Communication with S7 CPU via KNX Gateway

S7-1200, S7-1500, PROFINET, “Triple-X PROFINET +

KNX” Universal Gateway

https://support.industry.siemens.com/cs/ww/en/view/109739689

Siemens

Industry

Online

Support

Warranty and Liability

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

2

Siemens AG 2017 All rights reserved

Note

The Application Examples are not binding and do not claim to be complete

regarding the circuits shown, equipping and any eventuality. The Application

Examples do not represent customer-specific solutions. They are only intended

to provide support for typical applications. You are responsible for ensuring that

the described products are used correctly. These Application Examples do not

relieve you of the responsibility to use safe practices in application, installation,

operation and maintenance. When using these Application Examples, you

recognize that we cannot be made liable for any damage/claims beyond the

liability clause described. We reserve the right to make changes to these

Application Examples at any time without prior notice.

If there are any deviations between the recommendations provided in these

Application Examples and other Siemens publications – e.g. Catalogs – the

contents of the other documents have priority.

Security

information

Siemens provides products and solutions with industrial security functions that

support the secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber

threats, it is necessary to implement – and continuously maintain – a holistic,

state-of-the-art industrial security concept. Siemens’ products and solutions only

form one element of such a concept.

Customer is responsible to prevent unauthorized access to its plants, systems,

machines and networks. Systems, machines and components should only be

connected to the enterprise network or the internet if and to the extent necessary

and with appropriate security measures (e.g. use of firewalls and network

segmentation) in place.

Additionally, Siemens’ guidance on appropriate security measures should be

taken into account. For more information about industrial security, please visit

http://www.siemens.com/industrialsecurity.

Siemens’ products and solutions undergo continuous development to make them

more secure. Siemens strongly recommends to apply product updates as soon

as available and to always use the latest product versions. Use of product

versions that are no longer supported, and failure to apply latest updates may

increase customer’s exposure to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial

Security RSS Feed under http://www.siemens.com/industrialsecurity.

Warranty and Liability

We do not accept any liability for the information contained in this document.

Any claims against us – based on whatever legal reason – resulting from the use of

the examples, information, programs, engineering and performance data etc.,

described in this Application Example shall be excluded. Such an exclusion shall

not apply in the case of mandatory liability, e.g. under the German Product Liability

Act (“Produkthaftungsgesetz”), in case of intent, gross negligence, or injury of life,

body or health, guarantee for the quality of a product, fraudulent concealment of a

deficiency or breach of a condition which goes to the root of the contract

(“wesentliche Vertragspflichten”). The damages for a breach of a substantial

contractual obligation are, however, limited to the foreseeable damage, typical for

the type of contract, except in the event of intent or gross negligence or injury to

life, body or health. The above provisions do not imply a change of the burden of

proof to your detriment.

Any form of duplication or distribution of these Application Examples or excerpts

hereof is prohibited without the expressed consent of the Siemens AG.

Table of Contents

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

3

Siemens AG 2017 All rights reserved

Table of Contents

Warranty and Liability ................................................................................................. 2

1 Task ..................................................................................................................... 4

1.1 Introduction ........................................................................................... 4

1.2 Overview of the automation task .......................................................... 4

2 Solution............................................................................................................... 5

2.1 Overview............................................................................................... 5

2.2 Description of the core functionality ..................................................... 7

2.3 Hardware and software components ................................................... 8

3 Mode of Operation ........................................................................................... 10

3.1 Data points and signal chart ............................................................... 10

3.2 Data point mapping ............................................................................ 11

3.3 Correlation of the gateway configuration files .................................... 12

4 Configuration and Project Engineering ......................................................... 14

4.1 STEP 7 (TIA Portal) device configuration .......................................... 14

4.2 Gateway: Setting the LAN IP address ................................................ 16

4.3 Gateway: Data backup ....................................................................... 18

4.4 Gateway: Editing configuration files ................................................... 19

4.4.1 Editing in the integrated web server ................................................... 19

4.4.2 Configuration files ............................................................................... 20

4.4.3 “eib1.cfg” gateway file ........................................................................ 20

4.4.4 “eib1.txt” gateway file ......................................................................... 21

4.4.5 “pnetd1.txt” gateway file ..................................................................... 22

4.4.6 “pnetd1.cfg” gateway file .................................................................... 23

4.4.7 “dispatch.txt” gateway file ................................................................... 24

4.5 Gateway: Overview of the configuration ............................................ 25

4.6 Gateway: Restart ................................................................................ 26

5 Installation and Commissioning .................................................................... 27

5.1 Installing the software ......................................................................... 27

5.2 Installing the hardware ....................................................................... 27

5.2.1 Installation under laboratory conditions .............................................. 27

5.2.2 Installation under plant conditions ...................................................... 28

5.3 Commissioning ................................................................................... 29

5.3.1 Commissioning the gateway .............................................................. 29

5.3.2 Commissioning the S7-1200 CPU ..................................................... 31

6 Operation of the Application Example .......................................................... 33

7 Links & Literature ............................................................................................ 35

8 MBS GmbH – Contact ...................................................................................... 35

9 History............................................................................................................... 36

1 Task

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

4

Siemens AG 2017 All rights reserved

KNX devices

KNX

gateway

PROFINET

SIMATIC

CPU

KNX

1 Task

1.1 Introduction

Gateways enable communication between two networks/bus systems that use

different communications protocols.

KNX is a fieldbus for building automation. Technically, KNX is the successor to the

European Installation Bus (EIB), adding communication mechanisms and

transmission media.

The functionality of a KNX system can be extended by integrating an S7 CPU into

a KNX system via a gateway. An S7 CPU enables the use of various functions and

statements for creating a control program and processing data.

The “LGF (Library of general functions)” for STEP 7 (TIA Portal) and S7-1200 / S71500 additionally provides complementary functions such as an astronomical clock,

weekly timer, FIFO and many more (see \4\).

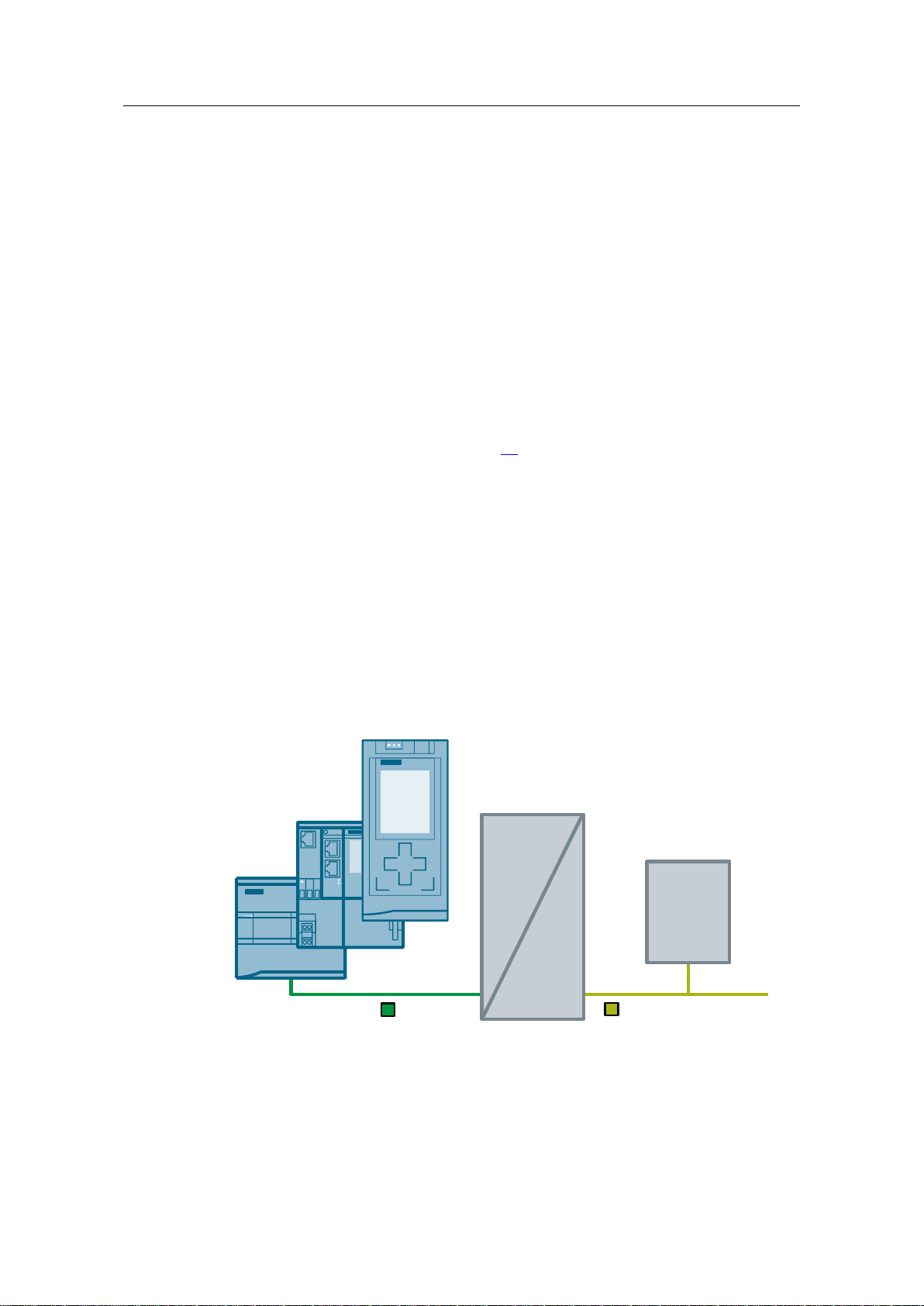

1.2 Overview of the automation task

The task is to establish, using a KNX gateway, a communication connection

between an S7 CPU via PROFINET (PN) and a KNX device via the KNX bus.

