Page 1

s

Preface, Contents

SIMATIC

Vision Sensor SIMATIC

VS 130-2/VS 130-2vcr

Manual

Product Overview

System Integration

Installation

Commissioning

Operator Input

Process Interface

Diagnostics

Appendix

Index

1

2

3

4

5

6

7

8

Edition 09/2005

A5E00475759-01

Page 2

Safety Guidelines

This manual contains notices you have to observe in order to ensure your personal safety, as well as to

prevent damage to property. The notices referring to your personal safety are highlighted in the manual

by a safety alert symbol, notices referring to property damage only have no safety alert symbol. The

!

!

!

notices shown below are graded according to the degree of danger.

Danger

indicates that death or severe personal injury will result if proper precautions are not taken.

Warning

indicates that death or severe personal injury may result if proper precautions are not taken.

Caution

with a safety alert symbol indicates that minor personal injury can result if proper precautions are not

taken.

Caution

without a safety alert symbol indicates that property damage can result if proper precautions are not

taken.

Qualified Personnel

Prescribed Usage

Notice

indicates that an unintended result or situation can occur if the corresponding notice is not taken into

account.

If more than one degree of danger is present, the warning notice representing the highest degree of

danger will be used. A notice warning of injury to persons with a safety alert symbol may also include a

warning relating to property damage.

The device/system may only be set up and used in conjunction with this documentation. Commissioning

and operation of a device/system may only be performed by qualified personnel

the safety notices in this documentation qualified persons are defined as persons who are authorized to

commission, ground and label devices, systems and circuits in accordance with established safety

practices and standards.

Note the following:

Warning

!

This device and its components may only be used for the applications described in the catalog or the

technical description, and only in connection with devices or components from other manufacturers

which have been approved or recommended by Siemens.

Correct, reliable operation of the product requires proper transport, storage, positioning and assembly

as well as careful operation and maintenance.

. Within the context of

Trademarks

All names identified by ® are registered trademarks of the Siemens AG.

The remaining trademarks in this publication may be trademarks whose use by third parties for their

own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and

software described. Since variance cannot be precluded entirely, we cannot guarantee full consistency.

However, the information in this publication is reviewed regularly and any necessary corrections are

included in subsequent editions.

Siemens AG

Automation and Drives

Postfach 4848

90437 NÜRNBERG

GERMANY

Copyright © Siemens AG 2005

A5E00475759-01

Siemens AG 2005

Technical data subject to change.

Page 3

Preface

Purpose of the Manual

This manual describes the vision sensors SIMATIC VS 130-2 and

VS 130-2vcr. It helps to install, commission and operate the sensors.

The documentation addresses personnel concerned with the engineering,

commissioning and service of automation systems and visualization equipment.

Guide

The manual contains the following guides which provide quick access to the

specific information you need:

• The manual opens with a complete directory.

• The manual closes with a detailed index for quick access to the information

you require.

Further information

An installation and wiring manual is included in paper form.

On your CD you will find the "Getting Started" guide for initial commissioning of

your SIMATIC VS 130-2 or VS 130-2vcr vision sensor.

Further support

If you have any questions concerning the use of products which are not answered

in this manual, please contact your local Siemens partner at your Siemens office.

You can find your local partner at:

http://www.siemens.com/automation/partner

You can find a guide to the technical documentation on offer for the individual

SIMATIC products and systems at:

http://www.siemens.de/simatic-tech-doku-portal

You can find the catalog and online ordering systems at:

http://mall.automation.siemens.com/

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

A5E00475759-01

iii

Page 4

Preface

Training center

To help you to learn about the vision sensors SIMATIC VS 130-2 and

VS 130-2vcr and the S7 automation system, we provide a range of training

courses. Please contact your regional training center or the central training center

in Nuremberg, Germany.

Telephone: +49 (911) 895-3200.

Internet: http://www.sitrain.com

Technical support

How to reach technical support for all A&D products

• With the Support Request form on the Web:

http://www.siemens.de/automation/support-request

• Telephone: + 49 180 5050 222

• Fax: + 49 180 5050 223

Further information about our technical support is available in the Internet at

http://www.siemens.com/automation/service

Service & Support on the Internet

The Siemens Service & Support team provides you with comprehensive additional

information on SIMATIC products in its online Internet services.

http://www.siemens.com/automation/service&support

There you can find:

• Current product information and downloads which you may find useful for your

product.

• The documents you require, using our Service & Support search engine.

• A forum where users and experts from all over the world exchange ideas

• Your local partner for Automation & Drives.

• Information about onsite services, repairs, spare parts. Lots more is available

to you on our "Service“ pages.

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

iv A5E00475759-01

Page 5

Contents

1 Product Overview 1-1

1.1 Product Description .......................................................................................... 1-1

1.2 Components ..................................................................................................... 1-4

1.3 Processing Configuration.................................................................................. 1-5

1.4 Important Requirements for Installation............................................................ 1-6

1.5 Applications ...................................................................................................... 1-6

1.6 The lamp multiplexer accessory ....................................................................... 1-9

1.7 Requirements for Codes and Legibility........................................................... 1-11

1.7.1 What is Required of Data Matrix and Vericodes? .......................................... 1-11

1.7.2 Requirements for QR codes ........................................................................... 1-15

1.7.3 Requirements for PDF417 codes ................................................................... 1-17

2 System Integration 2-1

2.1 Design............................................................................................................... 2-1

2.2 Application Examples ....................................................................................... 2-2

2.2.1 Reading codes or checking quality in stand-alone mode

with output over Ethernet.................................................................................. 2-2

2.2.2 Reading Codes or Quality in Stand-alone Mode with Output over RS-232 ..... 2-3

2.2.3 Reading Codes or Quality in a PROFIBUS Environment.................................2-4

2.2.4 Reading Codes or Quality in a PROFINET Environment ................................. 2-5

2.2.5 Reading codes or checking quality in a PROFINET environment

and outputting over Ethernet ............................................................................ 2-6

2.2.6 Mixed operation ................................................................................................ 2-6

3 Installation 3-1

3.1 Installing Components for VS 130-2................................................................. 3-1

3.2 Wiring Components .......................................................................................... 3-3

3.3 Guidelines on Interference-Proof Installation ................................................... 3-5

3.4 Guidelines for Installing PROFIBUS DP or PROFINET I/O ............................. 3-5

4 Commissioning 4-1

4.1 Introduction ....................................................................................................... 4-1

4.2 Turning on the Device....................................................................................... 4-1

4.3 Control and Display Panel ................................................................................ 4-3

4.4 Adjusting the Sensor with the Setup Support................................................... 4-5

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

A5E00475759-01

v

Page 6

Contents

5 Operator Input 5-1

5.1 Overview........................................................................................................... 5-1

5.2 Working with the Processing Unit..................................................................... 5-1

5.3 Working with the Setup Support ..................................................................... 5-26

5.3.1 Starting Setup Support in the Web Browser................................................... 5-28

5.3.2 User interface of the VS 130-2/VS 130-2vcr ..................................................5-29

5.3.3 Adjust Sensor .................................................................................................5-31

5.3.4 Connections.................................................................................................... 5-34

5.3.5 Train................................................................................................................ 5-37

5.3.6 Evaluating ....................................................................................................... 5-39

5.3.7 Options............................................................................................................ 5-40

5.3.8 Info .................................................................................................................. 5-44

5.3.9 Maintain ..........................................................................................................5-48

5.3.10 Stop.................................................................................................................5-48

5.4 Operator Control over Personal Digital Assistant (PDA)................................ 5-49

5.4.1 Prerequisites................................................................................................... 5-49

5.4.2 Establishing a Connection between PDA and Processing Unit......................5-49

5.4.3 Starting or stopping setup support from the PDA........................................... 5-50

5.4.4 User interface of the PDA............................................................................... 5-50

5.4.5 Known PDA problems..................................................................................... 5-54

6 Process Interface 6-1

6.1 Introduction ....................................................................................................... 6-1

6.2 Integrating the DP slave VS 130-2 in HW Config............................................. 6-2

6.3 Integrating the PROFINET I/O Device VS 130-2 in HW Config ....................... 6-4

6.4 Control Via the "DI/DO" I/O Interface ............................................................... 6-6

6.4.1 Control Signals .................................................................................................6-6

6.4.2 Selecting the Mode ........................................................................................... 6-7

6.5 Control over PROFIBUS DP and PROFINET IO ........................................... 6-11

6.5.1 File Transfer Principle over PROFIBUS DP and PROFINET IO.................... 6-11

6.5.2 Assignments for PROFIBUS DP and PROFINET IO-relevant Interfaces

for the Processing Unit ...................................................................................6-12

6.5.3 Sample program for data exchange if code length <= 27 bytes..................... 6-15

6.5.4 Programming the Data Block.......................................................................... 6-17

6.5.5 FB 79 "VS130-2_CONTROL"......................................................................... 6-19

6.6 Sample Programs ........................................................................................... 6-32

6.6.1 Sample Program for Interfacing the VS 130-2 to a SIMATIC Controller

with the Aid of FB79........................................................................................ 6-32

6.6.2 Sample Program for Outputting the Read Code to a PC or PG..................... 6-33

6.6.3 Sample Program for Archiving Diagnostic Information on a PC or a PG ....... 6-34

7 Diagnostics 7-1

7.1 Introduction ....................................................................................................... 7-1

7.2 Diagnostics with Messages .............................................................................. 7-1

7.2.1 Error Messages ................................................................................................7-2

7.2.2 Warnings/Notes ................................................................................................ 7-7

7.2.3 Read Results .................................................................................................. 7-10

7.3 Diagnostics Based on the "BF" LED............................................................... 7-11

7.3.1 "BF" LED with PROFIBUS DP........................................................................ 7-11

7.3.2 "BF" LED with PROFINET IO ......................................................................... 7-11

7.4 Slave Diagnostics or I/O Device Diagnostics .................................................7-12

7.4.1 Introduction ..................................................................................................... 7-12

7.4.2 Reading Out the Diagnostic Information with S7............................................ 7-12

7.4.3 Diagnostics for PROFIBUS DP ......................................................................7-13

7.4.4 Diagnostics for PROFINET IO........................................................................ 7-15

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

vi A5E00475759-01

Page 7

Contents

8

Appendix 8-1

8.1 Components of the Product .............................................................................. 8-1

8.2 Standards and Approvals .................................................................................8-6

8.3 Installation Dimensions..................................................................................... 8-7

8.4 Interface Assignment of the Processing Unit.................................................... 8-9

8.5 Calculating the C-mount Lens and the Size of the Field of View

for Data Matrix Codes at a Given Distance .................................................... 8-12

8.6 Technical Specifications ................................................................................. 8-15

8.6.1 Vision Sensor SIMATIC® VS 130-2/VS 130-2vcr .......................................... 8-15

8.6.2 General Specifications....................................................................................8-18

8.6.3 Interface Digital Inputs/Outputs ...................................................................... 8-21

Index Index-1

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

A5E00475759-01

vii

Page 8

Contents

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

viii A5E00475759-01

Page 9

1 Product Overview

1.1 Product Description

The Vision Sensor SIMATIC VS 130-2 is a code reader for data matrix codes of the

type ECC200 (with the exception of the types "Structured Append" and

"Reader Programming Code") and the codes PDF417 and QR (with the exception

of the types "ECI Code", "Byte Code", "Kanji Code", "Structured Append" and

"FNC1 Code"). The code type is detected during training and adjustment and

during training is saved as a code property.

The Vision Sensor VS 130-2vcr is Vericode reader.

You can use these readers to read the coded labeling of products and then pass

the read code to a PLC or a computer.

The SIMATIC VS 130-2/VS 130-2vcr operates with overhead lighting. The object is

lit from above with the supplied ring flash. With the lamp multiplexer accessory, it is

possible to select one of up to 4 lamps for the lighting.

The Vision Sensor SIMATIC VS 130-2/VS 130-2vcr is available in the following

models:

• SIMATIC VS130-2 for large code areas

(order number of the full package: 6GF1 130-1BA with 2.5 m cable length and

6GF1 130-1BA01 with 10 m cable length)

• SIMATIC VS130-2 for small code areas

(order number of the full package: 6GF1 130-2BA with 2.5 m cable length and

6GF1 130-2BA01 with 10 m cable length)

• SIMATIC VS130-2 for very small code areas

(order number of the full package: 6GF1 130-4BA with 2.5 m cable length and

6GF1 130-4BA01 with 10 m cable length)

• SIMATIC VS130-2 for variable code areas (order number of the basic package:

6GF1 130-3BC with 2.5 m cable length and 6GF1 130-3BC01 with 10 m cable

length) if you use the C- or CS-mount lenses (includes the high-resolution

sensor)

• SIMATIC VS130-2 for variable code areas

(order number of the basic package: 6GF1 130-3BB with 2.5 m cable length

and 6GF1 130-3BB01 at 10 m cable length), if you are using C or CS-mount

lenses and want to use the lens protective housing (6GF9 002-7AA01).

