Siemens SIMODRIVE POSMO A Function Manual

SIMOTION

Supplement to SIMODRIVE POSMO A Positioning Motor

Introduction

Fundamental safety

instructions

1

Function Manual

Description

Function blocks

Application example

Appendix

2

3

4

A

01/2015

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be

used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property

damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions. Qualified

personnel are those who, based on their training and experience, are capable of identifying risks and avoiding

potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended or

approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described.

Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in

this publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

Ⓟ 02/2015 Subject to change

Copyright © Siemens AG 2015.

All rights reserved

Introduction

Contents of the function manual

This document is part of the SIMOTION Programming - References documentation package.

This documentation serves as a supplement to the documentation on SIMODRIVE POSMO

A in the

This documentation is included in the SIMOTION SCOUT scope of delivery as electronic

documentation!

This manual describes how you can use function blocks to control and assign parameters for

a POSMO A drive from a SIMOTION program.

This manual describes differences in handling that arise when controlling and assigning

parameters for a POSMO A drive from the SIMOTION system as compared to the SIMATIC

system.

Function block

The function blocks for communication between the SIMOTION system and the distributed

SIMODRIVE POSMO A positioning motor are part of the program library of the "SIMOTION

SCOUT" engineering system.

Distributed Positioning Motor on PROFIBUS DP

user manual.

SIMOTION Documentation

An overview of the SIMOTION documentation can be found in the SIMOTION Documentation

Overview document.

This documentation is included as electronic documentation in the scope of delivery of

SIMOTION SCOUT. It comprises ten documentation packages.

The following documentation packages are available for SIMOTION V4.4:

● SIMOTION Engineering System Handling

● SIMOTION System and Function Descriptions

● SIMOTION Service and Diagnostics

● SIMOTION IT

● SIMOTION Programming

● SIMOTION Programming - References

● SIMOTION C

● SIMOTION P

● SIMOTION D

● SIMOTION Supplementary Documentation

Supplement to SIMODRIVE POSMO A Positioning Motor

Function Manual, 01/2015 3

Introduction

Hotline and Internet addresses

Additional information

Click the following link to find information on the following topics:

● Ordering documentation / overview of documentation

● Additional links to download documents

● Using documentation online (find and search manuals/information)

http://www.siemens.com/motioncontrol/docu

My Documentation Manager

Click the following link for information on how to compile documentation individually on the

basis of Siemens content and how to adapt it for the purpose of your own machine

documentation:

http://www.siemens.com/mdm

Training

FAQs

Technical support

Click the following link for information on SITRAIN - Siemens training courses for automation

products, systems and solutions:

http://www.siemens.com/sitrain

Frequently Asked Questions can be found in SIMOTION Utilities & Applications, which are

included in the scope of delivery of SIMOTION SCOUT, and in the Service&Support pages

in Product Support:

http://support.automation.siemens.com

Country-specific telephone numbers for technical support are provided on the Internet under

Contact:

http://www.siemens.com/automation/service&support

Supplement to SIMODRIVE POSMO A Positioning Motor

4 Function Manual, 01/2015

Table of contents

Introduction...................................................................................................................................................3

1 Fundamental safety instructions...................................................................................................................7

1.1 General safety instructions.......................................................................................................7

1.2 Industrial security.....................................................................................................................7

2 Description....................................................................................................................................................9

2.1 General....................................................................................................................................9

2.2 Installation and startup...........................................................................................................11

2.3 Inserting a SIMODRIVE POSMO A positioning motor into a SIMOTION project...................12

2.4 Integrating the function blocks in the user project..................................................................13

2.5 Creating I/O Variables............................................................................................................14

3 Function blocks...........................................................................................................................................17

3.1 Overview of function blocks...................................................................................................17

3.2 Function block _POSMOA_control.........................................................................................17

3.3 Function block _POSMOA_nControl......................................................................................24

