Page 1

RL 147 Positioning Relay Calibration

Product Description

This sheet provides the instructions to calibrate the

RL 147 Positioning Relay after it has been mounted

on an actuator.

Product Number

NOTE:

Installation Instructions

Document No. 129-125

Rev. 5, June, 2000

In some cases, the actuator stem travel or

stroke is not identical to the nominal value

of the relay feedback spring. See

Calculating The Span Setting

the span setting on the feedback arm.

to determine

147-2000

Required Tools

•

Medium flat-blade screwdriver

•

Tubing, pressure gauge, and squeeze bulb

(Part of Calibration kit 832-177)

•

Two 5/8-inch open end wrenches

•

Two 7/16-inch open end wrenches for valve

stems of 1/4-inch diameter

Expected Installation Time

10 Minutes

Prerequisites

•

For field installed relays, mount the

positioning relay on the actuator according

to the instructions that are packaged with

the mounting kit.

•

Check that you have the correct feedback

spring(s) attached.

−

If the positioning relay is mounted on a

valve, see

−

If the stroke of the No. 6 damper

actuator has been adjusted, see

Table 1

Identify the desired operating span and the start

point pressure.

Tables 4 and 6.

.

Installation

Setting the span

The positioning relay operating span can be set for

spans of 3 to 12 psig (21 to 83 kPa).

For spans of 3 through 10 psig (21 to 69 kPa)