• SIMATIC VS 130-2vcr (Vericode reader) for variable code areas (order number

of the basic package: 6GF1 130-3BB02)

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

A5E00475759-01

1-1

Page 10

Product Overview

Reading, matching or verifying code

SIMATIC VS 130-2/VS 130-2vcr can read codes, match the entire code or part of it

with a trained code and relate (verify) the quality values of the currently read code

to the quality values of a trained code.

The entire read character string or only part of it (in other words, filtered) can be

output. When it is output, further characters can de appended at the start or end as

a prefix or suffix.

The SIMATIC VS 130-2/VS 130-2vcr can operate both in standalone mode to

make good/bad decisions or as part of a control system to pass on the read codes

for further processing.

Performance Features

• Reliable reading of data matrix codes or Vericodes even under difficult

conditions (for example, for oil-smeared or needle-punched codes)

• Reading printed or lasered codes of the type PDF417 and QR on a

homogeneous background

• Overhead ring flash with VS 130-2

• Activation of up to 4 lamps using a special lamp multiplexer

• Linking of several trained codes that do not necessarily belong to the same

code type to form a code set with the VS 130-2

• It is possible to specify a region of interest with the VS 130-2

• Fully Web-based user interface

• When using data matrix codes, up to 20 codes can be read per second

• With Vericodes up to 5 code readings per second

• Calculating quality characteristics

• Extensive operator control and monitoring functions even in the processing

mode

• Wide-ranging diagnostics and logging functions: Error image memory and

event logging

• Firmware update over the user interface

• Control over digital I/O, trigger signal and also over RS-232 interface of an

RS-232 Ethernet converter or TCP server

• Acquiring the code without a trigger signal ("Continuous" mode)

• Event output over PROFIBUS DP, PROFINET I/O, RS-232 interface of an

RS-232 Ethernet converter, and TCP connection to PC

You will find the Technical Specifications of SIMATIC VS 130-2/VS 130-2vcr in the

appendix.

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

1-2 A5E00475759-01

Page 11

Product Overview

Code Properties

To improve clarity, the following terms are used in the table below:

• Variant 1: SIMATIC VS 130-2 for "large code areas" (6GF1 130-1BA and

6GF1 130-1BA01 with sensor head 6GF2 002-8DA01)

• Variant 2: SIMATIC VS 130-2 for "small code areas" (6GF1 130-2BA and

6GF1 130-2BA01 with sensor head 6GF2 002-8EA01)

• Variant 3: SIMATIC VS 130-2 for "very small code areas" (6GF1 130-4BA and

6GF1 130-4BA01 with sensor head 6GF2 002-8FA01)

• Variant 4: C/CS Mount (6GF1 130-3BB and 6GF1 130-3BB01 with sensor

head 6GF2 002-8CB)

• Variant 5: C/CS Mount (6GF1 130-3BC and 6GF1 130-3BC01 with sensor

head 6GF2 002-8GB)

• Variant 6: C/CS Mount (6GF1 130-3BB02 with sensor head 6GF2 002-8CB) for

acquiring Vericodes

Properties Configuration 1 Configuration 2 Configuration 3 Configuration 4

and

Configuration 6

CCD resolution 0,11 mm/pixel 0,06 mm/pixel 0.032 mm/pixel Image width /

640 pixels

Minimum dot size

(edge length)

Maximum dot

size (edge

length)

Minimum code

dimension

(rows * columns)

Maximum code

dimension

(rows * columns)

Clearance

sensor front edge

- test object

Image field 75 mm * 57 mm 45 mm * 34 mm 20 mm * 15 mm depending on

1)

With large code dimensions such as 72*72, make sure that the lens used does not cause any distortion

at the edges.

0,6 mm 0,35 mm 0,16 mm Image width /

120 pixels

3,5 mm 2 mm 1 mm Image width /

22 pixels

10 *10 10 *10 10 *10 10 *10 10 *10

48 *48 48 *48 48 *48

100 mm 90 mm 75 mm Depending on

72 *72

lens

lens

1)

72 *72 1)

Configuration 5

Image width /

1024 pixels

Image width /

200 pixels

Image width /

35 pixels

Depending on

lens

depending on

lens

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

A5E00475759-01

1-3

Page 12

Product Overview

1.2 Components

The complete Vision Sensor SIMATIC VS 130-2/VS 130-2vcr consists of the

following:

• Sensor head with CCD sensor chip (CCD = Charge Coupled Device) for

sensing the code

• LED overhead lighting unit, red, degree of protection IP65 as ring flash

(order number 6GF9 004-8BA01; only with VS 130-2)

• Processing unit for code processing, output of results, PROFIBUS DP and

PROFINET I/O communication and parameter assignment

• Cables to connect the individual components

• Installation instructions for installing and wiring the

SIMATIC VS 130-2/VS 130-2vcr

• CD with:

- This manual SIMATIC VS 130-2/VS 130-2vcr (German, English, French,

Spanish, Italian for VS 130-2, German and English for VS 130-2vcr)

- Online help (interfacing the Com Server of W&T, establishing the

connection, setup support)

- Getting Started

- Installation Instructions

- Compact Com Server manual from W&T

- The installation manual SIMATIC S7-300 Automation System, Hardware

and Installation

- Getting Started Collection for PROFINET I/O

- PROFINET System Manual, System Description

- PROFINET IO from PROFIBUS DP to PROFINET IO Programming

Manual

- PROFINET IO Structure of the Diagnostic Data Records Product

Information

- The device master data file SIEM8111.GSD and the corresponding bitmap

file VS1X0__N.DIB (for PROFIBUS DP)

- the GSD file GSDML-V1.0-Siemens-VS130-2-20041021.xml (General

Station Description) and the bitmap file vs100.bmp (for PROFINET I/O)

- Three sample programs (connecting the VS 130-2 to a SIMATIC controller

using FB79, output of the read code to a PC or a PG, archiving diagnostic

information on a PC or PG)

Overview of the complete package

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

1-4 A5E00475759-01

Note

If you want to use C or CS-mount sensors under IP65 conditions, use the lens

protective housing (6GF9 002-7AA01).

Page 13

Product Overview

1.3 Processing Configuration

Triggering

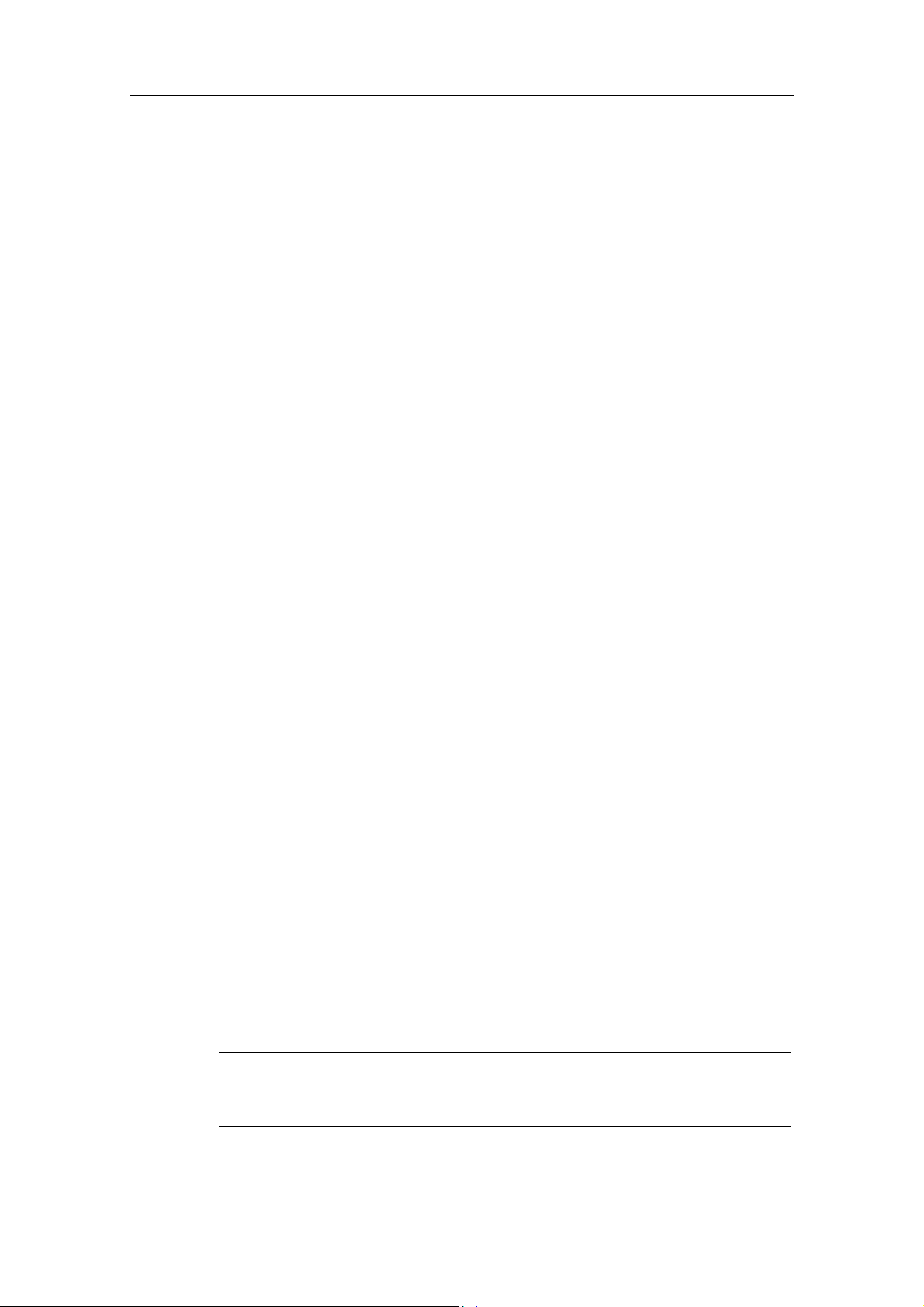

The objects with the code are fed past the sensor head with a suitable conveyor.

They must be located fully within the sensor field of view when being read.

In the training mode, the character content of the code is saved.

In the processing mode, the current code is read and, if required, compared with

the saved content of the trained code. The digital output signals are set according

to the read result: READ (code was localized and decoded), MATCH (code

matches the trained code), N_OK (code was not legible).

The read result is output over PROFIBUS DP, PROFINET IO or over the RS-232

interface of an RS-232 Ethernet interface converter or over a TCP server

depending on the parameter settings.

To read the code, you must make sure that the code is completely within in the

sensor field of view and clearly visible.

The code is captured at the trigger time. In this case, you generate an exact and

debounced trigger signal at the trigger time, for example with a laser light barrier.

As an alternative, you can record the code without a trigger signal (trigger source

"endless"). In this case the code is output again only when there is a code change.

This is required, for example, with rotating parts if the exact position of the code is

not known.

You can check your settings with the setup support of the VS 130-2/VS 130-2vcr.

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

A5E00475759-01

1-5

Page 14

Product Overview

1.4 Important Requirements for Installation

The following requirements must be met:

• The code must be clearly visible:

- There should be as few reflections as possible in the code field.

- The code field should be uniformly illuminated without shadows.

- All parts of the code should be sharply printed.

• The sensor can be up to 40° from the vertical.

• The distance between the code and the image edge should be at least two dot

widths.