3.4 Function block _POSMOA_rwParameter...............................................................................29

3.5 Function block _POSMOA_rwAllParameter...........................................................................32

3.6 Calling function blocks...........................................................................................................38

4 Application example...................................................................................................................................41

4.1 General information on the application example....................................................................41

4.2 Operator control and monitoring of the application example in the detail view......................43

4.3 Variables used in application example...................................................................................47

A Appendix.....................................................................................................................................................51

A.1 SIMOTION and SIMATIC names...........................................................................................51

A.2 List of abbreviations...............................................................................................................55

Index...........................................................................................................................................................57

Supplement to SIMODRIVE POSMO A Positioning Motor

Function Manual, 01/2015 5

Table of contents

Supplement to SIMODRIVE POSMO A Positioning Motor

6 Function Manual, 01/2015

Fundamental safety instructions

1.1 General safety instructions

WARNING

Risk of death if the safety instructions and remaining risks are not carefully observed

If the safety instructions and residual risks are not observed in the associated hardware

documentation, accidents involving severe injuries or death can occur.

● Observe the safety instructions given in the hardware documentation.

● Consider the residual risks for the risk evaluation.

WARNING

Danger to life or malfunctions of the machine as a result of incorrect or changed

parameterization

As a result of incorrect or changed parameterization, machines can malfunction, which in turn

can lead to injuries or death.

● Protect the parameterization (parameter assignments) against unauthorized access.

● Respond to possible malfunctions by applying suitable measures (e.g. EMERGENCY

STOP or EMERGENCY OFF).

1

1.2 Industrial security

Note

Industrial security

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, solutions, machines, equipment and/or networks. They are

important components in a holistic industrial security concept. With this in mind, Siemens’

products and solutions undergo continuous development. Siemens recommends strongly that

you regularly check for product updates.

For the secure operation of Siemens products and solutions, it is necessary to take suitable

preventive action (e.g. cell protection concept) and integrate each component into a holistic,

state-of-the-art industrial security concept. Third-party products that may be in use should also

be considered. For more information about industrial security, visit http://www.siemens.com/

industrialsecurity.

To stay informed about product updates as they occur, sign up for a product-specific

newsletter. For more information, visit http://support.automation.siemens.com

Supplement to SIMODRIVE POSMO A Positioning Motor

Function Manual, 01/2015 7

Fundamental safety instructions

1.2 Industrial security

WARNING

Danger as a result of unsafe operating states resulting from software manipulation

Software manipulation (e.g. by viruses, Trojan horses, malware, worms) can cause unsafe

operating states to develop in your installation which can lead to death, severe injuries and/

or material damage.

● Keep the software up to date.

Information and newsletters can be found at:

http://support.automation.siemens.com

● Incorporate the automation and drive components into a state-of-the-art, integrated

industrial security concept for the installation or machine.

For more detailed information, go to:

http://www.siemens.com/industrialsecurity

● Make sure that you include all installed products into the integrated industrial security

concept.

Supplement to SIMODRIVE POSMO A Positioning Motor

8 Function Manual, 01/2015

Description

2.1 General

Overview

SIMODRIVE POSMO A is an intelligent distributed positioning drive on the PROFIBUS DP

field bus (DP standard slave).

The power unit and all of the motion control are located in the motor.

All of the signals and data for commissioning and operating the drive are transferred via the

PROFIBUS DP.

The operating energy is supplied by a 24 VDC connection (for a 75 W motor) or a 48 VDC

connection (for a 300 W motor).

The integrated positioning functionality is suitable for a variety of simple single-axis

applications, such as adjusting endstops and formats.

Note

Hardware and software requirements

The following requirements apply for the functionalities described in this manual:

● Hardware release POSMO A 75 W: As of O

● Software release POSMO A 75 W: As of V3.0

● Hardware release POSMO A 300 W: As of G

● Software release POSMO A 300 W: As of V3.0

2

POSMO A positioning motors with different hardware and software requirements can be

controlled with function blocks integrated in SIMOTION SCOUT V4.1. The functionality is

restricted by the hardware/software release of the POSMO A positioning motor used.

