Siemens SDV7 Instruction Manual

Instruction manual

Type SDV7 non-arc-resistant distribution circuit breaker

Installation operation maintenance E50001-F710-K377-V6-4A00

www.usa.siemens.com/sdv7

Arc flash hazard and hazardous voltages.

Will cause death, serious injury or property damage.

Always de-energize and ground the equipment before maintenance.

Read and understand this instruction manual before using

equipment. Maintenance should be performed only by qualified

personnel. The use of unauthorized parts in the repair of the

equipment or tampering by unqualified personnel will result in

dangerous conditions which will cause death, severe injury or

equipment damage. Follow all safety instructions contained herein.

Important

The information contained herein is general in nature and not

intended for specific application purposes. It does not relieve the

user of responsibility to use sound practices in application,

installation, operation and maintenance of the equipment

purchased. Siemens reserves the right to make changes in the

specifications shown herein or to make improvements at any

time without notice or obligation. Should a conflict arise

between the general information contained in this publication

and the contents of drawings or supplementary material or

both, the latter shall take precedence.

Qualified person

For the purpose of this instruction manual a qualified person is one

who has demonstrated skills and knowledge related to the

installation, construction and operation of the equipment and the

hazards involved. In addition, this person has the following

qualifications:

Is trained and authorized to

de-energize, clear, ground and tag circuits and equipment in

accordance with established safety procedures.

Is trained in the proper care and use of protective equipment,

such as: rubber gloves, hard hat, safety glasses or face shields,

flash clothing, etc., in accordance with established safety

practices.

Is trained in rendering first aid.

Further, a qualified person shall also be familiar with the proper use

of special precautionary techniques, personal protective equipment,

insulation and shielding materials, and insulated tools and test

equipment. Such persons are permitted to work within limited

approach of exposed live parts operative at 50 volts or more, and

shall, at a minimum, be additionally trained in all of the following:

The skills and techniques necessary to distinguish exposed

energized parts from other parts of electric equipment

The skills and techniques necessary to determine the nominal

voltage of exposed live parts

The approach distances specified in NFPA 70E® and the

corresponding voltages to which the qualified person will be

exposed

The decision-making process necessary to determine the degree

and extent of the hazard and the personal protective equipment

and job planning necessary to perform the task safely.

Note:

These instructions do not purport to cover all

details or variations in equipment, nor to

provide for every possible contingency to be

met in connection with installation, operation

or maintenance. Should further information be

desired or should particular problems arise

that are not covered sufficiently for the

purchaser’s purposes, the matter should be

referred to the local sales office.

Table of contents

Introduction 04 – 05

General description 06 – 07

Receiving, handling and storage 08 – 10

Installation 11 – 13

Electrical connections 14

Instrument transformers 15 – 16

The contents of this instruction manual shall

not become part of or modify any prior or

existing agreement, commitment or

relationship. The sales contract contains the

entire obligation of Siemens Industry, Inc. The

warranty contained in the contract between

the parties is the sole warranty of Siemens

Industry, Inc. Any statements contained herein

do not create new warranties or modify the

existing warranty.

Installation of type SDV7-SE distribution circuit breaker

with stored-energy operator 17 – 24

Installation of type SDV7-MA distribution circuit breaker

with magnetic-actuator operator 25 – 34

Maintenance 35 – 42

Maintenance and troubleshooting 43 – 47

Appendix 48 – 55

Introduction

Arc flash hazard and hazardous voltages.

Will cause death, serious injury or property damage.

Always de-energize and ground the equipment before maintenance. Read

and understand this instruction manual before using equipment.

Maintenance should be performed only by qualified personnel. The use of

unauthorized parts in the repair of the equipment or tampering by

unqualified personnel will result in dangerous conditions which will cause

death, severe injury or equipment damage. Follow all safety instructions

contained herein.

Arc flash hazard, hazardous voltages and high-speed moving parts.

Will cause death, serious injury or property damage.

To avoid arc flash burns, electrical shock and entanglement in moving parts,

only qualified personnel should work on or around this equipment after

becoming thoroughly familiar with all danger or warning notices, and

procedures contained herein. Personnel must observe all applicable

regulations (e.g., OSHA), follow all requirements of NFPA 70E and adhere to

specific operating procedures applicable to the installation. Use appropriate

personal protective equipment (PPE) for the voltage and arc flash incident

energy exposure.

4

Introduction

The type SDV7 distribution circuit breaker is

designed to meet all applicable ANSI, NEMA

and IEEE standards. Successful application

and operation of this equipment depends as

much upon proper installation and

maintenance by the user as it does upon the

proper design and fabrication by Siemens.

The purpose of this instruction manual is to

assist the user in developing safe and

efficient procedures for the installation,

maintenance and use of the equipment.

This instruction manual applies to the type

SDV7 distribution circuit breaker enclosure,

including the type SDV7-SE model with

stored-energy operator and the type SDV7MA model with magnetic-actuator operator.

Refer to instruction manual E50001-F710K376-X-XXXX for instructions applicable to

the type 3AH35-SE stored-energy operator

used in the type SDV7-SE circuit breaker.

Refer to instruction manual E50001-F710K378-X-XXXX for instructions applicable to

the type 3AH35-MA magnetic-actuator

operator used in the type SDV7-MA circuit

breaker.

Field service operation and warranty

issues

Siemens can provide competent, well-trained

field service representatives to provide

technical guidance and advisory assistance

for the installation, overhaul, repair and

maintenance of Siemens equipment,

processes and systems. Contact regional

service centers, sales offices or the factory for

details, or telephone Siemens field service at

+1 (800) 347-6659 or +1 (919) 365-2200

outside the U.S.

For medium-voltage customer service issues,

contact Siemens at +1 (800) 347-6659 or +1

(919) 365-2200 outside the U.S.

Contact the nearest Siemens representative

if any additional information is desired.

Signal words

The signal words “danger,” “warning” and

“caution” used in this manual indicate the

degree of hazard that may be encountered by

the user. These words are defined as:

Danger - Indicates an imminently hazardous

situation that, if not avoided, will result in

death or serious injury.