Each KNX device has a physical address (PA) via which the device can be

accessed. The individual functions of a KNX device are addressed by group

addresses (GA).

Through bidirectional data exchange between a KNX gateway and an S7 CPU,

signals of a KNX device are to be processed in the S7 CPU or KNX devices are to

be controlled using the S7 CPU.

The figure below provides an overview of the automation task.

Figure 1-1: Block diagram of the automation task

2 Solution

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

5

Siemens AG 2017 All rights reserved

“Triple-X PROFINET+KNX”

universal gateway

PROFINET

KNX devices

S7-1200 CPU

KNX

1

2 Solution

2.1 Overview

Diagrammatic representation

Representing all SIMATIC controllers, this solution uses an S7-1200 CPU. The

diagrammatic representation below shows the most important components for

communication between an S7-1200 CPU and a KNX network using the “TripleX PROFINET + KNX” universal gateway from MBS GmbH.

Figure 2-1: Block diagram of the solution with the components used

The “Triple-X PROFINET + KNX” universal gateway enables communication

between an S7-1200 CPU and KNX devices via PROFINET and the KNX bus.

In this example, the KNX devices consist of:

KNX wall switch triple

KNX room control unit

KNX power supply1

Correct communication is verified with the KNX devices and a STEP 7 (TIA Portal)

watch table.

An external KNX power supply is necessary for operating a KNX network and is no

communication node in the network.

2 Solution

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

6

Siemens AG 2017 All rights reserved

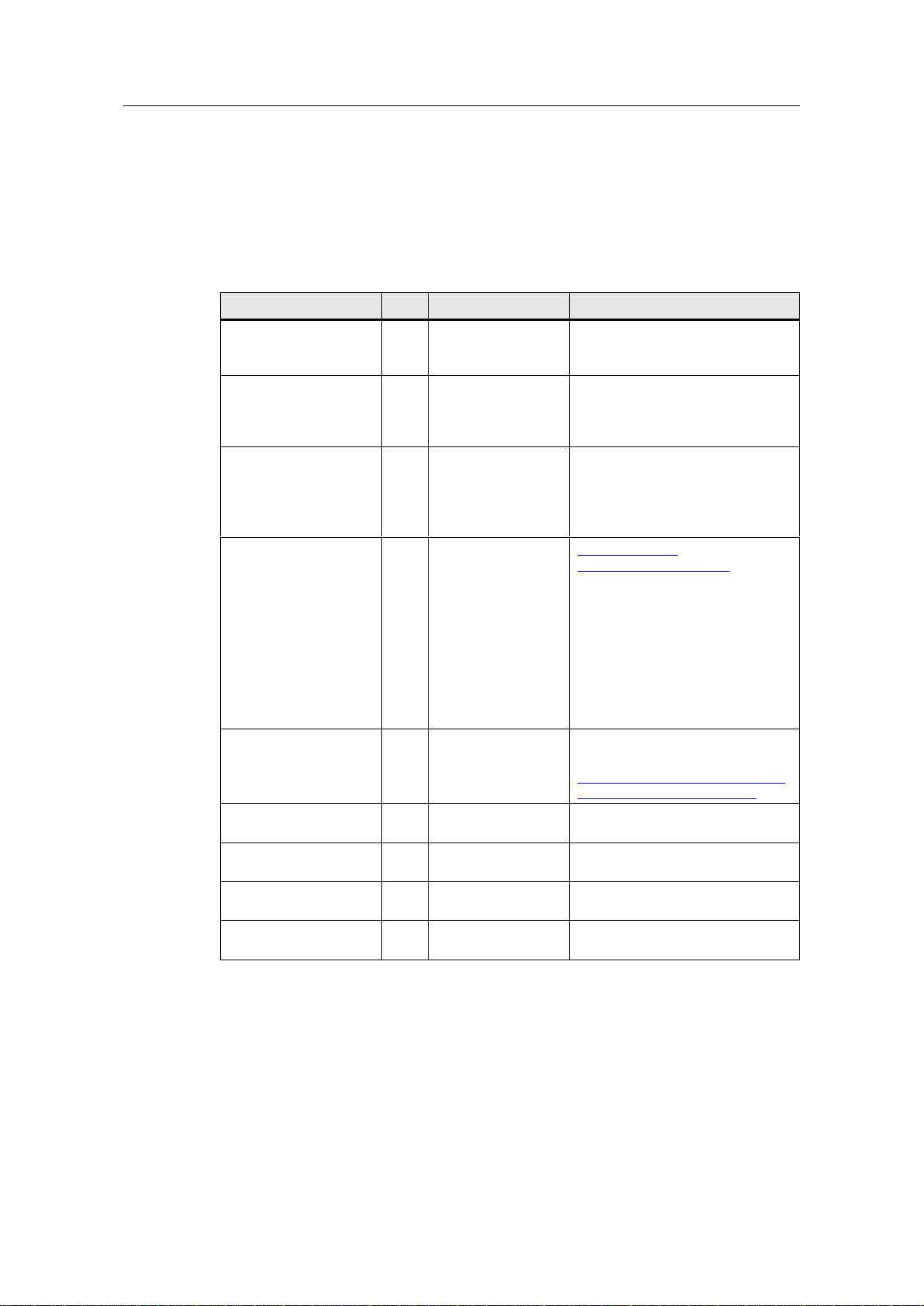

Interface label

Communication

medium

Network

Connected device

PROFINET 1 or

PROFINET 2

Ethernet

PROFINET

SIMATIC CPU

(S7-1200 CPU)

LAN

Ethernet

LAN

PG / PC

KNX

Twisted pair cable

KNX

KNX devices (incl. KNX

power supply)

