Preface, Contents

SIMATIC NET NCM for Industrial Ethernet

Manual

for NCM S7 V5.2 and higher

Communication via Ethernet CPs

in S7 Stations

Installing and Starting the

Ethernet CP with STEP 7

SEND/RECEIVE

interface

Configuring Communication

Connections

Programming Functions (FCs)

NCM S7 Diagnostics

Firmware Loader

Appendix

References

1

2

3

4

5

6

7

A

11/2002

C79000–G8976–C129

Release 06

Glossary

Linking to Other Systems with

FETCH/WRITE

Document History

Index

B

C

D

Classification of Safety–Related Notices

This manual contains notices which you should observe to ensure your own

personal safety, as well as to protect the product and connected equipment. These

notices are highlighted in the manual by a warning triangle and are marked as

follows according to the level of danger:

Danger

!

!

!

indicates that death or severe personal injury will result if proper precautions are

not taken.

Warning

indicates that death or severe personal injury can result if proper precautions are

not taken.

Caution

with warning triangle indicates that minor personal injury can result if proper

precautions are not taken.

Caution

without warning triangle indicates that damage to property can result if proper

precautions are not taken.

Notice

indicates that an undesirable result or status can occur if the relevant notice is

ignored.

Note

highlights important information on the product, using the product, or part of the

documentation that is of particular importance and that will be of benefit to the

user.

2

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

Trademarks

SIMATICR, SIMATIC HMIR and SIMATIC NETR are registered trademarks of

SIEMENS AG.

Third parties using for their own purposes any other names in this document which

refer to trademarks might infringe upon the rights of the trademark owners.

Safety Instructions Regarding your Product:

Before you use the product described here, read the safety instructions below

thoroughly.

Qualified Personnel

Only qualified personnel should be allowed to install and work on this equipment.

Qualified persons are defined as persons who are authorized to commission, to

ground, and to tag circuits, equipment, and systems in accordance with

established safety practices and standards.

Correct Usage of Hardware Products

Note the following

Warning

!

This device and its components may only be used for the applications described in

the catalog or the technical description, and only in connection with devices or

components from other manufacturers which have been approved or recommended by Siemens.

This product can only function correctly and safely if it is transported, stored, set

up, and installed correctly, and operated and maintained as recommended.

Before you use the supplied sample programs or programs you have written yourself, make certain that no injury to persons nor damage to equipment can result in

your plant or process.

EU Directive: Do not start up until you have established that the machine on which

you intend to run this component complies with the directive 89/392/EEC.

Correct Usage of Software Products

Note the following

Warning

!

This software may only be used for the applications described in the catalog or the

technical description, and only in connection with software products, devices, or

components from other manufacturers which have been approved or recommended by Siemens.

Before you use the supplied sample programs or programs you have written yourself, make certain that no injury to persons nor damage to equipment can result in

your plant or process.

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

3

Prior to Startup

Before putting the product into operation, note the following warning:

Caution

Prior to startup you must observe the instructions in the relevant documentation.

For ordering data of the documentation please refer to the catalogs or contact your

local SIEMENS representative.

Disclaimer of LiabilityCopyright E Siemens AG 2001–2002 All rights reserved

The reproduction, transmission or use of this document or its contents is not

permitted without express written authority. Offenders will be liable for

damages. All rights, including rights created by patent grant or registration of

a utility model or design, are reserved.

Siemens AG

Automation and Drives

Postfach 4848, D-90327 Nürnberg

4

Siemens Aktiengesellschaft G79000–G8976–C129–06

We have checked the contents of this manual for agreement with the hardware and software described. Since deviations cannot be precluded entirely,

we cannot guarantee full agreement. However, the data in this manual are

reviewed regularly and any necessary corrections included in subsequent

editions. Suggestions for improvement are welcomed.

Subject to technical change.

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

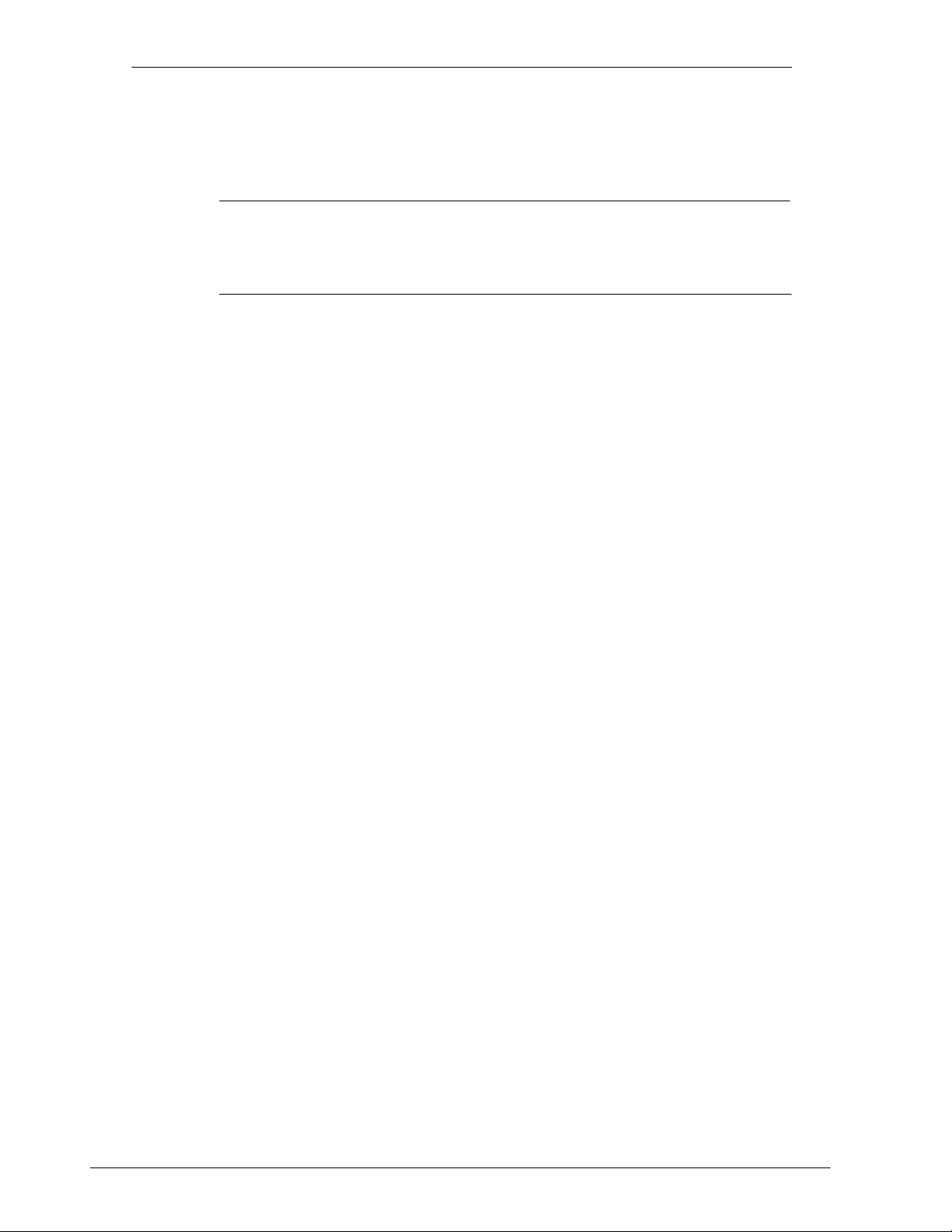

This Manual on SIMATIC NET NCM S7 for Industrial Ethernet

...supports you when using the communication services provided by the SIMATIC

NET communications processors (Industrial Ethernet CPs) for communication on

SIMATIC NET with Industrial Ethernet in the management and cell areas.

The documentation on your S7-CPs and NCM S7 is in several parts that fit

together as shown below:

S S7-CP

– selecting

– installing

– commissioning

– performance data

S S7-CP and STEP 7 / NCM S7

– familiarization

– testing interfaces

– commissioning

Manual

Primer

S7-CP

for

S7-300 /

S7-400

STEP 7

NCM S7

S Communication services

with STEP 7 / NCM S7

– programming

– configuring

– downloading /

commissioning

– diagnostics

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

NCM S7

Manual

5

This Manual on SIMATIC NET NCM S7 for Industrial Ethernet

Audience

This manual is intended for personnel responsible for installing and programming

STEP 7 programs and for service personnel.

Scope of this Manual

This manual applies to version 5.2 and higher of the NCM S7 configuration

software for Industrial Ethernet and to version 5.2 and higher of the STEP 7

software.

This version of the manual includes information relating to new functions in STEP 7

and NCM S7 as of V5.2.

In the main, this involves the following topics:

S S7 communication over routers (single-ended client and server functionality) via

an IE/PB Link or CP (see Section 1.4)

S Multiprojects

With the new multiproject functionality, projects can be split up and distributed

for engineering and then merged again.

Symbols used in this Manual

This symbol indicates functions requiring STEP 7 version V5.2.

This symbol appears in the margin to draw your attention to useful tips.

This symbol indicates recommended documentation.

Where you see this symbol, you should also refer to additional information in the

basic help system of STEP 7.

This symbol indicates where detailed context-sensitive help is available. You can

F1

display these help texts with the F1 key or by clicking on the “Help” button in the

relevant dialog.

6

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

This Manual on SIMATIC NET NCM S7 for Industrial Ethernet

You will find additional information in the following sources:

This manual is also part of the NCM S7 for Industrial Ethernet documentation

package. These documents are also on the Manual Collection CD supplied with

every S7-CP and they are also available on the Internet. The following table

provides you with an overview.

