Siemens SIMATIC CP 440 User Manual

Preface, Contents

SIMATIC

Point-to-point Communication

CP 440

Installation and Parameter

Assignment

Manual

Product Description

Basic Principles of Serial Data

Transmission

Commissioning the CP 440

Installing the CP 440

Configuring and

Parameterizing the CP 440

Communication Using Function

Blocks

Start-up Characteristics and

Operating Mode Transitions of

the CP 440

Diagnostics with the CP 440

Programming Example –

Standard Blocks

1

2

3

4

5

6

7

8

9

02/2000

A5E00057742

Edition 02

Appendices

Technical Specifications

Connecting Cables

Communication Matrix of the

Protocols

Accessories and Order

Numbers

Reference for SIMATIC S7

Index

A

B

C

D

E

Safety Guidelines

This manual contains notices which you should observe to ensure your own personal safety, as well as to

protect the product and connected equipment. These notices are highlighted in the manual by a warning

triangle and are marked as follows according to the level of danger:

Danger

!

indicates that death, severe personal injury or substantial property damage will result if proper precautions are not taken.

Warning

!

indicates that death, severe personal injury or substantial property damage can result if proper precautions are not taken.

Caution

!

indicates that minor personal injury or property damage can result if proper precautions are not taken.

Note

draws your attention to particularly important information on the product, handling the product, or to a

particular part of the documentation.

Qualified Personnel

Only qualified personnel should be allowed to install and work on this equipment. Qualified persons are

defined as persons who are authorized to commission, to ground, and to tag circuits, equipment, and systems in accordance with established safety practices and standards.

Correct Usage

Note the following:

Warning

!

Trademarks

The reproduction, transmission or use of this document or its

contents is not permitted without express written authority.

Offenders will be liable for damages. All rights, including rights

created b y patent grant or registration of a utility model or design, are

reserved.

Siemens AG

Bereich Automatisierungs- und Antriebstechnik

Geschaeftsgebiet Industrie-Automatisierungssysteme

Postfach 4848, D- 90327 Nuernberg

Index-2

Siemens Aktiengesellschaft A5E00057742

This device and its components may only be used for the applications described in the catalog or the

technical descriptions, and only in connection with devices or components from other manufacturers

which have been approved or recommended by Siemens.

This product can only function correctly and safely if it is transported, stored, set up, and installed correctly, and operated and maintained as recommended.

SIMATIC, SIMATIC HMI and SIMATIC NET are registered trademarks of SIEMENS AG.

Some of other designations used in these documents are also registered trademarks; the owner’s rights

may be violated if they are used by third parties for their own purposes.

Disclaimer of LiabilityCopyright { Siemens AG 2000 All rights reserved

We have checked the contents of this manual for agreement with the

hardware and software described. Since deviations cannot be precluded entirely, we cannot guarantee full agreement. However, the

data in this manual are reviewed regularly and any necessary corrections included in subsequent editions. Suggestions for improvement are welcomed.

Siemens AG 2000

Point-to-point connection CP 341Installation and Parameter Assignment

Technical data subject to change.

C79000-G7000-C341-02

Preface

Purpose

This manual explains how to establish and operate a point-to-point connection.

Contents of This Manual

The manual describes the hardware and software of the CP 440 communication

processor and its integration in an S7-400 programmable controller. It is divided up

into instruction-based chapters and a reference section (appendices).

The following subjects are covered:

• The basics of point-to-point communication with the CP 440

• Starting up the CP 440

• Installing the CP 440

• Communication with the CP 440

• Troubleshooting

• Application examples

• Properties and technical specifications

Scope of This Manual

This manual is valid for the following:

Product Order Number As of Version

CP 440 with the

X27 RS 422/485 interface

Note

The description of the CP 440 communication processor in this manual were

correct at the time of publication. We reserve the right to describe modifications to

the functionality of the modules in a separate Product Information.

Point-to-point connection CP 440 Installation and Parameter Assignment

A5E00057742-02

6ES7 440-1CS00-0YE0 01

iii

Preface

Structure of This Manual

To help you to quickly find the information you require, this manual offers the

following:

• You will find a full table of contents at the beginning of the manual.

• Finally, a comprehensive index allows quick access to information on specific

subjects.

iv

Point-to-point connection CP 440 Installation and Parameter Assignment

A5E00057742-02

Other Manuals Required

Appendix E contains a list of the other manuals on the subject of the S7-400 that

you will require in order to put your system into operation.

Electronic Manuals

The entire set of SIMATIC S7 documentation is available on CD-ROM.

Standards, Certificates and Approvals

The CP 440 communication processor meets the requirements and criteria of

IEC 1131, Part 2 and the requirements for CE marking. The CP 440 has CSA

certification, UL recognition and FM approval.

Recycling and Disposal

The CP 440 is an environment-friendly product. It is exceptional for the following:

Preface

• Housing plastic with halogen-free flame protection and is highly resistant to fire

• Laser inscriptions (i.e. no labels)

• Plastics identification in accordance with DIN 54840

• Fewer materials used due to size reduction; fewer parts due to integration in

ASICs

The CP 440 is suitable for recycling on account of the low level of contaminants in

its components.

For further information about environment-friendly recycling and the procedure for

disposing of your old equipment, please contact:

Siemens Aktiengesellschaft

Anlagenbau und Technische Dienstleistungen

ATD TD 3 Kreislaufwirtschaft

Postfach 32 40

D-91050 Erlangen, Germany

Phone: + 49 91 31/7-3 36 98

Fax: + 49 91 31/7-2 66 43

The people there will adapt their advice to suit your situation and provide a

comprehensive and flexible recycling and disposal system at a fixed price. After

disposal you will receive information giving you a breakdown of the relevant

material fractions and the associated documents as evidence of the materials

involved.

Point-to-point connection CP 440 Installation and Parameter Assignment

A5E00057742-02

v

Preface

Additional Assistance

Please contact your local Siemens representative if you have any queries about

the products described in this manual. A list of Siemens representatives worldwide

is contained, for example, in the “Siemens Worldwide” Appendix of the manual

S7-400 Programmable Controller, Hardware and Installation

If you have any questions or suggestions concerning this manual, please fill out the

form at the back and return it to the specified address. Please feel free to enter

your personal assessment of the manual in the form provided.

We offer a range of courses to help get you started with the SIMATIC S7

programmable controller. Please contact your local training center or the central

training center in Nuremberg, D-90027 Germany (tel. +49 911 895 3200).

Constantly Updated Information

You can obtain constantly updated information on the SIMATIC products on the

Internet at http://www.ad.siemens.de

.