2

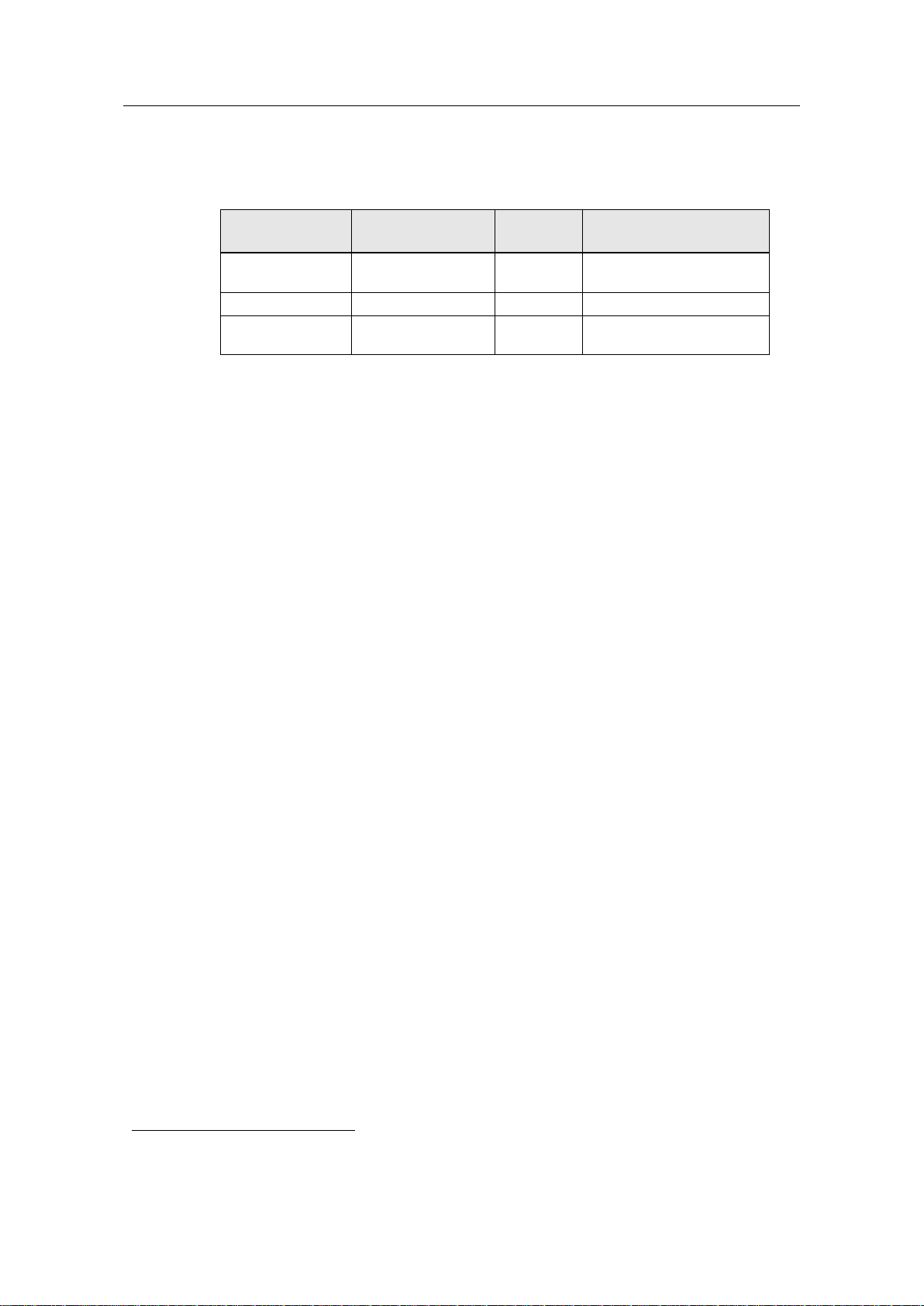

Advantages

The following table shows the relevant interfaces of the gateway for this application

example:

Table 2-1: Gateway interfaces

The solution presented here offers the following advantages:

Easy adaptation to other controller families. Representing all other SIMATIC

controllers with a PROFINET IO interface, this solution uses the S7-1200 CPU.

Easy adaptation when expanding plants. The gateway is configured directly in

the gateway’s integrated web server.

Integration of the gateway as a PROFINET IO device via a GSD file.

Gateway as distributed I/O with up to 340 bytes of input and 340 bytes of

output.

Up to 2500 data points possible for communication between PROFINET and

KNX.

Scope

This document does not replace the gateway manual. If there are any

differences in the documentation, the documentation provided by MBS GmbH

always takes precedence.

This application example only describes how to get started with KNX

communication with SIMATIC CPUs using a KNX gateway. For more

information about the KNX gateway, please refer to the gateway manual or

directly contact MBS GmbH.

Configuring the KNX devices using the ETS2 software and communication

between the gateway and the KNX devices are not part of this application

example.

Sales, distribution, training, service and support for the “Triple-

X PROFINET + KNX” universal gateway are provided exclusively by

MBS GmbH.

Required knowledge

Basic knowledge of STEP 7 (TIA Portal) programming and project engineering

Basic knowledge of PROFINET communication and configuration

Basic knowledge of the ETS software, KNX communication and KNX group

addresses

Engineering Tool Software (ETS) for programming nodes and assigning group addresses in a

KNX network.

2 Solution

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

7

Siemens AG 2017 All rights reserved

SIMATIC (S7-1200

CPU)

Gateway

KNX

PROFINET

KNX

BOOL

↔

BIT

UINT1 ↔ DPT-1

INT

↔

SINT16

SINT16 ↔ DPT-7

REAL

←

FLOAT32

SFLOAT ← DPT-9

2.2 Description of the core functionality

Configuration

The connection between the S7-1200 CPU and the gateway is configured via

the configuration of the gateway as distributed I/O in STEP 7 (TIA Portal).

configuration files of the gateway (cfg and txt files) (see Figure 3-3) that

reference each other.

The configuration files are downloaded to the gateway using the integrated web

server or directly edited.

Configuring and programming the gateway requires no ETS software. The gateway

can access existing data points (group addresses) in the KNX network and provide

its own data points locally on the gateway.

The assignment of the devices’ group addresses and physical addresses is not

part of this description. For more information, please refer to the supplied ETS5

sample project. The gateway’s physical address (KNX) is set using the “eib1.cfg”

configuration file (see 4.4.3).

Function and data types

This application example contains a STEP 7 project and a data record for the

gateway, where data of different data types is exchanged between an S7-1200

CPU and KNX devices in both directions via the gateway. A decimal value is

transferred from the S7-1200 CPU to the KNX control room unit’s display and a

status LED of the KNX wall switch is controlled via a binary signal. Conversely, the

value of the integrated temperature sensor and a configurable decimal value are

transferred from the KNX room control unit. Using the KNX wall switch, a boolean

variable is set/reset in the S7-1200 CPU.

The following data types are used and parameterized:

Table 2-2: SIMATIC / gateway data types

2 Solution

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

8

Siemens AG 2017 All rights reserved

Component

No.

Article number

Note

POWER MODULE

PM1207

1

6EP1332-1SH71

Power supply

input: 120/230 V AC

output: 24 V DC/2.5 A

SIMATIC S7-1214C

DC/DC/DC FW4.2

1

6ES7214-1AG400XB0

Alternatively, any other S7-1200

CPU (FW4.1 or higher) or S71500 CPU (FW1.7 or higher) can

be used.

Compact Switch

Module

1

6GK7277-1AA000AA0

(optional)

The switch is only required if you

want to simultaneously access

(without “replugging”) the S7-1200

and the gateway from the PG/PC.

“Triple-X PROFINET +

KNX”

universal gateway

(RS485)

1

Manufacturer: MBS

GmbH

Operating system:

Linux 2.6.34.7 #267

Software module:

V2_05W

Hardware module:

15.1.1

http://www.mbssolutions.de/profinet-knx

For the versions on the left, visit

the gateway web server’s page,

“Help > Device info”.

Alternative: RS232

Siemens Gamma KNX

room control unit

1

5WG1227-2AB11

Operating and installation

instructions

https://support.industry.siemens.c

om/cs/ww/en/view/76776544

Siemens Gamma KNX

wall switch triple

1

5WG1223-2DB13

-

Siemens Gamma KNX

bus coupling unit

1

5WG1117-2AB12

-

Siemens Gamma KNX

power supply

1

5WG1125-1AB01

Siemens Gamma KNX

USB interface

1

5WG1148-1AB12

Optional. Interface for

programming the KNX devices.

