Page 1

Page 2

Page 3

___________________

___________________

___________________

___________________

___________________

___________________

SIMATIC

S7-1500

S7-1500T Getting Started with

Kinematics

Getting Started

12/2018

A5E46089528

-AA

Warranty and liability

1

Preface

2

Description

3

Preparing the project

4

Adding and configuring

technology objects

5

Adding PLC tags and data

types

6

Add a global data block for

HMI tags

7

Create program for manual

mode

8

Create a program for

automatic mode

9

Main organization block Main

[OB1]

10

Testing the user program

11

Page 4

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E46089528-AA

Ⓟ

01/2019 Subject to change

Copyright © Siemens AG 2018.

All rights reserved

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Page 5

S7-1500T Getting Started with Kinematics

Getting Started, 12/2018, A5E46089528-AA

3

Table of contents

1 Warranty and liability ............................................................................................................................... 5

1.1 Security information .................................................................................................................. 6

2 Preface ................................................................................................................................................... 7

3 Description .............................................................................................................................................. 8

3.1 Requirements ............................................................................................................................ 8

3.2 Function scope .......................................................................................................................... 8

3.3 Task .......................................................................................................................................... 9

3.4 User program .......................................................................................................................... 10

3.5 Coordinate systems and positions .......................................................................................... 14

3.6 Program blocks ....................................................................................................................... 15

3.7 PLC tags ................................................................................................................................. 16

3.8 PLC data types ....................................................................................................................... 16

4 Preparing the project ............................................................................................................................. 20

5 Adding and configuring technology objects ............................................................................................ 21

5.1 Adding a kinematics technology object ................................................................................... 21

5.2 Configuring the kinematics technology object ........................................................................ 23

6 Adding PLC tags and data types ........................................................................................................... 25

7 Add a global data block for HMI tags ..................................................................................................... 26

8 Create program for manual mode .......................................................................................................... 27

8.1 Prepare function block ............................................................................................................ 27

8.2 Move kinematics to defined position ....................................................................................... 28

8.3 Controlling the axes ................................................................................................................ 34

8.4 Control of gripper .................................................................................................................... 36

9 Create a program for automatic mode ................................................................................................... 38

9.1 Prepare function block ............................................................................................................ 38

9.2 Querying preconditions ........................................................................................................... 40

9.3 Product type query .................................................................................................................. 43

9.4 Program section product type 1 .............................................................................................. 43

9.5 Program section product type 2 .............................................................................................. 49

9.6 Error handling in automatic mode ........................................................................................... 53

Page 6

Table of contents

S7-1500T Getting Started with Kinematics

4 Getting Started, 12/2018, A5E46089528-AA

10 Main organization block Main [OB1] ...................................................................................................... 54

11 Testing the user program ...................................................................................................................... 59

11.1 Preparing the watch table and the kinematics trace .............................................................. 59

11.2 Perform test ............................................................................................................................ 61

Page 7

S7-1500T Getting Started with Kinematics

Getting Started, 12/2018, A5E46089528-AA

5

1

Note

The Application Examples are not binding and do not claim to be complete regarding the

circuits or equipment shown, or every eventuality. The Application Examples do not

represent customer

-specific solutions. They are only intended to provide support for typical

applications. You are responsible for ensuring that the described products are used

correctly. These Application Examples do not relieve you of the responsibility to use safe

practices in application, installation, operation and maintenance. When us

ing these

Application Examples, you recognize that we cannot be made liable for any damage/claims

beyond the liability clause described. We reserve the right to make changes to this

Application Example at any time without prior notice. If there are any dev

iations between the

recommendations provided in this Application Example and other Siemens publications

–

e.g. catalogs

– the contents of the other documents have priority.

We do not accept any liability for the information contained in this document. Our liability for

damages resulting from using the examples, notes, programs, configuration and

performance data, etc. described in this Application Example regardless of the legal

background is excluded unless required by law, e.g. in cases of willful misconduct, gross

negligence, personal injury or death, failure to achieve guaranteed characteristics, fraudulent

concealment of a defect or in case of breach of fundamental contractual obligations. The

damages for breach of a substantial contractual obligation are, however, limited to

foreseeable damage, typical for the type of contract, except in the event of intent or gross

negligence or injury to life, body or health. The above provisions do not imply a change of

the burden of proof to your detriment.

Any form of duplication or distribution of these Application Examples or excerpts hereof is

prohibited without the express consent of Siemens AG.

Page 8

Warranty and liability

1.1 Security information

S7-1500T Getting Started with Kinematics

6 Getting Started, 12/2018, A5E46089528-AA

1.1 Security information

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions constitute one element of such a concept.

Customers are responsible for preventing unauthorized access to their plants, systems,

machines and networks. Such systems, machines and components should only be

connected to an enterprise network or the internet if and to the extent such a connection is

necessary and only when appropriate security measures (e.g. firewalls and/or network

segmentation) are in place.

For additional information on industrial security measures that can be implemented, please

visit (https://www.siemens.com/industrialsecurity).

Siemens' products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends that product updates are applied as soon as they are

available and that the latest product versions are used. Use of product versions that are no

longer supported, and failure to apply the latest updates may increase customers' exposure

to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed visit (https://www.siemens.com/industrialsecurity).

Page 9

S7-1500T Getting Started with Kinematics

Getting Started, 12/2018, A5E46089528-AA

7

2

Purpose of the documentation

This Getting Started leads you step-by-step through the configuration of a kinematics

technology object and the creation of the program for the automation task using a specific

example.

Basic knowledge required

The following knowledge is required to understand the Getting Started:

● General knowledge of automation engineering

● General knowledge in the field of drive engineering and motion control

Scope of validity of the documentation

This documentation is valid for the S7-1500 product range.

Additional support information

● The range of technical documentation for the individual SIMATIC products and systems is

available on the Internet (http://support.industry.siemens.com/cs/ww/en/view/109742705).

● The online catalog and online ordering system are available on the Internet

(http://mall.industry.siemens.com/).

Conventions

During the configuration of the technology objects, only the parameters required for the

example from the Getting Started are described.

Only the parameters used in the instructions are shown in the figures. Unused parameters

are hidden in the program.

The comments on the tags are optional and are used for the purpose of orientation.

Example project

The example described in this Getting Started is provided as a complete TIA Portal project.

In addition, all program blocks, technology objects, PLC tags, PLC data types and the watch

table are made available as master copies. You can load and use these as global library.

Page 10

S7-1500T Getting Started with Kinematics

8 Getting Started, 12/2018, A5E46089528-AA

3

3.1 Requirements

Software

You need the following software to run the Getting Started:

● SIMATIC STEP 7 Professional V15.1 and higher

● SIMATIC S7-PLCSIM V15.1 and higher

As an alternative to simulation via the SIMATIC S7 PLCSIM, you can perform the Getting

Started using a real controller SIMATIC S7-1500T (as of firmware version 2.5).

It may be necessary to adjust the application cycle of the "MC_Servo" organization block.

3.2 Function scope

Introduction

In this Getting Started example we show you how to create and configure a kinematics

technology object. The programming section shows you how to apply instructions for the

different functionalities of the kinematics technology object. The result is a complete user

program that consists of the described and applied functionalities.

Overview of functionalities

The following functionalities are covered in the Getting Started:

● Instructions for controlling the kinematics technology object

● Querying the job sequence

● Comparison of the coordinates and coordinate systems

● Travel with and without dynamic adaptation

Page 11

Description

3.3 Task

S7-1500T Getting Started with Kinematics

Getting Started, 12/2018, A5E46089528-AA

9

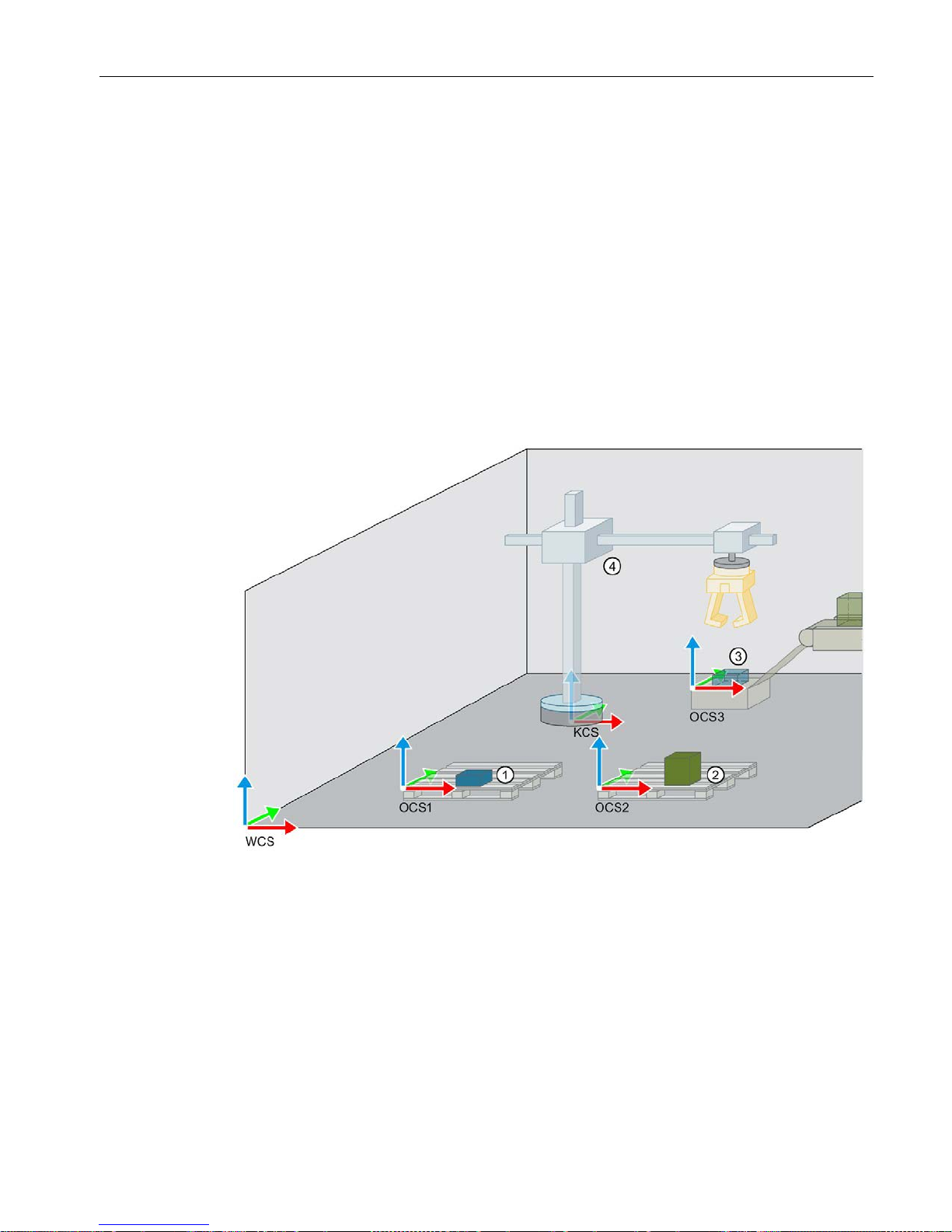

3.3 Task

Different products are transported on a conveyor belt and are to be distributed onto two

different product pallets by a cylindrical robot.

The products first reach the pickup position over a chute at the end of the conveyor belt. At

the pickup position, the products are picked up by the robot and transported to the respective

pallet.

