Page 1

Page 2

Page 3

SIMATIC RF600

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SIMATIC Ident

RFID systems

SIMATIC RF600

System Manual

xx/2014

J31069

Introduction

1

Safety Information

2

System overview of

SIMATIC RF600

3

RF600 system planning

4

Readers

5

Antennas

6

Transponder/tags

7

Integration into networks

8

System diagnostics

9

Accessories

10

Appendix

A

-D0171-U001-A15-7618

Page 4

Siemens AG

Industry Sector

Postfach 48 48

90026 NÜRNBERG

GERMANY

Order number: J31069-D0171-U001

Ⓟ

Copyright © Siemens AG 2005 - 2014.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

for the specific

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

06/2014 Subject to change

Page 5

Table of contents

1 Introduction ........................................................................................................................................... 17

2 Safety Information ................................................................................................................................. 21

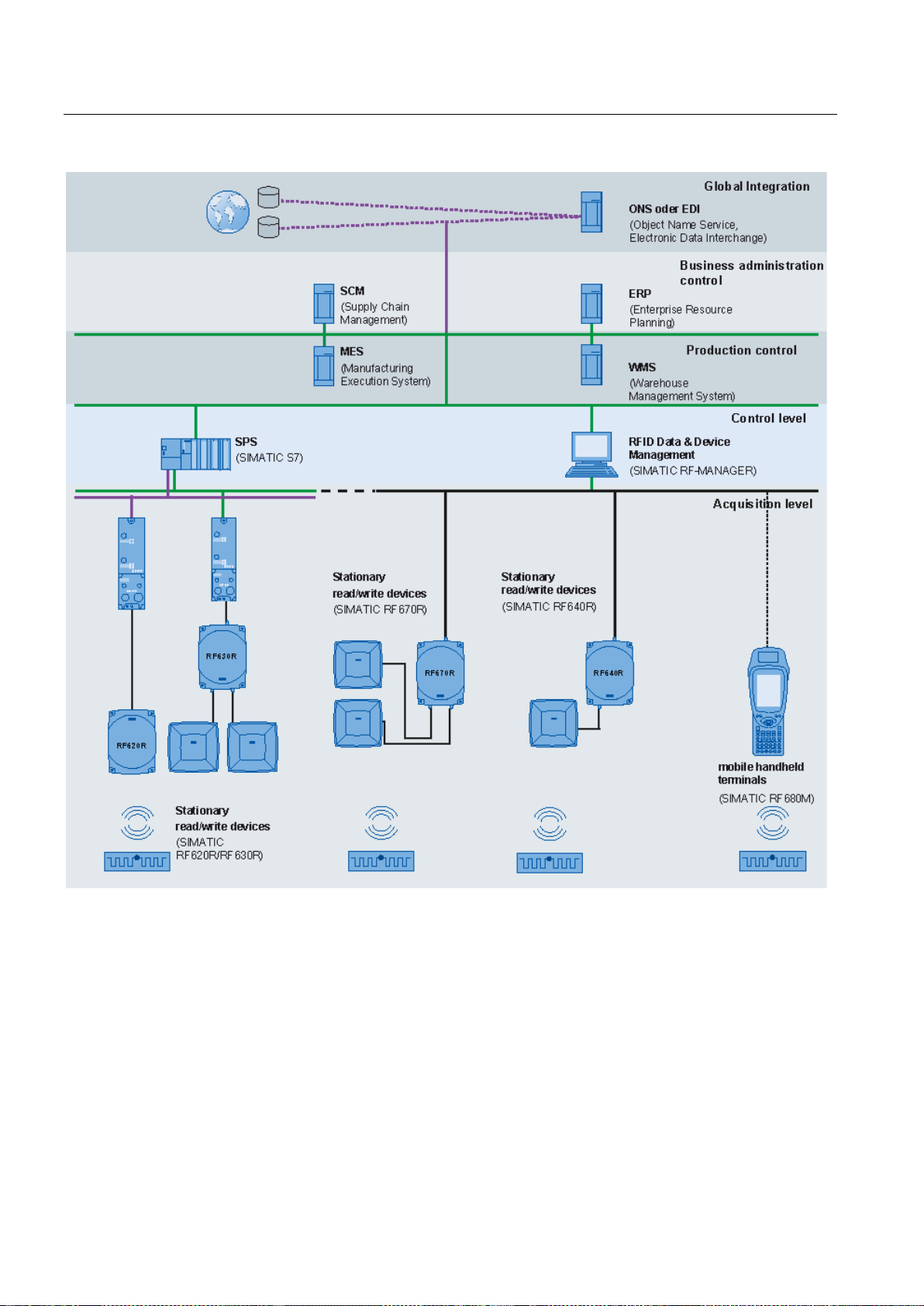

3 System overview of SIMATIC RF600 .................................................................................................... 29

4 RF600 system planning......................................................................................................................... 37

1.1 Preface ......................................................................................................................................... 17

1.2 Abbreviations and naming conventions ....................................................................................... 19

1.3 Navigating in the system manual ................................................................................................. 19

2.1 General safety instructions .......................................................................................................... 21

2.2 Safety instructions for third-party antennas as well as for modifications to the RF600

system .......................................................................................................................................... 23

