Page 1

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SIMATIC Ident

RFID systems

SIMATIC RF300

System Manual

07/2017

C79000

Introduction

1

Safety information

2

System overview

3

Planning the RF300 system

4

Readers

5

Antennas

6

RF300 transponder

7

ISO transponder

8

System integration

9

System diagnostics

10

Appendix

A

-G8976-C345-07

Page 2

Siemens AG

Division Process Industries and Drives

Postfach 48 48

90026 NÜRNBERG

GERMANY

Ⓟ

Copyright © Siemens AG 2005 - 2017.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

07/2017 Subject to change

Page 3

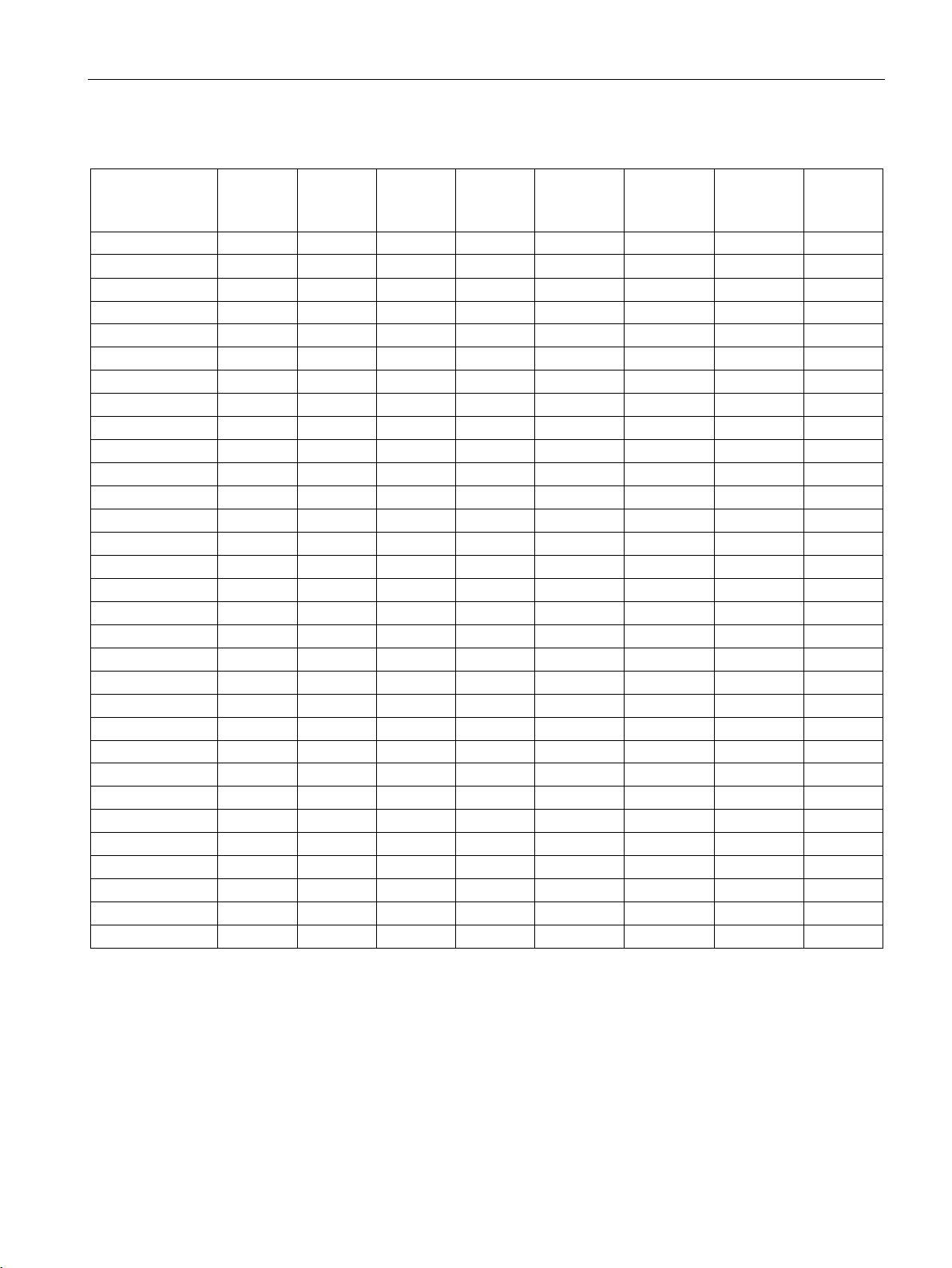

Table of contents

1 Introduction ........................................................................................................................................... 15

2 Safety information ................................................................................................................................. 19

3 System overview ................................................................................................................................... 23

4 Planning the RF300 system .................................................................................................................. 39

1.1 Navigating in the system manual ............................................................................................ 15

1.2 Preface .................................................................................................................................... 15

