Page 1

Page 2

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SIMATIC

S7-1500

S7-1500R/H redundant system

System Manual

10/2018

A5E41814787

Preface

Documentation guide

1

System overview

2

Application planning

3

Installation

4

Wiring

5

Configuration

6

Basics of program execution

7

Protection

8

Commissioning

9

Display

10

Maintenance

11

Test functions

12

Technical specifications

13

Dimension drawings

A

Accessories/spare parts

B

Safety symbols

C

-AA

Page 3

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E41814787-AA

Ⓟ

Copyright © Siemens AG 2018.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

09/2018 Subject to change

Page 4

Preface

Purpose of the documentation

Basic knowledge required

Validity of the documentation

Conventions

Note

A note contains important information on the product described in the

handling of the product or on the section of the documentation to which particular attention

should be paid.

Recycling and disposal

This documentation provides important information on the following aspects of the

S7-1500R/H redundant system:

● An overview of the redundant system

● Configuration and failure scenarios

● How to install, wire and commission the redundant system

● Information on maintenance and fault correction

General knowledge in the field of automation engineering is required to understand this

documentation.

This documentation applies to all products of the SIMATIC S7-1500R/H redundant system.

STEP 7: In this documentation, "STEP 7" is used as a synonym for all versions of the

configuration and programming software "STEP 7 (TIA Portal)".

Please also see the notes indicated as follows:

For environmentally friendly recycling and disposal of your old equipment, contact a certified

electronic waste disposal company and dispose of the equipment according to the applicable

regulations in your country.

documentation, on the

S7-1500R/H redundant system

System Manual, 10/2018, A5E41814787-AA

3

Page 5

Preface

Security information

Siemens Industry Online Support

Product support

Application examples

Services

Forums

mySupport

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens' products and solutions constitute one element of such a concept.

Customers are responsible for preventing unauthorized access to their plants, systems,

machines and networks. Such systems, machines and components should only be

connected to an enterprise network or the internet if and to the extent such a connection is

necessary and only when appropriate security measures (e.g. firewalls and/or network

segmentation) are in place.

For additional information on industrial security measures that may be implemented, please

visit (https://www.siemens.com/industrialsecurity).

Siemens' products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends that product updates are applied as soon as they are

available and that the latest product versions are used. Use of product versions that are no

longer supported, and failure to apply the latest updates may increase customers' exposure

to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under (https://www.siemens.com/industrialsecurity).

You can find current information on the following topics quickly and easily here:

●

All the information and extensive know-how on your product, technical specifications,

FAQs, certificates, downloads, and manuals.

●

Tools and examples to solve your automation tasks – as well as function blocks,

performance information and videos.

●

Information about Industry Services, Field Services, Technical Support, spare parts and

training offers.

●

For answers and solutions concerning automation technology.

●

Your personal working area in Industry Online Support for messages, support queries,

and configurable documents.

This information is provided by the Siemens Industry Online Support in the Internet

(https://support.industry.siemens.com).

S7-1500R/H redundant system

4 System Manual, 10/2018, A5E41814787-AA

Page 6

Preface

Industry Mall

The Industry Mall is the catalog and order system of Siemens AG for automation and drive

solutions on the basis of Totally Integrated Automation (TIA) and Totally Integrated Power

(TIP).

You can find catalogs for all automation and drive products on the Internet

(https://mall.industry.siemens.com).

S7-1500R/H redundant system

System Manual, 10/2018, A5E41814787-AA

5

Page 7

Table of contents

Preface ................................................................................................................................................... 3

1 Documentation guide ............................................................................................................................ 11

2 System overview ................................................................................................................................... 14

3 Application planning .............................................................................................................................. 49

2.1 What is the S7-1500R/H redundant system? ........................................................................ 14

2.1.1 Areas of application ............................................................................................................... 15

2.1.2 Operating principle of the S7-1500R/H redundant system .................................................... 19

2.1.3 Plant components and automation levels .............................................................................. 25

2.1.4 Scalability ............................................................................................................................... 26

2.1.5 Overview of features .............................................................................................................. 29

2.2 Configuration .......................................................................................................................... 30

2.2.1 Structure of the S7-1500R redundant system ....................................................................... 30

2.2.2 Structure of the S7-1500H redundant system ....................................................................... 31

2.2.3 Components ........................................................................................................................... 33

2.3 S7-1500 R/H-CPUs ................................................................................................................ 35

2.3.1 Overview of the CPU technical specifications ....................................................................... 35

2.3.2 Redundancy ........................................................................................................................... 36

2.3.3 Security .................................................................................................................................. 38

2.3.4 Diagnostics ............................................................................................................................. 39

2.3.5 Trace ...................................................................................................................................... 41

2.4 Communication ...................................................................................................................... 43

2.4.1 System and device IP addresses........................................................................................... 43

2.4.2 Integrated interfaces for communication ................................................................................ 45

2.4.3 HMI devices ........................................................................................................................... 46

2.5 Power supply .......................................................................................................................... 46

2.6 Software ................................................................................................................................. 47

2.6.1 TIA Portal ............................................................................................................................... 47

2.6.2 SINETPLAN ........................................................................................................................... 48

2.6.3 PRONETA .............................................................................................................................. 48

3.1 Requirements ......................................................................................................................... 49

3.2 Restrictions compared to the S7-1500 automation system ................................................... 51

3.3 Configuration versions ........................................................................................................... 54

3.3.1 S7-1500R/H configuration with IO devices in the PROFINET ring ........................................ 55

3.3.2 S7-1500R/H configuration with switches and linear topology ................................................ 57

3.4 Redundancy scenarios .......................................................................................................... 59

3.4.1 Introduction ............................................................................................................................ 59

3.4.2 Failure of the primary CPU .................................................................................................... 60

3.4.3 Failure of the backup CPU ..................................................................................................... 62

3.4.4 Failure of the PROFINET cable in the PROFINET ring ......................................................... 64

3.4.5 Specific redundancy scenarios for S7-1500H ........................................................................ 66

3.4.5.1 Failure of a redundancy connection in S7-1500H.................................................................. 66

3.4.5.2 Failure of both redundancy connections in S7-1500H > 1500 ms apart ............................... 68

3.4.5.3 Failure of both redundancy connections and the PROFINET cable in the PROFINET

ring ......................................................................................................................................... 70

S7-1500R/H redundant system

6 System Manual, 10/2018, A5E41814787-AA

Page 8

Table of contents

4 Installation ............................................................................................................................................ 96

5 Wiring ................................................................................................................................................. 108

3.5 Failure scenarios ..................................................................................................................... 72

3.5.1 Failure of an IO device in the PROFINET ring ....................................................................... 73

3.5.2 Failure of a switch (with line topology) in the PROFINET ring................................................ 75

3.5.3 Specific failure scenarios with S7-1500R ............................................................................... 77

3.5.3.1 Two cable interruptions in the PROFINET ring in S7-1500R > 1500 ms apart ...................... 77

3.5.3.2 Two cable interruptions in the PROFINET ring in S7-1500R within ≤ 1500 ms ..................... 79

3.5.3.3 Failure of the primary CPU when IO devices have failed in the PROFINET ring ................... 81

3.5.4 Specific failure scenarios with S7-1500H ............................................................................... 84

3.5.4.1 Failure of both redundancy connections in S7-1500H ≤ 1500 ms apart ................................ 84

3.5.4.2 Failure of one redundancy connection and the primary CPU in S7-1500H ............................ 86

3.6 Hardware configuration ........................................................................................................... 88

3.7 Use of a system power supply ................................................................................................ 90

3.8 Using HMI devices .................................................................................................................. 92

4.1 Basics...................................................................................................................................... 96

4.2 Installing the mounting rail ...................................................................................................... 98

4.3 Installing a load current supply ............................................................................................. 102

4.4 Installing a system power supply .......................................................................................... 104

4.5 Installing R/H-CPUs .............................................................................................................. 106

5.1 Rules and regulations for operation ...................................................................................... 108

5.2 Operation on grounded infeed .............................................................................................. 110

5.3 Electrical configuration .......................................................................................................... 113

5.4 Wiring rules ........................................................................................................................... 114

5.5 Connecting the supply voltage .............................................................................................. 115

5.6 Connecting system power supply and load current supply .................................................. 117

5.7 Connecting the CPU to the load power supply ..................................................................... 118

5.8 Connecting interfaces for communication with S7-1500R .................................................... 120

5.8.1 Connecting the PROFINET ring to S7-1500 ......................................................................... 120

5.9 Connecting interfaces for communication with S7-1500H .................................................... 123

5.9.1 Connecting redundancy connections (fiber-optic cables) ..................................................... 123

5.9.1.1 Synchronization modules for S7-1500H ............................................................................... 123

5.9.1.2 Selecting fiber-optic cables ................................................................................................... 124

5.9.1.3 Installing fiber-optic cables ................................................................................................... 128

5.9.1.4 Connecting redundancy connections (fiber-optic cables) to S7-1500H ............................... 130

5.9.2 Connecting the PROFINET ring to S7-1500H ...................................................................... 134

S7-1500R/H redundant system

System Manual, 10/2018, A5E41814787-AA

7

Page 9

Table of contents

6 Configuration ....................................................................................................................................... 136

7 Basics of program execution ................................................................................................................ 148

8 Protection ............................................................................................................................................ 168

9 Commissioning .................................................................................................................................... 178

6.1 Configuring the CPU ............................................................................................................ 136

6.2 Configuration procedure ...................................................................................................... 136

6.3 Project tree ........................................................................................................................... 143

6.4 Parameters ........................................................................................................................... 144

6.5 Process images and process image partitions .................................................................... 145

6.5.1 Process image - overview .................................................................................................... 145

6.5.2 Updating process image partitions in the user program ...................................................... 146

7.1 Programming the S7-1500R/H ............................................................................................. 148

7.2 Restrictions .......................................................................................................................... 150

7.3 Events and OBs ................................................................................................................... 153

7.4 Special instructions for S7-1500R/H redundant systems .................................................... 157

7.4.1 Disabling/enabling SYNCUP with the RH_CTRL instruction ............................................... 157

7.4.2 Determining the primary CPU with "RH_GetPrimaryID" ...................................................... 160

7.5 Asynchronous instructions ................................................................................................... 161

8.1 Overview of the protection functions .................................................................................... 168

8.2 Configuring access protection for the CPU .......................................................................... 168

8.3 Using the display to set additional password protection ...................................................... 172

8.4 Using the user program to set additional access protection ................................................ 172

8.5 Know-how protection ........................................................................................................... 173

8.6 Protection by locking the CPU ............................................................................................. 177

9.1 Overview .............................................................................................................................. 178

9.2 Check before powering on for the first time ......................................................................... 179

9.3 Commissioning procedure ................................................................................................... 180

9.3.1 Removing/plugging in SIMATIC memory cards ................................................................... 181

9.3.2 First power-on of the CPUs .................................................................................................. 184

9.3.3 CPU pairing .......................................................................................................................... 184

9.3.4 Redundancy IDs................................................................................................................... 187

9.3.5 Downloading projects to the CPUs ...................................................................................... 192

9.4 Operating and system states ............................................................................................... 197

9.4.1 Overview .............................................................................................................................. 197

9.4.2 STARTUP operating state ................................................................................................... 200

9.4.3 STOP operating state .......................................................................................................... 203

9.4.4 SYNCUP operating state ..................................................................................................... 203

9.4.5 RUN operating states ........................................................................................................... 204

9.4.6 SYNCUP system state ......................................................................................................... 205

9.4.7 System and operating state transitions ................................................................................ 217

9.4.8 Loss of redundancy .............................................................................................................. 226

9.4.9 Displaying and changing the system state .......................................................................... 229

S7-1500R/H redundant system

8 System Manual, 10/2018, A5E41814787-AA

Page 10

Table of contents

10 Display ................................................................................................................................................ 248

11 Maintenance ....................................................................................................................................... 257

12 Test functions ..................................................................................................................................... 282

13 Technical specifications ...................................................................................................................... 289

9.5 CPU memory reset ............................................................................................................... 231

9.5.1 Automatic memory reset ....................................................................................................... 232

9.5.2 Manual memory reset ........................................................................................................... 233

9.6 Backing up and restoring the CPU configuration .................................................................. 234

9.7 Time synchronization ............................................................................................................ 239

9.7.1 Example: Configuring the NTP server .................................................................................. 240

9.8 Identification and maintenance data ..................................................................................... 241

9.8.1 Reading out and entering I&M data ...................................................................................... 241

9.8.2 Record structure for I&M data ............................................................................................... 243

9.8.3 Example: Read out firmware version of the CPU with Get_IM_Data ................................... 245

10.1 CPU display .......................................................................................................................... 248

11.1 Replacing components of the S7-1500R/H redundant system ............................................ 257

11.1.1 Checking before replacing components ............................................................................... 257

11.1.2 Replacing defective R/H-CPUs ............................................................................................. 260

