Siemens SICAM TM Installation Manual

SICAM TM

________________________________

________________________________

___________

Preface, Table of Contents

___________________________________________________________________________

Architecture 1

___________________________________________________________________________

Components 2

___________________________________________________________________________

Installation

Assembly 3

___________________________________________________________________________

Wiring Communi cation

___________________________________________________________________________

Wiring for the Reception of Time Signals

___________________________________________________________________________

4

5

Wiring Watchdog and Error 6

___________________________________________________________________________

Power Supply 7

___________________________________________________________________________

Wiring Peripheral Elements 8

___________________________________________________________________________

Wiring Process Peripherals 9

___________________________________________________________________________

Shielding / Protective Earthing 10

___________________________________________________________________________

DC6-015-2.04

Labelling 11

___________________________________________________________________________

Parameter Setting Preparation 12

___________________________________________________________________________

Recommended and tested purchased

products

___________________________________________________________________________

A

Licensing Agreement B

___________________________________________________________________________

Literature

___________________________________________________________________________

Hint

Disclaimer of Liability

for conformity with the hardware and software described, we cannot

included in the next releases. Any suggestions for improvement are

welcome.

Copyright

Please observe Notes and Warnings for your own safety in the Preface.

Although we have carefully checked the contents of this publication

guarantee complete conformity since errors cannot be excluded.

The information provided in this manual is checked at regular

intervals and any corrections that might become necessary are

Subject to change without prior notice

Document Label:

SICRTUs-HBTMACPINSTALL-ENG-V2.04

Release date:

2014.10.17

Copyright © Siemens AG 2014

The reproduction, transmission or use of this document or its

contents is not permitted without express written authority.

Offenders will be liable for damages. All rights, including rights

created by patent grant or registration of a utility model or design,

are reserved.

Siemens AG Bestell nr. : D C6-015-2 .0 4

Preface

This document is applicable to the following product:

· SICAM TM

Purpose of this manual

This handbook describes how the hardware of a SICAM TM system is to be installed and

which preparations ar e to be made for th e subsequent parameter settings.

Thereby the following points are described step-by-step:

· Conception of the architecture

· Installation of the hardware

· Label

· Wiring

· Parameter Setting Preparation

Target Group

This handbook is intended for persons who are entrusted with the design and installation of

SICAM TM systems.

Conventions used

· Outputs visible on the screen are descri bed in thi s font.

· Inputs via keyboard or mouse keys and visible on the screen are also de sc ri be d in

this font .

· Cro ss ref eren ces to ot her cha pter s or manual s are rep res ent ed in ita lics , suc h as e.g.

Common Functions System and Basic System Elements, section "Information Objects".

SICAM TM, Installation 3

DC6-015-2.04, Edition 10.2014

Notes on Safety

This manual does not constitute a complete catalog of all safety measures required for

operating the equipment (module, device) in question because special operating conditions

might require additional measures. However, it does contain notes that must be adhered to for

your own personal safety and to avoid damage to property. These notes are highlighted with a

warning triangle and different keywords indicating different degrees of danger.

Danger

means that death, serious bodily injury or c onsiderable prop er ty damage will occur, if the appropriate

precaut ionary meas ures are n ot carried out.

Warning

means that death, serious bodily injury or c onsiderable prop er ty damage can occur, if the appropriate

precaut ionary meas ures are n ot carried out.

Caution

means that minor bodily injury or property damage c ould occur, if the ap propriate precautionary measures

are not c arr ied out.

Hint

is import ant information about t he product, the handli ng of the product or the respective part of the

documentation, to which special attention is to be given.

Qualified Personnel

Commis sioning and operat ion of the equipment (module, device) describ ed i n t his manual must be

perfor med by qu alified personnel only. As used in the safety notes contained in this manual, qualified

personn el are thos e p ersons wh o are authorized to commission, release, ground, and tag d evices,

systems, and el ectrical circuits in accordance with s afety standards.

Use as Pres cr ib ed

The equipment (device, module) must not be used for any other purposes than those described in the

Catalog and the T echnical Description. If it is used together with third-party devices and components ,

these mus t b e r ec ommend ed or approved b y Siemens.

Correct and saf e operation of the product r equires adequat e transportation, storage, installation, and

mounti ng as well as appropriate use and m aintenance.

During op eration of electrical equipm ent, it is unavoidable that certain parts of this equip ment will c arry

dangerous volt ages. Sever e injury or damage to property can occur if the appropriat e measures are not

taken:

· B efore making any conn ections at all, ground the equipment at the PE terminal.

· Hazardous volt ages can be present on all switching componen ts connected to the power suppl y.

· Even after the supply voltage has been disconnec ted, hazard ous voltag es can still be present in the

equipment (capacitor storage).

· Equipment with current transf ormer circuits must not be op erated while open.

· The limit values indicated in the manual or the operating instructions must not be exceeded; that also

applies to testing and commissioning.

4 SICAM TM, Installation

Edition 10.2014, DC6-01 5-2.04

Table of Contents

1. Architecture ................................................................................................................... 9

1.1. Mechan ical Design ......................................................................................... 10

1.2. Configu rations (Examples ).............................................................................. 11

1.2.1. 2 Periphera l E le men ts SIC AM TM, electr ically conne ct e d ......................... 11

1.2.2. 16 Periphe ral Elemen ts S IC AM TM, electrically con n e cted ....................... 12

1.2.3. 16 Periphe ra l Ele men ts SIC AM T M, optically conne cte d ........................... 13

1.2.4. 16 Peripheral Elements SICAM TM, electrically and optically connected ... 14

2. Components ................................................................................................................ 15

2.1. Maste r Contro l Modules .................................................................................. 16

2.2. Serial Interface Modules ................................................................................. 17

2.2.1. Serial Interface Proce sso r (SIP) ................................................................. 17

2.2.2. Netw ork Interface Proce sso r (NIP) ............................................................. 17

2.2.3. Field Bus Inter face Proce s s or (FIP) ........................................................... 18

2.3. Bus Interface Module ...................................................................................... 19

2.4. Powe r Supplies .............................................................................................. 19

2.5. Periphe ral Modules ......................................................................................... 20

3. Assembly ..................................................................................................................... 25

3.1. Necess ary Material ......................................................................................... 26

3.2. How an d wh e re ca n Installation ta ke place? ................................................... 27

3.2.1. Installat ion Location ................................................................................... 27

3.2.2. Installat ion Position .................................................................................... 27

3.2.3. Space Requirement ................................................................................... 28

3.2.4. Environ mental Condition s .......................................................................... 29

3.3. Installat ion of TS35 Rail (DIN Rail) .................................................................. 30

3.4. Installat ion of Cable Duct ................................................................................ 31

3.5. Installat ion o f Mas ter Con tro l Ele ment ............................................................. 32

3.5.1. Remova l/Sh ifting of the Master Contro l Ele ment ........................................ 3 3

3.5.2. Securing Mas ter Contro l Ele ment agains t Slipp ing ..................................... 34

3.6. Installat ion o f Bus Inte r fa ce Mod ules .............................................................. 35

3.6.1. Optical Ax Bus ........................................................................................... 3 5

3.6.1.1. Removin g/Sh ifting the Op tica l Bus Inter face Modu le ............................. 36

3.6.2. Electrica l Ax Bus ....................................................................................... 3 6

3.7. Installing TM Modules ..................................................................................... 37

3.7.1. Design an d Ele men ts o f a Module ............................................................. 37

3.7.2. Handling .................................................................................................... 38

3.7.3. Connection ................................................................................................ 39

3.7.4. Order ......................................................................................................... 40

SICAM TM, Installation 5

DC6-015-2.04, Edition 10.2014

Table of Contents

4. Wiring Communic ation ............................................................................................... 4 1

4.1. Introdu ction .................................................................................................... 42

4.2. Configuring Master Control Element with Serial Interface Modules (SIM) ........ 43

4.2.1. Opening the Hous ing ................................................................................. 4 4

4.2.2. Removin g/F itt ing the SIM Retaine r ............................................................ 45

4.2.3. Installing Pat ch Plugs and SIMs ................................................................. 4 6

4.2.4. Fixing the SIMs.......................................................................................... 47

4.2.5. Configu ration Notes ................................................................................... 4 9

4.3. Wiring Commu nica tion ................................................................................... 5 0

4.3.1. Serial Commun icat ion ............................................................................... 5 1

4.3.1.1. Point-to-Point Traffic / Multi-Point Traffic via Dedicated Line Modem and

WT Chann el Modem ............................................................................. 5 1

