Page 1

November 1999

RGZESDI

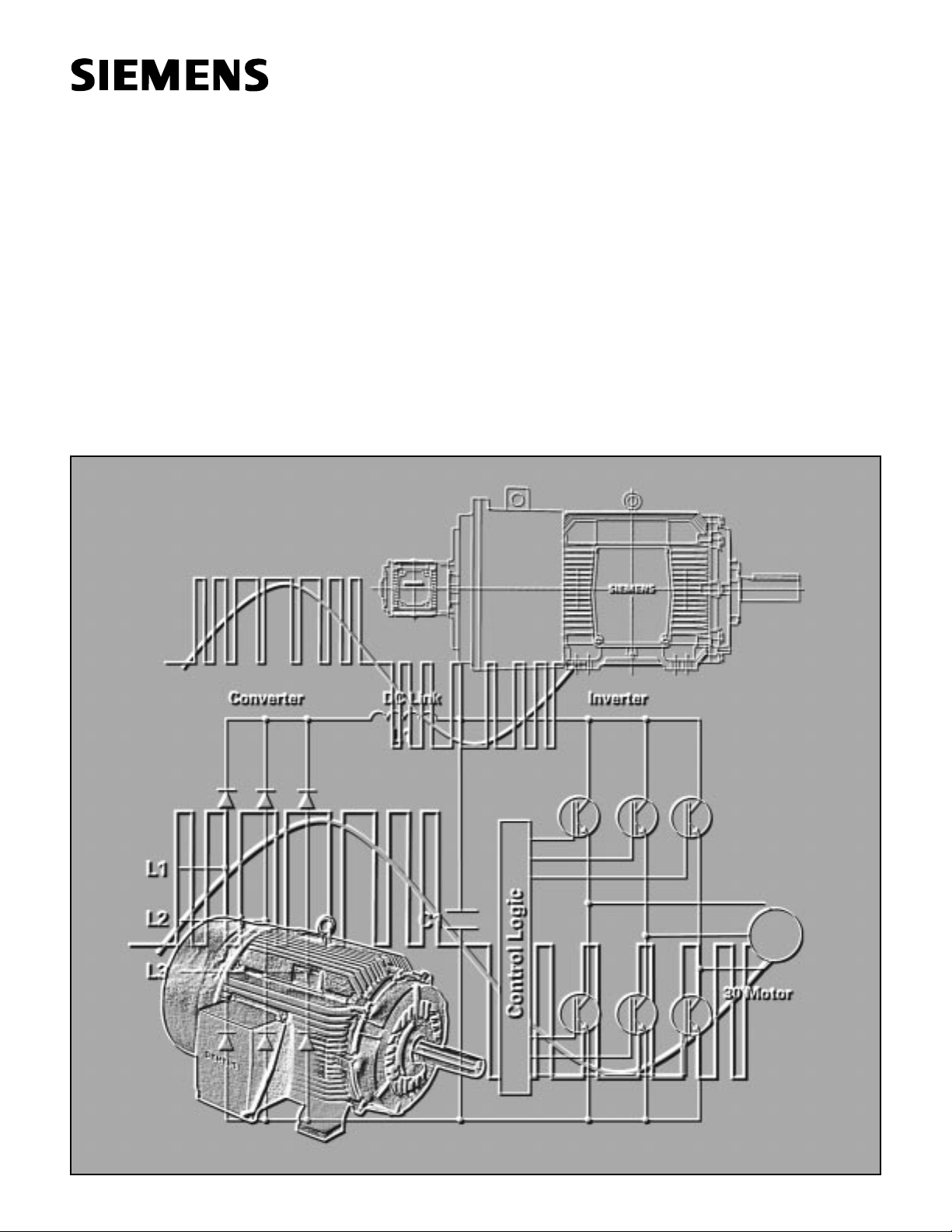

Inverter Duty AC Induction Motors

Installation • Operation • Maintenance Instructions

Frames: 143T through S449SS/LS

Page 2

QUALIFIED PERSON

For the purposes of this manual and product labels a qualified person is one who is familiar with the installation,

construction, operation or maintenance of the equipment and the hazards involved. In addition this person has

the following qualifications:

(a) Is trained and authorized to energize, de-energize, clear, ground and tag circuits and equipment in accor-

dance with established safety practices.

(b) Is trained in the proper care and use of protective equipment such as rubber gloves, hard hat, safety glasses

or face shields, flash clothing, etc., in accordance with established safety practices.

(c) is trained in rendering first aid.

SIGNAL WORDS

The signal words “Danger,” Warning” and “Caution” used in this manual indicate the degrees of hazard that

may be encountered by the user. These words are defined as:

Danger - Indicates death or serious injury will result if proper precautions are not taken.