11.1.3 Replacing defective redundancy connections ...................................................................... 261

11.1.3.1 Replacing two defective PROFINET cables with S7-1500R ................................................ 262

11.1.3.2 Replacing a defective redundancy connection with S7-1500H ............................................ 263

11.1.3.3 Replacing defective synchronization module with S7-1500H ............................................... 263

11.1.3.4 Replacing both defective redundancy connections with S7-1500H ..................................... 264

11.1.4 Replacing defective PROFINET cables ................................................................................ 265

11.1.5 Replacing a defective SIMATIC memory card ...................................................................... 266

11.1.6 Replacing a defective system power supply PS or load power supply PM .......................... 267

11.1.7 Replacing defective IO devices/switches.............................................................................. 268

11.2 Replacing the front cover ...................................................................................................... 269

11.3 Replacing the coding element at the power connector of the system power supply and

load current supply ................................................................................................................ 270

11.4 Firmware update ................................................................................................................... 272

11.5 Resetting CPUs to factory settings ....................................................................................... 277

11.6 Maintenance and repair ........................................................................................................ 281

12.1 Test functions ........................................................................................................................ 282

12.2 Reading out/saving service data ........................................................................................... 287

13.1 Standards and Approvals ..................................................................................................... 290

13.2 Electromagnetic compatibility ............................................................................................... 296

13.3 Shipping and storage conditions ........................................................................................... 298

13.4 Mechanical and climatic ambient conditions ........................................................................ 299

13.5 Information on insulation tests, protection class, degree of protection and rated voltage .... 300

13.6 Use of S7-1500R/H in Zone 2 hazardous area .................................................................... 301

S7-1500R/H redundant system

System Manual, 10/2018, A5E41814787-AA

9

Page 11

Table of contents

A Dimension drawings ............................................................................................................................. 302

B Accessories/spare parts ....................................................................................................................... 305

C Safety symbols .................................................................................................................................... 307

Glossary .............................................................................................................................................. 310

Index ................................................................................................................................................... 323

C.1 Safety-related symbols for devices without Ex protection ................................................... 307

C.2 Safety-related symbols for devices with Ex protection ........................................................ 308

S7-1500R/H redundant system

10 System Manual, 10/2018, A5E41814787-AA

Page 12

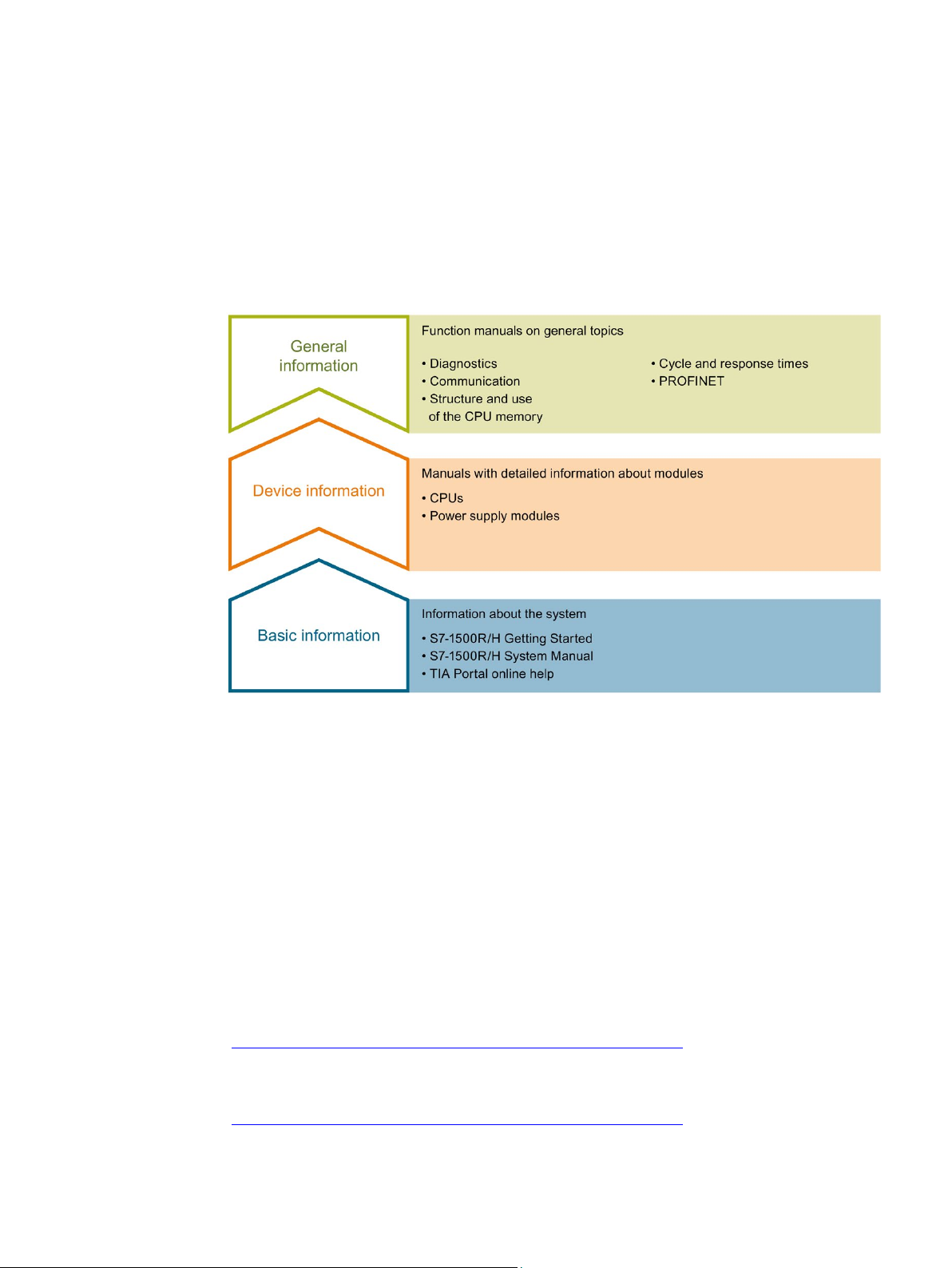

1

Basic information

Device information

General information

The documentation for the redundant S7-1500R/H system is divided into three areas.

This division enables you to access the specific content you require.

Figure 1-1 S7-1500R/H guide

The System Manual and Getting Started describe in detail the configuration, installation,

wiring and commissioning of the redundant S7-1500R/H system. The STEP 7 online help

supports you in the configuration and programming.

Product manuals contain a compact description of the module-specific information, such as

properties, wiring diagrams, characteristics and technical specifications.

The function manuals contain detailed descriptions on general topics regarding the

redundant S7-1500R/H system, e.g. diagnostics, communication.

You can download the documentation free of charge from the Internet

(https://support.industry.siemens.com/cs/ww/en/view/109742691).

Changes and supplements to the manuals are documented in a Product Information.

You can download the product information free of charge from the Internet

(https://support.industry.siemens.com/cs/ww/en/view/109742691).

S7-1500R/H redundant system

System Manual, 10/2018, A5E41814787-AA

11

Page 13

Documentation guide

S7-1500/ET 200MP Manual Collection

SIMATIC S7-1500 comparison list for programming languages

"mySupport"

"mySupport" - Documentation

"mySupport" - CAx data

The S7-1500/ET 200MP Manual Collection contains the complete documentation on the

redundant S7-1500R/H system gathered together in one file.

You can find the Manual Collection on the Internet

(https://support.industry.siemens.com/cs/ww/en/view/86140384).

The comparison list contains an overview of which instructions and functions you can use for

which controller families.

You can find the comparison list on the Internet

(https://support.industry.siemens.com/cs/ww/en/view/86630375).

With "mySupport", your personal workspace, you make the best out of your Industry Online

Support.

In "mySupport", you can save filters, favorites and tags, request CAx data and compile your

personal library in the Documentation area. In addition, your data is already filled out in

support requests and you can get an overview of your current requests at any time.

You must register once to use the full functionality of "mySupport".

You can find "mySupport" on the Internet (https://support.industry.siemens.com/My/ww/en/).

In the Documentation area in "mySupport" you can combine entire manuals or only parts of

these to your own manual.

You can export the manual as PDF file or in a format that can be edited later.

You can find "mySupport" - Documentation on the Internet

(https://support.industry.siemens.com/My/ww/en/documentation).

In the CAx data area in "mySupport", you can access the current product data for your CAx

or CAe system.

You configure your own download package with a few clicks.

In doing so you can select:

● Product images, 2D dimension drawings, 3D models, internal circuit diagrams, EPLAN

macro files

● Manuals, characteristics, operating manuals, certificates

● Product master data

You can find "mySupport" - CAx data on the Internet

(https://support.industry.siemens.com/my/ww/en/CAxOnline).

S7-1500R/H redundant system

12 System Manual, 10/2018, A5E41814787-AA

Page 14

Documentation guide

Application examples

PRONETA

SINETPLAN

The application examples support you with various tools and examples for solving your

automation tasks. Solutions are shown in interplay with multiple components in the system separated from the focus on individual products.

You will find the application examples on the Internet

(https://support.industry.siemens.com/sc/ww/en/sc/2054).

With SIEMENS PRONETA (PROFINET network analysis), you analyze the PROFINET

network during commissioning. PRONETA features two core functions:

● The topology overview independently scans PROFINET network and all connected

components.

● The IO check is a fast test of the wiring and the module configuration of a system.

You can find SIEMENS PRONETA on the Internet

(https://support.industry.siemens.com/cs/ww/en/view/67460624).

SINETPLAN, the Siemens Network Planner, supports you in planning automation systems

and networks based on PROFINET. The tool facilitates professional and predictive

dimensioning of your PROFINET installation as early as in the planning stage. In addition,

SINETPLAN supports you during network optimization and helps you to exploit network

resources optimally and to plan reserves. This helps to prevent problems in commissioning

or failures during productive operation even in advance of a planned operation. This

increases the availability of the production plant and helps improve operational safety.

The advantages at a glance

● Network optimization thanks to port-specific calculation of the network load

● Increased production availability thanks to online scan and verification of existing systems

● Transparency before commissioning through importing and simulation of existing STEP 7

projects

● Efficiency through securing existing investments in the long term and optimal exploitation

of resources

You can find SINETPLAN on the Internet (https://www.siemens.com/sinetplan).

S7-1500R/H redundant system

System Manual, 10/2018, A5E41814787-AA

13

Page 15

2

2.1

What is the S7-1500R/H redundant system?

S7-1500R/H redundant system

Aims of using redundant automation systems

WARNING

Please note the difference between fault-tolerant and fail-safe systems.

For the S7-1500R/H redundant system, the CPUs are duplicated, in other words redundant.

The two CPUs process the same project data and the same user program in parallel. The

two CPUs are synchronized over two redundancy connections. If one CPU fails, the other

CPU maintains control of the process.

Redundant automation systems are used in practice to achieve greater availability or failsafety.

● Purpose of fault-tolerant systems: to reduce the probability of production downtime by

operating two systems in parallel.

● Purpose of fail-safe systems: to protect life, the environment and capital with safe

shutdown to a secure state.

S7-1500R/H is a fault-tolerant automation system, but not a fail-safe system. The S71500R/H system must not be used to control safety-critical processes.

S7-1500R/H redundant system

14 System Manual, 10/2018, A5E41814787-AA

Page 16

System overview

2.1.1

Areas of application

Objective

Use

2.1 What is the S7-1500R/H redundant system?

The S7-1500R/H redundant system offers a high degree of reliability and system availability.

A redundant configuration of the most important automation components reduces the

probability of production downtimes and the consequences of component errors.

The higher the risks and costs of a production downtime, the more worthwhile the use of a

redundant system. You can compensate for the generally higher investment costs by

avoiding production downtimes.