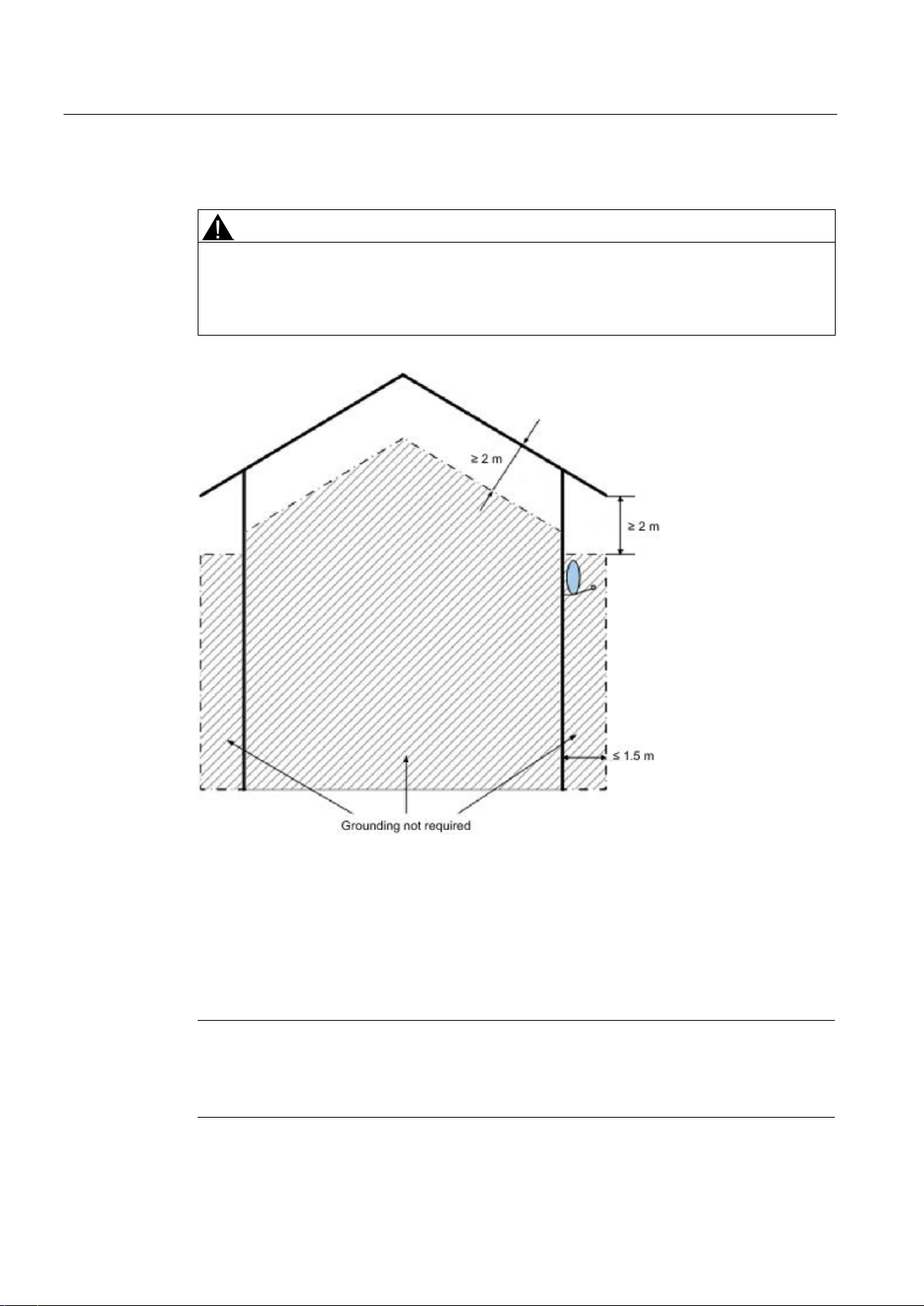

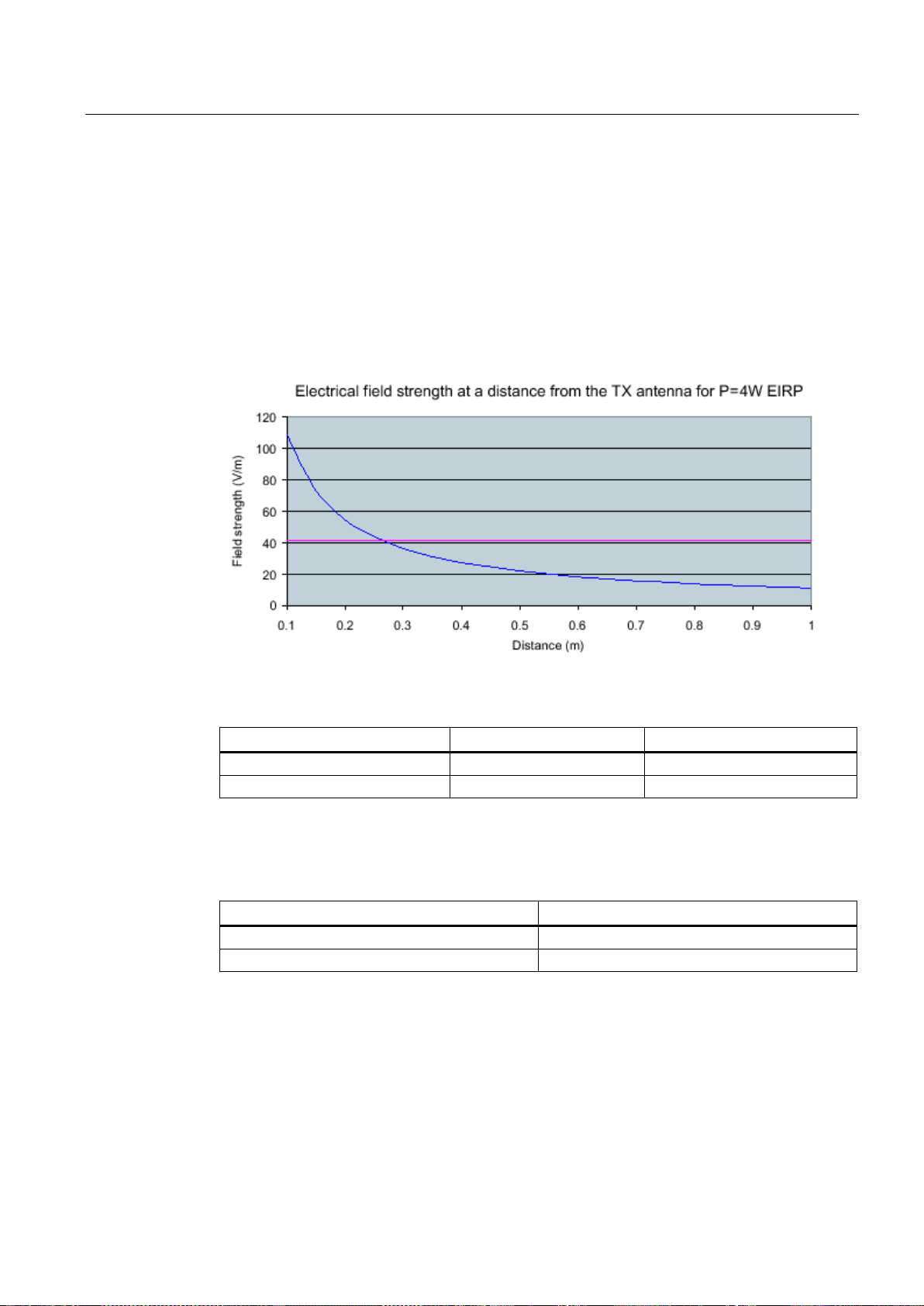

2.3 Safety distance to transmitter antenna ........................................................................................ 24

2.3.1 Safety distance between transmitter antenna and personnel ...................................................... 24

2.3.2 Minimum distance to antenna in accordance with ETSI .............................................................. 25

