Page 1

_

_

_

_

_

_

_

_

_

_

SIMATIC SIMATIC SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

SIMATIC

Preface

_____________

Requirements

_____________

Introduction

_____________

1

2

3

SM331; AI 8x12 Bit Getting Started

part 1: 4 -20mA

Getting Started

Mechanical setup of the

example station

_____________

Electrical connection

_____________

Configuration of the

SIMATIC Manager

_____________

Testing the user program

_____________

Diagnostic interrupt

_____________

Hardware interrupt

_____________

Appendix

_____________

4

5

6

7

8

9

A

11/2006

A5E00253410-02

Page 2

Safety Guidelines

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

Danger

indicates that death or severe personal injury will result if proper precautions are not taken.

Warning

indicates that death or severe personal injury may result if proper precautions are not taken.

Caution

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

Caution

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

Notice

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The device/system may only be set up and used in conjunction with this documentation. Commissioning and

operation of a device/system may only be performed by qualified personnel. Within the context of the safety notes

in this documentation qualified persons are defined as persons who are authorized to commission, ground and

label devices, systems and circuits in accordance with established safety practices and standards.

Prescribed Usage

Note the following:

Warning

This device may only be used for the applications described in the catalog or the technical description and only in

connection with devices or components from other manufacturers which have been approved or recommended by

Siemens. Correct, reliable operation of the product requires proper transport, storage, positioning and assembly

as well as careful operation and maintenance.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

Automation and Drives

Postfach 48 48

90437 NÜRNBERG

GERMANY

Order No.: A5E00253410-02

11/2006

Copyright © Siemens AG 2006.

Technical data subject to change

Page 3

Table of contents

1 Preface ................................................................................................................................................... 1-1

1.1 General ...................................................................................................................................... 1-1

2 Requirements ......................................................................................................................................... 2-1

2.1 Basics......................................................................................................................................... 2-1

3 Introduction............................................................................................................................................. 3-1

3.1 Example of an application.......................................................................................................... 3-1

4 Mechanical setup of the example station................................................................................................ 4-1

4.1 Mounting the example station.................................................................................................... 4-1

4.2 Mounting of analog module components................................................................................... 4-3

4.2.1 General ...................................................................................................................................... 4-3

4.2.2 Components of the SM331 ........................................................................................................ 4-4

4.2.3 Features of the analog modules ................................................................................................ 4-5

4.2.4 Measuring range modules ......................................................................................................... 4-6

4.2.5 Mounting the SM331 module..................................................................................................... 4-8

5 Electrical connection............................................................................................................................... 5-1

5.1 Overview .................................................................................................................................... 5-1

5.2 Wiring the power supply module and the CPU.......................................................................... 5-2

5.3 Wiring of the analog module ...................................................................................................... 5-4

5.3.1 Requirement............................................................................................................................... 5-4

5.3.2 Current transducer wiring - principle.......................................................................................... 5-4

5.3.3 Wiring of the analog module ...................................................................................................... 5-5

5.3.4 Test ............................................................................................................................................ 5-8

6 Configuration of the SIMATIC Manager.................................................................................................. 6-1

6.1 Creating a new STEP7 project................................................................................................... 6-1

6.1.1 Creating a new project ............................................................................................................... 6-1

6.1.2 CPU selection ............................................................................................................................ 6-3

6.1.3 Defining the basic user program................................................................................................ 6-4

6.1.4 Assigning the project name........................................................................................................ 6-5

6.1.5 Result S7 project is created ....................................................................................................... 6-6

6.2 Hardware configuration.............................................................................................................. 6-7

6.2.1 Creating the hardware configuration.......................................................................................... 6-7

6.2.2 Adding SIMATIC components.................................................................................................... 6-8

6.2.3 Configuring the analog module................................................................................................ 6-10

6.2.4 Test .......................................................................................................................................... 6-13

6.3 STEP 7 user program .............................................................................................................. 6-17

6.3.1 Tasks of the user program ....................................................................................................... 6-17

6.3.2 Creating a user program.......................................................................................................... 6-18

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

iii

Page 4

Table of contents

7 Testing the user program........................................................................................................................ 7-1

7.1 Downloading system data and user program ............................................................................ 7-1

7.2 Visualization of the sensor values.............................................................................................. 7-3

7.3 Analog value representation ...................................................................................................... 7-8

8 Diagnostic interrupt................................................................................................................................. 8-1

8.1 Reading diagnostic information from a PG ................................................................................ 8-1

8.2 General diagnostics ................................................................................................................... 8-3

8.3 Channel dependent diagnostic interrupts .................................................................................. 8-4

8.3.1 There are five channel dependent diagnostic interrupts............................................................ 8-4

8.3.2 Configuration / programming error............................................................................................. 8-4

8.3.3 Common mode error.................................................................................................................. 8-4

8.3.4 Wire break.................................................................................................................................. 8-5

8.3.5 Underflow ................................................................................................................................... 8-5

8.3.6 Overflow ..................................................................................................................................... 8-6

9 Hardware interrupt.................................................................................................................................. 9-1

9.1 Hardware interrupt ..................................................................................................................... 9-1

A Appendix.................................................................................................................................................A-1

A.1 Source of the user program .......................................................................................................A-1

Index................................................................................................................................................ Index-1

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

iv Getting Started, 11/2006, A5E00253410-02

Page 5

Preface

1.1 General

Purpose of the Getting Started

The Getting Started gives you a complete overview of the commissioning of the analog

module SM331. It assists you in the installation and configuration of the hardware of a 420mA sensor and the configuration with SIMATIC S7 Manager.

The intended readership of Getting Started is a novice with only basic experience in

configuration, commissioning and servicing of automation systems.

What to expect

The procedures, from mounting the module to storing analog values in the STEP7 user

program, are explained step-by-step and in detail based on an example. In the following

sections you will be introduced to:

● Problem analysis

● Mechanical setup of the example station

1

● Electrical connection of the example station

● Configure hardware with SIMATIC Manager

● Creating a small user program with STEP7 which stores the read analog values in a data

block

● Triggering and interpreting diagnostic and hardware interrupts

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

1-1

Page 6

Preface

1.1 General

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

1-2 Getting Started, 11/2006, A5E00253410-02

Page 7

Requirements

2.1 Basics

Basic Knowledge Required

No special knowledge of the field of automation technology is required in order to understand

the Getting Started guide. As the configuration of the analog module is done with the

software STEP7, proficiency in STEP7 would be advantageous.

Further information on STEP7 can be found in the electronic manuals that are supplied with

STEP7.

You will also need to know how to use computers or PC-like equipment (such as

programming devices) under Windows 95/98/2000/NT or XP.

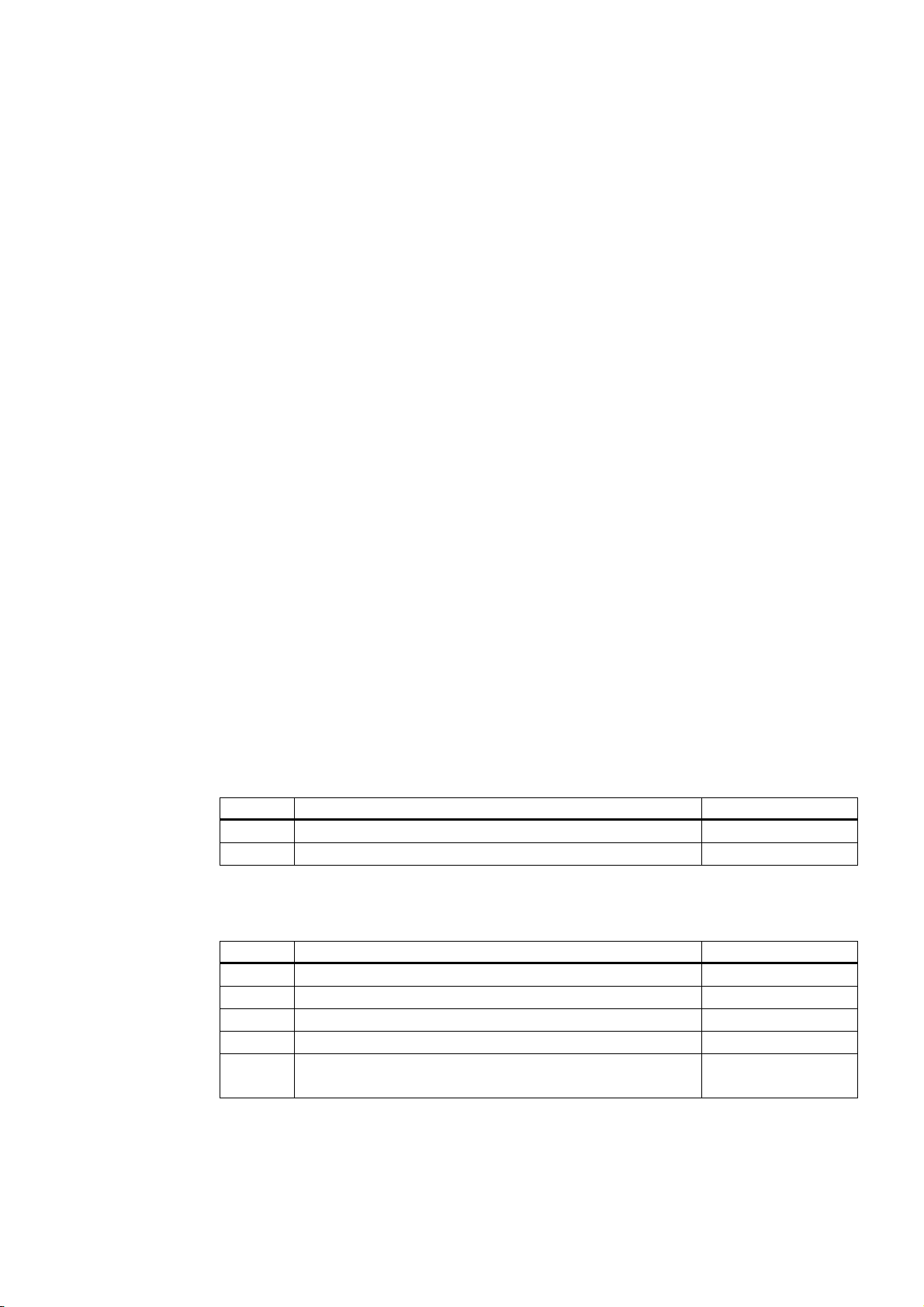

Required hardware and software

The scope of delivery of the analog module consists of 2 parts:

● The module itself

● A front connector, which enables you to conveniently connect the power supply and the

data cables.

2

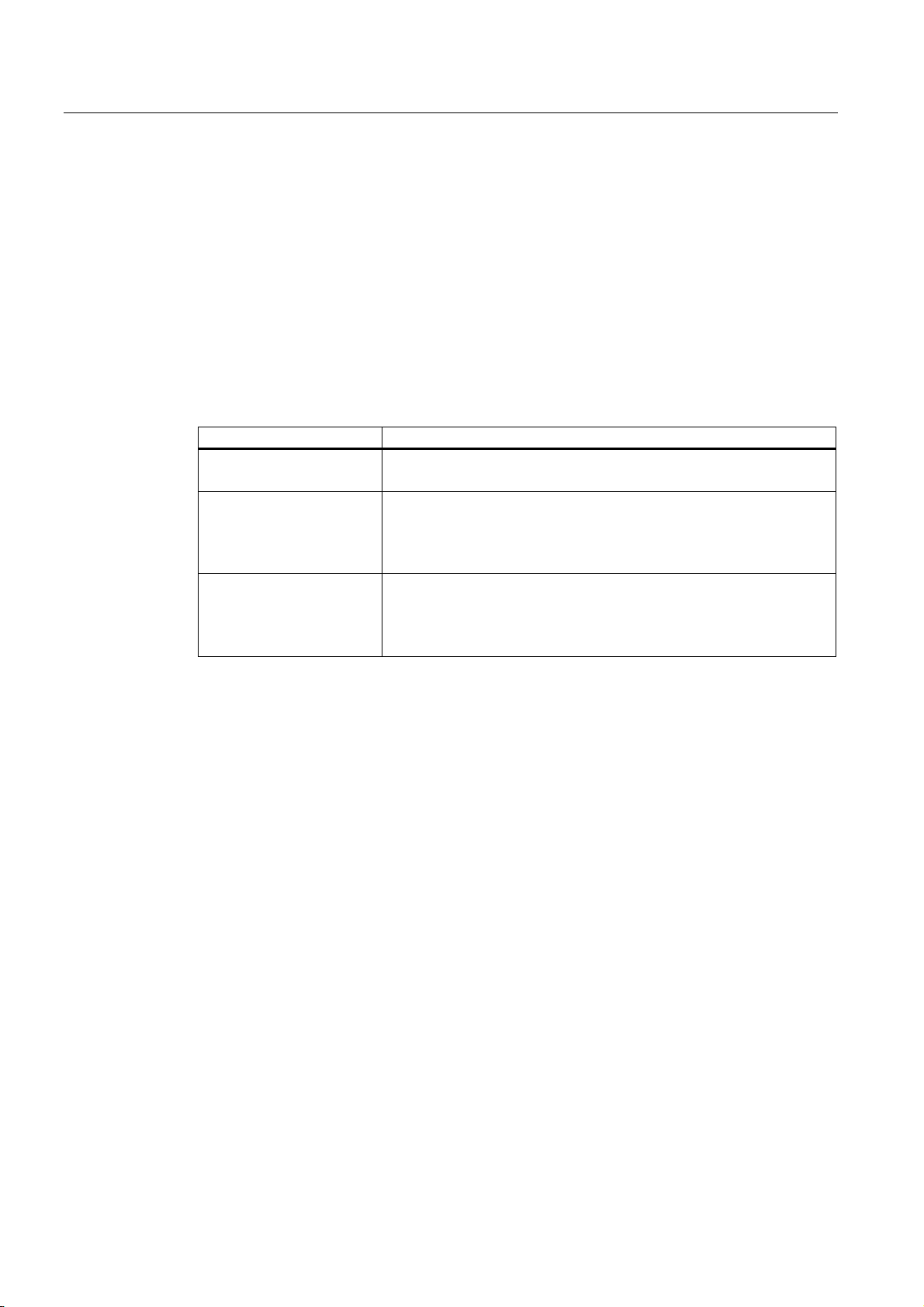

Analog module components

Quantity Article Order number

1 SM 331, Electrically ISOLATED 8 AI, ALARM DIAGNOSTICS 6ES7331-7KF02-0AB0

1 20-pin FRONT CONNECTOR with spring contacts 6ES7392-1BJ00-0AA0

The general SIMATIC components required for the example are as follows:

SIMATIC components of the example station

Quantity Article Order number

1 PS 307 Power Supply AC 120/230V, DC 24V, 5A 6ES7307-1EA00-0AA0

1 CPU 315-2 DP 6ES7315-2AG10-0AB0

1 MICRO MEMORY CARD, NFLASH, 4 MB 6ES7953-8LM00-0AA0

1 SIMATIC S7-300, RAIL L=530MM 6ES7390-1AF30-0AA0

1 Programming device (PD) with MPI interface and MPI cable

PC with corresponding interface card

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

depending on the

configuration

2-1

Page 8

Requirements

2.1 Basics

Software STEP7

Quantity Article Order number

1 STEP7 Software version 5.2 or later, installed on the

programming device.

6ES7810-4CC06-0YX0

The following current transducers can be used for the acquisition of analog signals:

Current transducers

Quantity Article Order number

1 2-Wire current transducer depending on the

manufacturer

1 4-Wire current transducer depending on the

manufacturer

Note

This "Getting Started" describes only the application of 4 – 20 mA current transducers in the

2-Wire or 4-Wire model. If you wish to use other transducers, you will need to wire and

configure the SM331 differently.

General tools and materials:

Quantity Article Order number

various M6-bolts and nuts (Length depending on the mounting position) commonly available

1 Screwdriver with 3,5 mm blade commonly available

1 Screwdriver with 4.5 mm blade commonly available

1 Side cutters and wire stripping tools commonly available

1 Tool for crimping wire-end ferrules commonly available

X m Cable for grounding the mounting rail with 10 mm2 cross-

section, ring terminal with 6.5 mm hole, length appropriate for

local requirements.

X m Flexible wire with 1mm2 diameter with fitting wire end sleeves,

form A in 3 different colors – blue, red and green

X m 3-wire power cord (AC 230/120V) with protective contact

socket, length according to local conditions.

1 Calibration device (measuring instrument for commissioning,

that can measure and supply current)

commonly available

commonly available

commonly available

depends on the

manufacturer

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

2-2 Getting Started, 11/2006, A5E00253410-02

Page 9

Introduction

3.1 Example of an application

Overview

You want to connect three analog inputs to your station. One of them should have a 2-wire

current transducer and the other two should share a 4-wire current transducer.

