Siemens SIDOOR AT40,SIDOOR ATD400V,SIDOOR ATD400K,SIDOOR ATD400S, ATE250S,SIDOOR ATD4xxW Series,SIDOOR ATD400T System Manual

Automatic Door Controls

SIDOOR

AT40, ATD400V, ATD400K, ATD4xxW, ATD400S, ATE250S, ATD400T

System Manual

siemens.com

06/2016Edition

AT40, ATD400V, ATD400K, ATD4xxW,

ATD400S, ATE250S, ATD400T

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

Automatic Door Controls

SIDOOR

AT40, ATD400V, ATD400K,

ATD4xxW, ATD400S, ATE250S,

ATD400T

System Manual

06/2016

A2B00096162

Introduction

1

General safety instructions

2

Product family

3

Areas of application

4

Product combinations

5

Controllers

6

Geared motors

7

Power supply

8

Connecting and

commissioning

9

Additional units

10

Appendix

A

-AN

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

A2B00096162-AN

Ⓟ

Copyright © Siemens AG 2012 - 2016.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

06/2016 Subject to change

Table of contents

1 Introduction ........................................................................................................................................... 11

2 General safety instructions .................................................................................................................... 14

3 Product family ....................................................................................................................................... 17

4 Areas of application .............................................................................................................................. 29

5 Product combinations............................................................................................................................ 32

6 Controllers ............................................................................................................................................ 33

3.1 Products ................................................................................................................................. 19

3.1.1 Controllers .............................................................................................................................. 19

3.1.2 Geared motors ....................................................................................................................... 21

3.1.3 Accessories ............................................................................................................................ 23

3.1.4 Power supply .......................................................................................................................... 26

3.1.5 Optional additional units ......................................................................................................... 27

3.1.6 Software ................................................................................................................................. 28

4.1 Elevators ................................................................................................................................ 29

4.2 Industrial applications ............................................................................................................ 30

4.3 Railways ................................................................................................................................. 31

6.1 Description ............................................................................................................................. 33

6.2 Drive functions ....................................................................................................................... 35

6.2.1 Overview ................................................................................................................................ 35

6.2.2 Light barrier ............................................................................................................................ 39

6.2.3 Motion detector ...................................................................................................................... 41

6.2.4 DCPS (Door Closed Position Sensor) ................................................................................... 41

6.2.5 DCOPS (door closed/opened position sensor) ...................................................................... 42

6.2.6 Type 2 ESPE .......................................................................................................................... 44

6.2.7 Pressure-sensitive edge (SR) ................................................................................................ 46

6.2.8 Gate interlocking .................................................................................................................... 47

6.2.9 Door locked ............................................................................................................................ 48

6.2.10 Nudge ..................................................................................................................................... 49

6.2.11 Stopping ................................................................................................................................. 49

6.2.12 Force and energy profiles (NDG mode) ................................................................................. 50

6.2.13 Slow driving curve profile ....................................................................................................... 51

6.2.14 Automatically delayed motion ................................................................................................ 52

6.2.15 Cord-operated switch ............................................................................................................. 53

6.2.16 DOOR CLOSE (command given via digital inputs) ............................................................... 54

6.2.17 DOOR OPEN (command given via digital inputs) ................................................................. 55

6.2.18 Partial opening ....................................................................................................................... 56

6.2.19 Restart after power failure ...................................................................................................... 57

6.2.20 Overload protection ................................................................................................................ 57

6.2.21 Vandalism protection/continuous door monitoring ................................................................. 58

AT40, ATD400V, ATD400K, ATD4xxW, ATD400S, ATE250S, ATD400T

4 System Manual, 06/2016, A2B00096162-AN

Table of contents

6.2.22 Obstruction detection .............................................................................................................. 59

6.2.22.1 Obstruction detection CLOSE ................................................................................................. 59

6.2.22.2 Obstruction detection OPEN ................................................................................................... 60

6.2.22.3 SIDOOR ATD4xxW obstruction detection .............................................................................. 61

6.2.23 ImpulseDrive ........................................................................................................................... 65

6.2.24 Automatic ImpulseDrive .......................................................................................................... 66

6.2.25 ImpulseStop ............................................................................................................................ 67

6.2.26 Automatic ImpulseStop ........................................................................................................... 68

6.2.27 AssistedDrive .......................................................................................................................... 69

6.2.28 Automatic AssistedDrive ......................................................................................................... 70

6.2.29 Initial run/reference run (Power ON) ....................................................................................... 71

6.2.30 Positioning mode .................................................................................................................... 72

6.2.31 Belt break monitoring .............................................................................................................. 73

6.2.32 Emergency power mode ......................................................................................................... 74

6.2.33 Friction compensation ............................................................................................................. 75

6.2.34 Oscillation protection............................................................................................................... 76

6.2.35 Automatic energy limitation ..................................................................................................... 77

6.2.36 External closing force.............................................................................................................. 81

6.2.37 Push to open ........................................................................................................................... 82

6.2.38 Pull to close ............................................................................................................................. 82

6.2.39 Emergency release ................................................................................................................. 82

6.2.40 Learn run ................................................................................................................................. 83

6.2.41 Force limit for learn run ........................................................................................................... 85

6.2.42 Output transmission ................................................................................................................ 86

6.2.43 Free function blocks (FBLOCK) .............................................................................................. 87

6.2.43.1 Overview ................................................................................................................................. 87

6.2.43.2 Configuring the logic ............................................................................................................... 88

6.2.43.3 Digital and logical input signals ............................................................................................... 90

6.2.43.4 Special function blocks ........................................................................................................... 91

6.2.43.5 Discrepancy analysis block ..................................................................................................... 91

6.2.43.6 Basic blocks ............................................................................................................................ 91

6.2.43.7 Frequency analysis blocks ...................................................................................................... 92

6.2.43.8 On delay block ........................................................................................................................ 92

6.2.43.9 Counter block .......................................................................................................................... 93

6.2.44 Drive orders ............................................................................................................................ 94

6.3 S

afety concept ATD4xxW ....................................................................................................... 98

6.3.1 Safe force output ..................................................................................................................... 98

6.3.2 Safe speed observance (energy limiting) ............................................................................... 98

6.3.3 Safe input signals according to PLd ....................................................................................... 98

6.3.3.1 Internal signal routing.............................................................................................................. 99

6.3.3.2 Redundant antivalent signal logic with discrepancy analysis ................................................. 99

6.3.3.3 Frequency-based input signals ............................................................................................. 101

6.3.3.4 Two-hand operation concept (according to Cat. IIIA) ........................................................... 101

6.3.3.5 Emergency stop concept in accordance with stop category 1 ............................................. 103

6.3.3.6 Concept of fail-safe digital control (door OPEN/CLOSE) with emergency stop via 4

digital inputs .......................................................................................................................... 104

6.3.3.7 Concept of fail-safe digital control (door OPEN/CLOSE) with emergency stop via 3

digital inputs .......................................................................................................................... 107

AT40, ATD400V, ATD400K, ATD4xxW, ATD400S, ATE250S, ATD400T

System Manual, 06/2016, A2B00096162-AN

5

Table of contents

6.4 Operation and parameter assignment ................................................................................. 109

6.4.1 Service buttons / Minimal editor ........................................................................................... 110

6.4.1.1 Service buttons .................................................................................................................... 110

6.4.1.2 Minimal editor ....................................................................................................................... 113

6.4.2 Terminal module .................................................................................................................. 116

6.4.3 Operating options via additional units .................................................................................. 118

6.4.4 Parameter names................................................................................................................. 118

6.4.5 Navigation structure ............................................................................................................. 120

6.5 Installation ............................................................................................................................ 126

6.6 Connecting terminals and interfaces ................................................................................... 129

6.6.1 Wiring instructions ................................................................................................................ 129

6.6.2 Digital input signals .............................................................................................................. 131

6.6.3 Voltage output*..................................................................................................................... 134

6.6.4 Relay module ....................................................................................................................... 135

6.6.5 CAN module ......................................................................................................................... 140

6.6.6 USS/PROFIBUS/PROFINET module .................................................................................. 143

6.6.6.1 USS module ......................................................................................................................... 143

6.6.6.2 PROFIBUS module .............................................................................................................. 145

6.6.6.3 PROFINET module .............................................................................................................. 148

6.6.6.4 Wiring and connecting a PROFIBUS/USS connector.......................................................... 154

6.6.6.5 Wiring and connecting a PROFINET connector .................................................................. 156

6.6.6.6 Wiring and connecting relay outputs .................................................................................... 157

6.6.7 Sensors and external sensor interface module (ATD4xxW) ................................................ 159

6.6.7.1 Overview .............................................................................................................................. 159

6.6.7.2 Type 2 ESPE ........................................................................................................................ 160

6.6.7.3 Pressure-sensitive edge (SR) .............................................................................................. 161

6.6.7.4 Sensor function test ............................................................................................................. 162

6.6.7.5 Reaction times ..................................................................................................................... 163

6.6.7.6 Stopping distances ............................................................................................................... 163

6.6.8 Motor plug ............................................................................................................................ 164

6.7 Parameters ........................................................................................................................... 165

6.7.1 Driving curve ........................................................................................................................ 165

6.7.2 Forces .................................................................................................................................. 166

6.7.3 Parameter assignment (ATD4xxW) ..................................................................................... 170

6.7.3.1 Driving parameters ............................................................................................................... 171

6.7.3.2 Other parameters

.7.3.3 Fieldbus parameters ............................................................................................................ 174

6

................................................................................................................. 172

6.7.3.4 Calibration and function parameters .................................................................................... 175

6.7.3.5 Obstruction and reversing parameters ................................................................................ 177

6.7.3.6 FBLOCK parameters ........................................................................................................... 180

6.8 Diagnostics ........................................................................................................................... 183

6.8.1 Operating state display ........................................................................................................ 183

6.8.2 Fault management (ATD4xxW) ........................................................................................... 185

6.9 Communication to PROFIBUS ............................................................................................. 186

6.9.1 Communication .................................................................................................................... 186

6.9.1.1 Parameter assignment ......................................................................................................... 186

6.9.1.2 Configuration ........................................................................................................................ 189

6.9.1.3 Diagnostics ........................................................................................................................... 190

AT40, ATD400V, ATD400K, ATD4xxW, ATD400S, ATE250S, ATD400T

6 System Manual, 06/2016, A2B00096162-AN

Table of contents

6.10 Communication to PROFINET .............................................................................................. 191

6.10.1 Parameterization/startup record ........................................................................................... 191

6.10.2 Configuration ......................................................................................................................... 193

6.10.3 Diagnostics ........................................................................................................................... 193

6.10.4 Device roles and provider-consumer model ......................................................................... 194

6.11 Structure of user data/process data ...................................................................................... 195

6.11.1 Parameter interface .............................................................................................................. 196

6.11.1.1 Parameter ID (PKE) .............................................................................................................. 197

6.11.1.2 Parameter index (IND) .......................................................................................................... 200

6.11.1.3 Parameter value (PWE) ........................................................................................................ 202

6.11.1.4 Parameter ID ......................................................................................................................... 203

6.11.1.5 Parameter description (PBE) ................................................................................................ 203

6.11.2 Process data ......................................................................................................................... 204

6.11.2.1 STW1 - control word (CtrlW) ................................................................................................. 205

6.11.2.2 TSW0 - technology control word 0 ........................................................................................ 206

6.11.2.3 TSW1 - technology control word 1 ........................................................................................ 206

6.11.2.4 TSW2 - technology control word 2 ........................................................................................ 207

6.11.2.5 ZSW1 - status word (StatW) ................................................................................................. 208

6.11.2.6 TZW0 - Technology status word 0 ........................................................................................ 209

6.11.2.7 TZW1 - Technology status word 1 ........................................................................................ 210

6.11.2.8 TZW2 - Technology status word 2 ........................................................................................ 212

6.11.2.9 TZW3 - Technology status word 3 ........................................................................................ 213

6.11.2.10 TZW4 - Technology status word 4 ........................................................................................ 214

6.11.2.11 TZW5 - Technology status word 5 ........................................................................................ 214

6.12 Local/master operation ......................................................................................................... 215

6.13 Master monitoring ................................................................................................................. 215

6.14 Sequential control ................................................................................................................. 216

6.15 Integration of SIMATIC S7 .................................................................................................... 218

6.15.1 Function block ....................................................................................................................... 219

6.15.1.1 "SIDOOR_CDat" data type ................................................................................................... 220

6.15.1.2 "SIDOOR_SDat" data type.................................................................................................... 221

6.15.2 Configuring PROFIBUS hardware (GSD file) ....................................................................... 222

6.15.3 Configuring PROFINET hardware (GSD file) ....................................................................... 222

6.

