Page 1

Installation Instructions

RDY2000 Commercial

System Compatibility

Conventional

Up to 3 Heating/3 Cooling stages

Heat Pumps

Up to 4 Heating/2 Cooling stages

Electrical Characteristics

Power Supply

24 Vac +/-20%, Class 2, 4A max .

Power Usage

4 VA (maximum)

Output Relay

Ratings

Pilot duty, 1A max. per output, 4A

max total

Ambient Limitations

Operating

Temperature

Storage/Shipping

Temperature

Relative Humidity

Up to 95% (non-condensing)

Enclosure

Rating

NEMA 1

CAUTION:

Equipment damage or loss of

specified.

CAUTION:

Document No. 129-905

March 26, 2015

Room Thermostat

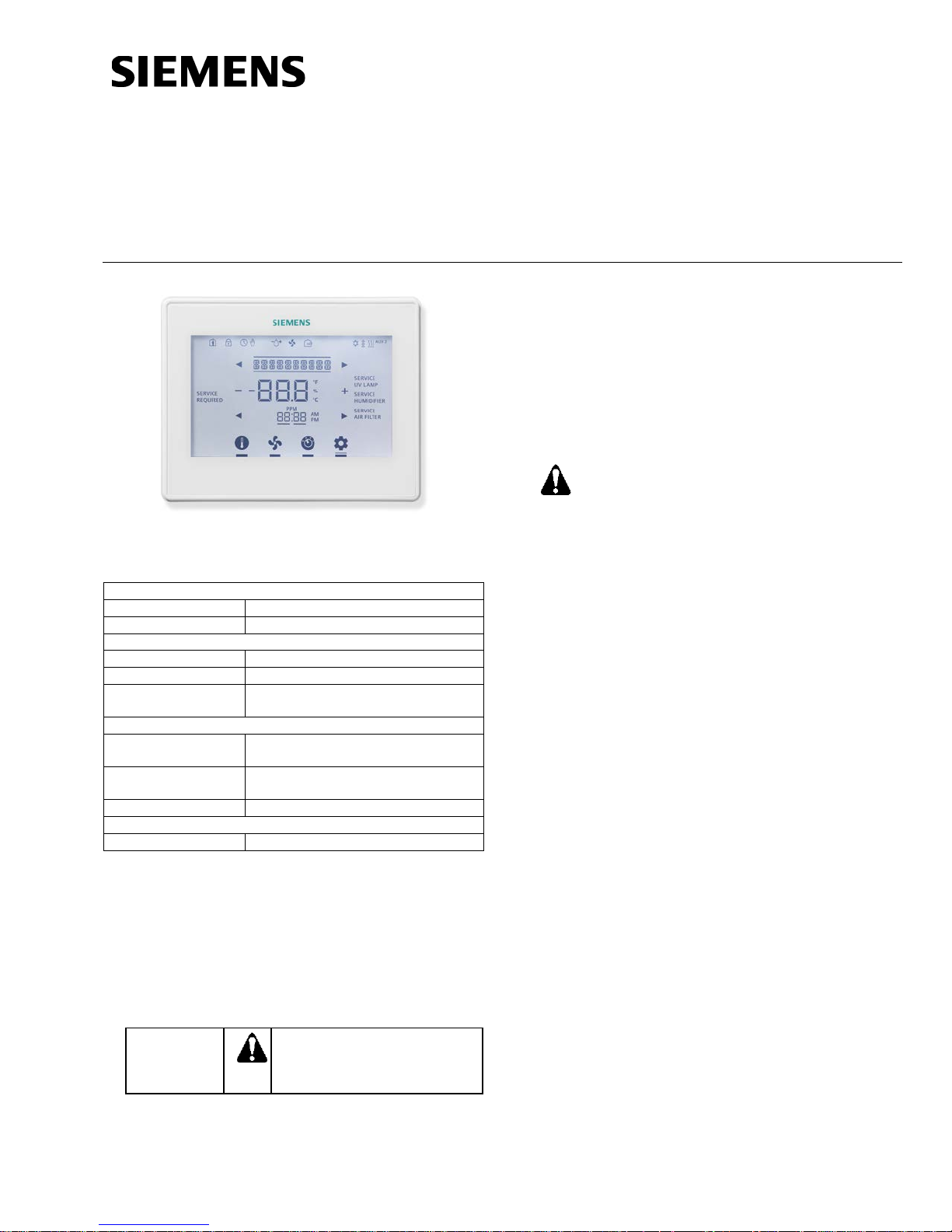

Figure 1. RDY2000 Thermostat.

Product Specifications

23°F to 122°F (-5°C to 50°C)

-13°F to 158°F (-25°C to 70°C)

NOTE: The RDY2000 is not battery-powered. It

requires 24 Vac power from the HVAC

equipment at terminals RH/RC and C.

Product Number

RDY2000

Required Tools

• No. 1 Phillips screwdriver

• 1/8” flat-blade screwdriver

• Drill with 1/8" drill bit

Expected Installation Time

15 minutes

The RDY2000 is an advanced controller

designed to be installed by professional

HVAC technicians. Installation by nonqualified personnel may result in degraded

system efficiency, occupant discomfort, or

equipment damage.

Prerequisites

• All work must be performed in accordance

with applicable codes and standards.

• Use 18 gauge thermostat wire for equipment

connections.

• 22 gauge shielded cable is recommended

for remote sensor wiring. Do not exceed 150

feet.

• To replace an existing thermostat, verify if

24 Vac is present between the RH/RC and

C terminals.

• Turn off power to the HVAC equipment

before attempting to remove the existing

thermostat.

• Record wiring connections to existing

thermostat terminals.

• Remove the existing thermostat before

proceeding.

Caution Notations

data may occur if you do not

follow the procedures as

Item Number 129-905, Rev. EA Page 1 of 18

Para accede al documento en Español, escanee el código QR que se encuentra en la parte trasera del termostato.

Installation

1. Install the thermostat base plate.

a. Feed the existing wires through the opening

in the base plate.

b. Secure the base plate to the mounting

surface using supplied hardware.

