Siemens SIMOCODE pro, SIMOCODE pro PCS 7 Programming And Operating Manual

Programming and

Operating Manual

Industrial Controls

Function Block Library SIMOCODE pro

for SIMATIC PCS 7

SIMOCODE pro PCS 7 Library V9.0

Edition

06/2017

siemens.com

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

Industrial Controls

SIMOCODE pro

SIMOCODE pro PCS 7 Library V9.0

Programming and Operating Manual

06/2017

A5E40899442002A/RS

Introduction

1

Templates

2

Block icons and faceplate

views

3

Description of the blocks

4

Maintenance Station

5

Parameter

A

Technical Data

B

Abbreviations

C

-AA/001

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E40899442002A/RS-AA/001

Ⓟ

Copyright © Siemens AG 2017.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

for the specific

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

06/2017 Subject to change

Table of contents

1 Introduction .............................................................................................................................................. 10

2 Templates ................................................................................................................................................ 38

1.1 Security information ............................................................................................................... 10

1.2 Product specific security information ..................................................................................... 10

1.3 Components of the software package ................................................................................... 11

1.4 Supported control functions ................................................................................................... 12

1.5 Configuration Steps ............................................................................................................... 14

1.5.1 Configuring in HW Config ...................................................................................................... 14

1.5.2 Configuring in CFC ................................................................................................................ 16

1.6 Driver generator ..................................................................................................................... 17

1.6.1 Driver generator ..................................................................................................................... 17

1.6.2 Requirements for generating the module drivers ................................................................... 19

1.6.3 Driver blocks .......................................................................................................................... 20

1.6.4 Object lists and action lists ..................................................................................................... 20

1.7 Example configurations .......................................................................................................... 21

1.7.1 SIMOCODE pro PROFIBUS and PROFINET Configuration ................................................. 21

1.7.2 SIMOCODE pro PROFIBUS configuration ............................................................................ 21

1.7.3 SIMOCODE pro PROFINET configuration ............................................................................ 24

1.8 Parameterization softwares ................................................................................................... 32

1.8.1 Parameterization Softwares ................................................................................................... 32

1.8.2 Configuring in SIMOCODE ES .............................................................................................. 32

1.8.2.1 Parameter settings ................................................................................................................. 34

1.8.3 Configuration with SIMATIC PDM .......................................................................................... 35

1.8.4 Device type selection in HW Config ....................................................................................... 35

1.9 Configuring of the fail-safe, digital PROFIsafe module .......................................................... 36

1.10 Update an existing PCS 7 project .......................................................................................... 37

1.11 Further documentation ........................................................................................................... 37

2.1 Overview of the templates, control functions and blocks ....................................................... 38

2.2 Using templates ..................................................................................................................... 39

2.3 Template OvlRly..................................................................................................................... 42

2.4 Template Direct ...................................................................................................................... 43

2.5 Template Reverse .................................................................................................................. 44

2.6 Template MCCB..................................................................................................................... 45

2.7 Template StarDel ................................................................................................................... 46

2.8 Template RevStarDel ............................................................................................................. 47

2.9 Template Dahland .................................................................................................................. 48

SIMOCODE pro PCS 7 Library V9.0

4 Programming and Operating Manual, 06/2017, A5E40899442002A/RS-AA/001

Table of contents

3 Block icons and faceplate views .............................................................................................................. 56

4 Description of the blocks .......................................................................................................................... 72

2.10 Template RevDahl .................................................................................................................. 49

2.11 Template PoleChng ................................................................................................................ 50

2.12 Template RevPoleCh .............................................................................................................. 51

2.13 Template SolValve .................................................................................................................. 52

2.14 Template Positner ................................................................................................................... 53

2.15 Template SoftStr ..................................................................................................................... 54

2.16 Template RevSoftStr............................................................................................................... 55

2.17 Sample Project ........................................................................................................................ 55

3.1 Block icons .............................................................................................................................. 56

3.2 Faceplates .............................................................................................................................. 58

3.2.1 Faceplates - Structure............................................................................................................. 58

3.2.2 Navigation between SIMOCODE pro faceplates .................................................................... 61

3.2.3 Views ...................................................................................................................................... 62

3.2.3.1 Batch view ............................................................................................................................... 62

3.2.3.2 Trend view .............................................................................................................................. 62

3.2.3.3 Alarm view .............................................................................................................................. 64

3.2.3.4 Memo view .............................................................................................................................. 66

3.2.3.5 Preview view ........................................................................................................................... 67

3.2.4 Scalable faceplates ................................................................................................................. 67

3.3 Central color management ..................................................................................................... 69

3.4 Web Navigator ........................................................................................................................ 70

3.5 APL Operator Trend Control (AOTC) for Digital Values ......................................................... 71

4.1 Functions for all blocks ........................................................................................................... 72

4.1.1 Calling OBs ............................................................................................................................. 72

4.1.2 Called blocks ........................................................................................................................... 73

4.1.3 Worst signal status .................................................................................................................. 74

4.1.4 Quality code ............................................................................................................................ 75

4.1.5 Error numbers ......................................................................................................................... 77

4.1.6 Reading and writing data records ........................................................................................... 78

4.1.7 Read Record error status ....................................................................................................... 79

4.1.8 Write Record error status ........................................................................................................ 79

4.1.9 Overview of the measuring point browser window ................................................................. 79

4.1.10 Configurable response using the Feature I/O ......................................................................... 80

4.1.10.1 Start-up characteristics ........................................................................................................... 80

4.1.10.2 Response for Out of service mode ......................................................................................... 81

4.1.10.3 Resets the commands for switching between modes ............................................................ 81

4.1.10.4 Enabling resetting of commands for the control settings ........................................................ 82

4.1.10.5 Setting switch or button mode ................................................................................................ 82

4.1.10.6 Set switching mode ................................................................................................................. 83

4.1.10.7 Enabling direct changeover between forward and reverse .................................................... 83

4.1.10.8 Resetting via input signals in the event of interlocking (Protection) or errors......................... 84

4.1.10.9 Exit local mode ........................................................................................................................ 84

4.1.10.10 Enable runtime for feedback signals ....................................................................................... 84

SIMOCODE pro PCS 7 Library V9.0

Programming and Operating Manual, 06/2017, A5E40899442002A/RS-AA/001

5

Table of contents

4.1.10.11 Separate monitoring time for stopping the motor ................................................................... 85

4.1.10.12 Enabling rapid stop via faceplate ........................................................................................... 85

4.1.10.13 Activate bumpless changeover to automatic mode ............................................................... 85

4.1.10.14 Activate fault status for external control system fault ............................................................. 86

4.1.10.15 Reset even in locked state ..................................................................................................... 86

4.1.10.16 Disable Feedback Tracking LocalSetting 2 & 4 ..................................................................... 86

4.1.10.17 Bumpless switchover to automatic mode .............................................................................. 87

4.1.10.18 Update acknowledgement and error status of the alarm ....................................................... 87

4.1.10.19 Activate local operator permission ......................................................................................... 87

4.1.10.20 Suppression of all messages ................................................................................................. 88

4.1.10.21 Interlock display with LocalSetting 2 or 4 ............................................................................... 88

4.1.10.22 Define reset as a function of the mode .................................................................................. 88

4.1.10.23 Enable reset of interlocks in manual mode ............................................................................ 90

4.1.10.24 Suppression of single alarm message ................................................................................... 91

4.1.10.25 Resetting control in case of invalid command ....................................................................... 91

4.1.10.26 Setting switch or button mode for local commands ............................................................... 91

4.1.10.27 Evaluation of the signal status of the interlock signals .......................................................... 92

4.1.10.28 Forcing operating modes in the "Local" mode ....................................................................... 93

4.1.10.29 Considering bad quality of automatic commands or external values .................................... 93

4.1.10.30 Separate interlock for each direction or position .................................................................... 93

4.2 Diagnostics block MMDiag ..................................................................................................... 94

4.2.1 Description of MMDiag ........................................................................................................... 94

4.2.2 Acyclic reading of data record 92 ........................................................................................... 95

4.2.3 Message characteristics ........................................................................................................ 95

4.2.4 Driver generator ..................................................................................................................... 96

4.2.5 Start-up characteristics .......................................................................................................... 97

4.2.6 Module error ........................................................................................................................... 97

4.2.7 IO station failure (PROFIBUS DP or PROFINET IO) ............................................................. 98

4.2.8 Failure of a PROFIBUS DP station ........................................................................................ 99

4.2.9 Malfunction when loading the OB .......................................................................................... 99

4.3 MMOprtn block ..................................................................................................................... 100

4.3.1 Description of MMOprtn ....................................................................................................... 100

4.3.2 Parameterizable functions via the Feature connection MMOprtn ........................................ 101

4.3.3 Operating modes ................................................................................................................. 102

4.3.4 Motor current ........................................................................................................................ 103

4.3.5 Device functions ................................................................................................................... 103

4.3.6 Current limits ........................................................................................................................ 106

4.3.7 Hysteresis ............................................................................................................................ 107

4.3.8 Emergency start ................................................................................................................... 107

4.3.9 Self-test ................................................................................................................................ 108

4.3.10 Trip reset .............................................................................................................................. 109

4.3.11 Group fault ........................................................................................................................... 109

4.3.12 Fault handling ....................................................................................................................... 110

4.3.13 Invalid input signals .............................................................................................................. 110

4.3.14 Message characteristics ...................................................................................................... 110

4.3.15 Messages via Event16Ts message block ............................................................................ 111

4.3.16 System text libraries for warning and trip ............................................................................. 113

4.3.17 Process images for the MMOprtn block ...............................................................................

116

4.3.18 Enabled operations .............................................................................................................. 130

4.3.19 Status information ................................................................................................................ 131

4.3.20 SIMOCODE pro slave diagnostics ....................................................................................... 132

SIMOCODE pro PCS 7 Library V9.0

6 Programming and Operating Manual, 06/2017, A5E40899442002A/RS-AA/001

Table of contents

4.3.21

3.22 Assignment of the diagnostics information ........................................................................... 140

4.

Diagnostics information ........................................................................................................ 133

4.3.23 Faceplate views .................................................................................................................... 148

4.3.23.1 MMOprtn - Standard ............................................................................................................. 148

4.3.23.2 MMOprtn - Limits .................................................................................................................. 150

4.3.23.3 MMOprtn - Diagnostics ......................................................................................................... 152

4.3.23.4 MMOprtn - Process image .................................................................................................... 153

4.4 Block for MMMeas measured value function ........................................................................ 154

4.4.1 Description of MMMeas ........................................................................................................ 154

4.4.2 Parameterizable functions via the Feature connection MMMeas ......................................... 155

4.4.3 Operating modes .................................................................................................................. 155

4.4.4 Measured values ................................................................................................................... 156

4.4.4.1 Read measured values ......................................................................................................... 158

4.4.4.2 Assignment of the cyclic process image ............................................................................... 159

4.4.4.3 Write analog output ............................................................................................................... 160

4.4.4.4 Acyclic reading ...................................................................................................................... 160

4.4.5 Message characteristics ....................................................................................................... 161

4.4.6 Start-up characteristics ......................................................................................................... 162

4.4.7 Status information ................................................................................................................. 163

4.4.8 Enabled operations ............................................................................................................... 164

4.4.9 Faceplate views .................................................................................................................... 165

4.4.9.1 MMMeas Standard ................................................................................................................ 165

4

.4.9.2 MMMeas - Standard 1 .......................................................................................................... 166

4.4.9.3 MMMeas - Standard 2 .......................................................................................................... 167

4.4.9.4 MMMeas - Standard 3 .......................................................................................................... 169

4.4.9.5 MMMeas - Standard 4 .......................................................................................................... 170

4.5 Block for statistical function MMStat ..................................................................................... 172

4.5.1 Description of MMStat........................................................................................................... 172

4.5.2 Parameterizable functions via the Feature connection MMStat ........................................... 173

4.5.3 Operating modes .................................................................................................................. 173

4.5.4 Statistical values ................................................................................................................... 173

4.5.5 Message characteristics ....................................................................................................... 175

4.5.6 Start-up characteristics ......................................................................................................... 176

4.5.7 Status information ................................................................................................................. 177

4.5.8 Enabled operations ............................................................................................................... 178

4.5.9 Faceplate views .................................................................................................................... 179

4.5.9.1 MMStat - Standard 1 ............................................................................................................. 179

4.5.9.2 MMStat - Standard 2 ............................................................................................................. 181

4.6 Block for timestamping MMLog ............................................................................................ 183

4.6.1 Description MMLog ............................................................................................................... 183

4.6.2 Parameterizable functions via the Feature connection MMLog ........................................... 184

4.6.3 Operating modes .................................................................................................................. 184

4.6.4 Logbook function ................................................................................................................... 185

4.6.5 Messages .............................................................................................................................. 188

4.6.6 Signaling response ...............................................................................................................