In addition, SIMATIC Customer Support provides you with up-to-date information

and downloads that can be useful to you when using SIMATIC products:

• On the Internet at http://www.ad.siemens.de/simatic-cs

• Via the SIMATIC Customer Support Mailbox (German) at 49 (911) 895-7100

or the SIMATIC Customer Support BBS (English).

The mailbox is best accessed with a modem up to V.34 (28.8 kbps) parameterized

as follows: 8, N, 1, ANSI, or via ISDN (x.75, 64 kbits).

You can contact SIMATIC Customer Support by phone at 49 (911) 895-7000 or

by fax at 49 (911) 895-7002. You can send questions by e-mail on the Internet or

to the above-mentioned mailbox.

vi

Point-to-point connection CP 440 Installation and Parameter Assignment

A5E00057742-02

Contents

1 Product Description 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Applications of the CP 440 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Components Required for a Point-to-Point Connection with the CP 440 1-3.

1.3 Design of the CP 440 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Features of the X27 (RS 422/485) Interface 1-8. . . . . . . . . . . . . . . . . . . . . . . . .

1.4.1 Cables for Connecting the CP 440 to a Communication Partner 1-8. . . . . . . .

2 Basic Principles of Serial Data Transmission 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Serial Transmission of a Character 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Transmission Procedure with a Point-to-Point Connection 2-6. . . . . . . . . . . . .

2.2.1 ISO 7-Layer Reference Model for Data Transmission 2-6. . . . . . . . . . . . . . . . .

2.2.2 Data Transmission with the ASCII Driver 2-11. . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.3 Data Transmission with the 3964(R) Procedure 2-24. . . . . . . . . . . . . . . . . . . . . .

3 Commissioning the CP 440 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Sequence of Steps to Be Taken 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Commissioning the Physical Interface 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Installing the CP 440 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 CP 440 Slots 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Installing and Removing the CP 440 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Installation Guidelines 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Configuring and Parameterizing the CP 440 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Configuring the CP 440 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Parameterizing the Communication Protocols 5-3. . . . . . . . . . . . . . . . . . . . . . .

5.3 Parameterization Data 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 Basic Parameters of the CP 440 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.2 Parameterization Data of the ASCII Driver 5-6. . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.3 Parameterization Data of the 3964(R) Procedure 5-14. . . . . . . . . . . . . . . . . . . .

5.4 Management of the Parameter Data 5-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 Uploading Firmware Updates 5-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Point-to-point connection CP 440 Installation and Parameter Assignment

A5E00057742-02

vii

Contents

6 Communication Using Function Blocks 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Communication Using Function Blocks 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Overview of the Function Blocks 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Notes on Program Structure 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 Using the Function Blocks 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.1 The S7 Transmits Data to a Communication Partner,

10 SEND_440 FB 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.2 S7 Receives Data from a Communication Partner, 9 RECV_440 FB 6-10. . . .

6.4.3 Deleting the Receive Buffer (11 “RES_RECV” FB) 6-14. . . . . . . . . . . . . . . . . . .

6.5 Programming the Function Blocks 6-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.1 General Information on Data Block Assignment 6-18. . . . . . . . . . . . . . . . . . . . .

6.5.2 Supplying the Block Parameters 6-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6 General Information on Program Processing 6-23. . . . . . . . . . . . . . . . . . . . . . . .

6.7 Technical Specifications of the Function Blocks 6-24. . . . . . . . . . . . . . . . . . . . . .

7 Startup Characteristics and Operating Mode Transitions of the CP 440 7-1. . . . .

7.1 Operating Modes of the CP 440 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Startup Characteristics of the CP 440 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Behavior of the CP 440 During Operating Mode Transitions of the CPU 7-3.

7.4 Behavior of the Sender Line Drivers of the Serial Interface

During Particular Operating Modes of the CP 440 7-4. . . . . . . . . . . . . . . . . . . .

8 Diagnostics with the CP 440 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Diagnostic functions of the CP 440 8-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Diagnosis via the Display Elements of the CP 440 8-3. . . . . . . . . . . . . . . . . . .

8.3 Diagnostic Messages of the Function Blocks 8-5. . . . . . . . . . . . . . . . . . . . . . . .

8.4 Diagnostics Using the Diagnostic Buffer of the CP 440 8-14. . . . . . . . . . . . . . .

9 Programming Example – Standard Blocks 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 General 9-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 Device Configuration 9-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 Settings 9-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4 Blocks Used 9-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5 Installation, Error Messages 9-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6 Activation, Startup Program and Cyclic Program 9-8. . . . . . . . . . . . . . . . . . . . .

9.6.1 “CP440 SEND RECV” Program Example 9-8. . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.2 “CP440 1 CYC” Program Example 9-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.3 “CP440 ASCII BCC” Program Example 9-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.4 “CP440 MASTER” Program Example 9-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.5 “CP440 SLAVE” Program Example 9-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii

Point-to-point connection CP 440 Installation and Parameter Assignment

A5E00057742-02

Contents

A Technical Specifications A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1 Technical Specifications of the CP 440 A-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2 Transmission Times A-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B Connecting Cables B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1 X27 (RS 422/485) Interface of the CP 440 B-2. . . . . . . . . . . . . . . . . . . . . . . . . .

C Communication Matrix of the Protocols C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D Accessories and Order Numbers D-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E Reference for SIMATIC S7 E-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index Index-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Point-to-point connection CP 440 Installation and Parameter Assignment

A5E00057742-02

ix

Contents

x

Point-to-point connection CP 440 Installation and Parameter Assignment

A5E00057742-02

Product Description

In Section You Will Find on Page

1.1 Applications of the CP 440 1-2

1.2 Components Required for a Point-to-Point Connection with the

CP 440

1.3 Design of the CP 440 1-6

1.4 Properties of the X27 (RS 422/485) Interface 1-8

1

1-3

Point-to-point connection CP 440 Installation and Parameter Assignment

A5E00057742-02

1-1

Product Description

1.1 Applications of the CP 440

The CP 440 communication processor enables you to exchange data between

programmable controllers or computers by means of a point-to-point connection.

The CP 440 is designed to transfer short, fast frames.

The following are typically connected to it:

• Scanners, barcode readers

• Sensors

• Weighing scales

Functionality of the CP 440

The CP 440 communication processor provides the following functionality:

• An integrated MPI (Multipoint) X27 (RS422/485) interface

• A maximum transmission length of 200 bytes

• A transmission rate of up to 115.2 kbps, full-duplex

• Integration of the most important transmission protocols in the module firmware

– ASCII driver

– 3964(R) procedure

• Customization of the transmission protocols by means of parameter assignment

with the

CP 440: Point-to-Point Communication, Parameter Assignment

parameterization interface.