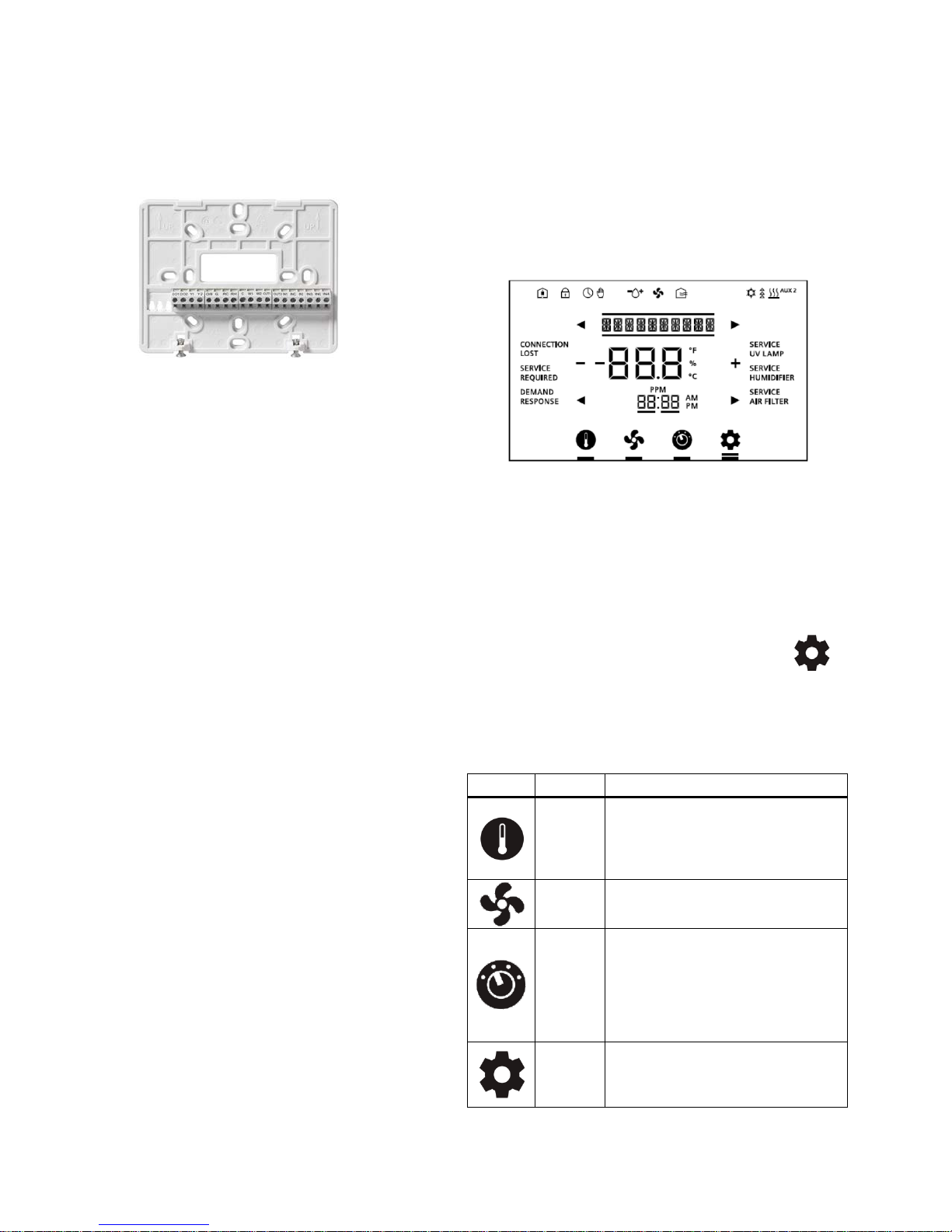

Page 2

Document No. 129-905

Enables adustment of temperature

cooling setpoint if in Cooling mode.

Enables fan relay to be controlled

to be on continuously (ON).

Enables manual changeover

control functions.

Enables Scheduler, Time/Date, and

and fault messages.

Installation Instructions

March 26, 2015

NOTE: Ensure that the UP ar ro ws embossed

on the base plate are pointed upward.

Figure 2. Thermostat Base Plate.

NOTE:

If 24 Vac was verified as being present

at the thermostat wires (see

Prerequisites), sk ip Step 2 and proceed

to Step 3.

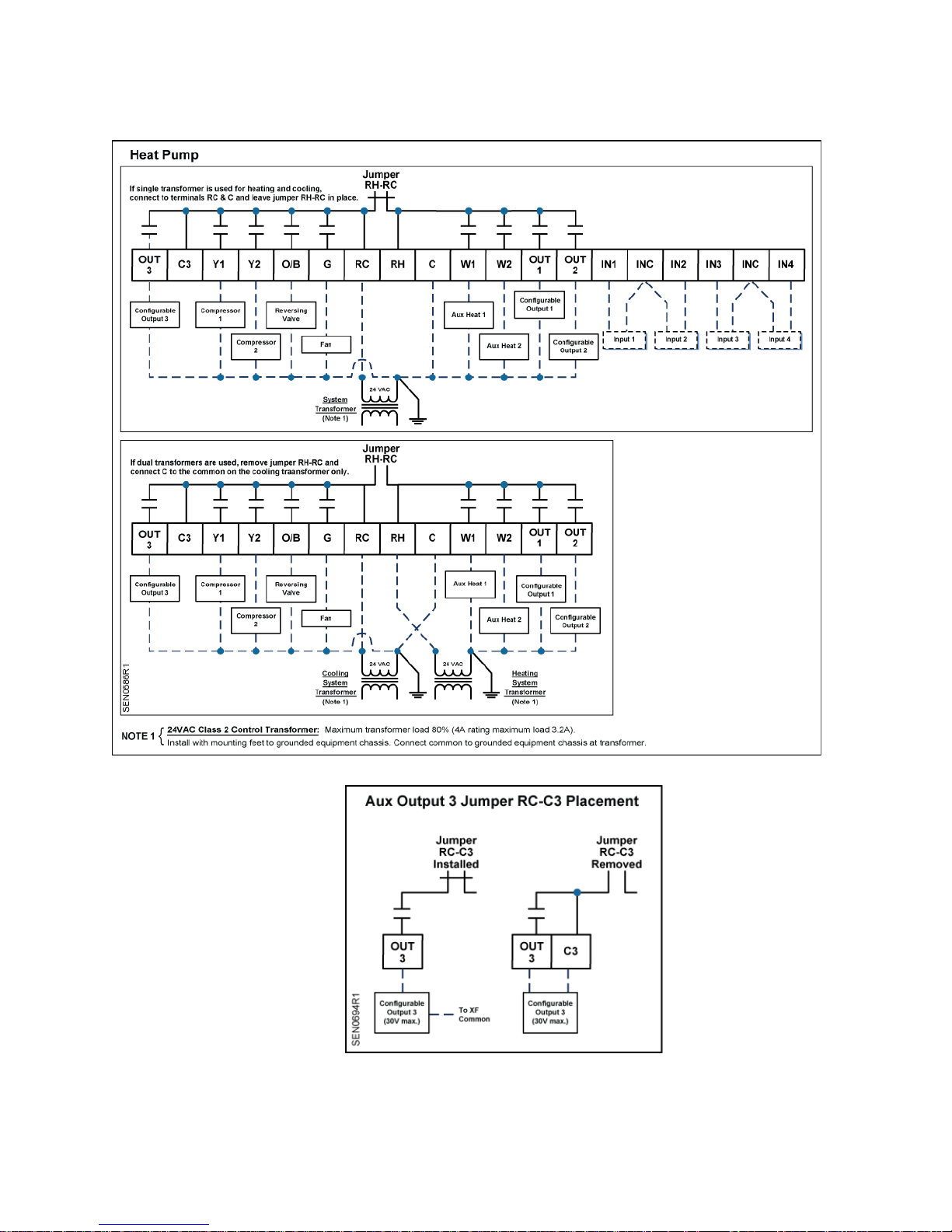

2. If 24 Vac is not present at the thermostat:

a. Locate the 24 Vac transformer or 24 Vac on

the terminal strip on the HVAC unit. Attach a

thermostat wire to the 24 Vac source. See

the HVAC equipment schematics to verify

the correct terminals.

b. Attach the other end of the unused wire to

the thermostat RH or RC terminal.

c. Verify that 24 Vac is present between the

RH/RC and C terminals.

3. Attach the existing wires to the appropriate

terminals on the thermostat base plate. See

Wiring Diagrams, Figure 4 and Figure 5.

Optional: If using Auxiliary Inputs 1 to 4 or

configurable outputs 1 to 3, use setup

parameters P301 to P320 to set functionality.

4. For systems with dual transformers, do the

following; otherwise, proceed to Step 5:

If separate transformers are used for heating

and cooling systems, connect 24 Vac from the

cooling system to RC, and 24 Vac from the

heating system to RH. Remove Jumper RHRC.

Optional: Auxiliary Output 3 can be changed to

a dry (unpowered) contact by removing Jumper

RC-C3 See Wiring Diagrams, Figure 6.

5. Attach thermostat to the base plate by engagi ng

tabs at the top and rotating the thermostat

downward until it is securely seated on the base

plate.

6. Secure the thermostat to the base plate with the

Phillips screws (provided), using the holes at

the bottom of the housing.

The installation is now complete. Restore power,

and continue to Thermostat Setup.

Thermostat Setup

Figure 3. Thermostat Display.

Thermostat Display

Navigation Bar

Only one function can be selected at a time. The

small bar (cursor) below the function icon indicates

that a function is selected. Pressing an icon twice

navigates back to the Main screen.