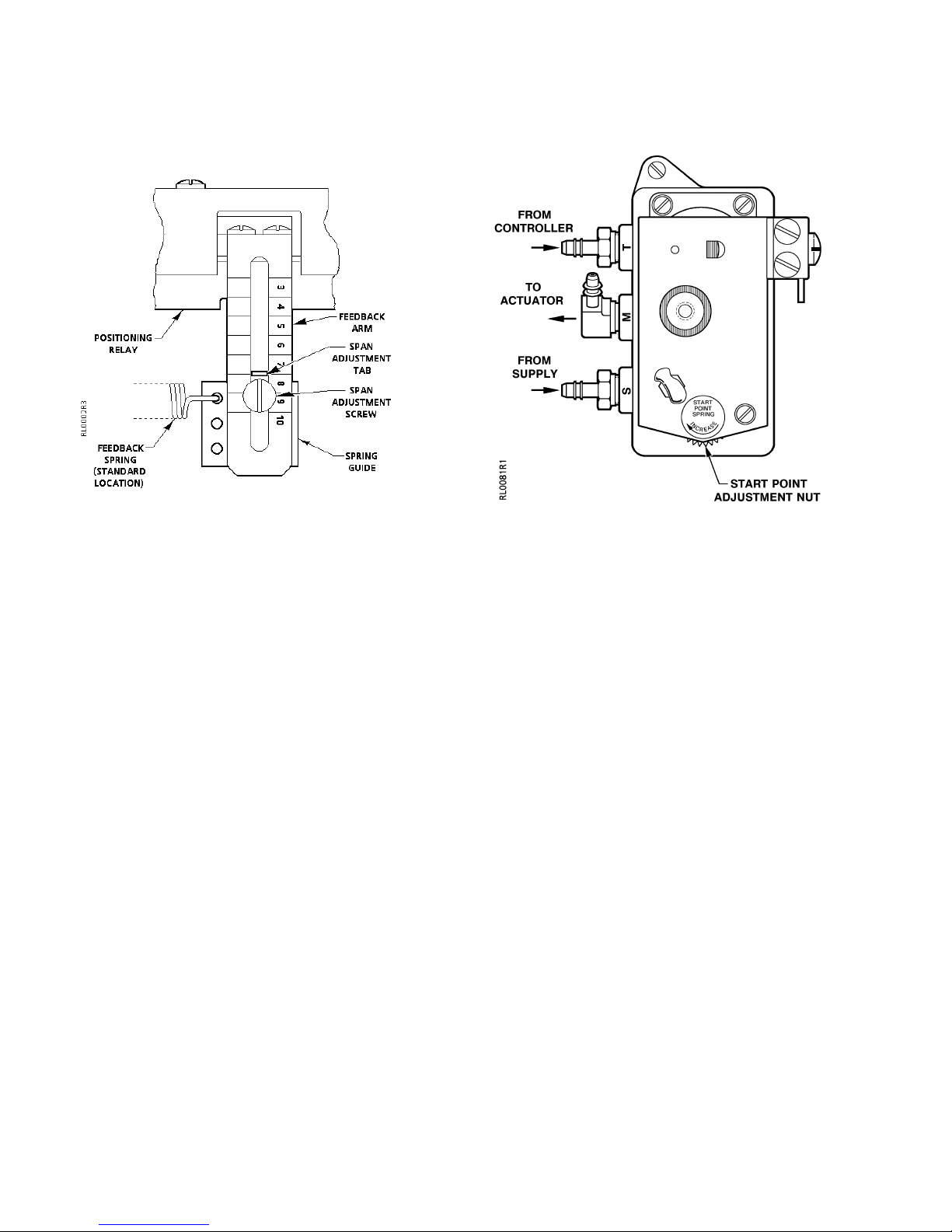

1. Check that the feedback spring is attached to

the spring guide in the hole across from the

span adjustment screw. This is identified as the

standard location in

2. With a screwdriver, loosen the span adjustment

screw. Move the spring guide on the feedback

arm until the span adjustment tab is at the

desired span setting reference number.

NOTE:

3. Tighten the span adjustment screw.

4. The feedback spring must be parallel to the

actuator shaft or valve stem. Use the open end

wrenches to loosen the hex nuts holding the

spring arm in position on the shaft or stem.

Align the feedback spring and tighten the hex

nuts.

5. The feedback spring should have no slack or no

stretch in it. Adjust the wing nuts and

adjustment nut, if necessary.

The line to the left of the number is the

setting.

(See

Figure 1.

Figure 1

)

Page 1 of 5

Page 2

Document No. 129-125

Installation Instructions

Rev. 5, June, 2000

Installation, Continued

Figure 1. Span Adjustment.

Shown at Span Setting 8.

For spans of 11 or 12 psig (76 or 83 kPa)

Figure 2. Start Point Adjustment

1. Move the span adjustment tab to the 10 setting

on the feedback arm. Follow steps 2 and 3 for

Setting the span

2. Move the feedback spring one hole away from

the standard location for a span of 11 psig

(76 kPa) and two holes away from the standard

spring location for a 12 psig (83 kPa) span. See

Figure 1

3. Follow steps 4 and 5 for

.

Adjusting the start point

The positioning relay can be adjusted to start

actuator movement at pressures between 3 and 10

psig (21 and 69 kPa).

1. Remove the relay cover.

2. Attach tubing with a pressure gauge and

squeeze bulb to the "T" port. Supply air should

be attached to the "S" port. The "M" port should

be attached to the connector on the actuator.

3. Using the squeeze bulb, apply pressure to the

relay. Watch the valve stem or actuator shaft to

see when it begins to move. Check the

pressure gauge; this is the start point pressure.

4. If this is not the desired start point pressure,

turn the start point adjustment nut (

clockwise to increase the start point pressure

and counterclockwise to decrease the pressure.

.

Setting the span

Figure 2

(see

.

Figure 2

)

)

Adjusting the span

1. Using the squeeze bulb, apply pressure to the

relay. Note the pressure at which the stem or

shaft begin to move.

2. Continue to apply pressure until the stem or

shaft completes its full stroke. Note the

pressure.

3. The difference between the two pressures is

the

span.

4. If the span is not the desired span, move the

spring guide to a higher reference number to

increase the span or lower number to decrease

the

span. See

5. Repeat steps 1 through 4 until you get the

desired

6.

If you have moved the spring guide, adjust the

spring arm so that the spring is parallel to the

stem or shaft.

7.

Check the feedback spring. There should be no

slack nor stretch in it. Adjust the wing nuts and

adjustment nut, if necessary.

8. Fasten the relay cover. Fill in the information on

the calibration label.