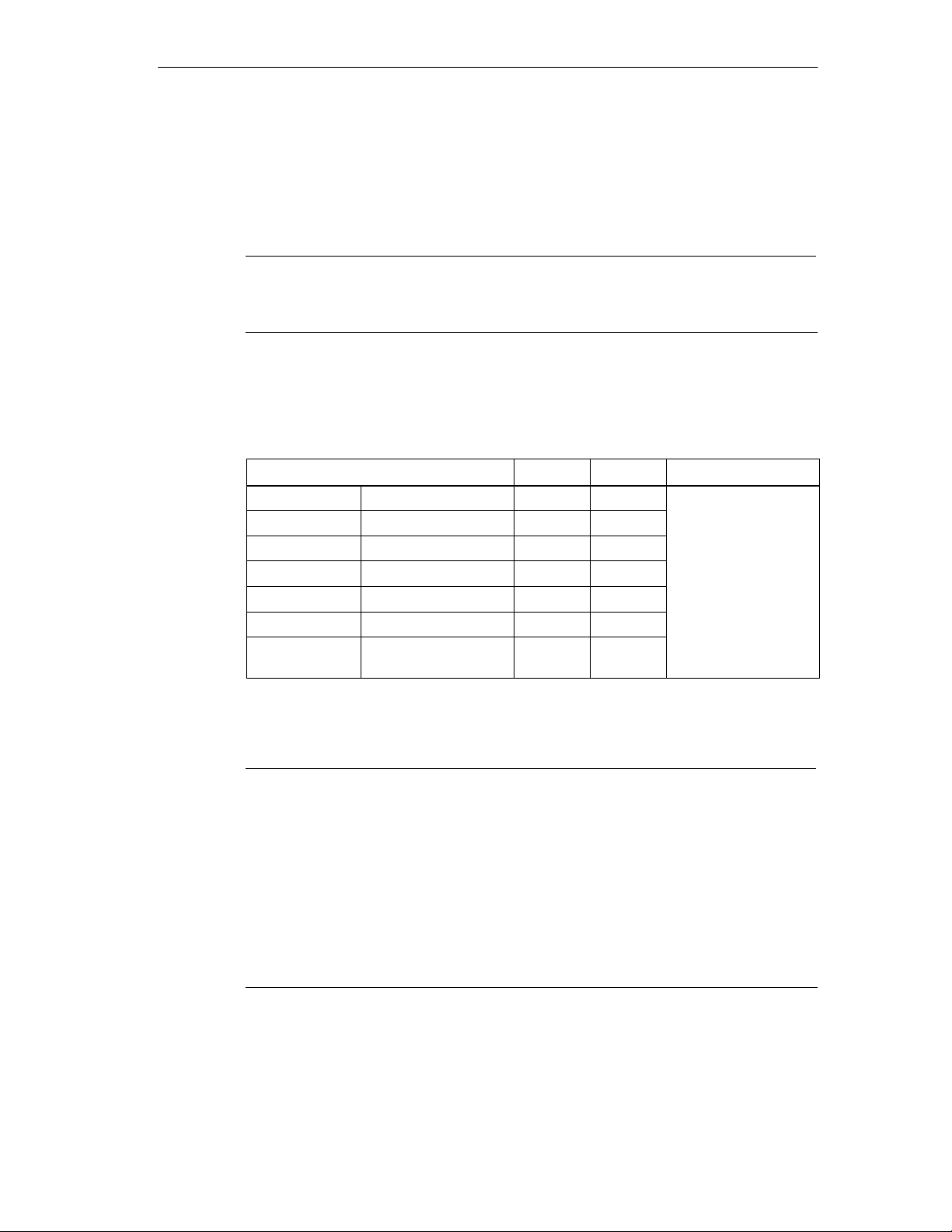

Title Content

S7-CPs for Industrial

Ethernet

Manual

This is available on the Internet at:

The manual S7-CPs for Industrial Ethernet contains information on the

characteristics of the CPs and instructions on installation and connections.

S General Section: http://www4.ad.siemens.de/view/cs/de/8777865

S CP 343-1: http://www4.ad.siemens.de/view/cs/de/8777308

S CP 343-1 PN: http://www4.ad.siemens.de/view/cs/de/8776538

S CP 343-1 IT: http://www4.ad.siemens.de/view/cs/de/8776544

S CP 443-1: http://www4.ad.siemens.de/view/cs/de/8776219

S CP 443-1 IT: http://www4.ad.siemens.de/view/cs/de/8776322

NCM S7 for Industrial

Ethernet

Primer

Based on simple examples, the primer introduces you to the methods of

connecting and networking SIMATIC S7 stations with CPs on Industrial

Ethernet. It shows you how the communications calls are entered in the user

program to allow you to use the services via the SEND/RECEIVE interface.

Y ou will learn how simple it is to create a configuration for standard

applications using STEP 7 and the NCM S7 optional package.

The examples described here can also be found in the project folder for

sample programs after you have installed STEP 7 and the NCM S7 for

Industrial Ethernet option!

This is available on the Internet at:

http://www4.ad.siemens.de/view/cs/de/1172503

NCM S7 for Industrial

Ethernet

Manual

IT-CP

Manual

Advanced PC

Configuration

Manual

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

The manual is intended as a guide and reference work for configuring and

programming an Industrial Ethernet CP.

This is available on the Internet at:

http://www4.ad.siemens.de/view/cs/de/1172423

The manual is intended as a guide and source of reference when working with

the IT-CP. In addition to the functions provided by an Ethernet CP, the IT-CP

also provides functions for Internet technology.

This is available on the Internet at:

http://www4.ad.siemens.de/view/cs/de/1172744

Advanced PC Configuration is the new tool with which you can commission a

PC station as part of an industrial communication network.

The manual supports you and helps you to make efficient use of

communications with your PC applications in conjunction with the SIMATIC

NET modules. This explains the steps involved in configuration with NCM S7.

This is available on the Internet at:

http://www4.ad.siemens.de/view/cs/

7

This Manual on SIMATIC NET NCM S7 for Industrial Ethernet

Quick Start CD: Samples covering all aspects of communication

The Quick Start CD that can be ordered separately is a

treasure-trove of sample programs and configurations.

You can order this directly over the Internet at:

http://www.ad.siemens.de/net/html_00/online_zugreifen.htm

Additional Information on SIMATIC S7 and STEP 7

The following documentation contains additional information about the STEP 7

standard software of the SIMATIC programmable controllers and can be obtained

from your local Siemens office.

Topic Document

Basic information for technical

personnel using the STEP 7

standard software for control

tasks with S7-300/400

programmable controllers.

STEP 7 basics with

S Configuring hardware with STEP 7

S Programming with STEP 7

S Manual for converting from S5 to S7

S Primer for a fast start

The reference works describing

the programming languages

LAD/FBD and STL as well as the

standard and system functions in

addition to the STEP 7 basic

knowledge.

STEP 7 reference manuals with

S Manuals for LAD/FBD/STL

S Standard and system functions for

S7-300/400

You will also find information on SIMATIC programmable controllers on the Quick

Start CD and from the Customer Support Online services at:

http://www.siemens.de/simatic–net General information

or

http://www.ad.siemens.de/csi/net Product information and downloads

8

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

This Manual on SIMATIC NET NCM S7 for Industrial Ethernet

Access to Online Help of STEP 7 and NCM S7

With the online help, you can obtain the following information:

S You can display the contents of the STEP 7 basic help system with the menu

command Help –> Contents.

S Context-sensitive help on the selected object using the Help –>

F1

Context-Sensitive Help menu command, the F1 function key or the question

mark in the toolbar.

You can then access further information relating to the current topic.

S Glossary for all STEP 7 applications by clicking the “Glossary” button.

Please note that each STEP 7 application has its own contents and

context-sensitive help.

Conventions

References to other manuals and documentation are indicated by numbers in

slashes /.../. These numbers refer to the titles of manuals listed in the References

section of the Appendix.

-

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

9

Contents

1 Communication via Ethernet CPs in S7 Stations 13. . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Industrial Ethernet 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 SIMATIC S7 Communication with S7 Ethernet CPs 15. . . . . . . . . . . . . . . . . .

1.3 PG/OP Communication via Industrial Ethernet 19. . . . . . . . . . . . . . . . . . . . . .

1.3.1 PG Communication with STEP 7 over Industrial Ethernet 21. . . . . . . . . . . . .

1.3.2 OP Operation: Connecting Operator Interface Devices via Industrial

Ethernet 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 S7 Communication on Industrial Ethernet 23. . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 S5-compatible Communication (SEND/RECEIVE Interface) 27. . . . . . . . . . .

1.6 FETCH/WRITE Services (Server) 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7 Networking Stations with STEP 7 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7.1 Network/Project Variant: One Subnet – One Project 33. . . . . . . . . . . . . . . . . .

1.7.2 Network/Project Variant: SIMATIC S5 and Non-SIMATIC Devices

on the Subnet 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7.3 Network/Project Variant: Two or More Subnets – One Project 35. . . . . . . . .

1.7.4 Network/Project Variant: One Subnet – More Than One (Sub)Project 36. . .

1.7.5 Network/Project Variant: Several Subnets in Several (Sub) Projects 39. . . .

1.7.6 Network/Project Variant: Connections between Subnets (TCP/IP) 41. . . . . .

2 Installing and Starting the Ethernet CP with STEP 7 43. . . . . . . . . . . . . . . . . . . . . . .

2.1 General Information About the NCM S7 for Industrial Ethernet Option 44. .

2.2 Procedure 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 Creating an Industrial Ethernet Subnet 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.2 Entering an Ethernet CP in the Hardware Configuration 49. . . . . . . . . . . . . .

2.2.3 Displaying the Network Attachments of a Station 52. . . . . . . . . . . . . . . . . . . .

2.2.4 Setting Further CP Properties 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.5 “Substitute Objects” in the STEP 7 Project 60. . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.6 Configuring Communication Services 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Assigning Addresses for the First Time (Applies to Latest CPs) 64. . . . . . . .

2.3.1 Addressing by Selecting the Target System in the SIMATIC Manager 65. . .

2.3.2 Addressing using the Properties Dialog in HW Config or NetPro 68. . . . . . .

2.4 Downloading the Configuration Data to the Target System 69. . . . . . . . . . . .

3 SEND/RECEIVE Interface in the User Program 73. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 How the SEND/RECEIVE Interface Works on the CPU 74. . . . . . . . . . . . . . .

3.2 Programming the SEND/RECEIVE Interface 75. . . . . . . . . . . . . . . . . . . . . . . .

3.3 Data Exchange S7 CPU <–> Ethernet CP 78. . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Additional Information 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.1 Programming Data Transfer on TCP Connections 80. . . . . . . . . . . . . . . . . . .

3.4.2 Recommendations for Use with a High Communications Load 81. . . . . . . . .

4 Configuring Communication Connections 83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Procedure 84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

Contents

4.2 Possible Connection Configurations 85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Connections 87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.1 Creating a New Connection 90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.2 Connections to Partners in Other Projects 93. . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.3 Further Functions 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.4 Connections Without Assignment 97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Configuring ISO Transport Connections 99. . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.1 Specifying the Local Connection Endpoint 100. . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2 Specifying ISO Transport Addresses 102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.3 Specifying ISO Transport Dynamic Properties 105. . . . . . . . . . . . . . . . . . . . . . .

