Page 1

ARCOSKOP

System Manual

Trouble-Shooting-Guide

SP

© Siemens AG 1999

The reproduction, transmission or

use of this document or its contents

is not permitted without express

written authority. Offenders will be

liable for damages. All rights, including rights created by patent

grant or registration of a utility

model _or_ design,_are_ reserved.

English

Print No.: SPR2-250.840.01.01.02 Doc. Gen. Date: 09.05

Replaces: SPR2-250.898.01.07.02

Page 2

0 - 2 Revision

Chapter Page Revision

all all 01

Document revision level

The document corresponds to the version/revision level effective at the time of system delivery. Revisions to hardcopy documentation are not automatically distributed.

Please contact your local Siemens office to order current revision levels.

Disclaimer

The installation and service of equipment described herein is to be performed by qualified personnel

who are employed by Siemens or one of its affiliates or who are otherwise authorized by Siemens or

one of its affiliates to provide such services.

Assemblers and other persons who are not employed by or otherwise directly affiliated with or authorized by Siemens or one of its affiliates are directed to contact one of the local offices of Siemens or

one of its affiliates before attempting installation or service procedures.

ARCOSKOP SPR2-250.840.01 Page 2 of 8 Siemens AG

System Manual Rev. 01 09.05 CS PS 24 Medical Solutions

Page 3

Contents 0 - 3

Page

1 _______Prerequisites __________________________________________________ 1 - 1

Required documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Required tools, measurement and auxiliary devices . . . . . . . . . . . . . . . . . . 1 - 1

Information regarding this document . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

Position designations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Information on the equivalent leakage current measurement . . . . . . . . . . . . 1 - 6

Regulations and scope for the subsidiaries . . . . . . . . . . . . . . . . . . . . . 1 - 6

Initial measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 6

Repeat measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 6

Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 7

Installing/removing the covers on the support . . . . . . . . . . . . . . . . . . . . 1 - 7

Installing/removing the covers on the C-arm mounting . . . . . . . . . . . . . . . 1 - 8

Cover over the horizontal carriage . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 9

Removing the cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 9

Attaching the cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 10

Installing/removing the cover at the C-arm/I.I. side . . . . . . . . . . . . . . . . 1 - 11

Monitor trolley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 12

Installing/ removing the covers on the monitor support system . . . . . . . . . . 1 - 12

Service position for the board access of the electronics box . . . . . . . . . . . . . 1 - 13

I.I. service position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 15

Moving the I.I. into the service position . . . . . . . . . . . . . . . . . . . . . . 1 - 15

Installing the I.I. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 16

2 _______Power supply adaptation ________________________________________ 2 - 1

Checking the line voltages on the monitor trolley . . . . . . . . . . . . . . . . . . . . 2 - 1

3 _______Checking the operating voltages __________________________________ 3 - 1

Low voltages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

Image intensifier voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

D41/D42 Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3

4 _______Operating software _____________________________________________ 4 - 1

Loading the operating software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

Backing up the system parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

Reading and storing the load counter data . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

Storing the actual load counter values. . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

Releasing the resetting of the load counter values . . . . . . . . . . . . . . . . . 4 - 3

Resetting the load counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

Returning the defective POWERPHOS incl. load counter data disk . . . . . . . . 4 - 3

Storing the error log in ASCII format . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 4

Prerequisites. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 4

5 _______Adjustments / Programming _____________________________________ 5 - 1

Siemens AG SPR2-250.840.01 Page 3 of 6 ARCOSKOP

Medical Solutions Rev. 01 09.05 CS PS 24 System Manual

Page 4

0 - 4 Contents

Page

Generator adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

mAs counter adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 2

Checking the generator adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 3

Dose rate adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 4

Automatic dose rate adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 4

Preparing the service PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 4

Dose rate value to be set for the automatic dose rate adjustment . . . . . . . . . 5 - 7

23 cm I.I. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 7

Setting the dose rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 8

Manual dose rate adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 9

Preparation of the service PC . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 9

23 cm I.I., in the order of the operating modes . . . . . . . . . . . . . . . . . . .5 - 12

23 cm I.I., in the order of the dose rate . . . . . . . . . . . . . . . . . . . . . . .5 - 14

Measuring setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 16

Setting the dose rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 17

Note on dose rate setting for EB (EB = Single Image mode). . . . . . . . . . . .5 - 17

Calibrating the TV iris diaphragm for automatic iris diaphragm regulation (AIR) . . . .5 - 18

Measuring the minimum dose rate with the TV iris diaphragm at max. aperture . .5 - 18

Calculating the dose rate values to be programmed . . . . . . . . . . . . . . . .5 - 18

Programming the calculated dose rate values . . . . . . . . . . . . . . . . . . .5 - 19

Concluding tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 19

Checking the set dose or dose rate . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 19

Measuring setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 19

Checking the dose rate values . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 20

Setting the maximum skin dose rate . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 22

Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 22

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 22

Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 22

Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 23

Checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 23

Collimator, X-Iris . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 24

Start adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 24

Full format, X-Iris open . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 24

Zoom format, X-Iris open . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 24

X-Iris minimum aperture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 25

Save values and end adjustment . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 25

Concluding tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 25

Collimator, slot diaphragm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 25

Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 25

Disable circle mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 26

Start adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 26

Slot diaphragm, 0° position . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 26

Full format, slot diaphragm open . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 26

Zoom format, slot diaphragm open . . . . . . . . . . . . . . . . . . . . . . . . .5 - 27

Slot diaphragm closed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 27

Enable circle mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 28

Save values and end adjustment . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 28

Concluding tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 28

ARCOSKOP SPR2-250.840.01 Page 4 of 6 Siemens AG

System Manual Rev. 01 09.05 CS PS 24 Medical Solutions

Page 5

Contents 0 - 5

Page

Collimator display on the monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 28

Prerequisites. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 28

Collimator display, X-Iris . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 28

Collimator display, slot diaphragm. . . . . . . . . . . . . . . . . . . . . . . . . 5 - 30