16 Technical specifications ........................................................................................................ 223

AT40, ATD400V, ATD400K, ATD4xxW, ATD400S, ATE250S, ATD400T

System Manual, 06/2016, A2B00096162-AN

7

Table of contents

7 Geared motors ..................................................................................................................................... 232

8 Power supply ....................................................................................................................................... 260

9 Connecting and commissioning ............................................................................................................ 280

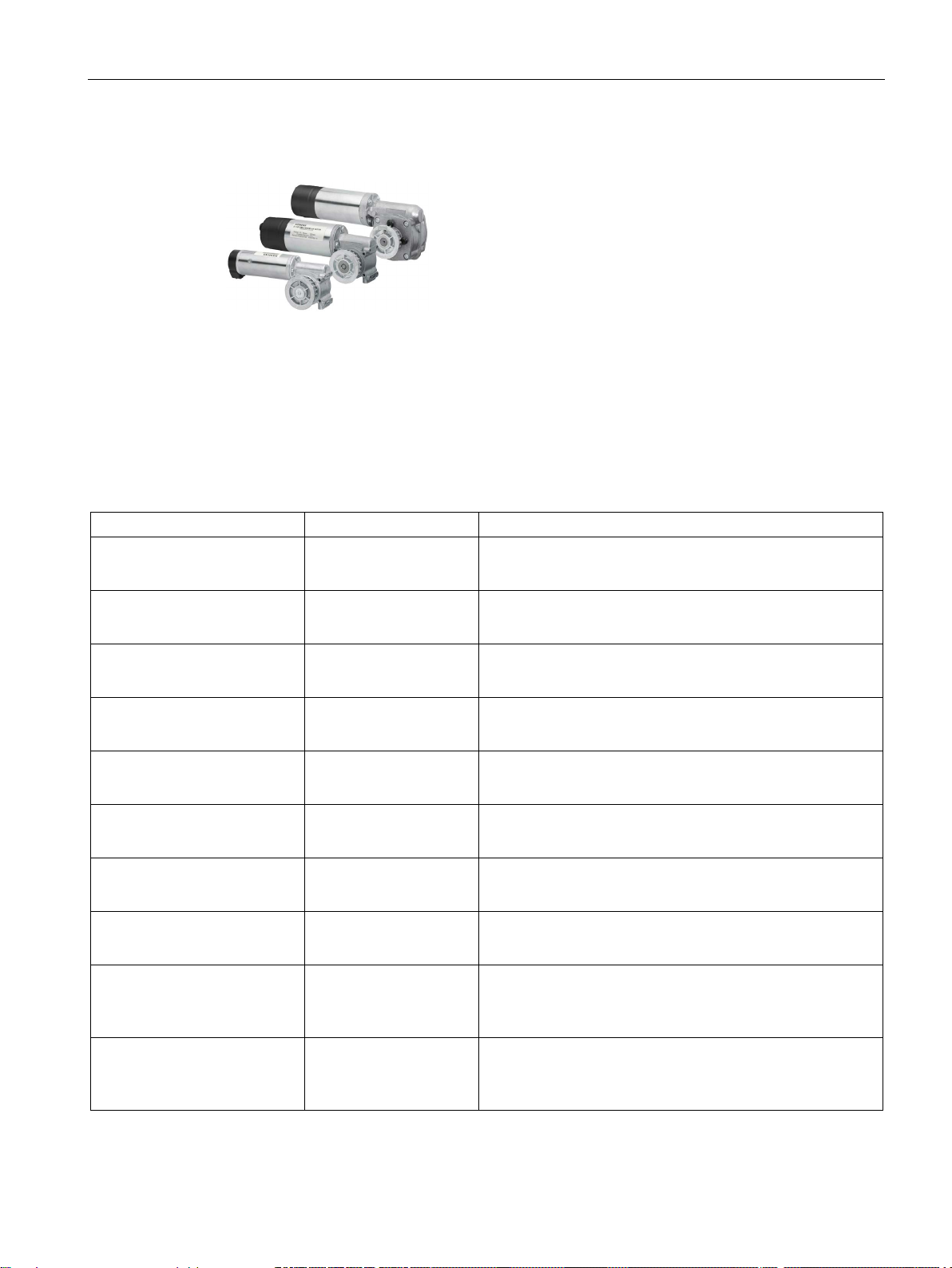

7.1 Description ........................................................................................................................... 232

7.2 Installation ............................................................................................................................ 233

7.3 Connecting terminals ........................................................................................................... 238

7.3.1 Conductor assignment of the motor plug ............................................................................. 238

7.4 Technical specifications ....................................................................................................... 239

7.4.1 Dimension drawing of SIDOOR M2 with rubber-metal anti-vibration mount and

mounting bracket.................................................................................................................. 248

7.4.2 Dimension drawing of SIDOOR M3 / MDG180 DIN EN 45545-2 with rubber-metal anti-

vibration mount and mounting bracket ................................................................................. 249

7.4.3 Dimension drawing of SIDOOR MDG180 with rubber-metal anti-vibration mount and

mounting bracket.................................................................................................................. 250

7.4.4 Dimension drawing SIDOOR MEG250 ................................................................................ 251

7.4.5 Dimension drawing of SIDOOR M4 with rubber-metal anti-vibration mount and

mounting bracket.................................................................................................................. 253

7.4.6 Dimension drawing of SIDOOR MDG400 with rubber-metal anti-vibration mount and

mounting bracket.................................................................................................................. 254

7.4.7 Dimension drawing of SIDOOR M5 ..................................................................................... 255

7.4.8 Dimension drawing MDG400NMS ....................................................................................... 256

7.4.9 Dimension drawing of MDG motor cable ............................................................................. 257

7.4.10 Dimension drawing of deflector pulley with tensioning device and mounting bracket ......... 258

7.4.11 Dimension drawing of door clutch holder ............................................................................. 259

8.1 SIDOOR NT40 ..................................................................................................................... 260

8.1.1 Description ........................................................................................................................... 260

8.1.2 Installation ............................................................................................................................ 262

8.1.3 Connecting terminals ........................................................................................................... 263

8.1.4 Technical specifications ....................................................................................................... 265

8.2 SIDOOR Transformer .......................................................................................................... 268

8.2.1 Description ........................................................................................................................... 268

8.2.2 Installation ............................................................................................................................ 269

8.2.3 Connecting terminals ........................................................................................................... 270

8.2.4 Technical specifications ....................................................................................................... 271

8.3 Uninterruptible power supply (UPS) .................................................................................... 273

8.4 Direct voltage supply provided by customer ........................................................................ 276

8.4.1 Requirements for SIDOOR ATD400T power supply ........................................................... 276

8.4.2 Requirements for SIDOOR ATD4xxW power supply ........................................................... 277

8.4.3 Installation ............................................................................................................................ 279

AT40, ATD400V, ATD400K, ATD4xxW, ATD400S, ATE250S, ATD400T

8 System Manual, 06/2016, A2B00096162-AN

Table of contents

10 Additional units ................................................................................................................................... 289

A Appendix............................................................................................................................................. 296

10.1 SIDOOR EMC FILTER ......................................................................................................... 289

10.1.1 Description ............................................................................................................................ 289

10.1.2 Installation ............................................................................................................................. 289

10.1.3 Connecting terminals ............................................................................................................ 290

10.1.4 Technical specifications ........................................................................................................ 291

10.2 SIDOOR Service Tool ........................................................................................................... 292

10.2.1 Description ............................................................................................................................ 292

10.2.2 Connection ............................................................................................................................ 292

10.2.3 Operation .............................................................................................................................. 293

10.2.4 Technical specifications ........................................................................................................ 294

A.1 Profiles and adjustment ranges ............................................................................................ 296

A.1.1 Profile name .......................................................................................................................... 296

A.1.2 SIDOOR M2 L / R ................................................................................................................. 297

A.1.2.1 SIDOOR AT40/ATD400S ..................................................................................................... 297

A.1.2.2 SIDOOR ATD400W .............................................................................................................. 298

A.1.2.3 SIDOOR M2 adjustment ranges ........................................................................................... 299

A.1.3 SIDOOR M3 L / R ................................................................................................................. 300

A.1.3.1 SIDOOR AT40/ATD400S ..................................................................................................... 300

A.1.3.2 SIDOOR ATD400K ............................................................................................................... 301

A.1.3.3 SIDOOR ATD400W .............................................................................................................. 302

A.1.3.4 SIDOOR ATD4xxW ............................................................................................................... 303

A.1.3.5 SIDOOR ATD400T ............................................................................................................... 304

A.1.3.6 SIDOOR M3 adjustment ranges ........................................................................................... 305

A.1.4 SIDOOR MDG180 L / R ........................................................................................................ 307

A.1.4.1 SIDOOR ATD4xxW ............................................................................................................... 307

A.1.4.2 Adjustment ranges SIDOOR MDG180 ................................................................................. 307

A.1.5 SIDOOR MDG180 L / R DIN EN 45545-2 ............................................................................ 307

A.1.5.1 SIDOOR ATD400T ............................................................................................................... 307

A.1.5.2 SIDOOR MDG180 DIN EN 45545-2 adjustment ranges ...................................................... 307

A.1.6 SIDOOR M4 L / R ................................................................................................................. 308

A.1.6.1 SIDOOR AT40/ATD400S ..................................................................................................... 308

A.1.6.2 SIDOOR ATD400K ............................................................................................................... 309

A.1.6.3 SIDOOR ATD400V ............................................................................................................... 310

A.1.6.4 SIDOOR ATD400W .............................................................................................................. 311

A.1.6.5 SIDOOR ATD4xxW ............................................................................................................... 312

A.1.6.6 SIDOOR ATD400T ............................................................................................................... 313

A.1.6.7 SIDOOR M4 adjustment ranges ........................................................................................... 314

A.1.7 SIDOOR MDG400 L / R ........................................................................................................ 316

A.1.7.1 SIDOOR ATD4xxW ............................................................................................................... 316

A.1.7.2 Adjustment ranges SIDOOR MDG400 ................................................................................. 316

A.1.8 SIDOOR MDG400NMS L / R ................................................................................................ 317

A.1.8.1 SIDOOR ATD4xxW ............................................................................................................... 318

A.1.8.2 SIDOOR MDG400NMS adjustment ranges.......................................................................... 319

AT40, ATD400V, ATD400K, ATD4xxW, ATD400S, ATE250S, ATD400T

System Manual, 06/2016, A2B00096162-AN

9

Table of contents

Index ................................................................................................................................................... 334

A.1.9 SIDOOR M5 L / R ................................................................................................................ 320

A.1.9.1 SIDOOR AT40 ..................................................................................................................... 320

A.1.9.2 SIDOOR ATD4xxW .............................................................................................................. 321

A.1.9.3 Adjustment ranges SIDOOR M5 .......................................................................................... 322

A.1.10 SIDOOR MEG250 ................................................................................................................ 324

A.1.10.1 SIDOOR ATE250S .............................................................................................................. 324

A.1.10.2 Adjustment ranges SIDOOR MEG250 ................................................................................ 325

A.2 Configuration record ............................................................................................................ 326

A.3 Standards, directives and laws ............................................................................................ 329

A.3.1 Safety ................................................................................................................................... 329

A.3.2 EMC ..................................................................................................................................... 329

A.3.3 Communications .................................................................................................................. 330

A.3.4 Application-specific standards ............................................................................................. 330

A.3.5 Protective devices ................................................................................................................ 331

A.4 Service & support ................................................................................................................. 333

AT40, ATD400V, ATD400K, ATD4xxW, ATD400S, ATE250S, ATD400T

10 System Manual, 06/2016, A2B00096162-AN

1

Content of the System Manual

Target group

This System Manual describes SIDOOR door drives. A SIDOOR door drive consists of at

least the following components:

● Controller

● Geared motor

● Power supply

Optional additional units can also be connected (for example, the SIDOOR Service Tool).