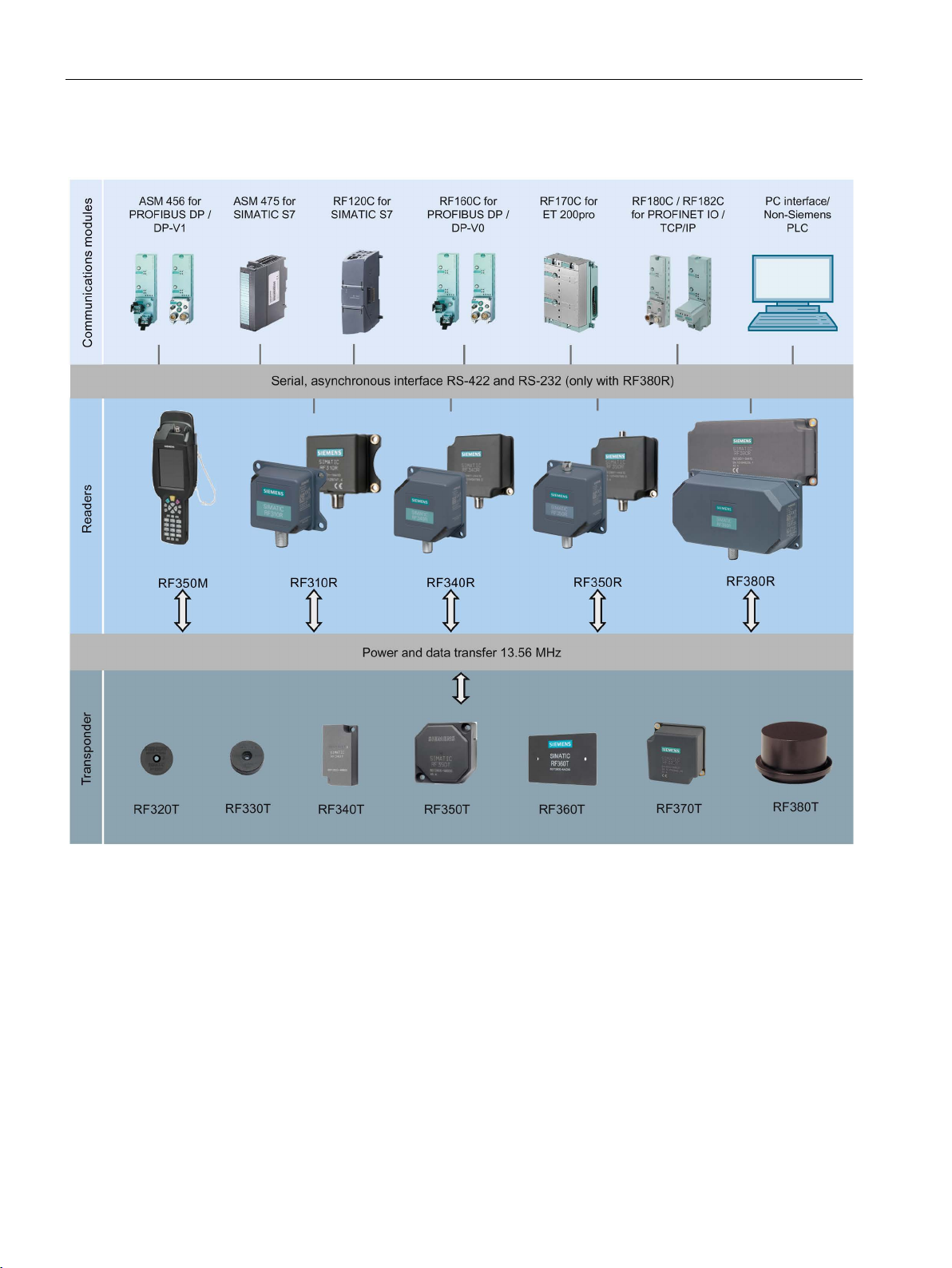

3.1 RFID systems ......................................................................................................................... 23

3.2 SIMATIC RF300 ...................................................................................................................... 24

3.2.1 System overview of SIMATIC RF300 ..................................................................................... 24

3.2.2 RFID components and their function ...................................................................................... 25

3.2.3 Application areas of RF300 .................................................................................................... 33

3.3 System configuration .............................................................................................................. 34

3.3.1 Overview ................................................................................................................................. 34

3.3.2 Assembly line example: Use of RF300 transponders ............................................................. 34

3.3.3 Example of container and cardboard container handling: Use of ISO transponders ............. 36

4.1 Fundamentals of application planning .................................................................................... 39

4.1.1 Selection criteria for SIMATIC RF300 components ................................................................ 39

4.1.2 Transmission window and read/write distance ....................................................................... 39

4.1.3 Width of the transmission window .......................................................................................... 42

4.1.4 Impact of secondary fields ...................................................................................................... 43

4.1.5 Setup help of the readers of the second generation ............................................................... 46

4.1.6 Permissible directions of motion of the transponder ............................................................... 47

4.1.7 Operation in static and dynamic mode ................................................................................... 47

4.1.8 Dwell time of the transponder ................................................................................................. 49

4.1.9 Communication between communications module, reader and transponder ........................ 50

4.2 Field data for transponders, readers and antennas ................................................................ 51

4.2.1 Field data of RF300 transponders .......................................................................................... 52

4.2.2 Field data of ISO transponders (MDS D) ................................................................................ 56

4.2.3 Field data of ISO transponders (MDS E) ................................................................................ 61

4.2.4 Minimum clearances ............................................................................................................... 64

4.3 Installation guidelines.............................................................................................................. 67

4.3.1 Overview ................................................................................................................................. 67

4.3.2 Reduction of interference due to metal ................................................................................... 67

4.3.3 Effects of metal on different transponders and readers .......................................................... 70

4.3.4 Impact on the transmission window by metal ......................................................................... 70

4.3.4.1 Impact on the transmission window by metal ......................................................................... 71

4.3.4.2 RF340R ................................................................................................................................... 75

4.3.4.3 RF350R ................................................................................................................................... 79

4.3.4.4 RF380R ................................................................................................................................... 93

4.3.4.5 RF382R ...................................................................................................................................