A double bar cursor below the Settings icon [

indicates that you are in Programming mode.

The navigation bar at the bottom of the display

consists of four function icons.

Table 1. Navigation Bar Icons.

Icon Name Purpose

and humidity (if applicable)

Setpoint

Selector

Settings

Fan

Control

Mode

setpoints. Unit will display heating

setpoint if in Heating mode or

as needed by thermostat (AUTO) or

between Heating and Cooling

mode. AUTO will enable the

thermostat to automatically switch

between heating and cooling mode

as required. OFF will disable all

Installer Set Up configuration. Also

enables access to service reminder

]

Page 2 of 18 Siemens Industry, Inc.

Page 3

Document No. 129-905

Space is occupied,

Sensor.

Unit is running on the

local schedule.

The Scheduler is being

control.

Droplet and (+) indicates

not appear.

Economizer Enable/

Ventilation relay is on.

The system is actively in

cooling mode.

The system is actively in

heating mode.

Each segment

heating or cooling.

Auxiliary heating stage:

2=Stage 2

Installation Instructions

March 26, 2015

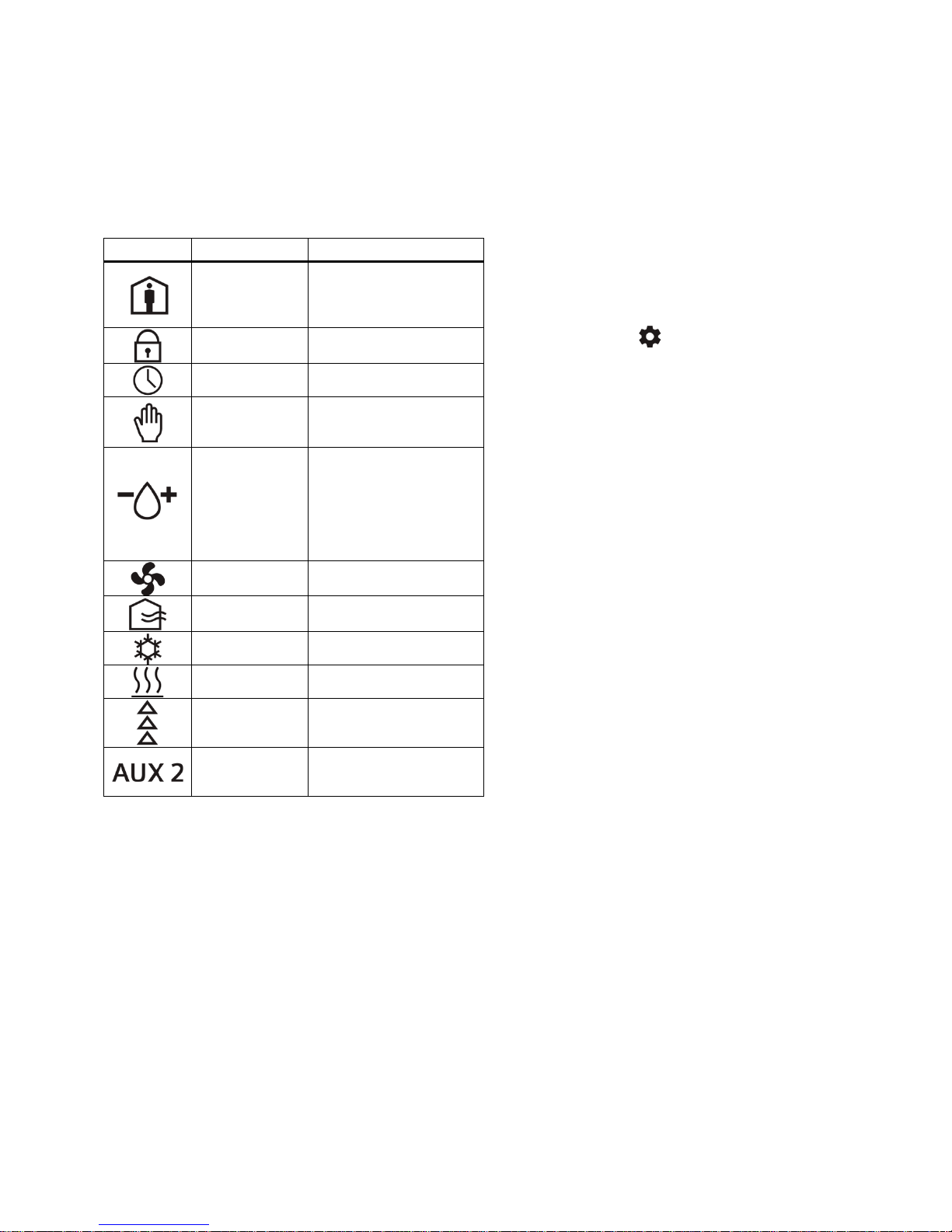

Status Bar

The status bar at the top of the display consists of

11 icons.

Table 2. Status Bar Icons.

Icon Name Meaning

Occupied

Keypad Lock Keypad is locked.

Scheduler

Override

Humidity

Control

Indicator

Fan Fan relay is on.

based on Schedule

and/or Occupancy

overridden by local

humidification relay is on.

Droplet and (-) indicates

dehumidific ation relay is

on. If neither relay is on,

the water droplet does

Service Reminders and Fault Messages

• Service reminders appear at the right side of the

screen:

– SERVICE UV LAMP

– SERVICE HUMIDIFIER

– SERVICE AIR FILTER

They are determined by the timer set in the Installer

Setup Menu, and can be cleared by pressing the

Settings icon [

], and then SERVICE. See

Clearing Service Reminders.

• Active fault messages appear at the left side of

the home screen:

– CONNECTION LOST (Not applicable to this

model)

– DEMAND RESPONSE (Not applicable to

this model)

– SERVICE REQUIRED (See Viewing Fault

Messages)

Fault messages are automatically cleared when the

root cause of the failure is resolved.

Fresh Air

Cool Mode

Heat Mode

Heating/Cooling

Stages

Auxiliary

Heating

represents one stage of

AUX=Stage 1: Aux

Siemens Industry, Inc.

Page 3 of 18

Page 4

Document No. 129-905

Installation Instructions

March 26, 2015

Wiring Diagrams

Figure 4. Wiring Schematic, Conventional System.

Page 4 of 18 Siemens Industry, Inc.

Page 5

Document No. 129-905

Installation Instructions

March 26, 2015

Siemens Industry, Inc.

Figure 5. Wiring Schematic, Heat Pump.

Figure 6. Wiring Schematic, Aux Output 3.

Page 5 of 18

Page 6

Document No. 129-905

Installation Instructions

March 26, 2015

Set-up Wizard

When the unit is powered up for the first time,

WIZARD displays. This tool is used to program the

basic system parameters. Additional parameters can

be accessed directly via the Installer/Ex per t Set-up

menus.

NOTE: The thermostat will not start the control

sequence until the Set-up Wizard is

complete.

1. Press WIZARD to access the menu.

2. Press + or – to change parameter settings, and

then use left and right arrows to select the

additional parameters.

3. After verifying all parameters, press Confirm to

save and complete.

4. INSTALLER displays. If setup is complete,

press the Settings icon [

Wizard. If further setup is needed, continue to

Step 6.

5. Press INSTALLER to access the Installer Menu

and more detailed setup. See Table 3 through

Table 7 for all parameter descriptions.

6. Use the space provided in Table 15 to record

modified parameter settings.

7. Press the Settings icon [

exit setup.

Programming Temperature Setpoints

1. Touch the center of the Home screen to access

the room temperature screen. Use the left []

and right [] arrows adjacent to the text line to

display the room temperature and humidity.

] to exit the Set-up

] when finished to

NOTE: If the screen is not touched for 10

seconds, the unit returns to the Home

screen.