Warning - Indicates a potentially hazardous

situation that, if not avoided, could result in

death or serious injury.

Caution - Indicates a potentially hazardous

situation that, if not avoided, may result in

minor or moderate injury.

Notice - Indicates a potentially hazardous

situation that, if not avoided, may result in

property damage.

5

General description

The instructions included in this instruction

manual are provided to aid you in obtaining

longer and more economical service from

your Siemens type SDV7 distribution circuit

breaker. For proper installation and operation,

this information should be distributed to your

operators and engineers.

By carefully following these instructions,

difficulties should be avoided. However, these

instructions are not intended to cover all

details of variations that may be encountered

in connection with the installation, operation

and maintenance of this equipment.

Should additional information be desired,

including replacement instruction manuals,

contact your local Siemens representative.

Scope

These instructions cover the installation,

operation and maintenance of Siemens type

SDV7 distribution circuit breaker using

vacuum interrupters. The equipment designs

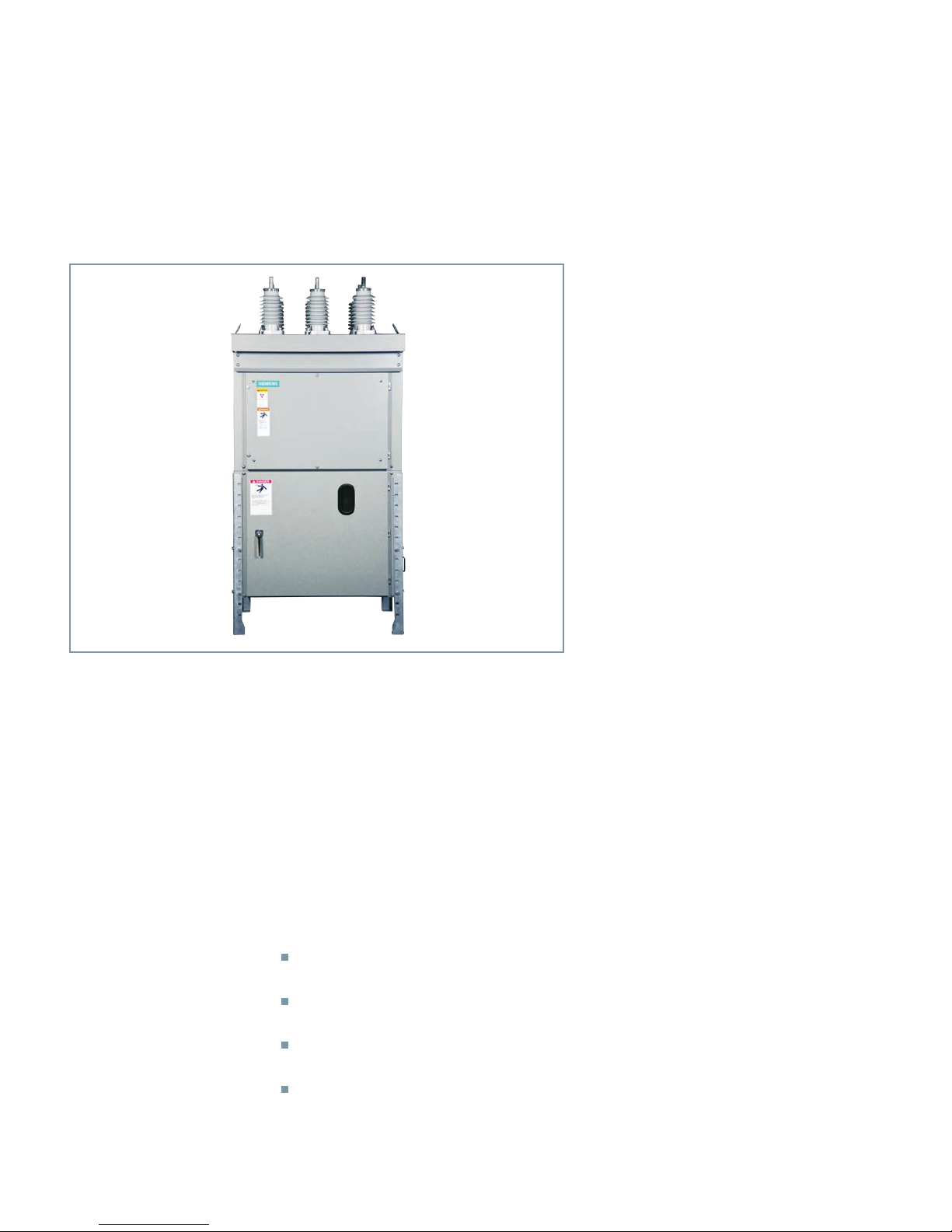

Figure 1: Typical type SDV7 distribution circuit breaker

Introduction

Siemens type SDV7 distribution circuit

breaker is precision built equipment designed

to function efficiently under normal operating

conditions. It is designed and manufactured

to operate within the parameters established

in ANSI/IEEE C37 and NEMA standards for

distribution circuit breakers. Performance

requirements of these standards have been

met or exceeded by these designs. Specific

standards which apply include:

ANSI/IEEE C37.04-1999 rating structure

for ac high-voltage circuit breakers

ANSI/IEEE C37.06-2009 preferred ratings

ac high-voltage circuit breakers

ANSI/IEEE C37.09-1999 test procedure for

ac high-voltage circuit breakers

NEMA SG4-2009 ac high-voltage circuit

breakers.

described in this instruction manual consists

of free-standing outdoor distribution circuit

breakers for application up to 38 kV. A typical

type SDV7 distribution circuit breaker is

shown in Figure 1: Typical type SDV7

distribution circuit breaker. All diagrams,

descriptions and instructions apply to all of

the above classes and designs unless noted

otherwise.

Standard construction details of the circuit

breaker enclosure are given in appropriate

sections of this instruction manual.

Standard construction details of the storedenergy operating mechanism of the circuit

breaker are detailed in the type 3AH35-SE

stored-energy operator instruction manual

E50001-F710-K376-X-XXXX.