Camera rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 34

Calibrating the area dose product measuring device . . . . . . . . . . . . . . . . . 5 - 37

CONSTANT parameters = T

Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 37

Checking the programmed value . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 38

Checking the accuracy of the area dose product measuring device . . . . . . . . . 5 - 39

Prerequisites. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 39

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 39

Dose measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 39

Calculating the area dose product . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 39

Evaluation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 40

Overview of ARCOSKOP parameters . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 41

Overview of MEMOSKOP Fast parameters . . . . . . . . . . . . . . . . . . . . . . 5 - 41

Cable module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 41

Holding force after orbital movement of C-arm . . . . . . . . . . . . . . . . . . 5 - 41

Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 41

LED D6 motor fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 41

. . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 37

w

6 _______Replacing boards / Replacing components _________________________ 6 - 1

Control board D1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

Replacement and additional work . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

Resetting the heat values after replacing board D1 . . . . . . . . . . . . . . . . . 6 - 2

Transferring the parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 2

Interface board D30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 3

Board D40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 3

Board D41/42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 3

Generator, D21 including MCB2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 3

Power supply unit D20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 4

Starting unit D115 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 4

Generator Elko buffer modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 5

POWERPHOS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 6

Removing the POWERPHOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 6

Installing the POWERPHOS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 7

Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 8

Collimator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 9

Diamentor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 9

Replacement of the I.I. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 9

Checking the temperature indicator . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 9

Dismantling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 10

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 11

Replacing the VIDEOMED DC . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 13

Camera rotation 0° position . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 14

Siemens AG SPR2-250.840.01 Page 5 of 6 ARCOSKOP

Medical Solutions Rev. 01 09.05 CS PS 24 System Manual

Page 6

0 - 6 Contents

Page

Checks and adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 14

I.I. minivoltage supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 15

Adjusting the I.I. minivoltage supply . . . . . . . . . . . . . . . . . . . . . . . .6 - 17

Replacing the Compact optics . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 19

Dismantling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 19

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 21

Basic unit control panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 24

Foot switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 24

Frequency converter FV 0-400 Hz (vertical lift). . . . . . . . . . . . . . . . . . . . .6 - 27

Power supply M14, +5 V / +15 V / -15 V). . . . . . . . . . . . . . . . . . . . . . . .6 - 27

Power supply M13, +13 V Videomed DC. . . . . . . . . . . . . . . . . . . . . . . .6 - 27

I.I. Laser targeting device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 28

Replacing the MEMOSKOP Fast . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 28

Replacing the MEMOSKOP Fast . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 28

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 28

Download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 28

Loading the parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 29

Loading the language file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 29

Programming the organ menus. . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 29

Programming the MEMOSKOP serial number . . . . . . . . . . . . . . . . . . .6 - 29

Programming the licenses (Options) . . . . . . . . . . . . . . . . . . . . . . . .6 - 29

Loading a LUT file (if present) . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 30

Concluding tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 30

MULTISPOT 2000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 30

Monitor support system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 31

Replacing the monitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 31

Replacing the keyboards, if present . . . . . . . . . . . . . . . . . . . . . . . .6 - 31

7 ______ Brakes ________________________________________________________7 - 1

Braking forces / Braking torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

Torque, pivot brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

Measuring the orbital movement forces . . . . . . . . . . . . . . . . . . . . . . 7 - 2

Measuring the angular movement forces . . . . . . . . . . . . . . . . . . . . . . 7 - 2

Replacement of the angulation brake . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 3

Angulation brake magnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 3

Compressed air brakes of the support . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 4

Setting the movement forces in the working condition . . . . . . . . . . . . . . . 7 - 4

Friction brake at the articulated joint 2 ( center articulated joint) . . . . . . . . . . 7 - 5

Setting the movement forces in the idle state . . . . . . . . . . . . . . . . . . . 7 - 6

8 ______ Appendix, Measuring the tube current _____________________________8 - 1

9 ______ Changes to previous version _____________________________________9 - 1

ARCOSKOP SPR2-250.840.01 Page 6 of 6 Siemens AG

System Manual Rev. 01 09.05 CS PS 24 Medical Solutions

Page 7

Prerequisites 1

Required documents 1

• ARCOSKOP circuit diagram

• Circuit diagram for monitor X2080 (if present)

• ARCOSKOP System Manual

1 - 1

• For the laser targeting device option, if

present:

Setting Instructions / Laser targeting

device RXR2-130.032.01...

Required tools, measurement and auxiliary devices 1

NOTE

• Digital multimeter (e.g. "Fluke 8060 A", part no. 97 02 101)

• Oscilloscope > 50 MHz (e.g. "Fluke Combi Scope PM 3390 A",

• Dose measuring device (e.g. "PTW-DIADOS", part no. 97 17 612)

• Protective ground tester (e.g. "Safety Tester Bender UNIMET 1000 ST",

• Service PC with WINDOWS 95 operating system *

• Service software (see ARCOSKOP System Manual) *

• Connection cable "Service-PC - ARCOSKOP" (e.g. part no. 99 00 440)

• 1 set of resolution tests (e.g. part no. 28 71 820)

• 1 set of radiation filters (e.g. part no. 97 98 596)

• Centering cross (e.g. part no. 96 60 051)

• Heat conducting paste WPS (e.g. part no. 20 48 650)

• Standard service equipment *

• 1 set of Allen keys *

• A 30 mm socket key (is required for adjusting the brake) *

• 200 N spring scale (e.g. part no. 44 15 113)

• Torque wrench 20 Nm to 100 Nm (e.g. part no. 80 86 159)

• Torque wrench 3 Nm to 20 Nm (e.g. part no. 34 24 553)

All tools, measurement and auxiliary devices with the exception

of those marked "*", are listed along with their specifications in

the STC (Service Tools Catalogue).

part no. 99 00 861)

part no. 51 38 727)