The individual products and their interactions are described in this System Manual.

The System Manual is intended for fitters, commissioning engineers, operators, service

personnel, and configuration engineers who work on elevators, machine tools and railway

doors.

AT40, ATD400V, ATD400K, ATD4xxW, ATD400S, ATE250S, ATD400T

System Manual, 06/2016, A2B00096162-AN

11

Introduction

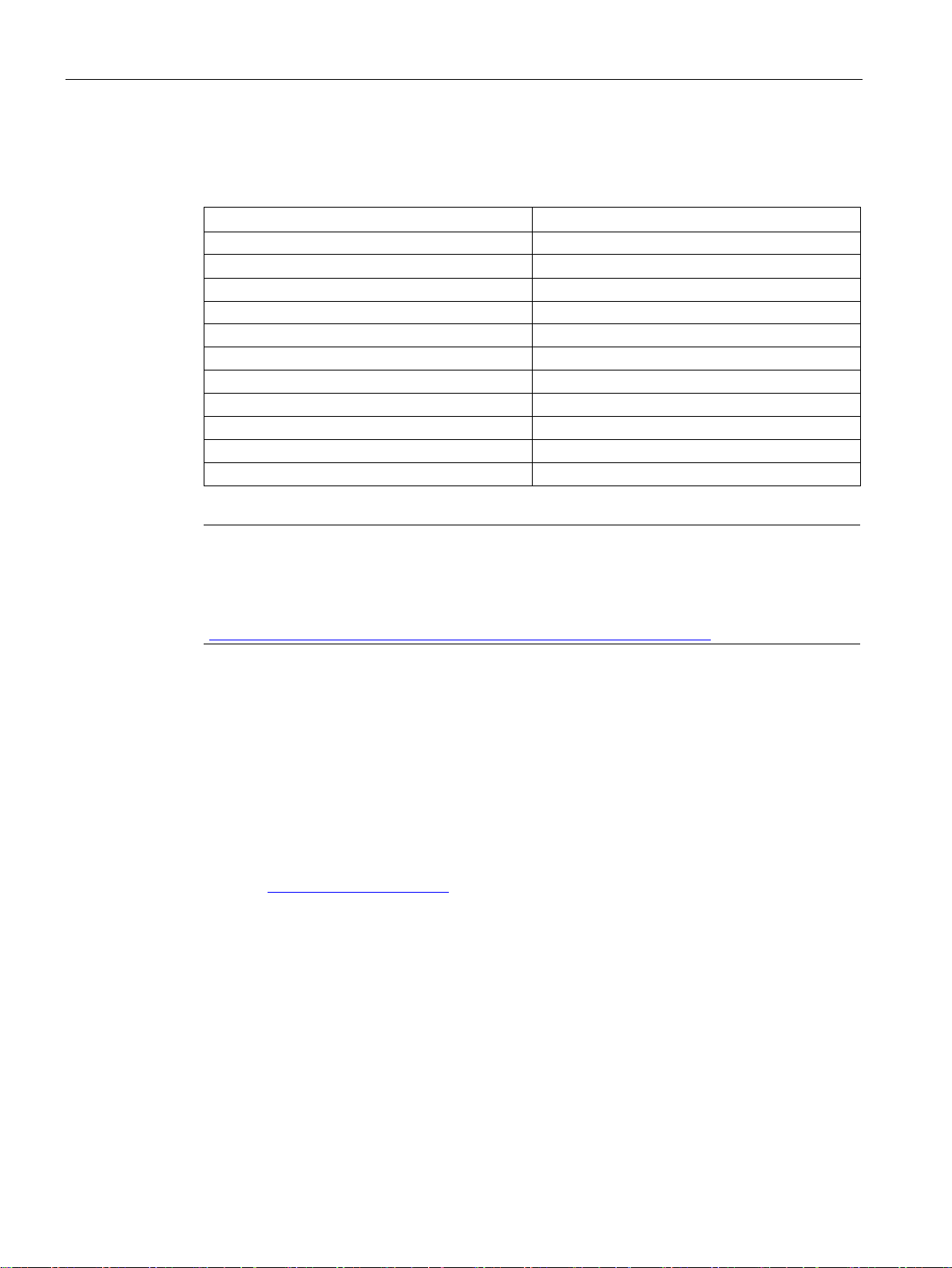

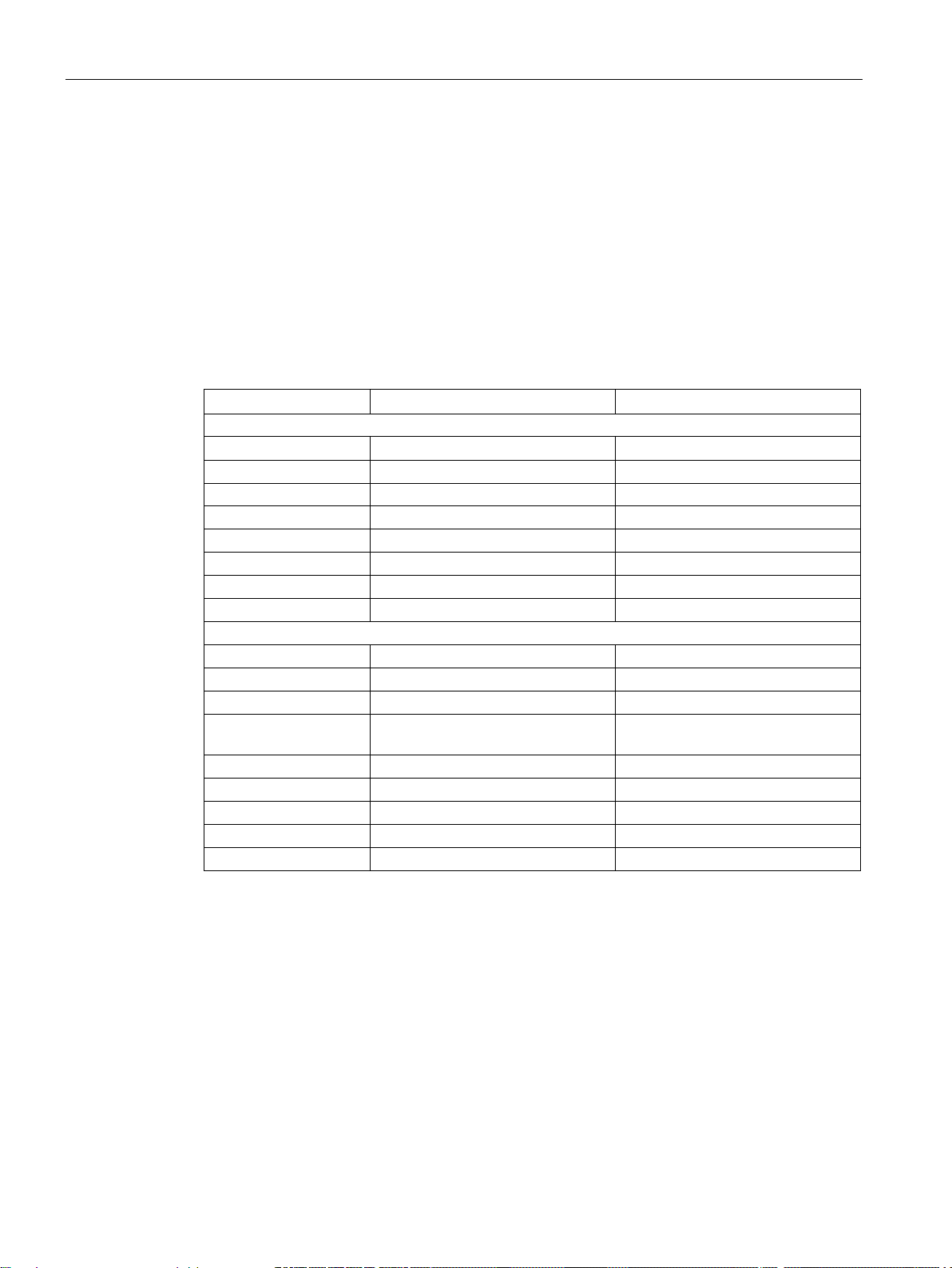

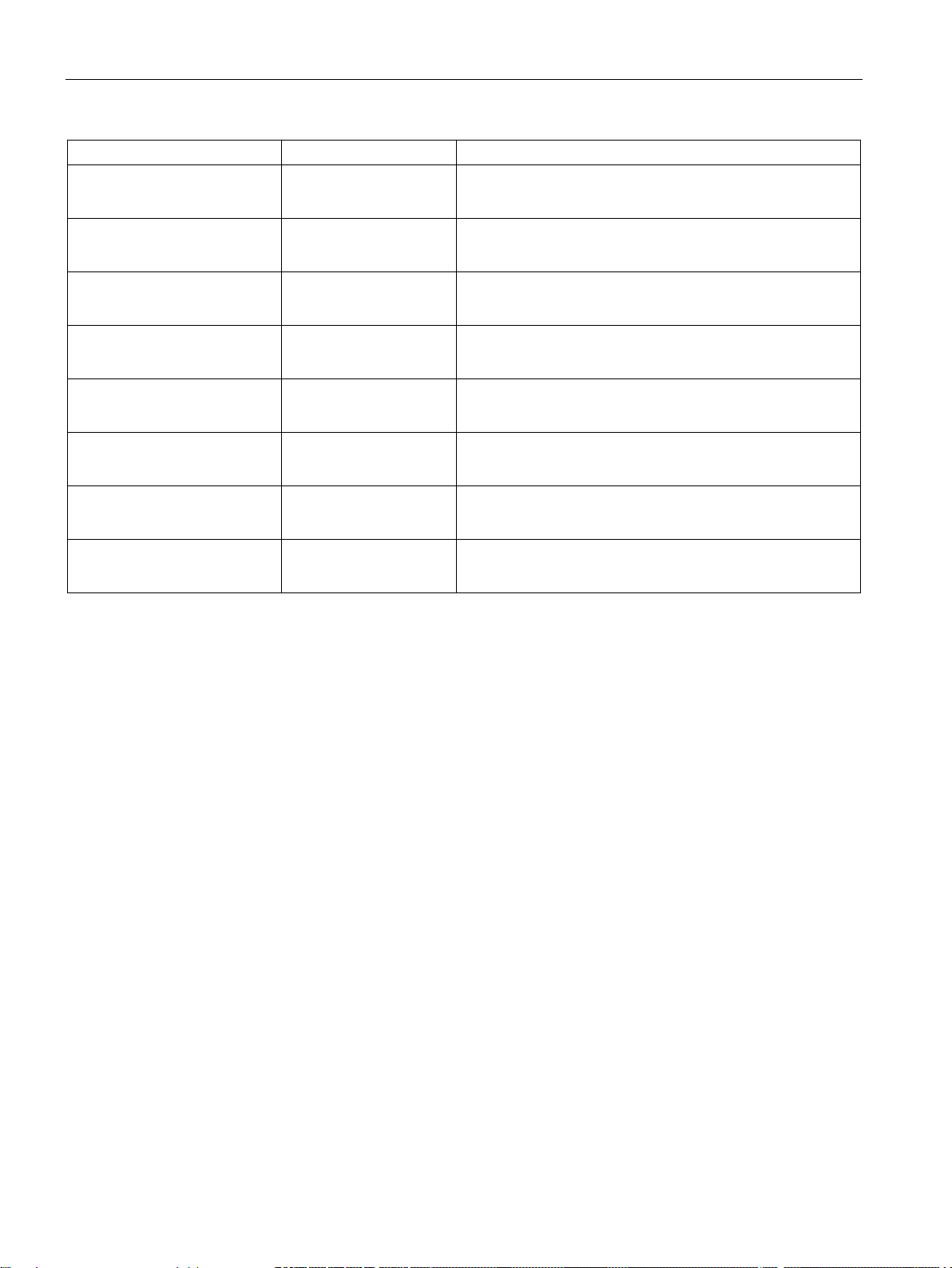

Firmware versions

as from

Controller

From firmware version

SIDOOR AT40

1.40

SIDOOR ATD400K RELAY LB

1.02

SIDOOR ATD400K RELAY RC

2.02

SIDOOR ATD401W

1.01

SIDOOR ATD410W

1.00

SIDOOR ATD420W

1.00

SIDOOR ATD430W

1.02

SIDOOR ATD400S

1.03

SIDOOR ATE250S

1.10

SIDOOR ATD400T RELAY

4.07

Note

SIDOOR ATD4xxW firmware versions

You will find the current firmware versions for SIDOOR ATD4xxW

Industry Online Support

(

Figures

Information on the Internet

Parameter documentation