1.5 Applications

Below, you will see several examples of data matrix codes, QR, PDF417 and

Vericodes:

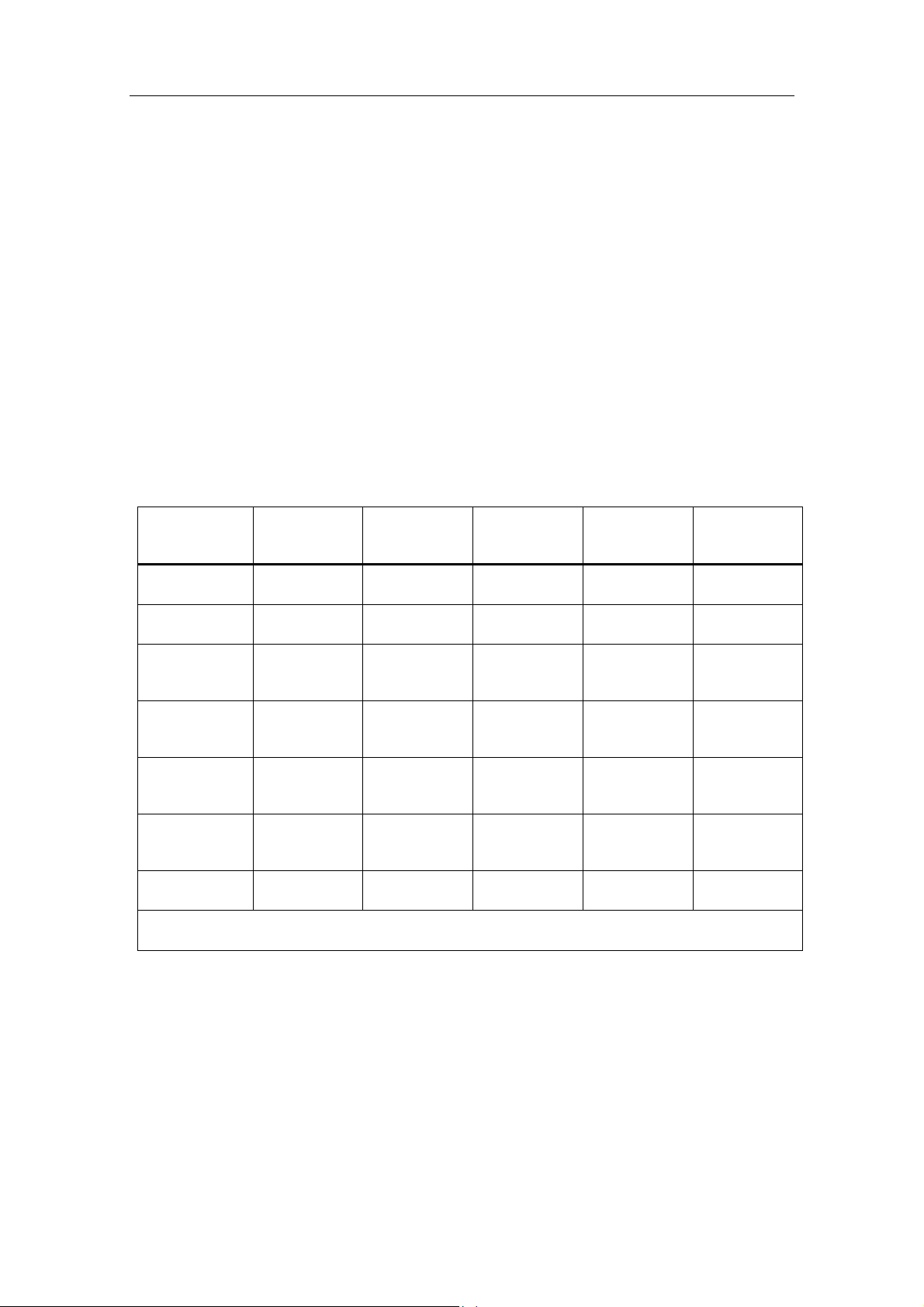

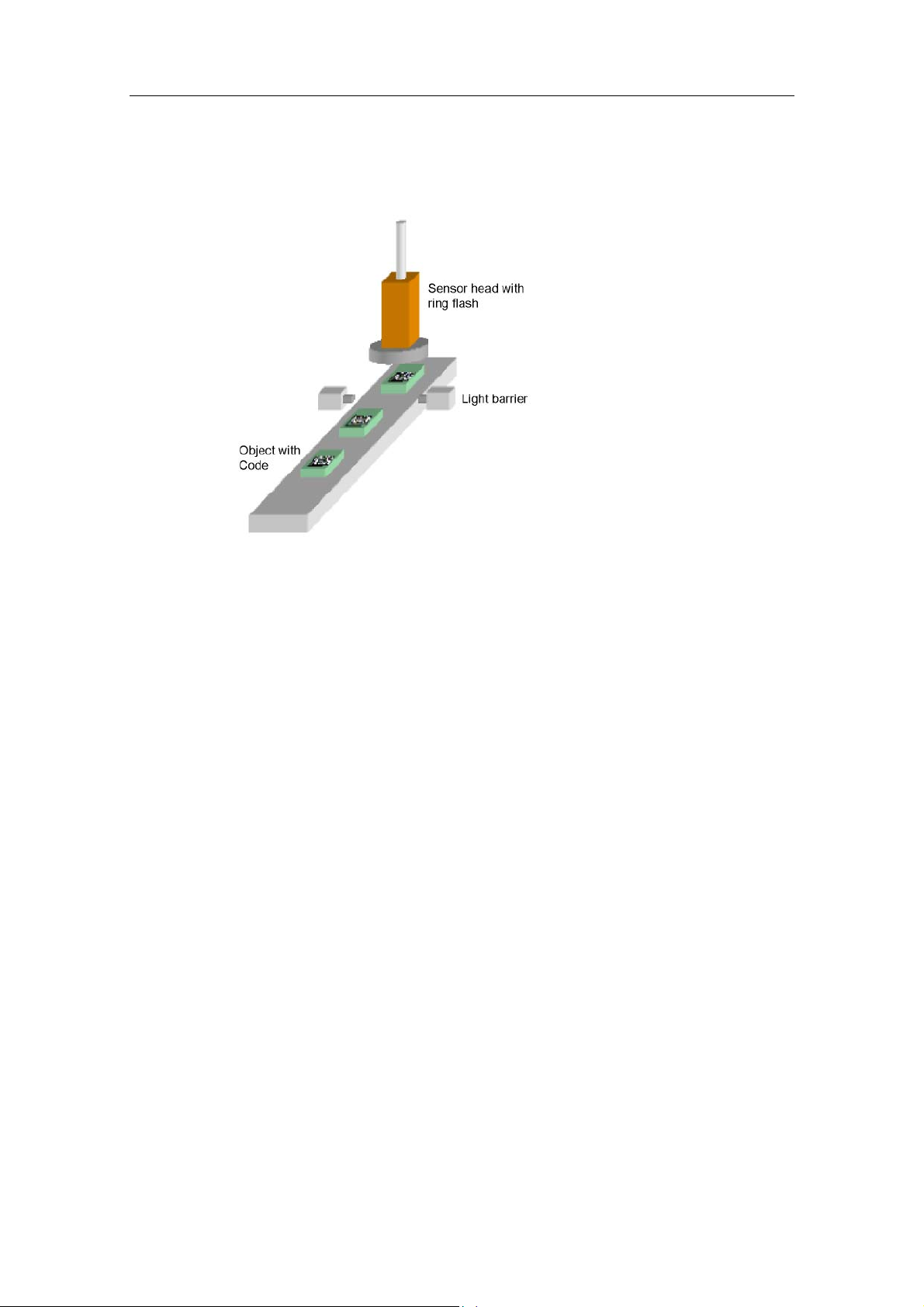

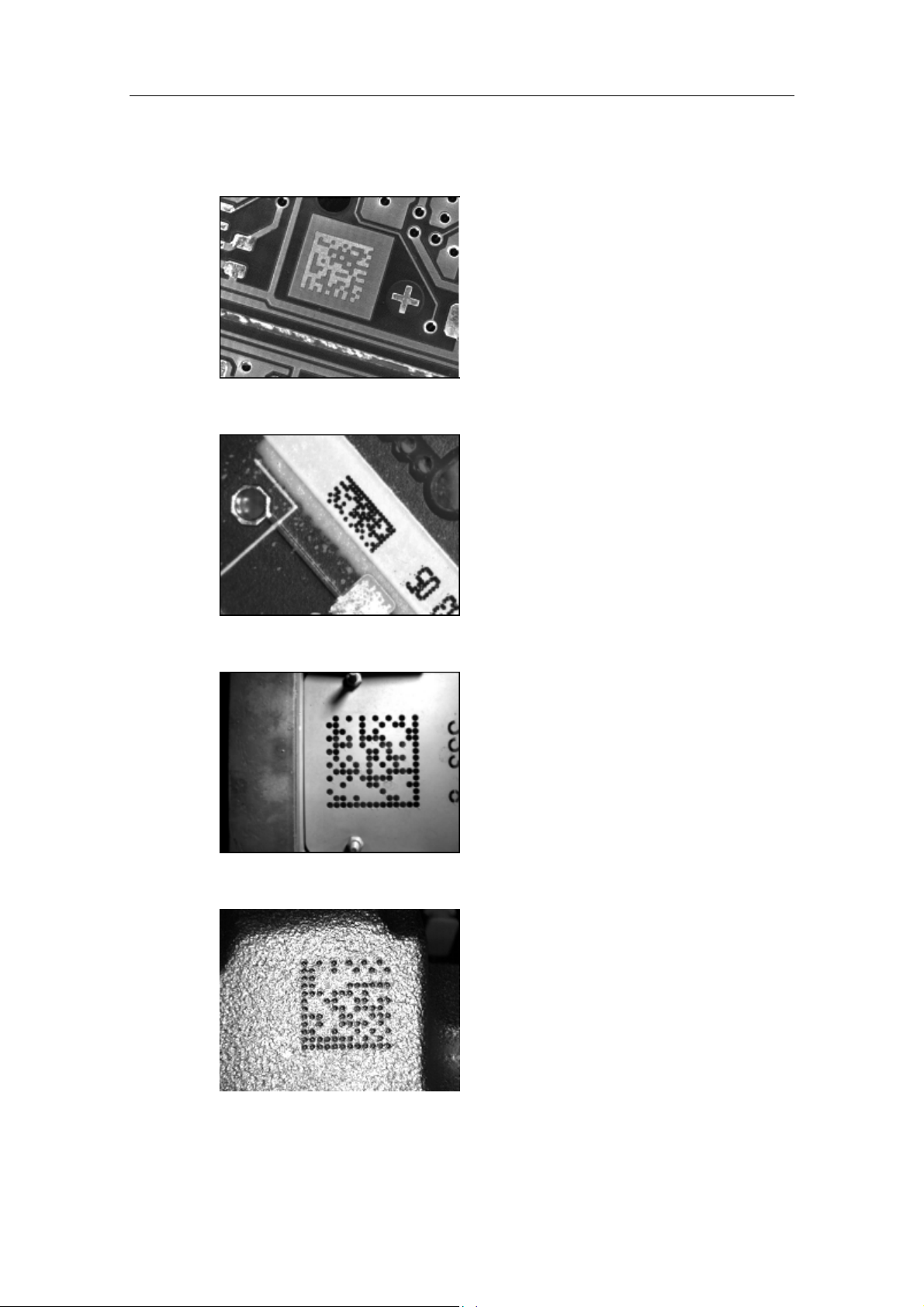

• Printed data matrix code

• Lasered data matrix code (plastic surface)

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

1-6 A5E00475759-01

Page 15

Product Overview

• Lasered data matrix code (pcb)

• Data matrix code created with inkjet printer

• Punched data matrix code

• Needle punched data matrix code

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

A5E00475759-01

1-7

Page 16

Product Overview

• Printed QR code

• Printed PDF417 code

• Vericode

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

1-8 A5E00475759-01

Page 17

Product Overview

1.6 The lamp multiplexer accessory

If there are varying lighting conditions in the vicinity of the sensor head, it is

sometimes advisable to work with different lamps at different times. You can

therefore connect up to 4 flash lamps to the Vision Sensor VS 130-2/VS 130-2vcr

using he lamp multiplexer (6GF9 002-7BA).

Note

The lamp multiplexer can only be used if you have set the multilight mode. If you

not activate the multilight mode, you must connect your lamp directly to the

processing unit.

The lamp multiplexer is shown in the figure below.

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

A5E00475759-01

1-9

Page 18

Product Overview

Connecting the lamp multiplexer

You connect to the processing unit as follows: Connect a lighting cable

(6GF9 002-8CE) to the LAMP socket of the processing unit and to the input socket

LIN. of the lamp multiplexer.

Connect each of the maximum four lamps to the lamp multiplexer over a lighting

cable. Lamp 1 is assigned to socket L1, lamp 2 to socket L2 etc.

Connect the socket connector "DI/DO" of the processing unit to the left-hand plug

connector "DI/DO" of the lamp multiplexer with the supplied special cable. You can

connect a digital communication cable (6GF9 002-8CB) to the right-hand plug

connector "DI/DO". Please remember that you must not then use the MATCH and

NOK signals. These are used to select a lamp.

Note

If you connect the lamp multiplexer with connected lamps to a

VS 130-2/VS 130-2vcr while this is operating, this can lead to the processing unit

resetting itself in some situations.

Installing the lamp multiplexer

You have the following installation options:

• Wall-mounting using the two holes at the upper end of the lamp multiplexer

• Installation on a standard rail: In this case, screw the supplied rail adapter to

the back of the lamp multiplexer.

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

1-10 A5E00475759-01

Page 19

Product Overview

1.7 Requirements for Codes and Legibility

1.7.1 What is Required of Data Matrix and Vericodes?

General Requirements for Data Matrix and Vericodes to Ensure Readability

VS 130-2 can read data matrix codes with properties corresponding to those

published in the standard for data matrix codes. In many ways, VS 130-2 reacts

tolerantly even when certain basic properties are absent and is capable of dealing

with difficulties that are not specified in the standard.