You need failure diagnostic capabilities and want two sensors to be able to trigger hardware

interrupts.

You have the analog input module SM331, AI8x12 Bit (order number 6ES7 331-7KF020AB0) available. The module is diagnostic and hardware interrupt capable and can process

up to 8 analog inputs. The module is diagnostic and hardware interrupt capable and can

process up to 8 analog inputs (e.g. 4- 20 mA; PT 100; thermocouple).

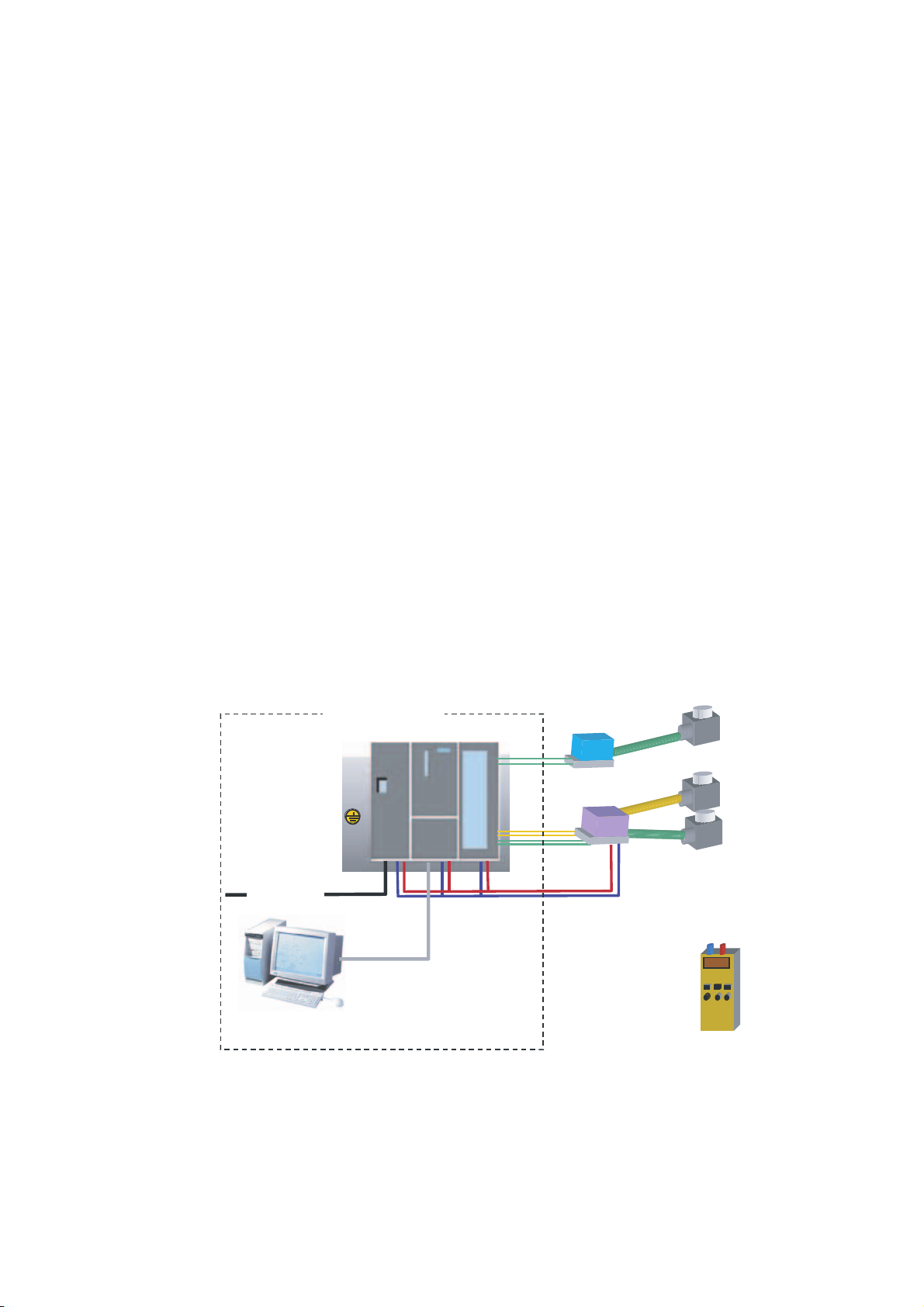

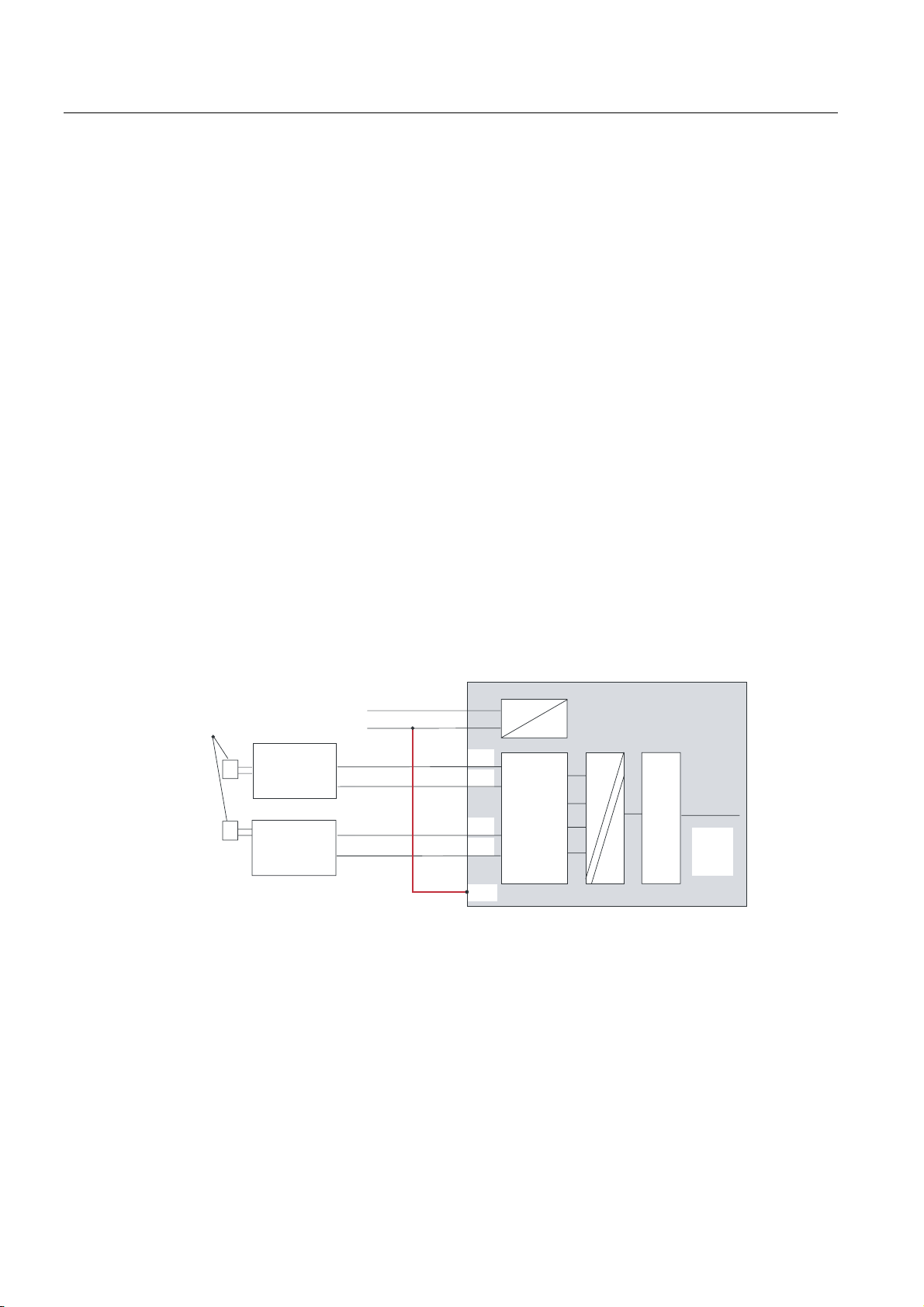

6\VWHPH[DPSOH

36

&38 60

7ZR ZL U H

&XUUHQWWUDQVGXFHUV

3

(QFRGHU

9$&+]

RU

9$&+]

03,FDEOH

3URJUDPPLQJGHYLFH

Figure 3-1 Sample station components

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

9'&

)RXUZLUH

&XUUHQWWUDQVGXFHUV

(QFRGHU

(QFRGHU

&DOLEUDWLRQ

GHYLFH

3-1

Page 10

Introduction

3.1 Example of an application

In the following sections you will be introduced to:

● Mechanical setup of the example station

– General mounting instructions for S7-300 modules

– Configuration of the SM331 for the two selected measurement transducer types

● Electrical connection of the example station

– Wiring the power supply module and the CPU

– Wiring of the analog module

– Standard pin assignment of two measurement transducer types

– Wiring of unused inputs

● Configuring the SIMATIC Manager

– Using the project wizard

– Completing the automatically generated hardware configuration

– Integrating the supplied user program source

● User program testing

– Interpreting the read values

– Converting the measured values into readable analog values

● Utilizing the diagnostic capabilities of the SM331 module

– Triggering a diagnostic interrupt

– Evaluating the diagnostics:

● Application of hardware interrupts

– Configuration of hardware interrupts

– Configuration and analysis of hardware interrupts

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

3-2 Getting Started, 11/2006, A5E00253410-02

Page 11

Mechanical setup of the example station

4.1 Mounting the example station

Overview

The setup of the example station is divided into two steps. First, the setup of the power

supply and the CPU is explained. After becoming acquainted with the analog module

SM331, the mounting of it is described.

Requirements

Before you can use the analog input module SM331, you need a basic setup of general

SIMATIC S7-300 components.

The order of the mounting takes place from left to right:

● Power supply PS307

● CPU 315-2DP

● SM331

4

Instructions (without SM331)

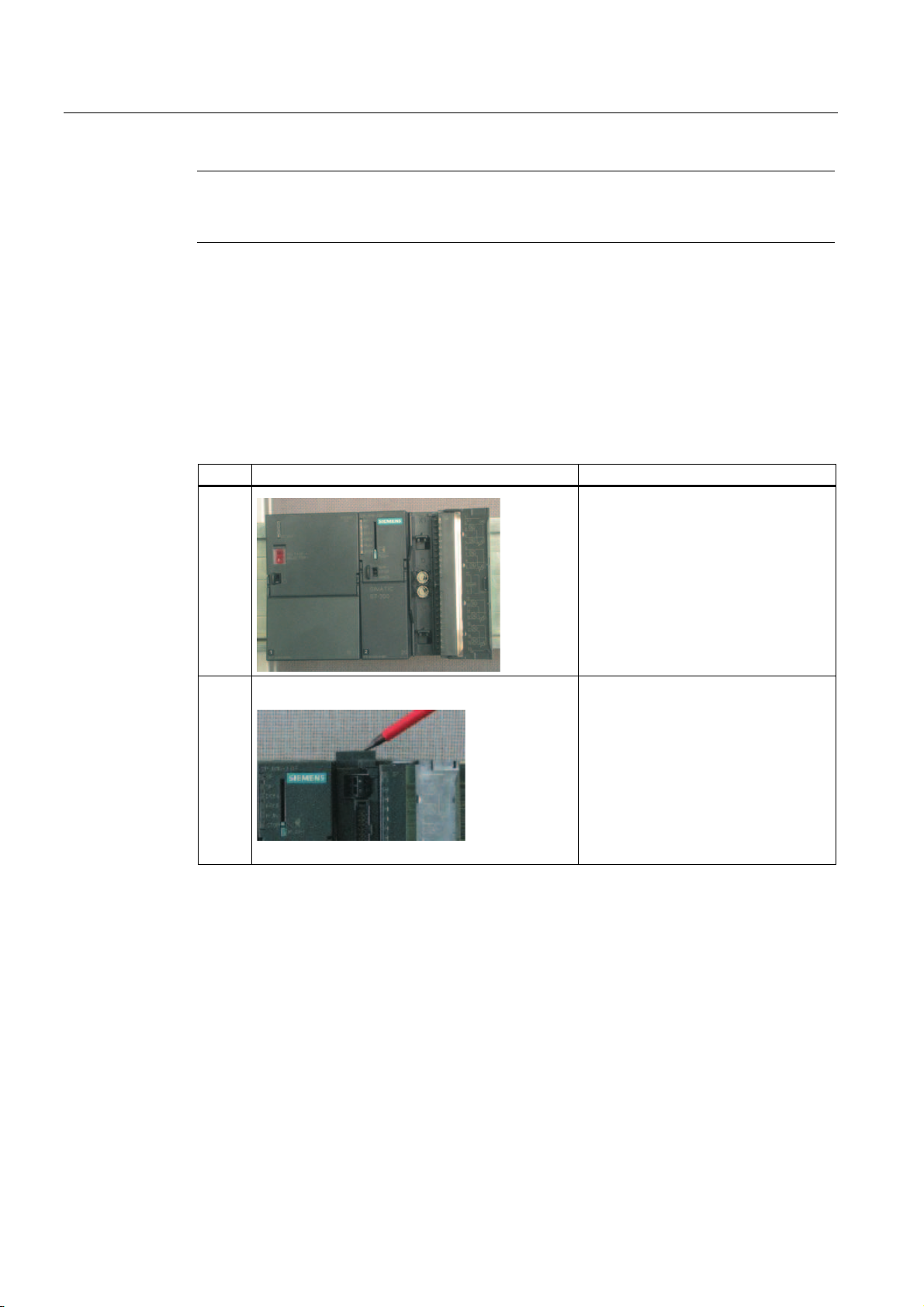

step Graphic controller Description

1 Screw on the mounting rail (screw size: M6) so that at

2

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

least 40 mm space remains above and below the rail.

When mounting it on a grounded steel panel or on a

grounded device mounting panel made of steel sheet,

make sure you have a low impedance connection

between the mounting rail and the mounting surface.

Connect the mounting rail with the protective conductor.

An M6 protective conductor screw is provided on the

mounting rail for this purpose.

4-1

Page 12

Mechanical setup of the example station

4.1 Mounting the example station

step Graphic controller Description

3

4

Mounting the power supply:

• Hang the power supply on to the top end of the rail

• Screw it tight to the rail underneath

Connect the bus connector (delivered with the SM331) to

the left connector on the back of the CPU

5

Mounting the CPU:

• Hang the CPU on to the top end of the rail

• Push it all the way left to the power supply

• Push it down

• Screw it tight to the rail underneath

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

4-2 Getting Started, 11/2006, A5E00253410-02

Page 13

Mechanical setup of the example station

4.2 Mounting of analog module components

4.2 Mounting of analog module components

4.2.1 General

Overview

Before the actual mounting of the SM331 the module has to be completed with a front

connector and the desired measurement mode of the inputs is set.