4.4.4 ISO Transport with the FETCH/WRITE Mode 107. . . . . . . . . . . . . . . . . . . . . . .

4.4.5 Checking ISO Transport Connection Properties 109. . . . . . . . . . . . . . . . . . . . .

4.5 Configuring ISO-on-TCP Connections Properties 110. . . . . . . . . . . . . . . . . . . .

4.5.1 Specifying the Local Connection Endpoint 111. . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.2 Specifying ISO-on-TCP Addresses 113. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.3 ISO-on-TCP with the FETCH/WRITE Mode 116. . . . . . . . . . . . . . . . . . . . . . . . .

4.5.4 Checking ISO-on-TCP Connection Properties 118. . . . . . . . . . . . . . . . . . . . . . .

4.6 Configuring TCP Connection Properties 119. . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6.1 Specifying the Local Connection Endpoint 120. . . . . . . . . . . . . . . . . . . . . . . . . .

4.6.2 Specifying TCP Addresses 122. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6.3 TCP with the FETCH/WRITE Mode 125. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6.4 Checking TCP Connection Properties 127. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 Configuring UDP Connection Properties 128. . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7.1 Specifying the Local Connection Endpoint 129. . . . . . . . . . . . . . . . . . . . . . . . . .

4.7.2 Specifying UDP Addresses 131. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7.3 UDP with Broadcast and Multicast 134. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7.4 Checking the Properties of a UDP Connection 138. . . . . . . . . . . . . . . . . . . . . . .

4.7.5 Free UDP Connection 139. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8 Routing to Distribute Load 140. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Programming FCs (Functions) and FBs for S7 Ethernet CPs 141. . . . . . . . . . . . . . .

5.1 General Notes on FCs / FBs 142. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Setting Parameters for FC Calls 145. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 Parameters for CP and Connection Assignment (input parameters) 145. . . .

5.2.2 Parameters for Specifying a CPU Data Area (input parameters) 147. . . . . . .

5.2.3 Status Information (output parameters) 147. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 FCs for Configured Connections 148. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 FC5 AG_SEND / FC50 AG_LSEND 152. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.2 FC6 AG_RECV / FC60 AG_LRECV 161. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 FCs for Access Coordination with FETCH/WRITE 167. . . . . . . . . . . . . . . . . . .

5.4.1 FC7 AG_LOCK 169. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.2 FC8 AG_UNLOCK 171. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 Numeric Data / Resource Requirements of the FCs 173. . . . . . . . . . . . . . . . . .

6 NCM S7 Diagnostics 175. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Overview 176. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Functions of NCM S7 Diagnostics 177. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

11

Contents

6.2.1 Installing and Starting NCM S7 Diagnostics 178. . . . . . . . . . . . . . . . . . . . . . . . .

6.2.2 General Menu Commands 180. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Starting Diagnostics – Establishing a Connection to the Ethernet CP 182. . .

6.4 How to Use Diagnostics 185. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 Call-Specific Diagnostic Functions 186. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6 Checklist for ‘Typical Problems‘ in a System 188. . . . . . . . . . . . . . . . . . . . . . . .

6.6.1 Checklist for General CP Functions 189. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.2 Communication Connections Checklist 190. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Firmware Loader 191. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Application 192. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Loading Firmware 193. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A References 197. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B Glossary 201. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1 General Section 202. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.2 Industrial Ethernet 206. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.3 PROFInet 208. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C Linking to Other Systems with FETCH/WRITE 211. . . . . . . . . . . . . . . . . . . . . . . . . . . .

D Document History 217. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E SIMATIC NET Support and Training 219. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Automation and Drives, Service & Support 219. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

Communication via Ethernet CPs in S7 Stations

The Ethernet CP for SIMATIC S7 provides a series of communications services for

different tasks.

This chapter explains the following:

S The types of communication possible with the Ethernet CP on Industrial

S The tasks handled by the Ethernet CP for the various services

S How to create the conditions for your communications requirements

You will find further information in the following sources:

S When installing the Ethernet CP, please refer to the instructions in the manual

S For the functions and use of the STEP 7 configuration software, some of which

1

Ethernet

/1/ supplied with the Ethernet CP. This also contains further information about

the performance of the Ethernet CP .

is used to configure the CP (such as hardware configuration), please refer to /6/

and /8/.

S For using, structuring and handling Industrial Ethernet, you will find detailed

information in /11/.

S For a general introduction to local area networks with TCP/IP refer to /16/ and

/17/.

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

13

Communication via Ethernet CPs in S7 Stations

1.1 Industrial Ethernet

Definition

Within the open, heterogeneous SIMATIC NET communication system, Industrial

Ethernet is the network for the management and cell level. Physically, Industrial

Ethernet is an electrical network that uses a shielded coaxial cable or twisted pair

or an optical network with fiber-optic cables.

Industrial Ethernet is defined by the international standard IEEE 802.3 (see /11/).

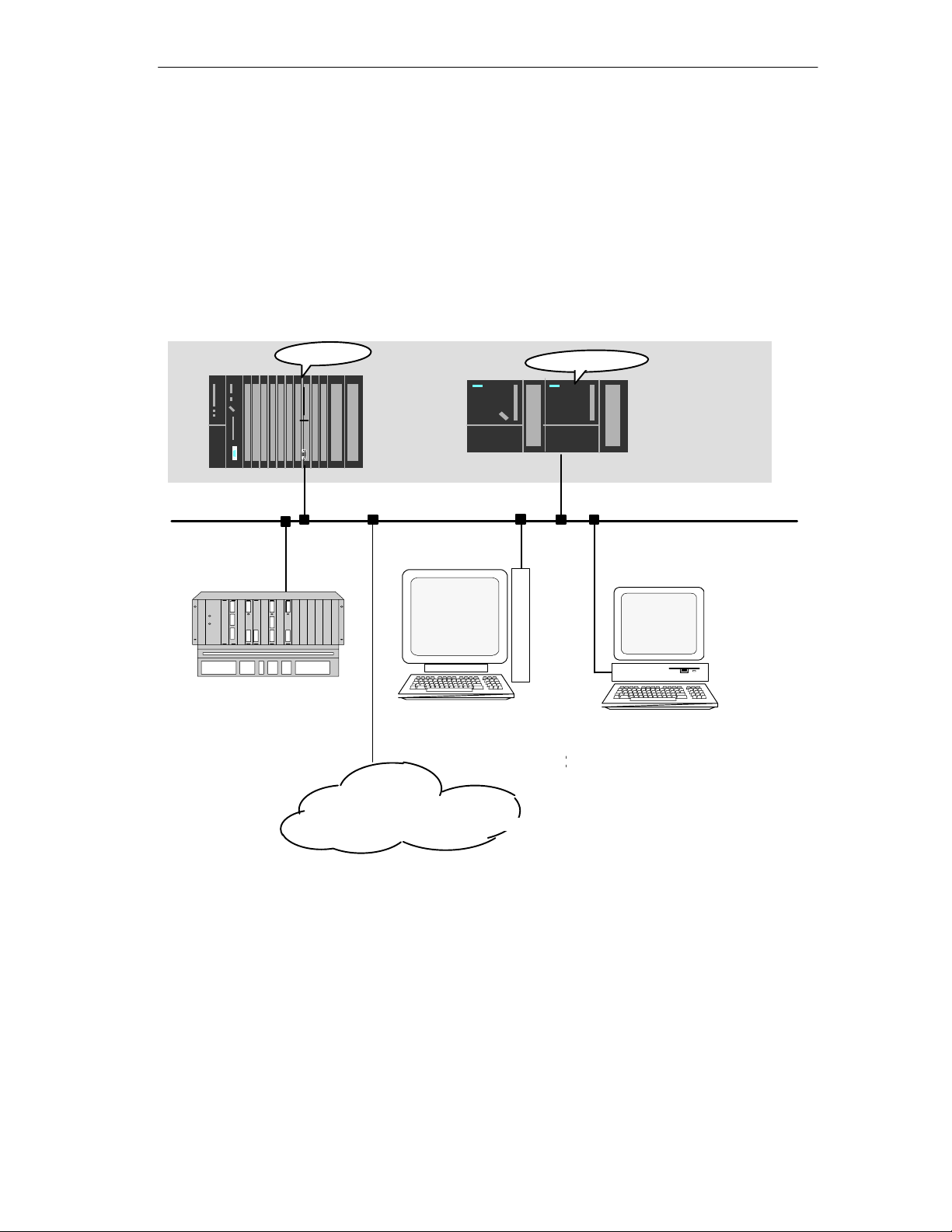

All-Round Communication in the Industrial Sector

Industrial Ethernet is integrated in the SIMATIC NET concept that allows

comprehensive networking of the management, cell and field levels in conjunction

with PROFIBUS and the AS-interface (AS-i).