As a result, VS 130-2 and VS 130-2vcr have a very wide range of application in

normal situations, a fact reflected in the following broad limits:

• It can read codes in which directly adjacent code points have a minimum

distance of only 5 pixels and up to a maximum distance of 35 pixels.

• The deviation of the sensor axis from the vertical can be between 0 ° und 40 °.

• The code field can approach the edge of the image up to a distance equivalent

to twice the code point diameter.

• The dominant polarity of the code points compared with the background is

required uniformly for all points (as it was during the training procedure). Slight

shadows or shiny areas are tolerated.

• The ratio of the distance to the closest neighbor and the diameter of any code

point can be between 2 and 0.8.

• Although code points must be printed according to a regular square grid

pattern, individual points can be displaced from their ideal position by up to 1/3

of the grid unit. Even slight parallelogram-shaped distortion is tolerated.

• With large-image but small-dimensioned codes, slight curves in the printed

material surface are tolerated. With high-value codes (for example, more than

14 x 14) or a strongly inclined sensor axis, curves are not allowed.

• Large tolerance of background disturbances that cannot be described

quantitatively

• Large tolerance of poor contrast conditions

• Due to the limited image resolution, codes with a maximum code dimension of

72x72 can be read.

In terms of these limit characteristics and when using minimum read rates due to

the requirements of the application (can be set with the "Cycletimelimit" parameter)

the tolerances are generally restricted, in some cases in stages, or other conditions

come into play. The limits described below are intended mainly as guidelines since

the actual conditions in a real application cannot be assessed accurately in

advance. It is therefore conceivable that higher read rates can be achieved even if

individual conditions are not fully adhered to.

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

A5E00475759-01

1-11

Page 20

Product Overview

Processing Method for Reliable Reading of Difficult Data Matrix Codes and

Vericodes

Settings:

• Speed = low

• Exposure = Manual or Auto V1 or Auto

The self-adapting recognition method of VS 130-2/VS 130-2vcr allows the most

difficult codes to be read reliably. The most reliable detection is reached by

VS 130-2/VS 130-2vcr when you make adequate time available for adaption by

setting a high cycle time limit.

The recognition method is designed for a variety of practical situations in which

various aspects of the read configuration cannot be considered ideal. For example:

• Any alignment and position of the code in the image

• Reading codes even when dots overlap or are largely isolated

• Reading codes recorded mirror-inverted

• Tolerance of distortion, due for example to inclined installation of the image

sensor (view angle down to a lower limit of approximately 50° to the printed

surface)

• Resistant to similar-looking foreign objects in the area of the code

• Resistant to interference patterns (grooves, granularity) in the area of the code

• Good tolerance of contrast fluctuations

• Good range of imaging size from 5 to 35 pixels per dot

Rectangular or square codes (with data matrix codes with maximum dimensions of

72 x 72 dots) can be read, whereby the brightness polarity (bright on dark or dark

on bright) is unimportant.

If individual conditions are particularly favorable and stable in a concrete situation

(and therefore less effort is required for internal adaption), the read rate of

VS 130-2/VS 130-2vcr can reach a peak of 20 per second. You can influence this

by setting the "Speed" and "Cycle time limit" parameters as described below.

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

1-12 A5E00475759-01

Page 21

Product Overview

Processing Method for Fast Reading of Data Matrix Codes and Vericodes with a

Guaranteed Read Rate up to 5Hz

Settings:

• Speed = medium

• Exposure:

- = Manual: guaranteed read rate of 5 Hz

- = Auto V1 and Auto: guaranteed read rate of 3.3 Hz

These read rates are achieved under the following conditions:

• The code dimension must not be greater than 40 x 40 dots.

• The code must be positioned so that there is always a clearance of at least 3

dots to the edge of the image.

• The code should not make contact with any other objects in the image (keep

the quiet zone free!)

• To allow the code to be found quickly, there must be no other objects (bus

structures count here as well) in the image with enclosed rectangle and of a

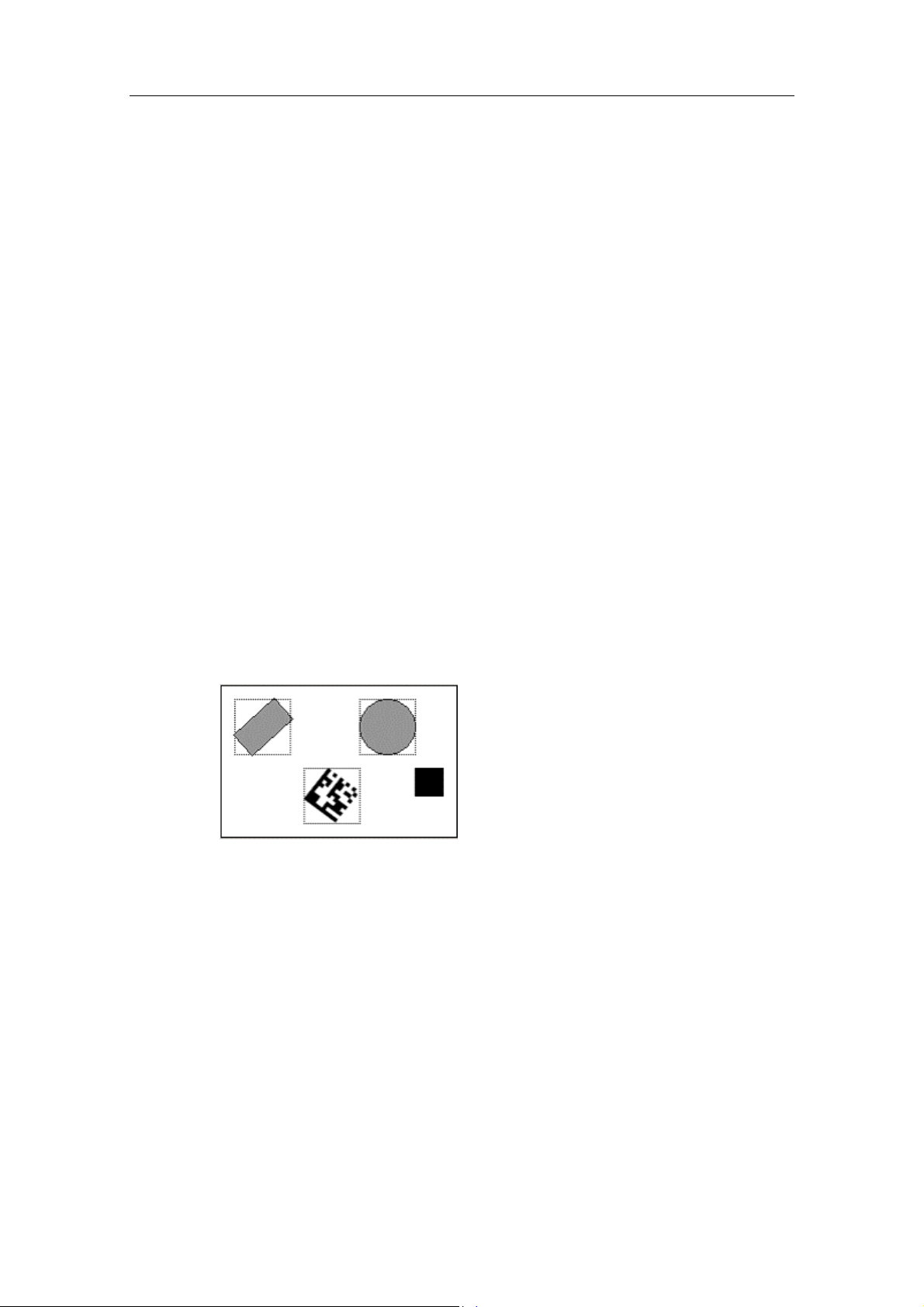

comparable size to the trained code. (See also the two following figures.)

• The minimum dot size is 5 pixels per dot without restrictions.

• The view angle must be greater than 70°.

The following figure shows you an illegal constellation for guaranteed read rates:

Two neighboring objects in the image have a rectangular border of a size similar to

that of the code.

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

A5E00475759-01

1-13

Page 22

Product Overview

The following figure shows you a legal constellation for guaranteed read rates: All

neighboring objects are clearly of a different size from the code. In this case,

rotation of the code from exposure to exposure would be acceptable since there is

no rectangle of another object that is compatible with the largest possible rectangle

around the code.

Note

Operating and monitoring via the setup support can lead to longer cycle times.

Processing Method for Fast Reading of Data Matrix Codes with a Guaranteed

Read Rate of 20Hz

Settings:

• Speed = high

• Exposure = manual (due to the short processing times, automatic exposure is

not possible with this method.)

These read rates are achieved under the following conditions:

• The illumination must be stable enough so that automatic shutter control is not

necessary.

• The code dimension must not be greater than 20 x 20 dots.

• Since the image is recorded "undersampled", the dots of the code must have a

minimum size of 10 pixels

• The code must be positioned in the sensor image so that there is always a

clearance of at least 3 dots to the edge of the image.

• The code must not make contact with any other objects in the image, the quiet

zone must be kept free.

• To allow the code to be found quickly, there must be no other objects (bus

structures count here as well) in the image with enclosed rectangle and of a

comparable size to the trained code. (See also the two following figures.)

• The diameter of the dots must be uniform over the entire code field. The

contrast between dots and the background must be approximately the same

over the entire code field.

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

1-14 A5E00475759-01

Page 23

Product Overview

• The image background must have a homogeneous brightness (no textures

such as stripes or grooves etc.).

• The view angle of the sensor to the printed surface must be approaching

vertical (80 to 90 degrees).

Note

Operating and monitoring via the setup support can lead to longer cycle times.

1.7.2 Requirements for QR codes

General Requirements for QR Codes and Legibility

The requirements are as follows:

• It can read codes in which directly adjacent code points have a minimum

distance of 5 pixels and up to a maximum distance of 35 pixels.

• The view angle of the sensor to the surface must be between 70 ° and 90 °.

• The diameter of the dots must be uniform over the entire code field.

• The contrast between dots and the background must be approximately the

same over the entire code field.

• The image background must have a homogeneous brightness (no textures

such as stripes or grooves etc.).

• The following code types are not supported: Micro QR code, Macro QR code

• Due to the limited image resolution, the maximum code dimension 89x89 (for

all sensor heads except 6GF2002-8GB) or 133x133 (for sensor head

6GF2002-8GB) can be read.

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

A5E00475759-01

1-15

Page 24

Product Overview

Requirements for QR codes for fast reading with guaranteed read rates up to

5 Hz (for all sensor heads except 6GF2002-8GB)

• The code dimension must not exceed 37 x 37.

• To allow the code to be found quickly, there must be no other objects (bus

structures count here as well) in the image with enclosed rectangle and of a

comparable size to the trained code.

• The code must be positioned in the sensor image so that there is always a

clearance of at least 3 dots to the edge of the image.

• The code should not make contact with any other objects in the image (keep

the quiet zone free: 4 dots).

• The dots of the code must have a minimum size of 10 pixels.

• The view angle of the sensor to the printed surface must be approaching

vertical (80 to 90 °).

• The code must not be mirrored compared with the trained code.

• The polarity must be the same as in the trained code.

• The code must have the same dimension as the trained code.

Characteristics of QR code

• Any alignment of the code in the image

• Up to 5 code readings per second

• Reading inverted code images

• Calculation of quality characteristics according to the AIM specification

• Display of the surrounding rectangle around the code position and code mid

point

• Display of the roll angle and tilt angle

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

1-16 A5E00475759-01

Page 25

Product Overview

1.7.3 Requirements for PDF417 codes

General Requirements for PDF417 Codes and Legibility

The requirements are as follows:

• Codes with a bar width of at least 3 pixels and in which the height of a single

row of symbols is at least 9 pixels can be read.

• The width of the black and white bars must be uniform over the entire code

field.

• The view angle of the sensor to the surface must be greater than 70 °.

• The code should not make contact with any other objects in the image (keep

the quiet zone free: twice the column width).

• Within the code, the ratio of contrast (difference between black and white) to

noise should be at least three and should be very similar over the entire code

field.

• The image background must have a homogeneous brightness (no textures

such as stripes or grooves etc.).

• The code must be positioned in the sensor image so that the entire code

(including start and stop pattern) always has a clearance of at least 3 pixels to

the edge of the image.

• The error correction codes (the lower part of the bar code) must not be

covered.

• The following code types are not supported: Truncated PDF417,

Macro PDF417, Micro PDF417

• At the minimum bar width, each symbol column requires 51 pixels. Along with

the four start and stop patterns, the width of the code with n code columns is:

Width = 51 * (n + 4) pixels. Due to the limited image resolution, codes with up

to a maximum of 40 code rows and up to a maximum of 6 code columns (for all

sensor heads except 6GF2002-8GB) or up to 60 code rows and up to 12 code

columns (for sensor head 6GF2002-8GB) can be read.