In this section, you will learn about:

● The components you need

● The properties of the analog input module

● What a measuring range module is and how it is configured

● Mounting a configured module

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

4-3

Page 14

Mechanical setup of the example station

4.2 Mounting of analog module components

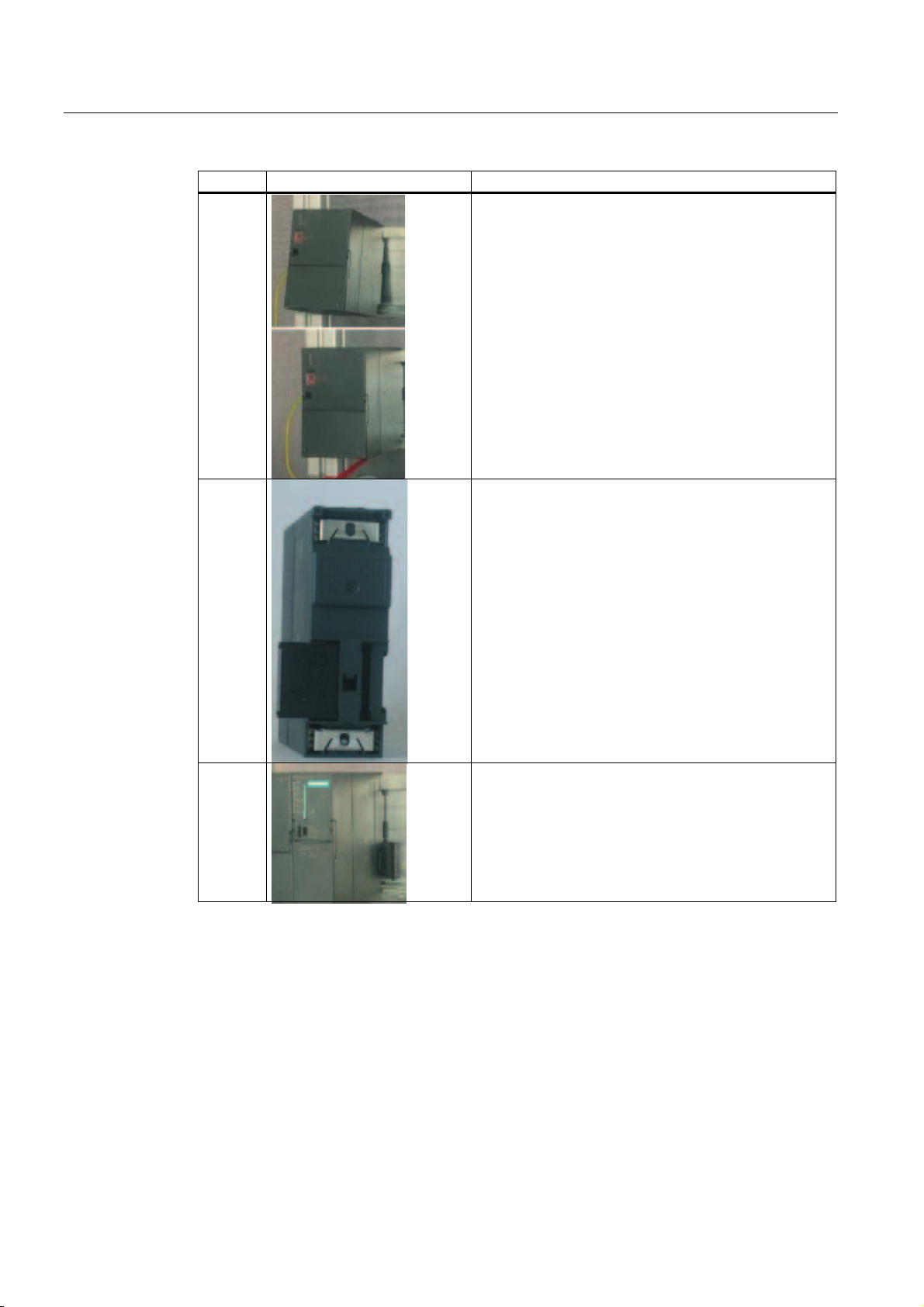

4.2.2 Components of the SM331

Overview

A functional analog module consists of the following components:

● Module SM331 (in our example 6ES7331-7KF02-0AB0)

● 20-pin front connector There are two different types of front connectors:

– With spring contacts (order number 6ES7392-1BJ00-0AA0)

– With screw contacts (order number 6ES7392-1AJ00-0AA0)

Figure 4-1 Components of the SM331

The scope of delivery of SM331

Components

Module

Labeling strips

Bus connectors

2 cable ties (not in the picture) to tie the external wiring

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

4-4 Getting Started, 11/2006, A5E00253410-02

Page 15

Mechanical setup of the example station

4.2 Mounting of analog module components

4.2.3 Features of the analog modules

Characteristics

● 8 inputs in 4 channel groups (each group with two inputs of same type)

● Measurement resolution adjustable for each channel group

● User defined measuring mode per channel group:

– Voltage

– Current

– Resistance

– Temperature

● Programmable diagnostic interrupt

● Two channels with limit alarms (only channel 0 and channel 2 are configurable)

● Electrically isolated against backplane bus

● Electrically isolated against load voltage (exception: at least one module is set to position

D)

The module is a universal analog module designed for the most commonly used

applications.

The desired measuring mode should be set up directly on the module with the measuring

range modules.

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

4-5

Page 16

Mechanical setup of the example station

4.2 Mounting of analog module components

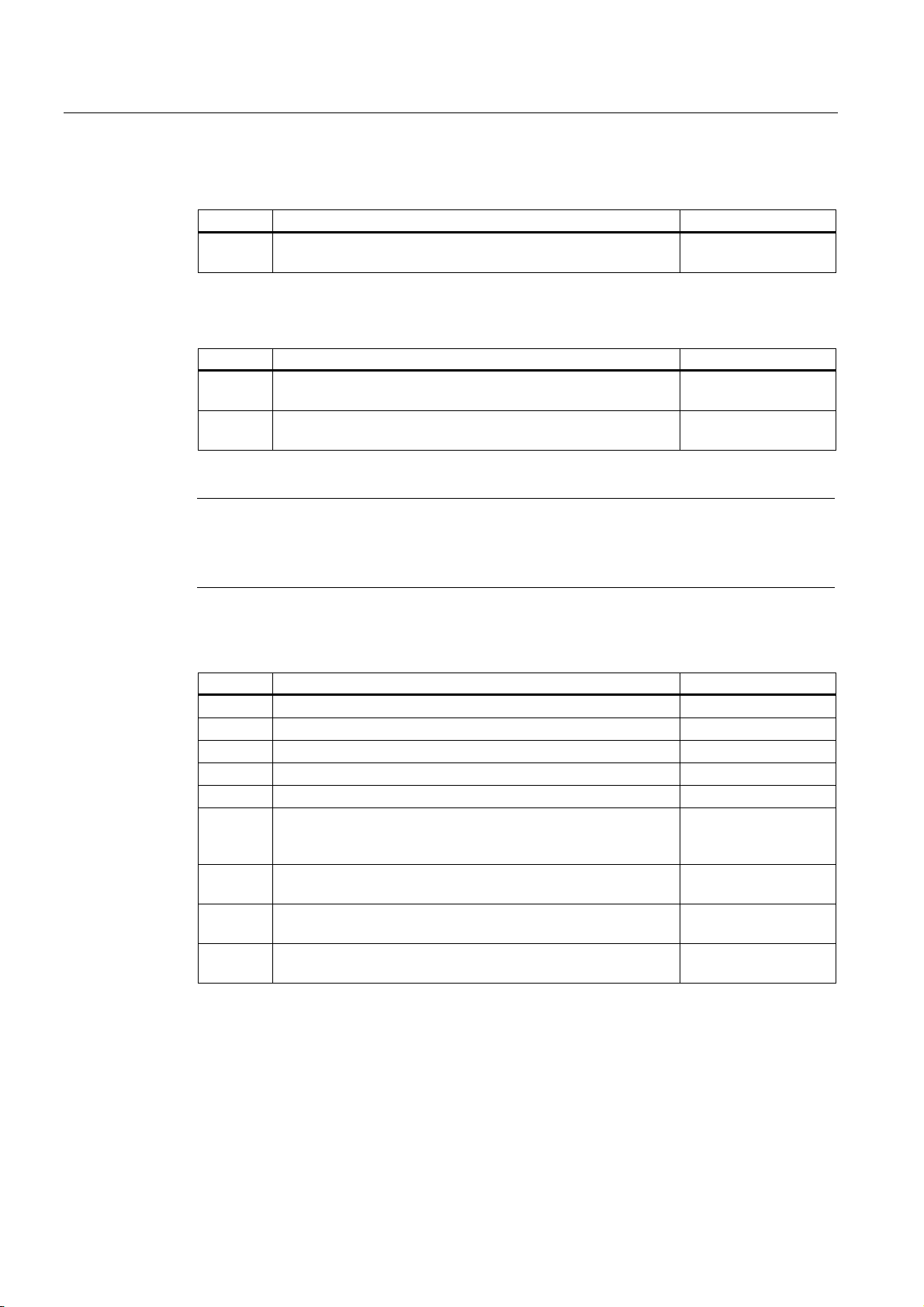

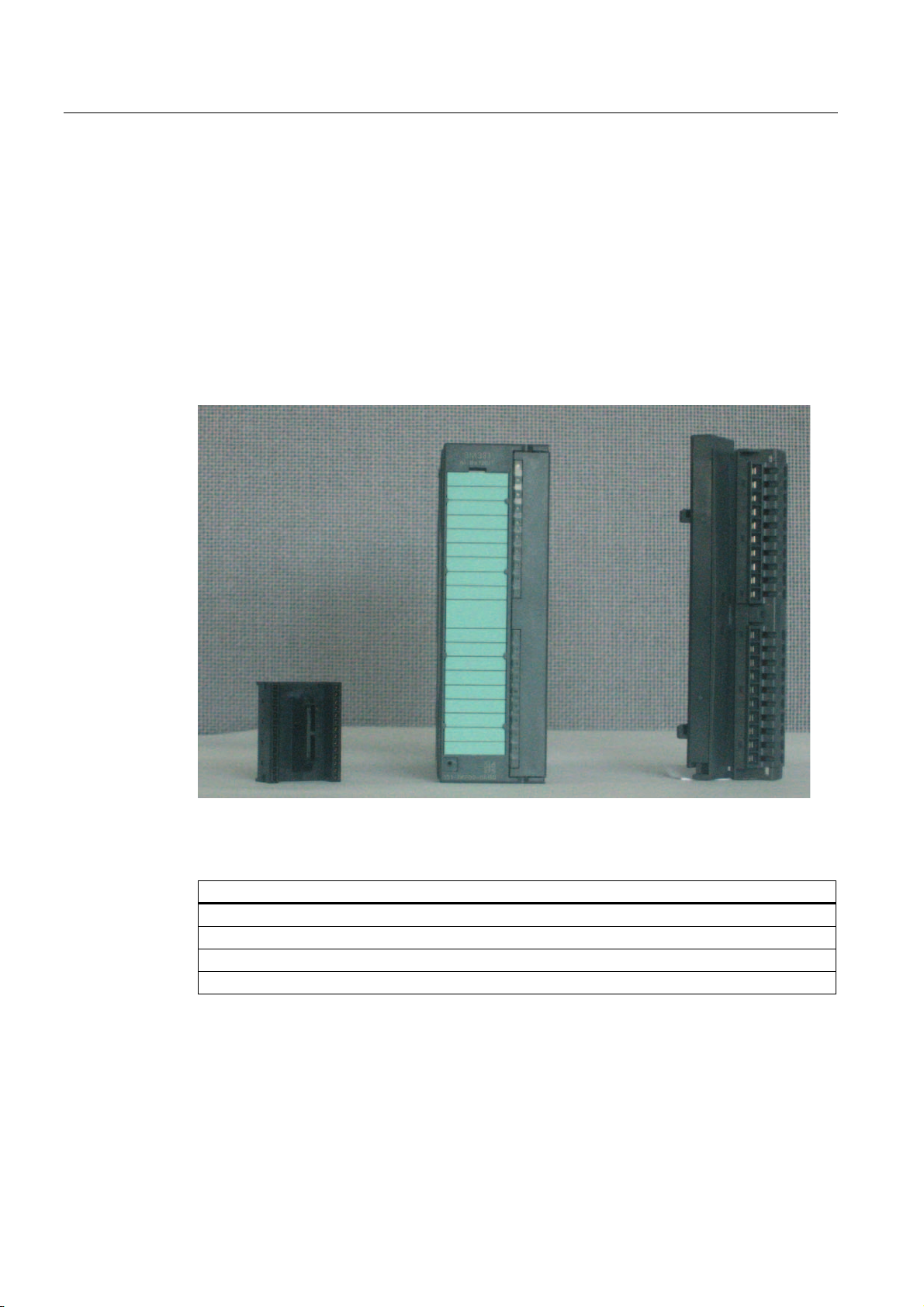

4.2.4 Measuring range modules

Terminal

The module SM331 has 4 measuring range modules (one per channel group). The

measuring range modules can be set to 4 different positions (A, B, C or D).

0HDVXULQJ

PRGH$'

3RVLWLRQ%

YROWDJH

VHWIRU&+

0HDVXULQJUDQJH

PRGXOH

5LVNRIGDPDJHZKHQPHDVXULQJUDQJHLVLQFRUUHFWO\VHW

'DQJHURIGDPDJHZKHQPHDVXULQJUDQJHLVLQFRUUHFWO\VHW

Figure 4-2 4 measuring range modules with default setting B (Voltage)

&KDQQHOJURXS

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

4-6 Getting Started, 11/2006, A5E00253410-02

Page 17

Mechanical setup of the example station

4.2 Mounting of analog module components

Positions of the measuring range modules

The position enables you to specify the transducer to be connected to the respective channel

group.

Position Type of measurement

A Thermocouple / resistance measurement

B Voltage (factory setting)

C Current (4-wire transducer)

D Current (2-wire transducer)

In our example, a sensor with a 4 to 20mA 2-wire transducer is connected to channel group

1 at input 0.

A 4-wire transducer is connected to channel group 2 at inputs 2 and 3.

Therefore, the first measuring range module should have position D and the second should

have position C.

Positioning of the measuring range modules

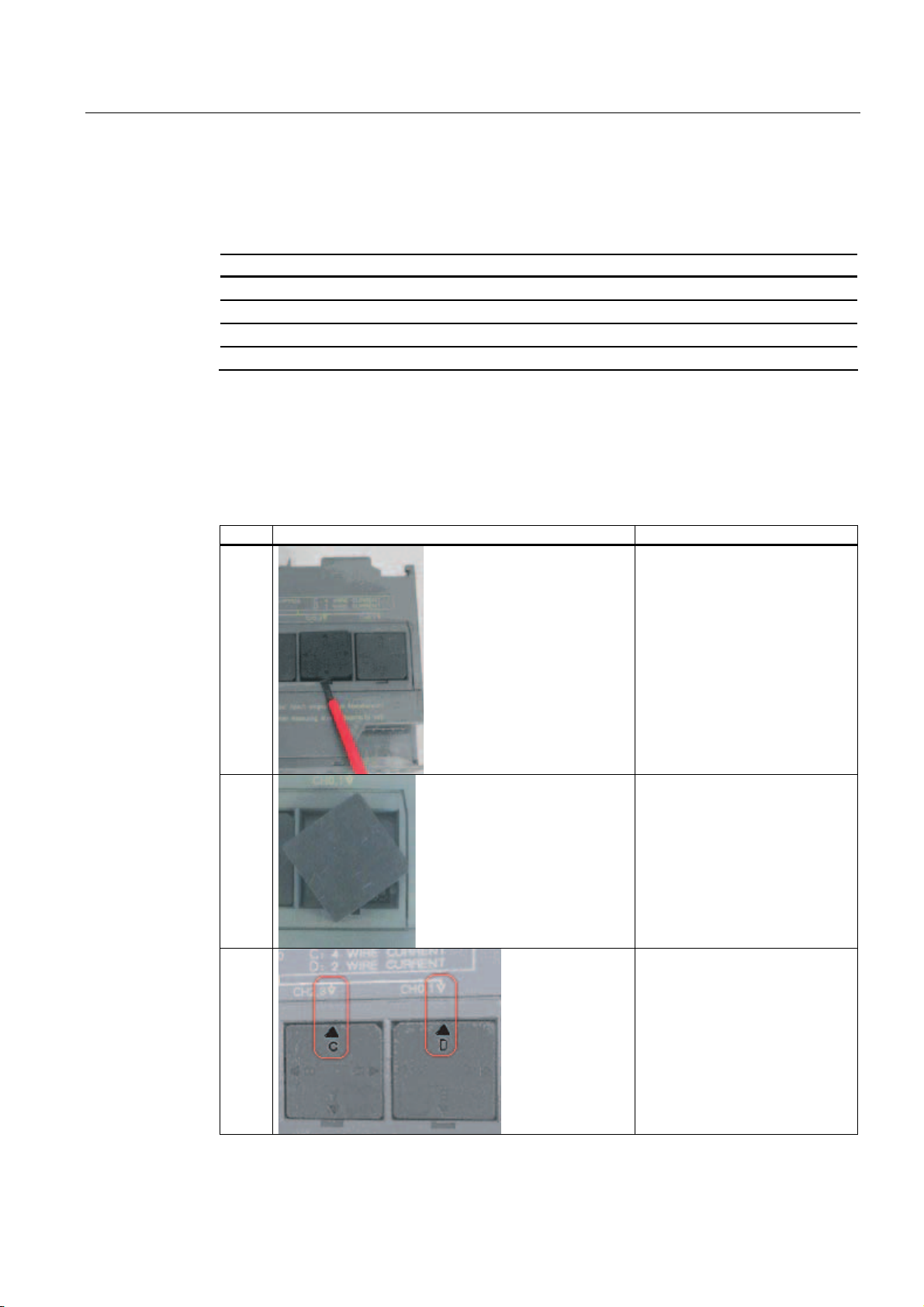

step Graphic controller Description

1

With a screwdriver, pull out the

two measuring range modules

2

3

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

Turn the measuring range module

to the desired position:

Plug the measuring range module

back into the module

In our example, the module

should have the following

positions:

CH0,1: D

CH2,3: C

4-7

Page 18

Mechanical setup of the example station

4.2 Mounting of analog module components

Note

When you use a 2-wire transducer, the electrical isolation against the load voltage is lost for

all the channels in the module (at least one measuring range module is set to position D)