Requirement

The following software versions are required for the standard functions described in this

documentation:

● SIMOTION SCOUT V4.1 or higher

● SIMOTION Kernel V4.1 or higher

● SIMOTION technology packages V4.1 or higher

Communication

The PROFIBUS DP field bus allows rapid cyclical data exchange between the DP slave

(POSMO A) and the higher-level DP master (SIMOTION hardware platform, such as

SIMOTION C2xx).

Supplement to SIMODRIVE POSMO A Positioning Motor

Function Manual, 01/2015 9

Description

2.1 General

Further information

Note

For more information, refer to the "Product brief" section of the

on PROFIBUS DP

This documentation is included in the SIMOTION SCOUT scope of delivery as electronic

documentation!

Installation and connection

For a description of how to install and connect a SIMODRIVE POSMO A and points you must

be aware of when doing so, refer to the "Installation and connection" section of the

Positioning Motor on PROFIBUS DP

On the SIMOTION device (hardware platform), connect SIMODRIVE POSMO A to one of the

PROFIBUS DP interfaces.

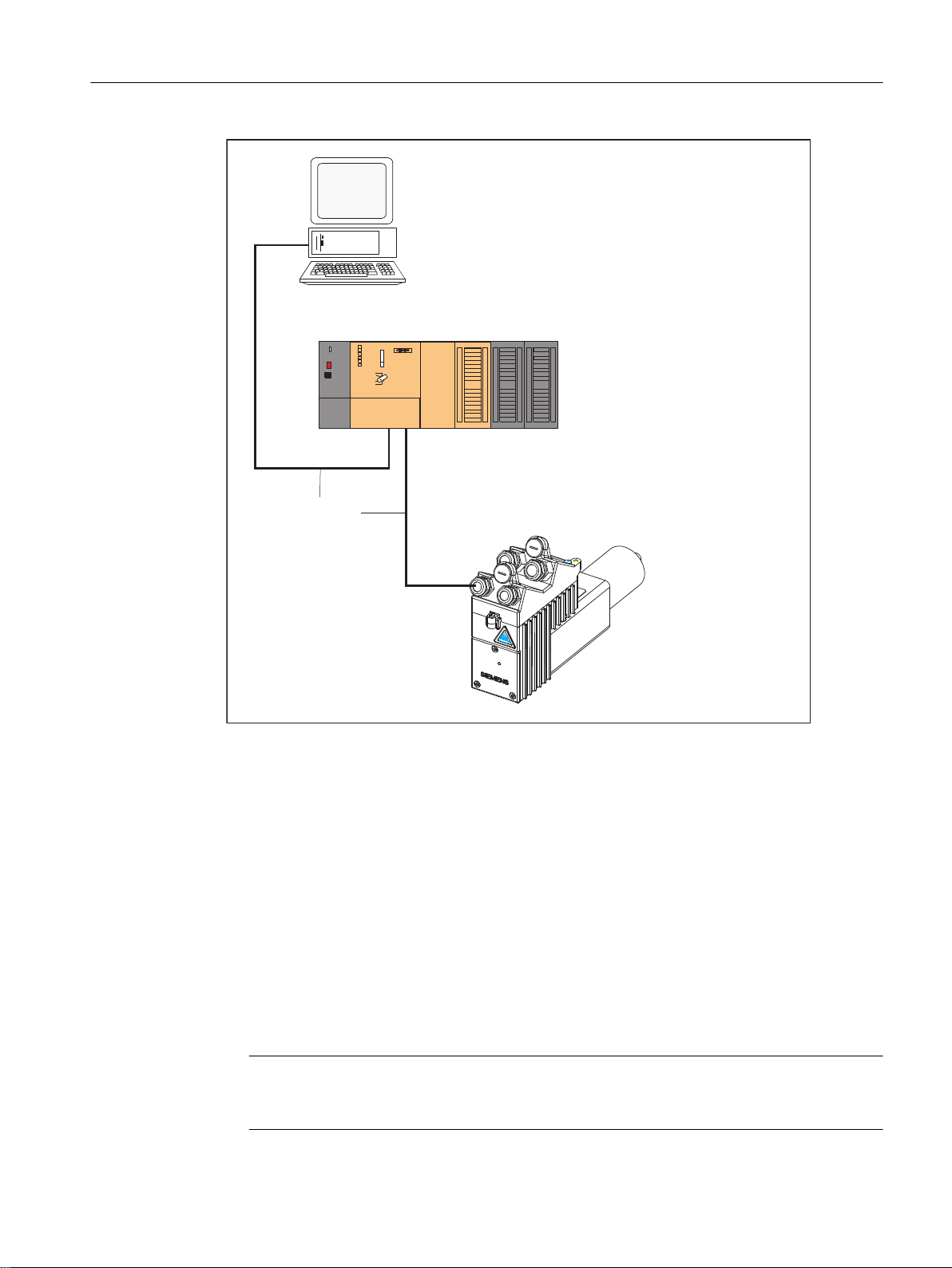

The following figure shows how to connect a SIMODRIVE POSMO A drive to a SIMOTION

hardware platform (such as SIMOTION C2xx).

Distributed Positioning Motor

user manual.

Distributed

user manual.

Supplement to SIMODRIVE POSMO A Positioning Motor

10 Function Manual, 01/2015

6,027,21

+DUGZDUHSODWIRUP

VXFKDV&[[

352),%86'3

&[[

60V36

3RVLWLRQLQJ0RWRU

:

3*3&

Description

2.2 Installation and startup

2.2 Installation and startup

Overview

Supplement to SIMODRIVE POSMO A Positioning Motor

Function Manual, 01/2015 11

Figure 2-1 Connection of SIMODRIVE POSMO A to the SIMOTION C2xx hardware platform

You must perform the following steps to commission the SIMODRIVE POSMO A and control