Standard construction details of the

magnetic-actuator operating mechanism of

the circuit breaker are detailed in the type

3AH35-MA magnetic-actuator operator

instruction manual E50001-F710-K378-XXXXX.

6

Special mechanical and electrical devices,

furnished in accordance with purchase order

requirements, are covered by supplementary

instructions submitted with this instruction

manual.

The equipment furnished has been designed

to operate in a system having the circuit

capacity specified by the purchaser. If for any

reason the equipment is used in a different

system or if the short-circuit capacity of the

system is increased, the ratings of the

equipment, including the momentary rating

and the interrupting capacity of the type

SDV7 distribution circuit breaker must be

checked. Failure on the part of the user to

receive approval of intended changes from

Siemens may cause the warranty to be void.

This instruction manual applies to the type

SDV7 distribution circuit breaker enclosure

structure.

Refer to instruction manual E50001-F710K376-X-XXXX for instructions applicable to

the type 3AH35-SE stored-energy operator.

Refer to instruction manual E50001-F710K378-X-XXXX for instructions applicable to

the type 3AH35-MA magnetic-actuator

operator.

General description

The distribution circuit breaker described in

this instruction manual is of the ac highvoltage outdoor circuit breaker type, as

defined in ANSI/IEEE C37 and NEMA SG4

standards. All high-voltage parts excluding

roof bushings are completely enclosed within

grounded barriers. The secondary control

devices and primary circuits are isolated from

each other by barriers.

Siemens type SDV7 distribution circuit

breakers carry a type designation, as shown

in Table 1: Type SDV7 distribution circuit

breaker designations. This designation may

appear on drawings and familiarity with them

will simplify communications with the

factory.

In this instruction manual, reference to type

SDV7 distribution circuit breaker is used when

the text applies to the circuit breaker with

either type of operating mechanism. When

relevant to the type of operator, the type

SDV7-SE (stored-energy) or type SDV7-MA

(magnetic-actuator) designations are used.

Operator Type

Stored energy SDV7-SE

Magnetic actuator SDV7-MA

Table 1: Type SDV7 distribution circuit breaker

designations

7

Receiving, handling

and storage

Receiving

Each type SDV7 distribution circuit breaker is

securely blocked and braced for shipment. It

is crated, boxed or covered as required by

shipping conditions. If special handling is

required, it is so indicated. Relatively delicate

instruments, protective relays and other

devices are included, and the type SDV7

distribution circuit breaker must be handled

carefully when unloading.

Inspection and unpacking

Inspect the equipment as soon as possible

after receipt for any damage that may have

occurred in transit. Before unpacking,

examine the package itself, as a damaged

package may indicate damage to the contents

of the package. Be careful when unpacking

equipment. The use of sledge hammers and

crowbars may damage the finish, or the

equipment itself. Use nail pullers. After

unpacking, examine equipment for any

possible damage. Check the shipping

manifest to be certain that all items have

been received.

Note: If there is a shortage, make certain it is

noted on the freight bill and contact the

carrier immediately. Notify Siemens mediumvoltage customer service at +1 (800) 3476659 (+1 (919) 365-2200 outside the U.S.) of

any shortage or damage.

1. When shipment arrives, note whether

equipment is properly protected from the

elements. Note trailer number on which

the equipment arrived. Note blocking of

equipment. During unloading, make sure

to count the actual items unloaded to

verify the contents as shown on the

delivery receipt.

2. Make immediate inspection for visible

damage upon arrival and prior to

disturbing or removing packaging or

wrapping material. This should be done

prior to unloading when possible. When

total inspection cannot be made on

vehicle prior to unloading, close

inspection during unloading must be

performed and visible damage noted on

the delivery receipt. Take pictures if

possible.

3. Any visible damage must be noted on the

delivery receipt and acknowledged with

the driver’s signature. The damage should

be detailed as much as possible. It is

essential that a notation “possible internal

damage, subject to inspection” be

included on delivery receipt. If the driver

will not sign the delivery receipt with

damage noted, the shipment should not

be signed for by the consignee or their

agent.

Shipping damage claims

Important: The manner in which visible

shipping damage is identified by consignee

prior to signing the delivery receipt can

determine the outcome of any damage claim

to be filed.

Notification to carrier within 15 days for

concealed damage is essential if loss resulting

from unsettled claims is to be eliminated or

minimized.

8

4. Notify Siemens immediately of any

damage, at +1 (800) 347-6659 or +1

(919) 365-2200 outside the U.S.

5. Arrange for a carrier inspection of damage

immediately.

Important: Do not move equipment from the

place it was set when unloading. Also, do not

remove or disturb packaging or wrapping

material prior to carrier damage inspection.

Equipment must be inspected by carrier prior

to handling after receipt. This eliminates loss

due to claims by carrier that equipment was

damaged or further damaged on site after

unloading.

6. Be sure equipment is properly

protected from any further damage by

covering it properly after unloading.

7. If practical, make further inspection for

possible concealed damage while the

carrier’s inspector is on site. If inspection

for concealed damage is not practical at

the time the carrier’s inspector is present,

it must be done within 15 days of receipt

of equipment. If concealed damage is

found, the carrier must again be notified

and inspection made prior to taking any

corrective action to repair. Also notify

Siemens immediately at +1 (800) 3476659 or +1 (919) 365-2200 outside the

U.S.

Note: Shipments are not released from the

factory without a clear bill of lading.

Approved methods are employed for

preparation, loading, blocking and tarping

of the equipment before it leaves the

Siemens factory. Any determination as to

whether the equipment was properly loaded

or properly prepared by shipper for over-theroad travel cannot be made at the

destination. If the equipment is received in a

damaged condition, this damage to the

equipment has to have occurred while en

route due to conditions beyond Siemens

control. If the procedure outlined above is

not followed by the consignee, purchaser or

their agent, Siemens cannot be held liable

for repairs. Siemens will not be held liable

for repairs in any case where repair work

was performed prior to authorization from

Siemens.

8. Obtain the original of the carrier

inspection report and forward it along

with a copy of the noted delivery receipt

to Siemens at +1 (800) 347-6659 or +1

(919) 365-2200 outside the U.S. Approval

must be obtained by Siemens from the

carrier before any repair work can be

performed. Before approval can be

obtained, Siemens must have the above

referenced documents. The carrier

inspection report and/or driver’s signature

on the delivery receipt does not constitute

approval to repair.