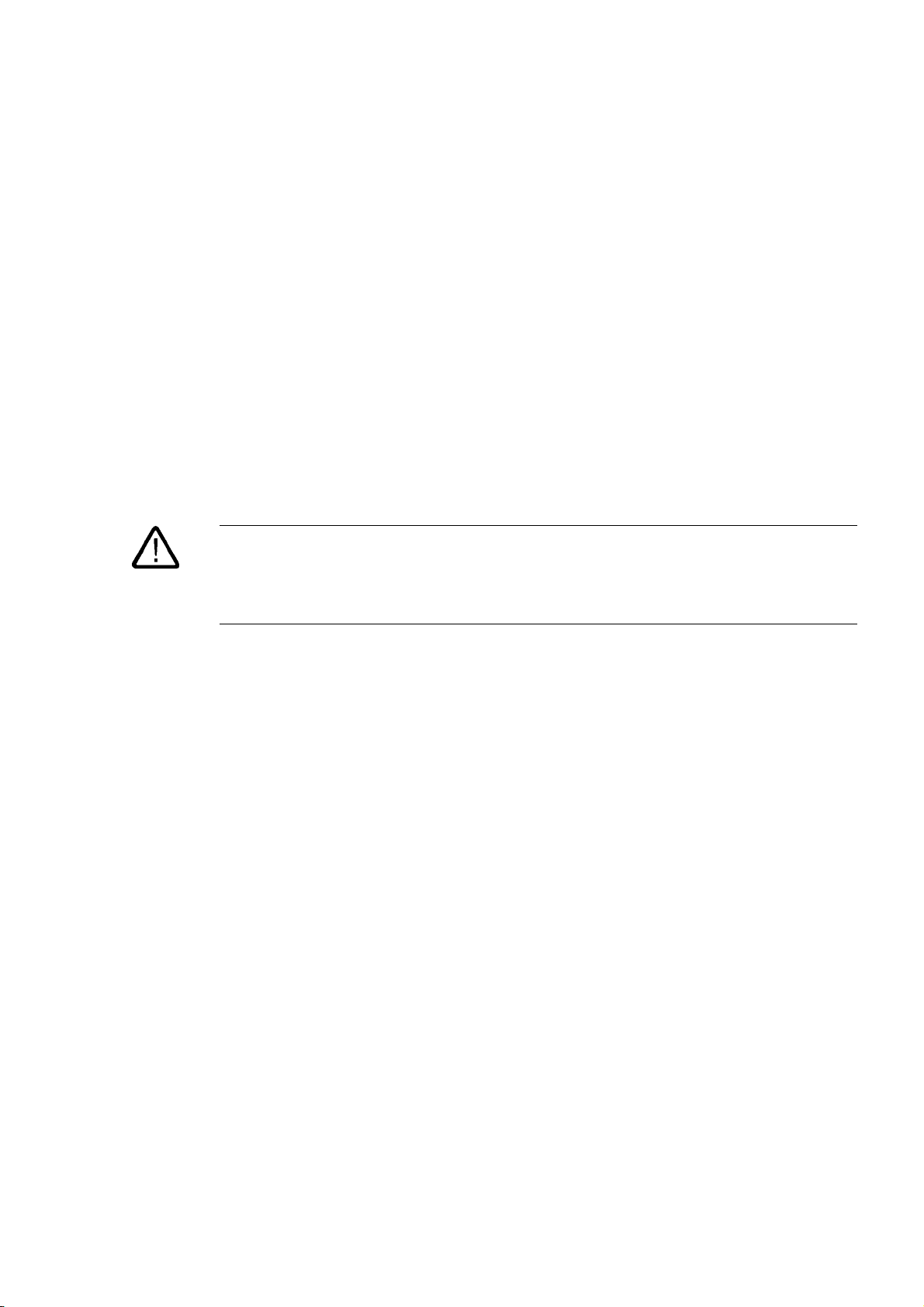

4.2.5 Mounting the SM331 module

Proceed as follows

After you have prepared the analog module accordingly, mount it to the rail as well.

step Graphic controller Description

1

Mounting the SM331:

• Hang the SM311 to the top end of

the rail

• Push it all the way to the left up to

the CPU

• Push it down

• Screw it tight to the rail underneath

2

The example station is now mechanically mounted.

Mounting the front connector:

• Press the upper release button of

the front terminal block

• Insert the front connector into the

module until it snaps in

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

4-8 Getting Started, 11/2006, A5E00253410-02

Page 19

Electrical connection

5.1 Overview

Overview

This chapter shows you how the various parts of the example station are electrically wired

from the power supply to the analog module.

Warning

You might get an electrical shock if the power supply PS307 is turned on or the power cord

is connected to the line.

Always switch off power before you start wiring the S7-300.

5

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

5-1

Page 20

Electrical connection

5.2 Wiring the power supply module and the CPU

5.2 Wiring the power supply module and the CPU

Overview

Figure 5-1 Wiring the power supply module and the CPU

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

5-2 Getting Started, 11/2006, A5E00253410-02

Page 21

Electrical connection

5.2 Wiring the power supply module and the CPU

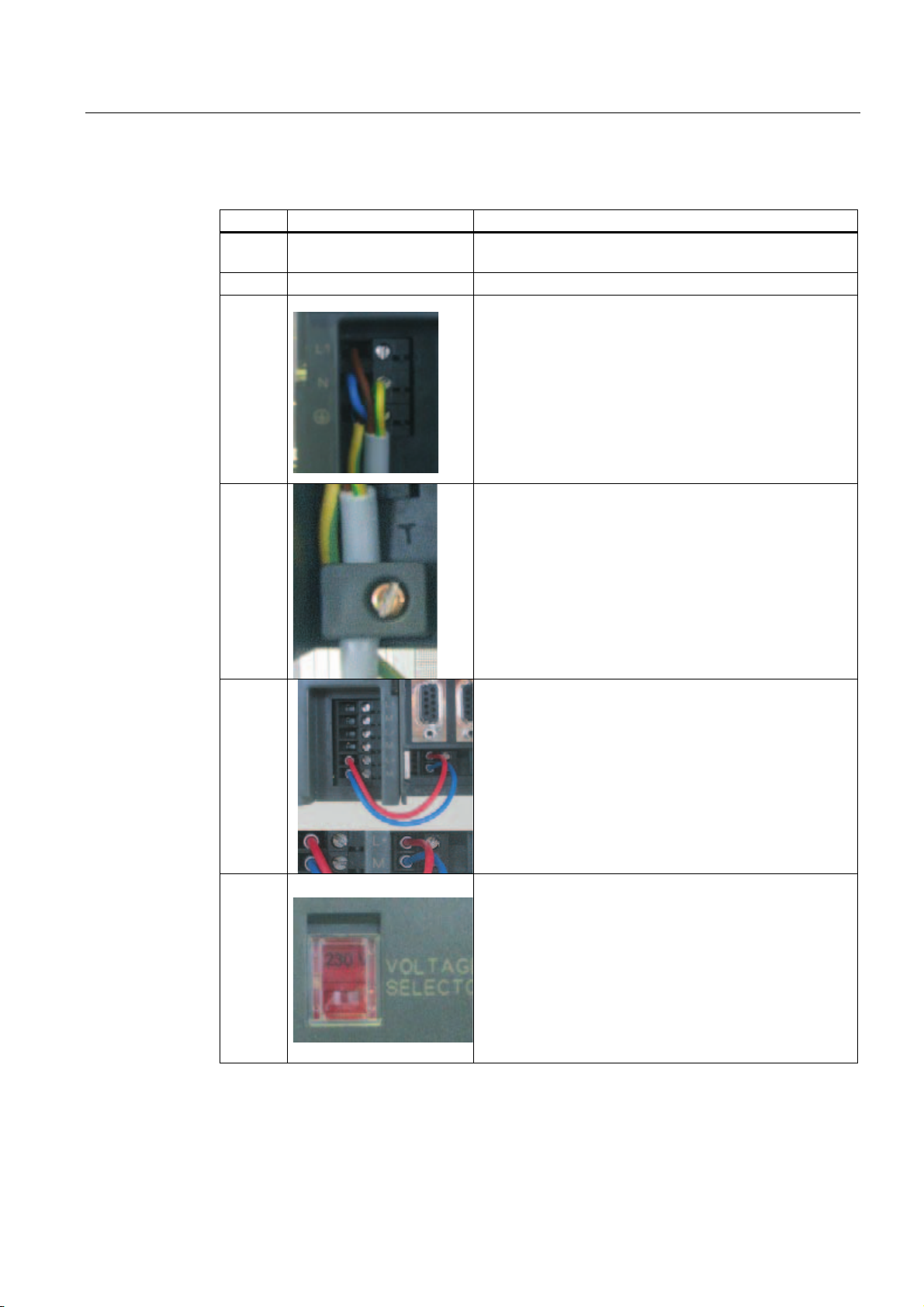

The example station requires a power supply. The wiring is done as follows:

Step Graphic controller Description

1 Open the front panel covers of the power supply module

and CPU.

2 Unscrew the cable grip on the power supply

3 Remove the insulation from the power cord, attach the cable

end sleeves (for stranded conductors) and connect it to the

power supply

4 Screw down the clamp of the cable grip.

5 Insert two connecting cables between the power supply and

the CPU and tighten them

6 Verify that the setting of the selector switch matches your

mains voltage.

The default line voltage setting for the power supply module

is 230 VAC. To change this setting, proceed as follows:

Remove the protective cap with a screwdriver, set the

selector switch to match your line voltage, then insert the

protective cap again.

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

5-3

Page 22

Electrical connection

5.3 Wiring of the analog module

5.3 Wiring of the analog module

5.3.1 Requirement

General

The wiring of an analog measurement transducer is depends on its type and not on the

SM331 module.

5.3.2 Current transducer wiring - principle

Options

Depending on the current transducer you use, you have to modify the wiring of the power

supply. We differentiate between the wiring of a 2-wire current transducer and a 4-wire

current transducer.

Wiring principles of a 2-wire current transducer

This transducer type is supplied with power from the analog input module.

6HQVRU

HJSUHVVXUHJDXJH

7ZR ZL U H

3

3

Figure 5-2 Wiring: 2-Wire current transducer

WUDQV

GXFHU

7ZR ZL U H

WUDQV

GXFHU

/

0

0

0

0

0

0DQD

$'&

/RJLF

%DFN

SDQH

EXV

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

5-4 Getting Started, 11/2006, A5E00253410-02

Page 23

Electrical connection

5.3 Wiring of the analog module

Wiring principles of a 4-wire current transducer

Unlike a 2-wire transducer, this transducer has its own power supply.

6HQVRU

HJSUHVVXUHJDXJH

/

0

)RXUZLUH

3

3

WUDQV

GXFHU

/ 0

Figure 5-3 Wiring: 4-Wire current transducer

5.3.3 Wiring of the analog module

Tasks

The wiring of the analog module consists of the following tasks:

● Connecting the power supply (red cable)

● Connecting the 2-wire current transducer (green cables)

0

0

0

0

0DQD

$'&

/RJLF

%DFN

SDQH

EXV

● Terminating unused channels with a resistor

● Connecting the 4-wire current transducer (green cables)

● Connecting the 4-wire current transducer (green cables)

● Connecting to ground and short-circuiting the other unused channels (blue wires)

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

5-5

Page 24

Electrical connection

5.3 Wiring of the analog module

SM331 Front connector wiring

Figure 5-4 SM331 Front connector wiring

Notice

Possible destruction of the module!

If you connect a defective 4-wire current transducer to an input, which is configured for a 2-

wire transducer, the module may be destroyed!

The required wiring tasks are explained below step-by-step:

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

5-6 Getting Started, 11/2006, A5E00253410-02

Page 25

Electrical connection

5.3 Wiring of the analog module

Proceed as follows

Step Graphic

controller

1 Open the front door of the SM331 The connection diagram is

2 Remove 6 mm of the insulation from the

3

4

5

6

7

8

Connecting-up Comment

ends of the wires that go into the front

connector. Attach cable end sleeves to

these ends.

Wire the front connector as follows:

Terminal 1: L +

Terminal 2: M+ sensor 1

Terminal 3: M- sensor 1

Connect terminal 4 and 5 with a 1.5 to 3.3

kΩ resistor

Terminal 6: M+ sensor 2

Terminal 7: M- sensor 2

Terminal 8: M+ sensor 3

Terminal 9: M- sensor 3

terminal 10 (Comp) and

connect terminal 11 (M

ana

) to M

Short-circuit terminals 12 to 19 and

connect with M

ana

Terminal 20: M

printed on the front flap

Power supply of the module

Standard wiring for 2-wire

current transducer

In order to maintain the

diagnostic capability of channel

group 0, the second unused

input must be connected to a

resistor.

Standard wiring for 4-wire

current transducer

For measuring current comp is

not used

Mandatory for 2-wire current

transducers

Unused channel groups should

be short-circuited with M

ana

in

order to achieve a maximum

interference resistance

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

5-7

Page 26

Electrical connection

5.3 Wiring of the analog module

5.3.4 Test

Proceed as follows

If you want to test the wiring, you may now switch the power supply on.

Do not forget to set the CPU to STOP (see the red circle)

Figure 5-5 Successful wiring, CPU in position STOP

If a red LED is lit, then there is an error in the wiring. Verify your wiring.

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

5-8 Getting Started, 11/2006, A5E00253410-02

Page 27

Configuration of the SIMATIC Manager

6.1 Creating a new STEP7 project

6.1.1 Creating a new project

"New Project..." Wizard

Use STEP7 V5.2 or later for configuring the new CPU 315-2 DP.

Start SIMATIC Manager by clicking the "SIMATIC Manager" icon on your Windows Desktop

and create a new project with the STEP7 "New Project" wizard.

6

3RVLWLRQ%

YROWDJH

VHWIRU&+

5LVNRIGDPDJHZKHQPHDVXULQJUDQJHLVLQFRUUHFWO\VHW

'DQJHURIGDPDJHZKHQPHDVXULQJUDQJHLVLQFRUUHFWO\VHW

Figure 6-1 Start the "New Project..." wizard

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

0HDVXULQJ

PRGH$'

0HDVXULQJUDQJH

PRGXOH

&KDQQHOJURXS

6-1

Page 28

Configuration of the SIMATIC Manager

6.1 Creating a new STEP7 project

A project wizard introduction window appears. The wizard guides you through the procedure

for creating a new project.

Figure 6-2 Wizard "New Project", start

The following must be specified during the creation procedure:

● The CPU type

● The basic user program

● The organization blocks

● Project name

Click "Next."

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

6-2 Getting Started, 11/2006, A5E00253410-02

Page 29

Configuration of the SIMATIC Manager

6.1 Creating a new STEP7 project

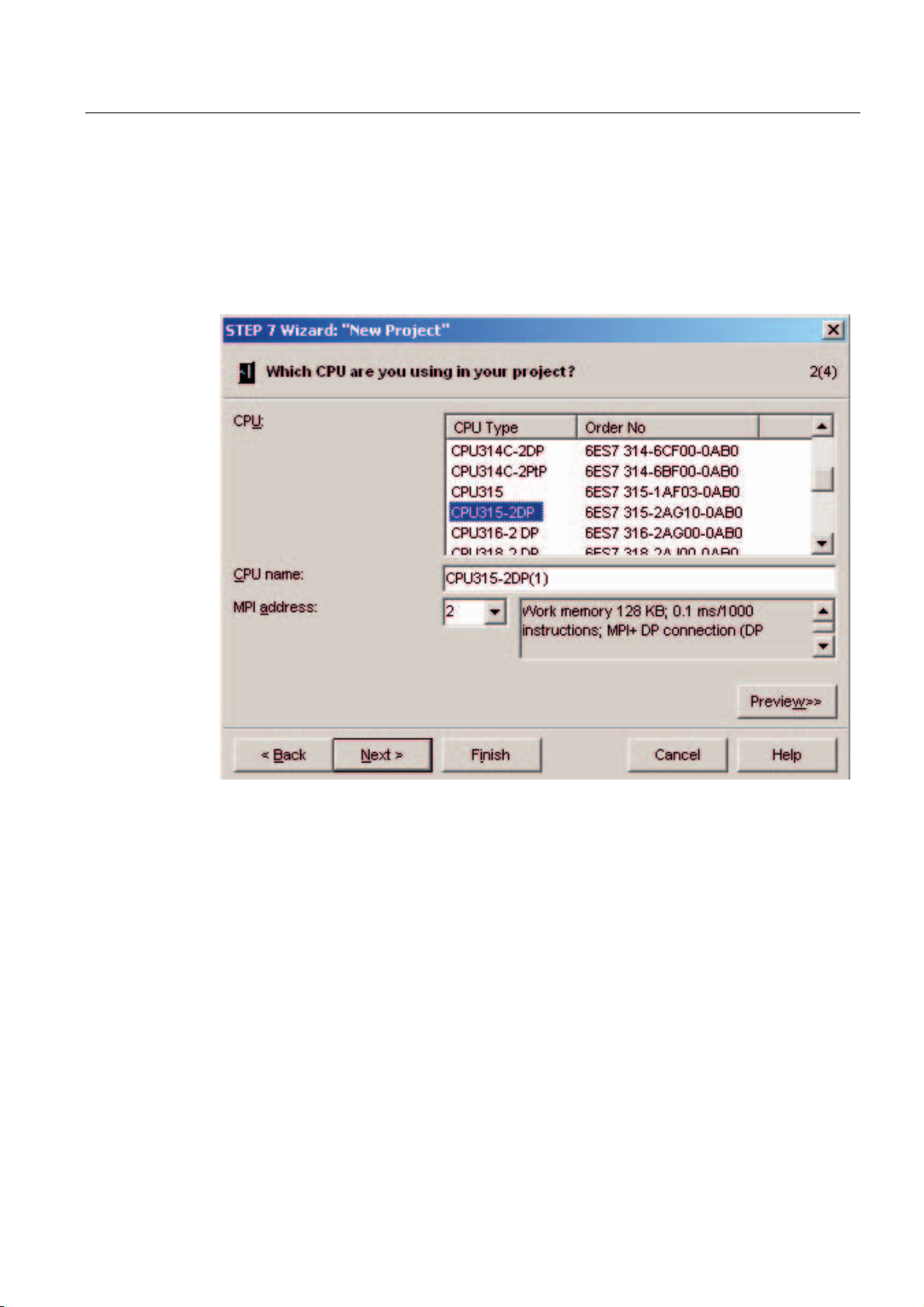

6.1.2 CPU selection

Proceed as follows

Choose the CPU 315-2DP for the example project. (You can also use our example for a

different CPU. Select the appropriate CPU in this case.)