it from the SIMOTION system:

1. Mount and wire the SIMODRIVE POSMO A positioning motor.

2. Set the PROFIBUS DP node address on the connection cover of the SIMODRIVE

POSMO A.

3. Switch on the terminating resistor at the first and last bus node.

Note

For steps 1 to 3, refer to

Motor on PROFIBUS DP

Section "Installation and Connection"

user manual.

of the

Distributed Positioning

Description

2.3 Inserting a SIMODRIVE POSMO A positioning motor into a SIMOTION project

4. You can use any of the following to commission the SIMODRIVE POSMO A:

– C1 master "SIMODRIVE POSMO A PROFIBUS MASTER"

– Commissioning tool "SimoCom A"

Note

Refer to the

Distributed Positioning Motor on PROFIBUS DP

user manual,

Section

"Commissioning of DP Master".

– "Drive ES" tool. This tool includes "SimoCom A"

Note

Refer to the

5. Insert the SIMODRIVE POSMO A into the SIMOTION project (refer to Section Inserting a

SIMODRIVE POSMO A positioning motor into a SIMOTION project (Page 12)).

6. Control the SIMODRIVE POSMO A from the SIMOTION system using function blocks, see

Section Function blocks (Page 17).

Note

Refer to the

information on the following topics:

● Axis commissioning

● Communication via PROFIBUS DP

● Description of functions

● Error handling and diagnostics

● Assembly and service

Drive ES Basic

Distributed Positioning Motor on PROFIBUS DP

function description.

user manual for more

2.3 Inserting a SIMODRIVE POSMO A positioning motor into a

SIMOTION project

Requirement

The following requirements must be met:

1. You have created a project in SIMOTION SCOUT and have inserted a rack with a

SIMOTION hardware platform in the hardware configuration.

2. You have configured a PROFIBUS subnet.

Note

For information on creating a project and configuring a PROFIBUS subnet, refer to the

online help for SIMOTION SCOUT.