96

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

3

Page 4

Table of contents

5 Readers ............................................................................................................................................... 123

4.4 Chemical resistance of the readers and transponders .......................................................... 97

4.4.1 Readers .................................................................................................................................. 97

4.4.1.1 Overview of the readers and their housing materials ............................................................ 97

4.4.1.2 Polyamide 12 ......................................................................................................................... 97

4.4.2 Transponder ........................................................................................................................... 99

4.4.2.1 Overview of the transponders and their housing materials ................................................... 99

4.4.2.2 Polyamide 6 and Polyamide 6.6 GF30 ................................................................................ 101

4.4.2.3 Polyamide 12 ....................................................................................................................... 102

4.4.2.4 Polyphenylene sulfide (PPS) ............................................................................................... 104

4.4.2.5 Polycarbonate (PC) .............................................................................................................. 105

4.4.2.6 Polyvinyl chloride (PVC) ...................................................................................................... 106

4.4.2.7 Epoxy resin .......................................................................................................................... 106

4.5 Guidelines for electromagnetic compatibility (EMC) ............................................................ 109

4.5.1 Overview .............................................................................................................................. 109

4.5.2 What does EMC mean? ....................................................................................................... 110

4.5.3 Basic rules ............................................................................................................................ 111

4.5.4 Propagation of electromagnetic interference ....................................................................... 112

4.5.5 Cabinet configuration ........................................................................................................... 116

4.5.6 Prevention of interference sources ...................................................................................... 119

4.5.7 Equipotential bonding .......................................................................................................... 120

4.5.8 Cable shielding..................................................................................................................... 121

5.1 SIMATIC RF310R ................................................................................................................ 124

5.1.1 Features ............................................................................................................................... 124

5.1.2 RF310R ordering data ......................................................................................................... 124

5.1.3 Pin assignment RF310R with RS-422 interface .................................................................. 125

5.1.4 LED operating display .......................................................................................................... 125

5.1.5 Ensuring reliable data exchange .......................................................................................... 125

5.1.6 Metal-free area ..................................................................................................................... 126

5.1.7 Minimum distance between RF310R readers ...................................................................... 126

5.1.8 Technical specifications ....................................................................................................... 127

5.1.9 Approvals ............................................................................................................................. 129

5.1.10 Dimension drawing .............................................................................................................. 130

5.2 SIMATIC RF310R with Scanmode ...................................................................................... 131

5.2.1 Features ............................................................................................................................... 131

5.2.2 Ordering data for RF310R with Scanmode .......................................................................... 131

5.2.3 Pin assignment RF310R special version Scanmode RS-422 interface ............................... 132

5.2.4 LED operating display .......................................................................................................... 132

5.2.5 Ensuring reliable data exchange .......................................................................................... 132

5.2.6 Metal-free area ..................................................................................................................... 133

5.2.7 Minimum distance between several readers ....................................................................... 133

5.2.8 Technical specifications ....................................................................................................... 134

5.2.9 Approvals ............................................................................................................................. 135

5.2.10 Dimension drawing .............................................................................................................. 136

5.3 SIMATIC RF310R - 2nd generation ..................................................................................... 137

5.3.1 Features ...............................................................................................................................

137

5.3.2 Ordering data ....................................................................................................................... 137

5.3.3 Pin assignment of the RS-422 interface .............................................................................. 138

5.3.4 LED operating display .......................................................................................................... 138

5.3.5 Ensuring reliable data exchange .......................................................................................... 139

SIMATIC RF300

4 System Manual, 07/2017, C79000-G8976-C345-07

Page 5

Table of contents

5.3.6 Metal-free area ...................................................................................................................... 139

5.3.7 Minimum distance between RF310R readers ...................................................................... 140

5.3.8 Technical specifications ........................................................................................................ 141

5.3.9 Approvals .............................................................................................................................. 142

5.3.10 Dimension drawing ............................................................................................................... 144

5.3.11 Using the reader in hazardous area ..................................................................................... 144

5.3.11.1 Using the reader in hazardous area for gases ..................................................................... 148

5.3.11.2 Using the reader in hazardous area for dust ........................................................................ 148

5.3.11.3 Installation and operating conditions for hazardous areas: .................................................. 149

5.4 SIMATIC RF340R/RF350R .................................................................................................. 150

5.4.1 SIMATIC RF340R ................................................................................................................. 150

5.4.1.1 Features ................................................................................................................................ 150

5.4.1.2 Ordering data for RF340R .................................................................................................... 150

5.4.1.3 Pin assignment of RF340R RS422 interface ........................................................................ 151

5.4.1.4 LED operating display ........................................................................................................... 151

5.4.1.5 Ensuring reliable data exchange .......................................................................................... 151

5.4.1.6 Metal-free area ...................................................................................................................... 152

5.4.1.7 Minimum distance between RF340R readers ...................................................................... 152

5.4.1.8 Technical specifications ........................................................................................................ 153

5.4.1.9 Approvals .............................................................................................................................. 155

5.4.1.10 Dimension drawing ............................................................................................................... 156

5.4.2 SIMATIC RF350R ................................................................................................................. 157

5.4.2.1 Features ................................................................................................................................