Applications of the CP 440

The CP 440 communication processor allows point-to-point communication with

SIMATIC modules and with non-Siemens products. The SIMATIC modules that

can be connected are listed in Appendix C.

Functions Supported by the Interfaces

Table 1-1 Functions of the CP 440

Function

3964(R) procedure Yes No

ASCII driver Yes Yes

• XON/XOFF flow control Yes No

CP 440

RS 422* RS 485*

1-2

* The RS 422 and RS 485 are distinguished by means of parameterization.

Point-to-point connection CP 440 Installation and Parameter Assignment

A5E00057742-02

Product Description

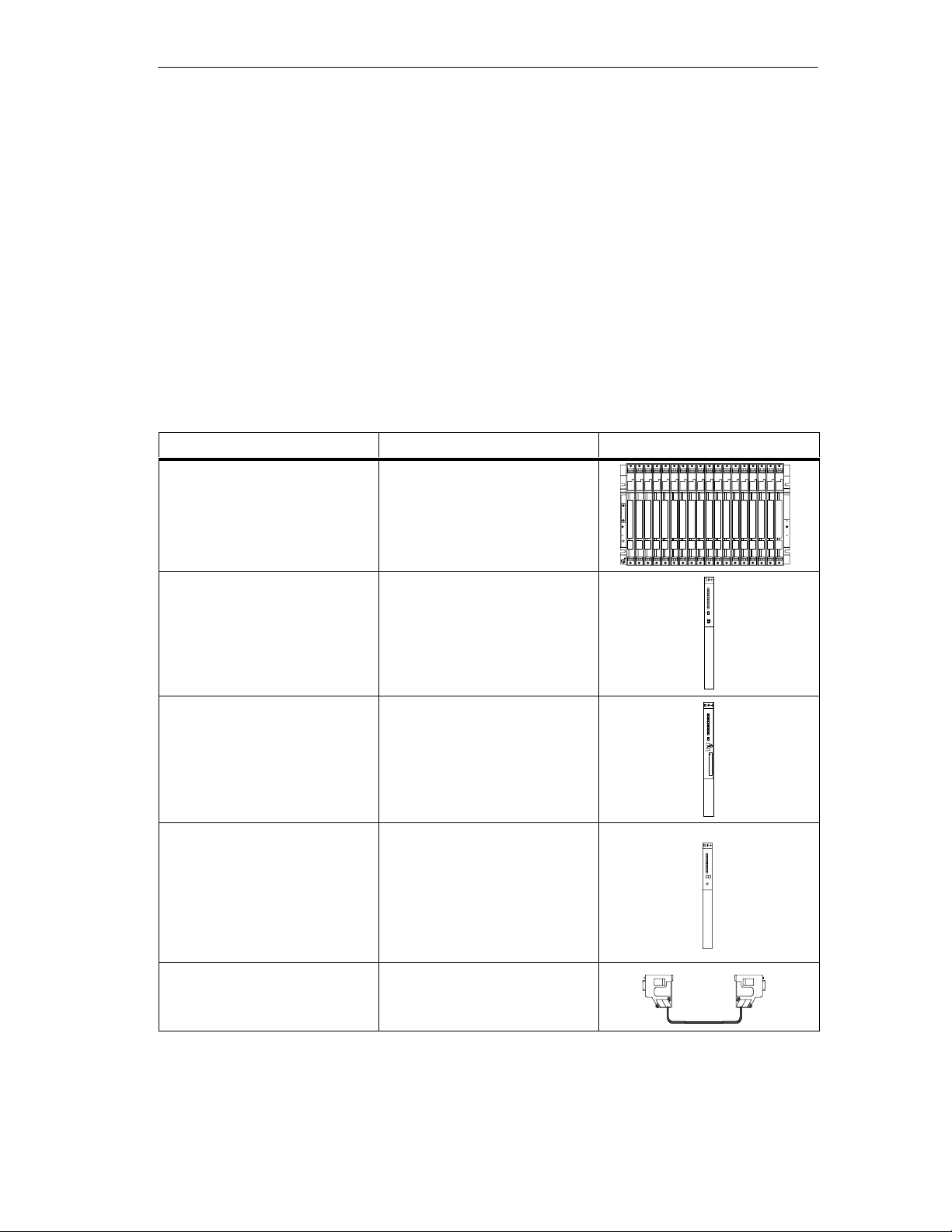

1.2 Components Required for a Point-to-Point Connection with the CP 440

To establish a point-to-point connection between the CP 440 communication

processor and a communication partner, you require certain hardware and

software components.

Hardware Components

The following table lists the hardware components required for establishing a

point-to-point connection with the CP 440.

Table 1-2 Hardware Components for a Point-to-Point Connection with the CP 440

Components

Rack ... provides the mechanical and

electrical connections of the

S7-400.

Power supply module (PS) ... converts the line voltage

(120/230 VAC or 24 VDC) into

the operating voltage of 24 V and

5 VDC required to supply the

S7-400.

CPU

The CPUs with which the CP 440

cannot be used are listed in

Tables 1-5 and 1-4.

Accessories: Memory card

Backup battery

CP 440 communication

processor

... executes the user program;

communicates via the MPI

interface with other CPUs or with

a programming device.

... communicates via the interface

with one or more communication

partners.

Function Diagram

Standard connecting cable ... connects the CP 440

communication processor to the

communication partner.

Point-to-point connection CP 440 Installation and Parameter Assignment

A5E00057742-02

1-3

Product Description

Table 1-2 Hardware Components for a Point-to-Point Connection with the CP 440, continued

Components DiagramFunction

Programming device cable ... connects a CPU to a

programming device/PC.

Programming device or PC ... communicates with the CPU of

the S7-400.

Software Components

The following table lists the software components required for establishing a

point-to-point connection with the CP 440.

Table 1-3 Software Components for a Point-to-Point Connection with the CP 440

Components

STEP 7 software package,

as of version 4.0.2

CP 440: Point-to-Point

Communication, Parameter

Assignment

interface, Version 5.1

Function blocks (FBs) with

programming examples

Parameterization

... configures, parameterizes,

programs and tests the S7-400.

... parameterizes the interfaces of

the CP 440.

... control communication

between the CPU and the

CP 440.