Supplement to SIMODRIVE POSMO A Positioning Motor

12 Function Manual, 01/2015

Inserting SIMODRIVE POSMO A

To integrate the SIMODRIVE POSMO A into the PROFIBUS subnet of your project, proceed

as follows:

1. In SIMOTION SCOUT, open the User Projects dialog box with the Project > Open menu

command. In this dialog box, select your project and confirm your choice with OK.

2. Open HW Config (by double-clicking the SIMOTION device in the project navigator of

SIMOTION SCOUT).

3. In the HW Config window, open the hardware catalog with the View > Catalog menu

command.

4. In the hardware catalog, open the PROFIBUS DP folder and the SIMODRIVE subfolder

and select SIMODRIVE POSMO A.

5. Use a drag-and-drop operation to move the SIMODRIVE POSMO A onto the PROFIBUS

subnet of your project.

The Properties - PROFIBUS Interface SIMODRIVE POSMO A dialog box is displayed. In

this dialog box, you select the address you set in the connection cover of POSMO A (see

Section "Installation and Connection" of the Distributed Positioning Motor on PROFIBUS

DP

user manual) and confirm with OK.

The SIMODRIVE POSMO A positioning motor you have selected is inserted into the project.

Description

2.4 Integrating the function blocks in the user project

6. Input and output addresses of the POSMO A.

When you insert the POSMO A into your SIMOTION project, the input and output addresses

are assigned default values. You can see these values when you select the inserted

POSMO A. You can read the input and output addresses in the lower part of the HW

Config window.

You must create these addresses as I/O variables in the symbol browser before calling the

function blocks; see Section Creating I/O Variables (Page 14).

2.4 Integrating the function blocks in the user project

Creating the instance of the FBs in the user project

The function blocks are part of the program library of the SIMOTION SCOUT engineering

system. For working with the blocks, an instance has to be created in the user project for each

function block used and if using the _POSMOA_rwAllParameter function block, a variable of

type Struct_POSMOA_params.

Example:

VAR_GLOBAL

...

myPosmoAControl : _POSMOA_control; // FB for controlling of POSMO A

myPosmoArwParameter : _POSMOA_rwParameter; // FB for handling single parameter

myPosmoArwAllParameter : _POSMOA_rwAllParameter; // FB for handling parameterset

myAllParaPosmoA : Struct_POSMOA_params; // Variable for structure of all

// parameters POSMO A

Supplement to SIMODRIVE POSMO A Positioning Motor

Function Manual, 01/2015 13

Description

2.5 Creating I/O Variables

...

END_VAR

Call (LAD representation)

The LAD representation of the individual function blocks can be found in the respective function

block descriptions.

Example of an application

The application example is contained on the "SIMOTION Utilities & Applications" CD-ROM

and is available for various SIMOTION hardware platforms.

The "SIMOTION Utilities & Applications" CD-ROM is provided free of charge and part of the

SIMOTION SCOUT scope of delivery.

