Page 1

Preface, Contents

General Technical Specifications

Racks

1

2

SIMATIC

S7-400, M7-400 Programmable

Controllers

Module Specifications

Reference Manual

Power Supply Modules

Digital Modules

Analog Modules

Interface Modules

IM 463-2

PROFIBUS DP Master Interface

IM 467/IM 467 FO

Cable Duct and Fan

Subassemblies

RS 485 Repeater

CPUs for M7-400

M7-400 Expansions

3

4

5

6

7

8

9

10

11

12

This manual is part of the documentation

package with the order number:

6ES7498-8AA03-8BA0

Edition 09/2003

A5E00069467-07

Interface Submodules

Appendices

Parameter Sets for

Signal Modules

Diagnostic Data of the

Signal Modules

Spare Parts and Accessories

Guidelines for Handling Electro-

static Sensitive Devices (ESD)

List of Abbreviations

Glossary, Index

13

LEERE

A

B

C

D

E

Page 2

Safety Guidelines

This manual contains notices intended to ensure personal safety, as well as to protect the products and

connected equipment against damage. These notices are highlighted by the symbols shown below and

graded according to severity by the following texts:

Danger

!

indicates that death, severe personal injury or substantial property damage will result if proper precautions are not taken.

Warning

!

indicates that death, severe personal injury or substantial property damage can result if proper

precautions are not taken.

Caution

!

indicates that minor personal injury can result if proper precautions are not taken.

Caution

indicates that property damage can result if proper precautions are not taken.

Notice

draws your attention to particularly important information on the product, handling the product, or to a

particular part of the documentation.

Qualified Personnel

Only qualified personnel should be allowed to install and work on this equipment. Qualified persons

are defined as persons who are authorized to commission, to ground and to tag circuits, equipment, and

systems in accordance with established safety practices and standards.

Correct Usage

Note the following:

Warning

!

Trademarks

Copyright W Siemens AG 1999-2003 All rights reserved

The reproduction, transmission or use of this document or its

contents is not permitted without express written authority.

Offenders will be liable for damages. All rights, including

rights created by patent grant or registration of a utility model

or design, are reserved.

Siemens AG

Bereich Automation and Drives

Geschaeftsgebiet Industrial Automation Systems

Postfach 4848, D- 90327 Nuernberg

Siemens Aktiengesellschaft A5E000069467-07

This device and its components may only be used for the applications described in the catalog or the

technical description, and only in connection with devices or components from other manufacturers

which have been approved or recommended by Siemens.

This product can only function correctly and safely if it is transported, stored, set up, and installed

correctly, and operated and maintained as recommended.

SIMATIC, SIMATIC HMI and SIMATIC NET are registered trademarks of SIEMENS AG.

Third parties using for their own purposes any other names in this document which refer to trademarks

might infringe upon the rights of the trademark owners.

Disclaim of Liability

We have checked the contents of this manual for agreement

with the hardware and software described. Since deviations

cannot be precluded entirely, we cannot guarantee full

agreement. However, the data in this manual are reviewed

regularly and any necessary corrections included in

subsequent editions. Suggestions for improvement are

welcomed.

Siemens AG 1999-2003

Technical data subject to change.

Page 3

Preface

Purpose of the Manual

The manual contains reference information on operator actions, descriptions of

functions and technical specifications of the central processing units, power supply

modules and interface modules of the S7-400.

How to configure, assemble and wire these modules in an S7-400 or M7-400

system is described in the installation manuals for each system.

Required Basic Knowledge

You will need a general knowledge of automation to understand this manual.

In addition, you are required to know how to use computers or devices with similar

functions (e. g. programming devices) under Windows 95/98/2000 or NT operating

systems. Since S7-400 is configured with the STEP 7 basic software, you have to

have a good working knowledge of the software. You can acquire this knowledge in

the manual “Programming with STEP 7”. Read the notes on the safety of electronic

controllers in the appendix of the Installation manual – especially when using a

S7-400 in safety–relevant areas.

Target Group

This manual is aimed at people with the required qualifications to commission,

operate and maintain the products described.

Where is this Manual valid?

The manual is valid for the S7-400, M7-400 programmable controller.

S7-400, M7-400 Programmable Controllers Module Specifications

A5E00069467-07

iii

Page 4

Preface

Changes Compared to the Previous Version

Since the previous version of the “Module Specifications” reference manual, the

following changes have been made:

• The descriptions of the CPU and the CPU relevant products and topics have

been put together in one manual, “CPU Specifications”.

• The descriptions of the H CPUs and their associated products and topics have

been moved to the manual “S7–400 H Programmable Controller, Redundant

Systems”

Note: The previous version of this “Module Specifications” reference manual can

be recognized by the number in the footer: A5E00069467-06.

The current number is: A5E00069467-07.

Certification

The SIMATIC S7-400 product range has the following certificates:

CE Labeling

C-Tick Mark

• Underwriters Laboratories, Inc.: UL 508 (Industrial Control Equipment)

• Canadian Standards Association: CSA C22.2 Nummer 142 (Process Control

Equipment)

• Factory Mutual Research: Approval Standard Class Number 3611.

You can find details on the certificates and approvals in the reference manual

“Module Specifications”.

The SIMATIC S7-400 product range complies with the requirements and protection

objectives of the following EU directives:

• EC low voltage directive 73/23/EEC

• EC electromagnetic compatibility directive 89/336/EEC

The SIMATIC S7-400 product range complies with the requirements of the

AS/NZS 2064 standard (Australia and New Zealand).

Standards

The SIMATIC S7-400 product range complies with the requirements and criteria of

the IEC 61131-2.

Place of this Documentation in the Information Environment

This manual forms part of the S7-400 and M7-400 documentation.

S7-400, M7-400 Programmable Controllers Module Specifications

iv

A5E00069467-07

Page 5

System Documentation Package

S7-400/M7-400 • S7-400, M7-400 Programmable Controllers; Hardware and

Finding Your Way

To help you find special information quickly, the manual contains the following

access aids:

• At the start of the manual you will find a complete table of contents and a list of

the diagrams and tables that appear in the manual.

• An overview of the contents of each section is provided in the left column on

each page of each chapter.

• You will find a glossary in the appendix at the end of the manual. The glossary

contains definitions of the main technical terms used in the manual.

Preface

Installation

• S7-400, M7-400 Programmable Controllers; Module Specifications

• Automation System S7-400 CPU Data

• S7-400 Instruction List

• At the end of the manual you will find a comprehensive index which gives you

rapid access to the information you need.

S7-400, M7-400 Programmable Controllers Module Specifications

A5E00069467-07

v

Page 6

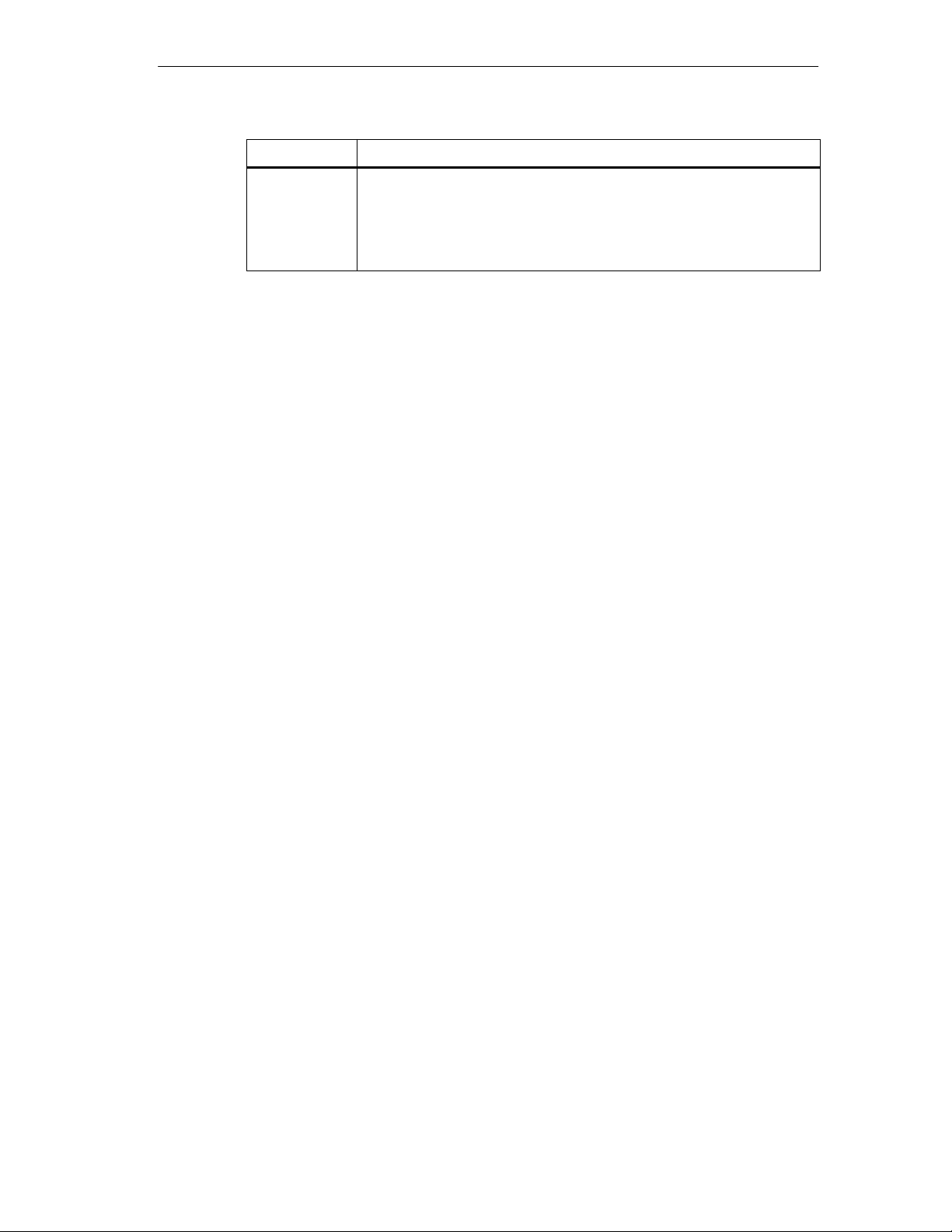

Preface

for S7-300 and

Description of the internal registers in the CPU

Specific Information for S7-400

You require the following manuals and manual packages in order to program and

commission an S7-400:

Manual/

Manual Package

Standard Software

for S7 and M7

STEP 7 Basic

Information

STEP 7 Reference

Information

Statement List (STL)

for S7-300 and

S7-400

Ladder Logic (LAD)

S7-400

Function Block

Diagram (FBD) for

S7-300 and S7-400

System and

Standard Functions

Manual

PG 7xx

Contents

• Installing and starting up STEP 7 on a programming device / PC

• Working with STEP 7 with the following contents:

Managing projects and files

Configuring and assigning parameters to the S7-400 configuration

Assigning symbolic names for user programs

Creating and testing a user program in STL/LAD

Creating data blocks

Configuring the communication between two or more CPUs

Loading, storing and deleting user programs in the CPU / programming device

Monitoring and controlling user programs

Monitoring and controlling the CPU

• Guide for efficiently implementing the programming task with the programming

device / PC and STEP 7

• How the CPUs work (for example, memory concept, access to inputs and

outputs, addressing, blocks, data management)

• Description of STEP 7 data management

• Using data types of STEP 7

• Using linear and structured programming

• Using block call instructions

• Using the debug and diagnostic functions of the CPUs in the user program (for

example, error OBs, status word)

• Basic procedure for working with STL, LAD, or FBD (for example, structure of

STL, LAD, or FBD, number formats, syntax)

• Description of all instructions in STEP 7 (with program examples)

• Description of the various addressing methods in STEP 7 (with examples)