This System Manual applies to controllers

SIDOOR ATD400V RELAY 1.03

the following firmware versions:

controllers online at

http://support.automation.siemens.com/WW/view/en/50247080/133100).

The figures in this System Manual illustrate SIDOOR User Software Version 1.11 and the

SIDOOR AT40 RELAY controller / CAN Version 1.40. The illustrations for other versions

may differ slightly.

You can find more information about SIDOOR door drives and their applications on the

Internet (www.siemens.com/sidoor).

After the optimal parameter settings have been determined, note them in the configuration

record (see Appendix "Configuration record (Page 326)"). Have this record to hand when

you call the Hotline.

AT40, ATD400V, ATD400K, ATD4xxW, ATD400S, ATE250S, ATD400T

12 System Manual, 06/2016, A2B00096162-AN

Introduction

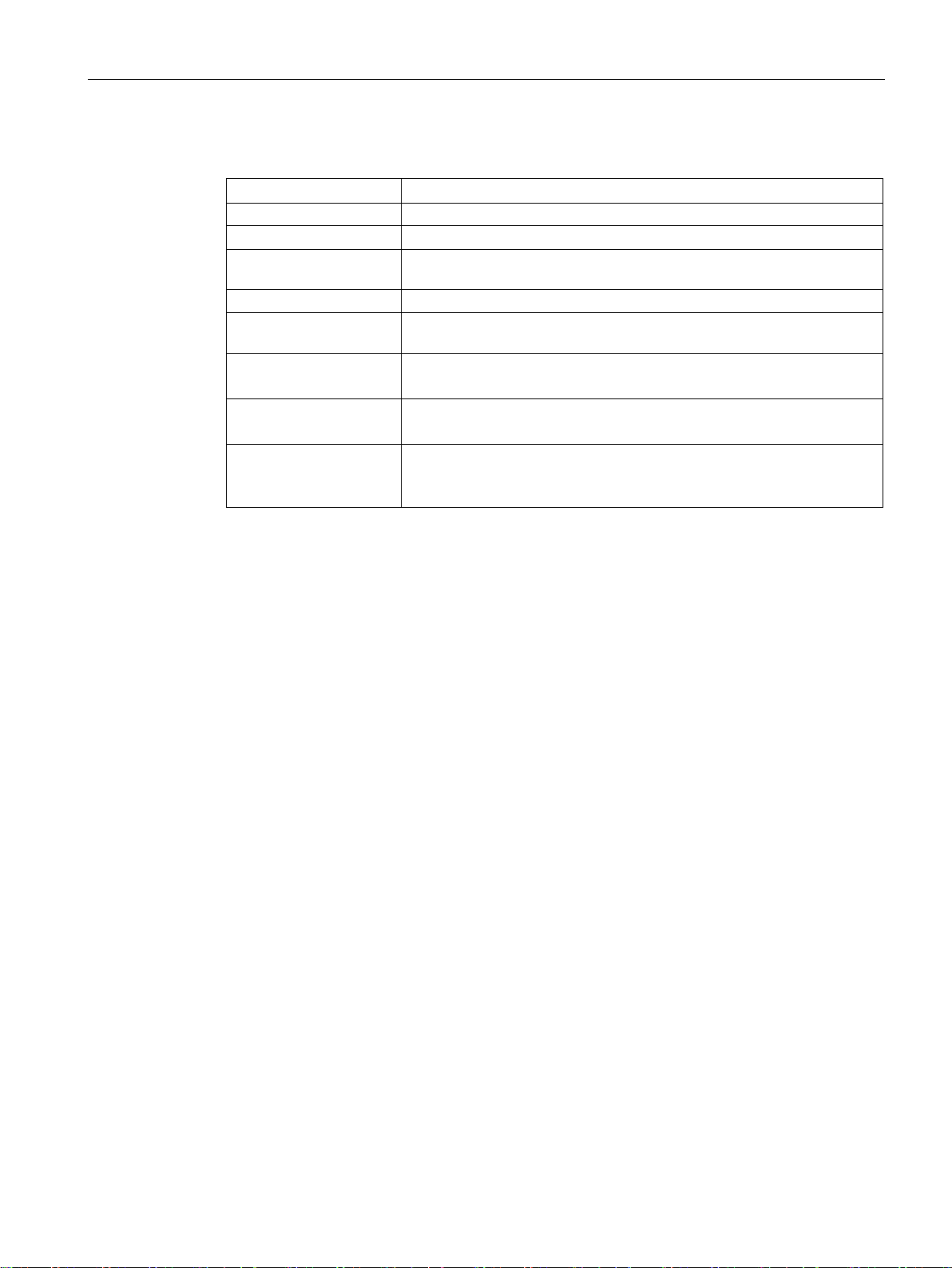

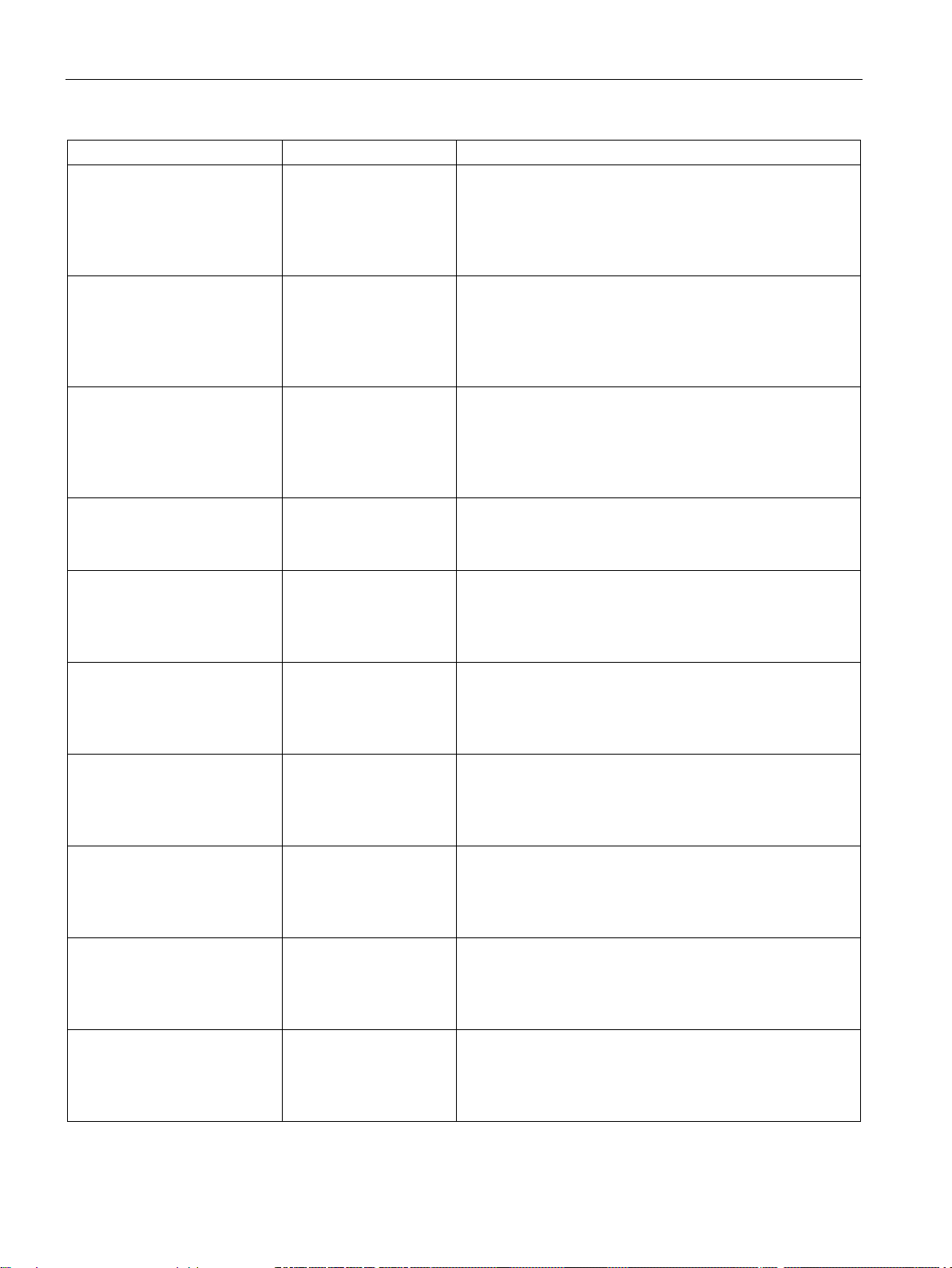

History

Version

Change

10/2010

First edition

ler.

ler.

SIDOOR ATD4xxW controller firmware version 1.03 expanded.