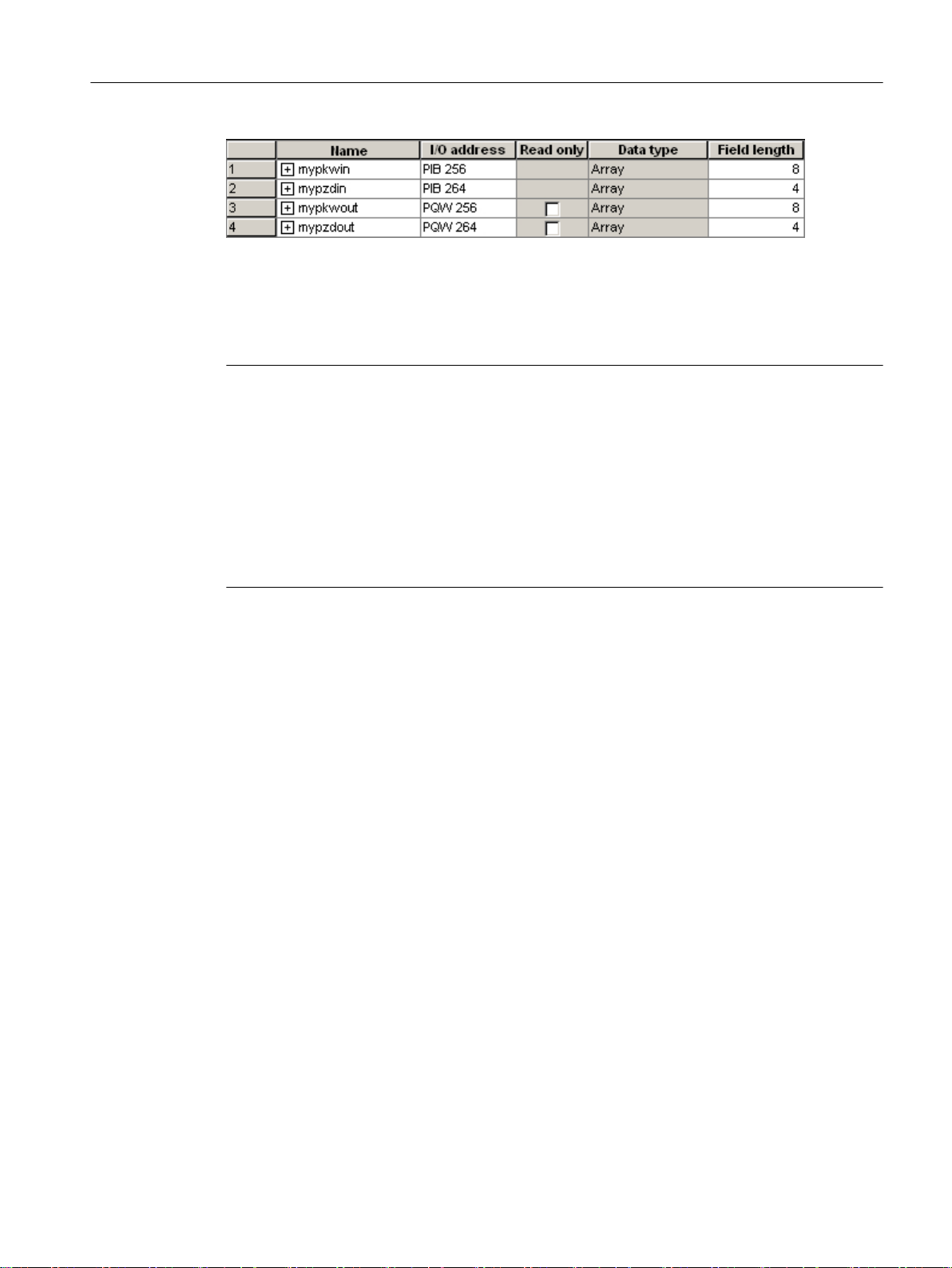

2.5 Creating I/O Variables

Overview

Communication between the SIMOTION hardware platform and the SIMODRIVE POSMO A

takes place through direct access to the I/O. I/O variables are used to address the direct read/

write access to the I/O.

You can freely assign the names of I/O variables in SIMOTION SCOUT. You must define the

I/O variables as ARRAY [0..7] and [0..3] of BYTE. You assign the address settings in the

hardware configuration to these I/O variables.

The names of the I/O inputs must be transferred to the function blocks as call parameters. The

prepared data for the I/O outputs are provided by the function block as in/out parameters. The

in/out parameters must be be supplied with variables of type ARRAY [0..7] of BYTE and [0..3]

of BYTE. Once the block has been called, these variables must be assigned to the I/O variables

for the I/O outputs; see call example in Section Calling function blocks (Page 38).

Note

The variable for supplying the in/out parameters must not be created as a temporary variable

(VAR_TEMP or local variable of a function).

The following example shows how to assign the module addresses to the I/O variables in

SIMOTION SCOUT.

