Siemens SIMATIC CPU 410, SIMATIC 410 SMART, SIMATIC PCS 7 System Manual

___________________

___________

___________

___________________

___________

___________________

___________________

___________________

___________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SIMATIC

PCS 7 process control system

CPU 410 Process Automation/CPU

410 SMART

System Manual

05/2017

A5E31622160

Preface

1

Introduction to the CPU 410

2

Configuration of the CPU

410

3

PROFIBUS DP

4

PROFINET IO

5

I/O configuration variants

6

System and operating states

of the CPU 410

7

Link-up and update

8

Special functions of the CPU

410

9

Time synchronization and

time stamping

10

Plant changes in RUN - CiR

11

Plant changes during

redundant operation - H-CiR

12

Replacement of failed

components during

redundant operation

13

Synchronization modules

14

System expansion card

15

Technical data

16

Properties and technical

specifications of CPU 410

SMART

17

Supplementary information

18

Characteristic values of

redundant automation

systems

A

Function and communication

modules that can be used in

a redundant configuration

B

Connection examples for

redundant I/Os

C

-AC

Siemens AG

Division Process Industries

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E31622160-AC

Ⓟ

Copyright © Siemens AG 2017.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

and Drives

06/2017 Subject to change

Table of contents

1 Preface ................................................................................................................................................. 17

2 Introduction to the CPU 410 .................................................................................................................. 23

3 Configuration of the CPU 410 ................................................................................................................ 35

4 PROFIBUS DP ..................................................................................................................................... 49

5 PROFINET IO ....................................................................................................................................... 51

6 I/O configuration variants ...................................................................................................................... 55

1.1 Preface .................................................................................................................................... 17

1.2 Security information ................................................................................................................ 20

1.3 Documentation ........................................................................................................................ 21

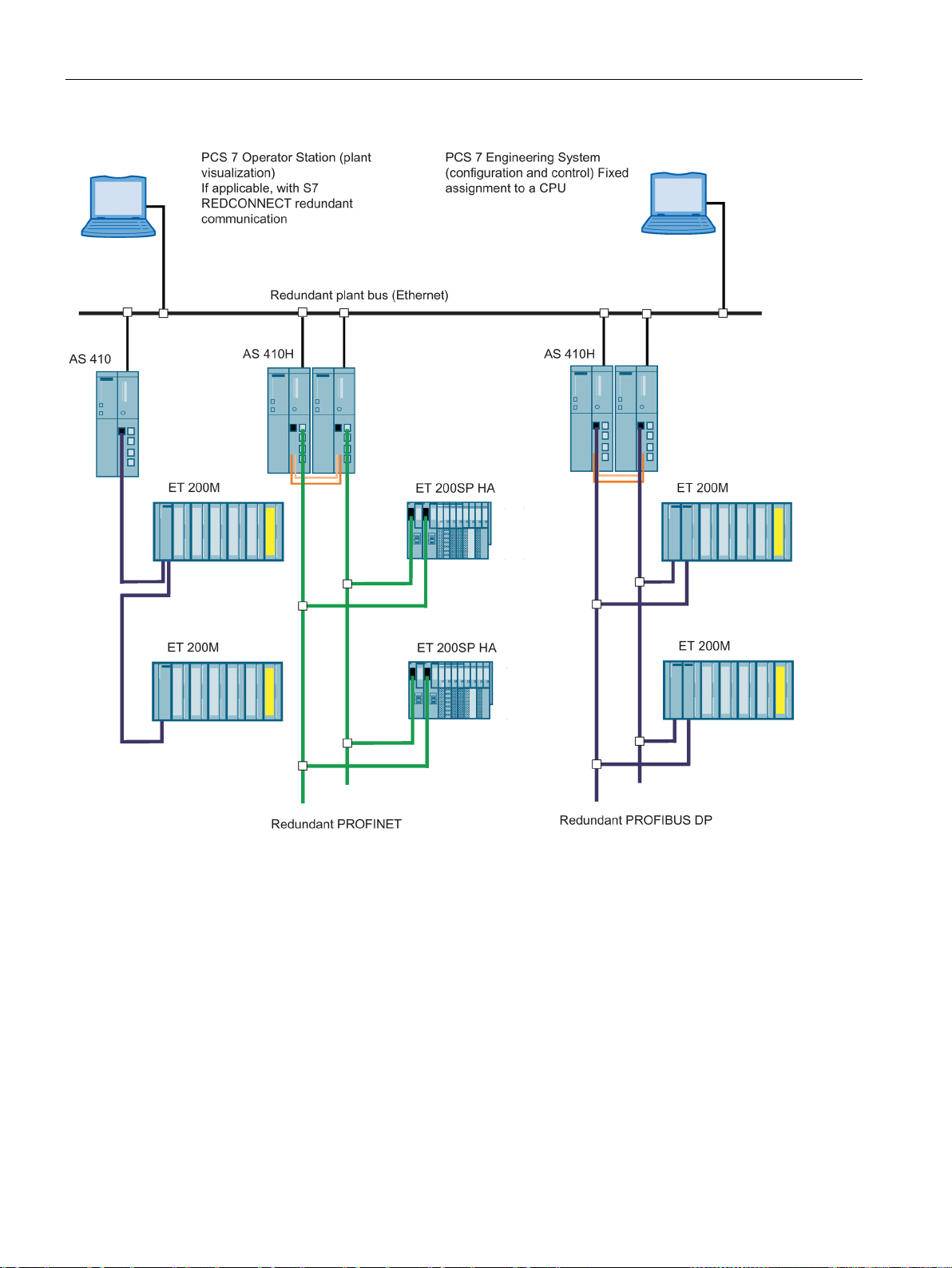

2.1 Area of application of the CPU 410 in SIMATIC PCS 7 ......................................................... 23

2.2 Possible applications .............................................................................................................. 25