• Description of all functions integrated in the CPUs

• Description of the internal registers in the CPU

• Description of all system functions integrated in the CPUs

• Description of all organization blocks integrated in the CPUs

• Description of the programming device hardware

• Connecting a programming device to various devices

• Starting up a programming device

vi

S7-400, M7-400 Programmable Controllers Module Specifications

A5E00069467-07

Page 7

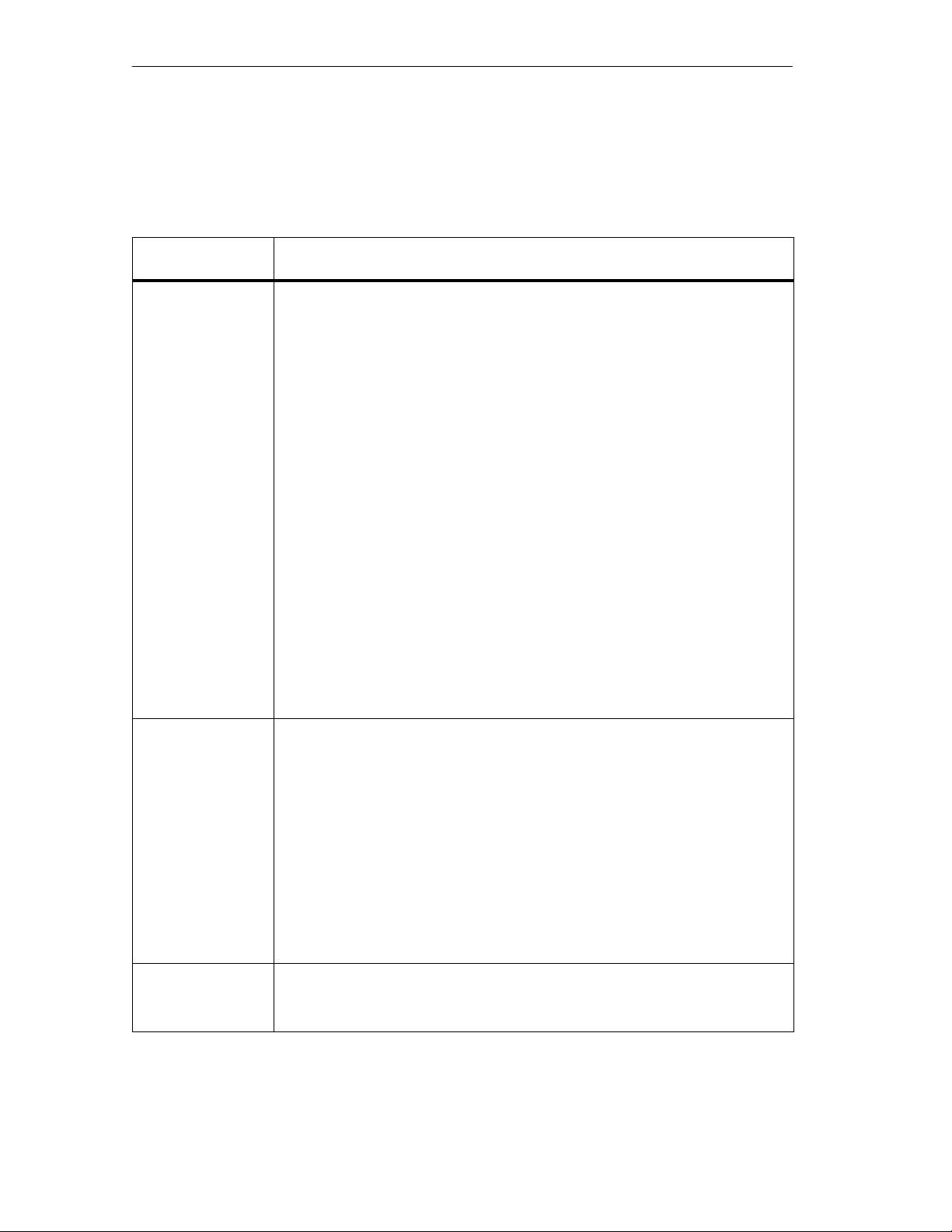

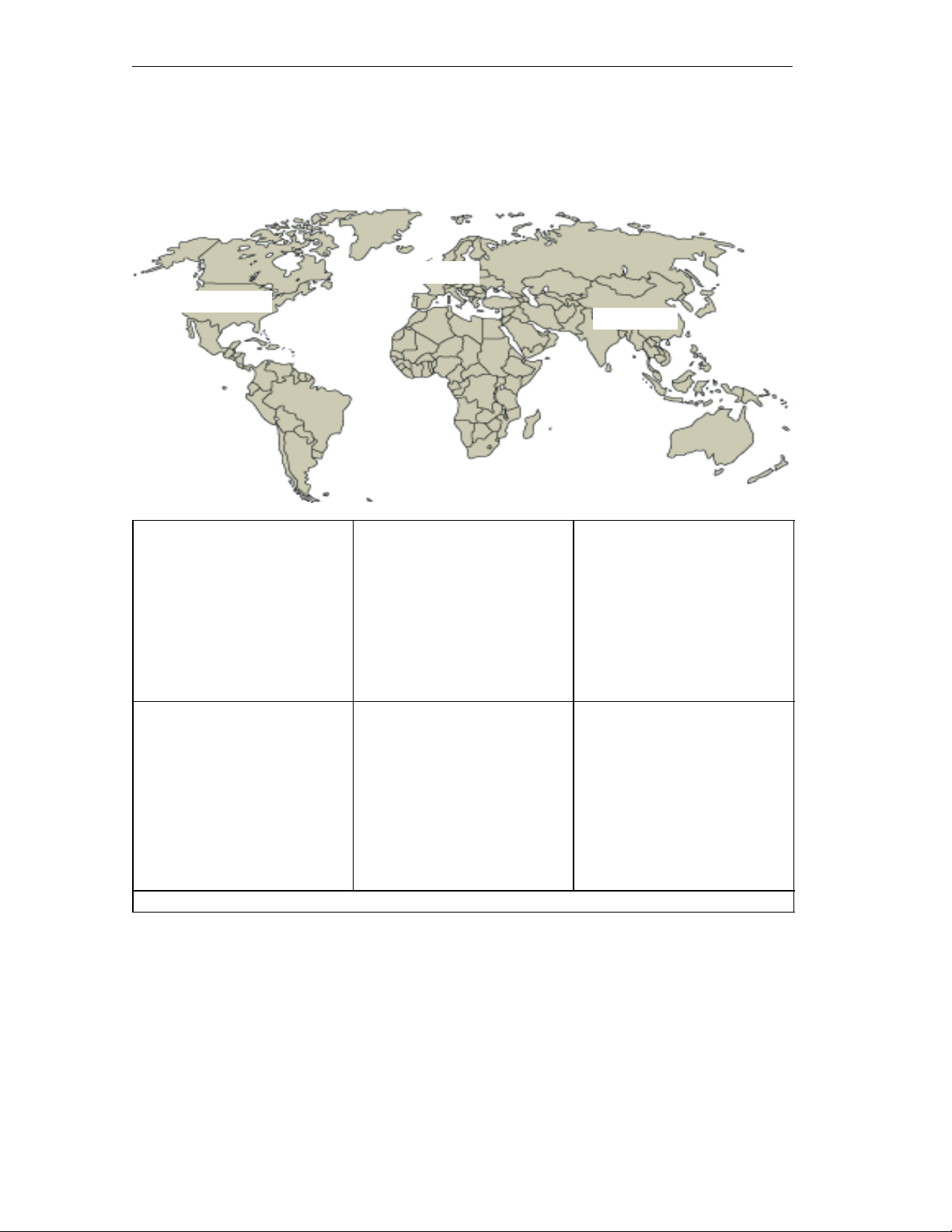

Specific Information for M7-400

This documentation package describes the hardware of the M7-400. You will need

the following additional documentation for programming and starting up an M7-400:

Documentation Contents Order No.

System Software for

M7-300/400 Program Design

Programming Manual

System Software for

M7-300/400 System and

Standard Functions

Reference Manual

System Software for

M7-300/400 Installation and

Operation

User Manual

Designing, writing and testing a C program

for M7 CPU/FM modules with the M7 SYS

programming package, using the M7 SYS

functions

Detailed description of the M7 SYS functions

and data structures, listing of messages

types

Installing and configuring the operating

system and system software

Preface

6ES7802-0FA14-0BA0

Recycling and Disposal

The S7-400 is environmentally friendly and can thus recyclable. Consult a certified

disposal agency for electronics junk to recycle and dispose of your old equipment

in an environmentally friendly manner.

Further Support

If you have any technical questions, please get in touch with your Siemens

representative or agent responsible.

http://www.siemens.com/automation/partner

Training Centers

Siemens offers a number of training courses to familiarize you with the SIMATIC S7

automation system. Please contact your regional training center or our central

training center in D 90327 Nuremberg, Germany for details:

Telephone: +49 (911) 895-3200.

Internet: http://www.sitrain.com

S7-400, M7-400 Programmable Controllers Module Specifications

A5E00069467-07

vii

Page 8

Preface

A&D Technical Support

Worldwide, available 24 hours a day:

Johnson City

Nuernberg

Beijing

Technical Support

Worldwide (Nuernberg)

Technical Support

24 hours a day, 365 days a year

Phone: +49 (180) 5050-222

Fax: +49 (180) 5050-223

E-Mail: adsupport@

GMT: +1:00

Europe / Africa (Nuernberg)

Authorization

Local time: Mon.-Fri.

8:00 AM to 5:00 PM

Phone: +49 (180) 5050–222

Fax: +49 (180) 5050-223

E-Mail: adsupport@

GMT: +1:00

The languages of the SIMATIC Hotlines and the authorization hotline are generally German and English.

siemens.com

siemens.com

United States (Johnson City)

Technical Support and

Authorization

Local time: Mon.-Fri.

8:00 AM to 500 PM

Phone: +1 (423) 262 2522

Fax: +1 (423) 262 2289

E-Mail: simatic.hotline@

sea.siemens.com

GMT: –5:00

Asia / Australia (Beijing)

Technical Support and

Authorization

Local time: Mon.-Fri.

8:00 AM to 5:00 PM

Phone: +86 10 64 75 75 75

Fax: +86 10 64 74 74 74

E-Mail: adsupport.asia@

siemens.com

GMT: +8:00

viii

S7-400, M7-400 Programmable Controllers Module Specifications

A5E00069467-07

Page 9

Service & Support on the Internet

In addition to our documentation, we offer our Know-how online on the internet at:

http://www.siemens.com/automation/service&support

where you will find the following:

• The newsletter, which constantly provides you with up–to–date information on

your products.

• The right documents via our Search function in Service & Support.

• A forum, where users and experts from all over the world exchange their

experiences.

• Your local representative for Automation & Drives via our representatives

database.

• Information on field service, repairs, spare parts and more under “Services”.

Preface

S7-400, M7-400 Programmable Controllers Module Specifications

A5E00069467-07

ix

Page 10

Preface

x

S7-400, M7-400 Programmable Controllers Module Specifications

A5E00069467-07

Page 11

Contents

1 General Technical Specifications 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Standards and Approvals 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Electromagnetic Compatibility 1-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Shipping and Storage Conditions for Modules and Backup Batteries 1-12. . . .

1.4 Mechanical and Ambient Climatic Conditions for Operating

the S7-400/M7-400 1-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 Information on Insulation Tests, Protection Class and

Degree of Protection 1-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6 Using S7-400 in a zone 2 explosion–risk area 1-19. . . . . . . . . . . . . . . . . . . . . . .

2 Racks 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Function and Structure of the Racks 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 The Racks UR1; (6ES7400-1TA01-0AA0) and

UR2; (6ES7400-1JA01-0AA0) 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 The Rack UR2-H; (6ES7400-2JA00-0AA0) 2-5. . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 The Rack CR2; (6ES7401-2TA01-0AA0) 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 The Rack CR3; (6ES7401-2TA01-0AA0) 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 The Racks ER1; (6ES7403-1TA01-0AA0)

and ER2; (6ES7403-1JA01-0AA0) 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Power Supply Modules 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Common Characteristics of the Power Supply Modules 3-2. . . . . . . . . . . . . . .

3.2 Redundant Power Supply Modules 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Backup Battery (Option) 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Controls and Indicators 3-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Fault/Error Messages via LEDs 3-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 Power Supply Module PS 407 4A; (6ES7407-0DA00-0AA0) 3-19. . . . . . . . . . .

3.7 Power Supply Module PS 407 4A; (6ES7407-0DA01-0AA0) 3-21. . . . . . . . . . .

3.8 Power Supply Modules

PS 407 10A; (6ES7407-0KA01-0AA0) and

PS 407 10A R; (6ES7407-0KR00-0AA0) 3-23. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9 Power Supply Module PS 407 20A; (6ES7407-0RA00-0AA0) 3-26. . . . . . . . . .

3.10 Power Supply Module PS 407 20A; (6ES7407-0RA01-0AA0) 3-28. . . . . . . . . .

3.11 Power Supply Module PS 405 4A; (6ES7405-0DA00-0AA0) 3-30. . . . . . . . . . .

S7-400, M7-400 Programmable Controllers Module Specifications

A5E00069467-07

xi

Page 12

Contents

3.12 Power Supply Module PS 405 4A; (6ES7405-0DA01-0AA0) 3-32. . . . . . . . . . .

3.13 Power Supply Module PS 405 10A; (6ES7405-0KA00-0AA0) 3-34. . . . . . . . . .

3.14 Power Supply Modules

PS 405 10A; (6ES7405-0KA01-0AA0) and

PS 405 10A R; (405-0KR00-0AA0) 3-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.15 Power Supply Module PS 405 20A; (6ES7405-0RA00-0AA0) 3-38. . . . . . . . . .

3.16 Power Supply Module PS 405 20A; (6ES7405-0RA01-0AA0) 3-40. . . . . . . . . .

4 Digital Modules 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Module Overview 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Sequence of Steps from Choosing to Commissioning the Digital Module 4-5

4.3 Digital Module Parameter Assignment 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.1 Parameters of the Digital Input Modules 4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.2 Parameters of the Digital Output Modules 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Diagnostics of the Digital Modules 4-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Interrupts of the Digital Modules 4-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 Input Characteristic Curve for Digital Inputs 4-15. . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 Digital Input Module SM 421; DI 32 24 VDC

(6ES7421-1BL00-0AA0) 4-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8 Digital Input Module SM 421; DI 32 24 VDC;

(6ES7421-1BL01-0AA0) 4-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.9 Digital Input Module SM 421; DI 16 24 VDC;

(6ES7421-7BH00-0AB0) 4-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.9.1 Assigning Parameters to the SM 421; DI 16 24 VDC 4-27. . . . . . . . . . . . . . .

4.9.2 Behavior of the SM 421; DI 16 24 VDC 4-29. . . . . . . . . . . . . . . . . . . . . . . . . .

4.10 Digital Input Module SM 421; DI 16 24 VDC;

(6ES7421-7BH00-0AB0) 4-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.10.1 Assigning Parameters to the SM 421; DI 16 24 VDC 4-36. . . . . . . . . . . . . . .