Extension control device SIDOOR ATD4xxW firmware version 1.05.

ATD430W.

02/2014 Revised and expanded edition

04/2014 Edition revised and expanded to include the SIDOOR ATD420W control-

07/2014 Revised and expanded edition

11/2014 Edition revised and expanded to include the SIDOOR ATD430W control-

04/2015 Revised and expanded edition.

01/2016 Revised and expanded edition.

06/2016 Revised and expanded edition.

Extension control devices for NFPA environment ATD401W ATD420W,

AT40, ATD400V, ATD400K, ATD4xxW, ATD400S, ATE250S, ATD400T

System Manual, 06/2016, A2B00096162-AN

13

2

Qualified personnel

Working on the door drive

WARNING

Risk of injury due to dangerous electrical voltages and moving mechanical parts.

WARNING

Risk of injury due to moving mechanical parts

CAUTION

Risk of injury due to moving mechanical parts

Qualified personnel have the following qualifications:

● Training, instruction or authorization to switch on and off electric circuits and

devices/systems in compliance with safety engineering standards.

● Training or instruction in the maintenance and use of appropriate safety equipment in

compliance with safety engineering standards.

● First aid training.

Disconnect the door drive by unplugging the power plug from the power supply before you

start work on the door drive.

If power-operated guards are used, ensure that they have been tested prior to initial

commissioning. Power-operated guards must also be tested annually.

If required by the drive application, suitable protective equipment must be installed for safe

door interlocking.

AT40, ATD400V, ATD400K, ATD4xxW, ATD400S, ATE250S, ATD400T

14 System Manual, 06/2016, A2B00096162-AN

General safety instructions

Parameter assignment and configuration

WARNING

Risk of injury and material damage due to excessive forces of the door

Note

Application-specific measures for emergency operation

In the event of a controller failu

according to the application.

Modifications to the door drive

CAUTION

Loss of liability for defects and material damage

Exceeding the maximum static closing force and opening force, if present, may lead to

injuries to persons or damage to the door drive and mechanical components of the door.

After commissioning, have the maximum static forces checked by the service personnel,

and adjusted to the limit value if it is excessive.

Observe the limit values of the applicable standards and adjust the set values accordingly.

re, measures must be taken for emergency operation

Changes to the door drive lead to the loss of liability for defects and compensation rights,

and the correct function of the door drive is no longer guaranteed.

Note the following rules:

• Do not make any modifications to the door drive (motor, controller, power supply).

• Do not make a permanent connection as this does not ensure a proper and required

necessary disconnection from the mains.

• Do not remove the protective Schuko-type socket under any circumstances (for example

by cutting it off).

• The power supply cable (SIDOOR Transformer or SIDOOR NT40) cannot be replaced.

Scrap the power supply if the supply cable is damaged.

AT40, ATD400V, ATD400K, ATD4xxW, ATD400S, ATE250S, ATD400T

System Manual, 06/2016, A2B00096162-AN

15

General safety instructions

Notes for servicing

Security information

Note

Using ATD410W, ATD420W und ATD430W fieldbus controllers

Installation in control cabinet only

The SIDOOR system should be included in the maintenance plan of the plant and be

inspected in the course of the maintenance intervals specified there.

An inspection should cover the following points:

● Visual inspection of the controller for contamination and damage

● Visual inspection of the motor for dirt and damage

● Visual and mechanical inspection of the mechanical system in as far as this belongs to

the SIDOOR elevator system. This includes checking the following components:

● Attachment of the motor holder, deflector pulley and mounting bracket

● Wear on the toothed belt

● Check and remeasure the parameters for the safety-relevant force and energy settings

set during commissioning

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, solutions, machines, equipment and/or networks. They are

important components in a holistic industrial security concept. With this in mind, Siemens’

products and solutions undergo continuous development. Siemens recommends strongly

that you regularly check for product updates.

For the secure operation of Siemens products and solutions, it is necessary to take suitable

preventive action (e.g. cell protection concept) and integrate each component into a holistic,

state-of-the-art industrial security concept. Third-party products that may be in use should

also be considered. Please find further information on industrial security at

(http://www.siemens.com/industrialsecurity) .

To stay informed about product updates as they occur, sign up for a product-specific

newsletter. You can find more information on this at (http://support.automation.siemens.com)

.

– to ensure access by authorized personnel only.

AT40, ATD400V, ATD400K, ATD4xxW, ATD400S, ATE250S, ATD400T

16 System Manual, 06/2016, A2B00096162-AN

3

SIDOOR

Overview of the product family

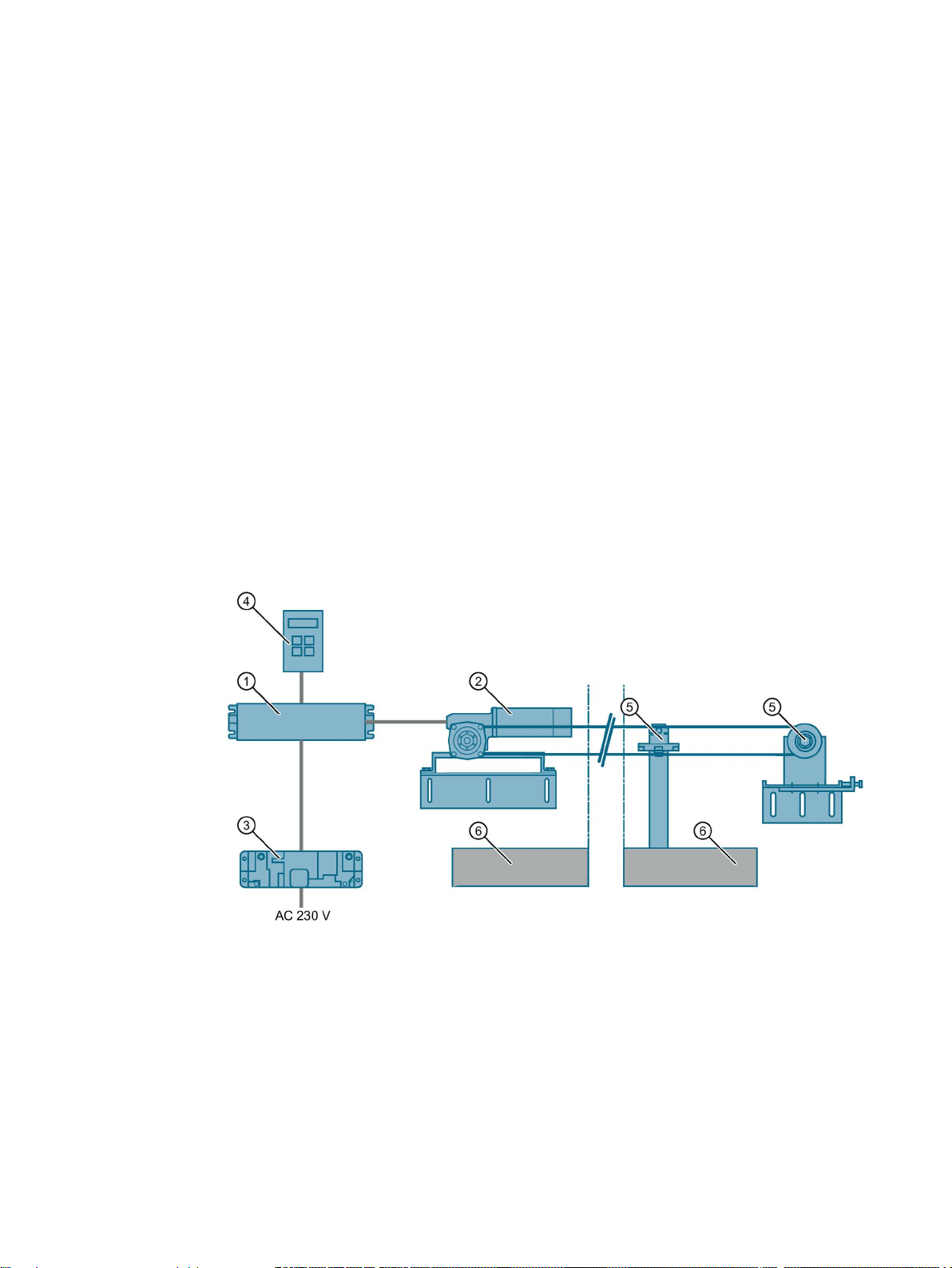

①

④

Software Kit)

②

Geared motor

⑤

Accessories

③

Power supply

⑥

Sliding door

Door control system is the general term for a controller of an access system.

The SIDOOR product family is primarily intended for operating sliding doors. Different

versions of SIDOOR controllers enable both horizontal and vertical doors to be operated.

Door control systems are characterized by the fact that there are always two defined states:

namely for the open and closed positions of the door. The door is always controlled between

these two positions in accordance with the guidelines of the respective application.

In a defined learn run initiated by "one-button operation", the door system independently

determines the values for the door width, the dynamic door weight and the drive direction of

the geared motor, and stores these data in a non-volatile memory.

