Page 1

SIPART PS2

6DR50xx

6DR51xx

6DR52xx

6DR53xx

Edition 10/2006

Manual

Electropneumatic Positioner for

Linear and Part-Turn Actuators

SIPART PS2 Manual

A5E00074630- -06

1

Page 2

Copyright e Siemens AG 2006 All rights reserved

Disclaimer of Liability

The reproduction, transmission or use of this document or its contents is not permitted without express written authority. Offenders will be liable for

damages. All rights, including rights created by patent grant or registration of a utility model or design,

are reserved.

Siemens AG

Bereich Automatisierungs-- und Antriebstechnik

Geschäftsgebiet Prozessinstrumentierung-- und

Analytik

D--76181 Karlsruhe

We have checked the contents of this manual for

agreement with the hardware and software described. Since deviations cannot be precluded entirely,

we cannot guarantee full agreement. However, the

data in this manual are reviewed regularly and any

necessary corrections included in subsequent editions. Suggestions for improvement are welcomed.

e Siemens AG 2006

Technical data subject to change.

Trademarks

SIMATIC, SIPART, SIREC, SITRANS are registered trademarks of Siemens AG.

Third parties using for their own purposes any other names in this document which refer to trademarks might infringe upon the rights of the trademark owners.

SIPART PS2 Manual

2

A5E00074630- -06

Page 3

Contents

0 Information for the Operator 5.............................................

0.1 General information 5...........................................

0.2 Classification of Safety Related Notices 6.........................

0.3 Qualified Personnel 7...........................................

0.4 Use as intended 9..............................................

0.5 Technical Documentation 9......................................

0.6 Warranty Information 9..........................................

0.7 Delivery Notes 10...............................................

0.8 Standards and Regulations 10....................................

1 Introduction 11............................................................

1.1 General information about the positioner 1 1.........................

2 Design and Method of Operation 15........................................

2.1 Overview 15....................................................

2.2 Design name plate 17............................................

2.3 Instrument Components 17.......................................

2.3.1 Motherboard 18.................................................

2.3.2 Electrical Connections 18.........................................

2.3.3 Pneumatic Connections 19.......................................

2.3.4 Mounting Kit 22.................................................

2.3.5 Purge air switching (not in the explosion proof version) 22............

2.3.6 Restrictors 22...................................................

2.4 Method of Operation 23..........................................

2.5 HART-function 26...............................................

2.6 State as supplied 26.............................................

2.7 Installation of options modules 27.................................

2.7.1 Installation of options modules in normal and intrinsically

safe versions 27................................................

2.7.2 Installation of options modules in explosion proof version 29..........

2.7.3 Iy-module 31...................................................

2.7.4 Alarm module 32................................................

2.7.5 SIA module 33..................................................

2.7.6 Mechanical limit switch module 35.................................

2.7.7 EMC filter module 38............................................

2.7.8 Accessories 39.................................................

3 Preparing for Operation 41.................................................

3.1 Instrument identification (type key) 41..............................

3.2 Dimensional drawings 41.........................................

3.3 Assembly 43....................................................

3.3.1 Instructions for using positioners in a wet environment 44.............

3.3.2 Instructions for using positioners which are exposed to strong

accelerations or vibrations 46.....................................

3.3.3 Mounting kit “linear actuator” 6DR4004-8V and 6DR4004-8L 49.......

3.3.4 Assembly procedure (see figure 3-7, page 51) 50....................

SIPART PS2 Manual

A5E00074630- -06

3

Page 4

3.3.5 Mounting kit “part-turn actuator” 6DR4004-8D 52....................

3.3.6 Assembly procedure (see figure 3-8 and figure 3-9) 53...............

3.4 Electrical Connection 57..........................................

3.4.1 Connection in non-intrinsically safe and explosion proof version 59.....

3.4.2 Connection in intrinsically safe version 62...........................

3.4.3 Connection in type of protection “n” version 68......................

3.5 Pneumatic Connection 71........................................

3.6 Commissioning 72...............................................

3.6.1 Preparations for linear actuators 73................................

3.6.2 Automatic initialization of linear actuator 74.........................

3.6.3 Manual initialization of linear actuator 76............................

3.6.4 Preparations for part-turn actuator 79..............................

3.6.5 Automatic initialization of part-turn actuator 79......................

3.6.6 Manual initialization of part-turn actuators 81........................

3.6.7 Automatic initialization (structograms) 82...........................

3.7 Copying initialization data (positioner exchange) 87..................

4 Operation 89..............................................................

4.1 Display 89......................................................

4.2 Input keys 89...................................................

4.3 Operating modes 92.............................................

4.4 Parameters 95..................................................

4.5 Diagnostics 122..................................................

4.5.1 Diagnostic display 122............................................

4.5.2 Meaning of the diagnostic values 123...............................

4.5.3 Online diagnostics 131............................................

4.5.4 Fault correction 136..............................................

4.6 Meaning of the other display text 139...............................

4.7 Optimizing the controller data 143..................................

5 Service and Maintenance 145................................................

6 Technical Data 147.........................................................

7 Scope of Delivery 153.......................................................

7.1 Scope of delivery of standard controller 154..........................

7.2 Scope of delivery of options 154....................................

7.3 Scope of delivery of accessories 155................................

7.4 List of Spare Parts 156............................................

8 Index 158..................................................................

9 Appendix 160..............................................................

9.1 Literature and catalogs 160........................................

4

SIPART PS2 Manual

A5E00074630- -06

Page 5

Information for the Operator

Information for the Operator

Dear customer,

Please read this manual before starting work!

It contains important information and data which, when observed,

ensure full availability of the equipment and save service costs. This

simplifies handling of this control instrument considerably and provides

accurate measuring results.

You have purchased an instrument which can be installed in various

configurations:

S SIPART PS2 without Ex-protection in a metal- or plastic housing.

S SIPART PS2 with EEx ia/ib-protection in a metal- or plastic hous-

ing.

S SIPART PS2 EEx d in a pressurized explosion proof housing

This manual takes each of these possibilities into consideration.

Any differences between the devices are indicated specially.

Scope of delivery, see chapter 7, page 153.

0

0.1 General information

The product described in this manual left the factory in a perfectly safe

and tested condition. To maintain this condition and to achieve perfect

and reliable operation of this product, it must only be used in the way

described by the manufacturer. Successful and safe operation of this

equipment is dependent on proper handling, installation, operation and

maintenance.

SIPART PS2 Manual

A5E00074631- -06

5

Page 6

Information for the Operator

This manual contains the information required for use as intended of

the product it describes. It is addressed to technically qualified personnel specially trained or having relevant knowledge of instrumentation

and control technology, hereafter called automation technology.

Familiarity with and proper technical observance of the safety notes

and warnings contained in this manual are essential for safe installation

and commissioning and for safety in operation and maintenance of the

product described. Only qualified personnel as defined in Chapter 0.3

has the necessary specialist knowledge to interpret the general safety

notes and warnings given in this document in specific cases and to

take the necessary action.

The documentation supplied with the instrument is listed in Chapter 0.5.

This manual is not a permanent part of the scope of supply. For reasons

of clarity, it does not contain every detail about every version of the

product described and cannot take every eventuality in installation, operation, maintenance and use in systems into account. If you require

further information or if problems occur that have not been dealt with in

sufficient detail in this document, please request the required information from your local Siemens office or the office responsible for you.

Functionality, commissioning and operation are described in this

manual.

Please pay special attention to the Warning and Note texts. These are

separated from the remaining text by horizontal lines and specially

marked with symbols (see Chapter 0.2).

0.2 Classification of Safety Related Notices

This manual contains notices which you should observe to ensure your

own personal safety, as well as to protect the product and connected

equipment. These notices are highlighted in the manual by a warning

triangle and are marked as follows according to the level of danger:

DANGER

!

!

indicates an immenently hazardous situation which, if not avoided, will

result in death or serious inury .

WARNING

indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury .

SIPART PS2 Manual

6

A5E00074631- -06

Page 7

Information for the Operator

CAUTION

!

used with the safety alert symbol indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

CAUTION

used without the safety alert symbol indicates a potentially hazardous

situation which, if not avoided, may result in property damage.

NOTICE

indicates a potential situation which, if not avoided, may result in an

undesirable result or state.

.

NOTE

highlights important information on the product, using the product,

or part of the documentation that is of particular importance and that

will be of benefit to the user.

0.3 Qualified Personnel

The result of unqualified intervention in the instrument or nonobservance of the warnings given in this manual or on product labels can be

severe personal injury and/or serious material damage. Therefore only

properly qualified personnel must make changes and settings in the

instrument.

For the purpose of the safety information in this manual and on the

product labels, qualified personnel are those who

S in the case of ex-proof equipment, are trained, instructed or

authorized to perform work on electrical circuits of equipment

subject to explosion hazard.

S if they are configuration personnel, are familiar with the safety

concepts of automation technology

SIPART PS2 Manual

A5E00074631- -06

S if they are operating personnel, have been instructed in the handling

of automation equipment and know the content of this manual

relating to operation

S if they are commissioning and/or service personnel, are trained to

repair such automation equipment and authorized to energize,

de-energize, clear ground and tag circuits and equipment according

to safety engineering standards.

S and instructed additionally in first aid

7

Page 8

Information for the Operator

WARNING

!

The instrument must only be installed and commissioned by qualified

personnel.

The device may be used solely for the purposes described in this

manual.

The instrument is designed for connection to functional and safety

extra low voltage.

Electrical safety depends only on the power supply equipment.

Pneumatic actuators exert considerable positioning forces. The safety

precautions of the actuator used must therefore be scrupulously

observed during installation and commissioning in order to prevent

injuries.

We explicitly draw your attention to the necessity of observing safety

regulations regarding operation in zones subject to explosion hazard,

if applicable.

The specifications of the examination certificate valid in your country

must be observed. Laws and regulations valid in your country must be

observed for the electrical installation in explosions hazardous areas.

In Germany these are for example:

-- Working reliability regulations

-- Regulations for installing electrical equipment in hazardous areas,

DIN EN 60079-14 (in the past VDE 0165, T1).

It should be checked whether the available power supply, insofar as

this is required, is compliant with the power supply specified on the

rating plate and specified in the examination certificate valid in your

country.

Take care to avoid electrostatic discharges within the hazardous area,

such as can arise if a dry cloth is used to clean the positioner in the

plastic housing.

Devices with the protection type “flameproof enclosure” may only be

opened when the power is off.

WARNING

!

Devices with the protection type “intrinsically safe” lose their certification as soon as they are operated with circuits that do not conform to

the specifications laid down in the examination certificate valid in your

country.

The successful and safe operation of this equipment is dependent

upon its proper handling, installation, operation and maintenance.

SIPART PS2 Manual

8

A5E00074631- -06

Page 9

WARNING

!

The device may not be operated while the leaflets are in the housing.

0.4 Use as intended

Use as intended for the purpose of this manual means that this product

must only be used for the applications described in the technical description (see also Chapter 3 of this manual).

The product described in this manual has been developed, manufactured, tested and documented observing the relevant safety standards.

If the handling rules and safety information for configuration, installation, use as intended and maintenance are observed, there is normally

no danger with regard to material damage or for the health of personnel. Extra low voltages that are connected must be fed in by safe isolation.

Information for the Operator

0.5 Technical Documentation

The operating instructions are a constituent part of the enclosed CD

“sipartp ps2 POSITIONERS” (order number A5E00214567) and is

available on the Internet at:

www.siemens.com/sipartps2

Click on “More Info” and --> “Instructions and Manuals”.

