Page 1

RWF40...

Compact Universal Controller

optimized for temperature and pressure control through the control of modulating or multi-stage burners

User Manual

The RWF40... controller and this User Manual are intended for use by OEMs which integrate the controller into

their products!

Siemens Building Technologies

CC1B7865E

February 10, 2000

Landis & Staefa Division

Page 2

2/56 CC1B7865E February 10, 2000 Landis & Staefa Division

Page 3

Contents

1.

1.1

1.2

1.3

1.3.1

1.3.2

1.3.3

2.

2.1

3.

3.1

3.2

3.3

3.4

3.5

3.6

Introduction ..........................................................................................6

General notes .................................................................................................................6

Description .....................................................................................................................6

Typographical conventions...........................................................................................7

Warning symbols .............................................................................................................7

Notification symbols .........................................................................................................7

Presentation.....................................................................................................................7

Type of unit........................................................................................... 8

Type field ........................................................................................................................8

Installation ............................................................................................9

Installation site and climatic conditions ......................................................................9

Dimensions.....................................................................................................................9

Side-by-side mounting.................................................................................................10

Mounting in a panel cutout..........................................................................................10

Cleaning the front panel ..............................................................................................11

Removing the controller module ................................................................................11

4.

4.1

4.2

4.3

4.4

5.

5.1

5.2

5.2.1

5.2.2

5.2.3

5.2.4

5.3

5.4

5.4.1

5.4.2

5.4.3

5.4.4

5.5

5.5.1

5.6

5.7

Electrical connections ....................................................................... 12

Installation notes..........................................................................................................12

Block diagram ..............................................................................................................13

Assignment of terminals .............................................................................................14

Galvanic separation .....................................................................................................17

Operating modes................................................................................18

Low-fire operation........................................................................................................18

High-fire operation .......................................................................................................18

Modulating burner, 3-position output..............................................................................18

Modulating burner, modulating output............................................................................19

Two-stage burner, 3-position output ..............................................................................19

Two-stage burner, modulating output ............................................................................20

Safety shutdown ..........................................................................................................20

Pre-defined setpoint ....................................................................................................20

Setpoint changeover «SP1 / SP2», analog setpoint shift ..............................................21

Setpoint changeover «SP1» / external setpoint.............................................................22

Setpoint «SP1», analog / binary setpoint shift ...............................................................23

External setpoint, binary setpoint shift ...........................................................................24

Weather-dependent setpoint shift ..............................................................................25

Heating curve slope .......................................................................................................26

Response threshold «Q».............................................................................................27

Cold start of the plant ..................................................................................................28

Landis & Staefa Division CC1B7865E February 10, 2000 3/56

Page 4

6.

Operation ............................................................................................29

6.1

6.1.1

6.2

6.2.1

6.2.2

6.2.3

6.2.4

6.2.5

6.3

6.3.1

6.4

6.4.1

7.

8.

8.1

8.2

8.3

8.3.1

8.3.2

8.3.3

8.3.4

8.3.5

8.3.6

8.3.7

8.3.8

8.3.9

8.3.10

Basic display................................................................................................................ 30

Meaning of the display and buttons............................................................................... 30

User level......................................................................................................................31

Changing the setpoints.................................................................................................. 31

Manual operation of a modulating burner...................................................................... 33

Manual operation of a two-stage burner........................................................................ 33

Start self-setting ............................................................................................................ 34

Display of the software version and unit of actual value ............................................... 34

Parameter level............................................................................................................ 35

Enter parameters........................................................................................................... 35

Configuration level ...................................................................................................... 35

Changing the configuration code................................................................................... 35

Parameter settings .............................................................................36

Configuration......................................................................................38

C111

C112

C113

SCL

SCH

SCL2

SCH2

SPL

SPH

OFF1

OFF2

OFF3

dF1

inputs............................................................................................................ 38

limit comparator, controller type, setpoint «SP1», locking ..................... 40

unit address, dimensional unit, out-of-range............................................ 44

scaling of standard signal range start, analog input 1 ................................... 45

scaling of standard signal range end, analog input 1.................................... 45

scaling of standard signal range start, analog input 2 ................................... 45

scaling of standard signal range end, analog input 2.................................... 46

lower setpoint limit......................................................................................... 46

upper setpoint limit ........................................................................................ 46

actual value correction for analog input 1 ..................................................... 46

actual value correction for analog input 2 ..................................................... 46

actual value correction for analog input 3 ..................................................... 46

2nd order digital filter for analog input 1 ......................................................... 46

9.

9.1

9.2

10.

10.1

Self-setting function...........................................................................47

Self-setting function in high-fire operation ............................................................... 47

Checking the controller parameters .......................................................................... 49

What to do if........................................................................................50

...numbers are flashing on the display ...................................................................... 50

4/56 CC1B7865E February 10, 2000 Landis & Staefa Division

Page 5

11.

Technical data ....................................................................................51

11.1

11.1.1

11.1.2

11.1.3

11.1.4

11.1.5

11.2

11.2.1

11.2.2

11.2.3

11.2.4

11.2.5

11.2.6

11.3

11.3.1

11.3.2

11.3.3

12.

12.1

12.2

12.3

Inputs ............................................................................................................................51

Analog input 1 (actual value) .........................................................................................51

Analog input 2 (external setpoint, setpoint shift) ............................................................51

Analog input 3 (outside temperature).............................................................................52

Binary input «D1»...........................................................................................................52

Binary input «D2»...........................................................................................................52

Outputs .........................................................................................................................52

Output 1 (release of burner)...........................................................................................52

Output 2, 3 (3-position output) .......................................................................................52

Output 4 (limit comparator) ............................................................................................52

Output 5, modulating output (option)..............................................................................53

Transducer supply..........................................................................................................53

Interface RS-485 (optional)............................................................................................53

General ratings.............................................................................................................53

Measured value accuracy ..............................................................................................54

Measured value circuit monitoring .................................................................................54

Environmental conditions...............................................................................................54

Current settings..................................................................................55

Process data.................................................................................................................55

Parameter level.............................................................................................................55

Configuration level.......................................................................................................56

Landis & Staefa Division CC1B7865E February 10, 2000 5/56

Page 6

1.1 General notes

)

*

1. Introduction

Please read this User Manual before starting up the controller. Keep the Manual in a

place that is accessible to all users at all times. Please help us improve the Manual.

Your suggestions will be welcome.

All necessary settings and, where required, settings inside the unit are described in this

User Manual, for controller software version 126.01.01.

1.2 Description

Use

Ö

Section 6.2.5

Should any difficulties arise during commissioning, you are asked not to carry out any

unauthorized manipulations on the unit. You could endanger your rights under the unit

warranty! Please contact us in such a case.

When returning modules, assemblies or components to Landis & Staefa, the regulations

of DIN EN 100 015 «Protection of electrostatically sensitive devices» must be observed.

Use only the appropriate

Please note that we cannot accept any liability for damage caused by ESD.

ESD = electrostatic discharge

The RWF40... is used primarily for controlling temperature or pressure in oil- or gas-fired

heating plants. It is a compact 3-position controller without position feedback that acts

on the burner. An external switch can be used to change it over to a 2-position controller

for the control of two-stage burners. The built-in thermostat function switches the burner

on and off. An adjustable response threshold is used to switch to a higher burner output

(high-fire operation).

«Display software version and dimensional unit»

ESD

packaging for transport.

Control

Options

A shift controller controls the temperature or pressure. Minimum and maximum limits for

the setpoint can be set. A self-setting function is available as a standard feature.

The plug-in controller module measures 96 x 48 x 127.5 mm and is especially suited for

mounting in control panels. The controller incorporates two 4-digit 7-segment displays

for the actual value (red) and setpoint (green). A limit comparator is also provided and

its switching behavior can be set on the configuration level.

A selection can be made between eight different limit comparator functions.

An RS-485 interface is used for integration into a data network. Output 5 can be used as

a modulating output for modulating or 2-stage operation.

All connections are made via screw terminals at the rear of the unit.

6/56 CC1B7865E February 10, 2000 Landis & Staefa Division

Page 7

1.3 Typographical conventions

1. Introduction

1.3.1 Warning symbols

Danger

Caution

*

Caution

1.3.2 Notification symbols

Note

)

Ö

abc¹

.

Reference

Footnote

The signs for

conditions:

This symbol is used where there may be a

disregarded or not strictly followed!

This symbol is used where there may be

instructions are disregarded or not strictly followed!

This symbol is used if

sensitive components.

This symbol is used to draw your

This symbol refers to

Footnotes are

parts:

markings

1) The

2) The

and a period

footnote text

Danger

additional information

comments, referring to specific parts of the text.

in the text are arranged as continuous superscript numbers

is placed at the bottom of the page and starts with a number

Caution

and

pre-cautions must be taken

are used in this Manual under the following

danger to personnel

damage to equipment or data

special attention

in other Manuals, chapters or sections.

if the instructions are

if the

in handling electrostatically

to a remark.