157

5.4.2.2 Ordering data for RF350R .................................................................................................... 157

5.4.2.3 Pin assignment of RF350R RS422 interface ........................................................................ 158

5.4.2.4 LED operating display ........................................................................................................... 158

5.4.2.5 Ensuring reliable data exchange .......................................................................................... 158

5.4.2.6 Metal-free area ...................................................................................................................... 158

5.4.2.7 Technical specifications ........................................................................................................ 159

5.4.2.8 Approvals .............................................................................................................................. 161

5.4.2.9 Dimension drawing ............................................................................................................... 162

5.4.3 Use of the reader in hazardous areas .................................................................................. 163

5.4.3.1 Use of the readers in hazardous areas for gases ................................................................. 164

5.4.3.2 Use of the readers in hazardous areas for dusts .................................................................. 164

5.4.3.3 Installation and operating conditions for the hazardous area ............................................... 165

5.5 SIMATIC RF340R/RF350R - 2nd generation ....................................................................... 166

5.5.1 SIMATIC RF340R - 2nd generation ...................................................................................... 166

5.5.1.1 Features ................................................................................................................................ 166

5.5.1.2 Ordering data ........................................................................................................................ 166

5.5.1.3 Pin assignment of the RS-422 interface ............................................................................... 167

5.5.1.4 LED operating display ........................................................................................................... 167

5.5.1.5 Ensuring reliable data exchange .......................................................................................... 167

5.5.1.6 Metal-free area ...................................................................................................................... 168

5.5.1.7 Minimum distance between RF340R readers ...................................................................... 168

5.5.1.8 Technical specifications ........................................................................................................ 169

5.5.1.9 Approvals .............................................................................................................................. 171

5.5.1.10 Dimension drawing ............................................................................................................... 172

5.5.2 SIMATIC RF350R - 2nd generation ...................................................................................... 173

5.5.2.1 Features ................................................................................................................................ 173

5.5.2.2 Ordering data ........................................................................................................................ 173

5.5.2.3 Pin assignment of the RS-422 interface ............................................................................... 174

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

5

Page 6

Table of contents

5.5.2.4 LED operating display .......................................................................................................... 174

5.5.2.5 Ensuring reliable data exchange .......................................................................................... 174

5.5.2.6 Metal-free area ..................................................................................................................... 175

5.5.2.7 Technical specifications ....................................................................................................... 175

5.5.2.8 Approvals ............................................................................................................................. 177

5.5.2.9 Dimension drawing .............................................................................................................. 178

5.5.3 Using the readers in a hazardous area ................................................................................ 179

5.5.3.1 Using the reader in hazardous area for gases ..................................................................... 182

5.5.3.2 Using the reader in hazardous area for dust ....................................................................... 182

5.5.3.3 Installation and operating conditions for hazardous areas: ................................................. 183

5.6 SIMATIC RF380R ................................................................................................................ 184

5.6.1 Features ............................................................................................................................... 184

5.6.2 RF380R ordering data ......................................................................................................... 184

5.6.3 Pin assignment of RF380R RS-232/RS-422 interface......................................................... 184

5.6.4 LED operating display .......................................................................................................... 185

5.6.5 Ensuring reliable data exchange .......................................................................................... 185

5.6.6 Metal-free area ..................................................................................................................... 186

5.6.7 Minimum distance between RF380R readers ...................................................................... 186

5.6.8 Technical specifications ....................................................................................................... 187

5.6.9 Approvals ............................................................................................................................. 189

5.6.10 Dimension drawing .............................................................................................................. 190

5.6.11 Use of the reader in a hazardous ......................................................................................... 190

5.6.11.1 Use of the reader in a hazardous area ................................................................................ 190

5.6.11.2 Use of the reader in hazardous areas for gases .................................................................. 191

5.6.11.3 Installation and operating conditions for hazardous areas: ................................................. 192

5.7 SIMATIC RF380R with Scanmode ...................................................................................... 193

5.7.1 Features ............................................................................................................................... 193

5.7.2 Ordering data for RF380R with Scanmode .......................................................................... 193

5.7.3 Pin assignment RF380R Scanmode RS-232 interface........................................................ 194

5.7.4 LED operating display .......................................................................................................... 194

5.7.5 Ensuring reliable data exchange .......................................................................................... 194

5.7.6 Metal-free area ..................................................................................................................... 195

5.7.7 Minimum distance between several RF380R Scanmode readers ....................................... 195

5.7.8 Technical specifications ....................................................................................................... 196

5.7.9 Approvals ............................................................................................................................. 197

5.7.10 Certificates and Approvals ................................................................................................... 198

5.7.11 Dimension drawing .............................................................................................................. 199

5.8 SIMATIC RF380R - 2nd generation ..................................................................................... 200

5.8.1 Features ............................................................................................................................... 200

5.8.2 RF380R ordering data ......................................................................................................... 200

5.8.3 Pin assignment of RF380R RS-232/RS-422 interface......................................................... 201

5.8.4 LED operating display .......................................................................................................... 201

5.8.5 Ensuring reliable data exchange .......................................................................................... 202

5.8.6 Metal-free area ..................................................................................................................... 202

5.8.7 Minimum distance between RF380R readers ...................................................................... 203

5.8.8 Technical specifications ....................................................................................................... 204

5.8.9 Approvals .............................................................................................................................