4.3.1.2. Multi-Po int Tra ffic via Glas s Fibre Optic and Star Conn ectio n ................ 52

4.3.1.3. Analog Dial-up Traffic ........................................................................... 5 3

4.3.1.3.1. Wester mo TD36 Modem with externa l Pow er Supp ly ....................... 54

4.3.1.4. Dial-up tra ffic analog /GSM /ISD N .......................................................... 55

4.3.1.5. GSM Dial-up Traffic .............................................................................. 56

4.3.2. LAN Communica tion (Ethern et TCP/IP) ..................................................... 5 8

4.3.3. Field Bus/Pro fi Bus Communication ........................................................... 5 9

5. Wiring for the Re c epti on of Tim e S igna ls .................................................................. 61

5.1. DCF77 Recei ver ............................................................................................. 62

5.2. GPS Satellite Receiver ................................................................................... 63

5.2.1. Wiring for the rece ip t of the minute p uls e ................................................... 63

5.2.2. Wiring for the rece ip t of the seria l time sign al ............................................. 64

5.3. LAN Time Server ............................................................................................ 65

6. Wiring Watchd og and Error ........................................................................................ 67

6.1. Introdu ction .................................................................................................... 68

7. Power Supply .............................................................................................................. 69

7.1. Introdu ction .................................................................................................... 70

7.2. Powe r Sup ply Mas te r Con trol E le men t ............................................................ 70

7.3. Power Supply Peripheral Element (Power Supply Module PS-663x) ............... 71

7.4. Powe r Supply Bus Interface Module (CM-08 42) .............................................. 72

7.5. Fuse Protection .............................................................................................. 73

7.6. Primary Ma ins U n it / Stand ard Type ............................................................... 7 3

8. Wiring Peripher al Elements ........................................................................................ 7 5

8.1. Introdu ction .................................................................................................... 76

8.2. Master Control El em ent CP-6014 ó Peripheral Control Module PE-6410 ...... 77

8.3. Master Control El em ent CP-6014 ó Bus Interface Mod ule CM-084 x ............. 78

8.4. Bus Interface Module CM-0843 ó Peripheral Control Module PE-6410 ......... 79

6 SICAM TM, Installation

Edition 10.2014, DC6-01 5-2.04

Table of Contents

8.5. Bus Interface Module CM-0842 ó Peripheral Control Module PE-6411, PE-

6412 ............................................................................................................... 80

8.6. Bus Interface Module CM-0842 ó Bus Interface Module CM-0843 ................ 8 1

9. Wiring Process Perip herals ........................................................................................ 83

9.1. Wiring Process Peripherals ............................................................................. 84

9.2. Peripheral Connector ...................................................................................... 85

9.3. TE-6450 – Wiring the Data Transmiss ion ........................................................ 8 6

9.4. Wiring of analog measu red values .................................................................. 88

10. Shieldi ng / Protect ive Earthing ................................................................................... 89

10.1. Shielding ........................................................................................................ 90

10.2. Protective Earthing / Grounding ...................................................................... 91

11. Labelling ...................................................................................................................... 93

11.1. Introduction .................................................................................................... 94

11.2. Labeling Master Control Element .................................................................... 95

11.2.1. Equip ment Identi ficat ion, Reg ion Number, Compo nen t Number ...................... 95

11.2.2. Plant- and Location Des igna tion ..................................................................... 96

11.3. Labeling Peripheral Element ........................................................................... 97

11.3.1. Region Number , Compon ent Numbe r, PBA Number ....................................... 9 7

11.3.2. Plant- and Location Des igna tion ..................................................................... 98

11.3.3. Equip ment Identifi cation (EI) ........................................................................... 99

11.4. Terminal Labeling ......................................................................................... 100

11.5. Individual Termina l Point Lab eling ................................................................ 101

11.6. Terminal Coding ........................................................................................... 102

12. Param eter Setting Prepara tion ................................................................................. 103

12.1. Introduction .................................................................................................. 104

12.2. Physical conne ct ion betwe e n SICAM TOOLBOX II and SICAM TM .............. 104

12.2.1. Direct connectio n via toolbox cable ............................................................... 105

12.2.2. Serial via mode m .......................................................................................... 1 06

12.2.3. Via Ethern et (TCP/ IP) ................................................................................... 10 7

12.2.4. Via Etherne t (TCP/IP) an d Termina l Ser ver (se rial) ....................................... 1 08

12.3. Logical Connection between SICAM TOOLBOX II and SICAM TM................ 109

12.4. Flash Card ................................................................................................... 110

12.4.1. Inserting Flas h Card ..................................................................................... 111

12.4.2. Withdra wing Flas h Card ............................................................................... 112

A. Recomm ended and tested purchase d products ...................................................... 113

A.1. Modem ......................................................................................................... 114

A.2. DCF77 Acces sories ...................................................................................... 115

A.3. GPS Satell ite Rece iver / Acce ss o ries............................................................ 116

A.4. LAN Time Server .......................................................................................... 117

SICAM TM, Installation 7

DC6-015-2.04, Edition 10.2014

Table of Contents

A.5. Powe r Supplies ............................................................................................ 117

B. Lice nsing Agreem ent ................................................................................................ 119

B.1. Open Sourc e So ftw a re us ed in SICAM TM ................................................... 119

B.1.1. Reado ut of ReadmOS S.h tm .................................................................... 1 19

8 SICAM TM, Installation

Edition 10.2014, DC6-01 5-2.04

1. Architecture

Content

1.1. Mechan ical Design ......................................................................................... 10

1.2. Configu rations (Examples ).............................................................................. 11

SICAM TM, Installation 9

DC6-015-2.04, Edition 10.2014

Architecture

SICAM

170

3

X1X11X4X12X14X16X15X1

3

WDE

R

X5X3X6X7X8X9X10

SIM

0

/

PK/LK/L

K/P

K

RXERxTX

SI3

SI2

SI1

SI0LO

C

PUSHTOUNLOC

K

ERCOMCPYRYRES

S

I

0SI2(FB

)SI1(ETO)SI

3

REL

EASEPUSHT

ORELEAS

E

USH

T

O

Peripheral control module (elektrical or optical)

Master control element

Bus interface module (electrical)

Bus interface module (optical)

