Page 1

Installation Instruct ions

1

2

9

10

1

4

3

6

4

1

3

6

2

1

1

2

7

8

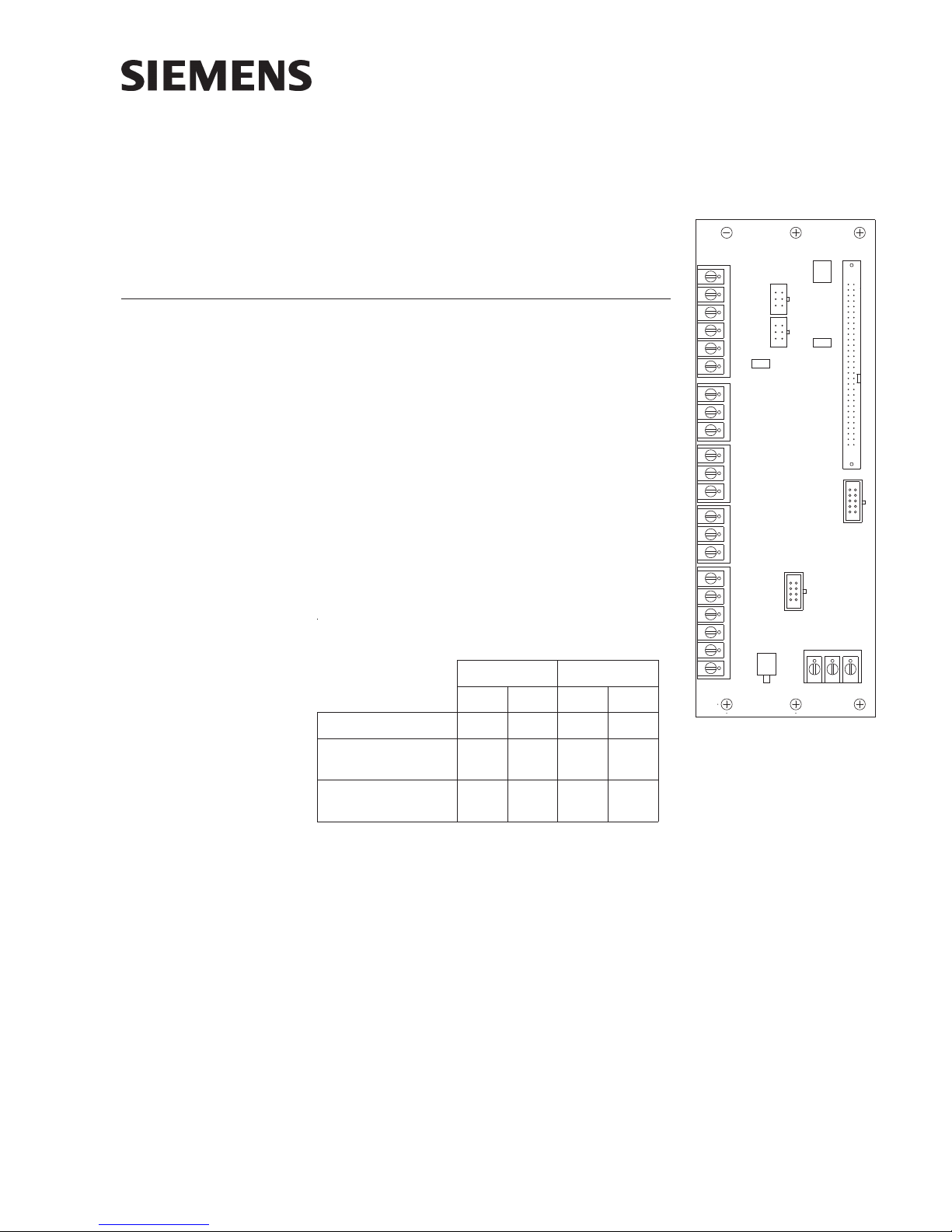

Model RNI

Remote Network Interface

INTRODUCTION The Model RNI from Siemens Industry, Inc., allows for

the remote installation of the PMI/PMI-2/PMI-3, Global

PMI/PMI-2/PMI-3 (on XNET), SSD-C-REM (on HNET),

and the LVM/LCM-8/SCM-8/FCM-6/SIM-16/OCM-16

(on CAN) modules. When used in a REMBOX4, the

FMT and LVM are also supported.

