Page 1

Preface, Contents

SIMATIC

S7-200

Programmable Controller,

CPU 210

System Manual

Installing the CPU 210

Installing and Using the

STEP 7-Micro/WIN Version 2.0

Software

Getting Started with a Sample

Program

Basic Concepts for

Programming the CPU 210

Instruction Set

Appendix

CPU 210 Data Sheets

Special Memory (SM)

1

2

3

4

5

A

B

C79000-G7076-C235-01

Error Handling and Error Codes

Converting STEP 7-Micro/DOS

Files to STEP 7-Micro/WIN Files

Execution Times for STL

Instructions

CPU 210 Order Numbers

Index

C

D

E

F

Page 2

Safety Guidelines

!

!

!

This manual contains notices which you should observe to ensure your own personal safety, as well as to

protect the product and connected equipment. These notices are highlighted in the manual by a warning

triangle and are marked as follows according to the level of danger:

Danger

indicates that death, severe personal injury or substantial property damage will result if proper precautions are

not taken.

Warning

indicates that death, severe personal injury or substantial property damage can result if proper precautions are

not taken.

Caution

indicates that minor personal injury or property damage can result if proper precautions are not taken.

Note

draws your attention to particularly important information on the product, handling the product, or to a particular

part of the documentation.

Qualified Personnel

Correct Usage

The device/system may only be set up and operated in conjunction with this manual.

Only qualified personnel should be allowed to install and work on this equipment. Qualified persons are

defined as persons who are authorized to commission, to ground, and to tag circuits, equipment, and systems in accordance with established safety practices and standards.

Note the following:

Warning

!

Trademarks

The reproduction, transmission or use of this document or its

contents is not permitted without express written authority.

Offenders will be liable for damages. All rights, including rights

created by patent grant or registration of a utility model or design, are

reserved.

Siemens Energy & Automation, Inc.

3333 Old Milton Parkway

Alpharetta, GA 30202

This device and its components may only be used for the applications described in the catalog or the technical

description, and only in connection with devices or components from other manufacturers which have been

approved or recommended by Siemens.

This product can only function correctly and safely if it is transported, stored, set up, and installed correctly, and

operated and maintained as recommended.

SIMATICR and SINECR are registered trademarks of SIEMENS AG.

Third parties using for their own purposes any other names in this document which refer to

trademarks might infringe upon the rights of the trademark owners.

Disclaimer of LiabilityCopyright E Siemens SE&A 1997 All rights reserved

We have checked the contents of this manual for agreement with the

hardware and software described. Since deviations cannot be

precluded entirely , we cannot guarantee full agreement. However ,

the data in this manual are reviewed regularly and any necessary

corrections included in subsequent editions. Suggestions for

improvement are welcomed.

Technical data subject to change.

E Siemens SE&A 1997

Siemens Energy & Automation

6ES7 298-8EA00-8BH0

S7-200 Programmable Controller, CPU 210

Page 3

Preface

Purpose

The CPU 210 is an addition to the S7-200 series micro-programmable logic controllers

(Micro PLCs). Its compact design, low cost, and powerful instruction set make the CPU 210

a perfect solution for controlling small applications. The selection of voltage options provides

you with the flexibility you need to solve your automation problems.

SIMA TIC S7-200 CPU 210 Programmable Controller System Manual

The

information about installing and programming the CPU 210 and the program development

station (PDS 210). This manual also includes descriptions and examples for the

programming instructions, typical execution times for the instructions, and the data sheets for

the CPU 210 and related equipment.

Audience

This manual is designed for engineers, programmers, installers, and electricians who have a

general knowledge of programmable logic controllers.

Scope of the Manual

The information contained in this manual pertains in particular to the following products:

S CPU 210 and the PDS 210

S STEP 7-Micro/WIN version 2.0 programming software

provides

How to Use This Manual

If you are a first-time (novice) user of S7-200 Micro PLCs, you should read the entire manual.

If you are an experienced user, refer to the table of contents or index to find specific

information.

The manual is organized in the following topics:

S “Installing the CPU 210” (Chapter 1) provides an overview of some of the features of the

equipment and the procedures, dimensions, and basic guidelines for installing the

CPU 210.

S “Installing and Using the STEP 7-Micro/WIN V ersion 2.0 Software” (Chapter 2) describes

how to install the programming software. It also provides a basic explanation about the

features of the software.

S “Getting Started with a Sample Program” (Chapter 3) helps you enter a sample program,

using the STEP 7-Micro/WIN software.

S “Basic Concepts for Programming the CPU 210” (Chapter 4) provides information about

how the CPU 210 processes data and executes a program.

S “Instruction Set” (Chapter 5) provides explanations and examples of the programming

instructions used by the CPU 210.

S7-200 Programmable Controller, CPU 210

C79000-G7076-C235-01

iii

Page 4

Preface

Additional information (such as the equipment data sheets, error code descriptions and

execution times) are provided in the appendices.

Additional Assistance

For assistance in answering technical questions, for training on this product, or for ordering,

contact your Siemens distributor or sales office.

iv

S7-200 Programmable Controller, CPU 210

C79000-G7076-C235-01

Page 5

Contents

1 Installing the S7-200 CPU 210

1.1 Product Overview 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Requirements 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Features of the CPU 210 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Pre-installation Considerations 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Configuration 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clearance Requirements for Installing a CPU 210 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . .

DIN Rail Requirements 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Panel-Mounting Dimensions 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Installing a CPU 210 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting a CPU 210 on a Panel 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing a CPU 210 on a DIN Rail 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing a CPU 210 in a Panel Box 1-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Installing the Field Wiring 1-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Guidelines 1-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Grounding and Circuit Referencing Guidelines for Using Isolated Circuits 1-9. . . . . . .

Using the Optional Field Wiring Connector 1-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Guidelines for AC Installation 1-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Guidelines for DC Installation 1-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 Using Suppression Circuits 1-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Protecting DC Transistors 1-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Protecting Relays Controlling DC Power 1-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Installing and Using the STEP 7-Micro/WIN Version 2.0 Software

2.1 Installing the STEP 7-Micro/WIN Version 2.0 Software 2-2. . . . . . . . . . . . . . . . . . . . . . .

Pre-installation Instructions 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Instructions for Windows 3.1 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Instructions for Windows 95 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting the Installation 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Establishing Communication with the PDS 210 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting Your Computer to the PDS 210 for PPI Communications 2-3. . . . . . . . . . .

Setting Up the Communications Parameters 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Configuring the Preferences for STEP 7-Micro/WIN 2-5. . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Creating and Saving a Project 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating a New Project 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Saving a Project 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S7-200 Programmable Controller, CPU 210

C79000-G7076-C235-01

v

Page 6

Contents

2.5 Creating a Program 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Entering Your Program in Ladder 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Entering Your Program in Statement List 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compiling the Program 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Viewing a Program in Ladder or Statement List 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 Downloading A Program 2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Downloading the Program to the PDS 210 2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Copying Your Program to the Memory Cartridge 2-1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transporting the Program to the CPU 210 2-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 Using Symbolic Addressing 2-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Guidelines for Entering Symbolic Addresses 2-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting the Symbol Table Editor 2-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Editing Functions within the Symbol Table 2-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sorting Table Entries 2-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Displaying the Symbolic Addresses 2-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8 Using the Status Chart 2-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reading and Writing Variables with the Status Chart 2-15. . . . . . . . . . . . . . . . . . . . . . . . .

Editing Addresses 2-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.9 Debugging and Monitoring Your Program 2-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Single/Multiple Scans to Monitor Your Program 2-16. . . . . . . . . . . . . . . . . . . . . . . .

Displaying the Status of the Program in Ladder Logic 2-16. . . . . . . . . . . . . . . . . . . . . . . .

2.10 Error Handling for the PDS 210 2-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Responding to Fatal Errors 2-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Responding to Non-Fatal Errors 2-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Getting Started with a Sample Program

3.1 Defining the Requirements for the Application Example 3-2. . . . . . . . . . . . . . . . . . . . . .

Defining the Inputs and Outputs for the Application 3-2. . . . . . . . . . . . . . . . . . . . . . . . . .

Creating Symbolic Names for the Elements of the Program 3-2. . . . . . . . . . . . . . . . . . .

3.2 Designing the Control Logic 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Defining the Operation of the Program 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Designing the Control Logic for Arming and Disarming the System 3-6. . . . . . . . . . . . .

Designing the Control Logic for Turning On the Low-Level Alert Notification 3-7. . . . .

Designing the Control Logic for Turning On the Alarm and Modem Dialer 3-8. . . . . . .

3.3 Putting the Control Logic into a Program 3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Creating a Project with STEP 7-Micro/WIN 3-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Creating a Symbol Table 3-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Entering the Symbol Names 3-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 Entering the Program 3-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming with Symbolic Addresses 3-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Ladder Editor to Enter the Program 3-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compiling the Program 3-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Saving the Sample Program 3-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7 Creating a Status Chart 3-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Building a Status Chart 3-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

S7-200 Programmable Controller, CPU 210

C79000-G7076-C235-01

Page 7

3.8 Downloading and Monitoring the Sample Program 3-23. . . . . . . . . . . . . . . . . . . . . . . . . . .

Downloading the Project to the PDS 210 3-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Ladder Editor to Monitor the Status of the Program 3-23. . . . . . . . . . . . . . . . .

Using the Status Chart to Monitor and Modify the Current V alues of the Program 3-24

3.9 Modifying the Sample Program 3-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating the Blink Patterns for the LED 3-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Turning the LED On and Off 3-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Basic Concepts for Programming the CPU 210

4.1 Guidelines for Designing a Micro PLC System 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Partitioning Your Process or Machine 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating the Functional Specifications 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Designing the Safety Circuits 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifying the Operator Stations 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating the PLC Configuration Drawings 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating a List of Symbolic Names 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Concepts for Creating a Program 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Relating the Program to Inputs and Outputs 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessing Data in the Memory Areas 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Organizing the Program 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Understanding the Scan Cycle of the CPU 210 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Understanding the Basic Scan Cycle of the CPU 210 4-6. . . . . . . . . . . . . . . . . . . . . . . .

Understanding the Basic Scan Cycle of the PDS 210 4-7. . . . . . . . . . . . . . . . . . . . . . . .

Using the Debug Option to Specify the Number of Scans 4-8. . . . . . . . . . . . . . . . . . . . .

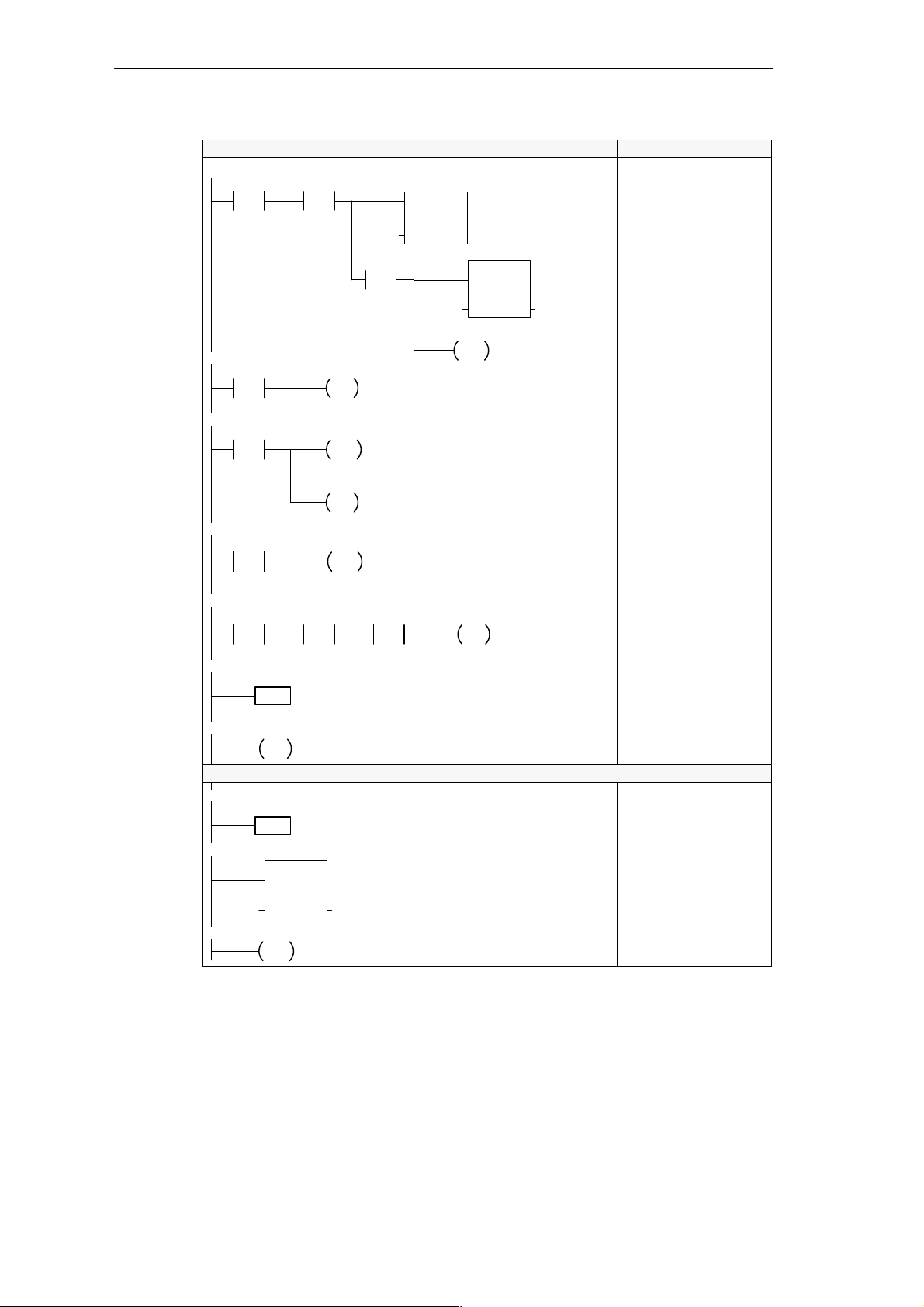

4.4 Understanding the Programming Languages 4-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Understanding the Basic Elements of Ladder 4-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Understanding the Statement List Instructions 4-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Understanding the Addresses of the Memory Areas 4-11. . . . . . . . . . . . . . . . . . . . . . . . .

Using the Memory Address to Access Data 4-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Addressing the Input Image Register (I) 4-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Addressing the Outputs (Q) 4-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Addressing the Bit Memory (M) Area 4-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Addressing the Special Memory (SM) Bits 4-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Addressing the Timer (T) Memory Area 4-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Addressing the Counter (C) Memory Area 4-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Constant Values 4-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 Sample Program Using an Interrupt Routine 4-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 Using the Analog Adjustment Potentiometer 4-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

5 Instruction Set

5.1 V alid Ranges for the CPU 210 and PDS 210 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

V alid Operand Ranges 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Contact Instructions 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Contacts 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Not 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Positive, Negative Transition 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compare Word Integer 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contact Examples 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output 5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set, Reset 5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S7-200 Programmable Controller, CPU 210

C79000-G7076-C235-01

vii

Page 8

Contents

Output Example 5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Timer Instructions 5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

On-Delay Timer 5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Understanding How the CPU 210 Updates the Timers 5-6. . . . . . . . . . . . . . . . . . . . . . .

Timer Example 5-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 Counter Instructions 5-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Up/Down Counter 5-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Counter Example 5-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6 Increment and Decrement Instructions 5-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Increment Word, Decrement Word 5-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Increment, Decrement Example 5-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7 Move Instruction 5-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Move Word 5-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Move Examples 5-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.8 Program Control Instructions 5-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

END 5-1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Watchdog Reset 5-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Considerations for Using the WDR Instruction to Reset the Watchdog T imer 5-11. . . .

END and WDR Example 5-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Jump to Label, Label 5-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Jump to Label Example 5-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9 Logic Stack Instructions 5-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

And Load 5-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Or Load 5-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic Stack Example 5-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.10 Interrupt Instructions 5-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interrupt Routine, Return from Interrupt Routine 5-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enable Interrupt, Disable Interrupt 5-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Guidelines and Restrictions for Using the Interrupt Routine 5-15. . . . . . . . . . . . . . . . . . .