Function Diagram

+

License

1-4

Point-to-point connection CP 440 Installation and Parameter Assignment

A5E00057742-02

Product Description

CPU Versions

The CP 440 can be operated with all CPU versions except the CPUs listed in the

tables below:

Table 1-4 CPU Versions with Which the CP 440 Can Be Used as of the Version Indicated

CPU MLFB

CPU 412-1 6ES7 412-1XF01-0AB0, Release 5

CPU 413-1 6ES7 413-1XG01-0AB0, Release 5

CPU 413-2 6ES7 413-2XG01-0AB0, Release 5

CPU 414-1 6ES7 414-1XG01-0AB0, Release 5

CPU 414-2 with 128k 6ES7 414-2XG01-0AB0, Release 5

CPU 414-2 with 348k 6ES7 414-2XJ00-0AB0, Release 7

CPU 416-1 6ES7 416-1XJ01-0AB0, Release 5

CPU 416-2 with 0.8 M 6ES7 416-2XK00-0AB0, Release 7

CPU 416-2 with 1.6 M 6ES7 416-2XL00-0AB0, Release 7

CPU 416-2 DP ISA Lite

6ES7 616-2PK00-0AB4, Release 3

CPU 416-2 DP ISA

CPU 412-2 DP PCI

CPU 416-2 DP PCI

Table 1-5 CPU Versions with Which the CP 440 Cannot be Used

CPU MLFB

CPU 412-1 6ES7 412-1XF00-0AB0

CPU 413-1 6ES7 413-1XG00-0AB0

CPU 413-2 6ES7 413-2XG00-0AB0

CPU 414-1 6ES7 414-1XG00-0AB0

CPU 414-2 with 128k 6ES7 414-2XG00-0AB0

CPU 416-1 6ES7 416-1XJ00-0AB0

Point-to-point connection CP 440 Installation and Parameter Assignment

A5E00057742-02

1-5

Product Description

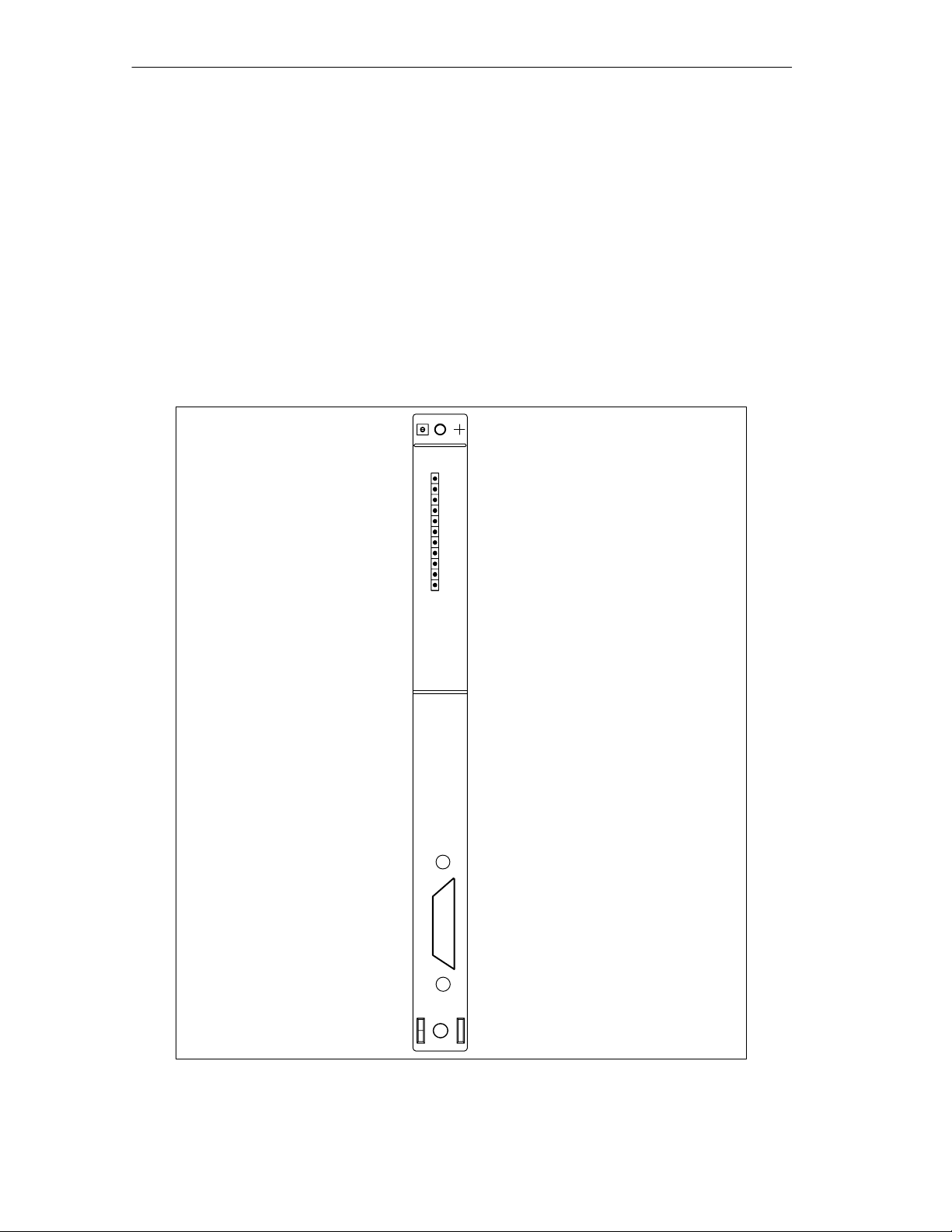

1.3 Design of the CP 440

Interface

The CP 440 communication processor is supplied with an integrated serial X27

(RS422/485) interface.

Arrangement of the Controls and Indicators

Fig. 1-1 shows the arrangement of the controls and indicators on the front panel of

the CP 440 communication processor.

CP 440

440 – 1CS00 – 0YE0

V1.0.0

INTF

EXTF

FAULT

TxD

RxD

CP 440

X 2

3 4

Firmware version

INTF

EXTF

FAULT

TxD

RxD

Integrated

X27

(RS422/485)

interface

1-6

Figure 1-1 Arrangement of the Controls and Indicators on the CP 440 Communication

Processor

Point-to-point connection CP 440 Installation and Parameter Assignment

A5E00057742-02

LEDs

Interface

Product Description

The following LEDs are located on the front panel of the CP 440:

• INTF (red) Indicates an internal fault

• EXFT (red) Indicates an external fault

• FAULT (red) Fault LED for interface

• TXD (green) interface sends

• RXD (green) interface receives

The operating modes and faults and errors indicated by these LEDs are described

in Section 8.2. Section 5.5 contains information on the LEDs that come on when

you download firmware updates.