Controller

Optional additional unit (e.g. SIDOOR Service Tool, SIDOOR

Image 3-1 System setup

AT40, ATD400V, ATD400K, ATD4xxW, ATD400S, ATE250S, ATD400T

System Manual, 06/2016, A2B00096162-AN

17

Product family

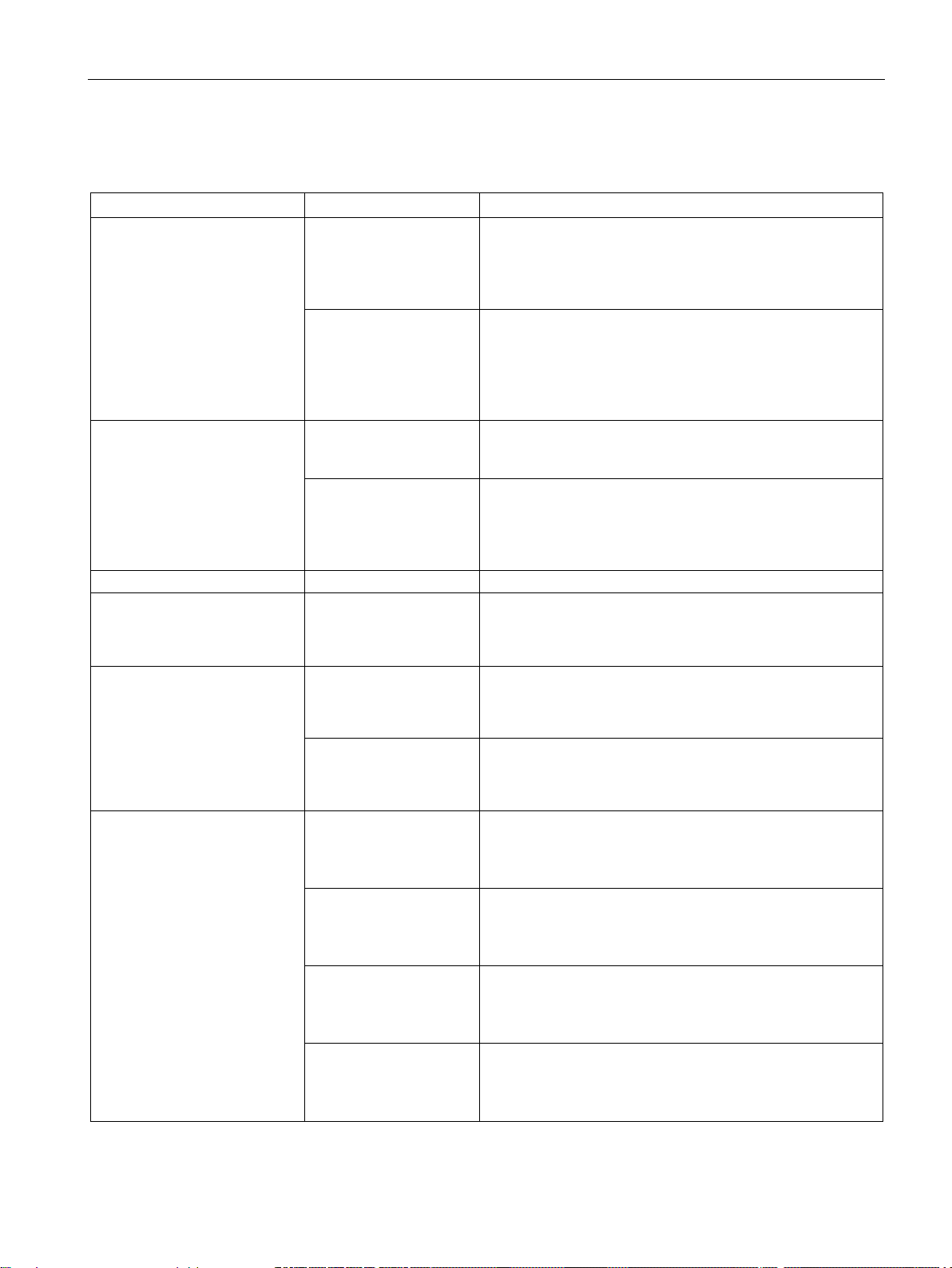

Technologies

DC technology

EC technology

DC technology

EC technology

Controllers

SIDOOR ATD400V ✓ —

SIDOOR ATD400K ✓ —

SIDOOR ATD400W ✓ —

SIDOOR ATD4xxW ✓ —

SIDOOR ATD400S ✓ —

SIDOOR ATE250S — ✓

SIDOOR ATD400T ✓ —

Geared motors

SIDOOR M2 ✓ —

SIDOOR M3 ✓ —

SIDOOR MDG180 ✓ —

DIN EN 45545-2

SIDOOR MEG250 — ✓

SIDOOR M4 ✓ —

SIDOOR MDG400 NMS

✓

—

SIDOOR MDG400 ✓ —

SIDOOR M5 ✓ —

Two different technologies are used in SIDOOR door control systems:

●

DC systems are two-phase driven, and have internal commutating brushes.

●

EC systems are three-phase driven, and are electronically commutated.

SIDOOR controllers and SIDOOR motors use the technologies as shown below:

Table 3- 1 Overview of technologies used

SIDOOR AT40 ✓ —

SIDOOR MDG180

AT40, ATD400V, ATD400K, ATD4xxW, ATD400S, ATE250S, ATD400T

✓ —

18 System Manual, 06/2016, A2B00096162-AN

Product family

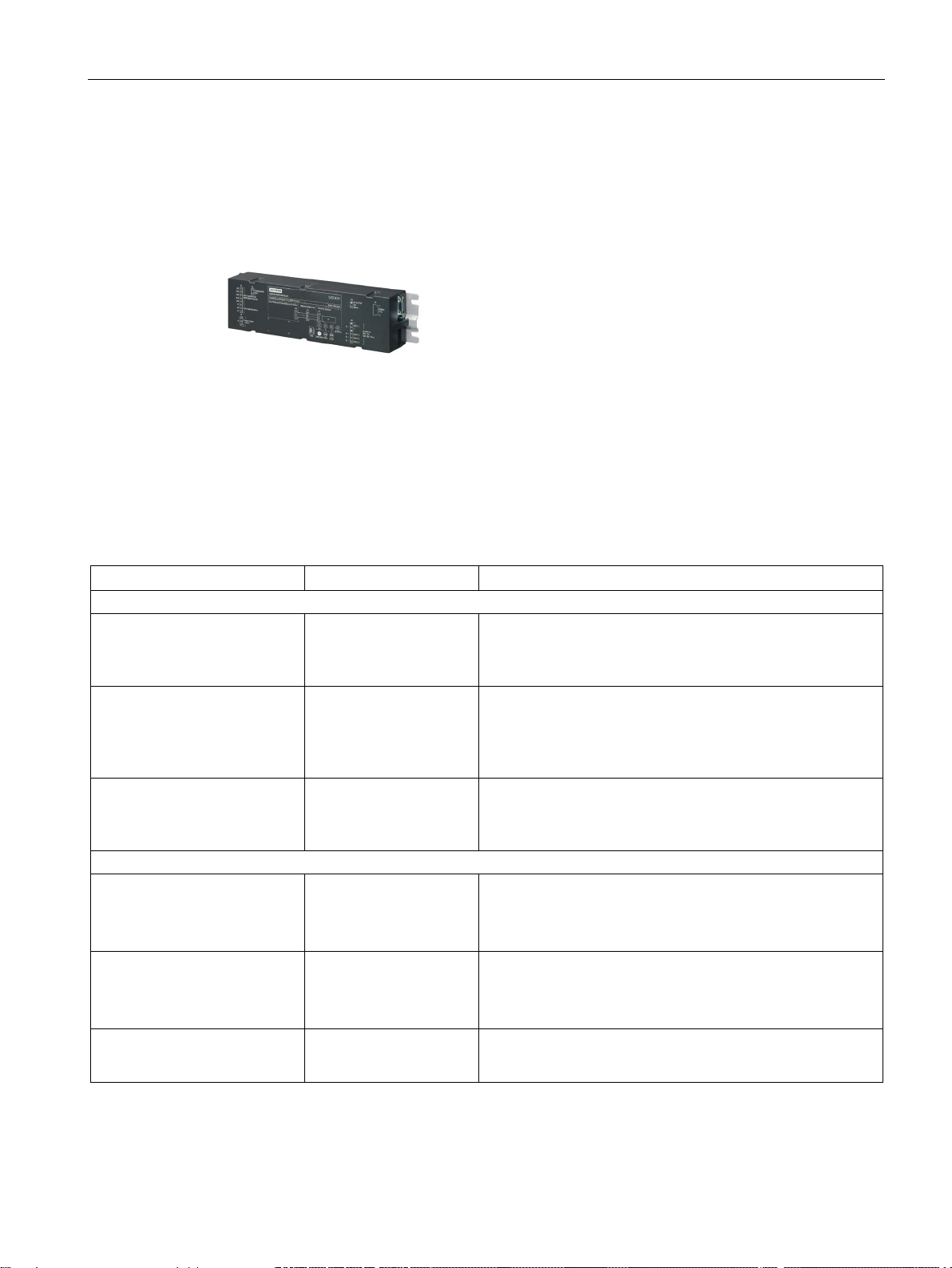

3.1

Products

3.1.1

Controllers

Versions

Controller

Article No.

Description

Elevators

Industrial applications

3.1 Products

Controllers are electronic controllers connected to the power supply via an external power

supply unit (SIDOOR NT40, SIDOOR Transformer). They are generally connected to the

higher-level controller via digital or fieldbus interfaces, and can be configured via a user

interface.

The controllers are designed for different areas of application. The following table provides

an overview of the available controllers.

SIDOOR AT40 RELAY 6FB1111-0AT10-3AT2

SIDOOR AT40 CAN 6FB1111-1AT10-3AT3

SIDOOR ATD400V RELAY 6FB1111-1AT10-3VE2

SIDOOR ATD400K RELAY LB 6FB1141-1AT10-3KU2

SIDOOR ATD400K RELAY RC 6FB1141-1AT11-3KU2

SIDOOR ATD401W 6FB1141-1AT11-3WE2

• Controller for horizontal elevator doors, up to 600 kg door

weight

• Relay module

• Controller for horizontal elevator doors, up to 600 kg door

weight

• Serial interface to the higher-level controller (CAN mod-

ule)

• Controller for rising gate and rolling shutter doors in the

elevator field of application, up to 400 kg door weight

• Relay module

• Controller for cold room gates, up to 400 kg door weight

• 1 DI for light barriers (LB)

• Relay module

• Controller for cold room gates, up to 400 kg door weight

• 1 DI for reed contact (RC)

• Relay module

• Controller for machine tools, up to 600 kg door weight

• Relay module

AT40, ATD400V, ATD400K, ATD4xxW, ATD400S, ATE250S, ATD400T

System Manual, 06/2016, A2B00096162-AN

19

Product family

Controller

Article No.

Description

Railways

Platform screen doors

Interior railway doors

3.1 Products

SIDOOR ATD410W 6FB1141-4AT10-3WE2

SIDOOR ATD420W 6FB1141-2AT10-3WE2

SIDOOR ATD430W 6FB1141-3AT10-3WE2

SIDOOR ATD400S 6FB1131-0BM10-3AT3

SIDOOR ATE250S 6FB1231-0BM10-0AT3

• Controller for machine tools, up to 600 kg door weight

• USS bus interface to the higher-level controller (USS

module)

• Controller for machine tools, up to 600 kg door weight

• PROFIBUS interface to the higher-level controller

(PROFIBUS module)

• Controller for machine tools, up to 600 kg door weight

• PROFINET interface to the higher-level controller

(PROFIBUS module)