On the enclosed CD, you will find an extract of the catalog FI 01 “Field

devices for process automation” with the current order data. The entire

FI 01 catalog is also available at the above Web address.

0.6 Warranty Information

We should like to point out that the content of this manual is not part of

and does not modify a previous or current agreement, undertaking or

legal relationship. Siemens is bound solely by the contract of sale,

which also contains the complete and exclusive warranty. The contractual warranty conditions are neither extended nor restricted by this

document.

SIPART PS2 Manual

A5E00074631- -06

9

Page 10

Information for the Operator

0.7 Delivery Notes

The scope of delivery is listed on the dispatch papers accompanying

the delivery in accordance with the valid contract of sale.

When you open the packaging please observe the information on the

packaging. Check that the delivery is complete and undamaged.

If possible, compare the order number on the rating plates with the ordering data.

For the scope of delivery please see Chapter 7, page 153.

0.8 Standards and Regulations

As far as possible, the harmonized European standards were used to

specify and manufacture this equipment. If harmonized European standards have not been applied, the standards and regulations of the Federal Republic of Germany apply (see also the Technical Data in Chapter 6, page 147).

If this product is used outside the area of applicability of these standards and regulations, please observe the standards and regulations in

force in the country where the product is operated.

10

SIPART PS2 Manual

A5E00074631- -06

Page 11

Introduction

Introduction

1.1 General information about the positioner

The positioner is used to adjust and control pneumatic actuators.

The controller operates electropneumatically with compressed air as an

energy supply.

Purpose

For example, the positioner can be used to control valves as follows:

S with linear actuator (figure 1-1, page 13) or

S with part-turn actuator VDI/VDE 3845 (figure 1-2, page 13)

Different mounting types are available for linear actuators:

S NAMUR or IEC 534

S integrated mounting to ARCA

1

Versions

Housing

S integrated mounting to SAMSON (non-explosion-proof version)

This means the positioner can be installed and operated on all common

actuator systems.

The positioner is available for the following actuators:

S double-acting and

S single-acting

For following applications:

S potentially explosive or

S not potentially explosive applications.

The electronics with display, position feedback and valve block are integrated in the housing.

The housing is available in three versions:

S Plastic housing for single and double-acting actuators

S Metal housing for single-acting actuators

S Explosion proof housing for single and double-acting actuators

SIPART PS2 Manual

A5E00074631- -06

11

Page 12

Introduction

Degree of

protection

Explosion

Protection

SIL applications

Options

The device is designed with IP66/NEMA4x degree of protection.

The intrinsically safe version can be used in hazardous areas in zone 1

or zone 2.

The explosion proof version can be used in hazardous areas in zone 1

or zone 2.

The version with the type of protection “n” can be used in hazardous

areas of zone 2.

The SIPART PS2 positioners in the variations 6DR501*, 6DR511*,

6DR521* and 6DR531* (i.e. with 0/4 up to 20 mA control signal in the

single-acting design) are also suitable for positioning on fittings with

pneumatic actuators, which satisfy the special requirements for safety

devices up to SIL 2 to IEC 61508/ IEC 61511-1. For this, the SIL safety

instructions (see “SIPAR T PS2 SIL safety manual” A5E00442120) must

be followed.

The positioner can be expanded with various options modules (chapter 2.7, page 27). The following modules are available in all:

S

-module: Two-wire current output 4 to 20 mA for position feedback

Iy

S Alarm module: 3 digital outputs and 1 digital input

Accessories

Environmental

Protection

S SIA module: one digital output for fault messages, two digital out-

puts for limit value alarms

S Manometer block: 2 or 3 manometers for single and double-acting

positioners

S Connection block (NAMUR) for safety valve block

S Mounting kits for linear and part-turn actuator

For decentralized installation of the positioner and position sensor:

S External position detection system

S Non-Contacting Position Sensor (NCS)

Only environmentally friendly materials have been used in the construction of the positioner.

The technical manual is printed on chlorine-free bleached paper.

12

SIPART PS2 Manual

A5E00074631- -06

Page 13

Introduction

1

2

3

1 Actuator

2 Positioner, single-acting in metal housing

3 Lantern

4 Manometer block, single-acting

5Valve

Figure 1-1 Positioner mounted on linear actuator (single-acting)

4

5

1

2

1 Positioner double-acting in plastic housing

2 Part-turn actuator

3 Manometer block, double-acting

Figure 1-2 Positioner mounted on part-turn actuator (double-acting)

SIPART PS2 Manual

A5E00074631- -06

3

13

Page 14

Introduction

1

2

4

3

1 Actuator

2 Positioner, single-acting in explosion proof housing

3 Lantern

4 Manometer block, single-acting

Figure 1-3 Explosion proof version of the positioner mounted on linear actuator (single-acting)

1

3

2

1 Positioner double-acting in explosion proof housing

2 Part-turn actuator

3 Manometer block, double-acting

Figure 1-4 Explosion proof version of the positioner mounted on part-turn actuator (double-acting)

Table 1-1

14

SIPART PS2 Manual

A5E00074631- -06

Page 15

Design and Functional Principle

Design and Method of Operation

The following chapter describes the mechanical and electrical design,

the instrument components and method of operation of the positioner.

2.1 Overview

Introduction

The electropneumatic positioner forms a control system in connection

with an actuator. The current position of the actuator is detected by a

servo potentiometer and fed back as actual value x. The setpoint and

actual value are output simultaneously on the display.

The setpoint w is formed by a current fed to the positioner which at

the same time serves to supply the positioner in two-wire operation.

In 3/4-wire operation the supply comes from a 24 V voltage input.

The positioner operates as a predictive five-point switch by the output

variable ±∆y of which the integrated actuating valves are controlled with

pulse length modulation.

2

These actuating signals cause fluctuations in pressure in the actuator

chamber(s) and thus adjustment of the actuator until the control error is

zero.

Operation (manual) and configuration (structuring, initialization and

parameterization) is effected by three keys and a display with the housing cover removed.

The standard controller has one digital input (DI1). This can be configured individually and can be used for blocking the operating modes for

example.

With the I

as a two wire signal I

In addition the actuator can be monitored for two programmable limit

values which respond on exceeding or dropping below the stroke or

angle of rotation.

The limit value alarms are output by the alarm option module which can

monitor and report the function of the positioner and the actuator additionally through a fault message output. The value of the control difference dependent on the travel time is monitored in automatic mode. The

fault signal is always set when the control error cannot be leveled after

a certain time because for example the valve is blocked or the mains

pressure is insufficient. The three digital outputs are implemented as

semiconductor outputs and are error self-reporting, i.e. the outputs re-

-option module, the current actuator position can be output

y

=4to20mA.

y

SIPART PS2 Manual

A5E00074631- -06

15

Page 16

Design and Functional Principle

spond even when the power supply fails or the electronics are defective.

The actuator can also be blocked or driven to its final positions depending on the configuration for example by an external event via a digital

input (DI2) on the alarm module.

If you require electrically independent limit value messages from the

standard controller, you will have to use the SIA module with the slot

initiators instead of the alarm module.

Communication with the controller is possible via the optional HART

interface.

To be able to use the positioner with a variety of different part-turn and

linear actuators, it has a friction clutch and switchable gearing.

The switchable gearing allows you to adjust the positioner for small and

large lifts. You can switch using the yellow switch (8, Fig. 2-11, page 28)

between 33_ (as delivered) and 90_.

The friction clutch (8, Fig. 2-1 1, page 28) allows you to set the working

range, particularly for linear actuators, after installation. You thus do not

have to ensure symmetrical mounting during the installation.

As it is not allowed to open the housing of an explosion-proof version in

a potentially explosive atmosphere, the shaft has an externally fitted,

additional friction clutch (8, Fig. 2-12, page 31).

NOTICE

for the explosion-proof version:

Only adjust the outer friction clutch (8, Fig. 2-12, page 31). The internal

friction clutch (8, Fig. 2-1 1 page 28) is fixed and, for the explosionproof version, must not be adjusted.

16

SIPART PS2 Manual

A5E00074631- -06

Page 17

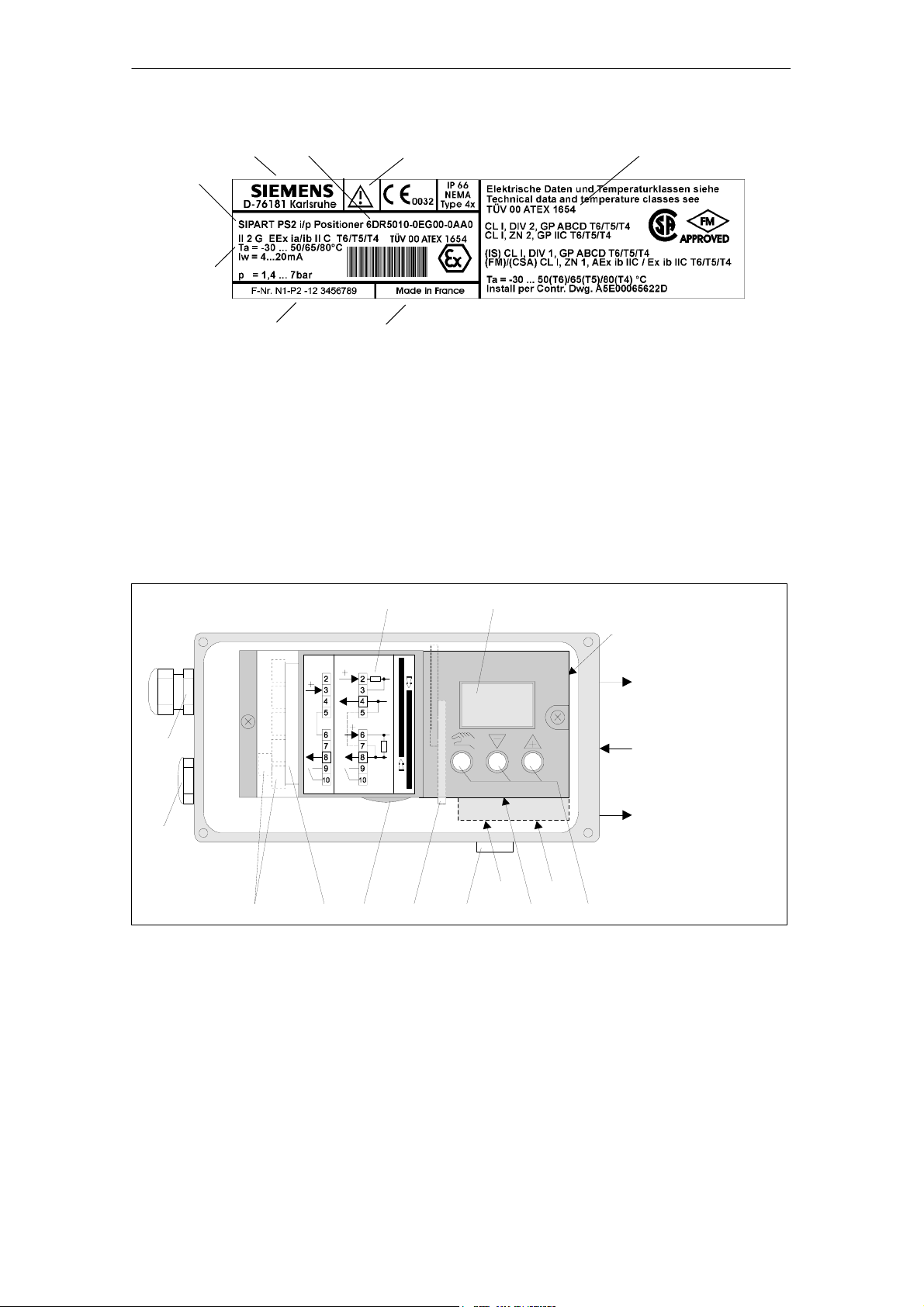

2.2 Name plate design

Design and Functional Principle

(2)