The transport routes should be as follows, depending on the product type:

● Products of product type 1 are stored on pallet 1. On its way to the parking position,

pallet 2 is bypassed with the help of additional intermediate destinations.

● Products of product type 2 are stored on pallet 2. The parking position is approached

directly and without intermediate destinations.

Layout of the work area

①

Pallet 1 (OCS1, for product type 1)

②

Pallet 2 (OCS2, for product type 2)

③

Pickup position (OCS3)

④

Cylindrical robot 3D (KCS)

The different objects and their position in the workspace (WCS) are to be defined by means

of different coordinate systems and frames.

The kinematics coordinate system (KCS) is connected to the kinematics. The position of the

KCS within the kinematics is fixed.

The product pallets and their position, as well as the pickup position are to be defined with

the user-defined object coordinate systems OCS1, OCS2 and OCS3. This means that the

reference for the target position and the target orientation of the kinematics motions to one of

the product pallets or the pickup position is directly specified on the respective OCS.

Page 12

Description

3.4 User program

S7-1500T Getting Started with Kinematics

10 Getting Started, 12/2018, A5E46089528-AA

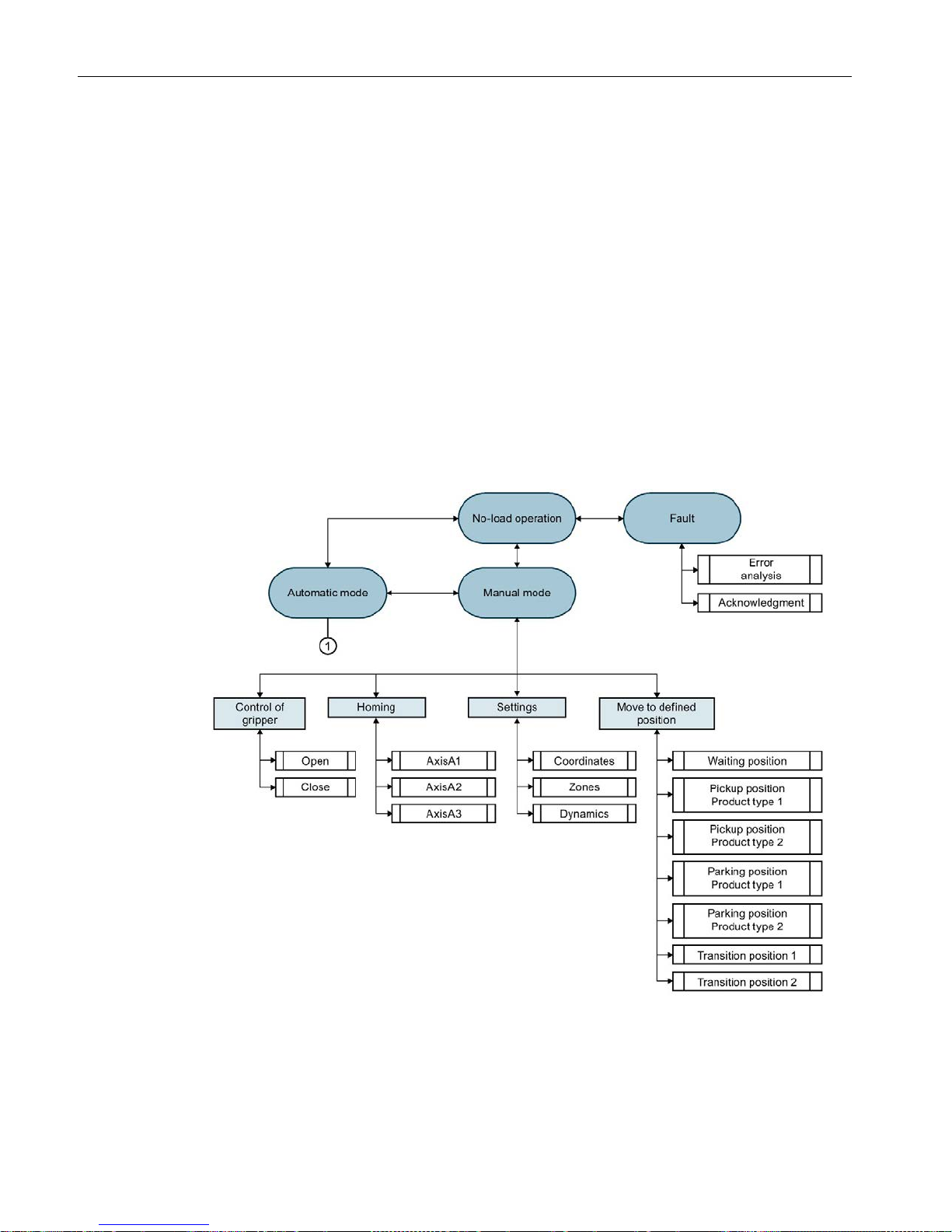

3.4 User program

Overview

A user program with the following operating modes is implemented for the described task:

● No-load operation (machine in idle state)

● Manual mode

● Automatic mode

● Fault

The user program executes all sequences of the task in automatic mode. The products are

picked up individually in automatic mode and transported to the parking position. The

sequence is repeated until automatic mode is exited.

In manual mode you set the various parameters and use individual functions from automatic

mode.

Page 13

Description

3.4 User program

S7-1500T Getting Started with Kinematics

Getting Started, 12/2018, A5E46089528-AA

11

Manual mode

Before you start automatic mode, make all the necessary settings in manual mode.

● Enable connected axes

● Define home position and home interconnected axes

● Define the coordinates of the defined positions

● Move the kinematics to the waiting position (= start position for automatic mode).

In manual mode, you can also move the kinematics to the defined positions using individual

motion instructions or change the coordinates.

You can test the gripper function by individually opening or closing the gripper (simulation).

The dynamic parameters allow you to observe the behavior of the kinematics motion when

dynamic adaptation is activated and deactivated.

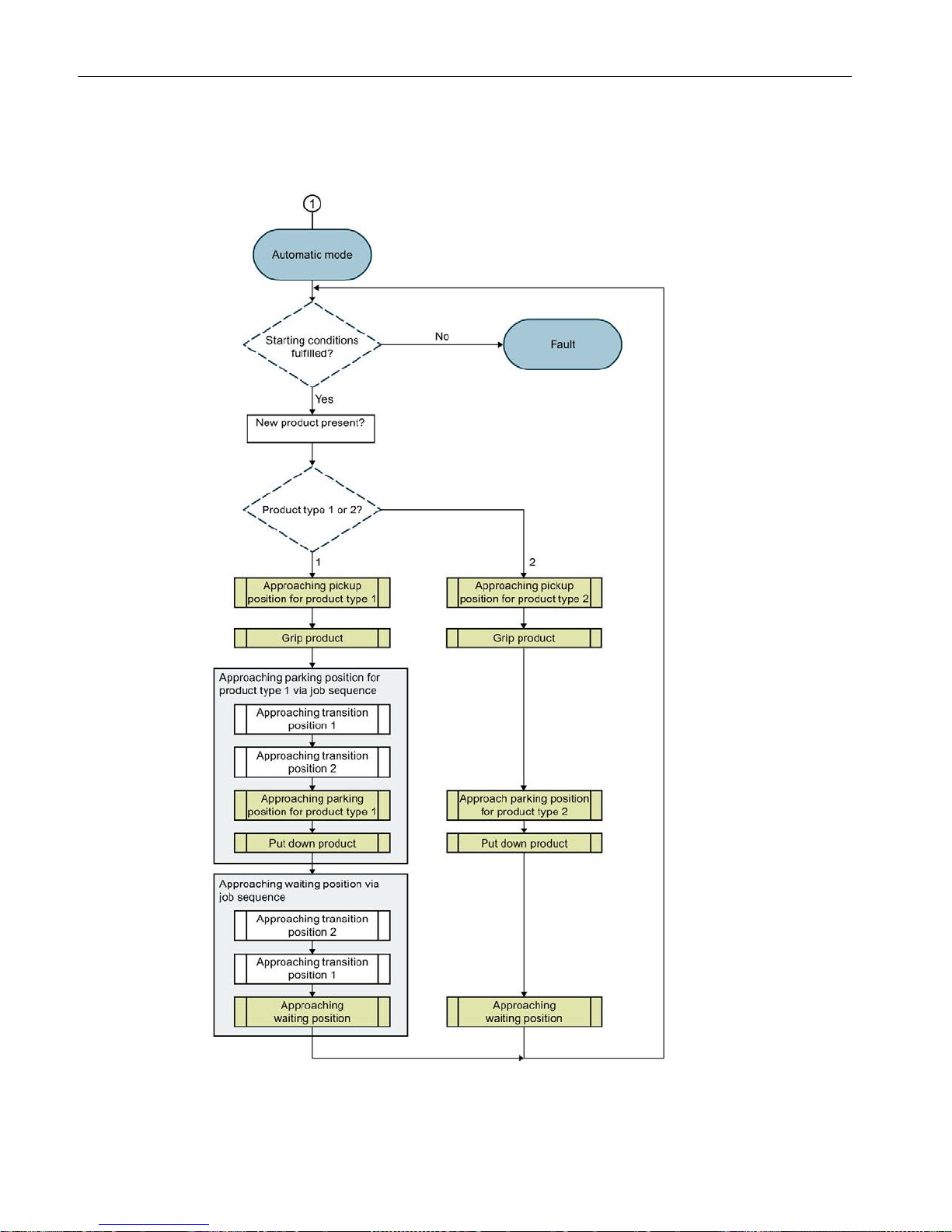

Automatic mode

When automatic mode is called, the following prerequisites for further processing of the

program are first queried.

● Cyclic queries in automatic mode:

– Is the communication to the drive system available?

– Is the drive switched on?

– Are all axes homed?

● Queries during start of automatic mode:

– Is the kinematics in the waiting position?

– Is the job sequence empty?

– Is the size of the job sequence set sufficiently?

When all starting conditions are fulfilled, the program checks whether a new product is

available and what type of product it is. With the information about the product type, the

kinematics moves to the pickup position and picks up the product.

The subsequent motions between the pickup position and one of the two parking positions

are defined as follows, depending on the product type:

●

Product type 1

Two transition positions are defined for the distance between the pickup position and

parking position. Three motion instructions are used to move the kinematics between the

pickup position and the parking position. The three motion instructions are executed via

the job sequence both for moving to the parking position and for returning to the waiting

position.

●

Product type 2

The kinematics moves with a motion between the pickup and the parking position.

Page 14

Description

3.4 User program

S7-1500T Getting Started with Kinematics

12 Getting Started, 12/2018, A5E46089528-AA

The product is parked when the parking position is reached. The kinematics then executes a

motion to the waiting position.

