Page 1

Release 1.0

Service Repair Documentation

Level 3 (basic)

S80/82/SFG75

Release Date Department Notes to change

R 1.0 22.12.2005 BenQ CC S CES New document

Technical Documentation

TD_Repair_L2.5L_S80_R1.0.pdf Page 1 of 18

Company Confidential

2005©BenQ

10/2005

Page 2

Release 1.0

Table of Content

1 Introduction ...............................................................................................................................3

1.1 PURPOSE ...............................................................................................................................3

1.2 SCOPE ...................................................................................................................................3

1.3 TERMS AND ABBREVIATIONS ...................................................................................................3

2 List of available level 3 basic parts..........................................................................................4

3 Hardware requirements ............................................................................................................4

4 S80 Board layout.......................................................................................................................5

5 SIM Card Problems ...................................................................................................................7

6 IO Connector Problems ............................................................................................................8

7 B to B connector (upper slider part) problems.....................................................................10

8 Main keypad illumination problems.......................................................................................11

9 Connector Battery...................................................................................................................12

10 Connector RF Internal Antenna .............................................................................................13

11 Connector Mini SD ..................................................................................................................14

12 Connector Vibra ......................................................................................................................15

13 Fuse..........................................................................................................................................16

14 Connector Sidekeys................................................................................................................17

15 Connector MMI ........................................................................................................................18

Technical Documentation

TD_Repair_L2.5L_S80_R1.0.pdf Page 2 of 18

Company Confidential

2005©BenQ

10/2005

Page 3

Release 1.0

1 Introduction

This document describes the performance description for Siemens service partners.

1.1 Purpose

This Service Repair Documentation is intended to carry out repairs on BenQ Mobile repair level 3

basic. The described failures shall be repaired in Siemens authorized local workshops only,

The level 3(former Level 2.5e) partners are obliged to repair level 2 classified boards, up to their

repair level, under consideration of the information given by level 3 repair instruction.

All repairs have to be carried out in an ESD protected environment and with ESD protected

equipment/tools. For all activities the international ESD regulations have to be considered.

Assembling/disassembling has to be done according to the latest S80 Level 2 repair documentation.

It has to be ensured that every repaired mobile Phone is checked according to the latest released

General Test Instruction document (both documents are available in the Technical Support section

of the C-market).

Check at least weekly C-market for updates and consider all S80 related Customer Care Information

S80 Part number on IMEI label:

Scrap Handling: All Scrap information given in this manual are related to the

SCRAP-Rules and instructions.

Attention: Consider the new "LEAD-FREE" soldering rules (available in the communication

market), avoid excessive heat.

1.2 Scope

This document is the reference document for all BenQ mobile authorised Service Partners which are

released to repair BenQ mobile phones up to level 2.5 light.