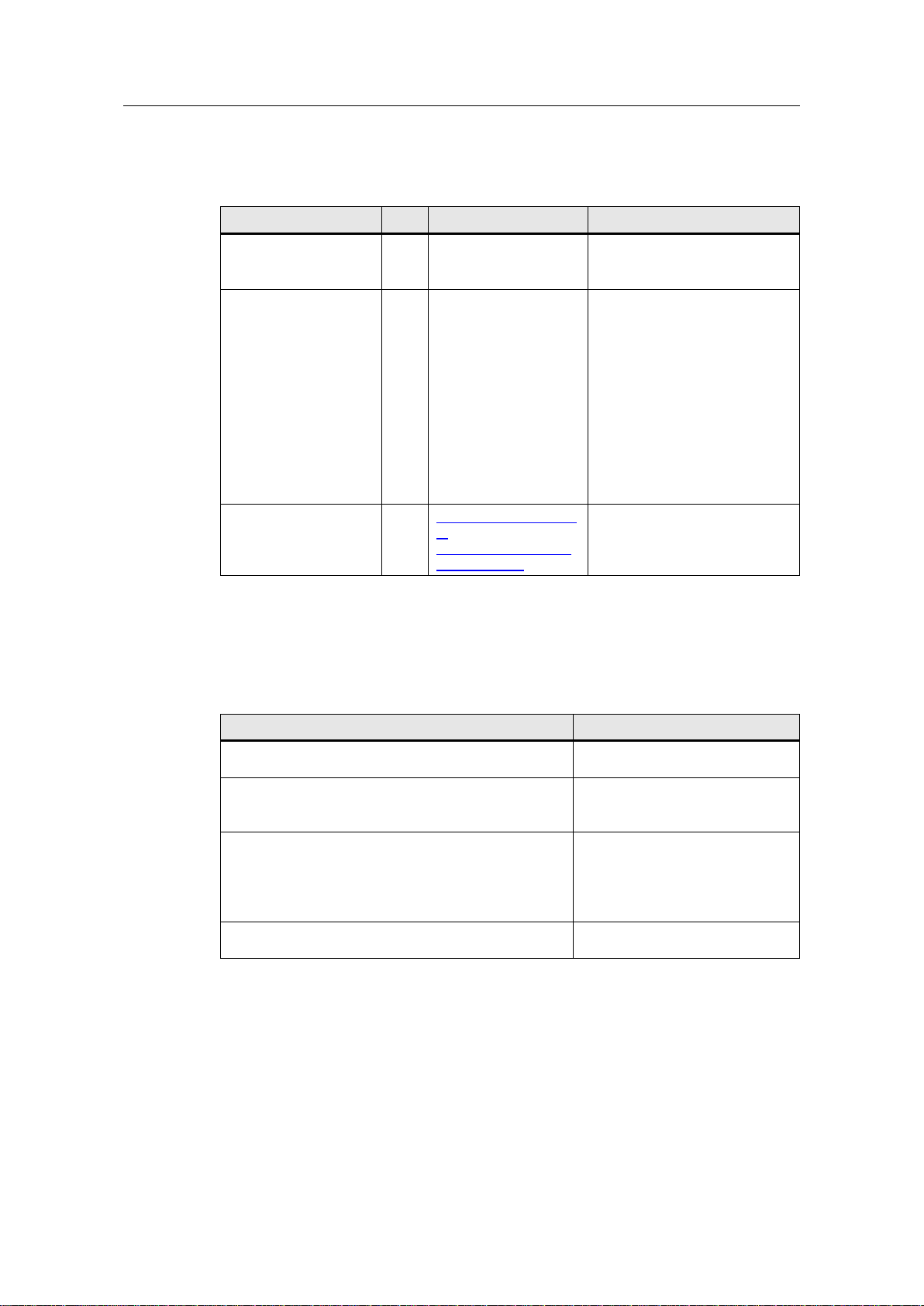

2.3 Hardware and software components

This application example was created with the following components:

Hardware components

Table 2-3: Hardware components

2 Solution

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

9

Siemens AG 2017 All rights reserved

Component

No.

Article number

Note

SIMATIC STEP 7

Professional V14 (TIA

Portal)

1

6ES7822-1..04-..

-

GSDML-V2.31-MBSMICRO3004-20150206

1

Manufacturer: MBS

GmbH

The latest GSDML files are

available directly from MBS

GmbH.

The GSDMLV2.31 file was

used in this example. The

files are available in the

“AdditionalFiles – GSD”

folder in the STEP 7 project.

When opening the project,

the GSD file is installed

automatically.

ETS5 Demo

1

https://www.knx.org/kn

xen/software/ets/downl

oad/index.php

Maximum of 5 KNX devices

per project.

Component

Note

109739689_KNX_DOC_V10_en.pdf

This document

109739689_KNX_S7_PROJ_V10.zip

This .zip file contains the

“MBS_KNX” STEP 7 project.

109739689_KNX_Gateway_RestoreFile_V10.zip

This zip file contains the

“ugwbackup.tgz” gateway

data backup with the

configuration files.

109739689_KNX_ETS5_PROJ_V10.zip

This .zip file contains the

ETS5 project.

Software components

Table 2-4: Software components

Sample files and projects

The following list contains all files and projects that are used in this example.

Table 2-5: Download files

3 Mode of Operation

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

10

Siemens AG 2017 All rights reserved

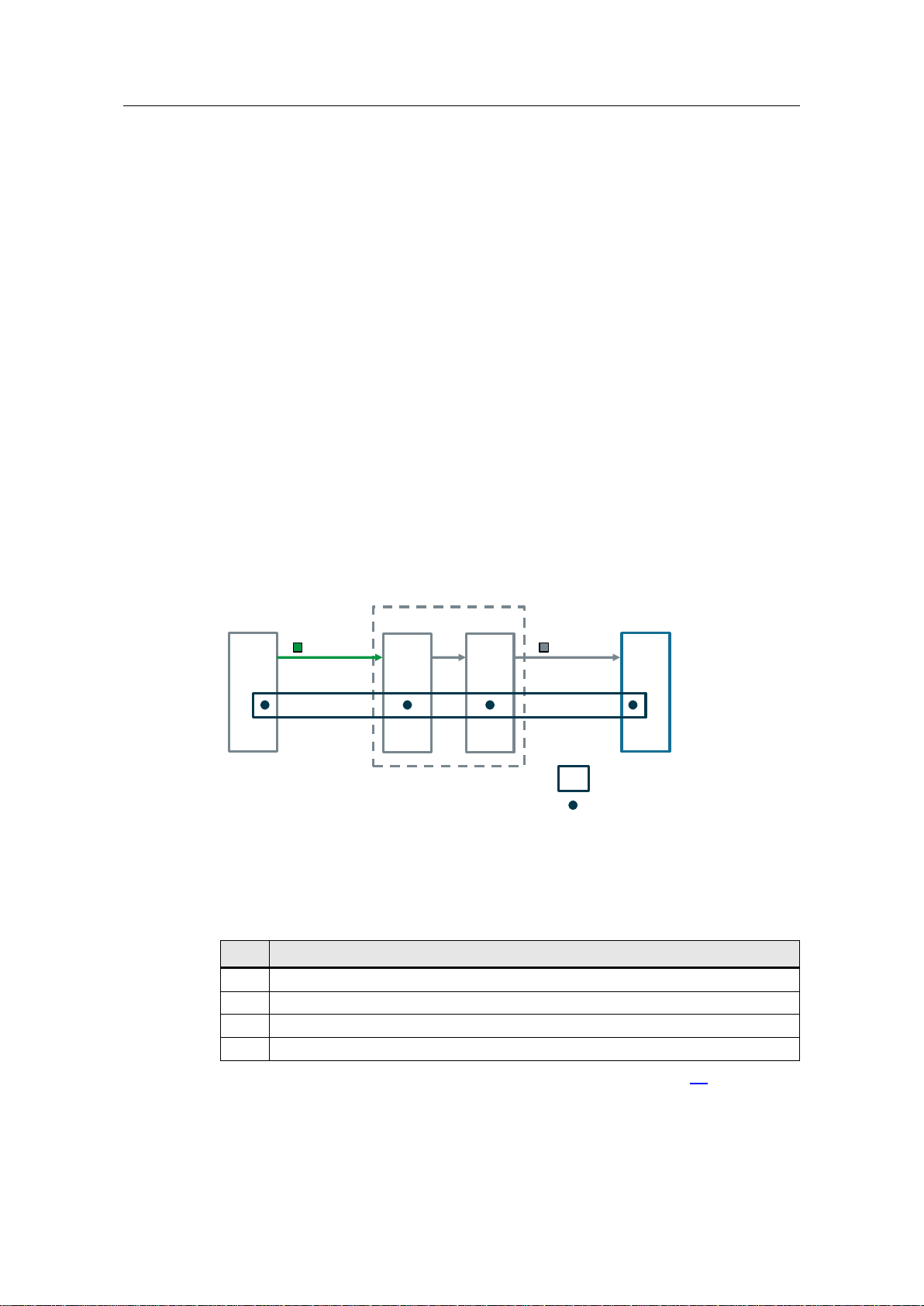

E

PROFINET KNX

Gateway

Q

outbit

outbyte

GA

S7-1200 CPU

KNX device

Signal chart

Q

Signal

Data point

E

GA

E

PROFINET KNX

Q Output

GA Group address

Type

Meaning

M

Integer value (binary data points, counts) that can only be read by the gateway.

S

Integer value that can be read and written by the gateway.

X

Analog value (with decimal places) that can only be read by the gateway.

Y

Analog value (with decimal places) that can be read and written by the gateway.

