Siemens SIDOOR AT12 User Manual

Answers for industry.

Products for specific requirements

SIDOOR

Elevator door drive AT12

Manual · 02/2012

Elevator door drive AT12

_

_________________

_

_

_________________

_

_

_________________

_

_

__________________

_

_________________

_

_

_________________

_

_

_________________

_

_

_________________

_

_

_________________

_

_

_________________

_

_

_________________

_

_

_________________

_

_

__________________

Introduction

1

Safety notes

2

Definitions

3

Products for specific requirements

Overview of controls

4

SIDOOR

Functions and device

responses

5

Mechanical installation and

setting

6

Elevator door drive AT12

Manual

Electric adjustment and

commissioning

7

The relay contacts

8

CAN

9

Travel curve

10

11

Operating status display

12

Technical data

Appendix

A

02/2012

A2B00086683A-04

Legal information

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the relevant information is not taken into account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG A2B00086683A-04 Copyright © Siemens AG 2012.

Industry Sector Ⓟ 02/2012 Technical data subject to change All rights reserved

Postfach 48 48

90026 NÜRNBERG

GERMANY

Table of contents

1 Introduction................................................................................................................................................ 7

2 Saf

ety notes............................................................................................................................................... 9

2.1 General safety inst

ructions ............................................................................................................9

3 Definit

ions................................................................................................................................................ 11

4 Overvie

w of controls ................................................................................................................................ 13

5 Function

s and device responses ............................................................................................................. 15

5.1 Learn and test run........................................................................................................

................15

5.2 DOOR OPEN command .........................................................................................................

.....15

5.3 DOOR CLOSE command

............................................................................................................15

5.4 Learn run button..........................................................................................................

.................16

5.5 Parameter settings.......................................................................................................................16

5.6

Blockage detection "CLOSE"................................................................................................

.......17

5.7 Blockage detection "OPEN".........................................................................................................17

5.8

Nudge...........................................................................................................................................17

5.9

Restart after

power failure............................................................................................................17

5.10 Closi

ng force ................................................................................................................................18

5.11 Emergency release

......................................................................................................................18

5.12 Ove

rload protection......................................................................................................................19

6 Mechanical i

nstallation and setting .......................................................................................................... 21

7 Electric adjustment and c

ommissioning................................................................................................... 23

8 The relay con

tacts ................................................................................................................................... 27

9 CAN..........................................................

............................................................................................... 29

10 Travel

curve............................................................................................................................................. 31

11 Operating stat

us display .......................................................................................................................... 33

11.1 Speed limit curve ........................................................................................................

.................34

12 Technical

data ......................................................................................................................................... 35

12.1 DC geared motor ..........................................................................................................

...............35

12.2 Control unit...................................................................................................................................35

12.3

Regulations and s

tandards ..........................................................................................................35

Elevator door drive AT12

Manual, 02/2012, A2B00086683A-04

5

Table of contents

Elevator door drive AT12

6 Manual, 02/2012, A2B00086683A-04

A Appendix.................................................................................................................................................. 37

A.1 Order nos. of the individual parts................................................................................................ 37

A.2 Dimension drawing of AT12 controller

........................................................................................ 38

A.3 24 V geared motor with r

ubber-metal anti-vibration mount and mounting bracket..................... 39

A.4 Deflector pull

ey with tensioning device and mounting bracket ................................................... 40

A.5 Door clutc

h holder....................................................................................................................... 41

A.6 Asse

mbly suggestion .................................................................................................................. 42

A.7 Terminal circuit diagram of c

ontrol inputs ................................................................................... 43

A.8 Diagnostics

and parameterization............................................................................................... 44

A.9 Settings record

............................................................................................................................ 45

Introduction

1

The comfort elevator door drive AT12 is an "intelligent" door drive with which the cabin and

shaft doors can be opened and closed at adjustable speeds and accelerations. This

maintenance-free drive unit consists of a speed-controlled DC motor with non-self-locking

gearing. The power is transmitted by a toothed belt. The toothed belt passes over a deflector

pulley, and can be fitted with two clutch holders. This enables it to drive both single-sided

and centrally-opening doors.

The AT12 is currently supplied with the following motor:

– 24 V / 1.8 A motor, suitable for a maximum total door panel weight of 120 kg

The door drive can be ordered with the drive pinion either on the left or right-hand side,

please see the drawing in the Appendix.

Operation of the door drive does not require limit switches.