Siemens AG SPR2-250.840.01 Seite 1 von 16 ARCOSKOP

Medical Solutions Rev. 01 09.05 CS PS 24 System Manual

Page 8

1 - 2 Prerequisites

back

left

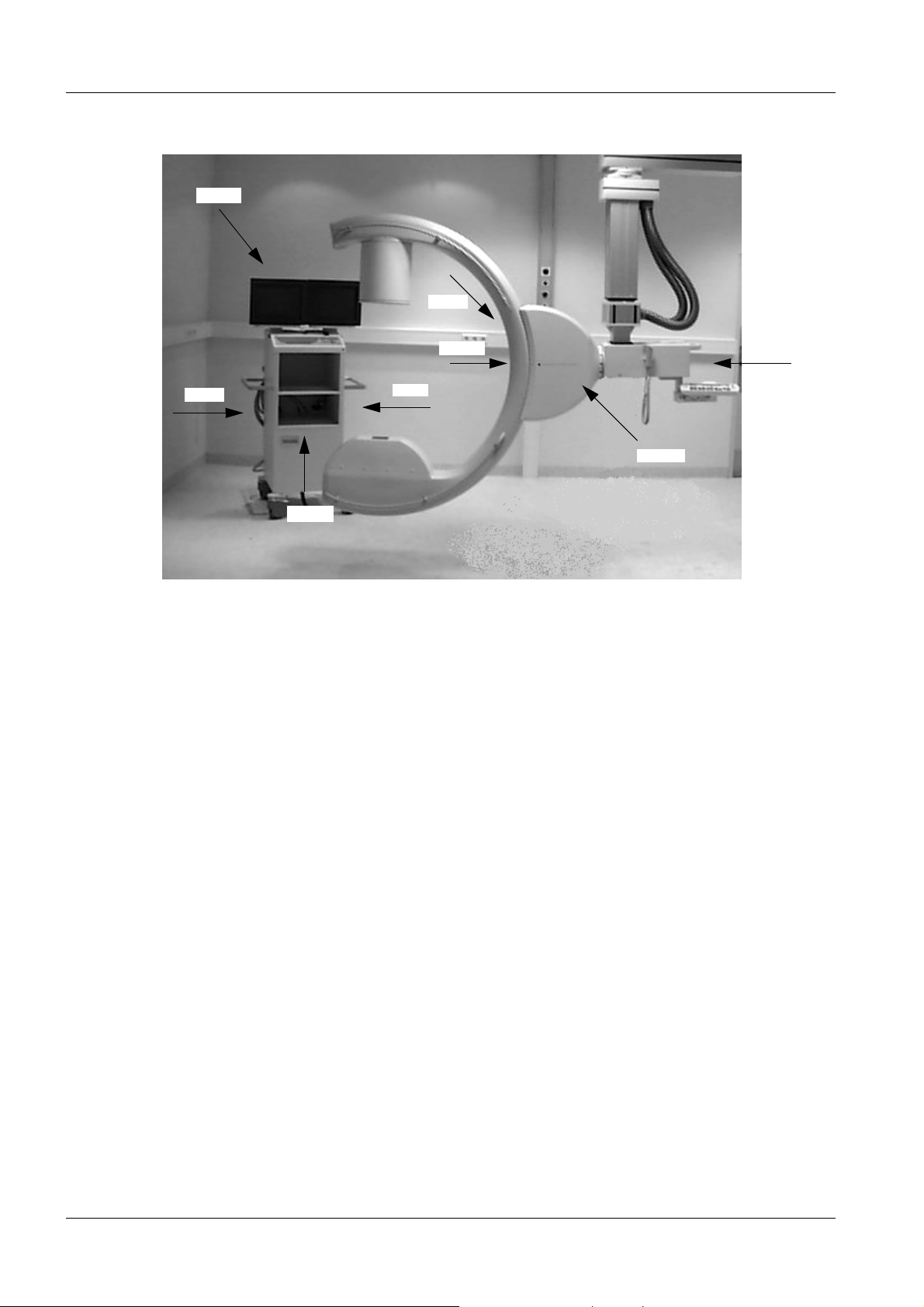

Fig. 1

left

front

right

right

front

back

Information regarding this document 1

These service instructions will assist you in adjusting the ARCOSKOP for routine

operation. Not every adjustment is required each time the system is serviced.

Position designations 1

The designations for the monitor trolley and the ARCOSKOP used in these instructions,

i.e. left, right, front and back, are explained in Fig.1.