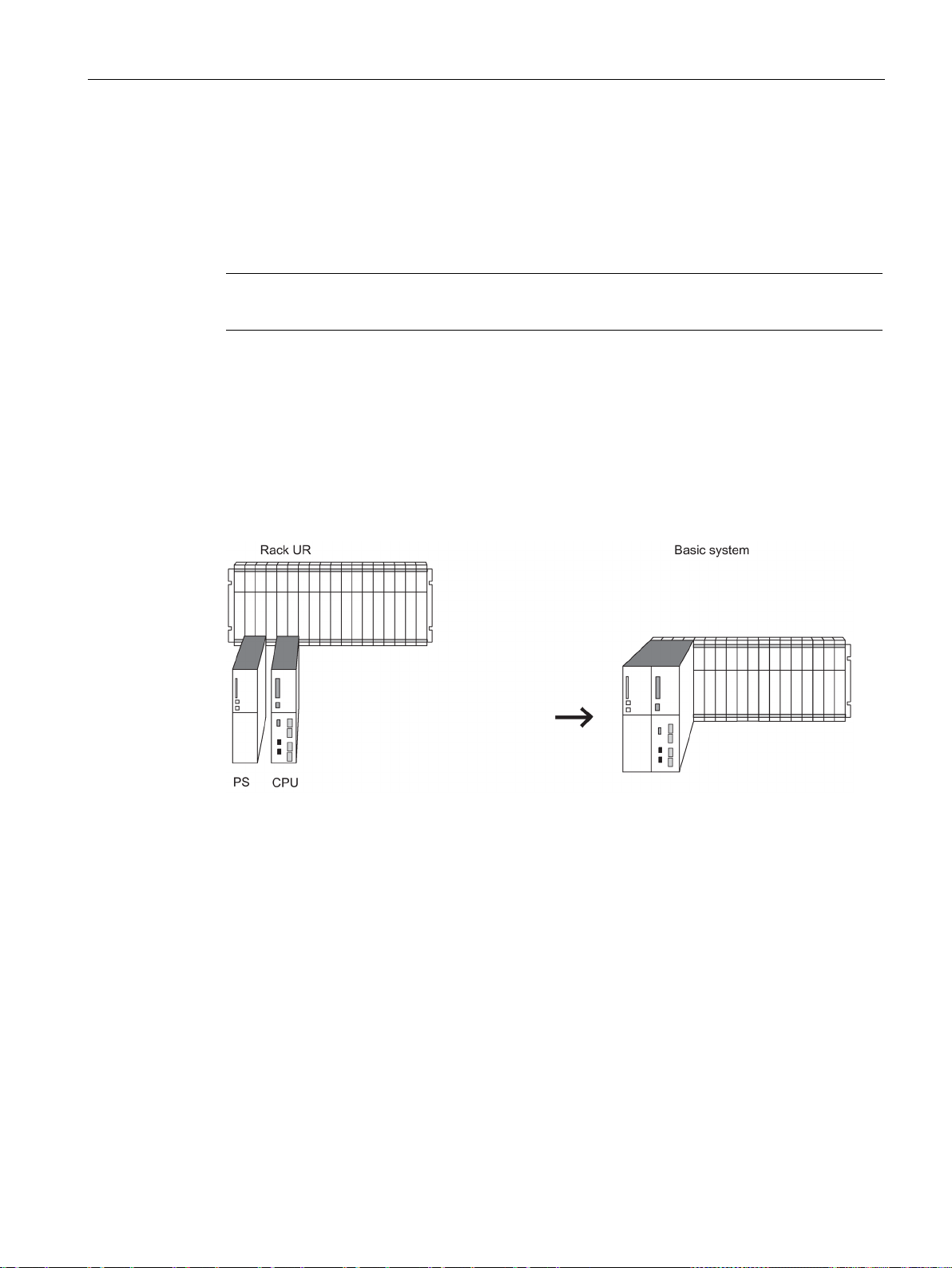

2.3 The CPU 410 basic system for stand-alone operation ........................................................... 27

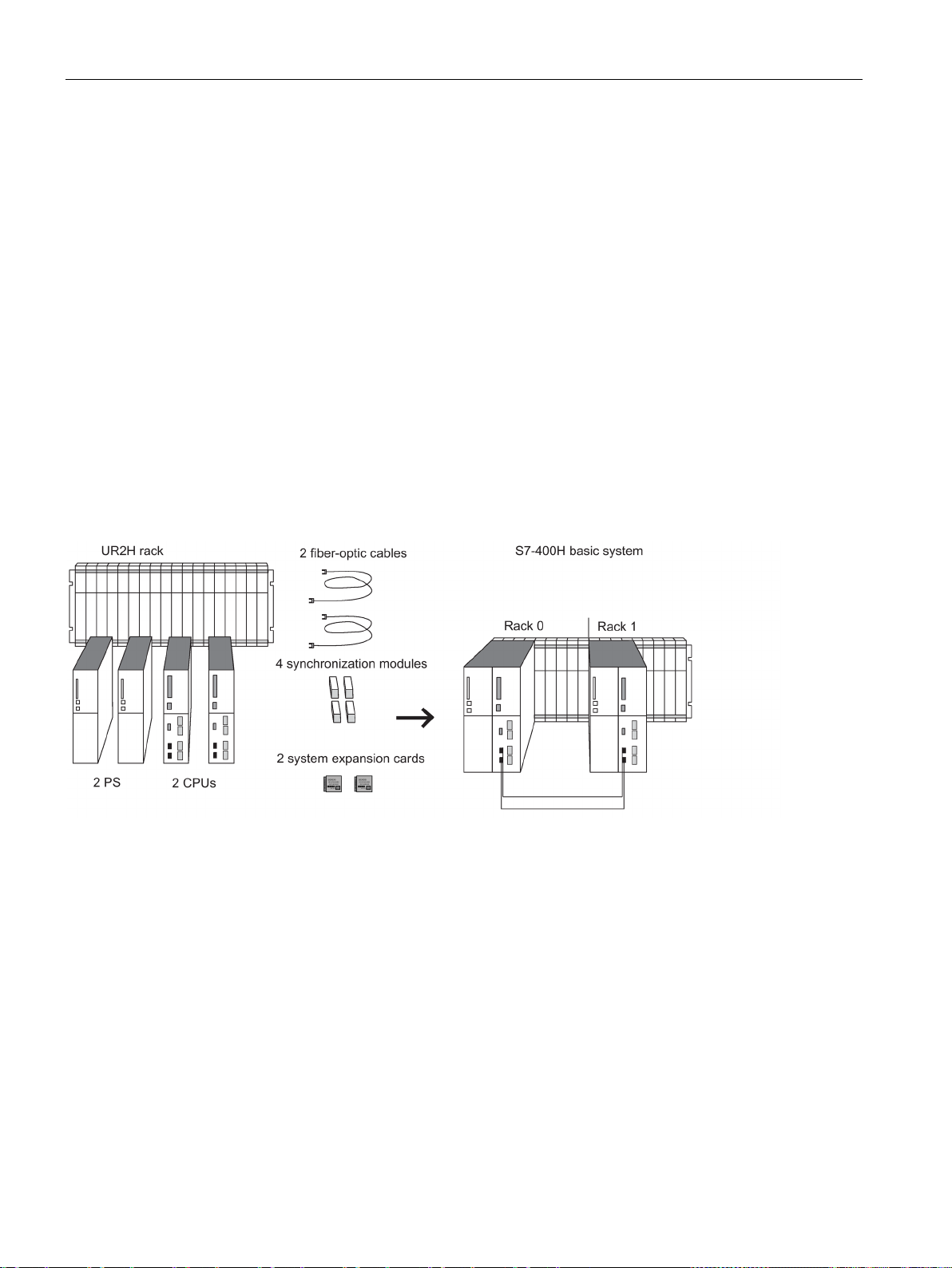

2.4 The basic system for redundant operation ............................................................................. 28

2.5 Rules for H station assembly .................................................................................................. 30

2.6 I/O for the CPU 410 ................................................................................................................ 30

2.7 I/O configuration variants of the fault-tolerant system ............................................................ 31

2.8 Configuration tools (STEP 7 HW Config, SIMATIC PCS 7) ................................................... 31

2.9 The SIMATIC PCS 7 project ................................................................................................... 31

2.9.1 Scaling and licensing (scaling concept) .................................................................................. 32

3.1 Operator controls and indicators on the CPU 410 .................................................................. 35

3.2 CPU 410 monitoring functions ................................................................................................ 39

3.3 Status and error displays ........................................................................................................ 41

3.4 PROFIBUS DP interface (X1) ................................................................................................. 45

3.5 PROFINET IO interfaces (X5, X8) .......................................................................................... 45

3.6 Summary of parameters for CPU 410 .................................................................................... 48

4.1 CPU 410 as PROFIBUS DP master ....................................................................................... 49

4.2 Diagnostics of the CPU 410 as PROFIBUS DP master ......................................................... 49

5.1 Introduction ............................................................................................................................. 51

5.2 PROFINET IO systems ........................................................................................................... 52

5.3 Device replacement without exchangeable medium / ES ...................................................... 53

6.1 Stand-alone operation............................................................................................................. 55

CPU 410 Process Automation/CPU 410 SMART

System Manual, 05/2017, A5E31622160-AC

3

Table of contents

7 System and operating states of the CPU 410 ....................................................................................... 101

8 Link-up and update .............................................................................................................................. 119

6.2 Fail-safe operation ................................................................................................................. 58

