Page 1

Installation Instructions

Model RDM-MXL

Remote Diagnostics Module

INTRODUCTION

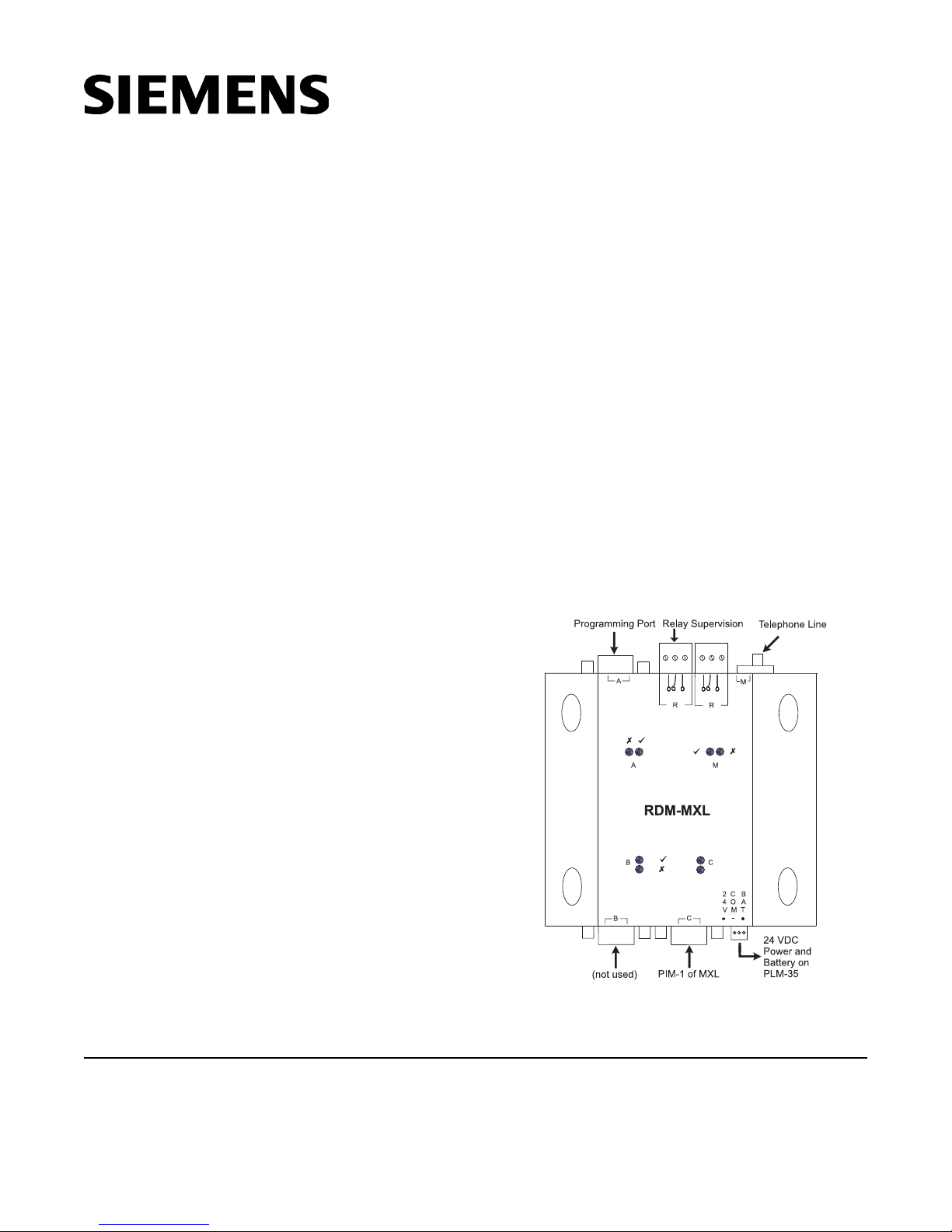

The Model RDM-MXL module (RDM for

connection to the MXL PIM-1) from Siemens

Industry, Inc., as shown in Figure 1, connects

the MXL to a remote location via a telephone

line. The module is designed to be installed

and serviced by fully qualified field engineers.