• Controller for platform screen doors, up to 400 kg door

weight

• Serial interface to the higher-level controller via the

SIDOOR AT-EB expansion unit

• Controller for platform screen doors, up to 250 kg door

weight

• Serial interface to the higher-level controller via the

SIDOOR AT-EB expansion unit

SIDOOR ATD400T RELAY 6FB1121-0BM13-3AT2

• Controller for interior railway doors, up to 400 kg door

weight

• Relay module

AT40, ATD400V, ATD400K, ATD4xxW, ATD400S, ATE250S, ATD400T

20 System Manual, 06/2016, A2B00096162-AN

Product family

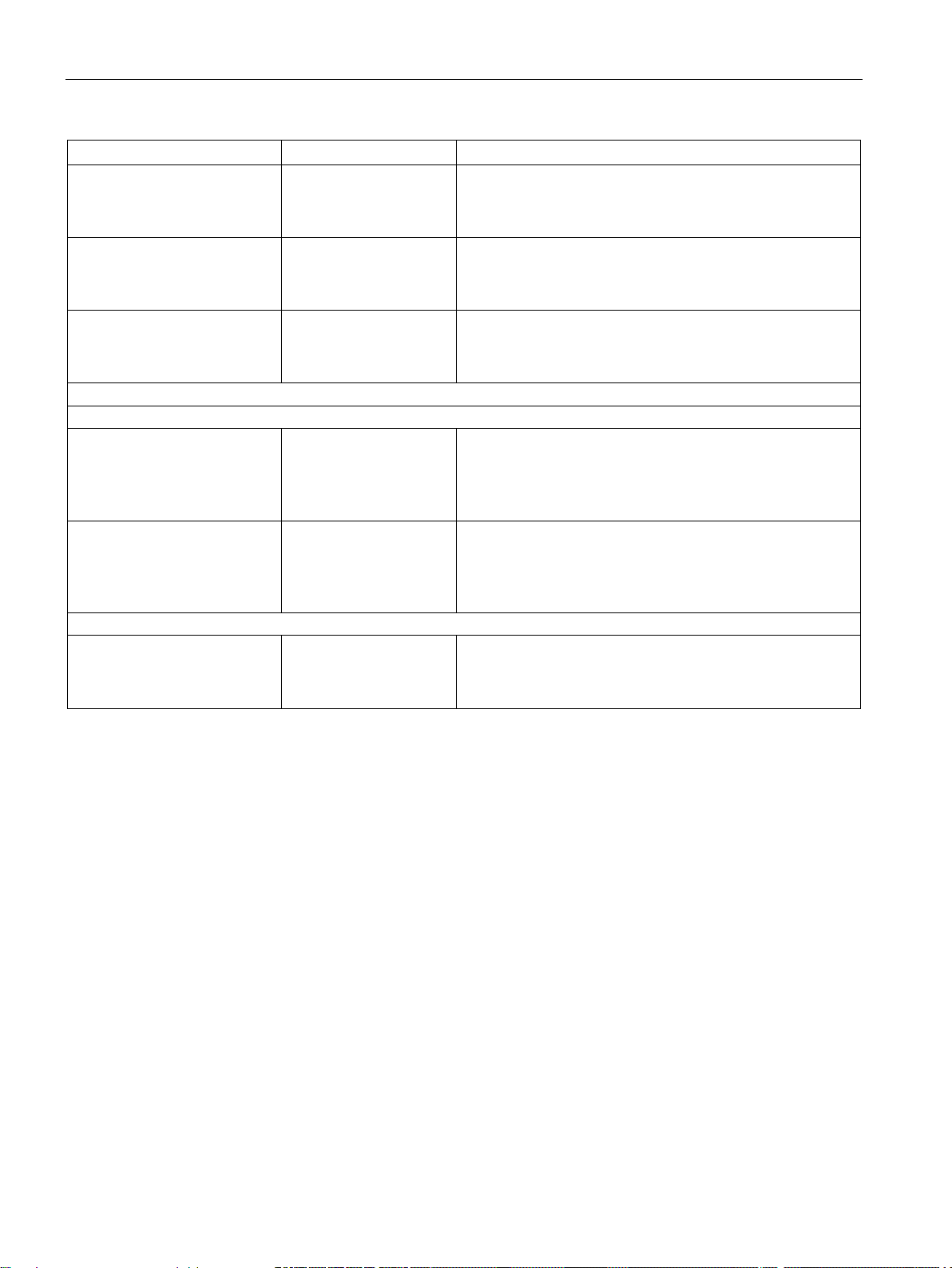

3.1.2

Geared motors

Versions

Geared motor

Article No.

Description

3.1 Products

Geared motors form the maintenance-free drive unit in the door drive. The geared motors

feature DC motors with non-self-locking gearing and are speed-controlled. The set force and

speed limits are not exceeded.

The power is transmitted by a gear rack or chain. Toothed belts or chains pass over a

deflector pulley, and can be fitted with 2 clutch holders. This enables it to drive both singlesided and centrally-opening doors.

SIDOOR M2 L 6FB1103-0AT10-5MA0

SIDOOR M2 R 6FB1103-0AT11-5MA0

SIDOOR M3 L 6FB1103-0AT10-4MB0

SIDOOR M3 R 6FB1103-0AT11-4MB0

SIDOOR MDG180 L 6FB1103-0AT14-4MB0

SIDOOR MDG180 R 6FB1103-0AT13-4MB0

SIDOOR MDG180 L

DIN EN 45545-2

SIDOOR MDG180 R

DIN EN 45545-2

SIDOOR MEG250 L 6FB1233-0BM00-0MP0

SIDOOR MEG250 R 6FB1233-0BM01-0MP0

6FB1103-0AT16-4MB0

6FB1103-0AT15-4MB0

• Geared motor, pinion left, max. 120 kg door weight

• Cable length 1.5 m

• Geared motor, pinion right, max. 120 kg door weight

• Cable length 1.5 m

• Geared motor, pinion left, max. 180 kg door weight

• Cable length 1.5 m

• Geared motor, pinion right, max. 180 kg door weight

• Cable length 1.5 m

• Geared motor, pinion left, max. 180 kg door weight

• Without cable*

• Geared motor, pinion right, max. 180 kg door weight

• Without cable*

• Geared motor, pinion left, max. 180 kg door weight

• Cable length 1.5 m

• Geared motor, pinion right, max. 180 kg door weight

• Cable length 1.5 m

• Electronically commutated geared motor, pinion left, max.

250 kg door weight

• Cable length 1.5 m

• Electronically commutated geared motor, pinion right,

max. 250 kg door weight

• Cable length 1.5 m

AT40, ATD400V, ATD400K, ATD4xxW, ATD400S, ATE250S, ATD400T

System Manual, 06/2016, A2B00096162-AN

21

Product family

Geared motor

Article No.

Description

3.1 Products

SIDOOR M4 L 6FB1103-0AT10-3MC0

SIDOOR M4 R 6FB1103-0AT11-3MC0

SIDOOR MDG400 L 6FB1103-0AT14-3MC0

SIDOOR MDG400 R 6FB1103-0AT13-3MC0

SIDOOR M5 L 6FB1103-0AT10-3MD0

SIDOOR M5 R 6FB1103-0AT11-3MD0

SIDOOR MDG400 NMS L 6FB1103-0AT14-3MC1

SIDOOR MDG400 NMS R 6FB1103-0AT13-3MC1

* Cable can be ordered: See Section Accessories (Page 23)

• Geared motor, pinion left, max. 400 kg door weight

• Cable length 1.5 m

• Geared motor, pinion right, max. 400 kg door weight

• Cable length 1.5 m

• Geared motor, pinion left, max. 400 kg door weight

• Without cable*

• Geared motor, pinion right, max. 400 kg door weight

• Without cable*

• Geared motor, pinion left, max. 600 kg door weight

• Cable length 1.5 m

• Geared motor, pinon right, max. 600 kg door weight

• Cable length 1.5 m

• Geared motor, without pinion, max. 400 kg door weight

• Without cable*

• Geared motor, without pinion, max. 400 kg door weight

• Without cable*

AT40, ATD400V, ATD400K, ATD4xxW, ATD400S, ATE250S, ATD400T

22 System Manual, 06/2016, A2B00096162-AN

Product family

3.1.3

Accessories

Accessories

Article No.

Description

motor is mounted

SIDOOR deflector pulley

6FB1104-0AT04-0AS0

Deflector pulley for deflecting the SIDOOR toothed belt

3.1 Products

SIDOOR rubber-metal antivibration mount

SIDOOR mounting bracket 6FB1104-0AT01-0AS0 Mounting bracket for mounting the SIDOOR rubber-metal

SIDOOR deflector unit 6FB1104-0AT03-0AS0

SIDOOR door clutch holder 6FB1104-0AT01-0CP0

SIDOOR toothed belt 6FB1104-0AT01-0AB0

6FB1104-0AT01-0AD0

6FB1104-0AT02-0AD0

6FB1104-0AT02-0AS0

6FB1104-0AT02-0CP0

6FB1104-0AT02-0AB0

6FB1104-0AT03-0AB0

6FB1104-0AT04-0AB0

• Rubber-metal anti-vibration mount for quiet operation of

the door drive system

• Recommended for mounting SIDOOR M4 R / L, MDG400

R / L, M5 R / L and MDG400 NMS R / L geared motors

• Rubber-metal anti-vibration mount for quiet operation of

the door drive system

• Recommended for mounting SIDOOR M2 R / L, M3 R / L,

MDG180 R / L, MDG180 R / L DIN EN 45545-2 and

MEG250 R / L geared motors

anti-vibration mount on which, in turn, a SIDOOR geared

• Mounting bracket with tensioning device for deflector

pulley

• For mounting the SIDOOR deflector unit and for tension-

ing the SIDOOR toothed belt

• Deflector unit with deflector pulley

• For deflecting the SIDOOR toothed belt in the same

height and depth, aligned with motor drive pinion

• Door clutch holder for 12 mm-wide toothed belt

• For attaching both ends of the toothed belt, and for con-

necting the respective door panel to the toothed belt

• Door clutch holder for 14 mm wide toothed belt

• For attaching both ends of the toothed belt, and for con-

necting the respective door panel to the toothed belt

• Single-toothed STS

• Super Torque toothed belt

• Length 4 m, width 12 mm.

• Single-toothed STS

• Super Torque toothed belt

• Length 45 m, width 12 mm.

• Single-toothed STS

• Super Torque toothed belt

• Length 4 m, width 14 mm.

• Single-toothed STS

• Super Torque toothed belt

• Length 55 m, width 14 mm.

AT40, ATD400V, ATD400K, ATD4xxW, ATD400S, ATE250S, ATD400T

System Manual, 06/2016, A2B00096162-AN

23

Product family

Accessories

Article No.

Description

3.1 Products

SIDOOR

CABLE-RS485-MM-2m

SIDOOR

CABLE-RS485-MM-5m

SIDOOR

CABLE-RS485-MM-10m

SIDOOR CABLE AT-EB USB 6FB1124-0BM03-0CB0

SIDOOR CABLE-MDG-0.5m 6FB1104-0AT00-0CB5

SIDOOR CABLE-MDG-1.5m 6FB1104-0AT01-0CB5

SIDOOR CABLE-MDG-5m 6FB1104-0AT05-0CB0

SIDOOR CABLE-MDG-7m 6FB1104-0AT07-0CB0

SIDOOR CABLE-MDG-10m 6FB1104-0AT10-0CB0

SIDOOR CABLE-MDG-15m 6FB1104-0AT15-0CB0

6FB1124-0BM00-0CB0

6FB1124-0BM01-0CB0

6FB1124-0BM02-0CB0

• Cable from the SIDOOR AT-EB expansion unit to the

SIDOOR ATD400S

(Can also be used to connect the SIDOOR AT-EB expansion unit to the SIDOOR ATE250S)

• Cable length 2 m

• Cable from the SIDOOR AT-EB expansion unit to the

SIDOOR ATD400S

(Can also be used to connect the SIDOOR AT-EB to the

SIDOOR ATE250S)

• Cable length 5 m

• Cable from the SIDOOR AT-EB expansion unit to the

SIDOOR ATD400S

(Can also be used to connect the SIDOOR AT-EB expansion unit to the SIDOOR ATE250S)

• Cable length 10 m

• Programming cable to connect the USB adapter of the

SIDOOR Software Kit to the AT-EB

• Cable length 2 m

• Cable for connecting SIDOOR MDG180 R / L, MDG400 R

/ L / MDG400 NMS geared motors to SIDOOR ATD4xxW

controllers

• Cable length 0.5 m

• Cable for connecting SIDOOR MDG180 R / L, MDG400 R

/ L / MDG400 NMS geared motors to SIDOOR ATD4xxW

controllers

• Cable length 1.5 m

• Cable for connecting SIDOOR MDG180 R / L, MDG400 R

/ L / MDG400 NMS geared motors to SIDOOR ATD4xxW

controllers

• Cable length 5 m

• Cable for connecting SIDOOR MDG180 R / L, MDG400 R

/ L / MDG400 NMS geared motors to SIDOOR ATD4xxW

controllers

• Cable length 7 m

• Cable for connecting SIDOOR MDG180 R / L, MDG400 R

/ L / MDG400 NMS geared motors to SIDOOR ATD4xxW

controllers

• Cable length 10 m

• Cable for connecting SIDOOR MDG180 R / L, MDG400 R

/ L / MDG400 NMS geared motors to SIDOOR ATD4xxW

controllers

• Cable length 15 m

AT40, ATD400V, ATD400K, ATD4xxW, ATD400S, ATE250S, ATD400T

24 System Manual, 06/2016, A2B00096162-AN

Product family

Accessories

Article No.