.6.7 Driver generator ....................................................................................................................

4

.6.8 Start-up characteristics ......................................................................................................... 192

4

190

192

4.6.9 Status information ................................................................................................................. 192

4.6.10 Enabled operations ............................................................................................................... 194

4.6.11 Faceplate views .................................................................................................................... 194

4.6.11.1 MMLog - Standard ................................................................................................................ 194

SIMOCODE pro PCS 7 Library V9.0

Programming and Operating Manual, 06/2017, A5E40899442002A/RS-AA/001

7

Table of contents

5 Maintenance Station .............................................................................................................................. 230

A Parameter .............................................................................................................................................. 234

4.6.11.2 MMLog - Logbook ................................................................................................................ 195

4.7 MMRevDhl motor block ........................................................................................................ 197

4.7.1 Application ............................................................................................................................ 197

4.7.1.1 Description of MMRevDhl .................................................................................................... 197

4.7.1.2 Operating modes ................................................................................................................. 198

4.7.1.3 Mode changeover error ........................................................................................................ 200

4.7.1.4 Forcing operating modes ..................................................................................................... 201

4.7.1.5 Control functions for directions ............................................................................................ 202

4.7.2 Parameterizable functions via the Feature connection MMRevDhl ..................................... 203

4.7.3 Output signal for ready to start ............................................................................................. 204

4.7.4 Resetting of the block .......................................................................................................... 204

4.7.5 Limit value monitoring with hysteresis ................................................................................. 205

4.7.6 Rapid stop ............................................................................................................................ 205

4.7.7 Specify warning times for controls ....................................................................................... 205

4.7.8 Issuing maintenance release ............................................................................................... 206

4.7.9 Suppressing messages using the MsgLock parameter ....................................................... 206

4.7.10 Simulation ............................................................................................................................ 206

4.7.11 Monitoring functions ............................................................................................................. 207

4.7.12 Motor Protection ................................................................................................................... 209

4.7.13 Interlocking ........................................................................................................................... 209

4.7.14 Disabling interlocks .............................................................................................................. 212

4.7.15 Group fault ........................................................................................................................... 212

4.7.16 User-defined auxiliary values and user-defined status ........................................................ 213

4.

7.17 Message characteristics ...................................................................................................... 213

4.7.18 Fault handling ....................................................................................................................... 216

4.7.19 Invalid input signals .............................................................................................................. 216

4.7.20 Enable for measurement and statistics ................................................................................ 216

4.7.21 Enabled operations .............................................................................................................. 216

4.7.22

4.

7.23 Restart lock after changing direction of rotation or switching off the motor using idle

Status information ................................................................................................................ 218

time ...................................................................................................................................... 221

4.7.24 Selecting a unit of measure ................................................................................................. 222

4.7.25 Faceplate views ................................................................................................................... 223

4.7.25.1 MMRevDhl - Standard ......................................................................................................... 223

4.7.25.2 MMRevDhl - Maintenance ................................................................................................... 225

4.7.25.3 MMRevDhl - Preview ........................................................................................................... 227

5.1 Maintenance Station ............................................................................................................ 230

A.1 MMDiag block parameter ..................................................................................................... 234

A.2 Structure of UDTs for MMDiag ............................................................................................. 237

A.3 Block parameter MMOprtn ................................................................................................... 244

A.4 Block parameter MMMeas ................................................................................................... 252

A.5 Block parameter MMStat ..................................................................................................... 260

A.6 Block parameter MMLog ...................................................................................................... 267

A.7 Block parameter MMRevDhl ................................................................................................ 273

SIMOCODE pro PCS 7 Library V9.0

8 Programming and Operating Manual, 06/2017, A5E40899442002A/RS-AA/001

Table of contents

B Technical Data ....................................................................................................................................... 283

C Abbreviations ......................................................................................................................................... 285

B.1 Header information ............................................................................................................... 284

SIMOCODE pro PCS 7 Library V9.0

Programming and Operating Manual, 06/2017, A5E40899442002A/RS-AA/001

9

1

1.1

Security information

1.2

Product specific security information

Product specific security information

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines, and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions only form one element of such a concept.

Customer is responsible to prevent unauthorized access to its plants, systems, machines

and networks. Systems, machines and components should only be connected to the

enterprise network or the internet if and to the extent necessary and with appropriate security

measures (e.g. use of firewalls and network segmentation) in place.

Additionally, Siemens’ guidance on appropriate security measures should be taken into

account. For more information about industrial security, please visit:

http://www.siemens.com/industrialsecurity.

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends to apply product updates as soon as available and to

always use the latest product versions. Use of product versions that are no longer supported,

and failure to apply latest updates may increase customer’s exposure to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under

http://www.siemens.com/industrialsecurity.

This library is designed to run under the PCS 7 environment. Therefore, it is recommended

to follow the security principles for PCS 7 to support a secure operation, such as:

● User rights

● Password protection of

– WinCC

– SIRIUS devices

For more information, click here

(https://support.industry.siemens.com/cs/document/60119725

).

SIMOCODE pro PCS 7 Library V9.0

10 Programming and Operating Manual, 06/2017, A5E40899442002A/RS-AA/001

Introduction

1.3

Components of the software package

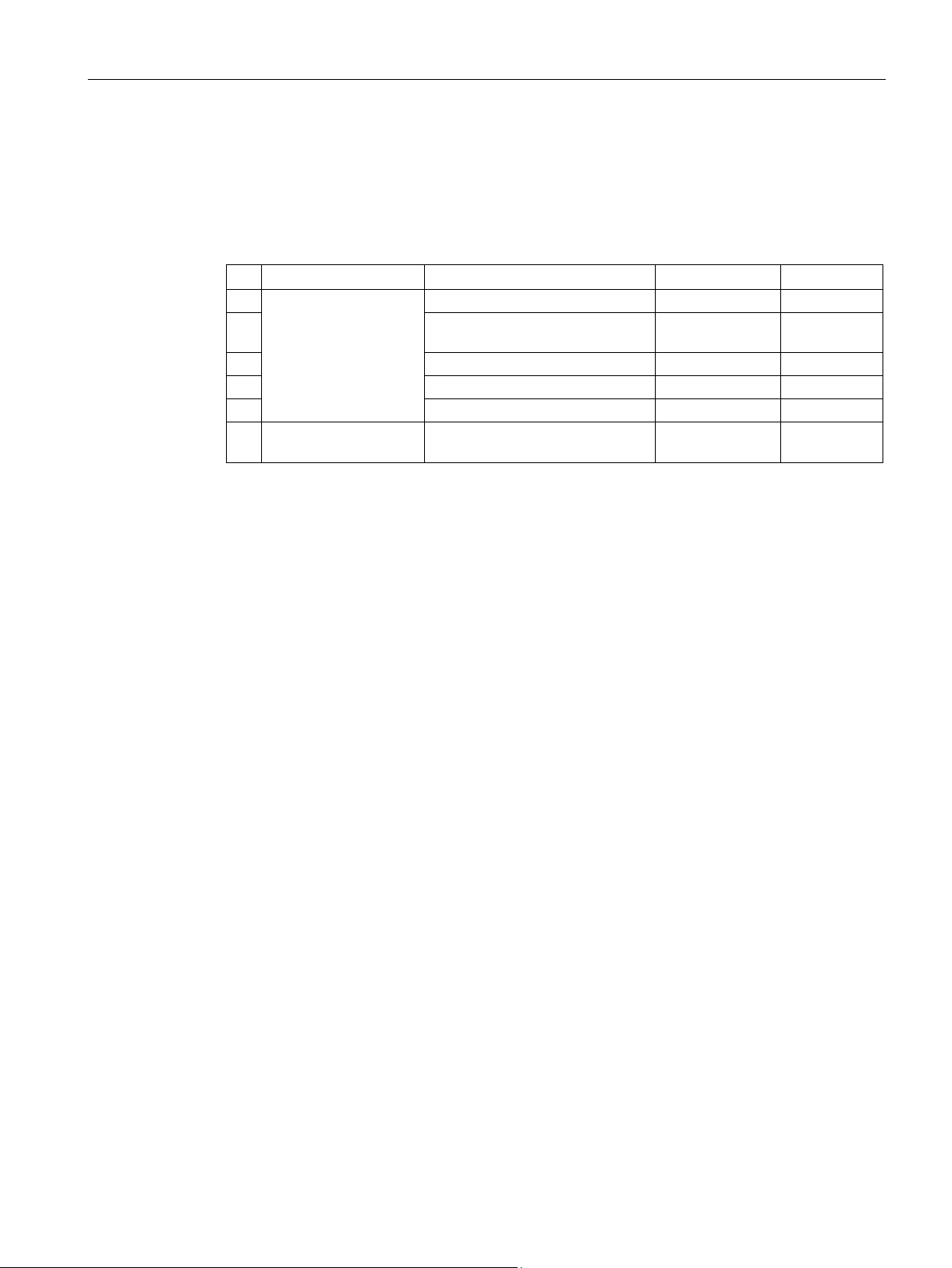

No.

Supported Hardware

Functions

Name

Name

1

Diagnostics function

MMDiag

FB1300

3

Measured value function

MMMeas

FB1302

4

Statistics function

MMStat

FB1303

5

Time stamping, logbook function

MMLog

FB1304

High Feature reversing starters

Reference

1.3 Components of the software package

The SIMOCODE pro PCS 7 Library V9.0 integrates SIMOCODE pro C / S / V devices into

the PCS 7 environment via blocks.

The SIMOCODE pro PCS 7 Library V9.0 contains the following components:

SIMOCODE pro DPV1

and SIMOCODE pro

2 Driver block for operating

PROFINET

SIMOCODE pro C / S / V devices

MMOprtn FB1301

6 SIMOCODE pro Motor block – control functions for

● List Manual

● Online help with context-sensitive help

● Installation program

● Readme file for installation

Description of MMDiag (Page 94)

Description of MMOprtn (Page 100)

Description of MMMeas (Page 154)

Description of MMStat (Page 172)

Description of MMLog (Page 183)

Description of MMRevDhl (Page 197)

MMRevDhl FB1305

SIMOCODE pro PCS 7 Library V9.0

Programming and Operating Manual, 06/2017, A5E40899442002A/RS-AA/001

11

Introduction

1.4

Supported control functions

The SIMOCODE pro library V9.0 supports the following control functions:

Control function

SIMOCODE

pro C

SIMOCODE

pro S

SIMOCODE

pro V

Overload relay

X X X

Reversing starter

X X X

Circuit breaker

X X X

Star-delta starter

– X X

Star-delta reversing starter

– – X

Dahlander – –

X

Dahlander reversing starter

– – X

Pole-changing starter

– – X

Pole-changing reversing starter

– – X

Valve – –

X

Positioners 1–5

– – X

Soft starter – X

X

Soft reversing starter

– – X

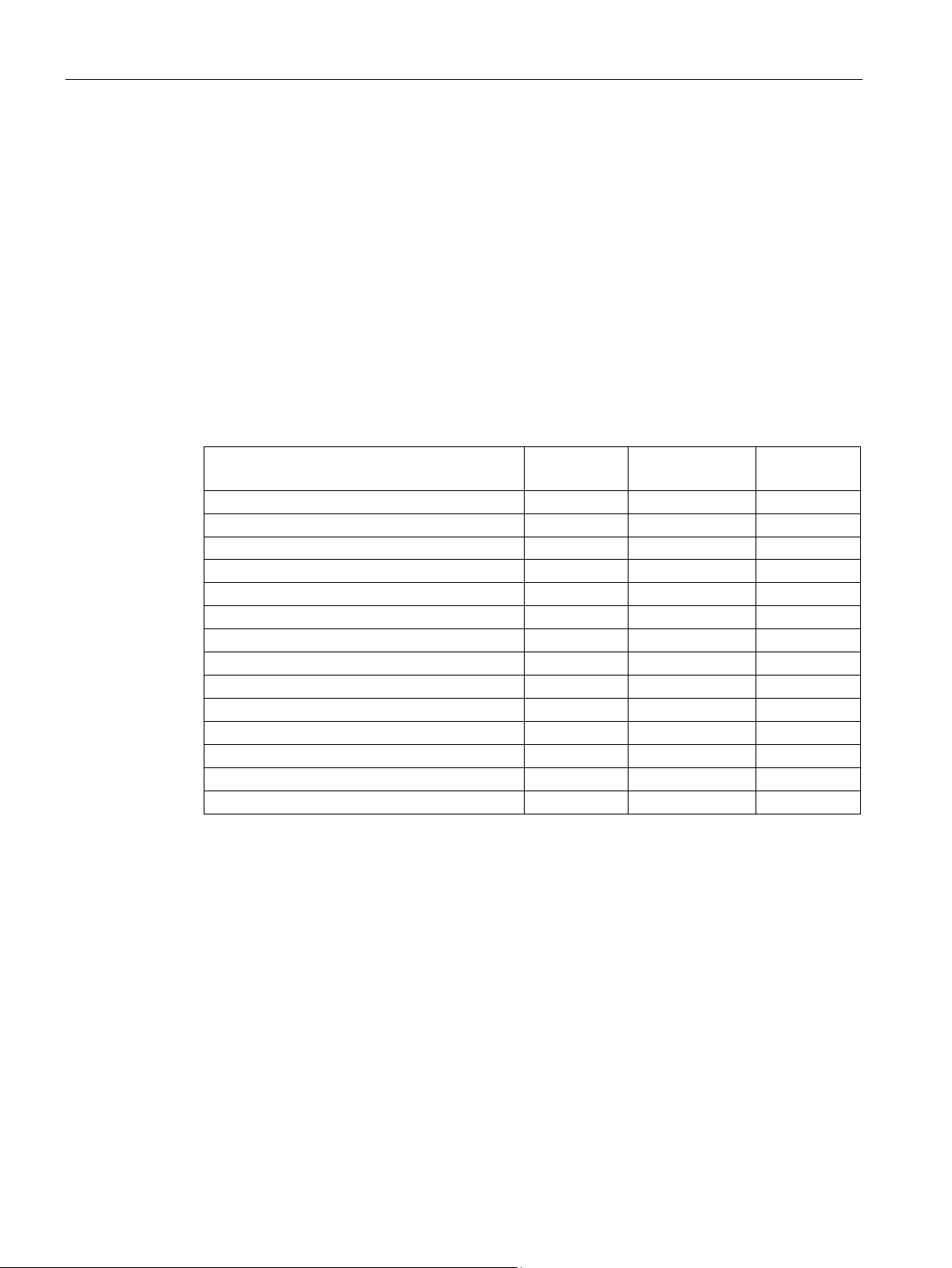

1.4 Supported control functions

The library supports all SIMOCODE pro control functions. Motor blocks of the Advanced

Process Library (APL) are used for this. For control functions that are not supported by the

APL motor blocks (two directions of rotation, two speeds), the library contains the block

MMRevDhl.

For communication with the SIMOCODE pro device, the channel block FbSwtMMS from the

APL is used.

Device-specific functions that do not belong to the standard of the APL motor blocks are

provided by the other blocks of the SIMOCODE pro Library.

Table 1- 1 Supported control functions

Direct starter X X X

SIMOCODE pro PCS 7 Library V9.0

12 Programming and Operating Manual, 06/2017, A5E40899442002A/RS-AA/001

Introduction

Control functions and blocks

Control functions

APL blocks

Blocks from the

SIMOCODE pro Library

Overload relay1

–

Soft reversing starter

Pole-changing starter

Valve

VlvL

Positioners 1–5

VlvMotL

MMLog

1

MMOprtn can be used for the overload relay control function without APL motor blocks.

1.4 Supported control functions

The table shows the control functions and the corresponding blocks with which the APL is

linked into the SIMOCODE pro PCS 7 Library V9.0.

Table 1- 2 Control functions and blocks

MMOprtn

Direct starter

Soft starter

Circuit breaker

Star-delta starter

Reversing starter

Star-delta reversing starter

MotL

MotRevL

MMDiag

MMMeas

MMStat

MMLog

Dahlander

Dahlander reversing starter

Pole-changing reversing starter

MotSpdL

– MMRevDhl

MMOprtn

MMDiag

MMMeas

MMStat

SIMOCODE pro PCS 7 Library V9.0

Programming and Operating Manual, 06/2017, A5E40899442002A/RS-AA/001

13

Introduction

1.5

Configuration Steps

1.5.1

Configuring in HW Config

Configuring in HW Config

1.5 Configuration Steps

The two bytes of the process image inputs (PII) are transferred from the SIMOCODE device

based on the logical address configured for the module. This is a manual configuration that a

user has to configure for both the inputs and outputs.

● Drag and drop the desired SIMOCODE pro object (OM, PDM or GSD) out of the HW

Catalog into the "Station" window of HW Config and connect it to the desired fieldbus

(PROFIBUS or PROFINET).

● HW Config assigns the logical address to the object which will be used for setting up of

the CFC template.

SIMOCODE pro PCS 7 Library V9.0

14 Programming and Operating Manual, 06/2017, A5E40899442002A/RS-AA/001

Introduction

Symbolic name in HW Config

1.5 Configuration Steps

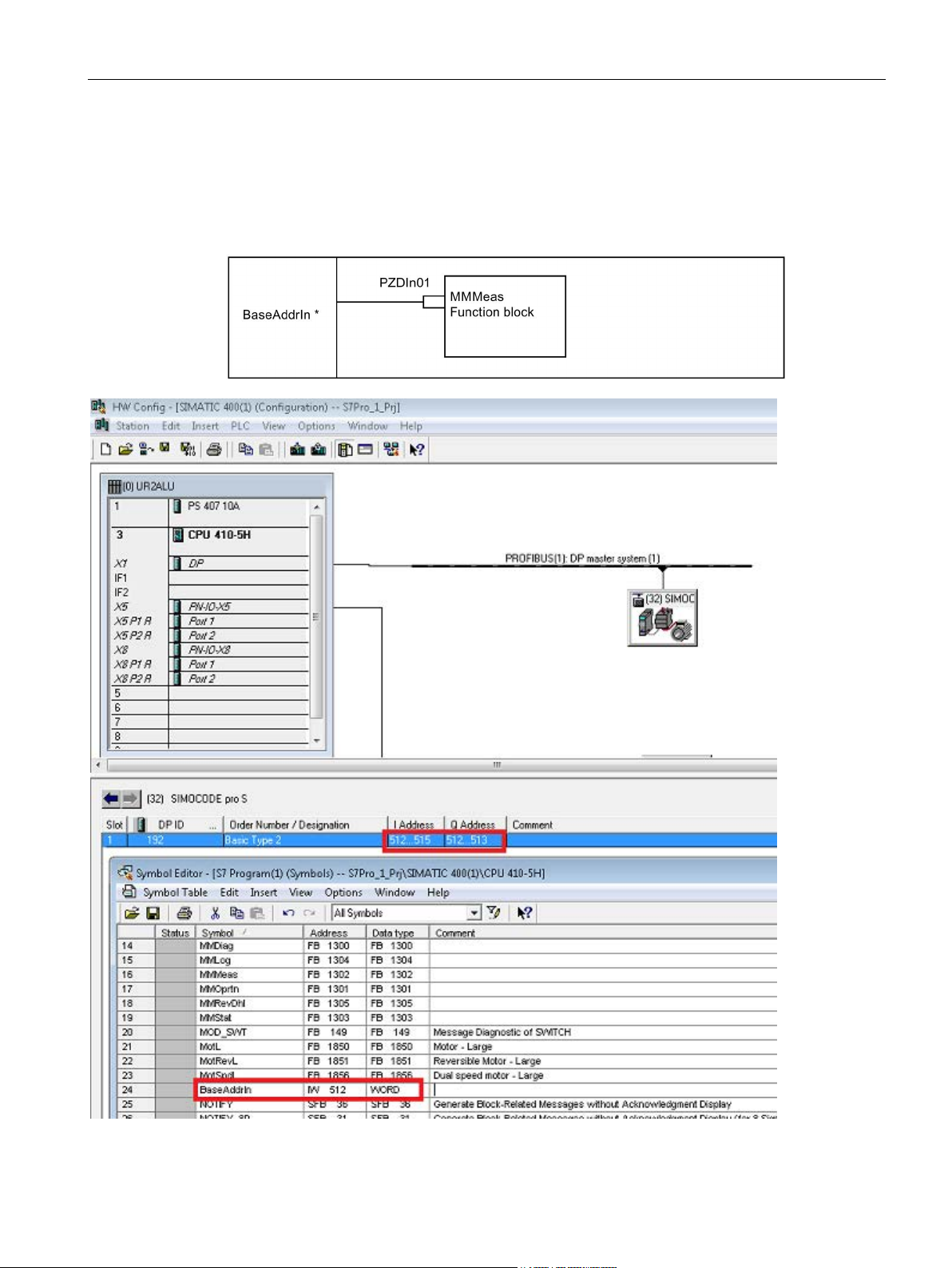

The PZDIn01 input parameter of the block is interconnected with the corresponding input of

the logical address of the device (

The logical word address can be assigned to a symbolic name (*).

LAddr).

Figure 1-1 Symbolic Name

SIMOCODE pro PCS 7 Library V9.0

Programming and Operating Manual, 06/2017, A5E40899442002A/RS-AA/001

15

Introduction

1.5.2

Configuring in CFC

Procedure

Reference

1.5 Configuration Steps

The two bytes of the process image inputs (PII) are transferred from the SIMOCODE device

based on the logical address configured for the module. This is a manual configuration that a

user has to configure.

Configuring with HW Config:

1. Configure the SIMOCODE pro device at HW config.

2. Open CFC-Editor.

3. If not yet done, instantiate an appropriate template and open it.

4. Refer to the input address of the SIMOCODE pro device at HW Config and assign this

address to the textual interconnection "Input WORD address of SIMOCODE pro Module

(IW x)".

Compile the CFC chart using the "Generate Module Driver" function.

Additional information is available in the "Process Control System PCS 7 Compendium

Part A - Configuration Guidelines" Operating Manual on the Internet

(https://support.industry.siemens.com/cs/document/63187279

).

SIMOCODE pro PCS 7 Library V9.0

16 Programming and Operating Manual, 06/2017, A5E40899442002A/RS-AA/001

Introduction

1.6

Driver generator

1.6.1

Driver generator

Purpose of the driver generator

Supported modules and configurations

1.6 Driver generator

The "Generate Module Drivers" function is available for signal processing in PCS 7. Once

the hardware has been configured in HW Config and the technological functions have been

configured in the CFC, this function automatically generates, interconnects, and

parameterizes the required module driver blocks, to the extent possible. These module driver

blocks are responsible for diagnosing and reporting errors during signal processing.

The Setup program installs XML files for connecting SIMOCODE pro C / S / V with the driver

generator.

A template is inserted for each SIMOCODE pro device. The connection to the hardware is

established using symbolic addressing.

The "Generate Module Driver" option inserts the additionally required blocks, and then

connects and assigns the corresponding parameters.

The driver concept for SIMOCODE pro C / S / V modules takes into account the operation of

various SIMOCODE control functions:

● As a DP slave direct on the DP master system (connection via GSD, PDM object or S7

module via OM SIMOCODE pro)

● As a DP slave behind a Y-Link (connection via GSD or PDM object)

● As a PROFINET IO Device direct on the PN-IO Controller (with or without system

redundancy, connection via GSD or S7 module via OM SIMOCODE pro PN or via EDD).

● As a shared PN IO Device in conjunction with a PROFIsafe configuration with DM-F

PROFIsafe fail-safe digital module on two different IO Controllers (connection via GSD or

S7 module via OM SIMOCODE pro PN or via EDD) for a GSD-file-based configuration.