(8)

(3)

(4)

(5)

(6)

(1) Order number (5) Serial number

(2) Manufacturer (6) Place of manufacture

(3) Product name (7) Protection class

(4) Technical data (8) Observe manual

Figure 2-1 Design name plate, example with protection class EEx ia/ib

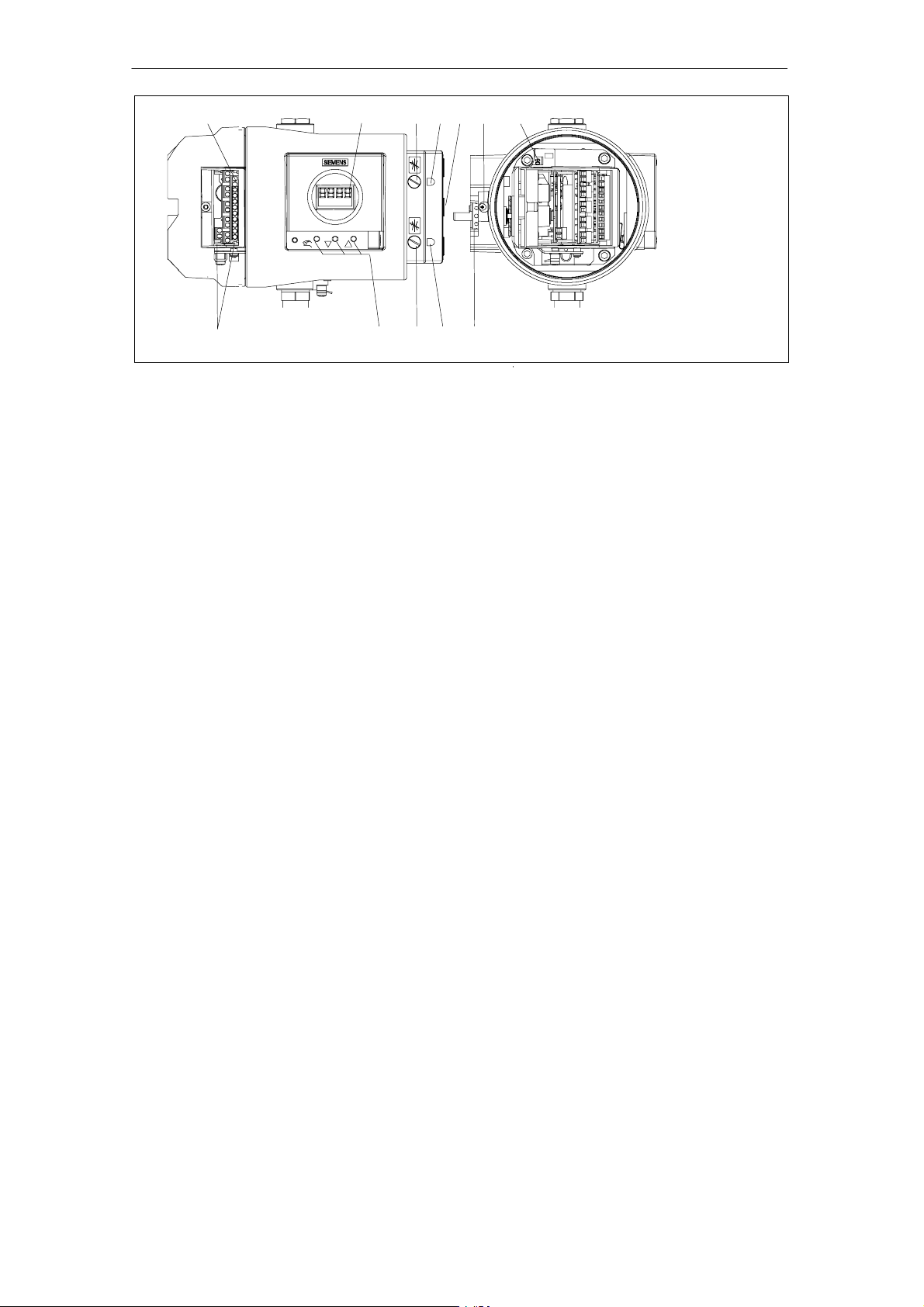

2.3 Instrument Components

(7)(1)

314

90°

DI1

O

33

O

90

13

3/4 W2W

4...20 mA

0/4...20 mA

33°

12

6.1 6.2

7891011

1 Input: Supply air 7 Silencer

2 Output: Actuating pressure Y1 8 Transmission ratio selector

3 Display 9 Adjusting wheel for frichtion clutch

4 Output: Actuating pressure Y2

5 Operating keys 12 Dummy plug

6 Restrictor 13 Screw-type cable gland

6.1 Restrictor Y1 14 Terminal plate on cover

6.2 Restrictor Y2

*)

in double-acting actuators

*)

*)

10 Terminals options modules

15 Purging air switch

56

15

2

1

4

Figure 2-2 View of the positioner in normal version (cover open)

SIPART PS2 Manual

A5E00074631- -06

17

Page 18

Design and Functional Principle

9

1

10

3

---++

10

1 Input: Supply air 7 Transmission ratio selector

2 Output: Actuating pressure Y1 (only possible with positioner open)

3 Display 8 Adjusting wheel for friction clutch

4 Output: Actuating pressure Y2

5 Operating keys 10 Terminals options modules

6.1 Restrictor Y1 12 Safety catch

6.2 Restrictor Y2

*)

in double-acting actuators

*)

*)

2121

6.1

138238 9

6.2

45

9 Terminals standard controller

7

8

Figure 2-3 View of the explosion proof version of the positioner

2.3.1 Motherboard

The motherboard contains all the electronic elements such as the CPU,

memory, A/D converter. It also contains the display and the operating

keys.

In addition, the terminal strips for connecting the options modules are

also on the motherboard.

2.3.2 Electrical Connections

The terminals of the standard controller, the Iy- and alarm-option module are arranged at the left-hand front edges and offset against each

other in staircase form.

A module cover protects the modules from being pulled out and prevents incorrect installation.

18

SIPART PS2 Manual

A5E00074631- -06

Page 19

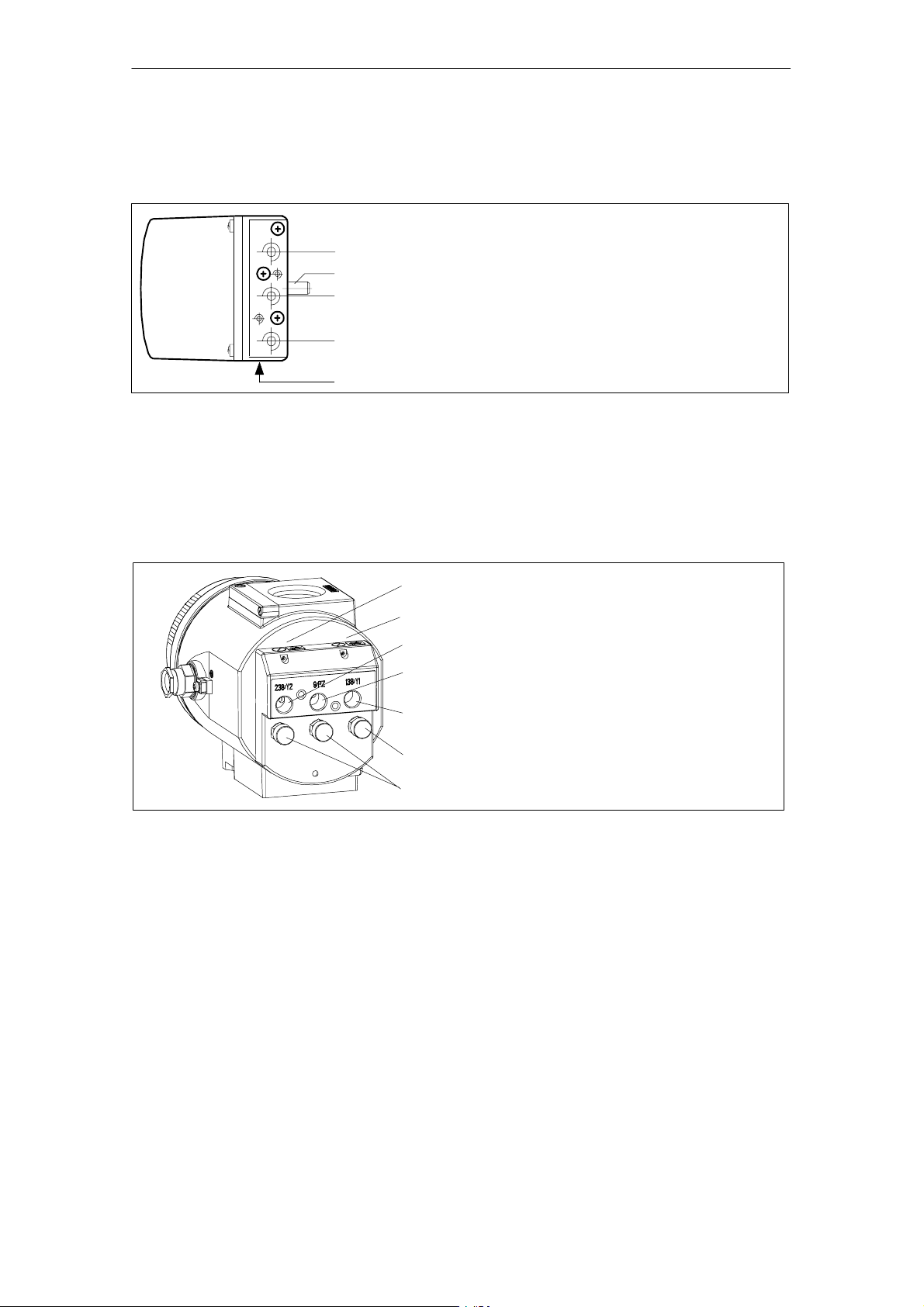

2.3.3 Pneumatic Connections

The pneumatic connections are on the right hand side of the positioner

(figure 2-4 and figure 2-5).

1

2

3

4

5

1 Actuating pressure Y1 in single- and double-acting actuators

2 Feedback shaft

3 Supply air P

4 Actuating pressure Y2 in double-acting actuators

5 Exhaust air output E with silencer on the bottom of the instrument

z

Design and Functional Principle

Figure 2-4 Pneumatic connection in normal version

1

2

3

4

5

6

7

1 Restrictor Y2 *) 5 Actuating pressure Y1

2 Restrictor Y1 6 Exhaust air output E

3 Actuating pressure Y2 *) 7 Housing ventilation (2x)

4 Supply air PZ

*)

in double-acting actuators

Figure 2-5 Pneumatic connection in explosion proof version

SIPART PS2 Manual

A5E00074631- -06

In addition, there are pneumatic connections on the back of the positioner for integrated installation in single-acting linear actuators.