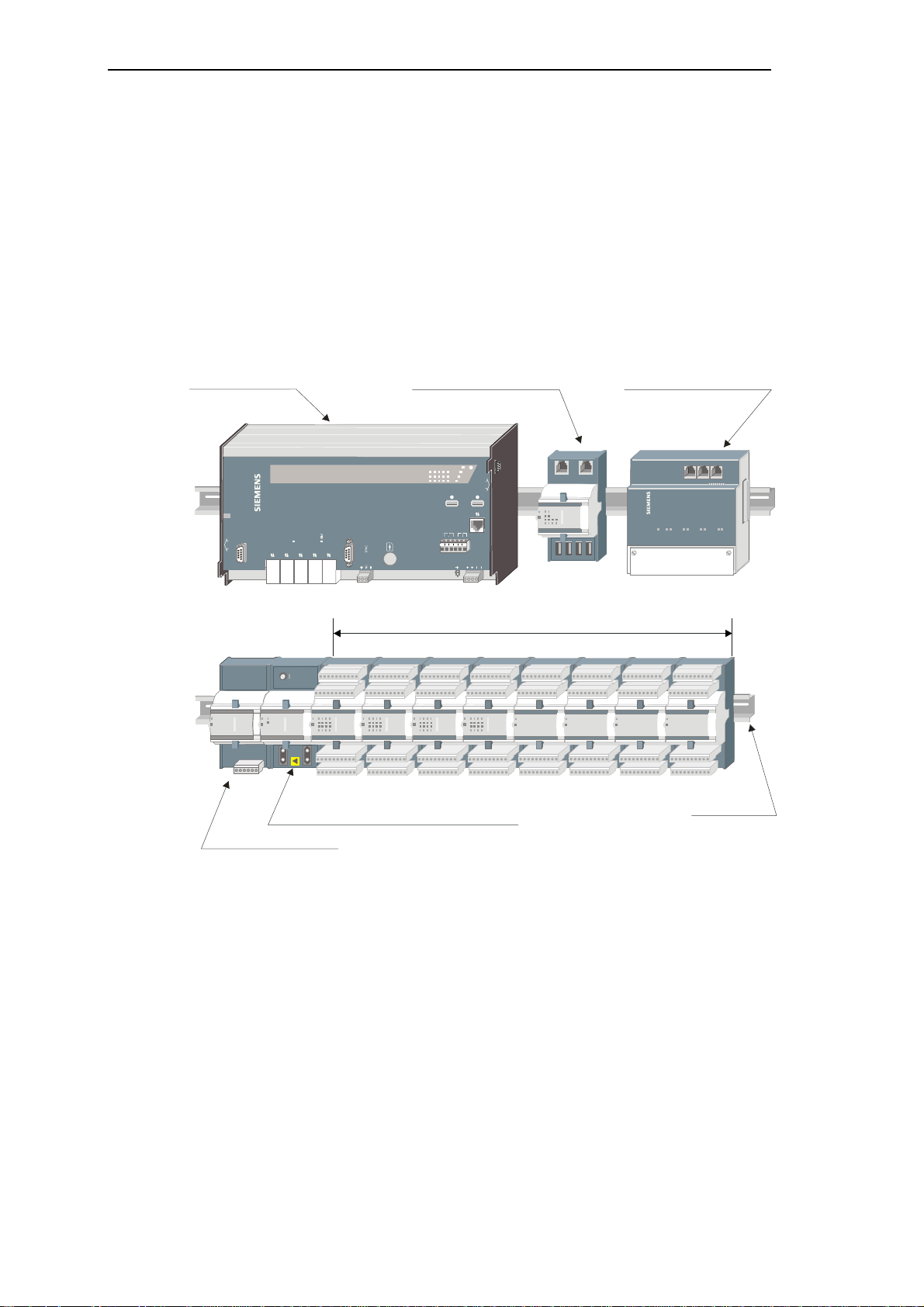

1.1. Mechanical Design

A SICAM TM system consists of one master control element, up to a maximum of 4 bus

interface modules (electrical and/or optical) and up to 16 peripheral elements.

A peripheral element consists of a power supply module, a peripheral control module and up

to a maximum of 8 I/O-modules. The modules are fitted on a TS35 rail (DIN rail).

Optionally the master control element can be configured with up to 2 serial interface modules

(SIM) for the communication with other automation units or control systems.

TM1703 ACP CP-6014

SICAM

TB

P

X2

M-PRE/0

M-PRE/1

NC

FB

M-PRE/2

M-PRE/3

1 2 3 4 5 6

PWR

24-60VDC

Power supply module

Max. 8 I/O-modul es

TS35 rail

10 SICAM TM, Installation

Edition 10.2014, DC6-01 5-2.04

1.2. Configurations (Examples)

C

P-601

4

X

1X11X4X12

X14X16X15X1

3

WDE

R

X5X3X6X7X8X9X10

S

IM0

/PK/LK/LK

/PK

RXERxTXSI

3SI

2SI

1SI

0LO

C

FBM-PRE/2M-PRE/3M-PRE/0M-PRE/1NCTBPWR24-60VDCPUSH

TOUNLOC

K

ERCOMCPYRYRES

SI0SI2(FB)SI1(ETO)SI3

RELEASEPU

SHTOREL

EASEPUSHT

O

X

2

. . . .

. . . .

. . . .

. . . .

