Page 1

Unrestricted © Siemens 2020

Version 2020-12-13

siemens.com/S7-1500Unrestricted @ Siemens 2020

SIMATIC S7-1500R/H

V16

Page 2

Unrestricted © Siemens 2020

Version 2020-12-13

▪ Motivation and Product Strategy

▪ System Overview

▪ System Redundancy and Network Configuration

▪ Communication

▪ S7-1500R/H and Safety

▪ HMI Connection

▪ Installation Recommendations

▪ New Features with TIA Portal V16

▪ Remaining Restrictions

▪ Ordering Information

SIMATIC S7-1500 Redundant Systems

New

Page 3

Unrestricted © Siemens 2020

Version 2020-12-13

Save on maintenance

Application solutions are mostly

complicated and difficult to maintain

Operation without persons locally

Maintenance trips can be better

planned

Preventing plant downtime

High availability during operation,

Avoidance of loss of production

Redundant systems reduce costs

Prevention of data losses

The data remain intact and long restart

times after a failure are eliminated.

Prevention of damages

Avoidance of unplanned production

stops where the product to be

processed would be permanently

damaged

SIMATIC S7-1500 Redundant Systems

Motivation

Page 4

Unrestricted © Siemens 2020

Version 2020-12-13

SIMATIC S7-1500 Redundant Systems

Product Strategy S7-1500R/H

Based on Standard S7-1500 CPUs and PROFINET

• Basis Hardware Standard-CPUs/Fail-safe CPUs

Transparent Programming

• Standard Engineering Tool TIA Portal

• Redundancy functions fully integrated in TIA Portal

• General handling like standard

• No deep Redundancy Know-How needed

Extensive Scalability

• Scalability of switch-over time

• Scalability of the Redundancy Architecture

• Scalability of the CPU Performance (1513 → 1517)