For a detailed description of the interface, see Section 1.4.

Base Connector for the S7 Backplane Bus

On the back panel of the CP 440 you will find the base connector for the S7-400

backplane bus.

The S7-400 backplane bus is the serial data bus via which the CP 440

communicates with the modules of the programmable controller.

Point-to-point connection CP 440 Installation and Parameter Assignment

A5E00057742-02

1-7

Product Description

1.4 Features of the X27 (RS 422/485) Interface

Definition

The X27 (RS 422/485) interface is a differential voltage interface used for serial

data transmission in compliance with the X27 standard.

Features

The X27 (RS 422/485) interface has the following features and meets the following

requirements:

• Type: differential voltage interface

• Front connector: 15-pin sub D female with screw fixing

• Max. transmission rate: 115.2 kbps

• Max. cable length: 1200 m at 19200 bps

*

• Standard: DIN 66259 Parts 1 and 3,

EIA-RS 422/485, CCITT V.11

• Degree of protection: IP00

Note

The X27 (RS 422/485) interface can only be run in 4-wire mode with the 3964(R)

protocol.

1.4.1 Cables for Connecting the CP 440 to a Communication Partner

Standard Connecting Cables

For point-to-point connection between the CP 440 and a communication partner,

Siemens offers standard connecting cables in various lengths.

The lengths and order numbers of these cables are listed in Appendix D.

Constructing Your Own Connecting Cables

If you make your own connecting cables, there are some points you must be

aware of. These are described in Appendix B, along with wiring plans and the pin

allocation for the sub D male connector.

* To find out which cable types you can use, see Appendix B.

Point-to-point connection CP 440 Installation and Parameter Assignment

1-8

A5E00057742-02

Basic Principles of Serial Data Transmission

In Section You Will Find on Page

2.1 Serial Transmission of a Character 2-2

2.2 Transmission Procedure with a Point-to-Point Connection 2-6

2

Point-to-point connection CP 440 Installation and Parameter Assignment

A5E00057742-02

2-1

Basic Principles of Serial Data Transmission

2.1 Serial Transmission of a Character

There are various networking alternatives for the transfer of data between two or

more communication partners. The simplest form of data interchange is via a

point-to-point connection between two communication partners.

Point-to-Point Connection

In a point-to-point connection the CP 440 communication processor forms the

interface between a programmable controller and a communication partner. In a

point-to-point connection with the CP 440, the data is transferred serially.

Serial Data Transmission

In serial transmission, the individual bits of each byte of information are transmitted

one after the other in a fixed order.

Drivers for Bidirectional Data Traffic

The CP 440 executes data transfer with communication partners independently via

the serial interface. The CP 440 is equipped with two different drivers for this

purpose.

Bidirectional Data Traffic:

• ASCII driver

• 3964(R) procedure

The CP 440 executes data transfer via the serial interface depending on the

selected driver.

2-2

Point-to-point connection CP 440 Installation and Parameter Assignment

A5E00057742-02

Bidirectional Data Traffic - Operating Modes

The CP 440 has two operating modes for bidirectional data traffic:

• Half-duplex operation (3964(R) procedure, ASCII driver)

Data is exchanged between the communication partners but only in one

direction at a time. In half-duplex operation, therefore, at any one time, data is

being either sent or received. The exception to this may be individual control

characters for data flow control (e.g. XON/XOFF), which can also be sent while

data is being received or received while data is being sent.

• Full-duplex operation (ASCII driver)

Data is exchanged between two or more communication partners in both

directions simultaneously. In full-duplex operation, therefore, data can be sent

and received at the same time. Each communication partner must be able to

send and receive simultaneously.

Only half-duplex mode can be used with an RS 485 (2-wire) setting.

Basic Principles of Serial Data Transmission

Asynchronous Data Transmission

With the CP 440, serial transmission takes place asynchronously. What is known

as timebase synchronization (a fixed timing code used in the transmission of a

fixed character string) is only upheld during transmission of a character. Each

character to be sent is preceded by a synchronization impulse, or start bit. The end

of the character transmission is signaled by the stop bit.

Declarations

As well as the start and stop bits, further declarations must be made between the

two communication partners before serial transmission can take place. These

include:

• Transmission rate (baud rate)

• Character and acknowledgment delay times

• Parity

• Number of data bits

• Number of stop bits

Section 2.2 describes the importance of the declarations in the various

transmission procedures, and how they are parameterized.