PS-663x

2

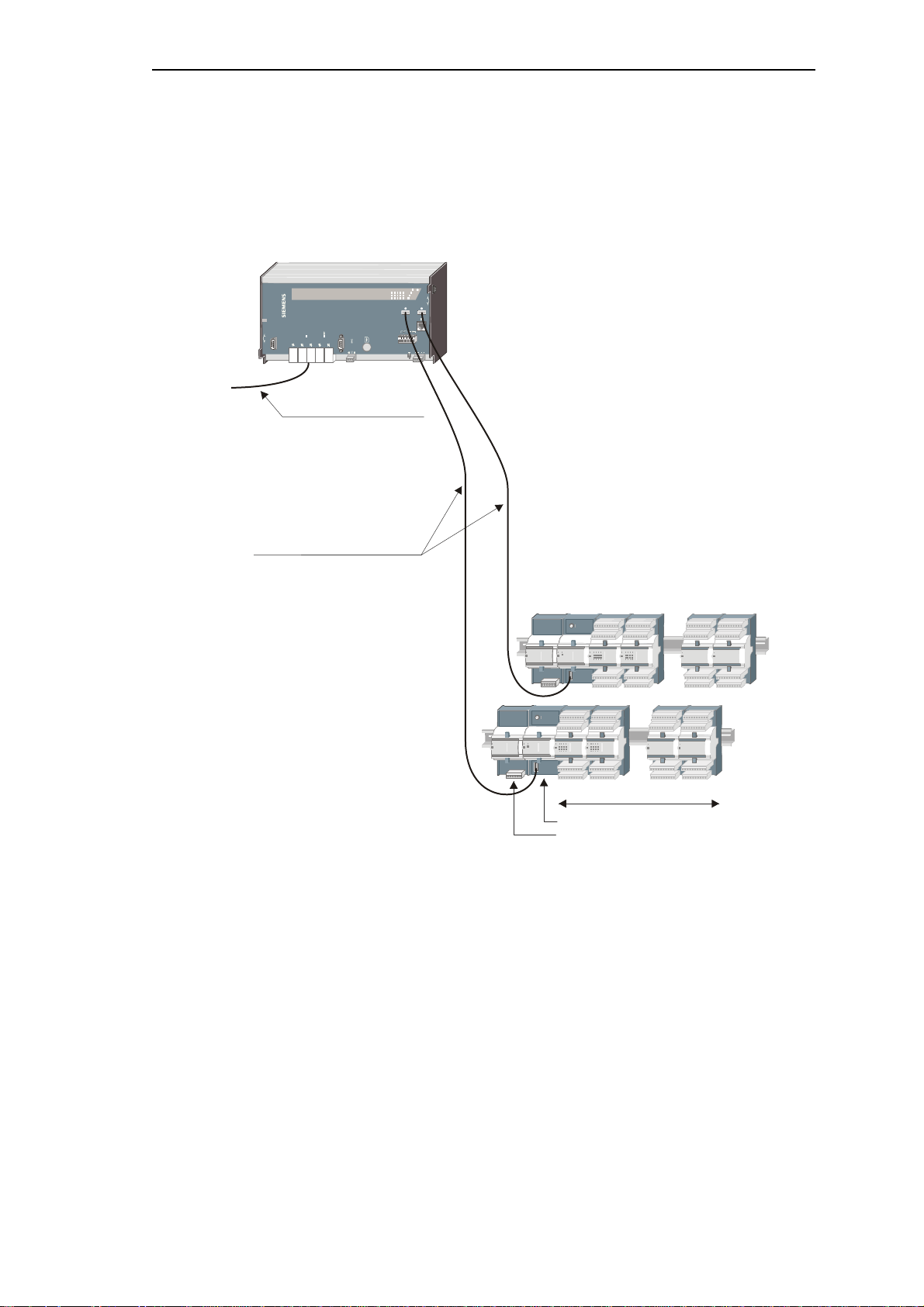

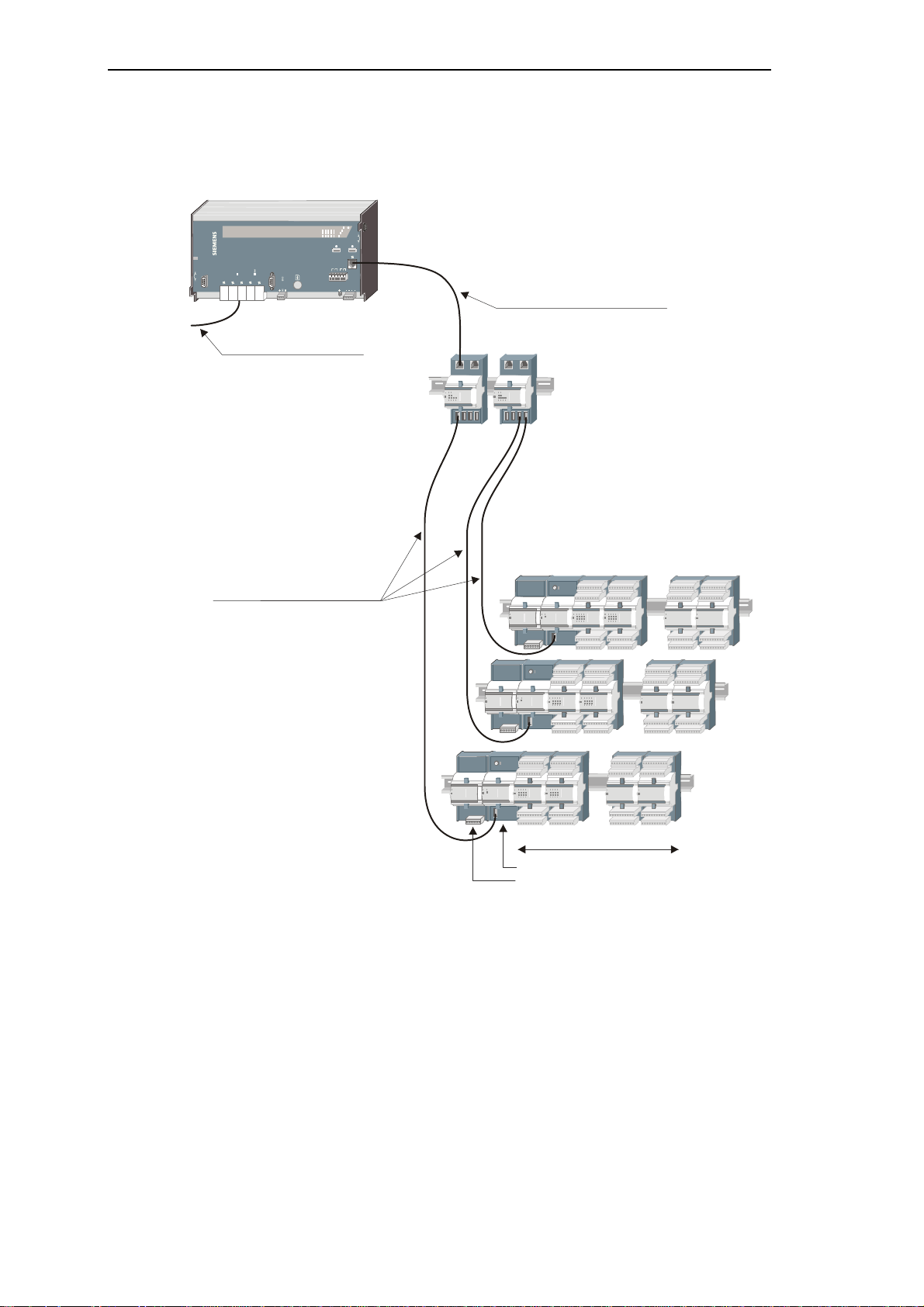

1.2.1. 2 Peripheral Elements SICAM TM, electrically connected

CP-6014

SICAM

TM1 703ACP

1 2 3 4 5 6

Communication with other

automation units

Architecture

Ax 1703 peripheral bus (electrical)

16 Mbps

USB cable, length up to 3 m

1

max. 8 I/O-modules

PE-6410

SICAM TM, Installation 11

DC6-015-2.04, Edition 10.2014

Architecture

014

X1X11X4X1

2X14X

16X

15X13

WDE

R

X

5X3X6X7X8X9X1

0

S

IM0

/

PK/

L

K

/

L

K

/

P

K

R

XERxTXSI3SI2SI1SI0LOC

PWR24

-

6

0VDCPUSHTOUNL

OCK

ERCOM

CPYRYRE

S

SI0SI2(FB)SI1

(ETO)SI

3

RELEASE

PUSHTOR

ELEASEP

USHTO

X

2

1 . . . 4

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

all in all up to 16 peripheral elements

PS-663x

16

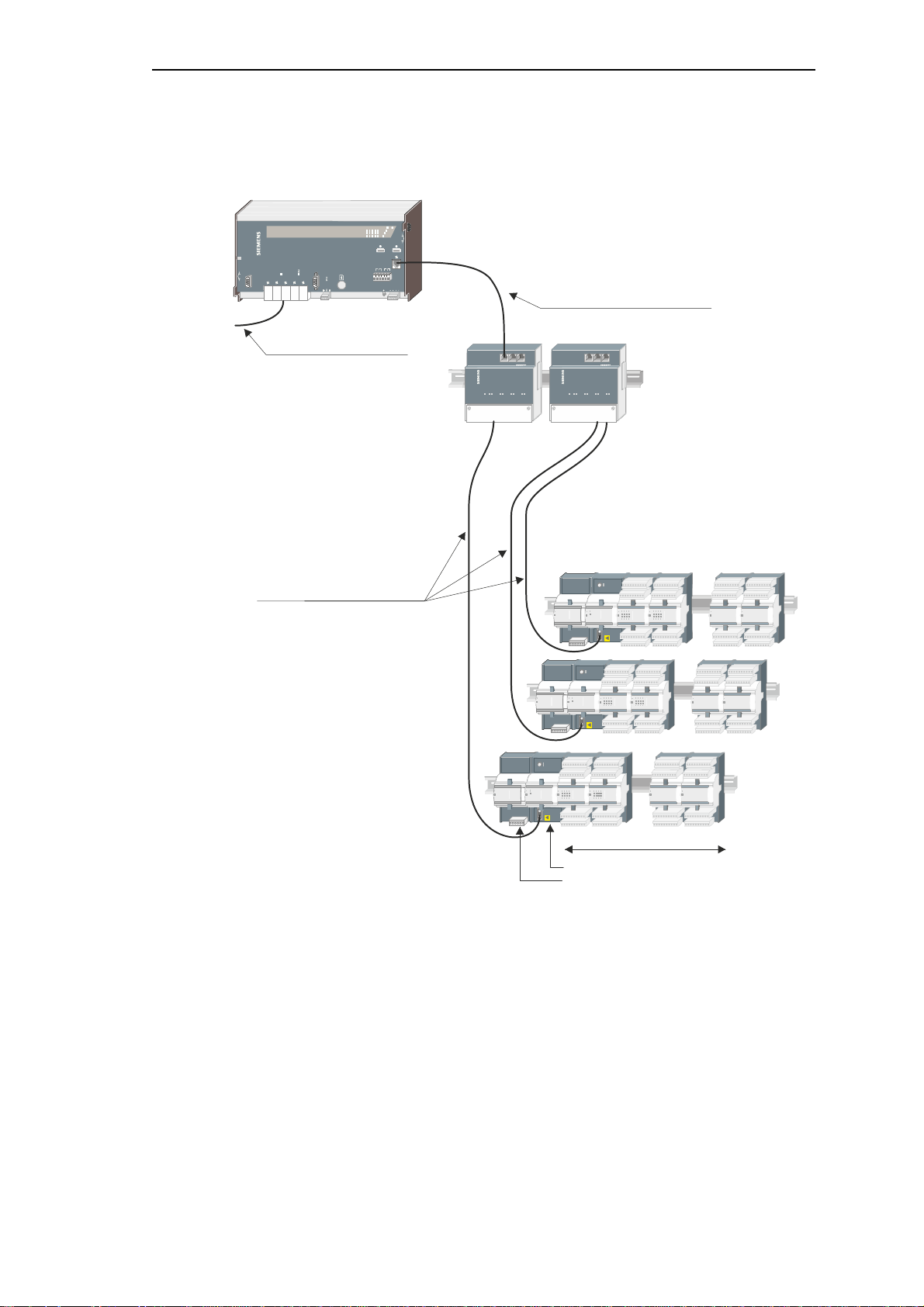

1.2.2. 16 Peripheral Elements SICAM TM, electrically connected

SICAM

TM1703 ACP CP-6

TB

NC

Communication with other

automation units

Ax 1703 peripheral bus (electrical)

16 Mbps

USB cable, length up to 3 m

FB

M-PRE/2

M-PRE/3

M-PRE/0

M-PRE/1

1 2 3 4 5 6

CP-6014

Note:

Ax 1703 peripheral bus (electrical)

16 Mbps

patch cable, length up to 3 m

CM-0843

..........