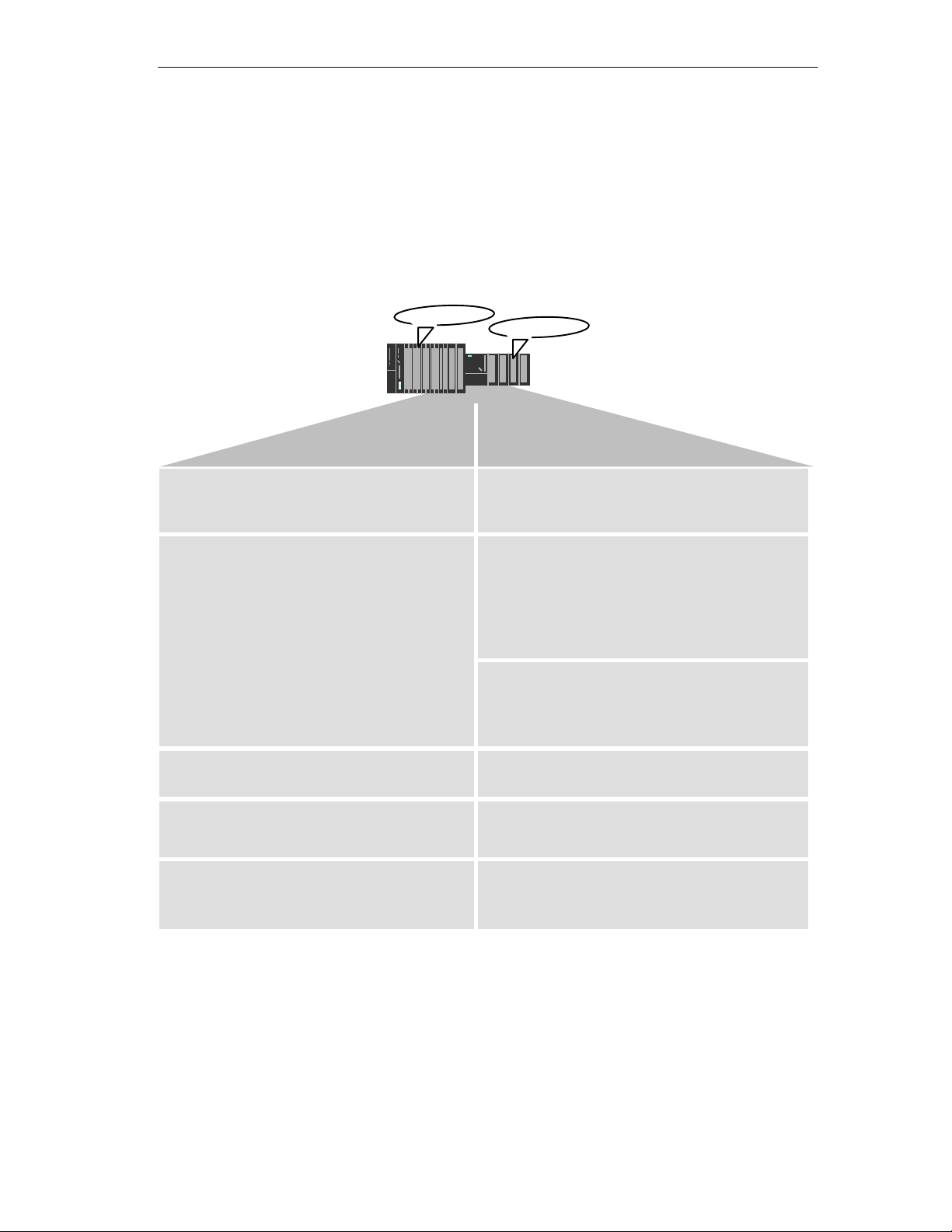

Figure 1-1 Industrial Ethernet in the SIMATIC NET Concept

Network Access

Industrial Ethernet is accessed using the CSMA/CD (Carrier Sense Multiple

Access with Collision Detection) network access technique specified in

IEEE 802.3.

Industrial

Ethernet

(IEEE 802.3)

PROFIBUS

(EN 50170 Vol. 2 PROFIBUS)

AS-Interface

(AS-i, Actuator-Sensor Interface)

14

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

Communication via Ethernet CPs in S7 Stations

1.2 SIMATIC S7 Communication with S7 Ethernet CPs

Types of Communication

The Ethernet CP for SIMATIC S7 supports the following types of communication

depending on the CP type:

Ethernet CP

S7/M7-400

Possible types of communication

S PG/OP communication

S S7 communication

S S5-compatible communication

S PROFInet communication

Ethernet CP

S7-300

Interfaces / Services /

Protocols

with the protocols

– ISO

– TCP/IP (RFC 1006)

with the SEND / RECEIVE interface and the protocols

– ISO Transport

– ISO-on-TCP (TCP/IP with RFC 1006)

– TCP/IP

– UDP

– E-mail:

with FETCH / WRITE services and the protocols

– ISO Transport

– ISO-on-TCP

– TCP/IP

with the protocols

– TCP/IP

S HTML process control with

web browser

S File management and file

access with FTP

S PG/OP communication

PG/OP communication is used to download programs and configuration data,

to run tests and diagnostic functions, and to control and monitor a plant from

OPs.

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

with the protocols

– HTTP / IP protocol

with the protocols

– FTP / IP protocol

15

Communication via Ethernet CPs in S7 Stations

S S7 communication

S7 communication forms a simple and efficient interface between SIMATIC S7

stations and PGs/PCs using communication function blocks.

S S5-compatible communication with SEND/RECEIVE interface

Depending on the CP type, the SEND/RECEIVE interface allows

program-controlled communication on a configured connection from a SIMATIC

S7 PLC to another SIMATIC S7 PLC, to a SIMATIC S5 PLC, to PCs/PGs, and

to any other station.

Depending on the CP type, the following communications services are available

on the SEND/RECEIVE interface:

– ISO Transport

optimized for top performance at the self-contained manufacturing level

– TCP/IP for internetwork communication with

ISO-on-TCP connections (RFC 1006), TCP connections and

UDP datagram service (including broadcast / multicast).

– Sending E-mail

The controller is capable of sending messages triggered by process events

(refer to the IT-CP manual for details /5/).

S S5-compatible communication with FETCH/WRITE services (server)

The FETCH/WRITE services (server) allow direct access to the system

memory areas on the SIMATIC S7 CPU from SIMATIC S5 or from devices of

other ranges.

Depending on the CP type, the following communications services are available

for FETCH/WRITE access:

– ISO Transport

optimized for top performance at the self-contained manufacturing level

– TCP/IP for internetwork communication with

ISO-on-TCP connections (RFC 1006), TCP connections.

S PROFInet communication

PROFInet is a standard of the PROFIBUS Users organization defining a

heterogeneous communications and engineering model.

An S7-300 station equipped with a CP capable of PROFInet can be

interconnected as a PROFInet component in SIMATIC iMap.

TCP connections are used for the PROFInet communication.

16

For more detailed information on PROFInet, refer to /23/.

S HTML process control

With an IT-CP, use the supplied functions and HTML pages to query important

system data using a Web browser (you should also refer to the instructions on

the IT-CP /5/).

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

Communication via Ethernet CPs in S7 Stations

S File management and file access with FTP

The IT-CP (S7-400 / S7-300) provides additional functions for FTP services.

You can use your S7 station both as an FTP client and as an FTP server (refer

to the manual of the IT-CP /5/).

– S7 Station as FTP Client

You can transfer data blocks from or to a file server.

– S7 Station as FTP Server

Another station, for example, a PC transfers data blocks to or from the S7

station the file system on the IT-CP.

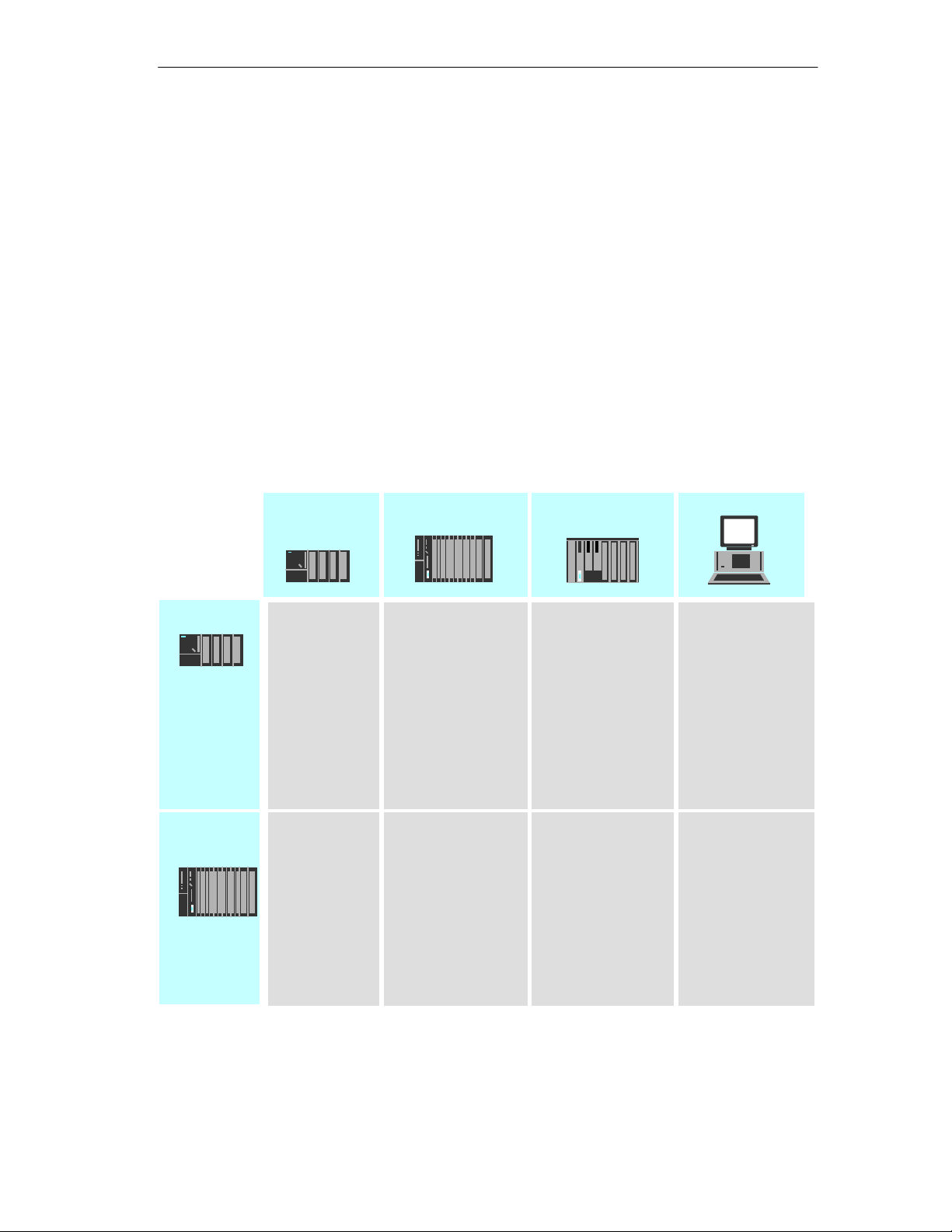

Possibilities for Communication between Device Types

The possible communication available with the types of communication listed

above is shown in the following table:

S7-300

S7/M7-400

S7 communication

SEND/RECEIVE

PROFInet

S7 communication

SEND/RECEIVE

1) PC only as client

S7-300

S7-400

S7 communication SEND/RECEIVE

SEND/RECEIVE

S7 communication

SEND/RECEIVE

FTP services

S5-115 to -155U/H

FETCH/WRITE

SEND/RECEIVE

FETCH/WRITE

PC

PG/OP

communication

S7 communication

SEND/RECEIVE

FETCH/WRITE

HTML process

control

PROFInet

FTP services

PG/OP

communication

S7 communication

SEND/RECEIVE

FETCH/WRITE

HTML process

control

FTP services

1)

1)

1)

1)

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

17

Communication via Ethernet CPs in S7 Stations

Configuration and Diagnostics

To connect and configure the Ethernet CP, you require the STEP 7 configuration

software and the SIMATIC NET NCM S7 for Industrial Ethernet option.

