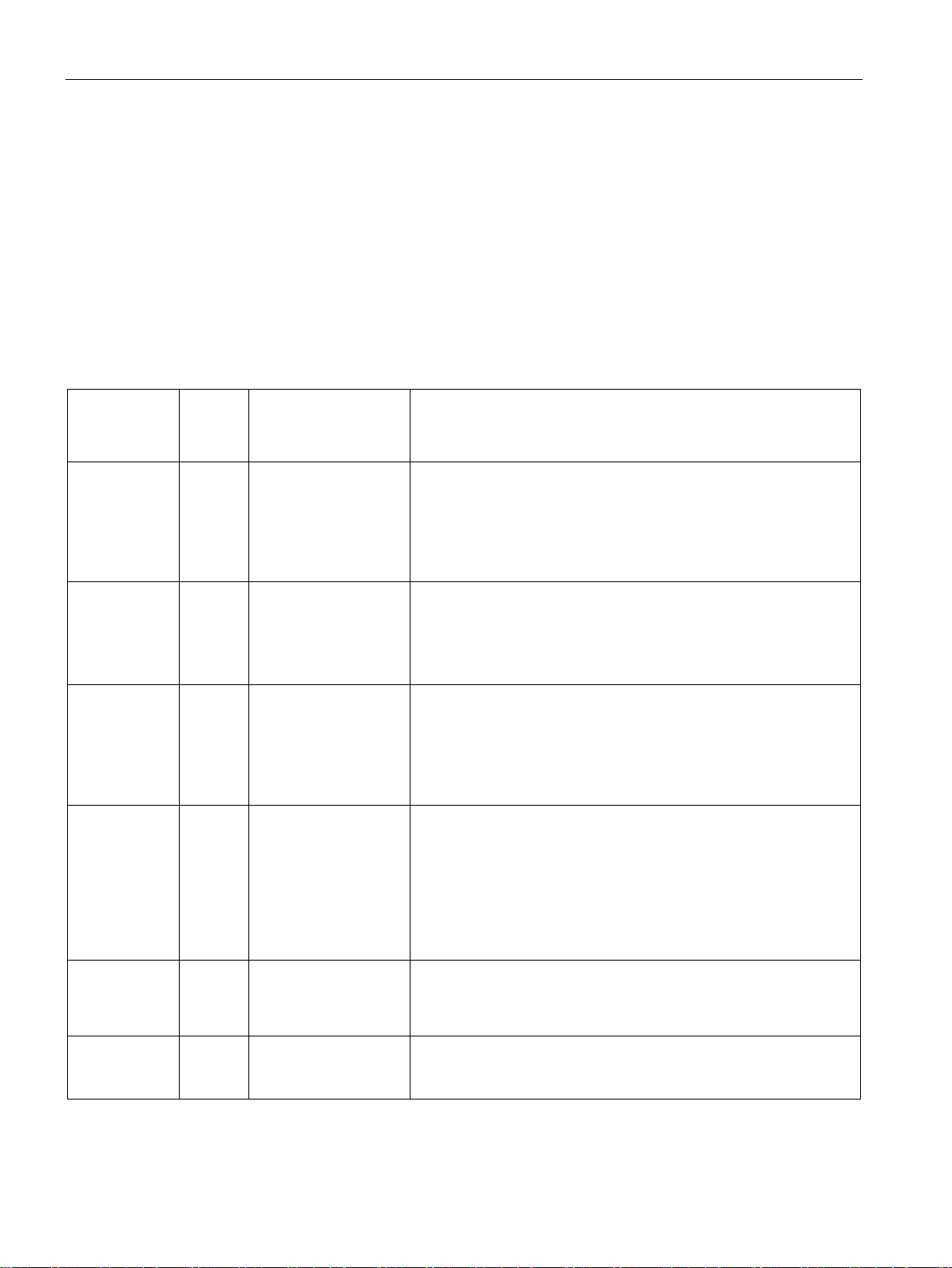

Communication telegrams if "basic positioner" has been configured

Communication telegrams for speed control

Depending on the Control Unit or inverter, there are different telegrams for communication

via PROFIBUS DP or PROFINET IO. The structure of the individual telegrams are listed

below.

The Startdrive commissioning tool or an operator panel only list the telegrams for selection

that are possible with your particular inverter.

How to commission the inverter and select a telegram are described in the operating

instructions.

Overview of the manuals (Page 232)

The inverter has the following telegrams if you have configured the "Basic positioner"

function:

● Standard telegram 7, PZD-2/2

● Standard telegram 9, PZD-10/5

● SIEMENS telegram 110, PZD-12/7

● SIEMENS telegram 111, PZD-12/12

● Telegram 999, free interconnection

Telegrams 7, 9, 110 and 111 are described in the "Basic positioner" Function Manual

Overview of the manuals (Page 232)

The send and receive telegrams of the inverter for closed-loop speed control are structured

as follows:

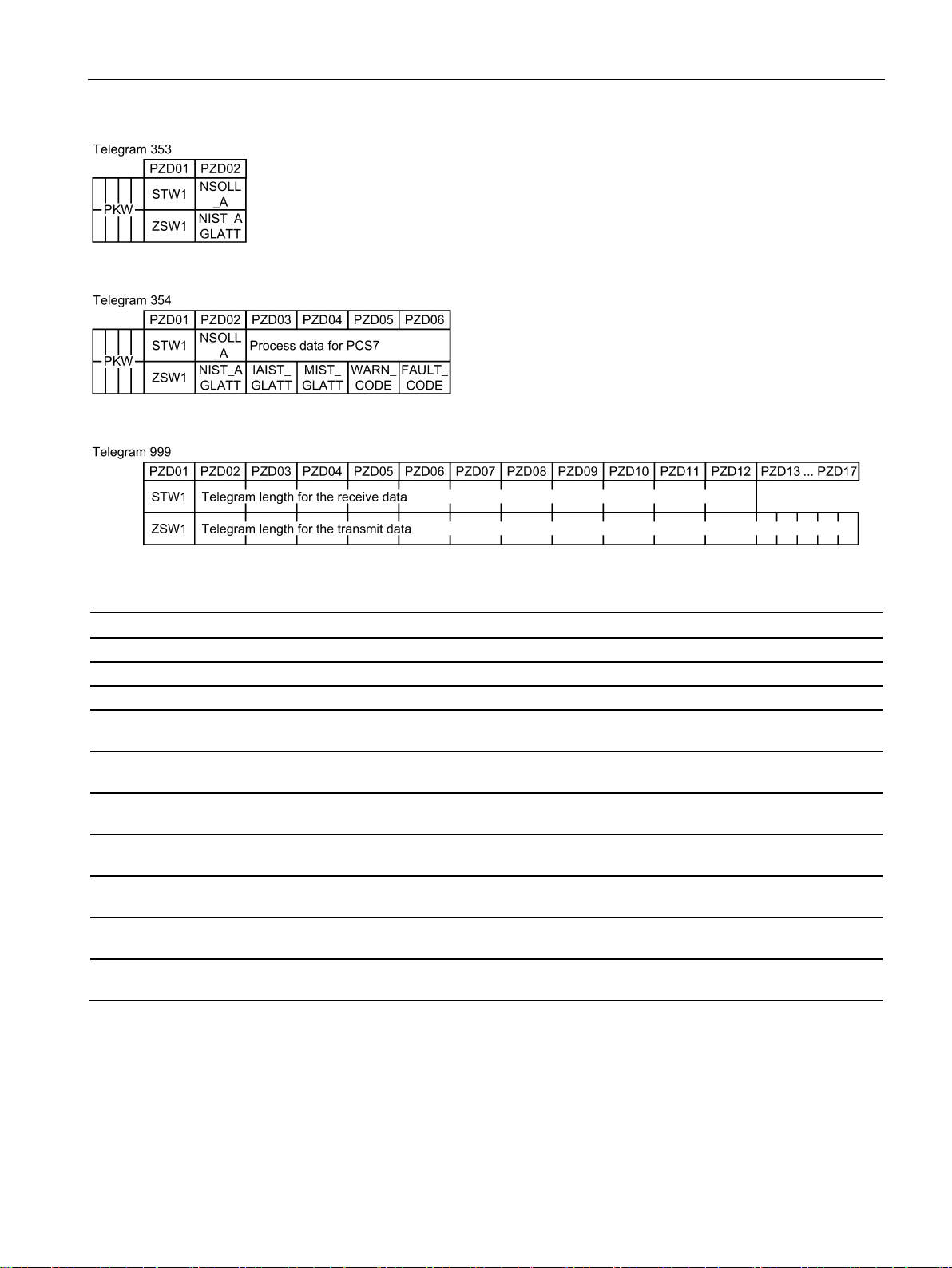

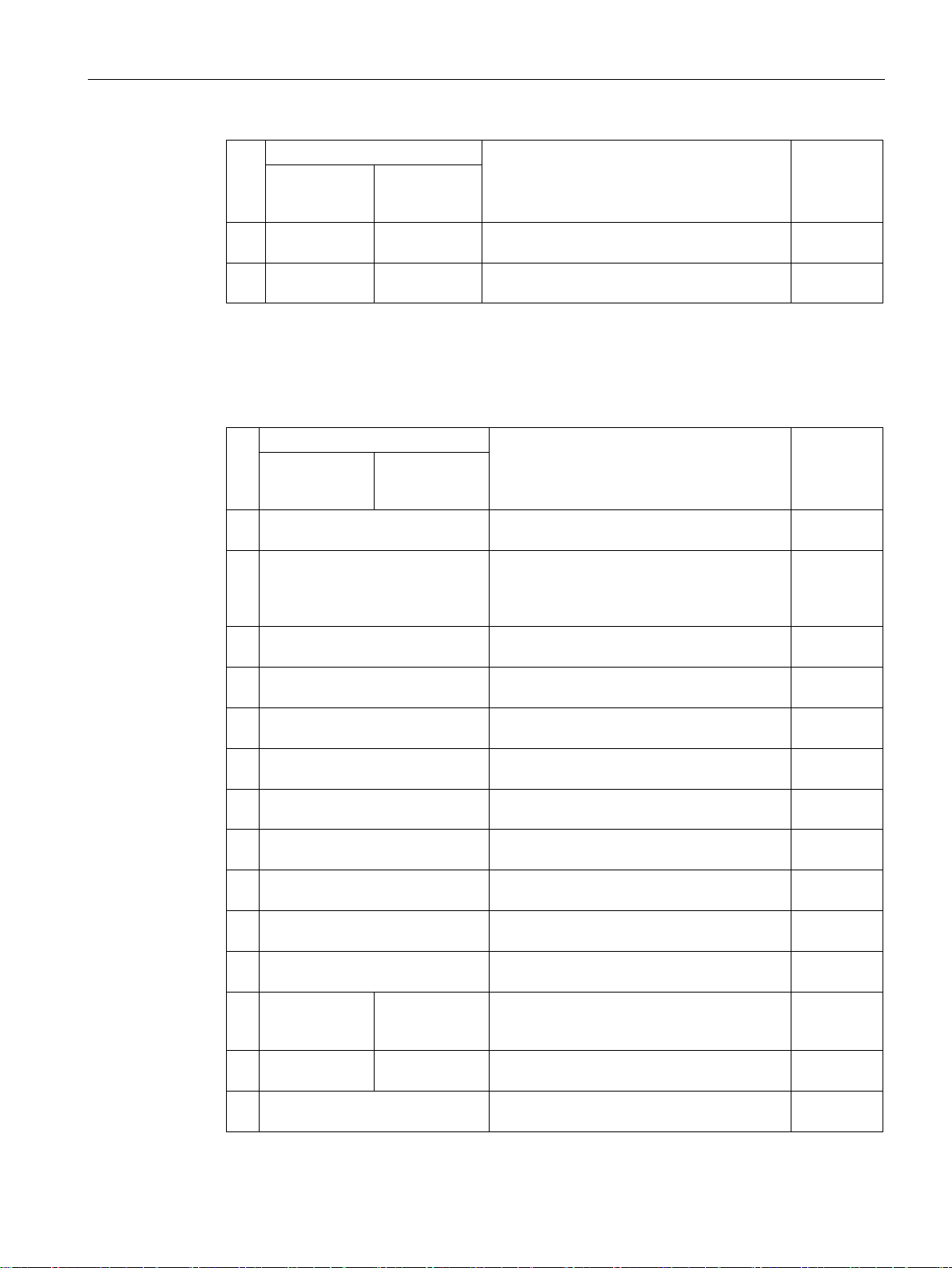

Figure 3-1 16-bit speed setpoint

Fieldbuses

Function Manual, 04/2018, FW V4.7 SP10, A5E34229197B AE

17

Communication via PROFIBUS and PROFINET

3.1 PROFIDRIVE profile - Cyclic communication

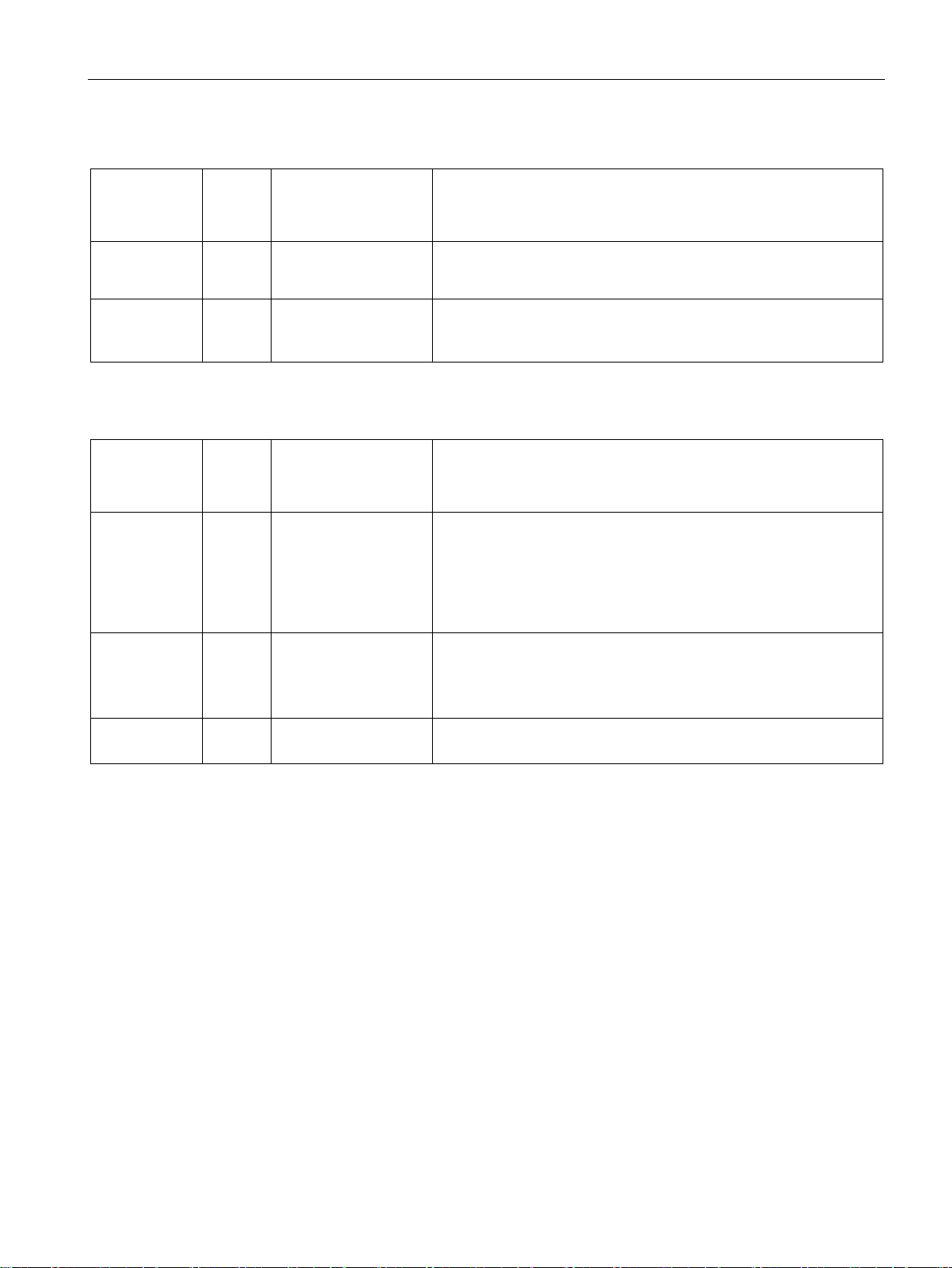

Figure 3-2 32-bit speed setpoint

Figure 3-3 32-bit speed setpoint with 1 position encoder

Figure 3-4 32-bit speed setpoint with 2 position encoders

Figure 3-5 16-bit speed setpoint for VIK-Namur

Figure 3-6 16-bit speed setpoint with torque limiting

Figure 3-7 16-bit speed setpoint for PCS7

Fieldbuses

18 Function Manual, 04/2018, FW V4.7 SP10, A5E34229197B AE

Communication via PROFIBUS and PROFINET

Abbreviation

Explanation

Abbreviation

Explanation

PZD

Process data

PKW

Parameter channel

STW

Control word

PIST_GLATT

Actual active power value, smoothed

ZSW

Status word

M_LIM

Torque limit

definition

G2_STW

G2_ZSW

G2_XIST1

encoder 2

G2_XIST2

encoder 2

3.1 PROFIDRIVE profile - Cyclic communication

Figure 3-8 16-bit speed setpoint with PKW range to read and write parameters

Figure 3-9 16-bit speed setpoint for PCS7 with PKW range to read and write parameters