ARCOSKOP SPR2-250.840.01 Seite 2 von 16 Siemens AG

System Manual Rev. 01 09.05 CS PS 24 Medical Solutions

Page 9

Prerequisites 1 - 3

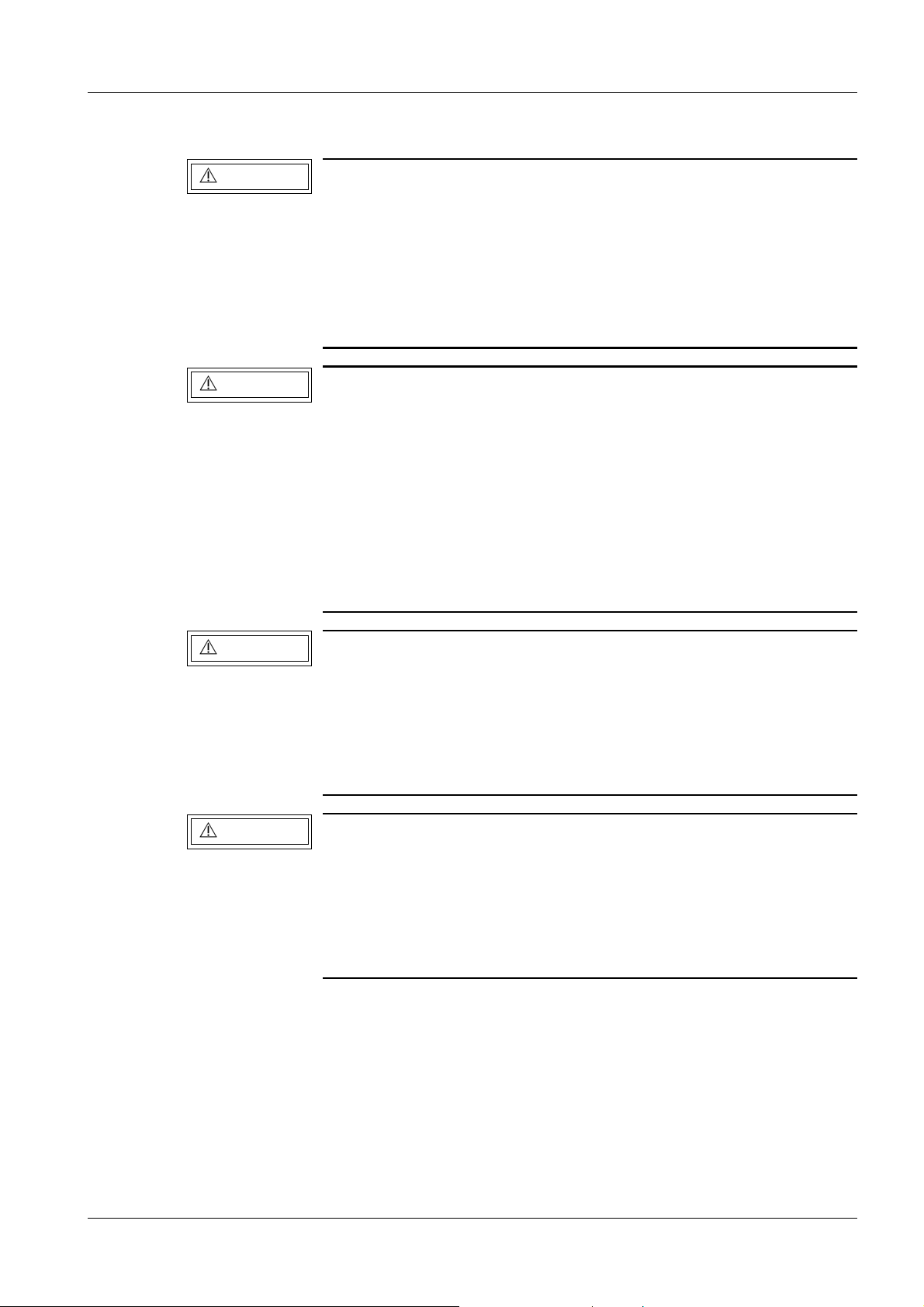

Safety Information 1

WAR NING

WAR NING

Danger of physical injury up to death and damage to property!

You must comply with

- the product-specific safety notes in these instructions,

- the general safety notes in the instructions

TD00-000.860.01... and

- the general safety instructions according to ARTD Part 2.

In the case of non-compliance death or physical injury or damage

to property can arise.

Electrical voltage!

In the case of non-compliance death or physical injury or damage

to property can arise.

Parts conducting voltage can be touched after covers of the

system have been removed. To avoid this danger disconnect the

system from the power supply before removing covers.

For this purpose pull out the mains plug or switch the line voltage

connection of the system free of voltage and secure it against

being switched back on. In the case of necessary service work in

connection with electrical voltage, observe the general safety

notes in the instructions TD00-000.860.01...

WAR NING

WAR NING

Electrical voltage!

In the case of non-compliance death or physical injury or damage

to property can arise.

After service work on the primary circuit of the power-up module

(e.g. replacement of the power-up module or parts of it) measure

and record the equivalent system leakage current (see system folder or logbook).

Danger of infection with pathogens!

In the case of non-compliance death or physical injury can arise.

This product is released for operation in operating rooms and can

be contaminated with infectious blood or other body secretions.

Avoid all contact with blood or other body secretions!

Comply strictly with the preventive measures against infectious

diseases specified in ARTD-002.731.37... !

Siemens AG SPR2-250.840.01 Seite 3 von 16 ARCOSKOP

Medical Solutions Rev. 01 09.05 CS PS 24 System Manual

Page 10

1 - 4 Prerequisites

WAR NING

WAR NING

CAUTION

Electrical voltage!

In the case of non-compliance death or physical injury or damage

to property can arise.

After completion of all service work and after attaching all covers

of the system perform a protective ground wire test according to

ARTD-002.731.17... . The protective ground wire resistance must

not exceed 0.2 ohms.

X-ray radiation!

In the case of non-compliance death or physical injury can arise.

The radiation protection regulations must be complied with

during service work in which X-ray radiation must be released.

Keep the radiation activity as low as possible (low kV, mA, short

radiation time).

Keep your distance from the radiation source as large as possible. Radiation protection devices (lead partitions, etc.) and radiation protection clothing (lead apron) must be used.

Danger of burns on hot modules or components! In the case of

non-compliance slight to medium burns, primarily on hands, can

occur.

CAUTION

WAR NING

After covers are removed modules or components (e.g. power

modules, heat sinks, magnetic brakes) that can have temperatures > 50° Celsius in operation can be touched. To avoid burns

switch the system free of voltage and wait for a cooling down time

of at least 5 minutes before touching modules or components.

Electrostatic voltage!

There can be damage to property in the case of non-compliance.

Comply with the ESD protection regulations in service work.

Electrical voltage!

In the case of non-compliance death or physical injury or damage

to property can arise.

The Elko batteries of the generator and the Elkos on the generator

board remain charged for a long time even after the system is

switched off. The Elkos must be discharged before working on the

Elko batteries and before working on the generator. Switch the

switch D21.S2 into the UZ_OFF position and wait until the LEDs

D21.X22 and D21.X23 no longer light up. Then check the voltage

between the test points X109.UZ_IST and X109.ANA_GND.

The voltage must be < 0.2 V (corresponds to Uz < 20 V).

ARCOSKOP SPR2-250.840.01 Seite 4 von 16 Siemens AG

System Manual Rev. 01 09.05 CS PS 24 Medical Solutions

Page 11

Prerequisites 1 - 5

CAUTION

CAUTION

Danger of injury when dismantling / assembling mechanical

parts! Non-compliance can lead to minor to medium severe injuries, especially to the hands!