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

A5E00475759-01

1-17

Page 26

Product Overview

Requirements for PDF417 codes for fast reading with guaranteed read rates up

to 5 Hz (for all sensor heads except 6GF2002-8GB)

• The view angle of the sensor to the printed surface must be approaching

vertical (view angle 80 to 90 °).

• To allow the code to be found quickly, there must be no other objects (bus

structures count here as well) in the image with enclosed rectangle and of a

comparable size to the trained code.

• The code dimension must not be greater than 20 rows and 2 columns.

• The bar width must be at least 6 pixels.

• The height of individual symbol rows must be at least 18 pixels.

• There must be no disturbances or overlaps within the code.

• The PDF417 error correction level must be at least 1.

• The polarity must be the same as in the trained code.

Characteristics of the PDF417 code

• Any alignment of the code in the image

• Up to 5 code readings per second

• Reading inverted code images

• Calculating the contrast quality characteristic

• Calculating the unused error correction

• Display of the surrounding rectangle around the code position and code mid

point

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

1-18 A5E00475759-01

Page 27

2 System Integration

2.1 Design

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

A5E00475759-01

2-1

Page 28

System Integration

2.2 Application Examples

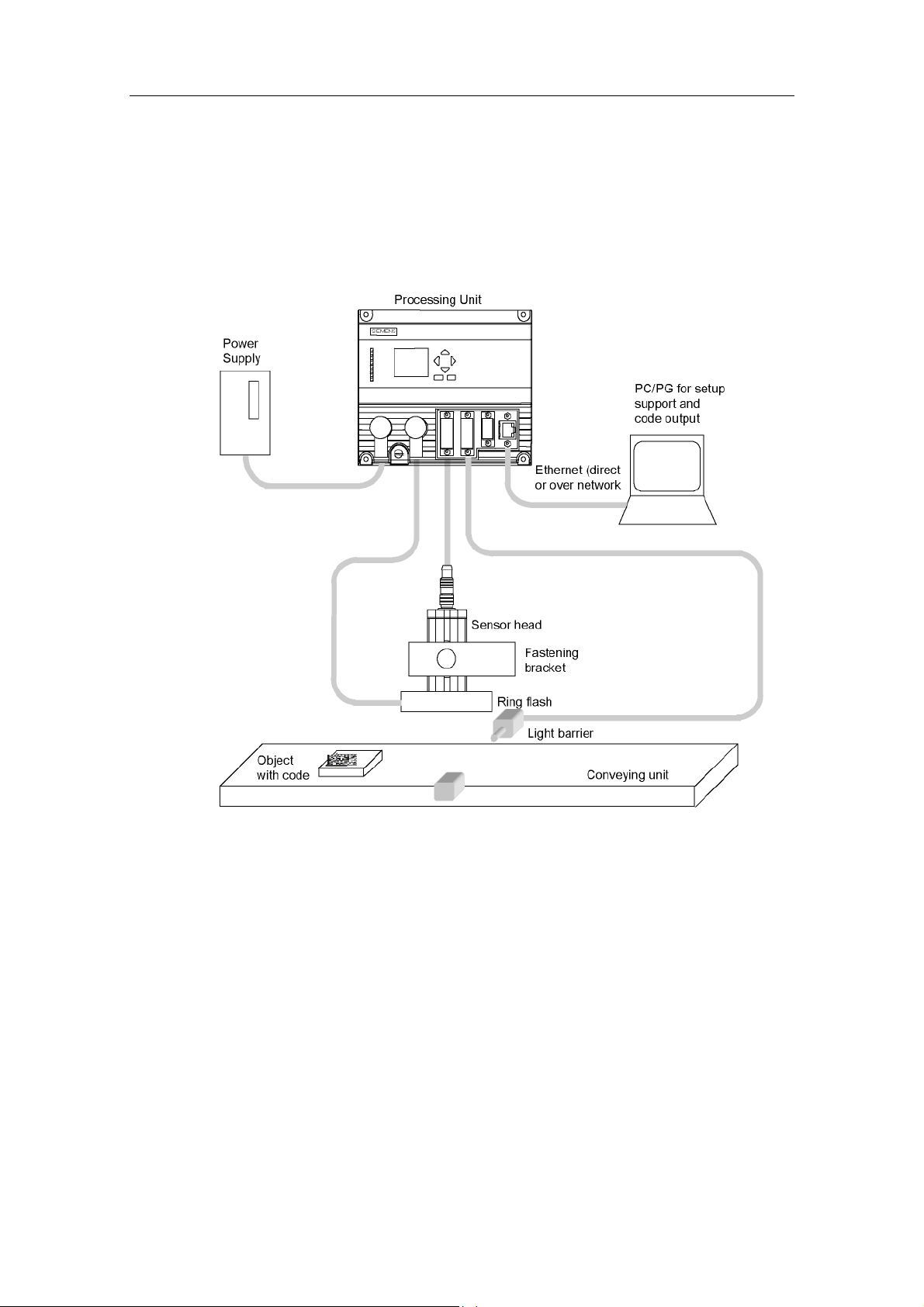

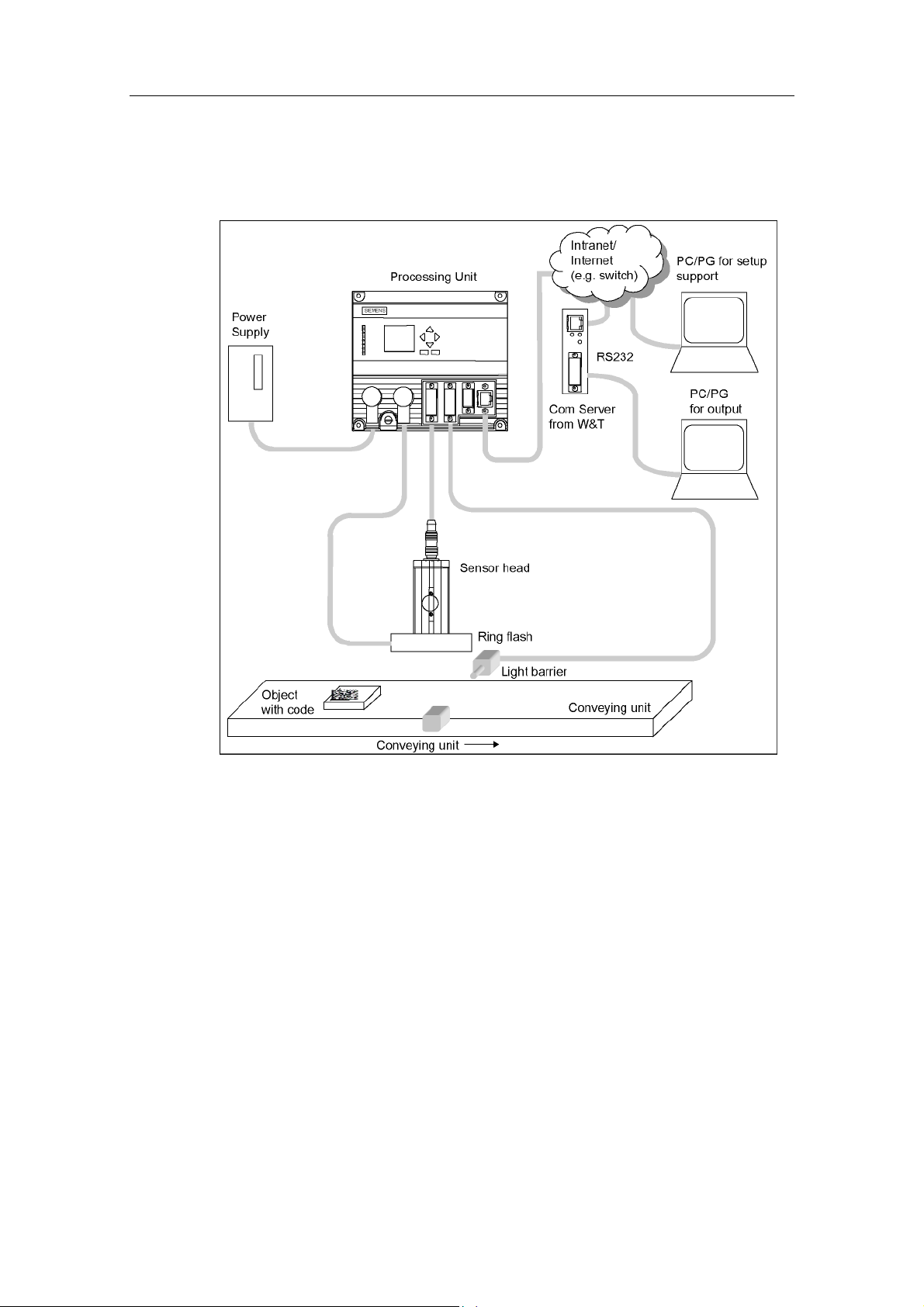

2.2.1 Reading codes or checking quality in stand-alone mode with output over Ethernet

VS 130-2/VS 130-2vcr reads the codes and outputs them to a PC/PG. The PC or

PG can be connected to the processing unit directly by a crossover cable or over a

network connection.

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

2-2 A5E00475759-01

Page 29

System Integration

2.2.2 Reading Codes or Quality in Stand-alone Mode with Output over RS-232

The code is output over the RS-232 port of the Com server from WuT. The PC or

PG for setup support is connected to the processing unit over a network (intranet or

Internet).