Sharing Data Between the Main Program and the Interrupt Routine 5-15. . . . . . . . . . . .

Interrupt Example 5-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A CPU 210 Data Sheets

A.1 General Technical Specifications A-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2 CPU 210 DC Power Supply, 24 VDC Inputs, 24 VDC Outputs A-4. . . . . . . . . . . . . . . . .

A.3 CPU 210 AC Power Supply, 24 VDC Inputs, Relay Outputs A-6. . . . . . . . . . . . . . . . . . .

A.4 CPU 210 AC Power Supply, AC Inputs, Relay Outputs A-8. . . . . . . . . . . . . . . . . . . . . . .

A.5 PDS 210 AC Power Supply, DC Inputs, Relay Outputs A-10. . . . . . . . . . . . . . . . . . . . . . .

A.6 Memory Cartridge 8K x 8 A-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.7 Memory Cartridge 16K x 8 A-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.8 PC/PPI Cable A-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.9 DC Input Simulator A-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S7-200 Programmable Controller, CPU 210

viii

C79000-G7076-C235-01

Page 9

Contents

BSpecial Memory (SM) B-1

CError Handling and Error Codes C-1

DConverting STEP 7-Micro/DOS Files to STEP 7-Micro/WIN Files D-1

EExecution Times for STL Instructions E-1

FCPU 210 Order Numbers F-1

Index Index-1

S7-200 Programmable Controller, CPU 210

C79000-G7076-C235-01

ix

Page 10

Contents

x

S7-200 Programmable Controller, CPU 210

C79000-G7076-C235-01

Page 11

Installing the S7-200 CPU 210

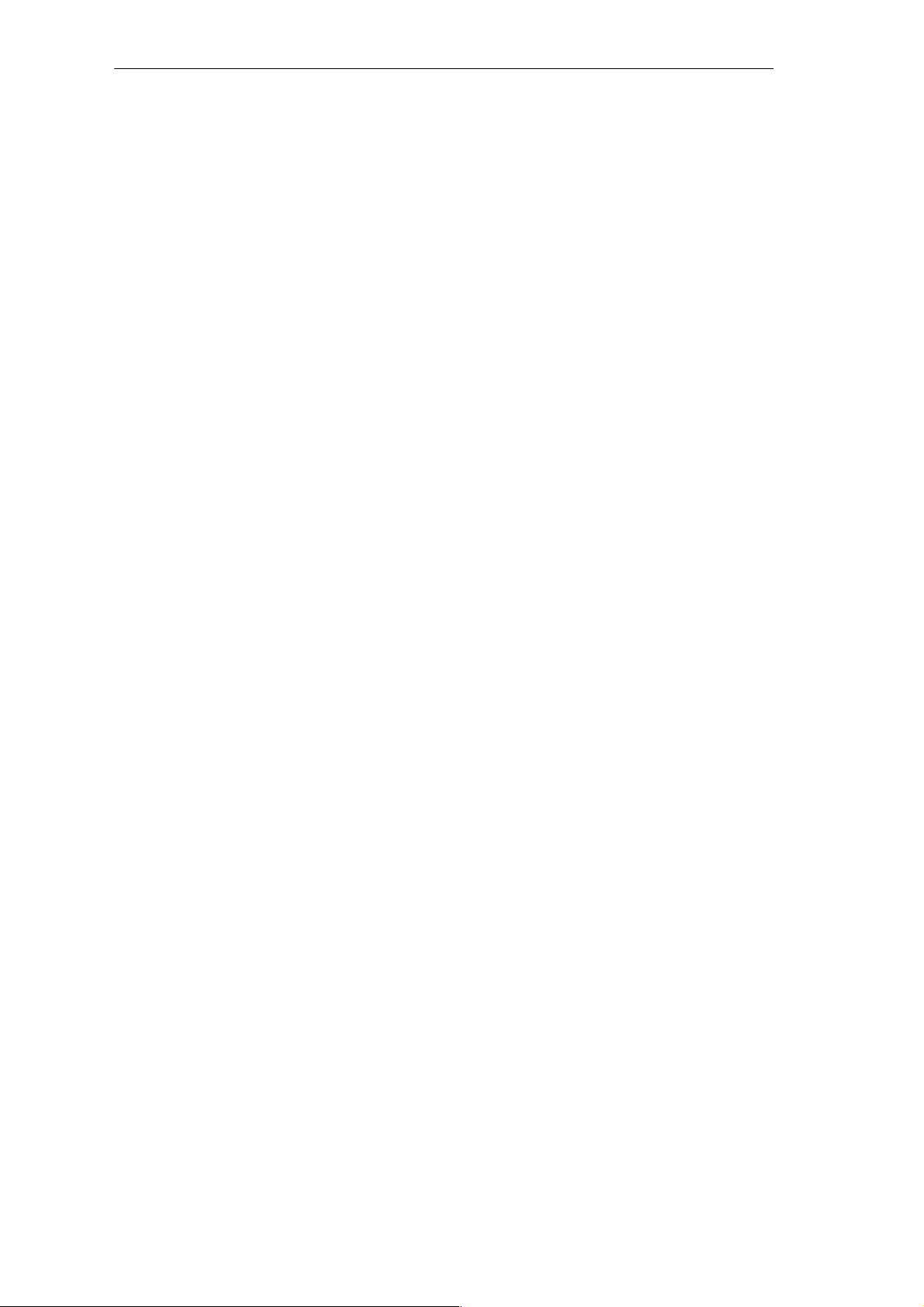

The S7-200 CPU 210 is one of the S7-200 series of micro-programmable logic controllers

(Micro PLCs) that can control a variety of automation applications. Figure 1-1 shows an

S7-200 CPU 210. The compact design and low cost of the CPU 210 make a perfect solution

for controlling small applications. In addition, the variety of input and output voltages provides

you with the flexibility you need to solve your automation problems with the maintenance-free

operation of the CPU 210.

The CPU 210 is easy to install. You can use the mounting holes to attach the module to a

panel, or you can use the built-in DIN clips to mount the module onto a DIN rail. The small

size of the CPU 210 allows you to make efficient use of space.

1

Figure 1-1 S7-200 CPU 210

Chapter Overview

Section Description Page

1.1 Product Overview 1-2

1.2 Pre-installation Considerations 1-4

1.3 Installing a CPU 210 1-6

1.4 Installing the Field Wiring 1-8

1.5 Using Suppression Circuits 1-12

S7-200 Programmable Controller, CPU 210

C79000-G7076-C235-01

1-1

Page 12

Installing the S7-200 CPU 210

1.1 Product Overview

The CPU 210 combines a central processing unit (CPU), power supply, and discrete I/O

points into a compact, stand-alone device.

S The CPU executes the program and stores the data for controlling the automation task or

process.

S The inputs and outputs are the system control points: the inputs monitor the signals from

the field devices (such as sensors and switches), and the outputs control pumps, motors,

or other devices in your process.

S Status lights provide visual information about the CPU mode (RUN) or whether a system

fault (SF) has been detected.

Equipment Requirements

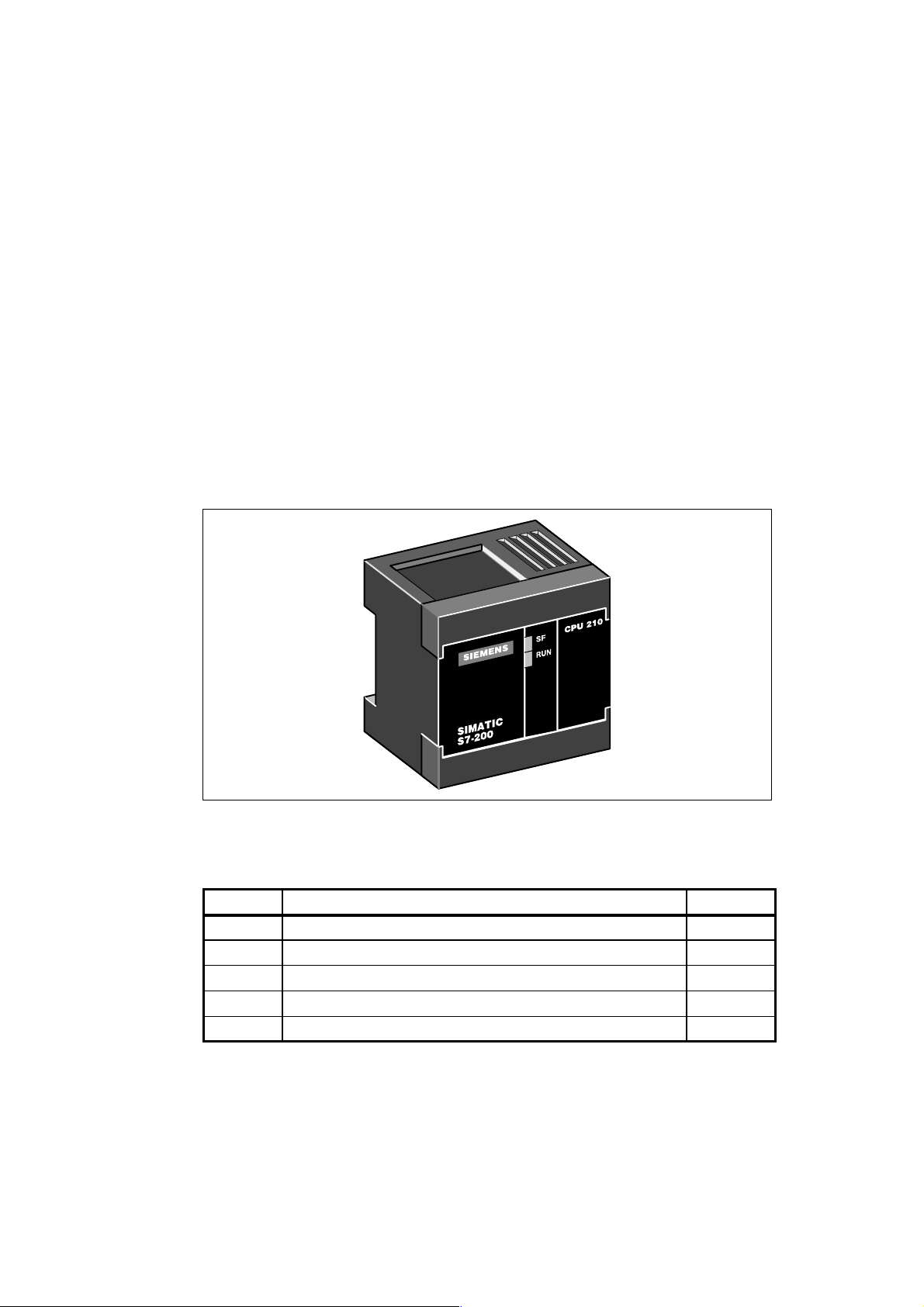

As shown in Figure 1-2, you use the STEP 7-Micro/WIN programming software with a

program development station (the PDS 210) to create and to test your program. The final

program is then loaded onto a memory cartridge, which is then installed in the CPU 210. You

need the following equipment to create programs for the CPU 210:

S Personal computer (PC) running the STEP 7-Micro/WIN programming software. Refer to

Chapter 2 for the requirements for installing the STEP 7-Micro/WIN software.

S Program development station (PDS 210).

S PC/PPI communications cable.

S Memory cartridge for transferring the program to the CPU 210.

Refer to the data sheets in Appendix A for order numbers and other specifications of this

equipment.

Components for developing a program for the CPU 210

Computer

STEP 7-Micro/WIN

PC/PPI Communications Cable

CPU 210

Figure 1-2 Components of a CPU 210 Micro PLC System

Program Development Station

(PDS 210)

Memory cartridge

transfers the program

to the CPU 210

1-2

S7-200 Programmable Controller, CPU 210

C79000-G7076-C235-01

Page 13

Features of the CPU 210

БББББББ

Á

Á

БББББББ

Á

y

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Inst

(36 total)

Á

Á

Á

Á

Á

Á

Á

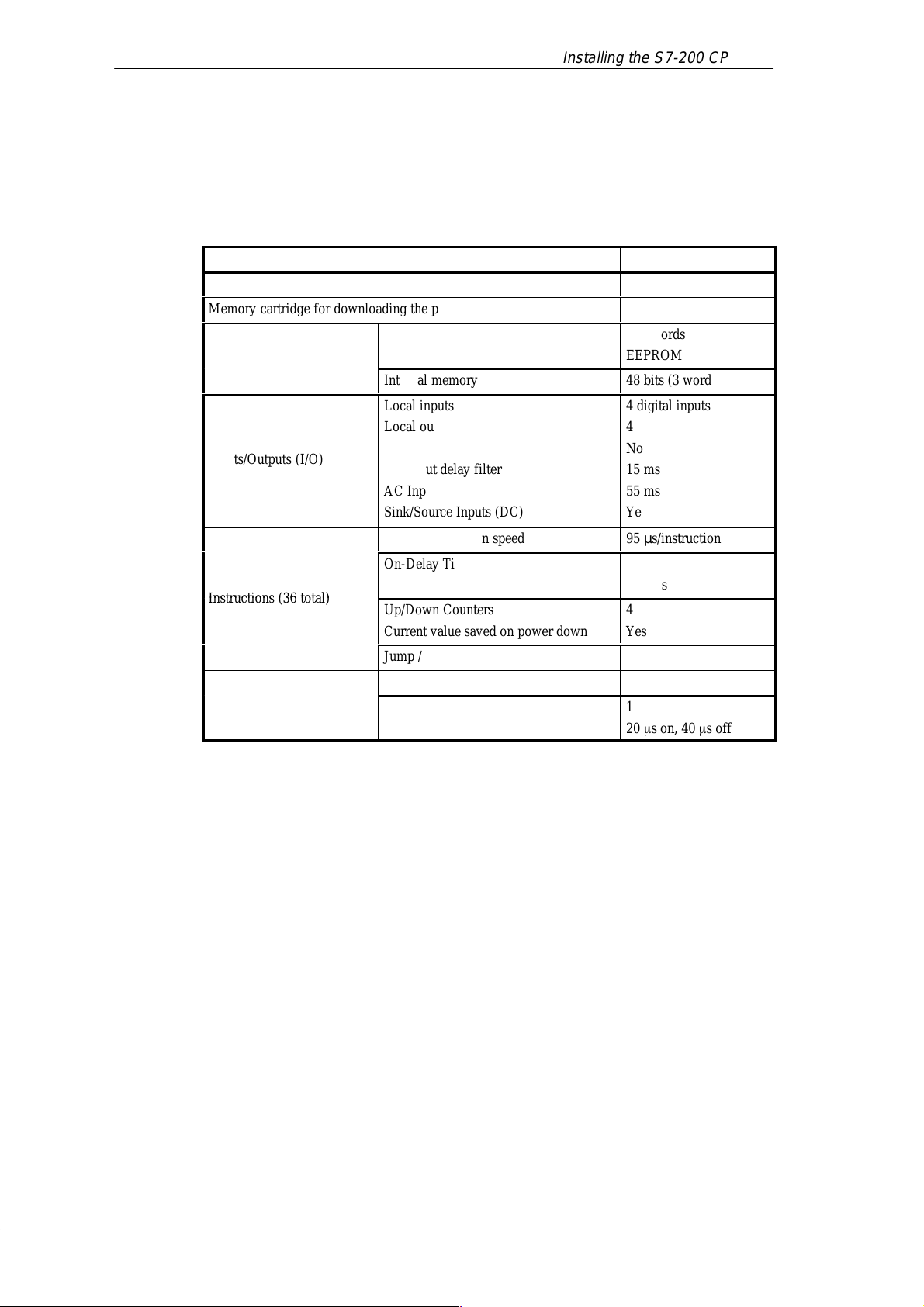

The CPU 210 is an integral part of the S7-200 family of Micro PLCs. Table 1-1 provides a

summary of the major features of the CPU 210.