They consist of two

▲

Action

Buttons

Button

combinations

✱✱✱✱

1.3.3 Presentation

PGM

EXIT

+

This symbol indicates that

The individual steps are indicated by an asterisk, e.g.:

Press the ▲ button

✱✱✱✱

Buttons are shown in a box. Either symbols or text are possible. If a button has multiple

assignments, the text shown is always the one that corresponds to the function

currently used.

The representation of buttons combined with a plus sign means that first the

EXIT

button must be pressed and held down and then the other button.

a required action

is described.

Landis & Staefa Division CC1B7865E February 10, 2000 7/56

Page 8

2.1 Type field

2. Type of unit

Location

Types

Factory setting

The type field is glued onto the housing. The type designation consists of operating

voltage and type reference of the unit.

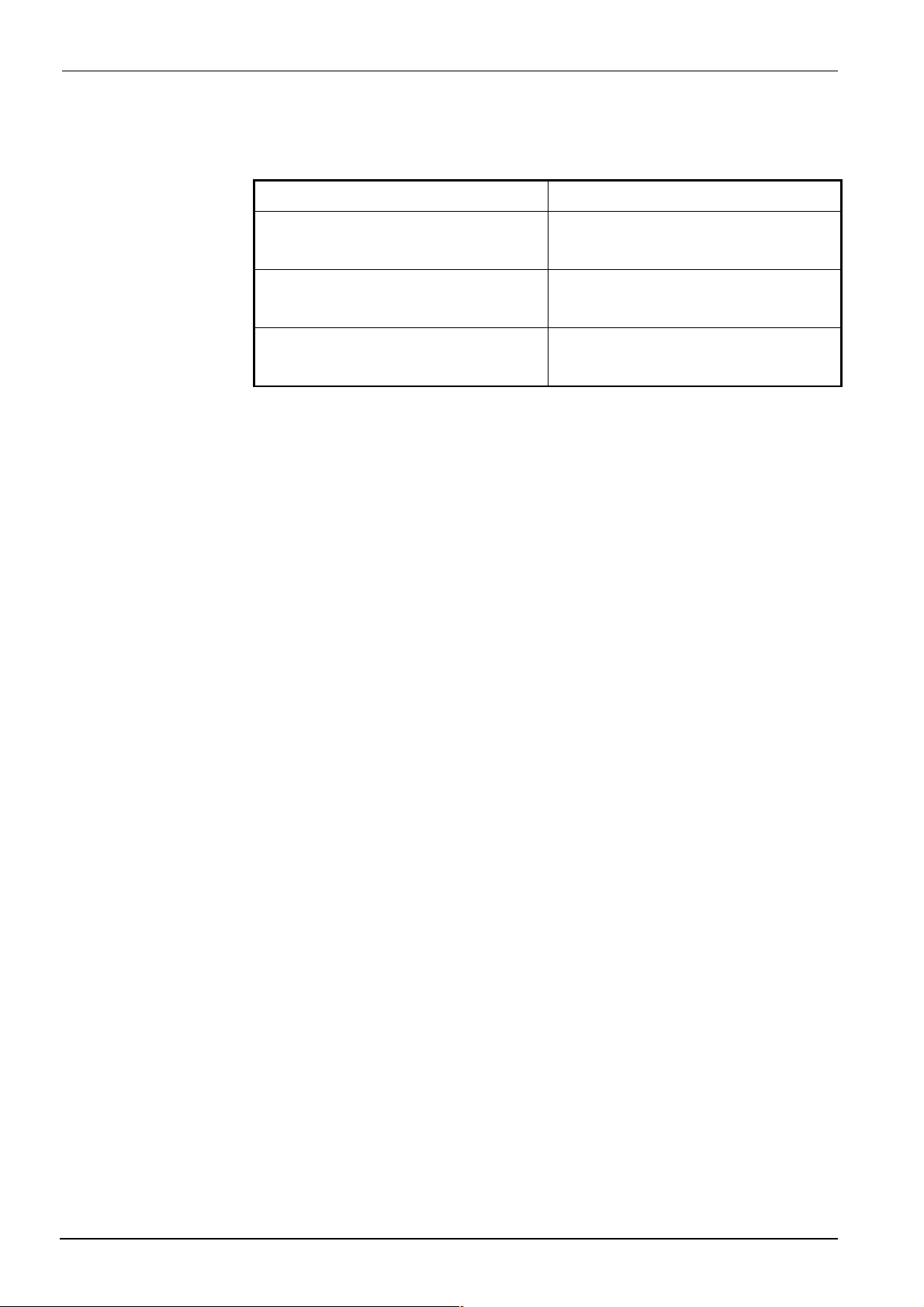

Type of unit Description

RWF40.000A97

RWF40.010A97 ¹·

RWF40.001A97

RWF40.011A97 ¹·

RWF40.002A97

RWF40.012A97 ¹·

¹· Packing variants

The supply voltage connected must match the voltage given on the type field.

Basic version with 3-position output

With additional modulating output

With additional modulating output and

RS-485 interface

*

The measured value range and the analog inputs are set at the factory.

Chapter 8 «Configuration»

Ö

Accessories

Adapter frame ARG40

which shall be converted to the RWF40... .

Bracket ARG41

DIN 46277.

Dummy cover AVA10.200/109

for plants where the pre-decessor model RWF32... was used,

for mounting the RWF40... on 35 mm DIN rails conforming to

for covering a control panel cutout for the RWF40...

8/56 CC1B7865E February 10, 2000 Landis & Staefa Division

Page 9

3.1 Installation site and climatic conditions

The installation site should be as free as possible from vibrations, dust and corrosive

−

media

The controller should be installed as far away as possible from sources of

−

electromagnetic fields, such as frequency converters or high-voltage ignition

transformers

Relative humidity: < 95 % (non-condensing)

Ambient temperature range: -20...+50 °C

Storage temperature range: -40...+70 °C

3.2 Dimensions

48

3. Installation

PGM

43,5

RWF40

EXIT

K6

96

15,5

91,5

112

Panel cutout to DIN 43700

+0,6

45

127,5

+0,8

92

7865m01e/0200

Landis & Staefa Division CC1B7865E February 10, 2000 9/56

Page 10

3.3 Side-by-side

If several controllers are mounted side-by-side or above one another in a control panel,

the minimum spacing must be observed, namely 30.5 mm vertically and 10.5 mm

horizontally.

3.4 Mounting in a panel cutout

Place the seal provided onto the controller housing.

✱✱✱✱

3. Installation

The unit must be installed with the seal

the housing!

*

Insert the controller from the front into the panel cutout.

✱✱✱✱

so that no water or oil can penetrate

7865z08/0200

✱✱✱✱

At the rear of the panel, push the fixing elements into the guide slots from the side

or top. The flat faces of the fixing elements must lie against the housing.

✱✱✱✱

Place the fixing elements against the rear of the panel, and tighten them evenly with

a screwdriver.

10/56 CC1B7865E February 10, 2000 Landis & Staefa Division

Page 11

3.5. Cleaning the front panel

The front panel can be cleaned with normal washing and rinsing agents or detergents.

not

It is

*

cleaning with high-pressure cleaners!

3.6 Removing the controller module

The controller module can be removed from the housing for servicing.

The rules of DIN EN 100 015 «Protection of electrostatically sensitive devices »

must be adhered to for internal work on the controller!

accepted for damage caused by electrostatic discharge.

3. Installation

resistant to corrosive acids, caustic solutions and abrasive cleaners, or

No liability

will be

7865z09/0200

✱✱✱✱

Press the ribbed surfaces together (at top and bottom) and pull out the controller

module.

Landis & Staefa Division CC1B7865E February 10, 2000 11/56

Page 12

4.1 Installation notes

4. Electrical connections

Safety regulations

Fusing

Interference suppression

The choice of cable, the installation and the electrical connections of the controller

−

must conform to the regulations of VDE 0100 «Regulations for the installation of

power circuits with nominal voltages below AC 1000 V», or appropriate local

regulations

The electrical connections may only be carried out by qualified personnel

−

If contact with live parts is possible while working on the unit, the controller must be

−

disconnected from the power supply at both poles

An internal current-limiting resistor interrupts the supply voltage in the event of a short-

−

circuit. The external fusing should not be rated above 1 A (slow). The output relays

must be fused for a maximum of 2 A to prevent contact welding in the event of a shortcircuit in the load circuit

Section 11.2 «Outputs»

Ö

No other loads may be connected to the supply terminals of the controller

−

The electromagnetic compatibility and interference suppression levels conform to

−

standards and regulations listed under «Technical data»

Chapter 11 «Technical data»

Ö

Input, output and supply cables should be routed separately, not parallel to one

−

another

Arrange sensor and interface cables as twisted and screened cables, and do not run

−

them close to power cables or components. Ground the screening to the controller

one end

Earth the «TE» terminal of the controller to the protective earth. This cable must have

−

a cross-sectional area that is at least as large as that of the supply cables. Earthing

cables must be wired in a star configuration to a common earthing point connected to

the protective earth of the supply. Earthing cables may not be looped from one

controller to another

to the «TE» terminal

at

Incorrect use

The unit is not suitable for installation in areas with an explosion hazard

−

Incorrect settings on the controller (setpoint, data of parameter and configuration

−

levels) can affect the proper functioning of the following process or lead to damage.

