Siemens SDP-6 Maintenance Manual

Procedure for Installation, Operation

and Maintenance Manual

SDP-6

Siemens AS

Ternetangen 65

N-5420 Rubbe stadneset

00007464 rev. H

Siemens Doc No : 00007464 Page : 2 of 12

Document Title : Procedure for Installation, Oper ation and Maintenance

Rev. : H

Manual SDP-6

Revision List

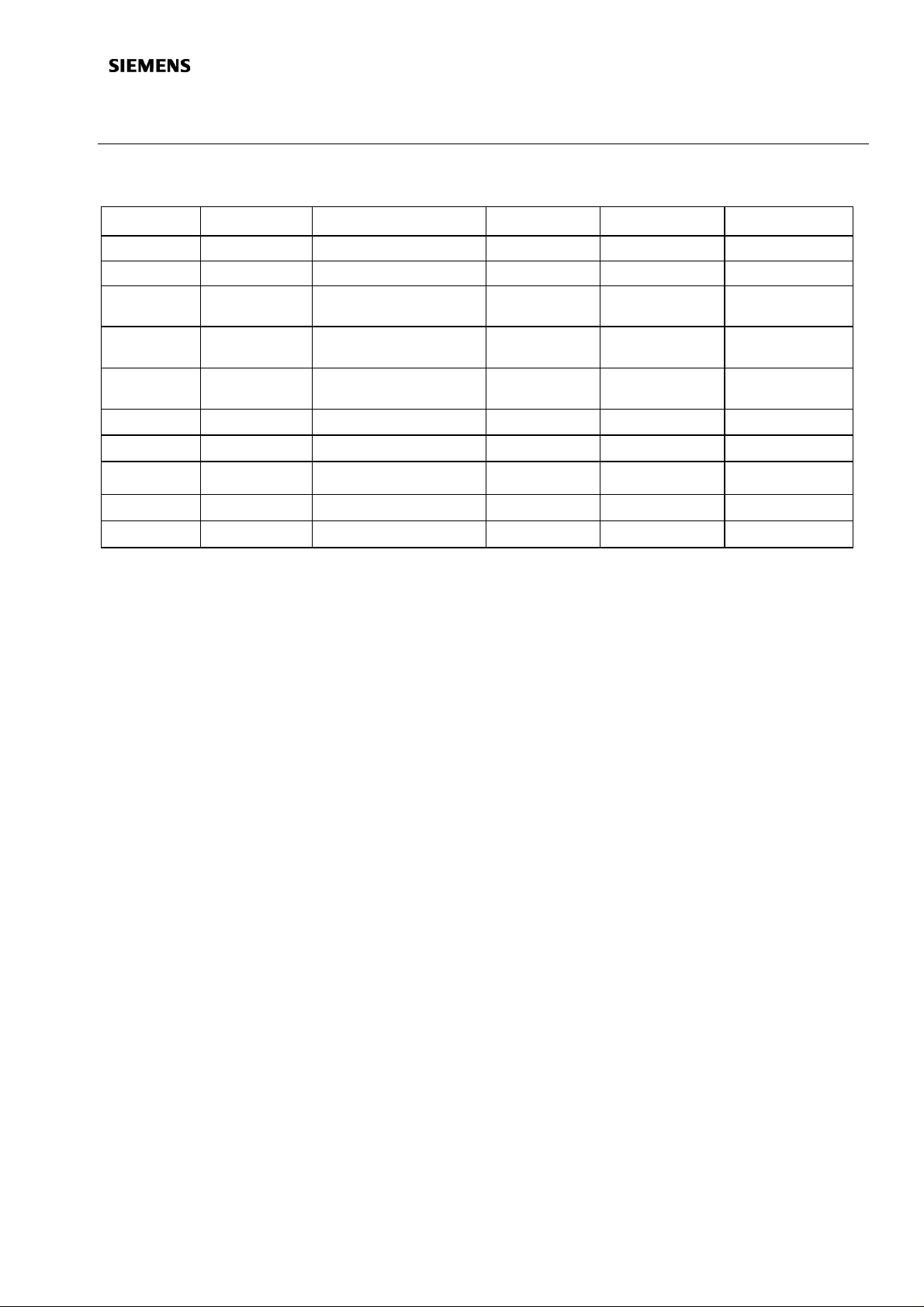

Rev Date Description Author Reviewed Approved

X1 11.12.01 REVIEW ESE

0 21.12.05 AFC HKA KH ESE

A

B 10.12.2009

C

D

E

F 25.06.2015

G 19.11.2015 Improved content BH CF AE

H 24.08.2017 Changed section 8 BH TKG EV

17.01.08

27.01.2010

11.08.2011

06.02.2013

New logo and layout,

inserted table of content

Revised, to cover di gital

SDP-6 sensors

Revised, to cover Lev el

Monitoring

Revised, Item 5

Changed Logo

Changed layout to TC

document, updated text.