205

5.8.10 Dimension drawing .............................................................................................................. 207

5.8.11 Using the reader in hazardous area..................................................................................... 207

5.8.11.1 Using the reader in hazardous area for gases ..................................................................... 210

5.8.11.2 Using the reader in hazardous area for dust ....................................................................... 211

SIMATIC RF300

6 System Manual, 07/2017, C79000-G8976-C345-07

Page 7

Table of contents

6 Antennas ............................................................................................................................................ 221

7 RF300 transponder ............................................................................................................................. 233

5.8.11.3 Installation and operating conditions for hazardous areas: .................................................. 211

5.9 SIMATIC RF382R with Scanmode ....................................................................................... 212

5.9.1 Characteristics ...................................................................................................................... 212

5.9.2 RF382R with Scanmode ordering data................................................................................. 212

5.9.3 Pin assignment RF382R Scanmode RS232 interface .......................................................... 213

5.9.4 LED operating display ........................................................................................................... 213

5.9.5 Ensuring reliable data exchange .......................................................................................... 213

5.9.6 Mounting on metal ................................................................................................................ 214

5.9.7 Minimum distance between several RF382R Scanmode readers ....................................... 214

5.9.8 Transmission window............................................................................................................ 214

5.9.9 Technical specifications ........................................................................................................ 218

5.9.10 Approvals .............................................................................................................................. 219

5.9.11 Dimensional diagram ............................................................................................................ 220

6.1 Features ................................................................................................................................ 221

6.2 Ordering data ........................................................................................................................ 224

6.3 Ensuring reliable data exchange .......................................................................................... 224

6.4 Metal-free area ...................................................................................................................... 225

6.5 Minimum distance between antennas .................................................................................. 228

6.6 Technical specifications ........................................................................................................ 229

6.7 Dimensional drawings ........................................................................................................... 230

7.1 Memory configuration of the RF300 transponders ............................................................... 234

7.2 SIMATIC RF320T ................................................................................................................. 236

7.2.1 Features ................................................................................................................................ 236

7.2.2 Ordering data ........................................................................................................................ 236

7.2.3 Mounting on metal ................................................................................................................ 237

7.2.4 Technical data ....................................................................................................................... 238

7.2.5 Dimension drawing ............................................................................................................... 239

7.3 SIMATIC RF330T ................................................................................................................. 240

7.3.1 Features ................................................................................................................................ 240

7.3.2 Ordering data ........................................................................................................................ 240

7.3.3 Mounting on/in metal............................................................................................................. 240

7.3.4 Technical specifications ........................................................................................................ 242

7.3.5 Dimension drawing ............................................................................................................... 243

7.4 SIMATIC RF340T ................................................................................................................. 244

7.4.1 Features ................................................................................................................................ 244

7.4.2 Ordering data ........................................................................................................................ 244

7.4.3 Mounting on metal ................................................................................................................ 245

7.4.4 Technical specifications ........................................................................................................ 246

7.4.5 Dimension drawing ............................................................................................................... 247

7.5 SIMATIC RF350T ................................................................................................................. 248

7.5.1 Features ................................................................................................................................ 248

7.5.2 Ordering data ........................................................................................................................ 248

7.5.3 Mounting on metal ................................................................................................................ 249

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

7

Page 8

Table of contents

8 ISO transponder .................................................................................................................................. 275

7.5.4 Mounting options .................................................................................................................. 250

7.5.5 Technical data ...................................................................................................................... 251

7.5.6 Dimension drawing .............................................................................................................. 252

7.6 SIMATIC RF360T................................................................................................................. 253

7.6.1 Features ............................................................................................................................... 253

7.6.2 Ordering data ....................................................................................................................... 253

7.6.3 Mounting on metal ............................................................................................................... 254

7.6.4 Technical data ...................................................................................................................... 257

7.6.5 Dimension drawing .............................................................................................................. 258

7.7 SIMATIC RF370T................................................................................................................. 259

7.7.1 Features ............................................................................................................................... 259

7.7.2 Ordering data ....................................................................................................................... 259

7.7.3 Mounting on metal ............................................................................................................... 260

7.7.4 Mounting instructions ........................................................................................................... 261

7.7.5 Technical specifications ....................................................................................................... 261

7.7.6 Dimensional drawing ............................................................................................................ 262

7.8 SIMATIC RF380T................................................................................................................. 263

7.8.1 Features ............................................................................................................................... 263

7.8.2 Ordering data ....................................................................................................................... 263

7.8.3 Installation guidelines for RF380T ....................................................................................... 264

7.8.3.1 Mounting instructions ........................................................................................................... 264

7.8.3.2 Metal-free area ..................................................................................................................... 267

7.8.4 Configuring instructions .......................................................................................................

268

7.8.4.1 Temperature dependence of the transmission window ....................................................... 268

7.8.4.2 Temperature response in cyclic operation ........................................................................... 268

7.8.5 Use of the transponder in the Ex protection area ................................................................ 271

7.8.5.1 Use of the transponder in hazardous areas for gases ......................................................... 272

7.8.5.2 Installation and operating conditions for the hazardous area .............................................. 272

7.8.6 Cleaning the mobile data memory ....................................................................................... 272

7.8.7 Technical specifications ....................................................................................................... 273

7.8.8 Dimensional drawing ............................................................................................................ 274

8.1 Memory configuration of ISO the transponders ................................................................... 276

8.2 MDS D100 ............................................................................................................................ 278

8.2.1 Characteristics ..................................................................................................................... 278

8.2.2 Ordering data ....................................................................................................................... 278

8.2.3 Metal-free area ..................................................................................................................... 279

8.2.4 Technical data ...................................................................................................................... 281

8.2.5 Dimension drawing .............................................................................................................. 282

8.3 MDS D117 ............................................................................................................................ 283

8.3.1 Features ............................................................................................................................... 283

8.3.2 Ordering data ....................................................................................................................... 283

8.3.3 Mounting in metal ................................................................................................................. 284

8.3.4 Technical specifications ....................................................................................................... 284

8.3.5 Dimension drawing .............................................................................................................. 285

8.4 MDS D124 ............................................................................................................................ 286

8.4.1 Characteristics ..................................................................................................................... 286

8.4.2 Ordering data ....................................................................................................................... 286

SIMATIC RF300

8 System Manual, 07/2017, C79000-G8976-C345-07

Page 9

Table of contents

8.4.3 Mounting on metal ................................................................................................................ 287