1.3 Terms and Abbreviations

Technical Documentation

TD_Repair_L2.5L_S80_R1.0.pdf Page 3 of 18

Company Confidential

2005©BenQ

10/2005

Page 4

Release 1.0

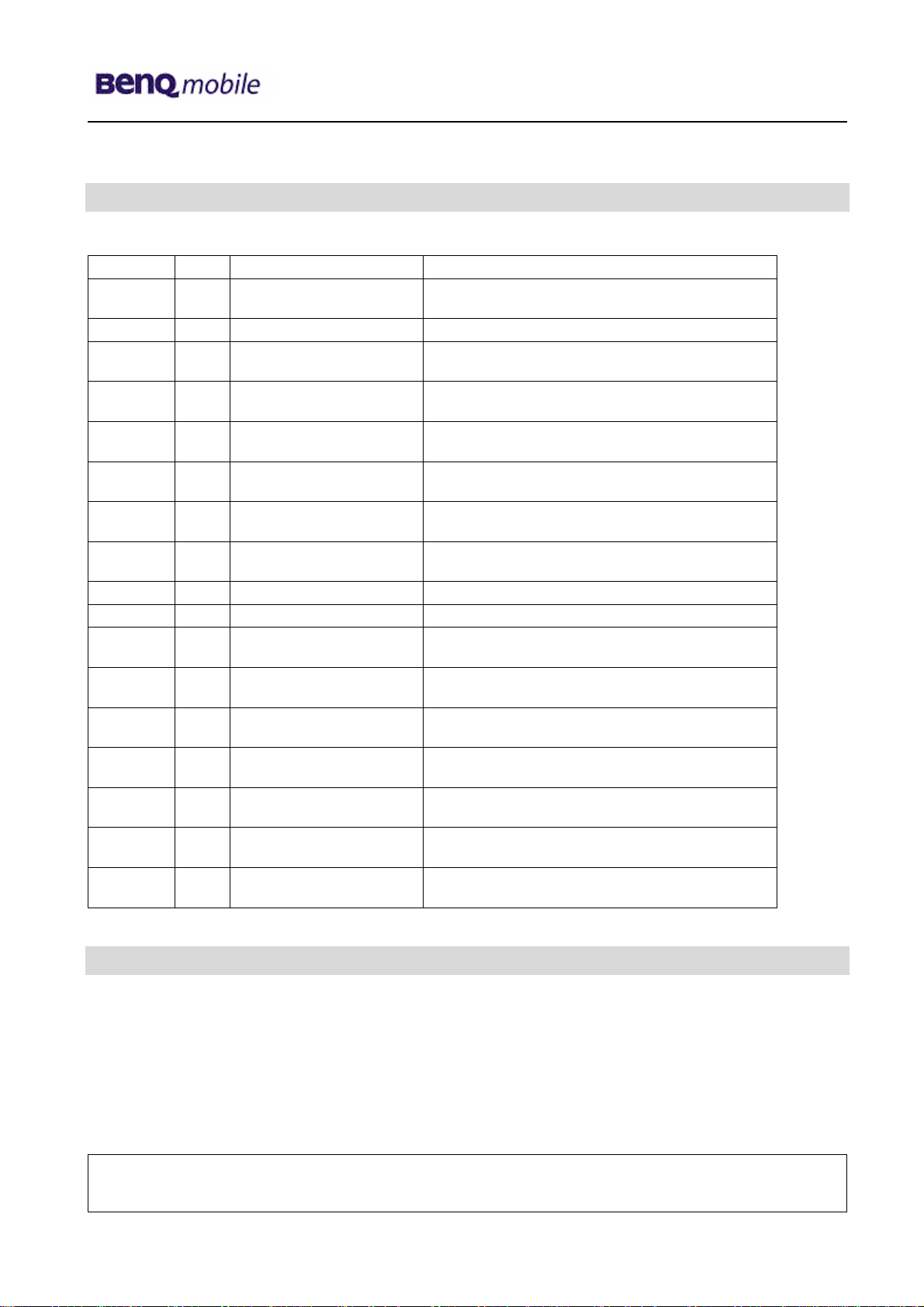

2 List of available level 3 basic parts

(According to Component Matrix V1.11 - check C-market for updates)

Product ID Order Number Description CM

S80 J200 L50334-Z97-C522

S80 U800 L50851-Z1901-A62 ANT 3*5.1*5 56E12 BQ20.M0007.021

S80 J302 L50334-Z97-C523

S80 J301 L50334-Z97-C524

S80 U852 L50334-Z97-C525

S80 J250 L50334-Z97-C526

S80 J351 L50334-Z97-C527

S80 J350 L50334-Z97-C528

S80 J201 L50334-Z97-C529 CONN BTB D1.5 18P BQ21.N1003.011

S80 J202 L50315-Z77-C261 SWI VOLUME KEY 5P BQ21.P0004.005

S80 J300 L50158-A185-A16-1

S80 J251 L50158-A185-A17-1

S80

S80

S80

S80 U801 L50145-K280-Y415

S80 L50851-Z1901-A63

MMI

board

MMI

board

F250

F300

L50840-L2133-D670

L50810-U6228-D670 IC PER HALL A3212ELH BQ74.03212.09Y

L50145-A820-Y23

CONNECT SKT60P AXK7L60227

BQ20.L1096.060

CONNECTOR DC PWR 2P

BQ20.N2002.021

CON BATT3P CBE-4517-2904H

BQ21.N0036.011

CONN SPRING SBS23-2K30F00

BQ21.N0045.011

CONN I/O 10P ACT/916-2941

BQ2K.N0083.001

CONN SIM 6P D2.54 302-368

BQ21.N0050.001

CONN MINI SD 9P 500525

BQ21.N0058.011

ASS LOUD SPEAK. CONN.