max. 8 I/O-modules

PE-6410

15

1

12 SICAM TM, Installation

Edition 10.2014, DC6-01 5-2.04

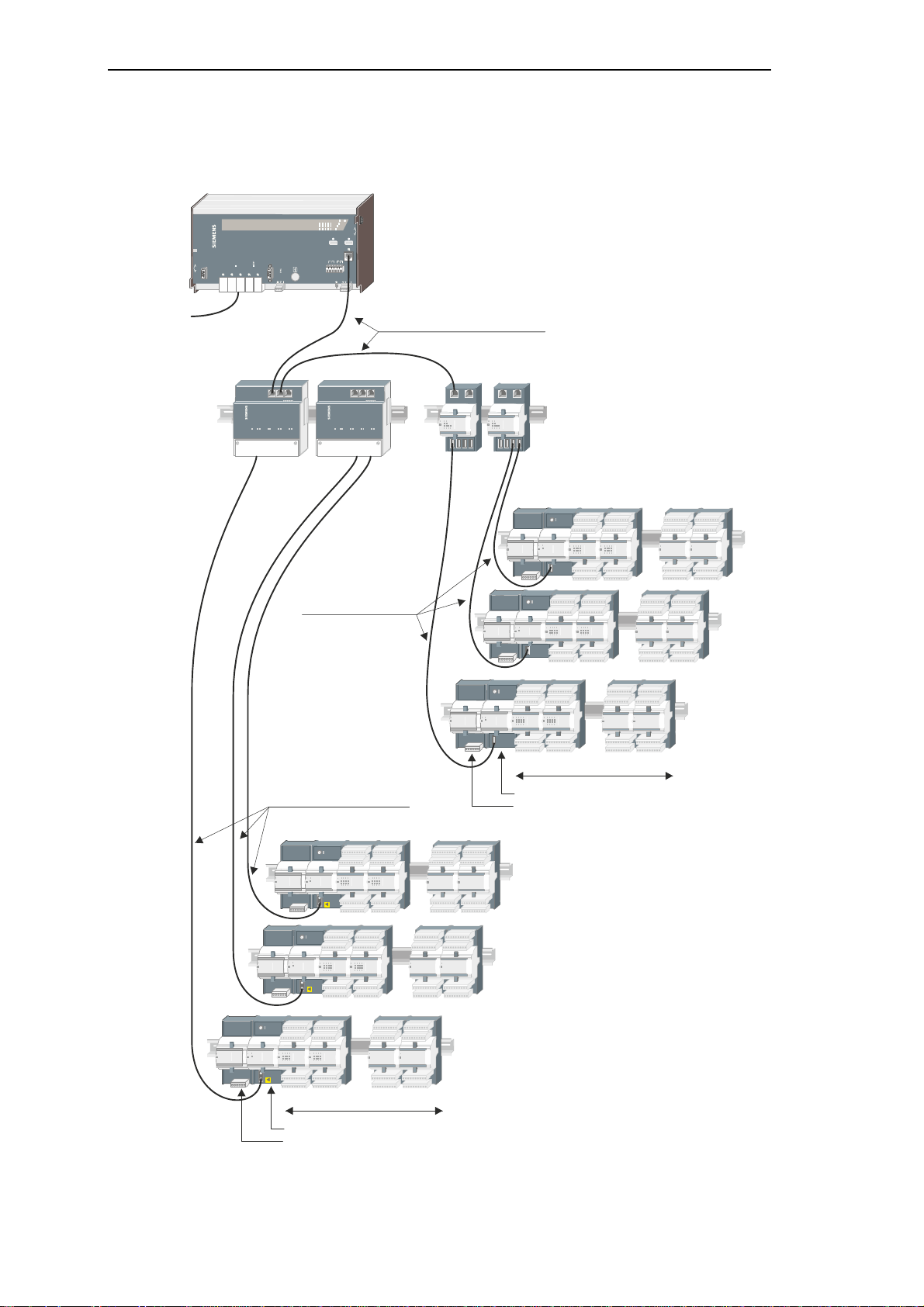

1.2.3. 16 Peripheral Elements SICAM TM, optically connected

SIC

A

M

170

3

014

X1X11X4X1

2X14X

16X

15X13

WDE

R

X

5X3X6X7X8X9X1

0

S

IM0

/

PK/LK/L

K

/

P

K

R

XERxTXSI3SI2SI1SI0LOC

PWR24

-60VDCPUSHTOUNL

OCK

ERCOM

CPYRYRE

S

SI0SI2(FB)SI1

(ETO)SI

3

RELEASE

PUSHTOR

ELEASEP

USHTO

X

2

SIC

A

M

170

3

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

all in all up to 16 peripheral elements

PS-663x

16

Architecture

SICAM

TM1703 ACP CP-6

TB

NC

Communication with other

automation units

Ax 1703 peripher al bus (optical)

16 Mbps, optical fibre,

length up to 200 m

FB

M-PRE/2

M-PRE/3

M-PRE/0

M-PRE/1

1 2 3 4 5 6

CP-6014

Note:

Ax 1703 peripheral bus (electrical)

16 Mbps

patch cable, length up to 3 m

1 . . . 4

CM-0842

..........

max. 8 I/O-modules

PE-6411

15

1

SICAM TM, Installation 13

DC6-015-2.04, Edition 10.2014

Architecture

0

1

4

X

1

X

11X4X

12X14X16X15X1

3

WDE

R

X5X3X6X7X8X9X

1

0

SIM

0

/

PK/LK/LK/

P

K

RXERxTX

S

I

3

S

I

2

S

I

1

S

I

0

LOC

P

W

R24-60VDCPUSHTOUNLO

C

K

ERCOMCP

YRY

RES

S

I0S

I2(FB)S

I1(

ETO)S

I

3

RELEASEPUSHTORELEASEPUSHT

O

X

2

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

PS-663x

16

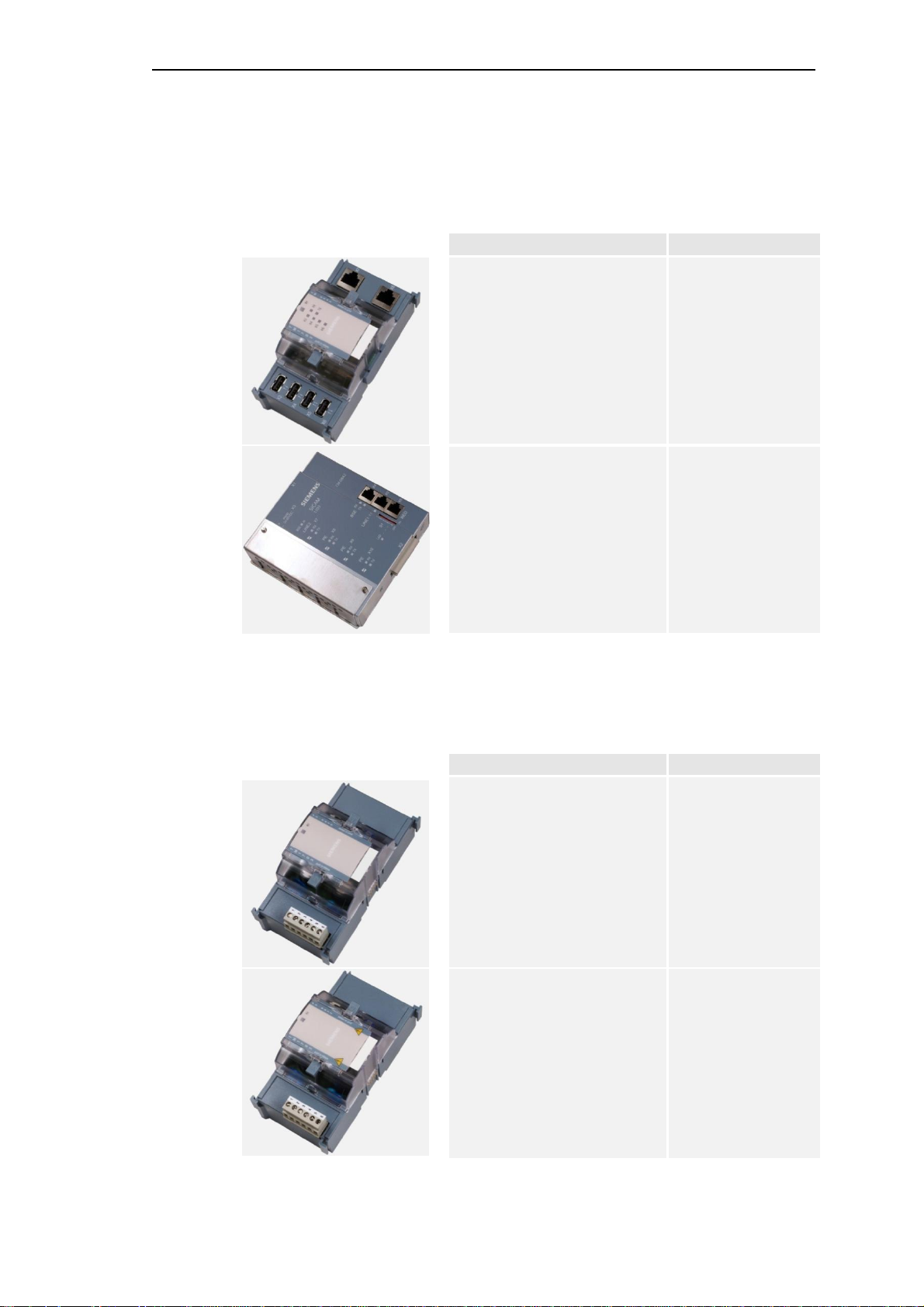

1.2.4. 16 Peripheral Elements SICAM TM, electrically and optically connected

SICAM

TM1703ACP CP-6

TB

NC

communication with other

automation units

FB

M-PRE/2

M-PRE/3

M-PRE/0

M-PRE/1

SICAM

1703

CM-0842

CP-6014

1 2 3 4 5 6

Ax 1703 peripheral bus (electrical)

16 Mbps

patch cable, length up to 3 m

1 . . . 4

SICAM

1703

Ax 1703 peripheral bus

(electrical)

16 Mbps

USB cable,

length up to 3 m

1 . . . 4

CM-0843

Note:

all in all up to 16 peripheral elements

15

Ax 1703 peripheral bus (optical)

16 Mbps, optical fibre,

length up to 200 m

. . . .

