Siemens Simantic ET200SP System Manual

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

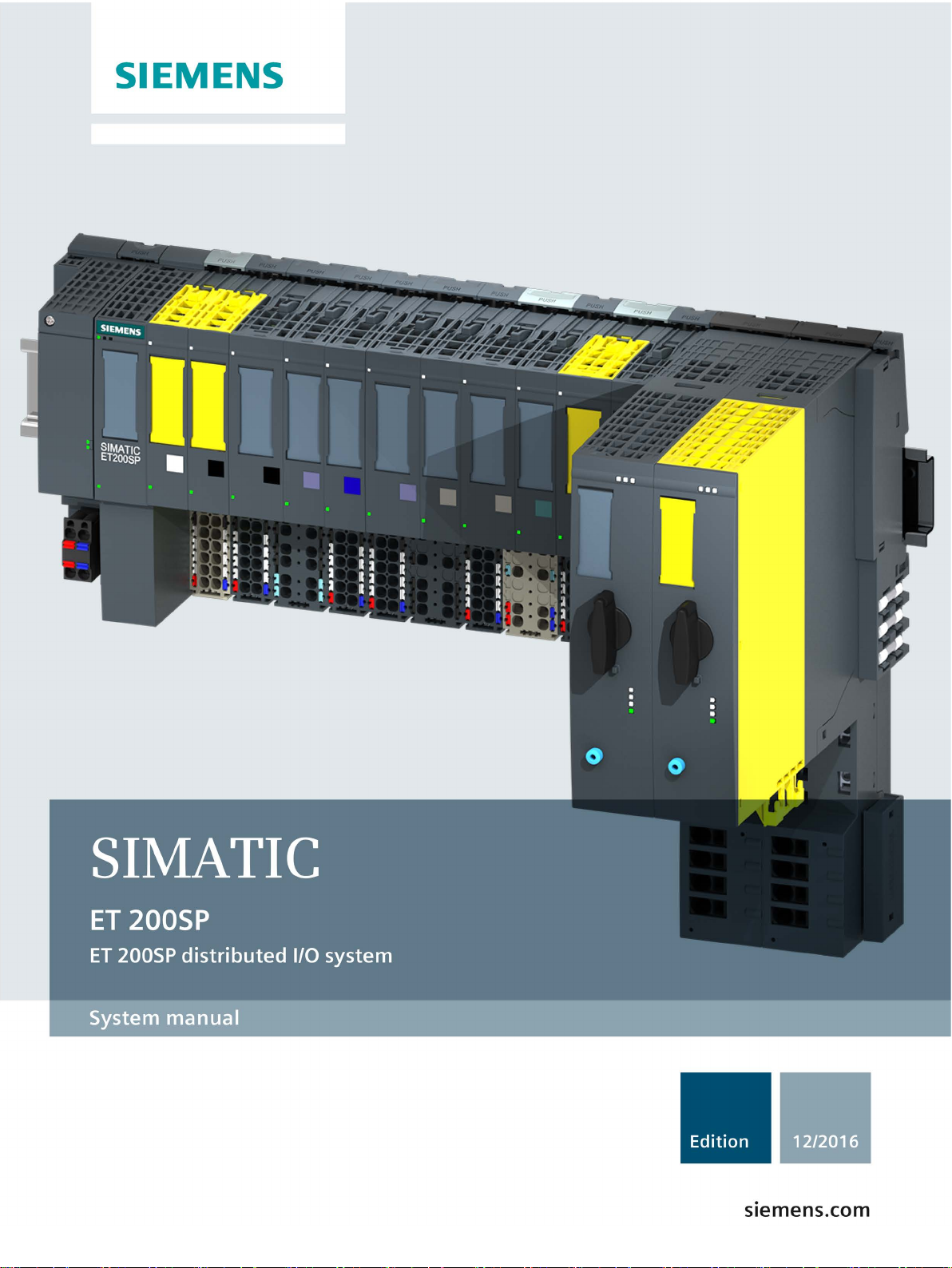

SIMATIC

ET 200SP

Distributed I/O system

System Manual

12/2016

A5E03576849

Preface

Guide to documentation

1

System overview

2

Application planning

3

Installation

4

Wiring

5

Configuring

6

Basics of program execution

7

Protection

8

Configuration control (option

handling)

9

Commissioning

10

SIMATIC memory card

11

Maintenance

12

Test functions and

eliminating problems

13

Technical specifications

14

Dimension drawings

A

Accessories/spare parts

B

Calculating the leakage

resistance

C

-AG

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E03576849-AG

Ⓟ

Copyright © Siemens AG 2012 - 2016.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

03/2017 Subject to change

Preface

Preface

Purpose of the documentation

Basic knowledge required

Validity of the documentation

Definition

Conventions

Note

Notes conta

documentation to which you should pay particular attention.

This documentation provides important information on configuring, installing, wiring and

commissioning the ET 200SP distributed I/O system.

A basic knowledge of automation technology is required to understand the documentation.

This documentation applies to the distributed I/O system, ET 200SP.

In this document, " motor starter" always refers to all variants of the ET 200SP motor

starters.

Please pay particular attention to notes highlighted as follows:

in important information on the product, handling the product or on part of the

Distributed I/O system

4 System Manual, 12/2016, A5E03576849-AG

Preface

Special information

WARNING

Hazardous Voltage

Can Cause Death, Serious Injury, or Property Damage.

Note

Important note for maintaining operational safety of your plant

Plants with safety

the part of the operator. Even suppliers are required to observe special measures during

product monitoring. For this reason, we inform you in the form of personal notifications about

product developments and features that are (or could be) relevant to operation of systems

from a safety perspective.

By subscribing to the appropriate notifications, you will ensure that you are always up

date

and ab

Log onto Industry Online Support. Go to the following links and, on the side, right click on

"email on update":

•

•

•

•

•

•

•

Note

When usin

SIMATIC Industrial Software SIMATIC Safety

(

Proper use of hardware products

This equipment is only allowed to be used for the applications described in the catalog and

in the technical description, and only in conjunction with non-Siemens equipment and

components recommended by Siemens.

Correct transport, storage, installation and assembly, as well as careful operation and

maintenance, are required to ensure that the product operates safely and without faults.

EU note: Start-up/commissioning is absolutely prohibited until it has been ensured that the

machine in which the component described here is to be installed fulfills the

regulations/specifications of Directive 2006/42/EC.

-related features are subject to special operational safety requirements on

le to make changes to your system, when necessary.

SIMATIC S7-300/S7-300F (https://support.industry.siemens.com/cs/ww/en/ps/13751)

SIMATIC S7-400/S7-400H/S7-400F/FH

(https://support.industry.siemens.com/cs/ww/en/ps/13828)

SIMATIC WinAC RTX (F) (https://support.industry.siemens.com/cs/ww/en/ps/13915)

SIMATIC S7-1500/SIMATIC S7-1500F

(https://support.industry.siemens.com/cs/ww/en/ps/13716)

SIMATIC S7-1200/SIMATIC S7-1200F

(https://support.industry.siemens.com/cs/ww/en/ps/13683)

Distributed I/O (https://support.industry.siemens.com/cs/ww/en/ps/14029)

STEP 7 (TIA Portal) (https://support.industry.siemens.com/cs/ww/en/ps/14667)

g F-CPUs in safety mode and fail-safe modules, observe the description of the

- Configuring and Programming

http://support.automation.siemens.com/WW/view/en/54110126) fail-safe system.

-to-

Distributed I/O system

System Manual, 12/2016, A5E03576849-AG

5

Preface

Recycling and disposal

Security information

The products are low in pollutants and can be recycled. For environmentally compliant

recycling and disposal of your electronic waste, please contact a company certified for the

disposal of electronic waste.

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions only form one element of such a concept.

Customer is responsible to prevent unauthorized access to its plants, systems, machines

and networks. Systems, machines and components should only be connected to the

enterprise network or the internet if and to the extent necessary and with appropriate security

measures (e.g. use of firewalls and network segmentation) in place.

Additionally, Siemens’ guidance on appropriate security measures should be taken into

account. For more information about industrial security, please visit

(http://www.siemens.com/industrialsecurity).

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends to apply product updates as soon as available and to

always use the latest product versions. Use of product versions that are no longer supported,

and failure to apply latest updates may increase customer’s exposure to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under (http://www.siemens.com/industrialsecurity).

Distributed I/O system

6 System Manual, 12/2016, A5E03576849-AG

Preface

Siemens Industry Online Support

Product support

Application examples

Services

Forums

mySupport

Industry Mall

You can find current information on the following topics quickly and easily here:

●

All the information and extensive know-how on your product, technical specifications,

FAQs, certificates, downloads, and manuals.

●

Tools and examples to solve your automation tasks – as well as function blocks,

performance information and videos.

●

Information about Industry Services, Field Services, Technical Support, spare parts and

training offers.

●

For answers and solutions concerning automation technology.

●

Your personal working area in Industry Online Support for messages, support queries,

and configurable documents.

This information is provided by the Siemens Industry Online Support in the Internet

(http://www.siemens.com/automation/service&support).

The Industry Mall is the catalog and order system of Siemens AG for automation and drive

solutions on the basis of Totally Integrated Automation (TIA) and Totally Integrated Power

(TIP).

Catalogs for all the products in automation and drives are available on the Internet

(https://mall.industry.siemens.com).