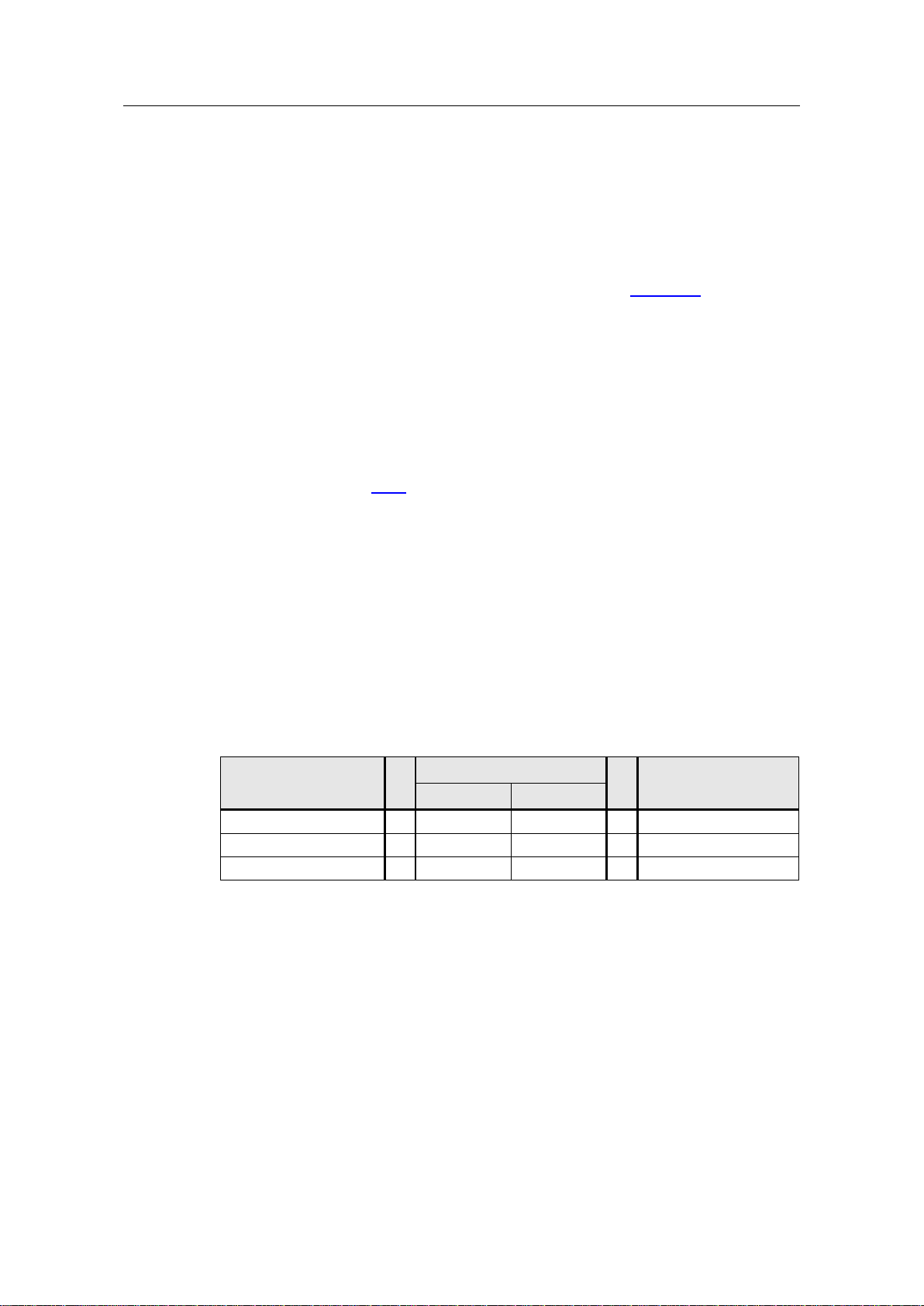

3 Mode of Operation

The data between the two bus systems, PROFINET and KNX, is exchanged

between the drivers (PROFINET, KNX) in the gateway via data point mapping.

The data points are described in the pnetd1.txt and eib1.txt configuration files and

mapped to each other in the dispatch.txt dispatch file.

For each data point, the format specifies how the driver should interpret the data at

the data point address.

3.1 Data points and signal chart

Each interface of a device (CPU, KNX) that is used to transfer data represents a

data point. As the gateway connects two different bus systems, it has two data

points – the source data point and the target data point.

The example in the following figure shows a signal that is generated in the S7-1200

CPU and transmitted to the gateway via PROFINET. The gateway converts the

PROFINET signal to a KNX telegram and sends it to the appropriate group address

of the KNX device. In the same way, a signal can also be transmitted from a KNX

device to the S7-1200 CPU.

Figure 3-1: S7-1200 CPU KNX device – signal chart

For the KNX driver and all other gateway drivers, the following types apply to the

definition of the data types:

Table 3-1: Definition of the data point types

For a definition of “data points”, please refer to the gateway manual (\3\), section 6

“Protocol properties and data points”.

3 Mode of Operation

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

11

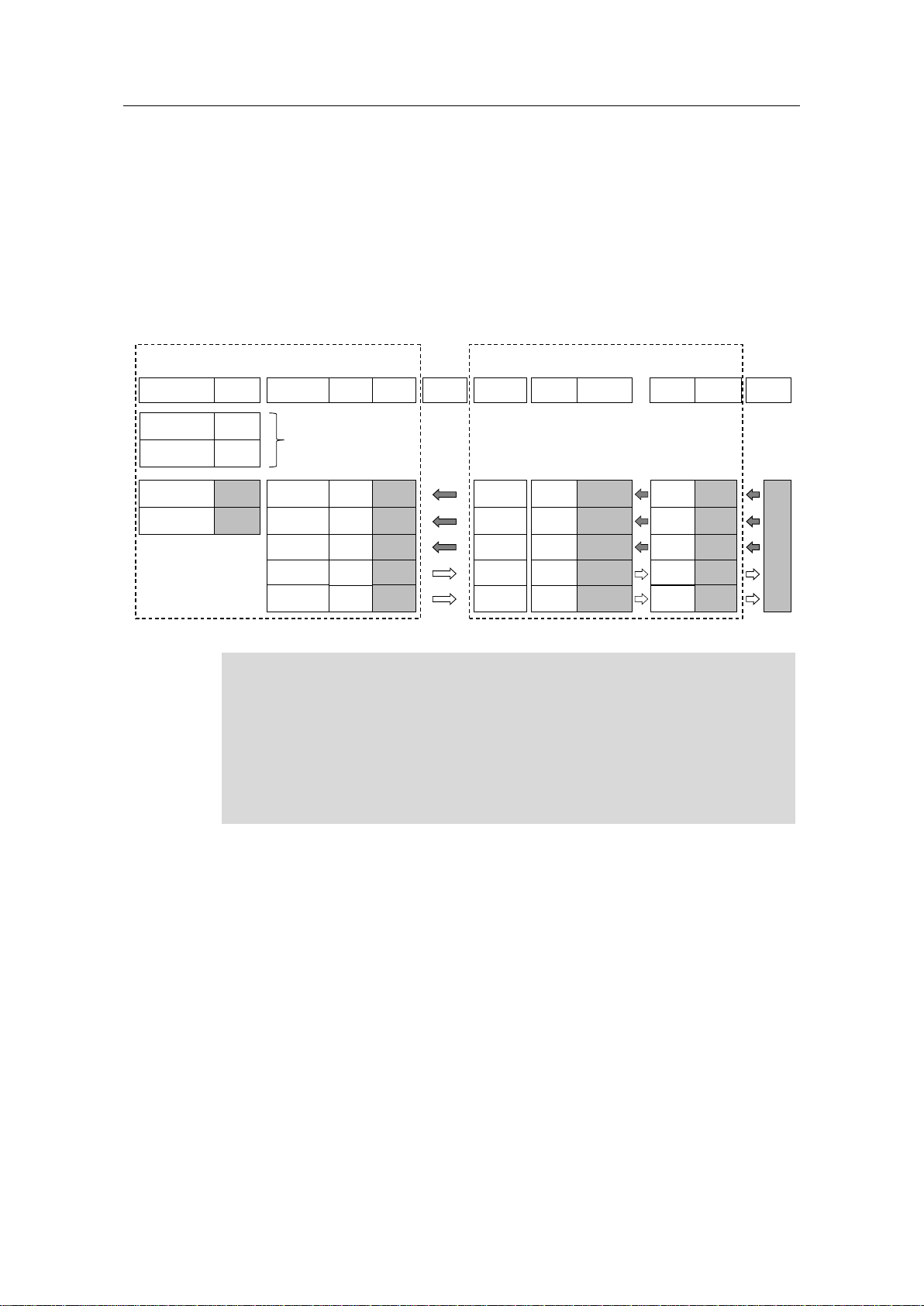

Siemens AG 2017 All rights reserved

OW 100

IW 100

O 102.0

O 102.0

setValInt

readValInt

setValBool

readValBool

PLC tags

Gateway

Name Data type

Length

Address Name AddressFormat

Length

PROFINET

S7-1200 CPU

Integrated

I/O

KNX-->S7

value

S inbyte 0SINT16

2 bytes

S7-->KNX

statusLED

M outbit 2.0BIT

1 bit

KNX-->S7

switch

S inbit 2.0BIT

1 bit

S7-->KNX

value

M outbyte 0

SINT16

2 bytes

INT

2 bytes

INT

2 bytes

BOOL

1 bit

BOOL

1 bit

PROFINET

AddressFormat

Length

M 1/1/1SINT16

2 bytes

S 1/1/4

UINT1

1 bit

M 1/1/3UINT1

1 bit

S 1/1/2SINT16

2 bytes

EIB/KNX

KNX

Process image

PLC_1 DI14

I 0 *

I/O Address

INPUT_32B_1 I

100..131

OUTPUT_32B_1 O

100..131

O 0 *

PLC_1 DO10_1

Data points

KNX devices

(wall switches, actuators…)

ID 103

readTemprInt REAL

4 bytes

KNX-->S7

temperature

Y inbyte 3

FLOAT32

4 bytes

X 1/1/5SFLOAT

2 bytes

Note

*Compact CPUs (e.g., S7-1200) with integrated digital inputs and outputs:

In STEP 7 (TIA Portal), the smallest address 0 is automatically assigned to the

integrated digital inputs and outputs.

Other modules / I/O are automatically assigned to the next available address.