Step by Step Product Launch Strategy

• First release with basic redundancy functions

• First release will not include all standard and

redundancy functions

• Step by Step increasing of feature set in future versions

Page 5

Unrestricted © Siemens 2020

Version 2020-12-13

SIMATIC S7-1500 Redundant Systems

New

▪ Motivation and Product Strategy

▪ System Overview

▪ System Redundancy and Network Configuration

▪ Failure Scenarios

▪ Communication

▪ S7-1500R/H and Safety

▪ HMI Connection

▪ Installation Recommendations

▪ New Features with TIA Portal V16

▪ Remaining Restrictions

▪ Ordering Information

Page 6

Unrestricted © Siemens 2020

Version 2020-12-13

SIMATIC S7-1500 Redundant Systems

System overview

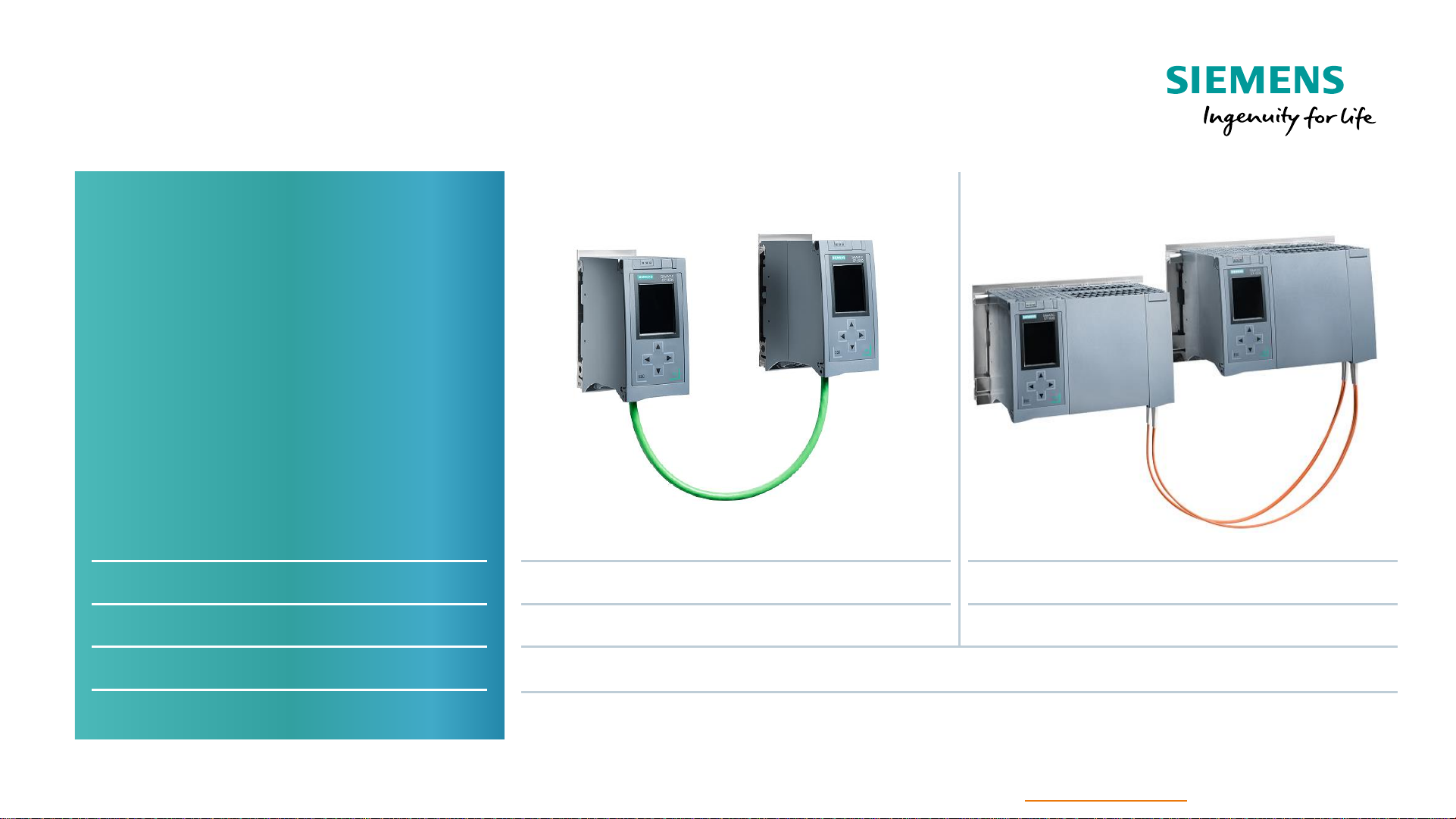

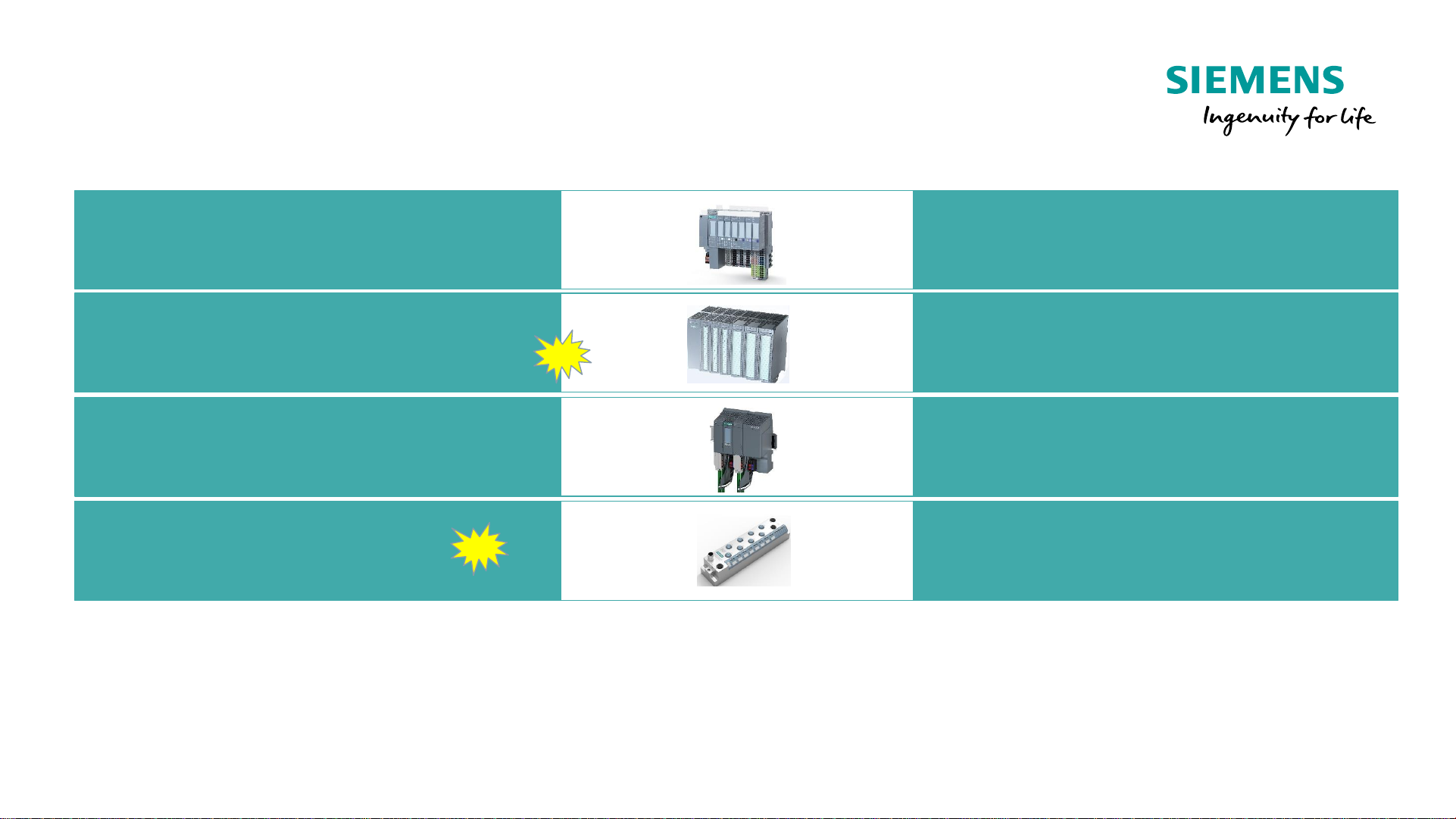

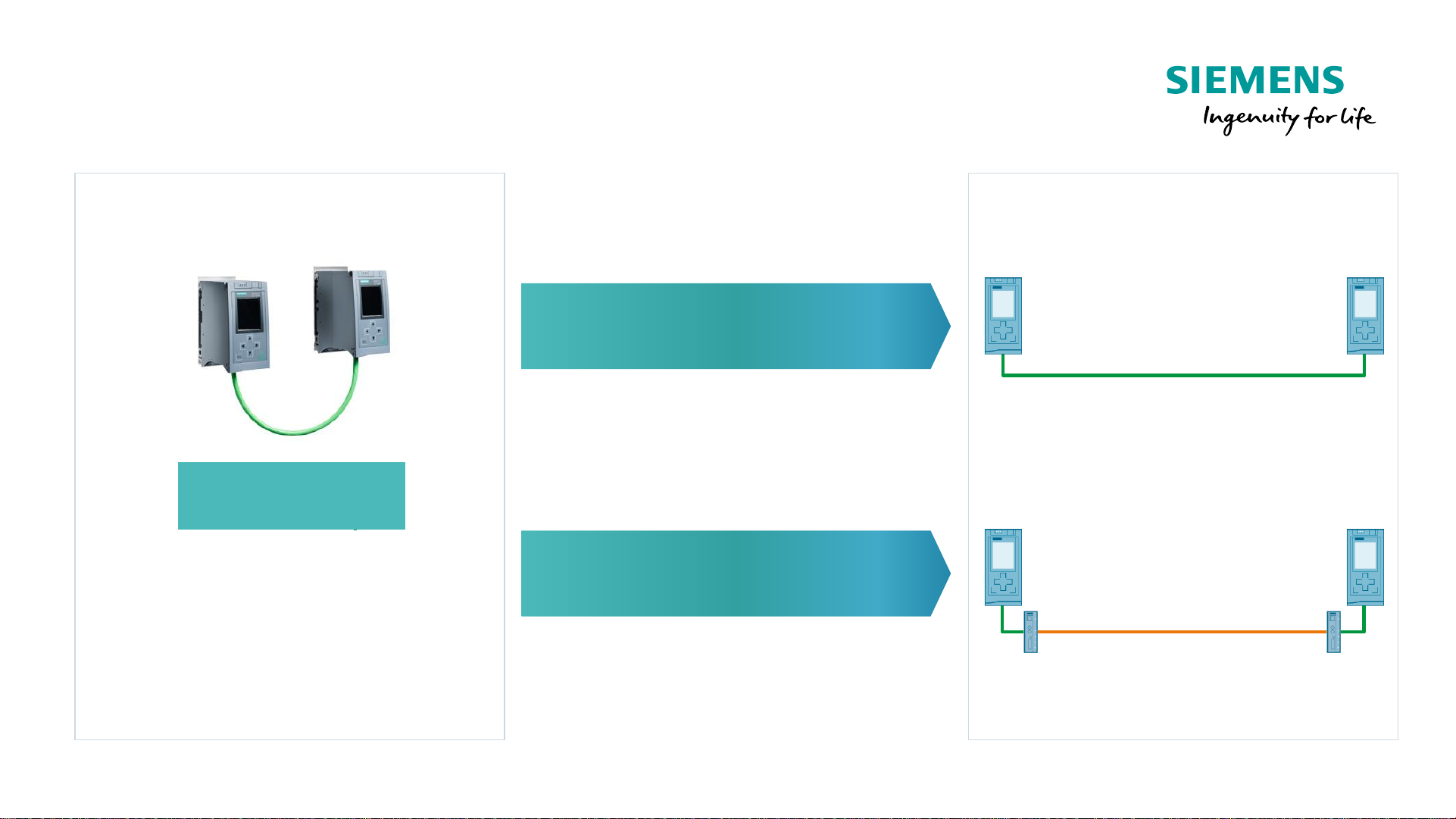

High Available – S7-1500H

CPU 1517H

via Sync-Module

50 ms

Consistent concept –

Identical synchronization

process

Scaling of the switching

performance over the available

bandwidth of the

sync connection

CPU type

Synchronization

Switchover time

I/O systems

Type of connection

Redundant – S7-1500R

CPU 1513R / CPU 1515R

via PROFINET Ring (MRP)

300 ms

ET 200SP and ET 200MP

1)

Single connection (PN redundancy S2) and switched S1

2)

1) ET 200eco PN M12-L in preparation 2) See slide Switched S1 Device

Page 7

Unrestricted © Siemens 2020

Version 2020-12-13

SIMATIC S7-1500 Redundant Systems

PLC Hardware

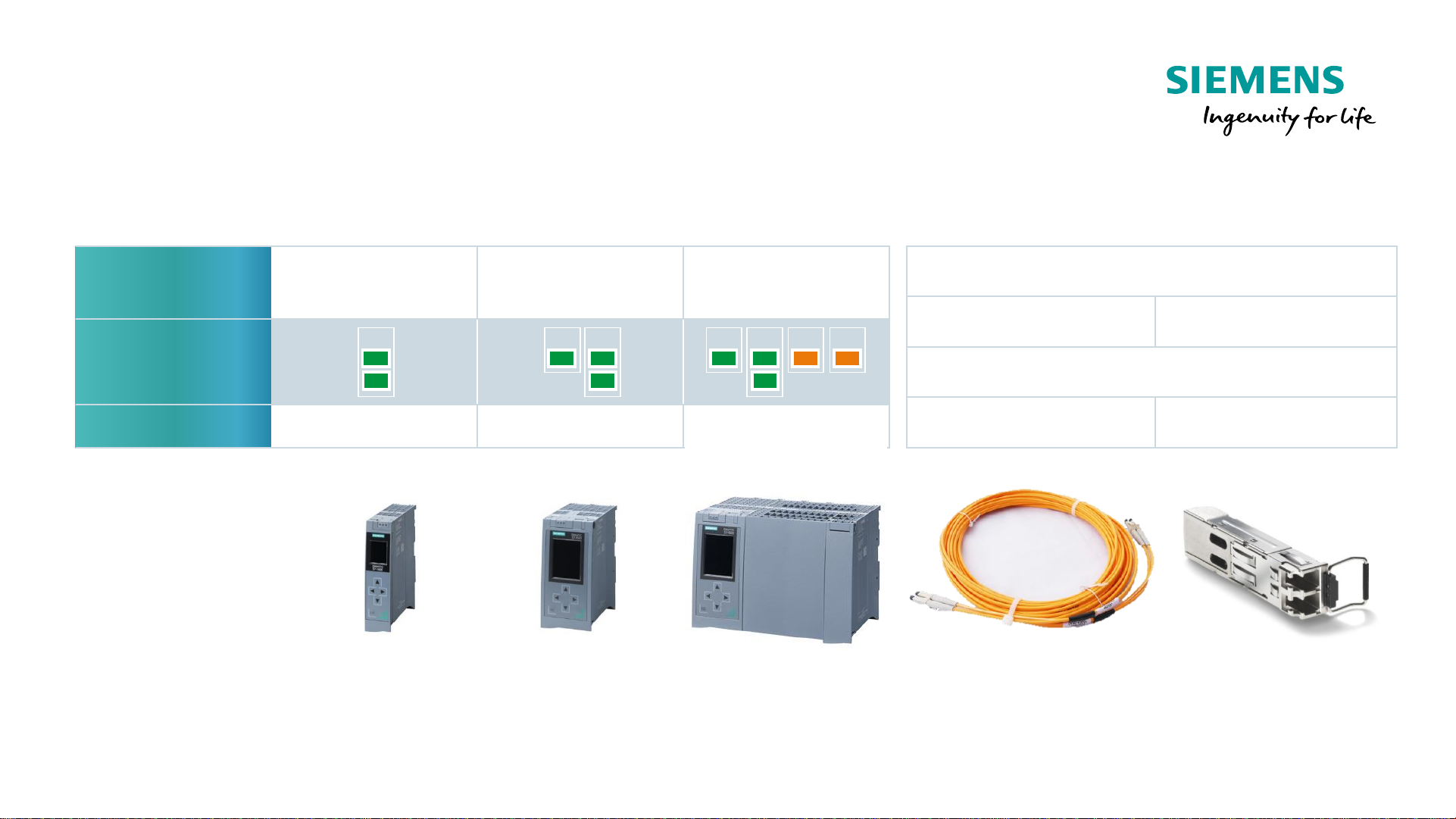

CPU 1513R

-1 PN

6ES7513-1RL00-0AB0

CPU 1515R

-2 PN

6ES7515-2RM00-0AB0

CPU 1517H

-3 PN

6ES7517-3HP00-0AB0

Program /

memory

350 kB code

1,5 MB data

500 kB code

3 MB data

2 MB code

8 MB data

Interfaces

Firmware

V2.8 V2.8 V2.8

X1 X1 X1X2 X2 X3 X4

Short Distance

<= 10m

Long Distance

<= 10km

Fiber Optic Cable

Plastic Glass fiber

Sync module SFP

6ES7960-1CB00-0AA5 6ES7960-1FB00-0AA5

SFP = Small Form-factor Pluggable

X1: PROFINET IO Controller, Supports RT, MRP, Transport Protocol TCP/IP, Open User Communication