Figure 3-10 Telegram with free interconnection and length

NSOLL_A Speed setpoint 16 bit FAULT_CODE Fault code

NSOLL_B Speed setpoint 32 bit WARN_CODE Alarm code

NIST_A Speed actual value 16 bit MELD_NAMUR Message according to the VIK-NAMUR

NIST_B Speed actual value 32 bit G1_STW /

IAIST Current actual value G1_ZSW /

IAIST_GLATT Current actual value, smoothed G1_XIST1 /

MIST_GLATT Torque actual value, smoothed G1_XIST2 /

Control word for encoder 1 or encoder 2

Status word for encoder 1 or encoder 2

Position actual value 1 from encoder 1 or

Position actual value 2 from encoder 1 or

Fieldbuses

Function Manual, 04/2018, FW V4.7 SP10, A5E34229197B AE

19

Communication via PROFIBUS and PROFINET

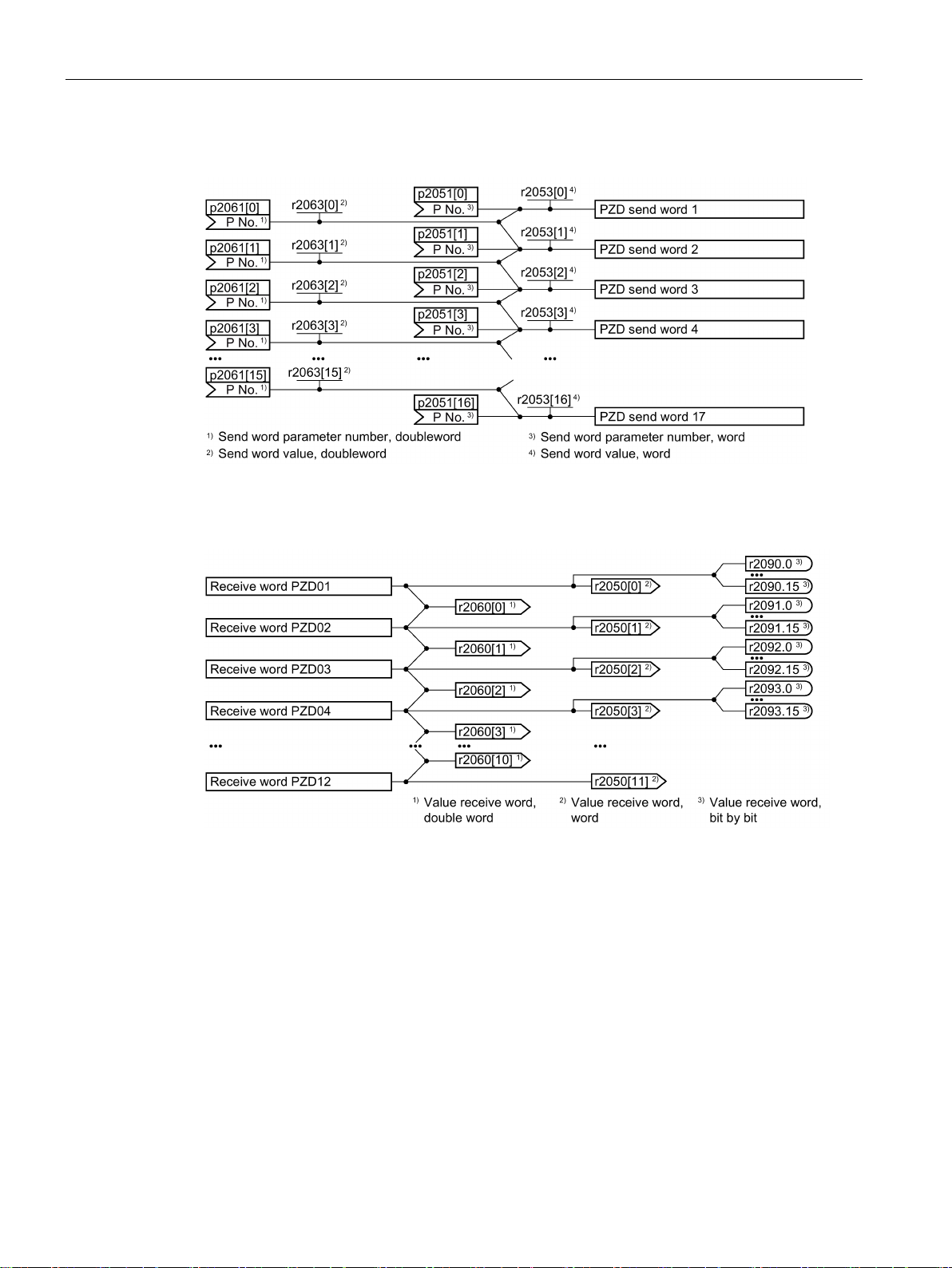

Interconnection of the process data

3.1 PROFIDRIVE profile - Cyclic communication

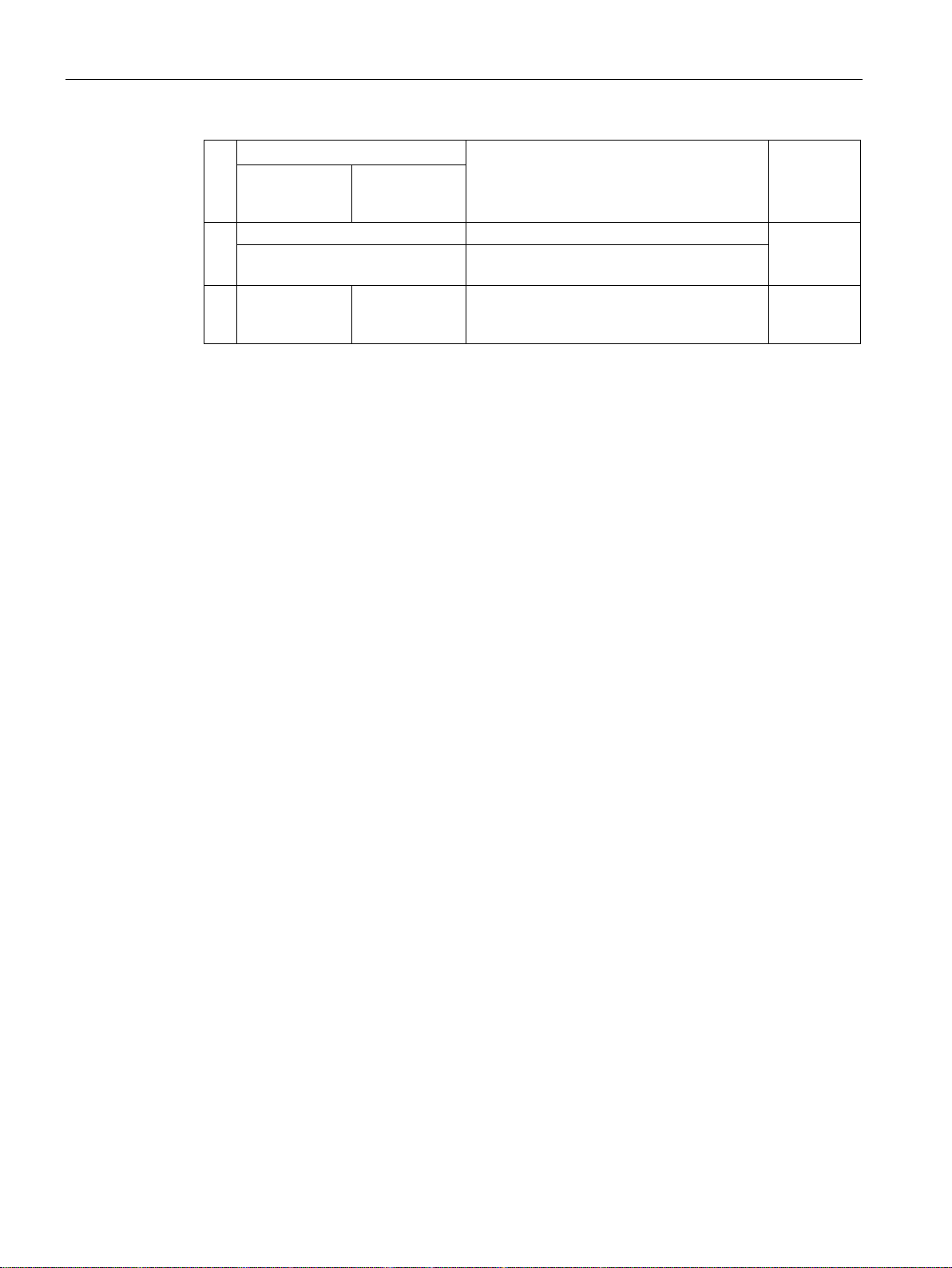

Figure 3-11 Interconnection of the send words

Figure 3-12 Interconnection of the receive words

The telegrams use - with the exception of telegram 999 (free interconnection) - the word-byword transfer of send and receive data (r2050/p2051).

If you require an individual telegram for your application (e.g. for transferring double words),

you can adapt one of the predefined telegrams using parameters p0922 and p2079. For

details, please refer to the List Manual, function diagrams 2420 and 2472.

Fieldbuses

20 Function Manual, 04/2018, FW V4.7 SP10, A5E34229197B AE

Communication via PROFIBUS and PROFINET

3.1.1

Assigning control and status words

3.1.1.1

Control and status word 1

3.1 PROFIDRIVE profile - Cyclic communication

Assigning control and status of words is specified in part by the definitions in the PROFIdrive

profile, Version 4.2 for the "Closed-loop speed control" operating mode; the other part is

assigned depending on the particular manufacturer.

A more detailed description of the individual control and status words is provided in the

following sections.

If you require an individual assignment for your application, you can adapt one of the existing

control and status words using p0922 and p2079.