● As a DP slave behind IE-PB-Link (connection via GSD, PDM object or S7 module via OM

SIMOCODE pro).

SIMOCODE pro PCS 7 Library V9.0

Programming and Operating Manual, 06/2017, A5E40899442002A/RS-AA/001

17

Introduction

Reference

Note

The SIMOCODE

Premium configuring software. To install, select the appropriate "SIMOCODE pro Integration

in STEP 7" option when executing the Setup program for SIMOCODE pro.

See also

1.6 Driver generator

1. You will find the GSD files for SIMOCODE pro C / S / V PROFIBUS

(https://support.industry.siemens.com

(https://support.industry.siemens.com/cs/document/38702563) on the Internet

(https://support.industry.siemens.com).

2. Enter one of the following search terms in the "Product Name / Article Number" field

under "Search Product Support Documents":

– SIMOCODE pro C GSD

– SIMOCODE pro S GSD

– SIMOCODE pro V GSD

– SIMOCODE pro V PN GSD

3. Under Downloads click the relevant entry,

e.g., "PROFINET GSD files : Switching Devices" or "PROFIBUS GSD files :

SWITCHGEARS".

4. This displays another Internet page where you can download the GSD files.

) and PROFINET

pro object manager (OM) is a component part of the SIMOCODE ES 2007

PROFIBUS (https://support.industry.siemens.com/cs/document/113630)

SIMOCODE pro PCS 7 Library V9.0

18 Programming and Operating Manual, 06/2017, A5E40899442002A/RS-AA/001

Introduction

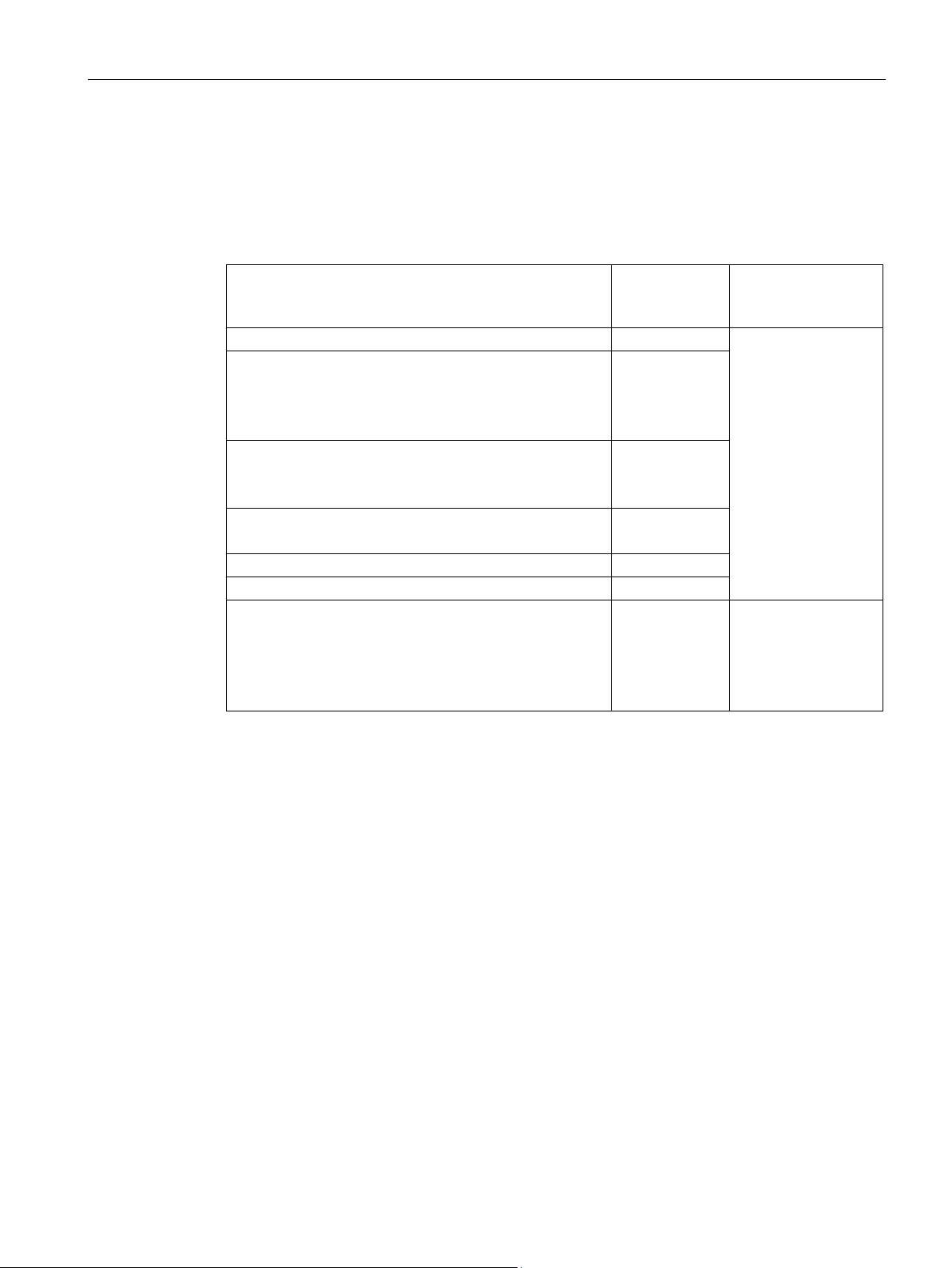

1.6.2

Requirements for generating the module drivers

Article number

SIMOCODE pro

Compatible modules

3UF7000-1A*00-0

SIMOCODE pro C (PROFIBUS DP)

yes

basic unit 1, 2 and 3 (PROFINET)

basic unit 1 and 2

1.6 Driver generator

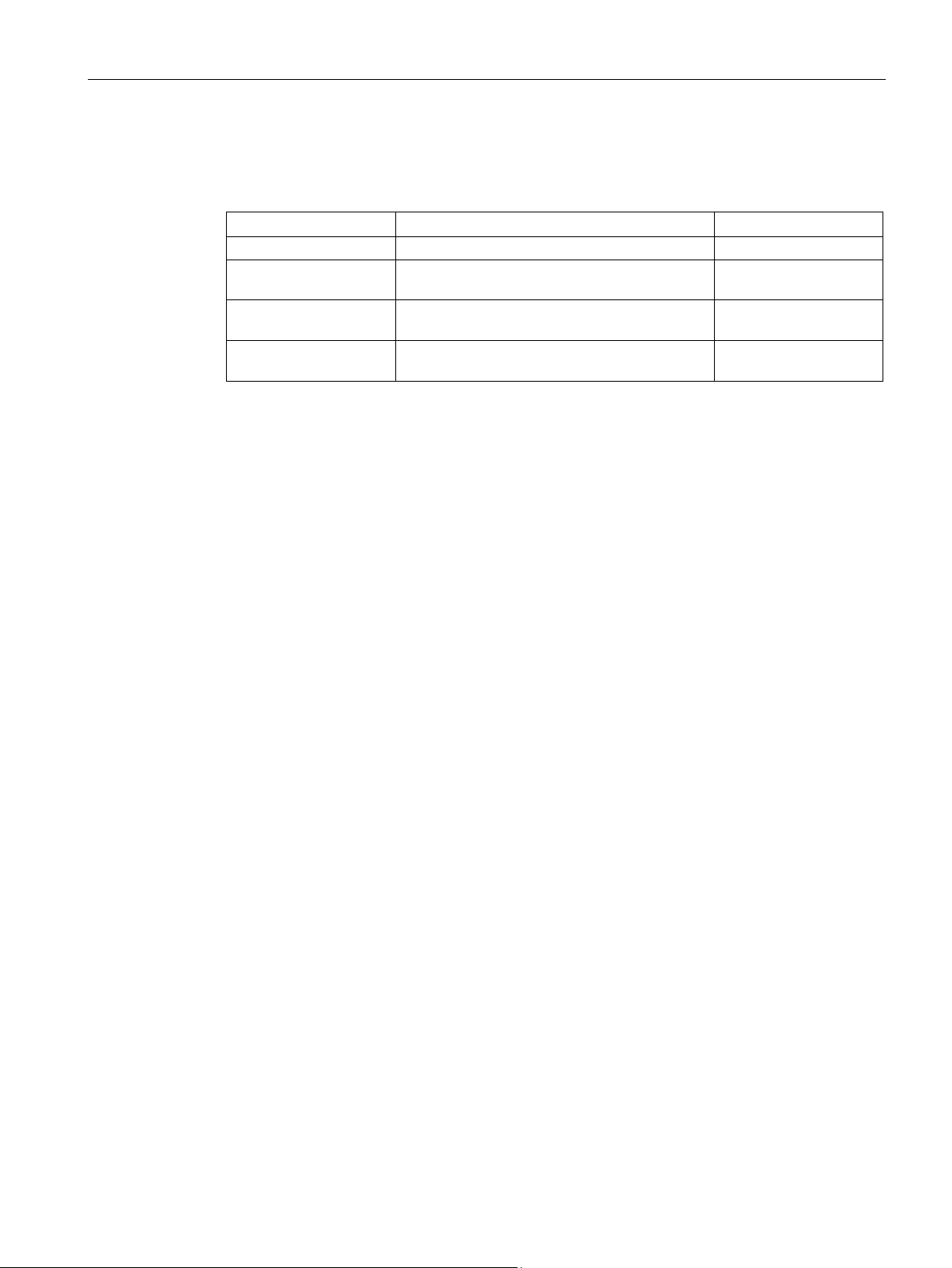

The following SIMOCODE pro modules are permitted for the PCS 7 Library V9.0:

3UF7010-1A*00-0 SIMOCODE pro V

basic unit 1 and 2 (PROFIBUS DP)

3UF7011-1A*00-0 SIMOCODE pro V PN

3UF7020-1A*01-0 SIMOCODE pro S

yes

yes

yes

The desired template is inserted into the CFC from the SIMOCODE library.

Assign the input address of the SIMOCODE pro device to the textual interconnection "Input

WORD address of SIMOCODE pro Module (IW x)" for linking the parameters PZDIn01

(SIMOCODE blocks) / PZDIn1(FbSwtMMS) with the logical address of the starter.

Reproduce the above steps for the other SIMOCODE pro function blocks at the CFC chart, if

you are planning to use any or all of the additional blocks (MMStat, MMMeas and/or MMLog)

shipped with this library.

PZDOut1(FbSwtMMS) also has to be connected to Output address (or), Input address and

Output address should be maintained same while configuring.

The CFC chart is compiled using the "Generate module driver" function.

SIMOCODE pro PCS 7 Library V9.0

Programming and Operating Manual, 06/2017, A5E40899442002A/RS-AA/001

19

Introduction

1.6.3

Driver blocks

Generating the driver blocks

1.6.4

Object lists and action lists

Description

1.6 Driver generator

Module driver generation for the signal blocks will insert driver blocks depending on the HW

Configuration.

The action includes the following steps:

● Determining and assigning the diagnostics address of the SIMOCODE pro device.

● Assigning the primary subnet address and module rack number for the SIMOCODE pro

device.

● Instantiating the OB_DIAG1 / OB_DIAG1_PN driver block for the SIMOCODE pro device.

● Instantiating the MMDiag driver block for reading the diagnostics information of the

SIMOCODE pro device.

● Setting the address of the device at the OB_DIAG1 / OB_DIAG1_PN, MMDiag and

MOD_SWT blocks.

● Creating interconnections between the OB_DIAG1 / OB_DIAG1_PN, MMDiag and

MOD_SWT blocks.

● Assigning the diagnostic address in the

● Making interconnections between the MMOprtn, MMMeas, MMStat and MMLog blocks

and the MMDiag and MOD_SWT blocks.

DAddr parameter.

Hardware modules, among other things, are configured in HW Config.

The object lists and the action lists are used to generate the module drivers for these

hardware modules.

The object list contains a unique object identification number for each of these hardware

modules. Each object list is assigned to a particular hardware configuration.