Safety devices that are independent of the controller, such as overpressure relief

valves or temperature limiters / monitors should therefore always be provided, and

only be capable of adjustment by qualified personnel. Please observe the appropriate

safety regulations. Since self-setting cannot be expected to handle all possible control

loops, the stability of the actual value that is produced should be checked

The analog inputs of the controller may not exceed a maximum voltage of AC 30 V or

−

DC 50 V against «TE»

Section 4.3 «Galvanic separation»

Ö

12/56 CC1B7865E February 10, 2000 Landis & Staefa Division

Page 13

4.2 Block diagram

4. Electrical connections

3 analog inputs

Input 1:

Actual value

for Pt100, Ni100, Pt1000,

Ni1000 thermocouples or

standard signals

Input 2:

External setpoint,

setpoint shift

for resistance 0 - 1 k ,

or linearised

standard signals

Input 3:

Outside temperature

for Pt1000, Ni1000

2 binary inputs

For potential-free

contacts

Input 1:

Operating mode

changeover

Input 2:

Setpoint shift / changeover

Ω

RWF40...

Release of burner

Output 1:

- Relay (N.O. contact)

3-position output

Output 2:

-Relay (reg. unit opens)

Output 3:

- Relay (reg. unit closes)

Limit comparator

Output 4:

- Relay (N.O. contact)

Transducer supply

DC 24 V, 30 mA

(short-circuit-proof)

Modulating output (optional)

Output 5:

Modulating output,

DC 0...10 V, DC 0...20 mA,

DC 4...20 mA

Operating voltage

AC 100 ...240 V,

±10 %, 48...63 Hz

7865f01e/0200

Serial interface (optional)

RS-485

MOD bus protocol

Baud rate 9600

Landis & Staefa Division CC1B7865E February 10, 2000 13/56

Page 14

4.3 Assignment of terminals

4. Electrical connections

Electrical connections may only be made

by qualified personnel!

X1+

X1-

G-

G+

GND

D1

D2

I1

M1

U1

G1+

XB6

M6

XU6

B9

M9

7865z07/1199

CB

CG

CA

TE

L1

N

Y2

Q

Y1

Q13

Q14

Q63

Q64

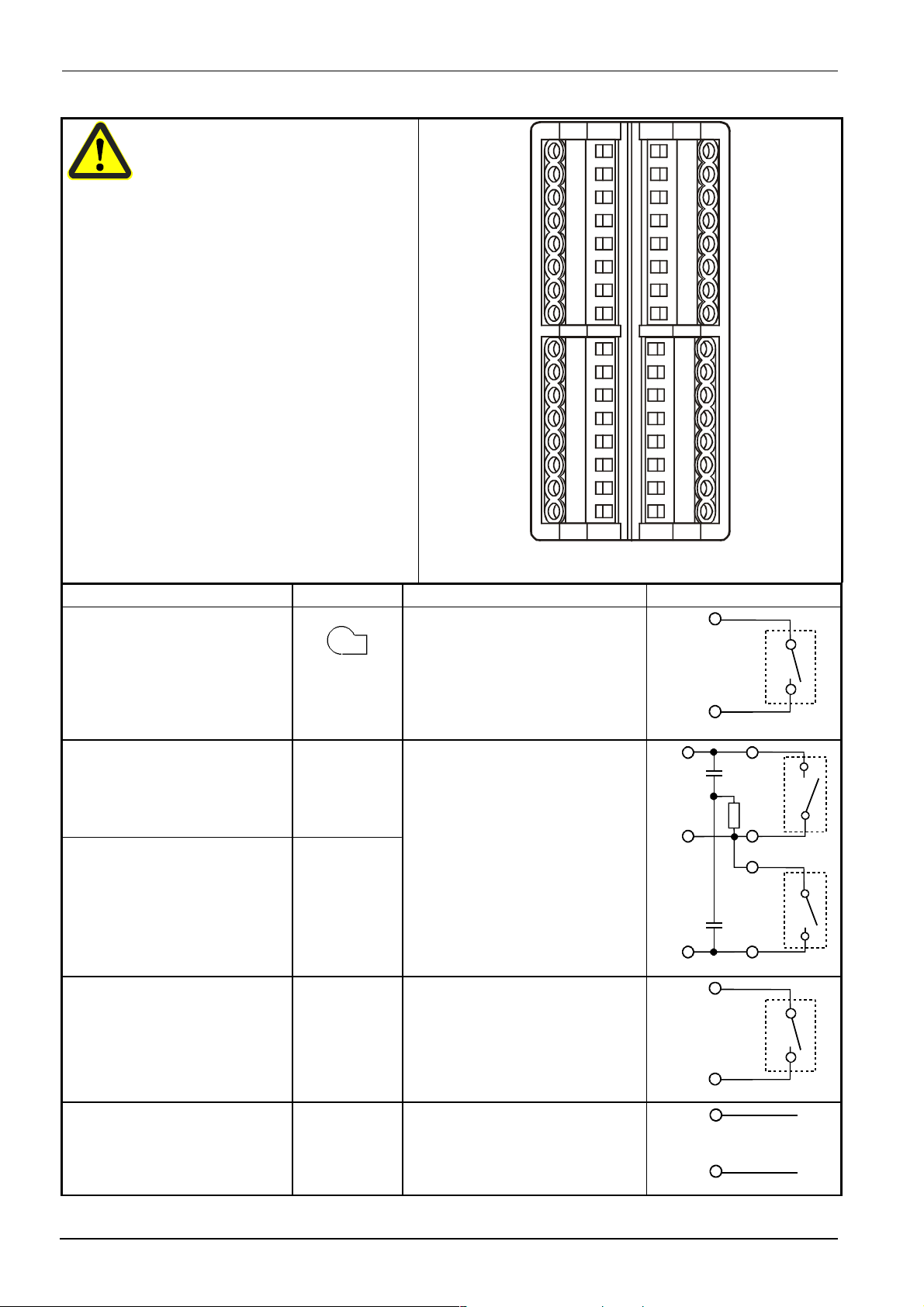

Outputs Display LED Terminal no. Connection diagram

Relay 1: release of burner

Contact protection:

Q14 pole

Q14

P

Varistor S07K275

S

Relay 2: regulating unit opens

Contact protection:

▲

Q13 N.O. contact

Y1 N.O. contact

Q13

7865a11/1199

Y1

S

RC unit

P

Q

Relay 3: regulating unit closes

Q common pole

▼

Contact protection:

RC unit

P

S

P

Relay 4: limit comparator

Contact protection:

Y2 N.O. contact

K6 Q64 pole

Y2

7865a16/1099

Q64

Varistor S07K275

S

Modulating output (optional)

Q63 N.O. contact

X1+

Q63

7865a15/1099

X1+

+

DC 0 (4)...20 mA, 0 (2)...10 V

X1-

X1-

7865a17/1099

-

14/56 CC1B7865E February 10, 2000 Landis & Staefa Division

Page 15

4. Electrical connections

Analog input 1 (actual value) Terminals Connection diagram

Thermocouple I1

I1

+

M1

Resistance thermometer in 3-wire circuit M1

G1+

I1

Resistance thermometer in 2-wire circuit, line

compensation through offset correction (OFF1)

Current input

DC 0...20 mA, 4...20 mA

Voltage input

DC 0...1 V, 0...10 V

M1

G1+

I1

M1

U1

M1

M1

7865a03/1099

M1

G1+

I1

7865a04/1099

M1

G1+

7865a05/1099

I1

M1

7865a06/1099

U1

M1

7865a07/1099

-

ϑ

ϑ

+

-

+

-

Analog input 2 (setpoint and setpoint shift) Terminals Connection diagram

Resistance potentiometer

Offset correction (OFF2)

Current input

DC 0..20 mA, 4...20 mA

Voltage input

DC 0...1 V, 0...10 V

Analog input 3 (outside temperature) Terminals Connection diagram

Resistance thermometer in 2-wire circuit, line

compensation through offset correction (OFF3)

XB6 start

M6 slider

M6 end

XB6

M6

XU6

M6

B9

XB6

M6

XB6

M6

7865a09/1099

XU6

M6

7865a10/1099

B9

A

S

E

7865a08/1099

ϑ

M9

M9

7865a13/1099

+

-

+

-

Landis & Staefa Division CC1B7865E February 10, 2000 15/56

Page 16

4. Electrical connections

Binary inputs Terminals Connection diagram

Operating mode selector

Section 5.2 «High-fire operation»

Ö

D1

D1

Setpoint shift / changeover

Sections 5.4.1...5.4.4

Ö

D2

D2

GND

Common ground

Operating voltage, interface Terminals Connection diagram

Operating voltage

AC 100...240 V ±10 %, 48...63 Hz

Technical earth

Operating voltage for transducer G+

Serial interface

RS-485

GND

L1 line

N neutral

TE

G-

CA

CB

CG

7865a12/1099

L1

N

TE

7865a18/1099

G+

DC 24 V / 30 mA

G-

7865a14/1099

RxD / TxD+

RxD / TxD-

GND

+

-

16/56 CC1B7865E February 10, 2000 Landis & Staefa Division

Page 17

4.4 Galvanic separation

4. Electrical connections

The diagram shows the maximum potential differences that may exist between the

function modules in the controller.