Programming Time and Date

1. Touch the center of the Home screen.

2. Press the Settings icon [

]. SCHEDULER

displays.

3. Use the left [] and right [] arrows to access

the Time menu. Press TIME. Press the two-digit

hour display to change the hour, or press the

two-digit minute display to change the minutes.

Press the left arrow to decrease the value, and

the right arrow to increase the value.

4. Press the Settings icon [

] to save.

5. Use the left [] and right [] arrows to access

the Date menu. Press DATE. Use the arrows to

select the month and year; use +/- to set the

date.

6. Press the Settings icon [

] to save.

Installer Menu

1. Touch the center of the Home screen.

2. Press the Settings icon [

]. SCHEDULER

displays.

3. Press the left arrow [].

4. Press INSTALLER.

5. Using the lower left [] and right [] arrows,

enter the password.

6. Press PASSWORD to accept the password.

2. Touch the Setpoint icon [

] of the screen to

access room temperature and humidity

setpoints.

NOTE: Only the setpoints in the current mode

display and can be modified. For

instance, if the thermostat is in heating

mode, only the heating setpoint

displays and can be modified. If the

thermostat is in AUTO mode, both the

heating and cooling setpoints will be

displayed and can be modified.

3. Use the left [] and right [] arrows to access

the different setpoints, and the + and – icons to

adjust the setpoints.

4. Touch the center of the screen to exit Setpoint

Programming.

Page 6 of 18

Siemens Industry, Inc.

NOTE: The Installer Level d ef ault pass wor d is

00:00

7. Press the Settings icon [

] to accept

changes and return the unit to the Home

screen.

NOTE: If you do not provide input, the thermostat

will automatically exit the Installer menu and

resume normal system control after five

minutes.

Page 7

Document No. 129-905

CAUTION:

Installation Instructions

March 26, 2015

Programming the Schedule

1. Touch the center of the Home screen.

2. Press the Settings icon [

display.

3. Press SCHEDULER.

4. Use the left [] and right [] arrows to select

the day. Press the day to select.

5. Use the + and – icons to set the temperature

setpoints.

6. Use the left [] and right [] arrows to adjust

the start time for each programming period. After

selecting the start time, confirm by touching

above the temperature display before moving to

the next programming period.

7. Depending on the setting on the Scheduler

(Parameter 107 – 108), set the schedule for

each period. See Table 10 through Table 13 for

default schedules.

Resetting the Unit to Factory Defaults

The following steps set ALL parameters to

factory defaults (including passwords), and

restart the Set-up Wizard.

1. Log in as either an Installer or Expert.

2. Press the left [] arrow. RESTORE displays.

3. Press + to change the setting to YES.

4. Press RESTORE.

This resets the unit and restarts the Set-up Wizard.

]. SCHEDULER will

4. Using the lower left [] and right [] arrows,

enter the INSTALLER password.

5. Press PASSWORD to accept the password.

6. Set Parameter 211 (Keypad Lockout) to zero to

disable keypad lockout.

7. Touch the Setpoint icon [

return to the Home screen.

Clearing Service Reminders

The thermostat displays SERVICE REQUIRED and

an associated service reminder if the reminder timer

(Parameters 208 - 210) has timed out. To clear

these, do the following:

1. Touch the center of the Home screen to access

the room temperature screen.

2. Press the Settings icon [

displays.

3. Use the left [] and right [] arrows to select

the service reminder.

4. To clear, touch the + icon and the display

changes from “-----“ to OFF.

5. Counter resets and reminder icons turn off.

Viewing Fault Messages

The thermostat displays SERVICE REQUIRED if a

sensor fails or a service reminder has timed out. To

view these, do the following:

1. Touch the center of the Home screen to access

the room temperature screen.

] of the screen to

] and SERVICE

Maintenance

Locking/Unlocking the Touch Screen

To prevent unauthorized access to thermostat

settings, use Parameter P211 to configure screen

lockouts. The lock icon [

screen is locked. To unlock the keypad, do the

following:

1. Touch the center of the Home screen to access

the room temperature screen.

2. Press the Settings icon [

LOCKED displays.

3. Press and hold the Settings icon [

seconds; PASSWORD displays.

Siemens Industry, Inc.

] indicates that the

] once and

] for 5

2. Press the Settings icon [

displays.

3. Press SERVICE and review faults. Use the left

[] and right [] arrows to see all faults.

NOTE: The fault message is automatically

cleared when the root cause of the

failure is resolved.

] and SERVICE

Page 7 of 18

Page 8

Document No. 129-905

0

3

YES = Fan Relay energized by thermostat

thermostat on call for heat

0 = Disable Scheduler

7 = Schedule each day individually

F

C

NOTE: Changing temperature units will reset all temperature-

related parameters to their default values.

This parameter does

cool only.

This parameter does

heating/cooling cycles.

Y = Auto adjust for Daylight Savings Time

Savings Time

Daylight Savings Time

USA schedule.

Installation Instructions

March 26, 2015

Table 3. 100 Series Parameters*.

Parameter Definition Display Value Range Default Extended Definition Notes

P101 System Type SYS TYPE

P102

P103

P104

P105 Fan Operation HTG FAN

P106

P107

Cooling

Stages

Heating

Stages

Aux Heating

Stages

Reversing

Valve

Scheduler

Days

COOL STGS

HEAT STGS

AUX HT STG

REV VALVE

SCHEDULER

CO

HP

1

2

0

1

2

3

0

1

2

NO

(YES if

P101=HP)

O

B

0

1

2

3

7

CO

YES

O

CO = Conventional System

HP = Heat Pump

2 Sets number of cooling stages.

2 Sets number of heating stages.

Sets number of auxiliary heat stages

0

available for heat pump control.

on call for heat

NO = F an rel ay not energi zed by

O = Energize reversing valve on cooling

B = Energize reversing valve on heating

1 = Schedule all days with same

schedule

2 = One schedule for M-F and another for

2

Sat + Sun

3 = One schedule for M-F, Sat + Sun

scheduled individually

This parameter only

appears if P101 = HP.

If HVAC unit does not

start fan on call for

heat, set P105 to YES.

This parameter only

appears if P101 = HP.

See Table 9 through

Table 13.

P108

P109 Units UNITS

P110 Auto Change AUT O CHNG E

P111

P112

* Included in Set-up Wizard

Program

Periods

Changeover

Deadband

Daylight

Savings

PERIODS

DEADBAND

DAYLT SAVE

2

4

YES

NO

3°F to 9°F

(2.0°C to

5.0°C)

NO

YES

2

F

YES

5°F

(3.0°C)

YES

Sets number of program periods per day:

2 = 2 periods (Day/Night)

4 = 4 periods (Wake/Day/Evng/Night)

Enables auto change between heating and

cooling.

Changeover deadband in degrees F (C)

N = Does not auto adjust for Daylight

This parameter only

appears if P107 > 0.

not appear on systems

that are heat only or

not appear if P110 =

NO.

This parameter forces a

separation between

heating and cooling

setpoints to prevent

short cycling of

adjustment is based on

Page 8 of 18

Siemens Industry, Inc.

Page 9

Document No. 129-905

Heat T emp

Limit

45°F to 95°F

(7.0°C to 35.0°C)

95°F

(35.0°C)

Sets maximum allowable heating set

point.

50°F to 95°F

35.0°C)

Temperature

Offset

-5°F to 5°F

3. 0°C)

Enables adjustment of control temp and display temperature in 1

only.

Number of hours that scheduled

--- = Unlimited

Number of degrees that are allowed

--- = Unlimited

OFF

45°F (7.0°C)

This parameter only appears

- P206 < P207.

This parameter only appears

- P207 > P206.

Number of calendar days until

0 = function disabled.

Number of calendar days until

0 = function disabled.

Number of calendar days until

0 = function disabled.