There are no user-serviceable or installation

parts inside the unit.

NOTE:

The minimum revisions required to operate the

RDM-MXL are listed below:

• MKB firmware Revision 7.0

• CSG-M Revision 7.0

• MXL Revision 7.2

• MXL-IQ Revision 2.0

The following items are supplied with the

RDM-MXL:

YTITNAUQMETI

1noitcennoC1-MIPLXMrof1-MDR

)eludoMscitsongaiDetomeR(

1tekcarBgnitnuoM

4swercSenihcaM4M

4srehsaWta

1LXM-MDRrofrotcennocrewoP

1LXM-MDRrofrotcennocyalernoisivrepuS

1leballavorppaCCFlanoitiddA

lF

The user will need to supply the following items:

YTITNAUQMETI

1rof1-MDRotyrettaBdnaLXMmorfelbaC

1-MIPLXM

1rof1-MDRot1-MIPmorfelbaCecafretnI

1enohpeleT11JRtnailpmoC86traPCCF

droC

1)088296-005N/P(etalPretpadAOFPM-LXM

1eludoMgnitimiLrewo

P53-MLP

weeS(1-MIPLXM

)094398-005N/P(

)noitamrofnigniri

Siemens Industry, Inc.

Building Technologies Division

Florham Park, NJ

P/N 315-096325-4

Figure 1

MXL-RDM Module General Configuration

Siemens Building Technologies, Ltd.

Fire Safety & Security Products

2 Kenview Boulevard

Brampton, Ontario

L6T 5E4 Canada

Page 2

POWER REQUIREMENTS

1-MIPLXMrof1-MDR

)ETD-niP9(CtroP232-SR

1-MIPLXM

)niP9(1-MIPfo1BT

25

34

49

52

Typical: 150mA at 24 VDC

Voltage Input: 20-30 VDC

NOTE: Be sure to include the RDM-MXL in

battery calculations.