In redundantly operated systems, failure or malfunction of individual automation components

must not impede the operation of the plant. S7-1500R/H redundant systems are used in the

following areas, for example:

● Tunnels

● Airports (for example baggage conveyors)

● Subways

● Shipbuilding

● Wastewater treatment plants

● High-bay warehouse

S7-1500R/H redundant system

System Manual, 10/2018, A5E41814787-AA

15

Page 17

System overview

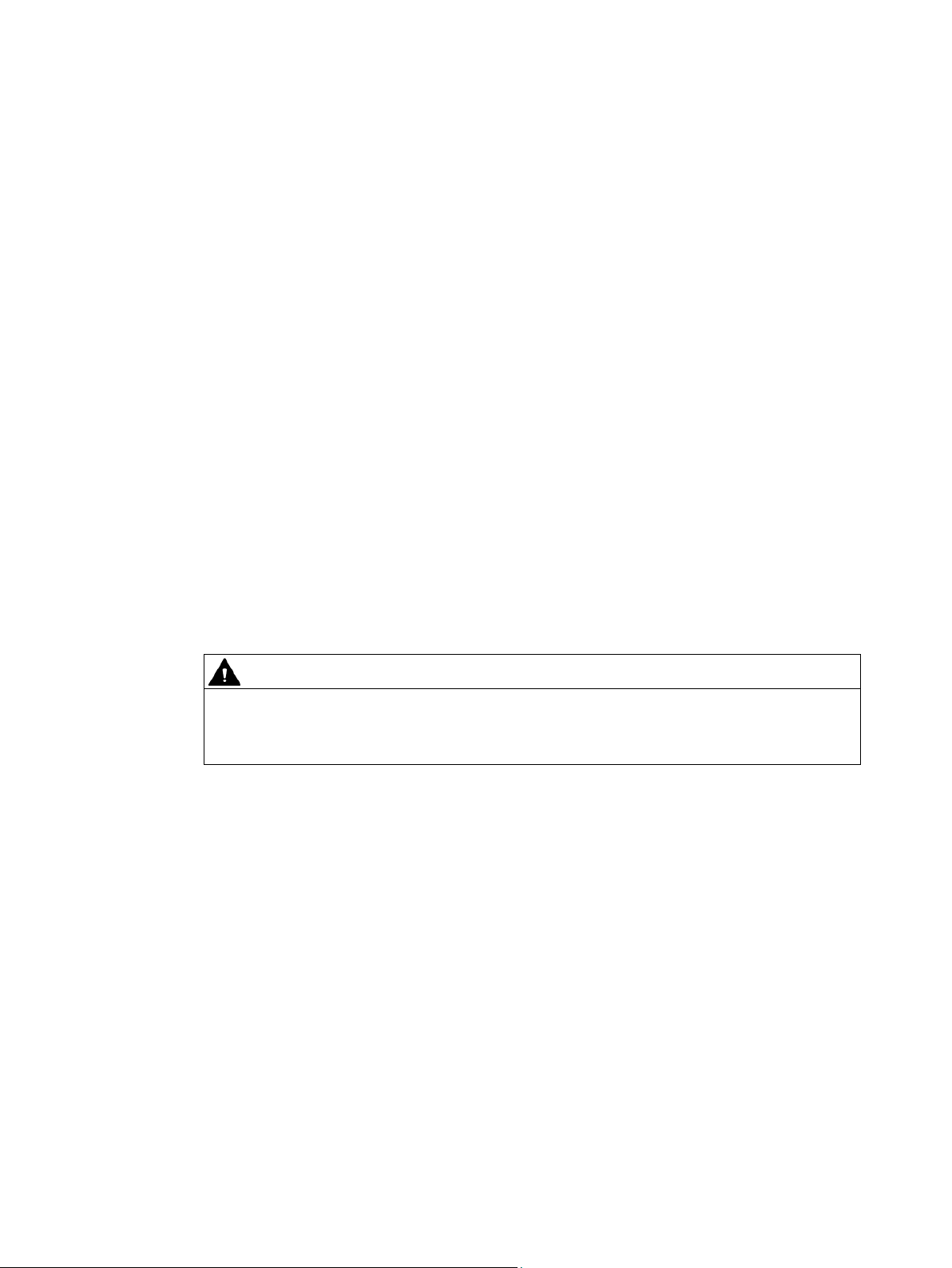

Example 1: Avoiding downtimes

Automation task

Feature

Solution

Benefits

2.1 What is the S7-1500R/H redundant system?

An automation solution is required for a road tunnel to:

● Control the lighting in the tunnel

● Control the ventilation in the tunnel in line with the concentration of pollutants in the tunnel

Uninterrupted operation of the ventilation system is required to keep the concentration of

pollutants below a set level. Constant availability must be ensured for the event that

individual automation components fail, for example because of a fire in the tunnel.

Three fans (M) ventilate the tunnel. The automation solution controls the fan speeds in line

with the measured pollutant concentration. Three sensors in the tunnel measure the pollutant

levels in the air. The S7-1500H redundant system with two redundant CPUs is used to

ensure fan availability.

As well as controlling the fans, the S7-1500H redundant system also controls the illumination

and the traffic lights.

Figure 2-1 Example: Tunnel automation

The user program for controlling the fans runs on both CPUs in the S7-1500H redundant

system. You can position the two CPUs up to 10 kilometers apart. If one CPU or one

redundancy connection fails due to a local incident, the incident does not affect the

controlled process. The fans continue to operate.

You can find a detailed description of tunnel automation with S7-1500H in Getting started

(https://support.industry.siemens.com/cs/ww/en/view/109757712) Redundant system S71500R/H.

S7-1500R/H redundant system

16 System Manual, 10/2018, A5E41814787-AA

Page 18

System overview

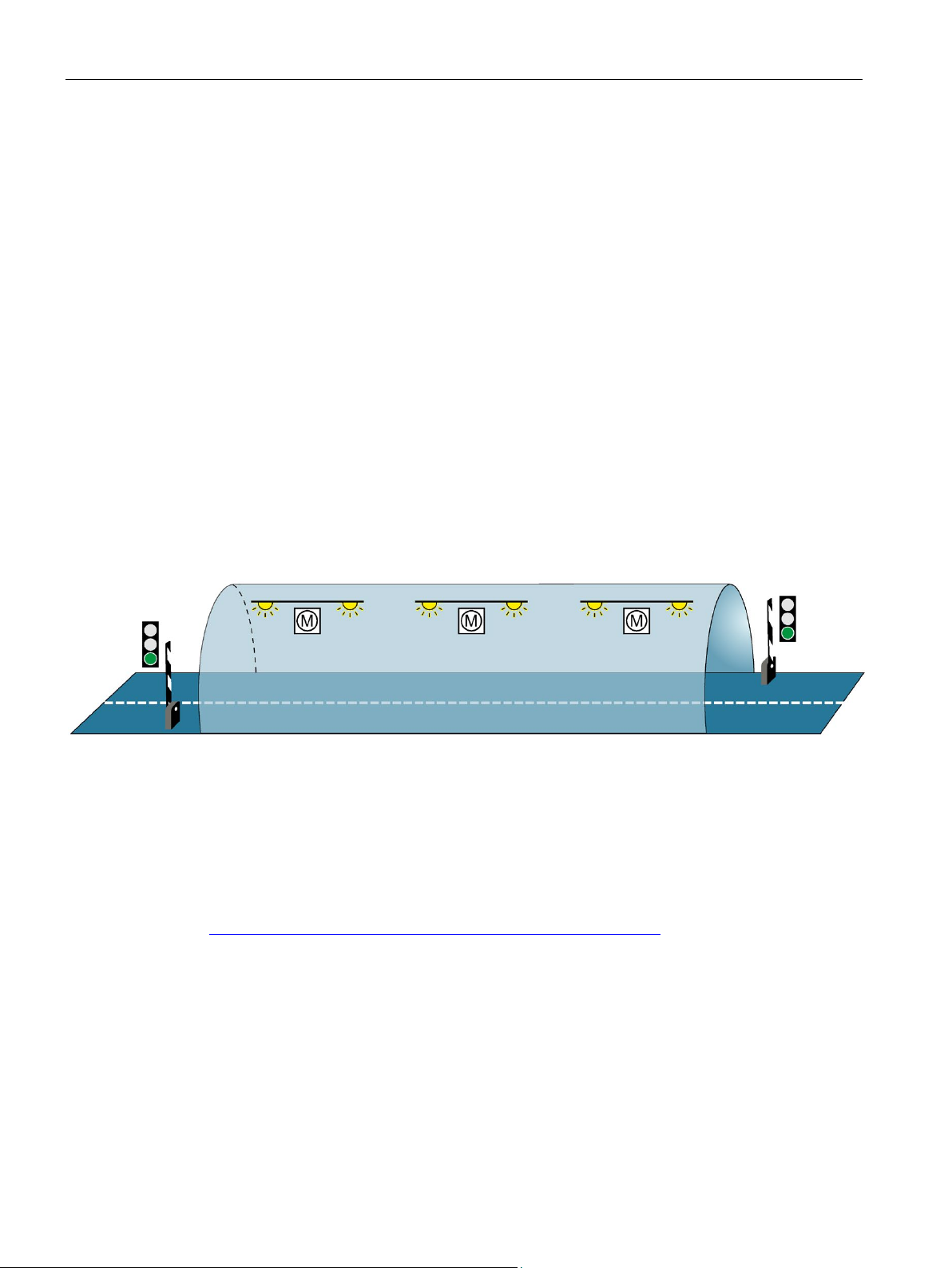

Example 2: Avoiding high system restart costs as a result of data loss

Automation task

Feature

Solution

Benefits

2.1 What is the S7-1500R/H redundant system?

A logistics company needs a matching automation solution for controlling the storage and

retrieval unit in a high-bay warehouse.

The failure of a controller would have serious consequences. After the system restart, you

would have to reposition the storage and retrieval units and record the content of the

containers again. The automation solution must ensure that no data is lost if a CPU fails and

that the warehouse can continue to operate.

To store goods in and retrieve them from the bays, the storage and retrieval unit moves

along an X, Y and Z axis. If the process is interrupted, data can be lost and the location of

the goods is not known. To guard against the loss of data, the storage and retrieval unit is

controlled by the S7-1500R redundant system.

Figure 2-2 Example: High-bay warehouse

If one CPU fails, the second CPU maintains control of the process. The project data and the

user program are saved redundantly and are not lost if a CPU fails. Once you have replaced

the defective CPU and switched it to RUN, the redundant system automatically synchronizes

the project data with the user program in the new CPU. The solution saves you service time

and downtime costs for the warehouse.

S7-1500R/H redundant system

System Manual, 10/2018, A5E41814787-AA

17

Page 19

System overview

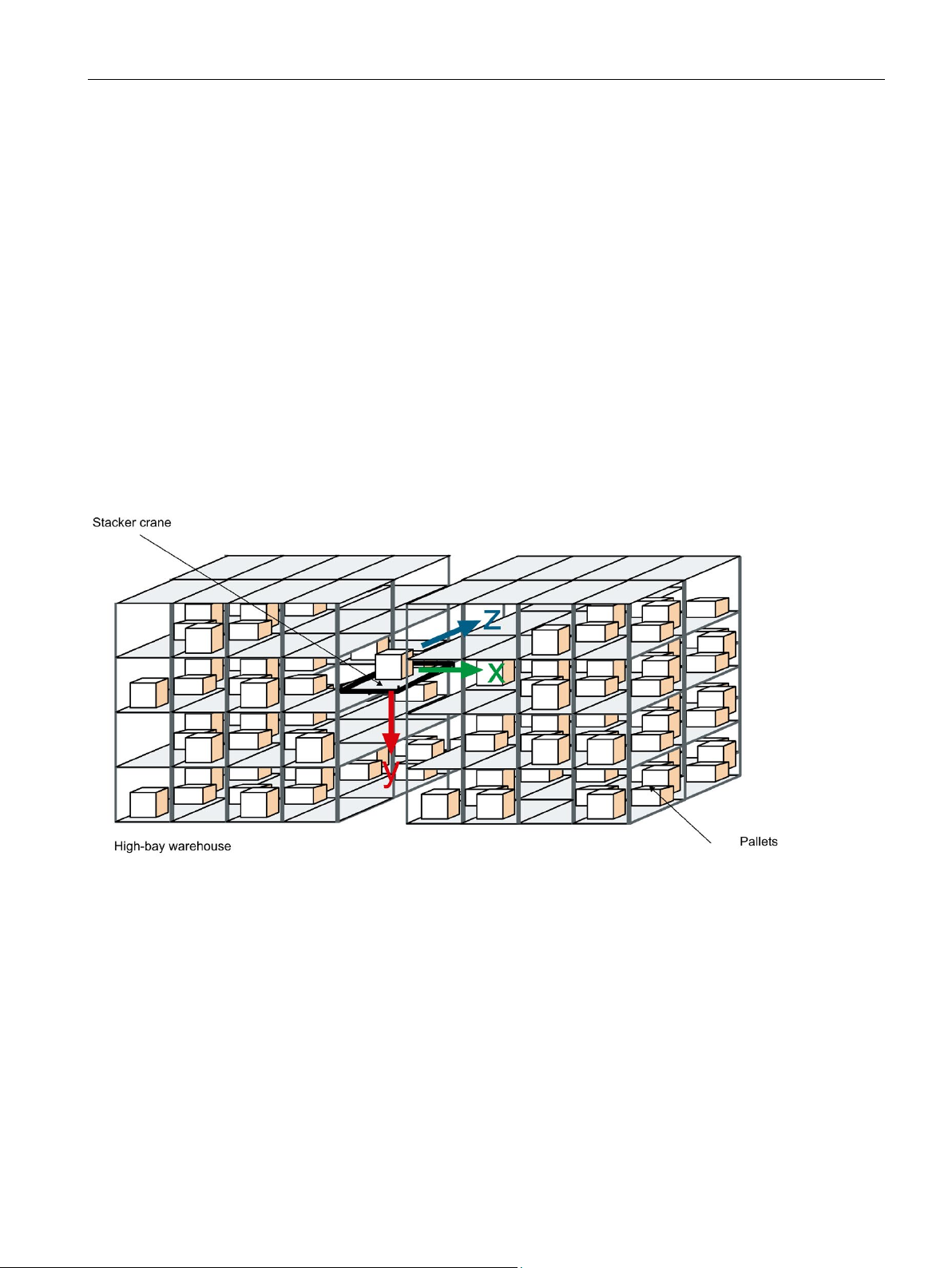

Example 3: Avoiding equipment and material damage

Automation task

Feature

Solution

Benefits

2.1 What is the S7-1500R/H redundant system?

A steel works needs a matching automation solution to control a blast furnace for the steel

production.