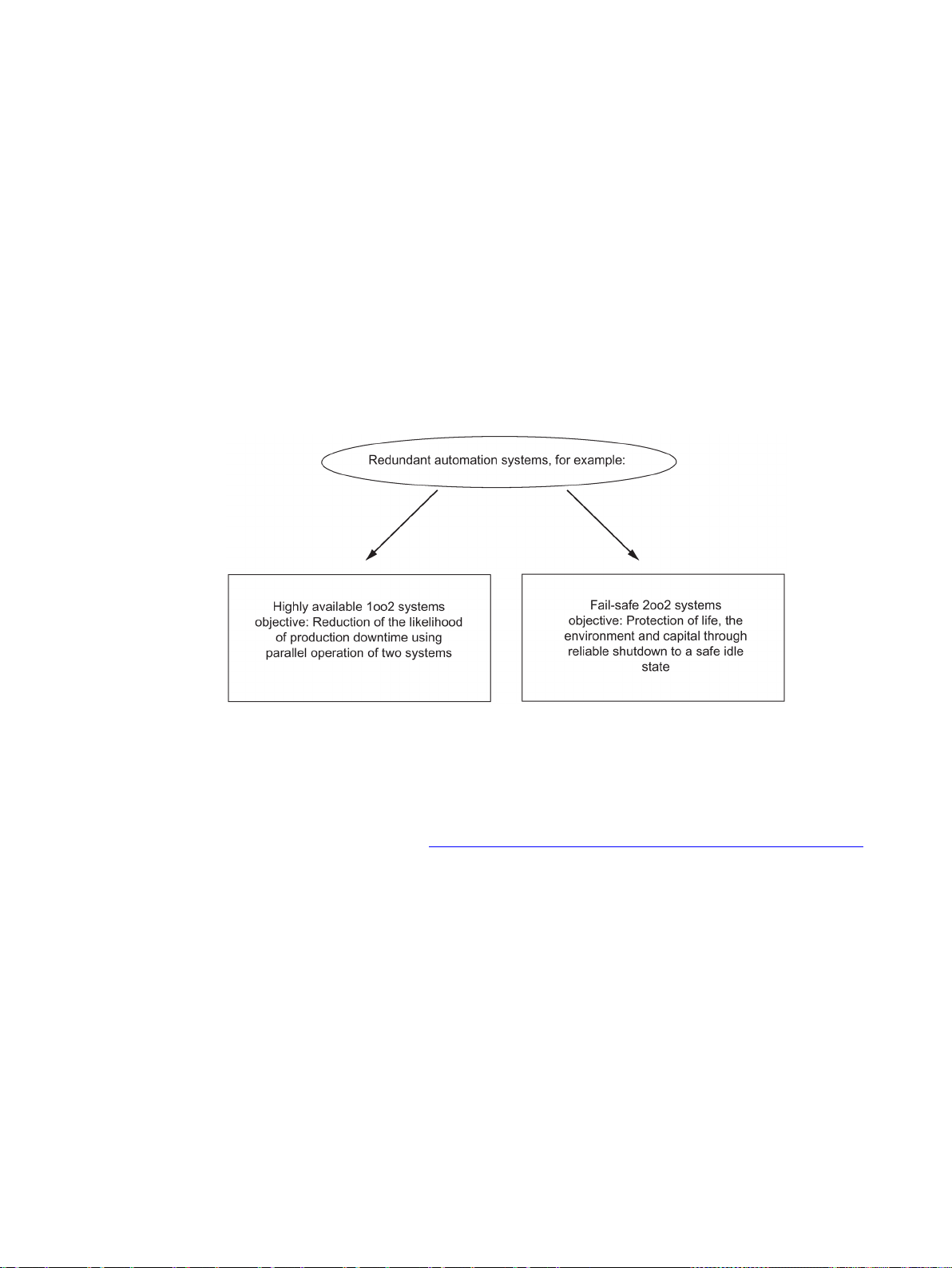

6.3 Fault-tolerant automation systems (redundancy operation) .................................................. 61

6.3.1 Redundant SIMATIC automation systems ............................................................................. 61

6.3.2 Increase of plant availability, reaction to errors ..................................................................... 62

6.4 Introduction to the I/O link to fault-tolerant system ................................................................ 65

6.5 Using single-channel switched I/O ......................................................................................... 66

6.6 Versions of I/O connection to the PROFINET IO interface .................................................... 73

6.6.1 Use of I/O connected to the PROFINET IO interface, system redundancy ........................... 73

6.6.2 Redundant I/O in an ET 200SP HA ....................................................................................... 76

6.7 Connection of two-channel I/O to the PROFIBUS DP interface ............................................ 80

6.7.1 Connecting redundant I/O ...................................................................................................... 80

6.7.2 Signal modules for redundancy ............................................................................................. 83

6.7.3 Evaluating the passivation status ........................................................................................... 97

6.8 Media redundancy ................................................................................................................. 97

7.1 CPU 410 operating modes ................................................................................................... 101

7.1.1 RUN mode ........................................................................................................................... 101

7.1.2 STOP mode ......................................................................................................................... 102

7.1.3 STARTUP mode .................................................................................................................. 103

7.1.4 HOLD mode ......................................................................................................................... 104

7.1.5 LINK-UP and UPDATE modes ............................................................................................ 105

7.1.6 ERROR-SEARCH mode ...................................................................................................... 105

7.1.7 DEFECTIVE state ................................................................................................................ 106

7.2 System states of the redundant CPU 410 ........................................................................... 107

7.2.1 Introduction .......................................................................................................................... 107

7.2.2 The system states of the fault-tolerant system .................................................................... 109

7.2.3 Displaying and changing the system state of a fault-tolerant system .................................. 110

7.2.4 System status change from the STOP system state ........................................................... 110

7.2.5 System status change from the standalone mode system status ....................................... 111

7.2.6 System status change from the redundant system state ..................................................... 111

7.2.7 System diagnostics of a fault-tolerant system ..................................................................... 112

7.3 Self-test ................................................................................................................................ 114

7.4 Performing a memory reset ................................................................................................. 117

8.1 Effects of link-up and updating ............................................................................................. 119

8.2 Link-up and update via an ES command ............................................................................. 120

8.3 Time monitoring ................................................................................................................... 120

8.3.1 Time response ..................................................................................................................... 123

8.3.2 Determining the monitoring times ........................................................................................ 123

8.3.3 Performance values for link-up and update ......................................................................... 130

8.3.4 Influences on time response ................................................................................................ 130

8.4 Special features in link-up and update operations ............................................................... 131

CPU 410 Process Automation/CPU 410 SMART

4 System Manual, 05/2017, A5E31622160-AC

Table of contents

9 Special functions of the CPU 410 ........................................................................................................ 133

10 Time synchronization and time stamping ............................................................................................. 151

11 Plant changes in RUN - CiR ................................................................................................................ 155

9.1 Security functions of the CPU 410 ........................................................................................ 133

9.2 Security levels ....................................................................................................................... 134

9.3 Security event logging........................................................................................................... 136

9.4 Field Interface Security ......................................................................................................... 139

9.5 Access-protected blocks ....................................................................................................... 139

9.6 Retentive load memory ......................................................................................................... 140

9.7 Type update with interface change in RUN .......................................................................... 141

9.8 Resetting the CPU 410 to delivery condition (reset to factory setting) ................................. 142

9.9 Reset during operation.......................................................................................................... 143

9.10 Response to fault detection .................................................................................................. 144

9.11 Reading service data ............................................................................................................ 145

9.12 Updating firmware in stand-alone operation ......................................................................... 146

9.13 Updating firmware in redundant mode.................................................................................. 148

11.1 Motivation for CiR via PROFINET IO .................................................................................... 155

11.2 Permitted changes over PROFINET IO ................................................................................ 157

11.3 Procedure for PROFINET IO ................................................................................................ 158

11.3.1 Overview ............................................................................................................................... 158

11.3.2 Add IO devices or I/O modules ............................................................................................. 159

11.3.3 Rebuild hardware when adding an IO device ....................................................................... 160

11.3.4 Change process image partition assignment ....................................................................... 160

11.3.5 Re-configuring existing I/O modules in IO devices ............................................................... 161

11.3.6 Replacing IO devices or I/O modules ................................................................................... 161

11.4 Re-configuring I/O modules and ports in IO devices ............................................................ 161

11.4.1 Requirements for Reconfiguration ........................................................................................ 161

11.4.2 I/O module response to re-configuration .............................................................................. 162

11.4.3 CPU response during reconfiguration ................................................................................... 162

11.4.4 Reconfiguration Procedure ................................................................................................... 164

11.4.4.1 Using a Previously Unused Channel .................................................................................... 164

11.4.4.2 Reconfiguring an already used channel. .............................................................................. 164

11.4.4.3 Delete an already used channel. .......................................................................................... 166

11.4.4.4 Change the update time ....................................................................................................... 166

11.5 Motivation for CiR via PROFINET DP .................................................................................. 166

11.6 Permitted changes over PROFIBUS DP .............................................................................. 168

11.7 CiR objects and CiR modules for PROFINET DP ................................................................ 170

11.7.1 Basic Requirements .............................................................................................................. 170

11.7.2 Types of CiR Elements ......................................................................................................... 170

11.7.3 CiR Elements and I/O Address Areas .................................................................................. 171

11.8 Procedure for PROFIBUS DP ............................................................................................... 172

CPU 410 Process Automation/CPU 410 SMART

System Manual, 05/2017, A5E31622160-AC

5

Table of contents

12 Plant changes during redundant operation - H-CiR ............................................................................... 197

11.8.1 Basic Procedures in STOP Mode ........................................................................................ 172

11.8.1.1 Overview .............................................................................................................................. 172

11.8.1.2 Defining CiR Elements ......................................................................................................... 174

11.8.1.3 Deleting CiR Elements ......................................................................................................... 176

11.8.2 Basic Procedure in RUN Mode ............................................................................................ 177

11.8.2.1 Overview .............................................................................................................................. 177

11.8.2.2 add slaves or modules ......................................................................................................... 178

11.8.2.3 Reconfigure the hardware when adding a slave .................................................................. 179

11.8.2.4 change process image partition assignment ....................................................................... 179

11.8.2.5 reconfigure existing modules in ET200M / ET200iSP stations ............................................ 179

11.8.2.6 Undo previous changes (Undo function): ............................................................................ 180

11.8.2.7 Replacing Slaves or Modules .............................................................................................. 180

11.8.2.8 Using CiR Elements in RUN Mode ...................................................................................... 181

11.8.2.9 Undoing Previous Changes ................................................................................................. 184

11.9 Reconfigure existing modules in ET200M / ET200iSP stations .......................................... 185

11.9.1 Requirements for Reconfiguration ....................................................................................... 185

11.9.2 Module Response During a Reconfiguration ....................................................................... 186

11.9.3 CPU response during reconfiguration .................................................................................. 186

11.9.4 Reconfiguration Procedure .................................................................................................. 188