S Actuating pressure Y1

S Exhaust air output E (not in explosion proof version)

In the ex-factory state, these connections are sealed by screws

(see figure 3-1, page 41, figure 3-3, page 42 and figure 3-4, page 43).

19

Page 20

Design and Functional Principle

The exhaust air output E can be provided for supplying dry instrument

air to the tapping chamber and spring chamber to prevent corrosion.

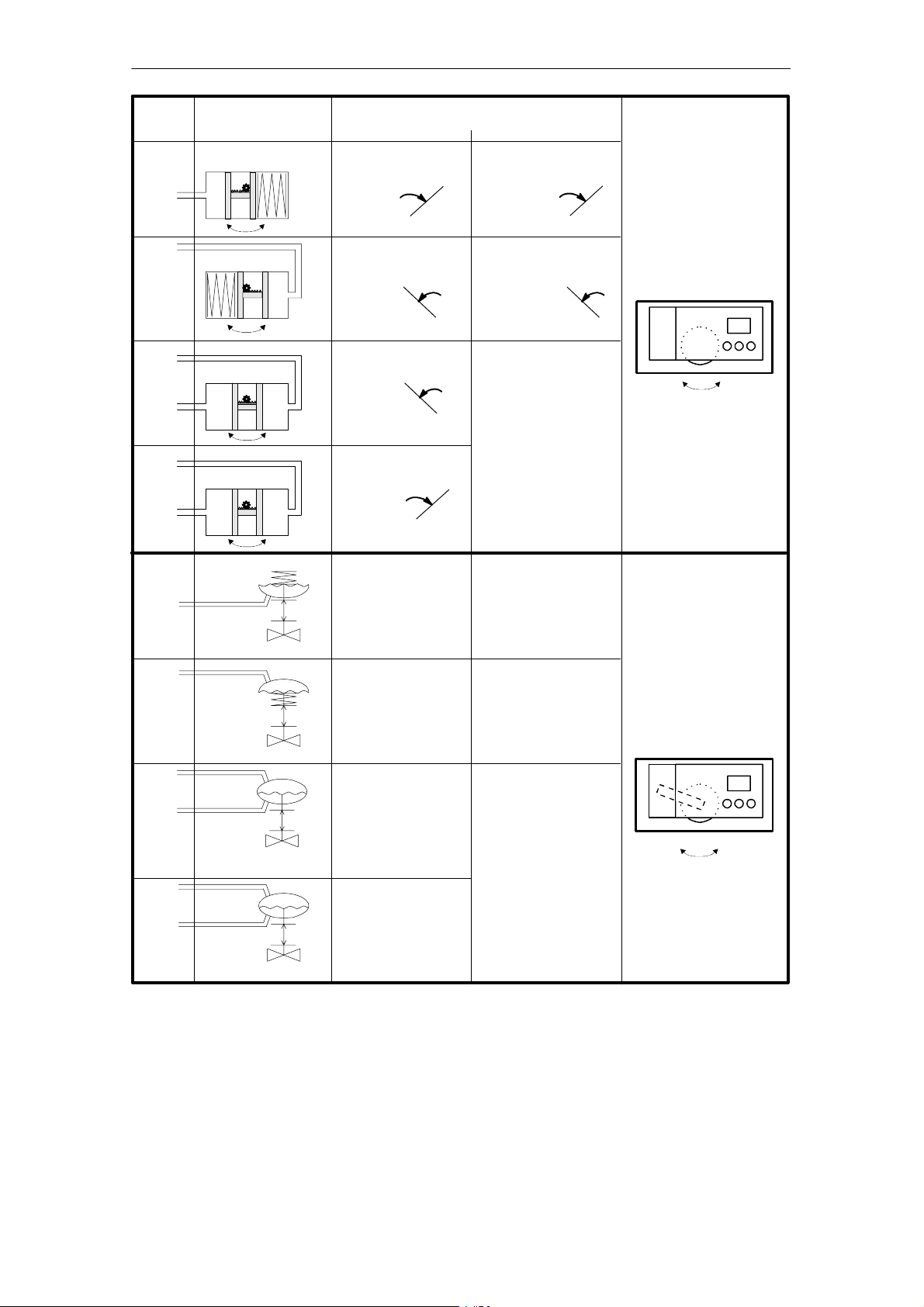

Figure 2-6, page 21 shows the pneumatic connection variants for the

different actuator types, the positioning action and the safety position

after power failure.

20

SIPART PS2 Manual

A5E00074631- -06

Page 21

Design and Functional Principle

Positioning

pressure

Connection

Y1

Y1

Y2

Y1

Y1

Y2

Closed

Closed

Actuator type

Open

Open

OpenClosed

OpenClosed

Safety position after power failure

electrical pneumatic

Closed Closed

Open Open

Open

Last position

(before power

failure)

Closed

In part-turn actuators the

direction of rotation

counterclockwise looking

onto the actuating shaft of

the valve is usually defined

as “Open”.

Open

Closed

Y1

up

Down Down

down

Y1

up

down

Up Up

Y2

Y1

up

down

Up

Y1

Y2

up

down

Down

Figure 2-6 Pneumatic connection positioning

Last position

(before power

failure)

up down

SIPART PS2 Manual

A5E00074631- -06

21

Page 22

Design and Functional Principle

2.3.4 Mounting Kit

The positioner can be mounted on almost all actuators with the appropriate mounting kit.

2.3.5 Purge air s witch in g (not in the explosion proof version)

The purge air switch is accessible above the pneumatic terminal strip

with the housing open (figure 2-7). In the IN position the inside of the

housing is purged with very small amounts of clean, dry instrument air.

In the OUT position the purge air is fed directly to the outside air.

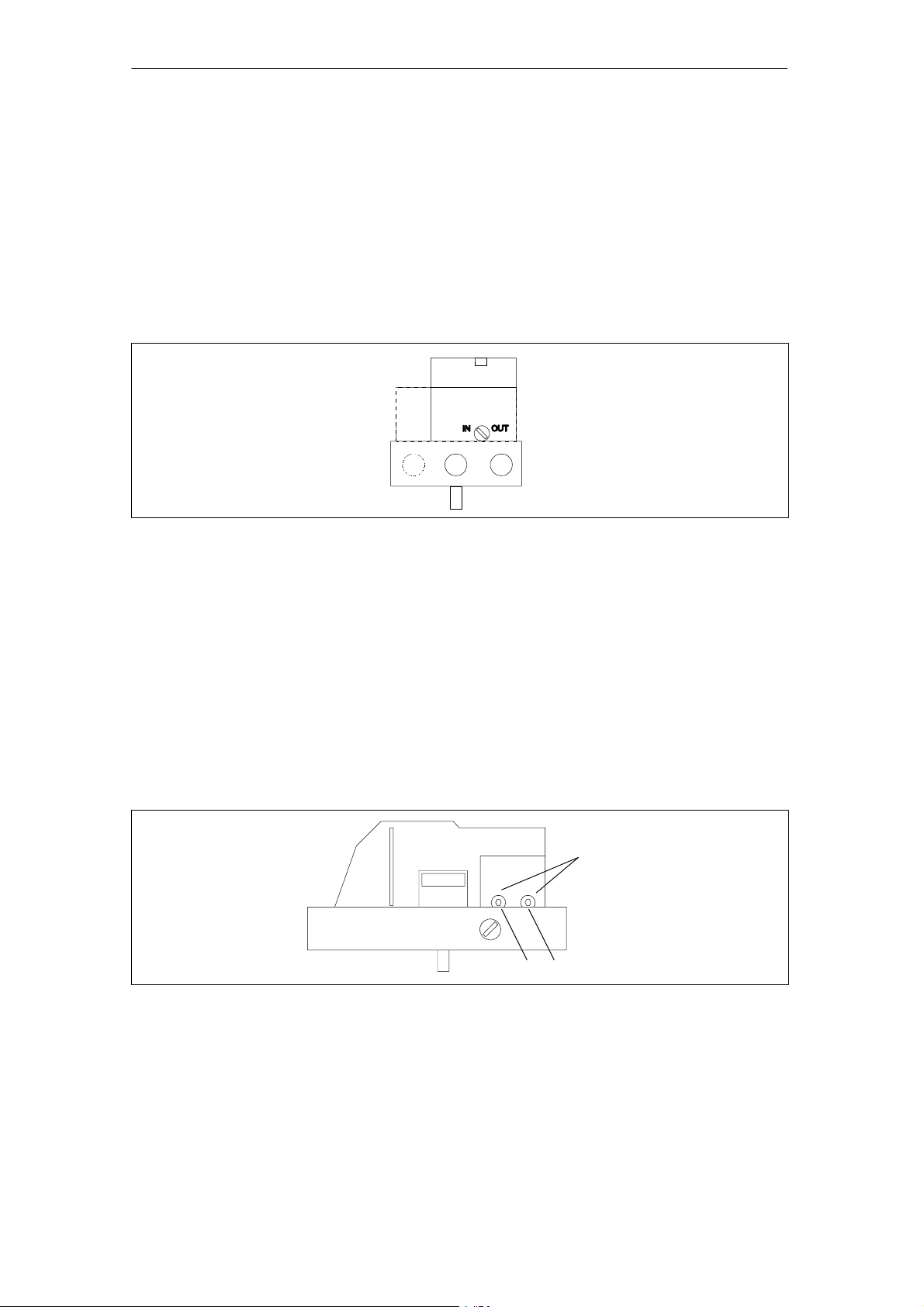

Figure 2-7 Purge air switch on the valve block, view of the positioner onto pneumatic connection side

with cover open

2.3.6 Restrictors

In order to achieve travel times of > 1.5 s in small actuators, the air rate

can be reduced with the restrictors Y1 and Y2 (figure 2-8, in explosion

proof version, see figure 2-5, page 19). By turning to the right the air

rate is reduced up to shutting off. To set the restrictors it is advisable to

close them and then open them slowly (see initialization RUN3).

In the case of double-acting valves make sure that both chokes are set

approximately equal.

Hexagon socket 2.5 mm

Y1 Y2

Figure 2-8 Restrictors

22

SIPART PS2 Manual

A5E00074631- -06

Page 23

2.4 Method of Operation

The electropneumatic positioner SIPAR T PS2 forms a control circuit

with the pneumatic actuator in which the actual value x is the position

of the actuator bar in linear actuators or the position of the actuator

shaft in part-turn actuators and the command variable w is the

actuating current of a controller or a manual control station of 4 to

20 mA.

The stroke or part-turn movement of the actuator is transferred by the

appropriate mounting accessories, the feedback shaft and a play-free

switchable gearwheel to a high quality conductive plastic potentiometer

and to the analog input of the microcontroller. The current position can

also be preset for the positioner via an external sensor. The detection

of the stroke or rotation andle is performed by a non-contacting position sensor (Non Contacting Position Sensor) directly at the actuator.

This may correct the angle error of the stroke tap, compares the

potemtiometer voltage as actual value x with the setpoint w fed in at

the terminals 3 and 7 and calculates the manipulated variable

increments Δy. Depending on the size and direction of the control

error (x-w) the piezo-controlled supply air or exhaust air valve is

opened. The volume of the actuator integrates the positioning

increments to actuating pressure y open which moves the actuator bar

or actuator shaft approximately proportionally. These positioning

increments change the actuating pressure until the control error

becomes zero.

Design and Functional Principle

The pneumatic actuators are available in single and double-acting

versions. Only one pressure chamber is aerated or deaerated in the

single-acting version. The resulting pressure operates against a spring.