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

A5E00475759-01

2-3

Page 30

System Integration

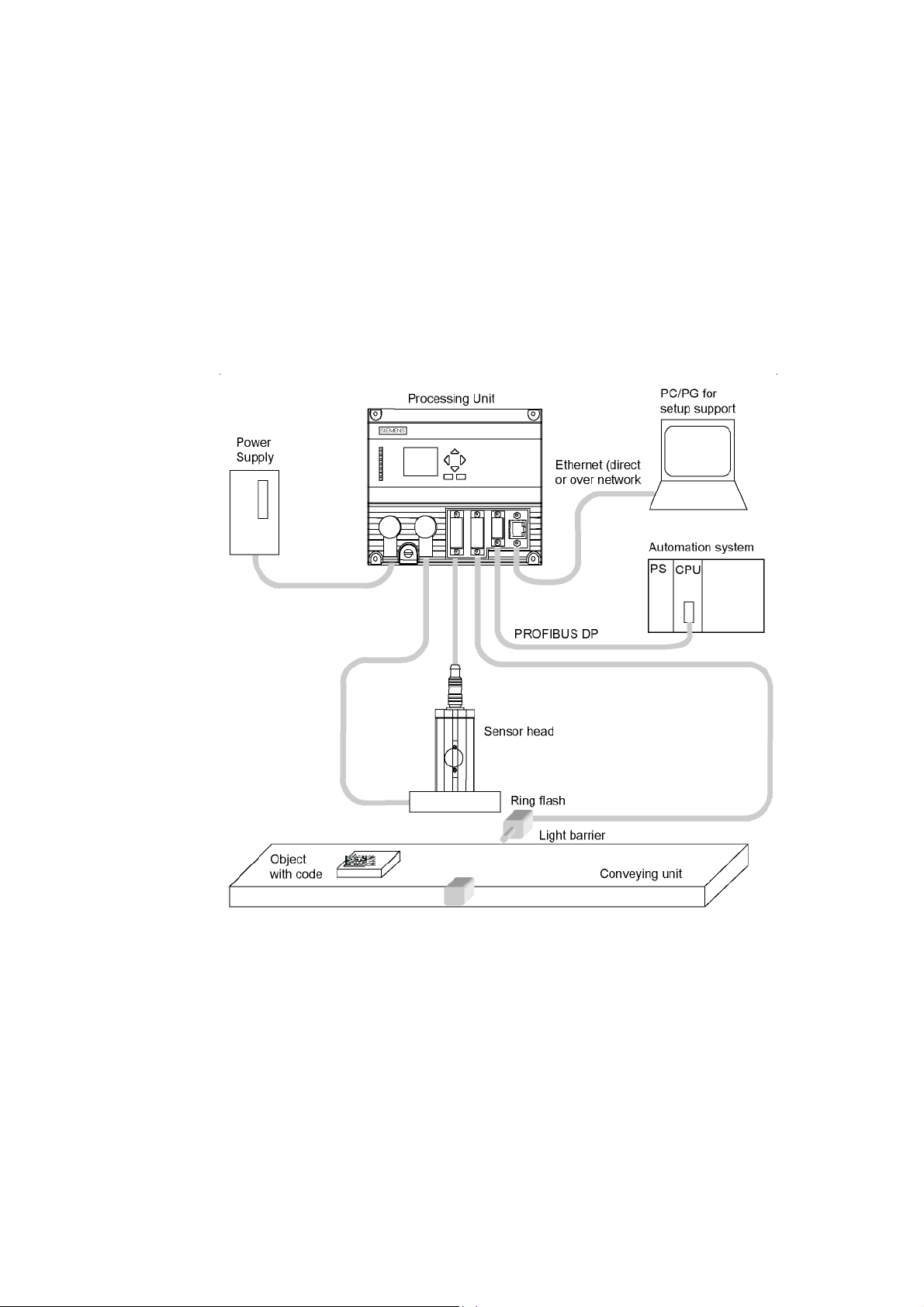

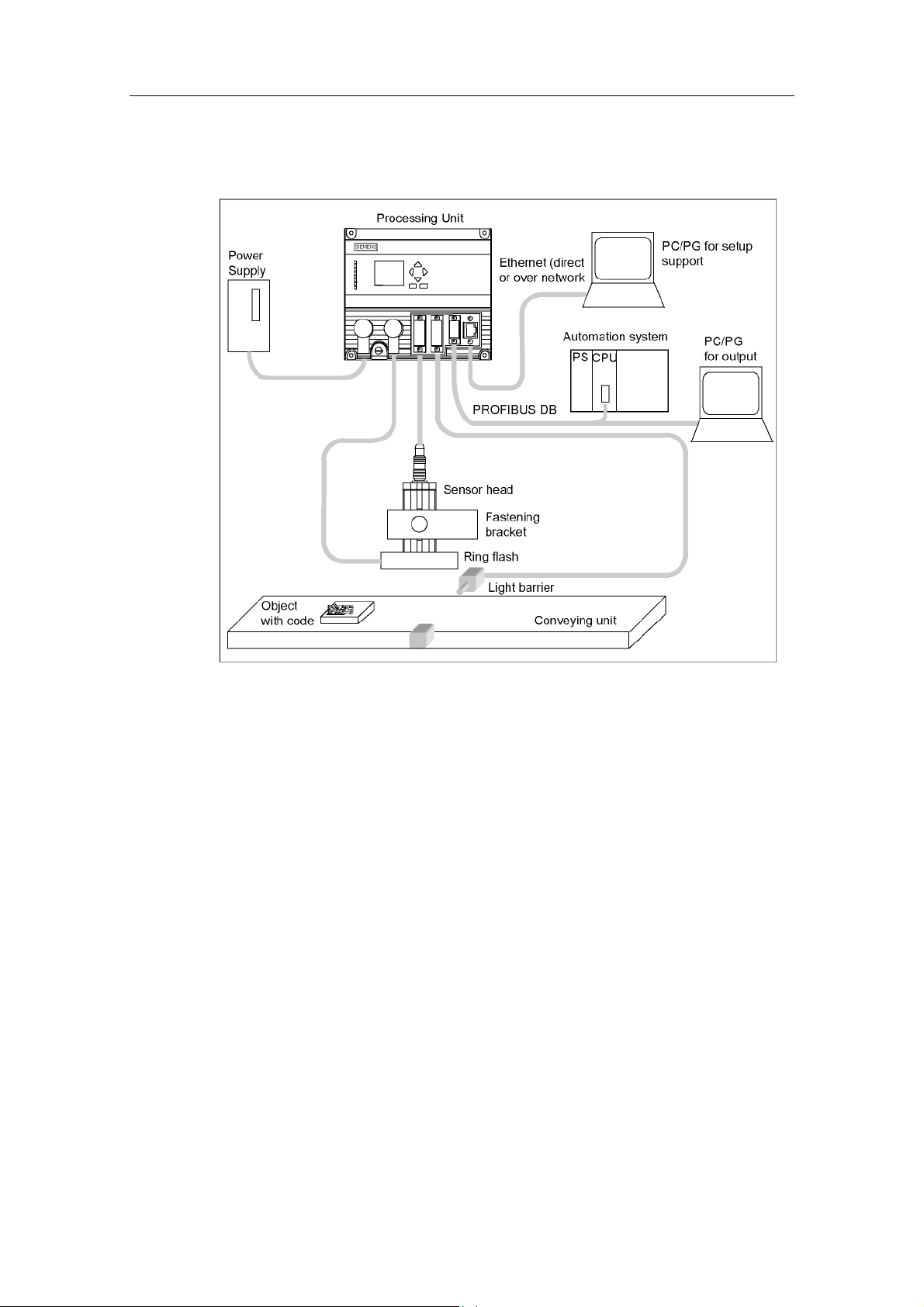

2.2.3 Reading Codes or Quality in a PROFIBUS Environment

A PC/PG intended solely for setup is connected over the Ethernet port. Via

PROFIBUS, there is a connection to a PLC and to another PC/PG.

VS 130-2/VS 130-2vcr is controlled over PROFIBUS by the automation system and

the codes output to this automation system or PC/PG once again over PROFIBUS.

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

2-4 A5E00475759-01

Page 31

System Integration

2.2.4 Reading Codes or Quality in a PROFINET Environment

A PC/PG dedicated for setup is connected over the Ethernet (TCP/IP). There is

also a connection to a PROFINET-capable automation system over the Ethernet.

VS 130-2/VS 130-2vcr is controlled over PROFINET by the automation system.

The code is also output over PROFINET to the automation system.

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

A5E00475759-01

2-5

Page 32

System Integration

2.2.5 Reading codes or checking quality in a PROFINET environment and outputting over Ethernet

Two PCs or PGs are connected over Ethernet (TCP/IP):

• One is used for setup.

• The other is used to output the read codes.

Note

It is also possible to connect only one PC/PG over Ethernet (TCP/IP). In this case,

the same machine is used for setup and for code output.

A connection to a PROFINET-capable automation system remains over Ethernet.

VS 130-2/VS 130-2vcr is controlled over PROFINET by the automation system.

2.2.6 Mixed operation

In addition to the connection options listed in the sections Reading Codes or

Quality in Stand-alone Mode and over Ethernet to Reading Codes or Checking

Quality in a PROFINET Environment and Outputting over Ethernet, mixed modes

are also possible, for example control over PROFIBUS DP and result output over

RS-232.

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

2-6 A5E00475759-01

Page 33

3 Installation

3.1 Installing Components for VS 130-2

Step Activity

1 A

Arrange the sensor head so that reflections are kept to a minimum. The angle of its central

axis should be typically 15° from vertical (angle α) (permitted range of angles for data matrix

and Vericode: 0 ≤ α ≤ 40°, for QR and PDF417 code: 0 ≤ α ≤ 30°).

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

A5E00475759-01

3-1

Page 34

Installation

Step Activity

1b If there is still too much reflection at an angle of 15°, select an arrangement in which the

sensor head and the ring flash are not concentric.

Note:

The mechanism for mounting the ring flash is not supplied with the product.

If the ring flash does not meet your requirements, please contact your sales partner who will

be able to recommend other suppliers of lighting for the VS 130-2C.

1c

2 Install the processing unit so that it is easily accessible for the operator.

3

4 Start the setup support on the PG/PC, and switch the processing unit to the Adjust mode. You

With both arrangements, maintain a clearance between the end of the sensor head and the

code to be read that is suitable for the lens you are using.

Caution:

If you have a large code area and the sensor is inclined at a large angle to the code area and

there is only a short distance between the sensor and code area, this can lead to image

distortion and diminished recognition performance.

Install the external triggering unit, for example a light barrier.

then see an image as seen by the sensor head.

• Check the trigger signal. by selecting the "Trg. only" check box in the "Read settings"

group of the "Adjust" task. Check whether VS 130–2 can read the codes with the sensor

head and ring flash in the current position. If necessary, correct the trigger point and/or

position of the sensor head.

• Select suitable values for the shutter speed and brightness. The image should not be too

bright.

Caution: If Exposure is set to Auto V1 or Auto, the code must remain fully in the image for at

least 100 ms.

As soon as after "Recognition" the message "Successfully finished" appears, the code has

been successfully decoded. You will see the result of the read in the "Result" box.

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

3-2 A5E00475759-01

Page 35

Installation

3.2 Wiring Components

Connect the processing unit with the other components using the connectors on

the front panel.

Port Pin Assignment of the Processing Unit

!

Do not connect or disconnect cables when the power supply is on.

Apart from the Ethernet cable, the cables are supplied with the product (See

Components of the Product).

Warning

Attention

!

Grounding the VS 130-2/VS 130-2vcr cancels the ungrounded installation of the

power unit used to operate the VS 130-2/VS 130-2vcr.

Connector Connector

Label

Functional earth - Screw terminal - - -

Power supply IN 24 V DC Circular connector M12 4 0.56 mm2 Pin

Illumination Unit LAMP Circular connector M12 4 0.23 mm2 Socket

Sensor head

(shielded cable)

I/O DI/DO D-sub 15 0.14 mm2 Socket

PROFIBUS DP DP D-sub 9 - Socket

Ethernet Ethernet RJ45 8 - Socket

* The supplied ferrite ring must be fixed to the sensor cable (approx. 50 mm from connector to

evaluation unit).

SENSOR HD D-sub * 26 0.09 mm2 Socket

Type Number

of pins

Cable Cross

Section

Type

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

A5E00475759-01

3-3

Page 36

Installation

Step Activity

1 Read the guidelines for preventing electrical interference (see Guidelines for Preventing

Electrical Interference).

2 Connect the processing unit to the sensor head and the lighting unit with the cables.

3 If you do not evaluate the result bits READ, MATCH, N_OK over PROFIBUS DP: Connect the

digital outputs READ, MATCH, N_OK as described in Control Signals.

4 Connect the trigger signal via the TRG digital input.

5 If you intend to control the SIMATICVS 130-2/VS 130-2vcr with a PLC, connect the other digital

inputs and outputs as described in Control Signals.

6 Connect functional ground of the processing unit to chassis ground (diameter of the ring: (M5,

cable cross section 1.5 mm

7 Connect the processing unit to the 24 V power supply (2 A).

8

Connect the PC/PG to the processing unit via Ethernet.

2

).

Note

The DC load power supply must meet the following requirements:

Only low voltage less than or equal to 24 V DC safely isolated from the power

supply network must be used for the load current supply. Safe isolation can be

implemented, for example, by adhering to the specifications

1. VDE 0100-410 / HD 384-4-41 S2 / IEC 60364-4-41

(functional low voltage with safe isolation) or

2. VDE 0805 / EN 60950 / IEC 60950

(as safety extra-low voltage SELV) or VDE 0106 Part 101.

Note

The supply chassis of the I/O and CPU must be connected to the supply chassis of

the processing unit.

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

3-4 A5E00475759-01

Page 37

Installation

3.3 Guidelines on Interference-Proof Installation

To avoid interference, you must shield your system. Low-frequency (LF) and highfrequency (HF) interference signals can result in an incorrect response if the

system is badly grounded or not shielded.

Interference signals can be caused, for example, by switching relays or contactors

(high rates of change in current or voltage, HF interference signals) or by different

ground potentials between two parts of a system (LF interference signals).

Using / Installing Interference-Proof Cable

• Always use the included patch cord to connect the sensor head.

• All plug-in connections must be secured by screws or a locking mechanism.

• Signal lines must not run parallel to power cables. A separate cable channel

must be used with a minimum clearance of 50 cm from power cables.

Note

For more detailed information, refer to the installation manual SIMATIC S7-300

Programmable Controller, Hardware and Installation in the section on "Wiring".

3.4 Guidelines for Installing PROFIBUS DP or PROFINET I/O

If you are using PROFIBUS DP or PROFINET I/O (to control the device and/or to

transfer the results) the installation and configuration guidelines must be kept to.

You will find this information in the installation manual SIMATIC S7-300

Programmable Controller, Hardware and Installation.

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

A5E00475759-01

3-5

Page 38

Installation

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

3-6 A5E00475759-01

Page 39

4 Commissioning

4.1 Introduction

You can operate the Vision Sensor SIMATIC VS 130-2/VS 130-2vcr interactively or

controlled by signals:

• In this chapter, you will learn about interactive operation using the operator

control and display field of the evaluation unit.

• The section Process interfacing explains the options open to you for signal-

controlled operation.

Note

The setup support for VS 130-2/VS 130-2vcr is described in detail in the Online

Help for Setup Support.

4.2 Turning on the Device

Turn on the power on the processing unit. The texts "Booting... SIMATIC V ..." and

then "Firmware Version V..." with the current firmware version appear on the

display.

The VS 130-2 or VS 130-2vcr then runs the following tests:

• Test of the sensor head

• Test of the stored settings and code data

• If applicable, check whether data can be exchanged from and to PROFIBUS

(this check is made if you have selected "DP" for one or more of the following

signal paths: Output of the result string, feeding the trigger signal to the

processing unit, signal path for DISA, SEL0, SEL1, SEL2, SEL3, TRN, RES,

IN_OP, TRD, RDY, READ, MATCH, N_OK).