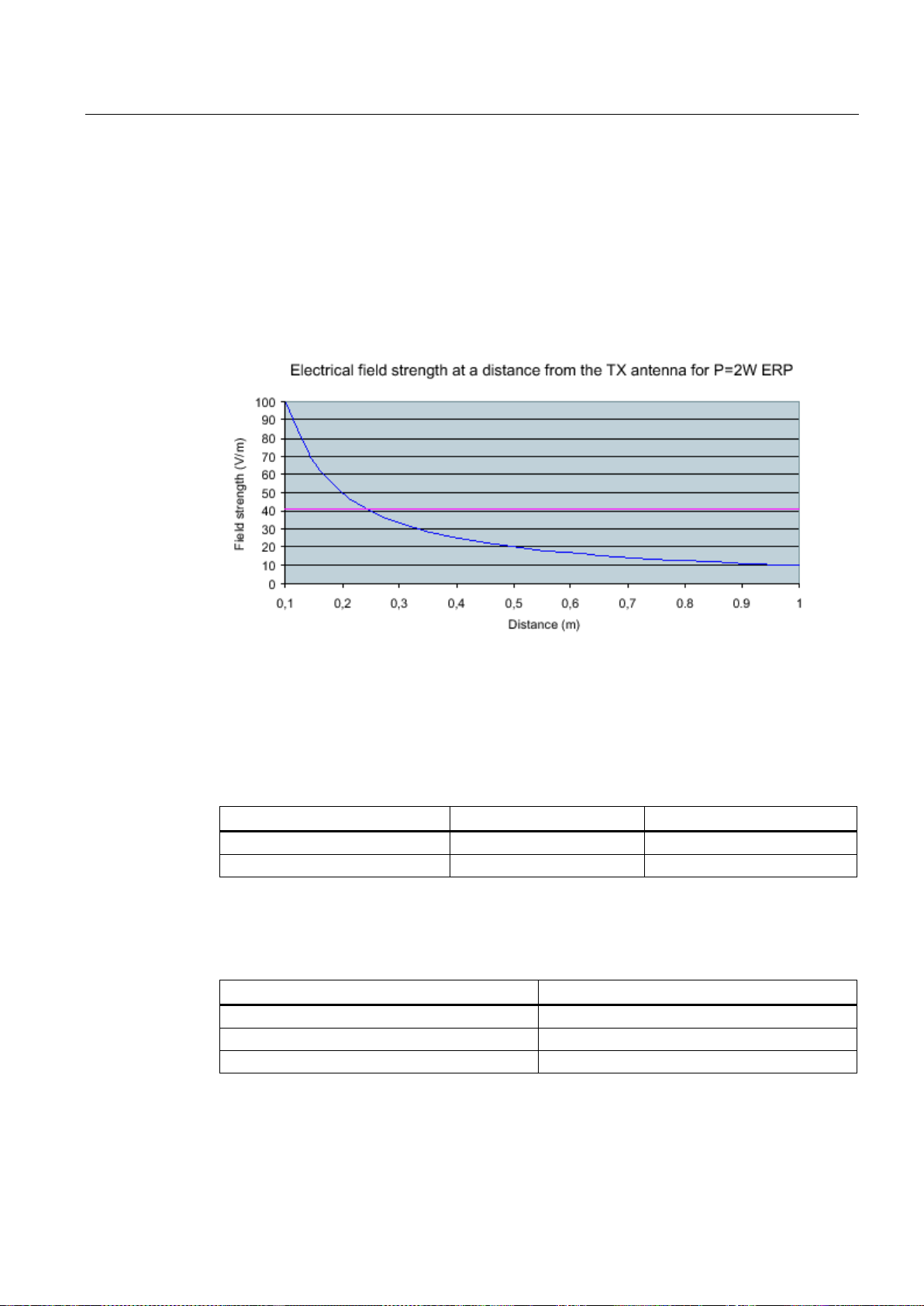

2.3.3 Minimum distance to antenna in accordance with FCC (USA) .................................................... 27

3.1 Application areas of RF600 .......................................................................................................... 31

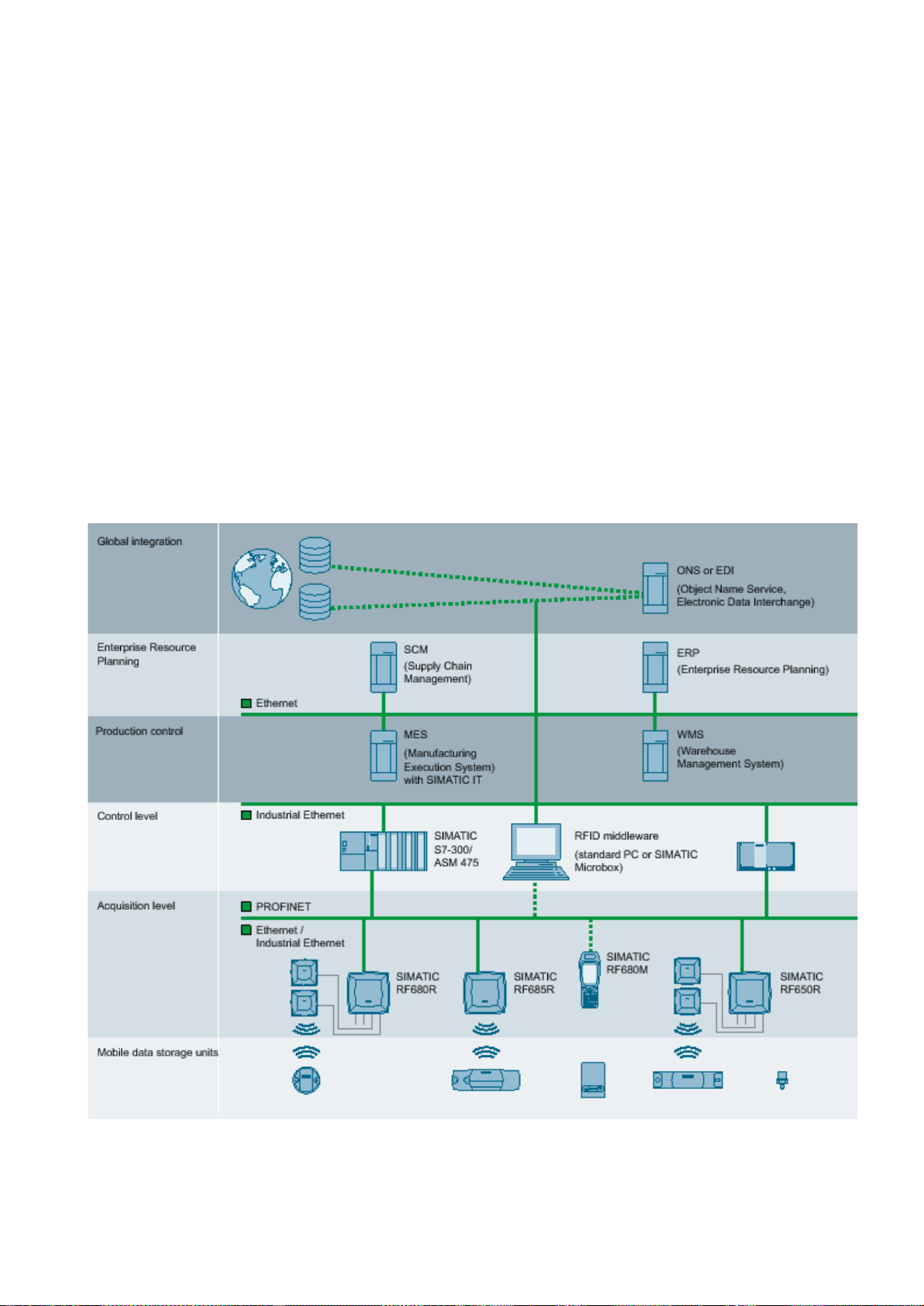

3.2 System components (hardware/software) ................................................................................... 32