11.9.4.1 Using a Previously Unused Channel ................................................................................... 188

11.9.4.2 Reconfiguring an already used channel. ............................................................................. 188

11.9.4.3 Delete an already used channel. ......................................................................................... 189

11.10 Notes on Reconfiguration in RUN Mode Depending on the I/O .......................................... 190

11.10.1 Modules in IO devices of the type ET 200SP HA ................................................................ 190

11.10.2 DP and PA Slaves ............................................................................................................... 190

11.10.3 Modules in ET 200M Modular Slaves .................................................................................. 193

11.10.4 Modules in ET200iSP Modular Slaves ................................................................................ 194

11.11 Effects on the process when re-configuring in RUN ............................................................ 194

11.11.1 Effects on Operating System Functions During the CiR Synchronization Time .................. 194

11.11.2 Behavior of the CPU after download of the configuration in RUN ....................................... 195

11.11.2.1 Overview .............................................................................................................................. 195

11.11.2.2 Error displays ....................................................................................................................... 196

12.1 The H-CiR wizard ................................................................................................................. 197

12.2 Replacing central components ............................................................................................. 198

12.3 Addition of interface modules ............................................................................................... 199

12.4 Motivation for H-CiR via PROFINET IO ............................................................................... 201

12.5 Permitted changes over PROFINET IO ............................................................................... 202

12.6 Motivation for H-CiR via PROFIBUS DP ............................................................................. 204

12.7 Permitted changes over PROFIBUS DP ............................................................................. 205

12.8 Adding components ............................................................................................................. 207

12.8.1 Modify hardware................................................................................................................... 207

12.8.2 Change hardware configuration offline ................................................................................ 208

12.8.3 Opening the H-CiR wizard ................................................................................................... 209

12.8.4 Modify and download the user program .............................................................................. 210

12.8.5 Use of free channels on an existing module ........................................................................ 211

CPU 410 Process Automation/CPU 410 SMART

6 System Manual, 05/2017, A5E31622160-AC

Table of contents

13 Replacement of failed components during redundant operation ........................................................... 223

14 Synchronization modules .................................................................................................................... 239

15 System expansion card ....................................................................................................................... 251

16 Technical data .................................................................................................................................... 253

17 Properties and technical specifications of CPU 410 SMART ................................................................ 283

12.9 Removal of components ....................................................................................................... 211

12.9.1 Change hardware configuration offline ................................................................................. 212

12.9.2 Modify and download the user program ............................................................................... 213

12.9.3 Opening the H-CiR wizard .................................................................................................... 214

12.9.4 Modify hardware ................................................................................................................... 215

12.9.5 Removal of interface modules .............................................................................................. 216

12.10 Editing CPU parameters ....................................................................................................... 217

12.10.1 Editing CPU parameters ....................................................................................................... 217

12.10.2 Changing CPU parameters offline ........................................................................................ 219

12.10.3 Opening the H-CiR wizard .................................................................................................... 219

12.11 Re-parameterization of a module ......................................................................................... 220

12.11.1 Re-configuring a module/PDEV submodule ......................................................................... 220

12.11.2 Editing parameters offline ..................................................................................................... 221

12.11.3 Opening the H-CiR wizard .................................................................................................... 221

13.1 Replacement of central components .................................................................................... 223

13.1.1 Replacement of a CPU during redundant operation ............................................................. 223

13.1.2 Replacement of a power supply module............................................................................... 225

13.1.3 Replacement of an input/output module or function module ................................................ 226

13.1.4 Replacement of a communication module............................................................................ 227

13.1.5 Replacement of synchronization module or fiber-optic cable ............................................... 228

13.1.6 Replacement of an IM 460 and IM 461 interface module ..................................................... 231

13.2 Replacement of components of the distributed I/O on PROFINET IO ................................. 231

13.2.1 Replacement of a PROFINET IO device .............................................................................. 231

13.2.2 Replacement of PROFINET IO cables ................................................................................. 232

13.3 Replacement of components of the distributed I/O on PROFIBUS DP ................................ 233

13.3.1 Replacement of a PROFIBUS DP master ............................................................................ 234

13.3.2 Replacement of a redundant PROFIBUS DP interface module ........................................... 236

13.3.3 Replacement of a PROFIBUS DP slave ............................................................................... 236

13.3.4 Replacement of PROFIBUS DP cables ................................................................................ 237

14.1 Synchronization modules for the CPU 410. .......................................................................... 239

14.2 Installation of fiber-optic cables ............................................................................................ 243

14.3 Selecting fiber-optic cables ................................................................................................... 245

15.1 Variants of the system expansion card ................................................................................. 251

16.1 Technical specifications of CPU 410-5H; (6ES7410-5HX08-0AB0) ..................................... 253

16.2 Technical specifications of CPU 410E (6ES7410-5HM08-0AB0) ........................................ 263

16.3 Technical specifications of the system expansion card ........................................................ 273

17.1 CPU 410 SMART .................................................................................................................. 283

17.2 Technical specifications of the CPU 410 SMART; (6ES7 410-5HN08-0AB0) ...................... 285

CPU 410 Process Automation/CPU 410 SMART

System Manual, 05/2017, A5E31622160-AC

7

Table of contents

18 Supplementary information .................................................................................................................. 297

17.3 Technical specifications of the SEC PO 800 ....................................................................... 295

18.1 Supplementary information on PROFIBUS DP ................................................................... 297

18.2 Supplementary information on diagnostics of the CPU 410 as PROFIBUS DP master ...... 298

18.3 System status lists for PROFINET IO .................................................................................. 301

18.4 Configuring with STEP 7 ...................................................................................................... 302

18.4.1 Rules for arranging fault-tolerant station components ......................................................... 302

18.4.2 Configuring hardware ........................................................................................................... 303

18.4.3 Assigning parameters to modules in a fault-tolerant station ................................................ 304

18.4.4 Recommendations for setting CPU parameters, fixed settings ........................................... 304

18.4.5 Networking configuration ..................................................................................................... 305

18.5 The STEP 7 user program ................................................................................................... 306

18.5.1 The user program................................................................................................................. 306

18.6 Programming device functions in STEP 7 ........................................................................... 308

18.7 Communication services ...................................................................................................... 308

18.7.1 Overview of communication services................................................................................... 308

18.7.2 PG communication ............................................................................................................... 310

18.7.3 OP communication ............................................................................................................... 310

18.7.4 S7 communication ............................................................................................................... 310

18.7.5 S7 routing ............................................................................................................................. 312

18.7.6 Data set routing .................................................................................................................... 316

18.7.7 SNMP network protocol ....................................................................................................... 317

18.7.8 Open Communication Via Industrial Ethernet ...................................................................... 318

18.8 Basics and terminology of fault-tolerant communication ..................................................... 321

18.9 Usable networks................................................................................................................... 325

18.10 Communication via S7 connections ..................................................................................... 325

18.10.1 Communication via S7 connections - one-sided mode........................................................ 326

18.10.2 Communication via redundant S7 connections ................................................................... 328

18.10.3 Communication via point-to-point CP on the ET 200M ....................................................... 329

18.10.4 Custom connection to single-channel systems .................................................................... 331

18.11 Communication via fault-tolerant S7 connections ................................................................ 332

18.11.1 Communication between fault-tolerant systems .................................................................. 334

18.11.2 Communication between fault-tolerant systems and a fault-tolerant CPU .......................... 337

18.11.3 Communication between fault-tolerant systems and PCs ................................................... 338

18.12 Consistent data .................................................................................................................... 340

18.12.1 Consistency of communication blocks and functions .......................................................... 340

18.12.2 Consistency rules for SFB 14 "GET" or read variable, and SFB 15 "PUT" or write

variable ................................................................................................................................. 340

18.12.3 Consistent reading and writing of data from and to DP standard slaves/IO devices ........... 341

18.13 Link-

up and update sequence .............................................................................................. 343

18.13.1 Link-up sequence ................................................................................................................. 346

18.13.2 Update sequence ................................................................................................................. 347

18.13.3 Switch to CPU with modified configuration .......................................................................... 351

18.13.4 Disabling of link-up and update ............................................................................................ 352

18.14 The user program................................................................................................................. 353

CPU 410 Process Automation/CPU 410 SMART

8 System Manual, 05/2017, A5E31622160-AC

Table of contents

A Characteristic values of redundant automation systems ...................................................................... 379

B Function and communication modules that can be used in a redundant configuration .......................... 389

C Connection examples for redundant I/Os ............................................................................................. 391

18.15 Other options for connecting redundant I/Os ........................................................................ 354

18.16 CPU 410 cycle and reaction times ........................................................................................ 357

18.16.1 Cycle time ............................................................................................................................. 357

18.16.2 Calculating the cycle time ..................................................................................................... 359

18.16.3 Cycle load due to communication ......................................................................................... 362