9

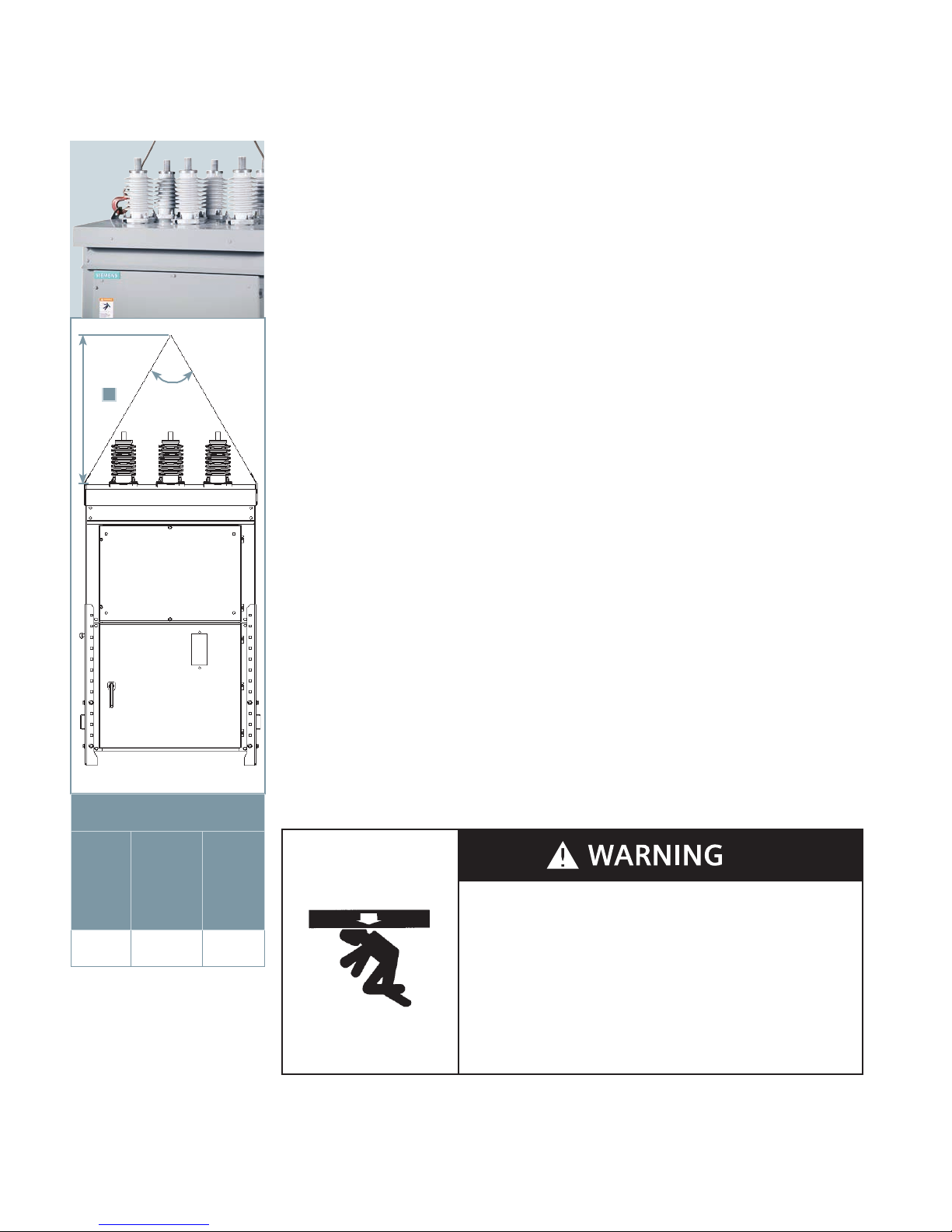

Lifting and moving

There are a number of methods that can be

used in handling the type SDV7 distribution

circuit breaker that, when properly

employed, will not damage the type SDV7

distribution circuit breaker. The handling

method used will be determined by

conditions and available equipment at the

installation site. Lifting with a crane by the

use of a sling and lifting lugs is the preferred

method of handling; however, overhead

obstructions often dictate that other

methods must be used. Forklift trucks may

A

~60°

be used prior to removal of wooden skids.

Verify the forklift blades pass completely

through the wooden skid under the circuit

breaker.

Each type SDV7 distribution circuit breaker

has provisions for attaching lifting cables.

Lifting lugs are provided on two sides of the

circuit breaker, which are designed for use

with a lift sling or hooks of the proper size

and a crane of adequate height and

capacity. Refer to the type SDV7 distribution

circuit breaker nameplate for the weight.

Lifting type SDV7 distribution circuit

breaker with crane

Recommended lifting of type SDV7

distribution circuit breakers is by means of

cables connected to an overhead crane. The

cables are connected to the lifting lugs on

the top of the type SDV7 distribution circuit

breaker as illustrated in Figure 2: Lifting

type SDV7 distribution circuit breaker with

crane. A crane with sufficient height should

be used so the load angle on the lifting

cable will be approximately 60° when

viewed from the front or rear.

Storage

When it is necessary to store a type SDV7

distribution circuit breaker in an area

exposed to the weather or under humid

conditions, energize the space heaters

provided and make certain that any vents

are uncovered to allow air to circulate. If at

all possible, install the type SDV7

distribution circuit breaker at the permanent

location even though it may be some time

before the equipment is used. It is also

recommended that the type SDV7

distribution circuit breaker receive periodic

inspection during storage.

dimensions in inches (mm)

15.5 kV,

1,200 A2,000 A

41

(1,040)

distribution circuit breaker with

Value A

15.5 kV

3,000 A

and

27.6 kV

1,200 A-

2,000 A

48

(1,220)

Figure 2: Lifting type SDV7

38.0 kV,

1,200 A2,500 A

(1,550)

61

crane

Access to the heater circuit is gained by

opening the door to the relay and control

compartment. Refer to the wiring diagram

drawing for space heater circuit

connections. Lubricate hinges and other

moving parts.