If parts that are under mechanical stress have to be dismantled or

assembled, as for example the cover over the horizontal carriage

of the basic unit, inattention can cause injuries due to crushing,

cutting or grazing the skin, especially to the hands.

Perform the corresponding work with special care and attentiveness.

Wear working gloves if necessary.

Danger of injury on mechanical parts!

Non-compliance can lead to minor up to moderately severe injuries, especially to the hands!

With covers removed, you can come into contact with parts such

as flat plugs, threaded bolts, cut off cable ties or edges of components on which, in the case of inattention, injuries can arise

due to crushing, cutting or grazing the skin, especially to the

hands.

Perform the corresponding work with special care and attentiveness.

Siemens AG SPR2-250.840.01 Seite 5 von 16 ARCOSKOP

Medical Solutions Rev. 01 09.05 CS PS 24 System Manual

Page 12

1 - 6 Prerequisites

Information on the equivalent leakage current measurement 1

Regulations and scope for the subsidiaries 1

Within the scope of DIN VDE0751 part 1, the equivalent leakage current test must be performed.

Outside the scope of DIN VDE0751, the subsidiaries must observe the following:

(see ARTD-002.731.731.17, Safety regulations for installation and maintenance).

The legal national regulations apply to the subsidiaries. In the event that there are no existing regulations, observe the following rules in the interest of safety for customers, patients, employees and third parties, as well as the company.

Initial measurement 1

The measurement was performed at the factory and the value measured was recorded in

test protocol 1b. The measurement was performed with the line voltage and line frequency

specified in the test protocol. During start-up of the ARCOSKOP on-site, the values were

checked and remeasured and recorded if they deviated from the line voltage. The protocol

is filed in Register 9 of the System Manual and System Owner Manual,

Register 6.

Repeat measurements 1

When performing service or repair work in the primary circuit of the power supply, the

equivalent leakage current must be measured again and compared to the initial value

measured. The measurement setup must match the measurement setup for the equivalent leakage current / protocol. During measurement, the ARCOSKOP must be switched

on.

When using the Bender safety tester, the tester must be set to manual measurement.

The values measured during repeat tests must not exceed the original value by more than

50%. In addition, the limit of 2 mA must not be exceeded. ARCOSKOP systems which

exceed this threshold must be serviced. The values measured are to be recorded in the

equivalent leakage current / protocol (see System Manual, Register 9).

Hand over a copy of the protocol to the customer for filing in the System Owner Manual.