18.16.4 Response time ...................................................................................................................... 364

18.16.5 Calculating cycle and response times .................................................................................. 369

18.16.6 Examples of calculating the cycle and response times ........................................................ 370

18.16.7 Interrupt response time ......................................................................................................... 373

18.16.8 Example of calculation of the interrupt response time .......................................................... 375

18.16.9 Reproducibility of delay and watchdog interrupts ................................................................. 376

18.17 Runtimes of the FCs and FBs for redundant I/Os ................................................................ 377

A.1 Basic concepts ...................................................................................................................... 379

A.2 Comparison of MTBF for selected configurations ................................................................ 383

A.2.1 System configurations with redundant CPU 410 .................................................................. 383

A.2.2 System configurations with distributed I/Os .......................................................................... 384

A.2.3 Comparison of system configurations with standard and fault-tolerant communication ...... 388

C.1 MTA terminal modules (Marshalled Termination Assemblies) ............................................. 391

C.2 Interconnection of output modules ........................................................................................ 391

C.3 8-channel HART analog input MTA ...................................................................................... 393

C.4 8-channel HART analog output MTA .................................................................................... 394

C.5 SM 321; DI 16 x DC 24 V, 6ES7 321–1BH02–0AA0 ............................................................ 395

C.6 SM 321; DI 32 x DC 24 V, 6ES7 321–1BL00–0AA0 ............................................................. 396

C.7 SM 321; DI 16 x AC 120/230V, 6ES7 321–1FH00–0AA0 .................................................... 397

C.8 SM 321; DI 8 x AC 120/230 V, 6ES7 321–1FF01–0AA0 ...................................................... 398

C.9 SM 321; DI 16 x DC 24V, 6ES7 321–7BH00–0AB0 ............................................................. 399

C.10 SM 321; DI 16 x DC 24V, 6ES7 321–7BH01–0AB0 ............................................................. 400

C.11 SM 326; DO 10 x DC 24V/2A, 6ES7 326–2BF01–0AB0 ...................................................... 401

C.12 SM 326; DI 8 x NAMUR, 6ES7 326–1RF00–0AB0 ............................................................... 402

C.13 SM 326; DI 24 x DC 24 V, 6ES7 326–1BK00–0AB0 ............................................................ 403

C.14 SM 421; DI 32 x UC 120 V, 6ES7 421–1EL00–0AA0 ........................................................... 404

C.15 SM 421; DI 16 x DC 24 V, 6ES7 421–7BH01–0AB0 ............................................................ 405

C.16 SM 421; DI 32 x DC 24 V, 6ES7 421–1BL00–0AB0 ............................................................. 406

C.17 SM 421; DI 32 x DC 24 V, 6ES7 421–1BL01–0AB0 ............................................................. 407

C.18 SM 322; DO 8 x DC 24 V/2 A, 6ES7 322–1BF01–0AA0 ...................................................... 408

C.19 SM 322; DO 32 x DC 24 V/0,5 A, 6ES7 322–1BL00–0AA0 ................................................. 409

CPU 410 Process Automation/CPU 410 SMART

System Manual, 05/2017, A5E31622160-AC

9

Table of contents

Index ................................................................................................................................................... 429

Tables

C.20 SM 322; DO 8 x AC 230 V/2 A, 6ES7 322–1FF01–0AA0 .................................................... 410

C.21 SM 322; DO 4 x DC 24 V/10 mA [EEx ib], 6ES7 322–5SD00–0AB0 .................................. 411

C.22 SM 322; DO 4 x DC 15 V/20 mA [EEx ib], 6ES7 322–5RD00–0AB0 .................................. 412

C.23 SM 322; DO 8 x DC 24 V/0.5 A, 6ES7 322–8BF00–0AB0 .................................................. 413

C.24 SM 322; DO 16 x DC 24 V/0.5 A, 6ES7 322–8BH01–0AB0 ................................................ 414

C.25 SM 332; AO 8 x 12 Bit, 6ES7 332–5HF00–0AB0 ................................................................ 415

C.26 SM 332; AO 4 x 0/4...20 mA [EEx ib], 6ES7 332–5RD00–0AB0 ......................................... 416

C.27 SM 422; DO 16 x AC 120/230 V/2 A, 6ES7 422–1FH00–0AA0 .......................................... 417

C.28 SM 422; DO 32 x DC 24 V/0.5 A, 6ES7 422–7BL00–0AB0 ................................................ 418

C.29 SM 331; AI 4 x 15 Bit [EEx ib]; 6ES7 331–7RD00–0AB0 .................................................... 419

C.30 SM 331; AI 8 x 12 Bit, 6ES7 331–7KF02–0AB0 .................................................................. 420

C.31 SM 331; AI 8 x 16 Bit; 6ES7 331–7NF00–0AB0 .................................................................. 421

C.32 SM 331; AI 8 x 16 Bit; 6ES7 331–7NF10–0AB0 .................................................................. 422

C.33 AI 6xTC 16Bit iso, 6ES7331-7PE10-0AB0 .......................................................................... 423

C.34 SM331; AI 8 x 0/4...20mA HART, 6ES7 331-7TF01-0AB0 ................................................. 424

C.35 SM 332; AO 4 x 12 Bit; 6ES7 332–5HD01–0AB0 ................................................................ 426

C.36 SM332; AO 8 x 0/4...20mA HART, 6ES7 332-8TF01-0AB0 ................................................ 427

Table 3- 1 LED displays on the CPUs ........................................................................................................... 36

Table 3- 2 Possible states of the RUN and STOP LEDs .............................................................................. 41

Table 3- 3 Possible states of the MSTR, RACK0 and RACK1 LEDs ............................................................ 42

Table 3- 4 Possible states of the INTF and EXTF LEDs ............................................................................... 42

Table 3- 5 Possible states of the BUS1F, BUS5F, and BUS8F LEDs .......................................................... 42

Table 3- 6 Possible states of the IFM1F and IFM2F LEDs ........................................................................... 43

Table 3- 7 Possible states of the LINK and RX/TX LEDs ............................................................................. 43

Table 3- 8 Possible states of the REDF LED ................................................................................................ 43

Table 3- 9 Possible states of the LINK1 OK and LINK2 OK LEDs ............................................................... 44

Table 4- 1 Meaning of the "BUSF" LED of the CPU 410 as DP master ....................................................... 49

Table 6- 1 System modifications during operation ........................................................................................ 56

Table 6- 2 Measures in PROFIsafe for error avoidance ............................................................................... 60

Table 6- 3 Interface modules for use of single-channel switched I/O configuration at the PROFIBUS

DP interface ................................................................................................................................. 67

Table 6- 4 Bus modules for hot swapping ..................................................................................................... 68

CPU 410 Process Automation/CPU 410 SMART

10 System Manual, 05/2017, A5E31622160-AC

Table of contents

Table 6- 5 Interface module for use of single-channel switched I/O configuration at the PROFINET

IO interface ................................................................................................................................... 71

Table 6- 6 Signal modules for redundancy ................................................................................................... 84

Table 7- 1 Causes of error leading to redundancy loss .............................................................................. 102

Table 7- 2 Overview of system states of the fault-tolerant system ............................................................. 109

Table 7- 3 Response to errors during the self-test ...................................................................................... 114

Table 7- 4 Response to a recurring comparison error ................................................................................ 115

Table 7- 5 Reaction to checksum errors ..................................................................................................... 115

Table 7- 6 Hardware fault with one-sided OB 121 call, checksum error, 2nd occurrence .......................... 116

Table 8- 1 Properties of link-up and update functions ................................................................................ 119

Table 8- 2 PG commands for link-up and update ....................................................................................... 120

Table 8- 3 Typical values for the user program part ................................................................................... 130

Table 9- 1 Protection levels of a CPU ......................................................................................................... 134

Table 9- 2 CPU properties in the factory settings ....................................................................................... 142

Table 9- 3 LED patterns .............................................................................................................................. 142

Table 12- 1 Modifiable CPU parameters ....................................................................................................... 218

Table 14- 1 Accessory fiber-optic cable ........................................................................................................ 246

Table 14- 2 Specification of fiber-optic cables for indoor applications .......................................................... 247

Table 14- 3 Specification of fiber-optic cables for outdoor applications ........................................................ 248

Table 18- 1 Reading the diagnostics data with STEP 7 ................................................................................ 298

Table 18- 2 Event detection of the CPU 41xH as a DP master .................................................................... 300

Table 18- 3 Comparison of the system status lists of PROFINET IO and PROFIBUS DP........................... 301

Table 18- 4 Communication services of the CPUs ....................................................................................... 308

Table 18- 5 Availability of connection resources ........................................................................................... 309

Table 18- 6 SFBs for S7 Communication ...................................................................................................... 311

Table 18-

7 Job lengths and "local_device_id" parameter ............................................................................ 320