Warning - Indicates death or serious injury or property damage can result if proper precautions are not taken.

Caution - Indicates some injury or property damage may result if proper precautions are not taken.

Page 3

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

VFD OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

ACCESSORIES

• THERMOSTATS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

• BLOWERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 7

• ENCODERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

MAINTENANCE

• BEARING LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

• INSULATION RESISTANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

• CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

November 1999

TABLE OF CONTENTS

3

IMPORTANT

These instructions do not purport to cover all details or variations in equipment, nor to provide for every possible

contingency to be met in connection with installation, operation or maintenance. Should further information be

desired or should particular problems arise which are not covered sufficiently for the purchaser’s purposes, the

matter should be referred to the local Siemens sales office. The contents of this instruction manual shall not

become part of or modify any prior or existing agreement, commitment or relationship. The sales contract contains the entire obligation of Siemens. The warranty contained in the contract between the parties is the sole

warranty of Siemens. Any statements contained herein do not create new warranties or modify the existing

warranty.

Page 4

STORAGE

Motors must be stored in a clean,

dry, well ventilated location free

from vibration and rapid or wide

temperature variations. If the unit is

to be stored longer than three

months, consult the factory. Ball

bearing motors are shipped from

the factory properly lubricated and

ready to operate. When in storage,

the motor shaft must be turned

several rotations every month and

the bearing re-lubricated every year.

On non-explosion-proof TEFC

motors, a removable plug in the

bottom of the frame or housing permits removal of accumulated mois-

ture. Drain regularly if storage

atmosphere results in formation of

condensation.

INSTALLATION

Qualified service or maintenance

personnel must handle installation,

The motor foundation must rigidly

support all four feet in the same

plane. Place shims under the motor

feet, as required; so they will not

be pulled out of plane when mounting bolts are tightened. All wiring to

the motor and control must be in

accordance with the National

Electrical Code and all local regulations. Before load is connected,

momentarily energize motor to

check that the direction of rotation

is proper. For direct connected

loads, accurate alignment is 0.004

inch/ft. (Radius to dial Indicator =

one foot)

Any change in shims requires rechecking alignment. When alignment is within limits, dowel two

feet of each unit. When installing

V-belt sheave, spur or helical pinion

or chain drives, be certain that they

are within NEMA limitations. Refer

to NEMA motor and general standards, MG1-14.07 and 14.41.

INTRODUCTION

THIS EQUIPMENT CONTAINS

HAZARDOUS VOLTAGES,

ROTATING PARTS AND HOT

SURFACES. SEVERE PERSONAL

INJURY OR PROPERTY DAMAGE CAN RESULT IF SAFETY

INSTRUCTIONS ARE NOT FOLLOWED. ONLY QUALIFIED PERSONNEL SHOULD WORK ON

OR AROUND THIS EQUIPMENT

AFTER BECOMING THOROUGHLY FAMILIAR WITH ALL

WARNINGS, SAFETY NOTICES,

AND MAINTENANCE PROCEDURES CONTAINED HEREIN.

THE SUCCESSFUL AND SAFE

OPERATION OF THIS EQUIPMENT IS DEPENDENT UPON

PROPER HANDLING, INSTALLATION, OPERATION AND MAINTENANCE.

INSPECTION

Care is taken at the factory to

assure that the motor arrives at its

destination in first class condition. If

there is evidence of rough handling

or damage in shipping, file a claim

at once with the carrier and notify

your Siemens Sales Office.

Examine the outside of the motor

carefully for damage, with particular

attention to conduit box, fans, and

covers. Inspect and tighten all hardware and accessories, which may

have become loosened during shipping and handling. Turn the shaft by

hand to be sure that it rotates

freely. If the motor has been mishandled sufficiently to break external parts, the end shield should also

be removed to check for internal

damage unless the motor is explosion proof. See warning below on

explosion proof motors.

November 1999

INSTALLATION & OPERATION

WARNING

4

Explosion.

Can cause death, serious injury or property damage.

When repairing and reassembling a motor that has an underwriter’s label, it is imperative that the unit be re-inspected and:

1 All original fits and tolerances are maintained.

2 All plugs and hardware be securely fastened.

3 Any parts replacements, including hardware, be accurate

duplicates of the Originals.

Repair work on explosion proof-motors can only be performed

by the original manufacturer or U.L. certified shops. Violations

of any of the above items will invalidate the significance of the

U.L. Label.

Page 5

5

VFD OPERATION

Special consideration must be paid

to ensure that the motor is operated within recommended guidelines

for torque and speed for the type

and size of RGZESDI motors selected. Under no circumstances should

the motor be operated at frequencies beyond the safe mechanical

limits shown below in this document.