3.3 Features ....................................................................................................................................... 35

4.1 Overview ...................................................................................................................................... 37

4.2 Possible system configurations .................................................................................................... 37

4.2.1 Scenario for material handling control ......................................................................................... 38

4.2.2 Scenario for workpiece identification ........................................................................................... 39

4.2.3 Scenario for Intra logistics ............................................................................................................ 40

4.2.4 Scenario incoming goods, distribution of goods and outgoing goods ......................................... 42

4.3 Antenna configurations ................................................................................................................ 43

4.3.1 Antenna configuration example ................................................................................................... 43

4.3.2 Possibilities and application areas for antenna configurations .................................................... 44

4.3.3 Transponder orientation in space ................................................................................................ 48

4.3.4 Specified minimum and maximum spacing of antennas ............................................................. 49

4.3.5 Mutual interference of readers (antennas) ................................................................................... 49

4.3.6 Read and write range ................................................................................................................... 52

4.3.7 Static/dynamic mode .................................................................................................................... 53

4.3.8 Operation of several readers within restricted space................................................................... 53

4.3.8.1 Dense Reader Mode .................................................................................................................... 53

4.3.8.2 Optimizing tag reading accuracy.................................................................................................. 54

4.3.8.3 Optimization of robustness of tag data accesses for readers that are operated

simultaneously ............................................................................................................................. 54

4.3.8.4 Frequency hopping ...................................................................................................................... 55

4.3.9 Guidelines for selecting RFID UHF antennas .............................................................................. 55

4.3.9.1 Note safety information ................................................................................................................ 55

SIMATIC RF600

System Manual, xx/2014, J31069-D0171-U001-A15-7618

5

Page 6

Table of contents

5 Readers ................................................................................................................................................ 87

4.3.9.2 Preconditions for selecting RFID UHF antennas ........................................................................ 55

4.3.9.3 General application planning....................................................................................................... 56

4.3.9.4 Antennas ..................................................................................................................................... 58

4.3.9.5 Antenna cables ........................................................................................................................... 69

4.3.9.6 Application example .................................................................................................................... 71

4.4 Environmental conditions for transponders/tags ......................................................................... 73

4.5 The response of electromagnetic waves in the UHF band ......................................................... 73

4.5.1 The effect of reflections and interference .................................................................................... 73

4.5.2 Influence of metals ...................................................................................................................... 74

4.5.3 Influence of liquids and non-metallic substances ....................................................................... 74

4.5.4 Influence of external components ............................................................................................... 74

4.6 Regulations applicable to frequency bands ................................................................................ 75

4.6.1 Overview of the frequency bands ............................................................................................... 75

4.6.2 Regulations for UHF frequency bands in China.......................................................................... 76

4.6.3 Regulations for UHF frequency bands in the USA...................................................................... 78

4.7 Guidelines for electromagnetic compatibility (EMC) ................................................................... 79

4.7.1 Overview ..................................................................................................................................... 79

4.7.2 What does EMC mean? .............................................................................................................. 79

4.7.3 Basic rules ................................................................................................................................... 80

4.7.4 Propagation of electromagnetic interference .............................................................................. 82

4.7.5 Equipotential bonding .................................................................................................................. 83

4.7.6 Cable shielding ............................................................................................................................ 84

5.1 Overview ..................................................................................................................................... 87

5.2 RF620R reader ........................................................................................................................... 90

5.2.1 Description .................................................................................................................................. 90

5.2.1.1 Ordering data .............................................................................................................................. 91

5.2.1.2 Status display .............................................................................................................................. 91

5.2.1.3 Pin assignment of the RS422 interface ....................................................................................... 92

5.2.1.4 Pin assignment of the connecting cable ..................................................................................... 93

5.2.1.5 Grounding connection ................................................................................................................. 94

5.2.2 Planning application .................................................................................................................... 94

5.2.2.1 Minimum mounting clearances of two readers ........................................................................... 94

5.2.2.2 Antenna diagram for RF620R (ETSI) .......................................................................................... 95

5.2.2.3 Antenna diagram for RF620R (FCC) .......................................................................................... 98

5.2.2.4 Interpretation of directional radiation patterns........................................................................... 101

5.2.2.5 Antenna/read point configurations ............................................................................................ 101

5.2.3 Installing/Mounting .................................................................................................................... 102

5.2.3.1 Mounting/Installing FCC ............................................................................................................ 102

5.2.4 Configuration/integration ........................................................................................................... 103

5.2.4.1 Transmission protocols ............................................................................................................. 104

5.2.5 Technical data ........................................................................................................................... 104

5.2.5.1 Mechanical data ........................................................................................................................ 104

5.2.5.2 Technical data according to EPC and ISO ............................................................................... 106

5.2.5.3 Maximum number of readable tags .......................................................................................... 107

5.2.6 Dimension drawings .................................................................................................................. 108

5.2.7 Certificates and approvals......................................................................................................... 109

5.2.7.1 C

ountry-specific certifications ................................................................................................... 109

5.2.7.2 FCC information ........................................................................................................................ 111

SIMATIC RF600

6 System Manual, xx/2014, J31069-D0171-U001-A15-7618

Page 7

Table of contents

5.2.7.3 IC-FCB information .................................................................................................................... 112

5.3 RF630R reader .......................................................................................................................... 113

5.3.1 Description ................................................................................................................................. 113

5.3.1.1 Ordering data ............................................................................................................................. 114

5.3.1.2 Status display ............................................................................................................................. 114

5.3.1.3 Pin assignment of the RS422 interface ..................................................................................... 115

5.3.1.4 Pin assignment of the connecting cable .................................................................................... 116

5.3.1.5 Grounding connection ................................................................................................................ 116

5.3.2 Planning application ................................................................................................................... 117

5.3.2.1 Minimum mounting clearances of two antennas of different readers ........................................ 117

5.3.2.2 Antenna/read point configurations ............................................................................................. 117

5.3.3 Installing/Mounting ..................................................................................................................... 118

5.3.3.1 Mounting/Installation .................................................................................................................. 118

5.3.4 Configuration/integration ............................................................................................................ 119

5.3.4.1 Transmission protocols .............................................................................................................. 120

5.3.5 Technical data ............................................................................................................................ 120

5.3.5.1 Mechanical data ......................................................................................................................... 120

5.3.5.2 Technical data according to EPC and ISO ................................................................................ 122

5.3.5.3 Maximum number of readable tags ........................................................................................... 123

5.3.6 Dimension drawings ................................................................................................................... 124

5.3.7 Certificates and approvals ......................................................................................................... 125

5.3.7.1 FCC information ......................................................................................................................... 127

5.3.7.2 IC-FCB information ....................................................................................................................

128

5.