NCM S7 for Industrial Ethernet is installed as a STEP 7 option and is therefore

integrated in STEP 7.

NCM S7 for Industrial Ethernet also provides a wide range of diagnostic functions

for the various types of communication.

When configuring PROFInet communication, you also use the engineering tool

SIMATIC iMap; for detailed information on SIMATIC iMap, refer to the manual

Component based Automation – Configuring Plants with SIMATIC iMap /23/.

18

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

Communication via Ethernet CPs in S7 Stations

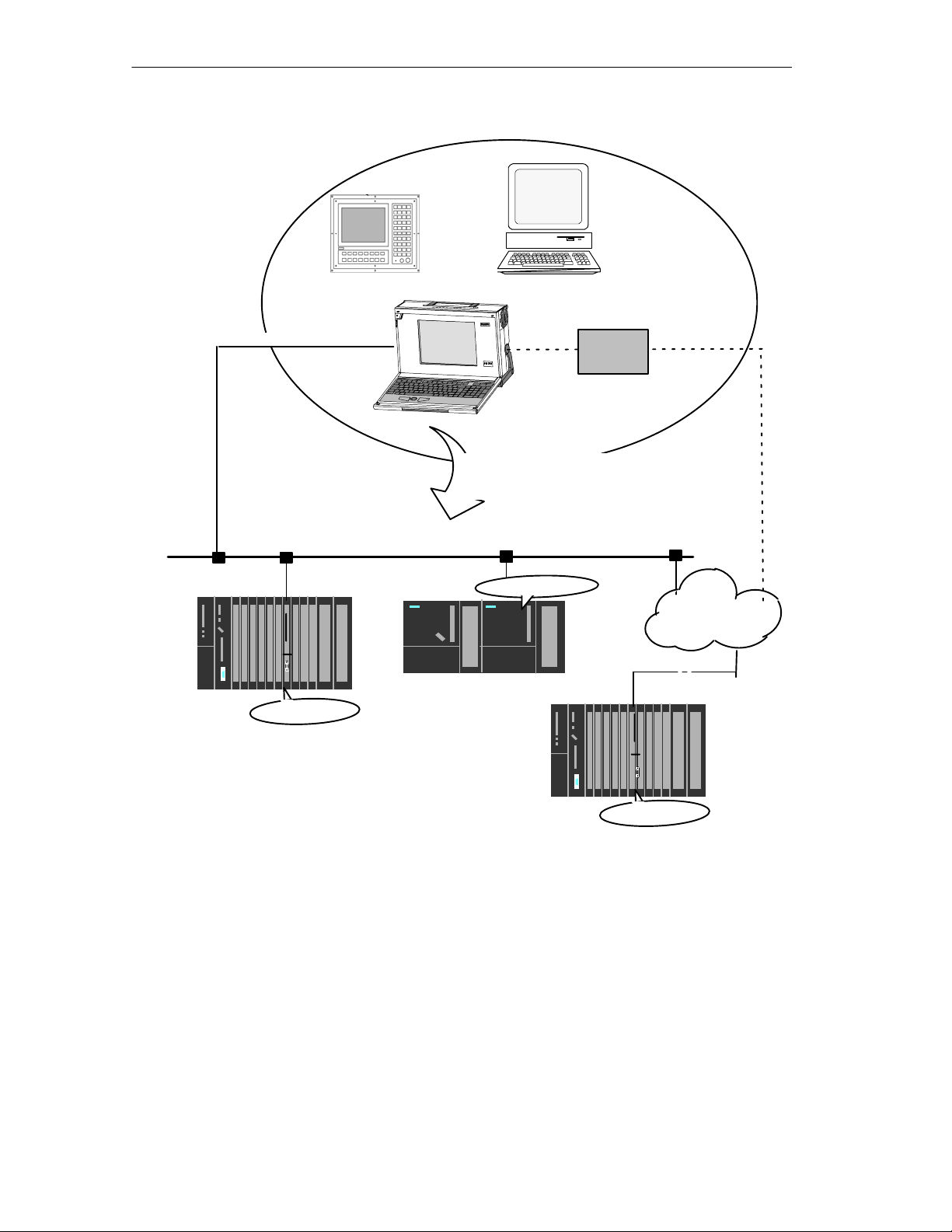

1.3 PG/OP Communication via Industrial Ethernet

Application

PG/OP communication provides functions that are already integrated in every

SIMATIC S7/M7/C7 device.

A distinction must be made between the following two types of function:

S PG communication

PG communication with STEP 7 PLCs on Industrial Ethernet means the

following:

– You can use the complete range of functions of STEP 7 on Industrial

Ethernet.

– You can use programming, diagnostic, operating and monitoring functions on

all modules in the SIMATIC S7 PLC via Industrial Ethernet.

S OP Operation

PG/OP communication on Industrial Ethernet allows the operation and

monitoring of all modules in a SIMATIC S7 PLC using operator interface

systems (TD/OP).

The Ethernet CP acts as a “communications relay” that relays the PG/OP

communication via Industrial Ethernet.

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

19

Communication via Ethernet CPs in S7 Stations

Operator Interface functions

Ethernet attachment

S7 – 400

Ethernet CP

OP

S7 – 300

PC with Ethernet CP

STEP 7

NCM S7

Create configuration data for

every CP and download to the

Ethernet CPs

Ethernet

Ethernet CP

S7 – 400

Modem /

ISDN

WAN *

* only TCP/IP

Figure 1-2 Configuration for PG/OP Operation

20

Ethernet CP

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

Communication via Ethernet CPs in S7 Stations

1.3.1 PG Communication with STEP 7 over Industrial Ethernet

Requirements for PG Communication

PG communication is possible when the following requirements are met:

S An Ethernet CP is installed in the PG or engineering station or there is a

modem/ISDN interface for remote access.

S The Ethernet CP must have an address (default MAC address or set the IP

address).

Networking the PG / Engineering Station

Depending on the configuration of the PG or Engineering Station, the following two

situations are possible when using PG communication:

S PG / Engineering Station in the Configured Mode

If you select this configuration when you commission the PG / engineering

station, the interfaces of the communication modules you are using are already

known. The option in “Set PG/PC Interface” is automatically set to

“PC-internal”.

Once you have downloaded this configuration to your PG / engineering station,

you can exchange PG functions with the accessible nodes in the network with

STEP 7 without requiring any further settings.

S PG / Engineering Station in PG Operation

If your PG or engineering station is configured for this mode, you must specify the

interface on the PG or engineering station explicitly with “Set PG/PC Interface”.

Follow the steps outlined below:

1. Open the “Set PG/PC Interface” dialog box in the Windows Control Panel.

2. Set the PG/PC interface according to the CPs available on your PG and

according to the bus attachment (interface parameter assignment used).

For more detailed information on the topic of PG operation and engineering station,

refer to /4/.

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

21

Communication via Ethernet CPs in S7 Stations

1.3.2 OP Operation: Connecting Operator Interface Devices via Industrial Ethernet

Requirements

Operation allowing operator interface functions is possible when the following

conditions are met:

S The operator interface device has:

– an Ethernet CP installed

– SOFTNET S7 for Ind. Ethernet or S7-1613/ WIN 95, WIN NT, MS-DOS,

Windows installed.

S The CPs in the S7 stations are supplied with a MAC/IP address (use the default

MAC address or set an IP address).

Procedure

To be able to use S7 communication, address the required module in the SIMATIC

S7 PLC on your operator interface system.

For more detailed information, refer to the description of your operator interface

system.

22

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

Communication via Ethernet CPs in S7 Stations

1.4 S7 Communication on Industrial Ethernet

Application

S7 communication via Industrial Ethernet allows program-controlled

communication using communication SFBs/FBs via configured S7 connections.

Per job, up to 64 Kbytes of user data can be transmitted.

The Ethernet CP acts as an “S7 communication relay” by passing on the S7

functions via Industrial Ethernet (see /8/). Depending on the configuration of the

Ethernet CP, data transfer is on the basis of the ISO transport or the ISO-on-TCP

protocol (TCP/IP with RFC 1006).

From the perspective of the user, S7 communication is identical over PROFIBUS

and Industrial Ethernet.

Nodes

Two cases can be distinguished depending on device type and plant configuration:

S Client and server functionality at both ends

S7 connections can be operated between the following nodes with the entire

functionality of S7 communication:

– between S7 stations S7-300 and S7-400;

– between S7 stations and PC/PG stations with an Ethernet CP.

S7 – 400

Ethernet

Ethernet CP

S7 – 300

Ethernet CP

PUT / GET

BSEND / BRECV

WAN *

USEND / URECV

M7

* only TCP/IP

PC/PG with Ethernet CP

Figure 1-3 Nodes Communicating on S7 Connections over Industrial Ethernet

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

S7 – 300 / 400

23

Communication via Ethernet CPs in S7 Stations

S Client and server functionality at one end only (S7 connections

configured at one end)

In the following situations, write and read functions can be implemented with

PUT / GET:

– S7 communication over router

PG/PC stations can access S7 stations if the PG/PC stations are connected

to a different subnet (PROFIBUS / Ethernet) via routers (for example, an

IE/PB Link); in this case, S7 stations are servers.

S7 communication is possible over a gateway.

Ethernet

S7 – 400

PROFIBUS

Ethernet CP

PC/PG Station

S7 – 300

PUT / GET

Ethernet

Ethernet CP

PC/PG Station

IE/PB Link

PUT / GET

Figure 1-4 PC/PG station communicates over a gateway with S7 stations on an underlying PROFIBUS

or Ethernet

For more detailed information on the features supported by your Ethernet CP, refer

to the manual /1/.

24

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

Communication via Ethernet CPs in S7 Stations

Configuring S7 Connections

Create S7 connections to use S7 communication for data exchange between two

SIMATIC S7 stations.

For more detailed information, refer to the STEP 7 Description /6/ /8/.