9. Attach the air line from the controller to the "T"

port.

Figure 1

span.

Setting the Span

and

.

5. Repeat steps 3 and 4 until the stem or shaft

begins to move at the desired pressure.

Page 2 of 5

Siemens Building Technologies, Inc.

Page 3

Document No. 129-125

Installation Instructions

Rev. 5, June, 2000

Installation, Continued

Table 1. Spring Selection for Adjustable Stroke

of the No. 6 Damper Actuator.

Actuator

Stroke

3-1/4 to 4

(82 to 102)

2-29/32 to

3-1/4

(74 to 82)

Dimensions in inches (millimeters).

Feedback Spring

Color Nominal Max

Blue 4

(102)

Cadmium 3

(76)

4-1/4

(108)

3-1/4

(82)

Adjusting

Screw

4-1/2 (114)

long

1-3/4 (44)

long

Calculating the span setting

1. Identify the stem/stroke travel from

3, 5, or 6.

2. If the stem travel matches a nominal spring

travel listed in

Table 4

there is no need to

calculate a new span setting.

3. If the stem travel does not match a nominal

spring travel listed in

Table 4

spring(s) whose maximum allowable travel is

equal to or greater than the actual stem travel.

4. Calculate the span setting with the following

formula:

Tables 1, 2,

, chose the

Formula for Span Setting

Span

setting

=

Desired

span

Nominal sp ring travel

Actuator stroke

Example:

Determine the span setting for a valve

having a desired span of 5 psig and

5/16-inch stroke.

Select a spring with a maximum allowable range

equal to or larger that the stroke. Use the 1/4-inch

spring with a 3/8-inch maximum allowable travel

range. See

Span

setting

Table 4

=5 x

.

0.25

=4

0.312

Set the span adjustment tab to line 4 on the

feedback arm to provide a 5 psig span for this valve.

Table 2. Stem Travel for VF 599 Valve Bodies.

Stem Travel in Inches (mm)Line size

in Inches

(mm)

1/2 through 2

(15 though 50)

2-1/2 (65) 3/4 (20) 3/4 (20)

3 (80) 3/4 (20) 3/4 (20)

4 (100) – 1-1/2 (40)

5 (125) – 1-1/2 (40)

6 (150) – 1-1/2 (40)

8-inch

Actuator

3/4 (20) –

12-inch

Actuator

Table 3. Stem Travel Listed by Valve Type.

Line Size

Inches

(mm)

1/2 (13) 3/8 (9.5) – 1/8 (3.2) – – –

3/4 (19) 3/4 (19) – 3/16 (4.8) – – –

1 (25) 3/4 (19) 3/16 (4.8) 1/4 (6.4) – – –

1-1/4 (32) 1 (25) 1/4 (6.4) 5/16 (7.9) – – –

1-1/2 (38) 1 (25) 1/4 (6.4) 5/16 (7.9) – – –

2 (51) 1 (25) 3/8 (9.5) N.O.

2-1/2 (64) 5/8 (16) 3/8 (9.5) N.O.

3 (76) 3/4 (19) 9/16 (14) 3/4 (19) 1-1/8 (29) 3/4 (19) 1 (25)

4 (102) 1 (25) 9/16 (14) 1 (25) 1-1/4 (32) 1-1/8 1-3/8 (35)

5 (127) – – – 1-1/2 (38) 1-1/4 (32) 1-3/8 (35)

6 (152) – – – 1-1/2 (38) 1-1/4 (32) 1-3/8 (35)

8 (203) – – – – 1-1/2 (38) –

VP 591

Single Seat

Double Seat

5/16 (7.9) N.C.

5/16 (7.9) N.C.

Siemens Building Technologies, Inc.

Flowrite™ Valve Stem Travel in Inches (mm)

VP 591

VP 591

WM

5/16 (7.9) – – –

5/8 (16) 1-1/8 (29) 3/4 (19) 1 (25)

VP 593

Single Seat

VP 593

Double Seat

VP 593

WM

Page 3 of 5

Page 4

Document No. 129-125

Installation Instructions

Rev. 5, June, 2000

Table 4. Spring Selection.