S80_BQ60.H0916.001

ASSY CONN. MIC WHITE

S80_BQ65.G0101.004

DISDIODE LED BL-HB536G

BQ83.00536.071

FUSE 1A 24V F0603 1608FF

BQ69.41004.001

SWITCH ANT MS-147 HIROSE

BQ69.50017.001

ANT 2.4GHz AT5020-B2R8HAA

BQ69.F0005.021

3 Hardware requirements

(According to General soldering information V1.3 - check C-market for updates)

Jigs, Tools and working materials for all described repairs:

hot air blower

soldering gun

tweezers

flux

solder

Technical Documentation

TD_Repair_L2.5L_S80_R1.0.pdf Page 4 of 18

Company Confidential

2005©BenQ

10/2005

Page 5

Release 1.0

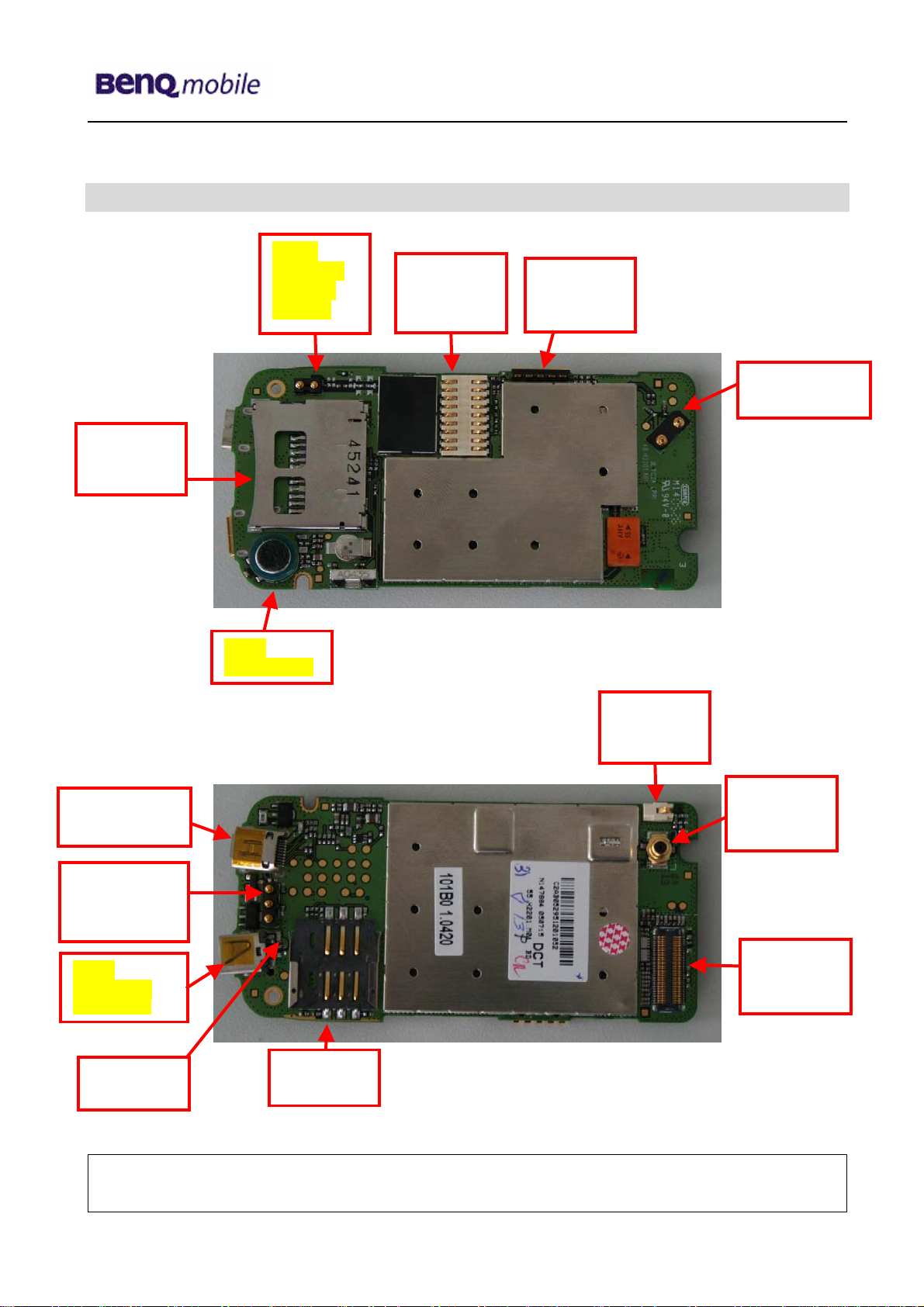

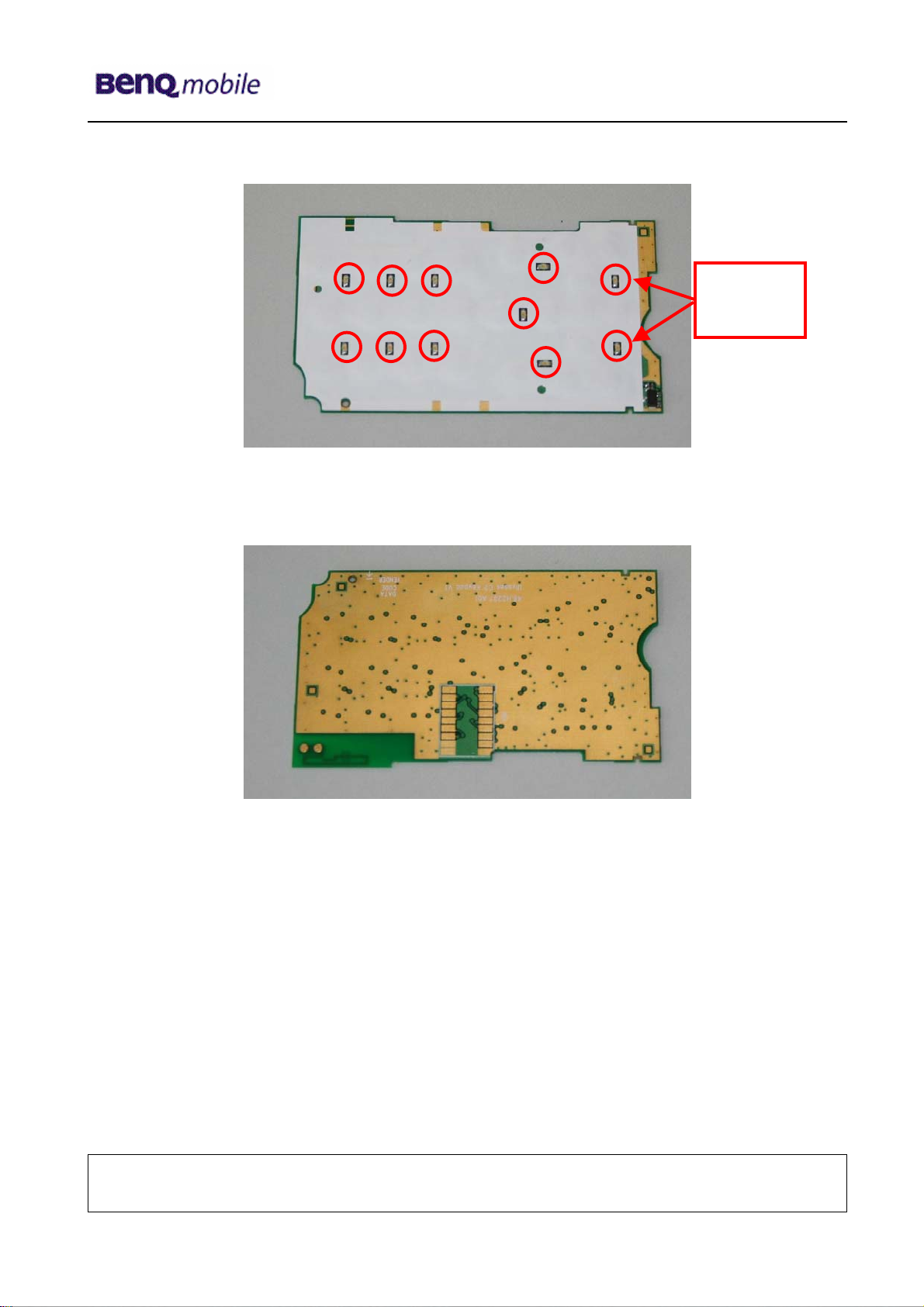

4 S80 Board layout

Upper board side

J350:

Mini SD

Connect

or

U852:

Bluetooth

Antenna

Contact

J201

MMI

Connector

Switch

volume Keys

J300:

Vibra Contact

Lower board side

J250:

IO Connector

J301:

Battery

Connector

J302:

Connector

Fuse 1A

J251:

Microphone

U800:

Antenna

Contact

U801:

Antenna

Switch

J200:

Connector

BTB

J351:

SIM Card

Technical Documentation

10/2005

TD_Repair_L2.5L_S80_R1.0.pdf Page 5 of 18

Company Confidential

2005©BenQ

Page 6

Release 1.0

MMI Board

Disdiode

Technical Documentation

10/2005

TD_Repair_L2.5L_S80_R1.0.pdf Page 6 of 18

Company Confidential

2005©BenQ

Page 7

Release 1.0

y

r

y

y

5 SIM Card Problems

Okay