4 RF640R reader .......................................................................................................................... 129

5.4.1 Description ................................................................................................................................. 129

5.4.1.1 Overview .................................................................................................................................... 129

5.4.1.2 Ordering data ............................................................................................................................. 130

5.4.1.3 Status display ............................................................................................................................. 131

5.4.1.4 Pin assignment of the digital I/O interface ................................................................................. 132

5.4.1.5 Connection scheme for the digital I/O interface ......................................................................... 133

5.4.1.6 Pin assignment for power supply ............................................................................................... 138

5.4.1.7 Pin assignment for Industrial Ethernet interface ........................................................................ 139

5.4.1.8 Grounding connection ................................................................................................................ 139

5.4.2 Planning the use ........................................................................................................................ 140

5.4.2.1 Selecting the antenna ................................................................................................................ 140

5.4.2.2 Internal antenna ......................................................................................................................... 140

5.4.2.3 External antenna ........................................................................................................................ 148

5.4.3 Installing / mounting ................................................................................................................... 148

5.4.4 Configuration/integration ............................................................................................................ 149

5.4.5 Technical data ............................................................................................................................ 150

5.4.5.1 Mechanical data ......................................................................................................................... 150

5.4.5.2 Technical data according to EPC and ISO ................................................................................ 152

5.4.6 Dimension drawings ................................................................................................................... 153

5.4.7 Certificates and approvals ......................................................................................................... 154

5.4.7.1 FCC information .........................................................................................................................

5

.4.7.2 IC-FCB information .................................................................................................................... 157

5.5 RF650R reader ..........................................................................................................................

5.

5.1 Description ................................................................................................................................. 158

156

158

5.5.1.1 Overview .................................................................................................................................... 158

5.5.1.2 Ordering data ............................................................................................................................. 158

5.5.1.3 Status display ............................................................................................................................. 160

SIMATIC RF600

System Manual, xx/2014, J31069-D0171-U001-A15-7618

7

Page 8

Table of contents

5.5.1.4 Pin assignment of the digital I/O interface ................................................................................ 160

5.5.1.5 Connection scheme for the digital I/O interface ........................................................................ 161

5.5.1.6 Pin assignment of the RS-422 interface ................................................................................... 167

5.5.1.7 Pin assignment for Industrial Ethernet interface ....................................................................... 167

5.5.1.8 Grounding connection ............................................................................................................... 168

5.5.2 Planning operation .................................................................................................................... 169

5.5.2.1 Antenna/read point configurations ............................................................................................ 169

5.5.3 Installation/mounting ................................................................................................................. 169

5.5.4 Configuration/integration ........................................................................................................... 170

5.5.5 Technical specifications ............................................................................................................ 171

5.5.6 Dimension drawing .................................................................................................................... 173

5.5.7 Certificates and approvals......................................................................................................... 174

5.5.7.1 FCC information ........................................................................................................................ 175

5.5.7.2 IC-FCB information ................................................................................................................... 176

5.6 RF670R reader ......................................................................................................................... 177

5.6.1 Description ................................................................................................................................ 177

5.6.1.1 Overview ................................................................................................................................... 177

5.6.1.2 Ordering data ............................................................................................................................ 178

5.6.1.3 Status display ............................................................................................................................ 179

5.6.1.4 Pin assignment of the digital I/O interface ................................................................................ 180

5.6.1.5 Connection scheme for the digital I/O interface ........................................................................ 181

5.6.1.6 Pin assignment for power supply .............................................................................................. 185

5.6.1.7 Pin assignment for Industrial Ethernet interface .......................................................................

5

.6.1.8 Grounding connection ............................................................................................................... 186

186

5.6.2 Planning the use ....................................................................................................................... 187

5.6.2.1 Antenna/read point configurations ............................................................................................ 187

5.6.3 Installing / mounting .................................................................................................................. 188

5.6.4 Configuration/integration ........................................................................................................... 189

5.6.5 Technical data ........................................................................................................................... 190

5.6.5.1 Mechanical data ........................................................................................................................ 190

5.6.5.2 Technical data according to EPC and ISO ............................................................................... 192

5.6.6 Dimension drawings .................................................................................................................. 193

5.6.7 Certificates and approvals......................................................................................................... 194

5.6.7.1 FCC information ........................................................................................................................ 196

5.6.7.2 IC-FCB information ................................................................................................................... 197

5.7 RF680R reader ......................................................................................................................... 198

5.7.1 Description ................................................................................................................................ 198

5.7.1.1 Overview ................................................................................................................................... 198

5.7.1.2 Ordering data ............................................................................................................................ 198

5.7.1.3 Status display ............................................................................................................................ 200

5.7.1.4 Pin assignment of the digital I/O interface ................................................................................ 200

5.7.1.5 Connection scheme for the digital I/O interface ........................................................................ 201

5.7.1.6 Pin assignment of the RS-422 interface ................................................................................... 207

5.7.1.7 Pin assignment for Industrial Ethernet interface ....................................................................... 207

5.7.1.8 Grounding connection ...............................................................................................................

5.

7.2 Planning operation .................................................................................................................... 208

5.7.2.1 Antenna/read point configurations ............................................................................................

5.

7.3 Installation/mounting ................................................................................................................. 209

207

208

5.7.4 Configuration/integration ........................................................................................................... 210

5.7.5 Technical specifications ............................................................................................................ 211

5.7.6 Dimension drawing .................................................................................................................... 213

SIMATIC RF600

8 System Manual, xx/2014, J31069-D0171-U001-A15-7618

Page 9

Table of contents

6 Antennas ............................................................................................................................................ 245

5.7.7 Certificates and approvals ......................................................................................................... 214

5.7.7.1 FCC information ......................................................................................................................... 215

5.7.7.2 IC-FCB information .................................................................................................................... 216

5.8 RF685R reader .......................................................................................................................... 217

5.8.1 Description ................................................................................................................................. 217

5.8.1.1 Overview .................................................................................................................................... 217

5.8.1.2 Ordering data ............................................................................................................................. 218

5.8.1.3 Status display ............................................................................................................................. 219

5.8.1.4 Pin assignment of the digital I/O interface ................................................................................. 219

5.8.1.5 Connection scheme for the digital I/O interface ......................................................................... 220

5.8.1.6 Pin assignment of the RS-422 interface .................................................................................... 226

5.8.1.7 Pin assignment for Industrial Ethernet interface ........................................................................ 226

5.8.1.8 Grounding connection ................................................................................................................ 226

5.8.2 Planning operation ..................................................................................................................... 227

5.8.2.1 Selecting the antenna ................................................................................................................ 227

5.8.2.2 Internal antenna ......................................................................................................................... 227

5.8.2.3 External antenna ........................................................................................................................ 235

5.8.3 Installation/mounting .................................................................................................................. 235

5.8.4 Configuration/integration ............................................................................................................ 236

5.8.5 Technical specifications ............................................................................................................. 237

5.8.6 Dimension drawing .................................................................................................................... 239

5.8.7 Certificates and approvals ......................................................................................................... 240

5.8.7.1 CE mark .....................................................................................................................................