4.10.2 Behavior of the SM 421; DI 16 24 VDC 4-38. . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.11 Digital Input Module SM 421; DI 16 120 VAC;

(6ES7421-5EH00-0AA0) 4-41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.12 Digital Input Module SM 421; DI 16 24/60 VUC;

(6ES7 421-7DH00-0AB0) 4-44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.12.1 Assigning Parameters to the SM 421; DI 16 24/60 VUC 4-47. . . . . . . . . . . .

4.13 Digital Input Module SM 421; DI 16 120/230 VUC;

(6ES7 421-1FH00-0AA0) 4-50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.14 Digital Input Module SM 421; DI 16 120/230 VUC;

(6ES7421-1FH20-0AA0) 4-53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.15 Digital Input Module SM 421; DI 32 120 VUC;

(6ES7421-1EL00-0AA0) 4-56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.16 Digital Output Module SM 422;

DO 16 24 VDC/2 A; (6ES7422-1BH10-0AA0) 4-59. . . . . . . . . . . . . . . . . . . . .

S7-400, M7-400 Programmable Controllers Module Specifications

xii

A5E00069467-07

Page 13

Contents

4.17 Digital Output Module SM 422;

DO 16 24 VDC/2 A; (6ES7422-1BH11-0AA0) 4-62. . . . . . . . . . . . . . . . . . . . .

4.18 Digital Output Module SM 422; DO 16 0-125 VDC/1.5 A;

(6ES7422-5EH10-0AB0) 4-65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.18.1 Assigning Parameters to the SM 422; DO 16 20-125 VDC/1.5 A 4-69. . . .

4.19 Digital Output Module SM 422; DO 32 24 VDC/0.5 A;

(6ES7422-1BL00-0AA0) 4-70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.20 Digital Output Module SM 422; DO 32 24 VDC/0.5 A;

(6ES7422-7BL00-0AB0) 4-73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.20.1 Assigning Parameters to the SM 422; DO 32 24 VDC/0.5 A 4-77. . . . . . . .

4.20.2 Behavior of the SM 422; DO 32 24 VDC/0.5 A 4-78. . . . . . . . . . . . . . . . . . . .

4.21 Digital Output Module SM 422; DO 8 120/230 VAC/5 A;

(6ES7422-1FF00-0AA0) 4-79. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.22 Digital Output Module SM 422; DO 16 120/230 VAC/2 A;

(6ES7422-1FH00-0AA0) 4-83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.23 Digital Output Module SM 422; DO 16 20-120 VAC/2 A;

(6ES7422-5EH00-0AB0) 4-87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.23.1 Assigning Parameters to the SM 422; DO 16 20-120 VAC/2 A 4-90. . . . . .

4.24 Relay Output Module SM 422; DO 16 30/230 VUC/Rel. 5 A;

(6ES7422-1HH00-0AA0) 4-91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Analog Modules 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Module Overview 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Sequence of Steps from Choosing to Commissioning

the Analog Modules 5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Analog Value Representation 5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 Analog Value Representation for Analog Input Channels 5-7. . . . . . . . . . . . . .

5.3.2 Analog Value Representation for Analog Output Channels 5-22. . . . . . . . . . . . .

5.4 Setting the Measuring Method and Measuring Ranges

of the Analog Input Channels 5-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 Behavior of the Analog Modules 5-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.1 Effect of Supply Voltage and Operating Mode 5-30. . . . . . . . . . . . . . . . . . . . . . . .

5.5.2 Effect of Range of Values of the Analog Values 5-31. . . . . . . . . . . . . . . . . . . . . .

5.5.3 Effect of Operational Limit and Basic Error Limit 5-32. . . . . . . . . . . . . . . . . . . . . .

5.6 Conversion, Cycle, Setting and Response Time of Analog Modules 5-34. . . . .

5.7 Analog Module Parameter Assignment 5-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7.1 Parameters of the Analog Input Modules 5-39. . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7.2 Parameters of the Analog Output Modules 5-41. . . . . . . . . . . . . . . . . . . . . . . . . .

5.8 Connecting Sensors to Analog Inputs 5-42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9 Connecting Voltage Sensors 5-45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.10 Connecting Current Sensors 5-46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.11 Connecting Resistance Thermometers and Resistors 5-49. . . . . . . . . . . . . . . . .

5.12 Connecting Thermocouples 5-52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S7-400, M7-400 Programmable Controllers Module Specifications

A5E00069467-07

xiii

Page 14

Contents

5.13 Connecting Loads/Actuators to Analog Outputs 5-58. . . . . . . . . . . . . . . . . . . . . .

5.14 Connecting Loads/Actuators to Voltage Outputs 5-59. . . . . . . . . . . . . . . . . . . . . .

5.15 Connecting Loads/Actuators to Current Outputs 5-61. . . . . . . . . . . . . . . . . . . . . .

5.16 Diagnostics of the Analog Modules 5-62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.17 Analog Module Interrupts 5-66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.18 Analog Input Module SM 431; AI 8 13 Bit; (6ES7431-1KF00-0AB0) 5-69. .

5.18.1 Commissioning the SM 431; AI 8 13 Bit 5-73. . . . . . . . . . . . . . . . . . . . . . . . . .

5.18.2 Measuring Methods and Measuring Ranges of the SM 431; AI 8 13 Bit 5-74.

5.19 Analog Input Module SM 431; AI 8 14 Bit; (6ES7 431-1KF10-0AB0) 5-76.

5.19.1 Commissioning the SM 431; AI 8 14 Bit 5-82. . . . . . . . . . . . . . . . . . . . . . . . . .

5.19.2 Measuring Methods and Measuring Ranges of the SM 431; AI 8 14 Bit 5-84.

5.20 Analog Input Module SM 431; AI 8 4 Bit; (6ES7431-1KF20-0AB0) 5-89. . .

5.20.1 Commissioning the SM 431; AI 8 14 Bit 5-93. . . . . . . . . . . . . . . . . . . . . . . . . .

5.20.2 Measuring Methods and Measuring Ranges

of the SM 431; AI 8 14 Bit 5-95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.21 Analog Input Module SM 431; AI 16 13 Bit; (6ES7431-0HH00-0AB0) 5-98

5.21.1 Commissioning the SM 431; AI 16 13 Bit 5-103. . . . . . . . . . . . . . . . . . . . . . . . .

5.21.2 Measuring Methods and Measuring Ranges

of the SM 431; AI 16 13 Bit 5-104. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.22 Analog Input Module SM 431; AI 16 16 Bit; (6ES7431-7QH00-0AB0) 5-106

5.22.1 Commissioning the SM 431; AI 16 16 Bit 5-114. . . . . . . . . . . . . . . . . . . . . . . . .

5.22.2 Measuring Methods and Measuring Ranges

of the SM 431; AI 16 16 Bit 5-117. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.23 Analog Input Module SM 431; AI 8 RTD 16 Bit;

(6ES7 431-7KF10-0AB0) 5-122. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.23.1 Commissioning the SM 431; AI 8 RTD 16 Bit 5-126. . . . . . . . . . . . . . . . . .

5.23.2 Measuring Methods and Measuring Ranges

of the SM 431; AI 8 RTD 16 Bit 5-129. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.24 Analog Input Module SM 431; AI 8 16 Bit;

(6ES7431-7KF00-0AB0) 5-130. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.24.1 Commissioning the SM 431; AI 8 16 Bit 5-135. . . . . . . . . . . . . . . . . . . . . . . . . .

5.24.2 Measuring Methods and Measuring Ranges of the SM 431;

AI 8 16 Bit 5-139. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.25 Analog Output Module SM 432; AO 8 13 Bit;

(6ES7432-1HF00-0AB0) 5-141. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.25.1 Commissioning the SM 432; AO 8 13 Bit 5-145. . . . . . . . . . . . . . . . . . . . . . . . .

5.25.2 Output Ranges of the Analog Output Module SM 432;

AO 8 13 Bit 5-145. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

xiv

S7-400, M7-400 Programmable Controllers Module Specifications

A5E00069467-07

Page 15

Contents

6 Interface Modules 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Common Features of the Interface Modules 6-2. . . . . . . . . . . . . . . . . . . . . . . . .

6.2 The Interface Modules

IM 460-0; (6ES7460-0AA00-0AB0, 6ES7460-0AA01-0AB0)

and IM 461-0; (6ES7461-0AA00-0AA0, 6ES7461-0AA01-0AA0) 6-7. . . . . . .

6.3 The Interface Modules

IM 460-1; (6ES7460-1BA00-0AB0, 6ES7460-1BA01-0AB0)

and IM 461-1; (6ES7461-1BA00-0AA0, 6ES7461-1BA01-0AA0) 6-10. . . . . . .

6.4 The Interface Modules

IM 460-3; (6ES7460-3AA00-0AB0, 6ES7460-3AA01-0AB0)

and IM 461-3; (6ES7461-3AA00-0AA0, 6ES7461-3AA01-0AA0) 6-14. . . . . . .

6.5 The Interface Modules

IM 460-4; (6ES7460-4AA01-0AB0) and

IM 461-4; (6ES7461-4AA01-0AA0) 6-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 IM 463-2 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Using SIMATIC S5 Expansion Units in an S7-400 7-2. . . . . . . . . . . . . . . . . . . .