INSTALLATION

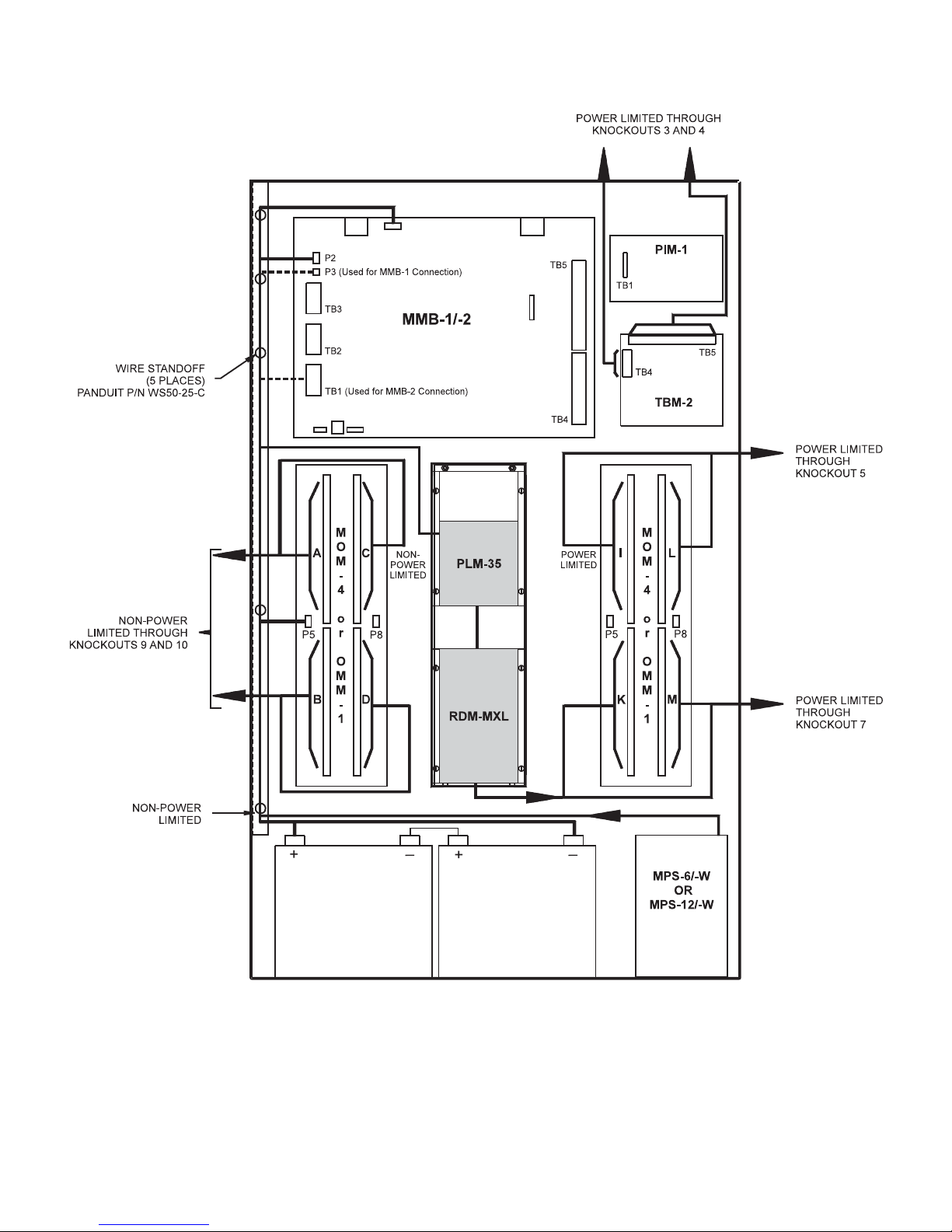

(Refer to Figures 2, 3, 4, and 5)

Remove all system power before installation,

first battery and then AC. (To power up, con-

nect the AC first and then the battery.)

1. The RDM-MXL must be installed in the MXL

enclosure.

2. The Power Terminal of the RDM-MXL must

be connected to the PLM-35. Refer to the

PLM-35 Installation Instructions, P/N 315-

093495.

3. The RDM-MXL is designed to mount on the

MXL-MPFO adapter plate for the MOM-4

position. This bracket has the same footprint

as the MOM-4 and can accommodate 2 RMDMXL modules. An assembly kit is included with

the bracket that contains four nuts and eight

screws. Mount the bracket in the enclosure

with four nuts at the positions labeled “X” in

Figure 2. Refer to Figure 3 for wiring in the

MXL/MXLV enclosure.

The RDM-MXL can also mount to a

SYS3-MPFO adaptor plate for System 3

enclosure (EA-31, EA-32, EA-35) mounting.