Failures, especially in the process industry, can result in damages to the system, workpieces

or material. In a steelworks, there is a danger of the pig iron cooling if the process is

interrupted. The pig iron then cannot be used for the production of steel. The automation

solution must ensure that the plant continues to run if a CPU fails and that the material is not

damaged.

The S7-1500R redundant system controls the blast furnace. The distributed automation

components of the redundant system control the temperature, volume and pressure

parameters.

Figure 2-3 Example: Blast furnace

The S7-1500R redundant system compensates for the possible failure of a CPU or

redundant connection. You do not have to interrupt the smelting process when replacing a

CPU while the plant is running. Uninterrupted plant operation avoids high restart and

material costs.

S7-1500R/H redundant system

18 System Manual, 10/2018, A5E41814787-AA

Page 20

System overview

2.1.2

Operating principle of the S7-1500R/H redundant system

Introduction

S7-1500 design and operating principle

①

S7-1500R CPU

②

PROFINET cable (redundancy connections, PROFINET ring)

③

IO device

④

Switch

2.1 What is the S7-1500R/H redundant system?

S7-1500R/H redundant systems tolerate the failure of one of the two CPUs or an interruption

in the PROFINET ring. The S7-1500R and S7-1500H systems differ in structure,

configuration limits and performance.

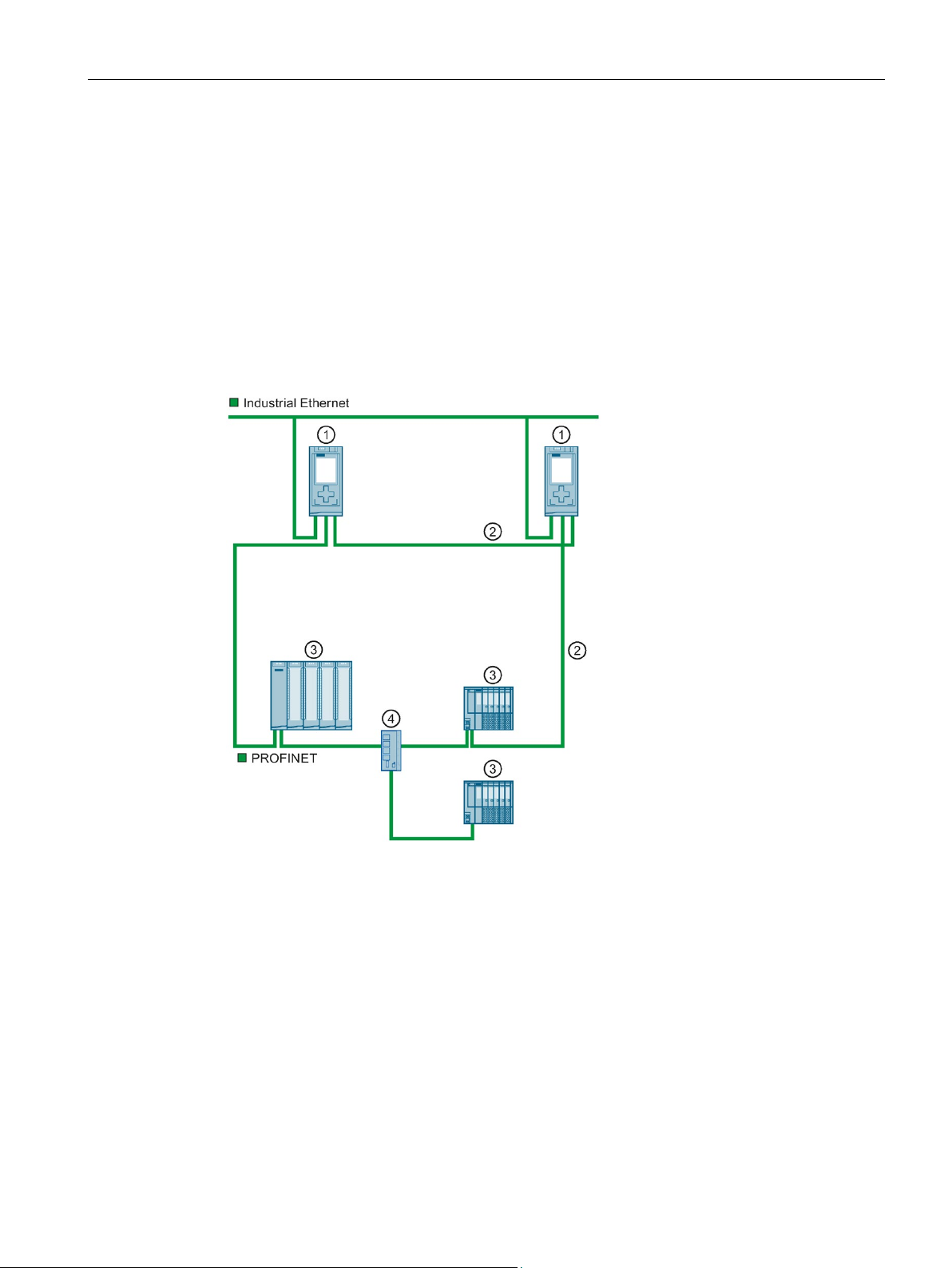

The figure below shows the typical structure of the S7-1500R redundant system.

Figure 2-4 Structure of an S7-1500R redundant system

S7-1500R/H redundant system

System Manual, 10/2018, A5E41814787-AA

19

Page 21

System overview

2.1 What is the S7-1500R/H redundant system?

The S7-1500R redundant system consists of:

● Two S7-1500R CPUs

● A PROFINET ring with the Media Redundancy Protocol

● IO devices

● if needed, Switches

All PROFINET IO devices assigned to the S7-1500R system must support system

redundancy S2. These PROFINET IO devices can be located in the PROFINET ring or they

can be separated with a switch.

All PROFINET devices in the PROFINET ring must support media redundancy (MRP). The

H-Sync forwarding function is also recommended. System redundancy S2 is not a

prerequisite. For example, you can use switches and HMI devices without system

redundancy S2.

The redundancy connections in an S7-1500R system are the PROFINET ring with MRP

The two CPUs must be directly connected to each other with a PROFINET cable. All nodes

can still communicate with each other in the event of an interruption in the ring. PROFINET

devices that do not support MRP must be separated from the ring with a switch

One of the two CPUs in the redundant system takes on the role of primary CPU. The other

CPU takes on the role of the following CPU (backup CPU). The role of the CPUs can change

during operation. Synchronization of primary and backup CPU ensures rapid switchover

between CPUs in the event of a failure of the primary CPU. If the primary CPU fails, the

backup CPU takes over control of the process as the new primary CPU.

The redundancy connections use part of the bandwidth on the PROFINET cable for the

synchronization of the R-CPUs. This bandwidth is therefore not available for PROFINET IO

communication.

③

①

②

④

②.

④.

S7-1500R/H redundant system

20 System Manual, 10/2018, A5E41814787-AA

Page 22

System overview

S7-1500H structure and operating principle

①

S7-1500H CPU

②

PROFINET cable (PROFINET ring)

③

Redundancy connections (fiber-optic cables)

④

IO device

⑤

Switch

2.1 What is the S7-1500R/H redundant system?

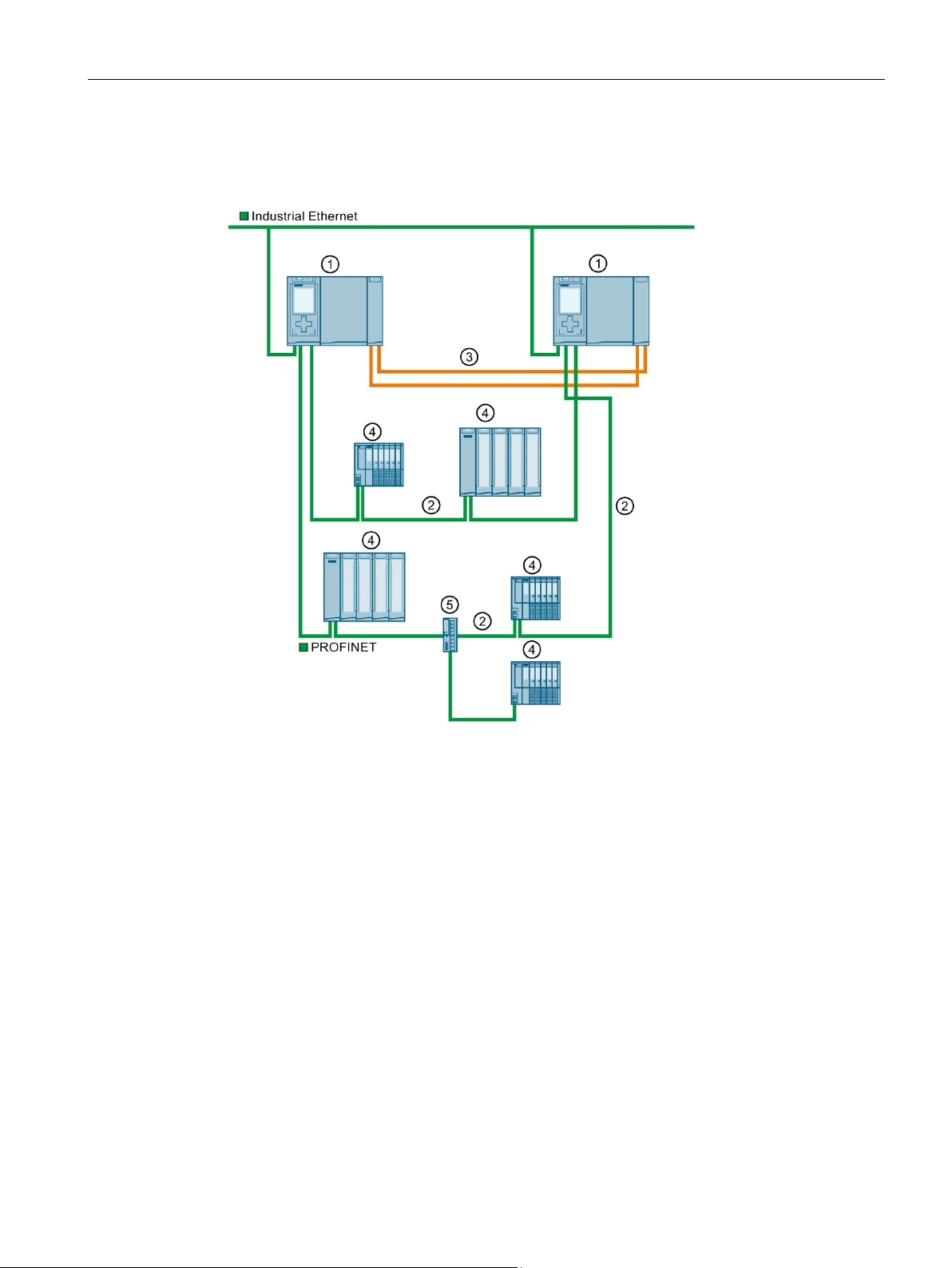

The figure below shows the typical structure of the S7-1500H redundant system.

Figure 2-5 Structure of an S7-1500H redundant system

S7-1500R/H redundant system

System Manual, 10/2018, A5E41814787-AA

21

Page 23

System overview

2.1 What is the S7-1500R/H redundant system?

The S7-1500H redundant system consists of:

● Two S7-1500H CPUs

● A PROFINET ring with the Media Redundancy Protocol

● Two redundancy connections

● IO devices

● if needed, Switches

All nodes in the redundant system must support system redundancy S2 and media

redundancy (MRP).

All PROFINET IO devices assigned to the S7-1500H system must support system

redundancy S2. These PROFINET IO devices can be located in the PROFINET ring or they

can be separated with a switch.

All PROFINET devices in the PROFINET ring must support media redundancy (MRP).

System redundancy S2 is not a prerequisite. For example, you can use switches and HMI

devices without system redundancy S2.

As with S7-1500R, the S7-1500H redundant system requires a PROFINET ring

the CPUs. All nodes can still communicate with each other in the event of an interruption in

the ring. Devices that do not support MRP must be separated from the ring with a switch

Unlike in S7-1500R, the PROFINET ring and redundancy connections in S7-1500H are

separate. The two redundancy connections are fiber-optic cables that connect the CPUs

directly over synchronization modules

One of the two CPUs in the redundant system takes on the role of primary CPU. The other

CPU takes on the role of the following CPU (backup CPU). The role of the CPUs can change

during operation.