The HNET/XNET can be wired either Style 4 or Style

7. The RNI must be placed in between two NIC-Cs

when used in a Style 7 Network with the Global PMI/

PMI-2/PMI-3 (on XNET) or the SSD-C-REM (HNET).

When using the PMI/PMI-2/PMI-3, the RNI may be

located in the middle or at the end of the HNET. Refer

to the table below for the allowable locations of

modules at the end of a HNET or XNET.

TB6

TB5

TB4

TB3

P6

P4

P3

X

H

OFF

P7

P5

ON

JP1

P1

RNI

P2

afodnEehttatnemecalPeludoM

krowteNTENXroTENH

TENHTENX

TB2

24 V

S1

TB1

4elytS7elytS4elytS7elytS

MER-C-DSSYN**

3-IMP/2-IMP/IMP

)TENH(

)TENX(3-IMP/2

YY* *

-IMP/IMPLABOLG

**YN

krowtensihtnodewollatoN*,dewollA=Y,dewollatoN=N

Figure 1

RNI Remote Network

Interface

The CAN network may only be wired Style 4. The RNI may be located at the end or in

the middle of a CAN network. A 24VDC input is also required. This can be obtained

from the PSC-12 power limited output (TB3) or any 24 VDC UL/ULC regulated, power

limited power supply listed for fire protective signaling use. Audio signals for the LVM

and FMT are connected to TB1 of the PSC-12.

The RNI mounts in the rear of either the REMBOX2 or REMBOX4 enclosures. It can

also be installed in a CAB1, CAB2, or CAB3 using the mounting plate RNI-CAB-BRKT.

The RNI provides terminal blocks for all field wiring connections. Internal connections

are made to plug in connectors specifically provided for each of the installed modules.

The HNET/XNET and the CAN networks can be used simultaneously.

P/N 315-033420-13

Building Building

Building

Building Building

Siemens Siemens

Siemens

Siemens Siemens

TT

ecec

hnologies Dihnologies Di

T

ec

hnologies Di

TT

ecec

hnologies Dihnologies Di

IndustryIndustry

Industry

IndustryIndustry

visionvision

vision

visionvision

,,

Inc. Inc.

,

Inc.

,,

Inc. Inc.

Page 2

+

–

PRE-INSTALLATION P7 enables or disables an audible device similar to the CSB. This audible sounds

whenever a switch is pressed on either the LVM, SCM-8 or the FCM-6. If this is not

desired the audible can be silenced by changing the jumper installed on P7 to

positions 2 and 3. P7 is configured in the factory (positions 1 and 2) to have the

audible active.

S1 is used to terminate the HNET/XNET. If the RNI is installed at the end of an HNET

network, S1 must be set to the ON position. If the RNI is in the middle of the HNET/

XNET, set S1 to the OFF position.

P5 must be set to the HNET (H) position to select HNET or the XNET (X) position to

select XNET. Only one network, either HNET or XNET, can be used.

INSTALLATION

Remove all system power before installation, first battery then AC. (To power up,

connect the AC first, then the battery.)