Page 15

Description

3.4 User program

S7-1500T Getting Started with Kinematics

Getting Started, 12/2018, A5E46089528-AA

13

Motion instructions used

The following instructions are used for the respective moves:

Motion

Instructions

Start

Destination

Waiting position Pickup position prod-

uct type 1 / product type 2

"MC_MoveLinearAbsolute" to pickup

position Product type 1 / Product type 2

Pickup position with offset

for product type 1

Parking position on pallet 1

1. "MC_MoveCircularAbsolute" to the

transition position 1

2. "MC_MoveLinearAbsolute" to the

transition position 2

3. "MC_MoveCircularAbsolute" to the

OCS1

Pickup position with offset

for product type 2

Parking position on pallet 2 "MC_MoveCircularAbsolute" to the

OCS2

Parking position on pallet 1 Waiting position

1. "MC_MoveCircularAbsolute" to the

transition position 2

2. "MC_MoveLinearAbsolute" to the

transition position 1

3. "MC_MoveCircularAbsolute" to the

waiting position

Parking position on pallet 2 Waiting position "MC_MoveCircularAbsolute" to the

waiting position

Definition of the circular path ("CircMode") for the instructions "MC_MoveCircularAbsolute"

With the "CircMode" parameter, you specify the definition of the circular path. In the example

project, the default setting "CircMode" = "0" is used for all circular motions and the circular

path is calculated using the start, intermediate and end points. With the auxiliary point of the

circular path ("AuxPoint"), you specify a point on the circular path via which the end point is

to be approached.

The function block "ModeAutomatic" shows an option for calculating the auxiliary points of

the circular path. The auxiliary points of the circular path are determined from the distance

between the start and end position and are thus in the middle of the distance. The

intermediate point is therefore consistent in each case with the specified start and end

points.

Page 16

Description

3.5 Coordinate systems and positions

S7-1500T Getting Started with Kinematics

14 Getting Started, 12/2018, A5E46089528-AA

3.5 Coordinate systems and positions

Kinematics and object coordinates

The values for the kinematics and object coordinates are entered in the Configuration of the

kinematics technology object (Page 23).

KCS

(Kinematics)

OCS1

(Pallet 1)

OCS2

(Pallet 2)

OCS3

(Pickup position at

the chute)

Position x

2000 mm

1000 mm

3000 mm

3500 mm

Position y

3000 mm 1000 mm 1000 mm 3000 mm

Position z

0 mm

100 mm

100 mm

300 mm

Positions and offsets

The values for the positions and offsets are entered via the HMI tags in the watch table

"HMI-Monitor (Page 59)".

Transition position 1

Transition position 2

Position x

3000 mm 2000 mm

Position y

2000 mm

2000 mm

Position z

1800 mm

1800 mm

Offset for waiting position

Offset for product type 1

Offset for product type 2

Position x

0 mm

0 mm

0 mm

Position y

0 mm

0 mm

0 mm

Position z

1000 mm

100 mm

200 mm

Home position

The home position for the interconnected axes can be entered using the corresponding tags

in the watch table "HMI-Monitor (Page 59)".

● Axis AxisA1: 10

● Axis AxisA2: 1

● Axis AxisA3: 1000

Page 17

Description

3.6 Program blocks

S7-1500T Getting Started with Kinematics

Getting Started, 12/2018, A5E46089528-AA

15

3.6 Program blocks

Function blocks

Function block

Function

Instance data block

"CtrlSingleAxis" Control of axes (ena-

ble/disable, reset, homing)

"InstAxisA1"

"InstAxisA2"

"InstAxisA3"

"ModeManual" Manual mode "InstModeManual"

"ModeAutomatic"

Automatic mode

"InstModeAutomatic"

"CtrlGripper" Gripper control (opening,

closing)

"InstGripper"

Functions

Function block

Function

Application

"Compare3D" Function for comparing posi-

tions

Function block "ModeAutomatic"

Query whether gripper is in the waiting

position

"DistanceXYHalf" Function for length calcula-

tion according to Pythagoras

Function block "ModeAutomatic"

Calculation of the respective auxiliary

point of the circular path for the instruc-

tion "MC_MoveCircularAbsolute".

Global data blocks

Data block

Function

Application

"HMI" Global data block for the

PLC data type "typeUserInterface"

Control of technology objects

and display of status values

in the watch table "HMI-

Monitor"

Function blocks "ModeManual"

and "ModeAutomatic"

Page 18

Description

3.7 PLC tags

S7-1500T Getting Started with Kinematics

16 Getting Started, 12/2018, A5E46089528-AA

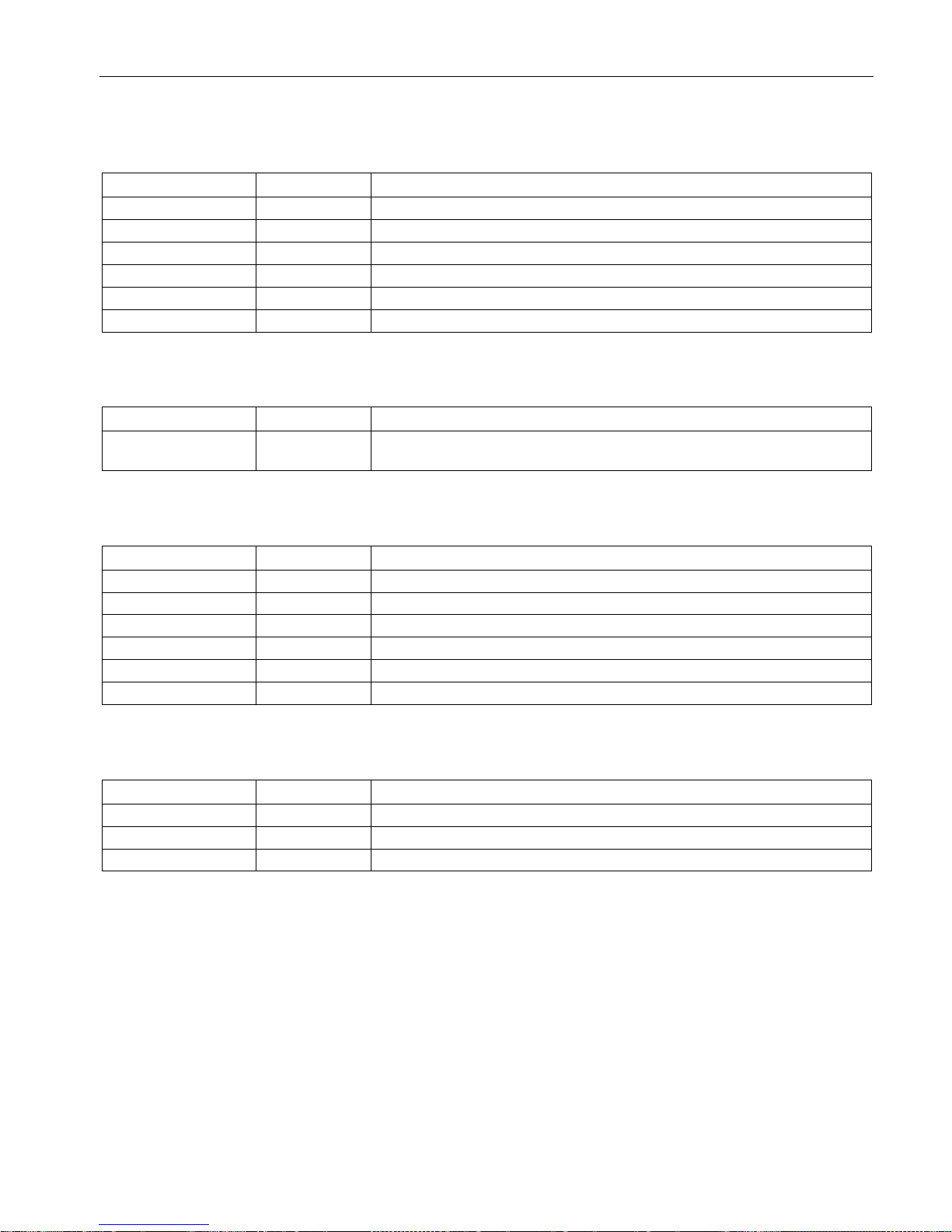

3.7 PLC tags

User constants

Define the following global user constants under PLC tags:

Name

Data type

Val

ue

Description

OPERATING_MODE_AUTO

UInt 3 Automatic mode

OPERATING_MODE_MANU

AL

UInt 2 Manual mode

OPERATING_MODE_IDLE

UInt 0 No-load operating mode

OPERATING_MODE_ERROR UInt 1 Fault operating mode

WCS

DInt

0

Specification of the respective reference system

of the specified target position and target orientation

OCS1

DInt 1 OCS2

DInt

2

OCS3

DInt

3

3.8 PLC data types

Overview

For the simple and uniform declaration of tags, add the following PLC data types:

Name

Description

typeAuxPosition

Specification of positions without orientation (x, y, z)

typeExecute

Summary of the parameters for the start of the motion instructions to the defined positions

typePosition

Specification of positions with orientation (x, y, z, A)

typePositionState

Summary of the parameters for the display of reached positions per sequence (0 = position not

reached, 1 = position reached)

typeSystemState

Summary of the parameters for the status display of the axes and the drive

typeUserInterface

Summary of the tags for the HMI

typeAuxPosition

Name

Data type

Description

auxPosition Array[1..3] of

LReal

Define the position without orientation (x, y, z)

Page 19

Description

3.8 PLC data types

S7-1500T Getting Started with Kinematics

Getting Started, 12/2018, A5E46089528-AA

17

typeExecute

Name

Data type

Description

waitingPos

Bool

Move to waiting position

pickupPos Bool Move to pickup position

destination1Pos

Bool

Move to the parking position for product type 1

destination2Pos

Bool

Move to the parking position for product type 2

transition1Pos

Bool

Move to the transition position 1

transition2Pos

Bool

Move to the transition position 2

typePosition

Name

Data type

Description

position Array[1..4] of

LReal

Defining position with orientation (x, y, z, A)

typePositionState

Name

Data type

Description

waitingPos

Bool

Waiting position

pickupPos

Bool

Pickup position

destination1Pos

Bool

Parking position for product type 1

destination2Pos

Bool

Parking position for product type 2

transition1Pos

Bool

Transition position 1

transition2Pos

Bool

Transition position 2

typeSystemState

Name

Data type

Description

communicationOK

Bool

Communication with the drive system is available

driveInOperation

Bool

Drive system in operation

homingDone

Bool

Encoder adjustment completed

Page 20

Description

3.8 PLC data types

S7-1500T Getting Started with Kinematics

18 Getting Started, 12/2018, A5E46089528-AA

typeUserInterface

Name

Data type

Description

waitingPosOffset

"typePosition"

Offset for the waiting position

product1Offset "typePosition" Offset for products of product type 1

product2Offset

"typePosition"

Offset for products of product type 2

transitionPos1

"typePosition"

Transition position 1 between conveyor belt and parking position 1

transitionPos2

"typePosition"

Transition position 2 between conveyor belt and parking position 1

productType UInt Enter product type

• 0 = No product / Product type unknown

• 1 = Product type 1

• 2 = Product type 2

operatingMode UInt Selecting the operating state

• 0 = Starting

• 1 = Fault

• 2 = Manual mode

• 3 = Automatic mode

• 4 = Reserved

enableAxes

Bool

Enable axes

executeMoveTo

"typeExecute"

Start motion instructions to the defined positions

interruptMove

Bool

Interrupt current motion

continueMove

Bool

Continue a motion stopped with "interruptMove"

acknowledge

Bool

Acknowledge error

gripper Bool Controlling the gripper

• 1 = Closing

• 0 = Opening

gripperState Bool Status indicator of gripper

• 0 = Open

• 1 = Closed

posState "typePosi-

tionState"

Status display of reached positions per sequence

startChecks "typeSystemSta-

tus"

Axis and drive status display

motionState UInt Status display of motion

• 0 = Inactive

• 1 = Fault

• 2 = Active

• 3 = Reserved

setReferenceAxisA1

Bool

Homing axis "AxisA1"

setReferenceAxisA2

Bool

Homing axis "AxisA2"

setReferenceAxisA3

Bool

Homing axis "AxisA3"

Page 21

Description

3.8 PLC data types

S7-1500T Getting Started with Kinematics

Getting Started, 12/2018, A5E46089528-AA

19

Page 22

S7-1500T Getting Started with Kinematics

20 Getting Started, 12/2018, A5E46089528-AA

4

Adding a controller

To edit the example from the Getting Started, create a SIMATIC S7-1500T controller (as of

firmware version 2.5) in the project.