X2: PROFINET Basic Services, Transport Protocol TCP/IP, Open User Communication

Page 8

Unrestricted © Siemens 2020

Version 2020-12-13

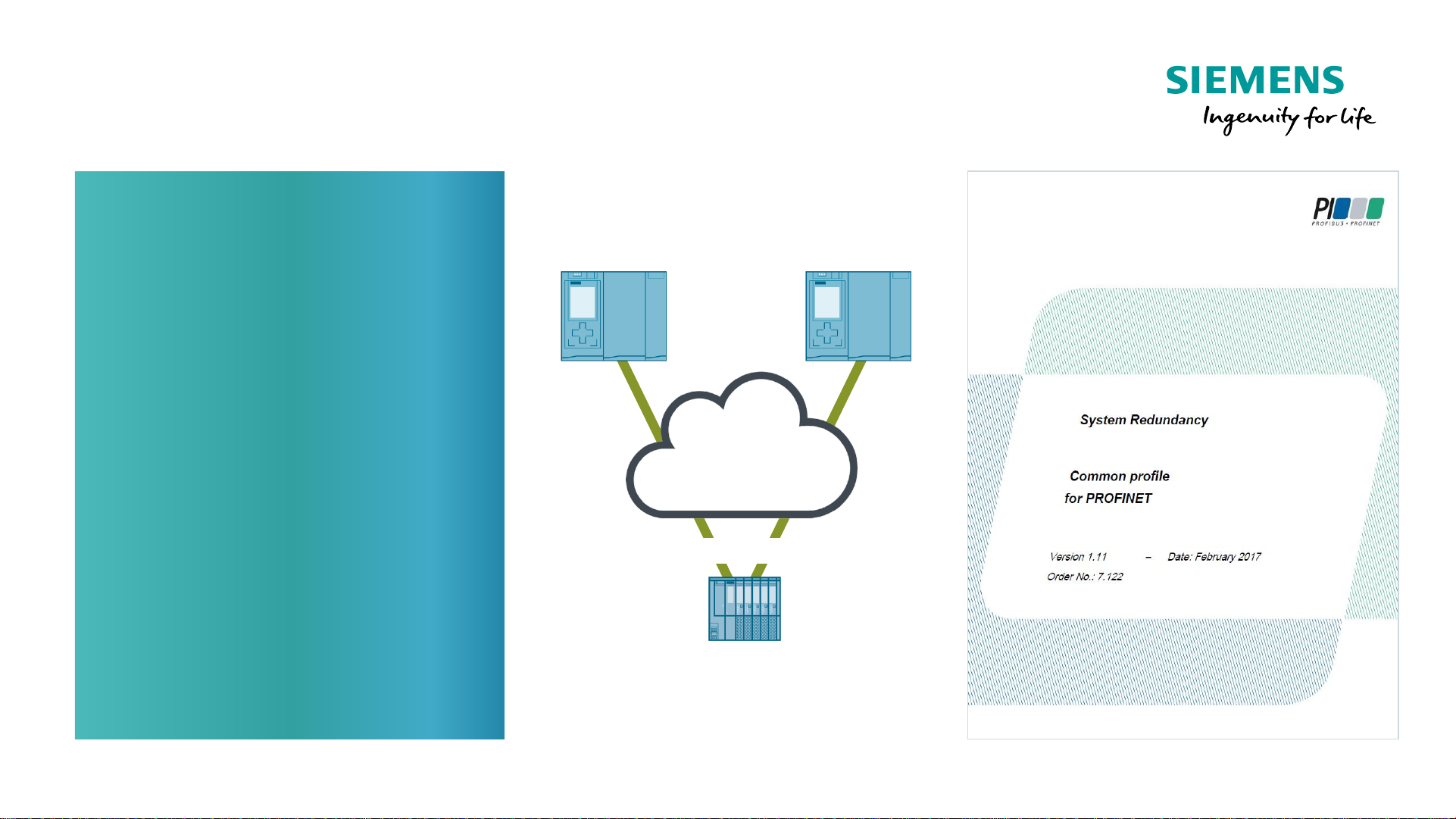

PROFINET System Redundancy

Concept

PROFINET SR

A System with redundant PN

controllers and single or

redundant PN devices.

Three levels:

1. PN Controller

2. PROFINET Network

3. PN Device

Redundancy at one level is

independent of redundancy at

each other level.

PN

Controller

PN

Controller

PN Device

PROFINET

Network

2 or 4 connections

Page 9

Unrestricted © Siemens 2020

Version 2020-12-13

PROFINET System Redundancy

PROFINET IO Network

S1 Device

S → Single interface

1 → one connection to one PLC

IM IO

PROFINET IO Network

IM IO

S2 Device

S → Single interface

2 → can switch between two connections

PROFINET IO Network

IM IOIM

R1 Device

R → Redundant interface

1 → each interface has one connection to

one PLC

Standard PLC + R/H For R/H PLC Future 1500H release

S1 Mode S2 Mode R1 Mode

PLC

Page 10

Unrestricted © Siemens 2020

Version 2020-12-13

PROFINET System Redundancy

Siemens PN IO-Devices with PN S2 Support

ET 200SP - IM155-6PN HF (FW>=4.2)

6ES7155-6AU01-0CN0

6ES7155-6AU30-0CN0

ET 200MP - IM155-5PN HF (FW>=4.2)

now also available with active backplane.

6ES7155-5AA00-0AC0

PN/PN-Coupler 6ES7158-3AD10-0XA0

I/O-Systems

ET 200eco PN M12-L 6ES7 14*-6**00-0BB0

1) In Vorbereitung

New

New

Page 11

Unrestricted © Siemens 2020

Version 2020-12-13

PROFINET System Redundancy

Siemens PN IO-Devices with PN S2 Support

SCALANCE XC-200 Serie 6GK5 2 . . - . . . 00 - 2 . C2

SCALANCE XF204-2BA

6GK5 204-2AA00-2GF2

Switches

SCALANCE XP-200 Serie

6GK5 2 . . - 0 . A00 - . . S6

Drives

S120, CU310-2PN (FW >=5.2)

(with gsdml)

6SL3040-1LA01-0AA0

S120, CU320-2PN (FW>=5.2)

(with gsdml)