• Test of the Ethernet connection

• If applicable, check for the connection to PROFINET and to Ethernet RS-232

converter or TCP server and to the PC/PG on which diagnostic information will

be stored (over TCP/IP)

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

A5E00475759-01

4-1

Page 40

Commissioning

If there are no errors in the self-test, either the ADJUST menu or the RUN menu or

the STOP menu is displayed depending on the status when you last shut down.

• "ADJUST" menu:

• "RUN" menu:

• "STOP" menu level

Note

Apart from controlling from the processing unit, you can also control

VS 130-2/VS 130-2vcr with the setup support, see Operating using the

Setup Support.

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

4-2 A5E00475759-01

Page 41

Commissioning

4.3 Control and Display Panel

The operator is guided by menus in the display panel.

• The menu items appear in the first three lines of the display panel. The cursor

">" points to the selected menu item.

• In the fourth line of the display panel, you can see which buttons of the control

panel are currently available (OK, ESC, V, W,

control panel, you can navigate within menus and from one menu to another:

, ). Using the buttons of the

- With the arrow buttons "V" and "W", you can move the cursor up and down

and select the menu command you require.

- With the "OK" button, you confirm your selection and move on to the next

step.

- With the "ESC" button, you open the previous menu.

Description of the LEDs

LEDs Function

SF Group error

POWER Power supply turned on

TRAINED Trained:

READY Ready:

READ Evaluation result: Code was localized and decoded.

MATCH Evaluation result: Code matches learned code.

N_OK • Code was not legible.

BF Bus error on PROFIBUS or PROFINET

• In Run:

from: Selected code has not been trained

On: Selected code has been trained

• In Training (TRN=1):

from: Training active

On: Acknowledgment signal (RDY=0)

• from: Device startup or SIMATIC VS 130-2/VS 130-2vcr in Stop

• On: SIMATIC VS130-2/VS 130-2vcr in run

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

A5E00475759-01

4-3

Page 42

Commissioning

Setting the number values

You select the places of a value with the arrow buttons " " and " ".

You change the value of a place in the number with the arrow buttons "V" and "W".

The speed at which the numeric value changes depends on how long you press

the arrow buttons. As soon as you release the arrow buttons, the rate of change

returns to the slowest level again.

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

4-4 A5E00475759-01

Page 43

Commissioning

4.4 Adjusting the Sensor with the Setup Support

Before you commission the SIMATIC VS 130-2/VS 130-2vcr, you must adjust the

sensor head correctly. using a Web-based setup support. You then see an image

as seen by the sensor head. For more detailed information on the setup support,

refer to the online help.

Step Activity

1

2

3

4

5

6

7

8

9

1. Switch on the PC or PG with the Internet Explorer.

2. Turn on the processing unit.

3. Establish the TCP/IP connection between the processing unit and the PC/PG. You can

either do this directly with a crossover cable or by including the processing unit in an existing

network. Both options are described in detail in the online help.

4. Enter the address of the processing unit the Internet Explorer.

Result:

Once the setup support has started, the sensor field of view is displayed on your PC/PG monitor.

The displayed image is updated several times per second.

Adjusting the Sensor

1. Bring the code into the image.

2. Set a sharp image by adjusting the distance between the end of the sensor head and the

code correctly.

3. Correct the shutter speed and the brightness if necessary or use one of the automatic

modes (Auto V1 or Auto).

4. Minimize reflected light by viewing the code at a slight angle.

5. Activate the "Triggered only" check box to test the trigger signal and the trigger settings

(trigger source).

6. Tune further settings as required.

Note:

If you have too many errors, clean the lens and diffuser with a lint-free cloth.

• Secure the sensor and then check the correct sensor position.

• Make other parameter settings.

• Check the read result.

• Set the parameters to specify the process interface.

• Train the codes, if already known.

• Change to the processing mode (RUN).

Analyze any errors that may occur.

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

A5E00475759-01

4-5

Page 44

Commissioning

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

4-6 A5E00475759-01

Page 45

5 Operator Input

5.1 Overview

There are two basic ways of controlling the VS 130-2/VS 130-2vcr:

• Using the Setup Support

• Using the Processing Unit

With a few exceptions, you can set all the parameters with either method. This is

illustrated based on the example of the "IP Mode" parameter:

• In the setup support, you will find this parameter in the "Connections" task in

the "Interfaces" tab in the "Ethernet" group in the "IP Mode" drop-down list box.

• On the processing unit, it is available at the ADJUST menu level (Connect >

Ports > Ethernet > IP Mode).

5.2 Working with the Processing Unit

The display of the processing unit is used to display the currently read code and to

navigate through the menus and make entries.

Example of the display of a code:

C 01 RUN √

=SERIES 7

OK:Menu

Note

In processing mode, it is not the currently read code that is displayed on the

processing unit when verifying but the string "Verifying=" followed by 4 quality

grades. These belong to the following quality characteristics: 1. Grade belongs to

the quality characteristic symbol contrast, 2. grade belongs to the quality

characteristic print growth, 3. grade belongs to the quality characteristic axial nonuniformity, 4. grade belongs to the quality characteristic unused error correction.

There are three menu levels:

• RUN

• Adjust

• STOP

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

A5E00475759-01

5-1

Page 46

Operator Input

The following table contains the menus of the RUN menu level.

Unless a temporary PROFIBUS DP or PROFINET IO error has occurred

(see Error Messages), the "Info" menu appears as follows:

Menu Meaning

Code Select the code number

STOP Processing and change to the STOP menu level

Info

ResetStat

Information function

Reset all statistical information (identical parameter to ResetStat in the

Options>Decode menu)

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

5-2 A5E00475759-01

Page 47

Operator Input

If one or more PROFIBUS DP or PROFINET IO errors have occurred

(see Error Messages), the "Info" menu appears as follows:

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

A5E00475759-01

5-3

Page 48

Operator Input

The following table lists the menus of the ADJUST menu level.

Menu

STOP Exits the ADJUST menu level

Adapt (only with Exposure = Manual) exposure adaptation

Trigger Trg.only An image is captured only on the trigger signal.

Auto (default) The images are acquired continuously.

Delay

Distort Correction of the image distortion caused by the lens

LightSrc. Specifies a light source (only in multilight mode)

Meaning

If you have made changes in the Adjust menu, you can save or discard them.

The processing unit changes to the STOP mode.

Specification of a maximum speed: Time by which the trigger signal will be

delayed (identical parameter to Delay in the Options>Integrate>Trigger menu)

Default: 0 ms

Default:

• Sensor head 6GF2 002-8DA01: 130

• Sensor head 6GF2 002-8EA01: 50

• Sensor head 6GF2 002-8FA01: 0

• Sensor head 6GF2 002-8CB: 0

• Sensor head 6GF2 002-8GB: 0

The menus of the STOP menu level are listed in the following table.

Menu Meaning

Adjust Changes to the setup mode

Connect Sets global connection parameters (interfaces, integration, result string)

Train Train a code

RUN Start evaluation of a code

Options Sets global device parameters (decoding, illumination and image capture,

diagnostics)

Maintain Delete trained codes and reset all parameters to their default values

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

5-4 A5E00475759-01

Page 49

Operator Input

The following four schematics provide you with an overview of all the parameters of

the VS 130-2 that can be set in the Connect and Options menus.

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

A5E00475759-01

5-5

Page 50

Operator Input

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

5-6 A5E00475759-01

Page 51

Operator Input

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

A5E00475759-01

5-7

Page 52

Operator Input

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

5-8 A5E00475759-01

Page 53

Operator Input

The following three schematics provide you with an overview of all the parameters

of the VS 130-2vcr that can be set in the Connect and Options menus.

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

A5E00475759-01

5-9

Page 54

Operator Input

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

5-10 A5E00475759-01

Page 55

Operator Input

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

A5E00475759-01

5-11

Page 56

Operator Input

The following table describes all the parameters of the Connect menu.

Parameter Path Possible

Values

Ports

Pulsetime Ports>DI/DO 5 to 999 30 Pulse time of the digital outputs

Address

(not active, if

IP Mode =

PNIO)

(only for

VS 130-2)

Timeout

(not active, if

IP Mode =

PNIO)

(only for

VS 130-2)

Pulsetime

(not active, if

IP Mode =

PNIO)

(only for

VS 130-2)

Swap

(not active, if

IP Mode =

PNIO)

(only for

VS 130-2)

Devname

(not active, if

IP Mode =

PNIO)

(only for

VS 130-2)

Timeout

(not active, if

IP Mode =

PNIO)

(only for

VS 130-2)

Pulsetime

(not active, if

IP Mode =

PNIO)

(only for

VS 130-2)

Ports>DP 1 to 125 7 Address on PROFIBUS DP

Ports>DP 100 to 2000 500 Handshake monitoring time in ms

Ports>DP 5 to 999 30 Pulse time of the digital outputs

Ports>DP S7, No S7 Specifies the byte order for data

Ports>PNIO String (0 to 9, A

to Z, a to z, ".",

"-"). The string

must match the

conventions of

the domain

name system.

Ports>PNIO 100 to 2000 500 Handshake monitoring time in ms

Ports>PNIO 5 to 999 30 Pulse time of the digital outputs

Default setting Meaning

READ, MATCH, N_OK in ms on the

DI/DO interface

READ, MATCH, N_OK in ms when

output is over PROFIBUS DP

types with a width of 16 bits or more:

1. S7: big endian

2. No: little endian

VS 130-2 Name of the device on PROFINET

Note: PROFINET is not case

sensitive

READ, MATCH, N_OK in ms when

output is over PROFIBUS I/O

Note: For the pulse time, select a

higher value than for the update time

of the PROFINET IO system in HW

Config.

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

5-12 A5E00475759-01

Page 57

Operator Input

Parameter Path Possible

Values

Swap

(not active, if

IP Mode =

PNIO)

(only for

VS 130-2)

IP mode Ports>Ethernet DHCP

IPAddress

(not

modifiable, if

IP Mode =

DHCP)

IP Mask

(not active, if

IP Mode =

DHCP)

Gateway

(not active, if

IP Mode =

DHCP)

MAC Info Ports>Ethernet Cannot be

IPAddress Ports>

IP Port Ports>

Ports>PNIO S7

no

Manual

DHCPSERV

PNIO (only for

VS 130-2)

Ports>Ethernet xxx.xxx.xxx.xxx

(xxx=0 to 255)

Ports>Ethernet 255.255.xxx.yyy 255.255.255.0 The subnet mask indicates which

Ports>Ethernet xxx.xxx.xxx.xxx

(xxx=0 to 255)

modified

xxx.xxx.xxx.xxx

TCP/RS-232

TCP/RS-232

(xxx=0 to 255)

device-specific 8000 RS-232 port of the Ethernet RS-232

Default setting Meaning

S7 Specifies the byte order for data

types with a width of 16 bits or more:

• S7: big endian

• No: little endian

DHCP Assignment of the IP address to the

processing unit in the network:

• DHCP: Automatic (DHCP =

Dynamic Host Configuration

Protocol)

• Manual: Manual

• DHCPSERV: The processing

unit can assign an IP address to

a PC connected by a crossover

cable if the PC obtains its IP

address automatically (DHCP

client).

• PNIO: Automatic by the I/O

controller

192.168.0.42 IP address of the processing unit

(An IP address consists of four

numbers separated by periods with

each number being in a range from 0

to 255.)

part of the IP address specifies the

network and which part specifies the

processing unit:

For xxx.yyy, binary requires that the

left part be made up of ones without

a gap and the right part be made up

of zeros without a gap. Example:

11111111.10100000 is not

permitted.

Note also: yyy <= 254

192.168.000.255 IP Address: IP address of the

network node that can establish

connections outside of the current

subnet

Devicedependent

192.168.000.043 IP address of the Ethernet RS-232

The MAC address (Media Access

Control) is the hardware address of

each network device and is used to

identify the device uniquely in the

network.

converter or of the PC/PG on which

a TCP server runs.

converter or IP port of the PC/PG on

which a TCP server runs

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

A5E00475759-01

5-13

Page 58

Operator Input

Parameter Path Possible

Values

Timeout Ports>

TCP/RS-232

IPAddress

(only for

VS 130-2)

Port

(only for

VS 130-2)

Timeout

(only for

VS 130-2)

Ports>

Arch/MMI

Ports>

Arch/MMI

Ports>

Arch/MMI

0 to 3600 0 • 0: There is no transfer of cyclic

xxx.xxx.xxx.xxx

(xxx=0 to 255)

Device-specific 8765 Corresponding port of this server

0 to 3600 10 • 0: There is no transfer of cyclic

Default setting Meaning

monitoring frames to determine

whether the connection still

exists between the processing

unit and the Ethernet RS-232

converter or the PC/PG on

which a TCP server runs.