Spring Travel Range Recommended Springs

Nominal

Inches (mm)

5/32 (5.0) 1/4 (6.4) 147-298 Small Green

1/4 (6.4) 3/8 (9.5) 147-289 Small Cadmium Plate

3/8 (9.5) 1/2 (13) (2)147-298 Small Green

1/2 (13) 3/4 (19) (2)147-289 Small Cadmium Plate

3/4 (19) 1 (25) 147-290 1-3/8" Red

1 (25) 1-1/4 (32) 147-291 Long Green

1-1/4 (32) 1-5/8 (41) 147-289

1-1/2 (38) 2 (51) (2)147-290 Small Red

1-3/4 (44) 2-1/4 (57) 147-290

2 (51) 2-1/2 (64) (2)147-291 Long Green

2-3/8 (60) N/A 147-105 2" Red

3 (76) 3-1/4 (83) 147-292 Long Cadmium Plate

3-3/4 (95) 4 (102) 147-301 3" Red

4 (102) 4-1/4 (108) 147-293 Blue

4 (102) 6 (152) 147-313 Zinc PI. or Yell. Chr.

7 (178) 12-1/4 (311) 147-330 Zinc Plate

Max. Allowable

Inches (mm)

Part No. Size & Color

Small Cadmium Plate

plus

147-291

plus

147-291

plus

Long Green

Small Red

plus

Long Green

Flowrite

Product

Number

599-05920 3/4 (20)

599-05921 3/4 (20)

599-05922 1-1/2 (40)

599-05923 1-1/2 (40)

599-05924 1-1/2 (40)

599-05930 3/4 (20)

599-05931 3/4 (20)

599-05932 1-1/2 (40)

599-05933 1-1/2 (40)

599-05934 1-1/2 (40)

599-05940 3/4 (20)

599-05941 3/4 (20)

599-05942 1-1/2 (40)

599-05943 1-1/2 (40)

599-05944 1-1/2 (40)

599-05950 3/4 (20)

599-05951 3/4 (20)

599-05952 1-1/2 (40)

599-05953 1-1/2 (40)

599-05954 1-1/2 (40)

599-05960 3/4 (20)

599-05961 3/4 (20)

599-05962 1-1/2 (40)

599-05963 1-1/2 (40)

599-05964 1-1/2 (40)

Stem Travel

Inches

(mm)

Table 5 Flowrite 599 Valve Body Listed by Product Number.

Flowrite

Product

Number

599-05970 3/4 (20)

599-05971 3/4 (20)

599-05972 1-1/2 (40)

599-05973 1-1/2 (40)

599-05974 1-1/2 (40)

599-05980 3/4 (20)

599-05981 3/4 (20)

599-05982 1-1/2 (40)

599-05983 1-1/2 (40)

599-05984 1-1/2 (40)

599-05990 3/4 (20)

599-05991 3/4 (20)

599-05992 1-1/2 (40)

599-05993 1-1/2 (40)

599-05994 1-1/2 (40)

599-06040 3/4 (20)

599-06041 3/4 (20)

599-06042 1-1/2 (40)

599-06043 1-1/2 (40)

599-06044 1-1/2 (40)

599-06050 3/4 (20)

599-06051 3/4 (20)

599-06052 1-1/2 (40)

599-06053 1-1/2 (40)

599-06054 1-1/2 (40)

Stem Travel

Inches

(mm)

Flowrite

Product

Number

599-06060 3/4 (20)

599-06061 3/4 (20)

599-06062 1-1/2 (40)

599-06063 1-1/2 (40)

599-06064 1-1/2 (40)

599-06070 3/4 (20)

599-06071 3/4 (20)

599-06072 1-1/2 (40)

599-06073 1-1/2 (40)

599-06074 1-1/2 (40)

599-06120 3/4 (20)

599-06121 3/4 (20)

599-06122 1-1/2 (40)

599-06123 1-1/2 (40)

599-06124 1-1/2 (40)

599-06130 3/4 (20)