Distributed I/O system

System Manual, 12/2016, A5E03576849-AG

7

Table of contents

Preface ................................................................................................................................................... 4

1 Guide to documentation ........................................................................................................................ 13

2 System overview ................................................................................................................................... 17

3 Application planning .............................................................................................................................. 32

4 Installation ............................................................................................................................................ 54

2.1 What is the SIMATIC ET 200SP distributed I/O system? ...................................................... 17

2.2 What are fail-safe automation systems and fail-safe modules? ............................................ 20

2.3 How are SIMATIC Safety F-systems structured with ET 200SP? ......................................... 21

2.4 Components ........................................................................................................................... 25

3.1 Selecting the BaseUnit for I/O modules ................................................................................. 36

3.1.1 Digital, fail-safe, communication, technology or analog modules without temperature

measurement ......................................................................................................................... 36

3.1.2 Analog modules with temperature measurement .................................................................. 37

3.2 Selecting motor starters with a suitable BaseUnit ................................................................. 38

3.2.1 Selecting a BaseUnit for motor starters ................................................................................. 38

3.2.2 Selecting the motor starter ..................................................................................................... 39

3.2.3 Selecting accessories for motor starters ................................................................................ 40

3.3 Hardware configuration .......................................................................................................... 41

3.4 Forming potential groups ....................................................................................................... 43

3.4.1 Basics ..................................................................................................................................... 43

3.4.2 Forming potential groups with AC I/O modules ..................................................................... 47

3.4.3 Forming potential groups with fail-safe modules ................................................................... 49

3.4.4 Forming potential groups with motor starters ........................................................................ 50

3.5 Configuration examples for potential groups ......................................................................... 52

4.1 Basics ..................................................................................................................................... 54

4.2 Installation conditions for motor starters ................................................................................ 58

4.3 Mounting the CPU/interface module ...................................................................................... 60

4.4 Installing the CM DP communication module ........................................................................ 62

4.5 Mounting BaseUnits for I/O modules ..................................................................................... 64

4.6 Mounting and dismantling BaseUnits for motor starters ........................................................ 66

4.7 Installing the server module ................................................................................................... 68

4.8 Mounting further accessories for motor starters .................................................................... 69

4.8.1 Mounting the cover for the 500 V AC infeed bus ................................................................... 69

4.8.2 Mounting the mechanical bracket for the BaseUnit ............................................................... 71

4.8.3 Mounting the BU cover .......................................................................................................... 74

Distributed I/O system

8 System Manual, 12/2016, A5E03576849-AG

Table of contents

5 Wiring ................................................................................................................................................... 75

5.1 Rules and regulations for operation ........................................................................................ 75

5.2 Additional rules and regulations for the operation of the ET 200SP with fail-safe

modules .................................................................................................................................. 77

5.2.1 Safety extra low voltage for fail-safe modules and fail-safe motor starters ............................ 77

5.2.2 Requirements for sensors and actuators for fail-safe modules and fail-safe motor

starters .................................................................................................................................... 78

5.2.3 Crosstalk of digital input/output signals .................................................................................. 81

5.3 Additional rules and instructions for operation with motor starters ......................................... 81

5.3.1 Protection against short circuit ................................................................................................ 81

5.4 Operating the ET 200SP on grounded incoming supply ........................................................ 82

5.5 Electrical configuration of the ET 200SP ................................................................................ 85

5.6 Wiring rules ............................................................................................................................. 87

5.7 Wiring BaseUnits for I/O modules ........................................................................................... 90

5.8 Connecting cable shields for I/O modules .............................................................................. 92

5.9 Wiring BaseUnits for motor starters ........................................................................................ 94

5.10 Connecting the 3DI/LC module for the motor starter .............................................................. 97

5.11 Connecting the supply voltage to the CPU/interface module ................................................. 99

5.12 Connecting interfaces for communication............................................................................. 101

5.12.1 Connecting PROFINET IO to the CPU/interface module via the bus adapter BA

2xRJ45 .................................................................................................................................. 101

5.12.2 Connecting PROFINET IO to the CPU/interface module via the BA 2xFC BusAdapter ...... 104

5.12.3 Connecting PROFINET IO to the CPU/interface module via BA 2xSCRJ BusAdapter ....... 108

5.12.4 Connecting PROFINET IO to the interface module via the BA SCRJ/RJ45 BusAdapter .... 111

5.12.5 Connecting PROFINET IO to the interface module via the BA SCRJ/FC BusAdapter ........ 113

5.12.6 Connecting PROFINET IO to the interface module via the BA 2xLC BusAdapter ............... 115

5.12.7 Connecting PROFINET IO to the interface module via the BA LC/RJ45 BusAdapter ......... 118

5.12.8 Connecting PROFINET IO to interface module via BA LC/FC BusAdapter ......................... 120

5.12.9 Connecting PROFINET IO (port P3) to the CPU .................................................................. 121

5.12.10 Connecting the PROFIBUS DP interface to the interface module/communications

module CM DP ...................................................................................................................... 123

5.13 Inserting I/O modules / motor starters and BU covers .......................................................... 124

5.14 Mounting/disassembly of motor starters ............................................................................... 126

5.14.1 Mounting the fan ................................................................................................................... 126

5.14.2 Mounting/disassembly of motor starters ............................................................................... 127

5.14.3 3DI/LC module ...................................................................................................................... 130

5.15 Labeling ET 200SP ............................................................................................................... 133

5.15.1 Factory markings .................................................................................................................. 133

5.15.2 Optional markings ................................................................................................................. 135

5.15.3 Applying color identification labels ........................................................................................ 137

5.15.4 Applying labeling strips ......................................................................................................... 138

5.15.5 Applying reference identification labels ................................................................................ 139

Distributed I/O system

System Manual, 12/2016, A5E03576849-AG

9

Table of contents

6 Configuring .......................................................................................................................................... 140

7 Basics of program execution ................................................................................................................ 150

8 Protection ............................................................................................................................................ 163

9 Configuration control (option handling) ................................................................................................. 172

6.1 Configuring ET 200SP ......................................................................................................... 140

6.2 Configuring the CPU ............................................................................................................ 143

6.2.1 Reading out the configuration .............................................................................................. 143

6.2.2 Addressing ........................................................................................................................... 145

6.2.3 Process images and process image partitions .................................................................... 147

6.2.3.1 Process image - overview .................................................................................................... 147

6.2.3.2 Automatically updating process image partitions ................................................................. 148

6.2.3.3 Update process image partitions in the user program ......................................................... 148

6.3 Configuring the interface module ......................................................................................... 149

7.1 Events and OBs ................................................................................................................... 150

7.2 CPU overload behavior ........................................................................................................ 153

7.3 Asynchronous instructions ................................................................................................... 155

8.1 Overview of the protective functions of the CPU ................................................................. 163

8.2 Configuring access protection for the CPU .......................................................................... 164

8.3 Using the user program to set additional access protection ................................................ 167

8.4 Know-how protection ........................................................................................................... 167

8.5 Copy protection .................................................................................................................... 170

9.1 Configuring ........................................................................................................................... 175

9.2 Creating the control data record .......................................................................................... 177

9.2.1 Introduction .......................................................................................................................... 177

9.2.2 Control data record for an ET 200SP CPU .......................................................................... 179

9.2.3 Control data record for an interface module ........................................................................ 180

9.2.4 Feedback data record for interface modules ....................................................................... 184

9.2.5 Data records and functions .................................................................................................. 186

9.3 Transferring control data record in the startup program of the CPU ................................... 187

9.4 Behavior during operation .................................................................................................... 191

9.5 Examples of configuration control ........................................................................................ 192

Distributed I/O system

10 System Manual, 12/2016, A5E03576849-AG

Table of contents

10 Commissioning ................................................................................................................................... 197

11 SIMATIC memory card ........................................................................................................................ 229

10.1 Overview ............................................................................................................................... 197

10.2 Commissioning the ET 200SP for PROFINET IO ................................................................ 199

10.2.1 ET 200SP CPU as an IO controller ...................................................................................... 199

10.2.2 ET 200SP CPU as an I-device ............................................................................................. 201

10.2.3 ET 200SP as an IO device ................................................................................................... 203

10.3 Commissioning the ET 200SP on PROFIBUS DP ............................................................... 204

10.3.1 ET 200SP as a DP master .................................................................................................... 204

10.3.2 ET 200SP as I-slave ............................................................................................................. 206

10.3.3 ET 200SP as a DP slave ...................................................................................................... 208

10.4 Startup of the ET 200SP with empty slots ............................................................................ 209

10.5 Removing/inserting a SIMATIC memory card on the CPU................................................... 209

10.6 Operating modes of the CPU ................................................................................................ 211

10.6.1 STARTUP mode ................................................................................................................... 211

10.6.2 STOP mode .......................................................................................................................... 214

10.6.3 RUN mode ............................................................................................................................ 215

10.6.4 Operating mode transitions ................................................................................................... 215

10.7 CPU memory reset ............................................................................................................... 217

10.7.1 Automatic memory reset ....................................................................................................... 218

10.7.2 Manual memory reset ........................................................................................................... 219

10.8 Reassigning parameters during operation ............................................................................ 220

10.9 Identification and maintenance data ..................................................................................... 221

10.9.1 Reading out and entering I&M data ...................................................................................... 221

10.9.2 Data record structure for I&M data ....................................................................................... 223

10.10 Shared commissioning of projects ........................................................................................ 225

10.11 Backing up and restoring the CPU configuration .................................................................. 225

10.11.1 Overview ............................................................................................................................... 225

11.1 SIMATIC memory card - overview ........................................................................................ 229

11.2 Setting the card type ............................................................................................................. 234

11.3 Data transfer with SIMATIC memory cards .......................................................................... 235

Distributed I/O system

System Manual, 12/2016, A5E03576849-AG

11

Table of contents

12 Maintenance ........................................................................................................................................ 236

13 Test functions and eliminating problems ............................................................................................... 259

14 Technical specifications ....................................................................................................................... 267

A Dimension drawings ............................................................................................................................. 284

B Accessories/spare parts ....................................................................................................................... 286

C Calculating the leakage resistance ....................................................................................................... 290

Glossary .............................................................................................................................................. 292

Index ................................................................................................................................................... 308

12.1 Removing and inserting I/O modules/motor starters ........................................................... 236

12.2 Changing the type of an I/O module .................................................................................... 239

12.3 Replacing an I/O module ..................................................................................................... 241

12.4 Replacing a motor starter ..................................................................................................... 242

12.5 Replacing the terminal box on the BaseUnit ........................................................................ 243

12.6 Firmware update .................................................................................................................. 245

12.7 Resetting CPU/interface module (PROFINET) to factory settings ...................................... 250

12.7.1 Resetting the CPU to factory settings .................................................................................. 250

12.7.2 Resetting interface module (PROFINET IO) to factory settings .......................................... 253

12.7.3 Resetting the interface module (PROFINET IO) to factory settings with a RESET

button ................................................................................................................................... 255

12.8 Reaction to faults in fail-safe modules and fail-safe motor starters ..................................... 256

12.9 Maintenance and repair ....................................................................................................... 258

12.10 Warranty ............................................................................................................................... 258

13.1 Test functions ....................................................................................................................... 259

13.2 Reading out/saving service data .......................................................................................... 265

14.1 Standards, approvals and safety notes ............................................................................... 268

14.2 Electromagnetic compatibility .............................................................................................. 274

14.3 Electromagnetic compatibility of fail-safe modules .............................................................. 277

14.4 Shipping and storage conditions .......................................................................................... 279