④

①

②

③

⑤

② closed by

⑤.

③.

Synchronization of primary and backup CPU ensures rapid switchover between CPUs in the

event of a failure of the primary CPU. If the primary CPU fails, the backup CPU takes over

control of the process as the new primary CPU.

The synchronization of the H-CPUs does not affect the bandwidth on the PROFINET.

S7-1500R/H redundant system

22 System Manual, 10/2018, A5E41814787-AA

Page 24

System overview

Differences between S7-1500R and S7-1500H

S7-1500R

S7-1500H

CPU 1513R-1 PN

CPU 1515R-2 PN

CPU 1517H-3 PN

Performance

Hardware

Range

Configuration limits

2.1 What is the S7-1500R/H redundant system?

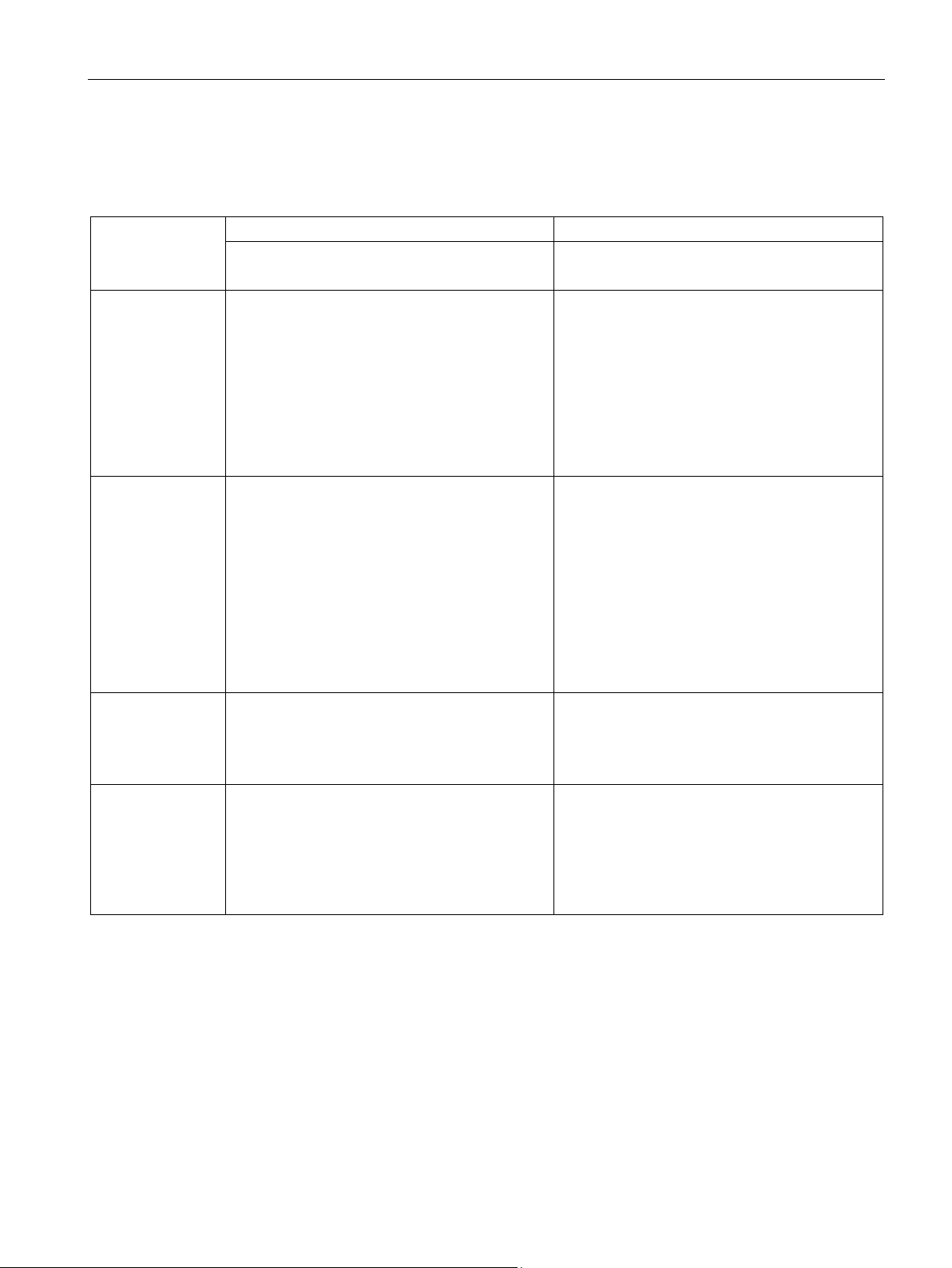

Table 2- 1 S7-1500R and S7-1500H system differences

• Transfer rate of 100 Mbps (for synchronization

and communication)

• Data work-memory:

– CPU 1513R-1 PN: max. 1.5 MB

– CPU 1515R-2 PN: max. 3 MB

• Code work-memory:

– CPU 1513R-1 PN: max. 300 KB

– CPU 1515R-2 PN: max. 500 KB

• The CPUs are identical in design with the

respective S7-1500 standard versions.

• Synchronization of the CPUs takes place over

the PROFINET ring.

• The H-Sync forwarding function is recom-

mended for all nodes in the PROFINET ring.

• Part of the bandwidth on the PROFINET cable

is required for synchronization of the CPUs.

Less bandwidth is therefore available for

PROFINET IO communication.

• Distance between the two R-CPUs:

– Max. 100 m without media converter

– Several kilometers with media converter

(depends on the media converter used)

• In the PROFINET ring: Max. 50 PROFINET

devices, including R-CPUs (max. 16

PROFINET devices recommended)

• In the PROFINET ring and separated with

switches (line): Max. 66 PROFINET devices

(including R-CPUs)

• Significantly greater performance than

S7-1500R due to

– separate redundancy connections over fi-

ber-optic cable

– high computing power

• transfer rate of 1 Gbps (for synchronization)

• Data work-memory: max. 8 MB

• Code work-memory: max. 2 MB

• Each CPU has two optical interfaces.

• Synchronization of the CPUs runs separately

from the PROFINET ring over fiber-optic cables.

• The full bandwidth of the PROFINET cable is

available for PROFINET IO communication.

• Distance between the two H CPUs:

– Maximum of 10 km (depends on the syn-

chronization modules used)

• In the PROFINET ring: Max. 50 PROFINET

devices (including H-CPUs)

• In the PROFINET ring and separated with

switches (line): Max. 258 PROFINET devices

(including H-CPUs)

S7-1500R/H redundant system

System Manual, 10/2018, A5E41814787-AA

23

Page 25

System overview

Comparison of S7-1500 standard system and S7-1500R/H

S7-1500

S7-1500R/H

CPU 1513-1 PN

CPU 1515-2 PN

CPU 1517-3 PN/DP

CPU 1513F-1 PN

CPU 1515F-1 PN

CPU 1517F-3 PN/DP

CPU 1513R-1 PN

CPU 1515R-2 PN

CPU 1517H-3 PN

Support for distributed I/O

✓ ✓ ---

Configuration control

✓ ✓ ---

✓ ✓

CPU redundancy

---

---

✓

System redundancy S2

---

---

✓

Isochronous mode

✓ ✓ ---

Shared Device ✓ ✓

---

IRT

✓ ✓ ---

MRP

✓ ✓ ✓

MRPD ✓ ✓

---

OPC UA ✓ ✓

---

Motion Control ✓ ✓

---

PID control ✓ ✓

✓1)

Security Integrated

✓ ✓ ✓

Protection function: Copy protection

✓ ✓ ---

Safety mode 2)

--- ✓ ---

Integrated system diagnostics

✓ ✓ ✓

1)

2)

For personal, environmental or investment protection, you will need fail-safe automation systems (F-systems).

2.1 What is the S7-1500R/H redundant system?

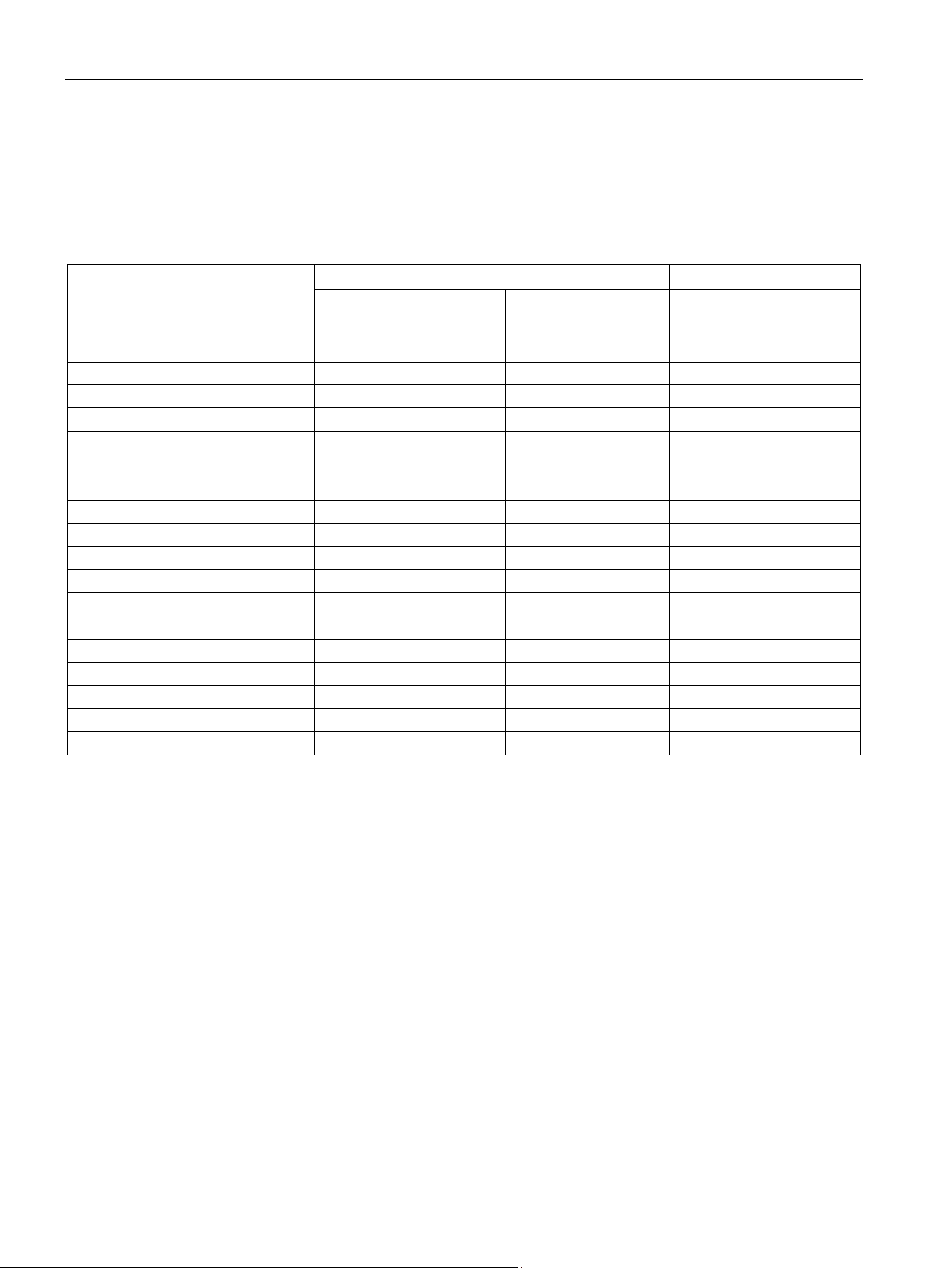

The table below sets out the key features of comparable CPUs of the S7-1500 automation

system and of the S7-1500R/H redundant system.

Table 2- 2 S7-1500 and S7-1500R/H comparison

Web server

Only support the PID basic functions (do not support PID_Compact, PID _3Step or PID_Temp).