• Otherwise: Time in seconds

after which a monitoring frame is

sent to determine whether the

connection still exists between

the processing unit and the

Ethernet RS-232 converter or

the PC/PG on which a TCP

server runs. The check is

implemented by sending the

"Idling string" ("Connections"

dialog "Part 3/3. Result and

String") to the recipient at the

intervals set with the parameter.

If the check fails, an error is

output (only when the

processing unit is in RUN or

Train) and the connection is

reestablished.

192.168.000.045 IP address of the server for

diagnostic information

monitoring frames to check the

connection between processing

unit and server.

• Otherwise: Time in seconds

after which a monitoring frame is

sent to check the connection

between processing unit and

server. If the server does not

respond to this frame within the

monitoring time, an error is

output (only when the

processing unit is in RUN or

Train) and the connection is

reestablished.

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

5-14 A5E00475759-01

Page 59

Operator Input

Parameter Path Possible

Values

Integrate

Source Integrate>

Trigger

String

(only if

Source=

TCP/RS-

232)

Delay Integrate>

String Integrate DP or PNIO

Result Integrate DP or PNIO

Control Integrate DP or PNIO

DiagImage

(only for

VS 130-2)

DiagReport

(only for

VS 130-2)

Integrate>

Trigger

Trigger

Integrate None

Integrate None

Endless

DI/DO

DP or PNIO

(only for

VS 130-2)

TCP/RS-232

ASCII

characters

0 to 9999 ms 0 ms Here, you specify the time by which

(only for

VS 130-2)

TCP/RS-232

None

(only for

VS 130-2)

DI/DO

None

(only for

VS 130-2)

DI/DO

Arch/MMI

Arch/MMI

Default setting Meaning

DI/DO Here, you set the port over which the

trigger signal is sent to the

processing unit.

M If the string specified here is sent

over the RS-232 port of an RS-232

Ethernet converter or a TCP server,

the processing unit generates a

trigger signal.

the trigger signal will be delayed in

ms (Identical parameter to Delay in

the Adjust menu).

None Here, you enter the port over which

the result string is output.

DI/DO Here, you specify the port over which

the result bits OK, N_OK, READ,

and MATCH are output.

DI/DO Here you specify the port for the

DISA, SEL0, SEL1, SEL2, SEL3,

TRN, RES, IN_OP, TRD, RDY

signals.

None Here, you specify whether the

currently captured image will be sent

to a server when an error occurs.

None Here, you specify whether the

corresponding data record will be

sent to a server when an error

occurs.

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

A5E00475759-01

5-15

Page 60

Operator Input

Parameter Path Possible

Values

String

option String>Filter Off

Position

ID

StartPos

(only if

String>

Filter

>Option=

Position)

Length

(only if

String>

Filter

>Option=

Position)

Separator

(only if

String>

Filter>

Option=ID)

ID

(only if

String>

Filter>

Option=ID)

String>Filter >=1 1 Position, starting at which the

String>Filter >=1 1 The part string consists of as many

String>Filter ASCII

characters

String>Filter ASCII

characters

Default setting Meaning

Off • Off: No character in the read

codes is suppressed. Nor are

any characters added.

• Position: Only part of the string

of the read codes is taken into

account. You specify this part

with the StartPos and Length

parameters.

• ID : Only parts of the string of

the read codes are taken into

account. You specify which

parts using the Separator and ID

parameters.

characters of a part string are output.

characters as you specify here.

+ Separators

- The substring start is identified by

the ID. If several sequences are

identified by the ID, only the first one

is used.

Vision Sensor SIMATIC VS 130-2/VS 130-2vcr

5-16 A5E00475759-01

Page 61

Operator Input

Parameter Path Possible

Values

Format String See "Meaning" %s Content and format of the string to

ReadErr String>

Messages

FilterErr String>

Messages

See "Meaning" Read Err (%s) Content and format of the string to

Freely

selectable

character string

Default setting Meaning

be output

The string can be a maximum of 100

bytes long and consists of any

combination of the following

elements:

• Characters whose ASCII

equivalent is between 01H and

FFH (%% causes a percentage

character to be displayed)

• Formatting instructions for

output of variables

A formatting instruction has the

following structure:

% [number of places] variable

{selection of variables}

Here, square brackets mean the

information is optional Braces mean

that the exactly one value must be

selected from within the braces The

following formatting instructions are

possible:

• %s

• %[03]q{0|1|2|3}

• %Q{0|1|2|3|4}

• %[03]p{0|1|2}

• %[{04|05}]c

• %u

• %U

• %l

be output with read errors

The string can be a maximum of 100

bytes long and consists of any

combination of the following

elements:

• Characters whose ASCII

equivalent is between 01H and

FFH (%% causes a percentage

character to be displayed)

• Formatting instructions for

output of variables

The following formatting instructions

are possible:

• %s

• %c

"%s" stands for the textual

description of the probable cause of

the error in English, "%c" for a

decimal number with the same

information

Filter error Text for the situation when the

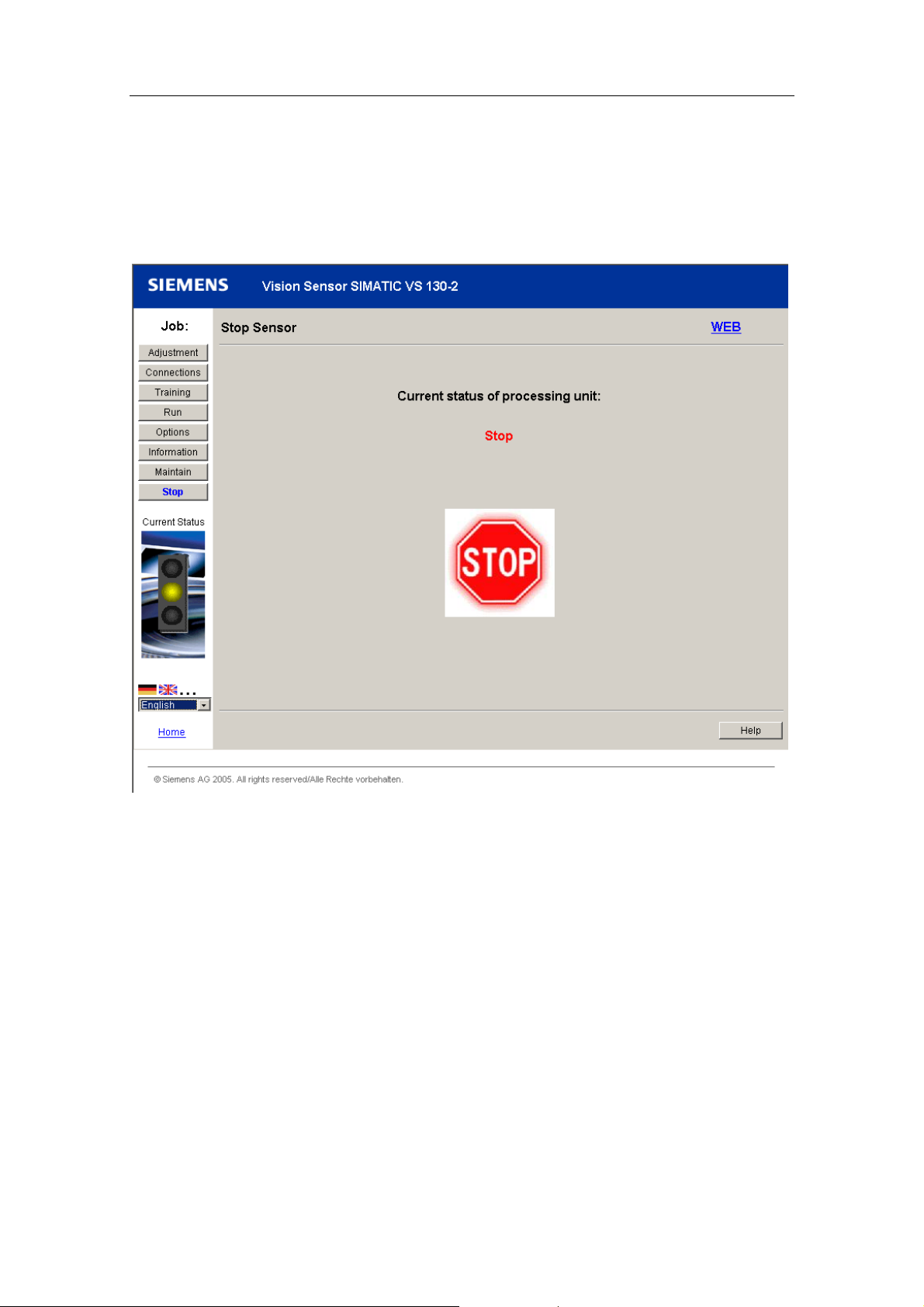

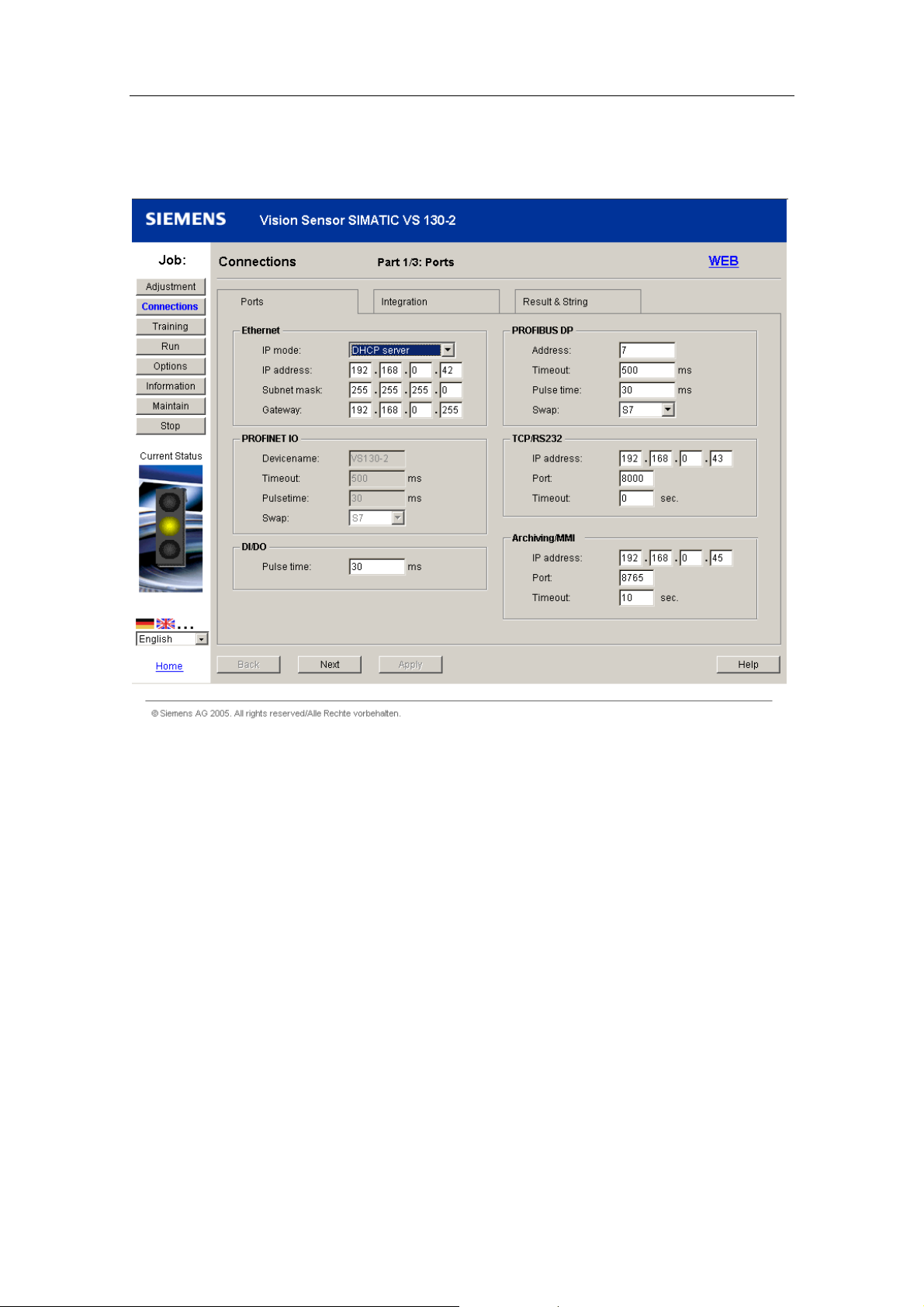

values for StartPos or ID for the