5

.8.7.2 Country-specific certifications .................................................................................................... 240

240

5.8.7.3 FCC information ......................................................................................................................... 241

5.8.7.4 IC-FCB information .................................................................................................................... 242

5.9 Reader RF680M......................................................................................................................... 243

5.9.1 Description ................................................................................................................................. 243

5.9.2 Field of application and features ................................................................................................ 243

6.1 Overview .................................................................................................................................... 245

6.2 RF620A antenna ........................................................................................................................ 247

6.2.1 Description ................................................................................................................................. 247

6.2.2 Ordering data ............................................................................................................................. 248

6.2.3 Installation and assembly ........................................................................................................... 248

6.2.3.1 RF620A mounting types ............................................................................................................ 248

6.2.4 Connecting an antenna to the reader ........................................................................................ 249

6.2.4.1 Overview .................................................................................................................................... 249

6.2.4.2 Connecting RF620A to an RF600 reader .................................................................................. 250

6.2.5 Parameter settings of RF620A for RF620R/RF630R ................................................................ 251

6.2.6 Parameter settings of RF620A for RF640R/RF670R ................................................................ 252

6.2.7 Setting RF620A parameters for RF650R/RF680R/RF685R ...................................................... 253

6.2.8 Alignment of transponders to the antenna ................................................................................. 254

6.2.9 Antenna patterns ........................................................................................................................ 257

6.2.9.1 Antenna pattern ETSI ................................................................................................................ 257

6.2.9.2 Antenna pattern FCC ................................................................................................................. 260

6.2.9.3 Interpretation of directional radiation patterns ........................................................................... 263

6.2.10 Read/write ranges ...................................................................................................................... 263

6.2.11 Technical data ............................................................................................................................ 270

6.2.12 Dimension drawing .................................................................................................................... 271

SIMATIC RF600

System Manual, xx/2014, J31069-D0171-U001-A15-7618

9

Page 10

Table of contents

6.2.13 Approvals & certificates ............................................................................................................. 271

6.3 Antenna RF640A ....................................................................................................................... 273

6.3.1 Description ................................................................................................................................ 273

6.3.2 Ordering data ............................................................................................................................ 274

6.3.3 Installation and assembly .......................................................................................................... 274

6.3.3.1 RF640A mounting types ............................................................................................................ 274

6.3.4 Connecting an antenna to the reader ....................................................................................... 275

6.3.4.1 Bending radii and bending cycles of the cable ......................................................................... 276

6.3.5 Parameter settings of RF640A for RF620R/RF630R ............................................................... 276

6.3.6 Parameter settings of RF640A for RF640R/RF670R ............................................................... 277

6.3.7 Setting RF640A parameters for RF650R .................................................................................. 278

6.3.8 Setting RF640A parameters for RF680R/RF685R ................................................................... 279

6.3.9 Antenna patterns ....................................................................................................................... 281

6.3.9.1 Antenna radiation patterns in the ETSI frequency band ........................................................... 281

6.3.9.2 Antenna radiation patterns in the FCC frequency band ............................................................ 286

6.3.9.3 Interpretation of directional radiation patterns........................................................................... 291

6.3.10 Technical data ........................................................................................................................... 292

6.3.11 Dimension drawing .................................................................................................................... 294

6.3.12 Approvals & certificates ............................................................................................................. 295

6.4 Antenna RF642A ....................................................................................................................... 296

6.4.1 Description ................................................................................................................................ 296

6.4.2 Ordering data ............................................................................................................................ 297

6.4.3 Installation and assembly .......................................................................................................... 297

6.4.3.1 R

F640A mounting types ............................................................................................................ 297

6.4.4 Connecting an antenna to the reader ....................................................................................... 298

6.4.4.1 Bending radii and bending cycles of the cable ......................................................................... 299

6.4.5 Alignment of transponders to the antenna ................................................................................ 300

6.4.6 Parameter settings of RF642A for RF620R/RF630R ............................................................... 303

6.4.7 Parameter settings of RF642A for RF640R/RF670R ............................................................... 304

6.4.8 Setting RF642A parameters for RF650R .................................................................................. 305

6.4.9 Setting RF642A parameters for RF680R/RF685R ................................................................... 306

6.4.10 Antenna patterns ....................................................................................................................... 307

6.4.10.1 Antenna radiation patterns in the ETSI frequency band ........................................................... 307

6.4.10.2 Antenna radiation patterns in the FCC frequency band ............................................................ 309

6.4.10.3 Interpretation of directional radiation patterns........................................................................... 311

6.4.11 Technical data ........................................................................................................................... 312

6.4.12 Dimension drawing .................................................................................................................... 313

6.4.13 Approvals & certificates ............................................................................................................. 314

6.5 RF660A antenna ....................................................................................................................... 315

6.5.1 Description ................................................................................................................................ 315

6.5.2 Installation and assembly .......................................................................................................... 316

6.5.2.1 RF660A mounting types ............................................................................................................ 316

6.5.3 Connecting an antenna to a reader .......................................................................................... 317

6.5.3.1 Bending radii and bending cycles of the cable ......................................................................... 318

6.5.4 Parameter settings of RF660A for RF620R/RF630R ...............................................................

6.

5.5 Parameter settings of RF660A for RF640R/RF670R ............................................................... 319

318

6.5.6 Setting RF660A parameters for RF650R .................................................................................. 320

6.5.7 Setting RF660A parameters for RF680R/RF685R ................................................................... 321

6.

5.8 Antenna patterns ....................................................................................................................... 323

6.5.8.1 Antenna pattern ......................................................................................................................... 323

6.5.9 Interpretation of directional radiation patterns........................................................................... 325

SIMATIC RF600

10 System Manual, xx/2014, J31069-D0171-U001-A15-7618

Page 11

Table of contents

7 Transponder/tags ................................................................................................................................ 333

6.5.10 Technical data ............................................................................................................................ 326

6.5.11 Dimension drawing .................................................................................................................... 328

6.5.12 Approvals & certificates ............................................................................................................. 329

6.6 Mounting types ........................................................................................................................... 330

6.6.1 Overview .................................................................................................................................... 330

6.6.2 Ordering data ............................................................................................................................. 330

6.6.3 Mounting with antenna mounting kit .......................................................................................... 331

7.1 Overview .................................................................................................................................... 333

7.1.1 Mode of operation of transponders/tags .................................................................................... 333

7.1.2 Transponder classes and generations ....................................................................................... 334

7.1.3 Electronic Product Code (EPC) ................................................................................................. 334

7.1.4 SIMATIC memory configuration of the RF600 transponders and labels ................................... 336

7.1.5 Minimum distances and maximum ranges ................................................................................ 344

7.1.5.1 Configurations of antenna and transponder .............................................................................. 344

7.1.5.2 Effects of the materials of the mounting surfaces on the range ................................................ 346

7.1.5.3 Maximum read/write ranges of transponders ............................................................................ 347

7.1.5.4 Minimum distances between antennas and transponders ........................................................ 349

7.2 SIMATIC RF630L Smartlabel .................................................................................................... 350

7.2.1 Features ..................................................................................................................................... 350

7.2.2 Ordering data ............................................................................................................................. 351

7.2.3 Minimum spacing between labels .............................................................................................. 351

7.2.4 Memory configuration of the smart label .................................................................................... 352

7.2.5 Technical data ............................................................................................................................ 352

7.2.6 Dimension drawings ................................................................................................................... 354

7.3 SIMATIC RF680L Smartlabel .................................................................................................... 356

7.3.1 Features ..................................................................................................................................... 356

7.3.2 Delivery format ........................................................................................................................... 357

7.3.3 Ordering data ............................................................................................................................. 357

7.3.4 Minimum spacing between labels .............................................................................................. 358

7.3.5 Memory configuration of the smart label .................................................................................... 358

7.3.6 Mounting on metal ..................................................................................................................... 359

7.3.7 Technical data ............................................................................................................................