Extend telegrams and change signal interconnection (Page 33)

Control word 1 is preassigned as follows:

● Telegrams 1, 2, 3 and 4:

– Bits 0 … 10 corresponding to the PROFIdrive profile,

– Bits 11… 15 manufacturer-specific

● Telegrams 7 and 9:

– Bits 0 … 11 corresponding to the PROFIdrive profile,

– Bits 12 … 15 manufacturer-specific

● Telegram 20 (VIK/NAMUR):

– Bits 0 … 11 corresponding to the PROFIdrive profile

– Bits 12 … 14 reserved

– Bit 15 corresponding to the PROFIdrive profile

Status word 1 is preassigned as follows:

● Telegrams 1, 2, 3 and 4:

– Bits 0 … 10 corresponding to the PROFIdrive profile,

– Bits 11… 15 manufacturer-specific

● Telegrams 7 and 9:

– Bits 0 … 13 corresponding to the PROFIdrive profile,

– Bits 14 … 15 manufacturer-specific

● Telegram 20 (VIK/NAMUR):

– Bits 0 … 11 corresponding to the PROFIdrive profile

– Bit 12 reserved

– Bits 13 … 15 corresponding to the PROFIdrive profile

Fieldbuses

Function Manual, 04/2018, FW V4.7 SP10, A5E34229197B AE

21

Communication via PROFIBUS and PROFINET

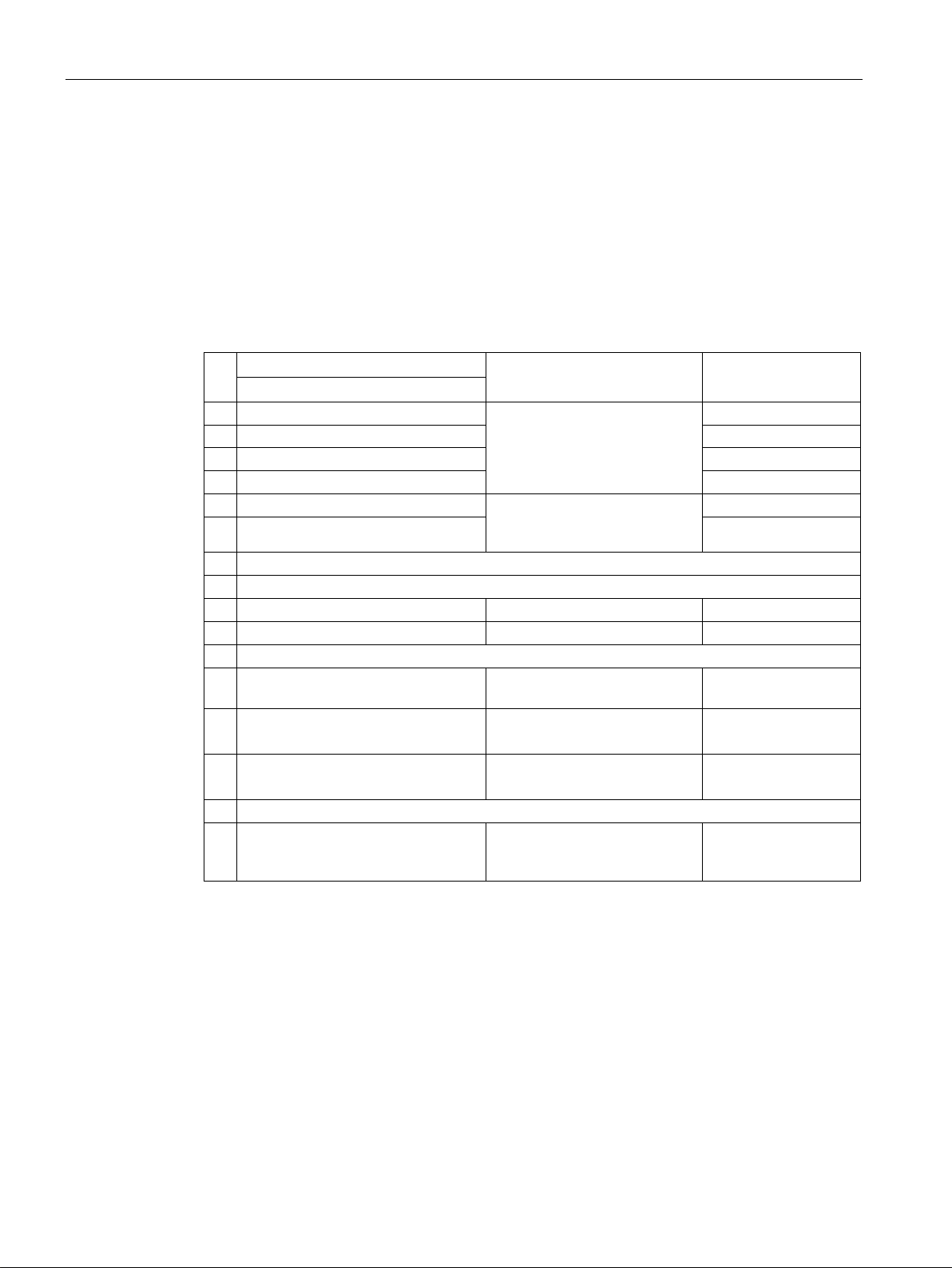

Control word 1 (STW1)

Bit

Significance

Explanation

Signal interconnection

in the inverter

Telegram 20

All other telegrams

inverter switches off the motor at standstill.

1, then the inverter switches on

the motor.

then coasts down to a standstill.

mand).

ramp-down time p1135 down to standstill.

mand).

0 = Inhibit operation

Immediately switch-off motor (cancel pulses).

1 = Enable operation

Switch-on motor (pulses can be enabled).

function generator output to 0.

1 = Do not disable RFG

The ramp-function generator can be enabled.

stops at the actual value.

follows the setpoint.

p1120 to the setpoint.

on inhibited" state.