Okay

Not

oka

Okay

Back to customer

without repair

Caused by customer

SCRAP - has to be send

separately to WSC

Exchange the

damaged Filter

- check for twisted or

bent contacts

- check for dry joints

Continue with

higher repair level

Fault Symptoms

Customer: GRT:

Handset does not accept SIM card SIM Card Problems

SIM Card Problems

Watch for oxidation and

damaged pads of the

SIM Card reader

Check the status of the

EMI Filter visually

Exchange

SIM Card reade

Connector SIM Card Reader

Use soldering iron to remove defective component. Avoid excessive heat! Watch surrounding

components! Resolder new component afterwards.

E-commerce order number: L50634-Z97-C406

E-commerce order name: CONNECTOR SIM CARD READER R65 (B)

Soldering temperature: ~ 360°C TIP Temp.

Not

oka

Not

oka

Check the status of the

SIM Card reader visually

Okay

Use the resistor test

function of a multimeter

to check connection

between spring

contacts and soldering

contacts.

The value must be ~0

Technical Documentation

10/2005

TD_Repair_L2.5L_S80_R1.0.pdf Page 7 of 18

Company Confidential

2005©BenQ

Page 8

Release 1.0

y

r

y

y

6 IO Connector Problems

Fault Symptoms

Customer: GRT:

Charging Problems No connection to GRT

Problems with external loudspeaker or microphone when using a

car kit

Problems with accessories connected at the IO connector