Heavy weight.

Can result in death, serious injury or property damage.

Observe all handling instructions in this instruction manual to prevent

tipping or dropping of equipment.

10

Installation

Preparation for installation

Prior to installation of the type SDV7

distribution circuit breaker, careful design,

planning and construction of the foundation

or base on which the circuit breaker will rest

must be made. A thorough analysis and

careful construction may alleviate many

problems at the time of installation, and

during operation. It is important that a

relatively level surface be provided capable

of supporting the weight of the type SDV7

distribution circuit breaker, and 0.75 inch

diameter anchor bolts are recommended.

Figure 4: Anchoring type SDV7 distribution

circuit breaker on page 13 illustrates typical

locations for anchor bolts. No special

leveling procedures are required.

Prior to installation of a type SDV7

distribution circuit breaker, study this

instruction book and the circuit breaker

drawings, such as general arrangement/

outline drawing, schematic diagram,

connection diagrams, current transformer

connection diagram, electrical bill of

material and nameplate engraving.

Special attention should be given to the

foundation information contained in this

instruction manual as well as the

information provided on the equipment

drawings. Verify the foundation conforms to

the requirements described in this

instruction manual and the general

arrangement/outline drawing.

The type SDV7 distribution circuit breaker is

shipped with the legs attached. The legs

must be set to the desired height.

Setting leg height

The type SDV7 distribution circuit breaker is

shipped with the legs set to a low level (and

on some units, turned outward). The legs

must be removed and installed correctly.

Remove the legs from the enclosure. Raise

the enclosure, and install the legs at the

desired height.

The legs must be installed and turned

inward, so that the two sides of the each leg

are adjacent to the enclosure sides and the

hole at the bottom of the leg is inside the

perimeter of the enclosure, as in Figure 3:

Outline drawing on page 12.

Use anti-seize compound (Loctite* 77164 or

77124 nickel anti-seize) on the

stainless steel cap screws used to secure the

legs to facilitate removal of the legs should

it be required in the future.

The height (as installed) between the

mounting surface (foundation) and the

bottom of the enclosure must be at least 4”

(102 mm) and no higher than 28”

(711 mm).

High-seismic installations

Figure 3: Outline drawing on page 12 shows

optional cross-braces installed for highseismic requirements.

Cross braces can be installed if the bottom

of the enclosure is at least 12” (330 mm)

above the foundation.

The cross braces consist of steel links that

are adaptable for all installation heights

(from 13” (330 mm) to 28” (711 mm).

Install the cross braces as shown in the

illustration. The end of the link with a single

hole is bolted to the lowest hole on the leg.

The opposite link is bolted with the singlehole end bolted to one of the two highest

exposed holes in the leg below the

enclosure. The highest hole or second

highest hole is used, as necessary to allow

alignment. Then, bolt the two links together

towards the middle, using whichever set of

holes align.

When optional cross braces are furnished,

install all eight cross braces (four sets) to

obtain the required seismic performance.

Location

The circuit breaker should be located so that

it is readily accessible for manual operation

and inspection. Ample clearance should be

provided for doors and panels to swing

open, or to be removed for servicing the

circuit breaker.

1

/2-13 SAE

* Loctite is a registered

trademark of Henkel

Corporation.