14.5 Mechanical and climatic environmental conditions .............................................................. 279

14.6 Insulation, protection class, degree of protection and rated voltage ................................... 281

14.7 Use of the ET 200SP in zone 2 potentially explosive atmospheres .................................... 283

A.1 Shield connector .................................................................................................................. 284

A.2 Labeling strip ........................................................................................................................ 284

A.3 Reference identification labels ............................................................................................. 285

B.1 Lightning protection and overvoltage protection for fail-safe modules ................................ 289

Distributed I/O system

12 System Manual, 12/2016, A5E03576849-AG

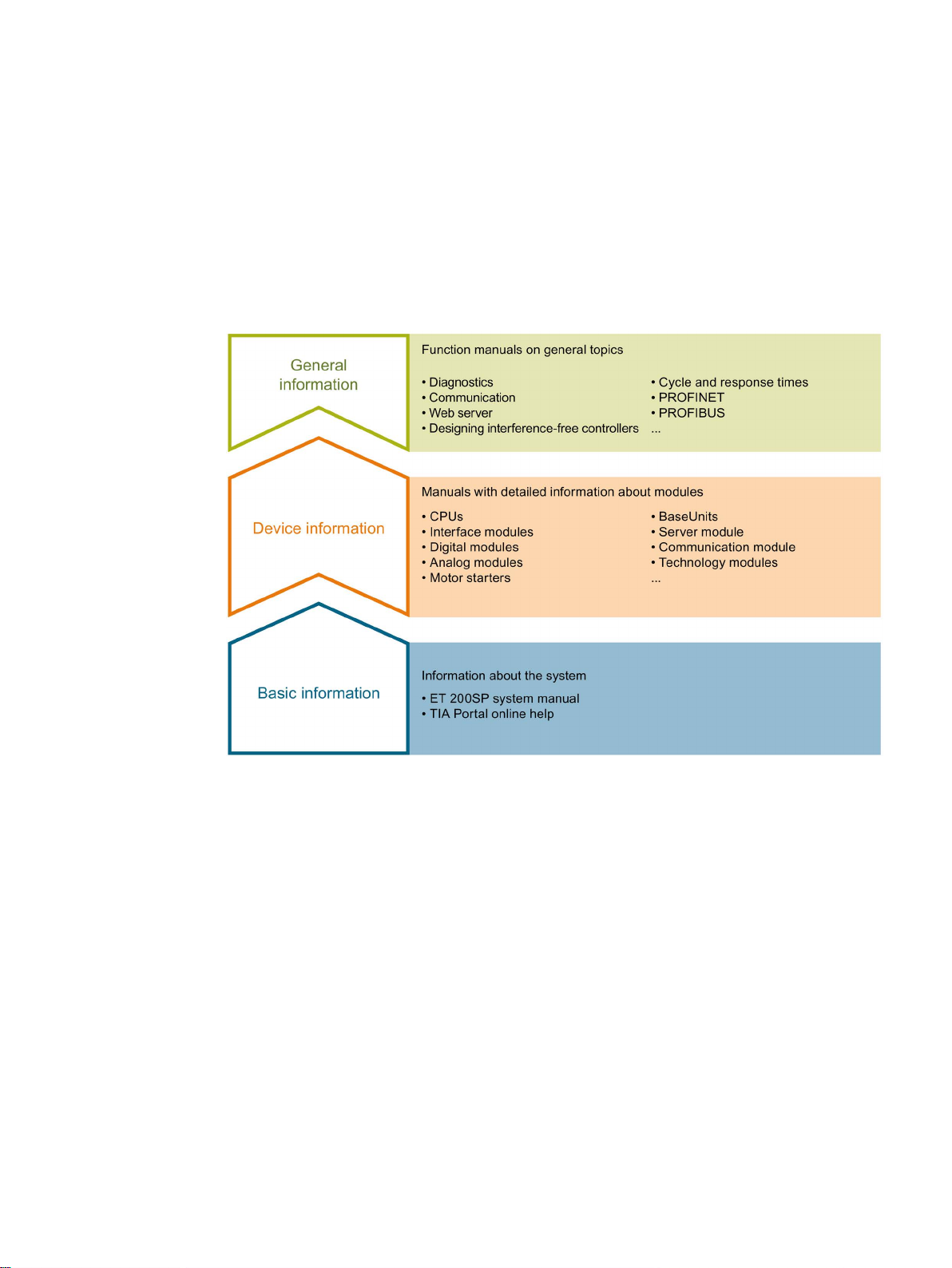

1

Basic information

Device information

The documentation for the SIMATIC ET 200SP distributed I/O system is arranged into three

areas.

This arrangement enables you to access the specific content you require.

The system manual describes in detail the configuration, installation, wiring and

commissioning of the SIMATIC ET 200SP. distributed I/O system. The STEP 7 online help

supports you in the configuration and programming.

Product manuals contain a compact description of the module-specific information, such as

properties, wiring diagrams, characteristics and technical specifications.

Distributed I/O system

System Manual, 12/2016, A5E03576849-AG

13

Guide to documentation

General information

Manual Collection ET 200SP

"mySupport"

"mySupport" - Documentation

The function manuals contain detailed descriptions on general topics regarding the SIMATIC

ET 200SP distributed I/O system, e.g. diagnostics, communication, Web server, motion

control and OPC UA.

You can download the documentation free of charge from the Internet

(http://w3.siemens.com/mcms/industrial-automation-systems-simatic/en/manual-

overview/tech-doc-et200/Pages/Default.aspx).

Changes and supplements to the manuals are documented in a Product Information.

You can download the product information free of charge from the Internet

(https://support.industry.siemens.com/cs/us/en/view/73021864).

The Manual Collection contains the complete documentation on the SIMATIC ET 200SP

distributed I/O system gathered together in one file.

You can find the Manual Collection on the Internet

(http://support.automation.siemens.com/WW/view/en/84133942).

With "mySupport", your personal workspace, you make the most of your Industry Online

Support.

In "mySupport" you can store filters, favorites and tags, request CAx data and put together

your personal library in the Documentation area. Furthermore, your data is automatically

filled into support requests and you always have an overview of your current requests.

You need to register once to use the full functionality of "mySupport".

You can find "mySupport" in the Internet (https://support.industry.siemens.com/My/ww/en).

In the Documentation area of "mySupport", you have the possibility to combine complete

manuals or parts of them to make your own manual.

You can export the manual in PDF format or in an editable format.

You can find "mySupport" - Documentation in the Internet

(http://support.industry.siemens.com/My/ww/en/documentation).

Distributed I/O system

14 System Manual, 12/2016, A5E03576849-AG

Guide to documentation

"mySupport" - CAx Data

Application examples

TIA Selection Tool

In the CAx Data area of "mySupport", you can have access the latest product data for your

CAx or CAe system.

You configure your own download package with a few clicks.

In doing so you can select:

● Product images, 2D dimension drawings, 3D models, internal circuit diagrams, EPLAN

macro files

● Manuals, characteristics, operating manuals, certificates

● Product master data

You can find "mySupport" - CAx Data in the Internet

(http://support.industry.siemens.com/my/ww/en/CAxOnline).

The application examples support you with various tools and examples for solving your

automation tasks. Solutions are shown in interplay with multiple components in the system separated from the focus in individual products.

You can find the application examples on the Internet

(https://support.industry.siemens.com/sc/ww/en/sc/2054).

With the TIA Selection Tool, you can select, configure and order devices for Totally

Integrated Automation (TIA).

This tool is the successor of the SIMATIC Selection Tool and combines the known

configurators for automation technology into one tool.

With the TIA Selection Tool, you can generate a complete order list from your product

selection or product configuration.

You can find the TIA Selection Tool on the Internet

(http://w3.siemens.com/mcms/topics/en/simatic/tia-selection-tool).

Distributed I/O system

System Manual, 12/2016, A5E03576849-AG

15

Guide to documentation

SIMATIC Automation Tool

PRONETA

You can use the SIMATIC Automation Tool to run commissioning and maintenance activities

simultaneously on various SIMATIC S7 stations as a bulk operation independently of the TIA

Portal.

The SIMATIC Automation Tool provides a multitude of functions:

● Scanning of a PROFINET/Ethernet network and identification of all connected CPUs

● Address assignment (IP, subnet, gateway) and station name (PROFINET device) to a

CPU

● Transfer of the data and the programming device/PC time converted to UTC time to the

module

● Program download to CPU

● Operating mode switchover RUN/STOP

● Localization of the CPU by means of LED flashing

● Reading out CPU error information

● Reading the CPU diagnostic buffer

● Reset to factory settings

● Updating the firmware of the CPU and connected modules

You can find the SIMATIC Automation Tool on the Internet

(https://support.industry.siemens.com/cs/ww/en/view/98161300).

With SIEMENS PRONETA (PROFINET network analysis), you analyze the plant network

during commissioning. PRONETA features two core functions:

● The topology overview independently scans PROFINET and all connected components.

● The IO check is a fast test of the wiring and the module configuration of a system.

You can find SIEMENS PRONETA on the Internet

(https://support.industry.siemens.com/cs/ww/en/view/67460624).

Distributed I/O system

16 System Manual, 12/2016, A5E03576849-AG

2

2.1

What is the SIMATIC ET 200SP distributed I/O system?