IO connector Problems

Watch for oxidation and

damaged pads of the

IO connector

Okay

Not

oka

Not

oka

Check the dust inside

the IO connector

Okay

Check the status of the

IO connector visually

Exchange

IO connecto

Connector IO Jack

Use soldering iron to remove defective component. Avoid excessive heat! Watch surrounding

components! Resolder new component afterwards.

E-commerce order number: L50334-Z97-C526

E-commerce order name: CONN I/O 10P ACT/916-2941 BQ2K.N0083.001

Soldering temperature: ~ 360°C TIP Temp.

IRIS Diagnose Code: 46100 Interface/Charging Connector/Mechanical Damage

Not

oka

Use the resistor test

function of a multimeter

to check connection

between spring

contacts and soldering

contacts.

The value must be ~0

Okay

47300 Interface/Data Interface/Mechanical Damage

4B100 Interface/Headset Connector/Mechanical Damage

Back to customer

without repair

Caused by customer

SCRAP - has to be send

separately to WSC

Clean IO connector

- check for twisted or

bent contacts

- check for dry joints

Continue with

higher repair level

Technical Documentation

10/2005

TD_Repair_L2.5L_S80_R1.0.pdf Page 8 of 18

Company Confidential

2005©BenQ

Page 9

Release 1.0

Important additional soldering hints

The MMC Reader is located on the opposite of the SLIM-Lumberg connector.