Figure 6-3 "New Project" wizard: selecting a CPU

Click "Next."

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

6-3

Page 30

Configuration of the SIMATIC Manager

6.1 Creating a new STEP7 project

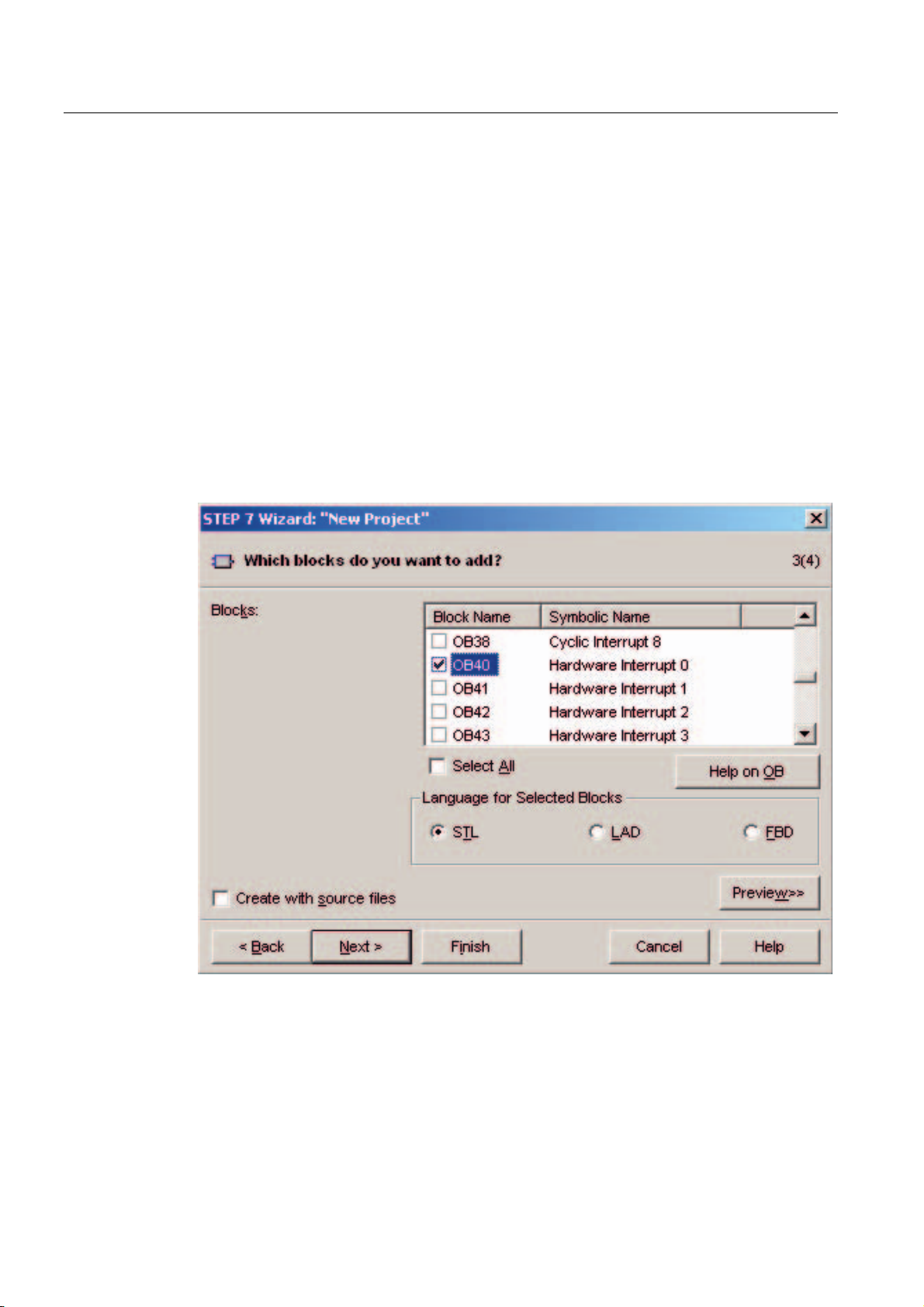

6.1.3 Defining the basic user program

Proceed as follows

Choose the SIMATIC language STL and select the following organization blocks (OBs):

● OB1 cyclically executed block

● OB40 hardware interrupt

● OB82 diagnostic interrupt

OB1 is required in every project and is called cyclically.

OB40 is called when a hardware interrupt occurs.

OB 82 is called when a diagnostic interrupt occurs.

If you use a module with diagnostic capabilities and OB82 is not inserted, the CPU changes

to STOP mode when a diagnostic alarm occurs.

Figure 6-4 "New Project" wizard: Inserting organization blocks

Click "Next."

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

6-4 Getting Started, 11/2006, A5E00253410-02

Page 31

Configuration of the SIMATIC Manager

6.1 Creating a new STEP7 project

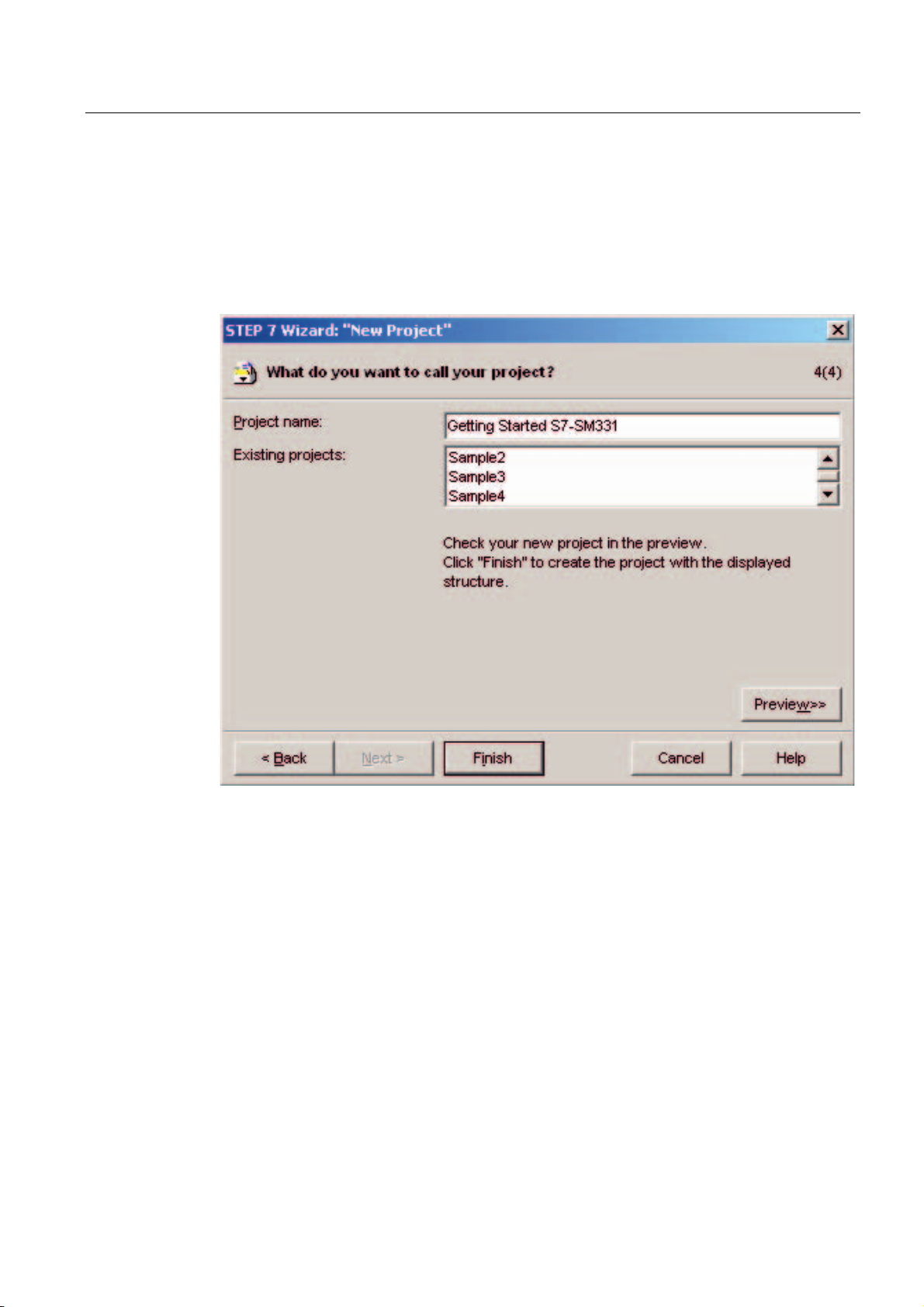

6.1.4 Assigning the project name

Proceed as follows

Select the “Project name” text box and overwrite the name in it with “Getting Started S7

SM331”.

Figure 6-5 "New Project" wizard: Assigning the project name

Click "Finish". The basic STEP7 project is created automatically.

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

6-3

Page 32

Configuration of the SIMATIC Manager

6.1 Creating a new STEP7 project

6.1.5 Result S7 project is created

Result

The wizard has created the project “Getting Started S7-SM331”. You can see the inserted

organization blocks in the right window.

Figure 6-6 "New Project" wizard results

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

6-6 Getting Started, 11/2006, A5E00253410-02

Page 33

Configuration of the SIMATIC Manager

6.2 Hardware configuration

6.2 Hardware configuration

6.2.1 Creating the hardware configuration

Requirements

The STEP7 wizard has created a basic S7 project. You also need a complete hardware

configuration in order to create the system data for the CPU.

Proceed as follows

You can create the hardware configuration of the example station with SIMATIC Manager.

To do this, select the folder "SIMATIC 300 Station" in the left window. Start the hardware

configuration by double clicking the folder "Hardware" in the right window.

Figure 6-7 Opening the hardware configuration

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

6-3

Page 34

Configuration of the SIMATIC Manager

6.2 Hardware configuration

6.2.2 Adding SIMATIC components

Proceed as follows

First select a power supply module from the hardware catalog.

If the hardware catalog is not visible, open it with the shortcut key Ctrl+K or by clicking the

catalog icon (blue arrow).

In the hardware catalog you can browse through the folder SIMATIC 300 to the folder PS-

300.

Select the PS307 5A and drag it into slot 1 (see red arrow).

Figure 6-8 Hardware configuration: Basic configuration

Result: PS 307 5A appears in the configuration of your rack.

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

6-8 Getting Started, 11/2006, A5E00253410-02

Page 35

Configuration of the SIMATIC Manager

6.2 Hardware configuration

Inserting an analog module

There are many SM331 analog modules. For this project we use an SM331, AI8x12 bit with

the order number 6ES7 331-7KF02-0AB0.

The order number is displayed at the bottom of the hardware catalog (see blue arrow).

Figure 6-9 Hardware configuration: SM331 insert

Drag the module into the first available field at slot 4 of your rack (see red arrow).

You have inserted all the modules into the hardware configuration. In the next step, you

configure the modules.

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

6-3

Page 36

Configuration of the SIMATIC Manager

6.2 Hardware configuration

6.2.3 Configuring the analog module

Overview

SIMATIC Manager inserts the analog module with its default settings. You can modify the

parameters to change the sensor types, diagnostics and interrupt capabilities.

Mounting the example station

The table shows, which parameters have to be set for our example station.

SM331 functions of the example station

Functions Description

Process reactions

Encoder 1

Encoder 2 & 3

• Diagnostics – enabled

• Hardware interrupt when limit exceeded - enabled

• 2-Wire current transducer

• Group diagnostics

• Check for wire break

• Measuring range 6 mA and 18 mA

• 4-Wire current transducer

• Group diagnostics

• Check for wire break

• Measuring range 6 mA and 18 mA

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

6-10 Getting Started, 11/2006, A5E00253410-02

Page 37

Configuration of the SIMATIC Manager

6.2 Hardware configuration

Opening the configuration

Double-click on slot 4 that has the SM331 in it.

Select the "Inputs" tab.

Configure the following functions:

● Diagnostic interrupt enabled

● Hardware interrupt enabled

● Input 0-1:

– Type of measurement: 2DMU

– Group diagnostics enabled

– Wire break enabled

● Input 2-3:

– Type of measurement: 2DMU

– Group diagnostics enabled

– Wire break enabled

● Input 4-5 and 6-7

– Type of measurement: Disabled (---)

● Interference frequency

– Select your power frequency (50 Hz or 60 Hz)

● Hardware interrupt trigger

– Upper limit value 18 mA

– Lower limit value 6 mA

Figure 6-10 SM331: Configuration

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

6-3

Page 38

Configuration of the SIMATIC Manager

6.2 Hardware configuration

Explanation of the individual settings

Measuring type:

2DMU and 4DMU stand for 2-wire and 4-wire current transducers

--- means that the channels are deactivated. If you deactivate channels, the remaining

channels are processed faster.

Measuring range modules

The required setting of the measuring range module is displayed.

Interference frequency (Interference frequency suppression)

The frequency of your AC power system can interfere with the measured value, particularly

when measuring in low voltage ranges and using thermocouple elements. With this

parameter you specify the frequency of your power supply on site.

This parameter also influences the granularity, integration time and the basic execution

period of the channel group.

● Resolution (accuracy)

The analog value is stored in a 16-bit word.

● Integration time

The module requires a certain amount of time to measure the analog signal. This time is

called integration time. The higher the required accuracy is, the longer the module needs

for measuring the voltage.

● Basic processing time

Besides the integration time, the module also needs a certain amount of time to provide

the binary value.