Here, the address space starting with 100 was selected in the process image.

This makes it easier to identify the connected tags between the S7-1200 CPU

and the gateway.

3.2 Data point mapping

The following figure shows all of the data used and the process image of the S71200 CPU for the configuration with the gateway.

Please note: The input or output signal type always refers to the “perspective” of

the respective device.

Figure 3-2: Interaction between the process image of the S7 CPU and the data points in the gateway

3 Mode of Operation

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

12

Siemens AG 2017 All rights reserved

pnetd1.cfg

PROFINET

pnetd1.txt

dispatch.txt

eib1.cfg

KNX

Protocol

information

Definition of

data points

Definition of

data points

Protocol

information

Assignment between

data points

eib1.txt

File

Contents

Description

pnetd1.cfg

PROFINET protocol

information

This file contains information and settings

for the PROFINET network, including the

I/O used in the network.

Here: I/O configuration of the gateway in

STEP 7 (TIA Portal)

pnetd1.txt

Definition of the

PROFINET data points

Defines how and with which data type the

data points are interpreted.

dispatch.txt

Assignment between

KNX data points and

PROFINET data points

This file describes the assignment of the

data points between the PROFINET side

(pnetd1.txt) and the KNX side (eib1.txt).

eib1.txt

Defines the KNX data

points

This file contains the description of the

individual data points on the KNX side.

eib1.cfg

KNX protocol

information

This file contains information and settings

for the KNX protocol.

3.3 Correlation of the gateway configuration files

The gateway is configured using various configuration files (cfg, txt files). Once

programming is complete, these files are uploaded in a text editor (for example,

Notepad++) using the integrated web server in the gateway or directly edited and

enabled in the integrated web server. A configuration check is performed in the

gateway and any errors are displayed.

As the gateway supports different bus systems (PROFINET, KNX, BACnet…),

there are different driver files with protocol information (files with the .cfg extension)

and a file with the definition of the data points (.txt extension).

The dispatch file (dispatch.txt) is an integral part. It contains the mapping of the

data points of the different protocols to each other.

The data points are programmed as objects. For the exact meaning and structure

of these files, please refer to the gateway manual (\3\). The gateway data backup

cfg and txt files also contain this information as comment lines.

For the complete configuration, please refer to the supplied “ugwbackup.tgz”

gateway data backup in the “ugw > config” folder and the included comments

(109740160_KNX_Gateway_RestoreFile_Vxx.zip).

Figure 3-3: Gateway configuration files

Table 3-2: Gateway configuration files

3 Mode of Operation

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

13

Siemens AG 2017 All rights reserved

Note

In the gateway configuration files, KNX objects are identified by “eib…” and

PROFINET objects are identified by “pnetd…”.

Note

In addition, the following configuration files exist that need to be downloaded to

the gateway but not edited:

driver.cfg

ugwc1.cfg

ugwc1.txt

gateway.cfg

ntp.cfg

plants.cfg

These files are not described in greater detail in this application. If you require

more information, please contact MBS GmbH.

This application example describes how to edit and customize these files so that

they can be used for data exchange (see Chapter 4.4 Gateway: Editing

configuration files). Along with this description, you are provided with a data backup

file with the ready-to-use sample files that you can customize for your own

application.

4 Configuration and Project Engineering

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

14

Siemens AG 2017 All rights reserved

Note

Before you can configure the gateway in STEP 7 (TIA Portal), you must install

the gateway’s GSD file. The GSD file can be found on the gateway’s web user

interface, “Profinet > GSDML file”. \6\ provides a description of how to install a

GSD file in TIA Portal.

When you open the supplied “MBS_KNX” STEP 7 project, the GSD file is

installed automatically, see 5.3.2 Commissioning the S7-1200 CPU.

No.

Action

Comment

1.

Create a STEP 7 (TIA Portal) project and

insert an S7-1200 CPU (S7-1214C DC/DC/DC

FW4.2).

Requirement: You have STEP 7 (TIA Portal)

V14 or higher installed on your computer.

2.

In “Devices & networks”, open the “Network

view”.

In the hardware catalog, navigate to “Head

module”, “UGW-micro”.

Make sure that the firmware version (V2.31) is

correct.

4 Configuration and Project Engineering

This chapter describes the configuration in STEP 7 (TIA Portal) and the

programming of the gateway configuration files.

If you want to use the sample configuration of this application example without any

changes, you can download the STEP 7 project directly to the S7-1200 CPU and

the gateway configuration to the gateway (see Chapter 5.3.1 Commissioning the

gateway).

4.1 STEP 7 (TIA Portal) device configuration

Table 4-1: Device configuration in STEP 7 (TIA Portal)

4 Configuration and Project Engineering

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

15

Siemens AG 2017 All rights reserved

No.

Action

Comment

3.

Use drag and drop to move the “UGW-micro”

from the hardware catalog to the “Devices &

networks” editor.

4.

Click “Not assigned”) for the UGW-micro and

select the interface of the S7-1200 CPU used

(“PLC_1.PROFINET…”).

5.

Set the following PROFINET IP address:

S7-1200 CPU: 192.168.0.1

UGW-micro: 192.168.0.2

6.

Double-click the UGW-micro to open the

UGW-micro device view.

7.

Open the hardware catalog and navigate to

the gateway’s input/output modules.

Equip the UGW-micro with the required

modules.

Change the I/Q addresses to the range

starting with 100.

8.

Create a PLC tag table, for example

“TagsUGW”, as shown in the figure on the

right.

9.

Create the watch table, for example

“WatchTableUGW”, to monitor and modify the

tags.

Note

As the tags directly access the process image, no system blocks (SFC, SFB) are

necessary.

4 Configuration and Project Engineering

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

16

Siemens AG 2017 All rights reserved

No.

Action

Comment

1.

Make sure that

your computer is in the same subnet as all

the components involved,

all the components are connected using

LAN cables,

all the components are connected to a

power supply and turned on.

See Chapter 5.2 Installing the hardware

2.

Start your preferred web browser and connect

to the gateway web server.

Factory default:

IP address: 169.254.0.1

User name: gw

Password: GATEWAY

3.

Select “General > IP-Network” to set the IP

address of the gateway’s LAN interface.

4.

1. Change the IP address.

2. Select “Save” to save the setting.

Note

After saving, you need to reconnect to the

gateway using the new IP address you have

just set.

Note

For successful communication with the

gateway, the IP address of your PC must be in

the same subnet. If necessary, change the IP

address of your PC.

4.2 Gateway: Setting the LAN IP address

Table 4-2: Setting the IP address of the gateway

4 Configuration and Project Engineering

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

17

Siemens AG 2017 All rights reserved

No.

Action

Comment

5.

When you have logged back on to the gateway

using the new IP address, a complete system

restart is required.

Click the “Restart required!” button to perform

a restart.

Use the “complete system restart” option to

restart the gateway as described in Chapter

4.6.

4 Configuration and Project Engineering

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

18

Siemens AG 2017 All rights reserved

No.

Action

Comment

1.

Make sure that

your computer is in the same subnet as all

the components involved,

all the components are connected using

LAN cables,

all the components are connected to a

power supply and turned on.

See Chapter 5.2 Installing the hardware

2.

Start your preferred web browser and connect

to the gateway web server.

Default settings:

IP address: 169.254.0.1

User: “gw”

Password: “GATEWAY”

3.

If necessary, back up all gateway configuration

files using the “Backup/Restore” menu that

allows you to restore the default settings if

necessary (see the “Help > Online help” UGW

menu item).

To back up data, navigate to “General >

Backup/Restore > Backup gateway

configuration”.

Click “Start” and follow the menu prompts.

4.3 Gateway: Data backup

Table 4-3: Perform the gateway data backup

4 Configuration and Project Engineering

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

19

Siemens AG 2017 All rights reserved

No.

Action

Comment

1.

From the top menu bar, select “EIB” to edit the

configuration files for the KNX protocol.

Alternative: From the top menu bar, select

“Profinet” to edit the files of the PROFINET

protocol.

2.

From the left menu bar, select “Files”.

3.

Click the Edit icon of the configuration file you

want to edit.

4.

A new window opens where you can make the

changes.

Click “Save” to save the changes.

5.

After saving, the window closes automatically

and the “Restart required!” message appears.

Restart the gateway as described in Chapter

4.6.

4.4 Gateway: Editing configuration files

This chapter provides a detailed description of the structure and editing of the

gateway configuration files.

You can edit the files directly in the integrated web server or download the files,

edit them with a text editor (for example, Notepad++) and then upload them back to

the gateway.

Chapter 3.3 Correlation of the gateway configuration files provides you with an

overview of how the configuration files correlate.

4.4.1 Editing in the integrated web server

The following instructions describe how to edit the configuration files directly in the

integrated web server.

Table 4-4: Editing in the integrated web server

4 Configuration and Project Engineering

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

20

Siemens AG 2017 All rights reserved

No.