. . . .

..........

. . . .

. . . .

max. 8 I/O-modules

PE-6411

..........

9

max. 8 I/O-modules

PE-6410

PS-663x

. . . .

8

. . . .

7

1

14 SICAM TM, Installation

Edition 10.2014, DC6-01 5-2.04

2. Components

Content

2.1. Maste r Contro l Modules .................................................................................. 16

2.2. Serial Interface Modules ................................................................................. 17

2.3. Bus Interface Module ...................................................................................... 19

2.4. Powe r Supplies .............................................................................................. 19

2.5. Periphe ral Modules ......................................................................................... 20

SICAM TM, Installation 15

DC6-015-2.04, Edition 10.2014

Components

2.1. Master Control Modules

CP6014 Master Control Module GC6-014

Designation Item Number/ MLFB

6MF11130GA140A A0

16 SICAM TM, Installation

Edition 10.2014, DC6-01 5-2.04

2.2. Serial Interface Modules

2.2.1. Serial Interface Processor (SIP)

SM-2551

Seria l Interfac e Pr ocessor 2 SI

Components

Designation Item Number/ MLFB

BC2-551

6MF101 30C F510 AA0

SM-0551

Seria l Interfac e Pr ocessor 1 SI

2.2.2. Network Interface Processor (NIP)

Designation Item Number/ MLFB

SM-2557

Network-Interf.Ethernet 2x100 TX

SM-2558 Ethernet-Interf. 1x100TX

+ 1 serial interface optional

BC0-551

6MF10130AF510AA0

BC2-557

6MF10130CF570AA0

BC2-558

6MF101 30CF580 AA0

SICAM TM, Installation 17

DC6-015-2.04, Edition 10.2014

Components

2.2.3. Field Bus Interface Processor (FIP)

Designation Item Number/ MLFB

SM-2545

Profibu s Interface (Mas ter)

BA2-54 5

6MF101 10C F4 50AA 0

18 SICAM TM, Installation

Edition 10.2014, DC6-01 5-2.04

2.3. Bus Interface Module

Designation Item Number/ MLFB

CM-0843

Ax 1703 b us interface electrical

Components

GA0-843

6MF111 10AJ430AA0

2.4. Power Supplies

CM-0842

Ax 1703- Businterface 4x fiber optical

Designation Item Number/ MLFB

PS-6630 Power Supply Module

24-60 VDC (EMC+)

GA0-842

6MF111 10AJ420AA0

GC6-630

6MF11130GG300AA0

PS-6632 Power Supply Module

110-220 VDC (EMC+)

SICAM TM, Installation 19

DC6-015-2.04, Edition 10.2014

GC6-632

6MF11130GG320AA0

Components

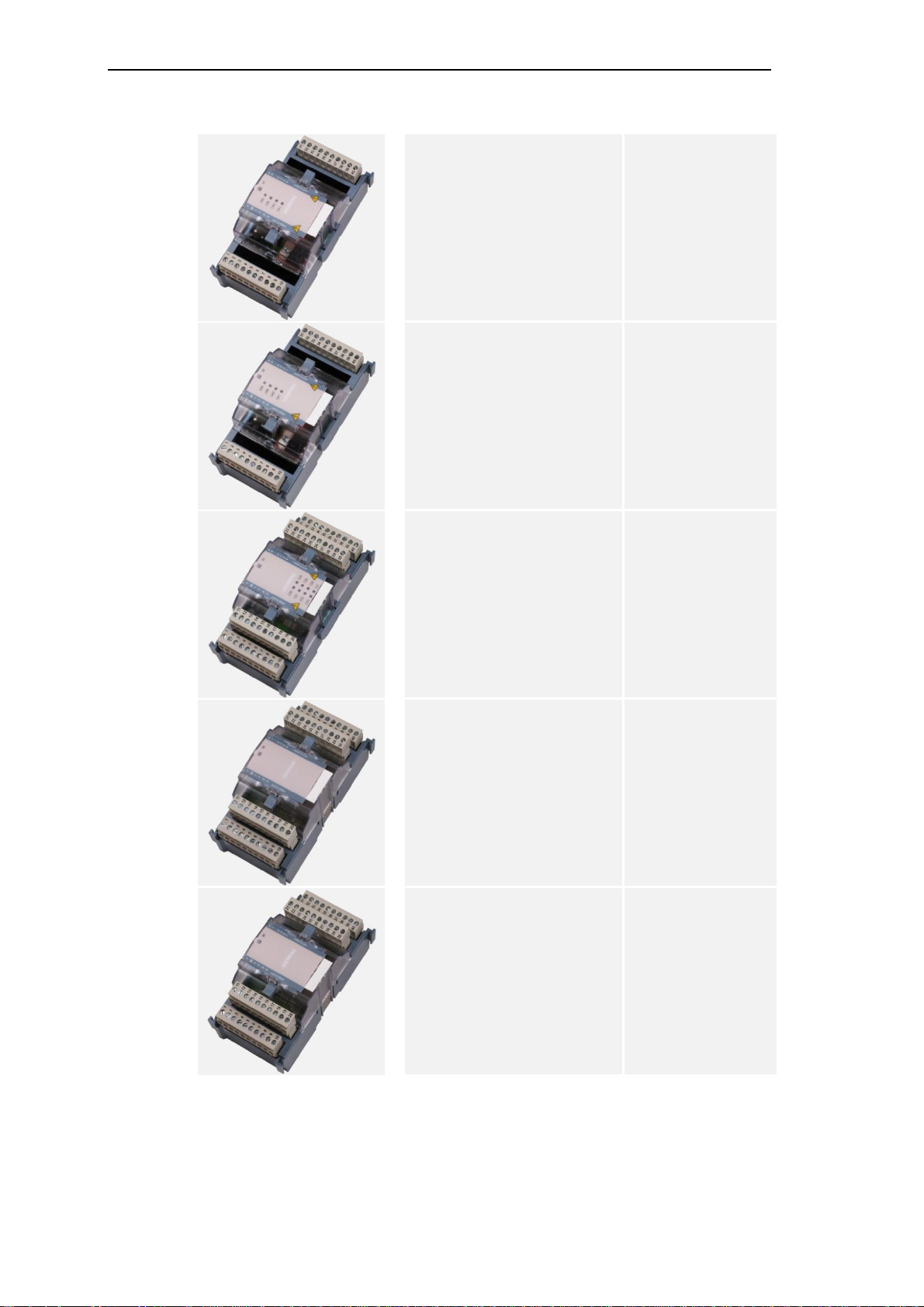

2.5. Peripheral Modules

PE-641 0 Peripher al Control Module

Ax-PE-Bus (electrical)

PE-641 1 Peripher al C ontroller

(1x Ax-PE bus opt)

PE-6412 Peripheriekopplung

(2x Ax-PE Bus opt)