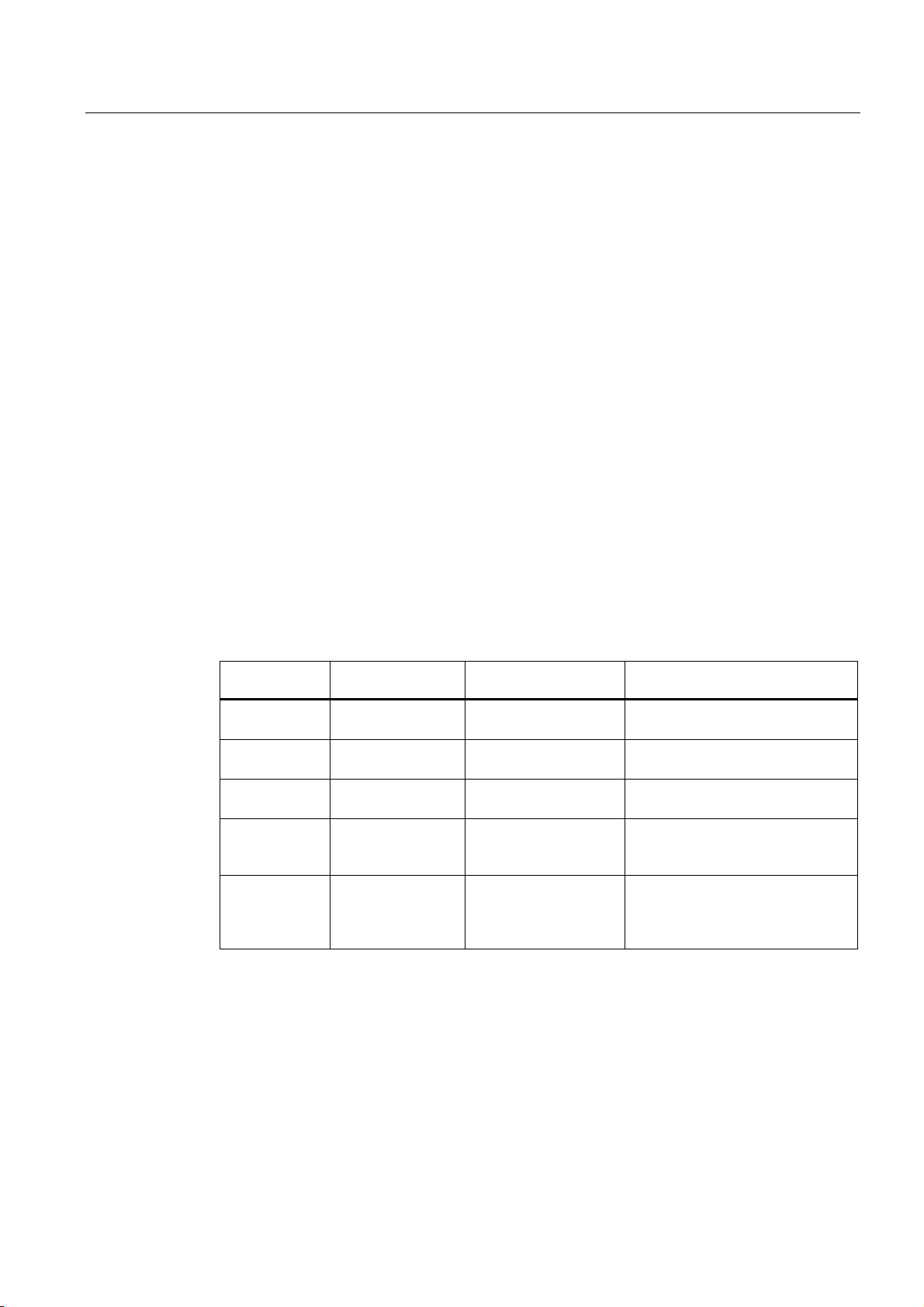

Relationship between accuracy, interference frequency and integration period

Resolution Interference

frequency

9 bits 400 Hz 2.5 ms 24 ms

12 bits 60 Hz 16.6 ms 136 ms

12 bits 20 Hz 20 ms 176 ms

14 bits 10 Hz 100 ms 816 ms

Hardware interrupt:

Only the channels 0 and 2 have hardware interrupt capabilities. You can use hardware

interrupts to trigger an alarm when the analog signal exceeds its high or low limit.

Finish the hardware configuration:

Close the window with the configuration.

Compile and save the project with the command Station > Save and Compile (Ctrl+S)

Integration time Basic processing time

This completes your hardware configuration for the project.

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

6-12 Getting Started, 11/2006, A5E00253410-02

Page 39

Configuration of the SIMATIC Manager

6.2 Hardware configuration

6.2.4 Test

Proceed as follows

For testing, do a power up test and download the system data.

Step Graphic controller Description

1 Erase your Micro Memory Card

with a Power PG or a PC with

external programming device:

In SIMATIC Manager click "File ->

S7 Memory Card > Delete …".

The MCC will be deleted.

2

3

4

5

Switch off the power supply to the

CPU.

Insert the MMC into the CPU.

Switch on the power supply.

If the CPU is in RUN mode, set it

to STOP mode.

Switch the power supply on again.

If the STOP LED blinks, the CPU

requests a reset. Acknowledge

this by turning the mode switch to

MRES for a moment.

Connect the CPU to the PG with

an MPI cable.

To do this, connect the MPI cable

with the CPU’s MPI port. Connect

the other end to the PG interface

of your programming device.

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

6-3

Page 40

Configuration of the SIMATIC Manager

6.2 Hardware configuration

Downloading hardware configuration

Download the hardware configuration into the CPU with HW Config.

Figure 6-11 Download CPU hardware configuration (1)

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

6-14 Getting Started, 11/2006, A5E00253410-02

Page 41

Configuration of the SIMATIC Manager

6.2 Hardware configuration

Click the "Load to module" icon (shown in the red circle).

When the dialog window "Select target module" appears, click OK.

Figure 6-12 Download CPU hardware configuration (2)

The dialog window "Select target address" is shown. Click "OK." The system data will now

be transferred to the CPU.

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

6-3

Page 42

Configuration of the SIMATIC Manager

6.2 Hardware configuration

Starting the CPU

Switch the CPU to RUN.

If the hardware configuration was undertaken correctly, two red LEDs (RUN and DC5V)

should be lit on the CPU.

Figure 6-13 CPU in error free state

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

6-16 Getting Started, 11/2006, A5E00253410-02

Page 43

Configuration of the SIMATIC Manager

6.3 STEP 7 user program

6.3 STEP 7 user program

6.3.1 Tasks of the user program

Overview

In our example, the sensor values are stored in a data block. Also, the hardware interrupt

status should be stored in a marker word. It should be possible to acknowledge the status

information by means of a bit.

Furthermore, the channel values (values of the input words) should be stored in another data

block.

The following tasks have to be performed in the user program:

● Cyclical storage of the analog input values in a data block (DB1)

● Cyclical conversion of the analog input values in floating point values (FC1) and storage

in a data block (DB2)

About OB82

● Acknowledgement of the hardware interrupt status when the acknowledge marker

(M200.0) is TRUE.

● Save the status in a marker word (MW100) when a hardware interrupt occurs.

The structure of the user program is depicted in the following table:

Call type Responsible

organization block

Cyclic

execution

Convert and store the

Acknowledge hardware

Hardware

interrupt

triggered call

Diagnostic

interrupt

triggered call

OB1 Save analog input

OB40 Save status MW100

OB82 Has to be implemented

Task to be programmed Used block or marker

DB1

values

FC1, DB2

sensor values

M200.0

interrupt

--because a module with

diagnostic capabilities

is used

OB82 is used for modules with diagnostic capabilities. If the diagnostic alarm is enabled for

such modules, OB82 requests for diagnoses when a failure is detected (incoming and

outgoing events). The operating system then calls OB 82.

In our example, we use OB82 to prevent the CPU from changing to STOP mode. You can

program reactions to diagnostic interrupts in OB82.

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

6-3

Page 44

Configuration of the SIMATIC Manager

6.3 STEP 7 user program

6.3.2 Creating a user program

Proceed as follows

There are two ways to create a user program.

● If you know how to program STEP7 SCL, then you can create and program the

necessary blocks and the function blocks in the Blocks folder of STEP7.

● You can insert the user program from an SCL source into the project. In this “Getting

started” we describe this method.

Creating a user program in STEP7 requires three steps:

1. Downloading the source file directly from the HTML page

2. Importing a source file

3. Compiling the source

Downloading the source file

You can download the source file directly from the HTML page from which you loaded this

“Getting Started”.

The German version of the source file has the name "GSSM331T1DE.AWL".

Save the source file to your hard drive.

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

6-18 Getting Started, 11/2006, A5E00253410-02

Page 45

Configuration of the SIMATIC Manager

6.3 STEP 7 user program

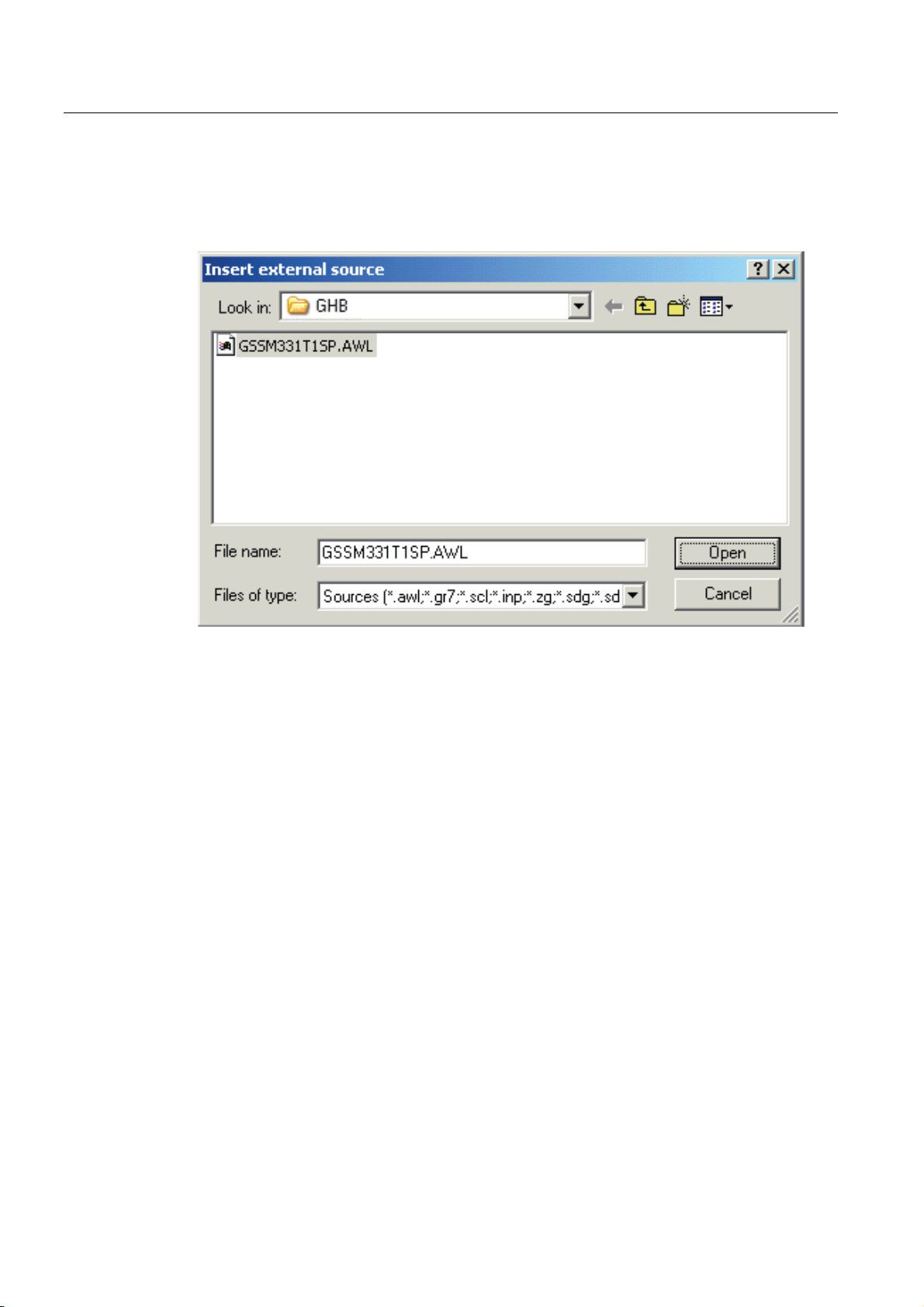

Importing a source file

You can import the source file into SIMATIC Manager as follows:

Right click the folder "Sources".

Select "Insert new Object > External Source...".

Figure 6-14 Importing an external source

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

6-3

Page 46

Configuration of the SIMATIC Manager

6.3 STEP 7 user program

In the "Insert external source" dialog browse for the source file GSSM331T1DE.AWL, which

you have already downloaded and saved on your hard disk.

Select the source file GSSM331T1DE.AWL (red arrow).

Figure 6-15 Importing an external source

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

6-20 Getting Started, 11/2006, A5E00253410-02

Page 47

Configuration of the SIMATIC Manager

6.3 STEP 7 user program

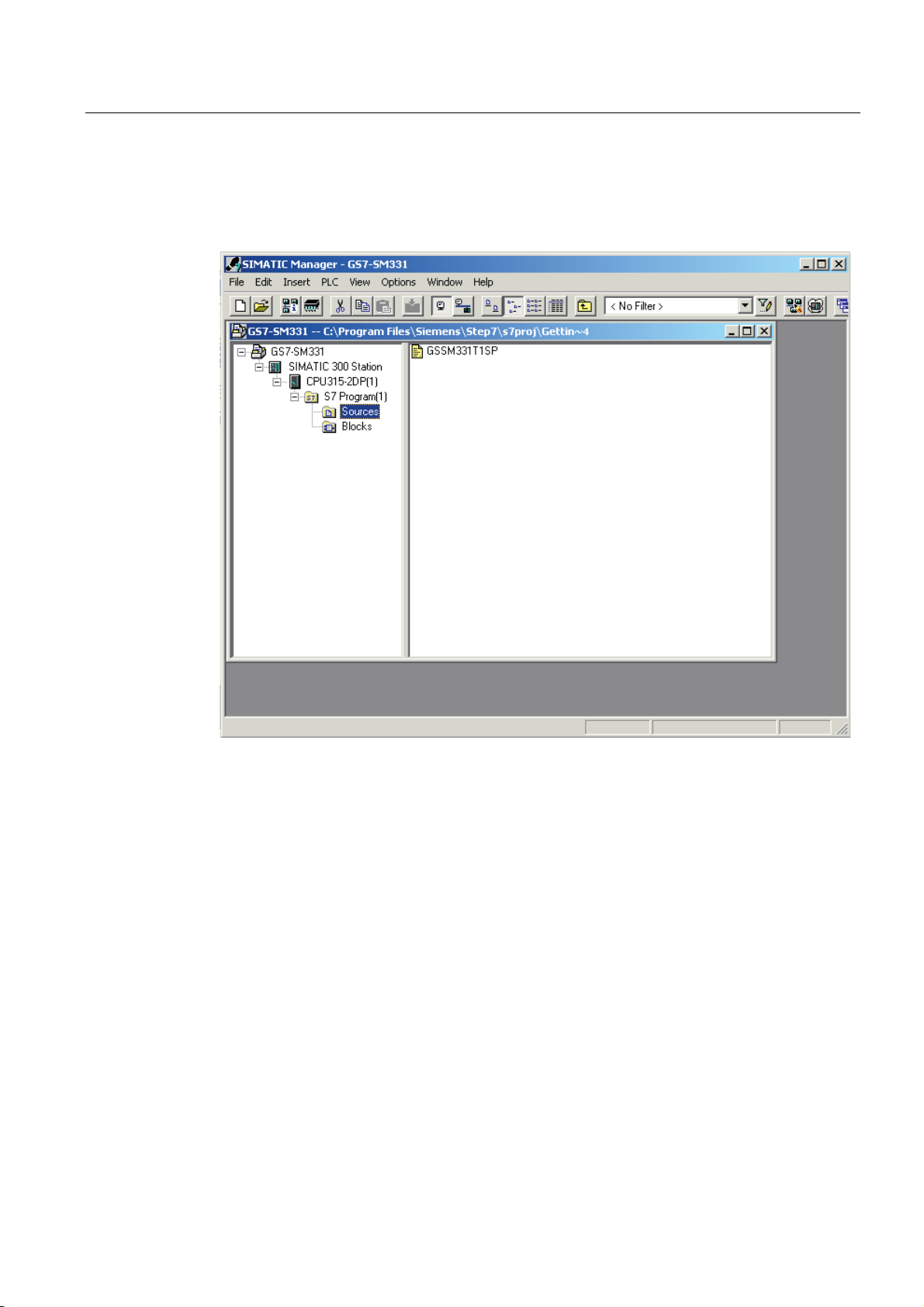

Click "Open".

SIMATIC Manager has opened the source file. In the right window you can see the source

file inserted.

Figure 6-16 Compiling the source code

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

6-3

Page 48

Configuration of the SIMATIC Manager

6.3 STEP 7 user program

Compiling the source code

In order to create an executable STEP7 program, the STL source has to be compiled.

Double-click the source file GSSM331T1DE in the Sources folder. The source code editor

opens.

In the window of the source code editor you can view the source code.

Figure 6-17 Source code editor

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

6-22 Getting Started, 11/2006, A5E00253410-02

Page 49

Configuration of the SIMATIC Manager

6.3 STEP 7 user program

After the source code is loaded, start the compilation.

Press the shortcut key Ctrl+B or select File > Compile. The compilation starts immediately.

Figure 6-18 Compiling STL source

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

6-3

Page 50

Configuration of the SIMATIC Manager

6.3 STEP 7 user program

In case of warning or error messages, check the source code.

Figure 6-19 Source code editor, messages after compilation

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

6-24 Getting Started, 11/2006, A5E00253410-02

Page 51

Configuration of the SIMATIC Manager

6.3 STEP 7 user program

Close the source code editor.