Description

Comment

1.

Make the necessary parameter settings such

as the physical address in the KNX network

(PhysicalAddress). The physical address

must be freely available in the KNX network.

You can also keep the default setting.

For a detailed description of the individual

parameters, please refer to the “eib1.cfg” file’s

comment.

…

[EIB]

Baudrate = 38400

Queuesize = 2000

ForceAuto = 0

MonitorMode = 0

AliveCheck = 0

BcuType = 2

PhysicalAddress = 1.1.99

…

4.4.2 Configuration files

For the configuration of the gateway, the following files are edited and then

downloaded to the gateway using the integrated web server or directly edited in the

integrated web server.

pnetd1.cfg

pnetd1.txt

eib1.cfg

eib1.txt

dispatch.txt

4.4.3 “eib1.cfg” gateway file

The KNX protocol settings are made in the “eib1.cfg” configuration file.

Table 4-5: Structure of the “eib1.cfg” gateway file

4 Configuration and Project Engineering

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

21

Siemens AG 2017 All rights reserved

No.

Description

Comment

1.

The KNX data points have the following

structure:

[<def> <group address>]

name = <name>

format = <format>

<def>:For the definition of data points, see

Table 3-1: Definition of the data point types

<group address>: Two- or three-digit

KNX group address.

Two-digit: <maj>/<min>

Three-digit: <maj>/<mid>/<ext>

<maj>: 0-31

<min>: 0-2047

<mid>: 0-7

<ext>: 0-255

<name>: Optional; you can specify plain text

for the data point.

<format>: Protocol-dependent properties of

the data point such as the data point for

interpreting the information stored at the

address.

If necessary, more parameters can be added

to the format, for example the poll rate (here:

P:10 for read value every 10 seconds):

format = <format> [F:<fact>]

[P:<poll>][U:<upd>] [I:<opt>]

[L:<loc>] [H:<prio>] [R:<addr>]

[D:<dly>]

For more driver-specific information such as

type, address, formats and other parameters,

please refer to the online documentation

provided by MBS at the following link:

http://wiki.mbssoftware.info/doku.php?id=eib_knx

[M failure]

name = EIB Failure

[M 1/1/1]

name = KNX-->S7 value

format = SINT16

[S 1/1/2]

name = S7-->KNX value

format = SINT16

[M 1/1/3]

name = KNX-->S7 switch

format = UINT1

[S 1/1/4]

name = S7-->KNX statusLED

format = UINT1

[X 1/1/5]

name = KNX-->S7 temperature

format = SFLOAT P:10

Note

For the driver to be provided with current values for all data points when starting

up the gateway, all data points defined in the driver must have the read flag set

on the ETS side.

4.4.4 “eib1.txt” gateway file

The data points of the KNX protocol and their properties are defined in the

“eib1.txt” configuration file.

Table 4-6: Structure of the “eib1.txt” gateway file

4 Configuration and Project Engineering

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

22

Siemens AG 2017 All rights reserved

No.

Description

Comment

1.

The addresses of the PROFINET data points

have the following structure:

[<def> <type> <byte>.<bit>]

name = <name>

format = <format>

<def>: For the definition of data points, see

Table 3-1: Definition of the data point types

<type>:

inbyte: Byte value that can be read by the

controller

inbit: Single bit that can be read by the

controller

outbyte: Byte value that can be written by

the controller

outbit: Single bit that can be written by the

controller

<byte>: 0..339 ( nth byte in the input/output

register)

<bit>: 0..7 (single bit within the nth byte)

<name>: Optional; you can specify plain text

for the data point.

<format>: Protocol-dependent properties of

the data point such as the data point for

interpreting the information stored at the

address.

If necessary, more parameters can be added

to the format, for example a poll rate (P:x):

format = <format> [F:<fact>]

[P:<poll>][U:<upd>] [I:<opt>]

[L:<loc>] [H:<prio>] [R:<addr>]

[D:<dly>]

For more driver-specific information such as

type, address, formats and other parameters,

please refer to the online documentation

provided by MBS at the following link or the

“pnetd1.txt” file:

http://wiki.mbssoftware.info/doku.php?id=profinet_io-device

#---------------------------------

# STATUS

#---------------------------------

[M failure]

name = profinet communication

state 0=ok / 1=fail

format = BIT

#---------------------------------

# INPUT BUFFER (max 340 bytes)

#--------------------------------[S inbyte 0]

name = KNX-->S7 16-bit dec

format = SINT16

[S inbit 2.0]

name = KNX-->S7 1-bit

format = BIT

[Y inbyte 3]

name = KNX-->S7 temperature

format = FLOAT32

#--------------------------------# OUTPUT BUFFER (max 340 bytes)

#---------------------------------

[M outbyte 0]

name = S7-->KNX 16-bit dec

format = SINT16

[M outbit 2.0]

name = S7-->KNX 1-bit

format = BIT

4.4.5 “pnetd1.txt” gateway file

The data points of the PROFINET protocol and their properties are defined in the

“pnetd1.txt” configuration file.

Table 4-7: Structure of the “pnetd1.txt” gateway file

4 Configuration and Project Engineering

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

23

Siemens AG 2017 All rights reserved

No.

Description

Comment

1.

The device configuration of the

gateway can be found in STEP 7

(TIA Portal).

2.

In the pnetd1.cfg configuration file,

the device configuration of the

gateway is programmed line by line

according to the device

configuration in STEP 7 (TIA Portal).

Each device is referred to as a

module (Mod001, Mod002,..).

For an example of how to

parameterize each module type,

please refer to the “pnetd1.cfg” file.

Mod001 = ID:0x16 IN:32 OUT:0 #INPUT_32B

Mod002 = ID:0x26 IN:0 OUT:32 #OUTPUT_32B

Note

When configuring, please note the following:

All modules following “Mod001” must be numbered consecutively and

without gaps.

Upper limit: 60 modules (“Mod060”)

The configuration is not applied until a power cycle (turn off and back on) of

the gateway is complete.

4.4.6 “pnetd1.cfg” gateway file

The PROFINET device settings are made in the “pnetd1.cfg” configuration file.

When configuring, make sure that the STEP 7 configuration and the gateway’s

configuration file match exactly.

Table 4-8: Structure of the “pnetd1.cfg” gateway file

4 Configuration and Project Engineering

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

24

Siemens AG 2017 All rights reserved

No.

Description

Comment

1.

Syntax of a dispatch entry:

[<route source> <type source>

<address>]

target = <route target> <type

target> <address>

<route source>: Source driver routing

address

<type source>: Source driver name

<route target>: Target driver routing

address

<type target>: Target driver name

<address>: Data point address

Note

For a data point to be used in the dispatch.txt

file, the data point must have previously been

declared in the driver-specific *.txt files.

# S7 --> KNX

[1190 pnetd outbyte 0]

target = 70 eib 1/1/2

[1190 pnetd outbit 2.0]

target = 70 eib 1/1/4

# KNX --> S7

[70 eib 1/1/1]

target = 1190 pnetd inbyte 0

[70 eib 1/1/3]

target = 1190 pnetd inbit 2.0

[70 eib 1/1/5]

target = 1190 pnetd inbyte 3

2.

For a driver’s routing address and name, go to

“General > Overview”.

Note

In the dispatch file, you can use formulas for calculating data points. For more

information about this and the dispatch mechanism, please refer to Links &

Literature, \5\.

4.4.7 “dispatch.txt” gateway file

The assignment between KNX data points and PROFINET data points is made in

the “dispatch.txt” configuration file.

Table 4-9: Structure of the “dispatch.txt” gateway file

4 Configuration and Project Engineering

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

25

Siemens AG 2017 All rights reserved

4.5 Gateway: Overview of the configuration

The following overview shows you the correlation of the gateway configuration files.

eib1.txt

[M 1/1/3]

name = KNXS7 switch

format = UINT1

[S 1/1/2]

name = S7KNX value

format = UINT1

dispatch.txt

# S7 KNX

[1190 pnetd outbyte 0]

target = 70 eib 1/1/2

…

# KNX S7

[70 eib 1/1/3]

target = 1190 pnetd inbit 2.0

pnetd1.txt

[M outbyte 0]

name = S7KNX value

format = SINT16

…

[S inbit 2.0]

name = KNXS7 switch

format = BIT

pnetd1.cfg

Mod001 = ID:0x16 IN:32 OUT:0 # INPUT_32B

Mod002 = ID:0x26 IN:0 OUT:32 # OUTPUT_32B

4 Configuration and Project Engineering

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

26

Siemens AG 2017 All rights reserved

Note

For changes of the configuration files to be activated, restart the gateway.

If changes are made in the “pnet1.cfg” PROFINET driver file, a complete restart

(de-energized) of the gateway is required.

No.

Action

Comment

1.

Click the “Restart required!” button.