3 analog inputs

Input 1:

Actual value

for Pt100, Ni100,

Pt1000, Ni1000

thermocouples or

standard signals

Input 2:

External setpoint,

setpoint shift

for resistance 0...1 k ,

or standard signals

Input 3:

Outside temperature

for Pt1000, Ni1000

2 binary inputs

for potential-free contacts

operating mode

D1:

changeover

setpoint shift /

D2:

changeover

Ω

Limit comparator

Output 4:

- Relay (N.O. contact)

Release of burner

Output 1:

- Relay (N.O. contact)

3-position output

Output 2:

- Relay (reg. unit opens)

Output 3:

- Relay (reg. unit closes)

L1, N:

L1, N:

Transducer supply

DC 24 V , 30 mA

(short-circuit proof)

Modulating output

(optional)

Output 5:

Modulating output,

DC 0...10 V,

DC 0...20 mA, 4...20 mA

Serial interface

RS-485 (optional)

MOD bus protocol

baud rate 9600

Technical earth TE

Operating voltage

AC 100...240 V 10 %,

48...63 Hz

L1, N:

±

Max. insulation voltages:

DC 50 V

AC 400 V

AC 4000 V

7865f07e/1299

Landis & Staefa Division CC1B7865E February 10, 2000 17/56

Page 18

5.1 Low-fire operation

5. Operating modes

Low-fire operation means that only small amounts of heat are drawn from the boiler. A twoposition controller maintains the setpoint, switching the burner on and off like a thermostat.

Thermostat function

5.2 High-fire operation

This control mode is therefore also known as

thermostat function

. An adjustable

switching differential ensures that the switching frequency of the burner can be selected to

reduce wear.

Modulating and 2-stage operation:

HYS3

W

HYS1

7865w03/1099

Actual value between «HYS1» and

«HYS3»

High-fire operation means that large amounts of heat are drawn from the boiler, so that

the burner is on all the time. If the heating load during the thermostat operation rises to a

level where the actual value begins to fall below the switch-on threshold «HYS1», the

controller does not immediately switch over to a higher burner output, but first makes a

dynamic test of the control deviation and only switches to the higher output when an

adjustable threshold «Q» is exceeded (A).

Section 5.6 «Response threshold Q»

Ö

Operating mode

changeover

In high-fire operation, depending on the application, the burner can be fired in

−

modulating

operation. The binary input «D1» can be used to switch between modulating and twostage operation

When the contact is open: modulating burner operation

−

When the contact is closed: two-stage burner operation

−

5.2.1 Modulating burner, 3-position output

In diagram area (1), the thermostat function is active. The modulating mode of burner

operation is shown in area (2). In high-fire operation, a 3-position controller acts on an

actuator through relay 2 (open) and relay 3 (close).

HYS3

db

W

HYS1

In area (3), the actual value exceeds the upper switch-off threshold «HYS3» and the

controller switches off the burner (B). The controller only starts low-fire operation when

the level falls below the switch-on threshold «HYS1» again. If «Q» is exceeded, the

controller switches to high-fire operation (A).

two-stage

or

(1)

operation, with a larger amount of fuel than in low-fire

B

q

A

(2)

7865w07/1099

(3)

q

A

Section 5.6 «Response threshold Q»

Ö

18/56 CC1B7865E February 10, 2000 Landis & Staefa Division

Page 19

5.2.2 Modulating burner, modulating output

In diagram area (1), the thermostat function is active.

In area (2), the controller is controlling to the adjusted setpoint.

5. Operating modes

HYS3

W

HYS1

100%

X1

0%

The positioning signal is delivered as a standard signal via the modulating output.

)

Ö

The modulating controller must be available and configured in the unit (optional).

Section 8.2 «C112 Limit comparator, controller type, setpoint «SP1», locking»

5.2.3 Two-stage burner, 3-position output

In diagram area (1), the thermostat function is active.

In area (2), a

relay 3 (close) by switching it into the circuit at the switch-on threshold «HYS1» / and

out of circuit at the switch-off threshold «HYS2».

q

(1)

two-position controller

B

A

7865w05/1 099

q

A

(2)

acts on the second stage, via relay 2 (open) and

HYS3

HYS2

W

HYS1

I

II

q

A

(2)(1)

B

7865w06/1099

q

A

In area (3), the actual value exceeds the upper switch-off threshold «HYS3» and the

controller shuts down the burner (B). The controller only starts low-fire operation when

the level falls below the switch-on level «HYS1» again. If «Q» is exceeded, the

controller switches to high-fire operation (A).

Section 5.6 «Response threshold Q»

Ö

Landis & Staefa Division CC1B7865E February 10, 2000 19/56

Page 20

5.2.4 Two-stage burner, modulating output

In this case, a standard binary signal switches the second stage into circuit with analog

output «X1» on reaching the switch-on threshold «HYS1» and switches it out of circuit

at the lower switch-off threshold «HYS2».

5. Operating modes

5.3 Safety shutdown

Functions

X1

HYS3

HYS2

W

HYS1

100%

0%

(1)

B

q

A

(2)

7865w04/1099

q

A

The modulating controller must be available and configured in the unit

)

Ö

(optional).

Section 8.2 «C112 Limit comparator, controller type, setpoint «SP1», locking»

In the event of a sensor failure, the controller cannot monitor the actual value of the

boiler temperature (analog input 1). A safety shutdown is automatically carried out to

guard against overheating.

This also applies to the acquisition of the external setpoint at analog input 2.

Burner off

−

3-position output for closing the regulating unit

−

Self-setting is ended

−

Manual operation is ended

−

5.4 Pre-defined setpoint

The setpoint is pre-selected with the buttons or the interface within pre-set limits.

It is possible to shift the setpoint, by either an analog or a binary signal, to influence it

according to the weather or to change it with an external contact.

20/56 CC1B7865E February 10, 2000 Landis & Staefa Division

Page 21

5.4.1 Setpoint changeover «SP1 / SP2», analog setpoint shift

)

and

C111

described in chapter 8

C112

are

5. Operating modes

C111: XX1X ... XX3X

Outside sensor

Heating curve slope H

Setting: 0.0 ... 4.0

Weather-dependent

setpoint shift:

C112: XX0X

SP1 via buttons

C111: XXX2

Section 5.4.4 "External setpoint, binary

setpoint shift"

Setpoint SP2

SP2 via buttons

C111: X6XX ... XAXX

Analog setpoint shift

No Yes

C111: XXX1

Setpoint changeover

D2 open

D2 closed

C112: XX1X

SP1 via outside sensor

C111: XXX0

No function

+

The setpoints SP1 and SP2 are

entered at the user level.

Section 6.2 "User level"

Connection of binary input D2

Section 4.2 "Assignment of terminals"

7865f05e/1199

SPH

SPL

Active setpoint

Landis & Staefa Division CC1B7865E February 10, 2000 21/56

Page 22

5.4.2 Setpoint changeover «SP1» / external setpoint

and

)

C111

described in chapter 8

C112

5. Operating modes

C111: XX1X ... XX3X

Outside sensor

are

Heating curve slope H

Setting: 0.0 ... 4.0

Weather-dependent

setpoint shift:

C112: XX0X

SP1 via buttons

C111: X1XX ... X5XX

External setpoint

C111: XXX0

No function

No Yes

C111: XXX1

Setpoint changeover

D2 closed

C112: XX1X

SP1 from outside sensor

C111: XXX2

Section 5.4.4 "External setpoint, binary

setpoint shift"

D2 open

Setpoint SP1 is entered at the

user level

Section 6.2 "User level"

Connection of binary input D2

Section 4.2 "Assignment of terminals"

7865f03e/1199

SPH

SPL

Active setpoint

22/56 CC1B7865E February 10, 2000 Landis & Staefa Division

Page 23

5.4.3 Setpoint «SP1», analog / binary setpoint shift

and

)

C111

described in chapter 8

C112

5. Operating modes

C111: XX1X ... XX3X

Outside sensor

are

Heating curve slope H

Setting: 0.0 ... 4.0

Weather-dependent

setpoint shift:

C112: XX0X

SP1 via buttons

C111: X6XX ... XAXX

Analog setpoint shift

C111: XXX1

Sections 5.4.1 and 5.4.2

"Setpoint changeover ..."