Therefore the risk to damage the plastic material of this MMC-Reader is potentially high if excessive

heat is used while removal or soldering of the SLIM-Lumberg connector.

Please follow these instructions:

a) Remove the SLIM-Lumberg connector with a soldering iron and Resolder Wick

b) Clean the Pads afterwards

c) Solder the new connecter by using soldering iron under consideration of the max. allowed

temperature range.

Samples of critical area:

Lock mechanism damaged Lock mechanism OK

Lock mechanism damaged Lock mechanism OK

Technical Documentation

TD_Repair_L2.5L_S80_R1.0.pdf Page 9 of 18

Company Confidential

2005©BenQ

10/2005

Page 10

Release 1.0

y

y

7 B to B connector (upper slider part) problems

Fault Symptoms

Customer: GRT:

Upper slider keyboard malfunction Keyboard malfunction

Upper slider keypad illumination does not work Current measured failed

Display problems

B to B connector problems

Watch for oxidation and

damaged pads of the

B to B connector

Okay

Not

oka

Check the status of the

B to B connector visually

Okay

Exchange

B to B

connector

Not

oka

Continue with

higher repair level

Connector Board to Board

Use hot air blower to remove defective component. Avoid excessive heat! Watch surrounding

components! Resolder new component afterwards.

E-commerce order number: L50334-Z97-C529

E-commerce order name: CONN BTB D1.5 18P BQ21.N1003.011

Soldering temperature: ~ 360°C TIP Temp.

IRIS Diagnose Code: 32100 Keys / Main / No Function

32200 Keys / Main / Reduced Functionality

36000 Keys / Illumination

Back to customer

without repair

Caused by customer

SCRAP - has to be send

separately to WSC

- check for twisted or

bent contacts

- check for dry joints

Technical Documentation

10/2005

TD_Repair_L2.5L_S80_R1.0.pdf Page 10 of 18

Company Confidential

2005©BenQ

Page 11

Release 1.0

y

r

y

y

8 Main keypad illumination problems

Fault Symptoms

Customer: GRT:

Main keypad illumination does not work Current measured failed

LED Problems

Watch for oxidation and

damaged pads of the

LED’s

Okay

Not

oka

Check the status of the

battery connector

visuall

Exchange

keypad LED’s

Not

oka

Use the diode test

function of a multimete

to check the status of

the diode. The typical

voltage drop on the

diode is 1.7 V when

testing the diode

function with the

multimeter.

Okay

LED WHITE TOP

Use soldering iron to remove defective component. Avoid excessive heat! Watch surrounding

components! Resolder new component afterwards.

Attention: Remove Metal Dome Sheet before!!!

E-commerce order number: L50840-L2133-D670

E-commerce order name: DISDIODE LED BL-HB536G BQ83.00536.071

Soldering temperature: ~ 360°C TIP Temp.

IRIS Diagnose Code: 36000 Keys / Illumination

Back to customer

without repair

Caused by customer

SCRAP - has to be send

separately to WSC

- check for twisted or

bent contacts

- check for dry joints

Continue with

higher repair level

Technical Documentation

10/2005

TD_Repair_L2.5L_S80_R1.0.pdf Page 11 of 18

Company Confidential

2005©BenQ

Page 12

Release 1.0

y

y

y

9 Connector Battery

Okay

Okay

Okay

Back to customer

without repair

Caused by customer

SCRAP - has to be send

separately to WSC

- check for twisted or

bent contacts

- check for dry joints

Continue with

higher repair level

Fault Symptoms

Customer: GRT:

Mobile does not switch on No connection to GRT

Not

oka

Exchange

battery

connector

Connector BATTERY

Use hot air blower to remove defective component. Avoid excessive heat! Watch surrounding components!

Resolder new component afterwards.