After compiling the STL source without errors the following blocks should appear in the

Blocks folder:

OB1, OB40, OB82, FC1, DB1 and DB2

Figure 6-20 Generated blocks

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

6-3

Page 52

Configuration of the SIMATIC Manager

6.3 STEP 7 user program

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

6-26 Getting Started, 11/2006, A5E00253410-02

Page 53

Testing the user program

7.1 Downloading system data and user program

Proceed as follows

The hardware and software are now ready. The next step is to download the system data

and the user program into the automation system. To do this, proceed as follows:

Downloading the system data and user program

Step Graphic controller Description

1 Using the SIMATIC Manager,

7

download the user program and the

system data (containing the

hardware configuration) into the

CPU.

2

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

Follow the instructions displayed on

the screen.

If all sensors are properly

connected, the CPU and the SM331

do not display an error light.

The status of the CPU is displayed

by the green "RUN" light.

7-1

Page 54

Testing the user program

7.1 Downloading system data and user program

Smart Label

The labeling strips for the modules were created with Siemens S7 Smart Label (order no:

2XV9 450-1SL01-0YX0).

A labeling strip in its actual size:

Figure 7-1 S7-SmartLabel labeling strip for the example

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

7-2 Getting Started, 11/2006, A5E00253410-02

Page 55

Testing the user program

7.2 Visualization of the sensor values

7.2 Visualization of the sensor values

Proceed as follows

In order to visualize the sensor values, insert a variable table as follows into the project. To

do this, select from the context menu of the Blocks folder:

Insert new object > Variable Table

Figure 7-2 Insert Variable Table

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

7-3

Page 56

Testing the user program

7.2 Visualization of the sensor values

Fill the new variable table as follows:

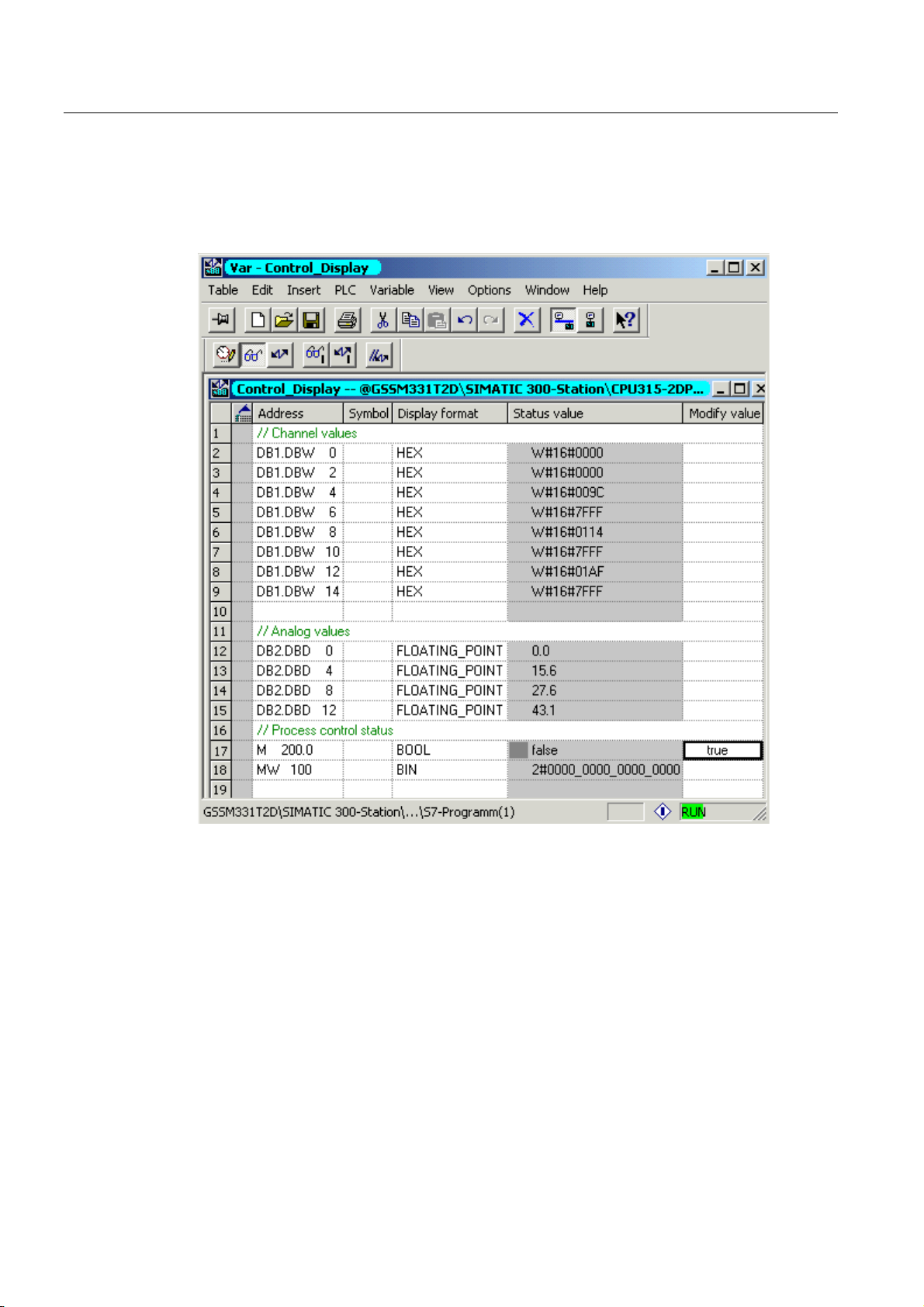

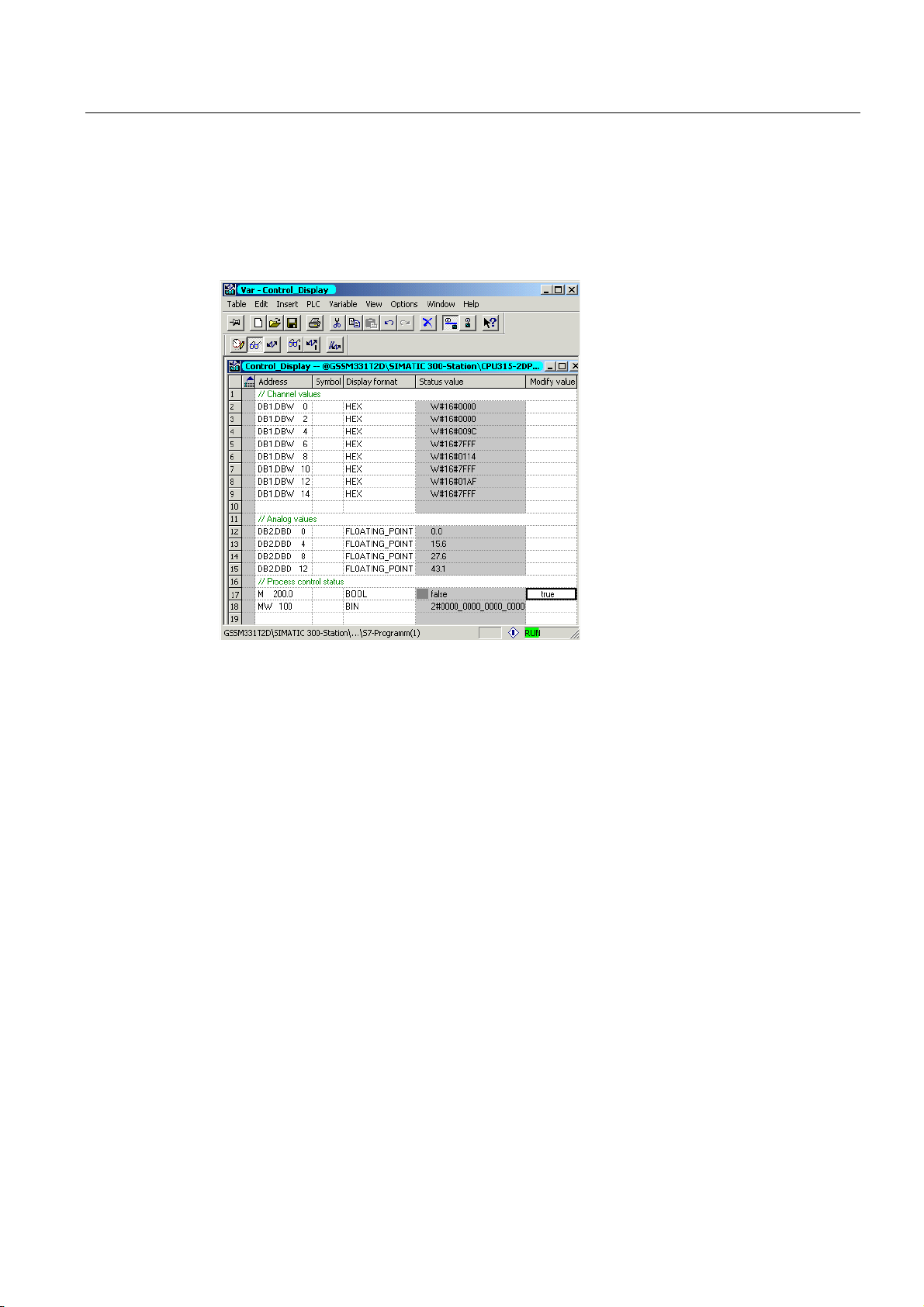

(1) In this area you can monitor the channel values

(2) In this area you can see the analog values

(3) In this area you can monitor and control the status signals

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

7-4 Getting Started, 11/2006, A5E00253410-02

Page 57

Testing the user program

7.2 Visualization of the sensor values

Variable description

Variables Description

DB1.DBW 0 Channel 0 Display of analog value

DB1.DBW 2 Channel 1 Display of analog value

DB1.DBW 4 Channel 2 Display of analog value

DB1.DBW 6 Channel 3 Display of analog value

DB1.DBW 8 Channel 4 Display of analog value

DB1.DBW 10 Channel 5 Display of analog value

DB1.DBW 12 Channel 6 Display of analog value

DB1.DBW 14 Channel 7 Display of analog value

DB2.DBD 0 Transducer1 current (mA)

DB2.DBD 4 Transducer2 current (mA)

DB2.DBD 8 Transducer3 current (mA)

MW 100 Status hardware interrupt

MW 200.0 Acknowledge hardware interrupt

M101.0 Channel 0 exceeded low limit

M101.1 Channel 0 exceeded high limit

M101.2 Channel 2 exceeded low limit

M101.3 Channel 0 exceeded high limit

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

7-3

Page 58

Testing the user program

7.2 Visualization of the sensor values

Monitoring values

In order to monitor values, open the online view of the controller by clicking the eye glasses

symbol. Now you can monitor the values in the data blocks and markers.

Figure 7-3 Online view of the variable table

(1) Channel values in hex format

(2) Converted analog value

(3) Status information

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

7-6 Getting Started, 11/2006, A5E00253410-02

Page 59

Testing the user program

7.2 Visualization of the sensor values

Controlling values

To control the process acknowledgement, enter the desired value (TRUE or FALSE,

depending on whether you want to activate or deactivate acknowledgement) into the column

"Control Value" and click the icon with the two arrows.

Controlling variables

(1) Channel value

(2) Analog value

(3) Status

Peculiarity in monitoring the values

While monitoring the values you will surely notice that the channel values are different from

the analog values. The reason for this is that the analog module only supports the binary

format “Word” (16 bits). Therefore, the values of the analog module have to be converted.

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

7-3

Page 60

Testing the user program

7.3 Analog value representation

7.3 Analog value representation

Proceed as follows

The analog values are only processed by the CPU in binary form. Analog input modules

convert the analog process signal into a digital format (16 bit word).

Five ranges have to be taken into account when converting from digital to analog values:

Representation of analog values in current measuring ranges 4 to 20 mA

Hex value Current range Comment Meaning

7FFF 22.96 mA

7F00

7EFF 22.81 mA

6C01

6C00 20 mA

5100 15 mA

1 4 mA + 578.7 nA

0 4 mA

FFFF

ED00 1.185 mA

ECFF

8000

Overflow From hex value 16#F700 on, the sensor

value is above the configured measurement

value range and is no more valid.

Overload range This range corresponds to a tolerance band

before the overflow range is reached. Within

this range the resolution is not optimal

though.

Rated range The nominal range is the normal range for

recording measurement values. This range

guarantees optimal resolution.

Underload range Range corresponding to the overload range

but for low values.

Underflow From hex value 16#ECFF on, the sensor

value is below the configured measurement

value range and is no more valid.

It is necessary to convert the binary format of the values in order to display analog process

values. In our example, mA are displayed. This is done by converting the display of analog

values in mA in a programmed function (FC1).

Note

In our example, we look at the values from the output of the transducer.

Using a amperemeter, you can now compare the values on the meter with the values of the

analog values display. The values will be identical.

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

7-8 Getting Started, 11/2006, A5E00253410-02

Page 61

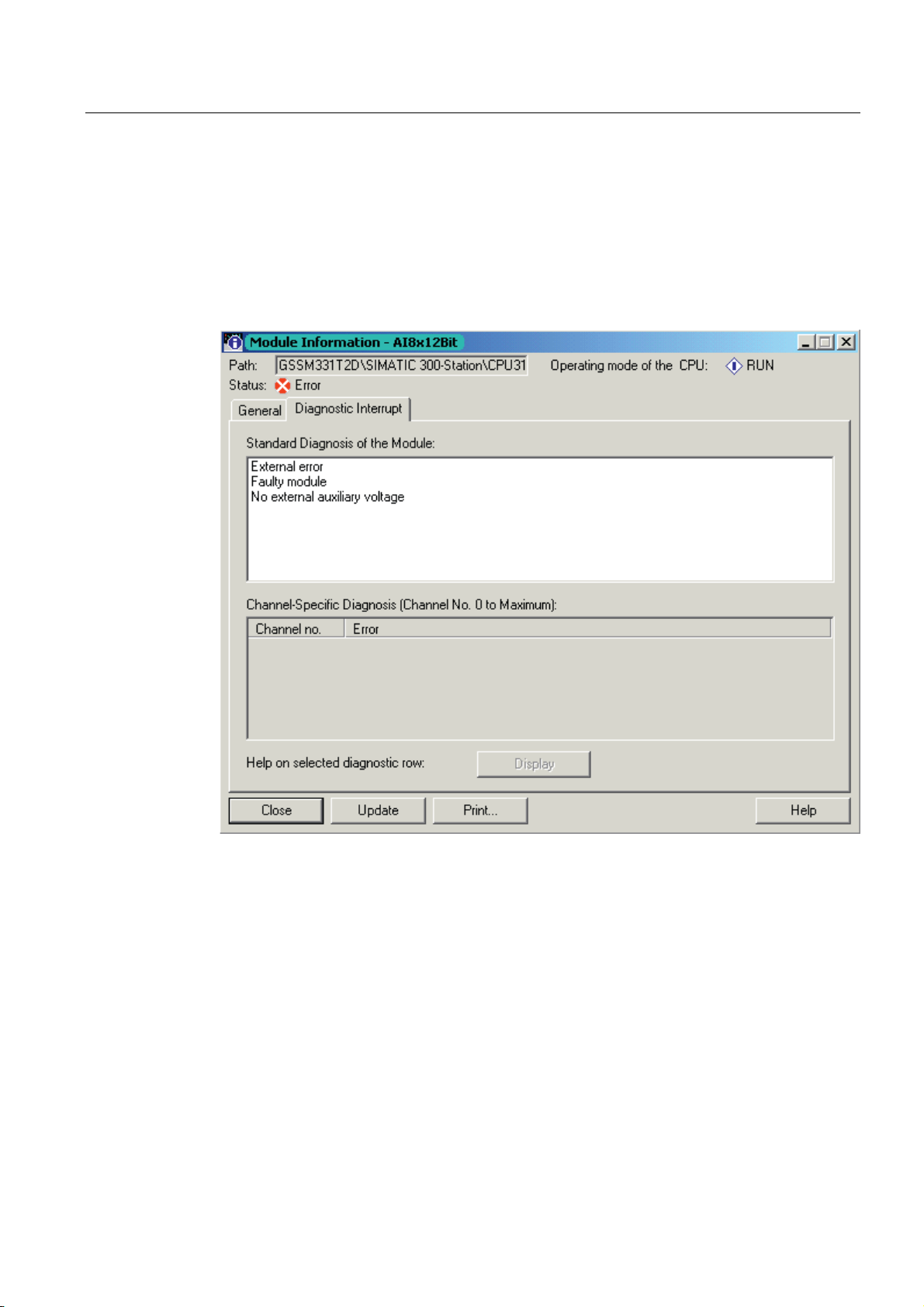

Diagnostic interrupt

8.1 Reading diagnostic information from a PG

Overview

Diagnostic interrupts enable the user program to react to hardware errors.

Modules must have diagnostic capabilities in order to generate diagnostic interrupts.