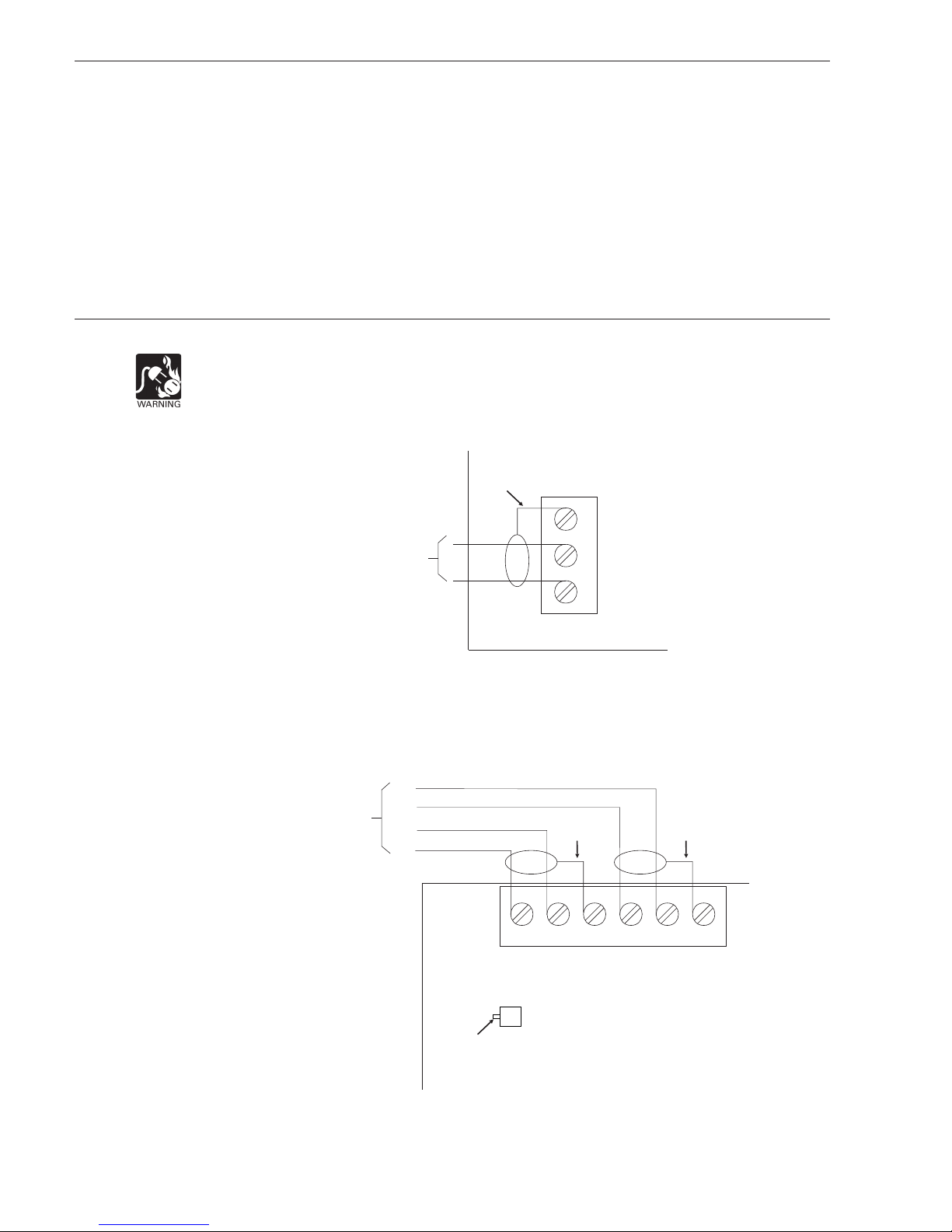

RNI

SHIELD

NOTES:

1. 14-18 AWG.

2. 2A max. input current.

3. Supervised

4. Refer to PSC-12/PSX-12

Installation Instructions,

P/N 315-033060 for

connection to TB3 and

ground fault detection

impedance.

NOTES:

1. No EOLR required.

2. 18 AWG min., 14 AWG max.

3. 2000 feet max. per pair.

4. Use twisted pair (Style 4/7)

or twisted shielded pair

(Style 4 only).

5. Power limited to NFPA 70

per NEC 760.

6. Refer to NIC-C Installation

Instructions, P/N 315033240 for connection of

A and B pairs and ground

fault detection impedance.

7. Omit B pair for Style 4.

8. All wiring supervised.

TO PSC-12 TB3

OR ANY UL/ULC

REGULATED,

POWER LIMITED

POWER SUPPLY

LISTED FOR FIRE

PROTECTIVE

SIGNALING USE

S3

24 V

–

2

1

+

TB1

Figure 2

Connecting The 24VDC Input

B+

FROM

NIC-C

B–

A+

A–

SHIELD

SHIELD

TB2

5

B+

6

S

PRESS

DOWN

1

A–

S1

2

A+

SET TO ON

4

3

B–

S

RNI

Figure 3

Connecting HNET/XNET At The End Of The Network (Style 4 and Style 7)

(HNET PMI/PMI-2/PMI-3 Only For Style 7)

Siemens Industry, Inc.