Point-to-point connection CP 440 Installation and Parameter Assignment

A5E00057742-02

2-3

Basic Principles of Serial Data Transmission

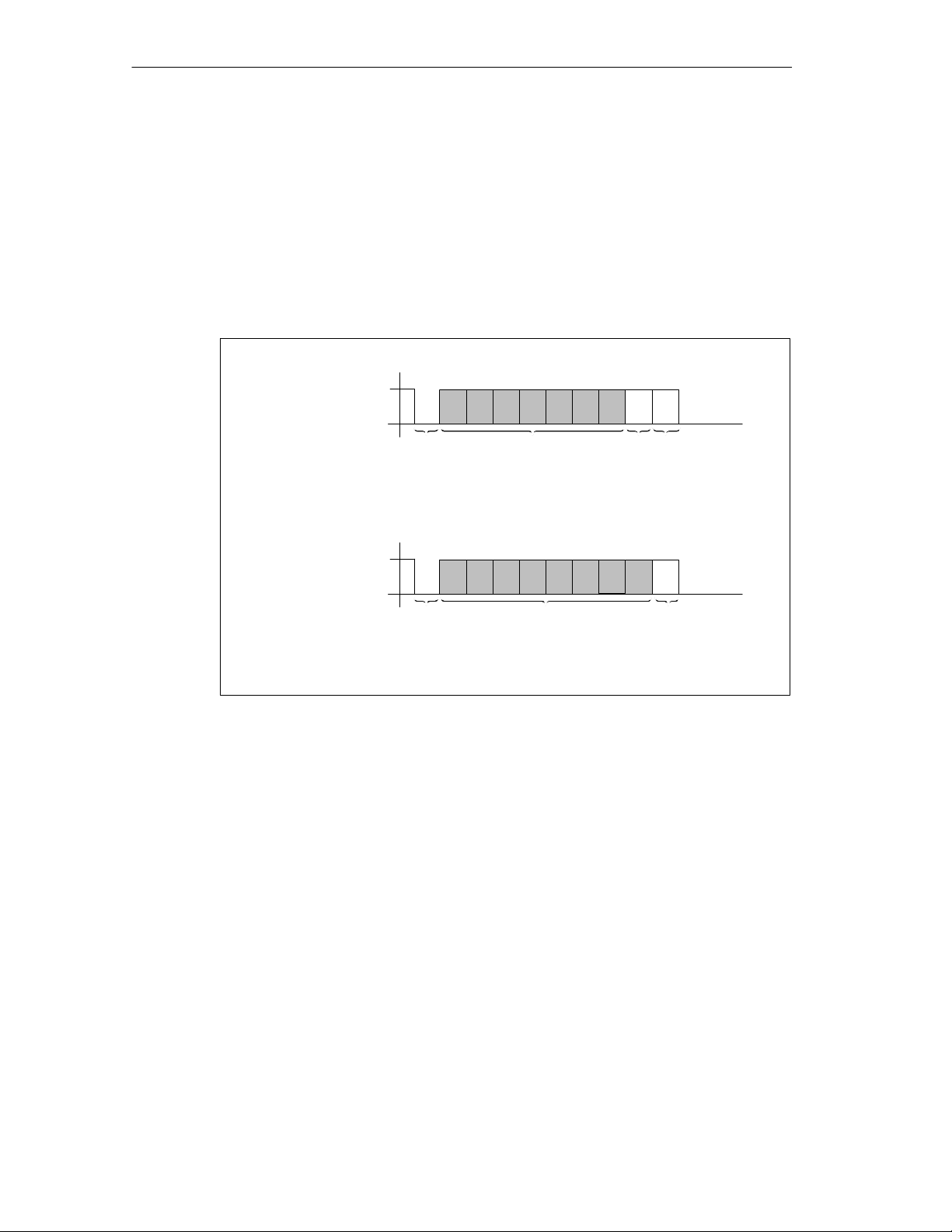

Character Frames

Data is transmitted between the CP 440 and a communication partner via the

serial interface in a character frame. Two data formats are available for each

character frame. 7 data bits without a parity bit are not supported. You can

parameterize the format for data transmission with the

Communication, Parameter Assignment

By way of example, the figure below shows the two data formats of the 10-bit

character frame.

7 data bits, 1 start bit, 7 data bits, 1 parity bit, 1 stop bit

Signal state “1”

1

Signal state “0”

CP 440: Point-to-Point

parameterization interface.

289

10

1 start bit

8 data bits: 1 start bit, 8 data bits, 1 stop bit

Signal state “1”

1

Signal state “0”

1 start bit

Figure 2-1 10-Bit Character Frame

7 data bits

2 109

8 data bits

1 stop bit

1 parity bit

1 stop bit

2-4

Point-to-point connection CP 440 Installation and Parameter Assignment

A5E00057742-02

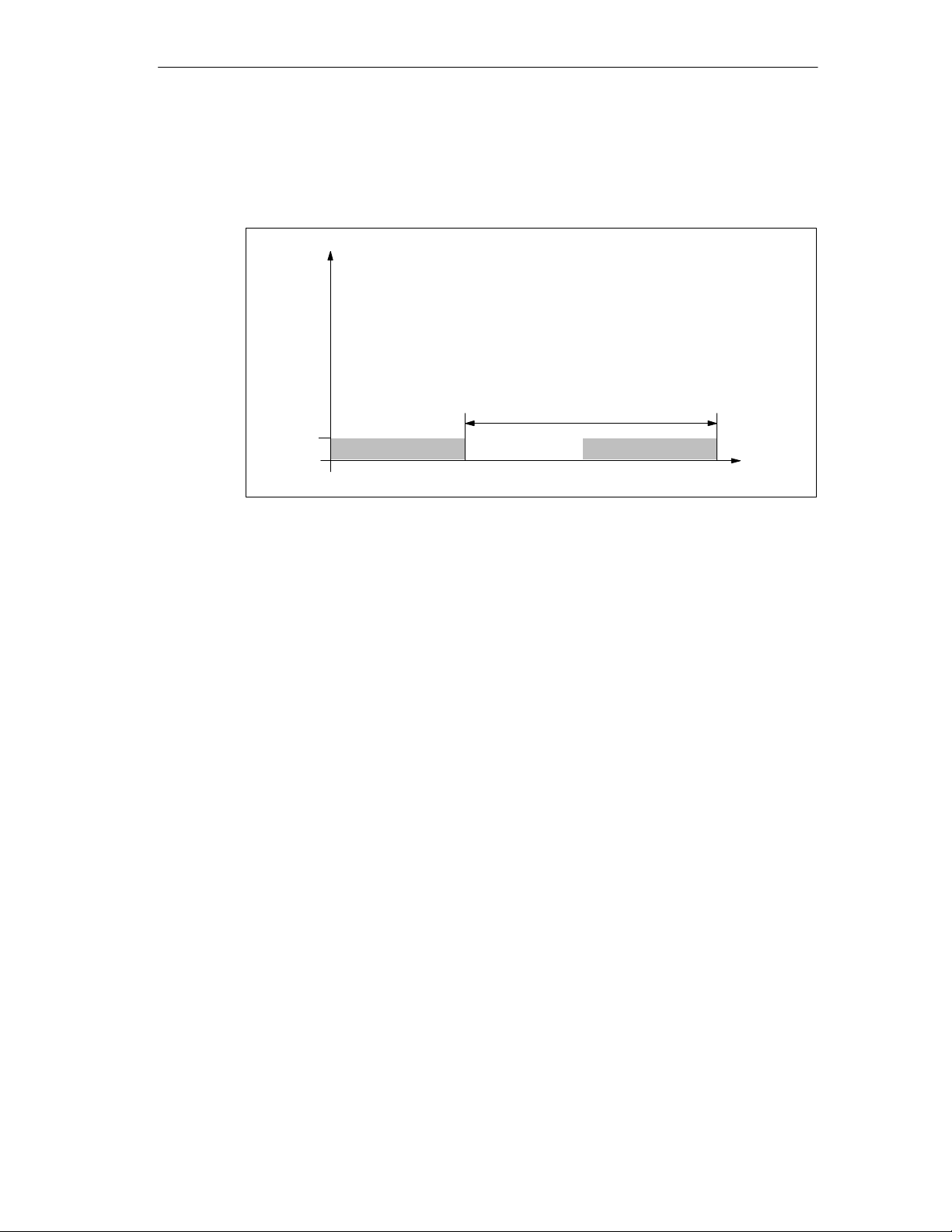

Character Delay Time

The figure below shows the maximum time permitted between two characters

received within a message frame. This is known as the character delay time.