Table 1-1 Features of the CPU 210

Installing the S7-200 CPU 210

Feature

CPU 210

Physical Size (length x width x depth) 90 x 80 x 62 mm

Memory cartridge for downloading the program

Program size

ББББББ

Memory

ББББББББББ

Storage type

Internal memory

Local inputs

ББББББ

ББББББ

Inputs/Outputs (I/O)

ББББББ

ББББББ

ББББББ

ББББББББББ

Local outputs

ББББББББББ

Expansion I/O

DC Input delay filter

ББББББББББ

AC Input delay filter

ББББББББББ

Sink/Source Inputs (DC)

ББББББББББ

Boolean execution speed

On-Delay Timers

ББББББÁББББББББББ

ructions

ББББББ

ББББББÁББББББББББ

Resolution

Up/Down Counters

Current value saved on power down

ББББББББББ

Jump / Label

Analog adjustment potentiometers

Additional Features

ББББББ

Hardware Input Interrupts

Interrupt response

ББББББББББ

Yes

256 words

ББББББ

EEPROM

48 bits (3 words)

4 digital inputs

ББББББ

4 digital outputs

ББББББ

No

15 ms

ББББББ

55 ms

ББББББ

Yes

ББББББ

95 µs/instruction

4

100 ms

ББББББ

4

Yes

ББББББ

Yes

ББББББ

1

1

20 s on, 40 s off

ББББББ

S7-200 Programmable Controller, CPU 210

C79000-G7076-C235-01

1-3

Page 14

Installing the S7-200 CPU 210

1.2 Pre-installation Considerations

Installation Configuration

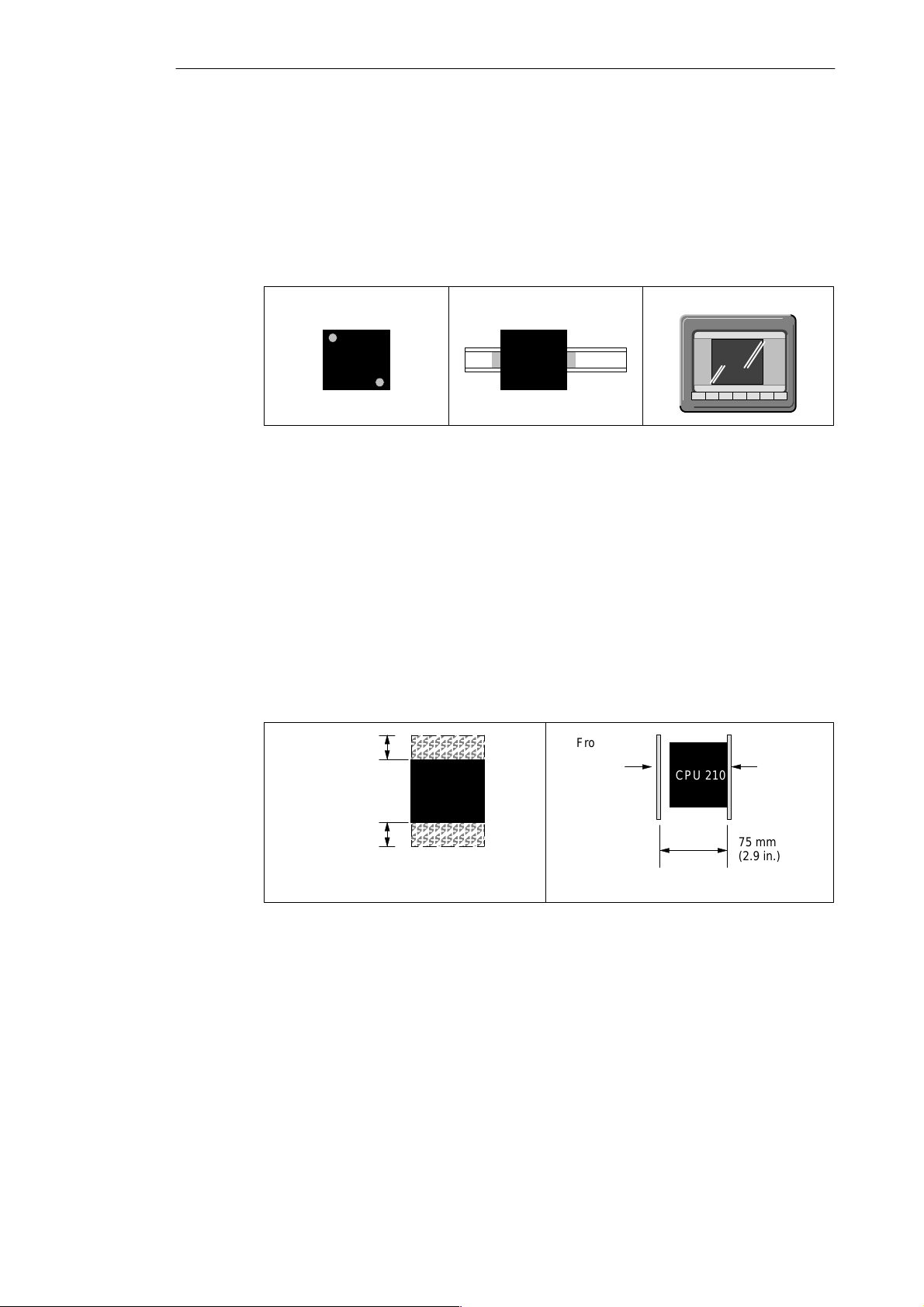

As shown in Figure 1-3, you can install a CPU 210 either on a panel or on a DIN rail. You can

mount the CPU 210 either horizontally or vertically.

Mounting on a Panel Mounting on a DIN Rail

CPU 210

Figure 1-3 Mounting Configurations

Clearance Requirements for Installing a CPU 210

Use the following guidelines as you plan your installation:

S The CPU 210 is designed for natural convection cooling. You must provide a clearance

of at least 25 mm (1 inch), both above and below the units, for proper cooling. See

Figure 1-4. Continuous operation of all electronic products at maximum ambient

temperature and load will reduce their life.

S If you are installing a CPU 210 on a panel, you must allow 75 mm (2.9 inches) for the

minimum panel depth. See Figure 1-4.

S Be sure to allow enough space in your mounting design to accommodate the I/O wiring

connections.

25 mm

(1 in.)

Clearance for cooling

CPU 210

CPU 210

Front of the

enclosure

Mounting in a Panel Box

CPU 210

Mounting

surface

CPU 210

1-4

25 mm

(1 in.)

Front View Side View

Figure 1-4 Clearance Requirements for Installing a CPU 210

S7-200 Programmable Controller, CPU 210

75 mm

(2.9 in.)

C79000-G7076-C235-01

Page 15

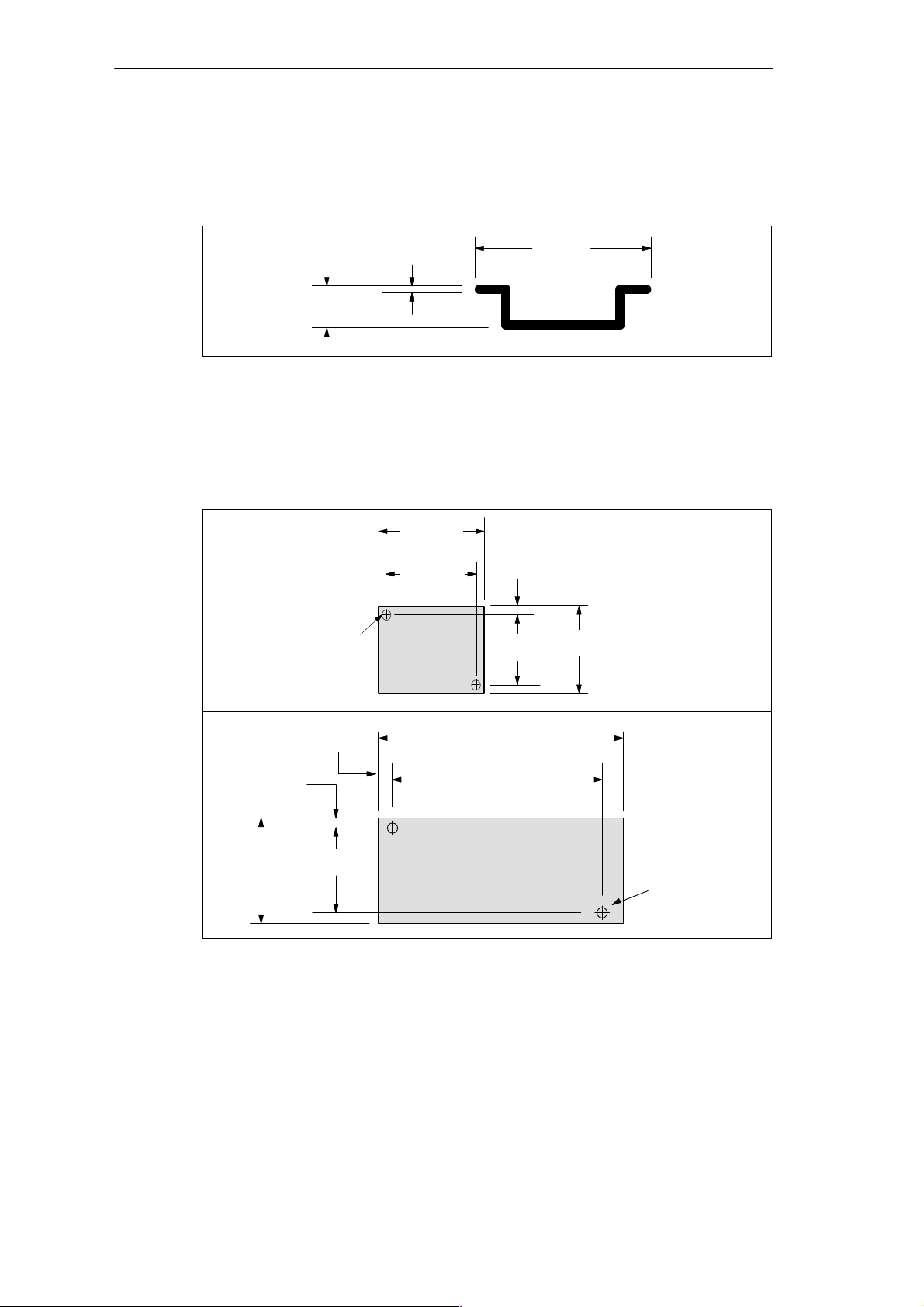

DIN Rail Requirements

The CPU 210 can be installed on a standard DIN rail (DIN EN 50 022). Figure 1-5 shows the

dimensions for this DIN rail.

Installing the S7-200 CPU 210

Figure 1-5 DIN Rail Dimensions

Panel-Mounting Dimensions

The CPU 210 and the PDS 210 include mounting holes to facilitate installation on panels.

Figure 1-6 provides the mounting dimensions.

Mounting Holes

(M4 or no. 8)

7.5 mm

(0.29 in.)

1.0 mm

(0.039 in.)

90 mm

(3.54 in.)

77.3 mm

(3.04 in.)

CPU 210

67.3 mm

(2.65 in.)

35 mm

(1.38 in.)

6.4 mm

(0.25 in.)

80 mm

(3.15 in.)

6.4 mm

(0.25 in.)

6.4 mm

(0.25 in.)

80 mm

(3.15 in.)

67.3 mm

(2.65 in.)

Figure 1-6 Mounting Dimensions for the CPU 210 and PDS 210

S7-200 Programmable Controller, CPU 210

C79000-G7076-C235-01

197 mm

(7.76 in.)

184.3 mm

(7.25 in.)

Program Development Station

(PDS 210)

Mounting Holes

(M4 or no. 8)

1-5

Page 16

Installing the S7-200 CPU 210

1.3 Installing a CPU 210

Warning

!

Mounting a CPU 210 on a Panel

Failure to disable all power to the CPU 210 and related equipment during installation or

removal procedures may result in death or serious personal injury , and/or damage to

equipment.

Disable all power to the CPU 210 and related equipment before installation or removal.

Always follow appropriate safety precautions and ensure that power to the CPU 210 is

disabled before installation.

To install a CPU 210 on a panel, follow these steps:

1. Locate, drill, and tap the mounting holes for DIN M4 or American Standard number 8

screws. Refer to Section 1.2 for mounting dimensions and other considerations.

2. Secure the CPU 210 onto the panel, using DIN M4 or American Standard number 8

screws.

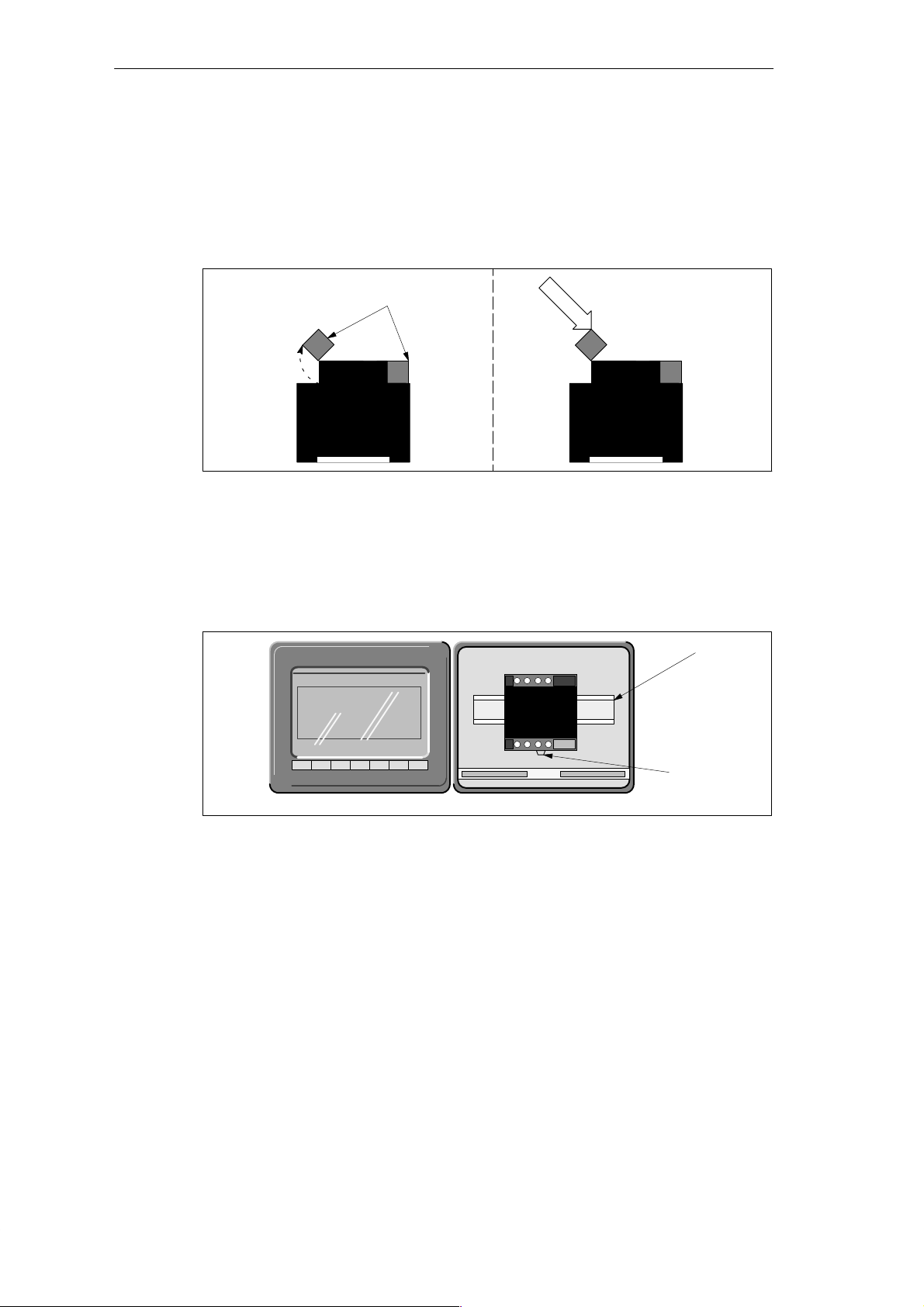

Installing a CPU 210 on a DIN Rail

To install a CPU 210 on a DIN rail (as shown in Figure 1-7), follow these steps:

1. Secure the DIN rail every 75 mm (approximately 3 inches) to the mounting panel.

2. Snap open the DIN clip (located on the bottom of the CPU 210) and hook the back of the

module onto the DIN rail.