Table 18- 8 For the monitoring times with redundant I/O .............................................................................. 357

Table 18- 9 Cyclic program processing ......................................................................................................... 358

Table 18- 10 Factors influencing cycle time .................................................................................................... 359

Table 18- 11 Portion of the process image transfer time, CPU 410-5H.......................................................... 360

Table 18- 12 Extending the cycle time ............................................................................................................ 361

Table 18- 13 Operating system execution time at the cycle control point ...................................................... 361

Table 18- 14 Extended cycle time due to nested interrupts ............................................................................ 361

Table 18- 15 Direct access of the CPUs to I/O modules in the central controller ........................................... 368

Table 18- 16 Direct access of the CPUs to I/O modules in the expansion unit with local link ........................ 368

CPU 410 Process Automation/CPU 410 SMART

System Manual, 05/2017, A5E31622160-AC

11

Table of contents

Figures

Table 18- 17 Direct access of the CPUs to I/O modules in the expansion unit with remote link, setting

100 m ......................................................................................................................................... 369

Table 18- 18 Example of calculating the response time ................................................................................. 370

Table 18- 19 Hardware and interrupt response times; maximum interrupt response time without com-

munication .................................................................................................................................. 373

Table 18- 20 Reproducibility of time-delay and cyclic interrupts of the CPUs ................................................ 376

Table 18- 21 Runtimes of the blocks for redundant I/Os ................................................................................. 377

Table C- 1 Interconnecting digital output modules with/without diodes ....................................................... 391

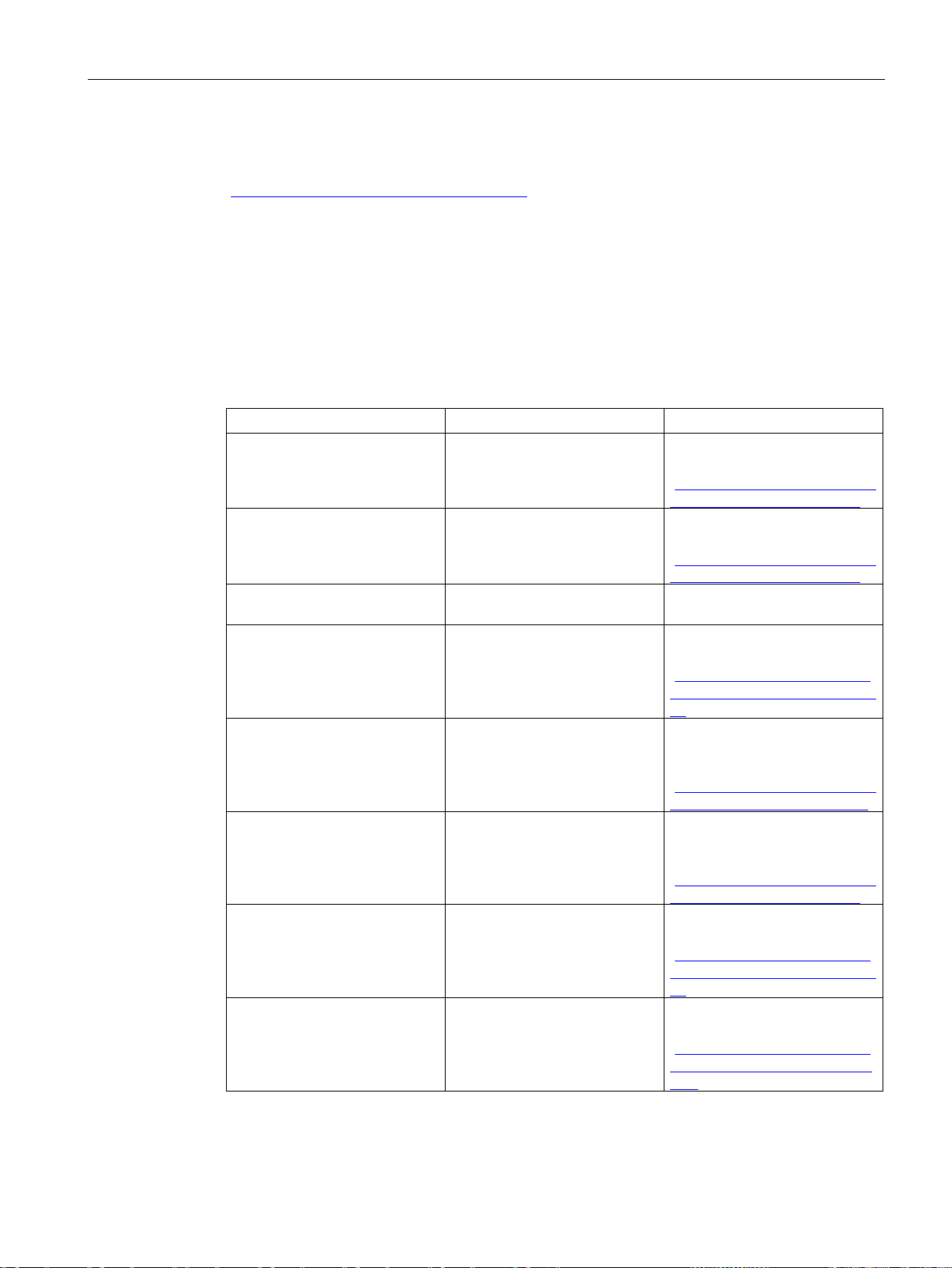

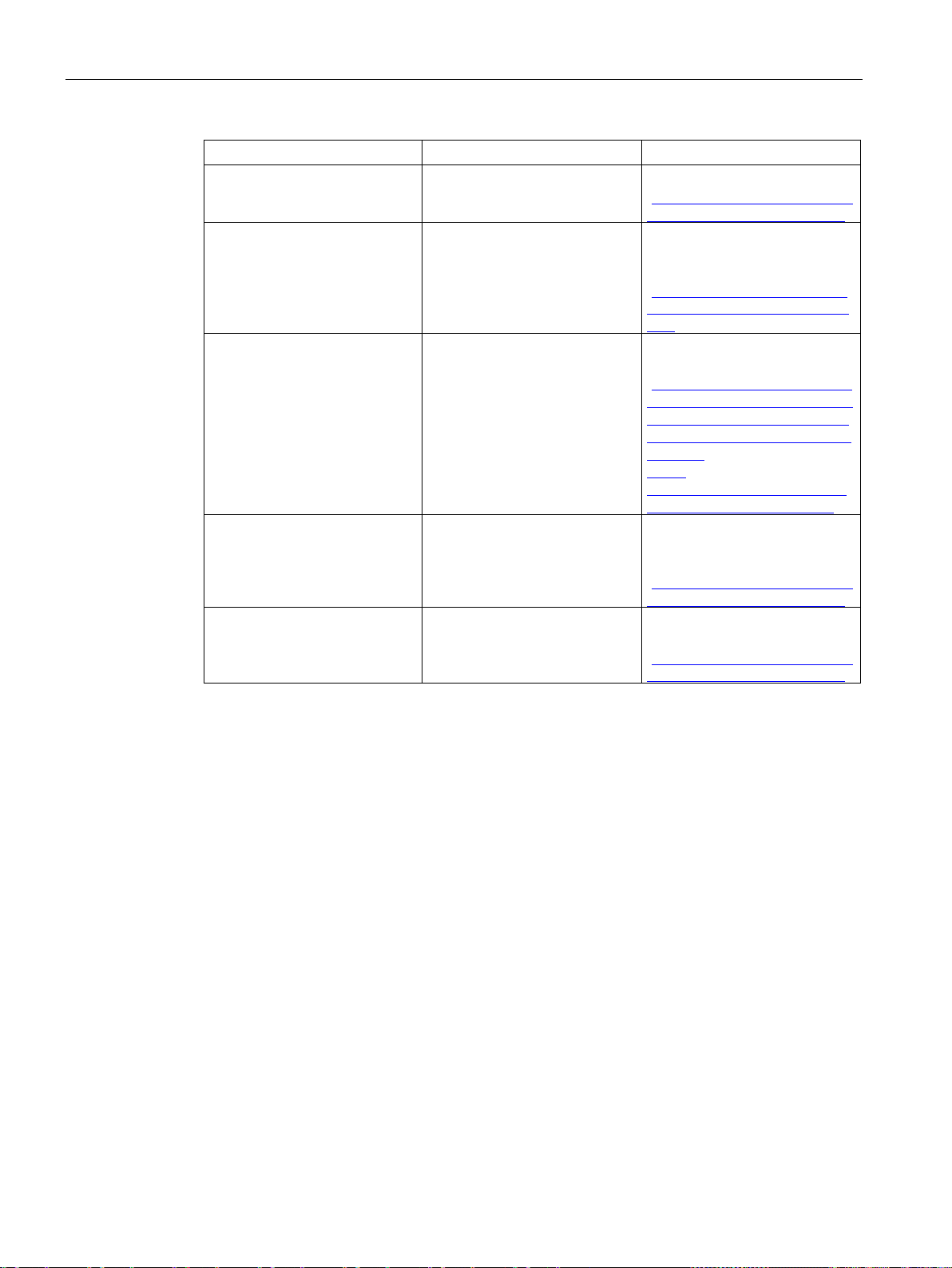

Figure 2-1 Purpose of redundant automation systems ................................................................................. 23