Notice

S7 connections via routers are supported only within a STEP 7 project but not between partners in different STEP 7 projects of a multiproject!

Interface in the User Program of the S7 Station

You use SFBs (for S7-400) and FBs (for S7-300) in the user program.

Block type

SFB / FB12 BSEND x – STEP 7

SFB / FB13 BRCV x

SFB / FB15 PUT x –

SFB / FB14 GET x –

SFB / FB8 USEND x –

SFB / FB9 URCV – x

SFC / FC62 CONTROL (S7-400) /

1) you do not need to configure a connection on the server

2) for S7-300

1)

C_CNTRL (S7-300)

Client Server Described in

Documentation /9/

1)

1)

x x

2)

Notice

Please remember the following points regarding data consistency in your user program:

In the CPU of the S7 station, the read or written information is taken from the S7

user program into the operating system or copied from the operating system to the

S7 user program in blocks of 8 or 32 bytes (depending on the firmware version).

If information in the word or double-word format is located across such boundaries, data inconsistency may arise during transmission using S7 communication!

For more detailed information, refer to the STEP 7 documentation /9/.

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

25

Communication via Ethernet CPs in S7 Stations

Notes on S7 communication between PC/PG station and S7 station

Applications in a PC/PG station communicate with the S7 station over an OPC

interface or SAPI-S7 interface for operator intervention, monitoring and control.

The S7 stations use the integrated communication SFBs/FBs (client and server

functionality at both ends).

The following general requirements must be met by a PC/PG station for S7

communication:

S On the PC/PG:

– an Ethernet CP installed

– there is an interface for S7 communication installed: SOFTNET S7 for Ind.

Ethernet or S7-1613/ WIN 95, WIN NT, MS-DOS, Windows.

S The CPs in the S7 stations are supplied with a MAC/IP address (use the default

MAC address or set an IP address).

To use S7 communication with the SIMATIC S7 PLC from a PC, address the

required CPU module in the SIMATIC S7 PLC that you want to communicate with

in your PC application.

S7 communication via routers (one-ended client and server functionality)

It is possible to reach the S7 station from an application (OPC server) of the

PC/PG station that is attached to another subnet. The subnets must be connected

over a router such as the IE/PB Link. An S7 station or a PC connected to both

subnets can also serve as a router.

In this configuration, the S7 station can only be addressed by the PC/PG station as

a communications server on S7 connections configured at one end.

The requirements for the configuration of the PC/PG station are identical to those

for operation in the same subnet (see above); the CP in the PC/PG station must

also have routing capability.

In this situation, configure a one-ended S7 connection to the PC/PG station in the

other subnet for the PC/PG station in STEP 7 NetPro. You can then access data in

the S7 station in your user program using the functions PUT (writing) and GET

(reading).

26

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

Communication via Ethernet CPs in S7 Stations

1.5 S5-compatible Communication (SEND/RECEIVE

1

Interface

Application

Using the SEND/RECEIVE interface, your S7 user program has access to

S5-compatible communication with configured transport connections.

Data transmission on a configured transport connection is suitable for

S the reliable transmission of related blocks of data between two Ethernet nodes

using

– TCP (see /17//19//20/) with ISO-on-TCP connection (see /18/) or TCP

– ISO transport connection

S simple (unacknowldeged) transfer of related blocks of data (datagram service)

between two Ethernet nodes with UDP (User Datagram Protocol) on IP.

)

connection;

The SEND/RECEIVE interface is also suitable for sending E-mail (refer to the

manual for the IT-CP /5/).

For TCP applications, there is an active network with IP protocol (see /20/).

ISO Transport Connection

ISO transport provides services for the reliable transfer of data on configured

connections. Due to the segmentation of the data, large amounts of data can be

transmitted.

Transmission reliability is extremely high due to automatic repetition and additional

field check mechanisms. The communications partner confirms reception of data

and the sender receives a return value on the SEND/RECEIVE interface.

ISO transport is operated only on Industrial Ethernet and is optimized for

high-performance operation at the self-contained manufacturing level.

1The previous name of the SEND/RECEIVE interface was S5S5 connections

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

27

Communication via Ethernet CPs in S7 Stations

IP (Internet Protocol)

For internetwork data transmission, the following services are available with

suitable CPs such as the CP 443-1 TCP:

S ISO-on-TCP connection

ISO-on-TCP is intended for reliable, internetwork data transmission.

The ISO-on-TCP service corresponds to the TCP/IP standard (Transmission

Control Protocol/Internet Protocol) with the RFC 1006 extension according to

layer 4 of the ISO reference model (see /18/).

RFC 1006 extends the TCP protocol by allowing the transmission of blocks of

data (“messages”) assuming that both partners support RFC 1006.

Transmission reliability is extremely high due to automatic repetition and

additional field check mechanisms. The communications partner confirms

reception of data and the sender receives a return value on the

SEND/RECEIVE interface.

S TCP connection

When using the SEND/RECEIVE interface on TCP connections, the Ethernet

CP supports the socket interface (for example, Winsock.dll) to TCP/IP found on

almost every system (PC or other system).

TCP is intended for reliable internetwork data transmission.

The TCP service complies with the TCP/IP standard (Transmission Control

Protocol/Internet Protocol; see /18/).

S UDP connection

UDP is intended for simple internetwork data transmission without confirmation.

If the connection is suitably configured, broadcast and multicast frames can

also be sent on UDP connections.

To avoid overload due to high broadcast load, the CP does not allow reception

of UDP broadcasts. As an alternative, use the multicast function over a UDP

connection. This allows you to register the CP as a node in a multicast group.

SEND/RECEIVE interface

Data transfer is triggered by the user program. The interface to the user program in

the SIMATIC S7 is formed by special SIMATIC S7 blocks of the type FC

(functions).

28

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

Stations

Communication via Ethernet CPs in S7 Stations

The SEND/RECEIVE interface allows program-controlled communication on

Industrial Ethernet between the SIMATIC S7 PLC and the following:

S SIMATIC S7 PLC with Ethernet CP

S SIMATIC S5 PLC with Ethernet CP

S PC/PG with Ethernet CP

S Other station with Industrial Ethernet attachment

S7 – 400

Ethernet

SIMATIC S5

with Ethernet CP

Ethernet CP

WAN

Internet

Router

S7 – 300

Other station with

Ethernet attachment

only TCP/IP

Ethernet CP

D D D

D D D

D D DD D D

PG/PC with Ethernet

attachment

Figure 1-5 SIMATIC S7 PLC with Possible Communications Partners on the SEND/RECEIVE Interface

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

29

Communication via Ethernet CPs in S7 Stations

1.6 FETCH/WRITE Services (Server)

Application

In addition to the SEND/RECEIVE interface, the FETCH/WRITE functionality

provides further services for S5-compatible communication on configured transport

connections.

The FETCH/WRITE interface is used primarily to attach SIMATIC S7 to SIMATIC

S5 and to other non-S7 stations (for example PCs).

S FETCH

The partner on the connection (SIMATIC S5 or non-S7 station) can read

system data on the SIMATIC S7 PLC.

S WRITE

The partner on the connection (SIMATIC S5 or non-S7 station) can write

system data on the SIMATIC S7 PLC.

From the point of view of the SIMATIC S7 PLC, this is a passive communication

function; the communications partner initiates the connection establishment.

For further information, refer to the system documentation of the SIMATIC S5 PLC

or the non-S7 station you are using.

Connection Types

To access a station with FETCH or WRITE functions, a FETCH passive or WRITE

passive connection must be configured. The following types are possible:

S ISO Transport

S ISO-on-TCP

S TCP

Coordinating Access Using the User Program

To coordinate access, you can use the FCs AG_LOCK and AG_UNLOCK.

With these FCs, you can coordinate access to system memory areas so that no

inconsistent data are created and transferred.

SIMATIC S5

30

On the SIMATIC S5 station, the FETCH/WRITE services are configured and

started by READ ACTIVE/PASSIVE and WRITE ACTIVE/PASSIVE.

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

Communication via Ethernet CPs in S7 Stations

1.7 Networking Stations with STEP 7

Configuring

To allow stations to communicate with each other the networks must be configured

in the STEP 7 projects.

Configuring a network or subnet involves the following:

1. You create one or more subnets of the required subnet type in the project.

2. You select the properties of the subnet. Normally the default settings are

adequate.

3. You connect the station “logically” to the subnet.

4. You set up connections for communication.

Networking in a Multiproject

Tools

STEP 7 as of Version V5.2 supports configuration in a multiproject.

Using a multiproject, for example, you can create a project for distributed editing by

various editors and distribute the stations to the projects according to their editors.

To allow this, functions are available for branching and merging (sub) projects.

Interproject subnets and connections can be created.

The SIMATIC Manager provides convenient tools for configuring and documenting

networks (also graphically with NetPro).

The chapters describing network configuration in /6/ and the online help system

also contain information about configuring SIMATIC S7 networks.

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

31

Communication via Ethernet CPs in S7 Stations

Variants

Before configuring networks with STEP 7, you should be aware of the various

configurations possible in the STEP 7 project. The following configurations are

typical for stations networked with CPs:

Variant (examples) Characteristics/Configuration

1 1 subnet – 1 project

2 Additional SIMATIC S5 stations and stations with equipment of other vendors

3 2 or more subnets – 1 project

4 1 subnet – more than one project

5 More than one subnet – more than one project

6 Internetwork connections (TCP)

These variants will be used as a basis to illustrate how real configurations can be

created in STEP 7 projects.

32

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

Communication via Ethernet CPs in S7 Stations

1.7.1 Network/Project Variant: One Subnet – One Project

Configuration of the System

In the simplest case, your system consists of SIMATIC S7 stations connected by

one subnet, for example of the type Industrial Ethernet.

View in a STEP 7 Project

You create an Industrial Ethernet object in the STEP 7 project. Stations created

in the same project refer to this object as soon as they are configured as

network nodes.

System

“Production”

Ethernet (1)

S7-400/1

S7-300/1

S7-300/2

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

33

Communication via Ethernet CPs in S7 Stations

1.7.2 Network/Project Variant: SIMATIC S5 and Non-SIMATIC Devices on the Subnet

Configuration of the System

In addition to SIMATIC S7 stations, SIMATIC S5 stations and non-SIMATIC

devices can be included in your system.

S7-400/1

System

“Production”

Ethernet (1)

S7-300/1

Non-SIMATIC

View in a STEP 7 Project

SIMATIC S5 stations you intend to include in the communication can be

selected directly. Non-SIMATIC devices must be entered in the configuration as

Other stations.