3. Snap the DIN clip closed, carefully checking to ensure that the DIN clip fastened the

module securely onto the rail.

Note

Modules in an environment with high vibration potential or modules that have been

installed in a vertical position may require DIN Rail Stops.

Figure 1-7 Installing a CPU 210 on a DIN Rail

CPU 210

Fasten DIN rail every 75 mm

(approximately 3 inches)

DIN Clip

1-6

S7-200 Programmable Controller, CPU 210

C79000-G7076-C235-01

Page 17

Installing a CPU 210 in a Panel Box

To install a CPU 210 in a panel box, follow these steps:

1. Open one of the I/O access covers on the CPU 210. As shown in Figure 1-8, remove the

access cover by gently pressing against the access cover until the hinges spring free.

Repeat this procedure for the other access cover.

Installing the S7-200 CPU 210

Open the access cover. Gently press against the

CPU 210

CPU 210

(Side View)

(Side View)

Access covers

access cover until the

access cover snaps off.

CPU 210

CPU 210

(Side View)

(Side View)

Figure 1-8 Removing the Access Covers from the CPU 210

2. Snap open the DIN clip (located on the bottom of the module).

3. Open the panel box and hook the back of the module onto the DIN rail. See Figure 1-9.

4. Snap the DIN clip closed, carefully checking to ensure that the DIN clip fastened the

module securely onto the rail.

DIN rail

CPU 210

Figure 1-9 Installing the CPU 210 in a Panel Box

S7-200 Programmable Controller, CPU 210

C79000-G7076-C235-01

DIN Clip

1-7

Page 18

Installing the S7-200 CPU 210

1.4 Installing the Field Wiring

Warning

!

General Guidelines

Failure to disable all power to the CPU 210 and related equipment during installation or

removal procedures may result in death or serious personal injury , and/or damage to

equipment.

Disable all power to the CPU 210 and related equipment before installing or removing field

wiring.

Always follow appropriate safety precautions and ensure that power to the CPU 210 is

disabled before installing field wiring.

The following items are general guidelines for designing the installation and wiring of your

S7-200 CPU 210:

S Ensure that you follow all applicable electrical codes when wiring the CPU 210. Install

and operate all equipment according to all applicable national and local standards.

Contact your local authorities to determine which codes and standards apply to your

specific case.

S Always use the proper wire size that will carry the required current. The CPU 210 accepts

wire sizes from 1.50 to 0.50 mm

S Ensure that you do not over-tighten the connector screws. The maximum torque is

0.56 N-m (5 inches-pounds).

S Always use the shortest wire possible (maximum 500 meters shielded, 300 meters

unshielded). Wiring should be run in pairs, with a neutral or common wire paired with a

hot or signal-carrying wire.

S Separate AC wiring and high-energy , rapidly switched DC wiring from low-energy signal

wiring.

S Properly identify and route the wiring to the CPU 210, using strain relief for the wiring as

required. For more information about identifying the terminals, see the data sheets in

Appendix A.

S Install appropriate surge suppression devices for wiring that is subject to lightning surges.

S External power should not be applied to an output load in parallel with a DC output point.

This may cause reverse current through the output, unless a diode or other barrier is

provided in the installation.

2

(14 to 22 AWG).

1-8

Warning

!

Control devices can fail in an unsafe condition, resulting in unexpected operation of

controlled equipment.

Such unexpected action could result in death or serious personal injury , and/or equipment

damage.

Consider using an emergency stop function, electromechanical overrides, or other

redundant safeguards that are independent of the programmable controller.

S7-200 Programmable Controller, CPU 210

C79000-G7076-C235-01

Page 19

Installing the S7-200 CPU 210

Grounding and Circuit Referencing Guidelines for Using Isolated Circuits

The following items are grounding and circuit guidelines for using isolated circuits:

S You should identify the reference point (0 voltage reference) for each circuit in the

installation, and the points at which circuits with possible different references can connect

together. Such connections can result in unwanted current flows that can cause logic

errors or damage circuits. A common cause of different reference potentials is grounds

which are physically separated by long distances. When devices with widely separated

grounds are connected with a sensor cable, unexpected currents can flow through the

circuit created by the cable and the ground. Even over short distances, load currents of

heavy machinery can cause differences in ground potential or directly induce unwanted

currents by electromagnetic induction. Power supplies that are improperly referenced

with respect to each other can cause damaging currents to flow between their associated

circuits.

S The CPU 210 includes isolation boundaries at certain points to help prevent unwanted

current flows in your installation. When you plan your installation, you should consider

where these isolation boundaries are, and where they are not provided. You should also

consider the isolation boundaries in associated power supplies and other equipment, and

where all associated power supplies have their reference points.

S You should choose your ground reference points and use the isolation boundaries

provided to interrupt unneeded circuit loops that could allow unwanted currents to flow.

Remember to consider temporary connections which may introduce a new circuit

reference, such as the connection of a programming device to the CPU.

S When locating grounds, you must also consider safety grounding requirements and the

proper operation of protective interrupting devices.

The following descriptions are an introduction to general isolation characteristics of the

CPU 210, but some features may be different on specific products. Consult the data sheet in

Appendix A for your product for specifications of which circuits include isolation boundaries

and the ratings of the boundaries. Isolation boundaries rated less than 1500 V AC are

designed as functional isolation only and should not be depended on as safety boundaries.

S CPU logic reference is the same as DC Sensor Supply M.

S CPU logic reference is the same as the input power supply M on a CPU with DC power

supply.

S CPU logic is isolated from ground to 100 VDC.

S DC digital inputs and outputs are isolated from CPU logic to 500 V AC.

S Relay outputs and AC inputs are isolated from CPU logic to 1500 V AC.

S Relay output groups are isolated from each other by 1500 V AC.

S AC power supply Line and Neutral are isolated from ground, the CPU logic, and all I/O to

1500 V AC.

S7-200 Programmable Controller, CPU 210

C79000-G7076-C235-01

1-9

Page 20

Installing the S7-200 CPU 210

Using the Optional Field Wiring Connector

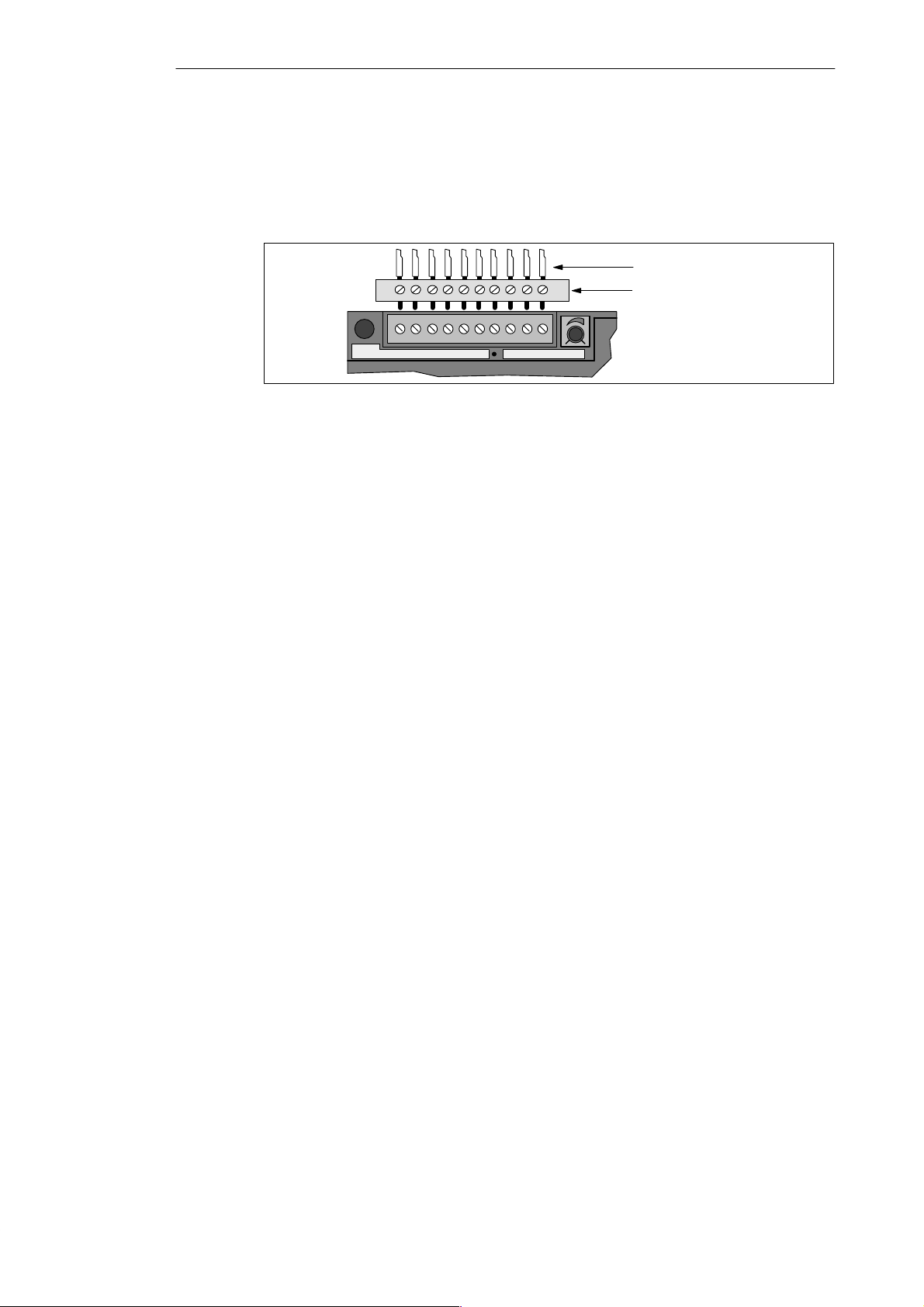

The optional field wiring fan-out connector (Figure 1-10) allows for field wiring connections to

remain fixed when you remove and re-install the CPU 210. Refer to Appendix F for the order

number.

DC

M L+ 0.0 0.1 0.2 0.3

OUTPUTS

Figure 1-10 Optional Field Wiring Connector

Guidelines for AC Installation

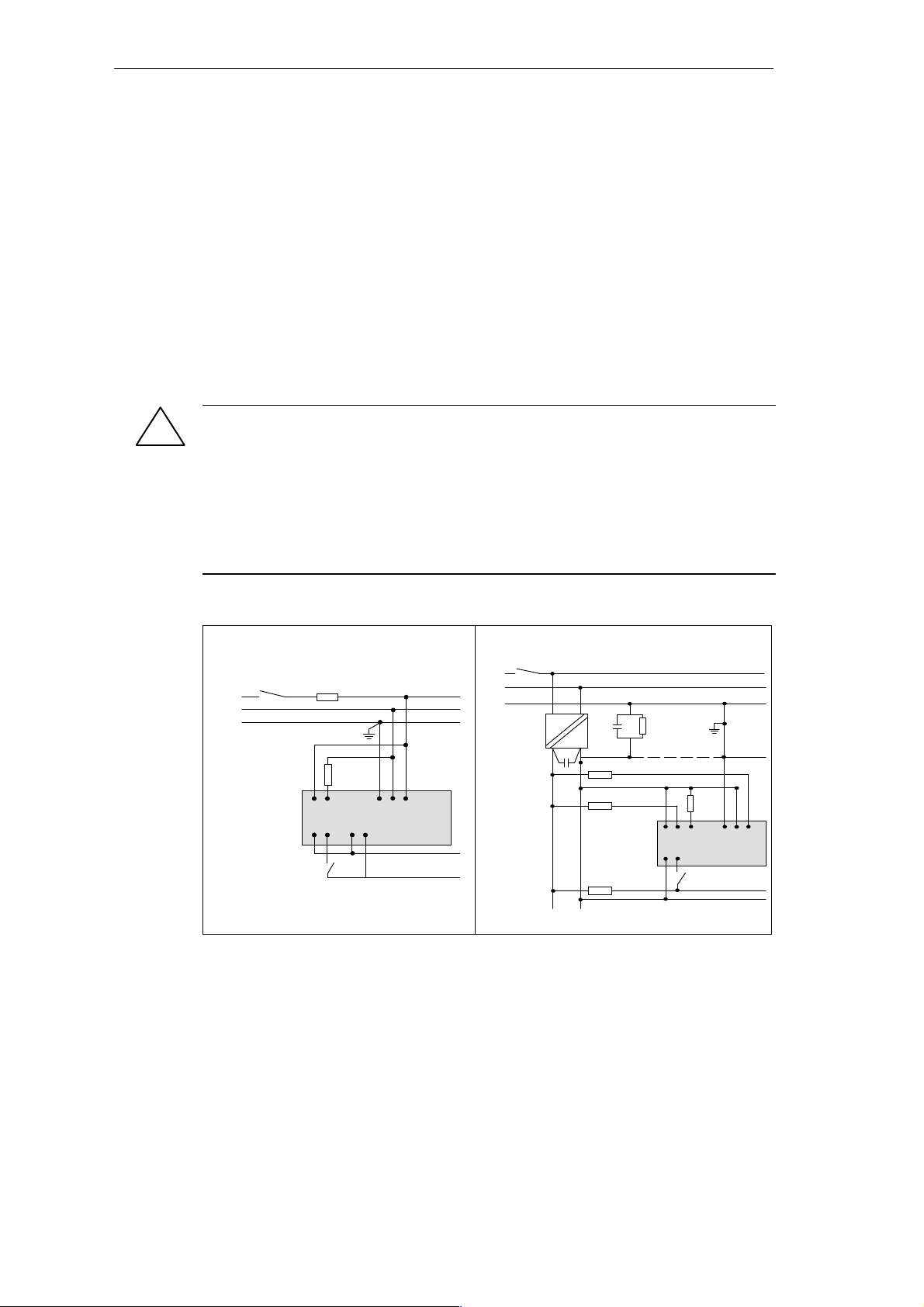

The following items are general wiring guidelines for AC installations. Refer to Figure 1-1 1.

S Provide a single disconnect switch (A) that removes power from the CPU, all input

circuits, and all output (load) circuits.

S Provide overcurrent devices (B) to protect the CPU power supply, the output points, and

the input points. You can also fuse each output point individually for greater protection.

External overcurrent protection for input points is not required when you use the 24 VDC

sensor supply (C) from the CPU 210. This sensor supply is short-circuit protected.

S Connect all CPU 210 ground terminals to the closest available earth ground (D) to

provide the highest level of noise immunity . It is recommended that all ground terminals

be connected to a single electrical point. Use 14 AWG or 1.5 mm

connection.

If required, you can use a DC Sensor Supply from the CPU 210 to supply power for the

inputs (E). Refer to the guidelines for DC installation, especially in regard to connecting and

external power supply in parallel with the power supply of the CPU 210.

↓ M L+ 24V DC

Field Wiring

Fan-out Connector

2

wire for this

Guidelines for DC Installation

The following items are general wiring guidelines for isolated DC installations. Refer to

Figure 1-1 1.

S Provide a single disconnect switch (1) that removes power from the CPU, all input

circuits, and all output (load) circuits.

S Provide overcurrent devices to protect the CPU power supply (2), the output points (3),

and the input points (4). You can also fuse each output point individually for greater

protection. External overcurrent protection for input points is not required when you use

the 24 VDC sensor supply from the CPU 210. This sensor supply is internally current

limited.

S Ensure that the DC power supply has sufficient surge capacity to maintain voltage during

sudden load changes. External capacitance (5) may be required.