Page 23

S7-1500T Getting Started with Kinematics

21 Getting Started, 12/2018, A5E46089528-AA

5

5.1 Adding a kinematics technology object

Requirement

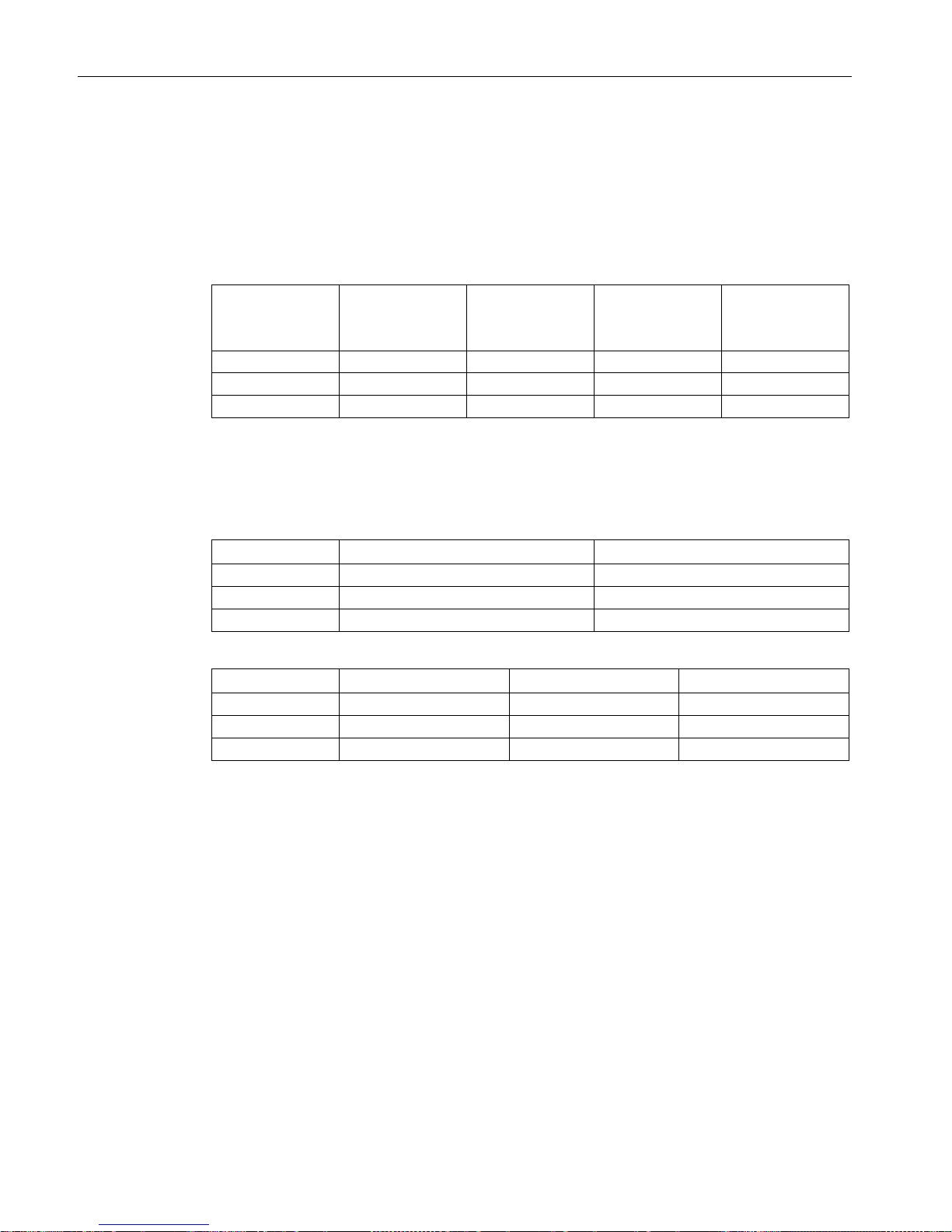

To connect the kinematics, create the following positioning axes:

Name

Axis type

Modulo

AxisA1

Virtual axis,

Rotary

• Enable modulo

• Modulo start value: -180°

• Modulo length: 360°

AxisA2

Virtual axis,

Linear

–

AxisA3

Virtual axis,

Linear

–

Page 24

Adding and configuring technology objects

5.1 Adding a kinematics technology object

S7-1500T Getting Started with Kinematics

22 Getting Started, 12/2018, A5E46089528-AA

Procedure

To add a kinematics technology object, follow these steps:

1. Open the CPU's folder in the project navigator.

2. Open the "Technology Objects" folder.

3. Double-click "Add new object".

The "Add new object" dialog opens.

4. Select "TO_Kinematics".

5. Enter the name "CylindricalRobot" in the "Name" entry field.

6. Select the "Add new and open" check box.

7. Click "OK".

Page 25

Adding and configuring technology objects

5.2 Configuring the kinematics technology object

S7-1500T Getting Started with Kinematics

Getting Started, 12/2018, A5E46089528-AA

23

5.2 Configuring the kinematics technology object

Basic parameters

Configure the basic properties of the kinematics technology object in the "Basic Parameters"

configuration window.

1. Select the Kinematics type "Cylindrical robot 3D" from the drop-down list.

2. In the drop-down list, select the desired units of measure for the position, velocity, angle

and angular velocity of the kinematics.

Interconnections

Configure the axes of kinematics in the "Interconnections" configuration window.

1. Interconnect the kinematics axes as follows:

– Kinematics axis A1: "AxisA1"

– Kinematics axis A2: "AxisA2"

– Kinematics axis A3: "AxisA3"

Geometry

Configure the geometric parameters of kinematics in the "Geometry" configuration window.

1. Enter the transformation parameters of the kinematics in these fields:

– Length L1: 2000 mm

– Length L2: 400 mm

– Flange length LF: 200 mm

2. In these fields, define the scaling in which the kinematics is displayed in the kinematics

trace:

– z minimum: 0 mm

– z maximum: 3000 mm

– A3 maximum: 3500 mm

Dynamics

In the example project, the default values are used for the dynamics, the dynamics limits and

the dynamic adaptation of the kinematics motion.

If you want to set certain default values for the Kinematics motion, configure them in the

"Dynamics" configuration window.

When dynamic adaptation is active, a velocity profile is calculated for the entire motion which

takes into account the dynamic limits of the axes and the kinematics. In this example project,

the default values for the dynamic limits of the connected axes are used. If you want to set

certain default values for the dynamic limits of the interconnected axes, configure them

under "Technology object > Configuration > Extended parameters > Limits > Dynamic limits".

Page 26

Adding and configuring technology objects

5.2 Configuring the kinematics technology object

S7-1500T Getting Started with Kinematics

24 Getting Started, 12/2018, A5E46089528-AA

Kinematics coordinate system

In the "Kinematics coordinate system" configuration window, configure the KCS frame and

therefore the position of the kinematics coordinate system (KCS) in the world coordinate

system (WCS).

Enter the values for the position of the kinematic coordinate system (Page 14).

Object coordinate systems

In the "Object coordinate system" configuration window, configure the OCS frames and

therefore the position of the object coordinate systems (OCS) in the world coordinate system

(WCS).

In the drop-down list, select the object coordinate systems "OCS1" to "OCS3" one after the

other and enter Values for the position of the respective object coordinate system (Page 14).

Page 27

S7-1500T Getting Started with Kinematics

25 Getting Started, 12/2018, A5E46089528-AA

6

Add user constants

Insert all required user constants in the default tag table.

A list can be found in the section PLC tags (Page 16).

Adding data types

1. Add all required data types:

– typeAuxPosition

– typeExecute

– typePosition

– typePositionState

– typeSystemState

– typeUserInterface

2. Enter the required tags and data types in the declaration tables of the data types.

A list can be found in the section PLC data types (Page 16).

Page 28

S7-1500T Getting Started with Kinematics

26 Getting Started, 12/2018, A5E46089528-AA

7

For the user interface parameters, add a new data block with the name "HMI" of the type

"typeUserInterface".

The data block "HMI" is created based on the PLC data type "typeUserInterface" (Page 16).

Page 29

S7-1500T Getting Started with Kinematics

27 Getting Started, 12/2018, A5E46089528-AA

8

8.1 Prepare function block

Prepare program block

1. Add the function block "ModeManual" (LAD).

2. Add the instance data block "InstManual".

Parameters in the function block "ModeManual"

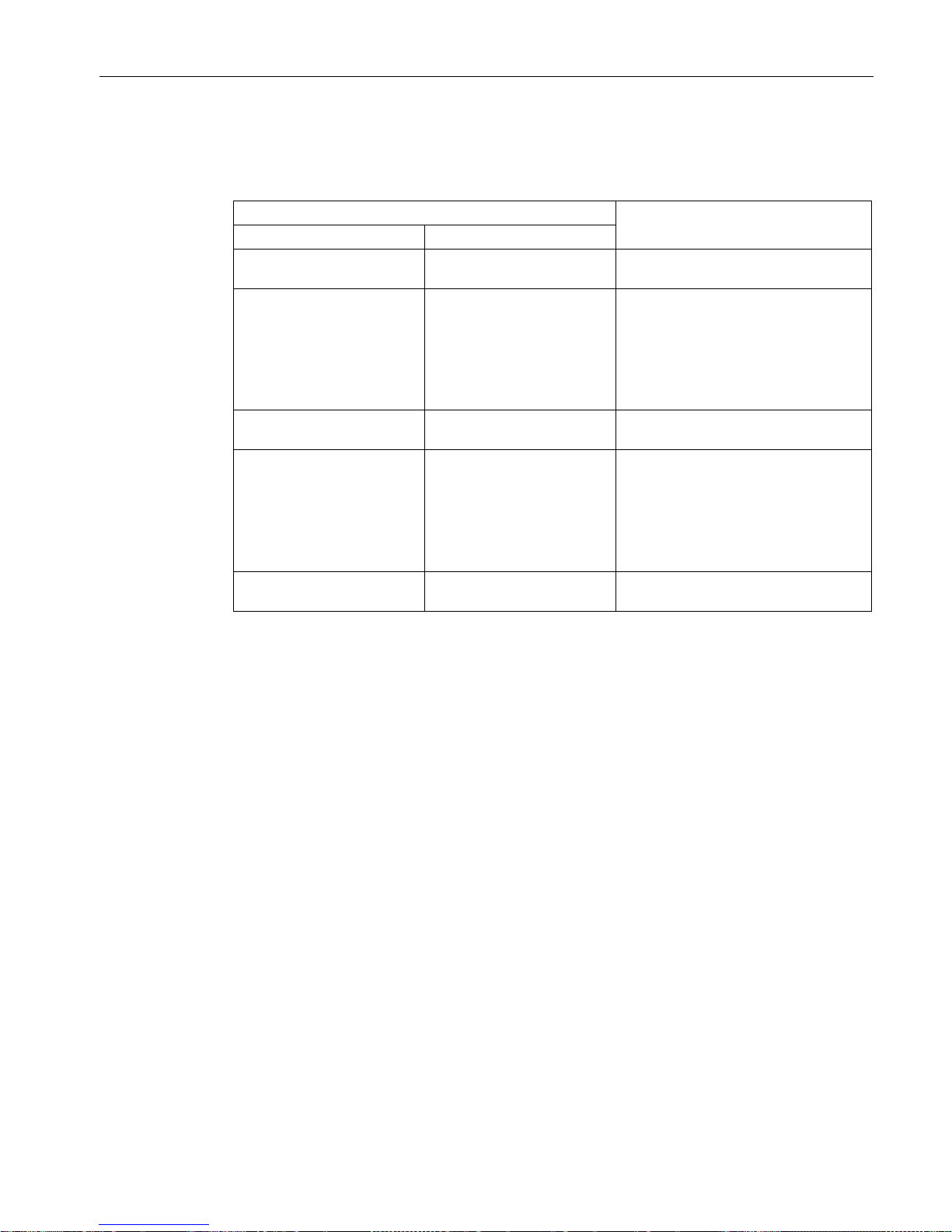

Create the following parameters in the "ModeManual" function block.