7

.3.7.1 Mechanical data ......................................................................................................................... 360

360

7.3.7.2 Electrical data ............................................................................................................................. 360

7.3.7.3 Memory specifications ............................................................................................................... 361

7.3.7.4 Environmental conditions ........................................................................................................... 361

7.3.8 Certificates and approvals ......................................................................................................... 361

7.3.9 Dimension drawing .................................................................................................................... 362

7.4 SIMATIC RF610T....................................................................................................................... 363

7.4.1 Features ..................................................................................................................................... 363

7.4.2 Ordering data ............................................................................................................................. 363

7.4.3 Safety instructions for the device/system .................................................................................. 364

7.4.4 Minimum spacing between labels .............................................................................................. 364

7.4.5 Memory configuration of the transponder .................................................................................. 364

7.4.6 Technical data ............................................................................................................................ 365

7.4.6.1 Mechanical data ......................................................................................................................... 365

7.4.6.2 Electrical data ............................................................................................................................. 365

7.4.6.3 Memory specifications ............................................................................................................... 366

SIMATIC RF600

System Manual, xx/2014, J31069-D0171-U001-A15-7618

11

Page 12

Table of contents

7.4.6.4 Environmental conditions .......................................................................................................... 366

7.4.7 Certificates and approvals......................................................................................................... 367

7.4.8 Dimension drawing .................................................................................................................... 367

7.5 SIMATIC RF610T ATEX ........................................................................................................... 368

7.5.1 Features .................................................................................................................................... 368

7.5.2 Ordering data ............................................................................................................................ 368

7.5.3 Safety instructions for the device/system .................................................................................. 369

7.5.4 Minimum spacing between labels ............................................................................................. 369

7.5.5 Memory configuration ................................................................................................................ 369

7.5.6 Technical specifications ............................................................................................................ 370

7.5.6.1 Mechanical data ........................................................................................................................ 370

7.5.6.2 Electrical data ............................................................................................................................ 370

7.5.6.3 Memory data ............................................................................................................................. 371

7.5.6.4 Environmental conditions .......................................................................................................... 371

7.5.6.5 Use of the transponder in the Ex protection area ..................................................................... 371

7.5.6.6 Use of the transponder in hazardous areas for gases .............................................................. 372

7.5.6.7 Use of the transponder in hazardous areas for dusts ............................................................... 373

7.5.7 Certificates and approvals......................................................................................................... 374

7.5.8 Dimension drawing .................................................................................................................... 374

7.6 SIMATIC RF620T ...................................................................................................................... 375

7.6.1 Characteristics .......................................................................................................................... 375

7.6.2 Ordering data ............................................................................................................................ 376

7.6.3 Planning the use .......................................................................................................................

.6.3.1 Optimum antenna/transponder positioning with planar mounting of the transponder on

7

376

metal .......................................................................................................................................... 376

7.6.3.2 Range when mounted on flat metallic carrier plates ................................................................. 377

7.6.3.3 Influence of conducting walls on the range ............................................................................... 378

7.6.3.4 Directional radio pattern of the transponder on metallic surfaces............................................. 380

7.6.3.5 Range when mounted on non-metallic carrier materials .......................................................... 381

7.6.3.6 Directional radio pattern of the transponder on non-metallic surfaces ..................................... 381

7.6.3.7 Range when mounted on ESD carrier materials....................................................................... 383

7.6.3.8 Communication with multiple transponders .............................................................................. 385

7.6.4 Mounting instructions ................................................................................................................ 385

7.6.5 Memory configuration of the transponder ................................................................................. 386

7.6.6 Technical Specifications ............................................................................................................ 387

7.6.6.1 Mechanical data ........................................................................................................................ 387

7.6.6.2 Electrical data ............................................................................................................................ 387

7.6.6.3 Memory specifications ............................................................................................................... 387

7.6.6.4 Environmental conditions .......................................................................................................... 388

7.6.6.5 Chemical resistance of the transponder RF620T ..................................................................... 388

7.6.7 Certificates and approvals......................................................................................................... 391

7.6.8 Dimension drawing .................................................................................................................... 392

7.7 SIMATIC RF622T ...................................................................................................................... 393

7.8 SIMATIC RF625T ...................................................................................................................... 393

7.8.1 Characteristics .......................................................................................................................... 393

7.8.2 Ordering data ............................................................................................................................

7.

8.3 Planning the use ....................................................................................................................... 394

393

7.8.3.1 Optimum antenna/transponder positioning with planar mounting of the transponder on

metal ..........................................................................................................................................

7

.8.3.2 Range when mounted on flat metallic carrier plates ................................................................. 395

SIMATIC RF600

394

12 System Manual, xx/2014, J31069-D0171-U001-A15-7618

Page 13

Table of contents

7.8.3.3 Range when mounted on non-metallic carrier materials ........................................................... 396

7.8.3.4 Influence of conducting walls on the range ................................................................................ 396

7.8.3.5 Mounting in metal ....................................................................................................................... 398

7.8.3.6 Directional radiation pattern of the transponder ......................................................................... 399

7.8.4 Mounting instructions ................................................................................................................. 402

7.8.5 Memory configuration of the transponder .................................................................................. 402

7.8.6 Technical Specifications ............................................................................................................ 402

7.8.6.1 Mechanical data ......................................................................................................................... 402

7.8.6.2 Electrical data ............................................................................................................................. 403

7.8.6.3 Information on memory .............................................................................................................. 403

7.8.6.4 Environmental conditions ........................................................................................................... 403

7.8.6.5 Chemical resistance of the RF625T transponder ...................................................................... 404

7.8.7 Certificates and approvals ......................................................................................................... 405

7.8.8 Dimension drawing .................................................................................................................... 405

7.9 SIMATIC RF630T....................................................................................................................... 406

7.9.1 Characteristics ........................................................................................................................... 406

7.9.2 Ordering data ............................................................................................................................. 407

7.9.3 Planning application ................................................................................................................... 407

7.9.3.1 Optimum antenna/transponder positioning with plane mounting of the transponder on

metal .......................................................................................................................................... 407

7.9.3.2 Range when mounted on flat metallic carrier plates .................................................................. 410

7.9.3.3 Influence of conducting walls on the range ................................................................................ 410

7.9.3.4 Directional radiation pattern of the transponder ......................................................................... 412

7.9.4 Mounting instructions .................................................................................................................