The action list contains a list of actions. These actions must be executed for the object

identification numbers that appear in the object list. Examples of such actions include:

● Assigning the device address

● Interconnecting the input and output parameters of the driver block

The "Generate Module Driver" function generates the module drivers when the CFC is

compiled.

SIMOCODE pro PCS 7 Library V9.0

20 Programming and Operating Manual, 06/2017, A5E40899442002A/RS-AA/001

Introduction

1.7

Example configurations

1.7.1

SIMOCODE pro PROFIBUS and PROFINET Configuration

SIMOCODE pro PROFIBUS and PROFINET configurations

Note

SIMOCODE pro is used in DP mode DPV1 with a

1.7.2

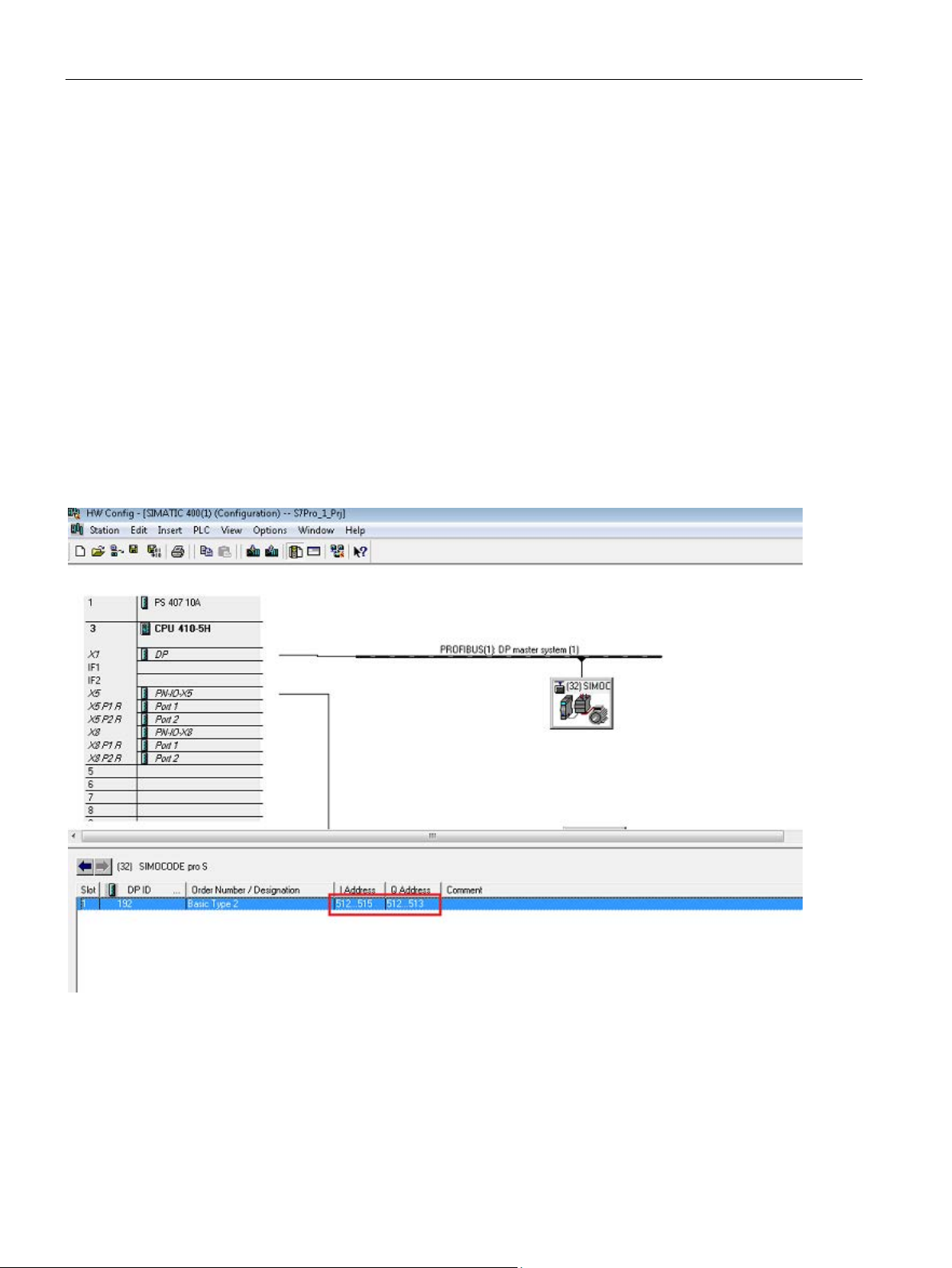

SIMOCODE pro PROFIBUS configuration

SIMOCODE pro C on DP master system

1.7 Example configurations

ctivated diagnostics and process interrupt.

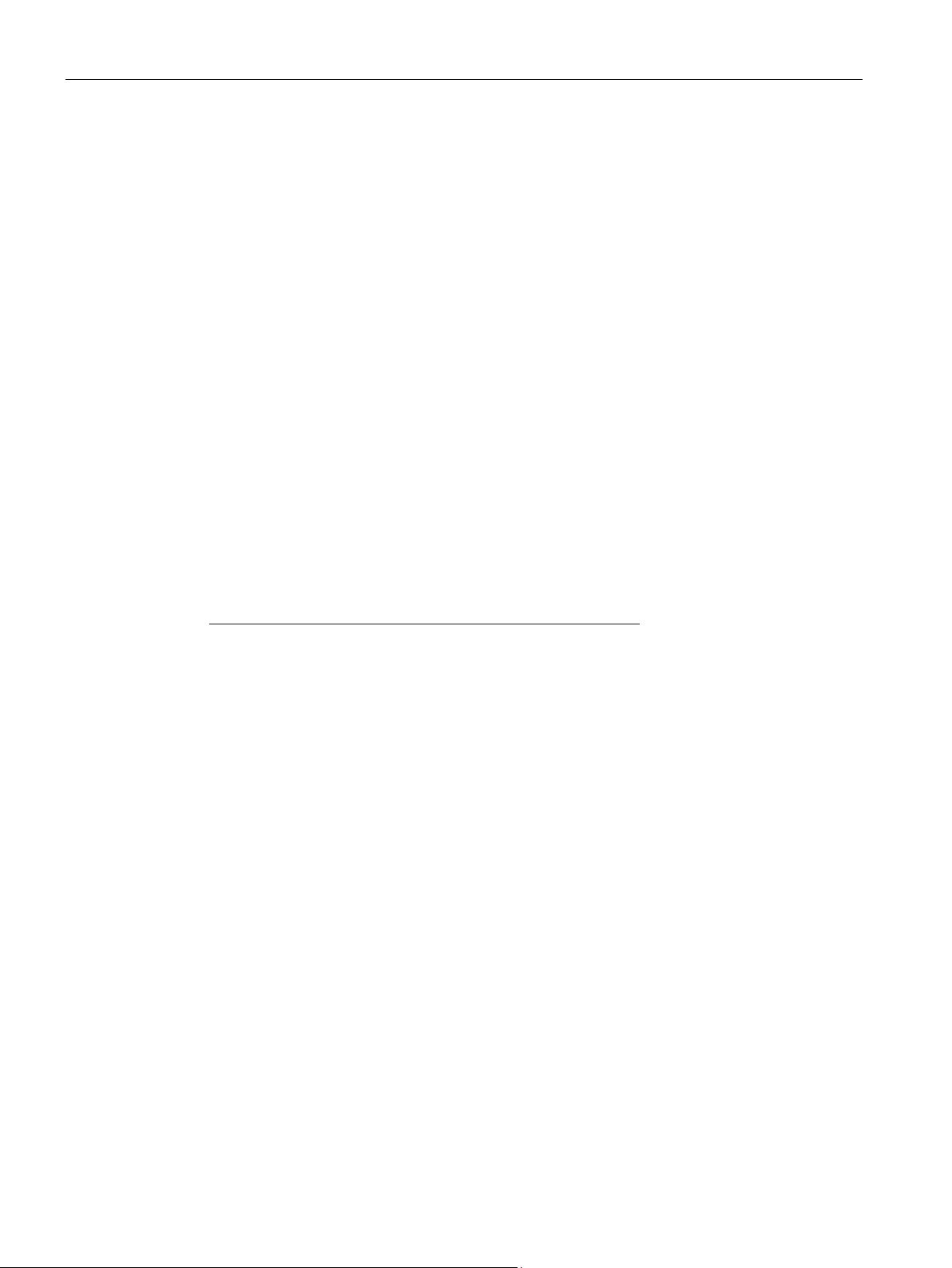

The SIMOCODE pro PROFIBUS and PROFINET devices along with their associated

components are inserted and configured in HW Config.