8.4.4 Technical specifications ........................................................................................................ 288

8.4.5 Use of the MDS D124 in hazardous area ............................................................................. 289

8.4.6 Dimension drawing ............................................................................................................... 291

8.5 MDS D126 ............................................................................................................................ 292

8.5.1 Characteristics ...................................................................................................................... 292

8.5.2 Ordering data ........................................................................................................................ 292

8.5.3 Mounting on metal ................................................................................................................ 293

8.5.4 Technical specifications ........................................................................................................ 294

8.5.5 Dimension drawing ............................................................................................................... 295

8.6 MDS D127 ............................................................................................................................ 296

8.6.1 Features ................................................................................................................................ 296

8.6.2 Ordering data ........................................................................................................................ 296

8.6.3 Mounting in metal .................................................................................................................. 297

8.6.4 Technical specifications ........................................................................................................ 298

8.6.5 Dimension drawing ............................................................................................................... 299

8.7 MDS D139 ............................................................................................................................ 300

8.7.1 Characteristics ...................................................................................................................... 300

8.7.2 Ordering data ........................................................................................................................ 301

8.7.3 Mounting on metal ................................................................................................................ 301

8.7.4 Cleaning the mobile data memory ........................................................................................ 302

8.7.5 Technical specifications ........................................................................................................ 303

8.7.6 Use of the MDS D139 in hazardous areas ...........................................................................

304

8.7.7 Dimension drawings .............................................................................................................. 306

8.8 MDS D160 ............................................................................................................................ 307

8.8.1 Characteristics ...................................................................................................................... 307

8.8.2 Information for RF300 compatibility ...................................................................................... 307

8.8.3 Ordering data ........................................................................................................................ 308

8.8.4 Mounting on metal ................................................................................................................ 308

8.8.5 Technical specifications ........................................................................................................ 309

8.8.6 Dimension drawings .............................................................................................................. 311

8.9 MDS D165 ............................................................................................................................ 312

8.9.1 Features ................................................................................................................................ 312

8.9.2 Ordering data ........................................................................................................................ 312

8.9.3 Technical data ....................................................................................................................... 312

8.9.4 Dimension drawing ............................................................................................................... 314

8.10 MDS D200 ............................................................................................................................ 314

8.10.1 Features ................................................................................................................................ 314

8.10.2 Ordering data ........................................................................................................................ 315

8.10.3 Mounting on metal ................................................................................................................ 315

8.10.4 Technical data ....................................................................................................................... 316

8.10.5 Dimension drawing ............................................................................................................... 318

8.11 MDS D261 ............................................................................................................................ 319

8.11.1 Features ................................................................................................................................ 319

8.11.2 Ordering data ........................................................................................................................ 319

8.11.3 Technical data ....................................................................................................................... 319

8.11.4 Dimension drawing ...............................................................................................................

321

8.12 MDS D324 ............................................................................................................................ 321

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

9

Page 10

Table of contents

8.12.1 Characteristics ..................................................................................................................... 321

8.12.2 Ordering data ....................................................................................................................... 322

8.12.3 Mounting on metal ............................................................................................................... 322

8.12.4 Technical specifications ....................................................................................................... 323

8.12.5 Dimension drawing .............................................................................................................. 325

8.13 MDS D339 ............................................................................................................................ 326

8.13.1 Characteristics ..................................................................................................................... 326

8.13.2 Ordering data ....................................................................................................................... 326

8.13.3 Mounting on metal ............................................................................................................... 327

8.13.4 Cleaning the mobile data memory ....................................................................................... 328

8.13.5 Technical specifications ....................................................................................................... 328

8.13.6 Use of the MDS D339 in hazardous areas .......................................................................... 330

8.13.7 Dimensional drawing ............................................................................................................ 332

8.14 MDS D400 ............................................................................................................................ 333

8.14.1 Features ............................................................................................................................... 333

8.14.2 Ordering data ....................................................................................................................... 333

8.14.3 Mounting on metal ............................................................................................................... 334

8.14.4 Technical specifications ....................................................................................................... 335

8.14.5 Dimension drawing .............................................................................................................. 337

8.15 MDS D421 ............................................................................................................................ 338

8.15.1 Characteristics ..................................................................................................................... 338

8.15.2 Ordering data ....................................................................................................................... 338

8.15.3 Mounting on metal ...............................................................................................................

339

8.15.4 Technical specifications ....................................................................................................... 341

8.15.5 Dimension drawing .............................................................................................................. 342

8.16 MDS D422 ............................................................................................................................ 343

8.16.1 Characteristics ..................................................................................................................... 343

8.16.2 Ordering data ....................................................................................................................... 343

8.16.3 Mounting in metal ................................................................................................................. 344

8.16.4 Technical specifications ....................................................................................................... 344

8.16.5 Dimension drawing .............................................................................................................. 346

8.17 MDS D423 ............................................................................................................................ 346

8.17.1 Characteristics ..................................................................................................................... 346

8.17.2 Ordering data ....................................................................................................................... 346

8.17.3 Mounting on metal ............................................................................................................... 347

8.17.4 Technical specifications ....................................................................................................... 348

8.17.5 Dimensional drawing ............................................................................................................ 350

8.18 MDS D424 ............................................................................................................................ 350

8.18.1 Characteristics ..................................................................................................................... 350

8.18.2 Ordering data ....................................................................................................................... 351

8.18.3 Mounting on metal ............................................................................................................... 351

8.18.4 Technical specifications ....................................................................................................... 352

8.18.5 Dimension drawing .............................................................................................................. 354

8.19 MDS D425 ............................................................................................................................ 354

8.19.1 Characteristics ..................................................................................................................... 354

8.19.2 Ordering data ....................................................................................................................... 355

8.19.3 Application example .............................................................................................................