1-10

S7-200 Programmable Controller, CPU 210

C79000-G7076-C235-01

Page 21

Installing the S7-200 CPU 210

S Install or equip ungrounded DC power supplies with a resistor and a capacitor in parallel

(6) from the power source common to protective earth ground. The resistor provides a

leakage path to prevent static charge accumulations, and the capacitor provides a drain

for high frequency noise. Typical values are 1M Ω and 4700 pf. You can also create a

grounded DC system by connecting the DC power supply to ground (7).

S Connect all CPU 210 ground terminals to the closest available earth ground (8) to

provide the highest level of noise immunity . It is recommended that all ground terminals

be connected to a single electrical point. Use 14 AWG or 1.5 mm

connection.

2

wire for this

S Always supply 24 VDC circuits from a source that provides safe electrical separation from

120/230 VAC power and similar hazards. Refer to the following documents for standard

definitions of “safe separation”: PEL V (protected extra low voltage) according to

EN60204-1, and Class 2 or Limited Voltage/Current Circuit according to UL 508.

Warning

!

Connecting an external 24 VDC power supply in parallel with the DC sensor supply of the

CPU 210 can result in a conflict between the two supplies as each seeks to establish its

own preferred output voltage level. The result of this conflict can be shortened lifetime or

immediate failure of one or both power supplies, with consequent unpredictable operation

of the PLC system. Unpredictable operation could result in death or serious injury to

personnel, and/or damage to equipment and property .

The CPU 210 DC Sensor Supply and any external power supply should provide power to

different points, with at most one connection between the two supplies.

120/230 V AC Using a Single Overcurrent

Switch to Protect the CPU and Load Wiring

L1

N

PE

24 VDC

L1

N

PE

(A)

(E)

DO

DI

(B)

(D)

(B)

Fuse

(C)

M L+

P/S

CPU 210

AC/DC/Rly

Figure 1-11 Wiring Guidelines for AC and DC Installation

Isolated DC System Installation

(1)

(5)

Floating (6) or Grounded (7)

AC

DC

(2)

(3)

(4)

L+ M

(6)

(7)

DO

DI

(8)

P/S

CPU 210

DC/DC/DC

S7-200 Programmable Controller, CPU 210

C79000-G7076-C235-01

1-11

Page 22

Installing the S7-200 CPU 210

1.5 Using Suppression Circuits

Install or equip inductive loads with suppression circuits that limit voltage rise on loss of

power. Use the following guidelines to design adequate suppression. The ef fectiveness of a

given design is dependent on the application, and you must verify it for a particular use. Be

sure all components are rated for use in the application.

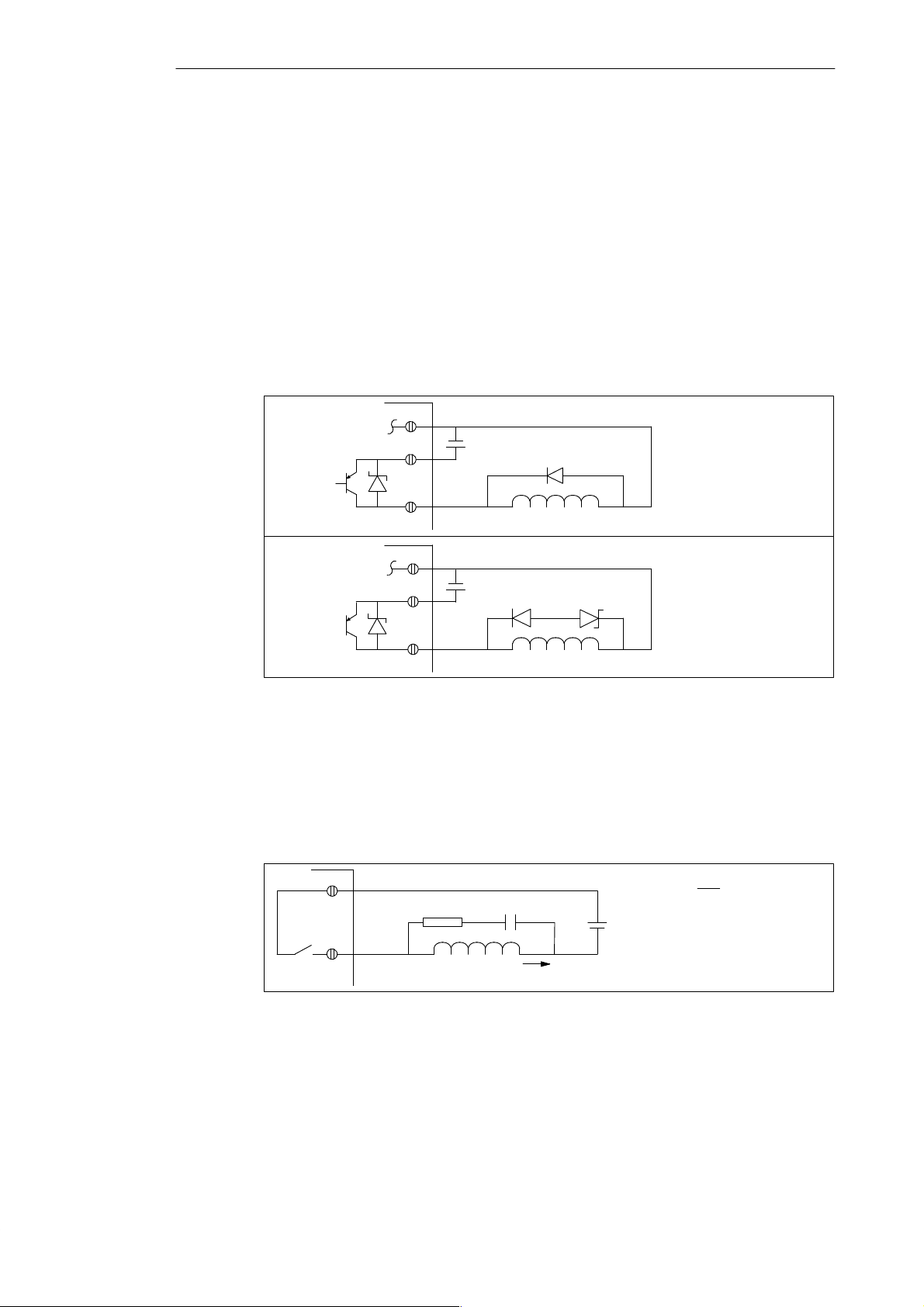

Protecting DC Transistors

The DC transistor outputs of the CPU 210 contain zener diodes that are adequate for many

installations. Use external suppression diodes for either large or frequently switched

inductive loads to prevent overpowering the internal diodes. Figure 1-12 shows typical

applications for DC transistor outputs.

Diode

Suppression

Zener Diode

Suppression

Figure 1-12 Diode Suppression and Zener Diode Suppression

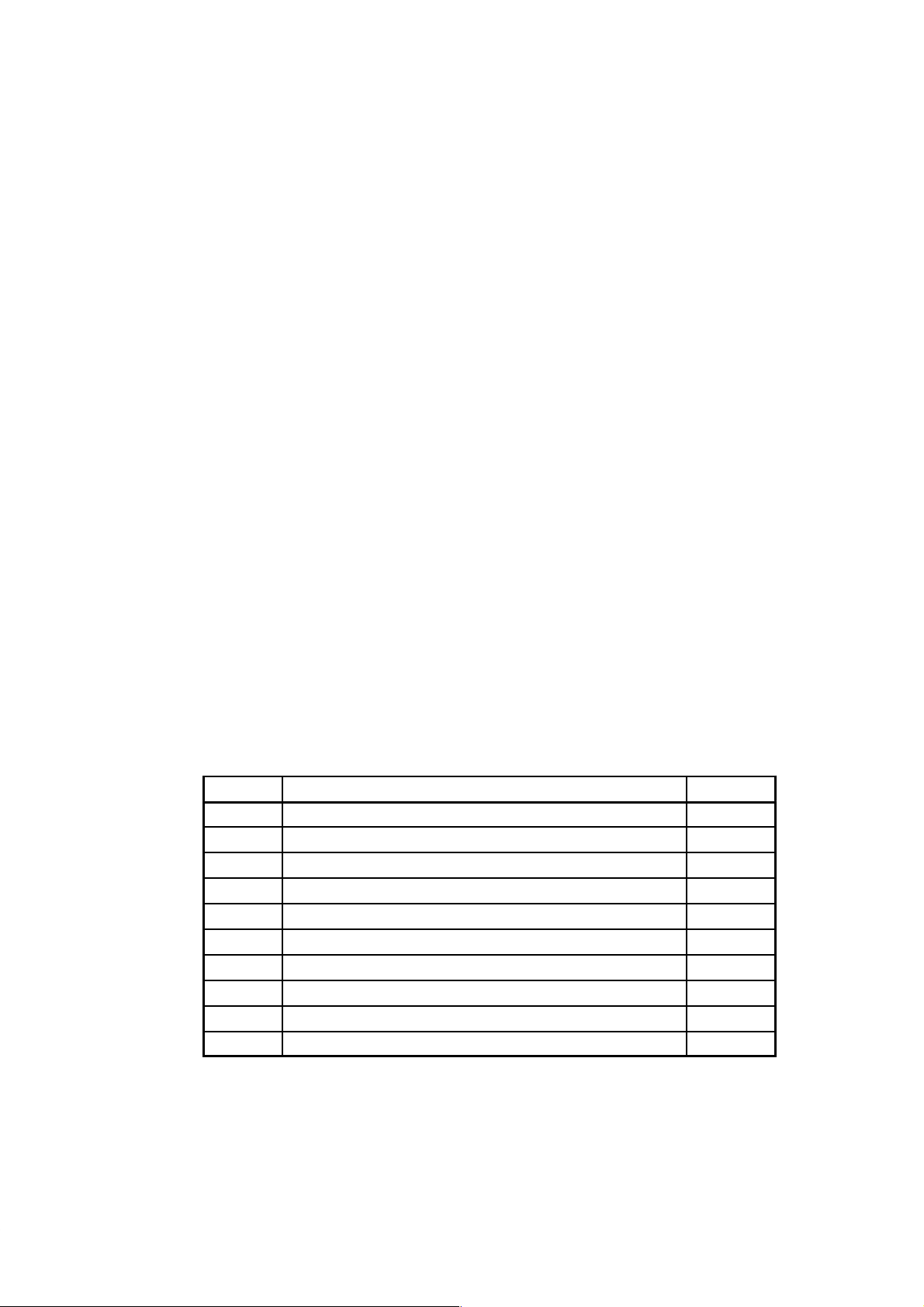

Protecting Relays Controlling DC Power

Resistor/capacitor networks, as shown in Figure 1-13, can be used for low voltage (30 V) DC

relay applications. Connect the network across the load. You can also use diode

suppression, as shown in Figure 1-12, for DC relay applications. A threshold voltage of up to

36 V is allowed if you use a reverse zener diode.

+VDC

+VDC

RC

Inductor

(1)

Inductor

(1) (2)

Inductor

I

L

+VDC

(1) IN4001 diode or

equivalent

(1) IN4001 diode or

equivalent

(2) 8.2 V zener, 5 W

V

DC

R

I

L

where minimum R = 12Ω

K

C I

L

where K is 0.5 to 1 µ F/A

1-12

Figure 1-13 Resistor/Capacitor Network on Relay-Driven DC Load

S7-200 Programmable Controller, CPU 210

C79000-G7076-C235-01

Page 23

Installing and Using the STEP 7-Micro/WIN Version 2.0 Software

This manual describes Version 2.0 of STEP 7-Micro/WIN. Previous versions of the software

may operate differently.

STEP 7-Micro/WIN is a Windows-based software application used for programming the

S7-200 Micro PLC (programmable logic controller). The STEP 7-Micro/WIN programming

software package provides a set of tools required to program the S7-210 in either statement

list (STL) or ladder logic (LAD) programming language.

In order to use STEP 7-Micro/WIN, you must have the following equipment:

S Recommended: a personal computer (PC) with an 80486 or greater processor and

8 Mbyte of RAM or a Siemens programming device (such as a PG 740);

computer requirement: 80386 with 8 Mbyte of RAM

S A PC/PPI cable connected to your communications port (COM)

S A program development station (PDS 210)

S VGA monitor, or any monitor supported by Microsoft Windows

S At least 35 Mbyte of free hard disk space (recommended)

S Microsoft Windows 3.1, Windows for Workgroups 3.11, Windows 95, or Windows NT 3.51

or greater

S Optional but recommended: any mouse supported by Microsoft Windows

STEP 7-Micro/WIN provides extensive online help. Use the Help menu command or press

F1 to obtain the most current information.

minimum

2

Chapter Overview

Section

2.1 Installing the STEP 7-Micro/WIN Version 2.0 Software 2-2

2.2 Establishing Communication with the PDS 210 2-3

2.3 Configuring the Preferences for STEP 7-Micro/WIN 2-5

2.4 Creating and Saving a Project 2-6

2.5 Creating a Program 2-7

2.6 Downloading a Program 2-10

2.7 Using Symbolic Addressing 2-13

2.8 Using the Status Chart 2-15

2.9 Debugging and Monitoring Your Program 2-16

2.10 Error Handling for the PDS 210 2-17

S7-200 Programmable Controller, CPU 210

C79000-G7076-C235-01

Description Page

2-1

Page 24

Installing and Using the STEP 7-Micro/WIN Version 2.0 Software

2.1 Installing the STEP 7-Micro/WIN Version 2.0 Software

Pre-installation Instructions

Before running the setup procedure, do the following:

S If a previous version of STEP 7-Micro/WIN is installed, back up all application programs

to diskette.

S Make sure all applications are closed, including the Microsoft Office toolbar.

Installation may require that you restart your computer.

Installation Instructions for Windows 3.1

If you have Windows 3.1 (Windows for Workgroups 3.11 or Windows NT) on your machine,

use the following procedure to install the STEP 7-Micro/WIN software:

1. Start by inserting Disk 1 in the disk drive of your computer (usually designated drive A: or

drive B:).

"

2. From the Program Manager, select the menu command File

3. In the Run dialog box, type a:\setup and click on the “OK” button. This starts the setup

procedure.

4. Follow the online setup procedure to complete the installation.

Run...

Installation Instructions for Windows 95

If you have Windows 95 on your machine, you can use the following procedure to install the

STEP 7-Micro/WIN software:

1. Start by inserting Disk 1 in the disk drive of your computer (usually designated drive A: or

drive B:).

2. Click once on the Start button to open the Windows 95 menu.

3. Click on the Run... menu item.

4. In the Run dialog box, type a:\setup and click on the “OK” button. This starts the setup

procedure.

5. Follow the online setup procedure to complete the installation.

Troubleshooting the Installation

The following situations can cause the installation to fail:

S Not enough memory: you need to have at least 35 Mbyte of free space on your hard disk.

S Bad diskette: verify that the diskette is bad, then call your salesman or distributor.

S Operator error: start over and read the instructions carefully .

S Failure to close any open applications, including the Microsoft Office toolbar .

Note

x

Review the README

about STEP 7-Micro/WIN. (In the

C = French, D = Spanish, E = Italian.)