In the double-acting version, two pressure chambers are counteractive.

In this case the one volume is deaerated when the other volume is

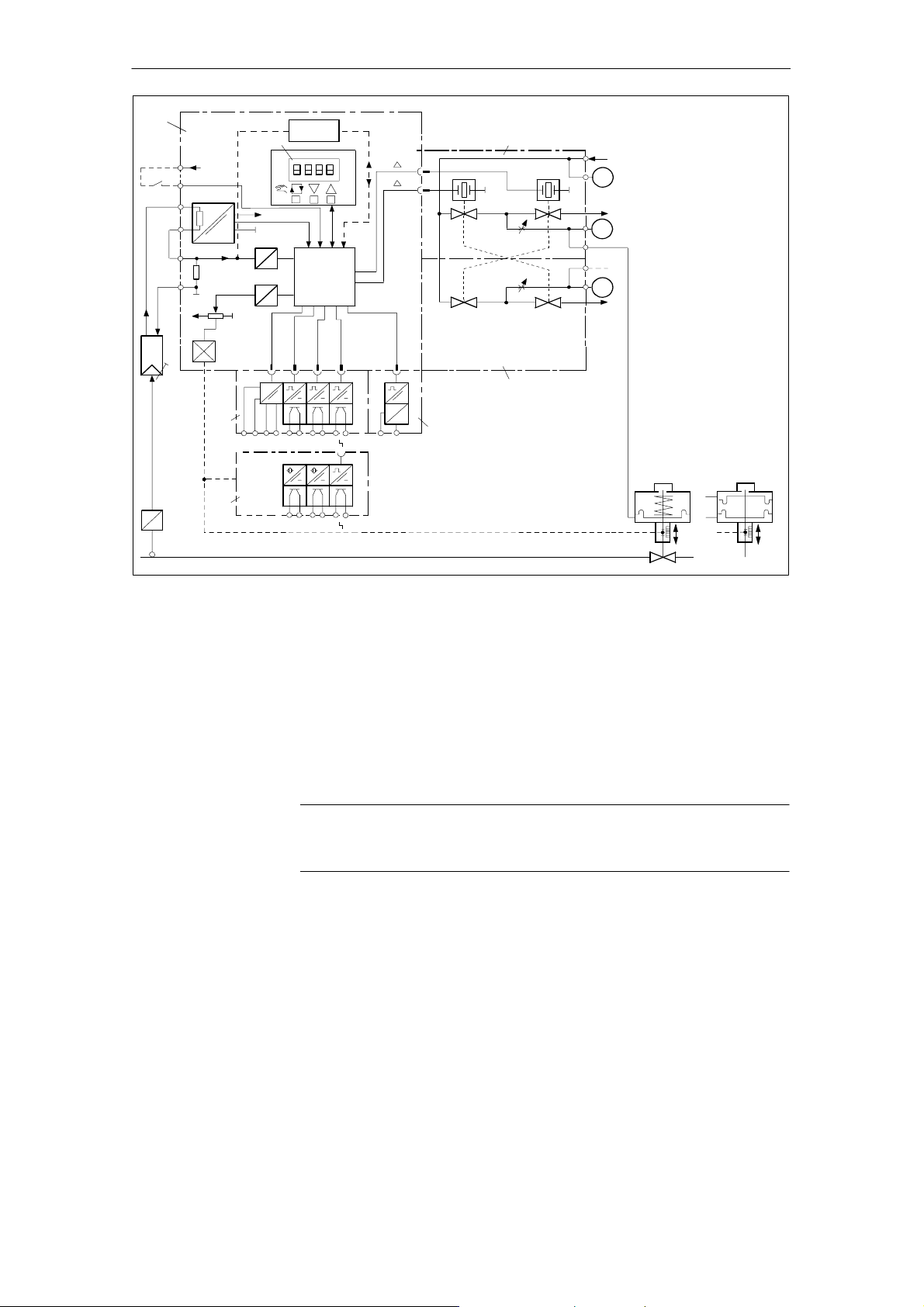

aerated. See the block diagram figure 2-10, page 25.

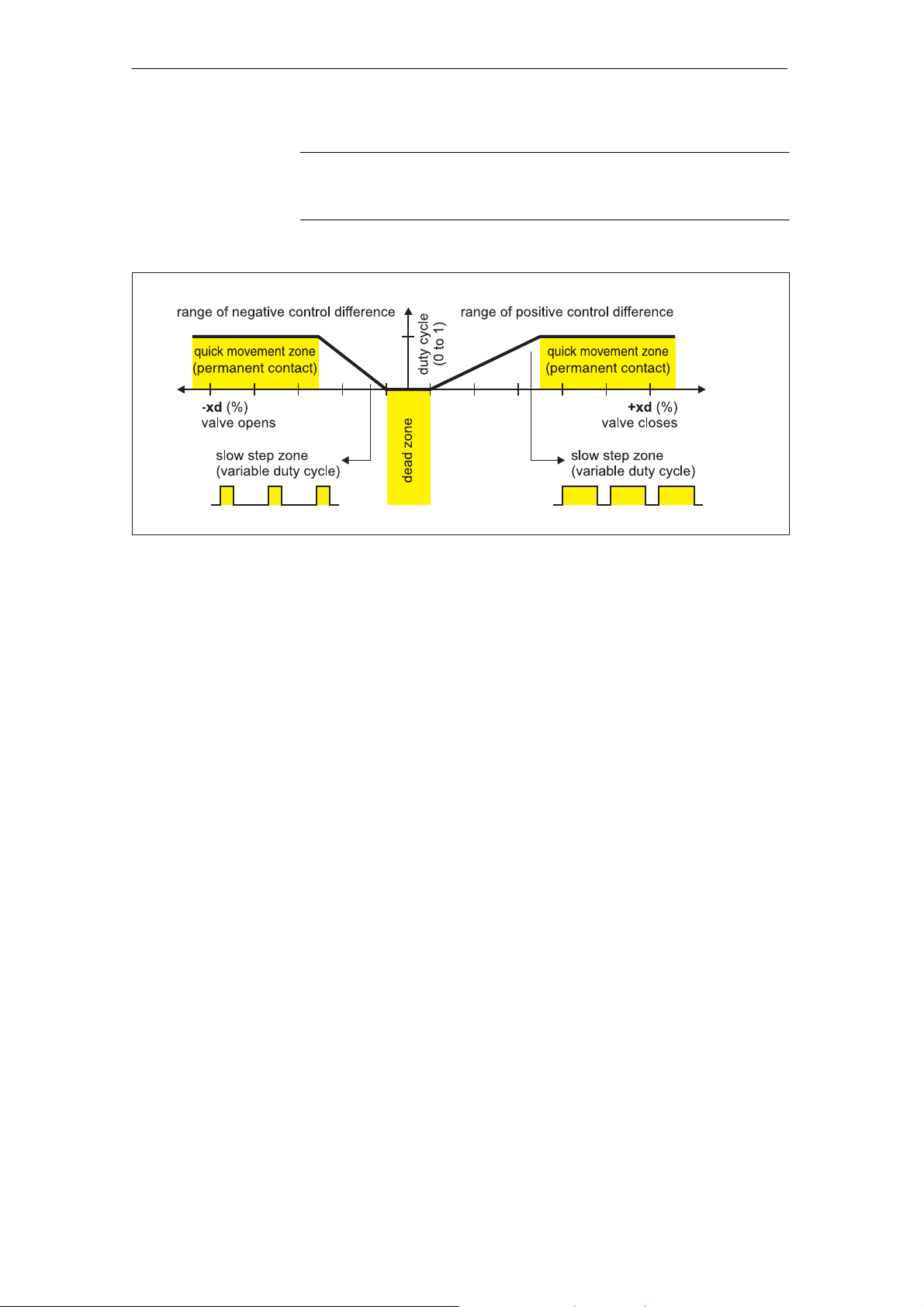

The control algorithm is an adaptive predictive five-point switch

(see figure 2-9, page 24).

The valves are controlled with continuous contact at large control errors

(fast step zone). At medium control errors the valve is controlled by

pulse length modulated pulses (short step zone).

No actuating pulses are output in the small control error zone (adaptive

dead zone). The dead zone adaptation and the continuous adaptation

of the minimum pulse lengths in automatic operation cause the best

possible control accuracy to be achieved at the lowest switching frequency. The start parameters are determined during the initialization

phase and stored in a non-volatile memory. These are basically the real

travel with the mechanical limit stops, the travel times, the size of the

dead zone etc.

In addition the number of fault messages, changes in direction and the

number of strokes are determined and stored every 15 minutes during

operation. These parameters can be read out and documented by the

communication programs such as PDM and AMS. Conclusions as to

the wear on the fitting can be drawn (diagnostic function) especially by

comparing the old value with the currently determined values.

SIPART PS2 Manual

A5E00074631- -06

23

Page 24

Design and Functional Principle

Figure 2-10, page 25 shows the block diagrams for single- and doubleacting actuators with the linear actuator as an example.

.

Figure 2-9 Method of operation five-point switch

NOTE

The exhaust air valve is always open when there is no current.

24

SIPART PS2 Manual

A5E00074631- -06

Page 25

Design and Functional Principle

1

BE1

I

I

y

0

+

x

W+

W-

3 V

W

+U

_

W

x

0

6

BE2

7

+5 V

A

A

2

+24 V

D

D

HART

_

Micro-

controller

A1 A2

II

A1 A2

3

_

y

y

+

+

U

U

I

5

4

Zuluft

Supply air

p

Z

Exhaust air

Abluft

p

1

p

p

p

2

Abluft

Exhaust

air

1

2

stroke

9

p

2

p

1

stroke

8

p

1

1 Motherboard with microcontroller and input circuit

2 Control panel with LC-display and momentary action switch

3 Piezo-valve unit, always built-in

4 Valve unit with double-acting positioner always built-in

5 Iy-module for positioner SIPART PS2

6 Alarm module for three alarm outputs and one digital input

7 SIA-module (Slot Initiator-Alarm-module)

8 Spring-loaded pneumatic actuator (single-acting)

9 Spring-loaded pneumatic actuator (double-acting)

Figure 2-10 Block diagram of the electro-pneumatic positioner, functional diagram

.

NOTE

Alarm module (6) and SIA module (7) can only be used alternatively.

SIPART PS2 Manual

A5E00074631- -06

25

Page 26

Design and Functional Principle

2.5 HART-function

Function

.

The positioner is also available with built-in HART-functions. The HART

protocol allows you to communicate with your instrument with a handheld communicatorR, PC or programming unit. This enables you to

configure your instrument comfortably, save configurations, call diagnostic data, display online measured values and much more. Communication takes place as frequency modulation over the existing signal

lines for the command variable from 4 to 20 mA.

The SPART PS2 is integrated in the following parameterization tools:

S Handheld communicatorR

S PDM (Process Device Manager)

S AMS (Asset Management System)

S Cornerstone (without diagnostic values/-functions)

NOTE

Operation on the positioner has priority over the settings via the HART

interface.

Communication is aborted by a power failure at the positioner.

2.6 State as supplied

There are no mechanical mounting accessories on the controller in the

state as supplied. These must be ordered and installed according to

the “operating instructions” depending on the application.

The respective connections for single or double-acting versions are

prepared at the factory as ordered.

The pneumatic connections on the rear are sealed.