Signal

1

Basic Principles of Serial Data Transmission

nth character (n + 1)th character

Character delay time

Time t

Figure 2-2 Character Delay Time

Point-to-point connection CP 440 Installation and Parameter Assignment

A5E00057742-02

2-5

Basic Principles of Serial Data Transmission

2.2 Transmission Procedure with a Point-to-Point Connection

When data is transmitted, all communication partners involved must follow fixed

rules for handling and implementing the data traffic. The ISO has defined a 7-layer

model, which is recognized as the basis for a worldwide standardization of

transmission protocols for computer-to-computer communication.

2.2.1 ISO 7-Layer Reference Model for Data Transmission

Protocol

All communication partners involved in data transmission must follow fixed rules for

handling and implementing the data traffic. Such rules are called protocols.

A protocol defines the following points:

Procedure

• Operating mode

Half-duplex or full-duplex mode

• Initiative

Which communication partners can initiate data transmission and under what

conditions

• Control characters

Which control characters are to be used for data transmission

• Character frame

Which character frame is to be used for data transmission

• Data backup

The data backup procedure to be used

• Character delay time

The time period within which an incoming character must be received

• Transmission speed

The transmission rate in bps

2-6

This is the specific process according to which the data is transmitted.

Point-to-point connection CP 440 Installation and Parameter Assignment

A5E00057742-02

ISO 7-Layer Reference Model

The reference model defines the external behavior of the communication partners.

Each protocol layer, except for the lowest one, is embedded in the next one down.

The individual layers are as follows:

1. Physical layer

– Physical conditions for communication, e.g. transmission medium,

transmission rate

2. Data link layer

– Security procedure for the transmission

– Access modes

3. Network layer

– Network connections

– Definition of the addressing for communication between two partners

4. Transport layer

Basic Principles of Serial Data Transmission

– Error-detection procedure

– Debugging

– Handshaking

5. Session layer

– Establishing communication

– Data exchange management

– Terminating communication

6. Presentation layer

– Conversion of the standard form of data representation of the

communication system into a device-specific form (data interpretation rules)

7. Application layer

– Defining the communication task and the functions it requires

Processing the Protocols

The sending communication partner runs through the protocols from the highest

layer (no. 7 – application layer) to the lowest (no. 1 – physical layer), while the

receiving partner processes the protocols in the reverse order, i.e. starting with

layer 1.

Not all protocols have to take all 7 layers into account. If the sending and receiving

partners both use the same protocol, layer 6 can be omitted.

Point-to-point connection CP 440 Installation and Parameter Assignment

A5E00057742-02

2-7

Basic Principles of Serial Data Transmission

Transmission Integrity

Transmission integrity plays an important role in the transmission of data and in

selection of the transmission procedure. Generally speaking, the more layers of the

reference model are applied, the greater the transmission integrity.

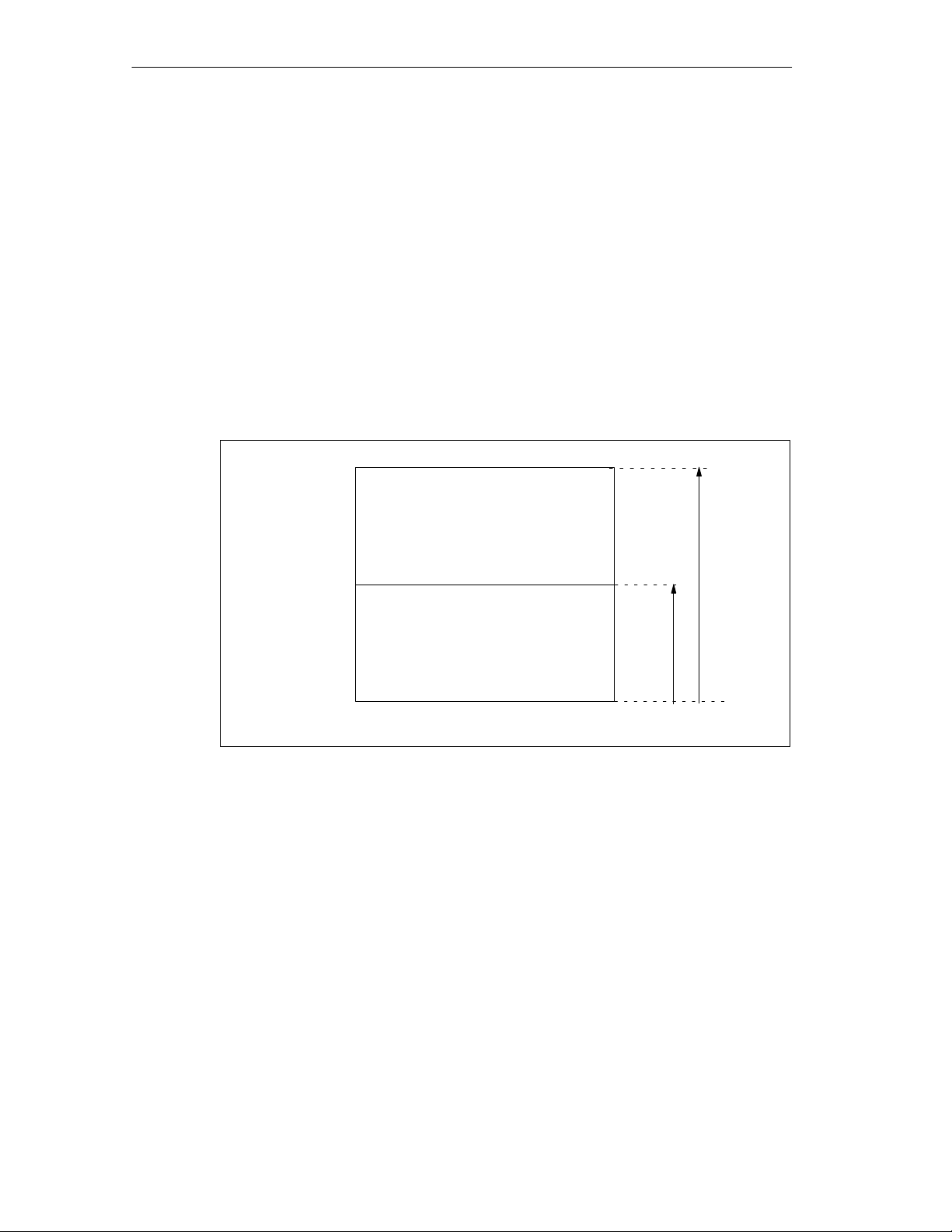

Classifying the Supplied Protocols

The CP 440 can handle the following protocols:

• ASCII driver

• 3964(R) procedure

The figure below illustrates how these protocols of the CP 440 fit into the ISO

reference model:

Data link layer

Layer 2

The data bytes are transmitted with

3964(R). Start and stop bits are added;

in the event of an error the transmission

may be repeated.