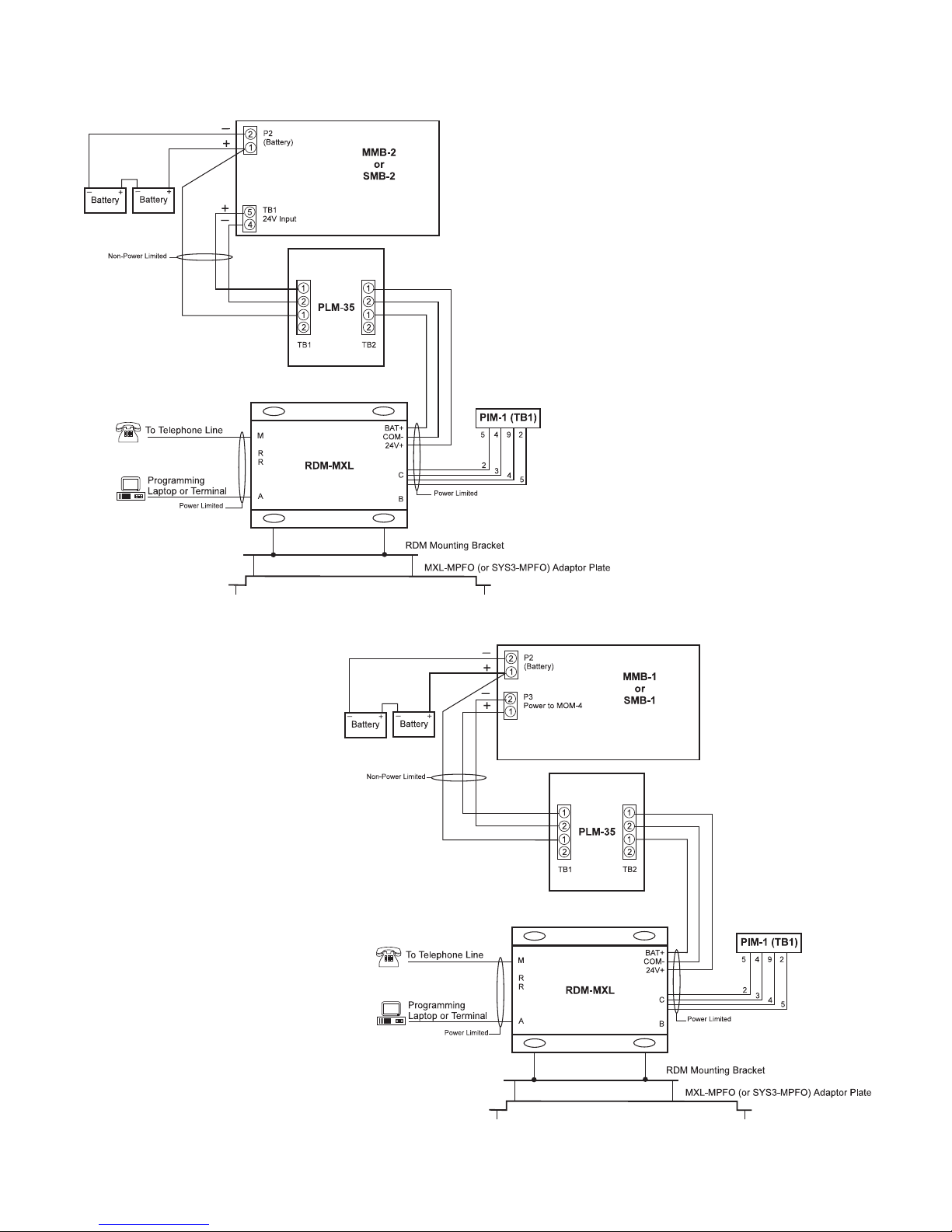

4. Connect the D9 RS-232 Port-C of RDM-MXL

to the PIM-1, according to the following

connection chart.

Figure 2

Mounting the RDM-MXL in the

2

MBR-2 or MME-3 Enclosure

Page 3

Wiring the RDM-MXL in an MBR-2 or MME-3 Enclosure

Figure 3

3

Page 4

Figure 4

Connecting the RDM-MXL to the MXL/MXL-IQ

System with MMB-2/SMB-2 Main Board

Figure 5

Connecting the RDM-MXL to the MXL/MXL-IQ

System with MMB-1/SMB-1 Main Board

4

Page 5

5. For programming of RDM-1 for MXL PIM-1, a

PC can be temporarily connected to Port 232A of RDM-1 for MXL PIM-1. Note that this is a

straight-through standard RS-232 cable for

laptops.

1-MIPLXMrof1-MDR

AtroP232-SR

)ECD-niP9(

2332

3223

402024

5775

231-TDVLXM

sniP52)52BD(

POTPAL/CP

)TROPMOC-52BD(

sniP52

POTPAL/CP

)TROPMOC-9BD(

niP9

6. If hardware supervision is required, connect

the relay output from the RDM-MXL to a

suitable input on the MXL (software supervision does not require this). There are two

relay sockets located next to the RJ11

connector; these relay sockets are IDENTICAL

and either one can be used. The relays will

energize when Supervision failure is

detected.