11

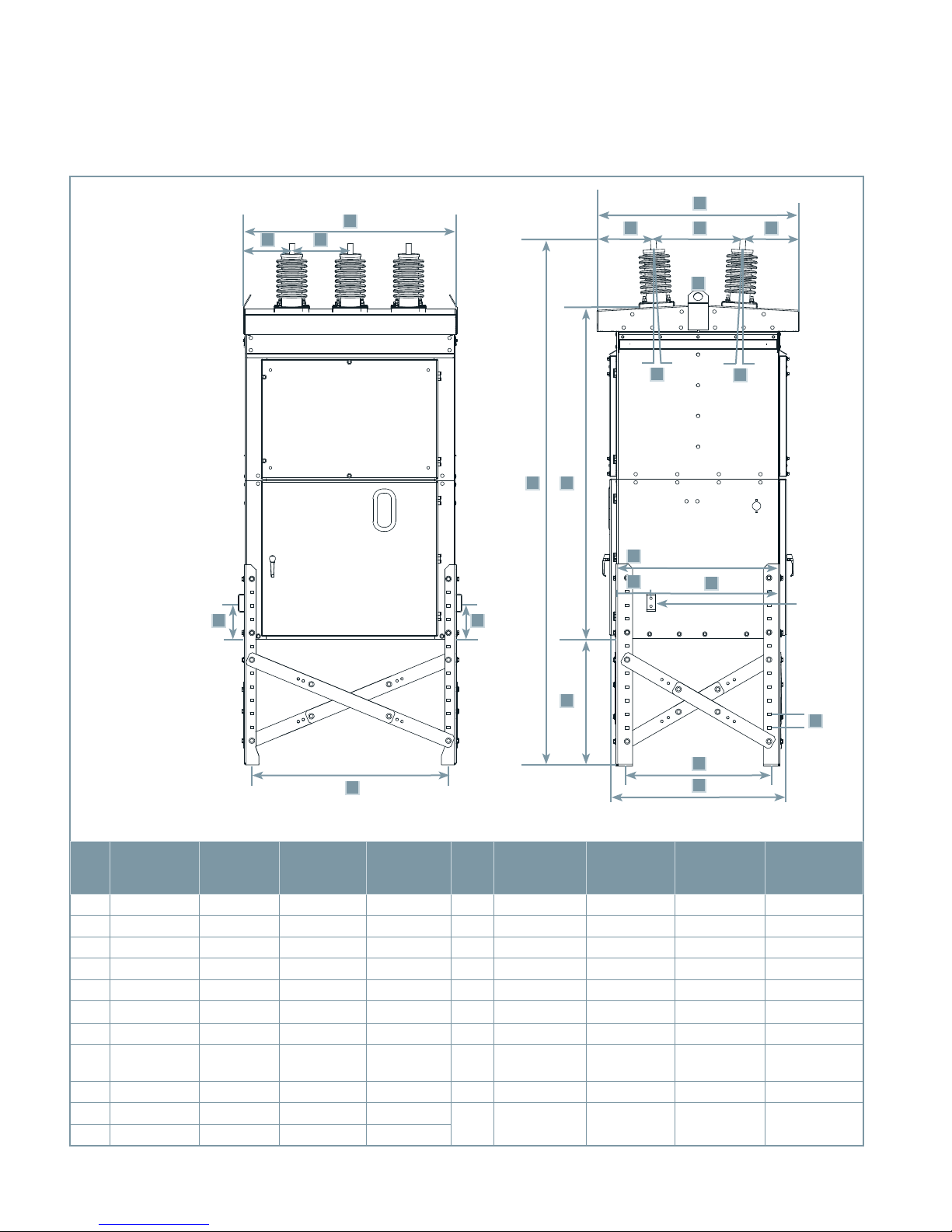

Figure 3: Outline drawing

1

Note 1: Shown with

optional cross-bracing

for high-seismic

loading, and with legs

installed at maximum

height 28" (711 mm).

Dimensions in inches

(mm)

A

B

C

E E

2-4-6 1-3-5

H

G

I

J

D

K

L

High-voltage

compartment

TU

Operator

compartment

M

N

Relay and

control

compartment

O

Ground

pads on

diagonally

opposite

corners

S

P

Note 1

Q

R

27.6 kV

1,200 A-

2,000 A

38.0 kV

1,200 A-

2,500 A

Item

15.5 kV

1,200 A-

2,000 A

15.5 kV

3,000 A

Note 1

27.6 kV

1,200 A-

2,000 A

F

38.0 kV

1,200 A-

2,500 A

Item

15.5 kV

1,200 A-

2,000 A

15.5 kV

3,000 A

A 47.1 (1,196) 56.3 (1,430) 56.3 (1,430) 65.7 (1,669) L 3.0° 3.0° 3.0° 3.0°

B 10.6 (269) 12.1 (307) 12.1 (307) 13.4 (340) M 35.8 (909) 44.2 (1,123) 44.0 (1,118) 55.6 (1,412)

C 13.0 (330) 16.0 (406) 16.0 (406) 19.5 (495) N 7.6 (193) 7.7 (196) 7.6 (193) 9.5 (241)

D 2.0 (51) 2.0 (51) 2.0 (51) 2.0 (51) O 28.4 (721) 36.5 (927) 36.4 (925) 46.1 (1,171)

E 8.0 (203) 8.0 (203) 8.0 (203) 8.0 (203) P 3.0 (76) 3.0 (76) 3.0 (76) 3.0 (76)

F 42.7 (1,085) 52.0 (1,321) 52.0 (1,321) 63.1 (1,603) Q 31.3 (795) 39.4 (1,001) 39.4 (1,001) 50.9 (1,293)

G 44.5 (1,130) 57.8 (1,468) 49.6 (1,260) 63.2 (1,605) R 38.8 (986) 47.0 (1,194) 46.8 (1,189) 58.4 (1,483)

H 8.0 (203) 18.4 (467) 11.5 (292) 20.4 (518) S

4.0 (102)-

28.0 (711)

4.0 (102)-

28.0 (711)

4.0 (102)-

28.0 (711)

4.0 (102)-

28.0 (711)

I 19.8 (503) 21.0 (307) 21.0 (307) 22.2 (564) T 73.5 (1,867) 77.2 (1,961) 77.6 (1,971) 93.5 (2,375)

J 8.0 (203) 18.4 (467) 11.5 (292) 20.4 (518)

K 3.0° 3.0° 3.0° 3.0°

U

92.0 (2,337)-

116.0 (2,945)

96.0 (2,337)-

120.0 (3,048)

96.0 (2,337)-

120.0 (3,048

120.5 (3,061)-

144.5 (3,670)