7.2 Rules for Connecting S5 Expansion Units 7-3. . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Operator Controls and Indicators 7-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 Installing and Connecting the IM 463-2 7-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5 Setting the Operating Modes of the IM 314 7-8. . . . . . . . . . . . . . . . . . . . . . . . . .

7.6 Configuring S5 Modules for Operation in the S7-400 7-10. . . . . . . . . . . . . . . . . .

7.7 Pin Assignments of the 721 Connecting Cable 7-11. . . . . . . . . . . . . . . . . . . . . . .

7.8 Terminating Connector for IM 314 7-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.9 Technical Specifications (6ES7463–2AA00–0AA0) 7-14. . . . . . . . . . . . . . . . . . .

8 PROFIBUS DP Master Interface IM 467/IM 467 FO 8-1. . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 PROFIBUS DP Master Interface IM 467/IM 467 FO 8-2. . . . . . . . . . . . . . . . . .

8.1.1 Indicators and the Mode Selector 8-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Configuration 8-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Connection to PROFIBUS DP 8-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.1 Bus Connector 8-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.2 Optical Connection to PROFIBUS DP 8-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.3 Connecting a Fiber-Optic Cable to the IM 467 FO 8-10. . . . . . . . . . . . . . . . . . . .

8.4 Technical Specifications 8-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.1 Technical Specifications of the IM 467 8-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.2 Technical Specifications of the IM 467 FO 8-13. . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Cable Duct and Fan Subassemblies 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 Fan Monitoring in the Fan Subassemblies 9-2. . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 Cable Duct; (6ES7408-0TA00-0AA0) 9-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 The 120/230 VAC Fan Subassembly; (6ES7408-1TB00-0XA0) 9-5. . . . . . . . .

9.4 The 24 VDC Fan Subassembly; (6ES7408-1TA00-0XA0) 9-7. . . . . . . . . . . . . .

S7-400, M7-400 Programmable Controllers Module Specifications

A5E00069467-07

xv

Page 16

Contents

10 RS 485 Repeater 10-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 Application and Characteristics (6ES7972-0AA01-0XA0) 10-2. . . . . . . . . . . . . .

10.2 Appearance of the RS 485 Repeater; (6ES7972-0AA01-0XA0) 10-3. . . . . . . .

10.3 RS 485 Repeater in Ungrounded and Grounded Operation 10-4. . . . . . . . . . . .

10.4 Technical Specifications 10-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11 CPUs for M7-400 11-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1 Performance Features 11-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.2 Technical Specifications 11-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3 Function Elements 11-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3.1 Status and Fault LEDs 11-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3.2 Memory Cards 11-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3.3 Mode Selector Switch 11-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3.4 Submodule Receptacles for Interface Submodules 11-11. . . . . . . . . . . . . . . . . . .

11.3.5 Memory Submodules Suitable for the Main Memory 11-13. . . . . . . . . . . . . . . . . .

11.3.6 Expansion Socket 11-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3.7 Multipoint Interface (MPI) 11-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4 The BIOS Setup 11-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4.1 BIOS Power Up 11-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4.2 BIOS Hot Keys 11-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4.3 Operator Inputs in the BIOS Setup 11-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4.4 Opening and Exiting the BIOS Setup 11-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4.5 Setup Page “User Help” 11-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4.6 Setup Page “IF modules” 11-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4.7 Setup Page “Timeout Function” 11-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4.8 Setup Page “Security” 11-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4.9 Setup Page “Date and Time” 11-33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4.10 “Hard Disk” Setup Page 11-34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4.11 Setup Page “Floppy/Card” 11-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4.12 Setup Page “Boot Options” 11-37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4.13 Setup Page “System” 11-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.5 I/O Addresses, Main Memory and Interrupt Assignments 11-41. . . . . . . . . . . . . .

12 M7-400 Expansions 12-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1 Overview 12-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.2 EXM 478 Expansion Module; (6ES7 478-2AC00-0AC0) 12-6. . . . . . . . . . . . . . .

12.2.1 Addressing the EXM 478 Expansion Module 12-7. . . . . . . . . . . . . . . . . . . . . . . . .

12.2.2 Interrupt Assignments, Signal Switching EXM 478 12-13. . . . . . . . . . . . . . . . . . . .

12.2.3 Technical Specifications of the EXM 478 Expansion Module 12-14. . . . . . . . . . .

12.3 ATM 478 AT Adapter Module; (6ES7 478-2CA00-0AC0) 12-15. . . . . . . . . . . . . .

12.3.1 Pin Assignments of the AT Module 12-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.3.2 Technical Specifications of the ATM 478 AT Adapter Module 12-19. . . . . . . . . . .

12.4 MSM 478 Mass Storage Module; (6ES7 478-2BA00-0AC0) 12-22. . . . . . . . . . . .

12.4.1 LPT1 Parallel Port 12-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.4.2 Technical Specifications of the MSM 478 Mass Storage Module 12-25. . . . . . . .

S7-400, M7-400 Programmable Controllers Module Specifications

xvi

A5E00069467-07

Page 17

Contents

13 Interface Submodules 13-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1 Interface Submodules Overview 13-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2 Submodule IDs and Insertion Rules 13-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.3 IF 962-VGA Interface Submodule for M7-300/400;

(6ES7962-1BA00-0AC0) 13-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.3.1 Pin Assignments 13-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.3.2 Addressing, Interrupts, and Submodule ID 13-7. . . . . . . . . . . . . . . . . . . . . . . . . .

13.3.3 Technical Specifications 13-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.4 IF 962-COM Interface Submodule for M7-300/400;

(6ES7962-3AA00-0AC0) 13-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.4.1 Pin Assignments 13-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.4.2 Addressing and Interrupts 13-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.4.3 Technical Specifications 13-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.5 IF 962-LPT Interface Submodule for M7-300/400;

(6ES7962-4AA00-0AC0) 13-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.5.1 Pin Assignments 13-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.5.2 Addressing and Interrupts 13-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.5.3 Technical Specifications 13-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.6 IF 961-DIO Interface Submodule for M7-300/400;

(6ES7961-1AA00-0AC0) 13-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.6.1 Pin Assignments 13-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.6.2 Addressing and Interrupts 13-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.6.3 Technical Specifications 13-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.7 IF 961-AIO Interface Submodule for M7-300/400;

(6ES7961-2AA00-0AC0) 13-33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.7.1 Pin Assignments and Terminal Connection Diagram 13-34. . . . . . . . . . . . . . . . . .

13.7.2 Connecting Measured Value Sensors to Analog Inputs 13-37. . . . . . . . . . . . . . . .

13.7.3 Connecting Loads/Actuators to Analog Outputs 13-42. . . . . . . . . . . . . . . . . . . . . .

13.7.4 Conversion Time and Cycle Time of the Analog Input Channels 13-44. . . . . . . .

13.7.5 Conversion Time, Cycle Time, Settling Time,

and Response Time of the Analog Output Channels 13-45. . . . . . . . . . . . . . . . . .

13.7.6 Starting Up the IF 961-AIO Interface Submodule 13-46. . . . . . . . . . . . . . . . . . . . .

13.7.7 Addressing 13-46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.7.8 Analog Output Function 13-47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.7.9 Analog Input Function 13-48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.7.10 Analog Value Representation for the Measuring Ranges

of the Analog Inputs 13-51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.7.11 Analog Value Representation for the Measuring Ranges

of the Analog Outputs 13-52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.7.12 Diagnostics, Interrupts, and Submodule ID 13-53. . . . . . . . . . . . . . . . . . . . . . . . . .

13.7.13 Technical Specifications 13-54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.8 IF 961-CT1 Interface Submodule for M7-300/400;

(6ES7961-3AA00-0AC0) 13-56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.8.1 What Can the IF961-CT1 Interface Submodule Do? 13-57. . . . . . . . . . . . . . . . . .

13.8.2 Addressing and Interrupts 13-59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.8.3 Technical Specifications 13-60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S7-400, M7-400 Programmable Controllers Module Specifications

A5E00069467-07

xvii

Page 18

Contents

13.9 IF 964-DP Interface Submodule for S7-400 and M7-400 13-61. . . . . . . . . . . . . .

13.9.1 Pin Assignments 13-63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.9.2 Addressing and Interrupts 13-64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.9.3 Technical Specifications 13-65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A Parameter Sets for Signal Modules A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1 How to Assign the Parameters for Signal Modules in the User Program A-2.

A.2 Parameters of the Digital Input Modules A-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.3 Parameters of the Digital Output Modules A-7. . . . . . . . . . . . . . . . . . . . . . . . . . .

A.4 Parameters of the Analog Input Modules A-10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

B Diagnostic Data of the Signal Modules B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1 Evaluating the Diagnostic Data of the Signal Modules

in the User Program B-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.2 Structure and Contents of

Diagnostic Data Bytes 0 and 1 B-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.3 Diagnostic Data of the Digital Input Modules

as of Byte 2 B-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.4 Diagnostic Data of the Digital Output Modules

as of Byte 2 B-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.5 Diagnostic Data of the Analog Input Modules

as of Byte 2 B-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C Spare Parts and Accessories C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D Guidelines for Handling Electrostatic Sensitive Devices (ESD) D-1. . . . . . . . . . . . . .