7. Connect the 24V DC power source (CZM) to

the supplied connector. The power

connector is next to the RS-232 Port C (See

Figure 1). Pin connections are written on the

board and are as follows:

• PWR (+24 VDC)

• RETURN / COM (0V)

• BATTERY (24V DC)

8. For MXL Connection, refer to Figures 4 and 5.

Connecting to the Telephone Network

1. Connect the telephone line to the RJ11 phone

socket on the RDM-MXL. An FCC Part 68

compliant telephone cord must be used.

2. If the RDM-MXL is mounted so that it

permanently obscures the FCC approval

label on the back of the RDM-MXL, an

additional adhesive label has been supplied.

In the case of the MXL Fire Indicator Panel,

this can be affixed to the door of the MXL

cabinet.

3. This equipment complies with Part 68 and

Part 15 of the FCC rules. On the back of the

RDM-MXL is a label that contains, among

other information, the FCC registration

number and ringer equivalence number

(REN). If requested, this information must be

supplied to the telephone company.

4. The REN is used to determine the quantity of

devices which may be connected to the

telephone line. Excessive RENs on the

telephone line may result in the devices not

ringing in response to an incoming call. In

most, but not all areas, the sum of RENs

should not exceed 5. To be certain of the

number of devices that may be connected to

a line, as determined by the total RENs,

contact the local telephone company.

5. If the RDM-MXL causes harm to the

telephone network, the telephone company

will notify you in advance that temporary

discontinuance of service may be required.

But if advance notice isn’t practical, the

telephone company will notify the customer

as soon as possible. Also, you will be

advised of your right to file a complaint with

the FCC if you believe it is necessary.

6. The telephone company may make changes

in its facilities, equipment, operations or

procedures that could affect the operation of

the equipment. If this happens the telephone

company will provide advance notice in order

for you to make necessary modifications to

maintain uninterrupted service.

5

Page 6

Operation of LEDs:

Each port has a green and a yellow LED. When

the green LED is lit, it means the port is operating normally. When the yellow LED is lit, it

means that the port is not operating properly or

there has been supervision failure on this port. If

both LEDs are off, then this port has been

disabled, is not in use, or is not supervised (For

example, Programming port).

• Port A (Programming and Monitoring Terminal port) and Port C (Connection to MXL):

Green LED indicates supervision is all right.

Yellow LED indicates supervision failure

• Port M (modem):

Green LED indicates modem has

established communication and is

operating properly.

Yellow LED indicates modem failure.

CONFIGURATION OF RDM-1 FOR

MXL PIM-1

1. Power up the RDM-MXL. After approximately

3 seconds, all LEDs on the RDM will turn on.

This allows for programming of the RDM-MXL

using the default configuration. The default

configuration requires that a laptop be

connected to port 232-A using a straightthrough RS-232 cable. A terminal program

such as Procom/Telix or Windows Terminal

using VT100 emulation, can be used with

communication parameters set to 9600, 8, N, 1.

2. If MXL-VDT is being used, set the emulation

to VT100 with communication parameters set

to 9600, 8, N, 1. After programming the

RDM-MXL, reset its emulation and

communication parameters to its previous

setting.

3. Type MENU while all the LEDs are turned on

to start the RDM menu. There is no need to

press <Enter>.

4. This is the only time the RDM-1

programming menu can be accessed.

After entering MENU, you will be prompted to

enter a login password before you can

configure the RDM-MXL. This password

corresponds to the password configured for

your login name. The RDM-MXL is shipped

with the highest level (level 1) password of

PWORD1. After entering the correct

password, the main menu will scroll on the

screen (entering the incorrect password will

exit the programming mode and revert the

RDM-MXL to normal operating mode).

5. Follow the menu options to set the following

information:

Site Name: The location of the MXL fire

alarm panel.

Supervision: This option is used to select

how the RDM-MXL supervises its serial

ports. If the supervision relay is not

connected, then SOFTWARE supervision

can be selected. This selection will allow the

MXL to annunciate a supervision failure.