In OB82 you program the reaction to diagnostic interrupts.

Display

The analog input module SM331 AI8x12 has diagnostic capabilities.

Diagnostic interrupts that occur are signaled by the red "SF" LED on the SM331 and on the

CPU.

8

Figure 8-1 Hardware error

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

8-1

Page 62

Diagnostic interrupt

8.1 Reading diagnostic information from a PG

The cause of the error can be determined "online" by requesting the hardware status.

In order to determine the state of module "online", proceed as follows:

Select the SM331 in the hardware configuration. Click the menu command CPU -> Module

Information... in order to perform a hardware diagnostics.

Figure 8-2 Module status

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

8-2 Getting Started, 11/2006, A5E00253410-02

Page 63

Diagnostic interrupt

8.2 General diagnostics

8.2 General diagnostics

Diagnostic interrupt tab

On the Diagnostic Interrupt tab you will find information for the reported error.

The interrupts are not channel dependent and apply to the entire module.

Figure 8-3 Diagnostics for SM331

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

8-3

Page 64

Diagnostic interrupt

8.3 Channel dependent diagnostic interrupts

8.3 Channel dependent diagnostic interrupts

8.3.1 There are five channel dependent diagnostic interrupts

There are five channel dependent diagnostic interrupts:

● Configuration / programming error

● Common mode error

● Wire break

● Underflow

● Overflow

Note

Here we show you only the channel specific diagnostics for the measuring modes 2 or 4-

wire current transducers. Other measuring modes are similar but not described here.

8.3.2 Configuration / programming error

Meaning

The position of the measuring range modules does not match the measuring mode set in the

hardware configuration.

8.3.3 Common mode error

Meaning

The voltage difference Ucm between the inputs (M-) and the common voltage potential of the

measuring circuit (M

In our example, this error cannot occur because M

transducer (fixed potential).

) is too high.

ana

is connected to M for a 2-wire

ana

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

8-4 Getting Started, 11/2006, A5E00253410-02

Page 65

Diagnostic interrupt

8.3 Channel dependent diagnostic interrupts

8.3.4 Wire break

Meaning

If wire break detection is enabled for 2-wire transducers, there will be no direct check for a

wire break. The diagnostics instead reacts on the shortfall of the low limit current value.

With 4 to 20 mA current transducer, the diagnostic message “Analog input wire break“ is

shown in the module diagnostics when the current goes below 3.6 mA.

Figure 8-4 Left: Diagnostic message with wire break / Right: Variable table

The display of the analog values shows an underflow (Hex 8000) immediately even if the

current measured is clearly above 1.1185 mA.

Underloading 3.6 mA is only possible if wire break detection has been disabled.

8.3.5 Underflow

Meaning

The display of the analog values shows an underflow immediately even if the current

measured is clearly above 1.1185 mA.

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

8-5

Page 66

Diagnostic interrupt

8.3 Channel dependent diagnostic interrupts

8.3.6 Overflow

Meaning

If the current exceeds 22.81 mA, an overflow message stating "Analog in-put measuring

range / High limit exceeded" is displayed.

The display of the analog value (HEX 7FFF) is in the overflow range.

Figure 8-5 Left: Diagnostic message with overflow / Right: Variable table

Note

Disabled channels also have 7FFF hex as the analog display value.

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

8-6 Getting Started, 11/2006, A5E00253410-02

Page 67

Hardware interrupt

9.1 Hardware interrupt

Overview

A special feature of the SM331 AI8x12bit is its capability to trigger hardware interrupts. Two

channels (0 and 2) can be correspondingly configured.

Hardware interrupts generally trigger alarm organization blocks in the CPU. In our example,

OB40 is called.

The limit values for hardware interrupts have to be specified in mA.

Example:

You have connected a pressure sensor with a 4-20mA transducer to channel 0. Here the

limit values should be specified in mA and not in Pascal (Pa).

limit values

In order to trigger a hardware interrupt, the limit values have to be within the nominal values

of the measuring mode.

9

Example:

If wire break detection (3.6 mA) is enabled, and you choose 3.5 mA for the low limit value,

this setting is accepted by the system. A hardware interrupt will not be triggered because the

diagnostic alarm is always triggered first.

In our example, 2 channels (sensor 1 and 2) are configured with the following limits:

● Lower limit value 6 mA

● Upper limit value 18 mA

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

9-1

Page 68

Hardware interrupt

9.1 Hardware interrupt

Determining functions

If a hardware interrupt occurs, OB40 is called. In the user program of OB40 you can program

the reaction of the automation system to hardware interrupts.

In the example user program, OB40 reads the cause of the hardware interrupt. This can be

found in the temporary variable structure OB40_POINT_ADDR (local words 8 to 11).

/%

Figure 9-1 OB40 start information: In the example, and triggered a hardware interrupt

8SSHUOLPLWYDOXHYLRODWHGFKDQQHO

/%

8SSHUOLPLWYDOXHYLRODWHGFKDQQHO

9LRODWLRQRIWKHOROLPLWDWFKDQQHO

9LRODWLRQRIWKHOROLPLWDWFKDQQHO

In the example, OB40 only transfers LD8 and LD9 into a marker word (MW100). The marker

word is monitored in the existing variable table. You can acknowledge the marker word in

OB1 by setting marker bit M200.0 or by setting it to TRUE in the variable table.

If you supply 5.71 mA with a calibration device to channel 0, you will get the value 0001 hex

for MW100 in the variable table. This means that OB40 was called and channel 0 exceeded

its low limit value (6 mA).

Figure 9-2 Hardware interrupt: Channel 0 exceeded low limit value

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

9-2 Getting Started, 11/2006, A5E00253410-02

Page 69

Appendix

A.1 Source of the user program

STL source code

In this section you find the source code of the user program from the example.

You can download the source file directly from the HTML page from which you loaded this

"Getting Started".

DATA_BLOCK DB 1

TITLE =Analog module channel values

VERSION : 1.0

STRUCT

BEGIN

END_DATA_BLOCK

DATA_BLOCK DB 2

TITLE =Current transducer (in mA)

VERSION : 1.0

BEGIN

CH_0 : WORD ; //Channel 0

CH_1 : WORD ; //Channel 1

CH_2 : WORD ; //Channel 2

CH_3 : WORD ; //Channel 3

CH_4 : WORD ; //Channel 4

CH_5 : WORD ; //Channel 5

CH_6 : WORD ; //Channel 6

CH_7 : WORD ; //Channel 7

END_STRUCT ;

CH_0 := W#16#0;

CH_1 := W#16#0;

CH_2 := W#16#0;

CH_3 := W#16#0;

CH_4 := W#16#0;

CH_5 := W#16#0;

CH_6 := W#16#0;

CH_7 := W#16#0;

STRUCT

SE_1 : REAL ; //Sensor 1 current value (mA)

SE_2 : REAL ; //Sensor 2 current value (mA)

SE_3 : REAL ; //Sensor 3 current value (mA)

END_STRUCT ;

.SE_1 := 0.000000e+000;

SE_2 := 0.000000e+000;

SE_3 := 0.000000e+000;

A

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

A-1

Page 70

Appendix

A.1 Source of the user program

END_DATA_BLOCK

FUNCTION FC 1 : VOID

TITLE =Conversion of a channel’s raw values in mA

VERSION : 1.0

VAR_INPUT

Raw : WORD ; // Analog value display

END_VAR

VAR_OUTPUT

END_VAR

VAR_TEMP

END_VAR

BEGIN

NETWORK

TITLE = Conversion of raw values in mA

// Only long integers can be converted into REAL format

END_FUNCTION

ORGANIZATION_BLOCK OB 1

TITLE = "Main Program Sweep (Cycle)"

VERSION : 1.0

VAR_TEMP

Current : REAL ; // Current in mA

TDoubleInt : DINT ;

TInt : INT;

L #Raw;

T #TInt;

L

#TInt;

ITD

;

T

#TDoubleInt;

L

#TDoubleInt;

DTR

;

T

#Current;

L

1.728000e+003;

/R

;

T

#Current;

L

4.000000e+000;

+R

;

T

#Current;

OB1_EV_CLASS : BYTE ; //Bits 0-3 = 1 (Coming event),

OB1_SCAN_1 : BYTE ; //1 (Cold restart scan 1 of OB 1),

OB1_PRIORITY : BYTE ; //Priority of OB Execution

OB1_OB_NUMBR : BYTE ; //1 (Organization block 1, OB1)

OB1_RESERVED_1 : BYTE ; //Reserved for system

OB1_RESERVED_2 : BYTE ; //Reserved for system

OB1_PREV_CYCLE : INT; //Cycle time of previous OB1 scan (milliseconds)

OB1_MIN_CYCLE : INT; //Minimum cycle time of OB1 (milliseconds)

OB1_MAX_CYCLE : INT; //Minimum cycle time of OB1 (milliseconds)

OB1_DATE_TIME : DATE_AND_TIME ; //Date and time OB1 started

// HEX value

// Current = --------------// 1728

// !

// ! /

// ! /

// ------- +----- /------ +----

//

// Offset correction

Bits 4-7 = 1 (Event class 1)

3 (Scan 2-n of OB 1)

/

4 20

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

A-2 Getting Started, 11/2006, A5E00253410-02

Page 71

Appendix

A.1 Source of the user program

END_VAR

BEGIN

NETWORK

TITLE =Read channels

// Channel values 0 to 7 are loaded and stored in DB1 (channel values)

NETWORK

TITLE = Conversion

// Conversion of the channel’s raw data into current values (mA)

NETWORK

TITLE = Reset hardware interrupt

// Even though the hardware interrupt was reset by the hardware upon terminating OB40

// the value of the hardware interrupt must be reset manually

L PEW 256;

T DB1.DBW 0;

L PEW 258;

T DB1.DBW 2;

L PEW 260;

T DB1.DBW 4;

L PEW 262;

T DB1.DBW 6;

L PEW 264;

T DB1.DBW 8;

L PEW 266;

T DB1.DBW 10;

L PEW 268;

T DB1.DBW 12;

L PEW 270;

T DB1.DBW 14;

CALL FC 1 (

Raw

Current

CALL FC 1 (

Raw

Current

CALL FC 1 (

Raw

Current

//Channel 0

//Channel 1

//Channel 2

//Channel 3

//Channel 4

//Channel 5

//Channel 6

//Channel 7

:= DB1.DBW 0,

:= DB2.DBD 0);

:= DB1.DBW 4,

:= DB2.DBD 4);

:= DB1.DBW 6,

:= DB2.DBD 8);

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

A-3

Page 72

Appendix

A.1 Source of the user program

NETWORK

TITLE =The End

END_ORGANIZATION_BLOCK

ORGANIZATION_BLOCK OB 40

TITLE = "Hardware Interrupt"

// Processing OB40_POINT_ADDR (L8 to L11)

//

//L8 High limit value exceeded

//L9 Low limit value exceeded

VERSION : 1.0

VAR_TEMP

OB40_EV_CLASS : BYTE ; //Bits 0-3 = 1 (Coming event),

OB40_STRT_INF : BYTE ; //16#41 (OB 40 has started)

OB40_PRIORITY : BYTE ; //Priority of OB Execution

OB40_OB_NUMBR : BYTE ; //40 (Organization block 40, OB40)

OB40_RESERVED_1 : BYTE ; //Reserved for system

OB40_IO_FLAG : BYTE ; //16#54 (input module), 16#55 (output module)

OB40_MDL_ADDR : WORD ; //Base address of module initiating interrupt

OB40_POINT_ADDR : DWORD ; //Interrupt status of the module

OB40_DATE_TIME : DATE_AND_TIME ; //Date and time OB40 started

U

SPBN

L

SSI

T

lbl0: NOP

BE;

M

lbl0;

MW

4;

MW

0;

200.0;

100;

100;

Bits 4-7 = 1 (Event class 1)

END_VAR

BEGIN

NETWORK

TITLE =Sensor 1 (Channel 0): Lower limit value

L001;

NETWORK

TITLE =Sensor 1 (Channel 0): Upper limit value

U L 9.0; // Channel 0 low limit value

SPBNB L001;

L W#16#1;

L MW 100;

OW ;

T MW 100;

NOP 0;

U L 8.0; // Channel 0 upper limit value

SPBNB L002;

L W#16#2;

L MW 100;

OW ;

T MW 100;

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

A-4 Getting Started, 11/2006, A5E00253410-02

Page 73

Appendix

A.1 Source of the user program

L002:

NETWORK

TITLE =Sensor 2 (Channel 2): Lower limit value

L003:

NETWORK

TITLE =Sensor 2 (Channel 2): Upper limit value

L004:

NETWORK

TITLE =Sensor 3 (Channel 3): Lower limit value

// Only for demonstration purposes. Channel 3 has now hardware interrupt capabilities

L005:

NETWORK

TITLE =Sensor 3 (Channel 3): Upper limit value

// Only for demonstration purposes. Channel 3 has now hardware interrupt capabilities

L006:

END_ORGANIZATION_BLOCK

NOP 0;

U L 9.2; // Channel 2 low limit value

SPBNB L003;

L W#16#4;

L MW 100;

OW ;

T MW 100;

NOP 0;

U L 8.2; // Channel 2 upper limit value

SPBNB L004;

L W#16#8;

L MW 100;

OW ;

T MW 100;

NOP 0;

U L 9.3; // Channel 3 low limit value

SPBNB L005;

L W#16#10;

L MW 100;

OW ;

T MW 100;

NOP 0;

U L 8.3; // Channel 3 upper limit value

SPBNB L006;

L W#16#20;

L MW 100;

OW ;

T MW 100;

NOP 0;

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

A-5

Page 74

Appendix

A.1 Source of the user program

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

A-6 Getting Started, 11/2006, A5E00253410-02

Page 75

Index

2

2-Wire current transducer

wiring principle, 5-4

4

4-Wire current transducer

wiring principle, 5-5

A

Add

SIMATIC components, 6-8

Adding SIMATIC components, 6-8

Analog module

Characteristics, 4-5

Configuring, 6-10

Inserting, 6-9

Installing, 4-3

The required hardware and software, 2-1

Wiring, 5-4, 5-5

Analog value representation, 7-8

in Current Measuring Ranges 4 to 20 mA, 7-8

Assigning

Project name, 6-5

B

Basic processing time, 6-12

Bus connectors

Insert, 4-2

C

Calling

Configuration, 6-11

Hardware configuration, 6-7

Channel group

Not used, 5-7

Characteristics

Analog module, 4-5

Check

Line voltage, 5-3

Clear / Reset, 6-13

Common mode error, 8-4

Components

SM331, 4-4

Components of the Product

SM331 modules, 4-4

Configuration

Calling, 6-11

Configuration / programming error, 8-4

Configuration language

STL, 6-4

Configuring

Analog module, 6-10

CPU 315-2DP, 6-1

Hardware configuration, 6-7

with SIMATIC Manager, 6-1

Connect

CPU with programming device, 6-13

Connecting-up

Errors, 5-8

test, 5-8

Control

Values, 7-7

Control value, 7-7

Converting

digital values to analog values, 7-8

CPU

CPU with programming device, 6-13

Installing, 4-2

Selecting, 6-3

start, 6-16

Wiring the power supply, 5-2

CPU 315-2DP

configuring, 6-1

Create

STEP 7 project, 6-1

User Program, 6-18

Current transducers

wiring principle, 5-4

SM331; AI 8x12 Bit Getting Started part 1: 4 -20mA

Getting Started, 11/2006, A5E00253410-02

Index-1

Page 76

Index

D

Define the basic user program

Defining, 6-4

Defining

Defining the basic user program, 6-4

Functions in event of hardware interrupts, 9-2

Delete

Micro memory card, 6-13

Diagnostic functionality, 5-7

Diagnostic information

read from a PG, 8-1

Diagnostics message

channel dependent, 8-4

General, 8-3

Digital value

convert to analog value, 7-8

Displays

Errors, 8-3

Download

source code, A-1

Source file, 6-18

Downloading

Download system data and user program into the

automation system, 7-1

Hardware configuration, 6-14

Downloading system data and user program

Downloading to automation system, 7-1

E

Hardware configuration

calling, 6-7

Configuring, 6-7

Downloading, 6-14

Finishing, 6-12

Hardware fault

find, 8-2

Hardware interrupt

limit values, 9-1

Hardware interrupt, 6-12, 9-1

I

Importing

Source file, 6-19

Insert

Bus connectors, 4-2

Inserting

Analog module, 6-9

Installation

Analog module, 4-3

CPU, 4-2

Front connector, 4-8

Plant, 4-1

Power supply, 4-2

SM331, 4-8

Integration time, 6-12

Interference frequency, 6-12

Interference frequency suppression, 6-12

Error display, 8-3

Errors

Connecting-up, 5-8

F

Fill out

Variable table, 7-4

Finish