The door width and the

"OPEN"

and

"CLOSED"

positions are determined automatically.

An LED display on the controller indicates the current operating states.

The Appendix includes all the important dimension drawings, an assembly suggestion, and

the identification numbers for ordering the individual drive components.

Note

For reasons of clarit

y, these operating instructions do not contain complete, detailed

information about all product types. Similarly, they cannot cover every conceivable type of

installation, operation or maintenance.

Additional information about this product and its application can be found in the Internet

(www.siemens.com/sidoor

).

Furthermore, the contents of these Operating Instructions shall not become a part of or

modify any prior or existing agreement, commitment, or legal relationship. The sales contract

contains the entire obligation of SIEMENS. The warranty contained in the contract between

the parties is the sole warranty of SIEMENS. Any statements contained in these operating

instructions neither expand nor restrict the scope of these contractual warranty conditions.

Elevator door drive AT12

Manual, 02/2012, A2B00086683A-04

7

Introduction

Elevator door drive AT12

8 Manual, 02/2012, A2B00086683A-04

Safety notes

2

Before commissioning

Please read through these instructions carefully. They contain essential information for the

installation, use and safety of the equipment.

2.1 General safety instructions

WARNING

Only appropriately qualified personnel should work on or in the vicinity of this equipment.

Personnel must be thoroughly familiar with all the warnings, notices, and functions of the

AT12 door controller described in the operating instructions.

In the context of the operating instructions and warning notices, a

qualified person

is a

person who is familiar with assembling, installing, commissioning, and operating the product,

and who has the relevant qualifications, such as:

● Training, instruction or authorization to commission electric circuits and devices/systems

in compliance with safety engineering standards.

● Training or instruction in the maintenance and use of appropriate safety equipment in

compliance with safety engineering standards.

● Training in first aid measures

The successful and safe operation of this equipment is dependent on proper transportation,

storage, installation, and assembly, as well as on careful operation and maintenance.

Before commissioning, all electrical connections must be inspected to ensure that all

contacts are secure.

Before starting work on the door drive, it must be disconnected from the power supply by

unplugging the power plug.

Elevator door drive AT12

Manual, 02/2012, A2B00086683A-04

9

Safety notes

2.1 General safety instructions

Elevator door drive AT12

10 Manual, 02/2012, A2B00086683A-04

3

Definitions

Initial speed

Reduced speed in the opening and closing directions after power on until normal operation is

detected.

Creep speed

Reduced speed in the vicinity of the OPEN position of the elevator door (creep distance).

Cutter speed

Reduced speed in the vicinity of the CLOSED position of the elevator door (cutter distance).

Creep distance

Range of door travel in the vicinity of the OPEN position.

Cutter distance

Range of door travel in the vicinity of the CLOSED position.