RGZESDI Constant Torque motors

provide full rated torque within their

listed speed range, without exceeding their Class F temperature rating

on PWM (pulse width modulated)

inverter power. Speed ranges are

based on use with vector type IGBT

inverters, set at a minimum 3 kHz

switching frequency, and are

designed for operation at 150% of

rated torque for one minute, up to

the base speed of the motor (overload capacity declines as the motor

reaches maximum speed).

OPERATION

Repeated trial starts can over heat

the motor and result in motor

burnout (particularly for across the

line starting). If repeated trial starts

are made, allow sufficient time

between trials to permit heat to dissipate from windings and rotor to

prevent overheating. Starting currents are several times running currents and heating varies as the

square of the current.

After installation is completed, but

before motor is put into regular service, make an initial start as follows:

1. Check motor connections and

VFD connections against wiring

diagrams.

2. Check voltage, phase, and all

loaded drive parameters against

motor nameplate. If an auxiliary

blower is supplied, check to see

that it is wired and operating

properly. The blower should be

wired to a separate 60 hz power

source.

3. If possible, remove external load

and turn shaft by hand to ensure

free rotation. This may have

been done during installation procedure; if so, and conditions have

not changed since, this check

may not be necessary.

a. If load is disconnected, run

motor at no load long enough

to be certain that no unusual

conditions develop. Listen and

feel for excessive noise, vibration, clicking, or pounding. If

present, stop motor immediately. Investigate the cause

and correct before putting

motor in service.

b. If load is not disconnected,

interrupt the starting cycle

after motor has decelerated to

a slow speed. Carefully

observe for unusual conditions

as motor coasts to a stop.

4. When checks are satisfactory,

operate at minimum load and

look for unusual conditions.

Increase load slowly to a maximum. Check unit for satisfactory

operation.

Electric motors operating under normal conditions become quite warm.

Although some places may feel too

hot to touch, the unit may be within

operational limits. Use a thermocouple to measure winding temperature when there is any concern.

The total temperature, not the temperature rise, is the measure of

safe operation. Investigate the

operating conditions if the total

temperature measured by a thermocouple placed on the winding

exceeds:

• 275°F (135°C) for class “F” insula-

tion

• 302° F(150°C) for class “H” insula-

tion

CAUTION

Electrical Overload.

May cause property damage.

To avoid the danger, guard against overloading. Overloading

causes overheating and overheating means shortened insulation

life. A motor subjected to a 10°C temperature rise above the

maximum limit for the insulation may cause the insulation life

to be reduced by 50%. To avoid overloading, be sure motor current does not exceed nameplate current when nameplate voltage

is applied.

Maximum Safe Mechanical

Speed Limits

Direct Connected Loads

(does not imply constant horsepower

capability)

Motor 3600 1800 1200

Frame rpm rpm rpm

143-184 7200 5400 2700

213-256 5400 4200 2700

284-286 5400 3600 2700

324-326 4500 3600 2700

364-365 4500 2700 2700

404-445 3600 2700 1800

447-449 3600 2250 1800

CAUTION

Electrical Overload.

May cause property damage.

To avoid damage to the motor, caution must be observed when

applying standard motors for continuous low speed, constant

torque operation. A standard motor’s self-cooling capacity

depends upon self-ventilation schemes that are greatly reduced

at decreased operating speeds.

CAUTION

Electrical Overload.

May cause property damage.

To avoid damage to the motor, it is the responsibility of the

startup personnel during commissioning of the VFD/ motor

combination to properly tune the drive to the motor for the

specific application. Application of motors which are not per

the guidelines of this document may void the warranty, if they

are not specifically approved by Siemens.

Page 6

MAINTENANCE

Failure to properly maintain the

equipment can result in severe personal injury and product failure. The

instructions contained herein

should be carefully reviewed.

understood and followed. The following maintenance procedures

should be performed regularly:

1. Bearing Lubrication

2. Insulation resistance check

3. Cleaning

This checklist does not represent

an exhaustive survey of maintenance steps necessary to ensure

safe operations of the equipment.

Particular applications may require

further procedures. Should further

information be desired or should

particular problems arise which are

not covered sufficiently for the purchaser’s purposes, the matter

should be referred to the local

Siemens Sales Offices.

The use of unauthorized parts in

the repair of the equipment, tampering by unqualified personnel, or

removal or alterations of guards or

conduit covers will result in dangerous conditions which can cause

severe personal injury or equipment

damage. Follow all safety instructions contained herein.