Supplement to SIMODRIVE POSMO A Positioning Motor

14 Function Manual, 01/2015

Description

2.5 Creating I/O Variables

Figure 2-2 Address assignment in SIMOTION SCOUT

Each input and output address has a range of 8 bytes (which corresponds to the parameter

identifier value (PKW) range of POSMO A) and a range of 4 bytes (which corresponds to the

process data (PZD) range of POSMO A).

Note

For additional information, refer to:

●

SIMOTION SCOUT

online help

● Programming Manual of the corresponding programming language, e.g.:

–

SIMOTION ST, Structured Text

–

SIMOTION MCC, Motion Control Chart Programming Manual

–

SIMOTION LAD/FBD, Ladder Diagram and Function Block Diagram Programming

Programming Manual

Manual

These documents are shipped with SIMOTION SCOUT in electronic form!

Supplement to SIMODRIVE POSMO A Positioning Motor

Function Manual, 01/2015 15

Description

2.5 Creating I/O Variables

Supplement to SIMODRIVE POSMO A Positioning Motor

16 Function Manual, 01/2015

Function blocks

3.1 Overview of function blocks

This section contains a description of all of the function blocks (FBs) and the data structure

you need for communication between a SIMOTION hardware platform and the SIMODRIVE

POSMO A.

The function blocks form the software interface between the SIMOTION system and the

SIMODRIVE POSMO A positioning motor.

These function blocks make it easier to control and assign parameters for a SIMODRIVE

POSMO A positioning motor from the SIMOTION program.

For example, you can assign parameters for a POSMO A without being familiar with

PROFIBUS parameter formats and request specifiers.

The function blocks must be called repeatedly (in cycles) from the user program.

The following function blocks are available:

● Function block _POSMOA_control (Page 17)

● Function block _POSMOA_nControl (Page 24) (V4.1 and higher):

● Function block _POSMOA_rwParameter (Page 29)

3

● Function block _POSMOA_rwAllParameter (Page 32)

Note

For the complete control and communication of the SIMODRIVE POSMO A from the

SIMOTION program, an instance must be created for each _POSMOA_rwParameter and

_POSMOA_rwAllParameter function block and, depending on the parameterized operating

mode (speed or position control mode), an instance of the _POSMOA_control or

_POSMOA_nControl function block.

Note

If the SIMODRIVE POSMO A is disconnected and then reconnected to the power system, any

MDI traversing block data (see the table titled "Parameters of the _POSMOA_control function

block") that had been transferred previously must be transferred to the POSMO A again.

3.2 Function block _POSMOA_control

Task

You can control the connected SIMODRIVE POSMO A with the _POSMOA_control function

block.

Supplement to SIMODRIVE POSMO A Positioning Motor

Function Manual, 01/2015 17

Function blocks

3.2 Function block _POSMOA_control

The functions are as follows:

● Initialize

Sets the drive in "ready to operate" mode.

Requirements:

– A drive fault has not been signaled (driveError = FALSE)

– Fault acknowledgement is not active (resetError = FALSE)

● Referencing

Sets the home position for the drive.

● Tippen

The drive travels at a controlled speed in a plus or minus direction.

● Program execution

Starts, stops, or aborts a single block addressed by blockNumber or a block within the

program.

● MDI

The drive travels at the assigned speed and acceleration to an assigned position.

The MDI parameters are transferred in block 3.

The MDI block can be started with blockNumber = 3 and start = TRUE.

● Fault acknowledgement

Acknowledges a fault in the drive.

Note

A fault must be acknowledged before the drive can move. This requires that parameter

enable = TRUE.

● Automatic single-block operation/automatic control

Checkback signals are as follows:

● Current traversing block

● Data Set Ready

● Warning and fault information

● Complete status (status word and checkback signal byte)

● Data transfer status

Supplement to SIMODRIVE POSMO A Positioning Motor

18 Function Manual, 01/2015

Loading...

Loading...