Alternative:

To restart the gateway, navigate to the

“General > Restart > Restart” menu item.

Alternative:

2.

The gateway automatically checks the

configuration files and, in the “Configuration

check” tab, displays errors and warnings and

the specific file and line where the cause can

be found.

Check the appropriate files/lines.

If the current configuration in the gateway is

correct, click “Next”.

3.

Go to the “Restart Gateway” tab.

Optionally, you can check the “complete

system restart” check box to perform a

complete system restart.

Click the “Restart” button to confirm the action

and follow the menu prompts.

4.

After the restart, the changes made are

activated.

Note

After a complete system restart, you have to

log back on to the gateway.

-

4.6 Gateway: Restart

Table 4-10: Restarting the gateway

5 Installation and Commissioning

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

27

Siemens AG 2017 All rights reserved

Note

Always follow the below installation guidelines:

“S7-1200 Programmable Controller” System Manual

Gateway manual

PROFINET 1 / 2

IP: 192.168.0.2

RS 232/485

PN

24V DC

LAN

PN

CSM / switch

24V DC

S7-1200 CPU

24V DC

PG/PC

IP: 192.168.0.1

IP: 192.168.0.3

KNX

+ -

“Triple-X PROFINET + KNX”

universal gateway

KNX

power supply

L

+

-

N PE

230 V AC

KNX

wall switch

+

-

KNX

room control

unit

+

-

USB

interface

+

-

KNX

PROFINET IE

LAN

USB

IP: 192.168.0.100

5 Installation and Commissioning

This chapter describes the steps necessary to start up the example.

5.1 Installing the software

Install the latest version (V14 or higher) of STEP 7 (TIA Portal) on your computer.

No additional software is needed for configuring the “Triple-X PROFINET+KNX”

universal gateway. It is configured using the integrated web server.

5.2 Installing the hardware

5.2.1 Installation under laboratory conditions

For the function test of this application under laboratory conditions, the following

installation using a switch is suitable. It allows you to simultaneously execute all of

the below functions (see the following advantages) with a single PG/PC.

Figure 5-1: Installation under “laboratory conditions”

5 Installation and Commissioning

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

28

Siemens AG 2017 All rights reserved

PROFINET 1 / 2

IP: 192.168.0.2

RS 232/485

“Triple-X PROFINET + KNX”

universal gatewy

LAN

PN

24V DC

S7-1200 CPU

24V DC

IP: 192.168.0.1

IP: 192.168.0.3

KNX

+ -

PROFINET IE

KNX

KNX

power supply

+ -

L N PE

KNX

wall switch

+ -

KNX

room

control unit

+ -

230V AC

5.2.2 Installation under plant conditions

Under “real” conditions, a SIMATIC controller is normally directly connected to a

KNX gateway. The gateway is integrated into a PROFINET network via the two

PROFINET interfaces and connected to the KNX network via the KNX interface.

Figure 5-2: Installation under plant conditions

5 Installation and Commissioning

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

29

Siemens AG 2017 All rights reserved

Note

For some actions in the gateway web server, you need a user name and

password.

Default setting (as-supplied state):

User name: gw IP address: 169.254.0.1

Password: GATEWAY

If this login does not work, please refer to the gateway manual or contact MBS

GmbH.

No.

Action

Comment

1.

Unzip the

“109740160_KNX_Gateway_RestoreFile_Vxx.

zip” file (e.g., using “7-Zip”).

You get the “ugwbackup.tgz” file.

2.

Start your preferred web browser and connect

to the gateway web server.

Factory default:

IP address: 169.254.0.1

User name: gw

Password: GATEWAY

3.

Navigate to “General > Backup/Restore” and

check the “Restore gateway configuration”

check box.

Click “Browse…” and navigate to the

“ugwbackup.tgz” file.

4.

Then click the “Start” button.

The contained data is unzipped and

downloaded directly to the gateway.

The following files are overwritten in the

gateway:

eib1.cfg

eib1.txt

dispatch.txt

driver.cfg

gateway.cfg

ntp.cfg

pnetd1.cfg

pnetd1.txt

ugwc1.cfg

ugwc1.txt

5.3 Commissioning

This chapter describes the steps for downloading the sample project to the

S7-1200 CPU and the sample configuration to the gateway.

5.3.1 Commissioning the gateway

Table 5-1: Commissioning the gateway

5 Installation and Commissioning

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

30

Siemens AG 2017 All rights reserved

No.

Action

Comment

5.

Click “OK” to confirm the following message.

Note

Restoring the data backup overwrites the

gateway’s IP address setting (here:

192.168.0.3).

6.

Enabling the restored configuration requires a

restart.

Select “Yes” to confirm the message.

5 Installation and Commissioning

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

31

Siemens AG 2017 All rights reserved

No.

Action

Comment

1.

Start STEP 7 (TIA Portal) and open the

“MBS_KNX” STEP 7 project from the

“109740160_KNX_S7_PROJ_Vxx.zip” file.

Note

The gateway’s GSD file is installed

automatically.

Requirement: You have STEP 7 (TIA Portal)

V14 or higher installed on your computer.

2.

Open “Devices & networks”.

-

3.

Right-click the connection and select

“Assign device name”.

4.

Assign the PROFINET device name to the

S7-1200 CPU and the gateway.

1. Select the device name you want to

assign.

2. Click “Update List”. The suitable device

type is automatically found in the network

and displayed in the list.

3. From the list, select the device to which

you want to assign the selected name.

4. Click “Assign name”.

5.

1. In the project tree, select the S7-1200

CPU (here: PLC_1).

2. In the menu bar, click the “Download to

device” button.

5.3.2 Commissioning the S7-1200 CPU

Table 5-2: Commissioning the S7-1200 CPU

5 Installation and Commissioning

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

32

Siemens AG 2017 All rights reserved

No.

Action

Comment

6.

Acknowledge the download dialogs and set

the S7-1200 CPU to RUN.

After the download, the devices have also

been assigned their PROFINET IP addresses.

-

7.

In the project tree, select the S7-1200 (PLC_1)

and in the menu bar, click “Go online”.

If everything was parameterized and

downloaded correctly, all icons are green.

6 Operation of the Application Example

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

33

Siemens AG 2017 All rights reserved

No.

Action

Comment

1.

In STEP 7 (TIA Portal), open the

“WatchTableUGW” watch table.

2.

1. Click the “Monitor all” button.

2. Monitor the room temperature of the KNX

room control unit.

3.

Compare the room temperature from the

watch table with the display in the KNX room

control unit.

4.

On the KNX room control unit, navigate to the

“SET” function named “KNXS7” and set a

new value.

5.

In the watch table, monitor the value change of

the “readValInt” tag.

2

6 Operation of the Application Example

You can verify communication between the S7-1200 and the KNX devices using

the watch table in TIA Portal and the functions of the KNX devices.

Table 6-1: Monitoring and modifying tags using the watch table

6 Operation of the Application Example

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

34

Siemens AG 2017 All rights reserved

No.

Action

Comment

6.

On the KNX wall switch triple, press A1.

7.

In the watch table, monitor the value change of

the “readValBool” tag.

8.

1. Enter a new value for the “setValInt” tag.

2. Click the button to modify the value.

9.

On the KNX room control unit, navigate to the

“i” function named “S7KNX” and monitor the

value change.

10.

1. Right-click the “setValBool” tag.

2. In “Modify”, select the “Modify to 1”

function.

11.

On the KNX switch, monitor the switching of

status LED A2.

7 Links & Literature

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

35

Siemens AG 2017 All rights reserved

Topic

\1\

Siemens Industry Online Support

https://support.industry.siemens.com

\2\

Download page of the entry

https://support.industry.siemens.com/cs/ww/en/view/109739689

\3\

Product page with gateway data sheet, manual

http://www.mbs-solutions.de/profinet-knx

\4\

Library of general functions (LGF) for STEP 7 (TIA Portal) and S7-1200 / S7-1500

https://support.industry.siemens.com/cs/ww/en/view/109479728

\5\

Dispatch mechanism of the gateway

http://wiki.mbs-software.info/doku.php?id=the_dispatch-mechanism

\6\

How do you install a GSD file in STEP 7 (TIA Portal)?

https://support.industry.siemens.com/cs/ww/en/view/109738401

7 Links & Literature

Table 7-1: Links

8 MBS GmbH – Contact

Figure 8-1: MBS GmbH

MBS GmbH

Römerstraße 15

47809 Krefeld, Germany

Phone: +49 2151 7294-0

Fax: +49 2151 7294-50

info@mbs-software.de

http://www.mbs-solutions.de/

9 History

Communication with S7 CPU via KNX Gateway

Entry ID: 109739689, V1.0, 06/2017

36

Siemens AG 2017 All rights reserved

Version

Date

Modifications

V1.0

06/2017

First version

9 History

Table 9-1

Loading...

Loading...