6SL3040-1MA01-0AA0

Page 12

Unrestricted © Siemens 2020

Version 2020-12-13

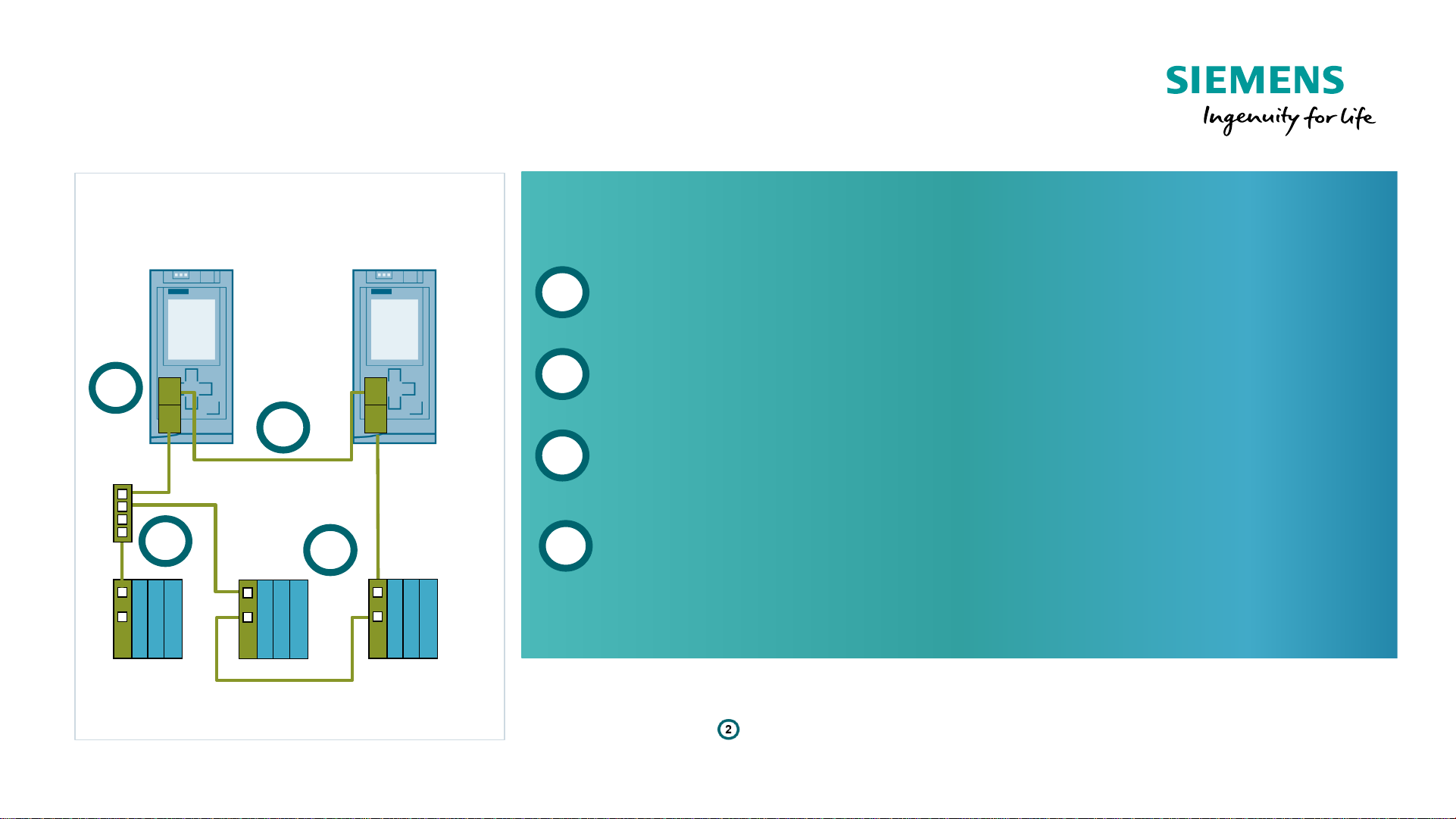

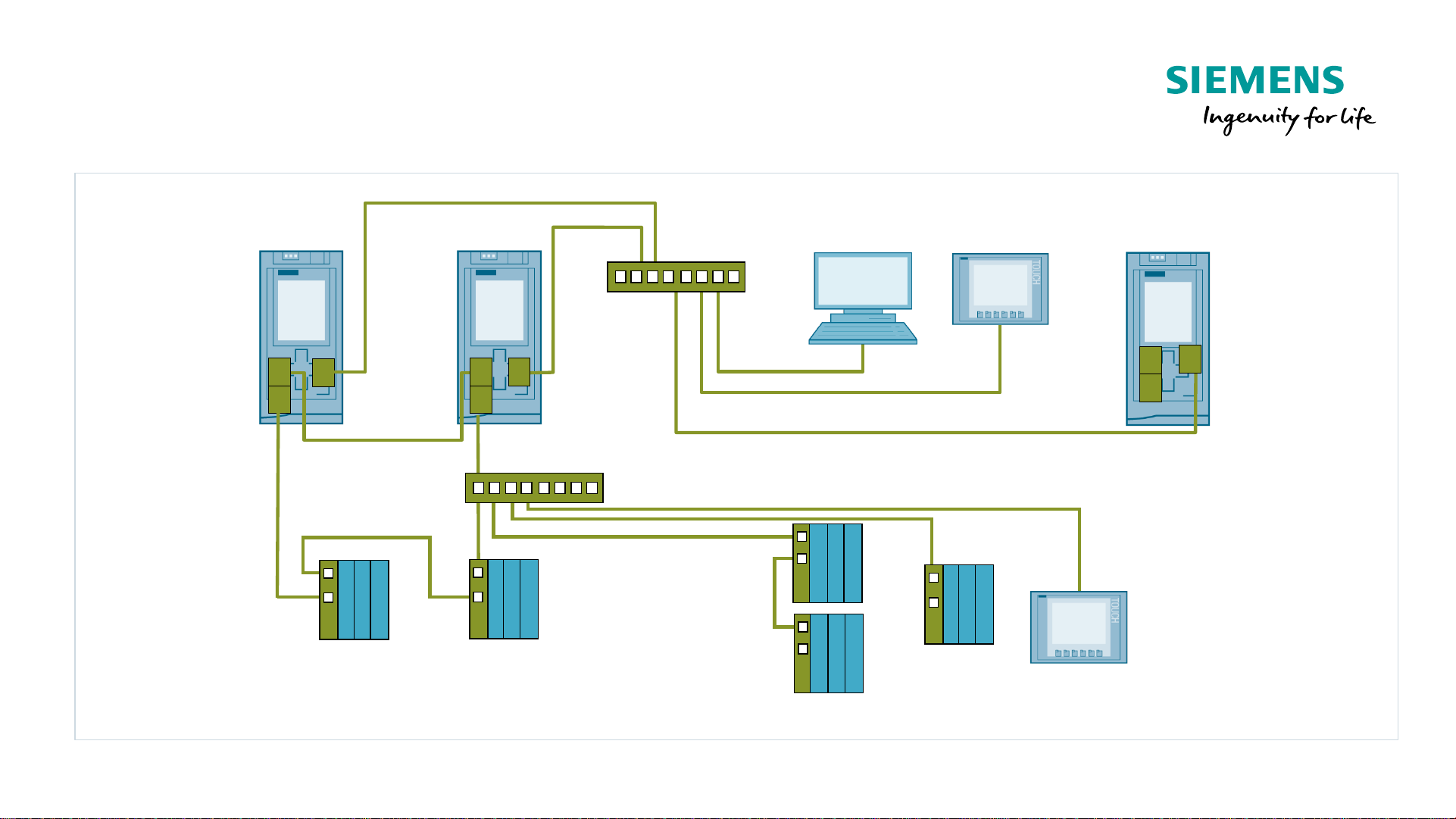

Network Configuration with S7-1500R/H

Requirements

Requirements for the

PROFINET network

configuration

• MRP Ring (default setting in

the configuration)

• PN IO only at X1 interface

• PLC’s need to be part of the

ring

• S7-1500R → no devices in the

connection between the two

PLC‘s

• PN Devices need to support

PN System redundancy

NAP S2 (V1.11)

High Available – S7-1500HRedundant – S7-1500R

Sync

Primary Backup

Single MRP Ring

H-Sync

Primary

Backup

Single MRP Ring

ET 200SP ET 200MP ET 200SP ET 200MP

Max. 16 devices in ring

*)

*) Recommendation

Max. 50 devices in ring

*)

Page 13

Unrestricted © Siemens 2020

Version 2020-12-13

Network Configuration with S7-1500R/H

Basic System Configuration for R-CPU

Structure

MRP-Ring must be connected to the X1 - Port

Synchronization over PN-Ring – no device in this segment

S1 Devices should be connected via a switch to the ring

1)

S2 Devices can be integrated into the ring or also separated

with a switch

1

2

3

PNPN

PN

CPU 151xR

Primary

CPU 151xR

Backup

PN

1

2

3

MRP Ring

4

S1

Switch

S2

S2

4

1) Reason: S1 devices do not forward H-sync telegrams during a MRP reconfiguration phase. This would lead to a high PLC cycle time

in the case that segment is interrupted.

See chapter „H-Sync Forwarding“ in the system manual of S7-1500R/H for details.

Page 14

Unrestricted © Siemens 2020

Version 2020-12-13

Network Configuration with S7-1500R

Length of the synchronization connection

Direct link up to 100 m

Fiber optic link

(media converter) up to 3 km

≤100 Meter

≤ 3 km

CPU 1513R

CPU 1515R

Page 15

Unrestricted © Siemens 2020

Version 2020-12-13

Configuration example

CPU 1515R

Panel

Switch

PNPN

PN

CPU 1515R

Primary

CPU 1515R

Backup

PN

MRP-RING

PN

Switch

PN

PN

PC Standard PLC

Panel

PN

PN

PN

PN

PN

S2S2

S2

S2

S1

Page 16

Unrestricted © Siemens 2020

Version 2020-12-13

Network Configuration with S7-1500H

Length of the synchronization connection

≤10 Meter

≤10 km

The sync cables are redundant.

The loss of one fiber optic cable has no impact on the runtime behavior.

Short distance Sync modules

up to 10 Meter (LED)

Long distance Sync modules

up to 10 km

CPU 1517H

Page 17

Unrestricted © Siemens 2020

Version 2020-12-13

Network Configuration with S7-1500H

Basic System Configuration

CPU 1517H

Primary

CPU 1517H

Backup

1

3

MRP-RING

3

PN

PN

PN

PN

2

2

3

Structure

MRP-Ring must be connected to X1 - Port

Synchronization over Sync-Modules –

Device connection possible

S1 and S2 devices can be integrated into the MRP ring

1

2

3

Page 18

Unrestricted © Siemens 2020

Version 2020-12-13

Configuration example SIMATIC S7-1500H

CPU 1517H

Panel

Switch

PN

PN

CPU 1517H

Primary

CPU 1517H

Backup

PN

MRP-RING

PN

Switch

PN

PN

PC Standard PLC

Panel

PN

PN

PN

PN

PN

PN

FO Sync.

S1S2

S2

S2

S1

S1

Page 19

Unrestricted © Siemens 2020

Version 2020-12-13

SIMATIC S7-1500 Redundant Systems

New

▪ Motivation and Product Strategy

▪ System Overview

▪ Add In and System Redundancy and Network Configuration

▪ Communication

▪ S7-1500R/H and Safety

▪ HMI Connection

▪ Installation Recommendations

▪ New Features with TIA Portal V16

▪ Remaining Restrictions

▪ Ordering Information

Page 20

Unrestricted © Siemens 2020

Version 2020-12-13

Engineering R/H System with TIA Portal Add-in

To connect a PROFINET device to a redundant system S7-1500R/H, it is necessary to set the correct

watchdog time for each device. The S7-1500R/H AddIn, as a context menu function for each PN IO device

connected to an R/H system, calculates the correct factor and updates it in the settings.

Free download: https://support.industry.siemens.com/cs/ww/en/view/109769093

Copy the add in into the folder

.\Program Files\Siemens\Automation\Portal V1x\Add-Ins

Page 21

Unrestricted © Siemens 2020

Version 2020-12-13

ET 200SP Connectivity

Module

func.

PtP

Connections

Bus

systems

3 Port IM Module

IO

-Link Master

AS

-I Master

Motorstarter

PtP

/ Modbus RTU

•

DALI

•

CAN

•

DMX512

ET200AL System

HART

R/H PROFINET Network configuration –

Connectivity ET200 Stations

H-Sync

Primary Backup

Connectivity ET 200SP

IO

-Link Master

PtP

/ Modbus RTU

Configuration with active backplane possible

64 Channels are now availabel

Connectivity ET 200MP

ET200AL

6ES7 155-6AU30-0CN0

New

Page 22

Unrestricted © Siemens 2020

Version 2020-12-13

SIMATIC S7-1500 / ET 200MP – New products

Summary of 64-channel modules and active backplane bus

Features / functions Benefits

New high-channel ET 200MP modules

64-channel digital modules:

• DI 64x24VDC BA (sinking/sourcing input)

• DQ 64x24VDC/0.3A BA

• DQ 64x24VDC/0.3A SNK BA (sinking output)

• DI 32x24VDC/DQ 32x24VDC/0.3A SNK BA

▪ Optimum price-performance

solution

for price-sensitive applications

▪ Very small footprint due to

greatest possible channel density

▪ Time savings during installation

due to toolless mounting of

shielding and TOP Connect

Active backplane bus / hot swapping

Hot swapping (module replacement during

runtime of the CPU) is possible also with

multiple modules through the use of the

active backplane bus for the ET 200MP. Up

to 12 S7-1500 / ET 200MP modules can be

inserted per station.