Building Technologies Division

P/N 315-033420-132

Page 3

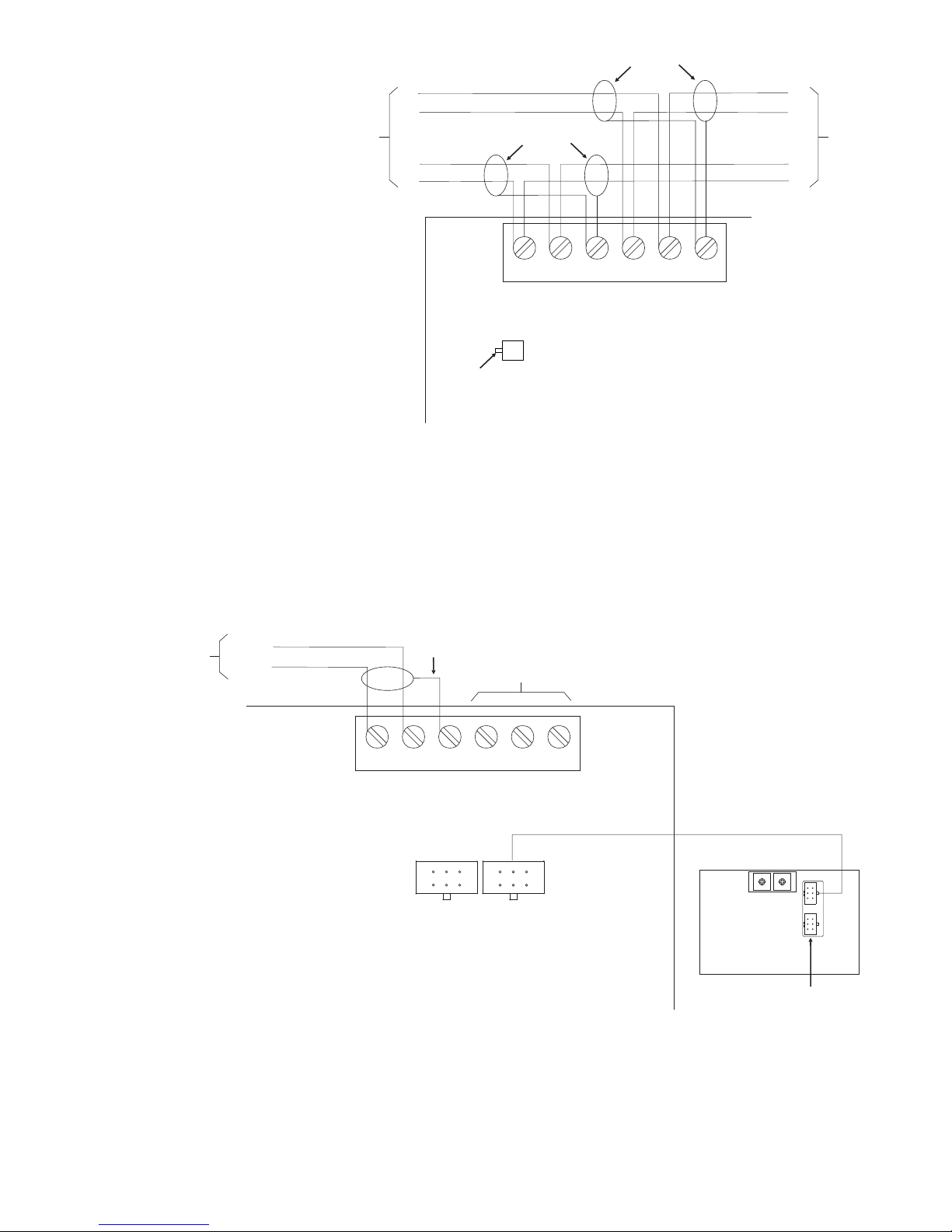

SHIELD

1

4

3

6

4

1

3

6

P3 P4

CAN +

CAN –

SHIELD

FROM

PSC-12

TB1

1

C+

2

C–

CCL (SUPPLIED WITH THE RNI)

3

S

4

C+

5

C–

6

S

RNI

TB6

DO NOT

USE

DO NOT

USE

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

LCM-8

OR

SCM-8

INSTALL

CAN TERMINATOR

P/N 110-134215

(SHIPPED WITH NIC-C)

MOUNT TO ID-MP

ON INNER DOOR

OF REMBOX2/4

†

†

NOTES:

1. No EOLR required.

2. 18 AWG min., 14 AWG max.

3. 2000 feet max. per pair

between NIC-Cs.

4. Use twisted pair (Style 4/7)

or twisted shielded pair

(Style 4 only).

5. Power limited to NFPA 70

per NEC 760.

6. Refer to NIC-C Installation

Instructions, P/N 315033240 for connection of

A and B pairs and ground

fault detection impedance.