599-06131 3/4 (20)

599-06132 1-1/2 (40)

599-06133 1-1/2 (40)

599-06134 1-1/2 (40)

599-06140 3/4 (20)

599-06141 3/4 (20)

599-06142 1-1/2 (40)

599-06143 1-1/2 (40)

599-06144 1-1/2 (40)

Stem Travel

Inches

(mm)

Flowrite

Product

Number

599-06150 3/4 (20)

599-06151 3/4 (20)

599-06152 1-1/2 (40)

599-06153 1-1/2 (40)

599-06154 1-1/2 (40)

599-06160 3/4 (20)

599-06161 3/4 (20)

599-06162 1-1/2 (40)

599-06163 1-1/2 (40)

599-06164 1-1/2 (40)

599-06165 3/4 (20)

599-06166 3/4 (20)

599-06167 1-1/2 (40)

599-06168 1-1/2 (40)

599-06169 1-1/2 (40)

599-06170 3/4 (20)

599-06171 3/4 (20)

599-06172 1-1/2 (40)

599-06173 1-1/2 (40)

599-06174 1-1/2 (40)

599-06175 3/4 (20)

599-06176 3/4 (20)

599-06177 1-1/2 (40)

599-06178 1-1/2 (40)

599-06179 1-1/2 (40)

Stem Travel

Inches

(mm)

Page 4 of 5

Siemens Building Technologies, Inc.

Page 5

Flowrite

Product

Number

Stem Travel

Inches

(mm)

591-6480 5/8 (16)

591-6490 3/4 (19)

591-6540 5/8 (16)

591-6600 1/8 (3.2)

591-6610 3/16 (4.8)

591-6620 1/4 (6.4)

591-6630 5/16 (7.9)

591-6640 5/16 (7.9)

591-6650 5/16 (7.9)

591-6720 5/8 (16)

591-6730 3/4 (19)

591-6740 1 (25)

591-6840 3/8 (9.5)

591-6850 9/16 (14)

591-6860 9/16 (14)

591-6870 5/16 (7.9)

591-6880 9/16 (14)

591-6890 9/16 (14)

591-6900 1/4 (6.4)

591-6910 1/4 (6.4)

591-6920 5/16 (7.9)

591-6930 9/16 (14)

591-6940 3/16 (4.8)

591-6950 1/4 (6.4)

591-6960 1/4 (6.4)

591-6970 3/8 (9.5)

591-6980 3/16 (4.8)

591-7000 1/4 (6.4)

591-7010 5/16 (7.9)

591-7020 3/16 (4.8)

591-7030 1/4 (6.4)

591-7040 1/4 (6.4)

591-7050 3/8 (9.5)

591-7060 3/8 (9.5)

591-7070 9/16 (14)

591-7080 9/16 (14)

591-7090 3/16 (4.8)

591-7100 5/16 (7.9)

591-7110 9/16 (14)

591-7870 3/4 (19)

References

Technical Inst ructions

RL147-2

155-038P25

Table 6. Stem Travel Listed by Product Number.

Flowrite

Product

Number

Stem Travel

Inches

(mm)

591-7871 3/4 (19)

591-7872 1 (25)

591-7873 1 (25)

591-7874 1 (25)

591-7875 3/4 (19)

591-7876 3/4 (19)

591-7877 1 (25)

591-7878 1 (25)

591-7879 1 (25)

591-7971 3/8 (9.5)

591-7972 3/4 (19)

591-7973 3/4 (19)

591-7974 1 (25)

591-7975 1 (25)

591-7976 1 (25)

591-7977 3/8 (9.5)

591-7978 3/4 (19)

591-7979 3/4 (19)

591-7980 1 (25)

591-7981 1 (25)

591-7982 1 (25)

591-8016 5/8 (16)

591-8017 5/8 (16)

591-8018 3/4 (19)

591-8019 3/4 (19)

591-8020 1 (25)

591-8021 1 (25)

591-8028 5/8 (16)

591-8029 3/4 (19)

591-8030 1 (25)

591-8071 3/8 (9.5)