SIMATIC S5

S7-300/2

34

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

Communication via Ethernet CPs in S7 Stations

1.7.3 Network/Project Variant: Two or More Subnets – One Project

Configuration of the System

Due to the different tasks of the stations or due to the extent of the system it may

be necessary to operate more than one network.

S7-400/1

System

”Production and

Management Level”

View in a STEP 7 Project

You can create the subnets in one STEP 7 project and configure the stations for

communication.

Ethernet (1)

Ethernet CP

S7-400/2

PROFIBUS CP

PROFIBUS (1)

S7-300/1 S7-300/2

This representation illustrates the following:

S More than one subnet can be managed in one project.

S Each station is created once in the project.

S Each station can be assigned to more than one subnet by assigning its CPs to

different subnets.

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

35

Communication via Ethernet CPs in S7 Stations

1.7.4 Network/Project Variant: One Subnet – More Than One (Sub)Project

Configuration of the System

In complex networked systems, during configuration it is sometimes more efficient

to manage plant sections in different (sub) projects.

The situation can arise that communication takes place over an interproject subnet

and that interproject connections must then also be created.

Example:

System section

System section

“Production 1”

“Production 2”

S7 400/1

S7 300/1 S7 – 300/2

Organization in a Multiproject

User-friendly and consistent configuration of such communication is supported in

STEP 7 as of Version V5.2 with the multiproject.

The functions for multiprojects in STEP 7 allow the following:

S Several projects can be managed in one multiproject and edited separately

S Projects can be branched and merged

Two different strategies can be distinguished in a multiproject:

S Several employees work at the same time on a multiproject in a networked

environment. The projects of the multiproject are in different network folders. In

this case, all connection partners are available for configuring connections.

S7 – 400/2

Ethernet (1)

S7 – 300/3

36

S One employee manages the multiproject centrally. This person creates the

structures for projects (when necessary locally) and contracts individual projects

out for external editing. The central configuration engineer then returns these

projects to the multiproject and synchronizes the interproject data with system

support and where necessary executes the required interproject functions.

In this case, agreement is necessary, for example, regarding the assignment of

connection names because it will be far easier when synchronizing the projects

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

Communication via Ethernet CPs in S7 Stations

to bring connections with identical connection names together.

The topic of multiprojects is dealt with in detail in the STEP 7 basic help.

Here, you will find information on the following topics:

S Requirements for interproject functions

S How to create multiprojects

S How to create a new project in a multiproject

S How to separate a project from a multiproject

S How to include projects in the multiproject

S How to synchronize projects in a multiproject

S Moving stations within a multiproject (when a station is moved from one project

of a multiproject to another project of the same multiproject (for example using

drag & drop), the interproject connections are retained).

S Possible problems in distributed projects and tips on how to avoid them

Possibilities for stations outside the current project

The addition of the multiproject functionality means that the following situations can

arise:

S Connection to a partner in an unknown project

The new multiproject functionality allows you to create a connection to a partner

in an unknown project. In this case, you can specify a connection name as a

reference in the properties dialog of the connection. When the projects are

merged, STEP 7 then supports you with automatic synchronization of the

separately configured connections.

The connection remains unspecified until the projects have been merged and

the connections synchronized. Only following this synchronization can the

configuration data be downloaded to the local station without inconsistencies.

You should therefore use this variant when you know that the projects will be

merged in a multiproject.

S Specified connections with representative objects

To allow you to create specified connections to stations in a different project (for

example production 2) or that are not managed with STEP 7, you can configure

these stations as other stations(example in the project production 1).

This makes it possible to create consistent, fully specified configuration data

and to download it to the local station.

It is also possible to create specified connections between these stations in

different, independent projects. The stations can then communicate

immediately over the created connections after the configuration data have

been downloaded.

Use this variant when you want to operate projects separately due to the

complexity.

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

37

Communication via Ethernet CPs in S7 Stations

Stations of the type SIMATIC S5 function in just the same way as

representative objects.

Merging projects in the multiproject:

If you have used the multiproject functions allowing you to use connections to a

partner in an unknown project, STEP 7 will automatically attempt to synchronize

two separately configured connections.

If you have configured projects with representative objects and want to merge

these projects into a multiproject, you have the following options:

S You can leave the representative objects with the configured connections

unchanged.

S You can reassign the connection partner and then delete the representative

objects.

38

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

Communication via Ethernet CPs in S7 Stations

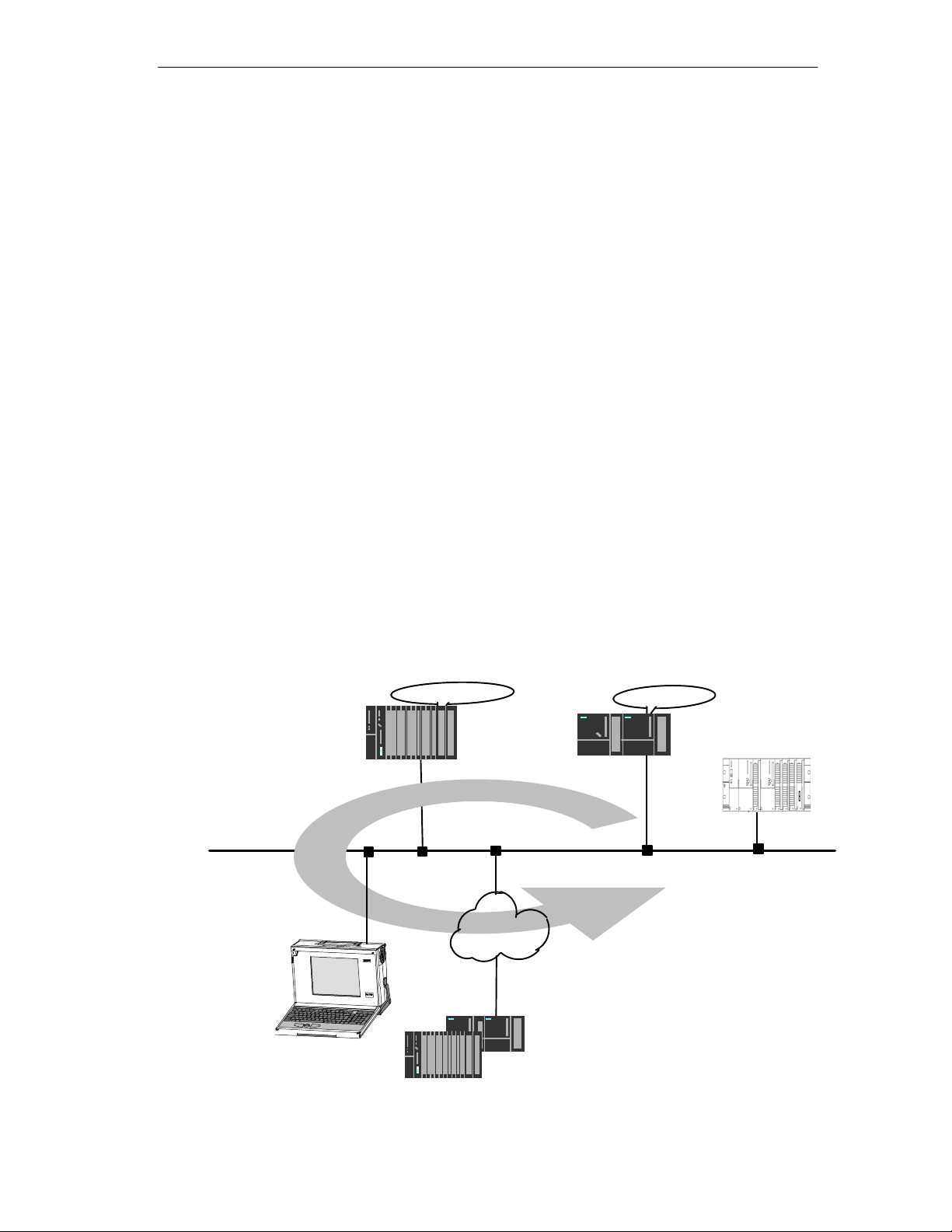

1.7.5 Network/Project Variant: Several Subnets in Several (Sub) Projects

Configuration of the System

If several network types need to be used and if these need to be managed in

different projects due to the different tasks of the stations or due to the large span

of the plant, stations can be created as follows:

S Using (sub) projects in the “multiproject”

S by configuring ”Other stations / SIMATIC S5” in the other project.

Ethernet (1)

S7 – 400/1

PROFIBUS (1)

Ethernet CP

PROFIBUS CP

S7 – 300/1

Cell level = (sub)project 1

Cell level = (sub)project 2

S7 – 300/2

Organization in a Multiproject

If you use a multiproject organization, follow the steps below to connect the

S7-400/1 station to the PROFIBUS (1) subnet:

Create a subnet of the type PROFIBUS in both subprojects and merge these two

subnets in NetPro.

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

39

Communication via Ethernet CPs in S7 Stations

Representative Objects for Stations Outside the Current Project

If you do not want to use the multiproject functions, you can fall back on the use of

representative objects as used previously.

To be able to network the representative objects, you must once again create a

subnet of the type PROFIBUS in both projects as shown in the example here.

40

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

Communication via Ethernet CPs in S7 Stations

1.7.6 Network/Project Variant: Connections between Subnets (TCP/IP)

Configuration of the System

If connections are required to stations on network structures connected by routers

due to the differing tasks of the stations or the large span of the network, the

stations in the other project can be reached by configuring “Other Stations”.

S7 – 400/1

Ethernet CP

Ethernet (1)

WAN

Internet *

View in a STEP 7 Project

If the stations in the two networks are managed in the same project, the

networking appears as shown below in NetPro.

Router *

Ethernet (2)

S7 – 400/2

Ethernet CP

S7 – 300/1

* only TCP/IP

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

41

Communication via Ethernet CPs in S7 Stations

-

42

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

Installing and Starting the Ethernet CP with STEP 7

To attach a SIMATIC station to Industrial Ethernet via the Ethernet CP, configure

the CP with the NCM S7 configuration software. The chapter explains the

following:

S How the CP is configured in the STEP 7 project

S How the various network configurations are managed (setting up access to

other systems)

S How to control and supply the CP with data using NCM S7

You will find further information in the following sources:

S When installing the Ethernet CP, please refer to the instructions in the manual

/1/ supplied with the Ethernet CP. This also contains further information about

the performance of the Ethernet CP .