D.1 What is ESD? D-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.2 Electrostatic Charging of Persons D-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.3 General Protective Measures Against Electrostatic Discharge Damage D-4.

E List of Abbreviations E-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary Glossary-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index Index-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

xviii

S7-400, M7-400 Programmable Controllers Module Specifications

A5E00069467-07

Page 19

Figures

1-1 Power supply to the backup battery 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1 Structure of a Rack with 18 Slots 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Dimensions of the UR1 18-Slot or UR2 9-Slot Rack 2-3. . . . . . . . . . . . . . . . . .

2-3 Rack Dimensions 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4 CR2 Rack 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5 CR3 Rack 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6 ER1 Rack with 18 Slots and ER2 Rack with 9 Slots 2-10. . . . . . . . . . . . . . . . . . .

3-1 Controls and Indicators on the PS 407 20A Power Supply Module 3-8. . . . . .

3-2 Controls and Indicators of the PS 407 4A 3-19. . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Controls and Indicators of the PS 407 4 A 3-21. . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Controls and Displays of the PS 407 10A and PS 407 10A R 3-23. . . . . . . . . .

3-5 Controls and Displays of the PS 407 20A 3-25. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6 Controls and Indicators of the PS 407 20 A 3-27. . . . . . . . . . . . . . . . . . . . . . . . . .

3-7 Controls and Indicators of the PS 405 4 A 3-29. . . . . . . . . . . . . . . . . . . . . . . . . . .

3-8 Controls and Indicators of the PS 405 4 A 3-31. . . . . . . . . . . . . . . . . . . . . . . . . . .

3-9 Controls and Indicators of the PS 405 10 A 3-33. . . . . . . . . . . . . . . . . . . . . . . . . .

3-10 Controls and Displays of the PS 405 10A and PS 405 10A R 3-35. . . . . . . . . .

3-11 Controls and Indicators of the PS 405 20 A 3-37. . . . . . . . . . . . . . . . . . . . . . . . . .

3-12 Controls and Indicators of the PS 405 20 A 3-39. . . . . . . . . . . . . . . . . . . . . . . . . .

4-1 Input Characteristic Curve for Digital Inputs 4-16. . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Terminal Assignment and Block Diagram of the SM 421; DI 32 x 24 VDC 4-18

4-3 Terminal Assignment and Block Diagram of the SM 421; DI 32 x 24 VDC 4-21

4-4 Terminal Assignment and Block Diagram of the SM 421; DI 16 x 24 VDC 4-24

4-5 Terminal Assignment Diagram for the Redundant Supply

of Sensors of the

SM 421; DI 16 x 24 VDC 4-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-6 Terminal Assignment and Block Diagram of the SM 421;

DI 16 x 24 VDC 4-33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-7 Terminal Assignment Diagram for the Redundant Supply

of Sensors of the

SM 421; DI 16 x 24 VDC 4-34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-8 Terminal Assignment Diagram of the SM 421; DI 16 120 VDC 4-42. . . . . . . .

4-9 Terminal Assignment and Block Diagram of the SM 421;

DI 16 x 24/60 VUC 4-45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-10 Circuit as for Active High or Active Low Input 4-49. . . . . . . . . . . . . . . . . . . . . . . .

4-11 Terminal Assignment and Block Diagram of the SM 421;

DI 16 x 120/230 VUC 4-51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-12 Terminal Assignment and Block Diagram of the SM 421;

DI 16 x 120/230 VUC 4-54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-13 Terminal Assignment and Block Diagram of the SM 421;

DI 32 x 120 VUC 4-57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-14 Terminal Assignment and Block Diagram of the SM 422;

DO 16 x 24 VDC/2 A 4-60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-15 Terminal Assignment and Block Diagram of the SM 422;

DO 16 x 24 VDC/2 A 4-63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-16 Terminal Assignment Diagram of the SM 422;

DO 16 x 20-125 VDC/1.5 A 4-66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-17 Terminal Assignment and Block Diagram of the SM 422;

DO 32 x 24 VDC/0.5 A 4-71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-18 Terminal Assignment and Block Diagram of the SM 422;

DO 32 x 24 VDC/0.5 A 4-74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

S7-400, M7-400 Programmable Controllers Module Specifications

A5E00069467-07

xix

Page 20

Contents

4-19 Terminal Assignment and Block Diagram of the SM 422;

DO 8 x 120/230 VAC/5 A 4-80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-20 Terminal Assignment and Block Diagram of the SM 422;

DO 16 x 120/230 VAC/2 A 4-84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-21 Terminal Assignment Diagram of the SM 422;

DO 16 x 20-120 VAC/2 A 4-88. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-22 Terminal Assignment and Block Diagram of the SM 422;

DO 16 x 30/230 VUC/Rel. 5 A 4-92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1 Levering the Measuring Range Module out of the Analog Input Module 5-29.

5-2 Inserting the Measuring Range Module into the Analog Input Module 5-30. . .

5-3 Example of the Relative Error of an Analog Output Module 5-34. . . . . . . . . . . .

5-4 Scan Time of an Analog Input or Output Module 5-35. . . . . . . . . . . . . . . . . . . . .

5-5 Example of the Influence of Smoothing on the Step Response 5-37. . . . . . . . .

5-6 Settling and Response Times of the Analog Output Channels 5-38. . . . . . . . . .

5-7 Connecting Isolated Sensors to an Isolated AI 5-44. . . . . . . . . . . . . . . . . . . . . . .

5-8 Connecting Non-Isolated Sensors to an Isolated AI 5-45. . . . . . . . . . . . . . . . . . .

5-9 Connecting Voltage Sensors to an AI 5-46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-10 Connecting Two-Wire Transmitters to an Isolated AI 5-48. . . . . . . . . . . . . . . . . .

5-11 Connecting Two-Wire Transmitters to an SM 431; 8 x 13 Bit 5-48. . . . . . . . . . .

5-12 Connecting Four-Wire Transmitters to an AI 5-49. . . . . . . . . . . . . . . . . . . . . . . . .

5-13 Connecting Four-Wire Transmitters to an SM 431; 8 x 13 Bit 5-49. . . . . . . . . . .

5-14 Four-Conductor Connection of Resistance Thermometers on an AI 5-51. . . . .

5-15 Three-Wire Connection of Resistance Thermometers to an AI 5-52. . . . . . . . .

5-16 Two-Wire Connection of Resistance Thermometers to an AI 5-52. . . . . . . . . . .

5-17 Design of Thermocouples 5-53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-18 Connection of Thermocouples without Compensation

or Using the Reference Temperature Value to an Isolated AI 5-56. . . . . . . . . . .

5-19 Connection of a Thermocouple with Reference Junction (Order No.

M72166-xxx00) to an Isolated AI 5-57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-20 Connection of Thermocouples of the Same Type

with External Compensation by Means of a Resistance Thermometer,

Connected to Channel 0 5-58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-21 Connecting Loads to a Voltage Output of an Isolated AO

over a Four-Conductor Connection 5-61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-22 Two-Conductor Connection of Loads to a Voltage Output

of an Isolated AO 5-61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-23 Connecting Loads to a Current Output of an Isolated AO 5-62. . . . . . . . . . . . . .

5-24 Start Information of OB 40: Which Event Triggered

the Hardware Interrupt at the Limit Value 5-68. . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-25 Block Diagram of the SM 431; AI 8 x 13 Bit 5-71. . . . . . . . . . . . . . . . . . . . . . . . . .

5-26 Terminal Assignment Diagram of the SM 431; AI 8 x 13 Bit 5-72. . . . . . . . . . . .

5-27 Block Diagram of the SM 431; AI 8 x 14 Bit 5-77. . . . . . . . . . . . . . . . . . . . . . . . . .

5-28 Terminal Assignment Diagram of the SM 431; AI 8 x 14 Bit 5-78. . . . . . . . . . . .

5-29 Step Response of the SM 431; AI 8 x 14 Bit 5-84. . . . . . . . . . . . . . . . . . . . . . . . .

5-30 Block Diagram of the SM 431; AI 8 x 14 Bit 5-90. . . . . . . . . . . . . . . . . . . . . . . . . .

5-31 Terminal Assignment Diagram of the SM 431; AI 8 x 14 Bit 5-91. . . . . . . . . . . .

5-32 Step Response of the SM 431; AI 8 x 14 Bit (6ES7 431-1KF20-0AB0) 5-96. .

5-33 Block Diagram of the SM 431; AI 16 x 13 Bit 5-100. . . . . . . . . . . . . . . . . . . . . . . . .

5-34 Terminal Assignment Diagram of the SM 431; AI 16 x 13 Bit 5-101. . . . . . . . . . .

5-35 Block Diagram of the SM 431; AI 16 x 16 Bit 5-108. . . . . . . . . . . . . . . . . . . . . . . . .

5-36 Terminal Assignment Diagram of the SM 431; AI 16 x 16 Bit 5-109. . . . . . . . . . .