E-commerce order number:

E-commerce order name: CON BATT3P CBE-4517-2904H BQ21.N0036.011

Soldering temperature: 240 - 255°C

IRIS Diagnose Code: 13000 Battery/Mechanical Damage

Battery connector problems

Watch for oxidation and

damaged pads of the

battery connector

Check the status of the

battery connector

visuall

Not

oka

Use the resistor test

function of a multimeter

to check connection

between spring

contacts and soldering

contacts. The value

must be ~ 0.

L50334-Z97-C524

Technical Documentation

10/2005

TD_Repair_L2.5L_S80_R1.0.pdf Page 12 of 18

Company Confidential

2005©BenQ

Page 13

Release 1.0

y

r

y

y

10 Connector RF Internal Antenna

Fault Symptoms

Customer: GRT:

Network search Failure by TX/RX measurements

No location update possible No location update possible

RF connector Problems

Watch for oxidation and

damaged pads of the

RF connector

Okay

Check the dust inside

the RF connector

Not

oka

Check the status of the

RF connector visually

Okay

Exchange

RF connecto

Not

oka

Use the resistor test

function of a multimeter

to check connection

between input and

output contacts.

The value must be ~0

Okay

Connector RF

Use hot air blower to remove defective component. Avoid excessive heat! Watch surrounding components!

Resolder new component afterwards.

E-commerce order number: L50145-K280-Y415

E-commerce name: SWITCH ANT MS-147 HIROSE BQ69.50017.001

Soldering temperature: 240 - 255°C

IRIS Diagnose Code:

81100 Radio / No Contact / Int. Antenna 81200 Radio / No Contact / Ext. Antenna

82100 Radio / Low Receiving Signal / Int. Antenna 82200 Radio / Low Receiving Signal / Ext. Antenna

83100 Radio / Dropped Calls / Int. Antenna 83200 Radio / Dropped Calls / Ext. Antenna

84100 Radios / Call Setup / Int. Antenna 84200 Radio / Call Setup / Ext. Antenna

Not

oka

Okay

Back to customer

without repair

Caused by customer

SCRAP - has to be send

separately to WSC

Clean RF

connector

- check for twisted or

bent contacts

- check for dry joints

Continue with

higher repair level

Technical Documentation

10/2005

TD_Repair_L2.5L_S80_R1.0.pdf Page 13 of 18

Company Confidential

2005©BenQ

Page 14

Release 1.0

y

y

11 Connector Mini SD

Fault Symptoms

Customer: GRT:

MMC malfunction Tbd.

MMC connector problems

Watch for oxidation and

damaged pads of the

MMC connector

Okay

Not

oka

Check the status of the

MMC connector visually

Okay

Exchange MMC

connector

Not

oka

Use the resistor test

function of a multimeter

to check connection

between spring

contacts and soldering

contacts. The value

must be ~ 0.

Connector MMC

Use soldering iron to remove defective component. Avoid excessive heat! Watch surrounding components!

Resolder new component afterwards.

E-commerce order number:

E-commerce order name: CONN MINI SD 9P 500525 BQ21.N0058.011

Soldering temperature: ~ 360°C TIP Temp.

IRIS Diagnose Code: 4E000 Interfaces/ Memory Card Reader

L50334-Z97-C528

Attention: Avoid excessive heat in order not to damage the plastic material of the

connector (see problem SLIM-Lumberg connector)

Okay

Back to customer

without repair

Caused by customer

SCRAP - has to be send

separately to WSC

- check for twisted or

bent contacts

- check for dry joints

Continue with

higher repair level

Technical Documentation

10/2005

TD_Repair_L2.5L_S80_R1.0.pdf Page 14 of 18

Company Confidential

2005©BenQ

Page 15

Release 1.0

y

y

12 Connector Vibra

Fault Symptoms

Customer: GRT:

VIBRA does not work Supported in April

Not

oka

Exchange vibra

connector

Not

oka

VIBRA Connector

Use hot air blower to remove defective component. Avoid excessive heat!

Watch surrounding components! Resolder new component afterwards.