ARCOSKOP SPR2-250.840.01 Seite 6 von 16 Siemens AG

System Manual Rev. 01 09.05 CS PS 24 Medical Solutions

Page 13

Prerequisites 1 - 7

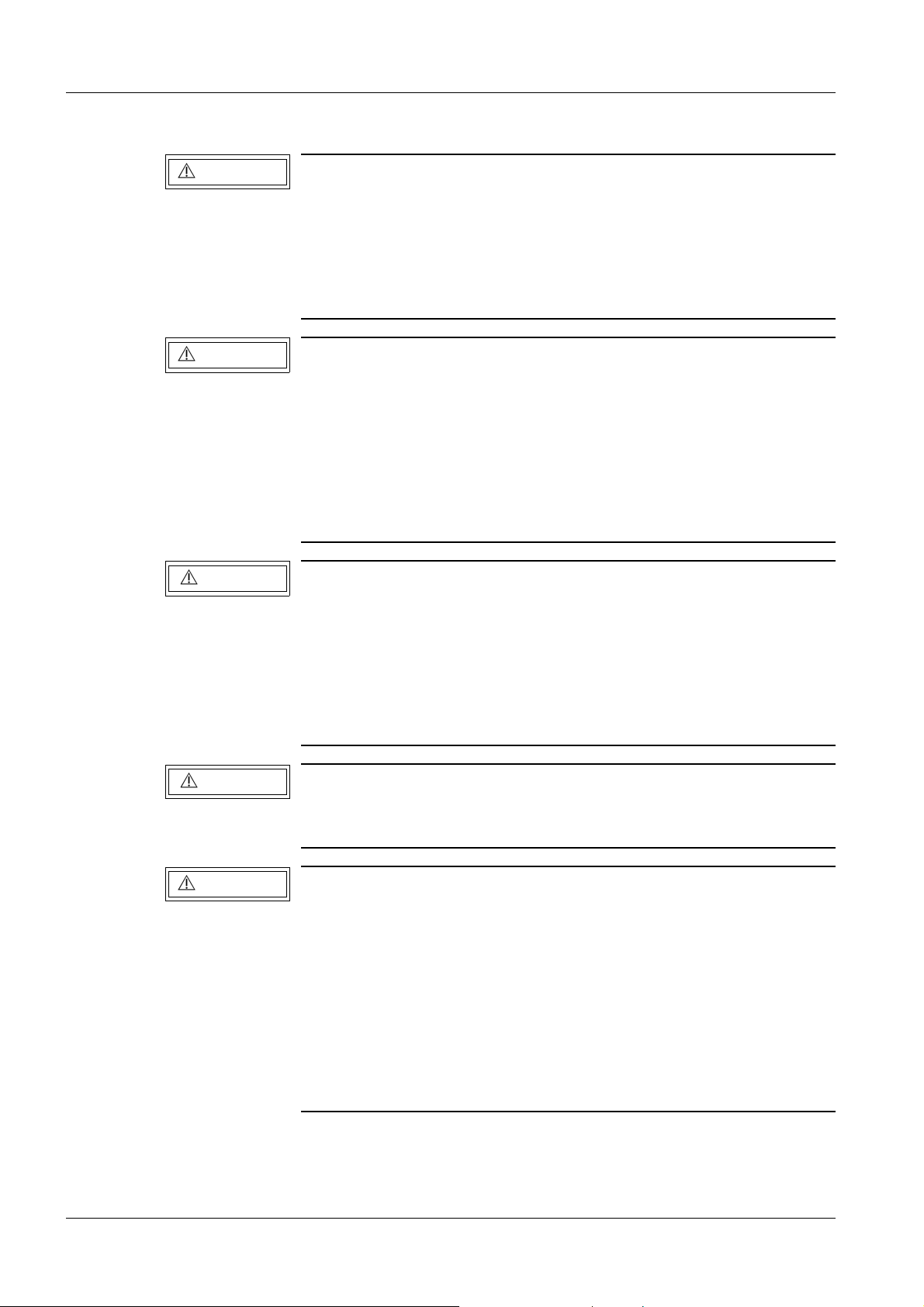

Fig. 2 Fig. 3

Fig. 4 Fig. 5

Covers 1

WAR NING

NOTE

Installing/removing the covers on the support 1

• To loosen the fastening screws for the end caps on the support arms, the rubber at the

ends must be pulled out from the slot, refer to Fig. 2 to Fig. 5. After removing the Phillips

screws, press the internally located retainer a little to the inside with a thin screwdriver

and simultaneously pull the end cap out a little. After the end cap has been loosened on

both sides it can be removed.

• To remove the two-part cover of the support on the false ceiling, remove the two white

rubber plugs and unscrew the Allen screws, refer to the figure at the right above. The two

parts must be pulled apart. Take care in this case that the two internally located retaining

Electrical voltage!

See Chapter 1, Safety Information.

Prior to removing the covers, switch off the line voltage supply to

the system and secure against accidental switch-on.

Switch off the compressed air brakes, turn off the compressed air

and let it escape.

Siemens AG SPR2-250.840.01 Seite 7 von 16 ARCOSKOP

Medical Solutions Rev. 01 09.05 CS PS 24 System Manual

Page 14

1 - 8 Prerequisites

rods remain in one half of the two covers in order to keep the space required for pulling

the halves apart small.

Installing/removing the covers on the C-arm mounting 1

• Remove the cover screws and remove both covers towards the side (Fig. 5).

• After completing the procedure, reinstall both covers in the reverse order.

ARCOSKOP SPR2-250.840.01 Seite 8 von 16 Siemens AG

System Manual Rev. 01 09.05 CS PS 24 Medical Solutions

Page 15

Prerequisites 1 - 9

Cover over the horizontal carriage 1

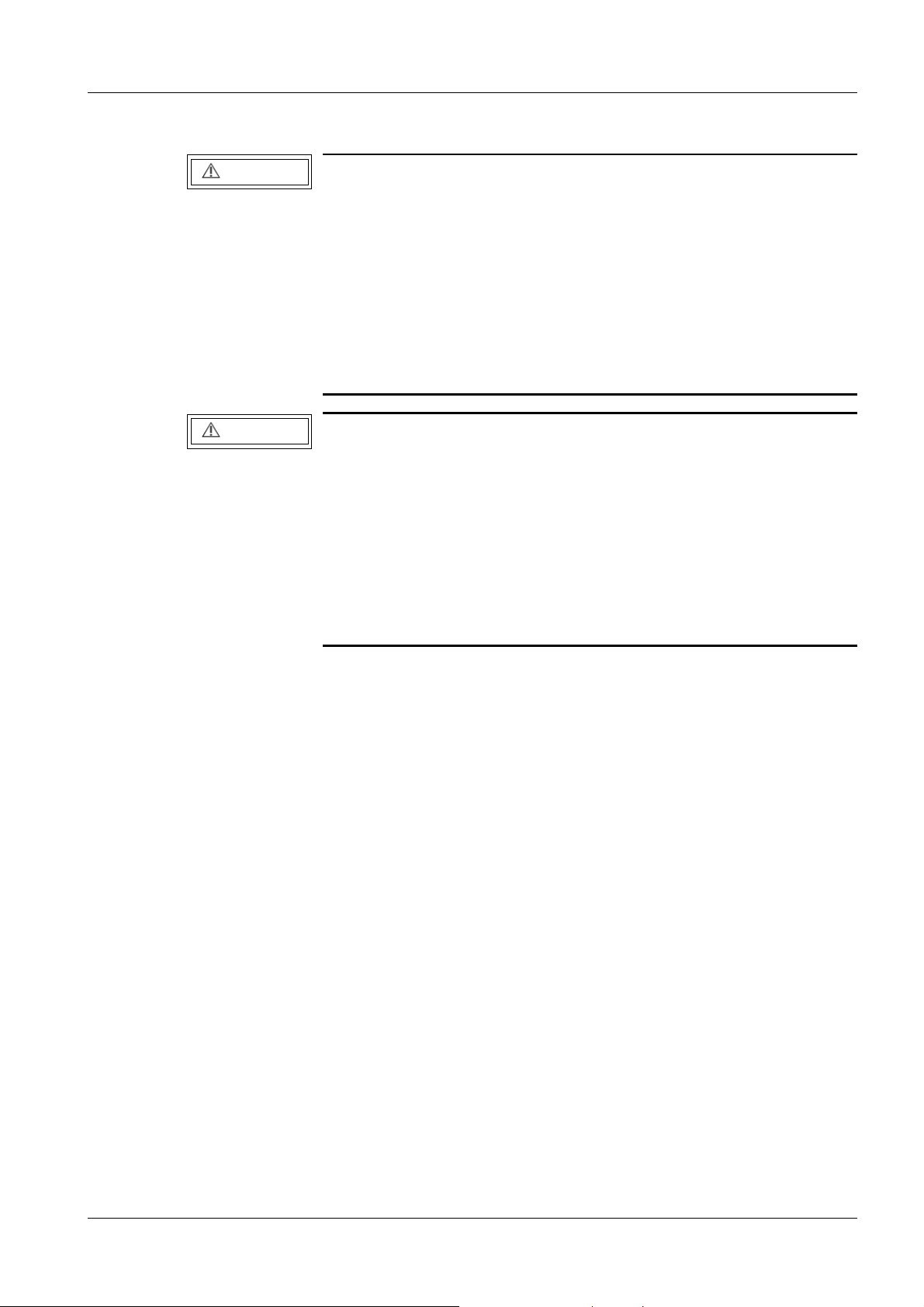

Fig. 6 Fig. 7

Removing the cover 1

NOTE

Fig. 6 and Fig. 7 are examples and show the cover of the SIREMOBIL Iso-C.