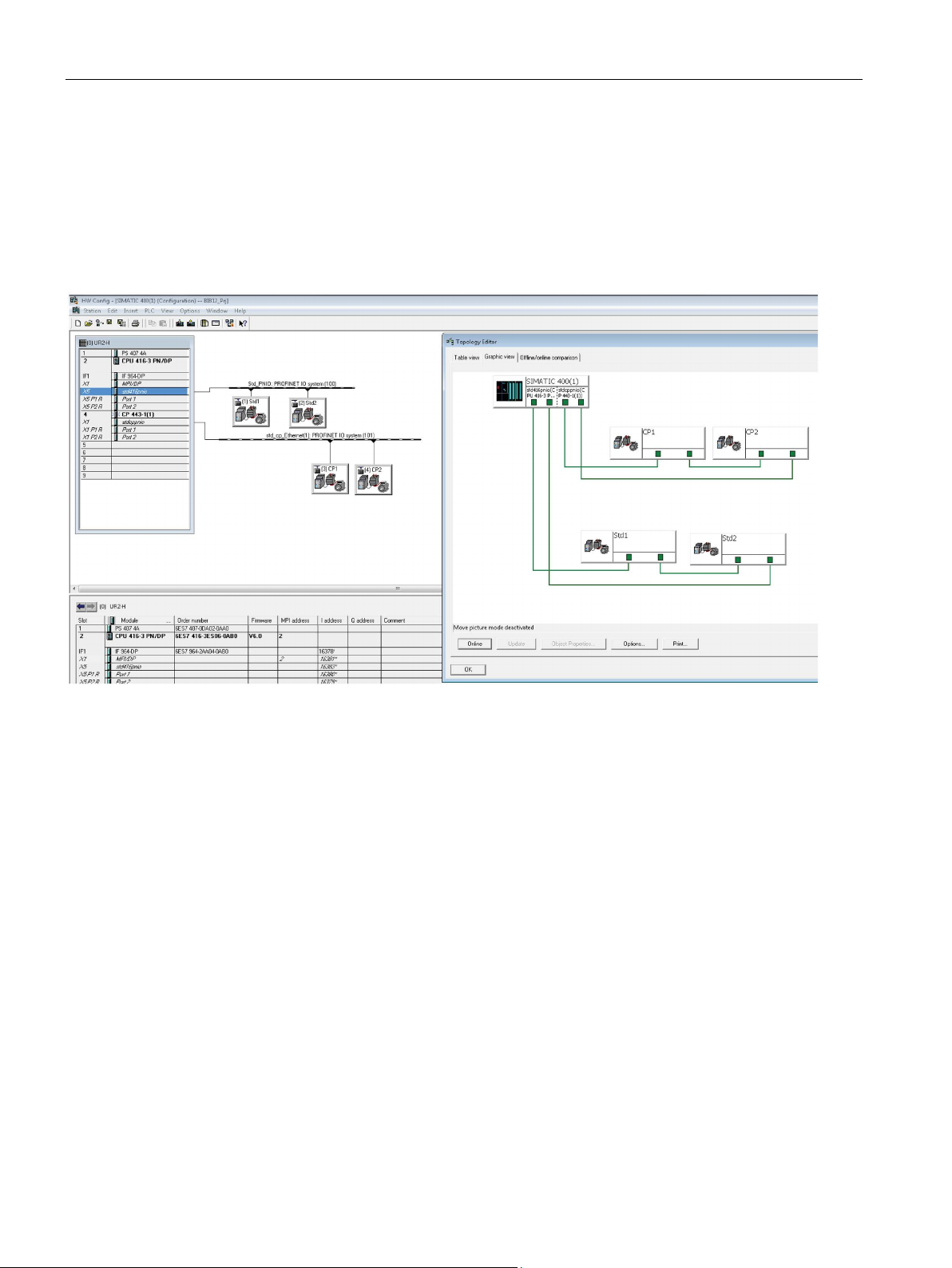

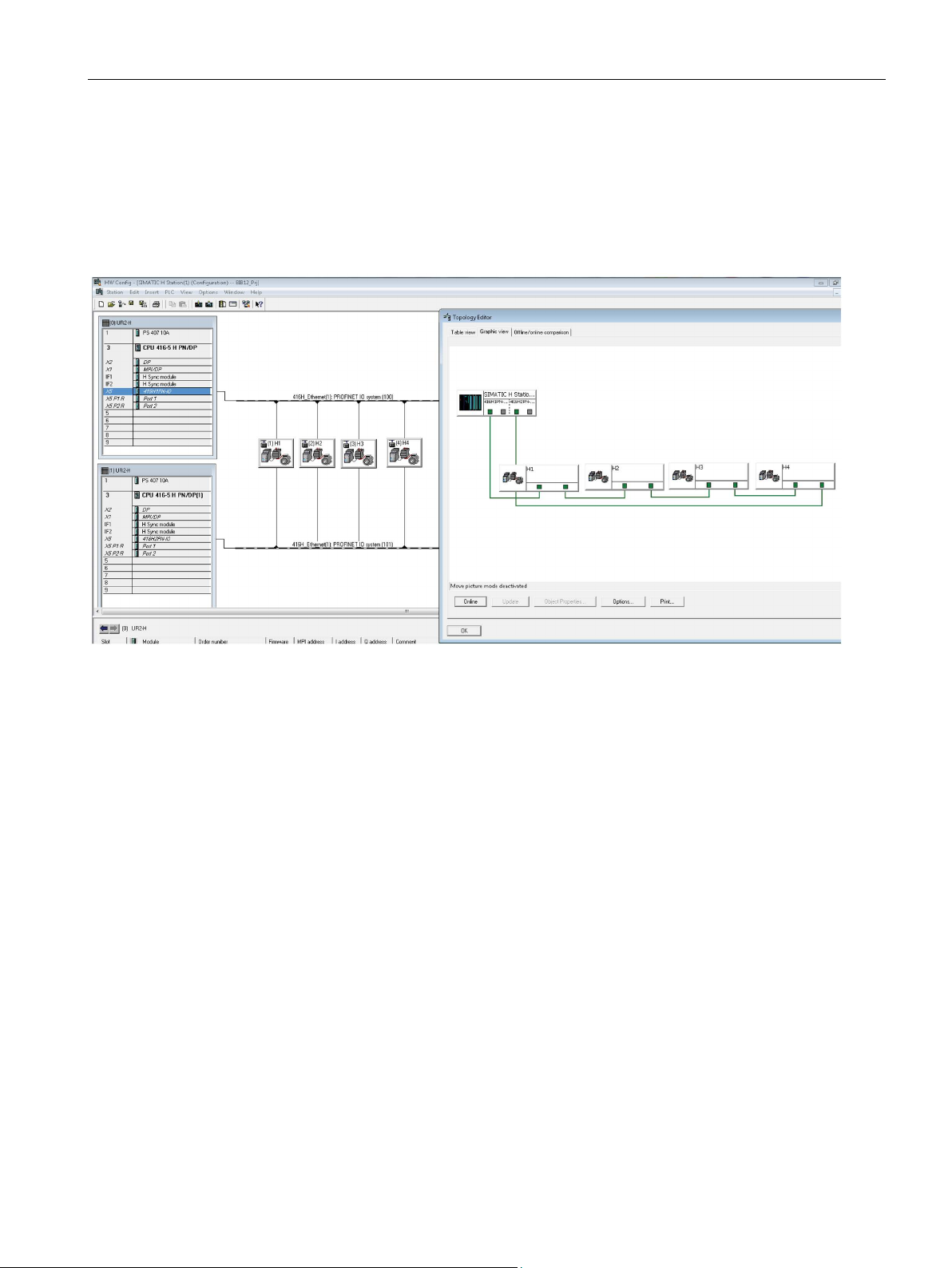

The following graphics show example configurations of SIMOCODE pro at HW Config in the

Netpro View.