Maximum machine/plant

availability because the CPU and

unaffected modules remain in

operation during failure and

replacement of one or more

modules.

High-channel

modules (shifted to 08/2020)

New

New

Active backplane bus

Page 23

Unrestricted © Siemens 2020

Version 2020-12-13

64-channel digital modules

Overview

Type Article number

DI 64x24VDC SNC/SRC BA

6ES7 521

-1BP00-0AA0

DQ 64x24VDC/0.3A BA

6ES7 522

-1BP00-0AA0

DQ 64x24VDC/0.3A SNK BA

6ES7 522

-1BP50-0AA0

DI 32 / DQ 32 x24VDC/0.3A SNK BA

6ES7 523

-1BP50-0AA0

Page 24

Unrestricted © Siemens 2020

Version 2020-12-13

S2 and S1 Devices can be connected

Network Configuration with S7-1500R/H

Connection of PROFINET Devices

H-Sync

Primary

Backup

S2

S2

S1

Switched S1 Mode

1)

(New in V16)

→ Not bump less

Connection of S1 Devices via PN/PN Coupler

with subordinated controller.

→ Bump less Switchover

S2

S1

S1

S1

S2 Mode

→ Bump less Switchover

Subordinated PLC

1) For S7-1500R, S1 devices should be

connected via a switch to the MRP ring

Page 25

Unrestricted © Siemens 2020

Version 2020-12-13

New in V16: Connection without PN/PN coupler is possible

Network Configuration with S7-1500R/H

Connection of Subordinated Controller

H-Sync

Primary

Backup

Option 1:

Integration as iDevice in „Switched S1 Mode“

Currently support only with GSD

→ Communication to RH is temporarily interrupted when a

RH failover occurs.

S2

Option 2:

Via PN/PN Coupler

→ Bump less switchover

S1

1) Not recommended for S7-1500R – see Installation recommendations

Option 3:

Open User Communication between H-

System and subordinated controller

1)

→ Communication to RH is temporarily

interrupted when a RH failover occurs.

Open User Communication

Page 26

Unrestricted © Siemens 2020

Version 2020-12-13

New in V16: Connection without PN/PN coupler is possible

Network Configuration with S7-1500R/H

Connection of PROFIBUS DP Slaves

H-Sync

Primary

Backup

S2

S1

PROFIBUS

PROFIBUS

Please note: IE/PB Link and IE/PB LINK HA are currently not supported

Open User Communication

PROFIBUS

Option 2:

Via PN/PN Coupler

→ Bump less switchover

1) Not recommended for S7-1500R – see Installation recommendations

Option 1:

Integration as iDevice in „Switched S1 Mode“

Currently support only with GSD

→ Communication to RH is temporarily interrupted when a

RH failover occurs.

Option 3:

Open User Communication between H-

System and subordinated controller

1)

→ Communication to RH is temporarily

interrupted when a RH failover occurs.

Page 27

Unrestricted © Siemens 2020

Version 2020-12-13

Network Configuration with S7-1500R/H

Network connections

H-Sync

Primary Backup

As a stitch over a switch

into the ring

As part of the ring

Page 28

Unrestricted © Siemens 2020

Version 2020-12-13

Additional SIMATIC tools –

Overview of existing tools for automation tasks

SINETPLAN

PRONETA

Configuration of the PROFINET devices

• Adjust IP address and device name

• manual / automatic / mass operations

Offline / Online Comparison

• Reference from STEP7 project or PRONETA snapshot

• Incl. check of the ET 200 module configuration

Show details of all modules

▪ Read and compare module configuration

IO test

▪ Automatically logging of IO signal changes

▪ Display device-specific diagnostics

▪ Create and export IO Check protocol

Simulation of the network load depending on topology and network

nodes

▪ Report function with detailed results

▪ Validation of the PROFINET planning guideline

▪ Online scan function

Seemsless integration via API and Standards

▪ Import of the configuration with AutomationML

▪ Import of STEP7 & TIA Portal projects

Port-by-port simulation

Page 29

Unrestricted © Siemens 2020

Version 2020-12-13

SIMATIC S7-1500 Redundant Systems

New

▪ Motivation and Product Strategy

▪ System Overview

▪ Add In and System Redundancy and Network Configuration

▪ Communication

▪ S7-1500R/H and Safety

▪ HMI Connection

▪ Installation Recommendations

▪ New Features with TIA Portal V16

▪ Remaining Restrictions

▪ Ordering Information

Page 30

Unrestricted © Siemens 2020

Version 2020-12-13

SIMATIC S7-1500 Redundant Systems

New

▪ Motivation and Product Strategy

▪ System Overview

▪ Add In and System Redundancy and Network Configuration

▪ Communication

▪ S7-1500R/H and Safety

▪ HMI Connection

▪ Installation Recommendations

▪ New Features with TIA Portal V16

▪ Remaining Restrictions

▪ Ordering Information

Page 31

Unrestricted © Siemens 2020

Version 2020-12-13

Communication

Communication with a

redundant PLC System without

special drivers

H-Sync

X1 X1

X1X1

WinCC / SCADA

Standard Controller

Basic/Comfort Panel

Industrial Ethernet

X2 X2

X2 X2

Third-Party

Page 32

Unrestricted © Siemens 2020

Version 2020-12-13

CPU 1517H SystemCPU 1515R System

Communication

System IP-Address

Accessing the R/H system by

using “System IP-Address”

X1 X1

X1X1

WinCC / SCADA

Standard Controller

Basic/Comfort Panel

Industrial Ethernet

X2 X2

X2 X2

Third-Party

Page 33

Unrestricted © Siemens 2020

Version 2020-12-13

CPU 151xR/H System

Communication

System IP-Address

Standard Controller

Industrial Ethernet

System: IP3

X2: IP1 X2: IP2

Using System IP instead of PLC interface IP

• Transparent communication between standard

PLC and R/H-System

• The standard communication partner is

automatically connected to the primary PLC

Page 34

Unrestricted © Siemens 2020

Version 2020-12-13

CPU 151xR/H System

Communication

System IP-Address

Backup

Standard Controller

Industrial Ethernet

System: IP3

Primary

Connection to IP 3

X2: IP1 X2: IP2

Using System IP instead of PLC interface IP

• Transparent communication between standard

PLC and R/H-System

• The standard communication partner is

automatically connected to the primary PLC

Page 35

Unrestricted © Siemens 2020

Version 2020-12-13

CPU 151xR/H System

Communication

System IP-Address – Switching Primary

Standard Controller

System: IP3

Primary

Industrial Ethernet

Connection to IP 3

X2: IP1 X2: IP2

Using System IP instead of PLC interface IP

• Transparent communication between standard

PLC and R/H-System

• The standard communication partner is

automatically connected to the primary PLC

Page 36

Unrestricted © Siemens 2020

Version 2020-12-13

Network Configuration with S7-1500R/H

Safety Devices

Safety Devices can be integrated via subordinated F-Controller

H-Sync

Primary

Backup

(Non safe) Communication

between RH and F-Controller

via iDevice or Open User

Communication

Safety Applicationis located

in a separated F-Controller

R/H-System (Non Safety) and

connected I/O

Page 37

Unrestricted © Siemens 2020

Version 2020-12-13

Network Configuration with S7-1500R/H

Safety Devices

Safety Devices can be integrated via subordinated F-Controller and PN/PN Coupler

H-Sync

Primary

Backup

MRP Ring

Optional

Usage of a second PN/PN Coupler to

avoid a single point of failure

R/H-System (Non Safety) and

connected I/O

Optional

Media Redundancy (MRP

Ring) increases availability in

case of network breakdown

Safety Applicationis located

in a separated F-Controller

(Non safe) Communication

between RH and F-Controller

via iDevice or Open User

Communication

Page 38

Unrestricted © Siemens 2020

Version 2020-12-13

HMI Connection

via 1 Network (Ring or Line)

X1 X1

Industrial Ethernet

X2 X2

System IP (X2)

Communication between S7-1500R/H and…

Via System-IP

(One HMI-

Connection)

WinCC Comfort V16 (Comfort Panels)

WinCC Advanced V16 (RT Advanced)

OK

WinCC Basic V16 (Basic Panels) OK

WinCC Professional V16 OK

WinCC V7.5 OK

WinCC OA V3.16 OK

Basic/Comfort Panel

WinCC OA

WinCC V7

WinCC V15.1

Page 39

Unrestricted © Siemens 2020

Version 2020-12-13

HMI Connection

via 1 Network (Ring or Line)

X1 X1

Industrial Ethernet

X2 X2

System IP (X2)

WinCC Red.