.TXT file included on your diskettes for the most recent information

x

position, the letter A = German, B = English,

2-2

S7-200 Programmable Controller, CPU 210

C79000-G7076-C235-01

Page 25

Installing and Using the STEP 7-Micro/WIN Version 2.0 Software

2.2 Establishing Communication with the PDS 210

Connecting Your Computer to the PDS 210 for PPI Communications

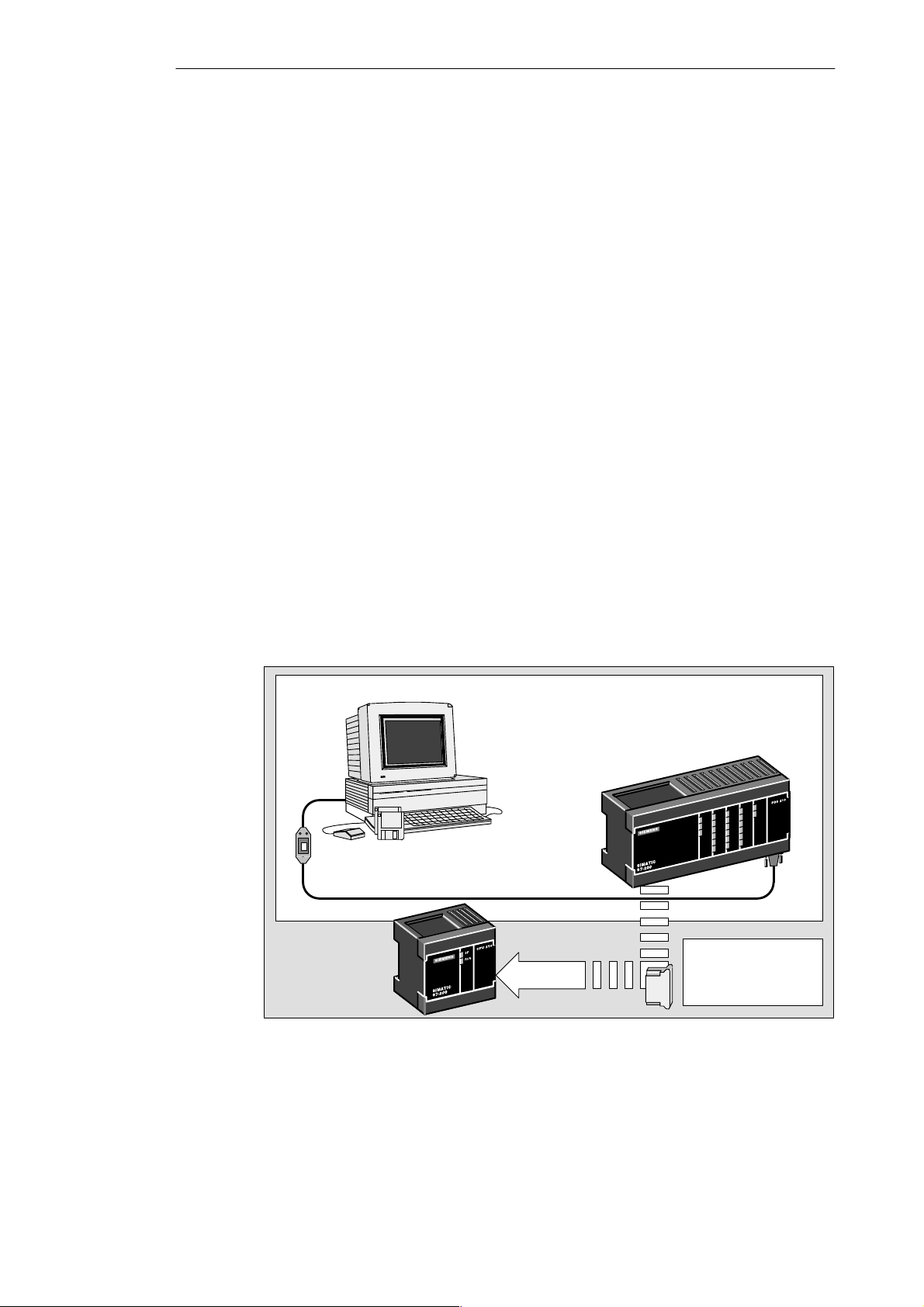

Figure 2-1 shows a typical configuration for connecting your personal computer to your

PDS 210 with the PC/PPI cable. To establish proper communications between the

components, follow these steps:

1. Set the dipswitches on the PC/PPI cable for the baud rate of 9600 baud.

2. Connect the RS-232 end of the PC/PPI cable labeled PC to the communications port of

your computer, either COM1 or COM2, and tighten the connecting screws.

3. Connect the other end (RS-485) of the PC/PPI cable to the communications port of the

PDS 210, and tighten the connecting screws.

Dipswitch Settings:

0 1 0 0 = 9600 baud

RS-232

Computer

PC/PPI cable

Figure 2-1 Communicating with a PDS 210 in PPI Mode

Program development station

(PDS 210)

RS-485

S7-200 Programmable Controller, CPU 210

C79000-G7076-C235-01

2-3

Page 26

Installing and Using the STEP 7-Micro/WIN Version 2.0 Software

Setting Up the Communications Parameters

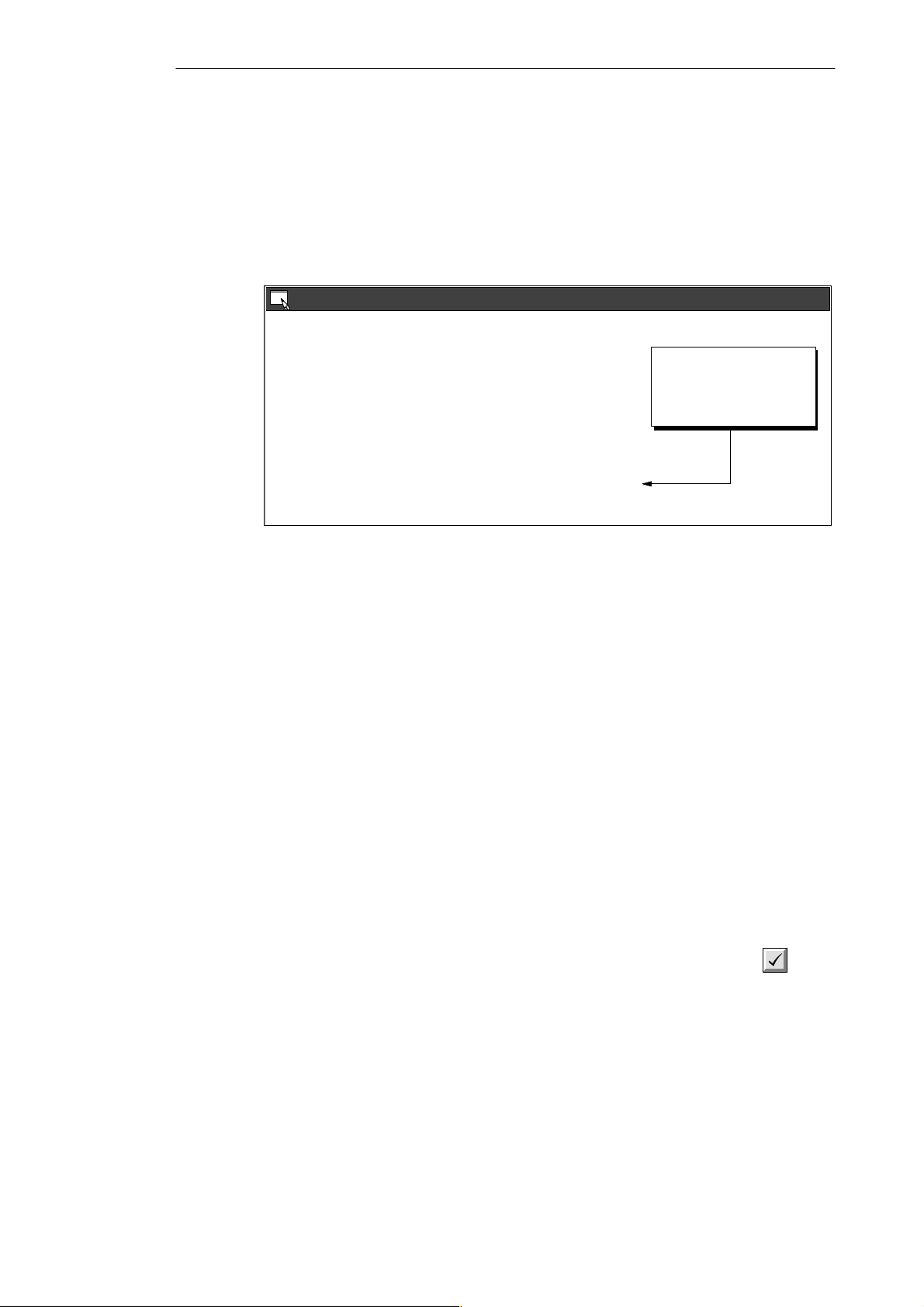

Figure 2-2 shows the Setup Communications dialog box. The first two port options are for PC

communication ports. The address for the PDS 210 is 2 and cannot be changed. To set up

the communication parameters, follow these steps:

1. Select the menu command Setup " Communications...

2. Verify that the information in the dialog box is correct for your configuration. Remember

that the CPU address for the PDS 210 is always 2, and that the baud rate is always

9600.

3. Confirm your selections by clicking the “OK” button.

Project Edit View CPU Debug Tools Setup Window Help

✂

Communications

Port

COM1

COM2

MPI Card

aud Rate:

B

9,600

RQ Number For MPI Card::

I

10

Setup

Preferences...

C

ommunications...

PU Address:

C

Micro/WIN A

ddress:

H

T

Figure 2-2 Setting Up Communications with the PDS 210

OK

Cancel

2

0

ighest Master Address:

31

arget Token Rotation Time::

39

Find

2-4

S7-200 Programmable Controller, CPU 210

C79000-G7076-C235-01

Page 27

Installing and Using the STEP 7-Micro/WIN Version 2.0 Software

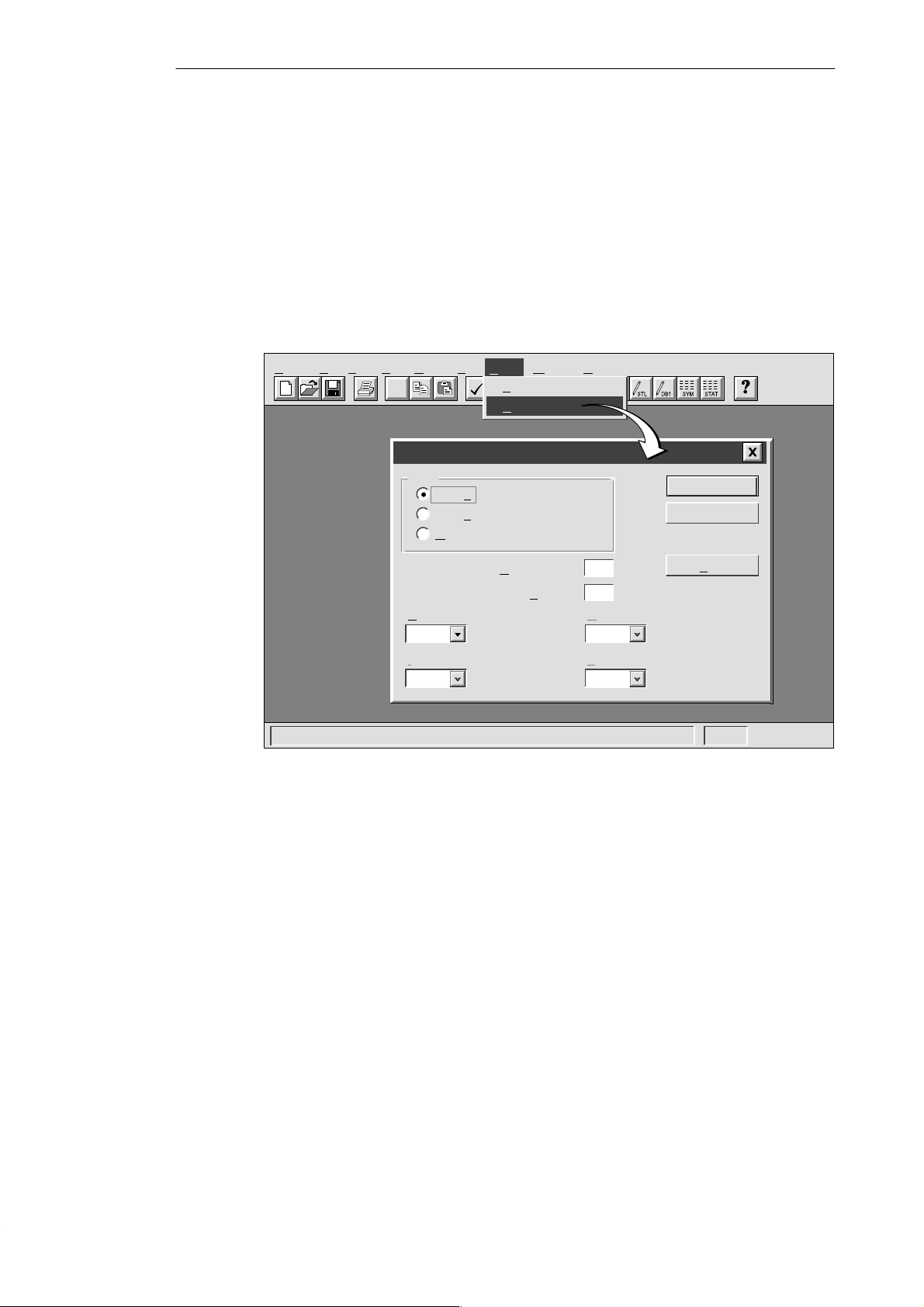

2.3 Configuring the Preferences for STEP 7-Micro/WIN

Before creating a new project, specify the preferences for your programming environment. To

select your preferences, follow these steps:

"

1. Select the menu command Setup

2. Select your programming preferences in the dialog box that appears.

3. Confirm your choices by clicking the “OK” button.

Preferences... as shown in Figure 2-3.

rmat

Setup

Preferences...

C

ommunications...

Language

English

Symbol Table

Minimized

Status Chart

Data Size

Project Edit View CPU Debug Tools Setup Window Help

✂

Preferences

Default Editor

STL Editor

L

adder Editor

Mnemonic Set

International

SIMATIC

Initial Window States

Maximize All

Program Editor

Normalized

Data Block Editor

Minimized Minimized

Options for an Uploaded Data Block

Retain Format and Comments

Data Fo

Hexadecimal Byte

OK

Cancel

Figure 2-3 Selecting Your Programming Preferences

S7-200 Programmable Controller, CPU 210

C79000-G7076-C235-01

2-5

Page 28

Installing and Using the STEP 7-Micro/WIN Version 2.0 Software

2.4 Creating and Saving a Project

Before you create a program, you must create or open a project. When you create a new

project, STEP 7-Micro/WIN opens the following editors:

S Ladder Editor or Statement List Editor (depending on your selected preference)

S Data Block Editor (not applicable for the PDS 210)

S Status Chart

S Symbol Table

Creating a New Project

The Project menu command allows you to create a new project, as shown in Figure 2-4.

Select the menu command Project

select the CPU type from the drop-down list box, the software displays only those options

which are available for your CPU. If you select “None,” no CPU-specific restrictions are

placed on your program. When you download the program, the CPU notifies you if you have

used options that are not available. For example, if your program uses an instruction that is

not supported by your CPU, the program is rejected.

"

New.... The CPU Type dialog box is displayed. If you

Note

STEP 7-Micro/WIN does not range-check parameters. For example, you can enter MW999

as a parameter to a ladder instruction even though it is an invalid parameter. This error

would be identified when you attempt to download the program.

Figure 2-4 Creating a New Project

Saving a Project

You can save a copy of the active project to a different name or location by selecting the

menu command Project " Save As... You can save all of the components of your project by

selecting the menu command Project

Project

Project View CPU Setup Help

New... Ctrl+N

O

pen... Ctrl+O

1

c:\microwin\project1.prj

2 c:\microwin\project2.prj

3

c:\microwin\project3.prj

Ex

it

✂

CPU Type

Select or read the CPU type from your PLC if you would like the software to

limit the available options to only those supported by a specific CPU.

LAD STL SYM STATDB1

PDS 210CPU Type:

OK

"

Save All or by clicking the Save button:

Read CPU Type

Communications...

Cancel

2-6

S7-200 Programmable Controller, CPU 210

C79000-G7076-C235-01

Page 29

Installing and Using the STEP 7-Micro/WIN Version 2.0 Software

2.5 Creating a Program

STEP 7-Micro/WIN allows you to create the user program (OB1) with either the Ladder Editor

or the Statement List Editor.