E-commerce order number:

E-commerce order name: CONN SPRING SBS23-2K30F00 BQ21.N0045.011

Soldering temperature:

IRIS Diagnose Code:

Vibra connector problems

Watch for oxidation and

damaged pads of the

vibra connector

Okay

Check the status of the

vibra connector visually

Okay

Use the resistor test

function of a multimeter

to check connection

between spring

contacts and soldering

contacts. The value

must be ~ 0.

L50334-Z97-C525

240 - 255°C.

75100: Acoustics / Vibra /No Function

Okay

Back to customer

without repair

Caused by customer

SCRAP - has to be send

separately to WSC

- check for twisted or

bent contacts

- check for dry joints

Continue with

higher repair level

Technical Documentation

10/2005

TD_Repair_L2.5L_S80_R1.0.pdf Page 15 of 18

Company Confidential

2005©BenQ

Page 16

Release 1.0

y

y

13 Fuse

Fault Symptoms

Customer: GRT:

Battery charging does not work Supported in April

Not

oka

Exchange fuse

Fuse

Use hot air blower to remove defective component. Avoid excessive heat!

Watch surrounding components! Resolder new component afterwards.

E-commerce order number:

E-commerce order name: FUSE 1A 24V F0603 1608FF BQ69.41004.001

Soldering temperature:

IRIS Diagnose Code:

Charging/ Accessory problems

Watch for oxidation and

damaged pads of the

PCB (area of fuse)

Okay

Check the status of the

fuse visually

Okay

Not

oka

Use the resistor test

function of a multimeter

to check fuse

resistance. The value

must be ~ 0.

L50145-A820-Y23

240 - 255°C

11000 Battery / No charging / deep discharge

Back to customer

without repair

Caused by customer

SCRAP - has to be send

separately to WSC

- Check for dry joints

Okay

Continue with

higher repair level

Technical Documentation

10/2005

TD_Repair_L2.5L_S80_R1.0.pdf Page 16 of 18

Company Confidential

2005©BenQ

Page 17

Release 1.0

y

p

14 Connector Sidekeys

Fault Symptoms

Customer: GRT:

Pressing feeling is bad Supported in April

No function while pressing Supported in April

Side keys switch problems

Watch for oxidation and

damaged pads on the

side keys switch

Not

oka

Back to customer

without repair

Caused by customer

Okay

SCRAP - has to be send

separately to WSC

Exchange fuse

Not

okay

Not

okay

Check the status on the

side keys switch

Okay

Use the resistor test

function of a multimeter

to check connection

between spring

contacts and . The

value must be ~ 0

when the switch is

ressed.

Okay

- check for twisted or

bent contacts

- check for dry joints

Continue with

higher repair level

Side key switch

Use hot air blower to remove defective component. Avoid excessive heat!

Watch surrounding components! Resolder new component afterwards.

E-commerce order number:

E-commerce order name: SWI VOLUME KEY 5P BQ21.P0004.005

Soldering temperature:

IRIS Diagnose Code:

L50315-Z77-C261

240 - 255°C

34100 Keys / Side

Technical Documentation

10/2005

TD_Repair_L2.5L_S80_R1.0.pdf Page 17 of 18

Company Confidential

2005©BenQ

Page 18

Release 1.0

SC

15 Connector MMI

Okay

Okay

Not okay

Back to customer

without repair

Caused by customer

SCRAP has to be

send separately to

W

- check for twisted or

bent contacts

- check for dry joints

Fault Symptoms

Customer: GRT:

Keyboard malfunction Keyboard malfunction

Not okay

Exchange

MMI connector

Connector MMI

Use soldering iron to remove defective component. Avoid excessive heat!

Watch surrounding components! Resolder new component afterwards.

E-commerce order number: L50315-Z77-C261

E-commerce order name: SWI VOLUME KEY 5P BQ21.P0004.005

Soldering temperature: 240 - 255°C

IRIS Diagnose Code: 34100 Keys / Side

MMI connection

problems

Watch for oxidation and

damaged of the MMI

connector

Check the status of the

MMI connector visually

Continue with

higher repair level

Technical Documentation

10/2005

TD_Repair_L2.5L_S80_R1.0.pdf Page 18 of 18

Company Confidential

2005©BenQ

Loading...

Loading...