The cover of the ARCOSKOP horizontal carriage is open to the

front in the area of the verical lifting column and has no emergency stop button and only 3 brake buttons.

However, the cover of the ARCOSKOP can be removed and attached in practically the same way.

• Loosen the 6 mounting screws (1/Fig. 6).

CAUTION

Danger of injury when dismantling / assembling mechanical

parts! Non-compliance can lead to minor up to moderately severe

injuries, especially to the hands!

The cover over the horizontal carriage is bent U-shaped and must

be pulled on the side to the outside when it is removed.

The cover is then under mechanical stress.

We recommend that you wear light working gloves to avoid injuries.

• Expand the cover at the rear end in the direction of the arrow (see Fig. 2) and remove it

downwards.

• If needed disconnect the protective ground wire, the cable of the keypad (brake buttons)

and the cable of the emergency stop button.

Siemens AG SPR2-250.840.01 Seite 9 von 16 ARCOSKOP

Medical Solutions Rev. 01 09.05 CS PS 24 System Manual

Page 16

1 - 10 Prerequisites

Attaching the cover 1

• Re-fasten or connect the protective ground wire, the cable of the keypad (brake buttons)

and the cable of the emergency stop button.

CAUTION

Danger of injury when dismantling / assembling mechanical

parts! Non-compliance can lead to minor up to moderately severe

injuries, especially to the hands!

When the cover is attached and pressed down, it is under mechanical stress and snaps into place over the bottom edge of the

horizontal carriage.

Expand the cover at the rear end (see Fig. 6) so far that as shown

in Fig. 7 it lies obliquely over the horizontal carriage in the edge 1/

Fig. 7.

Press on the surface on the top of the cover, without grasping the

sheet metal edges, until this slides over the lower edge of the

horizontal slide.

• Expand the cover at the rear end (see Fig. 6) so far that as shown in Fig. 7 it lies obliquely

over the horizontal carriage in the edge 1/Fig. 7.

• Press on the top surface of the cover, without grasping the sheet metal edges, until this

slides over the lower edge of the horizontal slide. Here make sure that the cover does not

slide out from the edge (1 / Fig. 7).

• Check the operation of the emergency stop button and of the brake buttons.

• Fasten the cover with the 6 Allen screws (1/ Fig. 6).