Figure 2-2 Overview ...................................................................................................................................... 26

Figure 2-3 Hardware of the S7-400H basic system ...................................................................................... 27

Figure 2-4 Hardware of the S7-400H basic system ...................................................................................... 28

Figure 3-1 Arrangement of the operator controls and indicators on the CPU 410 ........................................ 35

Figure 6-1 Processing chain: acquire, process, output ................................................................................. 58

Figure 6-2 Safety-related communication ..................................................................................................... 59

Figure 6-3 Operating objectives of redundant automation systems .............................................................. 61

Figure 6-4 Example of redundancy in a network without error ...................................................................... 63

Figure 6-5 Example of redundancy in a 1-out-of-2 system with error ........................................................... 64

Figure 6-6 Example of redundancy in a 1-out-of-2 system with total failure ................................................. 65

Figure 6-7 Single-channel switched distributed I/O configuration at the PROFIBUS DP interface............... 67

Figure 6-8 Single-channel switched distributed I/O configuration at the PROFINET IO interface ................ 70

Figure 6-9 System redundancy ..................................................................................................................... 74

Figure 6-10 IO devices in multiple cabinets..................................................................................................... 76

Figure 6-11 S7-400 H-system with sensors and actuators on module pairs (redundant signal pro-

cessing) ........................................................................................................................................ 78

Figure 6-12 AS 410 with redundant module pairs ........................................................................................... 79

Figure 6-13 Redundant I/O in the switched DP slave ..................................................................................... 80

Figure 6-14 Fault-tolerant digital input module in 1-out-of-2 configuration with one encoder ......................... 89

Figure 6-15 Fault-tolerant digital input modules in 1-out-of-2 configuration with two encoders ...................... 90

Figure 6-16 Fault-tolerant digital output modules in 1-out-of-2 configuration.................................................. 90

Figure 6-17 Fault-tolerant analog input modules in 1-out-of-2 configuration with one encoder ...................... 92

Figure 6-18 Fault-tolerant analog input modules in 1-out-of-2 configuration with two encoders .................... 94

CPU 410 Process Automation/CPU 410 SMART

12 System Manual, 05/2017, A5E31622160-AC

Table of contents

Figure 6-19 Fault-tolerant analog output modules in 1-out-of-2 configuration ................................................ 95

Figure 7-1 Synchronizing the subsystems .................................................................................................. 108

Figure 8-1 Meanings of the times relevant for updates ............................................................................... 122

Figure 8-2 Correlation between the minimum I/O retention time and the maximum inhibit time for

priority classes > 15 ................................................................................................................... 125

Figure 14-1 Synchronization modules 6ES7 960-1AA08-0XA0 and 6ES7 960-1Ax06-0xA0 ....................... 240

Figure 14-2 Fiber-optic cables, installation using distribution boxes ............................................................. 249

Figure 15-1 SEC ............................................................................................................................................ 252

Figure 18-1 Diagnostics with CPU 410 ......................................................................................................... 299

Figure 18-2 S7 routing ................................................................................................................................... 313

Figure 18-3 S7 routing gateways: PROFINET IO - DP - PROFINET IO ....................................................... 314

Figure 18-4 S7 routing: TeleService application example ............................................................................. 315

Figure 18-5 Data set routing .......................................................................................................................... 316

Figure 18-6 Example of an S7 connection .................................................................................................... 322

Figure 18-7 Example that shows that the number of resulting partial connections depends on the con-

figuration .................................................................................................................................... 324

Figure 18-8 Example of linking standard and fault-tolerant systems in a simple bus system ....................... 326

Figure 18-9 Example of linking standard and fault-tolerant systems in a redundant bus system ................. 327

Figure 18-10 Example of linking of standard and fault-tolerant systems in a redundant ring ......................... 327

Figure 18-11 Example of linking standard and fault-tolerant systems in a single bus system ........................ 328

Figure 18-12 Example of redundancy with fault-tolerant systems and a redundant bus system with re-

dundant standard connections ................................................................................................... 329

Figure 18-13 Example of connecting a fault-tolerant system to a single-channel third-party system via

switched PROFIBUS DP ............................................................................................................ 330

Figure 18-14 Example of connecting a fault-tolerant system to a single-channel third-party system via

PROFINET IO with system redundancy .................................................................................... 330

Figure 18-15 Example of linking a fault-tolerant system to a single-channel third-party system .................... 331

Figure 18-16 Example of redundancy with fault-tolerant system and redundant ring .....................................

335

Figure 18-17 Example of redundancy with fault-tolerant system and redundant bus system ........................ 335

Figure 18-18 Example of fault-tolerant system with additional CP redundancy .............................................. 336

Figure 18-19 Example of redundancy with fault-tolerant system and fault-tolerant CPU ............................... 337

Figure 18-20 Example of redundancy with fault-tolerant system and redundant bus system ........................ 339

Figure 18-21 Example of redundancy with a fault-tolerant system, redundant bus system and redun-

dant connection to the PC. ......................................................................................................... 339

Figure 18-22 Sequence of link-up and update ................................................................................................ 344

Figure 18-23 Update sequence ....................................................................................................................... 345

CPU 410 Process Automation/CPU 410 SMART

System Manual, 05/2017, A5E31622160-AC

13

Table of contents

Figure 18-24 Example of minimum signal duration of an input signal during the update ............................... 346

Figure 18-25 Redundant one-sided and switched I/O ..................................................................................... 354

Figure 18-26 Flow chart for OB 1 .................................................................................................................... 356

Figure 18-27 Elements and composition of the cycle time .............................................................................. 358

Figure 18-28 Formula: Influence of communication load ................................................................................ 362

Figure 18-29 Distribution of a time slice .......................................................................................................... 362

Figure 18-30 Dependency of the cycle time on communication load .............................................................. 363

Figure 18-31 DP cycle times on the PROFIBUS DP network ......................................................................... 365

Figure 18-32 Shortest response time .............................................................................................................. 366

Figure 18-33 Longest response time ............................................................................................................... 367

Figure A-1 MDT ............................................................................................................................................ 380

Figure A-2 MTBF .......................................................................................................................................... 381

Figure A-3 Common Cause Failure (CCF) .................................................................................................. 382

Figure A-4 Availability .................................................................................................................................. 383

Figure C-1 Interconnection example for SM 331, Al 8 x 0/4...20mA HART ................................................. 393

Figure C-2 Interconnection example for SM 322, Al 8 x 0/4...20mA HART ................................................. 394

Figure C-3 Example of an interconnection with SM 321; DI 16 x DC 24 V.................................................. 395

Figure C-4 Example of an interconnection with SM 321; DI 32 x DC 24 V.................................................. 396

Figure C-5 Example of an interconnection with SM 321; DI 16 x AC 120/230 V ......................................... 397

Figure C-6 Example of an interconnection with SM 321; DI 8 x AC 120/230 V ........................................... 398

Figure C-7 Example of an interconnection with SM 321; DI 16 x DC 24V................................................... 399

Figure C-8 Example of an interconnection with SM 321; DI 16 x DC 24V................................................... 400

Figure C-9 Example of an interconnection with SM 326; DO 10 x DC 24V/2A ........................................... 401

Figure C-10 Example of an interconnection with SM 326; DI 8 x NAMUR .................................................... 402

Figure C-11 Example of an interconnection with SM 326; DI 24 x DC 24 V.................................................. 403

Figure C-12 Example of an interconnection with SM 421; DI 32 x UC 120 V................................................ 404

Figure C-13 Example of an interconnection with SM 421; DI 16 x 24 V ........................................................ 405

Figure C-14 Example of an interconnection with SM 421; DI 32 x 24 V ........................................................