7. Omit B pair for Style 4.

8. All wiring supervised.

B+

B–

A+

A–

FROM

NIC-C

OR RNI

B+

B–

SHIELD

A+

A–

TB2

5

B+

RNI

6

S

PUSH

UP

1

A–

S1

2

A+

SET TO OFF

4

3

B–

S

Figure 4

Connecting HNET/XNET In The Middle Of The Network (Style 4 and Style 7)

TO NEXT

NIC-C

OR RNI

NOTES:

1. 18 AWG min., 14 AWG max.

2. 15 ohms max. for CAN

network.

3. Use twisted pair or twisted

shielded pair.

4. Power limited to NFPA 70

per NEC 760.

5. Refer to NIC-C Installation

Instructions, P/N 315033240 for connection of

CAN–, CAN+.

6. Only 1 SCM-8 shown. SCM8, LCM-8, FCM-6, OCM-16,

SIM-16 all allowed.

7. All field wiring supervised.

8. Refer to PSC-12 Installation

Instructions, P/N 315033060 for ground fault

detection impedance.

Siemens Industry, Inc.

Building Te chnologies Division

Figure 5

Connecting CAN At The End Of The Network

P/N 315-033420-133

Page 4

FROM

PSC-12

TB1

CAN –

CAN +

NOTES:

1. 18 AWG min., 14 AWG max.

2. 15 ohms max. for CAN

network.

3. Use twisted pair or twisted

shielded pair.

4. Power limited to NFPA 70

per NEC 760.

5. Refer to NIC-C Installation

Instructions, P/N 315033240 for connection of

CAN–, CAN+.

6. Only 1 SCM-8 shown.

SCM-8, LCM-8, FCM-6,

OCM-16, SIM-16 all allowed.

7. All field wiring supervised

8. Refer to PSC-12 Installation

Instructions, P/N 315033060 for ground fault

detection impedance.

SHIELD

SHIELD

CAN +

CAN –

TB6

6

5

4

3

2

1

S

C–

C+

S

C–

C+

CCL*

3

1

4

6

3

1

4

6

P3 P4

RNI

CCL*

*ONLY 1 CCL, P/N 599-634214 IS SUPPLIED WITH THE RNI

Figure 6

Connecting CAN In The Middle Of The Network

TO NEXT

RNI

†

0

0

1

1

9

9

2

2

8

8

3

3

7

7

4

4

6

6

5

5

†

LCM-8

OR

SCM-8

MOUNT TO ID-MP

ON INNER DOOR

OF REMBOX2/4

NOTES:

1. 18 AWG min., 14 AWG max.

2. 15 ohms max. per pair.

3. Use twisted shielded pair for

LVM microphone and

monitor speaker.

4. Use twisted pair or twisted

shielded pair for phone.

5. Power limited to NFPA 70

per NEC 760.

6. Microphone and phone

circuits are supervised.

7. Monitor speaker is NOT

supervised.

8 Refer to LVM Installation

Instructions, P/N 315-034090.

9. Refer to FMT Installation

Instructions, P/N 315-034100.

10. No End Of Line devices

required.

11. Refer to PSC-12 Installation

Instructions, P/N 315033060 for ground fault

detection impedance.

Figure 7

Connecting The LVM and FMT

Siemens Industry, Inc.

Building Technologies Division

P/N 315-033420-134

Page 5

The RNI mounts on studs in the rear of either the REMBOX2 or the REMBOX4. Four

#8/32 nuts are provided with the RNI. (Refer to the REMBOX2/REMBOX4 Installation

Instructions, P/N 315-033772.) For Global PMI/PMI-2/PMI-3 applications the RNI can

also be installed in a CAB1/CAB2/CAB3 using mounting plate, RNI-CAB-BRKT, P/N

500-650062. (Refer to RNI-CAB-BRKT Installation Instructions, P/N 315-050062.)

Install the RNI with the terminal blocks facing up to allow for easier connection of the

field wiring.

Connecting PMI/PMI-2/PMI-3 A 40 inch long 60 wire cable, P/N 555-133743 (shipped with the PMI/PMI-2/PMI-3),

connects the RNI to the PMI/PMI-2/PMI-3. Connect one end of the cable to JP1 on

the RNI and the other end of the cable to either JP3 on the PMI or J2 on the PMI-2/

PMI-3. Be sure that the PMI/PMI-2/PMI-3 address agrees with the ZEUS configuration. Refer to the PMI Installation Instructions, P/N 315-033070, the PMI-2 Installation

Instructions, P/N 315-050636, or the PMI-3 Installation Instructions, Document ID

A6V10446194.