Communication between S7-1500R/H and…

Via System-IP

(One HMI-

Connection)

WinCC Professional V16 OK

WinCC V7.5 OK

WinCC OA 3.16 OK

WinCC V7.5

WinCC V16

WinCC OA 3.16

WinCC V7.5

WinCC V16

WinCC OA 3.16

Page 40

Unrestricted © Siemens 2020

Version 2020-12-13

SIMATIC S7-1500 Redundant Systems

New

▪ Motivation and Product Strategy

▪ System Overview

▪ Add In and System Redundancy and Network Configuration

▪ Communication

▪ S7-1500R/H and Safety

▪ HMI Connection

▪ Installation Recommendations

▪ New Features with TIA Portal V16

▪ Remaining Restrictions

▪ Ordering Information

Page 41

Unrestricted © Siemens 2020

Version 2020-12-13

Installation Recommendations

for CPU 1513R-1 PN

X1 X1

Basic/Comfort Panel

PN/PN

100MBit/s

OK

Up to14 Devices in

MRP Ring

OK

PN/PN Coupler

Possible, but not recommended

Communication to additional PLC via Open

User Communication via X1

Reason: Generates high load internally and

on Sync-Line1)and increases PLC cycle time

1) Sync-Line runs with 100MBit/s on R-System

Page 42

Unrestricted © Siemens 2020

Version 2020-12-13

Industrial Ethernet

Installation Recommendations

for CPU 1515R-2 PN

X1 X1

X2

Basic/Comfort Panel

WinCC

X2

PN/PN

Standard PLC

100MBit/s

OK

PN/PN Coupler

OK

HMI Connection

via X2

Conditionally recommended

Communication to additional PLC via

Open User Communication via X2

Reason: Generates high load on Sync-

Line1)and increases PLC cycle time

1) Sync-Line runs with 100MBit/s on R-System

OK

Up to14 Devices in

MRP Ring

Possible, but not recommended

Communication to additional PLC via Open

User Communication via X1

Reason: Generates high load internally and

on Sync-Line1)and increases PLC cycle time

Page 43

Unrestricted © Siemens 2020

Version 2020-12-13

Installation Recommendations

for CPU 1517H-3 PN

X1 X1

Industrial Ethernet

X2

Basic/Comfort Panel

WinCC

X2

Subordinated PLCs

PN/PN

1 GBit/s

OK

Up to 48 Devices in

MRP Ring

OK

PN/PN Coupler

OK

Communication to additional

PLC via Open User

Communication via X2

OK

Communication to additional

PLC via Open User

Communication via X1

OK

HMI Connection

via X2

Page 44

Unrestricted © Siemens 2020

Version 2020-12-13

SIMATIC S7-1500 Redundant Systems

New

▪ Motivation and Product Strategy

▪ System Overview

▪ Add In and System Redundancy and Network Configuration

▪ Communication

▪ S7-1500R/H and Safety

▪ HMI Connection

▪ Installation Recommendations

▪ New Features with TIA Portal V16

▪ Remaining Restrictions

▪ Ordering Information

Page 45

Unrestricted © Siemens 2020

Version 2020-12-13

SIMATIC S7-1500 R/H

New Features with V16 and Firmware Version 2.8

Reduction of functional gaps compared with S7

-1500

Support of Alarm SFC’s and Diagnosis SFC‘s

Support of ProDiag und S7-Graph

Support of PNIO SFB’s

Support of Loop Control Blocks (PID)