26

SIPART PS2 Manual

A5E00074631- -06

Page 27

Design and Functional Principle

2.7 Installation of options modules

2.7.1 Installation of options modules in normal and intrinsically safe versions

The following option modules are available for the positioner in the

standard and the intrinsically safe version:

-module

-- l

y

-- Alarm module

-- SIA-module

-- Mechanical limit switch module

-- EMC filter module

The installation of the options modules is described below:

Installation

.

Open positioner

.

The option modules are secured by a assembly covering ((1), see

figure 2-11, page 28) and mechanically fixed.

NOTE

To install the option modules the housing of the positioner needs to be

opened. As soon as the positioner is opened, the IP66 degree of

protection is not guaranteed.

To open the positioner, the four screws of the housing cover must be

loosened with a Phillips screwdriver.

Disconnect or isolate the power supply cables.

Remove the module cover (1). To do this, the two screws (1.1) must be

removed with a screwdriver.

NOTE

To prevent premature wearing of the fixture by the self-tapping screws

(1.1), the following method of mounting the module cover (1) has

proven effective.

SIPART PS2 Manual

A5E00074631- -06

1. Turn the screws counterclockwise until you feel them snap into the

thread

2. Tighten both screws carefully in clockwise direction

27

Page 28

Design and Functional Principle

6

1

1.1

5

2.1

1.1

2.1

2

12

10

4

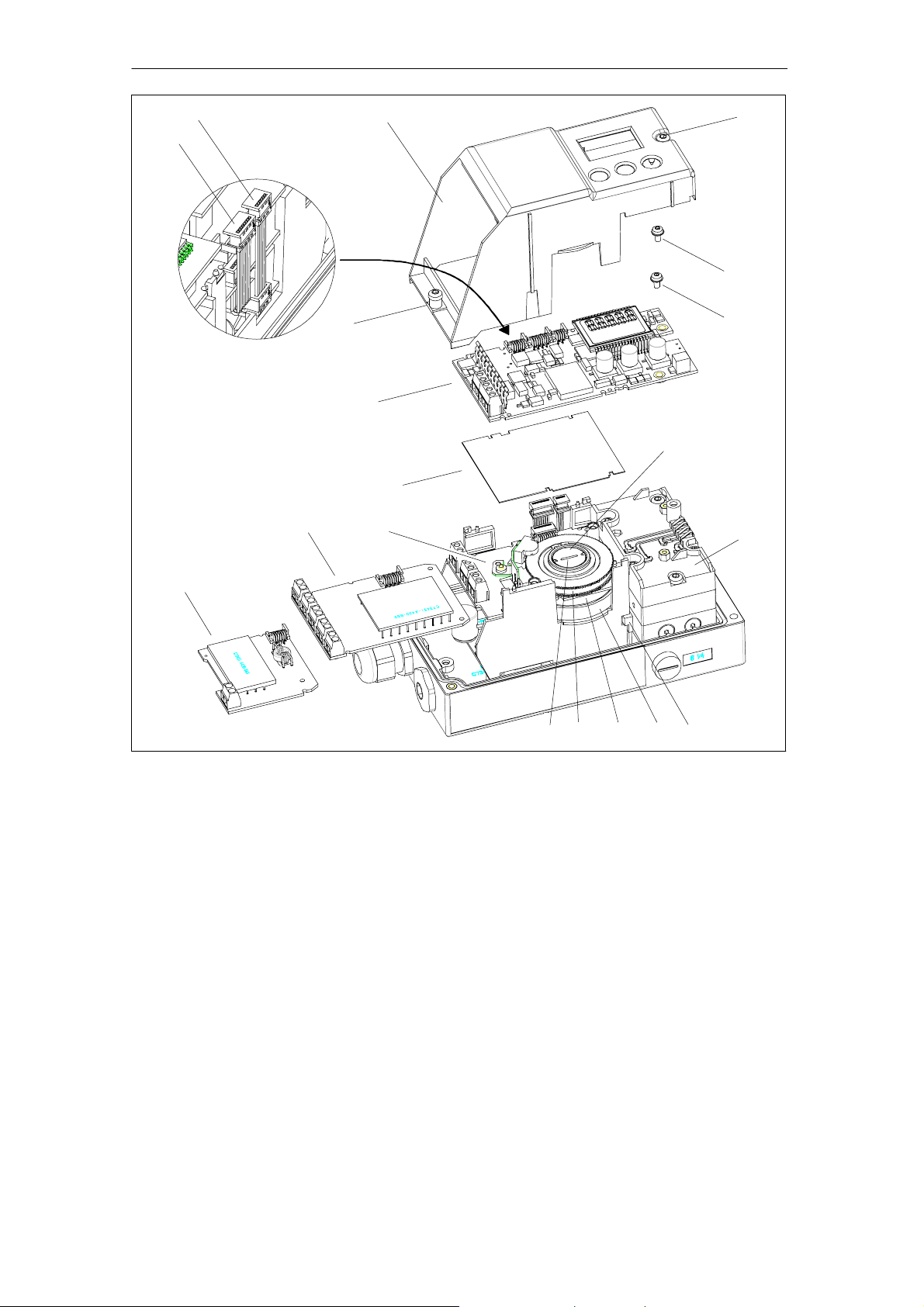

7

11

3

7.2 7.3

7.1 8 9

1 Module cover 7 SIA-module and mechanical limit switch module

1.1 Fixing screws 7.1 Special screw

2 Motherboard 7.2 Actuating disc for A1 (terminals 41 and 42)

2.1 Fixing screws 7.3 Actuating disc for A2 (terminals 51 and 52)

3I

-module with ribbon cable (6) 8 Adjusting wheel for friction clutch

y

4 Alarm module with ribbon cable (5) 9 Transmission ratio selector

5 Ribbon cable for alarm module 10 Insulating cover

6 Ribbon cable for Iy-module 11 Pneumatic block

Figure 2-11 Installation of Options Modules

12 Actuating disc bearings

28

SIPART PS2 Manual

A5E00074631- -06

Page 29

Design and Functional Principle

2.7.2 Installation of options modules in explosion proof version

The following option modules are available for the positioner in the explosion-proof version:

-module

--

Iy

-- Alarm module

Installation

.

The options modules are protected and mechanically fixed by a module

cover ((1), see figure 2-12, page 31).

NOTE

The housing must be opened to install the options modules. The

degree of protection IP66/NEMA4x is not guaranteed as long as the

positioner is open.

WARNING

!

In areas in which the atmosphere may be potentially explosive, the

explosion-proof positioner may only be supplied with electrical auxiliary

power when the housing is closed and when built-in, approved electronics are used.

The feed-though openings for the electronic connections must be

sealed with EEX-d certified cable glands or EEx-d certified plugs or

an ignition lock must be mounted at a maximum distance of 46 cm

(18 inches) when using the “conduit”-system.

Open the

positioner

SIPART PS2 Manual

A5E00074631- -06

See figure 2-12, page 31. Disconnect or isolate the power supply

cables first.

To open the positioner, the safety catch (12) must be opened and the

screw-on cover unscrewed.

After loosening the four fixing screws (13.1) the complete rack (13) can

be removed. The actuator may have to be turned so that the clutch can

be easily disengaged.

Remove the module cover (1). To do this, the two screws (1.1) must be

removed with a screwdriver.

29

Page 30

Design and Functional Principle

.

NOTE

To prevent premature wearing of the fixture by the self-tapping screw

(1.1) next to the display, the following method of mounting the module

cover (1) has proven effective.

1. Turn the screws counterclockwise until you feel them snap into the

thread.

2. Tighten both screws carefully in clockwise direction.

30

SIPART PS2 Manual

A5E00074631- -06

Page 31

1.1

Design and Functional Principle

10

13.1

12

8

7

13.1

56

13

1

1.1

2

4

3

11

1 Module cover 7 Transmission ratio selector

1.1 Fixing screws 8 Adjusting wheel for friction clutch

2 PA module 10 Housing

3I

module with ribbon cable 11 Screw-on cover

y

4 Alarm module with ribbon cable 12 Safety catch

5 Ribbon cable for alarm module 13 Rack

6 Ribbon cable for I

module 13.1 Fixing screws

y

Figure 2-12 Installation of the options modules in the explosion proof version

2.7.3 Iy-module

Function

SIPART PS2 Manual

A5E00074631- -06

With the Iyoption module, the current actuator position can be output

as a two wire signal I

= 4 to 20 mA – potentially isolated from the

y

standard controller. The dynamic control of the I

error self-reporting.

module makes it also

y

31

Page 32

Design and Functional Principle

Installation

2.7.4 Alarm module

Function

Insert the Iymodule (3) in the lower slot of the rack up to the stop and

use the 6-pin flat ribbon cable (6) provided to connect it to the

motherboard (see figure 2-11, page 28).

The alarm module contains

S 3 digital outputs and

S 1 digital input

The digital outputs serve to output fault messages and alarms. The

configuration is described in chapter 4.4, page 95, with the parameters 44 to 54.

By an external signal applied at digital input (DI2) the actuator can be

blocked or driven to its limit positions for example depending on the

configuration. The configuration is described in chapter 4.4, page 95,

with the parameters 43.

The alarm module is available in two versions:

S explosion protected for connecting to switching amplifier

EN 60947-5-6

Installation

S non-explosion protected for connection to voltage sources with a

maximum 35 V

The semiconductor outputs of the alarm module report an alarm (signal

state Low) by switching off with high resistance. They are conductive in

the High state (without alarm). The dynamic control makes them error

self-reporting.

The outputs are potentially isolated from the basic circuit and each

other.

The digital input is double.

S one potential isolated for voltage level

S one not potential isolated for floating contacts

These two inputs are designed as logic OR links.

Insert the alarm unit (4) below the motherboard in the rack up to the

stop and use the 8-pin flat ribbon cable (5) to connect it to the motherboard (see figure 2-1 1, page 28).

32

SIPART PS2 Manual

A5E00074631- -06

Page 33

2.7.5 SIA module

Design and Functional Principle

The SIA module contains:

S one binary output

S two binary outputs

Function

Installation

A collected fault message (see alarme module) is output via the binary

output. The floating digital output is implemented as a self error reporting semiconductor output.

The two binary outputs are used to report two mechanically adjustable

limit values (L1, L2) via slot initiators. These two outputs are electrically

independent of the rest of the electronics.

(Slot Initiator Alarm module) Proceed as follows for installation

(figure 2-11, page 28)::

1. Remove all the electrical connections from the motherboard (2).

2. Loosen the two fixing screws (2.1) of the motherboard.

3. Snap out the motherboard by carefully bending the four holders.

4. Insert the SIA module (7) from above until it reaches the upper

circuit board rail of the rack.

5. Push the SIA module into the circuit board rail of the rack approx.

3 mm towards the right.

6. Screw the special screw (7.1) through the SIA module into the axle

of the positioner (Torque: 2 Nm):

CAUTION

The pin pressed into the actuating disc bearing (12) must be adjusted

to just before touching with the special screw. The actuating disc bearing and the special screw must then be turned simultaneously so that

the pins slot into the special screw.

7. Place the insulating cover (10) over the SIA module underneath

the surface of the motherboard at the container wall on one side.

The recesses in the insulating cover must slot into the corresponding lugs on the container wall. Place the insulating cover on the

SIA module by carefully bending the container walls.

8. Snap the motherboard into the four holders and screw it tight again

with the two fixing screws (2.1).

SIPART PS2 Manual

A5E00074631- -06

33

Page 34

Design and Functional Principle

9. Make all the electrical connections between the motherboard and

the options with the ribbon cables provided and between the motherboard and potentiometers with the potentiometer cable.