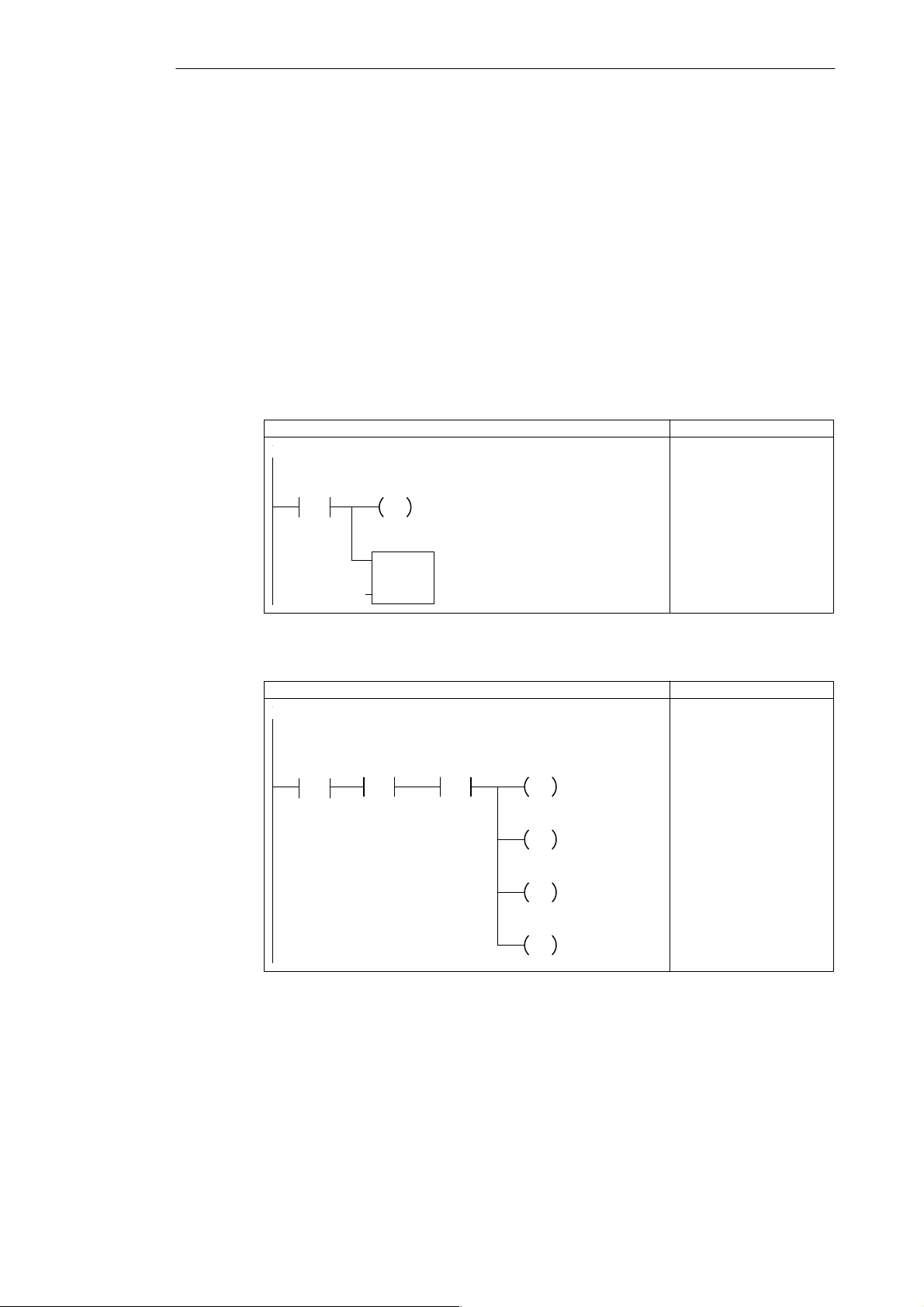

Entering Your Program in Ladder

The Ladder Editor window allows you to write a program using graphical symbols. See

Figure 2-5. The toolbar includes some of the more common ladder elements used to enter

your program. The first (left) drop-down list box contains instruction categories. You can

access these categories by clicking or pressing F2. After a category is selected, the second

drop-down list contains the instructions specific to that category . To display a list of all

instructions in alphabetic order, press F9 or select the All Instructions category.

Each network allows two types of comments:

S Single-line network title comments are always visible in the ladder display . You can

access the network editor by double-clicking anywhere in the network title region.

S Multi-line network comments are only visible through a dialog box, but can be printed (if

that option has been selected through the Page Setup dialog). You can access the

network comment editor by double-clicking anywhere in the network title region.

To start entering your program, follow these steps:

1. To enter a program title, select the menu command Edit

2. To enter ladder elements, select the type of element you want by clicking the

corresponding icon button or selecting from the instruction list.

3. Type the address or parameter in each text field and press ENTER.

To change or replace one of the elements, move the cursor to that element and select the

new element. You can also cut, copy, or paste elements at the cursor location.

"

Program Title.

Ladder Editor - project1.ob1

Contacts Normally Open

Network 1

NETWORK TITLE (single line)

I0.0

Figure 2-5 Ladder Editor Window

F3F2

Press ENTER or

double-click to

place element.

F4 F5 F8F7F6 F10

Double click here to

access the network title

and comment editor.

S7-200 Programmable Controller, CPU 210

C79000-G7076-C235-01

2-7

Page 30

Installing and Using the STEP 7-Micro/WIN Version 2.0 Software

Entering Your Program in Statement List

The Statement List (STL) Editor is a free-form text editor which allows a certain degree of

flexibility in the way you choose to enter program instructions. Figure 2-6 shows an example

of a statement list program.

You can cut, copy, and paste in the STL Editor. STEP 7-Micro/WIN also includes

search-and-replace functions.

STL

STL Editor - project1.ob1

// Program for a Home Security System

NETWORK 1 //Sound the alarm!

LD I0.3 // If (the panic alarm has been turned on)

LDW>= T0, +600 // or (if the alert timer is >= 60 seconds

A I0.2 // and the system is armed)

OLD // then

S M0.1, 1 // set the high-level alarm bit

S Q0.3, 1 // set the modem dialer bit

R M0.2, 1 // reset the low-level alarm bit

Network 2 //Evaluate the system status.

LDN I0.0 // If zone 1 is open

ON I0.1 // or if Zone 2 is open

To allow viewing the

program in STL or Ladder,

divide segments of code

with keyword NETWORK.

Figure 2-6 STL Editor Window with Sample Program

To enter an STL program, follow these guidelines:

S Start each comment with a double slash (//). Each additional comment line must also

begin with a double slash.

S End each line with a carriage return.

S Separate each instruction from its address or parameter with a space or tab.

S Do not use a space between the operand type and the address (for example, enter I0.0,

not I 0.0).

S Separate each operand within an instruction with a comma, space, or tab.

S Use quotation marks when entering symbol names. For example, if your symbol table

contains the symbol name Start1 for the address I0.0, enter the instruction as follows:

LD “Start1”

To be able to view an STL program in ladder, you must divide segments of code into

separate networks by entering the keyword NETWORK. (Network numbers are generated

automatically after you compile or upload the program.)

Compiling the Program

After completing a network or series of networks, you can check the syntax of your code by

selecting the menu command CPU

2-8

"

Compile or by clicking the Compile button:

S7-200 Programmable Controller, CPU 210

C79000-G7076-C235-01

Page 31

Installing and Using the STEP 7-Micro/WIN Version 2.0 Software

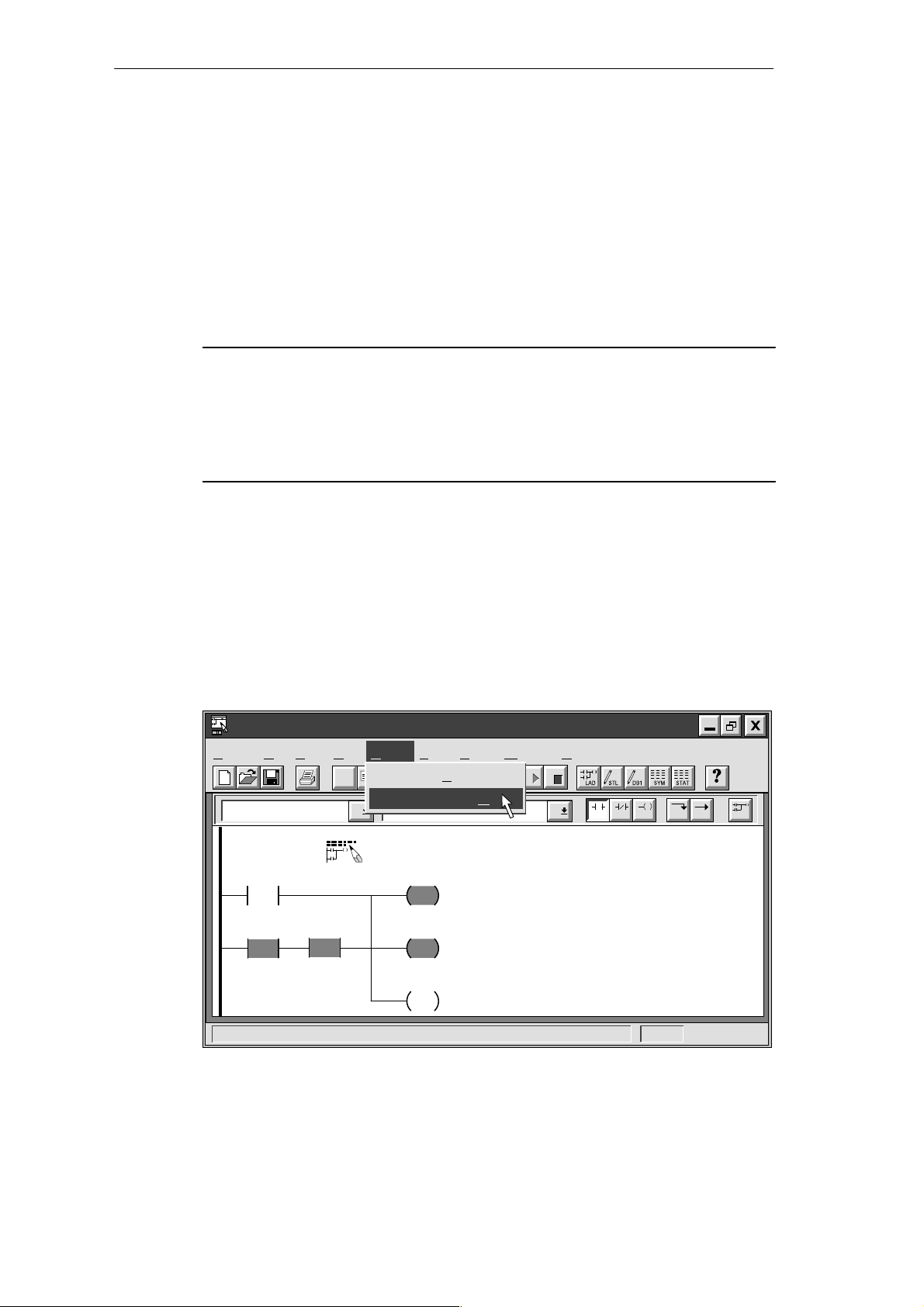

Viewing a Program in Ladder or Statement List

You can view a program in either ladder or STL by selecting the menu command View

"

or View

Ladder, as shown in Figure 2-7.

When you change the view from STL to ladder and back again to STL, you may notice

changes in the presentation of the STL program, such as:

S Instructions and addresses are changed from lower case to upper case.

S Spaces between instructions and addresses are replaced with tabs.

You can accomplish the same formatting of the STL instructions by selecting the menu

command CPU

Note

Certain combinations of statement list instructions cannot successfully be converted to

ladder view. In that case, the message “Illegal Network” marks the section of code that

cannot be represented in ladder. You can view the STL instructions for the “illegal” network

by clicking on the network title. Use the STL Editor to modify an illegal network so that it

can be viewed in ladder.

"

Compile while the STL Editor is active.

"

STL

STEP 7-Micro/WIN - c:\microwin\project1.prj

Project Edit View CPU Debug Tools Setup Window Help

Ladder Editor - untitled.ob1

Contacts

Network 1

“Start1” “E-Stop1” Q0.0

View

STL

✂

L

adder

D

ata Block

Symbol T

Status C

Cross R

Element U

✓

Sy

✓

Toolb

Sta

✓

Z

able

F2

Normally Open

hart

eference

Start/stop switch

sage

mbolic Addressing Ctrl+Y

ar

tus Bar

oom...

F3

STL

NETWORK 1 //Start/stop switch

LD “Start1”

AN “E-Stop1”

= Q0.0

NETWORK 2 //End

MEND

F4 F5 F8F7F6

STL Editor - untitled.ob1

Figure 2-7 Changing the Program View from Ladder to Statement List

F10

S7-200 Programmable Controller, CPU 210

C79000-G7076-C235-01

2-9

Page 32

Installing and Using the STEP 7-Micro/WIN Version 2.0 Software

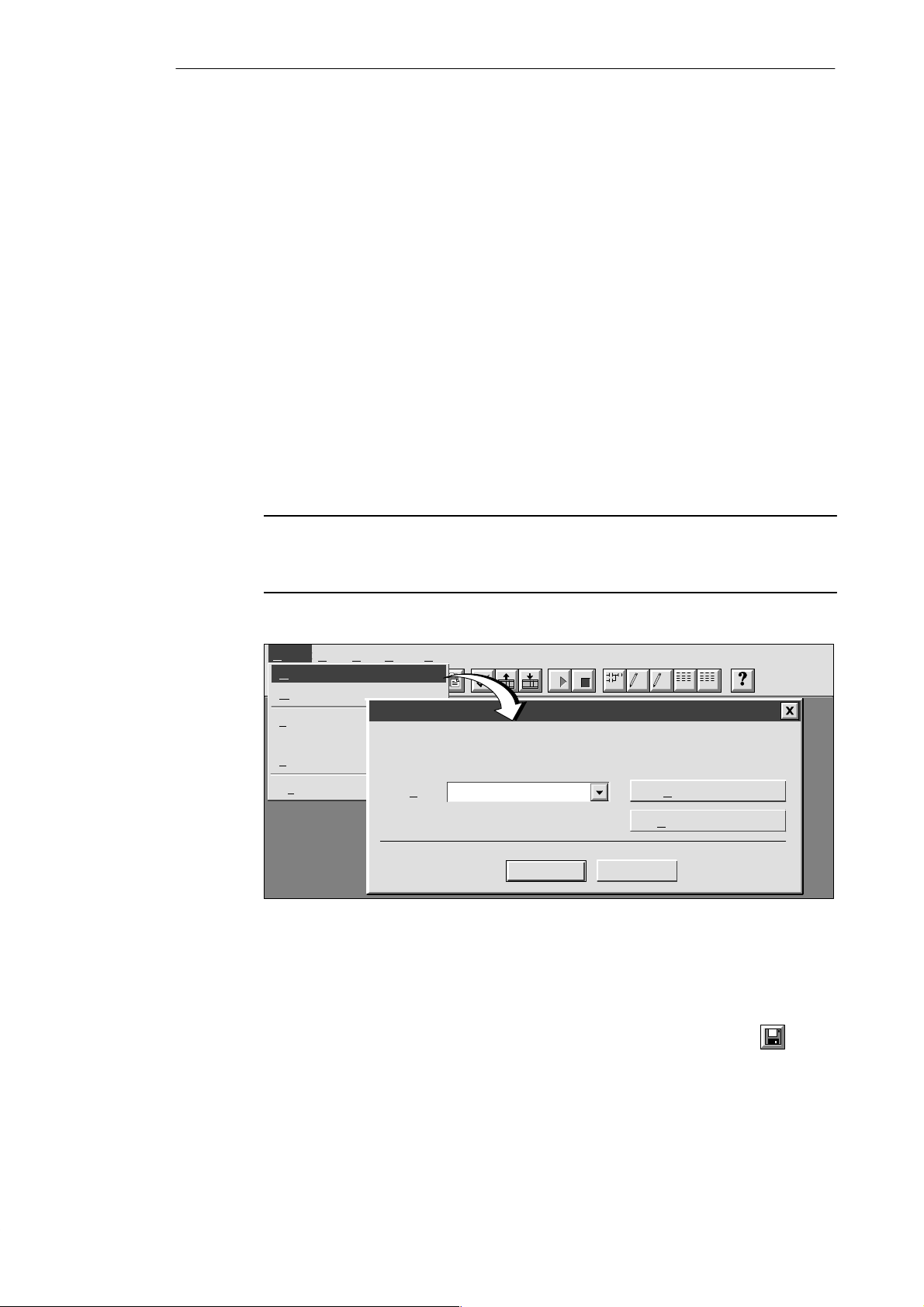

2.6 Downloading A Program

After developing and testing your program on the PDS 210, you must transfer the program to

the CPU 210 using the memory cartridge. In the same manner as you could use a diskette to

transfer files from one computer to another, you use a memory cartridge to transfer your

program from the PDS 210 to the CPU 210.