0 = No Lock out

2 = Total Lock out

12

24

12 = 12-hour format

24 = 24-hour format

Number of seconds that backlight

0 = Always off.

Installation Instructions

March 26, 2015

Table 4. 200 Series Parameters.

Parameter Definition Display Value Range Default Extended Definition Notes

P201

P202

P203

P204

P205

P206

P207

P208

Cool Temp

Limit

Display

Override

Time Limit

Override

Temp Limit

Heat Pump

Compressor

Lock Out

Heat Pump

Auxiliary

Heat Lockout

Service UV

Lamp

HEAT LIMIT

COOL LIMIT

TMP OFFSET

HRS OVR RD 0 t o 96 hours ---

TMP OVR RD

HP COMP LO

HP AUX LO

UV LAMP 0 to 365 days 0

(10.0°C to

(-3.0°C to

1°F to 10°F

(0.5°C to 4.0°C)

15°F (-9.0°C)

20°F (-6.0°C)

25°F (-3.0°C)

30°F (-1.0°C)

35°F (1.0°C)

40°F (4.0°C)

OFF

40°F (4.0°C)

45°F (7.0°C)

50°F (10.0°C)

55°F (13.0°C)

60°F (16.0°C)

50°F

(10.0°C)

0°F

(0°C)

---

OFF

OFF

Does not appear if P103 = 0.

Sets minimum allowable cooling set

point.

degree increments. Applies only to onboard temp sensor. Indoor temp

setpoint can be manually overridden.

0 = No override allowed

above or below scheduled setpoint.

Heat pump compressor will not

operate below this outdoor temp -forcing unit to auxiliary heat. An

outdoor temperature sensor is

required.

NOTE: If P206 ≠ OFF, set P508 = 1°F

(0.5°C).

Heat pump auxiliary heat will not

operate above this outdoor temp. An

outdoor temperature sensor is

required.

SERVICE UV LAMP message

displays.

Does not appear if P102 = 0.

This parameter will not

appear if P107 = 0.

This parameter will not

appear if P107 or P204 = 0.

for the following conditions:

- P101 = HP.

- P104 > 0.

- P105 = YES

- P301, P305, P309,

or P313=5

for the following conditions:

- P101 = HP.

- P104 > 0.

- P301, P305, P309,

or P313 = 5

P209

P210

P211

P212 Cl ock Format CLOCK

P213 Backlight LIGHT 0 to 99 seconds 15

Service

Humidifier

Service Air

Keypad

Lockout

Filter

HMDFR

SRVC

FLTR SRVC 0 to 365 days 0

KEY LOCK

0 to 365 days 0

0 = NONE

1 = PARTIAL

2 = FULL

Siemens Industry, Inc.

0

12

SERVICE HUMIDIFIER message

displays.

SERVICE AIR FILTER message

displays.

1 = Partial Lockout (only temp setpoint

can be adjusted)

stays on after screen is touched.

Keypad lock icon [ ]

displays if P211 > 0.

Page 9 of 18

Page 10

Document No. 129-905

0

9

0 = Not Used

9 = Fault

- Selections for inputs 1-4

RDY2000.

Temperature

Input 1 Type

0

1

0 = Type 2 Thermistor

1 = 0-10V

Only appears if

P301=1/2/3/4/5.

-58°F to

50.0°C)

P303 value

(120.0°C)

Calibrates thermostat to high end of

example, 10V = 250°F [120.0°C])

0

9

0 = Not Used

9 = Fault

- Selections for Inputs 1-4

RDY2000.

Temperature

Input 2 Type

0

1

0 = Type 2 Thermistor

1 = 0 to 10V

Only appears if P305 =

1/2/3/4/5.

-58°F to

50.0°C)

P307 value

(120.0°C)

Calibrates thermostat to high end of

example, 10V = 250°F).

0

9

0 = Not Used

9 = Fault

- Selections for Inputs 1-4

RDY2000.

Only appears if P309 =

Installation Instructions

March 26, 2015

Table 5. 300 Series Parameters.

Parameter Definition Display

P301

P302

P303

P304

P305

Configurable

Input 1 (IN1)

Temperature

Input 1 Low

Temperature

Input 1 High

Configurable

Input 2 (IN2)

INPUT 1

TMP I N 1

TMP 1 LO

TMP 1 HI

INPUT 2

Value

Range

1

2

3

4

5

6

7

8

120°F **

(-50.0°C to

** to 250°F

1

2

3

4

5

6

7

8

Default Extended Definition Notes

0

0

0°F

(-18.0°C)

120°F

(50.0°C)

0

1 = Indoor Temperature (Remote)

2 = Indoor Temperature (Average)

3 = Supply Temp

4 = Return Temp

5 = Outdoor Temp

6 = Humidity (0-10V)

7 = CO2 (0-10V)

8 = Occupancy (DI)

Calibrates thermostat to low end of temp

sensor signal (for example, 0V = -40°F

[4.4°C])

temp sensor signal at 10 volts (for

1 = Indoor Temperature (Remote)

2 = Indoor Temperature (Average)

3 = Supply Temp

4 = Return Temp

5 = Outdoor Temp

6 = Humidity (0-10V)

7 = CO2 (0-10V)

8 = Occupancy (DI)

cannot be duplicated.

- If set to 9 (fault), a DI here

causes SERVICE

REQUIRED segment to

activate.

- See Table 14

optional sensors

approved for use with the

- Only appears if P302=1

** P303<P304.

- Only appears if P302=1.

** P304>303.

cannot be duplicated.

- If set to 9 (fault), a DI

causes SERVIC E

REQUIRED segment to

activate

- See Table 14

optional sensors

approved for use with the

for a list of

for a list of

P306

P307

P308

P309

P310

Temperature

Input 2 Low

Temperature

Input 2 High

Configurable

Input 3 (IN3)

Temperature

Input 3 Type

TMP IN 2

TMP 2 LO

TMP 2 HI

INPUT 3

TMP I N 3

120°F **

(-50.0°C to

** to 250°F

1

2

3

4

5

6

7

8

0

1

0

0°F

(-18.0°C)

120°F

(50.0°C)

0

0

Calibrates thermostat to low end of temp

sensor signal (for example, 0V = -40°F)

temp sensor signal at 10 volts (for

1 = Indoor Temperature (Remote)

2 = Indoor Temperature (Average)

3 = Supply Temp

4 = Return Temp

5 = Outdoor Temp

6 = Humidity (0 to 10V)

7 = CO2 (0 to 10V)

8 = Occupancy (DI)

0 = Type 2 Thermistor

1 = 0-10V

- Only appears if P306 = 1.

** P307 < P308

- Only appears if P306 = 1.

** P308 > P307.

cannot be duplicated.

- If se t to 9 (fault), a DI

here causes SERVICE

REQUIRED segment to

activate.

- See Table 14

optional sensors

approved for use with the

1/2/3/4/5.

for a list of

Page 10 of 18 Siemens Industry, Inc.

Page 11

-58°F to

50.0°C)

P311 value

(120.0°C)

Calibrates thermostat to high end of

example, 10V = 250°F).

0

9

0 = Not Used

9 = Fault

- Selections for Inputs 1-4

RDY2000.

Temperature

Input 4 Type

0

1

0 = Type 2 Thermistor

1 = 0 to 10V

Only appears

P313=1/2/3/4/5.

-58°F to

50.0°C)

P315 value

(120.0°C)

Calibrates thermostat to high end of

example, 10V = 250°F [121.1°C]).

- Selections for Outputs 1-3

as Stage 3 cooling.

0

5

0 = Not Used

5 = Economizer Enable

0

5

0 = Not Used

5 = Economizer Enable

Yes = Humidification/dehumidification

energized.