10. Fix the enclosed module cover instead of the standard version with

the two screws (1.1).

1 1. Select the plates which already exist on the standard version of the

module cover from the set of plates enclosed. Stick the selected

plates according to the standard version to the mounted module

cover. In the case of the version which doesn’t feature explosion

protection, stick the warning sign onto the side of the ground plate

opposite the name plate.

12. Make the electrical connections.

Setting the two limit values:

.

.

NOTE

Connect a suitable display instrument such as the Initiator-Tester

type 2/Ex made by Peperl+Fuchs to the terminals 41 and 42 or terminals 51 and 52 of the SIA module to be able to see the switching state

of the slot initiators.

1. Drive the actuator to the first desired mechanical position.

2. Adjust the top actuating disc (7.2) by hand until the output signal

on terminals 41 and 42 changes.

3. Drive the actuator to the second desired mechanical position.

4. Adjust the bottom actuating disc (7.3) by hand until the output signal on terminals 51 and 52 changes.

NOTE

If you turn the actuating disc beyond the switching point up to the next

switching point, you can set a high-low or a low-high change.

To avoid the actuating discs being accidentally adjusted during operating, they are relatively sluggish. The following remedy might be of help

if you are having trouble with the adjustment: open and close the actuator several times while holding the actuating discs. This temporarily

reduces the friction. This allows an easier and finer adjustment.

34

SIPART PS2 Manual

A5E00074631- -06

Page 35

2.7.6 Mechanical limit switch module

The mechanical limit switch module contains the following:

S A binary output for the output of a group error message)

S Two switches for signaling two limit values that can be set mechani-

cally. These two switches are electrically independent from the rest

of the electronic system.

Design and Functional Principle

Installation

The installation has to be carried as follows (figure 2-11, page 28):

WARNING

!

!

When the mechanical limit switch module is run with AC > 16 V or

DC > 35 V (low voltage), the housing must be protected against

mechanical actions of > 1 Joule, since otherwise the proper functioning

of the IP66 protective system is not guaranteed.

DANGER

When the module is supplied with low voltage, you must observe the

basic safety rules before beginning work on the device, such as:

1. Deenergizing the module by disconnecting it via the disconnecting

device located directly upstream from the module

2. Securing it against being turned on again

3. Ensuring that the module is disconnected from the voltage supply

CAUTION

The following maximal values only refer to the clamps 41 and 42 as

well as the clamps 51 and 52.

SIPART PS2 Manual

A5E00074631- -06

Maximal voltage (not Ex) AC 250 V or DC 24 V

Maximal current (not Ex) AC/DC 4 A

Maximal voltage (Ex) DC 30 V

Maximal current (Ex) DC 100 mA

When you supply one circuit breaker with extra-low voltage (AC <16 V

or DC 35 < V) and the other with low voltage, you ensure that the cable insulation is doubled.

When operating the switch with low voltage, you must position the low

voltage circuits so that they are separated from the extra-low voltage

circuits.

35

Page 36

Design and Functional Principle

Follow the instructions below for installation:

1. Remove all electrical connections on the motherboard (2).

2. Loosen carefully both fixing screws (2.1) for the motherboard.

3. Insert the limit switch module (7) from above until it reaches the

upper printed circuit board rail of the container.

4. Insert the mechanical limit switch module (7) from above until it

reaches the upper circuit board rail of the rack.

5. Push the mechanical limit switch module (7) into the circuit board

rail of the rack approx. 3 mm towards the right.

6. Screw the special screw (7.1) through the mechanical limit switch

module into the axle of the positioner (torque: 2 Nm).

CAUTION

The pin pressed into the actuating disc bearing (12) must be adjusted just before it touches the special screw. In order that the pin

slot into the special screw, you must then turn the actuating disc

bearing and the special screw simultaneously

.

7. Place the insulating cover (10) over the mechanical limit switch

module underneath the surface of the motherboard onto the container on the wall. The recesses in the insulating cover must slot

into the corresponding lugs on the container wall. Place the insulating cover on the mechanical limit switch module by carefully bending the container walls.

8. Snap the motherboard board into the four holders and screw it tight

again with the two fixing screws (2.1).

9. Make sure all electrical connections between the motherboard and

the options using the ribbon cables provided and between the motherboard and potentiometer using the potentiometer cable.

10. Fix the enclosed module cover (1) instead of the standard version

using the two screws (1.1).

NOTE

To prevent premature wearing of the fixture by the self-tapping screws

(1.1), the following method of mounting the module cover (1) has proven effective:

S Turn the screws counterclockwise until you feel them snap into the

thread.

S Tighten both screws carefully in a clockwise direction.

36

SIPART PS2 Manual

A5E00074631- -06

Page 37

Design and Functional Principle

.

NOTE

Before connecting up the limit contact module, ensure that:

S only qualified personnel connect and set the limit contact module.

S all cables are de-energized.

S the cables are stripped so that the insulation is flush with the termi-

nal when plugging in the wires.

S the ends of stranded wires have sleeves.

S the connection cables are insulated according to the permitted cur-

rent load.

S the permissible working temperature of the cables exceeds the

maximal ambient temperature by >25 _C.

S the Ex-version is only allowed to be operated in intrinsically safe

circuits with approved switching amplifiers.

Connection

1. Loosen the screw (1) on the cover (2).

2. Push the cover (2) till it reaches the front stop.

3. Screw each cable tight in the appropriate terminal.

4. Push the cover (2) till it stops at the motherboard.

5. T ighten the screw (1) of the cover (2).

6. Fix the cables of each switch in pairs on the mounting eye using

Figure 2-13 Cable connection

the cable binders provided (3).

SIPART PS2 Manual

A5E00074631- -06

37

Page 38

Design and Functional Principle

Setting the two limit values:

1. Drive the actuator to the first desired mechanical position.

2. Adjust the top actuating disc (7.2) by hand until the output signal

on terminals 41 and 42 changes.

3. Drive the actuator to the second desired mechanical position.

4. Adjust the bottom actuating disc (7.3) by hand until the output signal on terminals 51 and 52 changes.

.

NOTE

To avoid the actuating discs (7.2/7.3) being accidentally adjusted during operation, they are relatively sluggish. The following remedy might

be of help if you are having trouble with the adjustment: open and

close the actuator several times while holding the actuating discs. This

temporarily reduces the friction. This allows an easier and finer adjustment.

2.7.7 EMC filter module

The positioner can also be driven by an external position sensor (potentiometer or NCS) (see page 46 “3.3.2 Instructions for using positioners which are exposed to strong accelerations or vibrations”). An EMC

filter module, order number C73451-A430-D23, is required for this.

38

SIPART PS2 Manual

A5E00074631- -06

Page 39

2.7.8 Accessories

Design and Functional Principle

Y1

Y1

PZ

Figure 2-14 Manometer block (left for single-acting, right for double-acting actuators)

Manometer block

The manometer block for single-acting actuator contains two manometers which are screwed to the lateral pneumatic connection of the

positioner with O-rings. The values for the input pressure (supply air

PZ) and output pressure (actuating pressure Y1) are displayed.

The manometer block for double-acting actuators contains three

manometers which are screwed to the lateral pneumatic connection of

the positioner with O-rings. The values for the input pressure (supply

air PZ) and output pressure (actuating pressure Y1 and Y2) are

displayed.

PZ

Y2

SIPART PS2 Manual

A5E00074631- -06

39

Page 40

Design and Functional Principle

Table 2-1 Scopetuator”

40

SIPART PS2 Manual

A5E00074631- -06

Page 41

Preparing for Operation

Preparing for Operation

This chapter describes all the preparations necessary for operating the

positioner.

3.1 Instrument identification (type key)

The order number of the positioner is printed on the rating plate and on

the packaging. Compare this with the order number in chapter 7.1,

page 154.

Installation of any modules required is described in chapter 2.7,

page 27 of this technical manual.

3.2 Dimensional drawings

3

60

50x4xM6

h9

7

9 deep

1

3729

48

M20 x 1.5 or NPT-adapter

15

14,5

95

2

Y1

65

80

13,5

96,6

23

88,5

E

58

33

M8, 9 deep

182

8

7

38,5

Y1

PZ

Y2

All air connections

G 1/4 or 1/4” NPT

29,5

72

29,5

11, 2

Figure 3-1 Dimensional drawing version plastic housing 6DR5xx0

SIPART PS2 Manual

A5E00074631- -06

41

Page 42

Preparing for Operation

14

25

12

10

5

3x

G1/4or

1/4” NPT

9.5

90

79.5

2xM6

29.5

58.75

82

Thread depth 5.5

50

3.5

5.3

20.5

M4

9.5

9

5

Figure 3-2 Dimensional drawing terminal strip for plastic housing

50x4xM6

9 deep

2

Y1

65

E

M8, 9 deep

23

58

182

13.5

96.5

88.5

8

7

38.5

7

34.5

M20 x 1.5 or NPT-adapter

h9

1

14.5

84

29

27.5

All air connections

G 1/4 or 1/4” NPT

15

12

6.5

Y1

29.5

29,5

11. 2

59

14

PZ

Figure 3-3 Dimensional drawing version metal housing 6DR5xx1

42

SIPART PS2 Manual

A5E00074631- -06

Page 43

Preparing for Operation

M8, 14 deep (4x)

43

65

M6, 11 deep (4x)

129.5

23

7.75

50

60

∅

3.5

All air connections

1/

or1/4”NPT

G

4

25

34

4.5

M6, 8 deep (2x)

M20, M25 or

1/

”NPT (2x)

2

10.25

19,25

1)

7.5

25.7

1)

Connection 238/Y2 only

E

12

87.2

14,3

33.5

7

33.5

in double action version

158.5

82,5

∅ 136.5

235,3

∅ 8h9

Figure 3-4 Dimensional drawing for positioner with metal housing in explosion proof

version 6DR5xx5

3.3 Assembly

General

WARNING

!

To avoid injury or mechanical damage to the positioner/mounting kit,

the following order must be observed for assembly:

1. Mechanical fitting of positioner this chapter

2. Connection of electric power supply see chapter 3.4, p. 57

3. Connection of pneumatic power supply see chapter 3.5, p. 71

4. Put into operation see chapter 3.6, p. 72

Please also observe the warning on page 58!

SIPART PS2 Manual

A5E00074631- -06

43

Page 44

Preparing for Operation

.

!

NOTE

The positioner will be equipped at the factory and delivered complete

with the necessary options at the customer’s request. Options modules

may only be retrofitted by our service technicians.

The positioner must be assembled – especially in a moist environment

– in such a way as to rule out freezing of the positioner axle at low

ambient temperature.

The operating keys must be covered to prevent liquid getting in.

WARNING

In the combination of components it must be ensured that only

positioners and options modules are combined which are approved

for the respective area of application. This applies especially for safe

operation of the positioner in areas in which the atmosphere is potentially explosive (zone 1 and 2). The instrument categories (2 and 3) of

the instrument itself and those of its options must be observed.

In addition, you must always make sure that no water gets into an open

housing or screw-type gland. This may be the case for example when

the positioner cannot be finally assembled and connected immediately.

It generally applies that the positioner may only be operated with dry

compressed air. Therefore use the normal water traps. An additional

drying unit may even be necessary in extreme cases. This is particularly important when operating the positioner at low ambient temperatures. Please set the purge air switch (on the valve block above the

pneumatic terminals) additionally to the “OUT” position.