S7-Routing

New Features and improvements

Connection of standard (non redundant) PN devices: Switched S1

Program Download in Run-Redundant Mode

IP Forwarding

Significantly reduced communication breakdown time during Sync-Up

Page 46

Unrestricted © Siemens 2020

Version 2020-12-13

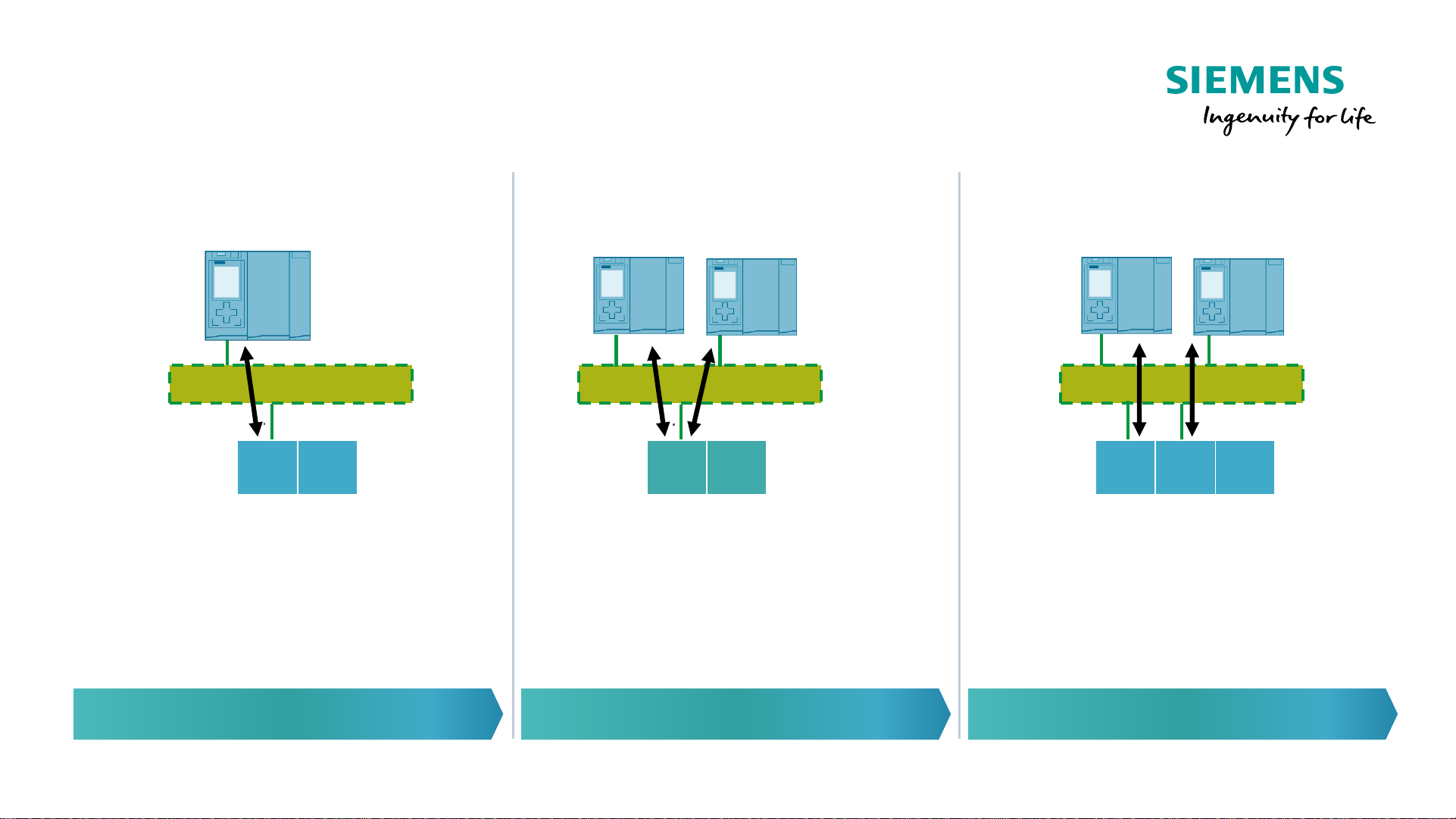

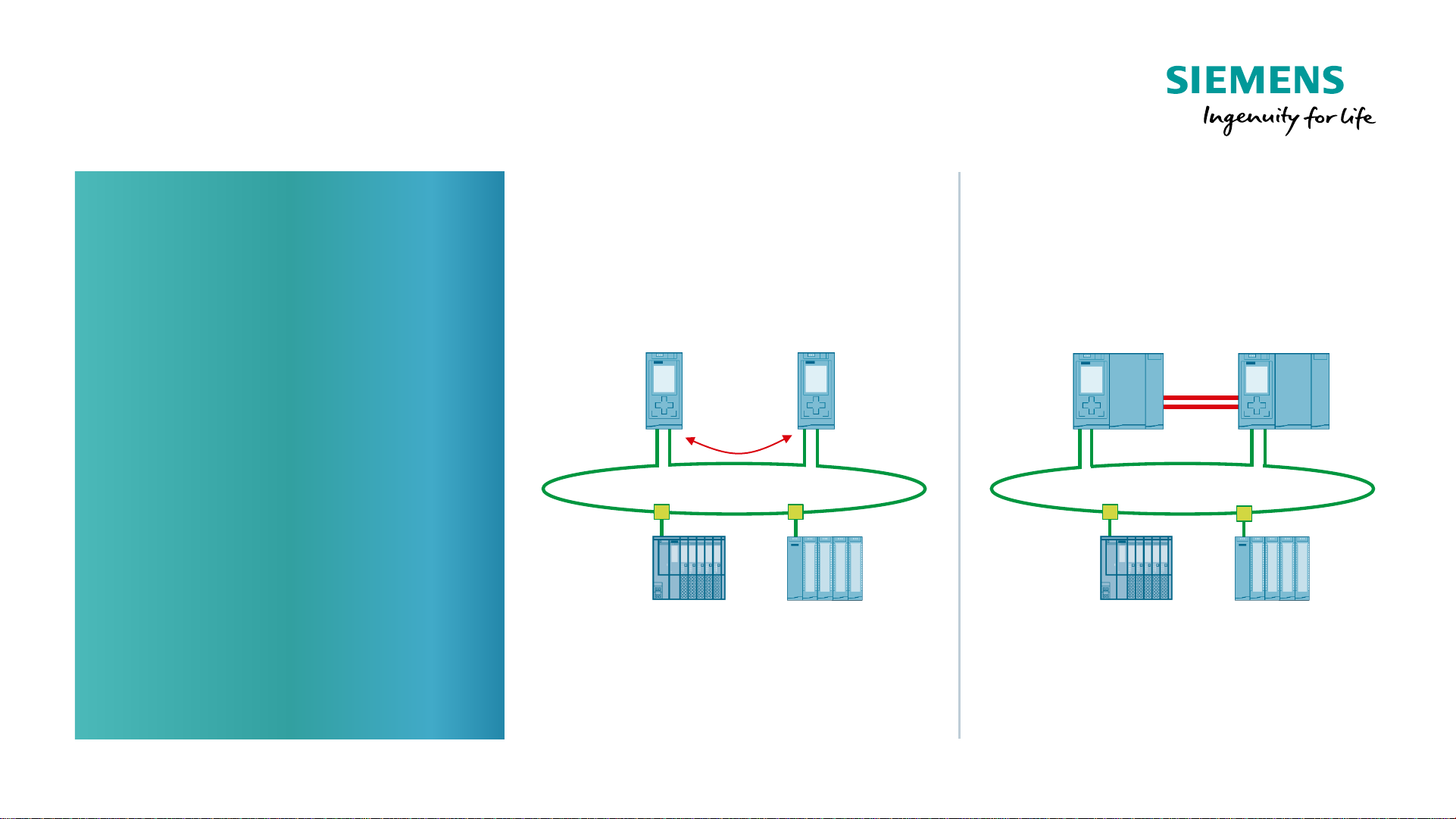

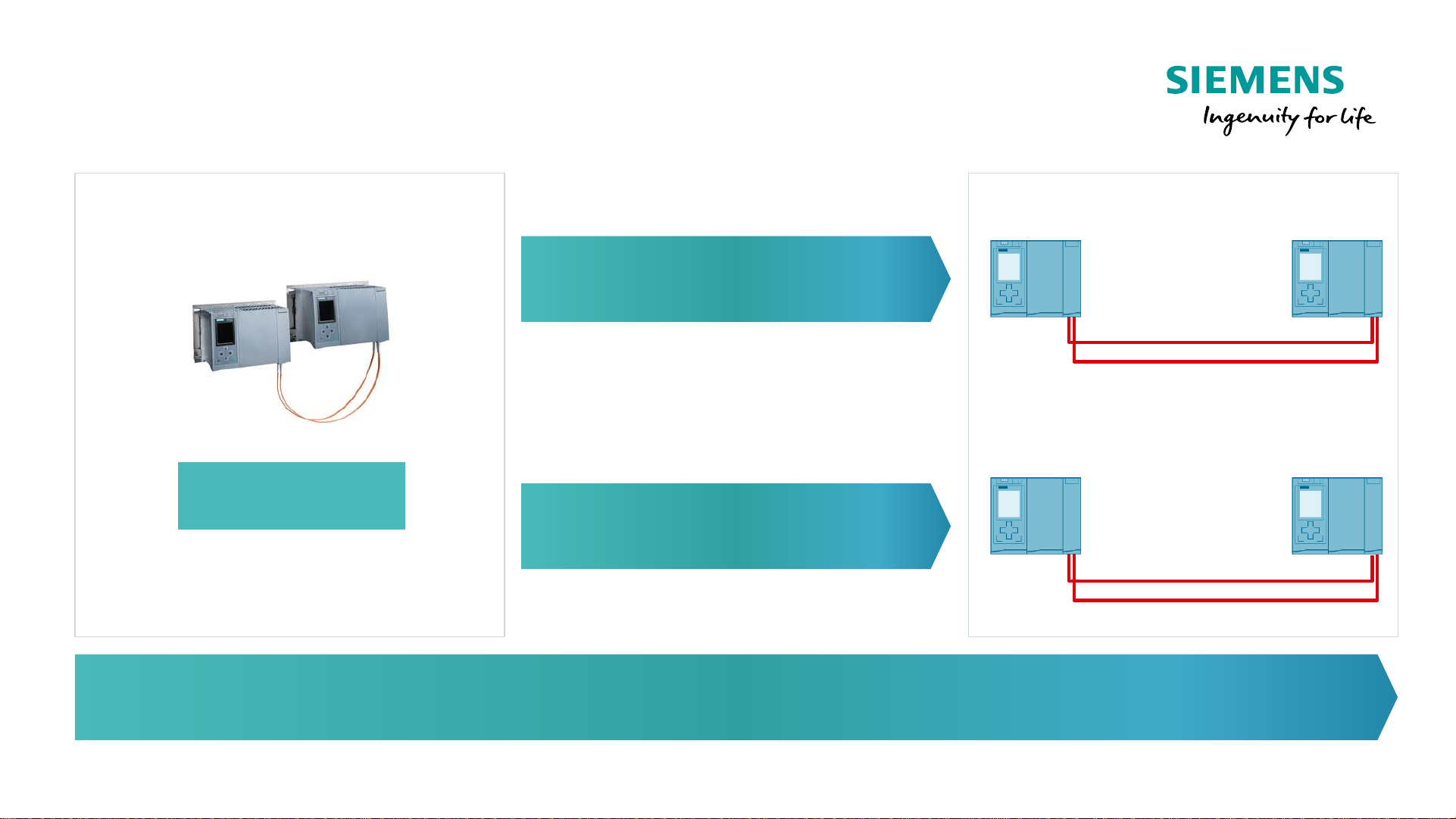

New in V16: Program Download in RUN-Redundant Mode

The Backup-PLC can remain in RUN redundant during program download

Primary Backup

ET 200SP

ET 200MP

RUN STOP

Primary Backup

ET 200SP

ET 200MP

RUN-Red RUN-Red

V15.1 V16

Benefits:

• No RUN/STOP handling of Backup PLC required

• No SyncUp Phase (with temporary loss of communication)

• User Program is synchronized automatically

Page 47

Unrestricted © Siemens 2020

Version 2020-12-13

New in V16: Mode „Switched S1 Device“

Also devices without System Redundancy Feature (S1) can be connected

Primary Backup

ET 200SP

ET 200MP

ET 200SP

ET 200MP

S2-Devices

e.g. ET 200pro

e.g. G120D

S1-Devices

Primary

Backup

H-Sync

New

System Behavior when

Primary

-Backup switch occurs

S2

-Devices

(with System Redundancy)

S1

-Devices

(without System Redundancy)

Activation time of device

Very short (50ms +) because backup

communication relation is already established

Some seconds (depended on the device

itself) since device is restarted

Behavior of Outputs

Keeps last valid value during failover

If the device supports the function “Hold

last value”

→ no difference to S2

Otherwise: Outputs switches to “0” during

activation time.

Page 48

Unrestricted © Siemens 2020

Version 2020-12-13

New in V16: Mode „Switched S1 Device“

Comparison with System Redundancy S2

Primary Backup

S2

Primary Backup

S1

Initial Situation

Primary AR

Backup AR

Single AR

Failover R/H

RUN Solo

S2

RUN Solo

S1

Backup AR

X

X

Connection established

RUN Solo

S1

X

X

Single AR

Time

Behavior with

System Redundancy S2

Two AR are established

AR = Application Relation

Only 1 AR to primary

PLC established

Backup AR takes over

S2 Device continues communication

AR to primary PLC gets lost

S1 Device without communication

New AR is created by RUN solo PLC to

S1 device

Behavior with

“Switched S1”

Page 49

Unrestricted © Siemens 2020

Version 2020-12-13

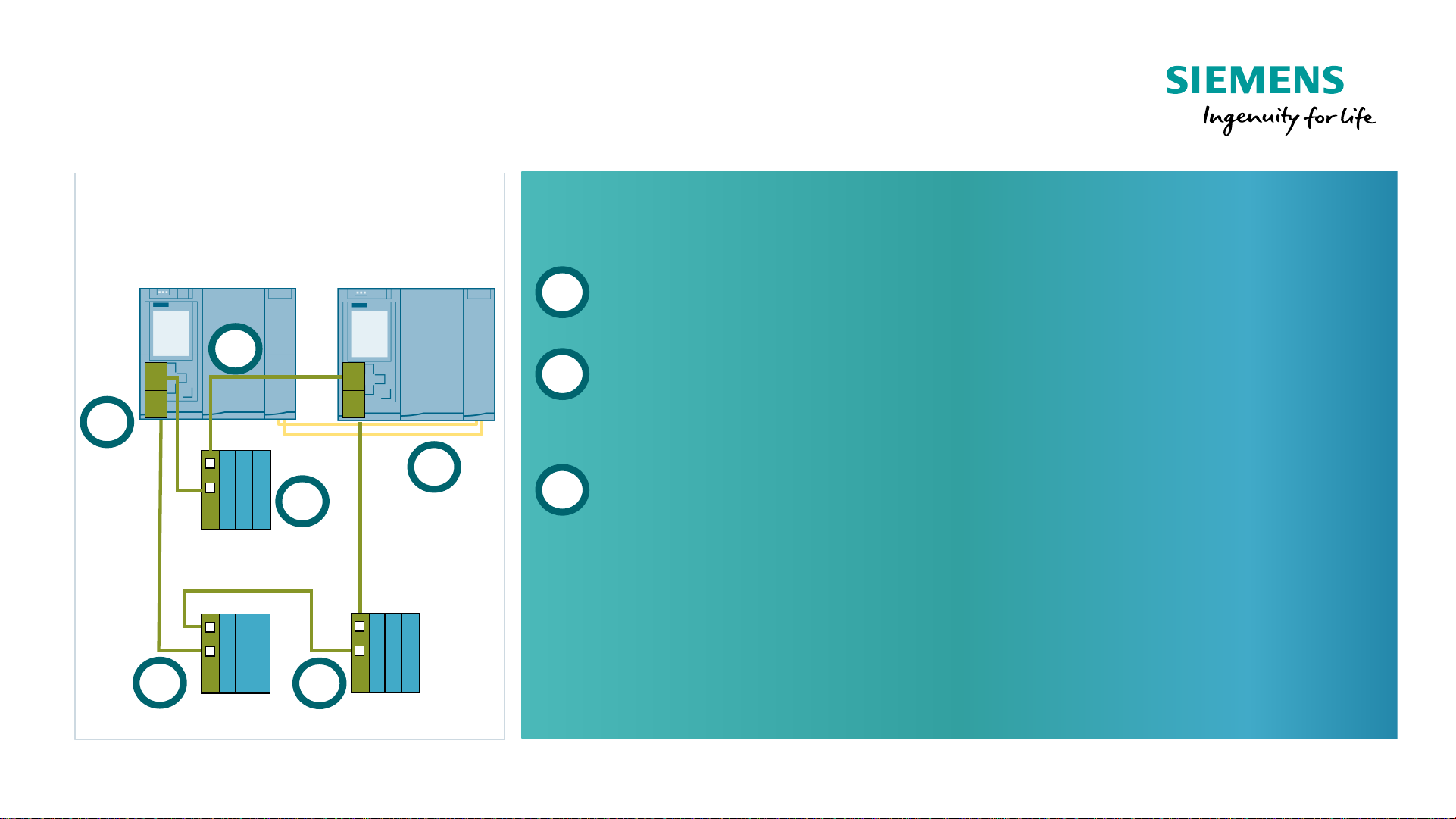

New in V16: Mode „Switched S1 Device“

Visualization of redundancy modes in TIA Portal

In the network view S1 and

S2 devices are marked as

„Multi-assigned“

Differences are shown in the column

„Mode“ of the I/O communication table.