KAA

SM SM Tkg

SM SM TKG

SM RM TKG

CS MN RM

BH CF AE

Siemens Doc No : 00007464 Page : 3 of 12

Document Title : Procedure for Installation, Oper ation and Maintenance

Manual SDP-6

Rev. : H

TABLE OF CONTENTS

1 GENERA L ...................................................................................................................................... 4

2 PURPOS E ...................................................................................................................................... 4

2.1 GENERAL ............................................................................................................................... 4

2.2 PACKING AND TRA NP OR TA TION ......................................................................................... 4

3 HEALTH AND SAFETY STATEMENTS.......................................................................................... 5

4 TESTING ........................................................................................................................................ 6

4.1 FUNCTI ON AL TESTING.......................................................................................................... 6

4.2 EQUIPME NT ........................................................................................................................... 6

4.3 HOOK UP ................................................................................................................................ 7

4.4 VERIFIC ATION O F SENS OR READ INGS ............................................................................... 7

5 INSTA LLATION .............................................................................................................................. 8

5.1 INSTALLATION POSITION AN D DIRECTION ......................................................................... 8

5.2 INSTALLATION OF REMOTE SEALS ..................................................................................... 8

5.3 ROUTIN G OF THE CAPILLARY TUBES ................................................................................. 8

5.4 SDP-6 USED F OR FL OW MONI TOR IN G ................................................................................ 8

5.5 SDP-6 USED FOR LEVEL MON IT ORING ............................................................................... 9

5.6 INTRODUC TION ..................................................................................................................... 9

5.7 REQUIRED INF ORMA TI ON .................................................................................................... 9

5.8 ZERO ADJUSTMEN T .............................................................................................................. 9

5.9 CAPILLAR Y TUBES ...............................................................................................................10

5.10 MEMBRANE SYSTEM........................................................................................................10

5.11 FIXING TOOLS...................................................................................................................10

5.12 WELDING ...........................................................................................................................10

5.13 PAINTIN G ON STRUCTUR E ..............................................................................................11

6 OPERA TION INSTRUC TION .........................................................................................................11

7 MAINTENANCE .............................................................................................................................11

8 STORA GE .....................................................................................................................................12

8.1 GENERAL CONDITIONS .......................................................................................................12

8.2 STORAGE ..............................................................................................................................12

Siemens Doc No : 00007464 Page : 4 of 12

is appropriate for the instrument /

Document Title : Procedure for Installation, Oper ation and Maintenance

Manual SDP-6

Rev. : H

1 GENERAL

WARNING: Ensure that this Installation, Operation and

Maintenance manual

sensor(s).

2 PURPOSE

2.1 GENERAL

The purpose of this Manual is to ensure that the Installation, Operation and

Maintenance are carried out properly in order to ensure the customer of the Subsea

sensor’s conformance to the specifications given in The Procurement Specification.

This is a generic procedure covering several different types and combinations of

SIEMENS AS, Subsea sensors hereafter called SDP-6.

2.2 PACKING AND TRANPORTATION

Avoid excessive shock and vibrations during transport and handling, even though the

equipment itself is resistant towards shock and vibration, this is only true when the units

are properly fixed and secured.

The SDP-6 sensor consists of 1 sensor body and 2 flanges connected together by a

capillary tube. A Special transport case is prepared for packing, storing and transport of

the SDP-6. Inside the box the sensor 3 parts are bolted onto a metal plate and we

strongly advise that the units are kept secured in this box/metal plate until the final

installation destination is reached.

The transportation case must be in its upright position at all times (see marking on the

case).

The SDP-6‘s considerable high own weight makes a dangerous combination if the

transportation cases is handled roughly (dropped, turned from upright positions etc).

When the unit is to be lifted from the transportation case, use a lifting crane and the

supplied hooks, never attempt to lift the unit by hand.

Due to the weight difference between the vulnerable capillary tubes, remote seals and

the main body of the sensor, the capillary tubes are at high risk for damage during

installation and handling, special care is therefore required.

Loading...

Loading...