591-8072 3/4 (19)

591-8073 3/4 (19)

591-8074 1 (25)

591-8075 1 (25)

591-8076 1 (25)

591-8077 3/8 (9.5)

591-8078 3/4 (19)

591-8079 3/4 (19)

591-8080 1 (25)

Flowrite

Product

Number

Stem Travel

Inches

(mm)

591-8081 1 (25)

591-8082 1 (25)

591-8330 5/8 (16)

591-8331 5/8 (16)

591-8332 3/4 (19)

591-8336 5/8 (16)

591-8337 5/8 (16)

591-8338 3/4 (19)

591-8339 3/4 (19)

591-8340 1 (25)

591-8341 1 (25)

593-8342 1-1/2 (38)

593-8344 1-1/2 (38)

593-8350 1-1/8 (29)

593-8351 1-1/8 (29)

593-8352 1-1/8 (29)

593-8353 1-1/8 (29)

593-8354 1-1/8 (29)

593-8355 1-1/8 (29)

593-8356 1-1/8 (29)

593-8357 1-1/8 (29)

593-8358 1-1/4 (32)

593-8359 1-1/4 (32)

593-8360 1-1/2 (38)

593-8362 1-1/2 (38)

593-8364 1-1/8 (29)

593-8365 1-1/8 (29)

593-8366 1-1/8 (29)

593-8367 1-1/8 (29)

593-8368 1-1/8 (29)

593-8369 1-1/8 (29)

593-8370 1-1/8 (29)

593-8371 1-1/8 (29)

593-8372 1-1/4 (32)

593-8373 1-1/4 (32)

593-8374 1-1/2 (38)

593-8376 1-1/2 (38)

593-8378 1-1/4 (32)

593-8379 1-1/4 (32)

593-8380 1-1/4 (32)

Document No. 129-125

Installation Instructions

Rev. 5, June, 2000

Flowrite

Product

Number

593-8381 1-1/4 (32)

593-8382 1-1/2 (38)

593-8383 1-1/2 (38)

593-8388 3/4 (19)

593-8389 3/4 (19)

593-8390 3/4 (19)

593-8391 3/4 (19)

593-8392 1-1/8 (29)

593-8393 1-1/8 (29)

593-8394 1-1/4 (32)

593-8395 1-1/4 (32)

593-8396 1-1/4 (32)

593-8397 1-1/4 (32)

593-8398 1-1/4 (32)

593-8399 1-1/4 (32)

593-8400 1-1/4 (32)

593-8401 1-1/4 (32)

593-8402 1-1/2 (38)

593-8403 1-1/2 (38)

593-8404 1-1/4 (32)

593-8405 1-1/4 (32)

593-8406 1-1/4 (32)

593-8407 1-1/4 (32)

593-8410 1-1/2 (38)

593-8411 1-1/2 (38)

593-8412 1-3/8 (35)

593-8413 1-3/8 (35)

593-8415 1 (25)

593-8416 1 (25)

593-8419 1 (25)

593-8420 1 (25)

593-8421 1-3/8 (35)

593-8422 1-3/8 (35)

593-8423 1-3/8 (35)

594-8343* 1-1/2 (38)

594-8345* 1-1/2 (38)

594-8361* 1-1/2 (38)

594-8363* 1-1/2 (38)

594-8375* 1-1/2 (38)

594-8377* 1-1/2 (38)

* RL 147 is standard with

this product.

Stem Travel

Inches

(mm)

Information in this publication is based on current specifications. The company reserves the right to make changes in specifications and

models as design improvements are introduced. Flowrite is a t rademark of Siemens Building Technologies, Inc. © 2000 Siemens Building

Technologies, Inc.

Siemens Building Technologies, Inc.

Landis & Staefa Division

1000 Deerfield Parkway

Buffalo Grove, IL 60089-4513

U.S.A.

Your feedback is important to us. If you have

comments about this document, please send

them to technical.editor@ sb t .siemens.com

Document No. 129-125

Printed in the U.S.A.

Page 5 of 5

Loading...

Loading...