3964(R)

Layer 1

Figure 2-3 How the Protocols of the CP 440 Fit into the ISO Reference Model

Physical layer

The physical transmission of the

data bytes is defined.

ASCII driver

2-8

Point-to-point connection CP 440 Installation and Parameter Assignment

A5E00057742-02

Transmission Integrity with the ASCII Driver

Data Integrity When Using the ASCII Driver:

• When data is transmitted by means of the ASCII driver, there are no measures

to ensure data integrity other than the use of a parity bit (which can also be

canceled, depending on how the character frame is set). This means that,

although data transmission with the ASCII driver is very efficient in terms of the

throughput rate, the integrity of the data is not checked.

• Using the parity bit ensures that the inversion of a bit in a character to be

transmitted can be detected. If two or more bits of a character are inverted, this

error can no longer be detected.

• To increase transmission integrity, a checksum and length specification for a

message frame can be employed. These measures must be implemented by

the user.

• A further increase in data integrity can be achieved by means of

acknowledgment message frames in response to send or receive message

frames. This is the case with high-level protocols for data communication (see

ISO 7-layer reference model).

Basic Principles of Serial Data Transmission

Transmission Integrity with 3964

Enhanced Data Integrity with the 3964R Procedure:

• The Hamming distance with the 3964R is 3. This measures the integrity of data

transmission.

• The 3964R procedure ensures high transmission integrity on the data line. This

high integrity is achieved by means of a fixed message-frame setup and

cleardown as well as the use of a block check character (BCC).

Two different procedures for data transmission can be used, either with or without

a block check character:

• Data transmission without a block check character: 3964

• Data transmission with block check character: 3964R

In this manual, the designation 3964(R) is used when descriptions and notes refer

to both data transmission procedures.

Point-to-point connection CP 440 Installation and Parameter Assignment

A5E00057742-02

2-9

Basic Principles of Serial Data Transmission

Performance Limits with 3964(R)

Performance Limits of the 3964(R) Procedure:

• Further processing of the send/receive data by the PLC program in the

communication partner is not guaranteed. You can only ensure this by using a

programmable acknowledgment mechanism.

• The block check of the 3964(R) procedure (EXOR logic operation) cannot

detect missing zeros (as a whole character) because a zero in the EXOR logic

operation does not affect the result of the calculation.

Although the loss of an entire character (this character has to be a zero!) is

highly unlikely, it could possibly occur under very bad transmission conditions.

You can protect a transmission against such errors by sending the length of the

data message along with the data itself, and having the length checked at the

other end.

2-10

Point-to-point connection CP 440 Installation and Parameter Assignment

A5E00057742-02

Basic Principles of Serial Data Transmission

2.2.2 Data Transmission with the ASCII Driver

The ASCII driver controls data transmission via a point-to-point connection

between the CP 440 and a communication partner. This driver contains the

physical layer (layer 1 of the ISO reference model.)

The structure of the message frames is left open through the S7 user passing on

the complete send message frame to the CP 440. For the receive direction, the

end criterion of a message must be parameterized. The structure of the send

message frames may differ from that of the receive message frames.

The ASCII driver allows data of any structure (all printable ASCII characters as

well as all other characters from 00 through FFH (with 8 data bit character frames)

or from 00 through 7FH (with 7 data bit character frames)) to be sent and received.

Both RS422 and RS485 operation are possible.

RS422 Operation

In RS422 operation, the data is transmitted via four cables (four-wire mode). Two

cables (differential signal) are available for the send direction and two for the

receive direction. This means you can send and receive data at the same time

(full-duplex operation).

RS485 Operation

In RS485 operation, the data is transmitted via two cables (two-wire mode). The

two cables (differential signal) are alternately available for the send direction and

the receive direction. This means you can either send or receive data at the same

time (half-duplex operation). After a send operation, the cable is immediately

switched over to receive (the sender becomes high-impedance). The maximum

switchover time is 0.1 ms.

Point-to-point connection CP 440 Installation and Parameter Assignment

A5E00057742-02

2-11

Basic Principles of Serial Data Transmission

Sending Data with the ASCII Driver

When you send data, you specify the number of user data bytes to be transferred

in the “LEN” parameter of the call of the SEND_440 function block.

When you work with the end criterion “character delay time expired” when

receiving data, the ASCII driver pauses between two message frames when

sending. You can call the SEND_440 FB at any time, but the ASCII driver does not

begin its output until a period longer than the parameterized character delay time

has elapsed since the last message frame was sent.

If you work with the “end-of-text character” criterion, you have a choice of

three options:

• Send up to and including the end-of-text character

The end-of-text character must be included in the data to be sent. Data is sent

only up to and including the end-of-text character, even if the data length

specified in the FB is longer.

• Send up to length parameterized at the FB

Data is sent up to the length parameterized at the FB. The last character must

be the end-of-text character.

• Send up to the length parameterized at the FB and automatically append the

end-of-text character or characters

Data is sent up to the length parameterized at the FB. The end-of-text

character(s) is/are automatically appended; in other words, the end-of-text

characters must not be included in the data to be sent. 1 or 2 characters more

than the number specified by the FB are sent to the partner, depending on the

number of end-of-text characters.

When you work with the end criterion “fixed frame length”, the number of data

bytes transferred in the send direction is as specified for the “LEN” parameter of

the SEND_440 FB. The number of data bytes transferred in the receive direction,

i.e. in the receive DB, is as specified at the receiver using the “fixed message

frame length” parameter in the parameterization interface. The two parameter

settings must be identical, in order to ensure correct data traffic. If an end code is

not detected when data is sent, a pause equal to the length of the monitoring time

is inserted between two message frames to allow the partner to synchronize

(identify the beginning of the message frame).

If some other method of synchronization is used, the pause in sending can be

deactivated by means of the parameterization interface.

2-12

Note

When XON/XOFF flow control is parameterized, the user data must not contain

any of the parameterized XON or XOFF characters. The default settings are DC1

= 11H for XON and DC3 = 13H for XOFF.

Point-to-point connection CP 440 Installation and Parameter Assignment

A5E00057742-02

Loading...

Loading...