Name

Data type

Default value

Description

InOut

axesGroup

TO_Kinematics

–

Reference to the technology object

hmi

"typeUserInterface"

–

User interface parameters (control, status query)

Static

statInstMoveLinAbs MC_MOVELINEARAB

SOLUTE

– Instances of the individual motion control instruc-

tions (see data type) for the kinematics process

statInstReset

MC_RESET

–

statInstGroupInterrupt MC_GROUPINTERRU

PT

–

statInstGroupContinue MC_GROUPCONTIN

UE

–

Temp

tempTargetPos typePosition – Absolute target coordi-

nate from the executed

motion instruction

Using this temporary

local data, pass the

values from the respective instruction to the

motion instruction.

tempCoordSystem DInt – Reference system of the

specified target position

and target orientation

tempDone Bool – The value for the completed motion control instruc-

tion "MC_MoveLinearAbsolute" is passed via this

tag to the query of the position reached.

Page 30

Create program for manual mode

8.2 Move kinematics to defined position

S7-1500T Getting Started with Kinematics

28 Getting Started, 12/2018, A5E46089528-AA

8.2 Move kinematics to defined position

Requirements

The following requirements apply to executing the program in manual mode:

● All interconnected axes are switched on and homed.

● At the time of calling a motion instruction in manual mode:

– No motion control instruction "MC_GroupInterrupt" is active.

– If no further motion instruction is active.

– No further motion instruction is activated.

Page 31

Create program for manual mode

8.2 Move kinematics to defined position

S7-1500T Getting Started with Kinematics

Getting Started, 12/2018, A5E46089528-AA

29

Start motion instruction

1. The motion instructions are started individually in manual mode. For each component of

"hmi.executeMoveTo", insert a normally open contact in parallel.

2. The respective target coordinate ("tempTargetPos.position") and the respective reference

system ("tempCoordSystem") are transferred to the motion instruction via the instruction

"Move value" (MOVE).

Page 32

Create program for manual mode

8.2 Move kinematics to defined position

S7-1500T Getting Started with Kinematics

30 Getting Started, 12/2018, A5E46089528-AA

3. In manual mode, the kinematics is positioned exclusively with a linear motion. Insert a

motion control instruction "MC_MoveLinearAbsolute".

4. To use the completed job signal to display the reached position, assign the tag

"tempDone" to the output parameter "Done".

Page 33

Create program for manual mode

8.2 Move kinematics to defined position

S7-1500T Getting Started with Kinematics

Getting Started, 12/2018, A5E46089528-AA

31

Display of the position reached

1. Insert a new network.

2. Insert an NO contact for the tag "tempDone".

3. Insert all components of the parameter "hmi.executeMoveTo" in parallel.

4. To output the status of the position reached, add the respective component of the

parameter "hmi.posState".

Page 34

Create program for manual mode

8.2 Move kinematics to defined position

S7-1500T Getting Started with Kinematics

32 Getting Started, 12/2018, A5E46089528-AA

Interrupt / continue motion execution

1. Insert a new network.

2. To interrupt a motion execution, insert the motion control instruction "MC_GroupInterrupt".

3. To continue a motion execution, insert the motion control instruction

"MC_GroupContinue".

Acknowledge error

1. Insert a new network.

2. To reset all technology alarms and restart the interconnected kinematic axes, insert a

motion control instruction "MC_Reset".

Page 35

Create program for manual mode

8.2 Move kinematics to defined position

S7-1500T Getting Started with Kinematics

Getting Started, 12/2018, A5E46089528-AA

33

Evaluating errors

1. Insert a new network.

2. Insert NO contacts for all "Error" parameters of the motion control instructions from the

function block "ModeManual" in parallel.

3. As long as the signal state of all "Error" parameters is "0" (no error), manual mode is

active and the parameter "hmi.operatingMode" has the value "2". If an error occurs, the

user program switches to Fault operating state. The value of the parameter

"hmi.operatingMode" changes to "1" in the case of an error.

To transfer the respective value to the "hmi.operatingMode" parameter, use the

instruction "Move value" (MOVE).

Page 36

Create program for manual mode

8.3 Controlling the axes

S7-1500T Getting Started with Kinematics

34 Getting Started, 12/2018, A5E46089528-AA

8.3 Controlling the axes

Creating blocks

1. Add a new function block with the name "CtrlSingleAxis" (SCL).

2. Add the following instance data blocks:

– "InstAxisA1"

– "InstAxisA2"

– "InstAxisA3"

Parameters in the CtrlSingleAxis function block

Create the following parameters in the "CtrlSingleAxis" function block.

Name

Data type

Default

value

Comment

Input

axis TO_PositioningAxis – Reference to the technology object

cmdPowerOn

Bool

False

Enable (1) or disable (0) axis using MC_Power

pwrOffMode

Int 0 "StopMode" for "MC_Power"

cmdAcknErr

Bool

False

Run "MC_Reset"

cmdHome

Bool

False

Run "MC_Home"

homePosition

LReal

0.0

Home position for "MC_Home"

operatingMode Int 0 Operating mode

0 = Starting

1 = Fault

2 = Manual mode

3 = Automatic mode

Output

axisActualPos LReal 0.0 Current object position (from the technology object data

block)

summaryError

Bool

False

Error on the axis or in the motion control function

systemState

"typeSystemStatus"

–

Axis and drive status display

Static

statMcPower

MC_POWER

–

Instances of the individual motion control instructions (see

data type) for enabling, resetting and homing the interconnected axes

statMcReset

MC_RESET

–

statMcHome

MC_HOME

–

statPowerErr Bool False Error in the motion control function

statResetErr

Bool

False

statHomeErr

Bool

False

Page 37

Create program for manual mode

8.3 Controlling the axes

S7-1500T Getting Started with Kinematics

Getting Started, 12/2018, A5E46089528-AA

35

Procedure

1. Add the parameters for controlling the axes.

2. Summarize all parameters for error output of the axis control instructions in the

"summaryError" parameter.

3. Assign the corresponding tags from the technology data block to the following output

parameters:

– Current position of the axis technology object

– Communication with the drive system is available

– Drive systems switched on

– Axis homed

Page 38

Create program for manual mode

8.4 Control of gripper

S7-1500T Getting Started with Kinematics

36 Getting Started, 12/2018, A5E46089528-AA

8.4 Control of gripper

Creating blocks

1. Add the function block "CtrlGripper" (LAD).

2. Add the instance data block "InstGripper".

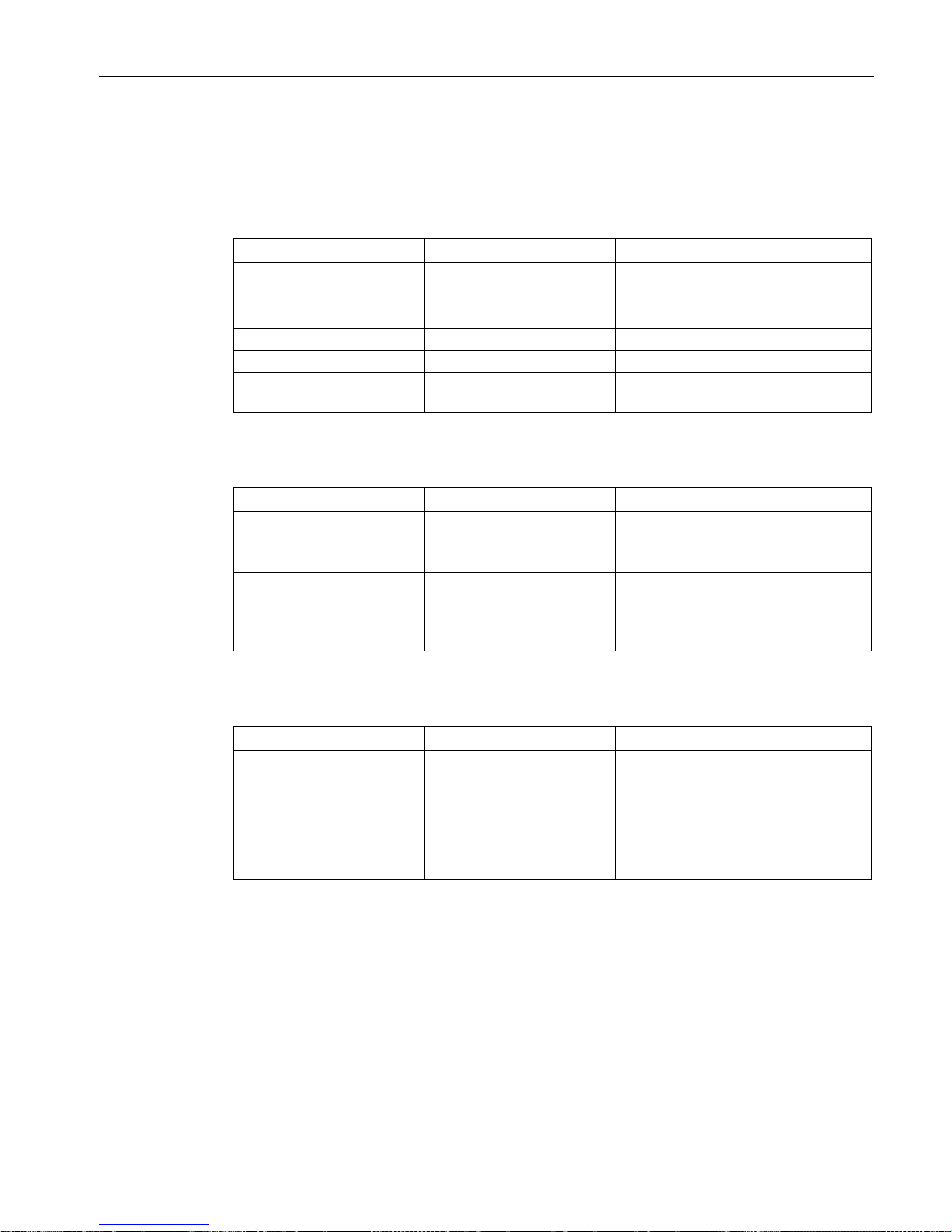

Parameters in the function block "CtrlGripper"

Create the following parameters in the "CtrlGripper" function block.