---

S7-1500R/H redundant system

24 System Manual, 10/2018, A5E41814787-AA

Page 26

System overview

2.1.3

Plant components and automation levels

Plant components and automation levels

2.1 What is the S7-1500R/H redundant system?

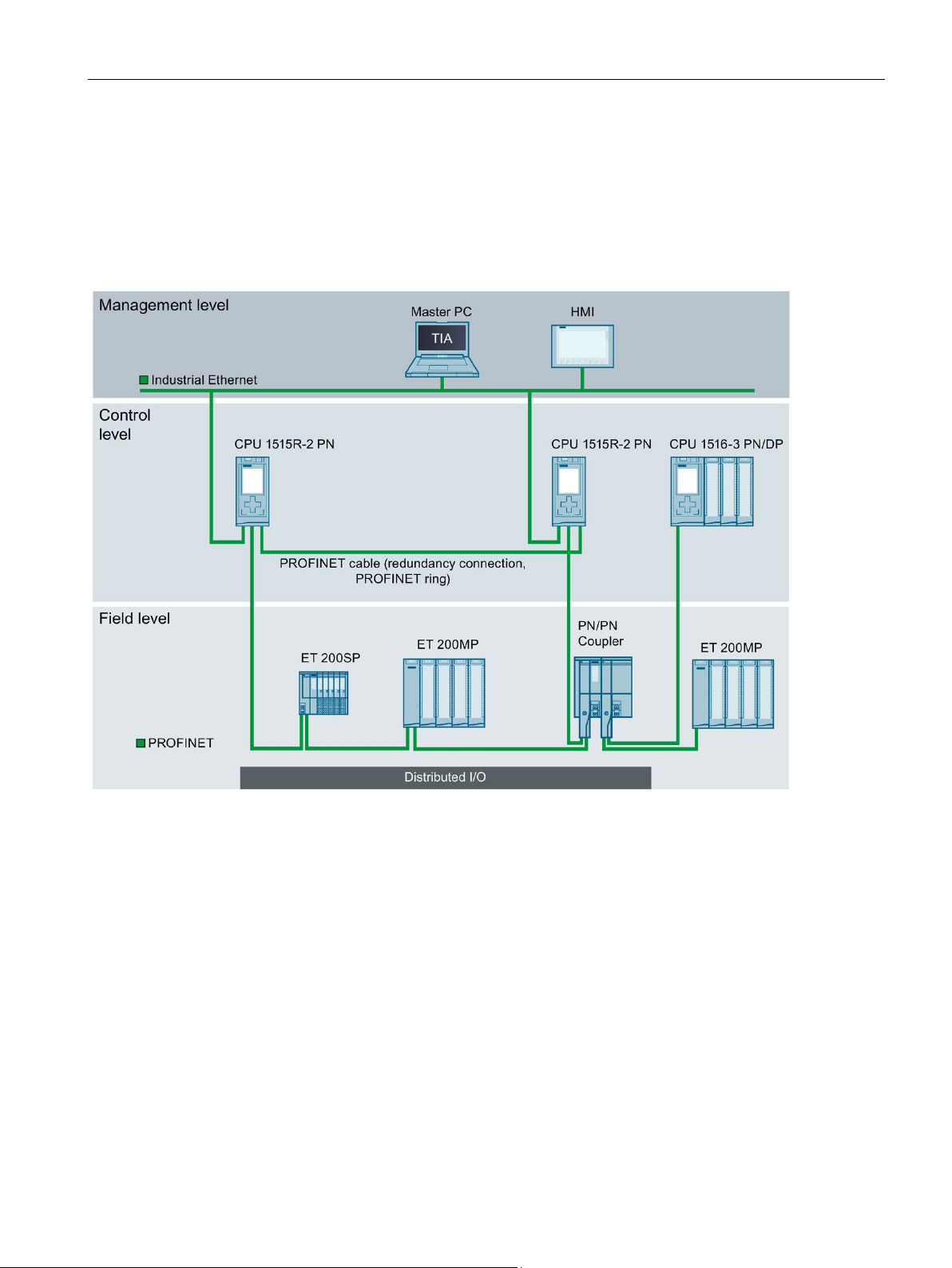

The schematic diagram below shows the key components of the redundant system from the

management level to the control level and the field level.

Figure 2-6 Possible configuration at the management, control and field level using the example of S7-1500R

From the management level, the master PC accesses the various devices at the control and

field level. The master PC is connected to the CPUs over Industrial Ethernet.

The R-CPUs at the control level are redundant in design. The IO devices at the field level are

connected to the R-CPUs within a PROFINET ring.

The redundant S7-1500R system cyclically exchanges IO data with another PROFINET IO

system via a PN/PN coupler. The left-hand side of the PN/PN coupler is assigned to the

S7-1500R redundant system. The right-hand side of the PN/PN coupler is assigned to the

CPU 1516-3 PN/DP (IO controller).

The configuration tolerates the failure of one CPU or an interruption in the PROFINET ring.

The primary CPU and the backup CPU execute the user program in parallel. If one CPU

fails, the second CPU maintains control of the process.

If the PROFINET ring is interrupted, for example as a result of a cable break or an IO device

failure, redundancy in the ring is lost. However, the IO devices that have not failed continue

to operate and can be accessed.

S7-1500R/H redundant system

System Manual, 10/2018, A5E41814787-AA

25

Page 27

System overview

2.1.4

Scalability

Introduction

S7-1500R

Note

Recommendation for S7-1500R: Operate a maximum of 16 PROFINET devices (including

R-CPUs) in the PROFINET ring.

The number of devices in the PROFINET ring affects the availability of the S7

system. You should therefore operate no more than 16 PROFINET devices (

CPUs) in the PROFINET ring. Operating significantly more devices in the PROFINET ring

will reduce the availability of the IO devices and the R

The technical specifications in the documentation are based on the recommended maximum

of 16 PR

2.1 What is the S7-1500R/H redundant system?

Redundant systems are more cost-intensive to use than non-redundant systems:

● There are two CPUs.

● The physical connections (PROFINET ring and redundancy connections) can be required

over large distances.

The S7-1500R/H redundant system is scalable. In other words, the S7-1500R and S7-1500H

systems have the same functional scope, but differ in terms of:

● Performance

● Hardware

● Range

● Configuration limits

● Costs

You connect the CPUs to the Industrial Ethernet over X2 PROFINET interfaces of CPUs S71515R-2 PN or using an additional switch.

S7-1500R supports the following number of PROFINET devices (switches, S7-1500R/H

CPUs, S7-1500 CPUs (V2.5 or later), HMI devices, and IO devices such as ET 200MP and

ET 200SP):

● In the PROFINET ring: max. 50 (recommended: max. 16)

● In the PROFINET ring and separated with switches (line): max. 66

-1500R

including R-

-CPUs.

OFINET devices in the ring in S7-1500R.

S7-1500R/H redundant system

26 System Manual, 10/2018, A5E41814787-AA

Page 28

System overview

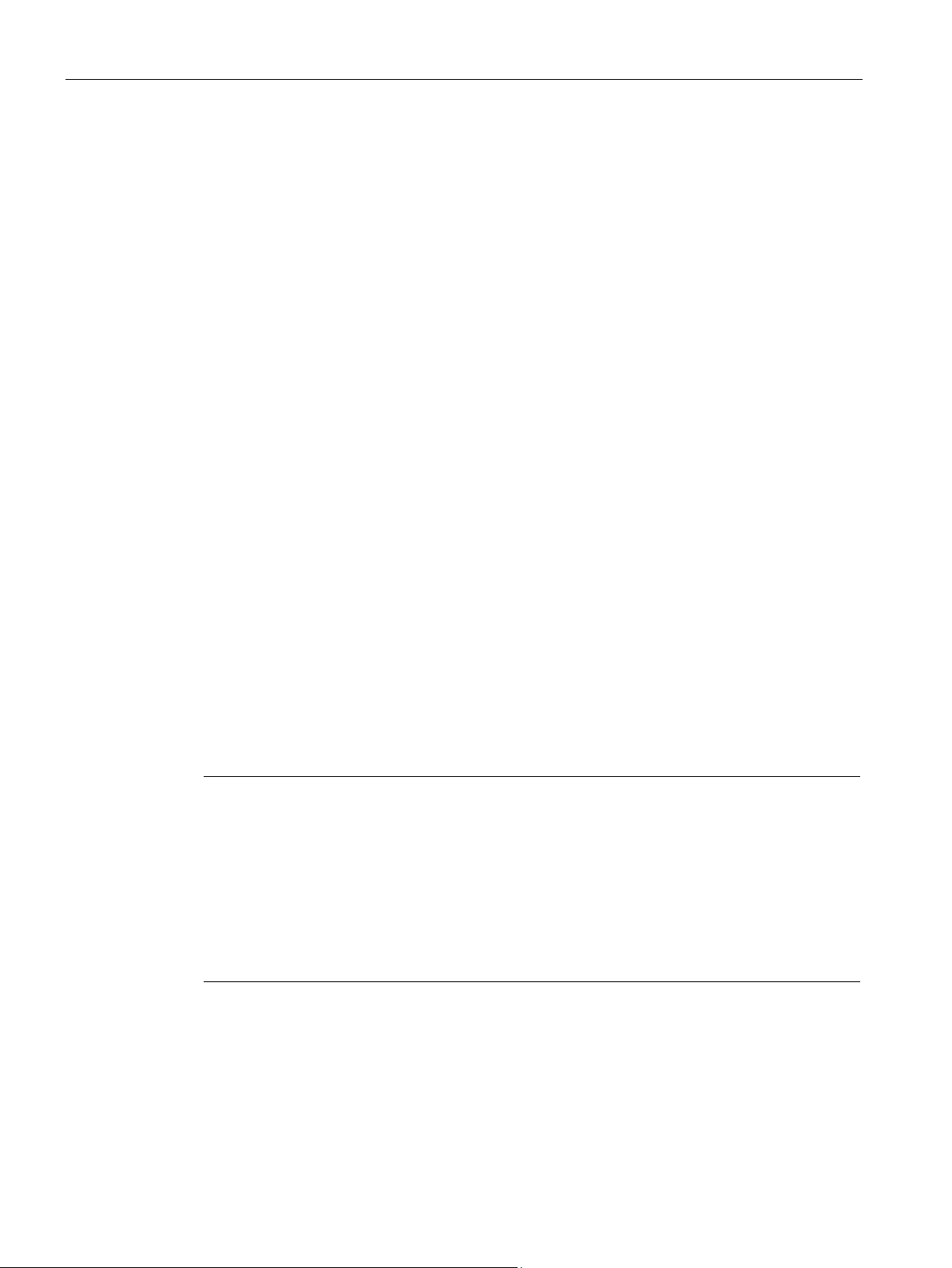

①

Load power supply (optional)

②

CPU S7-1515R-2 PN

③

PROFINET cable (redundancy connections, PROFINET ring)

④

IO device in the PROFINET ring

⑤

Switch

⑥

IO device outside the PROFINET ring (separated with a switch)

2.1 What is the S7-1500R/H redundant system?

The redundancy connections in S7-1500R are the PROFINET ring with MRP. The CPUs are

synchronized over the PROFINET ring.

Figure 2-7 S7-1500R configuration version

S7-1500R/H redundant system

System Manual, 10/2018, A5E41814787-AA

27

Page 29

System overview

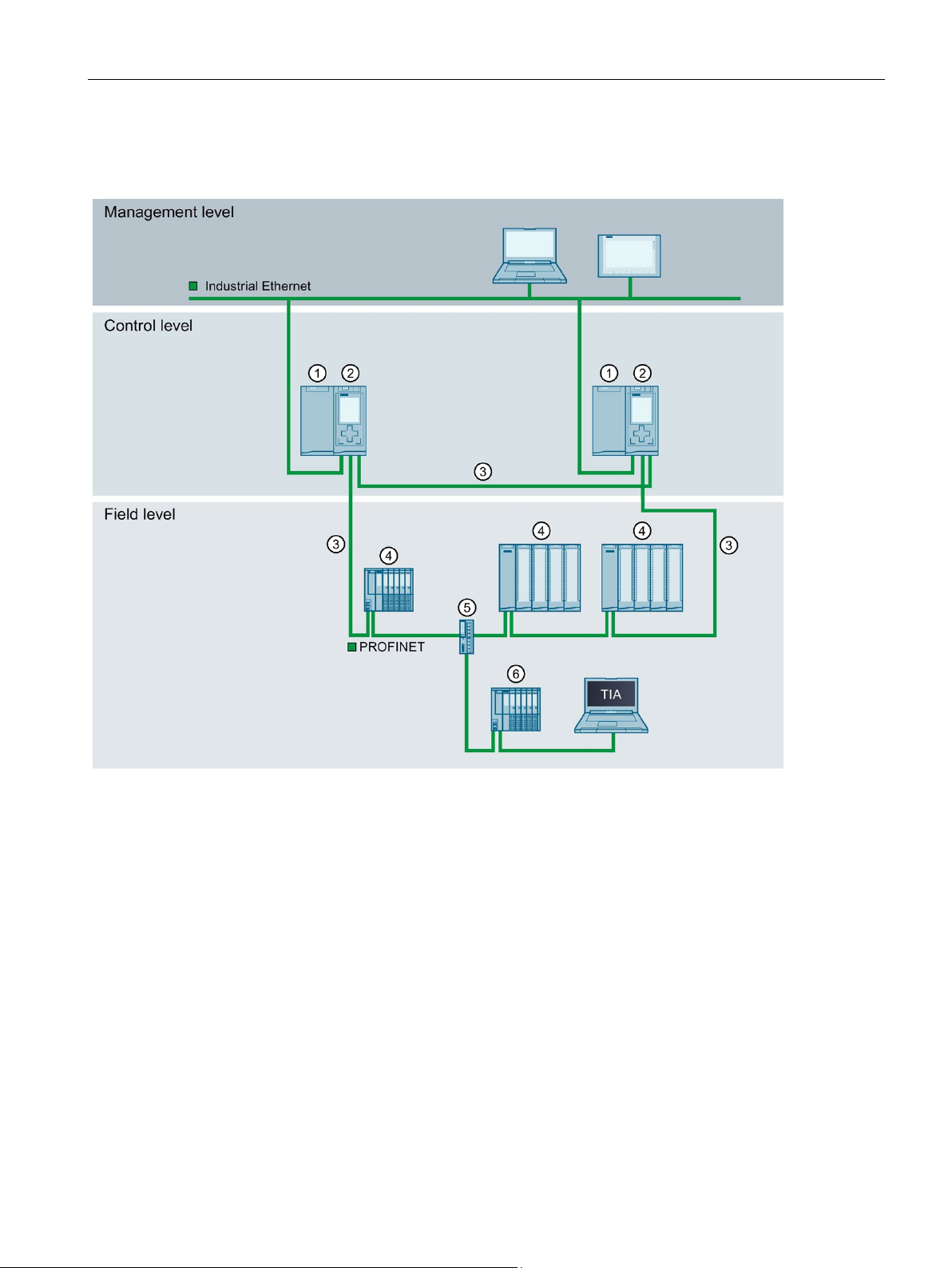

S7-1500H

①

Load power supply (optional)