355

8.19.4 Technical specifications ....................................................................................................... 355

8.19.5 Dimension drawing .............................................................................................................. 357

SIMATIC RF300

10 System Manual, 07/2017, C79000-G8976-C345-07

Page 11

Table of contents

8.20 MDS D426 ............................................................................................................................ 357

8.20.1 Characteristics ...................................................................................................................... 357

8.20.2 Ordering data ........................................................................................................................ 358

8.20.3 Mounting on metal ................................................................................................................ 358

8.20.4 Technical specifications ........................................................................................................ 359

8.20.5 Dimension drawing ............................................................................................................... 360

8.21 MDS D428 ............................................................................................................................ 361

8.21.1 Characteristics ...................................................................................................................... 361

8.21.2 Ordering data ........................................................................................................................ 361

8.21.3 Application example .............................................................................................................. 362

8.21.4 Technical specifications ........................................................................................................ 362

8.21.5 Dimension drawing ............................................................................................................... 364

8.22 MDS D460 ............................................................................................................................ 364

8.22.1 Characteristics ...................................................................................................................... 364

8.22.2 Ordering data ........................................................................................................................ 365

8.22.3 Mounting on metal ................................................................................................................ 365

8.22.4 Technical specifications ........................................................................................................ 366

8.22.5 Dimension drawings .............................................................................................................. 367

8.23 MDS D521 ............................................................................................................................ 368

8.23.1 Characteristics ...................................................................................................................... 368

8.23.2 Ordering data ........................................................................................................................ 368

8.23.3 Mounting on metal ................................................................................................................ 368

8.23.4 Technical specifications ........................................................................................................

370

8.23.5 Dimension drawing ............................................................................................................... 372

8.24 MDS D522 ............................................................................................................................ 372

8.24.1 Characteristics ...................................................................................................................... 372

8.24.2 Ordering data ........................................................................................................................ 372

8.24.3 Mounting in metal .................................................................................................................. 373

8.24.4 Technical specifications ........................................................................................................ 373

8.24.5 Dimension drawing ............................................................................................................... 375

8.25 MDS D522 special variant .................................................................................................... 375

8.25.1 Characteristics ...................................................................................................................... 375

8.25.2 Ordering data ........................................................................................................................ 375

8.25.3 Mounting in metal .................................................................................................................. 376

8.25.4 Installation instructions.......................................................................................................... 376

8.25.5 Technical specifications ........................................................................................................ 378

8.25.6 Dimensional drawing............................................................................................................. 379

8.26 MDS D524 ............................................................................................................................ 380

8.26.1 Characteristics ...................................................................................................................... 380

8.26.2 Ordering data ........................................................................................................................ 380

8.26.3 Mounting on metal ................................................................................................................ 381

8.26.4 Technical specifications ........................................................................................................ 382

8.26.5 Dimension drawing ............................................................................................................... 383

8.27 MDS D525 ............................................................................................................................ 384

8.27.1 Characteristics ...................................................................................................................... 384

8.27.2 Ordering data ........................................................................................................................ 384

8.27.3 Application example ..............................................................................................................

385

8.27.4 Technical specifications ........................................................................................................ 385

8.27.5 Dimension drawing ............................................................................................................... 387

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

11

Page 12

Table of contents

9 System integration ............................................................................................................................... 397

10 System diagnostics .............................................................................................................................. 413

A Appendix ............................................................................................................................................. 423

8.28 MDS D526 ............................................................................................................................ 388

8.28.1 Characteristics ..................................................................................................................... 388

8.28.2 Ordering data ....................................................................................................................... 388

8.28.3 Mounting on metal ............................................................................................................... 389

8.28.4 Technical specifications ....................................................................................................... 390

8.28.5 Dimension drawing .............................................................................................................. 391

8.29 MDS D528 ............................................................................................................................ 392

8.29.1 Characteristics ..................................................................................................................... 392

8.29.2 Ordering data ....................................................................................................................... 392

8.29.3 Application example ............................................................................................................. 393

8.29.4 Technical specifications ....................................................................................................... 393

8.29.5 Dimension drawing .............................................................................................................. 395

9.1 Introduction .......................................................................................................................... 397

9.2 ASM 456 .............................................................................................................................. 399

9.3 ASM 475 .............................................................................................................................. 400

9.3.1 Features ............................................................................................................................... 400

9.3.2 Ordering data ....................................................................................................................... 401

9.3.3 Indicators .............................................................................................................................. 402

9.3.4 Configuration ........................................................................................................................ 404

9.3.5 Shield connection ................................................................................................................. 406

9.3.6 Technical data ...................................................................................................................... 406

9.4 RF120C ................................................................................................................................ 408

9.5 RF160C ................................................................................................................................ 409

9.6 RF170C ................................................................................................................................ 410

9.7 RF180C ................................................................................................................................ 411

9.8 RF182C ................................................................................................................................ 411

10.1 Error codes of the RF300 readers ....................................................................................... 413

10.2 Diagnostics functions - STEP 7 ........................................................................................... 415

10.2.1 Overview .............................................................................................................................. 415

10.2.2 Reader diagnostics with "reader status" (SLG-STATUS) .................................................... 416

10.2.3 Transponder diagnostics with "Tag status" (MDS-STATUS) ............................................... 420

A.1 Certificates and approvals ................................................................................................... 423

A.2 Accessories .......................................................................................................................... 425