RDM-MXL Communications Setup: This

submenu sets the communication parameters

to the MXL (Port C) and the monitoring port

(Port A). Make sure that the Port C settings

are the same as the PIM settings in CSG-M.

Also note that for proper supervision, the PIM

should be set for MXL VDT-132.

Dialup Communications Setup: This

submenu selects the settings for the modem

interface between RDM-MXL and RDM-PC.

Dialup Logins: This submenu selects the

LOGIN, the telephone number the RDM-MXL

will call and the password it will verify. Up to

8 different login names can be configured.

Menu Options

• Press the key in brackets to select a

particular menu option (For example, press

<1> to select option 1).

• When entering in letters (For example, the

Sitename or Login name), press the <Enter>

key when finished to save the entry.

• Most other options use the <SPACE BAR> to

step through each available setting for that

option (For example, Baud Rate 1200, 2400,

4800, 9600, 19200).

6

Page 7

• To back out of a menu (and return to the Main

Menu) without saving any changes that were

made, press the <Esc> key or the (q) key.

• The Main Menu is displayed after you type the

correct password from the programming

terminal or PC.

• All Menu options show the factory default for

each setting.

MXL. When failure occurs, the RDM will get

no further events from the MXL.

Relay Rating: 30V, 1A (resistive)

125 VAC, 0.250A (resistive)

Please note that the relays are not set to fail-safe

mode. Both relays will energize when supervision

failure is detected on any supervised ports or on

modem failure.

Main Menu

(1) Sitename

This is displayed to identify the site to which you

are connected. A maximum of 16 characters can

be entered.

(3) RDM-MXL Communication Setup

Options 1-5 set the RDM-1 communication

parameters for MXL communication.

Options 6-A set the RDM-1 communication

parameters for terminal programming and monitoring port.

(2) Supervision Trouble

This option selects how the monitoring port (Port

A) is supervised if a supervised device such as

the MXL-VDT is installed at this port.

Relay Only: When this option is selected,

supervision failure on Port A will transfer the

supervision relays but will not annunciate a

trouble condition on the MXL. This is the

default setting.

Software: When this option is selected,

supervision failure on Port A will transfer the

supervision relays and will annunciate a

Printer Offline trouble-in condition on the

NOTE: BE SURE TO CHECK THE TERMINAL

PROTOCOL SETTING.

(1) For proper MXL supervision, the MXL

protocol should be set for MXL VDT

132. This must also be set in CSG-M

for the PIM-1 port. If No Device is

selected, the RDM will not be

supervised by the MXL.

(2) - (5) For proper communication, set the

MXL communication parameters the

same as the CSG-M settings for the

PIM-1 module.

7

Page 8

(6) The terminal protocol should be set to

XL Graphics or MXL VDT 132 if super-

vision to the terminal (Port A) is required during monitoring. Otherwise, set

it to No Device if this port is going to be

used for programming only.

(7) - (A) This setting should match the communi-

cation parameter of the device to which

this port connects.

The terminal settings can be left at the factory

defaults (indicated above) to allow for connection

of a VDT Terminal or PC for programming

purposes.

NOTE: When the MXL-VDT is connected to Port

A of the RDM-MXL and its supervision is

required, the MXL communication

parameters must match the terminal

communication parameters.

(4) Dialup Communication Setup

(3) - (6) The communications parameters for

Dialup Connections between RDM-MXL

and RDM-PC should not be changed

unless explicitly required.

(7) Show Diagnostics is a special mode

which should only be activated by

technicians in order to resolve modem

communication problems at installation. The default setting is set to NO.

(5) Dialup Logins

(1) The Setup String is for modem com-

munication and it should not be

changed from the factory default

(indicated above).

(2) Dialing is normally set to TONE, but

PULSE dialing can be set if required by

the telephone exchange.

Options (1) to (4) are required for each Login Name.

(1) Login: Name which will be used to

identify who is calling in from RDM-PC.

Login names must be unique for each

entry.

(2) Phone Number: The telephone

number which the RDM-MXL will use

to call back to connect to the RDM-PC.