5-37 Step Response of the SM 431; AI 16 x 16 Bit (6ES7431-7QH00-0AB0) 5-116.

xx

S7-400, M7-400 Programmable Controllers Module Specifications

A5E00069467-07

Page 21

Contents

5-38 Block Diagram of the SM 431; AI 8 x RTD x 16 Bit 5-123. . . . . . . . . . . . . . . . . . . .

5-39 Terminal Assignment Diagram of the SM 431; AI 8 x RTD x 16 Bit 5-124. . . . . .

5-40 Step Response of the SM 431; AI 8 x RTD x 16 Bit 5-127. . . . . . . . . . . . . . . . . . .

5-41 Block Diagram of the SM 431; AI 8 x 16 Bit 5-131. . . . . . . . . . . . . . . . . . . . . . . . . .

5-42 Terminal Assignment Diagram SM 431; AI 8 x 16 Bit 5-132. . . . . . . . . . . . . . . . . .

5-43 Step Response at 10 Hz Interference Frequency Suppression

of the SM 431; AI 8 x 16 Bit 5-137. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-44 Step Response at 50 Hz Interference Frequency Suppression

of the SM 431; AI 8 x 16 Bit 5-137. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-45 Step Response at 60 Hz Interference Frequency Suppression

of the SM 431; AI 8 x 16 Bit 5-138. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-46 Step Response at 400 Hz Interference Frequency Suppression

of the SM 431; AI 8 x 16 Bit 5-138. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-47 Block Diagram of the SM 432; AO 8 x 13 Bit 5-141. . . . . . . . . . . . . . . . . . . . . . . . .

5-48 Terminal Assignment Diagram of the SM 432; AO 8 x 13 Bit 5-142. . . . . . . . . . .

6-1 Example: Configuration with Send IMs, Receive IMs and Terminators 6-5. . .

6-2 Position of the Operator Controls and Indicators of the IM 460-0

and IM 461-0 6-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3 Position of the Operator Controls and Indicators of the IM 460-1

and IM 461-1 6-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-4 Position of the Operator Controls and Indicators of the IM 460-3

and IM 461-3 6-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-5 Position of the Operator Controls and Indicators of the IM 460-4

and IM 461-4 6-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1 Layout of the Controls and Indicators of the IM 463-2 7-4. . . . . . . . . . . . . . . . .

7-2 Settings of the IM 314 with Expansion Units 7-8. . . . . . . . . . . . . . . . . . . . . . . . .

7-3 Connection Variant for CCs and EUs via the IM 463-2 and IM 314 7-10. . . . . .

8-1 Configuration of the IM 467/467 FO 8-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-2 LEDs of the IM 467/467 FO 8-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-3 Connecting the Bus Connector to the IM 467 8-8. . . . . . . . . . . . . . . . . . . . . . . .

8-4 Connector Pin Assignment 8-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-5 Optical Connection to PROFIBUS DP 8-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-6 Installing the Connector 8-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-7 Inserting the Fiber-Optic Cables into the IM 467 FO 8-11. . . . . . . . . . . . . . . . . .

9-1 Example of a Message Concept 9-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-2 Front View of the Cable Channel 9-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-3 Controls and Indicators of the Fan Subassembly 120/230 VAC

(6ES7408-1TB00-0XA0) 9-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-4 Controls and Indicators of the Fan Subassembly 24 VDC

(6ES7408-1TA00-0XA0) 9-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-1 RC Network with 10 MW for Configuration with

Ungrounded Reference Potential 10-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-2 Isolation Between the Bus Segments 10-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-3 Block Diagram of the RS 485 Repeater 10-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-1 Front and Rear View of a CPU 486-3 and CPU 488-3

without Covering Flap 11-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-2 Status and Fault LEDs on the CPU 486-3 and CPU 488-3 11-6. . . . . . . . . . . . .

11-3 Mode Selector Switch 11-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-4 Position of the Receptacles for Interface Submodules

on the CPU 486-3 and CPU 488-3 11-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-5 Submodule Receptacle Numbers on the CPU486-3/CPU488-3

and EXM478 11-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S7-400, M7-400 Programmable Controllers Module Specifications

A5E00069467-07

xxi

Page 22

Contents

11-6 POST Window for a CPU 488-3 11-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-7 Warm Restart Window for a CPU 11-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-8 Context-Sensitive Help Window 11-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-9 Setup Menu 11-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-10 “Setup Exit” Dialog Box 11-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-11 “User Help” Setup Page 11-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-12 “IF Modules” Setup Page 11-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-13 Setup Page “Timeout Function” 11-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-14 “Security” Setup Page 11-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-15 “Date and Time” Setup Page (Default) 11-33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-16 “Hard Disk” Setup Page with only the Master Hard Disk Present 11-34. . . . . . .

11-17 “Floppy/Card” Setup Page 11-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-18 “Boot Options” Setup Page 11-37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-19 “System” Setup Page 11-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-1 Positions of Expansion Socket and Expansion Connector 12-3. . . . . . . . . . . . .

12-2 Maximum Expansion with Expansion Modules 12-4. . . . . . . . . . . . . . . . . . . . . . .

12-3 EXM 478 Expansion Module 12-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-4 Submodule Receptacle Numbers for the FM 456-4 and EXM 478 12-8. . . . . .

12-5 Submodule Receptacle Numbers for the CPU 486-3, CPU 488-3,

and EXM 478 12-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-6 Base Addresses of the Expansion Modules

and the Interface Submodules 12-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-7 ATM 478 AT Adapter Module 12-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-8 ATM 478 AT Adapter Module, 98-Pin Standard Direct Connector 12-16. . . . . . .

12-9 Dimension Specifications for AT Modules to be Installed in an ATM 478 12-21.

12-10 MSM 478 Mass Storage Module 12-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13-1 IF 962-VGA Interface Submodule 13-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13-2 X2 Socket, Keyboard Plug Connection IF 961-VGA

(6-Pin Mini DIN Socket Connector) 13-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13-3 IF 962-COM Interface Submodule 13-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13-4 IF 962-LPT Interface Submodule 13-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13-5 IF 961-DIO Interface Submodule 13-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13-6 X1 Socket Assignments, IF 961-DIO (25-Pin Sub D Connector) 13-24. . . . . . . .

13-7 Circuit Block Diagram and Terminal Connection Diagram

for Wiring the Digital Inputs 13-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13-8 Circuit Block Diagram and Terminal Connection Diagram

for Wiring the Digital Outputs 13-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13-9 IF 961-AIO Interface Submodule 13-33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13-10 X1 Socket Assignments (25-Pin Sub D Connector)

and Terminal Connection Diagram of the IF 961-AIO 13-34. . . . . . . . . . . . . . . . . .

13-11 Circuit Block Diagram of the IF 961-AIO Interface Submodule 13-35. . . . . . . . . .

13-12 Grounding the Analog Inputs/Outputs of the

Interface Submodule IF 961-AIO 13-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13-13 Connection of Isolated Measured Value Sensors 13-38. . . . . . . . . . . . . . . . . . . . .

13-14 Connection of Non-Isolated Measured Value Sensors 13-39. . . . . . . . . . . . . . . . .

13-15 Connection of Voltage Sensors 13-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13-16 Connection of Two-Wire Transducers 13-40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13-17 Connection of Four-Wire Transducers 13-40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13-18 Four-Wire Connection of Resistance Thermometers/Resistances

with One Constant Current Source Each 13-41. . . . . . . . . . . . . . . . . . . . . . . . . . . .

13-19 Four-Wire Connection of Resistance Thermometers/Resistances

with a Common Constant Current Source 13-41. . . . . . . . . . . . . . . . . . . . . . . . . . .

xxii

S7-400, M7-400 Programmable Controllers Module Specifications

A5E00069467-07

Page 23

Contents

13-20 Connecting Loads/Actuators via a Two-Wire Connection

to a Current Output 13-42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13-21 Connecting Loads/Actuators via a Three-Wire Connection

to a Voltage Output 13-43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13-22 Cycle Time of the Analog Input Module 13-44. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13-23 Response Time of the Analog Output Channels 13-45. . . . . . . . . . . . . . . . . . . . . .

13-24 IF 961-CT1 Interface Submodule 13-56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13-25 IF 964-DP Interface Submodule 13-61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A-1 Data Record 1 of the Parameters of the Digital Input Modules A-5. . . . . . . . . .

A-2 Data Record 1 for Parameters of the Digital Input Modules A-6. . . . . . . . . . . .

A-3 Data Record 1 for Parameters of the Digital Output Modules A-8. . . . . . . . . . .

A-4 Data Record 1 for Parameters of the Digital Output Modules A-9. . . . . . . . . . .

A-5 Data Record 1 for Parameters of the Analog Input Modules A-11. . . . . . . . . . . .

B-1 Bytes 0 and 1 of the Diagnostic Data B-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B-2 Bytes 2 and 3 of the Diagnostic Data of the SM 421; DI 16 x 24 VDC B-4. . .

B-3 Bytes 4 to 8 of the Diagnostic Data of the SM 421; DI 16 x 24 VDC B-5. . . . .

B-4 Diagnostic Byte for a Channel of the SM 421; DI 16 x 24 VDC B-5. . . . . . . . .