Downloading the Program to the PDS 210

After completing your program, you can download the project to the PDS 210. To download

your program, select the menu command Project

button in the main window.

The Download dialog box that appears allows you to specify the project components you

want to download, as shown in Figure 2-8. Select only “Program Code Block” for the

PDS 210: the data block and the CPU configuration are not used by the CPU 210.

Click on the “OK” button to confirm your choices and to execute the download operation.

STEP 7-Micro/WIN - c:\microwin\project1.prj

Project

Project Edit View CPU Debug Tools Setup Window Help

New... Ctrl+N

O

pen... Ctrl+O

C

lose

✂

"

Download... or click the Download

S

ave All Ctrl+S

Save A

s...

I

mport

E

xport

U

pload... Ctrl+U

D

ownload... Ctrl+D

Pag

e Setup...

P

rint Preview...

P

rint... Ctrl+P

Pr

int Setup...

Ex

it

Download

ll

A

Program Code Block

D

ata Block

Configuration

CPU

Figure 2-8 Downloading Project Components to the CPU

OK

Cancel

2-10

S7-200 Programmable Controller, CPU 210

C79000-G7076-C235-01

Page 33

Installing and Using the STEP 7-Micro/WIN Version 2.0 Software

Copying Your Program to the Memory Cartridge

You can copy your program to the memory cartridge only when the PDS 210 is powered up

and the memory cartridge is installed. (You can install or remove the memory cartridge while

the PDS 210 is powered up.)

Caution

!

Electrostatic discharge can damage the memory cartridge or the receptacle on the

PDS 210 or CPU 210.

You should make contact with a grounded conductive pad and/or wear a grounded wrist

strap when you handle the cartridge. You should store the cartridge in a conductive

container.

To install the memory cartridge, remove the protective tape from the memory cartridge

receptacle and insert the memory cartridge into the receptacle located under an access

cover of the PDS 210. (The memory cartridge is keyed for proper installation.) After the

memory cartridge is installed, use the following procedure to copy the program:

1. If the program has not already been downloaded to the PDS 210, use the menu

"

command Project

2. Use the menu command CPU

Download... to download the program. (See Figure 2-8.)

"

memory cartridge. See Figure 2-9.

3. Remove the memory cartridge from the PDS 210.

Program Memory Cartridge to copy the program to the

STEP 7-Micro/WIN - c:\microwin\project1.prj

Project Edit View CPU Debug Tools Setup Window Help

Ladder Editor - untitled.ob1

Contacts

Network 1

“Zone_1” “Zone_2” Q0.0

CPU

Run

✂

S

top

C

ompile

F2

Normally Open

Cl

ear

I

nformation

Start/stop switch

Co

nfigure

Program Memory Cartridge

✓

Time of Day Clock

Compare Project to CPU

T

ype

Figure 2-9 Copying the Program to the Memory Cartridge

Transferring the Program to the CPU 210

To transfer the program from the memory cartridge to the CPU 210, follow these steps:

1. Turn off the power to the CPU 210.

2. Insert the memory cartridge in the CPU 210. (The memory cartridge is keyed for proper

installation.)

3. Turn on the power to the CPU 210.

4. After the RUN LED turns on, remove the memory cartridge from the CPU 210.

S7-200 Programmable Controller, CPU 210

C79000-G7076-C235-01

2-11

Page 34

Installing and Using the STEP 7-Micro/WIN Version 2.0 Software

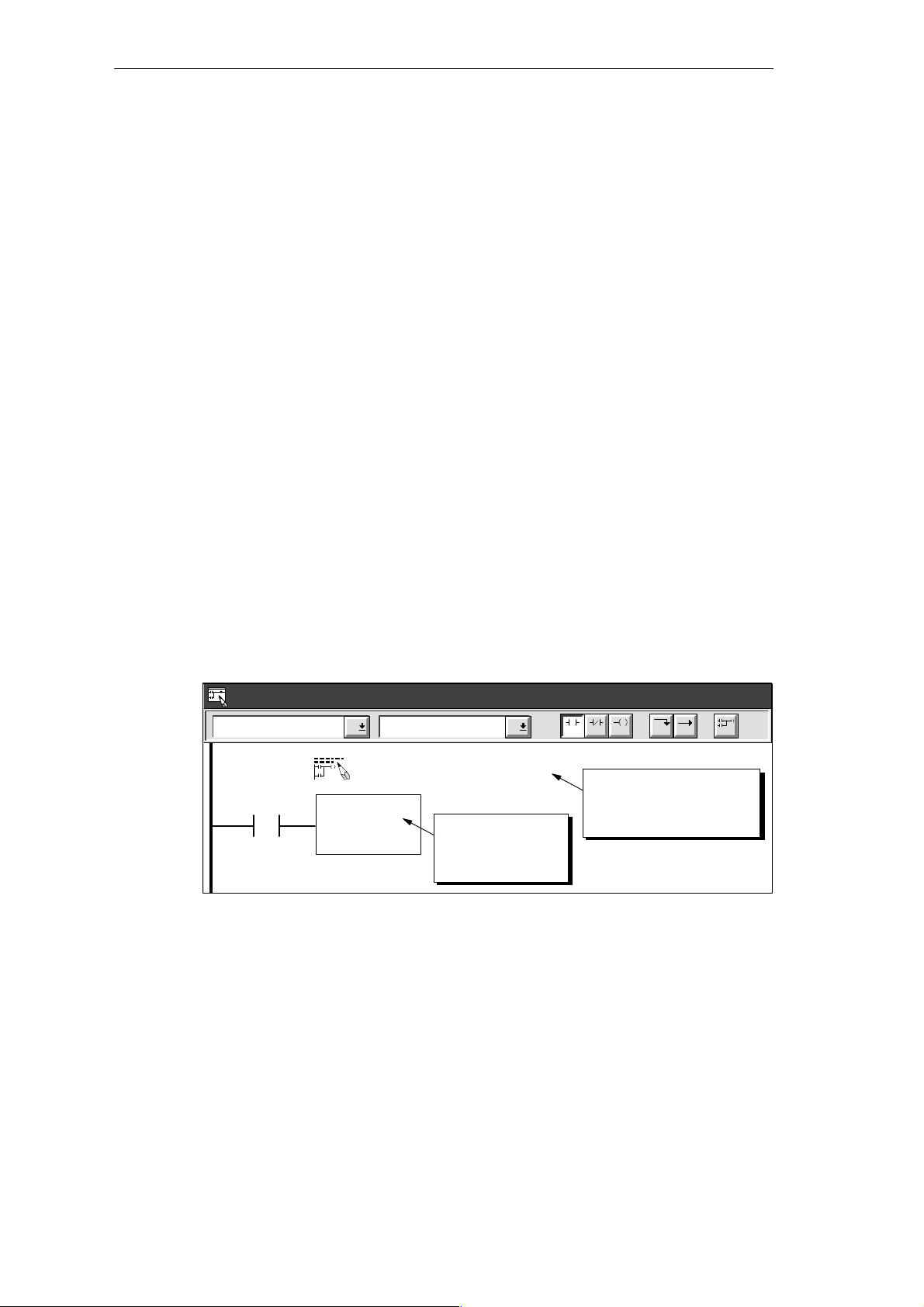

As shown in Figure 2-10, the CPU 210 performs the following tasks after you turn the power

on when a memory cartridge is installed in the CPU 210:

S The M, T, and Q areas of memory are cleared.

S The current values for the counters (which are stored in the permanent memory) are

cleared. (The current values for the counters are erased only when the memory cartridge

is installed in the CPU 210. If a memory cartridge is not installed, the current values are

retained.)

S The user program is copied from the memory cartridge to the permanent EEPROM

memory .

Always remove the memory cartridge from the CPU 210 after the program has been

installed.

Note

Turning the power on with a blank memory cartridge in the CPU 210 causes an error and

lights the error LED. Any program stored in the permanent EEPROM is not affected or

overwritten. To correct the error condition, remove the memory cartridge and cycle the

power again.

When a valid program is installed, the CPU 210 automatically goes to RUN mode when

power is applied.

As your program runs, the CPU 210 updates the values stored in the RAM memory (the

values stored in M memory , the current values for the four counters, and the current values

for the four timers).

When you turn the power off, the CPU 210 saves the current values of the four counters to

the permanent EEPROM memory . The other values stored in RAM (such as M memory,

current values for the timers, and the copy of the user program) are cleared.

Unless a memory cartridge is installed in the CPU 210, the current values for the counters

are retentive. The current values for the counters are automatically restored to the RAM

memory when you turn power on for the CPU 210 (with no memory cartridge installed).

When the memory cartridge is installed in the CPU 210,

Memory

Cartridge

User Program

Current values

of the counters

EEPROM Memory (Permanent)

turning on the power copies the user program to the

permanent memory

RAM Memory

M memory

Counter values

Current values

of the counters

Current values

of the timers

2-12

Figure 2-10 Loading a Program with the Memory Cartridge

S7-200 Programmable Controller, CPU 210

C79000-G7076-C235-01

Page 35

Installing and Using the STEP 7-Micro/WIN Version 2.0 Software

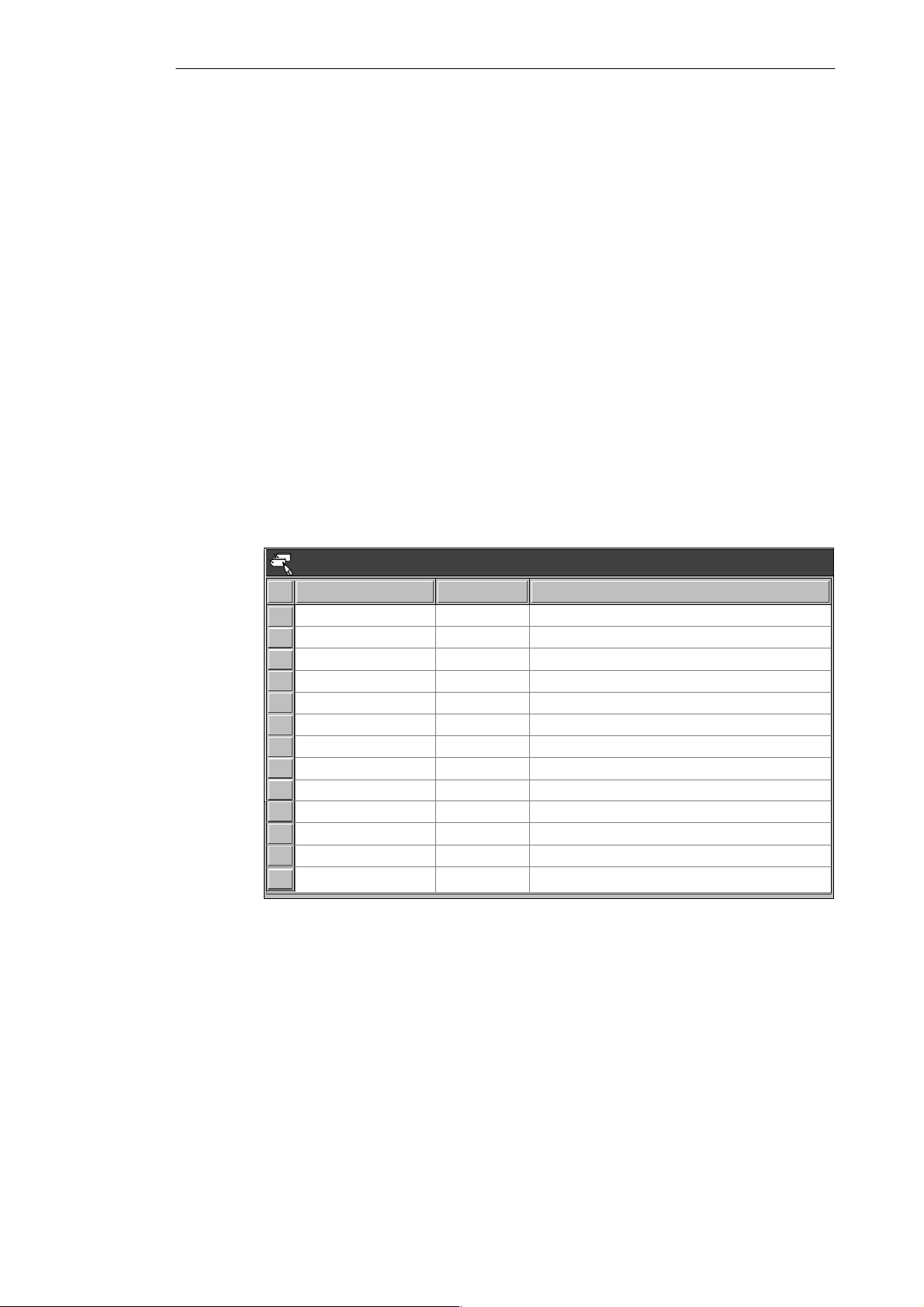

2.7 Using Symbolic Addressing

The Symbol Table allows you to give symbolic names to inputs, outputs, and internal

memory locations. See Figure 2-1 1. You can use the symbols you have assigned to these

addresses in the Ladder Editor, STL Editor, and Status Chart of STEP 7-Micro/WIN.

Guidelines for Entering Symbolic Addresses

The first column of the Symbol Table is used to select a row. The other columns are for the

symbol name, address, and comment. For each row, you assign a symbolic name to the

absolute address of a discrete input, output, memory location, special memory bit, or other

element. A comment for each assigned symbol is optional. Follow these guidelines when

creating a Symbol Table:

S You can enter symbol names and absolute addresses in any order.

S You can use up to 23 characters in the Symbol Name field; however, depending on the

font size of your Windows environment, you may not see the full name displayed in the

Ladder Editor.

S You can define up to 500 symbols.

S The Symbol Table is case-sensitive: for example, “Low_Alert” is considered a different

symbol from “low_alert”.

S All leading and trailing spaces will be removed from the symbol name. All adjacent

internal spaces will be converted to a single underscore. For example, if you type

“Zone 1” and press ENTER, the symbol name appears as: “Zone_1”.

S Duplicate symbol names and/or addresses will be marked by blue italics, will not be

compiled, and cannot be used in the program. Overlapping addresses are not flagged as

duplicates; for example, MW0 and MW1 overlap in memory but are not flagged as

duplicates.

Starting the Symbol T able Editor

The Symbol Table editor appears by default as a minimized window icon at the bottom of the

main window. To access the Symbol Table, double-click the icon, or click the Restore or

Maximize button on the icon (in Windows 95).

Symbol Table - untitled.sym

Symbol Name Address Comment

Zone_1

Zone_2

Armed

Panic_Alarm

LED

Alarm

Low_Alert

LED_Bit

LED_Bit

Figure 2-11 Example of a Symbol Table

To clear a cell, press

I0.0

delete key or spacebar

I0.1

when cell is selected.

I0.2

I0.3

Q0.0

Q0.1

Duplicate symbols

Q0.2

are displayed in

M0.0

italics.

M0.1

Zone 1 (switches A to F)

Zone 2 (switches H to M)

Enables the security system

Turns on the siren

S7-200 Programmable Controller, CPU 210

C79000-G7076-C235-01

2-13

Page 36

Installing and Using the STEP 7-Micro/WIN Version 2.0 Software

Editing Functions within the Symbol T able

The Symbol Table provides the following editing functions:

S Edit

S Edit

S Edit

"

Cut / Copy / Paste within a cell or from one cell to another.

"

Cut / Copy / Paste one or several adjacent rows.

"

Insert Row(s) above the row containing the cursor. You can also use the INSERT