Name

Data type

Default

value

Comment

Input

close Bool False Control of gripper

• 0 = Opening

• 1 = Closing

time

Time

t#1000 ms

Time for the status change (open ↔ close)

Output

state Bool False Gripper status

• 0 = Open

• 1 = Closed

Static

statInstTime

TP_TIME

–

Instance of the "Create pulse" (TP_TIME) instruction

statPuls

Bool

False

Status change transfer

statClosePos

Bool

False

Edge bit memory "close" (positive signal edge)

statCloseNeg

Bool

False

Edge bit memory "close" (negative signal edge)

statPulsNeg

Bool

False

Edge bit memory "statPuls"

Page 39

Create program for manual mode

8.4 Control of gripper

S7-1500T Getting Started with Kinematics

Getting Started, 12/2018, A5E46089528-AA

37

Procedure

1. For edge detection of the signal at the "close" input, add the following instructions in

network 1:

– Query positive signal edge with edge bit memory "statClosePos"

– Query negative signal edge with edge bit memory "statCloseNeg"

2. To open or close the gripper, the signal at the "close" input should remain unchanged for

a specified time. For this purpose, add a "Generate a pulse" (TP_TIME) instruction.

When an edge change occurs at the "close" input, the specified time period PT expires. If

the specified period has expired and no new edge change has been detected at the

"close" input, the "statPuls" output is set.

3. Create a new network 2 for the "Close gripper" operation.

4. To scan the signals at the "close" input and at the "statPuls" output, use an NO contact

for each.

5. For output of the "state" parameter with a "1", insert the "Set output" instruction.

6. Create a new network 3 for the "Open gripper" operation.

7. Use an NC contact to query the signal at the "close" input.

8. Insert an NO contact for the signal at the "statPuls" output.

9. For output of the "state" parameter with a "0", insert the "Reset output" instruction.

Page 40

S7-1500T Getting Started with Kinematics

38 Getting Started, 12/2018, A5E46089528-AA

9

9.1 Prepare function block

Adding blocks

1. Add a new function block with the name "ModeAutomatic" (SCL).

2. Add a new instance data block with the name "InstAutomatic".

Parameters in the function block "ModeAutomatic"

Create the following parameters in the "ModeAutomatic" function block.

Name

Data type

Default

value

Comment

Output

errorID

Int 0 Error ID (0 = no error, < 0 see constants)

InOut

axesGroup

TO_Kinematics

–

Reference to the technology object

hmi

typeUserInterface

–

Static

statStateAuto Int #STATE_-

CHECK

Program status in automatic mode (see constants)

statMovPickup

Bool

False

Motion to pickup position

Tags for starting the motion

instructions to the defined

positions

statMovDest1

Bool

False

Motion to parking position 1

statMovDest2

Bool

False

Motion to parking position 2

statMovWait

Bool

False

Motion to waiting position

statInstMov-

eToPickupPos

MC_MOVELINEARAB

SOLUTE

– Move linear motion to

pickup position

Instances of the individual

motion control instructions

(see data type) for the kinematics process

statInstMoveToTransi-

tionCirc

MC_MOVECIRCULAR

ABSOLUTE

– Circular motion to the tran-

sition position

statInstMoveToTransi-

tionLin

MC_MOVELINEARAB

SOLUTE

– Linear motion to the transi-

tion position

statInstMoveToDesti-

nation1

MC_MOVECIRCULAR

ABSOLUTE

– Circular motion to the park-

ing position 1

statInstMoveToDesti-

nation2

MC_MOVECIRCULAR

ABSOLUTE

– Circular motion to the park-

ing position 2

statInstMov-

eToWaitPos

MC_MOVECIRCULAR

ABSOLUTE

– Circular motion to the wait-

ing position

staInstGroupInterrupt MC_GROUPINTERRU

PT

– Stopping motion execution

statInstGroupContinue MC_GROUPCONTIN

UE

– Continue motion execution

Page 41

Create a program for automatic mode

9.1 Prepare function block

S7-1500T Getting Started with Kinematics

Getting Started, 12/2018, A5E46089528-AA

39

Name

Data type

Default

value

Comment

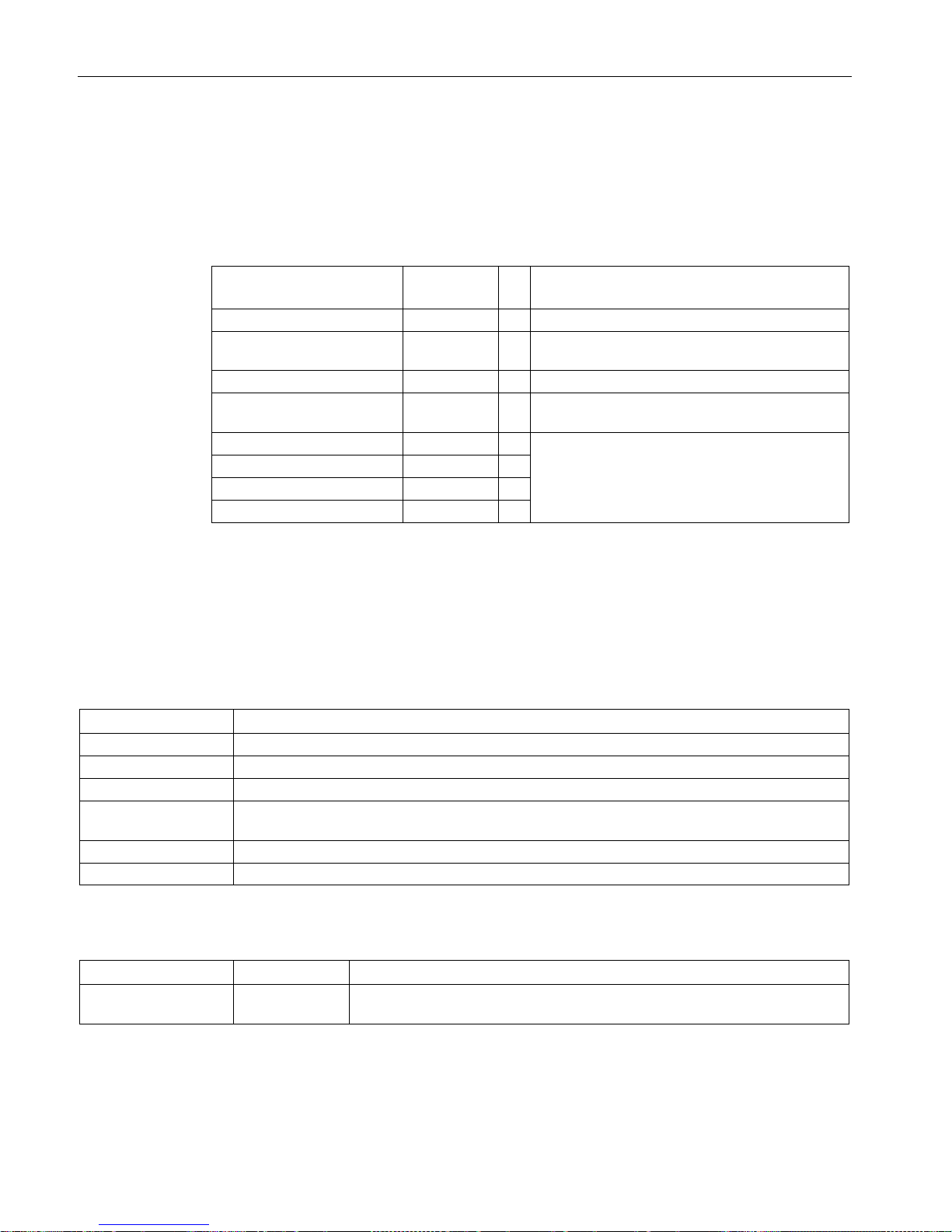

statWatchdog

TON_TIME

–

Monitoring of automatic mode

statWatchExpired Bool False Output signal change after wait time elapses

statHoldTime

TON_TIME

–

Wait time at the waiting position

Temp

tempErrorSummary Bool – Error in one of the motion control instructions for the

kinematics process

tempStateWaitingPos typeAuxPosition – Signal output at the end of the wait time at the waiting

position

tempAuxPosition LReal – Transfer of the calculated auxiliary point of the circular

path to the respective motion instruction.

tempLengthhalf LReal – Transfer of the calculated value from the additional length

calculation to the z position of an auxiliary point of the

circular path

Constant

ERR_NONE

Int 0 No error

ERR_STARTPOS

Int

-20

Kinematics is not in waiting position

ERR_PRODUCT_UNS

PECIFIED

Int -21 Entered product type is unknown

ERR_QUEUE_SIZE Int -22 Maximum number of jobs in the job sequence is not suffi-

cient

ERR_QUEUE_CLEAR

Int

-23

Job sequence is not empty

ERR_SYSTEM_CHECK Int -24 Error in communication, in the drive or during homing

ERR_MC_OUTPUT_E

RROR

Int -200 Error in the motion control instruction

STATE_CHECK Int -2 Test conditions for automat-

ic mode

Program status in automatic

mode

STATE_CLEAR Int -1 Program cycle to reset the

Execute inputs

STATE_PRODUCT_W

AIT

Int 0 Product is unknown (wait-

ing for new product)

STATE_PRODUCT_1_

DELIVER

Int 1 Part 1 of the program se-

quence for product type 1 is

active

STATE_PRODUCT_1_

RETURN

Int 2 Part 2 of the program se-

quence for product type 1 is

active

STATE_PRODUCT_2_

DELIVER

Int 3 Program sequence for

product type 2 is active

STATE_RES

Int 4 Not used (reserved)

GRIPPER_CLOSE

Bool

1

Gripper closed

GRIPPER_OPEN

Bool

0

Gripper open

TRANS_DISTANCE

LReal

10

Default values for transition parameters[1]

HOLDTIME

Time

T#1S

Dwell time at the waiting position

WATCHDOGTIME

Time

T#200MS

Time for call check of the automatic mode

Page 42

Create a program for automatic mode

9.2 Querying preconditions

S7-1500T Getting Started with Kinematics

40 Getting Started, 12/2018, A5E46089528-AA

9.2 Querying preconditions

After calling the automatic mode, the program first checks all preconditions for further

processing.

System status

To query the status of the axis and the drive, use the structure components of the formal

parameter "hmi.systemChecks".

Page 43

Create a program for automatic mode

9.2 Querying preconditions

S7-1500T Getting Started with Kinematics

Getting Started, 12/2018, A5E46089528-AA

41

Kinematics starting position

The kinematics starting position at the beginning of the automatic mode is the defined

waiting position ("hmi.waitingPosOffset"). Therefore, the program must check at the start of

automatic mode whether the position of the kinematics corresponds to the default waiting

position.

Add a new function (FC) with the name "Compare3D". In the function "Compare3D" the

program compares positions.

You assign the actual parameters of the positions to be compared in the function block

"ModeAutomatic".

If the condition for the start position is not fulfilled, the corresponding error ("errorID" =

"ERR_STARTPOS") is output and the automatic mode program is no longer processed. In

manual mode, the pending error must be acknowledged and the kinematics moved to the

waiting position. Automatic mode can then be called again.

If the kinematics is in the waiting position, the status display for the waiting position is set to

"True" and the program is processed further.

Page 44

Create a program for automatic mode

9.2 Querying preconditions

S7-1500T Getting Started with Kinematics

42 Getting Started, 12/2018, A5E46089528-AA

Status of the job sequence

To ensure that there is sufficient space in the job sequence for the subsequent motion

instructions, add the following queries to the job sequence:

● Is the job sequence designed for the required number of jobs?