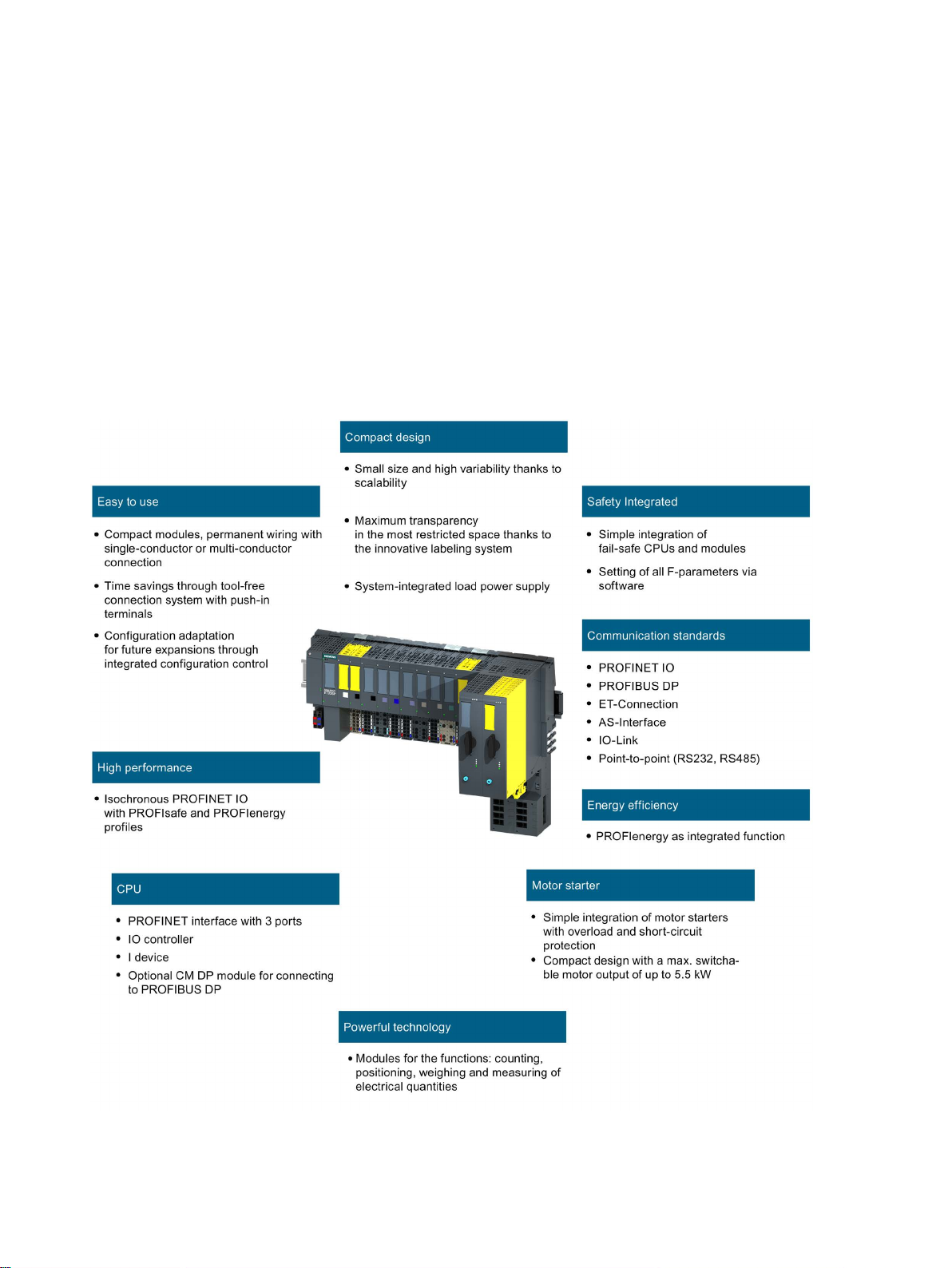

SIMATIC ET 200SP

Customer benefits of the system

SIMATIC ET 200SP is a scalable and highly flexible distributed I/O system for connecting

process signals to a higher-level controller via a fieldbus.

Figure 2-1 SIMATIC ET 200SP distributed I/O system - Customer benefits

Distributed I/O system

System Manual, 12/2016, A5E03576849-AG

17

System overview

Area of application

Configuration

2.1 What is the SIMATIC ET 200SP distributed I/O system?

Thanks to its multifunctionality, the SIMATIC ET 200SP distributed I/O system is suitable for

a wide range of applications. Its scalable design allows you to tailor your configuration to

local requirements. Different CPUs/interface modules are available for connection to

PROFINET IO or PROFIBUS DP.

SIMATIC ET 200SP with CPU allows intelligent pre-processing to relieve the higher-level

controller. The CPU can also be used as standalone device.

By using fail-safe CPUs, you can implement applications for safety engineering.

Configuration and programming of your safety program takes place the same way as for

standard CPUs.

A wide range of I/O modules rounds off the product range.

SIMATIC ET 200SP is designed with degree of protection IP20 and is intended for

installation in a control cabinet.

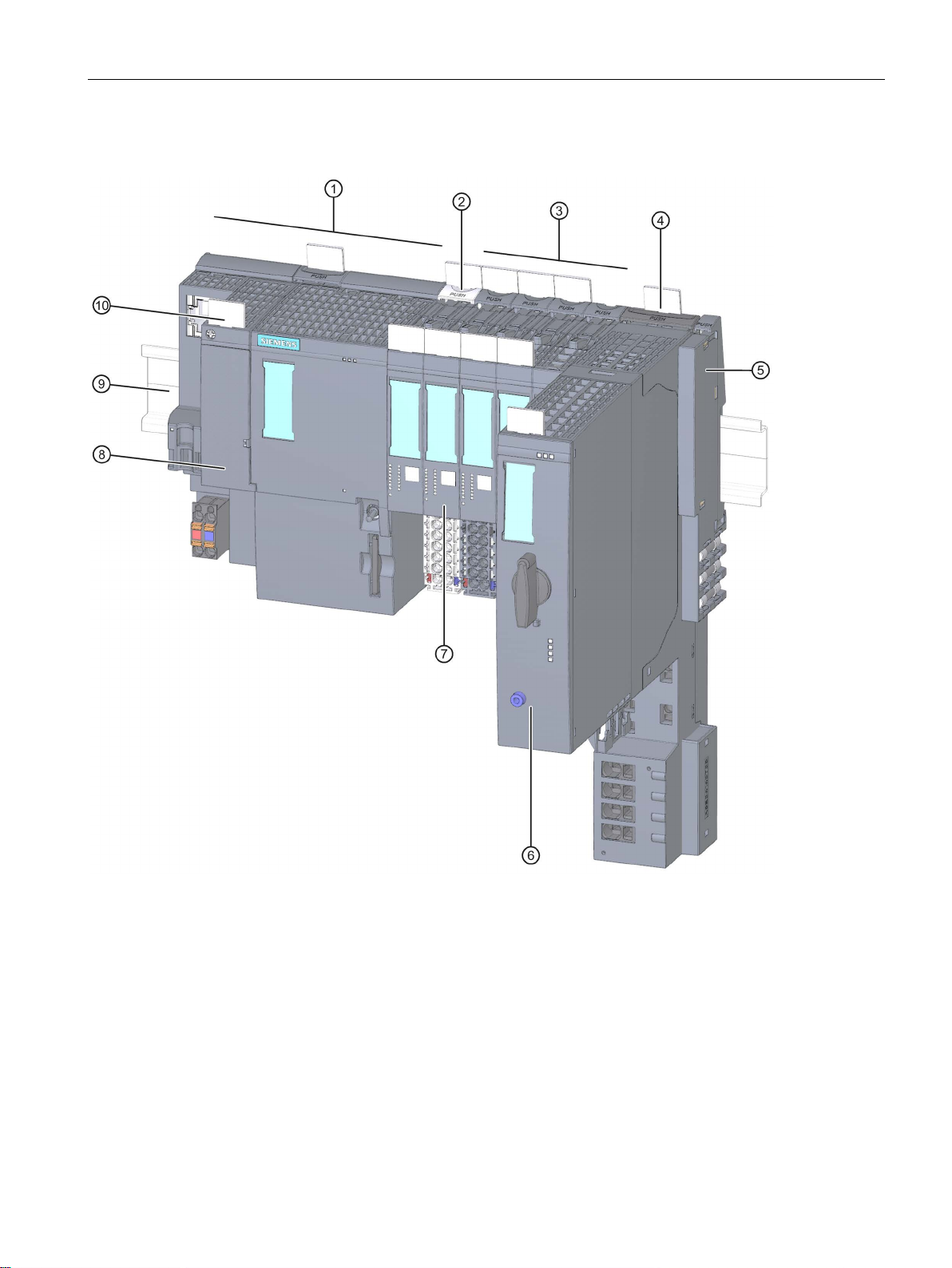

The SIMATIC ET 200SP distributed I/O system is installed on a mounting rail. It consists of:

● CPU/interface module

● Up to 64 I/O modules, which can be plugged into BaseUnits in any combination

● Up to 31 motor starters

● A server module that completes the configuration of the ET 200SP.

Distributed I/O system

18 System Manual, 12/2016, A5E03576849-AG

System overview

Configuration example

①

CPU/interface module

②

Light-colored BaseUnit BU..D with infeed of supply voltage

③

Dark-colored BaseUnits BU..B for extending the potential group

④

BaseUnit for motor starter

⑤

Server module (included in the scope of delivery of the CPU/interface module)

⑥

ET 200SP motor starter

⑦

I/O module

⑧

BusAdapter

⑨

Mounting rail

⑩

Reference identification label

2.1 What is the SIMATIC ET 200SP distributed I/O system?

Figure 2-2 Configuration example of the ET 200SP

Distributed I/O system

System Manual, 12/2016, A5E03576849-AG

19

System overview

2.2

What are fail-safe automation systems and fail-safe modules?

Fail-safe automation systems

Safety Integrated

Fail-safe modules

Fail-safe motor starters

Area of application of ET 200SP with fail-safe I/O modules

2.2 What are fail-safe automation systems and fail-safe modules?

Fail-safe automation systems (F-systems) are used in systems with higher safety

requirements. F-systems control processes and ensure that they are in a safe state

immediately after shutdown. In other words, F-systems control processes in which an

immediate shutdown does not endanger persons or the environment.

Safety Integrated is the integrated safety concept for automation and drive technology from

Siemens.

Proven technologies and systems from automation technology are used for safety systems.

Safety Integrated includes the complete safety sequence, ranging from sensor, actuator and

fail-safe modules right through to the controller, including safety-related communication via

standard fieldbuses. Drives and controllers handle safety tasks in addition to their actual

functions.

The key difference between fail-safe modules (F-modules) and standard modules is that they

have an internal two-channel design. This means the two integrated processors monitor

each other, automatically test the input and output circuits, and switch the fail-safe module to

a safe state in the event of a fault.

The F-CPU communicates with a fail-safe module via the safety-related PROFIsafe bus

profile.

Fail-safe motor starters enable safety-related tripping of motor loads. Fail-safe motor starters

are not PROFIsafe nodes. Motor starters operate together with the fail-safe modules of the

ET 200SP system.

By using the ET 200SP distributed I/O system with fail-safe I/O modules, you are replacing

conventional safety engineering configurations. This includes the replacement of switching

devices for emergency STOP, protective door monitors, two-hand operation, etc.

Distributed I/O system

20 System Manual, 12/2016, A5E03576849-AG

System overview

2.3

How are SIMATIC Safety F-systems structured with ET 200SP?