Connecting The Optional Connect the HTSW-1 (required for UL1076) to P6 on the RNI using the connector

HTSW-1 Tamper Switch supplied with HTSW-1. Refer to the REMBOX Installation Instructions, P/N 315-

033772 and the HTSW-1 Installation Instructions, P/N 315-033350.

Connecting The Mount the LCM/SCM/FCM to the ID-MP (Refer to the LCM/SCM/FCM Installation

LCM/SCM/FCM Instructions, P/N 315-033040). Mount the ID-MP to the inner door of the REMBOX2/4.

Connecting The Mount the SSD-C-REM to the inner door of the REMBOX2/4. Using the 8-wire cable

SSD-C-REM supplied with the SSD-C-REM, connect the SSD-C-REM to P2 on the RNI.

POST-INSTALLATION Before applying power to the RNI check the following:

• Ensure that the 24VDC power input on TB1 is connected and that the

polarity is correct.

• Check the setting of S1. If the RNI is at the end of the HNET is must be set

to on. If the RNI is in the middle of the HNET/XNET it must be set to off. If

the HNET/XNET is not used the position of S1 does not matter.

• Check the position of P5. It must be set to H for HNET or X for XNET.

• Check the CAN termination. If the RNI is at the end of the CAN network, a

CAN terminator (P/N110-134215, supplied with the NIC-C) must be installed

into the last CAN module in the REMBOX.

If the RNI is in the middle of the CAN network no CAN terminators can be

installed. If CAN is not used then the terminator can be stored in P4. It will

be needed if CAN modules are added to the REMBOX at a later time. Refer

to the NIC-C Installation Instructions P/N 315-033240 for examples of CAN

installation and termination.

• Check the setting of P7. If the local sound is required, make sure P7 is set to

ON. Otherwise, set it to OFF.

COMPATIBILITY The RNI is compatible with the FireFinder XLS HNET, XNET and CAN networks only.

The RNI can not be used with the MXL MNET.

Siemens Industry, Inc.

Building Te chnologies Division

P/N 315-033420-135

Page 6

ELECTRICAL RATINGS

tnerruCenalPkcaBV420

tnerruCV42lanimreTwercS*.xaMAm03

tnerruCenalPkcaBV2.60

tnerruCybdnatSV42*.xaMAm03

etwercsCDV42ehtedulcnioteruseB.ylnotnerrucINR*

lanimr

snoitaluclacyrettabrosnoitaluclacgnidaolylppusrewop

.

rewoPtuptuO

gnimrofrepnehwseludomNACdnaTENX/TENHrehtollaroftnerruc

riaP

krowteNNACdnaTENX/TENHhcaE

tkaepV8

.xamkaepo

.xamAm57

)noissimsnartgsmgnirud(

Siemens Industry, Inc.

Building Technologies Division

P/N 315-033420-136

Page 7

CYBER SECURITY DISCLAIMER

Siemens products and solutions provide security functions to ensure the secure

operation of building comfort, fire safety, security management and physical security

systems. The security functions on these products and solutions are important

components of a comprehensive security concept.

It is, however, necessary to implement and maintain a comprehensive, state-of-theart security concept that is customized to individual security needs. Such a security

concept may result in additional site-specific preventive action to ensure that the

building comfort, fire safety, security management or physical security system for

your site are operated in a secure manner. These measures may include, but are not

limited to, separating networks, physically protecting system components, user

awareness programs, defense in depth, etc.

For additional information on building technology security and our offerings, contact

your Siemens sales or project department. We strongly recommend customers to

follow our security advisories, which provide information on the latest security

threats, patches and other mitigation measures.

http://www.siemens.com/cert/en/cert-security-advisories.htm

Siemens Industry, Inc.

Building Te chnologies Division

P/N 315-033420-137

Page 8

THIS PAGE HAS BEEN LEFT INTENTIONALLY BLANK.

For CE applications in Siemens E100 systems refer to

Installation Instruction A24205-A334-B844 (English) or A24205-A334-A844 (German).

Siemens Industry, Inc.

Building Technologies Division

Florham Park, NJ

Siemens Canada, Ltd.

1577 North Service Road East

Oakville, Ontario

L6H 0H6 Canada

I BT FS SYS MCH

D-81379 München

P/N 315-033420-13Siemens AG

Document ID A6V10239117

Loading...

Loading...