● Is the job sequence empty at the time of the query?

Resetting the Execute parameters

The program should reset all Execute parameters to their default value in the first cycle. This

ensures that all and any Execute parameters that are already switched are reset and can be

edited.

To control the reset, use the constant "STATE_CLEAR" as program status.

Page 45

Create a program for automatic mode

9.3 Product type query

S7-1500T Getting Started with Kinematics

Getting Started, 12/2018, A5E46089528-AA

43

9.3 Product type query

When all preconditions are met and all Execute parameters are reset, the program queries

the required product information.

To do this, use a CASE instruction (multiple branches) in which you query whether a new

product exists and what type of product it is.

9.4 Program section product type 1

Preconditions

To run the program section for product type 1, the result of the product type query must be

"1" and the tag "#statStateAuto" must have the value "#STATE_PRODUCT_1_DELIVER".

Insert the query of the tag tatStateAu"#sto".

If the automatic mode is processed in the first cycle, the tag "#statStateAuto" has the value

"#STATE_CLEAR". In this case, insert the command to reset the Execute parameters of the

motion instructions in program section 1.

Page 46

Create a program for automatic mode

9.4 Program section product type 1

S7-1500T Getting Started with Kinematics

44 Getting Started, 12/2018, A5E46089528-AA

Pick up the product and transport it to the pallet

1. The kinematics moves to the pickup position to pick up the product.

Insert the linear motion instruction ("statInstMoveToPickupPos") and enter the following

parameters:

– To start the motion job, assign the tag "statMovPickUp".

– Enter the position offset for product type 1 as the end position in OCS3.

– To output the signal when the motion instruction has been successfully executed,

assign the "hmi.posState.pickUpPos" parameter.

2. Once the pickup position has been reached, the product is picked up by closing the

gripper.

For this purpose, assign the value "GRIPPER_CLOSE" ("1") to the "hmi.gripper"

parameter.

3. After the product has been picked up, the kinematics moves with a circular motion to the

transition position 1.

The function "DistanceXYHalf" is used to calculate the respective z position of an

auxiliary point of the circular path with a Pythagorean length calculation.

For the length calculation, create a new function (FC) named "DistanceXYHalf".

4. Assign the actual parameters for the length calculation in the function block

"ModeAutomatic".

Page 47

Create a program for automatic mode

9.4 Program section product type 1

S7-1500T Getting Started with Kinematics

Getting Started, 12/2018, A5E46089528-AA

45

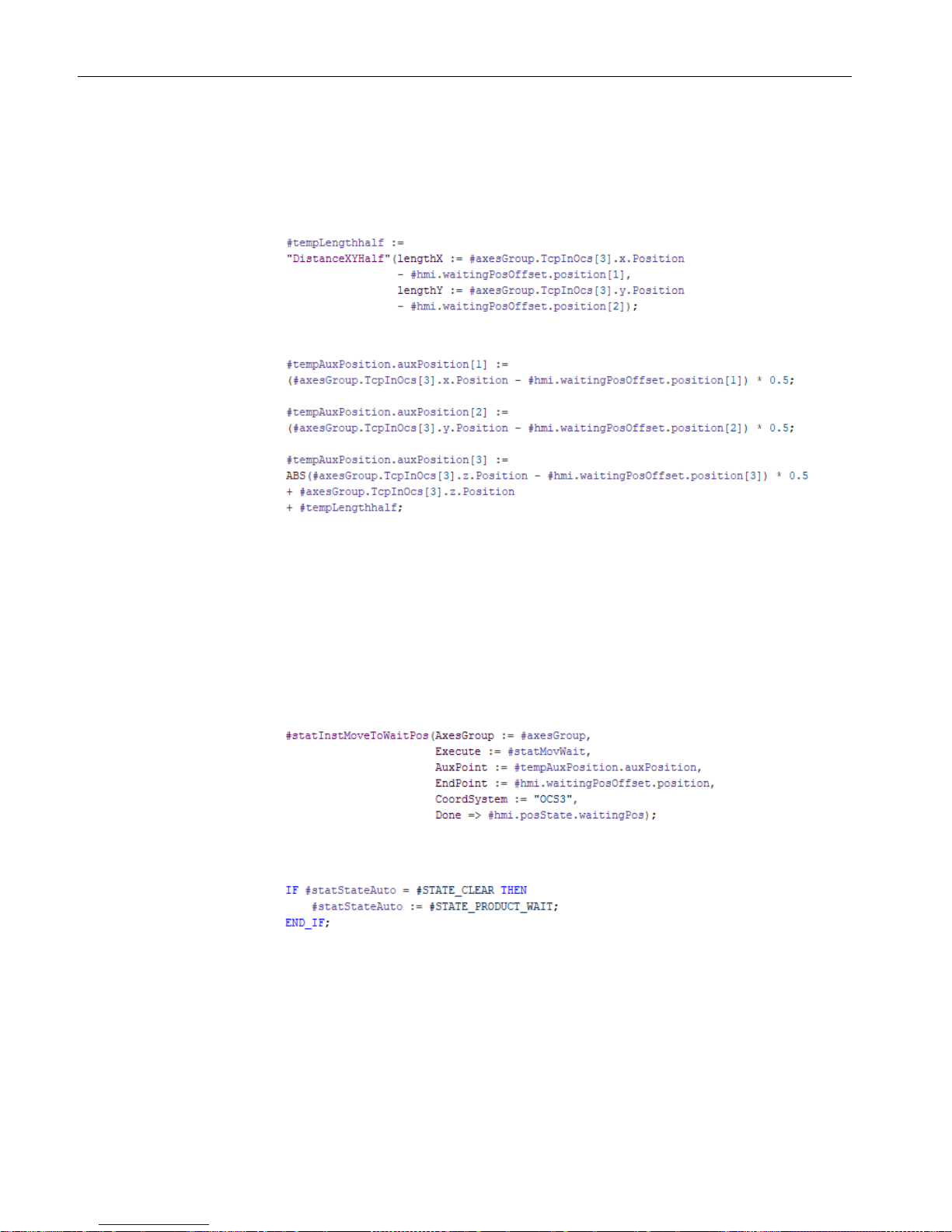

5. Insert the calculation for the coordinates (x, y, z) of the auxiliary point of the circular path:

6. Insert the circular motion instruction ("statInstMoveToTransitionCirc") and enter the

following parameters:

– To start the motion job, assign the tag "statMovDest1".

– Assign the previously calculated circular path auxiliary position using the tag

"tempAuxPosition.auxPosition".

– Enter transition position 1 as the end position in the WCS.

– To output the signal when the motion instruction was executed successfully, use the

parameter "hmi.posState.transition1Pos".

7. To move the kinematics to transition position 2, insert the linear motion instruction

("statInstMoveToTransitionLin") and enter the following parameters:

– To start the motion job, assign the tag "statMovDest1".

– Enter transition position 2 as the end position in the WCS.

– Set the motion transition parameter to "2". When the blending distance is reached, the

current motion is blended with the motion of this job. The lower velocity of both jobs is

then used.

– To output the signal when the motion instruction was executed successfully, use the

parameter "hmi.posState.transition2Pos".

Page 48

Create a program for automatic mode

9.4 Program section product type 1

S7-1500T Getting Started with Kinematics

46 Getting Started, 12/2018, A5E46089528-AA

8. The kinematics moves with a circular motion to the parking position on pallet 1.

To calculate the auxiliary point of the circular path, add the function "DistanceXYHalf" and

assign the actual parameters for the length calculation.

Insert the calculation for the coordinates (x, y, z) of the auxiliary point of the circular path:

9. Insert the circular motion instruction ("statInstMoveToDestination1") and enter the

following parameters:

– To start the motion job, assign the tag "statMovDest1".

– Assign the previously calculated circular path auxiliary position using the tag

"tempAuxPosition.auxPosition".

– Enter the offset for product type 1 as end position in OCS1.

– Set the motion transition parameter to "2".

– To output the signal when the motion instruction was executed successfully, use the

parameter "hmi.posState.destination1Pos".

10.Once the parking position has been reached, the product is set down by opening the

gripper.

For this purpose, assign the value "GRIPPER_OPEN" ("0") to the "hmi.gripper"

parameter.

Page 49

Create a program for automatic mode

9.4 Program section product type 1

S7-1500T Getting Started with Kinematics

Getting Started, 12/2018, A5E46089528-AA

47

Return to the waiting position

1. To pick up a new product, the kinematics first moves back to the waiting position. For this

purpose, add the same three motion instructions but in reverse order.

– Circular motion to transition position 2

– Linear motion to transition position 1

Page 50

Create a program for automatic mode

9.4 Program section product type 1

S7-1500T Getting Started with Kinematics

48 Getting Started, 12/2018, A5E46089528-AA

– Circular motion to the waiting position

2. To observe the status of the tag "hmi.posState.waitingPos", use the instruction "Start time

as ON time" ("statHoldTime").

3. At the end of the program section, assign the value "#STATE_CHECK" to the tag

"statStateAuto".

The program continues with the check of the preconditions for the automatic mode.

Page 51

Create a program for automatic mode

9.5 Program section product type 2

S7-1500T Getting Started with Kinematics

Getting Started, 12/2018, A5E46089528-AA

49

9.5 Program section product type 2

Preconditions

To run the program section for product type 2, the result of the product type query must be

"2" and the tag "#statStateAuto" must have the value "#STATE_PRODUCT_2_DELIVER".

Insert the query of the tag "#statStateAuto".

If the automatic mode is processed in the first cycle, the tag "#statStateAuto" has the value

"#STATE_CLEAR". In this case, insert the command to reset the Execute parameters of the

motion instructions in program section 2.

Page 52

Create a program for automatic mode

9.5 Program section product type 2

S7-1500T Getting Started with Kinematics

50 Getting Started, 12/2018, A5E46089528-AA

Pick up the product and transport it to the pallet

1. The kinematics moves to the pickup position to pick up the product.

Insert the linear motion instruction ("statInstMoveToPickupPos") and enter the following

parameters:

– To start the motion job, assign the tag "statMovPickUp".

– Enter the position offset for product type 2 as the end position in OCS3.

– To output the signal when the motion instruction has been successfully executed,

assign the "hmi.posState.pickUpPos" parameter.

2. Once the pickup position has been reached, the product is picked up by closing the

gripper.

For this purpose, assign the value "GRIPPER_CLOSE" ("1") to the "hmi.gripper"

parameter.

3. After the product has been picked up, the kinematics moves with a circular motion to the

parking position on pallet 2.

To calculate the auxiliary point of the circular path, add the function "DistanceXYHalf" and

assign the actual parameters for the length calculation.

4. Insert the calculation for the coordinates (x, y, z) of the auxiliary point of the circular path:

Page 53

Create a program for automatic mode

9.5 Program section product type 2

S7-1500T Getting Started with Kinematics

Getting Started, 12/2018, A5E46089528-AA

51

5. Insert the circular motion instruction ("statInstMoveToTransitionCirc") and enter the

following parameters:

– To start the motion job, assign the tag "statMovDest2".

– Assign the previously calculated circular path auxiliary position using the tag

"tempAuxPosition.auxPosition".

– Enter the offset for product type 2 as the end position in OCS2.

– To output the signal when the motion instruction was executed successfully, use the

parameter "hmi.posState.transition2Pos".