Parameter Definition Display

Value

Range

Document No. 129-905

Installation Instructions

March 26, 2015

Default Extended Definition Notes

P311

P312

P313

P314

P315

P316

P317

Temperature

Input 3 Low

Temperature

Input 3 High

Configurable

Input 4 (IN4)

Temperature

Input 4 Low

Temperature

Input 4 High

Aux Output 1

(OUT1)

TMP 3 LO

TMP 3 HI

INPUT 4

TMP I N 4

TMP 4 LO

TMP 4 HI

AUX OUT 1

120°F **

(-50.0°C to

** to 250°F

1

2

3

4

5

6

7

8

120°F **

(-50.0°C to

** to 250°F

0

1

2

3

4

5

0°F

(-18.0°C)

120°F

(50.0°C)

0

0

0°F

(-18.0°C)

120°F

(50.0°C)

0

Calibrates thermostat to low end of temp

sensor signal (Example: 0V = -40°F).

temp sensor signal at 10 volts (for

1 = Indoor Temperature (Remote)

2 = Indoor Temperature (Average)

3 = Supply Temp

4 = Return Temp

5 = Outdoor Temp

6 = Humidity (0 to 10V)

7 = CO2 (0 to 10V)

8 = Occupancy (DI)

Calibrates thermostat to low end of temp

sensor signal (for example, 0V = -40°F

[4.4°C]).

temp sensor signal at 10 volts (for

0 = Not Used

1 = Humidification

2 = Dehumidification

3 = Occupied

4 = Air Quality

5 = Economizer Enable

- Only appears if P310 = 1.

** P311 < P312.

- Only appears if P310 = 1.

** P312 < P311.

cannot be duplicated.

- If set to 9 (fault), a DI here

causes SERVIC E

REQUIRED segment to

activate.

- See Table 14

optional sensors

approved for use with the

- Only appears if P314 = 1.

** P315 < P316.

Only appears if P314=1.

** P316>P315.

cannot be duplicated.

- Air Quality not an option

unless P301, P305, P309,

or P313 = 7.

- If system is conventional

with 3H +3C, AO1 is fixed

for a list of

P318

P319

P320

Aux Output 2

(OUT2)

Aux Output 3

(OUT3 & C3)

Independent

Humidity

Control

AUX OUT 2

AUX OUT 3

IND HMDTY

1

2

3

4

1

2

3

4

Yes

No

0

0

No

1 = Humidification

2 = Dehumidification

3 = Occupied

4 = Air Quality

1 = Humidification

2 = Dehumidification

3 = Occupied

4 = Air Quality

relays can be energized

independent of heating/cooling

relays.

No = Humidification/dehumidification

relays are only energized if

heating or cooling relay is

-- Selections for Outputs 1-3

cannot be duplicated.

- Air Quality is not an option

unless P301, P305, P309,

or P313 = 7.

- Selections for Outputs 1-3

cannot be duplicated.

- Air Quality is not an option

unless P301, P305, P309,

or P313 = 7.

Select YES to activate

humidity control systems

regardless of whether there

is a need for heating or

cooling.

Siemens Industry, Inc.

Page 11 of 18

Page 12

Document No. 129-905

Value

Allows HVAC unit number to be

displayed on thermostat home screen.

For optimum human

parts per million.

Pre-Occupancy Purge will

without a schedule.

Occupancy

Run Timer

Minimum run time to remain in

from Occupancy Sensor.

Fan relay will be continuously energized

Sensor.

Only shown if a schedule is

Sensor.

Installer

Password

00:00 to

49.99

NOTE: If Installer Password is changed, a new password should be

recorded for future reference.

Firmware

Revision

Installation Instructions

March 26, 2015

Table 6. 400 Series Parameters.

Parameter Definition Display

P401 Unit Number UNIT NMB R 1 to 999 ---

P402 CO2 Setpoint CO2 SET PT

P403

P404

P405

P407

P701

Pre-

Occupancy

Purge

Sensor Min

Semi-

Continuous

Fan

PRE OC PRG

OCC MRT

CONT FAN

INSTALL PW

FIRMWARE X.X N/A Read Only

Range

500 to

2000

PPM

0

1

2

3

hours

3 to 60

minutes

No

Yes

Expert Level Menus

1. Touch the center of the Home screen.

2. Press the Settings icon [

]. SCHEDULER

displays.

Default Extended Definition Notes

800

0

30

NO

00:00

If CO2 level, as measured by an

external sensor exceeds setpoint, the

Ventilation sequence is initiated.

0 = Disabled

1 = 1 Hour

2 = 2 Hours

3 = 3 Hours

Occupied mode upon receipt of signal

when space is occupied, as determined

by schedule or external Occupancy

performance, CO2 levels

should be kept below 1000

energize the Economizer

Enable and Fan relays prior

to the start of the first

scheduled occupancy period.

Not applicable to systems

Only shown if an input is set

to Occupancy Sensor.

present or if an input is

configured for Occupancy

Recovering a Lost Password

If either of the default passwords is changed, the new

password(s) should be recorded and maintained for

future reference. If the records are misplaced, the

following procedure can be used to set new passwords:

3. Press the left [] arrow.

4. Press INSTALLER.

5. Using the lower left [] and right [] arrows,

enter the password.

6. Press PASSWORD to accept the password and

return the unit to the Setup Menu.

NOTE: The Expert Le ve l default password is

99:99.

7. See Table 3 through Table 8 and Wiring

Diagrams for additional information.

8. Press the Settings icon [

and return the unit to the Home screen.

] to accept changes

1. Cycle power to the thermostat. This can be done

by loosening the securing screws on the bottom

of the housing and momentarily separating the

thermostat from the base plate.

2. Within 50 seconds of restoring power, navigate

to the Installer Set-up screen and enter 98:21 as

the passcode.

3. The thermostat will go directly to the Expert

Level password screen. A new Expert Level

password can now be set.

4. After setting a new Expert Level password, the

thermostat will return to the Home screen.

5. The new Expert Level password can be used to

enter the full Expert Level set-up menu where

both the Expert Level and Installer Level

passwords can now be set to new values.

Page 12 of 18 Siemens Industry, Inc.

Page 13

Document No. 129-905

Time delay before next stage of cooling will be

activated.

1°F (0.5°C) to

10°F (5.0°C)

1°F

(0.5°C)

Degrees above cooling deadband before Stage

Delay timer is initiated.

Delay in minutes before system will automatically

switch from heating to cooling (or vice versa).

The deadband is divided equally above and below

deadband.

Time delay before next stage of heating will be

activated.

Conv. = 1°F

(1.0°C)

Conv = 3

HP = 10

The deadband is divided equally above and below

deadband.

Installation Instructions

March 26, 2015

Table 7. 500 Series Expert Settings Parameters.

(Only available if logged in as an Expert.)

NOTE: P500 Series parameters are factory-set for optimum system performance. Changing these settings may degrade

efficiency and/or compromise occupant comfort.

Parameter Definition Display Value Range Default Extended Definition

P501 Stage Delay - Cooling STG DLY CL 1 to 10 minutes 2

P502 Stage Differential - Cooling STG DIF CL

P503 Cooling Minimum Off Time M O T CL 1 to 10 minutes 3 Minim um time between compressor st arts.

P504 Cooling Minimum On Time M R T CL 1 to 10 minutes 5 Mini mum run time for any stage of cooling.

P505 Changeover Delay C-O DLY 1 to 60 3

P506 Cooling Deadband CL DEADBND

P507 Stage Delay - Heating ST G DLY HT 1 to 10 minutes 2

P508 Stage Differential - Heating STG DIF HT

P509 Heating Minimum Off Time M O T HT 1 to 10 minutes 5 Minimum time between heating starts.