D2 closed

dSP

No Yes

+

C111: XXX2

Binary setpoint shift

+

C112: XX1X

SP1 via outside sensor

C111: XXX0

No function

0,0

D2 open

The values dSP and SP1 are entered

at the user level

Section 6.2 "User level"

Connection of binary input D2

Section 4.2 "Assignment of terminals"

SPH

SPL

Active setpoint

7865f04e/1199

Landis & Staefa Division CC1B7865E February 10, 2000 23/56

Page 24

5.4.4 External setpoint, binary setpoint shift

5. Operating modes

)

and

C111

described in chapter 8

C112

are

C111: XXX1

Sections 5.4.1 and 5.4.2

"Setpoint changeover ..."

D2 closed

dSP

0

D2 open

The values dSP and SP1 are entered at

the user level

Section 6.2 "User level"

C111: X1XX ... X5XX

External setpoint

C111: XXX2

Binary setpoint shift

+

C111: XXX0

No function

SPH

SPL

Connection of binary input D2

Section 4.2 "Assignment of terminals"

7865f02e/1199

Active setpoint

24/56 CC1B7865E February 10, 2000 Landis & Staefa Division

Page 25

5.5 Weather-dependent setpoint shift

The RWF40... can be configured in such a way that if a Landis & Staefa Ni1000 outside

sensor (e.g. QAC22) is connected, a weather-dependent setpoint shift is implemented.

The minimum and maximum setpoint values can be set by the lower setpoint limit

«SPL» and the upper setpoint limit «SPH». Parameter «P» can be used to apply a

parallel displacement to the heating curve.

Each RWF40... must have its own separate outside sensor connected (no

*

parallel connection)!

5. Operating modes

Parallel displacement of

the heating curve

Chapter 7 «Parameter settings»

Ö

160

140

120

100

SPH

80

60

Boiler temperature setpoint (°C)

SPL

40

20

4

3.8

3.6

3.4

3.2

3

2.8

2.6

2.4

2.2

2

1.8

1.6

1.4

1.2

1

0.8

0.6

0.4

0.2

Heating curve slope

0

20

Landis & Staefa Division CC1B7865E February 10, 2000 25/56

15

17.5

10

12.5

5

7.5

Outside temperature (°C)

0

2.5

-2.5

-5

-10

-7.5

-12.5

-15

-20

-17.5

7865d02e/1199

Page 26

5.5.1 Heating curve slope

5. Operating modes

Slope «H» of the heating curve can be used to adjust the setpoint in response to the

outside temperature, as shown in the diagram. The common origin of the heating curves

is set at (20 °C / 20 °C). The effective range of the weather-adjusted setpoint is

restricted by the setpoint limits «

Setpoint (°C)

SPH»

H larger

and

«SPL»

.

HYS3

SPH

H smaller

HYS1

SPL

+20

+20

7865d01e/1199

«HYS1»

already described, they act with the set shift relative to the weather-controlled setpoint.

Ö

Ö

is the switch-on point for the burner, and «

Section 5.2.1 «Modulating burner, 3-position output»

Section 5.2.2 «Modulating burner, modulating output»

0

-1010

Outside temperature (°C)

HYS3»

is the switch-off point. As

26/56 CC1B7865E February 10, 2000 Landis & Staefa Division

Page 27

5.6 Response threshold «Q»

The response threshold «Q» defines how long and how low the actual value can drop

before the system switches over to high-fire operation.

An internal mathematical calculation using an integration function determines the sum of

all the areas Q

the control deviation (x-w) falls below the value for the switching threshold «HYS1». If

the actual value increases, integration is stopped.

If «Q

level), this causes the second stage of the burner to be switched on or - in the case of a

3-position controller / modulating controller – the regulating unit to open.

If the actual boiler temperature reaches the required setpoint, Q

HYS1

5. Operating modes

= Q1 + Q2 + Q3 , as shown in the diagram. This only takes place when

eff

» exceeds the pre-set response threshold «Q» (can be adjusted at the parameter

eff

is set to 0 .

eff

Temperature (°C)

x

w

Q

7865d19e/1199

1

Q

2

Q

3

Q = 0

eff

Actual value monitoring ensures that the switching frequency is kept low in the

transitional range from low- to high-fire operation in order to reduce wear.

t

Landis & Staefa Division CC1B7865E February 10, 2000 27/56

Page 28

5.7 Cold start of the plant

When a heating system is switched off for a longer period of time, the actual value will

fall.

To achieve a faster control response, the controller starts immediately in high-fire

operation as soon as the control deviation (x-w) has dropped below a certain limit value.

This limit is calculated as follows:

Limit value = 2 * (HYS1-HYS3)

5. Operating modes

Example

Operating mode: modulating, 3-position output

HYS1 = -3 K

HYS3 = +5 K

w = 60 °C

Limit value = 2 * (-3 - 5) = 2 * (-8) = -16 K

At an actual value below 44 °C, the heating up procedure starts immediately in high-fire

operation, instead of in thermostat mode.

°C

HYS3

W

X

HYS1

2 x (HYS1 - HYS3)

db

t

7865d20/10 99

28/56 CC1B7865E February 10, 2000 Landis & Staefa Division

Page 29

6. Operation

Assignment of levels

All levels can be accessed from the basic display via the

diagram.

The upper actual value display (red) indicates the actual value and the parameter values

for the various levels.

The setpoint and the parameters are indicated in the lower setpoint display (green).

PGM

button, as shown in the

BASIC DISPLAY

1.

Min. 2 s

USER

LEVEL

Min. 2 s

PARAMETER LEVEL

Min. 2 s

CONFIGURATION

LEVEL

7865f08e/1299

1.

or time-out (approx. 30 s)

1.

1)

After using «PGM» to step through all the parameters of a level, an automatic return

occurs after the last parameter has been confirmed.

Landis & Staefa Division CC1B7865E February 10, 2000 29/56

Page 30

6.1 Basic display

The diagram shows the RWF40... after switching on power. This condition is called the

basic display. The actual value and the currently active setpoint are shown here. Manual

operation, self-setting, the user, parameter and configuration levels can be activated

from here.

6.1.1 Meaning of the display and buttons

Actual value

display (red)

6. Operation

Release of burner

Regulating unit CLOSE / 1st stage

Regulating unit OPEN / 2nd stage

2-stage operation

503

Setpoint display

(green)

Decrease value

PGM button

639

Manual operation

Limit comparator

Increase value

EXIT button

7865p02e/0200

30/56 CC1B7865E February 10, 2000 Landis & Staefa Division

Page 31

6. Operation

Initialization

Manual operation

Self-setting function

Actual value display

flashes

2-stage operation

Time-out

All displays are lit up; the setpoint display flashes for about 10 seconds after switching

on power.

The actual value is indicated on the upper display. The LED for manual operation is on.

Depending on the operating mode and the type of controller, the setpoint or the level of

the manual actuator position is shown on the setpoint display (green).

Section 6.2.2 «Manual operation of a modulating burner»

Ö

The actual value is shown on the actual value display (red) and the text «

on the setpoint display (green).

Section 9.1 «Self-setting function in high-fire operation»

Ö

Chapter 10 «What to do if...»

Ö

Section 5.2 «High-fire operation»

Ö

If there is no action by the operator, the controller returns automatically to the

)

basic display after about 30 seconds.

tunE»

flashes

6.2 User level

6.2.1 Changing the

setpoints

This level is started from the basic display. Setpoints «SP1», «SP2 / dSP» can be

altered, and the analog inputs «E2» (external setpoint / setpoint shift) and «E3» (outside

temperature) can be displayed.