8, 9

Reserved

fieldbus.

cess data from the fieldbus.

r2090.11

12

Not used

potentiometer.

r2090.13

3.1 PROFIDRIVE profile - Cyclic communication

0 0 = OFF1 The motor brakes with the ramp-down time

p1121 of the ramp-function generator. The

0 → 1 = ON The inverter goes into the "ready" state. If, in

addition bit 3 =

1 0 = OFF2 Switch off the motor immediately, the motor

1 = No OFF2 The motor can be switched on (ON com-

2 0 = Quick stop (OFF3) Quick stop: The motor brakes with the OFF3

1 = No quick stop (OFF3) The motor can be switched on (ON com-

3

4 0 = Disable RFG The inverter immediately sets its ramp-

5 0 = Stop RFG The output of the ramp-function generator

1 = Enable RFG The output of the ramp-function generator

p0840[0] =

r2090.0

p0844[0] =

r2090.1

p0848[0] =

r2090.2

p0852[0] =

r2090.3

p1140[0] =

r2090.4

p1141[0] =

r2090.5

6 0 = Inhibit setpoint The inverter brakes the motor with the ramp-

1 = Enable setpoint Motor accelerates with the ramp-up time

7 0 → 1 = Acknowledge faults Acknowledge fault. If the ON command is still

10 0 = No control via PLC Inverter ignores the process data from the

1 = Control via PLC Control via fieldbus, inverter accepts the pro-

11 1 = Direction reversal Invert setpoint in the inverter. p1113[0] =

13 ---1) 1 = MOP up Increase the setpoint saved in the motorized

Fieldbuses

22 Function Manual, 04/2018, FW V4.7 SP10, A5E34229197B AE

down time p1121 of the ramp-function generator.

active, the inverter switches to the "switching

p1142[0] =

r2090.6

p2103[0] =

r2090.7

p0854[0] =

r2090.10

p1035[0] =

Communication via PROFIBUS and PROFINET

Bit

Significance

Explanation

Signal interconnection

in the inverter

Telegram 20

All other telegrams

potentiometer.

r2090.14

1)

telegram is kept.

Status word 1 (ZSW1)

Bit

Significance

Remarks

Signal interconnection

in the inverter

Telegram 20

All other telegrams

ized; pulses locked.

r0899.0

motor.

bit 3.

r0899.2

using STW1.7.

r2139.3

r0899.4

r0899.5

an OFF1 followed by ON.

r0899.6

edgement is necessary.

r2139.7

tolerance range

tolerance range.

r2197.7

cept the inverter control.

r0899.9

1 = Comparison speed reached or

exceeded

sponding maximum speed.

r2199.1

reached

r1407.7

brake open

brake.

r0899.12

r2135.14

3.1 PROFIDRIVE profile - Cyclic communication

14 ---1) 1 = MOP down Reduce the setpoint saved in the motorized

15 CDS bit 0 Reserved Changes over between settings for different

If you change over from another telegram to telegram 20, then the assignment of the previous

0 1 = Ready for switching on Power supply switched on; electronics initial-

1 1 = Ready Motor is switched on (ON/OFF1 = 1), no fault

2 1 = Operation enabled Motor follows setpoint. See control word 1,

3 1 = Fault active The inverter has a fault. Acknowledge fault

operation interfaces (command data sets).

is active. With the command "Enable operation" (STW1.3), the inverter switches on the

p1036[0] =

p0810 =

r2090.15

p2080[0] =

p2080[1] =

r0899.1

p2080[2] =

p2080[3] =

4 1 = OFF2 inactive Coast down to standstill is not active. p2080[4] =

5 1 = OFF3 inactive Quick stop is not active. p2080[5] =

6 1 = Switching on inhibited active It is only possible to switch on the motor after

7 1 = Alarm active Motor remains switched on; no acknowl-

8 1 = Speed deviation within the

9 1 = Master control requested The automation system is requested to ac-

10

11 1 = current or

torque limit

12 ---1) 1 = Holding

13 0 = Alarm, motor overtemperature -- p2080[13] =

1 = torque limit

reached

Setpoint / actual value deviation within the

Speed is greater than or equal to the corre-

Comparison value for current or torque has

been reached or exceeded.

Signal to open and close a motor holding

p2080[6] =

p2080[7] =

p2080[8] =

p2080[9] =

p2080[10] =

p2080[11] =

r0056.13 /

p2080[12] =

Fieldbuses

Function Manual, 04/2018, FW V4.7 SP10, A5E34229197B AE

23

Communication via PROFIBUS and PROFINET

Bit

Significance

Remarks

Signal interconnection

in the inverter

Telegram 20

All other telegrams

1 = Motor rotates clockwise

Internal inverter actual value > 0

overload

r2135.15

1)

telegram is kept.

3.1 PROFIDRIVE profile - Cyclic communication

14

0 = Motor rotates counter-

Internal inverter actual value < 0

p2080[14] =

r2197.3

clockwise

15 1 = CDS display 0 = Alarm, in-

verter thermal

p2080[15] =

r0836.0 /

If you change over from another telegram to telegram 20, then the assignment of the previous

Fieldbuses

24 Function Manual, 04/2018, FW V4.7 SP10, A5E34229197B AE

Communication via PROFIBUS and PROFINET

3.1.1.2

Control and status word 2

Control word 2 (STW2)

Bit

Meaning

Signal interconnection in the

inverter

Telegrams 2, 3 and 4

Telegrams 9, 110 and 111

0

1 = drive data set selection DDS bit 0

p0820[0] = r2093.0

1

1 = drive data set selection DDS bit 1

p0821[0] = r2093.1

7

1 = parking axis is selected

p0897 = r2093.7

active

9…11

Reserved

12

1 = master sign-of-life bit 0

13

1 = master sign-of-life bit 1

14

1 = master sign-of-life bit 3

15

1 = master sign-of-life bit 4

Status word 2 (ZSW2)