②

CPU 1517H-3 PN

③

PROFINET cable (redundancy connections, PROFINET ring)

④

Redundancy connections (two duplex fiber-optic cables)

⑤

IO device in the PROFINET ring

⑥

Switch

⑦

IO device outside the PROFINET ring (separated with switch)

2.1 What is the S7-1500R/H redundant system?

You connect the CPUs to the Industrial Ethernet over a PROFINET interface or using an

additional switch.

S7-1500H supports the following number of PROFINET devices (switches, S7-1500R/H

CPUs, S7-1500 CPUs (V2.5 or later) and HMI devices):

● In the PROFINET ring: max. 50

● In the PROFINET ring and separated with switches (line): max. 258

The redundancy connections in S7-1500H are two duplex fiber-optic cables that connect the

CPUs directly with plug-in synchronization modules.

Figure 2-8 S7-1500H configuration version

S7-1500R/H redundant system

28 System Manual, 10/2018, A5E41814787-AA

Page 30

System overview

2.1.5

Overview of features

2.1 What is the S7-1500R/H redundant system?

The S7-1500R/H redundant system meets all the requirements for a fault-tolerant system.

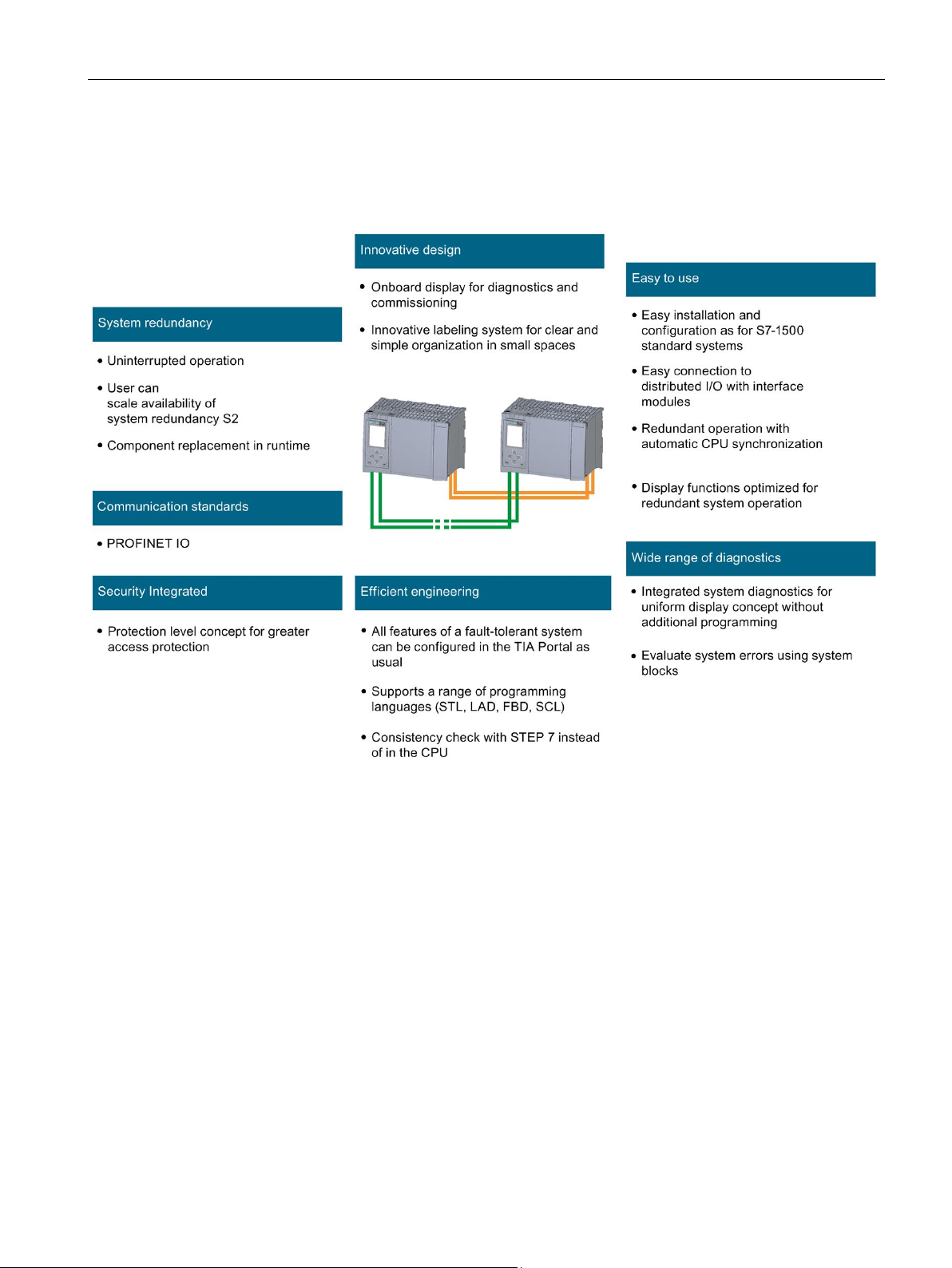

The figure below sets out the main features.

Figure 2-9 S7-1500R/H features

S7-1500R/H redundant system

System Manual, 10/2018, A5E41814787-AA

29

Page 31

System overview

2.2

Configuration

2.2.1

Structure of the S7-1500R redundant system

Configuration

2.2 Configuration

The S7-1500R redundant system comprises the following components:

● Two R-CPUs

● Two SIMATIC memory cards

● PROFINET cable (redundancy connections, PROFINET ring)

● IO devices

● Load power supply (optional)

● System power supply (optional)

The S7-1500R redundant system should be installed either on one shared mounting rail or

on two separate mounting rails. Connecting the PROFINET cable to the PROFINET

interfaces X1 P2 R of the CPUs directly connects the two CPUs. You set up the PROFINET

ring from the first CPU to the IO devices and the second CPU with the PROFINET interfaces

X1 P1 R of the CPUs.

S7-1500R/H redundant system

30 System Manual, 10/2018, A5E41814787-AA

Page 32

System overview

Configuration example

①

Optional load or system power supply

②

CPU

③

Mounting rail with integrated DIN rail profile

④

PROFINET cable (redundancy connections, PROFINET ring)

2.2.2

Structure of the S7-1500H redundant system

Configuration

2.2 Configuration

Figure 2-10 S7-1500R configuration example

The S7-1500H redundant system comprises the following components:

● Two H-CPUs

● Two SIMATIC memory cards

● Four synchronization modules (two synchronization modules in each H-CPU)

● Two redundancy connections (two duplex fiber-optic cables)

● IO devices

● Load power supply (optional)

● System power supply (optional)

The S7-1500H redundant system should be installed either on one shared mounting rail or

on two separate mounting rails. You connect the two CPUs with fiber-optic cables to two

synchronization modules in each CPU. You set up the PROFINET ring with the PROFINET

interfaces X1 P1 R and X1 P2 R of the CPUs.

S7-1500R/H redundant system

System Manual, 10/2018, A5E41814787-AA

31

Page 33

System overview

Configuration example

①

Optional load or system power supply

②

CPU (with two synchronization modules, connected underneath, not visible in the diagram)

③

Mounting rail with integrated DIN rail profile

④

Redundancy connections (fiber-optic cables)

⑤

PROFINET cable (PROFINET ring)

2.2 Configuration

Figure 2-11 S7-1500H configuration example

S7-1500R/H redundant system

32 System Manual, 10/2018, A5E41814787-AA

Page 34

System overview

2.2.3

Components

Components of the S7-1500R/H redundant system

Component

Function

Diagram

2.2 Configuration

Table 2- 3 S7-1500R/H components

Mounting rail The mounting rail is the rack of the S7-1500R/H automation

system. You can use the entire length of the mounting rail.

You can order the mounting rail as Accessories/spare parts

(Page 305).

PE connection element for mounting rail

R/H-CPUs The CPU runs the user program.

The screw set is inserted in the mounting rail's T-profile

groove, and is required for grounding the mounting rail.

The set of screws is included in the scope of delivery of the

mounting rails in the standard lengths (160 mm to 830 mm)

and can be ordered as Accessories/spare parts (Page 305).

Additional features and functions of the CPU:

• Communication via Industrial Ethernet

• Communication via PROFINET IO

• Redundant mode

• HMI communication

• Integrated system diagnostics

• Integrated protection functions (access and know-how

protection)

PROFINET cable You connect the CPUs and the IO devices in a PROFINET

S7-1500R/H redundant system

System Manual, 10/2018, A5E41814787-AA

ring using PROFINET cables.

33

Page 35

System overview

Component

Function

Diagram

ply and can be ordered as spare part.

2.2 Configuration

Synchronization modules (for S7-1500H)

Fiber-optic cable (for

S7-1500H)

4-pin connection plug

for CPU supply voltage

System power supply

(PS)

You create two redundancy connections between the H-CPUs

with fiber-optic cables using a total of four synchronization

modules (two in each H-CPU).

The following synchronization module versions can be ordered:

• Sync module 1 GB FO 10 m: for fiber-optic cables up to

10 m in length

• Sync module 1 GB FO 10 km: for fiber-optic cables up to

10 km in length

You connect the two synchronization modules for each CPU in

a pair with a fiber-optic cable. The following lengths of fiberoptic cables can be ordered:

• 1 m

• 2 m

• 10 m

• Up to 10 km (on request)

The 4-pin connection plug provides the supply voltage.

The system power supply can be connected to the backplane

bus using a U connector. In the S7-1500R/H redundant system, the system power supply does not support diagnostics.

Various models of system power supplies are available:

• PS 25 W 24 V DC

• PS 60 W 24/48/60 V DC

• PS 60 W 24/48/60 V DC HF

Extended retentivity of the PS is not supported in S71500R/H.

• PS 60 W 120/230 V AC/DC

A power cable connector with coding element and U connector

is included in the scope of delivery for the system power sup-

Load power supply

(PM)

The load power supply (PM) supplies the system power supply

(PS) and central modules (CPU) with 24 V DC.

If you are using load power supplies, we recommend the devices from our SIMATIC series. These devices can be mounted on the mounting rail.

Various models of load power supply are available:

• PM 70 W 120/230 V AC

• PM 190 W 120/230 V AC

S7-1500R/H redundant system

34 System Manual, 10/2018, A5E41814787-AA

Page 36

System overview

2.3

S7-1500 R/H-CPUs

2.3.1

Overview of the CPU technical specifications

CPU 1513R-1 PN

CPU 1515R-2 PN

CPU 1517H-3 PN

Data work-memory, max.

1.5 MB

3 MB

8 MB

Code work-memory, max.

300 KB

500 KB

2 MB

Plug-in load memory (SIMATIC memory

card), max.

32 GB

32 GB

32 GB

I/O address area, max.

32 KB/32 KB

32 KB/32 KB

32 KB/32 KB

PROFINET IO interfaces

1 1 1

PROFINET interfaces

- 1 1

Processing time for bit operations

0.04 μs

0.03 μs

0.002 μs

Display screen size

3.45 cm

6.1 cm

6.1 cm

Suitable PROFINET devices (switches,

PROFINET ring, max.

50 (recommended: max.

50 (recommended: max.

50

Suitable PROFINET devices (see

rated with switches (line), max.

66

66

258

Modules per rack, max.

2 (PM/PS and CPU)

2 (PM/PS and CPU)

2 (PM/PS and CPU)

Distance between CPUs, max.