SIMATIC Safety F-system with ET 200SP

Fail-safe ET 200SP I/O modules

ET 200SP fail-safe motor starters

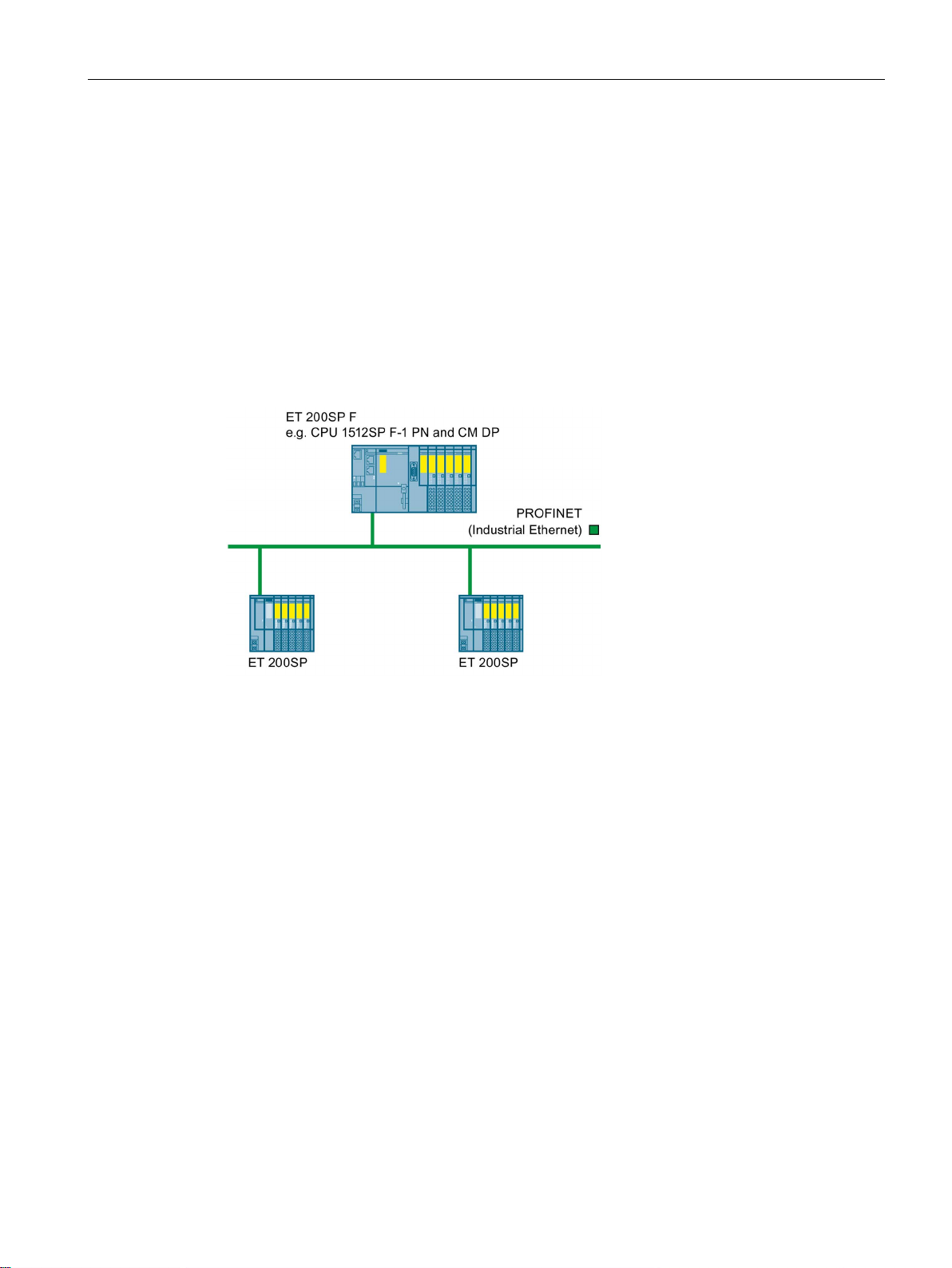

2.3 How are SIMATIC Safety F-systems structured with ET 200SP?

The figure below shows an example of a configuration for a SIMATIC Safety F-system with

ET 200SP distributed I/O system and PROFINET IO. The PROFINET IO lines can be set up

with copper cable, fiber-optic cable or WLAN.

Fail-safe I/O modules and non-fail-safe I/O modules can be combined in an ET 200SP

configuration.

The fail-safe IO controller (F-CPU) exchanges safety-related and non-safety-related data

with fail-safe and non-fail-safe ET 200SP modules.

Figure 2-3 Fail-safe SIMATIC Safety automation system (sample configuration)

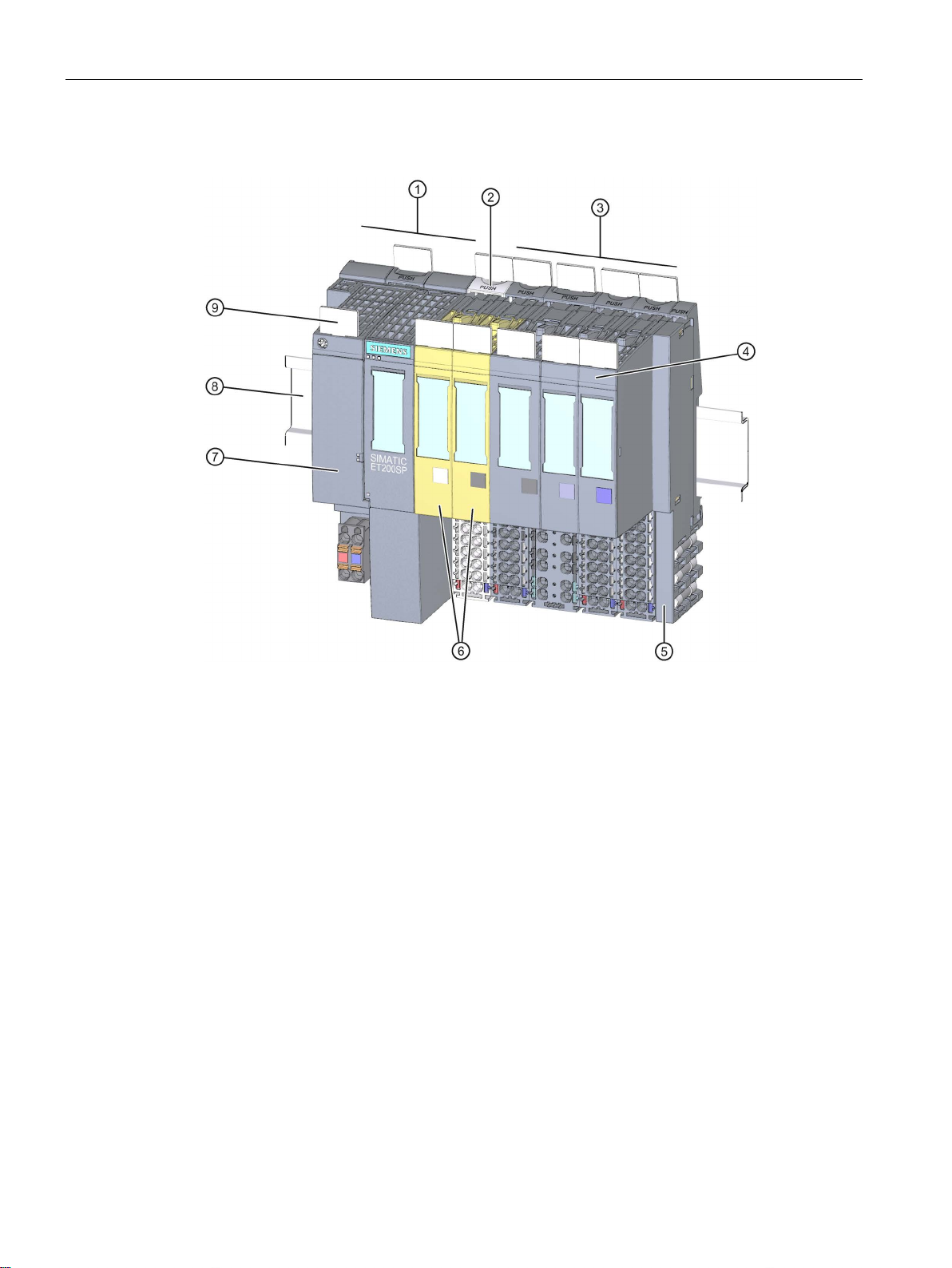

The following fail-safe I/O modules are available for the ET 200SP distributed I/O system:

● Fail-safe power modules are used to supply the potential group load voltage and for the

safety-related tripping of the load voltage for non-fail-safe output modules.

● Fail-safe digital input modules detect the signal states of safety-related sensors and send

the relevant safety frames to the F-CPU.

● Fail-safe digital output modules are suitable for safety-related shutdown procedures with

short circuit and cross-circuit protection up to the actuator.

Fail-safe motor starters are suitable for safety-related tripping of motor loads.

Distributed I/O system

System Manual, 12/2016, A5E03576849-AG

21

System overview

Example of a configuration with fail-safe I/O modules

①

Interface module

②

Light-colored BaseUnitBU..D with infeed of supply voltage

③

Dark-colored BaseUnitsBU..B for conducting the potential group further

④

I/O module

⑤

Server module (ships with the interface module)

⑥

Fail-safe I/O modules

⑦

BusAdapter

⑧

Mounting rail

⑨

Reference identification label

2.3 How are SIMATIC Safety F-systems structured with ET 200SP?

Figure 2-4 Example of a configuration of the ET 200SP with fail-safe I/O modules

Distributed I/O system

22 System Manual, 12/2016, A5E03576849-AG

System overview

Hardware and software requirements

Note

Configuration of

G

Use in safety mode only

2.3 How are SIMATIC Safety F-systems structured with ET 200SP?

ET 200SP fail-safe modules are supported by interface modules IM155-6PN BA, firmware

V3.2 or higher, IM155-6PN ST, firmware V1.1.1 or higher, IM155-6PN HF, firmware V2.0 or

higher, IM155-6PN HS firmware V4.0 or higher and IM155-6DP HF, firmware V1.0 or higher.

You require the STEP 7 Safety Advanced option package, V12 or higher including HSP 54,

for configuration and programming of the ET 200SP fail-safe modules with the SIMATIC

Safety fail-safe system.

You require the F-Configuration Pack V5.5 SP10 for configuration and programming of the

ET 200SP fail-safe modules with the Distributed Safety fail-safe system.