S For more information about the functions and applications of STEP 7 in which

the NCM S7 option is integrated, please read the following topics:

2

– For using the help functions, read the section Working with STEP 7 in /6/.

– Configuring and assigning parameters to modules in /6/

– Configuring networks in /6/. You will find this information in the online help

with integrated in STEP 7 by selecting Help " Contents.

S You will find examples of configurations in the Primer /3/.

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

43

Installing and Starting the Ethernet CP with STEP 7

2.1 General Information About the NCM S7 for Industrial Ethernet Option

Installation

Please follow the instructions in the README file when installing the NCM S7 for

Industrial Ethernet option on your PG/PC under STEP 7.

Functions

NCM S7 consists of the following:

S CP-specific index dialogs that you call using the properties dialog box of the

modules.

S Dialogs for the connection configuration

S Diagnostic functions that you obtain as follows:

Operation

– Using the “Diagnostics” tab in the properties dialog

– Using the standard Start menu of Windows with which you can call the

SIMATIC program group

S Functions displayed with SIMATIC " NCM... in the Start menu of Windows:

– Diagnostics

– Help for functions (FCs)

– “Readme” file with current information about NCM

– Firmware loader

Operating and handling the software package is as explained in the STEP 7 user

manual /6/.

44

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

2.2 Procedure

A CP is managed in an S7 project just as the other modules. You use STEP 7 to

configure the hardware and create and manage the user software (see /6/).

Configuring a CP involves the following basic steps (the broken lines indicate

options):

Installing and Starting the Ethernet CP with STEP 7

Create the Industrial Ethernet subnet (see 2.2.1)

Check or set the network properties

Enter the Ethernet CP in the hardware configuration

(see 2.2.2)

Attach the Ethernet CP to the Ethernet subnet

(see 2.2.2)

Display the network attachments of a station (see 2.2.3)

Make further CP settings (see 2.2.4)

Program the SEND/RECEIVE interface (Chap. 3)

Configuring communication services (Chap 4)

– S7 connections /6/

– ISO transport connections

– ISO-on-TCP connections

– TCP connections

– UDP

Configuration data in

the STEP 7 project

Download the configuration to the PLC (see 2.4).

The steps are explained in detail in the sections shown.

Fields with broken lines are optional.

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

45

Installing and Starting the Ethernet CP with STEP 7

2.2.1 Creating an Industrial Ethernet Subnet

Aims

To be able to attach the SIMATIC stations to a subnet, you create the subnet in

your project. This means that all the parameters for the entire subnet are managed

centrally.

Procedure

It is advisable to create the subnet before you configure the stations since the

assignment of the SIMATIC stations is then performed largely automatically.

It is also possible to create the subnet at a later point in time when configuring a

CP. This is explained in more detail later in the chapter.

Follow the steps outlined below:

1. Select the project in the SIMATIC Manager.

2. Select Insert " Subnet " Industrial Ethernet.

Result: An object of the type network is created in the project. This allows all

the SIMATIC stations created in the project to be attached to this subnet.

Figure 2-1 Project with Assigned Ethernet Network

46

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

Installing and Starting the Ethernet CP with STEP 7

3. If you prefer a NetPro graphic network display, select the network object

“Ethernet” and confirm with Edit " Open Object.

Figure 2-2 Graphic Network Representation (here showing stations not yet networked)

From this graphic representation, you can also activate all the functions for

networking and configuring connections with the Ethernet CPs.

You can also create the subnets in NetPro! Open the catalog using the menu

command Insert " Network Objects.

Organization in a Multiproject

If you use the multiproject form of organization, this has the following effects when

creating subnets.

You create subnets initially in the subprojects as described above. To be able to

network S7 stations, you will, for example, need to create a suitable subnet of the

type Industrial Ethernet in each subproject.

If this is physically a subnet that extends beyond the boundaries of the subproject,

you should first merge the subnets before configuring the communication

connections between the S7 stations.

If you do not merge the subnets, NetPro assumes that you are connecting the

subnets via routers and displays warning messages to this effect.

Properties of Merged Subnets (Multiproject)

When you merge subnets, transferable subnet properties such as the subnet ID of

the master subnet will be transferred to the other subnets of the group.

Some parameters relate specifically to a subproject and remain unchanged; these

include, for example, descriptive parameters such as the name, author, and any

comments.

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

47

Installing and Starting the Ethernet CP with STEP 7

Notice

Preserving Consistency in Merged Subnets

After merging the subnets, you should check the consistency throughout the multi-

project using the menu command Network > Check Interproject Consistency in

NetPro to make sure that there is consistency throughout the multiproject. This

check detects, for example, S7 subnet IDs that are not unique within the multiproject.

48

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

Installing and Starting the Ethernet CP with STEP 7

2.2.2 Entering an Ethernet CP in the Hardware Configuration

Procedure

By installing and assigning the Ethernet CP in the rack of a SIMATIC station, you

establish the logical attachment between the Internet CP and the subnet.

1. Select the station in your project that you want to attach to Industrial Ethernet

using an Ethernet CP.

2. Select the CP in the hardware configuration just like any other module by

selecting it in the hardware catalog and then selecting the slot in the rack.

You select CPs in the hardware catalog using a short text and the order

number. Once you have installed NCM S7, the CPs are available in the catalog.

Result: The CP is assigned to the SIMATIC station.

For information about the permitted slots, refer to /1/.

How to configure a module is described in detail in /6/.

Subnet Attachment

To allow you to activate the network attachment of the Ethernet CP, the SIMATIC

Manager displays the following dialog:

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

49

Installing and Starting the Ethernet CP with STEP 7

Note

You can open the dialog for setting the interface at any time from the Properties

dialog of the CP in the “General” tab.

1. If you have not yet created a subnet in the project or have not yet created the

selected subnet, you can now create a subnet. To do this, select the “New”

button.

Result: An object of the type network is created in the project.

2. Check the addresses and if necessary change them. The system enters the

next free address automatically.

You will find detailed information on the address ranges in the online help.

Please note the following additional information:

– MAC address

The latest Ethernet CPs are supplied with a default MAC address (address

printed on the module). To be sure that you have a unique address

assignment, do not enter a MAC address in the configuration (the option is

deactivated). This means that the module automatically uses the factory–set

address. If you want to use ISO services, we recommend that you enter the

address printed on the module in the configuration.

Note

The ”IP address” and ”Subnet mask” input fields have no significance for ISO

transport (option ”IP protocol being used”).

3. Select the required subnet type in the “Subnet” list box.

4. You can display the properties dialog box for the selected subnet by clicking the

Properties button.

5. Enter information specific to the subnet node in the “General” tab.

6. You must finally confirm your input with OK, otherwise the networking is not

entered (refer to Point 3.).

Result: The CP is now configured as a network node for the corresponding S7

station.

50

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

Installing and Starting the Ethernet CP with STEP 7

Setting Addresses in the Configuration and Addressing for the First Time

The address settings described here are made on the CP only after you download

the configuration data.

With the latest Ethernet CPs, the situation is as follows:

To be able to reach the CP using these addresses before you download the

configuration data, you can address the CP using its default MAC address and

then supply it with project-specific address information.

How to do this is described in Section 2.3.

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

51

Installing and Starting the Ethernet CP with STEP 7

2.2.3 Displaying the Network Attachments of a Station

Procedure

You can easily get an overview of the network attachment configurations of a

SIMATIC station in one of the following ways:

S A graphic overview in NetPro;

S An overview in table form in the Properties dialog of the station

Graphic Overview in NetPro

The NetPro view provides you with a good overview of the networked stations:

Follow the steps below:

1. Double-click one of the network objects, for example Ethernet in your project in

the SIMATIC Manager.

Figure 2-3 NetPro View of a Subnet of the Type Industrial Ethernet

SIMATIC NET NCM S7 for Industrial Ethernet

52

C79000-G8976-C129–06

Overview in Table Form

The table view in the Properties dialog of the station provides a detailed overview

of the components used for network attachment.

Follow the steps below:

1. Using the SIMATIC Manager, select the station in your project that you want to

check.

2. Select the Object Properties using the menu option Edit " Object Properties

or by double-clicking the station symbol.

3. Select the “Interfaces” tab.

Result:

Installing and Starting the Ethernet CP with STEP 7

Figure 2-4 “Interface” Tab in the “SIMATIC 300/400” Properties Dialog Box

In the displayed dialog, you can see the subnet attachments that were configured

for the SIMATIC station.

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

53

Installing and Starting the Ethernet CP with STEP 7

2.2.4 Setting Further CP Properties

Overview

In addition to the network attachment, you can also make further settings for the

specific module or you can call functions.

1. Select the Ethernet CP in the hardware configuration.

2. Select Edit " Object Properties. In the dialog, you will see further tabs in

addition to the “General” tab described in Section 2.2.2 depending on the type

and CP, some of which are shown in the example of a CP 443-1:

Figure 2-5 Example of the “General” Tab of the “Properties CP” Dialog Box for the CP 443-1 TCP

Please read the description of the Properties dialog of the CP in the integrated

F1

help. The functions are explained in detail there.

Addresses Tab

The Addresses tab displays the address at which the module can be addressed by

the user program. You require this address when calling the FCs for transport

connections –> see Chapter 5.

54

SIMATIC NET NCM S7 for Industrial Ethernet

C79000-G8976-C129–06

Notice

Please note the following information on S7–300 stations:

If you selected the option ”Update OB1 process image cyclically” in the CPU confi-

guration, (default), make sure that the start address of the CP is outside the process image area (start addresses in the ”Addresses” tab).

Example: if the process image selected for the CPU = 1024 (0...1023), an address

>= 1024 must be selected for the CP.

Options Tab

Depending on the CP type, you can make the following settings:

Table 2-1 Settings in the “Options” Tab

Installing and Starting the Ethernet CP with STEP 7

Option

Meaning / Effect

S Time-of-Day Synchronization Here, you decide whether the CP passes on time-of-day frames or

not. You require this function if you have several CPs in a station

since only one CP (on the same network) is permitted to pass on the

time synchronization messages.

Note

The time-of-day synchronization function does not exist for all module

types.

S Data transfer > 240 bytes With this option, you specify whether or not the CP will support jobs

with a data length of more than 240 bytes (for S7-300 stations).

Notes

S The transfer of more than 240 bytes of data is supported by