12

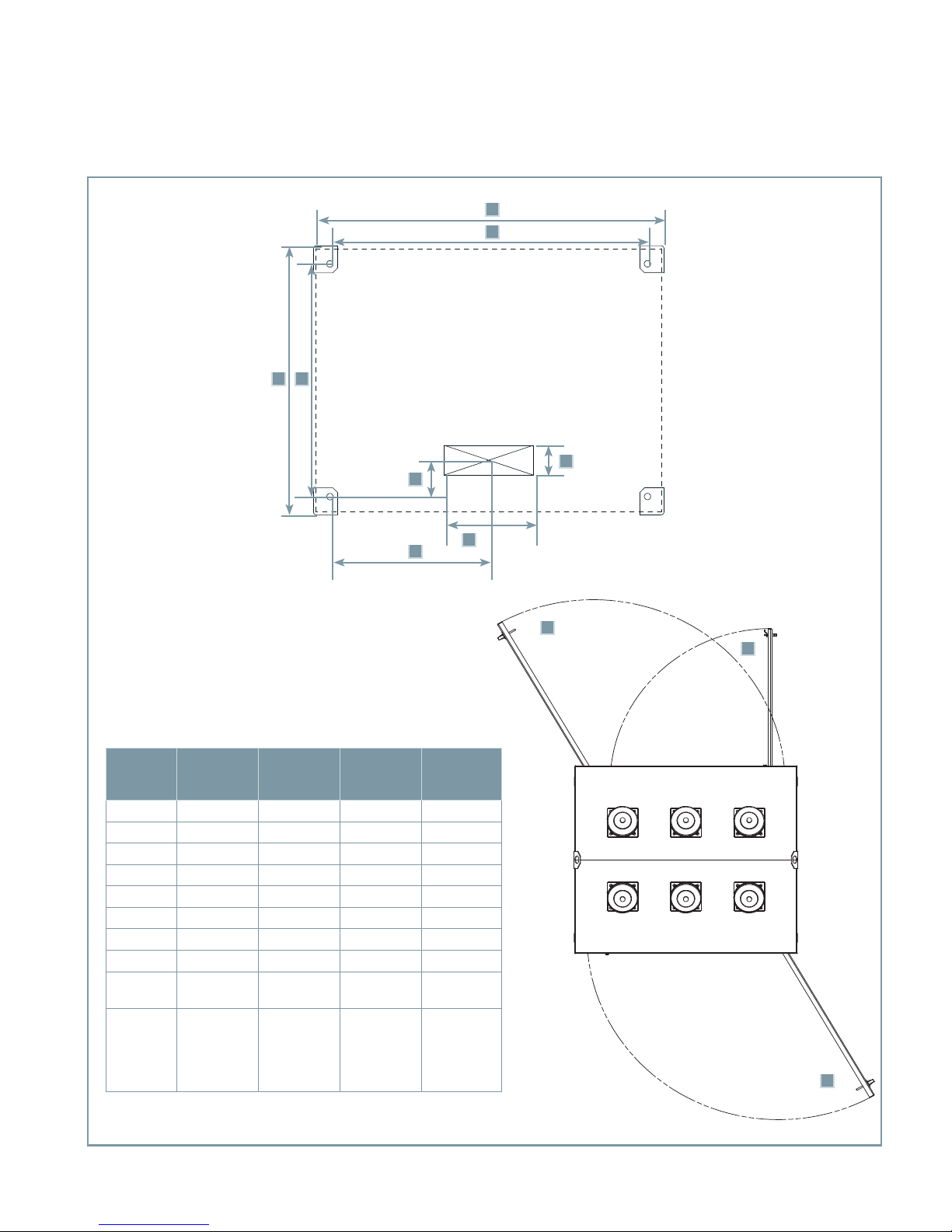

Figure 4: Anchoring type SDV7 distribution circuit breaker

A

B

GH

C

F

E

Dimensions in inches (mm)

Item

A 47.1 (1,196) 56.5 (1,435) 56.5 (1,435) 67.8 (1,722)

B 42.7 (1,085) 52.0 (1,321) 52.0 (1,321) 63.1 (1,603)

C 6.0 (152) 6.0 (152) 6.0 (152) 6.0 (152)

D 12.0 (305) 12.0 (305) 12.0 (305) 12.0 (305)

E 21.3 (541) 26.0 (660) 26.0 (660) 31.5 (800)

F 4.9 (124) 3.9 (99) 4.9 (124) 5.1 (130)

G 31.3 (795) 39.4 (1,001) 39.4 (1,001) 50.7 (1,288)

H 36.1 (917) 44.2 (1,123) 44.2 (1,123) 55.6 (1,412)

I (Outer

door)

J (Inner

relay

panel,

when

supplied)

15.5 kV

1,200 A-

2,000 A

40.0 (1,016) 46.5 (1,181) 46.5 (1,181) 46.8 (1,189)

36.0 (914) 42.8 (1,087) 42.8 (1,087) 41.3 (1,049)

15.5 kV

3,000 A

27.6 kV

1,200 A-

2,000 A

D

38.0 kV

1,200 A-

2,500 A

I

I

J

J

I

I

13

Electrical connections

Hazardous voltages and high speed moving parts.

Will cause death, serious injury or property damage.

Do not work on energized equipment. Always de-energize and ground highvoltage conductors before working on or near them. The user must adjust

the circuit breaker height to ensure compliance with safety codes for

electrical clearance.

14

Primary lead connections

The primary leads must be routed to the

bushing terminals so as to maintain

adequate dielectric clearance between

different phase conductors and to ground.

Conductors must be supported so that the

circuit breaker bushings are not subjected to

excessive strains, both during normal

service and in the event of a short-circuit

condition. The leads should be sized to have

a capacity at least equal to the maximum

operating current of the circuit and within

the rating of the type SDV7 distribution

circuit breaker. Connections are to be made

to the bolted terminals of the bushings and

must be securely tightened to a clean,

bright surface to assure good contact.

Ground connections

Grounding pads on diagonally opposite

corners of the enclosure are provided for

connecting the cabinet to ground. The

grounding conductors should be at least 4/0

AWG conductor on each ground pad. A good

low-resistance ground is essential for

adequate protection and for proper

functioning of electronic components such

as protective relays. Connections to ground

pads must be made in such a manner that a

reliable ground connection is obtained.

Consult latest National Electrical Code® or

National Electric Safety Code® for ground

connection standards.

Secondary control wiring

All secondary control wiring installed by the

factory is neatly routed and secured in

place. Complete all field connections in a

similar manner. Check that the protective

relay panel (if so equipped) clears any

additional wiring installed.

A conduit panel opening is provided in the

bottom of the relay and control

compartment for the connection of control

circuits. The control wires should be run

separately from high-voltage wiring to

prevent inductive coupling between them

and should be sized for full operating

current to avoid a drop in voltage below that

specified on the nameplate. All conduits

should be sealed off at their entrance to the

relay and control compartment.

Terminal blocks are provided inside the relay

and control compartment for the

connections necessary for the control wiring

and protective relay panel (if so equipped).

Terminal blocks for current transformer

wiring are located in the operator

compartment and wires can easily be routed

from the conduit panel opening in the relay

and control compartment to the current

transformer circuit terminal blocks in the

operator compartment. Consult the

connection diagrams for the location of

connection terminal points for each circuit.

Connection diagrams are provided with

each type SDV7 distribution circuit breaker

and will be found in the pocket inside the

relay and control compartment door.

Instrument

transformers

Hazardous voltages.

Will cause death, serious injury or property damage.

Do not operate current transformers with the secondary open circuited.

Current transformers must be either connected to a load or short circuited.

Current transformer secondary circuits also must be grounded.