You require the F-Configuration Pack V5.5 SP12 for configuration and programming of the

ET 200SP fail-safe modules with the F/FH Systems fail-safe system.

ET 200SP fail-safe motor starters are supported by interface modules IM155-6PN BA,

firmware V3.2 or higher, IM155-6PN ST, firmware V3.1 or higher, IM155-6PN HF, firmware

V3.1 or higher and IM155-6DP HF firmware V3.0 or higher.

You require SIMATIC Step 7 V14 or higher for configuration and programming of ET 200SP

fail-safe motor starters. The F-Configuration Pack is not needed for configuration and

programming of the ET 200SP fail-safe motor starter.

SD file (GSDML).

Safety mode is the F-I/O operating mode that allows safety-related communication using

safety frames.

Safety mode of motor starters is characterized by the fail-safe digital input (F-DI) and

availability of the 24 V power supply.

You can only use the ET 200SP fail-safe I/O modules in safety mode. They cannot be used

in non-fail-safe mode.

ET 200SP motor starters, SIMATIC Step 7 V13 or higher, is possible with a

Distributed I/O system

System Manual, 12/2016, A5E03576849-AG

23

System overview

Achievable safety classes

Safety class in safety mode

According to IEC 61508

According to ISO 13849-1:2006

SIL2

Category 3

(PL) Performance Level d

SIL3

Category 3

(PL) Performance Level e

Additional information

2.3 How are SIMATIC Safety F-systems structured with ET 200SP?

The fail-safe modules are equipped with integrated safety functions for safety mode.

You can achieve the safety classes of the table below:

● With the appropriate parameter assignment of the safety functions in STEP 7

● With a specific combination of fail-safe and non-fail-safe I/O modules

● With a special arrangement and wiring of the sensors and actuators

Table 2- 1 Safety classes that can be achieved with ET 200SP in safety mode

SIL3 Category 4 (PL) Performance Level e

You will find the use cases and wiring for the relevant safety class in the manuals of the failsafe I/Os and the fail-safe motor starters.

Distributed I/O system

24 System Manual, 12/2016, A5E03576849-AG

System overview

2.4

Components

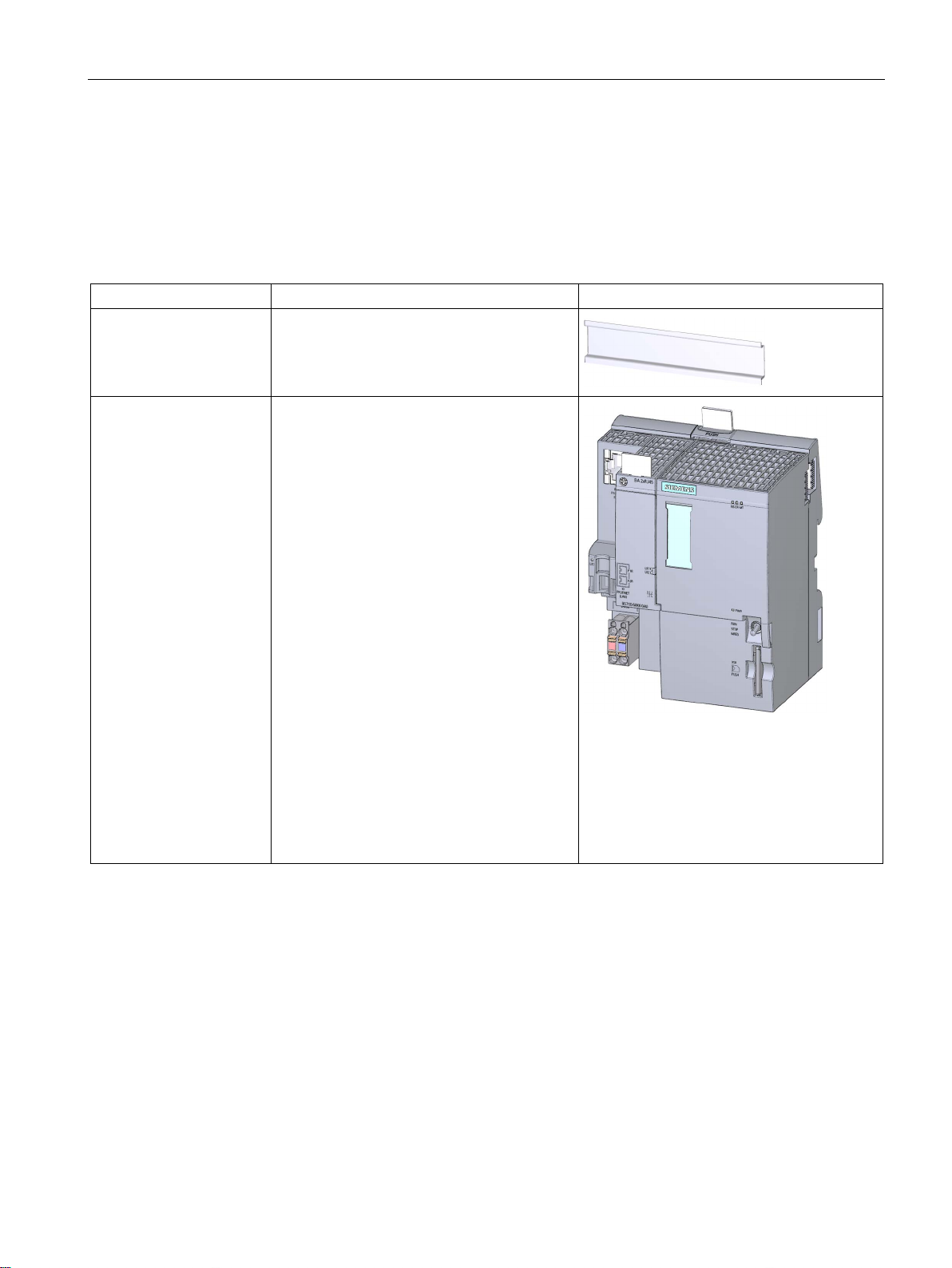

Basic components of the ET 200SP distributed I/O system

Basic component

Function

Figure

2.4 Components

Table 2- 2 Basic components of the ET 200SP

Mounting rail in accordance with EN 60715

CPU/Fail-safe CPU The (F) CPU:

The mounting rail is the rack of the ET 200SP.

The ET 200SP is installed on the mounting

rail. The mounting rail is 35 mm high.

• Runs the user program. The F-CPU also

runs the safety program.

• Can be used as an IO controller or I-

Device on PROFINET IO or as a

standalone CPU

• Links the ET 200SP to the IO devices or

the IO controller

• Exchanges data with the I/O modules via

the backplane bus.

Additional CPU functions:

• Communication via PROFIBUS DP (the

CPU can be used as a DP master or DP

slave in combination with the CM DP

communication module)

• Integrated Web server

• Integrated technology

• Integrated trace functionality

• Integrated system diagnostics

• Integrated safety

• Safety mode (when using fail-safe CPUs)

Distributed I/O system

System Manual, 12/2016, A5E03576849-AG

25

System overview

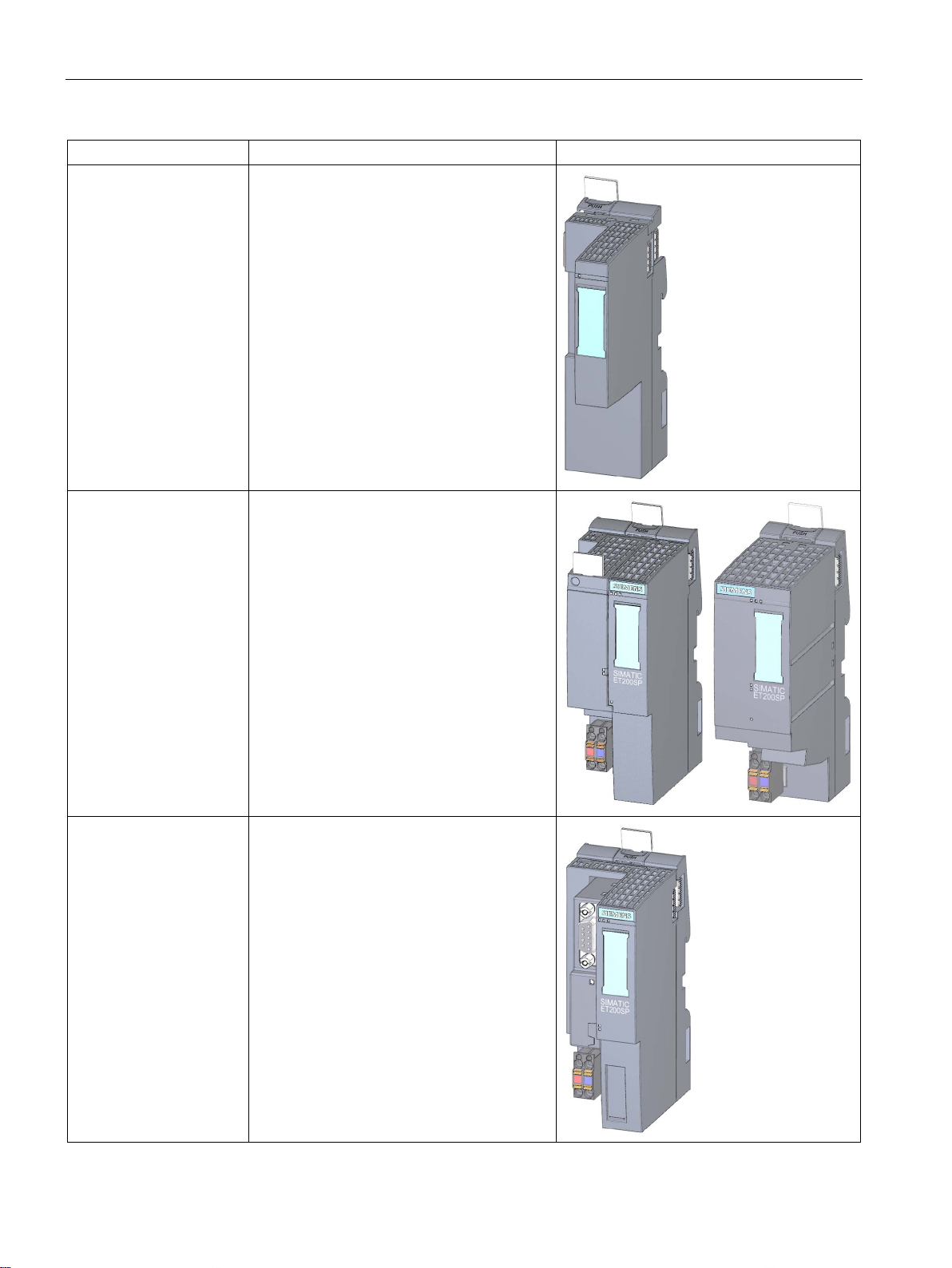

Basic component

Function

Figure

2.4 Components

Communication module

CM DP

Interface module for

PROFINET IO

The communication module CM DP

• Connects the CPU with PROFIBUS DP

• The bus connection is an RS485 interface

The interface module:

• Can be used as IO device on

PROFINET IO

• Links the ET 200SP with the IO controller

• Exchanges data with the I/O modules via

the backplane bus.