MAINTENANCE

DANGER

Hazardous Voltages.

Will cause death or serious injury.

To avoid the danger, always de-energize all power sources and

ground the equipment before maintenance. Only qualified

personnel should perform maintenance.

Thermostats

All RGZESDI motors are equipped

with Class F normally closed thermostats for detection of overload

conditions. The thermostat is a

device that is intended to be used

in the alarm or protective circuit of

an RGZESDI motor. It is in direct

contact with the stator coil and is

useful in guarding against loss of

normal ventilation air, high ambient

temperature, and prolonged operation of self-ventilated motors at

very low speeds.

Blowers (if Equipped)

Blower motors, where supplied,

must be in operation to supply cooling air before loading totally

enclosed blower cooled (TEBC)

motors. Blower should be checked

for correct rotation. Air movement

should be from non-drive end

toward drive end of the motor.

The nameplate voltage and fre-

quency should agree with the

power supply. Motors will operate

successfully on line voltage within

+/- 10% of the nameplate value or

frequency within +/- 5%. The combined variation shall not exceed

+/- 10%.

Wiring of Blower motor should

meet the National Electric Code

and local building codes.

Encoders (if Equipped)

Follow encoder instructions supplied with the RGZESDI motor for

encoder operation and wiring.

ACCESSORIES

6

WARNING

Hazardous Voltages and Entanglement.

Can cause death, serious injury, or property damage.

To avoid the danger, the control circuit should be designed to

prevent the automatic starting of the motor when the

thermostat resets. Always de-energize all power sources and

ground the equipment before maintenance. Only qualified

personnel should perform maintenance.

Page 7

BEARING LUBRICATION

Bearing life is assured by maintaining proper alignment, proper belt or

chain tension, and good lubrication

at all times.

Prior to shipment, motor bearings

are lubricated with the proper

amount and grade to provide six

months of satisfactory service

under normal operating conditions.

For best results, grease should be

compounded from a polyurea base

and a good grade of petroleum oil.

It should be of No. 2 consistency

and stabilized against oxidation.

Operating temperature range

should be from -15°F to +300°F for

class F and H. Most leading oil

companies have special bearing

grease that is satisfactory.

Re-lubricate bearings every six

months (more often if conditions

require) as follows:

1. Stop the motor. Lock out the

switch.

2. Thoroughly clean off pipe plugs

and remove from housings.

3. Remove hardened grease from

drains with stiff wire or rod.

4. Add grease to inlet until small

amount of new grease is forced

out of the drain.

5. Remove excess grease from

ports, replace inlet plugs, and run

motor 1/2 hour before replacing

drain plugs.

6. Put motor back in operation.

INSULATION RESISTANCE

Check insulation resistance periodically. Any approved method of measuring insulation resistance may be

used, provided the voltage across

the insulation is at a safe value for

the type and condition of the insulation. A hand-cranked megger of not

over 500 volts is the most convenient and safest method. Standards

of the Institute of Electrical and

Electronics Engineers, Inc. (IEEE)

recommend that the insulation

resistance of stator windings at

75°C, measure at 500 volts DC,

after one Minute should not be less

than:

Rated Voltage of Insulation

Machine + 1000 = resistance in

1000 Megohms

This formula is satisfactory for most

checks. For more information, see

IEEE Standard No.43,

“Recommended Practice for

Insulation Resistance Testing of AC

Rotating Machinery”

7

CAUTION

Entanglement.

May cause injury or property damage.

To avoid the danger, do not lubricate motor while in operation,

since excess grease will be forced through the bearings and into

the motor before it will force its way out of the drain plug. Excess

grease accumulation on windings reduces the insulation life.

CLEANING

The motor exterior must be keep

free of oil, dust, dirt, water, and

chemicals. For fan cooled motors, it

is particularly important to keep the

air intake openings free of foreign

material. Do not block air outlet or

inlet.

On non-explosion proof TEFC

motors, a removable plug in the

bottom of the motor bearing housing permits removal of accumulated

moisture. Drain regularly.

SERVICE

For immediate action on your motor

problems, call your certified service

center or contact your nearest

Siemens District Office.

WARNING

Entanglement.

Can cause death, serious injury, or property damage.

To avoid the danger, do not attempt to clean motor while it is

operating. Contact with rotating parts can cause severe

personal injury or property damage. Stop the motor and lock

out switch before cleaning.

Page 8

© 1999 Siemens Energy & Automation, Inc. Bulletin NMIM-L1006

15M1199TI Printed in U.S.A.

Siemens Energy & Automation, Inc.

Industrial Products Division

14000 Dineen Drive

Little Rock, Arkansas 72206

Loading...

Loading...