(3) Password: Once the RDM-MXL has

called back the RDM-PC, this password is used for additional security. It

is also used to identify the person

logging on (using the MENU option

during programming the RDM-MXL).

(4) Dialup Allowed: Setting this option to

Yes allows the RDM-MXL to dial out to

a remote location. Setting this option to

No disables the RDM-MXL from dialing

back. Use the NO setting to temporarily

8

Page 9

disallow access to the system. The

RDM-PC will indicate a logging error

message when a login attempt is made.

Up to 8 login names can be programmed. Use the

Prev and Next options to step through each login

name.

NOTE: Depending on the password you entered

at startup (password entered after typing

MENU), you may not have access to all

login names. For example, if you entered

a password for entry number 7, you can

only access the login details for entry 7

and entry 8. The password for entry

number 1 has full access and can configure details for all logins.

IF TROUBLE IS EXPERIENCED WITH the

RDM-MXL, please contact the Siemens Industry, Inc., Technical Support Department at

(800) 248-7976.

U.S.A. - FCC EQUIPMENT LIMITATIONS:

• An FCC Part 68 compliant telephone cord

must be used.

• This equipment complies with Part 68 and

Part 15 of the FCC rules. On the back of the

RDM-MXL is a label that contains, among

other information, the FCC registration

number and ringer equivalence number (REN).

If requested, this information must be

supplied to the telephone company.

• The REN is used to determine the quantity of

devices which may be connected to the

telephone line. Excessive RENs on the

telephone line may result in the devices not

ringing in response to an incoming call. In

most, but not all areas, the sum of RENs

should not exceed 5. To be certain of the

number of devices that may be connected to

a line, as determined by the total RENs,

contact the local telephone company.

• If the RDM-MXL causes harm to the

telephone network, the telephone company

will notify you in advance that temporary

discontinuance of service may be required.

But if advance notice isn’t practical, the

telephone company will notify the customer

as soon as possible. Also, you will be advised

of your right to file a complaint with the FCC

if you believe it is necessary.

• The telephone company may make changes

in its facilities, equipment, operations or

procedures that could affect the operation of

the equipment. If this happens the telephone

company will provide advance notice in order

for you to make necessary modifications to

maintain uninterrupted service.

9

Page 10

INDUSTRY CANADA - EQUIPMENT ATTACHMENT LIMITATIONS:

NOTICE: The Industry Canada label identifies certified equipment. This certification means that the

equipment meets telecommunications network protective, operational and safety requirements as

prescribed in the appropriate Terminal Equipment Technical Requirements document(s). The Department does not guarantee the equipment will operate to the user’s satisfaction.

Before installing this equipment, users should ensure that it is permissible to be connected to the

facilities of the local telecommunications company. The equipment must also be installed using an

acceptable method of connection. The customer should be aware that compliance with the above

conditions may not prevent degradation of service in some situations.

Repairs to certified equipment should be coordinated by a representative designated by the supplier.

Any repairs or alterations made by the user to this equipment, or equipment malfunctions, may give the

telecommunications company cause to request the user disconnect the equipment.

Users should ensure for their own protection that the electrical ground connections of the power utility,

telephone lines and internal metallic water pipe system, if present, are connected together. This precaution may be particularly important in rural areas.

Caution: Users should not attempt to make such connections themselves, but should contact appropriate electric inspection authority, or electrician, as appropriate.

NOTICE: The Ringer Equivalence Number (REN) assigned to each terminal device provides an

indication of the maximum number of terminals allowed to be connected to a telephone interface. The

termination on an interface may consist of any combination of devices subject only to the requirement

that the sum of the Ringer Equivalence Numbers does not exceed 5.

10

Page 11

11

Page 12

Siemens Industry, Inc.

Building Technologies Division

Florham Park, NJ

P/N 315-096325-4

Siemens Building Technologies, Ltd.

Fire Safety & Security Products

2 Kenview Boulevard

Brampton, Ontario

L6T 5E4 Canada

Loading...

Loading...