A.2.1 Transponder holders ............................................................................................................ 425

A.2.2 MOBY I migration ................................................................................................................. 432

A.2.3 DVD "Ident Systems Software & Documentation" ............................................................... 435

A.3 Connecting cable ................................................................................................................. 436

A.3.1 RF3xxR reader (RS-422) with ASM 456 / RF160C / RF170C / RF180C / RF182C ............ 436

A.3.2 Reader RF3xxR (RS422) with ASM 475 ............................................................................. 438

A.3.3 Reader RF3xxR (RS-422) with RF120C .............................................................................. 439

A.3.4 Reader RF380R (RS232) - PC ............................................................................................ 440

SIMATIC RF300

12 System Manual, 07/2017, C79000-G8976-C345-07

Page 13

Table of contents

Index................................................................................................................................................... 453

A.4 Ordering data ........................................................................................................................ 441

A.5 Service & Support ................................................................................................................. 451

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

13

Page 14

Table of contents

SIMATIC RF300

14 System Manual, 07/2017, C79000-G8976-C345-07

Page 15

1

1.1

Navigating in the system manual

Structure of the content

Content

Introduction

Purpose, structure and description of the important topics.

regulations.

System overview

Overview of all RF identification systems, system overview of SIMATIC RF300

ning, tools for finding suitable SIMATIC RF300 components.

Reader

Description of readers which can be used for SIMATIC RF300

Antennas

Description of antennas which can be used for SIMATIC RF300

RF300 transponder

Description of RF300 transponders which can be used for SIMATIC RF300

ISO transponder

Description of ISO transponders which can be used for SIMATIC RF300

SIMATIC RF300

System diagnostics

Description of system diagnostics available for SIMATIC RF300

1.2

Preface

Purpose of this document

Contents Detailed organization of the documentation, including the index of pages and chapters

Safety Information Refers to all the valid technical safety aspects which have to be adhered to while installing,

Planning the RF300 system Information about possible applications of SIMATIC RF300, support for application plan-

commissioning and operating from the product/system view and with reference to statutory

System integration Overview of the communications modules and function blocks that can be used for

Appendix

• Certificates and approvals

• Accessories

• Connecting cables

• Ordering data

• Service & Support

This system manual contains all the information needed to plan and configure the system.

It is intended both for programming and testing/debugging personnel who commission the

system themselves and connect it with other units (automation systems, further

programming devices), as well as for service and maintenance personnel who install

expansions or carry out fault/error analyses.

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

15

Page 16

Introduction

Scope of validity of this document

Additional information

Registered trademarks

History

Edition

Remark

05/2005

First Edition

RF360T; ASM 452, ASM 456, ASM 473 and ASM 475

and ANT 30

components added: RF370T, RF380T and RF170C

degrees of protection changed for the RF300 readers

components added: RF380R and RF180C

06/2008

Revised edition

the SIMATIC RF310R and SIMATIC RF380R readers

1.2 Preface

This documentation is valid for all variants of the SIMATIC RF300 system and describes the

devices shipped as of July 2016.

You will find further information about the readers RF350M, RF310R Scanmode and

RF382R Scanmode in the relevant manuals.

Additional information (https://support.industry.siemens.com/cs/ww/en/ps/15033/man

SIMATIC ®, SIMATIC RF ®, MOBY ®, RF MANAGER ® and SIMATIC Sensors ® are

registered trademarks of Siemens AG.

Currently released versions of the SIMATIC RF300 system manual:

11/2005 Revised edition, components added: RF310R with RS-422 interface, RF350T and

04/2006 Revised edition,

12/2006 Revised edition,

07/2007 Revised edition,

09/2007 Revised edition,

)

components added: RF340R as well as RF350R with the antenna types ANT 1, ANT 18

01/2009 Revised edition,

expanded by the reader functionalities "RF300 transponder" and "ISO transponder" for

SIMATIC RF300

16 System Manual, 07/2017, C79000-G8976-C345-07

Page 17

Introduction

Edition

Remark

Abbreviations and naming conventions

Reader

Write/read device (SLG)

Transponder, tag

Data carrier, mobile data storage, (MDS)

Communications module (CM)

Interface module (ASM)

1.2 Preface

03/2014 Revised edition,

expanded by the reader functionalities "RF300 transponder" and "ISO transponder" for

the SIMATIC RF340R and SIMATIC RF350R readers

Expanded by the following components:

• Reader

RF310R with Scanmode, RF382R with Scanmode

• Communications module

RF120C

• Antennas

ANT 12 (in conjunction with RF350R) and ANT 8 (in conjunction with RF310M)

• RF300 transponder

RF330T

• ISO transponder

MDS D117, D126, D127, D165, D200, D261, D339, D400, D422, D423, D425, D426

10/2016 Revised and expanded edition

Expanded by the following components:

• Readers of the second generation

RF310R, RF340R, RF350R

• Reader

RF380R Scanmode

• Antenna

ANT 3, ANT 3S

• ISO transponder

MDS D5xx

• MOBY I migration in SIMATIC RF300

05/2017 Revised and expanded edition

Expanded by the following components:

• Readers of the second generation

RF380R

The following terms/abbreviations are used synonymously in this document:

SIMATIC RF300

System Manual, 07/2017, C79000-G8976-C345-07

17

Page 18

Introduction

1.2 Preface

SIMATIC RF300

18 System Manual, 07/2017, C79000-G8976-C345-07

Page 19

2

WARNING

Opening the device

NOTICE

Alterations not permitted

Installation instructions

NOTICE

Switch/fuse to disconnect the reader from the power supply

Operating temperature

CAUTION

Danger of burns