Description

controller

cable

higher-level SIMATIC controller

controllers

3.1 Products

SIDOOR CABLE-MDG-20m 6FB1104-0AT20-0CB0

PROFIBUS FC bus connector

RS 485

PROFIBUS FC Standard Cable

GP

IE FC RJ45 plug 180 4X2 6GK1901-1BB11-2AB0 Plug connector with axial cable outlet (180°) for connecting

IE FC TP Standard Cable GP 6XV1878-2A Cable for connecting the SIDOOR ATD430W controller to the

DIN rail holder 6FB1144-0AT00-3AS0 DIN rail holder with fixing screws for SIDOOR ATD4xxW

6GK1500-0FC10 Bus connector with axial cable outlet (180°, 20m) for connect-

6XV1830-0EH10 PROFIBUS cable for connecting SIDOOR ATD410W and

• Cable for connecting SIDOOR MDG180 R / L, MDG400 R

/ L / MDG400 NMS geared motors to SIDOOR ATD4xxW

controllers

• Cable length 20 m

ing SIDOOR ATD410W and SIDOOR ATD420W controllers

to the USS / PROFIBUS bus cable

SIDOOR ATD420W controllers to the higher-level SIMATIC

the SIDOOR ATD430W controller to the PROFINET bus

You will find more accessories in the Industry Mall (http://www.siemens.com/siplus/mall)

AT40, ATD400V, ATD400K, ATD4xxW, ATD400S, ATE250S, ATD400T

System Manual, 06/2016, A2B00096162-AN

25

Product family

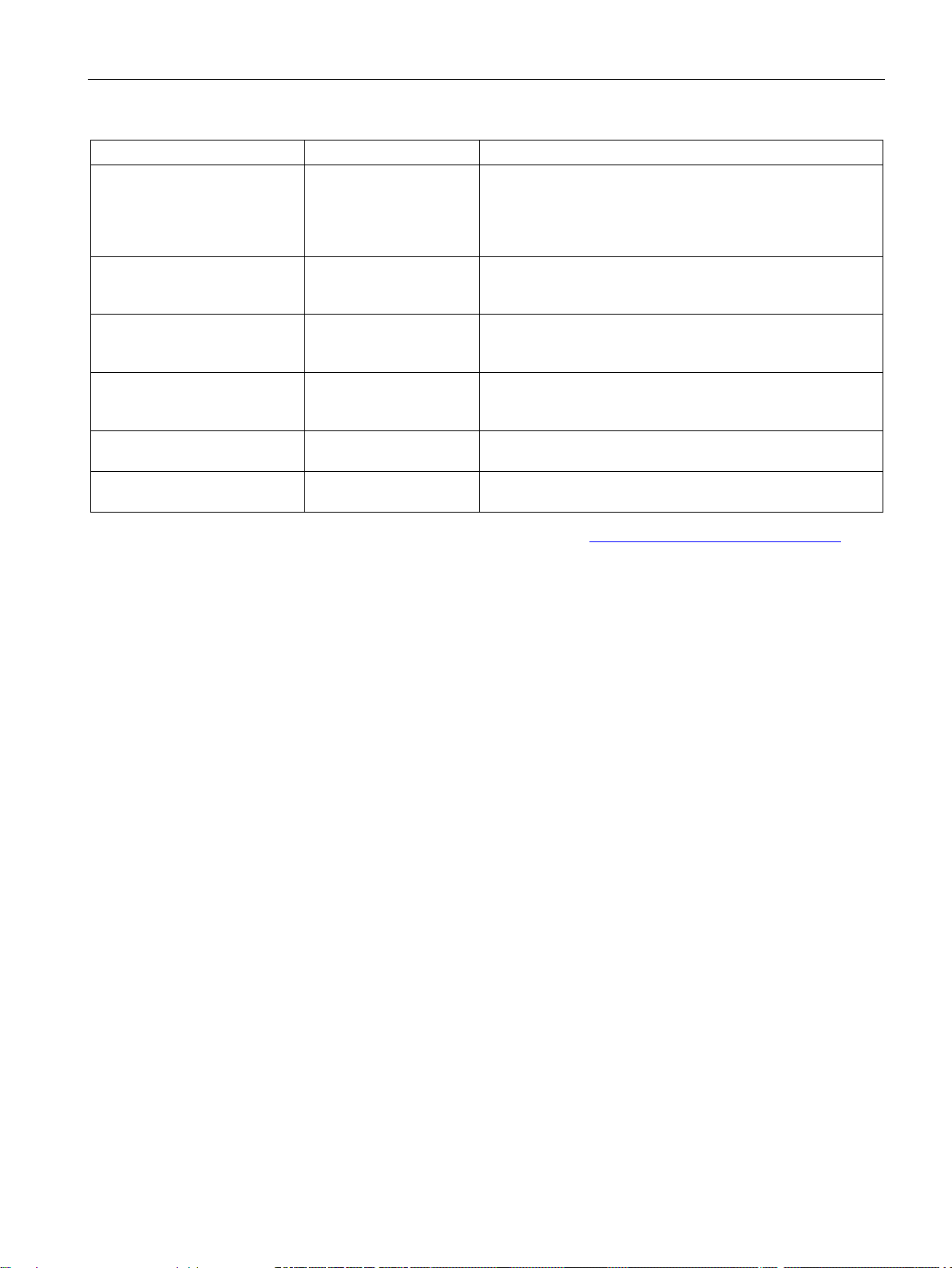

3.1.4

Power supply

Device selection

Power supply

Article No.

Description

SIDOOR NT40

6FB1112-0AT20-3PS0

SIDOOR Transformer

6FB1112-0AT20-2TR0

DC voltage supply (Page 276)

-

3.1 Products

SIDOOR power supplies connect the controllers to the respective application-specific power

supply.

Power supply for controllers without an integrated power

supply unit.

AT40, ATD400V, ATD400K, ATD4xxW, ATD400S, ATE250S, ATD400T

26 System Manual, 06/2016, A2B00096162-AN

Product family

3.1.5

Optional additional units

Selection of additional units

Additional unit

Article No.

Description

2.

control systems via the proprietary RS 485 interface.

data and the current firmware version.

3.1 Products

Additional units meet a range of customer requirements in order to ensure the universal

implementation and maintenance of the system.

The additional units are easy to connect to a deenergized controller via the interfaces

provided – and are available for use as soon as the power supply is connected.

SIDOOR EMC FILTER 6FB1104-0AT20-0AT0 A line filter must be installed in the DC power supply to the

SIDOOR ATD400T RELAY controller to comply with the EMC

requirements for emitted interference set out in EN 50121-3-

SIDOOR AT-EB expansion unit

(with FW1.10)

SIDOOR Service Tool 6FB1105-0AT01-6ST0 The SIDOOR Service Tool may be used to input door com-

6FB1135-2BM10-0CP0 The SIDOOR AT-EB expansion unit enables SIDOOR con-

trollers to be connected via a PROFIBUS DP interface, and

makes additional input and output signals available.

The SIDOOR AT-EB expansion unit controls up to two door

mands, to change drive parameters and to read the learnt

parameters, door states, input and output signals, service

AT40, ATD400V, ATD400K, ATD4xxW, ATD400S, ATE250S, ATD400T

System Manual, 06/2016, A2B00096162-AN

27

Product family

3.1.6

Software

Selection

Software

Article No.

Description

3.1 Products

The optional SIDOOR Software Kit facilitates user-friendly operation and detailed diagnostics

via a PC.

SIDOOR Software Kit 6FB1105-0AT01-6SW0 The package includes the following components:

• Installation CD (Software Kit)

– Sidoor User Software

– Siemens HCS12 Firmware Loader

– Sidoor USB to UART Bridge driver

– License provisions

– SIDOOR Software Kit Operating Instructions

• 1 x USB adapter

• 1 x USB connecting cable

• 1x D-SUB connecting cable (9-pin, plug/socket)

• 1x D-SUB connecting cable (9-pin, socket/socket)

The contents of the SIDOOR Software Kit installation CD are also available as an Installation

package (http://support.automation.siemens.com/WW/view/en/92418945) from Industry

Online Support.

You can find more information about the SIDOOR Software Kit in the SIDOOR Software Kit

Operating Instructions (http://support.automation.siemens.com/WW/view/en/92711247).

AT40, ATD400V, ATD400K, ATD4xxW, ATD400S, ATE250S, ATD400T

28 System Manual, 06/2016, A2B00096162-AN

4

4.1

Elevators

SIDOOR AT40

SIDOOR ATD400V

SIDOOR door drives are drives for doors and gates in various areas of application. The

controllers are optimally configured for their areas of application.

The following controllers are offered for elevator applications:

●

The comfort SIDOOR AT40 elevator door drive is an "intelligent" door drive with which

cabin and shaft doors can be opened and closed at adjustable speeds and accelerations.

●

The SIDOOR ATD400V hoisting and rolling shutter drive for elevators is an "intelligent"

door drive for the operation of vertical door systems on elevators.

AT40, ATD400V, ATD400K, ATD4xxW, ATD400S, ATE250S, ATD400T

System Manual, 06/2016, A2B00096162-AN

29

Areas of application

4.2

Industrial applications

Industrial applications

SIDOOR ATD400K

SIDOOR ATD4xxW

SIDOOR ATD401W

SIDOOR ATD410W

USS bus

SIDOOR ATD420W

PROFIBUS DP

SIDOOR ATD430W

PROFINET IO

4.2 Industrial applications

We offer the following controllers for industrial applications:

●

The SIDOOR ATD400K RELAY LB and SIDOOR ATD400K RELAY RC industrial door

drives offer the optimal drive solutions for cold room gates weighing up to 400 kg. The

ATD400K RELAY LB model enables the connection of light barriers with "LB" logic, and

the ATD400K RELAY RC model enables the direct connection of a cord-operated switch

to open the gate.

Both drives meet the requirements of EN ISO 13849-1:2008 with regard to safety of

machinery and EN 12453:2000, section 5.2 with regard to safety in use of power

operated doors.

●

ATD4xxW machine tool door drives are "intelligent" door drives that can be used to

operate protective doors on machine tools. The safe functions - force limitation, energy

limitation and end position detection - fulfill the requirements according to

DIN EN ISO 13849-1:2008 for Category 2 and Performance Level d. The drives are

suitable for power-operated guards according to EN 953:1997+A1:2009 Section 5.2.5.2

"Actuating forces".

The SIDOOR ATD4xxW door controller enables connection to diverse fieldbus systems.

This makes integration into the industrial//Simatic environment possible. PROFINET IO,

PROFIBUS DP and USS are currently specified as fieldbuses. The PROFIBUS "variablespeed drives" profile is generally used as the higher-level device profile.

–

The "offline" relay variant can be used for simple automation tasks. As there is no

possibility of interfacing to a bus, it provides a limited scope of functions.

–

The controller is interfaced to a

You can find more detailed information about the USS protocol online at Industry

Online Support (http://support.automation.siemens.com/WW/view/de/24178253/0/en).

–

The

(AT-PB). This is an intelligent module that comes with its own firmware.

interface is realized by means of a modular PROFIBUS module

by means of a modular USS module.

–

The

(AT-PN). This is an intelligent module that comes with its own firmware.

AT40, ATD400V, ATD400K, ATD4xxW, ATD400S, ATE250S, ATD400T

30 System Manual, 06/2016, A2B00096162-AN

interface is realized by means of a modular PROFINET module

Loading...

Loading...