To alter «SP1», «SP2» or «dSP»:

Change to the user level with

✱✱✱✱

Alter the setpoint «SP1» with ▼ and

✱✱✱✱

Change to setpoint «SP2» or «dSP» with

✱✱✱✱

Alter the setpoint «SP2» or «dSP» with ▼ and

✱✱✱✱

Return to the basic display with

✱✱✱✱

After 2 seconds, the value that is set will automatically be adopted. The value

)

can only change within the permitted value range

PGM

▲

PGM

▲

EXIT

or automatically by time-out after about 30 s

Landis & Staefa Division CC1B7865E February 10, 2000 31/56

Page 32

Basic display

User level

(Display depends on

code 111)

6. Operation

60.3

65.0

PGM

EXIT

65.0

SP 1

PGM

Depending on the

configuration of

binary input 2:

- dSP

-Sp2

Measurement of the

outside temperature

via analog input 3

Measurement of the

external setpoint or

a setpoint shift

via analog input 2

7865f06e/1199

EXIT

70.0

SP 2

EXIT

10.0

50.0

SP.E

PGM

tA

PGM

PGM

or

10.0

dSP

32/56 CC1B7865E February 10, 2000 Landis & Staefa Division

Page 33

6.2.2 Manual operation, modulating burner

6. Operation

3-position controller

Modulating controller

Thermostat mode

Press

✱✱✱✱

The LED above the hand symbol lights up.

✱✱✱✱

Relay 2 opens the regulating unit as long as ▲ is pressed.

Relay 3 closes the regulating unit as long as ▼ is pressed.

The LEDs for the regulating units indicate if «OPEN» or «CLOSE» is activated.

Change the regulating unit’s position with ▲ and

✱✱✱✱

The modulating output delivers the regulating unit’s position that was entered.

Return to automatic operation by pressing

✱✱✱✱

)

Manual operation can only be activated if the thermostat function has set relay 1 to

active

If the thermostat function sets relay 1 to

operation is terminated.

EXIT

for 5 s

Change the regulating unit’s position with ▲ and

When manual operation is activated, the regulating unit’s position is set to 0

until another entry with the buttons is made.

.

inactive

EXIT

▼

▼

for 5 s

during manual operation, manual

6.2.3 Manual operation, two-stage burner

Press

✱✱✱✱

Press ▲ briefly

✱✱✱✱

Relay 2 is active, relay 3 is inactive

−

Analog output (optional) delivers DC 10 V

−

The regulating unit opens

Or press ▼ briefly

✱✱✱✱

Relay 2 is inactive, relay 3 is active

−

Analog output (optional) delivers DC 0 V

−

The regulating unit closes

Return to automatic operation by pressing

✱✱✱✱

)

EXIT

If the thermostat function sets relay 1 to

manual operation is terminated.

for 5 s

EXIT

for 5 s

inactive

during manual operation,

Landis & Staefa Division CC1B7865E February 10, 2000 33/56

Page 34

6.2.4 Start self-setting

6. Operation

Start self-setting with

✱✱✱✱

Cancel with

✱✱✱✱

PGM

7865z10/1199

When «

Accept the parameters that have been determined by pressing ▲ (press the button

✱✱✱✱

for at least 2 s!)

▲

tunE

» stops flashing, self-setting has stopped.

It is not possible to start «

PGM

+

▼

)

6.2.5 Display of the software version and unit of actual value

tunE

» in manual operation or thermostat operation.

PGM

PGM

+

+

▲

Press

✱✱✱✱

Available units:

°C, °F and % (for standard signals)

7865z11/1199

34/56 CC1B7865E February 10, 2000 Landis & Staefa Division

Page 35

6.3 Parameter level

6. Operation

The parameters involved in the adaptation of the controller to the controlled system are

set here after the system has been started up.

PGM

Within the level, you can proceed to the next parameter by pressing

.

6.3.1 Enter parameters

6.4 Configuration level

)

The entry and alteration of parameters is made through a continuous alteration of the

value. The longer you keep the button pressed, the faster the rate of change becomes.

✱✱✱✱

✱✱✱✱

✱✱✱✱

✱✱✱✱

)

Ö

The settings made here are those required for commissioning a specific installation and

therefore rarely need to be altered, such as acquisition of measured value or type of

controller.

Within the level, you can proceed to the next parameter by pressing

The display of the individual parameters depends on the type of controller.

Increase value by pressing

Reduce value by pressing

Accept entry by pressing

or

Cancel entry by pressing

After 2 seconds, the value that is set will automatically be accepted. The value

can only change within the permitted value range.

Chapter 7 «Parameter settings»

▲

▼

PGM

EXIT

PGM

.

6.4.1 Changing the configuration code

Select position by pressing ▼ (position flashes!)

✱✱✱✱

Alter value by pressing

✱✱✱✱

Accept code by pressing

✱✱✱✱

or

Cancel entry by pressing

✱✱✱✱

Chapter 8 «Configuration»

Ö

▲

PGM

EXIT

Landis & Staefa Division CC1B7865E February 10, 2000 35/56

Page 36

7. Parameter settings

The parameter is shown on the lower setpoint display (green) and the value on the

upper / actual value display (red).

10

AL

7865p06/0200

Parameter Display Value range Factory

setting

Limit value for limit

comparator

Switching differential

for limit comparator

1)

Proportional band

Derivative time

Integral action time

Contact spacing

(dead band)

1)

1)

1)

AL

HYSt

Pb.1

dt

rt

db

-1999...+9999 digit 0

0...999.9 digit 1 Switching differential at the edges for

0.1...999.9 digit 10 Affects the P-response of the controller

0...9999 s 80 Affects the D-response of the controller.

0...9999 s 350 Affects the I-response of the controller.

0...999.9 digit 1 For 3-position output

Remarks

Output 4

HYSt

7865d10e/0300

Chapter 8.2 «

Ö

comparator, controller type, setpoint

«SP1», locking»

the limit comparators

Chapter 8.2 «

Ö

comparator, controller type, setpoint

«SP1», locking»

Within dt = 0, the controller has no Dresponse.

For modulating controllers, dt = rt / 4 or

0 must be entered.

With rt = 0, the controller has no Iresponse

Y

100%

AL

db

w

C112

C112

Measured value

– limit

– limit

W

-100%

7865d11/1099

1)

This parameter is affected by the setting of the decimal place.

36/56 CC1B7865E February 10, 2000 Landis & Staefa Division

X

Page 37

7. Parameter settings

The parameter is shown on the lower / setpoint display (green) and the value on the

upper / actual value display (red).

10

AL

7865p06/0200

Parameter

Actuator running

time

Switch-on threshold

for burner stage II

Switch-off threshold

stage II

Upper switch-off

threshold

Response threshold

Heating curve slope

Parallel

displacement

1)

1)

1)

1)

Display

tt

HYS1

HYS2

HYS3

q

H

P

1)

This parameter is affected by the setting of the decimal place.

Value range Factory

setting

10...3000 s 15 s Utilized running time of the valve for

0...-199.9 digit -5

0...HYS3 digit 3

0...999.9 digit 5

0...999.9 0

0...4 1

-90...+90 0

Remarks

3-position controllers

Section 5.5.1 «Heating curve slope»

Ö

Section 5.2 «High-fire operation»

Ö

Section 5.2 «High-fire operation»

Ö

Section 5.6 «Response threshold

Ö

Q»

Section 5.5.1 «Heating curve slope»

Ö

Section 5.5 «Weather-dependent

Ö

setpoint shift»

Landis & Staefa Division CC1B7865E February 10, 2000 37/56

Page 38

8.1 C111 inputs

0000

C111

Analog input 1

Pt100, 3-wire 0

Pt100, 2-wire 1

Ni100, 3-wire 2

Ni100, 2-wire 3

Pt1000, 3-wire, Landis & Staefa IEC 751 4

Pt1000, 2-wire, Landis & Staefa IEC 751 5

Ni1000, 3-wire, DIN 43760 6

Ni1000, 2-wire, DIN 43760 7

Ni1000, 3-wire, Landis & Staefa 8

Ni1000, 2-wire, Landis & Staefa 9

NiCr-Ni / K A

Cu-CuNi / T b

NiCroSil-NiSil / N C

Fe-CuNi / J d

Standard signal DC 0…20 mA E

Standard signal DC 4…20 mA F

Standard signal DC 0…10 V G

Standard signal DC 0…1 V H

8. Configuration

7865p03/0200

Analog input 2

No function 0

External setpoint, 1 kΩ resistance potentiometer 1

External setpoint, DC 0…20 mA 2

External setpoint, DC 4…20 mA 3

External setpoint, DC 0…10 V 4

External setpoint, DC 0…1 V 5

Analog setpoint shift, 1 kΩ resistance potentiometer 6

Analog setpoint shift, DC 0…20 mA 7

Analog setpoint shift, DC 4…20 mA 8

Analog setpoint shift, DC 0…10 V 9

Analog setpoint shift, DC 0…1 V A

38/56 CC1B7865E February 10, 2000 Landis & Staefa Division

Page 39

8. Configuration

0000

C111

Analog input 3

No function 0

Outside sensor Pt1000, 2-wire, Landis & Staefa IEC 751 1

Outside sensor Ni1000, 2-wire, DIN 43760 2

Outside sensor Ni1000, 2-wire, Landis & Staefa 3

Function of binary input «D2»