7.

9.5 Memory configuration of the transponder .................................................................................. 413

413

7.9.6 Technical specifications ............................................................................................................. 414

7.9.6.1 Mechanical data ......................................................................................................................... 414

7.9.6.2 Electrical data ............................................................................................................................. 414

7.9.6.3 Memory specifications ............................................................................................................... 414

7.9.6.4 Environmental conditions ........................................................................................................... 415

7.9.6.5 Chemical resistance of the transponder .................................................................................... 415

7.9.7 Certificates and approvals ......................................................................................................... 417

7.9.8 Dimension drawing .................................................................................................................... 417

7.10 SIMATIC RF640T Gen 2 ............................................................................................................ 418

7.10.1 Characteristics ........................................................................................................................... 418

7.10.2 Ordering data ............................................................................................................................. 419

7.10.3 Planning the use ........................................................................................................................ 419

7.10.3.1 Optimum antenna/transponder positioning with plane mounting of the transponder on

metal .......................................................................................................................................... 419

7.10.3.2 Range when mounted on flat metallic carrier plates .................................................................. 420

7.10.3.3 Range when mounted on non-metallic carrier materials ........................................................... 421

7.10.3.4 Influence of conducting walls on the range ................................................................................ 421

7.10.3.5 Directional radiation pattern of the transponder ......................................................................... 423

7.10.3.6 Use of the transponder in the Ex protection area ...................................................................... 424

7.10.3.7 Use of the transponder in hazardous areas for gases ............................................................... 425

7.10.3.8 Use of the transponder in hazardous areas for dusts ................................................................ 427

7.10.4 Mounting instructions .................................................................................................................

7.

10.5 Memory configuration of the transponder .................................................................................. 431

7.10.6 Technical Specifications ............................................................................................................

10.6.1 Mechanical data ......................................................................................................................... 432

7.

7.10.6.2 Electrical data ............................................................................................................................. 432

SIMATIC RF600

System Manual, xx/2014, J31069-D0171-U001-A15-7618

431

432

13

Page 14

Table of contents

8 Integration into networks ...................................................................................................................... 461

9 System diagnostics .............................................................................................................................. 469

7.10.6.3 Memory specifications ............................................................................................................... 432

7.10.6.4 Environmental conditions .......................................................................................................... 433

7.10.6.5 Chemical resistance of the RF640T transponder ..................................................................... 434

7.10.7 Certificates and approvals......................................................................................................... 436

7.10.7.1 EC Declaration of Conformity according to directive 94/9EC RF640T Gen 2 UHF Tool

Tag Version 1 ............................................................................................................................ 436

7.10.8 Dimension drawing .................................................................................................................... 437

7.11 SIMATIC RF680T ...................................................................................................................... 438

7.11.1 Characteristics .......................................................................................................................... 438

7.11.2 Ordering data ............................................................................................................................ 439

7.11.3 Planning the use ....................................................................................................................... 439

7.11.3.1 Optimum antenna/transponder positioning with plane mounting of the transponder on

metal .......................................................................................................................................... 439

7.11.3.2 Range when mounted on flat metallic carrier plates ................................................................. 440

7.11.3.3 Influence of conducting walls on the range ............................................................................... 441

7.11.3.4 Directional radiation pattern of the transponder on metallic surfaces ....................................... 443

7.11.3.5 Range when mounted on non-metallic carrier materials .......................................................... 444

7.11.3.6 Directional radiation pattern of the transponder on non-metallic surfaces ............................... 444

7.11.3.7 Relationship between performance and reading range ............................................................ 446

7.11.3.8 Use of the transponder in hazardous areas .............................................................................. 447

7.11.3.9 Use of the transponder in hazardous areas for gases .............................................................. 448

7.11.3.10 Use of the transponder in hazardous areas for dusts .......................................................... 451

7.11.4 Mounting instructions ................................................................................................................ 454

7.11.5 Memory configuration of the transponder ................................................................................. 454

7.11.6 Technical specifications ............................................................................................................ 455

7.

11.6.1 Mechanical data ........................................................................................................................ 455

7.11.6.2 Electrical data ............................................................................................................................ 455

7.11.6.3 Memory specifications ............................................................................................................... 455

7.11.6.4 Environmental conditions .......................................................................................................... 456

7.11.6.5 Chemical resistance of the RF680T transponder ..................................................................... 457

7.11.7 Certificates and approvals......................................................................................................... 458

7.11.7.1 EC Declaration of Conformity according to directive 94/9/EG RF680T Version 1 .................... 458

7.11.8 Dimension drawing .................................................................................................................... 459

8.1 Overview of parameterization of RF600 reader ........................................................................ 461

8.2 Integration in IT networks via the user application .................................................................... 461

8.3 Integration in SIMATIC networks .............................................................................................. 462

9.1 Error messages and flash codes for RF620R/RF630R ............................................................ 469

9.2 Flashing codes RF640R/RF670R ............................................................................................. 479

9.3 Error messages RF640R/RF670R ............................................................................................ 479

9.4 LED displays RF650R/RF680R/RF685R .................................................................................. 480

9.4.1 LED operating display ............................................................................................................... 481

9.4.2 Error display by LEDs ............................................................................................................... 481

SIMATIC RF600

14 System Manual, xx/2014, J31069-D0171-U001-A15-7618

Page 15

Table of contents

10 Accessories ........................................................................................................................................ 483

A Appendix............................................................................................................................................. 501

Glossary ............................................................................................................................................. 507

Index................................................................................................................................................... 521

10.1 Wide-range power supply unit for SIMATIC RF systems .......................................................... 483

10.1.1 Features ..................................................................................................................................... 483

10.1.2 Scope of supply.......................................................................................................................... 484

10.1.3 Ordering data ............................................................................................................................. 484

10.1.4 Safety Information ...................................................................................................................... 485

10.1.5 Connecting ................................................................................................................................. 487

10.1.6 Technical specifications ............................................................................................................. 488

10.1.7 Pin assignment of DC outputs and mains connection ............................................................... 490

10.1.8 Dimension drawing .................................................................................................................... 491

10.1.9 Certificates and approvals ......................................................................................................... 492

10.2 The PC adapter for SIMATIC RF-DIAG ..................................................................................... 493

10.2.1 Description ................................................................................................................................. 493

10.2.2 Pin assignment of the RS-422 interface .................................................................................... 494

10.2.3 Technical specifications ............................................................................................................. 497

10.2.4 Dimension drawing .................................................................................................................... 499

10.2.5 Certificates and approvals ......................................................................................................... 500

A.1 Certificates and approvals ......................................................................................................... 501

A.2 Service & support ....................................................................................................................... 504

SIMATIC RF600

System Manual, xx/2014, J31069-D0171-U001-A15-7618

15

Page 16

Table of contents

SIMATIC RF600

16 System Manual, xx/2014, J31069-D0171-U001-A15-7618

Page 17

REVIEW

1

1.1