P510 Heating Minimum On Time M R T HT 1 to 10 minutes

P511 Heating Deadband HT DEADBND

1°F (0.5°C) to

5°F (4.0°C)

1°F (0.5°C) to

5°F (5.0°C)

1°F (0.5°C) to

5°F (4.0°C)

1°F

(0.5°C)

HP = 2°F

1°F

(0.5°C)

setpoint. Cooling will begin when temperature

exceeds upper point of deadband and ceases

when temperature falls below lower point of

Degrees below heating deadband before Stage

Delay timer is initiated.

NOTE: If P206 ≠ OFF, set P508 = 1°F (0.5°C)

Minimum run time for any stage of heating.

setpoint. Heating will begin when temperature

falls below lower point of deadband and ceases

when temperature rises above upper port of

Siemens Industry, Inc.

Page 13 of 18

Page 14

Document No. 129-905

CAUTION:

Installation Instructions

March 26, 2015

Table 8. 900 Series Expert Settings Parameters.

(Only available if logged in as an Expert.)

P900 Series parameters are used by professional HVAC technicians during the system commissioning

process. Interlocks and time delays are defeated while using P900 parameters. Use of these parameters by

non-qualified personnel may result in equipment damage.

Parameter Definition Display Value Range Default Extended Definition

P901 Test Compressor 1 Y1 TEST

P902 Test Compressor 2 Y2 TEST

P903 Test Reversing Valve O/B T EST

P904 Test Fan G TEST

P905 Tes t Heat St g 1 W1 TEST

P906 Tes t Heat St g 2 W2 TEST

P907 Test Output 1 OUT1 TST

P908 Test Output 2 OUT2 TST

P909 Test Output 3 OUT3 TST

P911 Expert Password XP RT PW 50:00 to 99:99 99:99

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF = Relay not energized

ON = Relay energized

OFF = Relay not energized

ON = Relay energized

OFF = Relay not energized

ON = Relay energized

OFF = Relay not energized

ON = Relay energized

OFF = Relay not energized

ON = Relay energized

OFF = Relay not energized

ON = Relay energized

OFF = Relay not energized

ON = Relay energized

OFF = Relay not energized

ON = Relay energized

OFF = Relay not energized

ON = Relay energized

Auxiliary Sequences

The RDY2000 primary sequences are designed to

control single and multi-stage heating/cooling systems to

maintain a user-selected temperature setpoint.

The following auxiliary sequences are available to

optimize occupant comfort and system efficiency:

Humidification

Parameters

• P317/ P318/P319: One of these must be set to 1

• P320: NO (default) = Humidification will only

occur if there is a call for heating. YES =

Humidification relay will be energ i zed

independently of heating and cooling relays.

Page 14 of 18 Siemens Industry, Inc.

• Humidity Setpoint: User adjustable to desired

level in humidification mode.

Sensors: Onboard humidity sensor or optional remote

humidity sensor.

The humidification relay will energize when measured

humidity drops approximately 4% below setpoint and will

de-energize when measured humidity reaches setpoint.

Deadbands and proof timers are in force to prevent short

cycling.

Page 15

Document No. 129-905

Installation Instructions

March 26, 2015

Dehumidification

Parameters

• P317/ P318/P319: One of these must be set to 2

• P320: NO (default) = Dehumidification will only

occur if there is a call for cooling. YES =

Dehumidification relay will be energized

independently of heating and cooling relays.

• Dehumidity Setpoint: User adjustable to desired

level in dehumidification mode.

Sensors: Onboard humidity sensor or optional remote

humidity sensor.

The dehumidification relay will energize when measured

humidity rises approximately 4% above setpoint and will

de-energize when measured humidity reaches setpoint.

Deadbands and proof timers are in force to prevent short

cycling

Economizer Enable

Parameters

• P317/P318/P319: One of these must be set to 5.

• P301/P305/P309/P313: One of these must be

set to 8 if the optional occupancy sensor is used.

Sensors: None required, however an optional occupancy

sensor can be used instead of, or in conjunction with the

scheduler to determine occupancy.

The Economizer Enable relay will be energized

whenever a cooling relay is energized or the space is

occupied. The thermostat will use the scheduled

setpoints to predict when s pace is occ upie d. An opt ion al

occupancy sensor can also be used for definitive proof

of occupancy.

An output configured for Occupancy Notification can also

be used for Economizer Enable.

Pre-Purge

Parameters

• P317/P318/P319: One of these must be set to 5.

• P403

Sensors: None required.

To enable the economizer and energize the fan relay

prior to scheduled occupancy, set P403 to the number of

hours before scheduled occupancy for pre-purge to

begin. This function requires a schedule to be

configured.

Occupancy Notification

Parameters

• P301/P305/P309/P313: If the optional occupancy

sensor is used, one of these must be set to 8.

• P317/P318/P319: To signal an external device that

the space is occupied, one of these must be set to 3

• P404: If the optional occupancy sensor is used,

P404 can be used to set a minimum run timer for

any actions that are activated by occupancy, such

as Economizer Enable, control to occupied

temperature setpoints, and so on. Note that many

occupancy sensors also have onboard proof timers.

There are two primary methods by which the thermostat

can assume the space is occupied.

1. In Cooling mode, it will assume that scheduled

periods with lower setpoint(s) indicate

occupancy. In Heating mode, it will assume

occupancy during periods of higher setpoints.

2. During periods in which the schedule indicates

the space is unoccupied, any human interaction

with the thermostat (for example, setpoint

adjustment) will put the therm ostat into

Occupied mode.

The optional occupancy sensor can be used in

conjunction with the schedule. The thermostat will follow

the assumptions above, but an input from the occupancy

sensor during a scheduled unoccupied period will put the

thermostat in the Occupied mode for the duration of the

timer set in P404.

To utilize the Occupancy functions, the thermos tat must

have an active schedule.

Air Quality Management

Parameters

• P301/P305/P309/P313: One of these must be

set to 7.

• P317/P318/P319: One of these must be set to 4.

• P402: CO2 Setpoint

Sensors: Optional CO2 Sensor

• If measured CO2 exceeds setpoint by 200 PPM,

the Air Quality output and fan relays will be

energized. The minimum run time is 5 minutes.

• When measured CO2 falls below setpoint and

appropriate minimum run time has been met, the

Air Quality output relay will be de-energ i zed an d

the fan relay shall revert to normal operation.

Siemens Industry, Inc.

Page 15 of 18

Page 16

Document No. 129-905

Per Day

Per Day

Phase

Day

Night

Wake

Day

Evng

Night

Setpoint

Heat, °F

70

62

70

62

70

62

Setpoint

Cool,°F

75

82

75

78

75

82

Time

6:00

AM

10:00

PM

6:00

AM

11:00

AM

1:00

PM

10:00

PM

NOTE: 2 Periods per Day

Phase

Day

Night

Day

Night

Wake

Day

Evng

Night

Wake

Day

Evng

Night

Setpoint

Heat, °F

70

62

70

62

70

68

70

62

70

68

70

62

Setpoint

Cool, °F

75

82

75

82

75

78

75

82

75

78

75

82

Time

6:00

AM

10:00

PM

8:00

AM

10:00

PM

6:00

AM

11:00

AM

1:00

PM

10:00

PM

8:00

AM

11:00

AM

1:00

PM

10:00

PM

Phase

Day

Night

Day

Night

Day

Night

Setpoint

Heat, °F

70

62

70

62

70

62

Setpoint

Cool, °F

75

82

75

82

75

82

Time

6:00

AM

10:00

PM

8:00

AM

10:00

PM

8:00

AM

10:00

PM

Phase

Wake

Day

Evng

Night

Wake

Day

Evng

Night

Wake

Day

Evng

Night

Setpoint

Heat

70

68

70

62

70

68

70

62

70

68

70

62

Setpoint

Cool

75

78

75

82

75

78

75

82

75

78

75

82

Time

6:00

AM

11:00

AM

1:00

PM

10:00

PM

8:00

AM

11:00

AM

1:00

PM

10:00

PM

8:00

AM

11:00

AM

1:00

PM

10:00

PM

Installation Instructions

March 26, 2015

Table 9. Single Schedule.