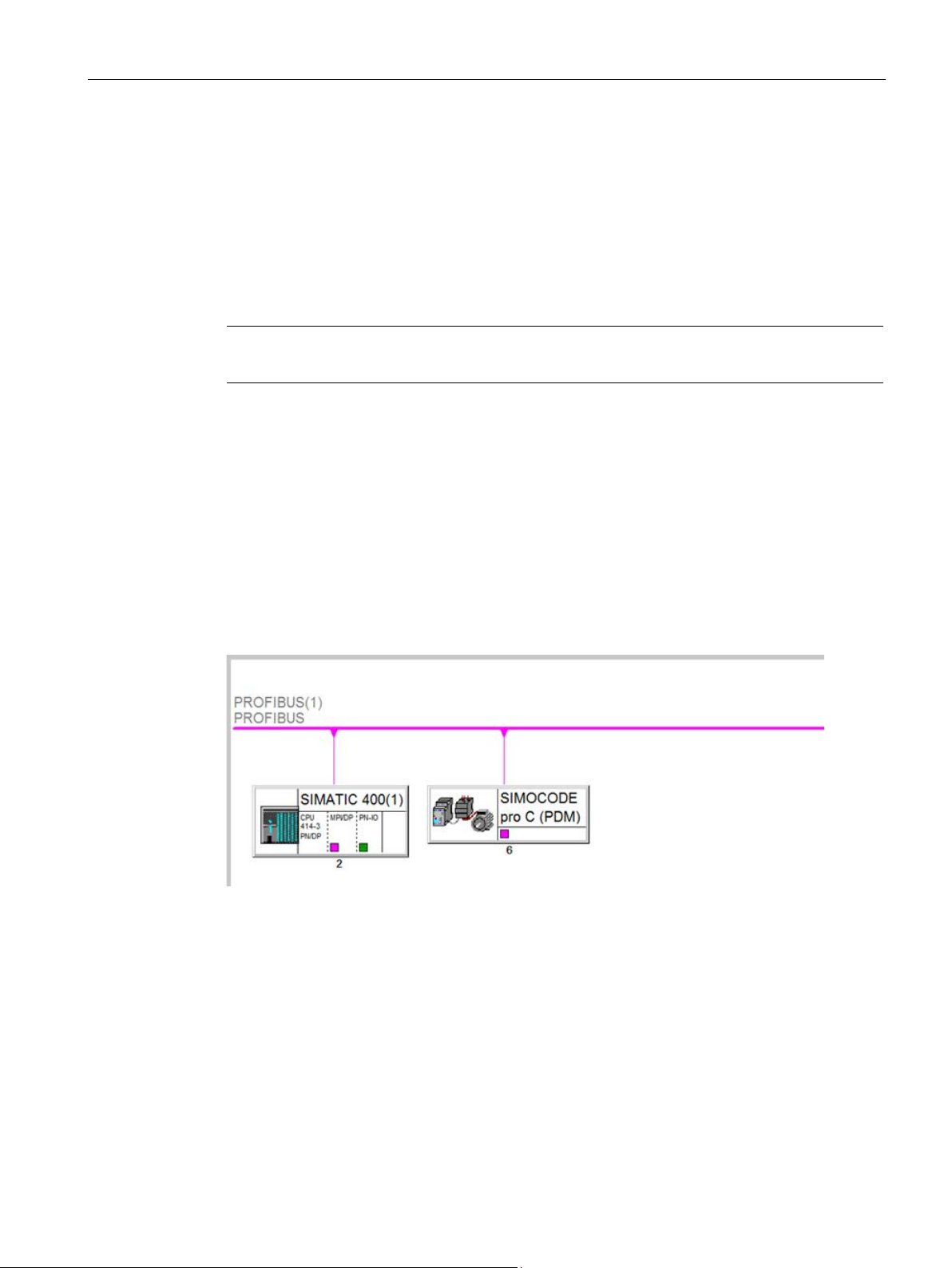

Figure 1-2 SIMOCODE pro C on DP master system

SIMOCODE pro PCS 7 Library V9.0

Programming and Operating Manual, 06/2017, A5E40899442002A/RS-AA/001

21

Introduction

SIMOCODE pro S on DP master system

SIMOCODE pro V on DP master system

1.7 Example configurations

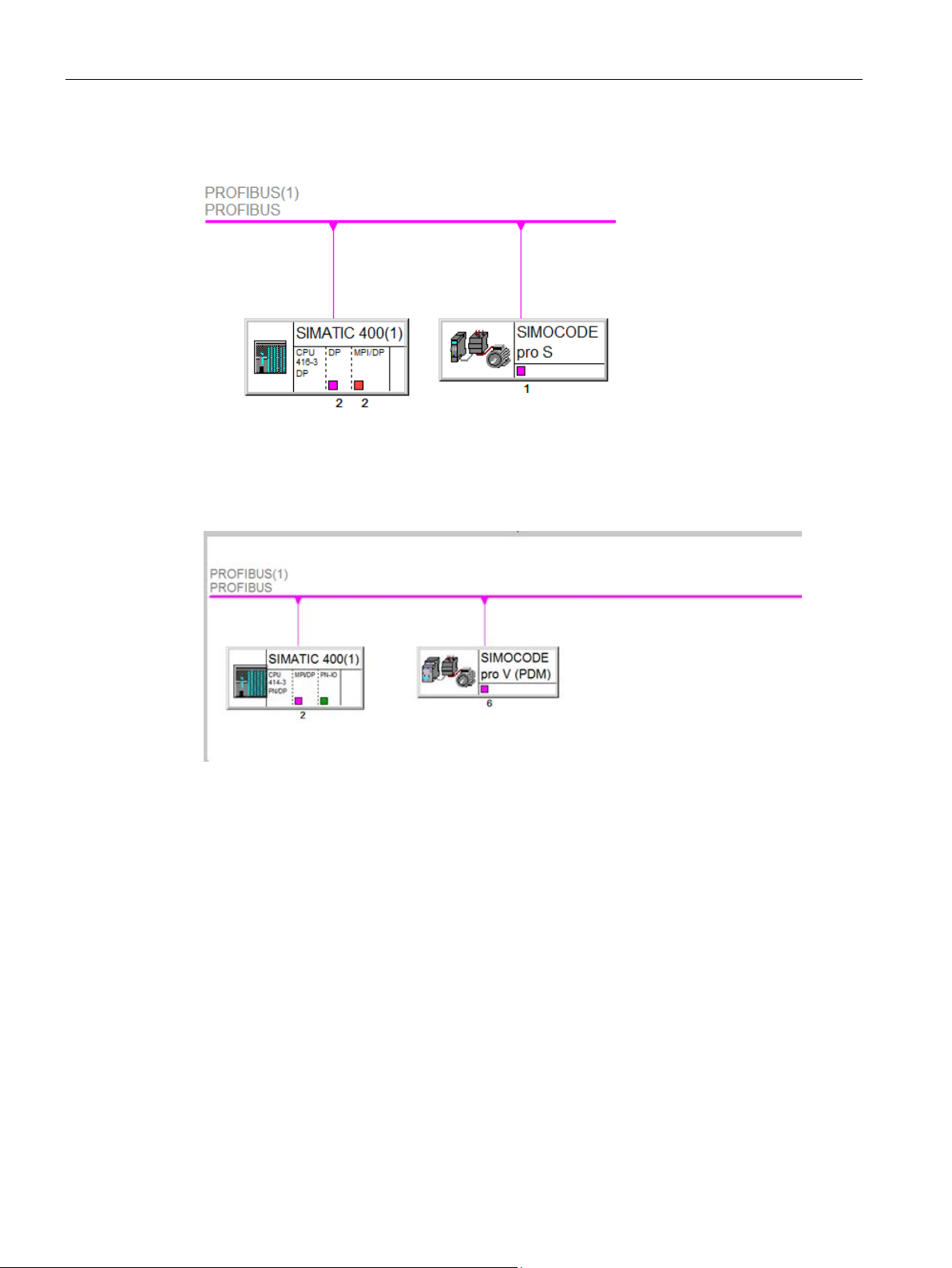

Figure 1-3 SIMOCODE pro S on DP master system

Figure 1-4 SIMOCODE pro V on DP master system

SIMOCODE pro PCS 7 Library V9.0

22 Programming and Operating Manual, 06/2017, A5E40899442002A/RS-AA/001

Introduction

SIMOCODE pro S on PROFIBUS DP behind a Y-link

SIMOCODE pro V on PROFIBUS DP behind a Y-link

1.7 Example configurations

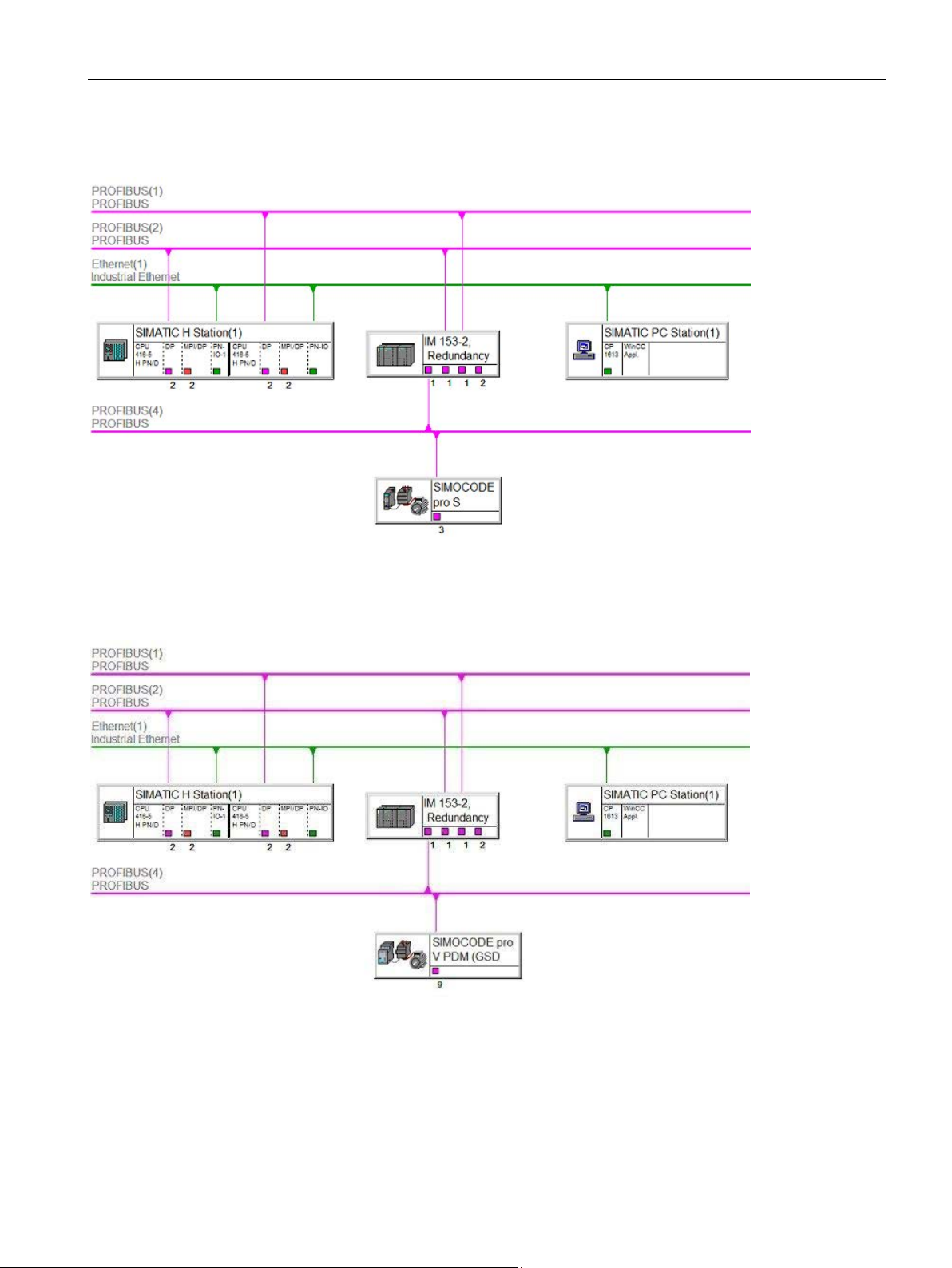

Figure 1-5 SIMOCODE pro S on PROFIBUS behind a Y-link

Figure 1-6 SIMOCODE pro V on PROFIBUS behind a Y-link

SIMOCODE pro PCS 7 Library V9.0

Programming and Operating Manual, 06/2017, A5E40899442002A/RS-AA/001

23

Introduction

SIMOCODE pro C / S / V behind IE-PB-Link (OM / GSD)

1.7.3

SIMOCODE pro PROFINET configuration

SIMOCODE pro V PN Configurations

Standalone Configurations (With Internal CPU/External PROFINET card interface)

In CPU

1.7 Example configurations

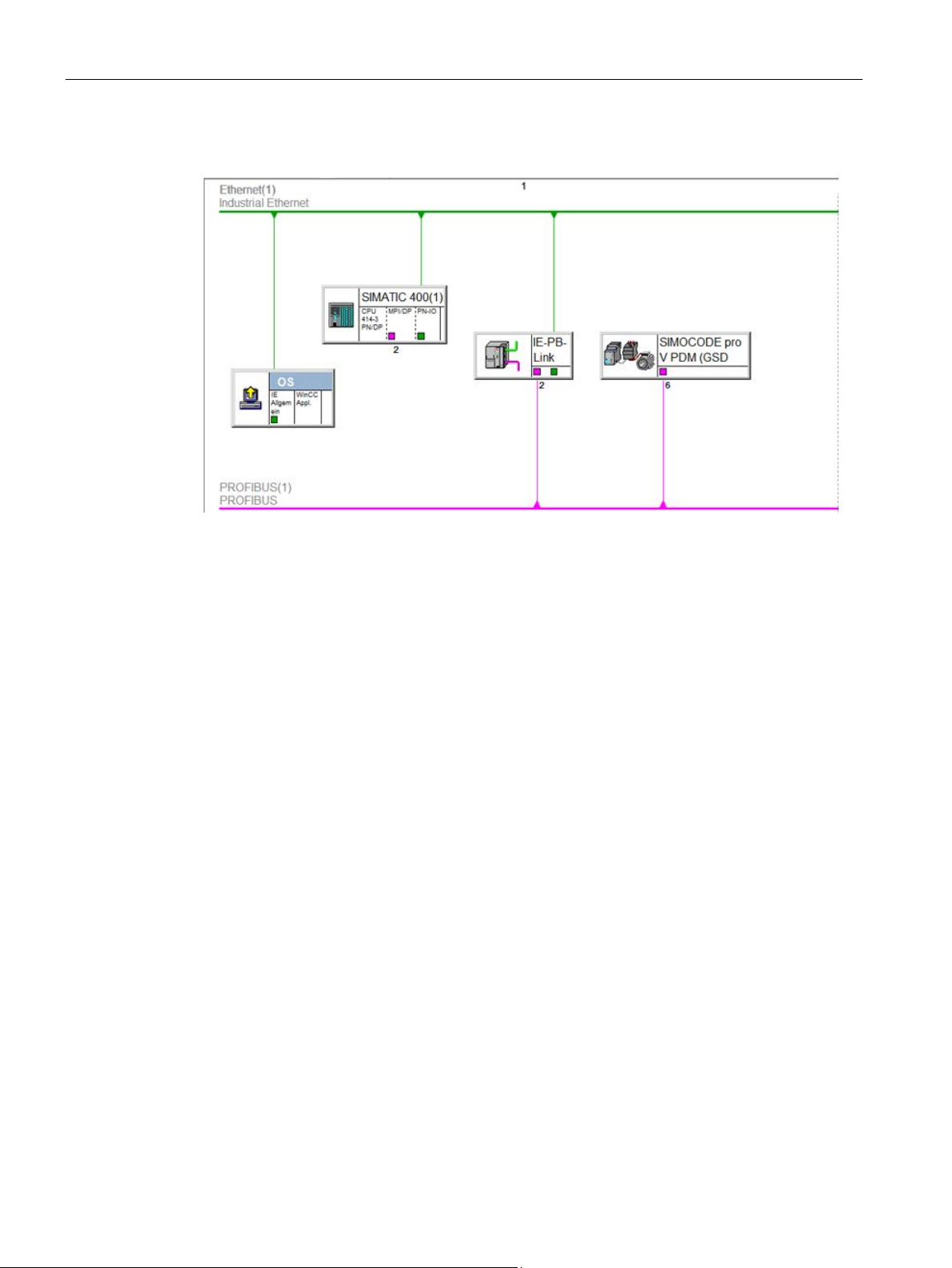

Figure 1-7 SIMOCODE pro C / S / V behind IE-PB-Link (OM / GSD)