Current transformers (CTs)

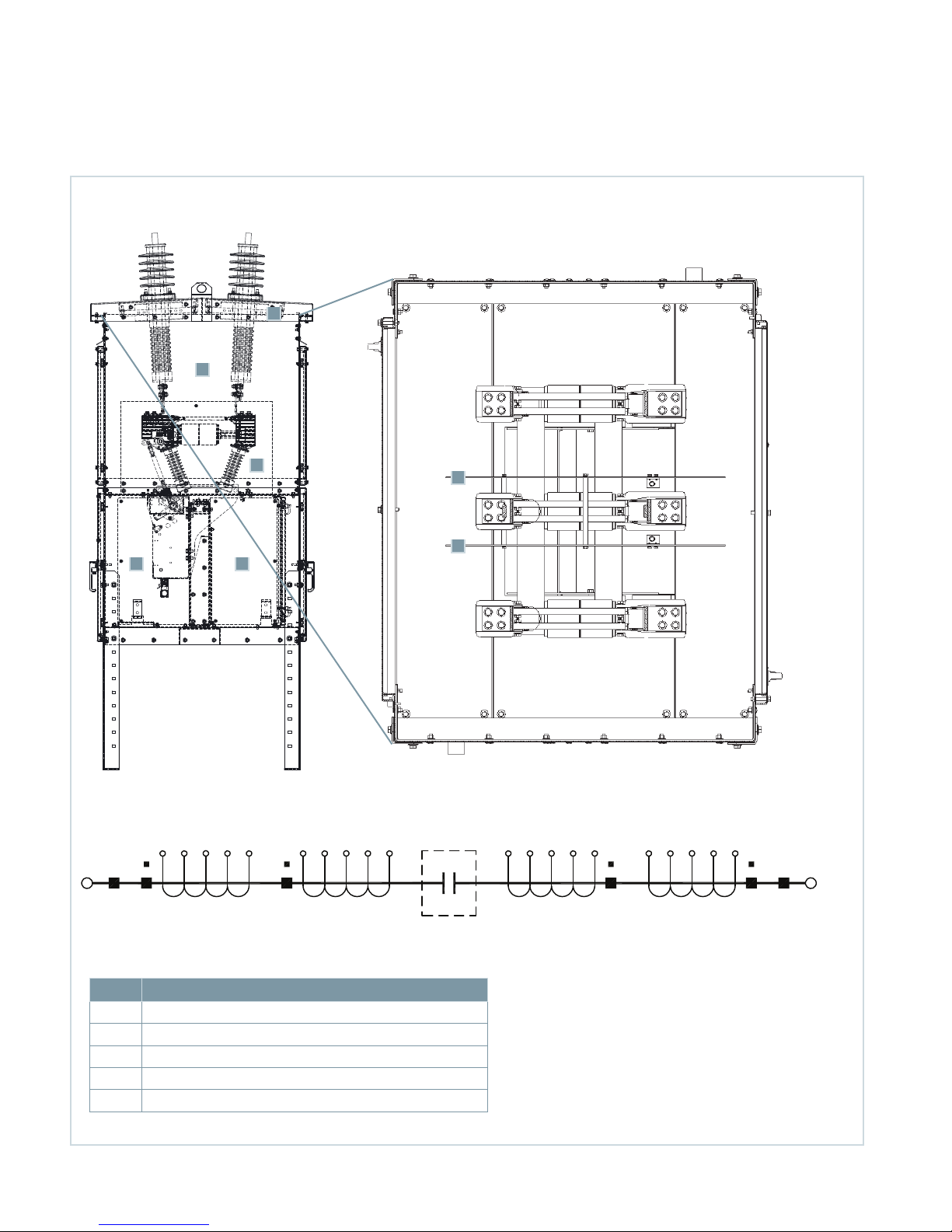

Figure 5: Type SDV7 distribution circuit

breaker with interphase barriers and

bushing current transformers installed in

primary compartment on page 16 illustrates

bushing (toroidal) CTs installed in the

primary compartment of a type SDV7

distribution circuit breaker. The roof

bushings pass through the CTs. Up to two

CTs may be mounted around each roof

bushing. The bushing CT connections are

wired to separate terminal blocks located in

the low-voltage operator compartment.

Phase barriers

Phase barriers are provided on all 27.6 kV

and 38 kV class type SDV7 distribution

circuit breakers as shown in Type SDV7

distribution circuit breaker with interphase

barriers and bushing current transformers

installed in primary compartment on page

16. These plates of insulating material are

attached to the circuit breaker housing and

provide suitable electrical insulation

between the vacuum interrupter primary

circuits.

15

Figure 5: Type SDV7 distribution circuit breaker with interphase barriers and bushing current transformers installed in primary compartment

2-4-6 1-3-5

A

E

Bushings

2-4-6

B

B

B

D C

Vacuum

interrupter

X1 X2 X3 X4 X5 X1 X2 X3 X4 X5 X5 X4 X3 X2 X1 X5 X4 X3 X2 X1

X XY Y

Current transformer positions Current transformer positions

Bushings

1-3-5

Item Description

A Bushing current transformer (one per bushing shown)

B Phase barriers apply only in 27.6 kV and 38 kV

C Relay and control compartment

D Operator compartment

E High-voltage compartment

16

Note: Arrangement shown with four sets of multi-ratio

current transformers (five-lead type). Consult drawings for

the specific quantity and location of current transformers on

your circuit breaker.

Installation of type

SDV7-SE circuit

breaker with storedenergy operator

Hazardous voltages and high speed moving parts.

Will cause death, serious injury or property damage.

Read instruction manuals, observe safety instructions and use qualified

personnel.

Introduction

This section provides a description of the

inspections, checks and tests to perform on

the type SDV7-SE distribution circuit breaker

prior to operation.

Inspections, checks and tests without

control power

Type SDV7-SE vacuum circuit breakers are

normally shipped with the primary contacts

open and the springs discharged. However,

prior to starting the inspection process, it is

critical to first verify that the control power

is de-energized, the spring-loaded

mechanisms are in the discharged condition

and the circuit breaker main contacts are

open.

De-energizing control power in a power

circuit breaker

To de-energize the control power, open the

disconnect device in the relay and control

compartment. Figure 6: Relay and control

and operator compartments for type

SDV7-SE circuit breaker with stored-energy

operator on page 19 presents the location

of this disconnect in a standard type

SDV7-SE distribution circuit breaker.

The disconnect means shown in the photo

are knife switches with fuses. Molded-case

circuit breakers or pullout type fuse holders

can be furnished instead when specified.

The control power disconnect device is

located on the control panel in the relay and

control compartment.

17

Loading...

Loading...