7865p03/0200

No function 0

Setpoint changeover 1

Setpoint shift (binary) 2

Factory setting 9 0 3 0

Landis & Staefa Division CC1B7865E February 10, 2000 39/56

Page 40

8. Configuration

0

8.2 C112 limit comparator, controller type, setpoint «SP1», locking

0000

C112

Limit comparator

No function (lk off) 0

lk1, input 1 1

lk2, input 1 2

lk3, input 1 3

lk4, input 1 4

lk5, input 1 5

lk6, input 1 6

lk7, input 1 7

lk8, input 1 8

lk7, input 2 9

lk8, input 2 A

lk7, input 3 b

lk8, input 3 C

7865p04/020

Controller type

3-position controller 0

Modulating controller DC 0…20 mA 1

Modulating controller DC 4…20 mA 2

Modulating controller DC 0...10 V 3

Setpoint «SP1»

«SP1» via buttons 0

«SP1» with outside sensor (analog input 3 must be configured) 1

Locking

No locking 0

Locking of configuration level 1

Locking of parameter level 2

Locking of buttons

Locking of the buttons can be entered only

*

all button operations are locked and can only be enabled again by the manufacturer!

Factory setting 0 0 1 0

once

and adapted with

PGM

. After this,

3

40/56 CC1B7865E February 10, 2000 Landis & Staefa Division

Page 41

8. Configuration

Function Ik1

Function Ik2

Window function:

around the setpoint (w).

Example: w = 80 °C, AL = 5,

Measured value rising: relay «K6» switches on at 76 °C and off at 86 °C.

Measured value falling: relay «K6» switches on at 84 °C and off at 74 °C.

Output 4

relay «K6» is active when the measured value lies within a window

HYSt

= 2

AL

HYSt

7865d10e/0300

As for lk1, but with inverted switching function.

Output 4

w

Measured value

AL

Function Ik3

HYSt

7865d09e/0300

HYSt

= switching differential of the window edges

AL

= interval from setpoint (half the window-width)

Lower limit signaling

Function: relay inactive when measured value < (setpoint – limit value).

Example: w = 80 °C, AL = 10,

Measured value rising: relay «K6» switches on at 71 °C.

Measured value falling: relay «K6» switches off at 69 °C.

Output 4

HYSt

w

= 2

AL

HYSt

Measured value

7865d04e/0300

Landis & Staefa Division CC1B7865E February 10, 2000 41/56

w

Measured value

Page 42

8. Configuration

Function Ik4

Function Ik5

As for lk3, but with inverted switching function.

Output 4

AL

HYSt

7865d03e/0300

HYSt

= switching differential

AL

= interval from setpoint

Chapter 7 «Parameter settings»

Ö

Upper limit signaling

Function: relay inactive when measured value > (setpoint + limit value).

Example: w = 80 °C, AL = 10,

Measured value rising: relay «K6» switches off at 91 °C.

Measured value falling: relay «K6» switches on at 89 °C.

HYSt

w

= 2

Measured value

Function Ik6

Output 4

AL

HYSt

7865d05e/0300

As for lk5, but inverted switching function.

Output 4

w

AL

HYSt

7865d06e/0300

w

Measured value

Measured value

42/56 CC1B7865E February 10, 2000 Landis & Staefa Division

Page 43

8. Configuration

Function Ik7

Function Ik8

The switching point is independent of the controller setpoint; only the limit value «

determines the switching point.

Function: relay is active when measured value > limit value.

Example: AL = 50,

Measured value rising: relay «K6» switches on at 51 °C.

Measured value falling: relay «K6» switches off at 49 °C.

Output 4

HYSt

= 2

HYSt

7865d07e/0300

Measured value

AL

As for lk7, but with inverted switching function.

Output 4

AL»

HYSt

7865d08e/0300

AL

HYSt

= switching differential

AL

= limit value

Chapter 7 «Parameter settings»

Ö

Measured value

Landis & Staefa Division CC1B7865E February 10, 2000 43/56

Page 44

8. Configuration

8.3 C113 instrument address, dimensional unit, out-of-range

The setting for the decimal place affects actual

*

value-dependent parameters!

0000

C113

Unit address

Address 0 0 0

Address 1 01

... ...

Address 99 99

7865p05/0200

*

Decimal places, dimensional unit

No decimal place, °C 0

One decimal place, °C 1

No decimal place, °F 2

One decimal place, °F 3

Signal for out-of-range

Limit comparators OFF 0

Limit comparators ON 1

Factory setting 0 1 1 0

44/56 CC1B7865E February 10, 2000 Landis & Staefa Division

Page 45

8.3.1 «SCL» scaling of standard signal range start, analog input 1

8. Configuration

Example

8.3.2 «SCH» scaling of standard signal range end, analog input 1

Example

SCL = 20; SCH = 100 °C

0 mA

(start) corresponds to a measured value of 20 °C

0 mA 20 mA

0 °C 20 °C 100 °C

Value range: -1999...+9999 digit

Factory setting: 0 digit

SCH = 80; SCL = 0 °C

20 mA

(end) corresponds to a measured value of 80 °C

0 mA 20 mA

0 °C 80 °C 100 °C

Value range: -1999...+9999 digit

Factory setting: 100 digit

8.3.3 «SCL2» scaling of standard signal range start, analog input 2

Example

SCL2 = 20:

0 mA

corresponds to a measured value of 20 °C, as already described

Value range: -1999...+9999 digit

Factory setting: 0 digit

Landis & Staefa Division CC1B7865E February 10, 2000 45/56

Page 46

8.3.4 «SCH2» scaling of standard signal range end, analog input 2

8. Configuration

Example

8.3.5 «SPL» lower setpoint limit

8.3.6 «SPH» upper setpoint limit

8.3.7 «OFF1» actual value correction for analog input 1

SCH2 = 80:

20 mA

Value range: -1999...+9999 digit

Factory setting: 100 digit

The controller restricts the setpoints to the value that is set.

Value range: -1999...+9999 digit

Factory setting: 0 digit

The controller restricts the setpoints to the value that is set.

Value range: -1999...+9999 digit

Factory setting: 100 digit

corresponds to a measured value of 80 °C, as already described

The actual value correction can be used for correction of the measured value upwards

or downwards by a specific amount. It is also used for line compensation when

resistance thermometers are connected in a 2-wire circuit.

Value range: -1999...+9999 digit

Factory setting: 0 digit

Example

8.3.8 «OFF2» actual value correction for analog input 2

8.3.9 «OFF3» actual value correction for analog input 3

Measured value Offset Displayed value

294.7 +0.3 295

295.3 -0.3 295

Value range: -1999...+9999 digit

Factory setting: 0 digit

Value range: -1999...+9999 digit

Factory setting: 0 digit

nd

8.3.10 «dF1» 2

46/56 CC1B7865E February 10, 2000 Landis & Staefa Division

order digital filter for analog input 1

Value range for filter time constant: 0...100 s

Factory setting: 1 s

Page 47

9.1 Self-setting function in high-fire operation

tunE»

«

is only possible in high-fire operation, in the «modulating burner» mode.

)

9. Self-setting function

The self-setting function «

the controller. In the «modulating» mode of operation, «

controlled system to steps of the positioning signal according to a special procedure. A

complex control algorithm uses the response of the controlled system (actual value) to

calculate and store the control parameters for a PID or PI controller (set dt = 0!). The

tunE»

«

procedure can be repeated as often as required.

tunE»

is a pure software function unit that is integrated into

tunE»

tests the response of the

Self-setting Start

PID controller

settings

Identification of

the controlled

system

W

Controller

Controlled

system

X

7865f09e/1199

Y

Two procedures

tunE»

The «

depending on the dynamic state of the actual value and the difference from the setpoint

at the start. «

If there is a

activated, a switching line is established around which the controlled variable performs

forced oscillations during the self-setting procedure. The switching line is set at such a

level that the actual value should not exceed the setpoint.

function uses two different methods that are automatically selected

tunE»

can be started from within any dynamic actual value sequence.

large difference between actual value and setpoint

when «

tunE»

is

x

Start

w

Switching

level

7865d12e/1199

With a

controlled system has stabilized, a forced oscillation is performed around the setpoint.

small deviation

between setpoint and actual value, for instance when the

t

Landis & Staefa Division CC1B7865E February 10, 2000 47/56

Page 48

9. Self-setting function

x

Start

w

Conditions

7865d13/1099

The controlled system data which are recorded for the forced oscillations are used to

calculate the controller parameters «rt, dt, Pb.1» and a filter time constant for actual

value filtering that is optimized for this controlled system.

High-fire operation in the «modulating burner» mode.