Day

2 Periods

4 Periods

NOTE: Daily Schedule – 2 periods per day: Parameter 107 = 1; Parameter 108 = 2

Daily Schedule – 4 periods per day: Parameter 107 = 1; Parameter 108 = 4; Parameter 109 = F

Table 10. Work Week Schedule with Weekend.

(Factory Default)

Parameter 107 = 2;

Day

Parameter 108 = 2;

Parameter 109 = F

Work Week

(Monday-

Friday)

Weekend

(Saturday-

Sunday)

NOTE: 4 Periods per Day

Parameter 107 = 2; Parameter 108 = 4; Parameter 109 = F

Work Week

(Monday-Friday)

Weekend

(Saturday-Sunday)

Table 11. Work Week Schedule with Sep arat e Week end D ays - 2 Periods per Day.

Day Work Week

Saturday

Sunday

(Monday-

Friday)

NOTE: Individual Days, periods per day: Parameter 107 = 3; Parameter 108 = 2; Parameter 109 = F

Table 12. Work Week Schedule with Separate Weekend Days – 4 Periods Per Day.

Work Week (Monday-Friday) Saturday Sunday

NOTE: Parameter 107 = 3; Parameter 108 = 4; Parameter 109 = F

Page 16 of 18 Siemens Industry, Inc.

Page 17

Document No. 129-905

Siemens Indus try, Inc.

+1-847-215-1000

Your feedback is important to us. If you have

Document No. 129-905

Phase

Day

Night

Wake

Day

Evng

Night

Setpoint Heat

70

62

70

62

70

62

Setpoint Cool

75

82

75

78

75

82

Time

6:00 AM

10:00 PM

6:00 AM

11:00 AM

1:00 PM

10:00 PM

Siemens Part

Number

Installation Instructions

March 26, 2015

Table 13. Individual Days (Monday – Sunday).

Day 2 Periods

Per Day

4 Periods

Per Day

NOTE: Daily Schedule – 2 periods per day: Parameter 107 = 7; Parameter 108 = 2; Parameter 109 = F

Daily Schedule – 4 periods per day: Parameter 107 = 7; Parameter 108 = 4; Parameter 109 = F

Table 14. Suggested Sensors for Use with RDY2000.

Description Signal Format

QAA2330.EWNN

QFA33SS.EWNN

QAM2030.010

QFM2160U

QPA2000 Wall-Mounted CO2 Sensor 0-10V

QPA2062 Wall-Mounted Temperature + Humidity + CO2 Sensor 0-10V

QPM2162

QAC2030

QAD2030

Remote Wall-Mounted Sensor – Temperature Only 10K Ohm, Type II NTC

Remote Wall-Mounted Temperature and Humidity Sensor 0-10V

Duct-Mounted Temperature Sensor 10K Ohm, Type II NTC

Duct-Mounted Temperature & Humidity Sensor 0-10V

Duct-Mounted Temperature + Humidity + CO2 Sensor 0-10V

Outdoor Air Temperature Sensor 10K Ohm, Type II NTC

Surface-Mount Pipe Temperature Sensor 10K Ohm, Type II NTC

Federal Communications Commission Notice

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC rules. These limits are

designed to provide reasonable protection against harmful interference in a residential installation. This equipment generat es, uses, and can radiate

radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communicat i ons.

However, there is no guarantee that interference will occur in a particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or

more of the following measures:

--Reorient or relocate the receiving antenna.

--Increase the separation between the equipment and the receiver.

--Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

--Consult the dealer or an experienced radio/TV technician for help.

Modifications

This device complies with Part 15 of the FCC rules and IC rules. Changes or modifications not expressly approved by Siemens Industry Inc. could void

the user’s authority to operate the equipment.

Industry Canada

This Class B digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe B respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.

CAN ICES-3 (B)/NMB-3 (B)

Limited Warranty

Siemens Product Guard Warranty warrants the purchased from it or its authorized reseller to be free from defects in material and workmanship under

normal use during the two-year period commencing on the date of purchase. The written proof of purchase is required for such warranty period to apply.

The software included in this Siemens product is licensed for use subject to the Siemens end-user license agreement (“EULA”) posted at

www.usa.siemens.com/btcpseula (Siemens’ EULA web site) for this software identifi ed by product model or part number on the Siemens EULA web site.

Information in this publication is based on current specifications. The company reserves the right to make changes in specifications and models as

design improvements are introduced. Other product or company names mentioned herein may be the trademarks of their respective owners. © 2015

Siemens Industry, Inc.

Building Technologies Division

1000 Deerfield Parkway

Buffalo Grove, IL 60089-4513

USA

comments about this document, please send them

to SBT_technical.editor.us.sbt@siemens.com

Printed in the USA

Page 17 of 18

Page 18

Parameter

Definition

Default

Field Value

P101

System Type

CO

P102

Cooling Stages

2

P103

Heating Stages

2

P104

Aux Heating Stages

0

P105

Fan Operation

NO

P106

Reversing Valve

O

P107

Scheduler Days

2

P108

Program Periods

2

P110

Auto Change

YES

P111

Changeover Deadband

5°F (2.5°C)

P112

Daylight Savings

YES

P201

Heat Temp Limit

95°F (35.0°C)

P202

Cool Temp Limit

50°F (10.0°C)

P203

Temperature Display Offset

0°F (0°C)

P204

Override Time Limit

---

P205

Override Temp Limit

---

P206

Heat Pump Compressor Lock Out

OFF

P207

Heat Pump Auxiliary Heat Lockout

OFF

P208

Service UV Lamp

0

P209

Service Humidifier

0

P210

Service Air Filter

0

P211

Keypad Lockout

0

P213

Backlight

15

P301

Configurable Input 1 (IN1)

0

P302

Temperature Input 1 Type

0

P303

Temperature Input 1 Low

0°F (-18.0°C)

P304

Temperature Input 1 High

120°F (50°C)

P305

Configurable Input 2 (IN2)

0

P306

Temperature Input 2 Type

0

P307

Temperature Input 2 Low

0°F (-18.0°C)

P308

Temperature Input 2 High

120°F (50.0°C)

P309

Configurable Input 3 (IN3)

0

P310

Temperature Input 3 Type

0

P311

Temperature Input 3 Low

0°F (-18.0°C)

P312

Temperature Input 3 High

120°F (50.0°C)

P313

Configurable Input 4 (IN4)

0

P314

Temperature Input 4 Type

0

P315

Temperature Input 4 Low

0°F (-18.0°C)

P316

Temperature Input 4 High

120°F (50.0°C)

P317

Aux Output 1 (OUT1)

0

P318

Aux Output 2 (OUT2)

0

P319

Aux Output 3 (OUT3 & C3)

0

P320

Independent Humidity Control

No

P401

Unit Number

---

P402

CO2 Setpoint

800

P403

Pre-Occupancy Purge

0

P404

Occupancy Sensor Min Run Timer

30

P405

Semi-Cont i nuous Fan

NO

P407

Installer Password

0000

P701

Firmware Revision

N/A

P501

Stage Delay - Cooling

2

P502

Stage Differential - Cooling

1°F (0.5°C)

P503

Cooling Minimum Off Time

5

P504

Cooling Minimum On Time

3

P505

Changeover Delay

10

P506

Cooling Deadband

1°F

P507

Stage Delay - Heating

2

P508

Stage Differential - Heating

Conv. = 1°F (0.5°C); HP = 2°F (1°C)

P509

Heating Minimum Off Time

5

P510

Heating Minimum On Time

5 (10 if heat pump)

P511

Heating Deadband

1°F (0.5°C)

P911

Expert Password

99:99

Table 15. Record Field Settings.

Page 18 of 18 Siemens Industry, Inc.

Loading...

Loading...