Depends on media con-

100 m)

Depends on media con-

100 m)

Depends on the synchro-

Redundancy connections (synchronization link)

PROFINET ring

PROFINET ring

Fiber-optic cable

System redundancy

Yes

Yes

Yes

Switchover time 1)

300 ms

300 ms

50 ms

1)

The switchover time is the time between failure of the primary CPU until the backup CPU takes over control of the

process as the primary CPU at the point of interruption. The switchover time can lengthen the cycle time.

2.3 S7-1500 R/H-CPUs

The S7-1500R/H redundant system tolerates the failure of one of the two R- or H-CPUs in

the PROFINET ring. If the primary CPU fails, the backup CPU takes over control of the

process as the new primary CPU at the point of the interruption.

All relevant data is permanently synchronized between the CPUs over the redundancy

connections between primary CPU and backup CPU.

The primary CPU and the backup CPU execute the user program in parallel.

The display of the CPU shows you the control and status information in various menus.

Quick access to diagnostic alarms minimizes plant downtimes in the event of a service call.

For effective commissioning and fast optimization of drives and controls, the CPUs support

trace functions for all CPU tags.

The table below sets out the main technical specifications for the S7-1500 R/H CPUs.

Table 2- 4 Overview of the R/H-CPU technical specifications

S7-1500R/H CPUs, S7-1500 CPUs

(V2.5 or later) and HMI devices) in the

above) in the PROFINET ring and sepa-

16)

verter used (with

PROFINET cable, max.

16)

verter used (with

PROFINET cable, max.

nization module used:

max. 10 km

S7-1500R/H redundant system

System Manual, 10/2018, A5E41814787-AA

35

Page 37

System overview

Reference

2.3.2

Redundancy

Introduction

Media redundancy

2.3 S7-1500 R/H-CPUs

The full technical specifications can be found in the manuals for the CPUs and on the

Internet (https://mall.industry.siemens.com).

The S7-1500R/H redundant system is based on media redundancy (MRP) in the PROFINET

ring.

All PROFINET IO devices assigned to the S7-1500R system must support system

redundancy S2. These PROFINET IO devices can be located in the PROFINET ring or they

can be separated with a switch.

All PROFINET devices in the PROFINET ring must support media redundancy (MRP). The

H-Sync forwarding function is also recommended for S7-1500R. System redundancy S2 is

not a requirement. For example, you can use switches and HMI devices without system

redundancy S2.

Media redundancy is a function for ensuring network and plant availability.

The two CPUs in the redundant system must be located in a PROFINET ring that uses the

MRP media redundancy protocol.

S7-1500R uses the PROFINET ring to synchronize the two CPUs. S7-1500H uses the

redundancy connections over fiber-optic cables to synchronize the two CPUs. The

PROFINET ring (over PROFINET interfaces X1) of the H CPUs is also mandatory for S71500H.

To set up a ring topology with media redundancy, you need to bring together the free ends of

a linear network topology in one device using two ports (ring ports, port label "R"). You

specify the ring ports in the device configuration.

In the S7-1500R/H redundant system, you need to set the media redundancy role for each of

the two CPUs to Manager (Auto). For all other PROFINET devices in the PROFINET ring,

the media redundancy role Client must be configured. There is a communication connection

based on MRP between the redundancy manager and the redundancy clients. The Media

Redundancy Protocol (MRP) automatically reconfigures the data paths between the

individual devices if the ring is interrupted at any point.

You configure the media redundancy role for PROFINET devices with system

redundancy S2 in STEP 7. For switches without system redundancy S2, you set the media

redundancy role to "Client" over the Web interface.

S7-1500R/H redundant system

36 System Manual, 10/2018, A5E41814787-AA

Page 38

System overview

System redundancy S2

Reference

2.3 S7-1500 R/H-CPUs

An IO device with system redundancy S2 supports system redundancy ARs.

In a redundant system, an IO device with system redundancy S2 has a system redundancy

AR with each of the two CPUs (IO controllers). An IO device thus supports ARs of two IO

controllers simultaneously (for the same modules).

A system redundancy AR can be the primary AR or the backup AR. There must only ever be

one primary AR for one IO device at any given time. The other AR, if there is one, must be

the backup AR. An IO device activates the data of the primary AR at the outputs. The data of

the backup AR is merely saved.

● Behavior in the RUN-Redundant system state:

Both CPUs are IO controllers. PROFINET communication runs on both system

redundancy ARs simultaneously, in each case between one of the CPUs (IO controller)

and the IO device. If the primary CPU then fails, the backup CPU becomes the primary

CPU and also switches the backup AR to primary AR. The data of this AR then becomes

active at the outputs.

● Behavior in the RUN-Solo system state:

Only the primary CPU is the IO controller. PROFINET communication runs on the primary

AR between the primary CPU (IO controller) and the IO device. There is no AR between

the backup CPU and the IO device.

In STEP 7, you configure system redundancy S2 for an IO device by assigning the IO device

to both CPUs of the S7-1500R/H redundant system.

Additional information on media redundancy and system redundancy S2 can be found in the

PROFINET function manual

(http://support.automation.siemens.com/WW/view/en/49948856).

S7-1500R/H redundant system

System Manual, 10/2018, A5E41814787-AA

37

Page 39

System overview

2.3.3

Security

Protection functions

Protection function

Description

and an integrated firewall

CPU lock

Protection against unauthorized access by locking the front cover with a seal or a lock

Access protection example

cannot

2.3 S7-1500 R/H-CPUs

Security means the protection of technical systems against sabotage, espionage and human

error.

For the setup of secure networks, the S7-1500R/H redundant system has an integrated

security concept from authorization levels up to block protection:

Table 2- 5 Overview of protection functions

Access protection Protection against unauthorized configuration changes through four authorization levels

Know-how protection Protection against unauthorized access and modifications to algorithms with password

protection

You can choose from four different access levels in the TIA Portal to restrict user access to

functions and memory areas.

Figure 2-12 Access protection

If you only want to allow users access over HMI, for example, select the access level "HMI

access" in the TIA Portal. Only HMI access and access to diagnostics data is then possible

without entering a password.

Users can read and write tags over an HMI device with this access level.

Users

● Download blocks or the hardware configuration to the CPU

● Upload blocks or the hardware configuration from the CPU to the PG/PC

● Run writing test functions

● Change the operating state from the PG/PC

:

● Run firmware updates

S7-1500R/H redundant system

38 System Manual, 10/2018, A5E41814787-AA

Page 40

System overview

Advantages and customer benefits of protection functions

Reference

2.3.4

Diagnostics

2.3 S7-1500 R/H-CPUs

The protection functions listed above protect your investments from unauthorized access

and manipulation, helping to secure plant availability.

You can find additional information on the protection functions described in the section

Protection (Page 168) and in the STEP 7 online help.

Siemens products and solutions are only one element of a comprehensive industrial security

concept. Please note the additional information on Industrial Security

(http://www.siemens.com/industrialsecurity).

All levels of automation in the S7-1500R/H redundant system have integrated diagnostics.

All SIMATIC products have integrated diagnostic functions that you can use to analyze,

localize and log faults and errors efficiently.

System diagnostics is integrated into the firmware of the CPUs and works independently of

the cyclic user program. Faults in the plant are immediately detected and reported on the

display devices.

A uniform display concept visualizes error messages as plain text information over:

● TIA Portal

● HMI devices

● CPU displays

S7-1500R/H redundant system

System Manual, 10/2018, A5E41814787-AA

39

Page 41

System overview

Displaying faults in an IO device

Advantages and customer benefits

2.3 S7-1500 R/H-CPUs

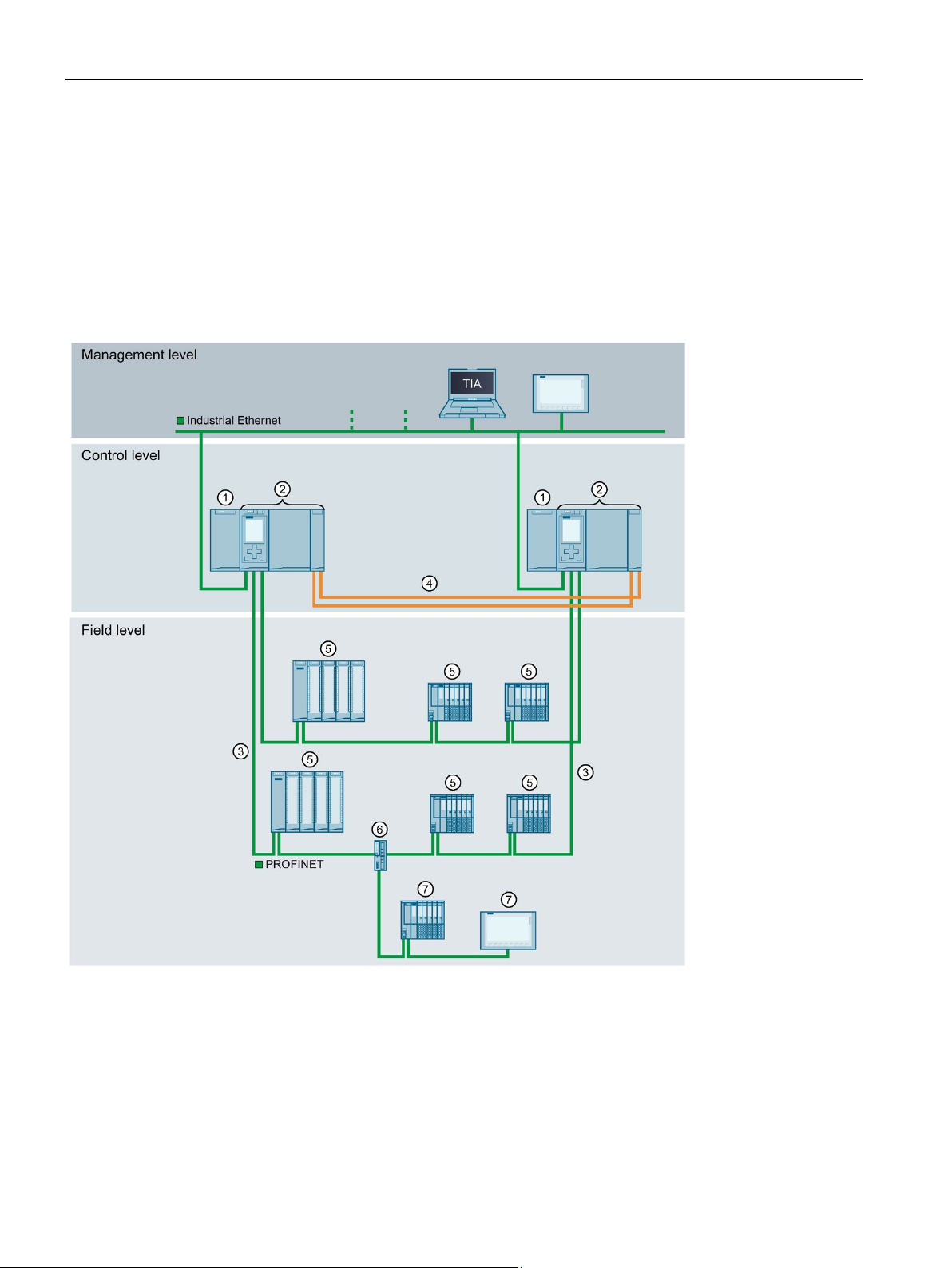

The various components of the S7-1500R/H redundant system are connected over

PROFINET/Industrial Ethernet (IE). The devices detect faults in their modules (for example

IO device ET 200SP) and send diagnostics data to the assigned CPU. The CPU analyzes

this diagnostic information and notifies the connected display media. The information

analyzed is shown in graphic form in the configuration and programming software (TIA

Portal), on the HMI devices and on the CPU displays.

Figure 2-13 Overview of system diagnostics in a plant

Integrated system diagnostics offers the following advantages:

● Diagnostics is always consistent with the actual state of the plant. In S7-1500R/H

redundant mode, the diagnostic information is synchronized between the CPUs.

● The uniform display concept enables efficient error analysis.

● The immediate identification of the error source in the event of an error speeds up

commissioning and minimizes production downtimes.

● By configuring diagnostics events, you tailor the diagnostics to the requirements of your

automation task.

S7-1500R/H redundant system

40 System Manual, 10/2018, A5E41814787-AA

Page 42

System overview

Reference

2.3.5

Trace

Note

Trace restrictions

The S7

SIMATIC memory card.

2.3 S7-1500 R/H-CPUs

You will find more information on diagnostics in the Diagnostics

(https://support.industry.siemens.com/cs/ww/en/view/59192926) function manual.

The trace functionality facilitates troubleshooting and optimization for the user program.

Trace records device tags and evaluates the recordings. This allows you to analyze

defective signal responses. Tags are, for example, drive parameters or the system and user

tags of a CPU. Because the CPU records tags directly, the trace and logic analyzer function