406

Figure C-15 Example of an interconnection with SM 421; DI 32 x 24 V ........................................................ 407

Figure C-16 Example of an interconnection with SM 322; DO 8 x DC 24 V/2 A ........................................... 408

Figure C-17 Example of an interconnection with SM 322; DO 32 x DC 24 V/0.5 A ...................................... 409

Figure C-18 Example of an interconnection with SM 322; DO 8 x AC 230 V/2 A.......................................... 410

Figure C-19 Example of an interconnection with SM 322; DO 16 x DC 24 V/10 mA [EEx ib] ....................... 411

Figure C-20 Example of an interconnection with SM 322; DO 16 x DC 15 V/20 mA [EEx ib] ....................... 412

Figure C-21 Example of an interconnection with SM 322; DO 8 x DC 24 V/0.5 A ........................................ 413

Figure C-22 Example of an interconnection with SM 322; DO 16 x DC 24 V/0.5 A ...................................... 414

CPU 410 Process Automation/CPU 410 SMART

14 System Manual, 05/2017, A5E31622160-AC

Table of contents

Figure C-23 Example of an interconnection with SM 332, AO 8 x 12 Bit ...................................................... 415

Figure C-24 Example of an interconnection with SM 332; AO 4 x 0/4...20 mA [EEx ib] ............................... 416

Figure C-25 Example of an interconnection with SM 422; DO 16 x 120/230 V/2 A ...................................... 417

Figure C-26 Example of an interconnection with SM 422; DO 32 x DC 24 V/0.5 A ...................................... 418

Figure C-27 Example of an interconnection with SM 331, AI 4 x 15 Bit [EEx ib] ........................................... 419

Figure C-28 Example of an interconnection with SM 331; AI 8 x 12 Bit ........................................................ 420

Figure C-29 Example of an interconnection with SM 331; AI 8 x 16 Bit ........................................................ 421

Figure C-30 Example of an interconnection with SM 331; AI 8 x 16 Bit ........................................................ 422

Figure C-31 Example of an interconnection AI 6xTC 16Bit iso ...................................................................... 423

Figure C-32 Interconnection example 1 SM 331; AI 8 x 0/4...20mA HART ................................................... 424

Figure C-33 Interconnection example 2 SM 331; AI 8 x 0/4...20mA HART ................................................... 425

Figure C-34 Example of an interconnection with SM 332, AO 4 x 12 Bit ...................................................... 426

Figure C-35 Interconnection example 3 SM 332; AO 8 x 0/4...20mA HART ................................................. 427

CPU 410 Process Automation/CPU 410 SMART

System Manual, 05/2017, A5E31622160-AC

15

Table of contents

CPU 410 Process Automation/CPU 410 SMART

16 System Manual, 05/2017, A5E31622160-AC

1

1.1

Preface

Purpose of this manual

Changes compared with the previous version

Scope of the manual

The information in this manual enables you to look up operator inputs, function descriptions

and technical specifications of the CPU 410-5H Process Automation, CPU 410E Process

Automation and CPU 410 SMART.

For information on installing and wiring this and other modules in order to set up an

automation system, refer to Manual

Changes compared with the previous version of the SIMATIC PCS 7 Process Control

System CPU 410-5H Process Automation/CPU 410 SMART, 09/2014 edition

(A5E32631620-AB):

Automation System S7-400, Hardware and Installation

.

● CPU 410E has been added.

● The connection of redundant I/O via the PROFINET interface is described.

● The "Configuration changes during operation" functionality via the PROFINET interface is

● The "Configuration changes during redundant operation" functionality via the PROFINET

● The retentive load memory is described.

● A two-step firmware update procedure is described.

● Time synchronization for purposes of time stamping via PROFINET is described.

● The signaling of security events via SysLog is described.

The manual is relevant to the following components:

● CPU 410-5H Process Automation; 6ES7 410-5HX08-0AB0 as of Firmware Version V8.2

● CPU 410E Process Automation; 6ES7410-5HM08-0AB0 as of Firmware Version V8.2

● CPU 410 SMART; 6ES7 410-5HN08-0AB0 as of firmware version V8.2

described.

interface is described.

CPU 410 Process Automation/CPU 410 SMART

System Manual, 05/2017, A5E31622160-AC

17

Preface

Note

CPU 410-5H and CPU 410E

Except for different technical specifications and quantity frameworks, the CPU 410E behaves

the same as a CPU 410

CPU 410 apply to both the CPU 410

Note

CPU 410 and CPU 410 SMART

Except for the special features described in the s

specifications of CPU 410 SMART

While taking this section into co

410 also apply to the CPU 410 SMART.

Basic knowledge required

Approvals

Online help

1.1 Preface

Use of the current version of PCS 7 or the engineering tools is only required if the current

CPU has new functions compared to the last firmware version and you want to use these

functions. The same applies when an old CPU is replaced by a CPU with current firmware: If

you do not want to use any properties beyond the scope of the replaced CPU, you can use

the CPU with the old article number and old firmware version when configuring in HW

Config.

-5H. For this reason, the statements made in this manual about a

-5H and the CPU 410E.

ection Properties and technical

(Page 283), CPU 410 SMART reacts like a CPU 410.

nsideration, the statements made in this manual about CPU

This manual requires general knowledge of automation engineering.

Knowledge of the use of computers or PC-like tools such as programming devices with a

Windows operating system is also required. The SIMATIC PCS 7 readme includes

information on which operating system is suitable for your SIMATIC PCS 7 configuration.

The CPU 410 is configured using the SIMATIC PCS 7 software, and you should therefore be

familiar with this software.

In particular when operating a CPU 410 in potentially explosive atmospheres, please always

observe the information on the safety of electronic control systems provided in the appendix

Automation System S7-400, Hardware and Installation

to the

For details on certifications and standards, refer to Manual

Module Data

specification for the entire S7-400.

You will need the SIMATIC PCS 7 Programming Package V9.0 or higher to work with CPU

410.

In addition to the manual, you will find detailed support on how to use the software in the

integrated online help system of the software.

manual.

S7-400 Automation System,

, section 1.1, Standards and Certifications. Here you will also find the technical

CPU 410 Process Automation/CPU 410 SMART

18 System Manual, 05/2017, A5E31622160-AC

Preface

Help

Contents

Configuring fault-tolerant systems

Using Help

Recycling and disposal

Additional support

Functional Safety Services

1.1 Preface

The help system can be accessed using various interfaces:

● The

help on fault-tolerant systems in

●

● The context-sensitive help system provides information on the current context, for

example, on an open dialog or active window. You can call this help by clicking "Help" or

using the F1 key.

● The status bar provides a further form of context-sensitive help. It shows a short

description of each menu command when you position the mouse pointer over a

command.

● A short info text is also shown for the toolbar buttons when you hold the mouse pointer

briefly over a button.

If you prefer to read the information of the online help in printed form, you can print individual

topics, books or the entire help system.

Because it is constructed from environmentally compatible materials, the CPU 410 can be

recycled. For ecologically compatible recycling and disposal of your old device, contact a

certificated disposal service for electronic scrap.

menu contains several commands:

provides detailed instructions on using the online help system.

opens the Help index. You will find

.

If you have any questions relating to the products described in this manual, and do not find

the answers in this documentation, please contact your Siemens partner at our local offices.

You will find information on who to contact at:

Contact partners (http://www.siemens.com/automation/partner)

A guide to the technical documents for the various SIMATIC products and systems is

available at:

Documentation (http://www.automation.siemens.com/simatic/portal/html_76/techdoku.htm)

You can find the online catalog and order system under:

Catalog (http://mall.automation.siemens.com/)

Siemens Functional Safety Services is a comprehensive performance package that supports

you in risk assessment and verification all the way to plant commissioning and

modernization. We also offer consulting services for the application of fail-safe and faulttolerant SIMATIC S7 automation systems.

Additional information is available at:

Functional Safety Services (http://www.siemens.com/safety-services)

Submit your requests to:

Mail Functional Safety Services (mailto:safety-services.industry@siemens.com)

CPU 410 Process Automation/CPU 410 SMART

System Manual, 05/2017, A5E31622160-AC

19

Preface

Training center

Technical Support

Service & Support on the Internet

1.2

Security information

1.2 Security information

We offer a range of relevant courses to help you to get started with the SIMATIC S7

automation system. Please contact your local training center or the central training center.

Training (http://www.sitrain.com/index_en.html)

For technical support of all Industry Automation products, fill in and submit the online

Support Request:

Support Request (http://www.siemens.de/automation/support-request)

In addition to our documentation, we offer a comprehensive online knowledge base on the

Internet at:

Service & Support (http://www.siemens.com/automation/service&support)

There you will find:

● The newsletter containing the latest information on your products.

● The latest documents via our search function in Service & Support.

● A forum for global information exchange by users and specialists.

● Your local Automation representative.

● Information on field service, repairs and spare parts. Much more can be found under

"Services".

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines, and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions only form one element of such a concept.

Customer is responsible to prevent unauthorized access to its plants, systems, machines

and networks. Systems, machines and components should only be connected to the

enterprise network or the internet if and to the extent necessary and with appropriate security

measures (e.g. use of firewalls and network segmentation) in place.

Additionally, Siemens’ guidance on appropriate security measures should be taken into

account. For more information about industrial security, please visit:

http:/www.siemens.com/industrialsecurity.