Interface module for

PROFIBUS DP

Distributed I/O system

The interface module:

• Can be used as DP slave on PROFIBUS

DP

• Links the ET 200SP with the DP master

• Exchanges data with the I/O modules via

the backplane bus.

26 System Manual, 12/2016, A5E03576849-AG

System overview

Basic component

Function

Figure

2.4 Components

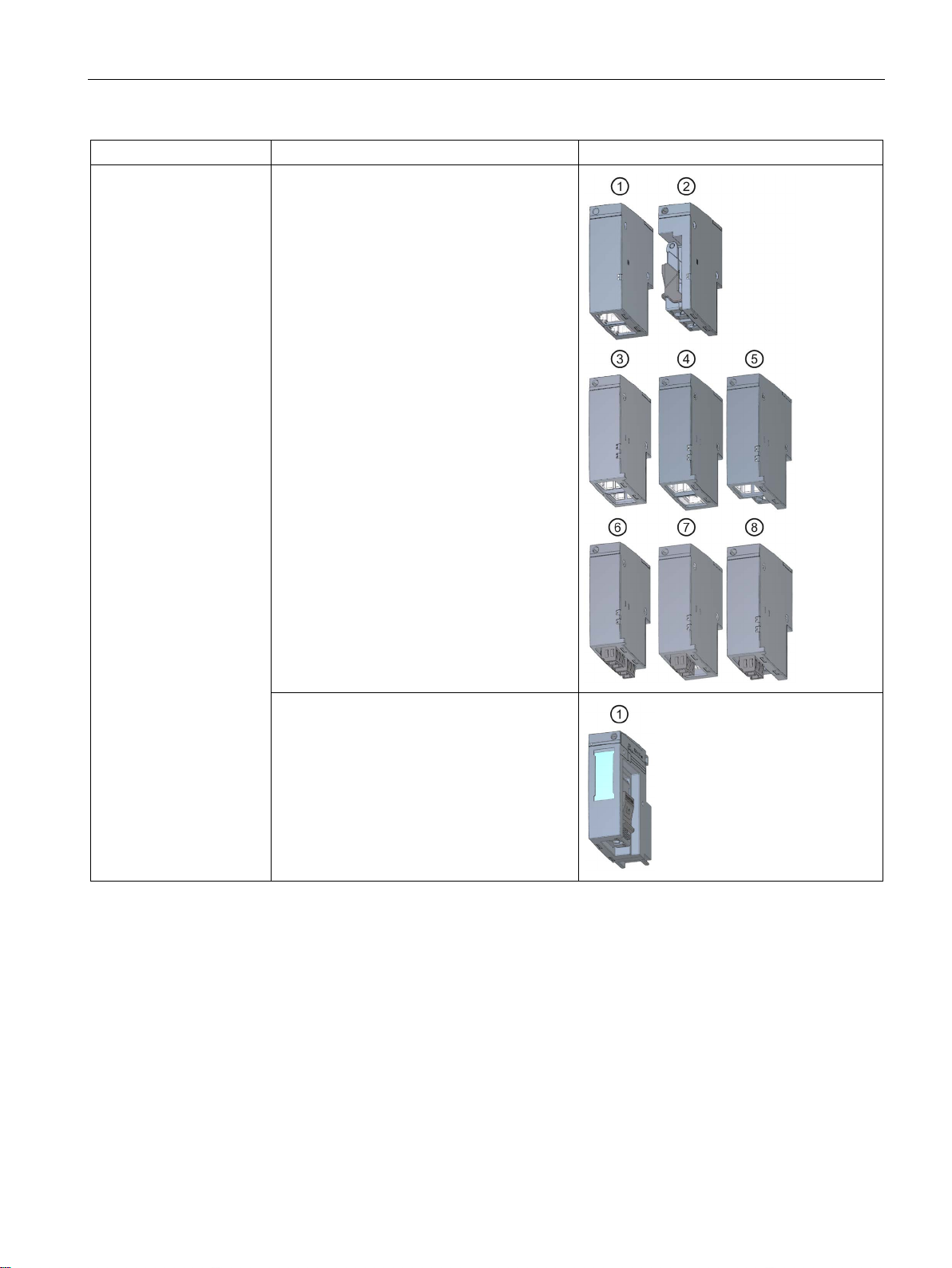

BusAdapter The BusAdapters allow free selection of the

connection technology for PROFINET IO. The

following versions are available for

PROFINET CPU/interface modules:

• For standard RJ45 connector (BA 2×RJ45)

①

• For direct connection of the bus cable

(BA 2×FC) ②

• For POF/PCF fiber-optic cable (BA

2xSCRJ) ③

• As media converter for POF/PCF fiber-

optic cable ⇔ standard RJ45 plug (BA

SCRJ/RJ45)

• As media converter for POF/PCF fiber-

optic cable ⇔ direct connection of the bus

cable (BA SCRJ/FC)

• For glass fiber-optic cable (BA 2xLC)

• As media converter for glass fiber-optic

cable ⇔ standard RJ45 plug (BA LC/RJ45)

④

⑤

⑥

⑦

• As media converter for glass fiber-optic

cable ⇔ direct connection of the bus cable

(BA LC/FC)

⑧

For mixed ET 200SP/ET 200AL configuration,

you require the BusAdapter BA-Send 1xFC

① (plugged into the BaseUnit BU-Send).

Connect the bus cable for ET-Connection to

the BusAdapter BA-Send 1xFC.

Distributed I/O system

System Manual, 12/2016, A5E03576849-AG

27

System overview

Basic component

Function

Figure

2.4 Components

BaseUnit The BaseUnits provide the electrical and me-

chanical connection of the ET 200SP modules. Place the I/O modules or the motor

starter onto the BaseUnits.

Suitable BaseUnits are available for each of

the different requirements (see Selecting the

BaseUnit for I/O modules (Page 36)).

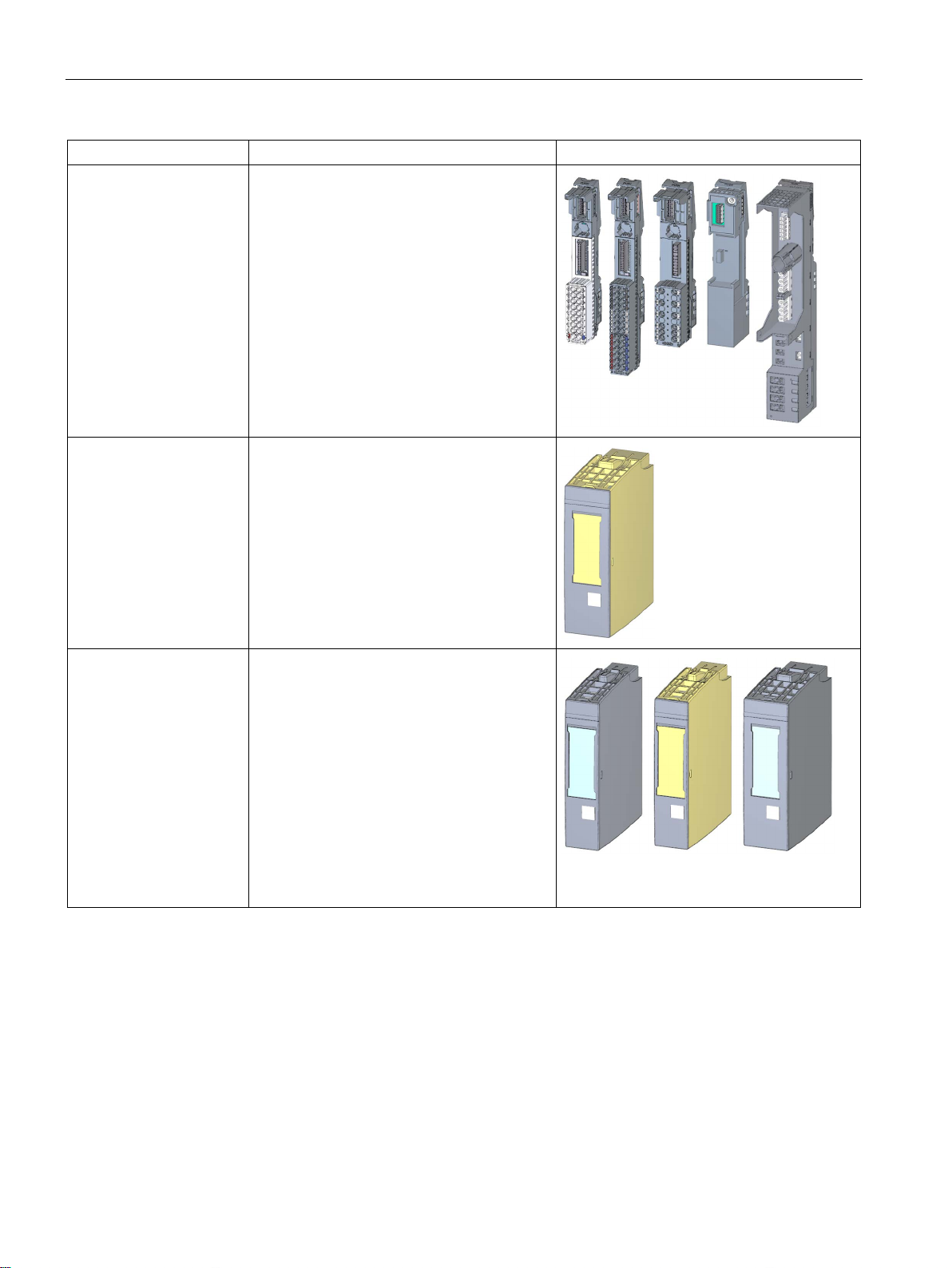

Fail-safe power module The fail-safe power module allows the safety-

related shutdown of digital output modules /

fail-safe digital output modules.