Use a sufficiently rugged console (e.g. plate thickness > 4 mm with

reinforcements) for part-turn actuators and the mounting kit “linear

actuator” or integrated connection for linear actuators.

3.3.1 Instructions for using positioners in a wet environment

This information gives you important instructions for the assembly and

operation of the positioner in a wet environment (frequent, heavy rain

and/or prolonged tropical condensation) in which the IP66 degree of

protection is no longer sufficient and especially when there is a danger

that water may freeze.

To prevent water getting into the instrument in normal operation (e.g.

through the exhaust air openings) or the display being poorly legible,

please avoid the unfavorable installation positions illustrated in

figure 3-5.

44

SIPART PS2 Manual

A5E00074631- -06

Page 45

Figure 3-5 Favorable and unfavorable installation positions

If conditions oblige you to operate the positioner in a unfavorable

installation position, you can take additional precautionary measures to

prevent penetration by water.

Preparing for Operation

Procedure

.

NOTE

Never clean the positioner with a high pressure water jet because the

IP66 degree of protection is inadequate protection for this.

The necessary additional measures to prevent penetration by water

depend on the installation position chosen and you may additionally

require:

S screw-type gland with sealing ring (e.g. FESTO: CK –1 / 4–PK–6)

S plastic hose approx. 20 to 30 cm (e.g. FESTO PUN- 8X1,25 SW)

S cable straps (number and length depends on local conditions)

S Connect the pipes in such a way that rain water which runs along

the pipes can drip off before it reaches the terminal strip of the positioner.

S Check the electrical connections for perfect firm contact.

S Check the seal in the housing cover for damage and contamination.

Clean and replace if necessary .

S Mount the positioner if possible so that the sinter bronze silencer

faces downwards on the underside of the housing (vertical installation position). If this is not possible, the silencer should be replaced

by a suitable screw-type gland with a plastic hose.

SIPART PS2 Manual

A5E00074631- -06

45

Page 46

Preparing for Operation

Assembly of the screw-type gland with plastic hose

S Unscrew the sinter bronze silencer from the exhaust air opening on

the underside of the housing.

S Screw the screw-type gland mentioned above into the exhaust air

opening.

S Mount the above mentioned plastic hose on the screw-type gland

and check the good fit.

S Fix the plastic hose with a cable strap to the fitting so that the open-

ing faces downwards.

S Make sure that the hose has no kinks and the exhaust air can flow

out unhindered.

3.3.2 Instructions for using positioners which are exposed to strong accelerations or vibrations

NOTICE

for explosion-proof versions:

Only adjust the outer friction clutch (8, Fig. 2-12, page 31). The internal

friction clutch (8, Fig. 2-1 1, page 28) is fixed and, for the explosionproof version, must not be adjusted.

The electro-pneumatic positioner SIPART PS2 has a friction clutch and

switchable gearing and can thus be used universally for part-turn and

linear actuators. This means that, for part-turn actuators you don’t have

to worry about the zero point and for linear actuators, you don’t have to

worry about symmetrical mounting, as you can adjust the working

range after installation, with the help of the friction clutch.

The switchable gearing allows you to also adjust the positioner for

small or large lifts.

Occasionally it can happen, that in the rough environment of process

systems (e.g. due to incorrectly fitted valves or if “steam pulses” occur)

that the shaft to monitor the position of the SIPART PS2 positioner is

exposed to extreme acceleration, which far exceeds its specified load

limits, and which could result in an unwanted shift in the friction clutch

or in the gears in the position monitoring jumping briefly out.

For cases like this, as standard, the SIPART PS2 positioner is fitted

with a locking device for the friction clutch and you can also lock the

setting of the transmission ratio selector. This means that an unwanted

change to the position monitoring due to the above mentioned effects

can be reliably prevented.

46

Both of these locking options are labeled via additional tags inside the

device (see Figure 3-6, page 47). Note that these locks are only required if extreme acceleration or strong vibration might be present

within your process.

SIPART PS2 Manual

A5E00074631- -06

Page 47

Preparing for Operation

Procedure After you have installed the positioner and put it fully into operation, you

can set the torque for the friction clutch as follows:

S On the module cover, insert an ordinary 4 mm wide screwdriver into

a slot on the yellow wheel.

S Now use the screwdriver to move the yellow wheel to the left, until

you can feel that it clicks in. This increases the torque of the friction

clutch.

S You can recognize a locked friction clutch by an approx. 1 mm wide

gap between the yellow and black wheels.

S If you have to set the zero pint e.g. after exchanging the actuator,

first reduce the torque by turning the yellow wheel to the right until

you hit the stop. After setting the zero point, you can refix the friction

clutch as described above.

Starting from the neutral setting (as delivered), you can lock the transmission ratio selector as follows:

S Adjust the yellow wheel underneath the terminals with an ordinary

4 mm wide screwdriver to correspond to the setting that you would

like (33_ or 90_), turning to the left or right, until you can feel that it

clicks in.

S Please note that you can only adjust the transmission ratio selector

after releasing the fixing.

For this reason you first have to put the yellow ring into the neutral

position, if you have to adjust the transmission ratio selector

e.g. after exchanging the actuator).

90_

(1)

(1) Transmission ratio selector interlock

(2) Open

(3) Friction clutch

(4) Close

90

(2)

(3)

33

33_

(4)

Figure 3-6 Locking and fixing mechanisms

SIPART PS2 Manual

A5E00074631- -06

47

Page 48

Preparing for Operation

External position

displacement

sensor

Applications in which the measures described above are inadequate

are also conceivable. This applies for instance with continuous and

heavy vibration, increased or too low ambient temperatures and in the

case of nuclear radiation.

The separate attachment of position displacement sensor and

controller unit can help here. A universal component is available which

is suitable both for linear and part-turn actuators.

You require the following:

S The external position detection system (order no.

C73451-A430-D78). This consists of a SIP ART-PS2-housing with

integrated friction clutch, built-in potentiometer and various dummy

plugs and seals.

S or a Non-Contacting Position Sensor (e.g. 6DR4004-6N).

S The controller unit, any positioner version.

S The EMC filter module, this is is a set together with cable clips

and M-20 screw-type cable gland and has the order number

C73451-A430-D23. The EMC filter module must be installed in the

positioner. The installation instructions enclosed with the EMC filter

module explain how to assemble the components.

S A 3-wire cable for connecting the components.

This EMC filter module should always be used for the controller unit

when any actuator-mounted potentiometer (resistance 10 kΩ)isto

be used instead of the position detection system C73451-A430-D78.

WARNING

!

The explosion-proof version may not be run together with the external

position detection system.

48

SIPART PS2 Manual

A5E00074631- -06

Page 49

Preparing for Operation

3.3.3 Mounting kit “linear actuator” 6DR4004-8V and 6DR4004-8L

The scope of delivery of the mounting kit “linear actuator IEC 534

(3 mm to 35 mm)” are contained (ser. no. see figure 3-7, page 51):

Ser. no. pieces Designation Note

1 1 NAMUR mounting kit bracket

IEC 534

2 1 Pick-up bracket Guides the roller with carrier pin and turns lever

3 2 Clamping assembly Mounting of pick-up bracket on actuator spindle

4 1 Carrier pin Assembly with roll (5) on lever (6)

5 1 Roll Assembly with driver pin (4) on lever (6)

6 1 Lever NAMUR Forstrokerange3mmto35mm

7 2 U bolt Only for actuators with columns

8 4 Hexagon head screw M8 x 20 DIN 933-A2

9 2 Hexagon head screw M8 x 16 DIN 933-A2

10 6 Lock washer A8 -- DIN 127-A2

11 6 Flat washer B 8,4 -- DIN 125-A2

12 2 Flat washer B 6,4 -- DIN 125-A2

13 1 Spring VD--115E 0.70 x 11.3 x 32.7 x 3.5

14 1 Spring washer A6 -- DIN 137A-A2

15 1 Lock washer 3.2 -- DIN 6799-A2

16 3 Spring washer A6 -- DIN 127-A2

17 3 Socket cap screw M6 x 25 DIN 7984-A2

18 1 Hexagon nut M6 -- DIN 934-A4

19 1 Square nut M6 -- DIN 557-A4

21 4 Hexagon nut M8 -- DIN 934-A4

Standardized connection for mounting console with

ledge, column or plane surface

arm

For stroke ranges> 35 mm to 130 mm (special delivery), lever 6DR4004-8L is required additionally

Table 3-1 Scope of delivery of the mounting kit “linear actuator”

SIPART PS2 Manual

A5E00074631- -06

49

Page 50

Preparing for Operation

3.3.4 Assembly procedure (see figure 3-7, page 51)

1. Mount clamping assembly (3) with hexagon socket cap screws

(17) and lock washer (16) on the actuator spindle.

2. Insert the pick-up bracket (2) into the recesses of the clamping

assembly. Set the necessary length and tighten the screws so that

the pick-up bracket can still be shifted.

3. Insert the pin (4) in the lever (6) and assemble with nut (18), spring

washer (14) and washer (12).

4. The value of the stroke range specified on the actuator or if this

does not exist as a scaling value, the next greatest scaling value is

set. The center of the pin must be in line with the scaling value.

The same value can be set later under parameter 3.YWAY in

commissioning to display the way in mm after initialization.

5. Assemble the hexagon socket cap screw (17), spring washer (16),

washer (12) and square nut (19) on the lever.

6. Push the premounted lever onto the positioner axis up to the stop

and fix with the hexagon socket cap screw (17).

7. Fit the mounting bracket (1) with two hexagon head screws (9),

lock washer (10) and flat washer (11) on the rear of the positioner.

.

8. Selection of the row of holes depends on the width of the actuator

yoke. The pin (4) should engage in the pick-up bracket (2) as close

as possible to the spindle but may not touch the clamping

assembly.

9. Hold the positioner with the mounting bracket on the actuator so

that the pin (4) is guided within the pick-up bracket (2).

10. Tighten the pick-up bracket.

1 1. Position the mounting parts according to the type of actuator.

-- Actuator with ledge: Hexagon head screw (8), flat washer (11)

and lock washer (10).

-- Actuator with plane surface: Four hexagon head screws (8), flat

washer (11) and lock washer (10).

-- Actuator with columns: Two U bolts (7), four hexagon nuts (21)

with flat washer (11) and lock washer (10).

12. Secure positioner onto the yoke using the previously positioned

mounting parts.

NOTE

Set the height of the positioner so that the horizontal lever position is

reached as close to the stroke center as possible. You can use the

lever scale as orientation. It must be guaranteed that the horizontal

lever position is passed through within the stroke range.

50

SIPART PS2 Manual

A5E00074631- -06

Page 51

Preparing for Operation

2

16

17

1)

3

Without explosion-proof version:

11

10

9

1

17

16

12

19

18

14

12

6

4

11

10

3)

9

Explosion-proof version:

11

10

9

1

11

10

3)

Figure 3-7 Assembly procedure (linear actuator)

9

SIPART PS2 Manual

A5E00074631- -06

51

Page 52

Preparing for Operation

1

10

8

Mounting on yoke

11

with ledge

4)

11

Mounting on yoke

with plane surface

11

Mounting on yoke

with columns

10

8

10

7

21

as required

Figure 3-7 Assembly procedure (linear actuator) continued

3.3.5 Mounting kit “part-turn actuator” 6DR4004-8D

The scope of delivery of the mounting kit “part-turn actuator” contains (ser. no. see figures 3-8

and 3-9):