GC6-410

6MF11130GE000AA0

GC6-411

6MF11130GE110AA0

GC6-412

6MF11130GE120AA0

DI-6100 Binary Input 2x8,

24-60VD C

DI-6101 Binary Input 2x8,

110/220VDC

GC6-100

6MF11130GB000A A0

GC6-101

6MF11130GB010A A0

20 SICAM TM, Installation

Edition 10.2014, DC6-01 5-2.04

Components

DI-6102 Binary Input 2x8,

24-60VDC 1ms

DI-6103 Binary Input 2x8,

110/220 VD C 1ms

DI-610 4 Bin ary Input 2x8, 220VD C GC6-104

GC6-102

6MF11130GB020AA0

GC6-103

6MF111 30GB030A A0

6MF111 30GB040AA0

DO-6200 Binary Outp ut Tr ans is t or

2x8, 24-60 VD C

DO-6212 Binary Out put R el ays 8 x

24-220VD C/ 23 0VAC

GC6-200

6MF111 30GC000AA 0

GC6-212

6MF111 30GC200AA 0

SICAM TM, Installation 21

DC6-015-2.04, Edition 10.2014

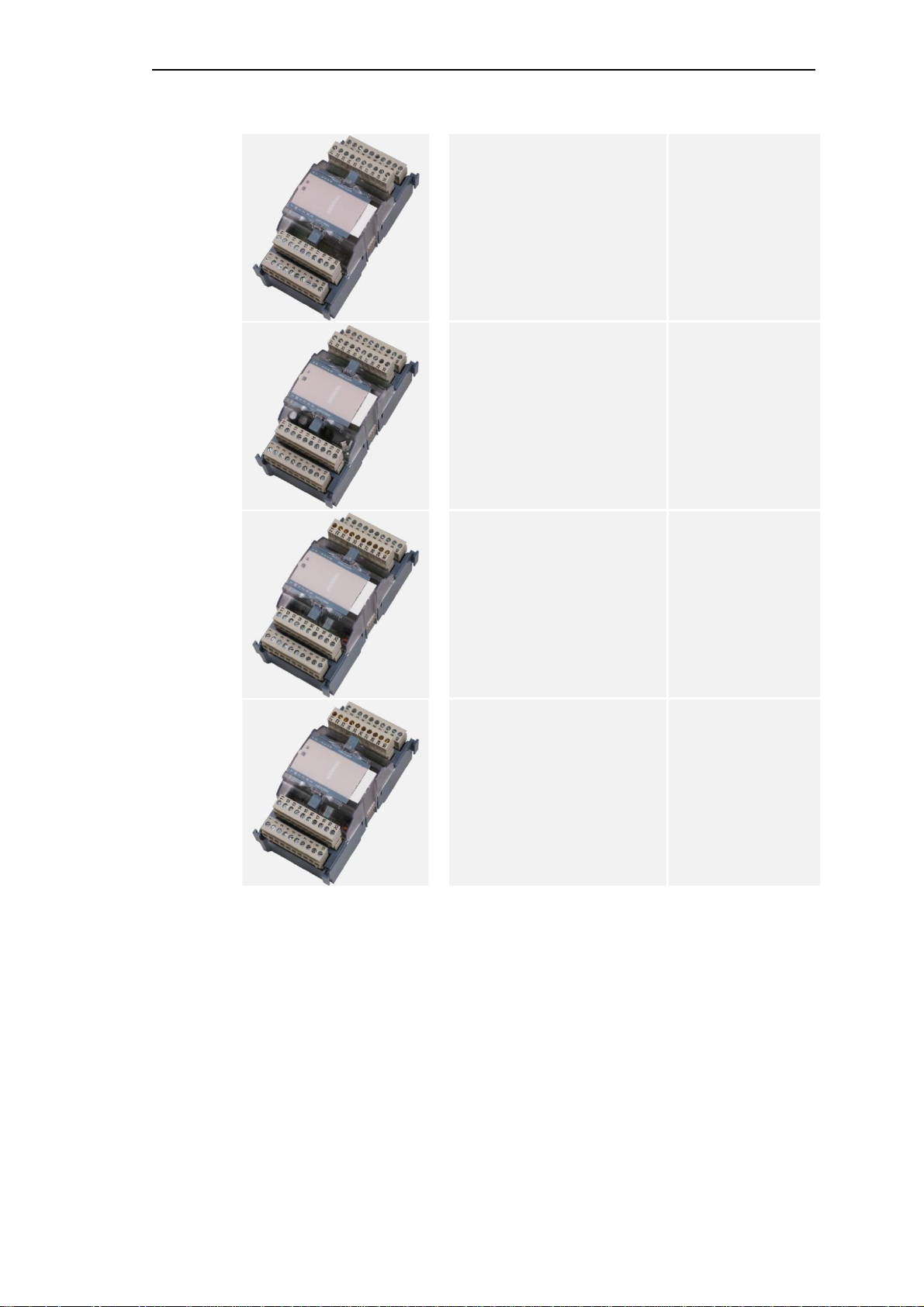

Components

DO-6220 Command Out Basic

Module

DO-6221 Command Out Basic

Module Measure

DO-6230 Command Out Rela y

Module

GC6-220

6MF111 30G C200AA0

GC6-221

6MF11130GC210AA0

GC6-230

6MF111 30G C300AA0

AI-6300 Analog Input 2x2

±20mA/±1 0V

AI-6307 Analog Input 2x2 ±5mA GC6-307

GC6-300

6MF11130GD000AA 0

6MF111 30GD070AA 0

22 SICAM TM, Installation

Edition 10.2014, DC6-01 5-2.04

Components

AI-6310 Analog Input 2x2

Pt100/Ni100

AO-6380 Analog Output 4x

±20mA/±10mA/±10V

TE-6420 Speed Measurem ent 2x2

5VDC/24VDC/NAMUR

GC6-310

6MF11130GD100AA 0

GC6-380

6MF111 30GD 80 0AA0

GC6-420

6MF111 30GE200A A0

TE-6450 Position Acquisiti on 2x2

SSI/RS-422

GC6-450

6MF111 30GE500A A0

SICAM TM, Installation 23

DC6-015-2.04, Edition 10.2014

3. Assembly

Content

3.1. Necess ary Material ......................................................................................... 26

3.2. How an d wh e re ca n Installation ta ke place? ................................................... 27

3.3. Installat ion of TS35 Rail (DIN Rail) .................................................................. 30

3.4. Installat ion of Cable Duct ................................................................................ 31

3.5. Installat ion o f Mas ter Con tro l Ele ment ............................................................. 32

3.6. Installat ion o f Bus Inte r fa ce Mod ules .............................................................. 35

3.7. Installing TM Modules ..................................................................................... 37

SICAM TM, Installation 25

DC6-015-2.04, Edition 10.2014

Assembly

3.1. Necessary Material

Due to the different circumstances with the local installation of the SICAM TM systems, not all

details such as e.g. screw sizes, cable lengths and the like can be dealt with in this document.

Therefore only recommendations and minimum requirements are specified concerning

consumables.

The fitter himself must ensure that suitable materials and tools necessary for the installation

are available.