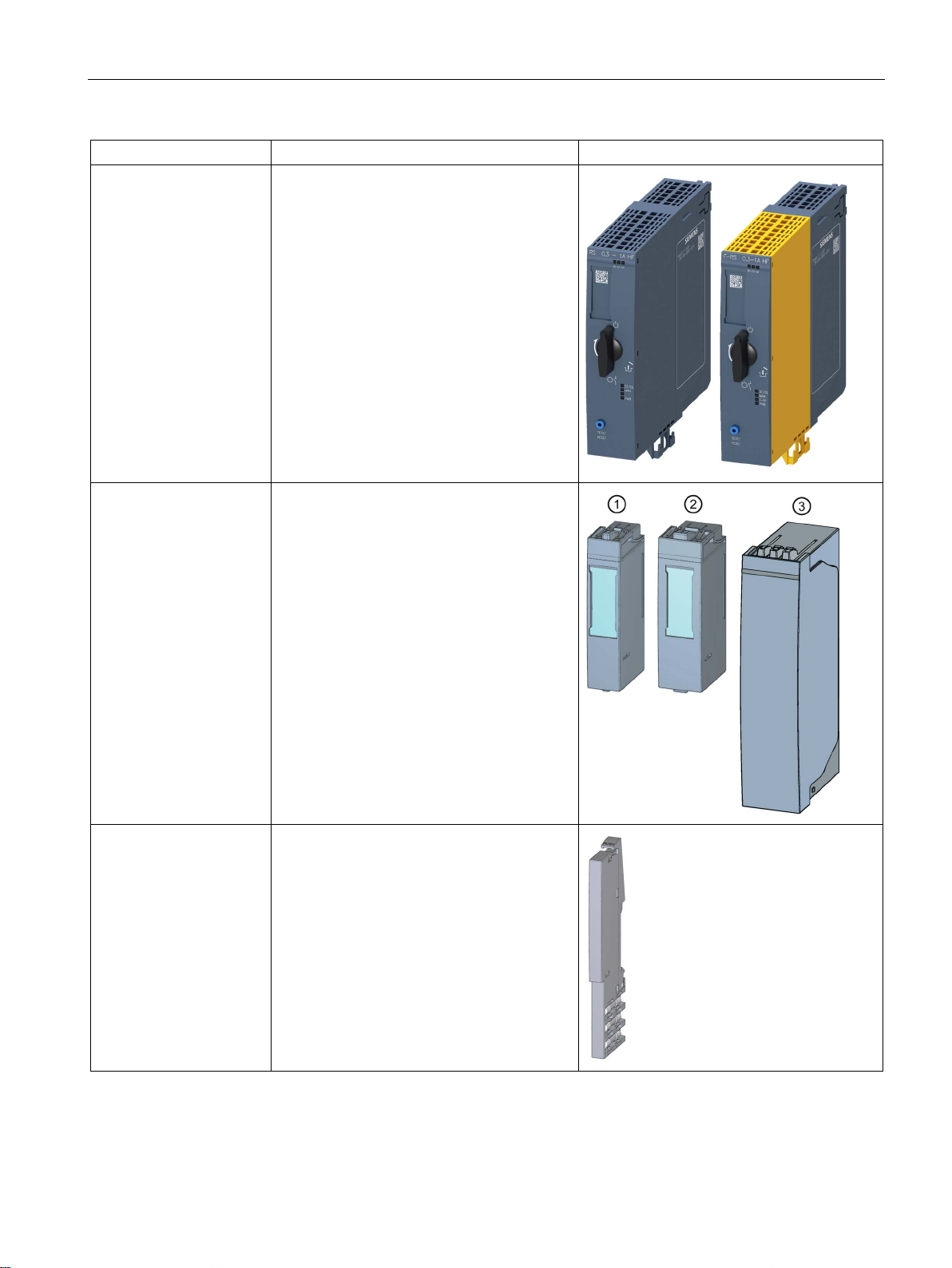

I/O module / fail-safe I/O

module

The I/O module determines the function at the

terminals. The controller detects the current

process state via the connected sensors and

actuators, and triggers the corresponding

reactions. I/O modules are divided into the

following module types:

• Digital input (DI, F-DI)

• Digital output (DQ, F-DQ, F-RQ)

• Analog input (AI)

• Analog output (AQ)

• Technology module (TM)

• Communication module (CM)

Distributed I/O system

28 System Manual, 12/2016, A5E03576849-AG

System overview

Basic component

Function

Figure

2.4 Components

Motor starter/fail-safe

motor starter

BU cover Insert the BU cover on the BaseUnits:

The motor starter is a switching and protection

device for 1-phase and 3-phase loads.

The motor starter is available as a direct-online and reversing starter.

• Whose slots are not occupied by I/O mod-

ules /motor starters

• Whose slots have been reserved for future

expansion (as empty slots).

You can keep a reference identification label

for the planned I/O module inside the BU

cover.

There are three versions:

• For BaseUnits with a width of 15 mm

• For BaseUnits with a width of 20 mm

• For BaseUnits of motor starters with a

width of 30 mm ③

①

②

Server module The server module completes the configura-

Distributed I/O system

System Manual, 12/2016, A5E03576849-AG

tion of the ET 200SP. The server module

includes holders for 3 spare fuses

(5 × 20 mm).

The server module ships with the

CPU/interface module.

29

System overview

Basic component

Function

Figure

Accessories of the ET 200SP distributed I/O system

Accessories

Function

Figure

printers.

(Page 286).

2.4 Components

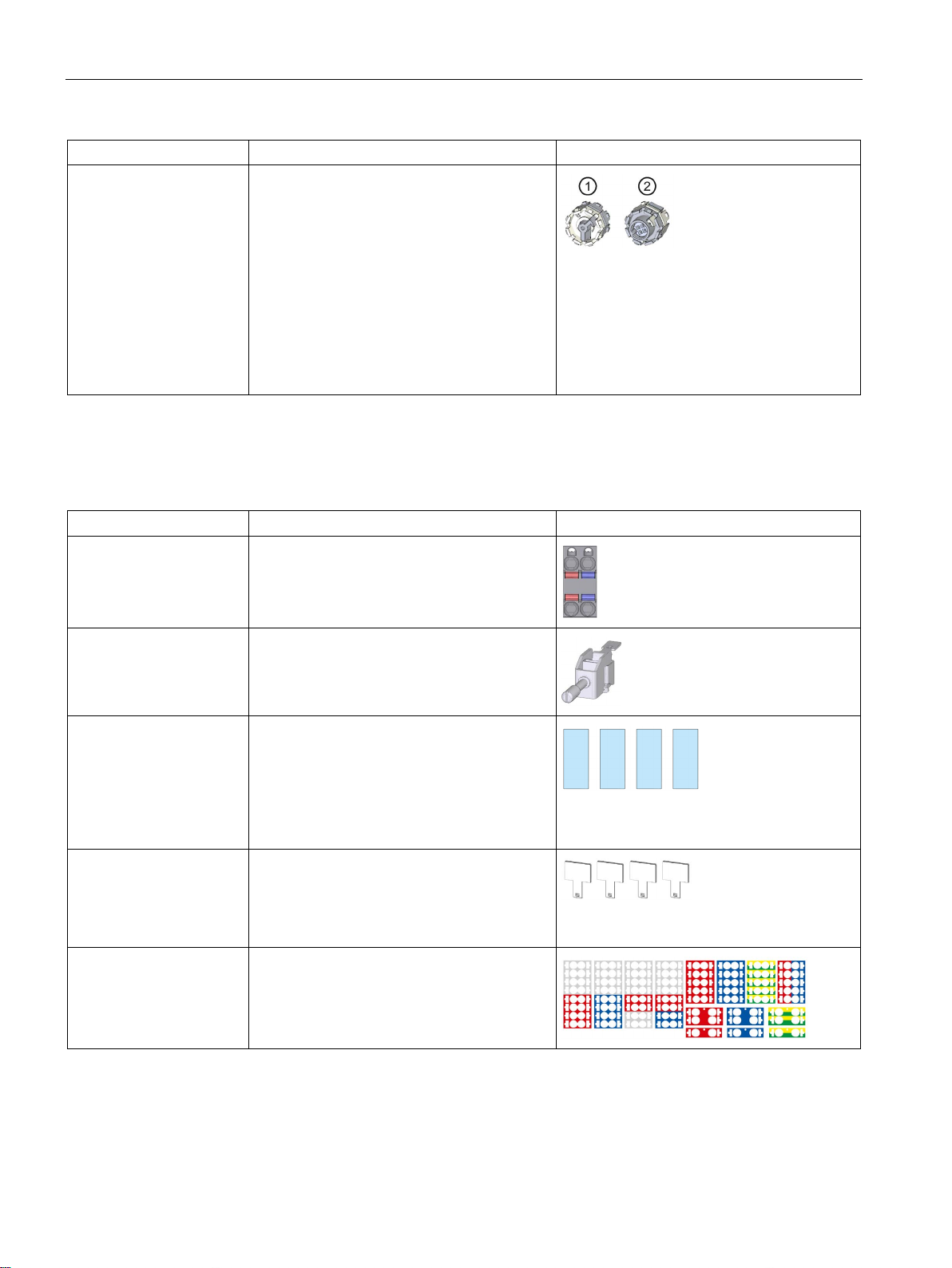

Coding element The coding element codes the I/O module

with the BaseUnit.

There are two versions:

• Mechanical coding element

the coding

• Electronic coding element ②: This version

also has an electronic, rewritable memory

for module-specific configuration data

(such as the F-destination address for failsafe modules, parameter data for the IO

link master).

①: Ensures

Table 2- 3 Accessories of the ET 200SP

24 V DC connector Applying the 24 V DC supply at the connector

and connection with the IM.

Shield connection The shield connection allows the low-

impedance contacting of cable shields with

minimum installation times.

Labeling strips Attach the labeling strips to the modules for

system-specific labeling of the ET 200SP. The

labeling strips can be printed.

The labeling strips can be ordered as accessories (Page 286) on a roll for thermal transfer

printers or as DIN A4 format sheets for laser

Reference identification

labels

Color identification labels The color identification labels are module-

The labels enable the reference identification

labeling of the ET 200SP components.

The labels can be ordered on a mat for thermal transfer and inkjet printers as accessories

specific and can be ordered for the process

terminals, AUX terminals and additional terminals as accessories (Page 286).

Distributed I/O system

30 System Manual, 12/2016, A5E03576849-AG

Loading...

Loading...