Bit

Meaning

Signal interconnection in the

inverter

0

1 = Drive data set DDS effective, bit 0

p2081[0] = r0051.0

1

1 = Drive data set DDS effective, bit 1

p2081[1] = r0051.1

2…4

Reserved

5

1 = Alarm class bit 0

p2081[5] = r2139.11

6

1 = alarm class bit 1

p2081[6] = r2139.12

7

Reserved

8

1 = travel to fixed stop active

p2081[8] = r1406.8

9

Reserved

10

1 = pulses enabled

p2081[10] = r0899.11

11

Reserved

12

Slave sign-of-life bit 0

14

Slave sign of life bit 2

3.1 PROFIDRIVE profile - Cyclic communication

Control word 2 is preassigned as follows:

● Bits 0 … 11 manufacturer-specific

● Bits 12 … 15 corresponding to the PROFIdrive profile

Status word 2 is preassigned as follows:

● Bits 0 … 11 manufacturer-specific

● Bits 12 … 15 corresponding to the PROFIdrive profile

2…6 Reserved

8 1 = travel to fixed stop

Reserved p1545[0] = r2093.8

p2045 = r2050[3]

13 Slave sign of life bit 1

15 Slave sign of life bit 3

Fieldbuses

Function Manual, 04/2018, FW V4.7 SP10, A5E34229197B AE

Internally interconnected

25

Communication via PROFIBUS and PROFINET

3.1.1.3

Control and status word 3

Control word 3 (STW3)

Bit

Meaning

Explanation

Signal interconnection

in the inverter 1)

Telegram 350

1

1 = fixed setpoint bit 1

p1021[0] = r2093.1

2

1 = fixed setpoint bit 2

p1022[0] = r2093.2

3

1 = fixed setpoint bit 3

p1023[0] = r2093.3

4

1 = DDS selection bit 0

sets).

p0820 = r2093.4

6

Not used

7

Not used

8

1 = technology controller enable

--

p2200[0] = r2093.8

9

1 = enable DC braking

--

p1230[0] = r2093.9

10

Not used

ler droop.

0 = speed control active

0 = external fault is active (F07860)

14

Not used

(command data sets).

1)

p1020, … to "0". Exception: p2106 = 1.

3.1 PROFIDRIVE profile - Cyclic communication

Control word 3 is preassigned as follows:

● Bits 0 … 15 manufacturer-specific

Status word 3 is preassigned as follows:

● Bits 0 … 15 manufacturer-specific

0 1 = fixed setpoint bit 0 Selects up to 16 different fixed

5 1 = DDS selection bit 1 p0821 = r2093.5

p1020[0] = r2093.0

setpoints.

Changes over between settings

for different motors (drive data

11 1 = Enable droop Enable or inhibit speed control-

12 1 = torque control active

13 1 = no external fault

15 1 = CDS bit 1 Changes over between settings

If you switch from telegram 350 to a different one, then the inverter sets all interconnections

Changes over the control mode

for vector control.

-- p2106[0] = r2093.13

for different operation interfaces

p1492[0] = r2093.11

p1501[0] = r2093.12

p0811[0] = r2093.15

Fieldbuses

26 Function Manual, 04/2018, FW V4.7 SP10, A5E34229197B AE

Communication via PROFIBUS and PROFINET

Status word 3 (ZSW3)

Bit

Meaning

Description

Signal interconnection in the

inverter

0

1 = DC braking active

--

state detection

speed

threshold value 2

threshold value 2

6

1 = |n_act | ≧ r1119

Speed setpoint reached

value

value

ed

active.

the lower limit

p2292

the upper limit

put > p2291

13

Not used

15

Not used

3.1 PROFIDRIVE profile - Cyclic communication

p2051[3] = r0053

1 1 = |n_act | > p1226 Absolute current speed > stationary

2 1 = |n_act | > p1080 Absolute actual speed > minimum

3 1 = i_act ≧ p2170 Actual current ≥ current threshold

value

4 1 = |n_act | > p2155 Absolute actual speed > speed

5 1 = |n_act | ≦ p2155 Absolute actual speed < speed

7 1 = DC link voltage ≦ p2172 Actual DC link voltage ≦ threshold

8 1 = DC link voltage > p2172 Actual DC link voltage > threshold

9 1 = ramp-up or ramp-down complet-

10 1 = technology controller output at

11 1 = technology controller output at

12 Not used

14 Not used

Ramp-function generator is not

Technology controller output ≦

Technology controller out-

Fieldbuses

Function Manual, 04/2018, FW V4.7 SP10, A5E34229197B AE

27

Communication via PROFIBUS and PROFINET

3.1.2

NAMUR message word

Fault word according to the VIK-NAMUR definition (MELD_NAMUR)

Bit

Significance

P no.

0

1 = Control Unit signals a fault

2

1 = DC link overvoltage

4

1 = inverter overtemperature

5

1 = ground fault/phase fault in the motor cable or in the motor

6

1 = motor overload

7

1 = communication error to the higher-level control system

8

1 = fault in a safety-relevant monitoring channel

10

1 = fault in the internal inverter communication

11

1 = line fault

15

1 = other fault

3.1 PROFIDRIVE profile - Cyclic communication

Table 3- 1 Fault word according to the VIK-NAMUR definition and interconnection with parameters

in the inverter

p2051[5] = r3113

1 1 = line fault: Phase failure or inadmissible voltage

3 1 = Power Module fault, e.g. overcurrent or overtemperature

Fieldbuses

28 Function Manual, 04/2018, FW V4.7 SP10, A5E34229197B AE

Loading...

Loading...