6. Once the parking position has been reached, the product is set down by opening the

gripper.

For this purpose, assign the value "GRIPPER_OPEN" ("0") to the "hmi.gripper"

parameter.

Page 54

Create a program for automatic mode

9.5 Program section product type 2

S7-1500T Getting Started with Kinematics

52 Getting Started, 12/2018, A5E46089528-AA

Return to the waiting position

1. The kinematics returns to the pickup position to pick up a new product.

To calculate the auxiliary point of the circular path, add the function "DistanceXYHalf" and

assign the actual parameters for the length calculation.

2. Insert the calculation for the coordinates (x, y, z) of the auxiliary point of the circular path:

3. To move the kinematics to the waiting position, insert the instruction to the circular motion

"statInstMoveToWaitPos" and enter the following parameters:

– To start the motion job, assign the tag "statMovWait".

– Assign the previously calculated circular path auxiliary position using the tag

"tempAuxPosition.auxPosition".

– Enter the waiting position as end position in OCS3.

– To output the signal when the motion instruction was executed successfully, use the

parameter "hmi.posState.waitingPos".

4. To finish resetting the Execute tags, assign the value "STATE_PRODUCT_WAIT" to the

tag "statStateAuto".

Page 55

Create a program for automatic mode

9.6 Error handling in automatic mode

S7-1500T Getting Started with Kinematics

Getting Started, 12/2018, A5E46089528-AA

53

The program continues with the check of the preconditions for the automatic mode.

5. To observe the status of the tag "hmi.posState.waitingPos", use the instruction "Start time

as ON time" ("statHoldTime").

6. At the end of the program section, assign the value "#STATE_CHECK" to the tag

"statStateAuto".

The program continues with the check of the preconditions for the automatic mode.

9.6 Error handling in automatic mode

Handling errors in motion control instructions

1. If errors occur while processing one of the motion control instructions, they are to be

output via the tag "ErrorID" with the value "-200" ("ERR_MC_OUTPUT_ERROR").

To do this, combine all "Error" parameters of the motion control instructions from the

"ModeAutomatic" function block in the "tempErrorSummary" tag.

2. You can control the behavior in case processing of the automatic mode is canceled by

means of the instruction "Create ON delay".

Page 56

S7-1500T Getting Started with Kinematics

54 Getting Started, 12/2018, A5E46089528-AA

10

Overview

Integrate the previously created part programs and create the main program in the cycle OB

"Main".

Structure of main program

● Control of kinematics in manual mode using the function block "CtrlSingleAxis"

● Query of the status for encoder adjustment, communication and drive using the

parameters from the data block "HMI"

● Control of kinematics in manual mode with the function block "ModeManual"

● Control of kinematics in automatic mode with the function block "ModeAutomatic"

● Gripper control (simulation) using the function block "CtrlGripper".

Page 57

Main organization block Main [OB1]

S7-1500T Getting Started with Kinematics

Getting Started, 12/2018, A5E46089528-AA

55

Controlling the axes

1. Insert the function block "CtrlSingleAxis" for controlling the axes. Use a block instance of

the function block "CtrlSingleAxis" for each axis to do this.

2. Assign the parameters for controlling enabling, homing and restarting to the respective

axis.

3. To enable the axes, exclude no-load mode and fault mode.

4. The axes should only be homed in manual mode.

Network – axis "AxisA1"

You can copy the network of the axis "AxisA1" for the axes "AxisA2" and "AxisA3" and adapt

the following parameters for each:

AxisA1

AxisA2

AxisA3

①

Parameter for homing the

axis

HMI.setReferenceAxi

sA1

HMI.setReferenceAxi

sA2

HMI.setReferenceAxi

sA3

②

Interconnected axis (TO)

AxisA1 AxisA2 AxisA3

③

Instance DB

InstAxisA1 InstAxisA2 InstAxisA3

Page 58

Main organization block Main [OB1]

S7-1500T Getting Started with Kinematics

56 Getting Started, 12/2018, A5E46089528-AA

Status of encoder adjustment, communication and drive

1. Create a new network for each status query.

2. The status feedback is output together for all interconnected axes. Therefore, insert the

parameters of the axes one after the other on a path.

3. To output the signal, assign the respective parameter from the data block "HMI".

Encoder adjustment status

Communication status

Drive status

Page 59

Main organization block Main [OB1]

S7-1500T Getting Started with Kinematics

Getting Started, 12/2018, A5E46089528-AA

57

Control of kinematics in manual mode

1. Insert the function block "ModeManual".

2. To call the block, set the parameter for selecting manual mode.

3. Assign the parameters for the user interface from the data block "HMI".

Controlling the kinematics in automatic mode

1. Insert the function block "ModeAutomatic".

2. To call the block, set the parameter for selecting automatic mode.

3. Assign the parameters for the user interface from the data block "HMI".

Page 60

Main organization block Main [OB1]

S7-1500T Getting Started with Kinematics

58 Getting Started, 12/2018, A5E46089528-AA

Gripper control (simulation)

1. Insert the function block "CtrlGripper" for controlling the gripper.

2. Assign the parameters for controlling the gripper.

Page 61

S7-1500T Getting Started with Kinematics

59 Getting Started, 12/2018, A5E46089528-AA

11

11.1 Preparing the watch table and the kinematics trace

Overview

To test the user program, use the following functionalities in the TIA Portal:

● Kinematics trace

● Watch table

Kinematics trace

In the kinematics trace, you track the current kinematics motion, record it and then play it

back.

The kinematics trace of the kinematics technology object can be found in the project

navigator under "Technology objects > CylindricalRobot > Kinematics trace".

Watch table

Control and monitor the HMI tags using the watch table.

1. Create a new watch table "HMI-Monitor".

2. Insert all parameters from the "HMI" data block into the watch table.

3. Add other relevant parameters for the interconnected axes (

①):

– Home position control

– Display of possible errors

4. Add other relevant parameters for the kinematics technology object (

②):

– Default for velocity and dynamic limitation for the maximum velocity of the path

– Activating/deactivating dynamic limitation

– Velocity override

– Display the current path velocity (setpoint reference)

– Display of possible errors

5. Add other relevant parameters (

③):

– Display of program status in automatic mode

– Display of error ID in automatic mode

Page 62

Testing the user program

11.1 Preparing the watch table and the kinematics trace

S7-1500T Getting Started with Kinematics

60 Getting Started, 12/2018, A5E46089528-AA

6. You can use comment lines to better structure the watch table.

Page 63

Testing the user program

11.2 Perform test

S7-1500T Getting Started with Kinematics

Getting Started, 12/2018, A5E46089528-AA

61

11.2 Perform test

Preparing the simulation

To carry out the test, prepare the simulation as follows:

● Compile the project data and make sure that the compilation process was completed

without errors.

● Start the simulation and load the configuration into the CPU.

● Open the watch table "HMI-Monitor" and the kinematics trace.

Activate the function "Split editor space vertically" so that both items are displayed next to

each other.

Evaluating the path motion

You can save the recordings of the path motions as measurements and load and display

them in the trace. Trace offers you extended evaluation options to analyze path motions in

detail.

In addition, you can create a trace for the velocity and acceleration of the kinematics and the

axes:

● Path velocity ("StatusPath.Velocity")

● Acceleration ("StatusPath.Acceleration")

● Axis velocity ("ActualVelocity")

● Axis acceleration ("ActualAcceleration")

Signal waves from different measurements can be put together in the trace as an overlay

measurement and compared with each other. If you want to use this function, make sure that

the trigger is identical for the recordings that are to be combined.

Page 64

Testing the user program

11.2 Perform test

S7-1500T Getting Started with Kinematics

62 Getting Started, 12/2018, A5E46089528-AA

Prepare kinematics in manual mode

1. Select manual mode by controlling the tag "HMI.operatingMode" with the value "2".

2. Enable the axes using the tag "HMI.enableAxes".

3. Enter the home position (Page 14) for the interconnected axes.

4. Home the axes using "HMI.setReferenceAxisA1", "HMI.setReferenceAxisA2" and

"HMI.setReferenceAxisA3".

5. Enter the control values for the defined positions.

A list of the positions and offsets can be found in the section Coordinate systems and

positions (Page 14).

6. Now you can test the functionalities described below or call automatic mode.

However, before leaving the manual mode, move the kinematics to the waiting position.

This ensures that the condition for positioning the kinematics for starting automatic mode

is fulfilled.

Move kinematics to defined position

1. Move the kinematics to one of the defined positions by controlling one of the

"HMI.executeMoveTo" tags.

2. Check whether the position was reached and whether it is output by the corresponding

status tag.

3. Modify the tag from step 1 back to "0".

Changing position values

1. Change the default position values.

2. Move the kinematics to the new position by controlling the corresponding

"HMI.executeMoveTo" tag.

3. In the kinematics trace, check whether the kinematics moves to the newly configured

position.

4. Check whether the position was reached and whether it is output by the corresponding

status tag.

Opening/closing the gripper

1. Open and close the gripper using the tag "HMI.gripper".

2. Observe whether the state is output via the status tag "HMI".gripperState".

Page 65

Testing the user program

11.2 Perform test

S7-1500T Getting Started with Kinematics

Getting Started, 12/2018, A5E46089528-AA

63

Move kinematics in automatic mode

1. You have already performed the described steps 1 to 6 to prepare the kinematics in

manual mode.

2. Select automatic mode by modifying the tag "HMI.operatingMode" with the value "3".

3. Enter one of the two product types with "HMI".productType".

4. Check whether the following status tags are output correctly:

– Display of the current positions

– The gripper is closed after reaching a pickup position.

– The gripper is opened after reaching a parking position.

5. Change the product type specification with "HMI".productType".

6. Check whether all status tags from step 4 are output correctly.

7. Test the interruption and continuation of a motion using the tags "HMI.interruptMove" and

"HMI.continueMove".

Changing dynamic values

1. Change the velocity defaults for the path:

– Enter the velocity of the path using the "DynamicDefaults.Path.Velocity" parameter.

Due to the activated dynamic adaptation, first enter a velocity that is below the preset

dynamic limits at the interconnected axes.

– Enter a dynamic limitation for the maximum velocity of the path using the

"DynamicLimits.Path.Velocity" parameter. First enter a limit that is above the specified

velocity.

– Check whether the path velocity output via the tag "StatusPath.Velocity" corresponds

to the specified velocity.

2. Use the dynamic adaptation:

– At the Kinematics technology object, enter a velocity that lies above the specified

dynamic limits at the interconnected axes.

– You can observe the behavior through dynamic adaptation in the trace.

3. Deactivate dynamic adaptation with the parameter "DynamicDefaults.DynamicAdaption"

(="0").

4. Dynamic limitation for the maximum velocity of the path

– Use the parameter "DynamicLimits.Path.Velocity" at the kinematics technology object

to enter a dynamic limit that is below the specified velocity of the path.

– Check the limitation of the current path velocity with the tag "StatusPath.Velocity".

– Enter a percentage correction of the velocity specification using the tag

"Override.Velocity".

– Check the limitation of the current path velocity with the tag "StatusPath.Velocity".

Page 66

Testing the user program

11.2 Perform test

S7-1500T Getting Started with Kinematics

64 Getting Started, 12/2018, A5E46089528-AA

Troubleshooting

1. To acknowledge pending errors to the user program, select the manual mode by

modifying the tag "HMI.operatingMode" with the value "2".

2. Acknowledge the error with the tag "HMI.acknowledge".

Loading...

Loading...