−

The thermostat function (relay 1) must be constantly activated, otherwise «

−

be cancelled and no optimized controller parameters will be adapted

The above mentioned actual value oscillations during self-setting may not exceed the

−

upper threshold of the thermostat function (increase if necessary, and lower the

setpoint)

t

tunE»

will

48/56 CC1B7865E February 10, 2000 Landis & Staefa Division

Page 49

9.2 Checking the controller parameters

The optimum adjustment of the controller to the controlled system can be checked by

recording a startup sequence with the control loop closed. The following diagrams

indicate possible incorrect adjustments, and their correction.

9. Self-setting function

Example

w

x

7865d17/1099

x

rd

The response to a setpoint change is shown here for a 3

PID controller. The method used for adjusting the controller parameters can, however,

also be applied to other controlled systems.

A favourable value for «dt» is «rt» / 4.

«PB too small» «PB too large»

order controlled system for a

x

w

t

«rt, dt» too small «rt, dt» too large

7865d15/1099

x

t

w

7865d16/1099

x

w

7865d18/1099

w

t

Optimum adjustment

7865d14/1099

t

t

Landis & Staefa Division CC1B7865E February 10, 2000 49/56

Page 50

10. What to do, if ...

10.1 ...numbers are flashing on the display

This is an indication that a measured value is not being acquired correctly.

The detection of measured value range crossings depends on the type of

)

Ö

Display Description Cause / controller behavior / remedy

1999

60.0

7865p08/0200

1999

tA

sensor used.

Section 11.3.2 «Measured value circuit monitoring»

Actual value display

(red) shows «1999»

flashing.

Setpoint display shows

the setpoint.

When analog input 3 is

configured for outside

temperature (C111) and

the measured value is

called up, the actual

value display (red)

shows «1999» flashing.

*

*

Overrange or underrange on analog

input 1.

The actual value is not being measured.

Controller initiates lockout.

Section 5.3 «Safety shutdown»

Ö

The limit comparator responds to analog

input 1 according to the configuration

(C113).

Check the electrical connections for

✱✱✱✱

open-circuit of sensor

Overrange or underrange on analog

input 3.

The outside temperature is not being

measured!

The weather-dependent setpoint is

inactive!

Check the electrical connections for

✱✱✱✱

open-circuit of sensors

7865p10/0200

1999

SP.E

7865p09/0200

53.2

1999

When analog input 2 is

configured (C111) and

the measured value is

called up, the process

value display (red)

shows «1999» flashing.

Actual value display

(red) shows «XXXXXX».

Setpoint display (green)

shows «1999» flashing.

*

*

Overrange or underrange on analog

input 2.

The external setpoint is not being

measured. Controller initiates lockout

Section 5.3 «Safety shutdown»

Ö

Check the electrical connections for

✱✱✱✱

open-circuit of sensors

Overrange or underrange on analog

input 2.

The setpoint shift is not being measured.

Controller initiates lockout

Section 5.3 «Safety shutdown»

Ö

Check the electrical connections for

✱✱✱✱

open-circuit of sensor

7865p 07/0200

50/56 CC1B7865E February 10, 2000 Landis & Staefa Division

Page 51

11.1 Inputs

11.1.1 Analog input 1 (actual value)

For resistance thermometers, thermocouples or standard signals with 2nd order digital

filter (configurable).

11. Technical data

Resistance thermometers

Thermocouples

Standard signals

In 2-wire or 3-wire circuit:

Type Measured value range

Pt100, Pt1000 -200...+850 °C

Ni100, Ni1000 DIN 43760 -60...+250 °C

Ni1000 from Landis & Staefa -50...+160 °C

Line resistance

Line compensation

Not required for a 3-wire circuit.

When using a resistance thermometer in a 2-wire circuit, line compensation can only be

made by means of the offset correction.

Type Measured value range

Fe-CuNi «J» -200...+1000 °C

NiCr-Ni «K» -200...+1372 °C

Cu-CuNi «T» -200...+400 °C

NiCrSi-NiSi «N» -100...+1300 °C

Cold-junction temperature

Signal Internal resistance Ri

DC 0...10 V Ri = 2 M

DC 0...1 V Ri = 2 M

DC 0...20 mA

DC 4...20 mA

: < 30

Ω

: internal

Voltage drop

Ue = < 1 V

∆

Ue = < 1 V

∆

Ue

∆∆∆∆

Ω

Ω

Sampling time: 210 ms

11.1.2 Analog input 2 (external setpoint, setpoint shift)

Resistance measured value 0…1 kΩ standard signals without linearization.

Potentiometer

Standard signals

With 2-wire circuit

R = 0…1 k

Signal Internal resistance Ri

DC 0...10 V Ri = 2 M

DC 0...20 mA

DC 4...20 mA

Sampling time: 630 ms

Ω

Voltage drop

Ue = 1 V

∆

Ue = 1 V

∆

Ue

∆∆∆∆

Ω

Landis & Staefa Division CC1B7865E February 10, 2000 51/56

Page 52

11.1.3 Analog input 3 (outside temperature)

For resistance thermometers in a 2-wire circuit, with fixed filter time constants

(21 h 18 min for the weather-dependent setpoint enable)

11. Technical data

Resistance thermometer

Type Measured value range

Pt1000 -200...+850 °C

Ni1000 DIN 43760 -60...+250 °C

Ni1000 from Landis & Staefa -50...+160 °C

Sampling time: 6 s

11.1.4 Binary input «D1»

11.1.5 Binary input «D2»

Potential-free contact for operating mode changeover:

Modulating burner, when the contact is open, LED on the front is not lit

−

2-stage burner, when the contact is closed, LED on the front is lit

−

Potential-free contact for the following functions, depending on the configuration:

No function

−

Setpoint shift

−

Setpoint changeover

−

11.2 Outputs

4 relay outputs, 1 modulating analog output (optional) and a transducer supply are

provided as standard.

11.2.1 Output 1 (release of burner)

Relay output (N.O. contact)

Contact rating:

Contact life:

Internal contact protection:

11.2.2 Output 2, 3 (3-position output)

2 relay outputs (N.O. contacts) with a common pole, for regulating unit open / close

Contact rating:

Contact life:

Internal contact protection:

11.2.3 Output 4 (limit comparator)

Relay output (N.O. contact)

Contact rating:

Contact life:

Internal contact protection:

AC 24…240 V, 2 A at p.f. (cos ϕ) > 0.6

> 2 x·10

5

switching cycles at rated load

Varistor S07K275

AC 24…240 V, 2 A at cos ϕ > 0.6

> 2 x·10

5

switching cycles at rated load

RC combination (C = 2.5 nF, R = 100 Ω)

AC 24…240 V, 2 A at cos ϕ > 0.6

> 2 x·10

5

switching cycles at rated load

Varistor S07K275

52/56 CC1B7865E February 10, 2000 Landis & Staefa Division

Page 53

11.2.4 Output 5, modulating output (option)

Continuous output, electrically isolated from the analog inputs:

U < AC 30 V , ∆U < DC 50 V

∆

Standard signals Load, burden

DC 0…10 V (short-circuit-proof) Load = > 500

DC 0…20 mA Burden = < 500

DC 4…20 mA Burden = < 500

11. Technical data

Ω

Ω

Ω

Accuracy:

11.2.5 Transducer supply

DC 24 V, 30 mA (short-circuit-proof)

11.2.6 Interface RS-485 (optional)

Baud rate:

Protocol:

Unit address:

Galvanic separation between supply voltage, analog inputs and outputs.

Section 4.3 «Galvanic separation»

Ö

11.3 General ratings

Weight:

0.25 %, ±50 ppm / K

±

9600

MOD bus

1…99

approx. 430 g

Data backup:

Operating voltage:

Power consumption:

Electrical connection:

Electrical safety:

Case:

EEPROM

AC 100…240 V ±10 %, 48…63 Hz

approx. 5 VA

at the rear, via pug-in screw terminal strips, angled

at 45°

to EN 60730

mounting depth 130 mm

plastic body with rear panel, self-extinguishing

flammability class: UL94 V0

seal between case and control panel

Landis & Staefa Division CC1B7865E February 10, 2000 53/56

Page 54

11.3.1 Measured value accuracy

11. Technical data

Resolution:

Measured value accuracy Ambient temperature error

Resistance thermometer:

0.05 %

≤

Thermocouples:

0.25 %

≤

Standard signals:

0.1 %

≤

The values include the linearization tolerances.

11.3.2 Measured value circuit monitoring

Transducer Probe break Short-circuit

Resistance thermometer X X

Thermocouples X DC 0…10 V - DC 0…20 mA - DC 4…20 mA X X

> 15 bit

50 ppm / K

≤

100 ppm / K

≤

100 ppm / K

≤

- = is