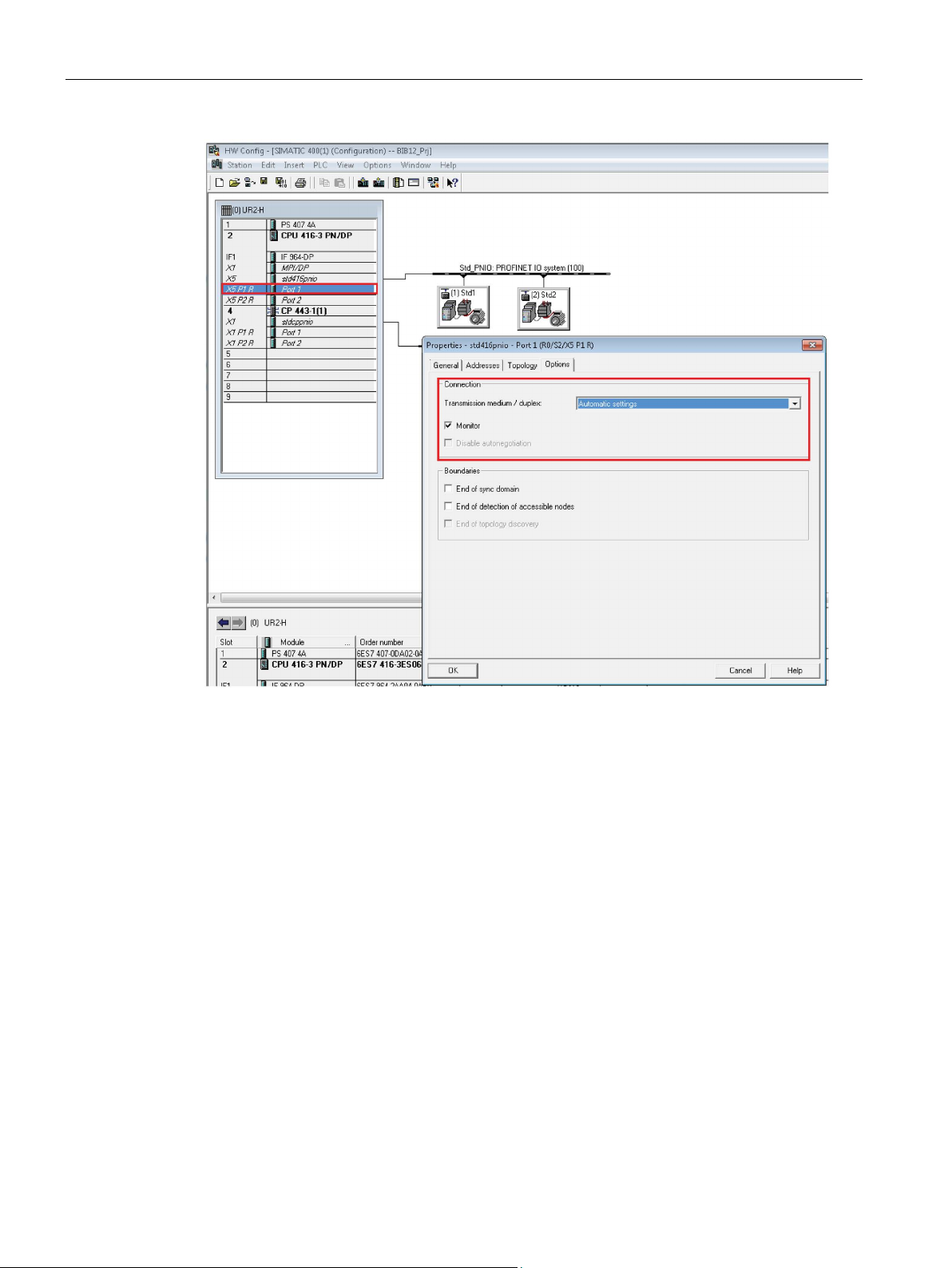

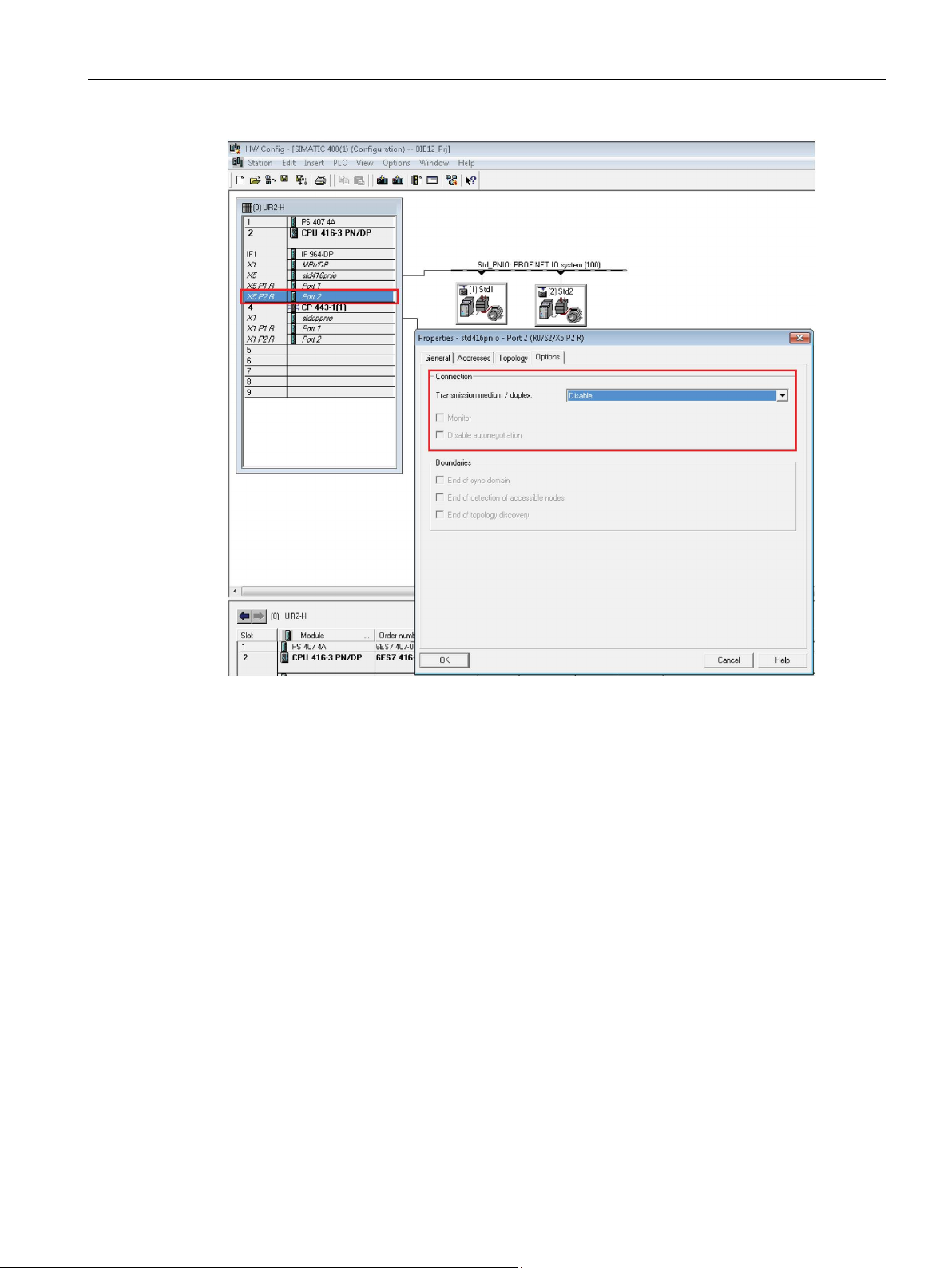

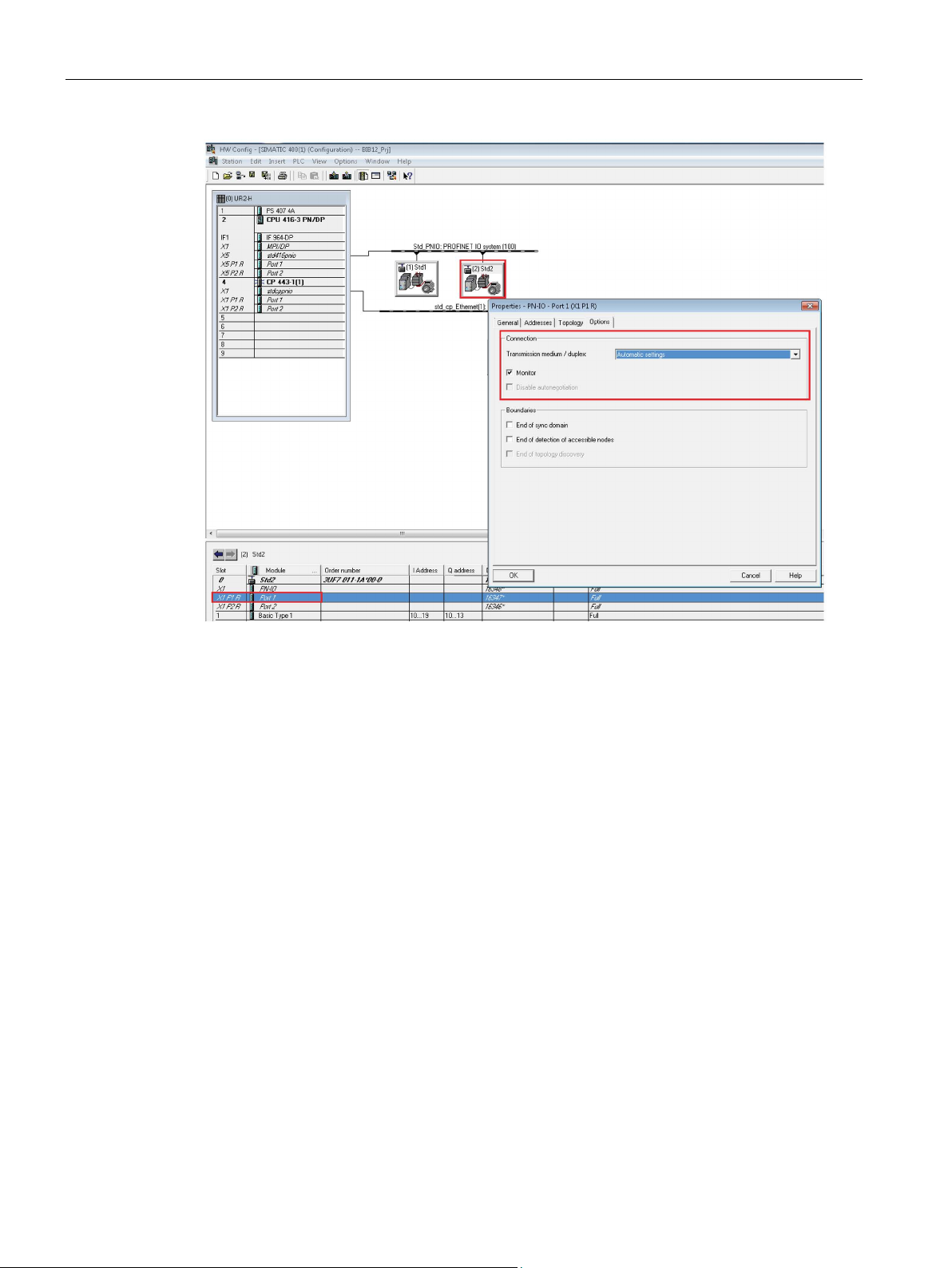

PROFINET port monitoring settings are made mandatory. When multiple devices are

connected to the CPU/CP card interface, used and unused PROFINET port settings are

required to distinguish between actual Rack failure and Device Failure.

When multiple devices are connected to the PROFINET interface, then the following settings

needs to be done.

1. In Port 1 of the PROFINET interface, "Transmission medium" should be automatic and

2. In Port 2 of the PROFINET card, "Transmission medium" and the "Monitor" checkbox

the "Monitor" checkbox needs to activated as shown in figure.

needs to be disabled as shown in figure.

SIMOCODE pro PCS 7 Library V9.0

24 Programming and Operating Manual, 06/2017, A5E40899442002A/RS-AA/001

Introduction

In Device

Note

By default when you add a device “Transmission medium” is set to Automatic and Monitor”

checkbo

1.7 Example configurations

Similarly "Transmission medium" should be automatic and "Monitor" checkbox needs to be

activated for Port1 and Port 2 of all the SIMOCODE pro V PN devices (see figure) except for

the last device in the network loop where Port 2 should be disabled as shown in figure.

These settings are applicable in both internal PROFINET interface of the PLC and external

PROFINET interface of CP Card.

Figure 1-8 Standalone configurations

x is disabled.

SIMOCODE pro PCS 7 Library V9.0

Programming and Operating Manual, 06/2017, A5E40899442002A/RS-AA/001

25

Introduction

MRP Redundancy (With Internal CPU/External PROFINET card interface)

System Redundancy (S2) configuration with Redundant PLC

At the Master CPU:

At the Standby CPU:

1.7 Example configurations

When multiple devices are connected in MRP configuration, then the topology below with the

required port settings needs to be done as given below

● In Port 1 and Port 2 of the CPU PROFINET interface and the Simocode pro V PN

devices, “Transmission medium” should be automatic and the “Monitor” checkbox needs

to be activated.

Figure 1-9 MRP configuration

In a redundant CPU configuration,”S2 Redundancy” can be achieved with SIMOCODE pro V

PN devices by connecting with the internal PROFINET interface of the CPU as shown with

the required port settings needs to be done as given below.

1. In Port 1 of the PROFINET interface, “Transmission medium” should be automatic and

the “Monitor” checkbox needs to activated as shown in figure.

2. In Port 2 of the PROFINET card, “Transmission medium” and the “Monitor” checkbox

needs to be disabled as shown in figure.

1. In Port 1 of the PROFINET interface, "Transmission medium" should be automatic and

the "Monitor" checkbox needs to activated as shown in figure.

2. In Port 2 of the PROFINET card, "Transmission medium" and the "Monitor" checkbox

needs to be disabled as shown in figure.

SIMOCODE pro PCS 7 Library V9.0

26 Programming and Operating Manual, 06/2017, A5E40899442002A/RS-AA/001

Introduction

At SIMOCODE pro V PN Device:

1.7 Example configurations

Similarly “Transmission medium” should be automatic and “Monitor” checkbox needs to

activated for Port1 and Port 2 of all the SIMOCODE pro V PN devices connected in

redundant configuration.

Figure 1-10 System Redundancy (S2) configuration

SIMOCODE pro PCS 7 Library V9.0

Programming and Operating Manual, 06/2017, A5E40899442002A/RS-AA/001

27

Introduction

1.7 Example configurations

Figure 1-11 Enabling Port1 of the CPU Interface

SIMOCODE pro PCS 7 Library V9.0

28 Programming and Operating Manual, 06/2017, A5E40899442002A/RS-AA/001

Introduction

1.7 Example configurations

Figure 1-12 Disabling Port2 of the CPU Interface

SIMOCODE pro PCS 7 Library V9.0

Programming and Operating Manual, 06/2017, A5E40899442002A/RS-AA/001

29

Introduction

1.7 Example configurations

Figure 1-13 Enabling Port1 of the Device Interface

SIMOCODE pro PCS 7 Library V9.0

30 Programming and Operating Manual, 06/2017, A5E40899442002A/RS-AA/001

Loading...

Loading...