B-5 Bytes 2 and 3 of the Diagnostic Data of the SM 421; DI 16 x 24/60 VUC B-6

B-6 Bytes 4 to 8 of the Diagnostic Data of the SM 421; DI 16 x 24/60 VUC B-6. .

B-7 Diagnostic Byte for a Channel of the SM 421; DI 16 x 24/60 VUC B-7. . . . . .

B-8 Bytes 2 and 3 of the Diagnostic Data of the SM 422;

DO 16 x 20-125 VDC/1.5 A B-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B-9 Bytes 4 to 8 of the Diagnostic Data of the SM 422;

DO 16 x 20-125 VDC/1.5 A B-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B-10 Diagnostic Byte for a Channel of the SM 422;

DO 16 x 20-125 VDC/1.5 A B-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B-11 Bytes 2 and 3 of the Diagnostic Data of the SM 422;

DO 32 x 24 VDC/0.5 A B-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B-12 Bytes 4 to 10 of the Diagnostic Data of the SM 422;

DO 32 x 24 VDC/0.5 A B-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B-13 Diagnostic Byte for a Channel of the SM 422; DO 32 x 24 VDC/0.5 A B-12. . .

B-14 Bytes 2 and 3 of the Diagnostic Data of the SM 422;

DO 16 x 20-120 VAC/2 A B-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B-15 Bytes 4 to 8 of the Diagnostic Data of the SM 422;

DO 16 x 20-120 VAC/2 A B-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B-16 Diagnostic Byte for a Channel of the SM 422; DO 16 x 20-120 VAC/2 A B-13.

B-17 Bytes 2 and 3 of the Diagnostic Data of the SM 431; AI 16 x 16 Bit B-14. . . . .

B-18 Bytes 4 to 8 of the Diagnostic Data of the SM 431; AI 16 x 16 Bit B-15. . . . . . .

B-19 Diagnostic Byte for a Channel of the SM 431; AI 16 x 16 Bit B-15. . . . . . . . . . .

B-20 Bytes 2 and 3 of the Diagnostic Data of the SM 431; AI 8 x RTD x 16 Bit B-16

B-21 Bytes 4 to 7 of the Diagnostic Data of the SM 431; AI 8 x RTD x 16 Bit B-16. .

B-22 Even Diagnostic Byte for a Channel of the SM 431; AI 8 x RTD x 16 Bit B-17.

B-23 Odd Diagnostic Byte for a Channel of the SM 431; AI 8 x RTD x 16 Bit B-17. .

B-24 Bytes 2 and 3 of the Diagnostic Data of the SM 431; AI 8 x 16 Bit B-18. . . . . .

B-25 Bytes 4 to 7 of the Diagnostic Data of the SM 431; AI 8 x 16 Bit B-18. . . . . . . .

B-26 Even Diagnostic Byte for a Channel of the SM 431; AI 8 x 16 Bit B-19. . . . . . .

B-27 Odd Diagnostic Byte for a Channel of the SM 431; AI 8 x 16 Bit B-19. . . . . . . .

D-1 Electrostatic Voltages which Can Build up on a Person D-3. . . . . . . . . . . . . . . .

S7-400, M7-400 Programmable Controllers Module Specifications

A5E00069467-07

xxiii

Page 24

Contents

Tables

1-1 Use in an Industrial Environment 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Products that Fulfill the Requirements of the Low-Voltage Directive 1-3. . . .

1-3 Power Supply Modules 1-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 Pulse-Shaped Interference 1-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-5 Sinusoidal Interference 1-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-6 Interference emission of electromagnet fields 1-11. . . . . . . . . . . . . . . . . . . . . . .

1-7 Interference emission via the mains AC power supply 1-11. . . . . . . . . . . . . . .

1-8 Power Supply Modules that Comply with System Perturbation Standards 1-11

1-9 Shipping and Storage Conditions for Modules 1-12. . . . . . . . . . . . . . . . . . . . . . .

1-10 Mechanical Conditions 1-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-11 Ambient Mechanical Conditions for the MSM 478 Mass Storage Module in

Operation 1-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-12 Ambient Mechanical Conditions Test 1-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-13 Ambient Climatic Conditions for the S7-400 1-15. . . . . . . . . . . . . . . . . . . . . . . . .

1-14 Power Supply Modules for Use at up to + 1500 m 1-16. . . . . . . . . . . . . . . . . . . .

1-15 Ambient Climatic Conditions for the M7-400 1-17. . . . . . . . . . . . . . . . . . . . . . . . .

1-16 Test Voltages 1-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1 Compliance with the NAMUR recommendation 3-3. . . . . . . . . . . . . . . . . . . . . .

3-2 Redundant power supply modules 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 INTF, DC 5V, DC 24 V LEDs 3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 BAF, BATTF LEDs 3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5 BAF, BATT1F, BATT2F LEDs 3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6 Function of the operator controls of the power supply modules 3-11. . . . . . . .

3-7 Error messages of the power supply modules 3-13. . . . . . . . . . . . . . . . . . . . . . .

3-8 INTF, DC5V, DC24V LEDs 3-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-9 BAF, BATTF; BATT INDIC LEDs on BATT 3-16. . . . . . . . . . . . . . . . . . . . . . . . . . .

3-10 BAF, BATT1F, BATT2F; BATT INDIC LEDs on 1BATT 3-17. . . . . . . . . . . . . . . . .

3-11 BAF, BATT1F, BATT2F; BATT INDIC LEDs on 2BATT 3-18. . . . . . . . . . . . . . . . .

4-1 Digital Input Modules: Characteristics at a Glance 4-3. . . . . . . . . . . . . . . . . . . .

4-2 Digital Output Modules: Characteristics at a Glance 4-4. . . . . . . . . . . . . . . . . .

4-3 Relay Output Module: Characteristics at a Glance 4-4. . . . . . . . . . . . . . . . . . . .

4-4 Sequence of Steps from Choosing to Commissioning the Digital Module 4-5

4-5 Static and dynamic parameters of the digital modules 4-6. . . . . . . . . . . . . . . .

4-6 Parameters of the Digital Input Modules 4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-7 Parameters of the Digital Output Modules 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . .

4-8 Diagnostic Messages of the Digital Modules 4-10. . . . . . . . . . . . . . . . . . . . . . . . .

4-9 Diagnostic Messages of the Digital Modules,

Causes of Errors and Remedial Measures 4-11. . . . . . . . . . . . . . . . . . . . . . . . . .

4-10 Parameters of the SM 421; DI 16 24 VDC 4-27. . . . . . . . . . . . . . . . . . . . . . . .

4-11 How the Input Values Depend on the Operating Mode

of the CPU and on the Supply Voltage L+ of the SM 421;

DI 16 24 VDC 4-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-12 How the Input Values Are Affected by Faults and by

the Parameter Assignment of the

SM 421; DI 16 24 VDC 4-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-13 Parameters of the SM 421; DI 16 24 VDC 4-36. . . . . . . . . . . . . . . . . . . . . . . .

4-14 How the Input Values Depend on the Operating Mode of the CPU

and on the Supply Voltage L+ of the SM 421; DI 16 24 VDC 4-38. . . . . . . .

4-15 How the Input Values Are Affected by Faults and by the

Parameter Assignment of the SM 421; DI 16 24 VDC 4-39. . . . . . . . . . . . .

4-16 Parameters of the SM 421; DI 16 24/60 VUC 4-47. . . . . . . . . . . . . . . . . . . . .

xxiv

S7-400, M7-400 Programmable Controllers Module Specifications

A5E00069467-07

Page 25

Contents

4-17 Parameters of the SM 422; DO 16 20-125 VDC/1.5 A 4-69. . . . . . . . . . . . . .

4-18 Parameters of the SM 422; DO 32 24 VDC/0.5 A

(6ES7422-7BL00-0AB0) 4-77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-19 Dependence of the Output Values on the Operating Mode of the CPU

and on the Supply Voltage L+ of the SM 422; DO 32 24 VDC/0.5 A 4-78.

4-20 Parameters of the SM 422; DO 16 20-120 VAC/2 A 4-90. . . . . . . . . . . . . . . .

5-1 Analog Input Modules: Characteristics at a Glance 5-3. . . . . . . . . . . . . . . . . . .

5-2 Analog Output Modules: Characteristics at a Glance 5-4. . . . . . . . . . . . . . . . . .

5-3 Sequence of Steps from Choosing to Commissioning the Analog Module 5-6

5-4 Example: Bit Pattern of a 16-Bit and a 13-Bit Analog Value 5-8. . . . . . . . . . . .

5-5 Possible Resolutions of the Analog Values 5-9. . . . . . . . . . . . . . . . . . . . . . . . . .

5-6 Bipolar Input Ranges 5-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-7 Unipolar Input Ranges 5-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-8 Life-Zero Input Ranges 5-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-9 Analog Value Representation in

Voltage Measuring Ranges + 10 V to + 1 V 5-11. . . . . . . . . . . . . . . . . . . . . . . . . .

5-10 Analog Value Representation in

the Voltage Measuring Ranges + 500 mV to + 25 mV 5-12. . . . . . . . . . . . . . . . .

5-11 Analog Value Representation in