26 SICAM TM, Installation

Edition 10.2014, DC6-01 5-2.04

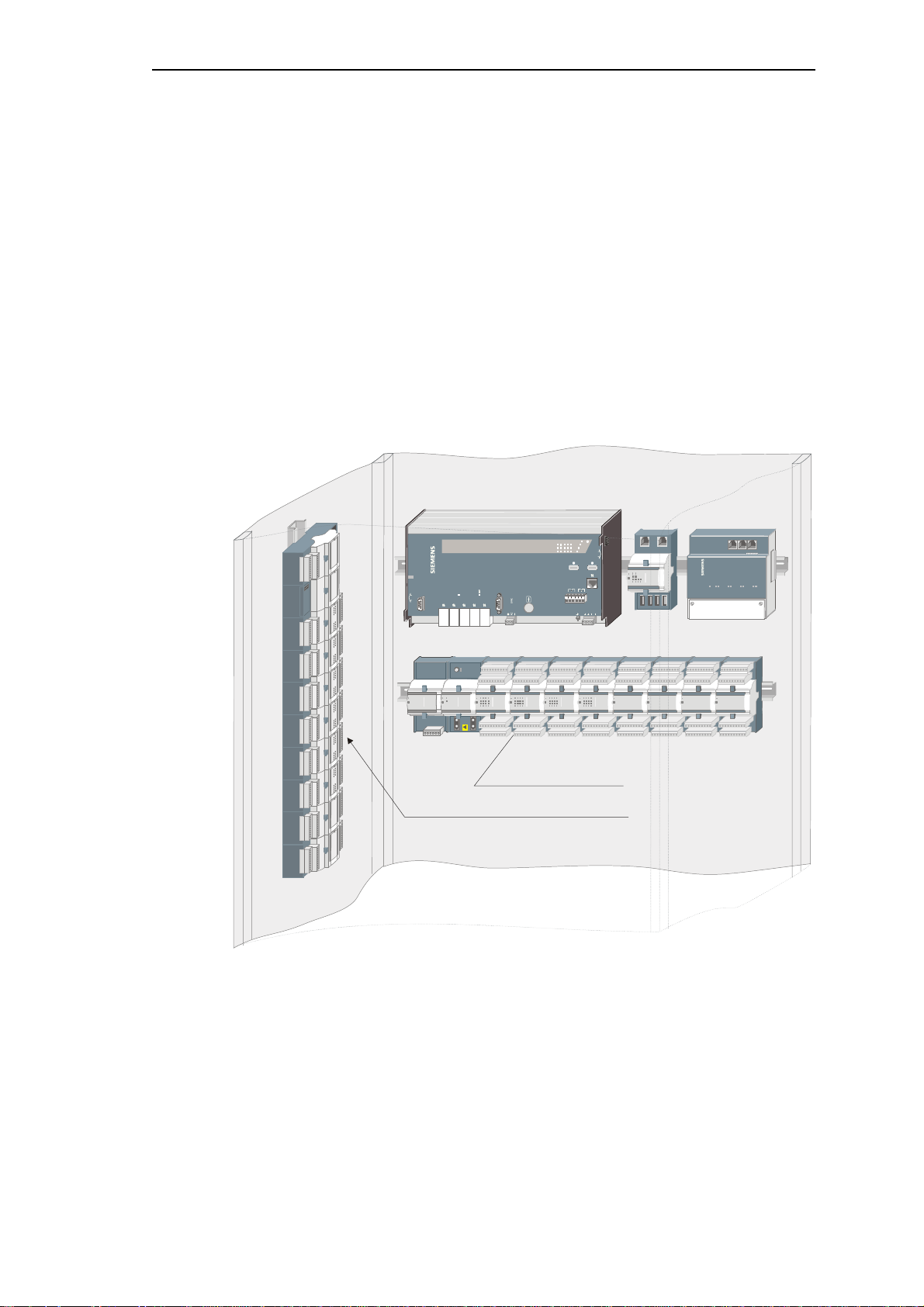

3.2. How and where can Installation take place?

SIC

A

M

170

3

S

ICA

M

TM1703ACPCP-601

4

X1X11X4X12X14X16X15X1

3

WDE

R

X5X3X6X7X8X

9X1

0

SIM

0

/PK/LK/LK/P

K

RXERxTXSI3SI2SI1SI0

LOC

FBM-PRE/2M-PRE/3M-PRE/0M-PRE/1NCTBPWR24-60VDCPUSHTOUNLOCK

ERCOMCP

YRYRE

S

SI0SI2(FB)SI1(ETO)SI3

RELEA

SEPUSHTOR

E

L

E

ASEPUSHTO

X

2

1 2 3 4 5 6

3.2.1. Installation Location

The terminal modules are designed for the in stallation in a cabinet, rack or on t he wall.

3.2.2. Installation Position

SICAM TM systems may only be installed horizontally or vertically. The vertical installation is

to be preferred, since this provides a considerably more space-saving and efficient

installation. The cabling of external cables is also made significantly easier as a result.

Assembly

horizontal installation

vertical installation

Not permissible are installations on the ceiling (own weight) and on the floor (dust level).

SICAM TM, Installation 27

DC6-015-2.04, Edition 10.2014

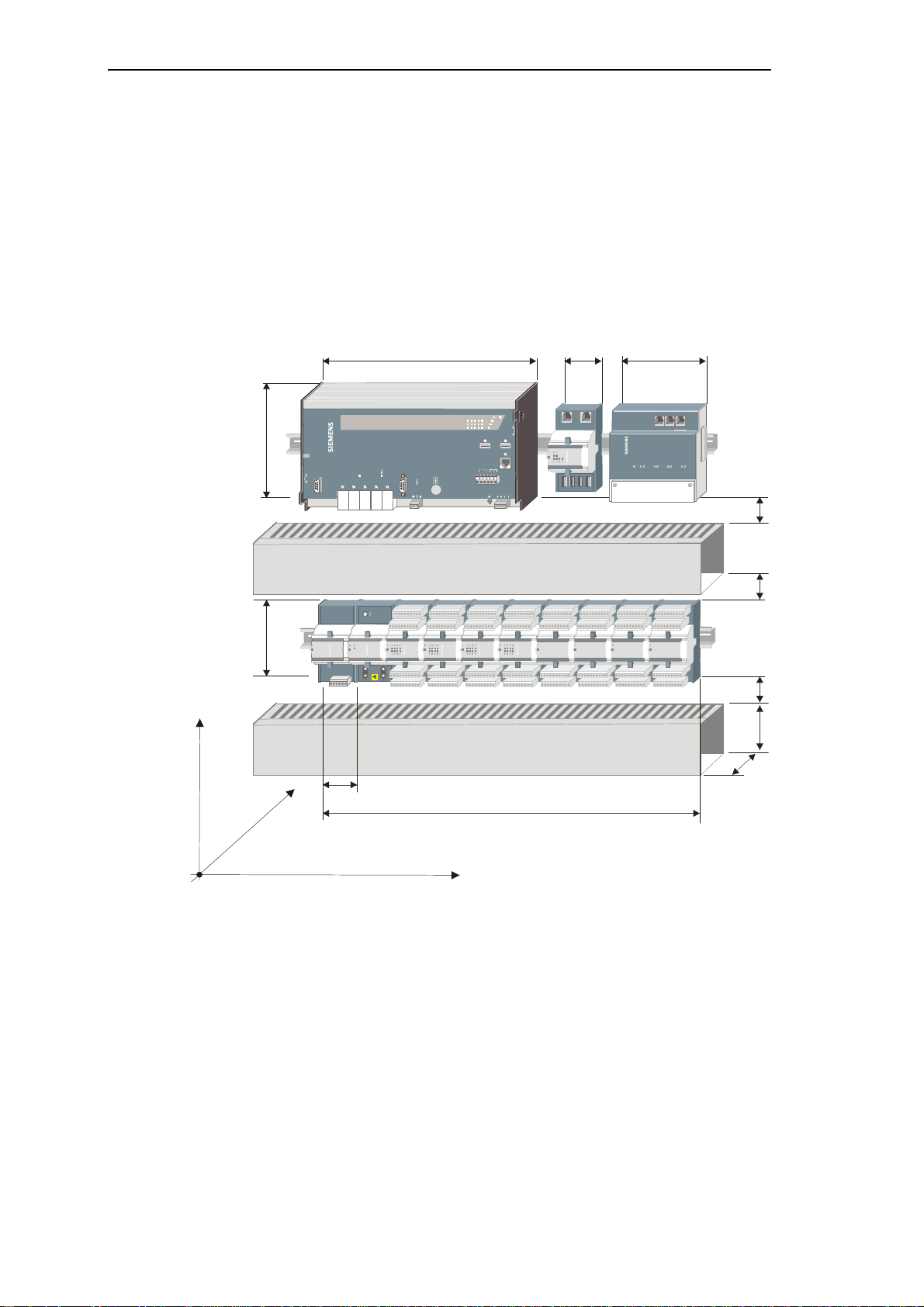

Assembly

306

141

63

80

8

0

SICAM

170

3

SICAM

TM1703ACPCP-601

4

X1X11X4X12X14X16X15X1

3

WDE

R

X

5

X3X6X7X8X

9X1

0

SIM

0

/PK/L

K/LK/PK

RXERxTXSI3SI2SI1SI0LO

C

F

BM-PR

E/2M-PR

E/3M-PR

E/0M-PR

E/1NCTBPWR24-60VDCPUSHTOUNLOC

K

E

RCOMCPYRYRE

S

S

I

0SI2(FB

)SI1(ETO)SI

3

RELEA

SEPUSHTORELEASEPUSHTO

X

2

630 (system with 8 I/O modules)

H

EIGHT(mm)

3.2.3. Space Requirement

The spac e requirem ent of a complet ely configured SICAM TM peripheral element ( power

supply, master control unit, up to 8 I/O modules) in the width co mes to 630 mm (without end

bracket and terminal strip marker for the system designation).

The space requirement for the height depends on several factors. Besides the size of the

module itself (130mm), the size of the cable ducts used and their minimum distance to the

modules is to be taken into account. This distance is 20 mm if no lead labeling is to take place

and 30 mm if the leads are to be fitted with labeling bushes.

155

1 2 3 4 5 6

20 or

30

20 or

30

130

20 or

30

HÖHE

63

)

m

m

(

H

T

P

E

D

WIDTH (mm)

28 SICAM TM, Installation

Edition 10.2014, DC6-01 5-2.04

3.2.4. Environmental Conditions

The permissible temperature range for the operation of the modules is about –25°....+70°C

(except CM-0842, only up to +55°C).

For details on the subject of environmental conditions, please refer to the SICAM TM System

Data Sheet (MC6-007-1), chapter: "Climatic Ambient Conditions and Electrical Ambient

Conditions".

Assembly

SICAM TM, Installation 29

DC6-015-2.04, Edition 10.2014

Assembly

3.3. Installation of TS35 Rail (DIN Rail)

For the installation of the modules a TS35 rail is used. This must conform to the European

standard EN 50 022.

The orientation and position in which the TS35 rail is to be installed must be determined

locally. Take into account the details specified in chapter 3.2 .3

, "Space Requirement"

Caution

By means of the connection TS35 rail - cabinet/rack a r eliable grounding connection must be guar anteed.

30 SICAM TM, Installation

Edition 10.2014, DC6-01 5-2.04

Loading...

Loading...