Elevator door drive AT12

Manual, 02/2012, A2B00086683A-04

11

Definitions

Elevator door drive AT12

12 Manual, 02/2012, A2B00086683A-04

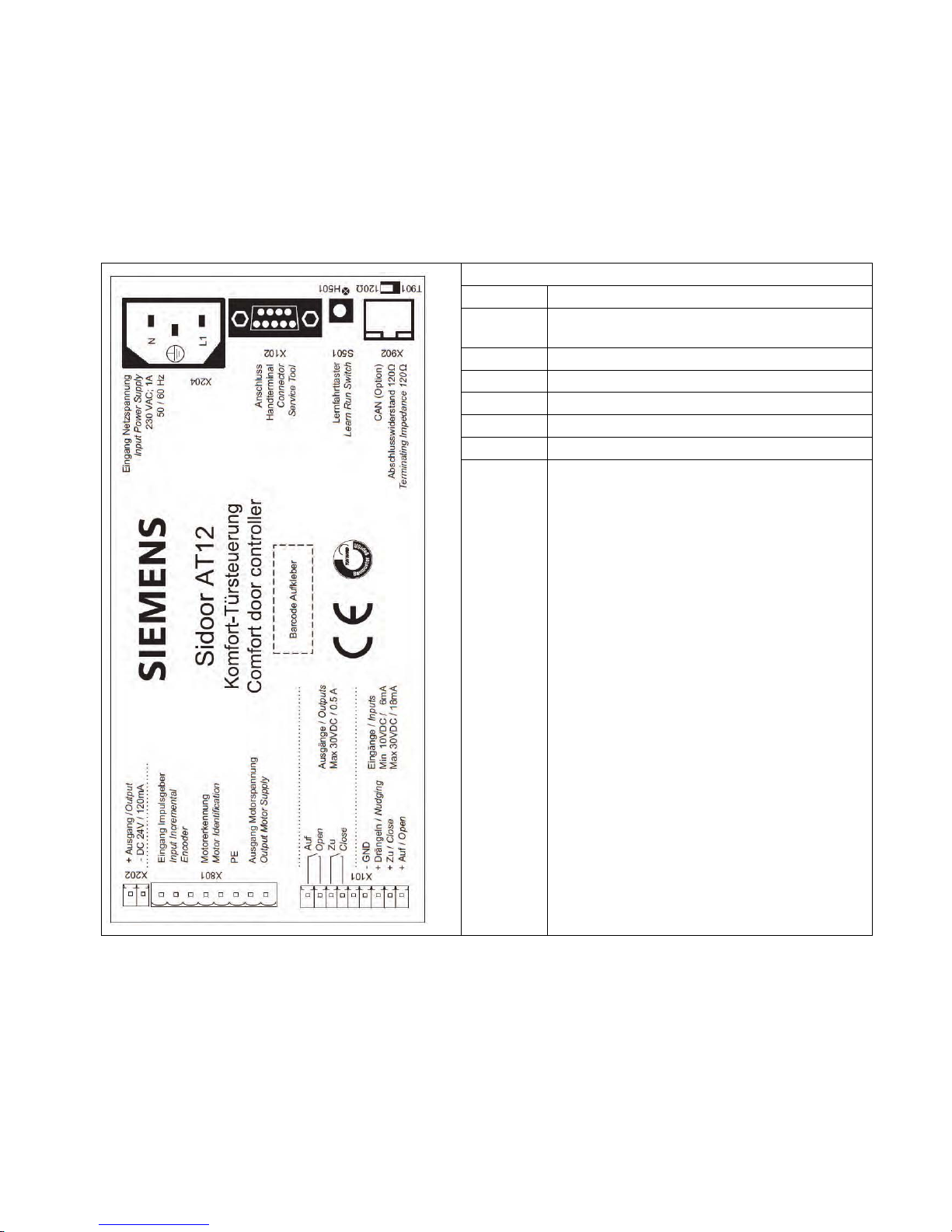

4

Overview of controls

Sidoor AT12:

X204: Mains connection 230 V (1 A, 50 / 60 Hz)

X102: Connector for Service Tool and USB adapter

(Software Kit)

S501: Learn run button

X902: CAN connector (CAN OPEN RJ45)

T901: Switchable CAN terminating resistor 120 ohms

X202: Voltage output 24 VDC / 120 mA

X801: Motor plug

X101: Connector for output signals

• Open

• Closed

Connector for input signals:

• Nudge

• Close

• Open

Elevator door drive AT12

Manual, 02/2012, A2B00086683A-04

13

Overview of controls

Elevator door drive AT12

14 Manual, 02/2012, A2B00086683A-04

5

Functions and device responses

5.1 Learn and test run

Pressing the learn run button for more than five seconds

(S501)

executes the automatic

determination of the parameters:

1. Detection of the direction of door movement and the

"CLOSED"

position

2. Determination of the friction values of the door system and the weight of the door.

3. Determination of the door width and the

"OPEN"

position. Closure of the door until it has

traveled through the entire determined door width and reached the

"CLOSED"

position.

These parameters are then saved, which takes three seconds.

5.2 DOOR OPEN command

The

DOOR OPEN

command opens the door according to the set speed of travel curve as

long as the command is present.

The transitions along the speed of travel curve (e.g. from acceleration to constant velocity)

are smoothed to prevent noises possibly arising from the play between the cabin and shaft

doors. The door reaches the

"OPEN"

position at creep speed. Then, if the

DOOR OPEN

command is present, the door is held open with a reduced torque.

● The

DOOR OPEN

command must remain present throughout the entire opening

movement.

● The

DOOR OPEN

command must remain present continuously in order to maintain

continuous torque in the

OPEN

position.

The

DOOR OPEN

command has priority over all other control commands.

5.3 DOOR CLOSE command

The

DOOR CLOSE

command must remain present continuously in order to close the door.

After the door has closed, it is held in this position with reduced torque as long as the

DOOR

CLOSE

command remains present.

Elevator door drive AT12

Manual, 02/2012, A2B00086683A-04

15

Loading...

Loading...