Here: ET 200MP is connected as S2

device

Page 50

Unrestricted © Siemens 2020

Version 2020-12-13

SIMATIC S7-1500 R/H

New in V16: Support of STEP 7 Graph

Function

• The graphical engineering language

STEP 7 GRAPH is available for the S7-1500 R/ H

Controller

Benefit of the function

• Graphical programming language for creating of

sequence controls and processes on S7-1500 R/H

CPUs

• Identical behavior regarding used language and

editor for S7-1500 R/H CPUs and „standard“ CPUs

• Depending on the application the user is free to

choose the appropriate programming language

within the engineering of S7-1500 R/H CPUs

Primary

Backup

H-Sync

SCL KOP FUP AWL Graph*

*S7-Graph blocks need because of their functionality an extended processing time within the CPU. This is caused by additional implicit diagnosis, integrated coordination of the program sequence,

the realized operating modes regarding sequence controls

Identical engineering languages for Standard- and S7-1500R/H controllers

Page 51

Unrestricted © Siemens 2020

Version 2020-12-13

New in V16: Support of additional blocks

Advances Instructions

GETIO / GETIO_PART

Read process image

SETIO / SETIO_PART

Transfer process image

GetStationInfo

Read information of an IO device

DeviceStates

Read module state information in an IO system

GEN_DIAG

Generate diagnostics information

Technology

PID_Compact

Universal PID controller with integrated optimization

PID_3Step

PID controller with integrated optimization for valves

PID_Temp

PID controller

for temperature

Program Block

Program_Alarm

Generate program alarm with associated values

Get_AlarmState

Output alarm state

Gen_UsrMsg

Generate user diagnostic messages

Get_Alarm

Read pending alarm

Ack_Alarms

Acknowledge alarms

Page 52

Unrestricted © Siemens 2020

Version 2020-12-13

Restrictions for S7-1500R/H

Restrictions of the configuration for S7

-1500R/H

S7-1500R/H S7-1500 S7-400H

Single PLC projectable

(H/R CPUs as redundant System only)

no N/A yes

Central periphery or central CPs / CMs projectable

no yes yes

Configure System-PS

no yes yes

Only MRP-Ring PN-Networks are supported

(no „open Ring“ like in 400H)

yes no no

Operation as Shared Device or I-Device

no yes no

Page 53

Unrestricted © Siemens 2020

Version 2020-12-13

Restrictions for S7-1500R/H

Functional restrictions for S7

-1500R/H

S7-1500R/H S7-1500 S7-400H

S7-Com, E-Mail, FDL, ISO,

(OUC with dynamic connections is supported)

no

1)

yes yes

OPC UA

no yes no

System-supported H-communication

(but the System IP-Address)

no no yes

Webserver

no yes no

System-supported redundant I/Os

no

2)

no yes

PROFIsafe

no F-CPU yes

Technology Objects

some

3)

yes no

Support for MRPD, clock synchrony and IRT

no yes no

CiR and firmware update in run is supported

no no yes

Direct migration through hardware replacement

(Import of user programs via

Copy/Paste)

no n.a. no

PLCsim and PLCsim advanced are supported

no yes yes

1) S7-Communikation as server is supported

2) Can be realized on application layer: See SIOS article 109767576

3)TO Count, Measuring, PID are supported

Page 54

Unrestricted © Siemens 2020

Version 2020-12-13

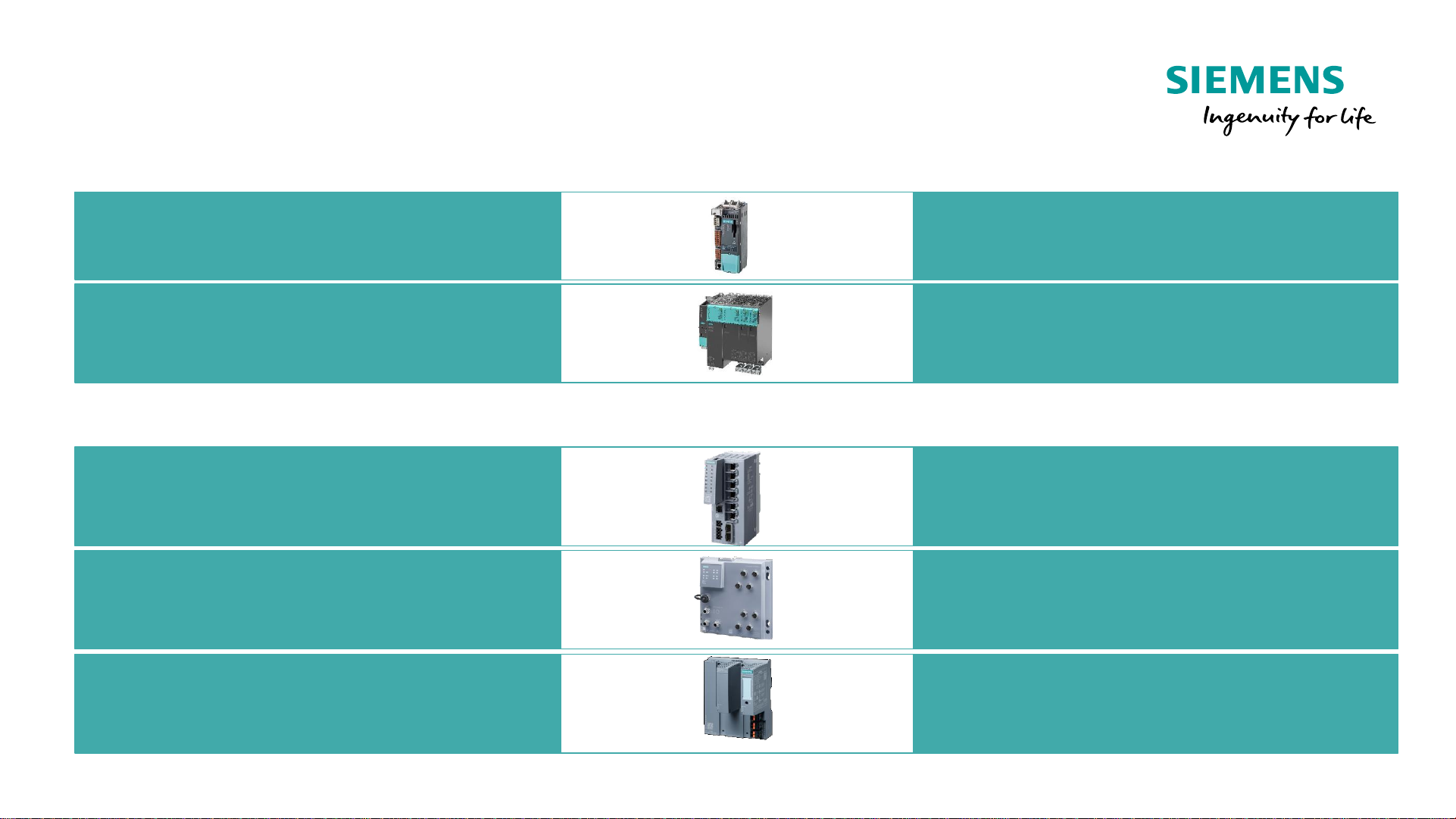

CPU S7-1500R

• CPU 1513R-1 PN 6ES7 513-1RL00-0AB0

• CPU 1515R-2 PN 6ES7 515-2RM00-0AB0

CPU S7-1500H

• CPU 1517H-3 PN 6ES7 517-3HP00-0AB0

Distance up to 10m between the S7-1500H PLCs

Use of the Synchronization Modules for

FO cables up to 10 m

• MLFB Module: 6ES7960-1CB00-0AA5

• MLFB LWL-Cable 1m: 6ES7960-1BB00-5AA5

• MLFB LWL-Cable 2m: 6ES7960-1BC00-5AA5

• MLFB LWL-Cable 10m: 6ES7960-1CB00-5AA5

Distance up to 10km between the PLCs

• MLFB Module: 6ES7960-1FB00-0AA5

• Monomode LWL-Cable LC/LC Duplex Crossed 9/125µ

S7-1500H Bundle (Consisting of 2 CPU 1517-3 PN,

4 Sync-Modules 10m and 2 Sync-Cables 1m)

• 6ES7500-0HP00-0AB0

Ordering Information

Page 55

Unrestricted © Siemens 2020

Version 2020-12-13

Thanks for listening

Steve Harris

Applications Engineer Factory Automation

Siemens Australia

DI FA

185 Great Eastern Hwy

Belmont WA 6104

Mobile: +61 427 501 185

steveharris@siemens.com

Restricted © Siemens 2020

Loading...

Loading...