ARCOSKOP SPR2-250.840.01 Seite 10 von 16 Siemens AG

System Manual Rev. 01 09.05 CS PS 24 Medical Solutions

Page 17

Prerequisites 1 - 11

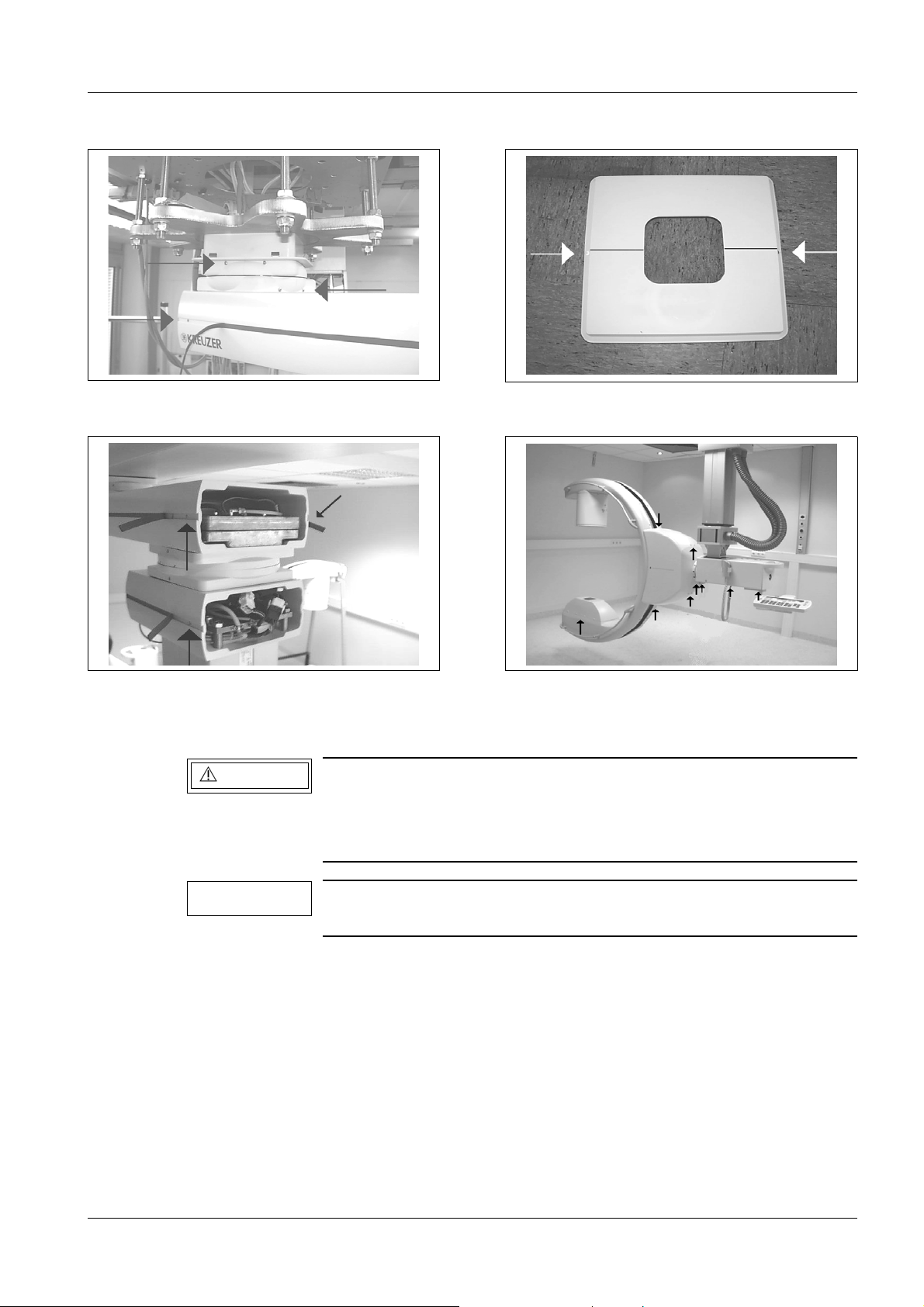

Fig. 8

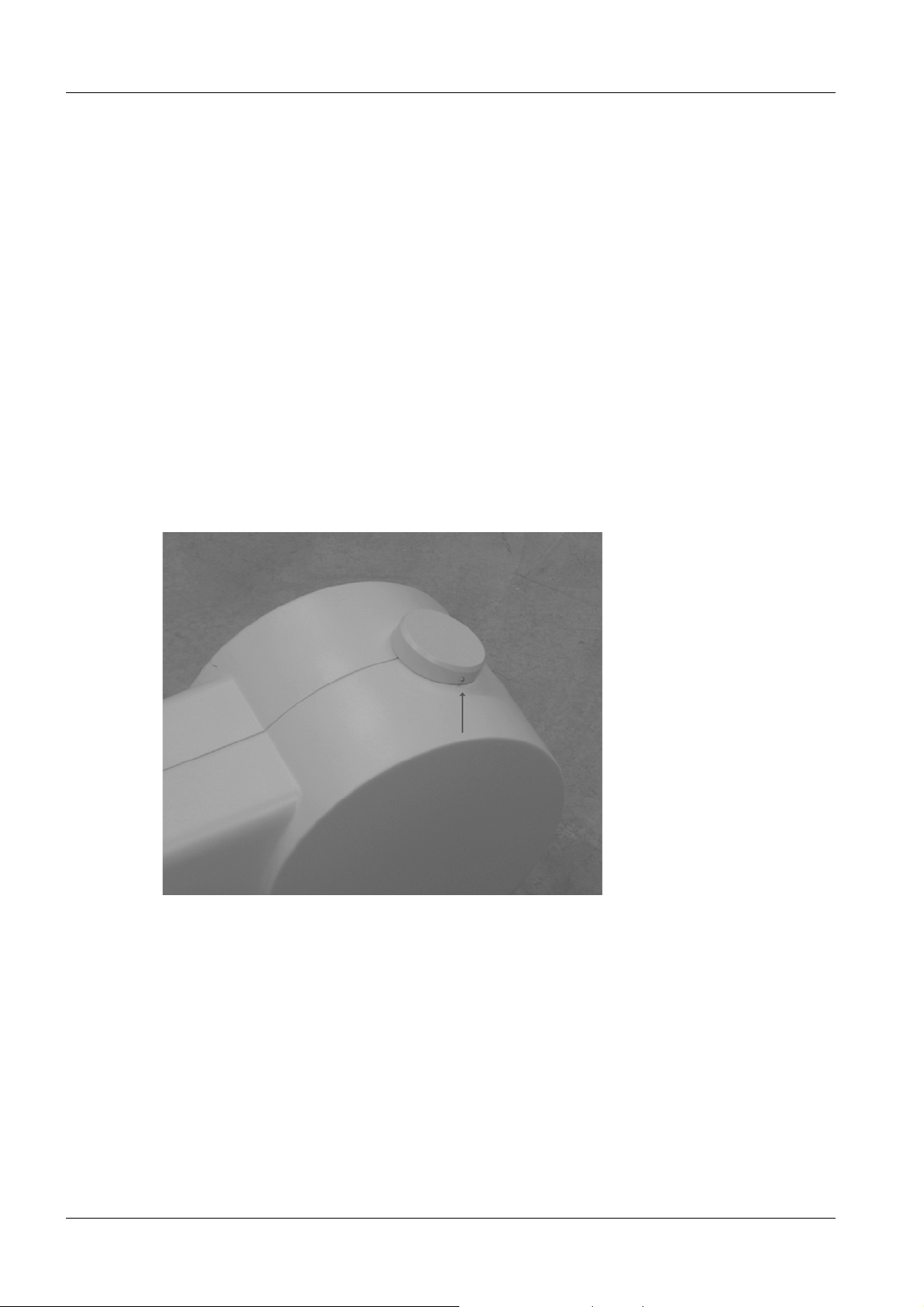

Installing/removing the cover at the C-arm/I.I. side 1

CAUTION

Danger of injury!

In the case of non-compliance death or physical injury or damage

to property can arise.

The C-arm cover contains counterbalance weights and weighs

> 10 kg.

Hold the cover firmly when installing or removing it.

Before the C-arm cover is loosened, the C-arm must be moved to

its middle orbital position.

If the C-arm covers are loosened, the C-arm must not be moved to

its orbital end positions (I.I. or POWERPHOS in the orbital end

position).

• Remove the 4 fastening screws (Fig. 8). Hold the covers firmly while removing them.

• Install them in the reverse order.

Siemens AG SPR2-250.840.01 Seite 11 von 16 ARCOSKOP

Medical Solutions Rev. 01 09.05 CS PS 24 System Manual

Page 18

1 - 12 Prerequisites

Monitor trolley 1

Removing the covers

• Remove the upper back cover plate of the log book compartment.

• Remove the protective ground wire.

• Remove the lateral Allen screws from the lower back cover.

• Remove the protective ground wire from the cover.

Installing the covers

• Begin with the lower back cover.

• Reattach the protective ground wire for the lower cover.

• Install the cover and tighten the screws.

• Reattach the protective ground wire for the log book compartment.

• Install the cover and tighten the screws.

Installing/ removing the covers on the monitor support system 1

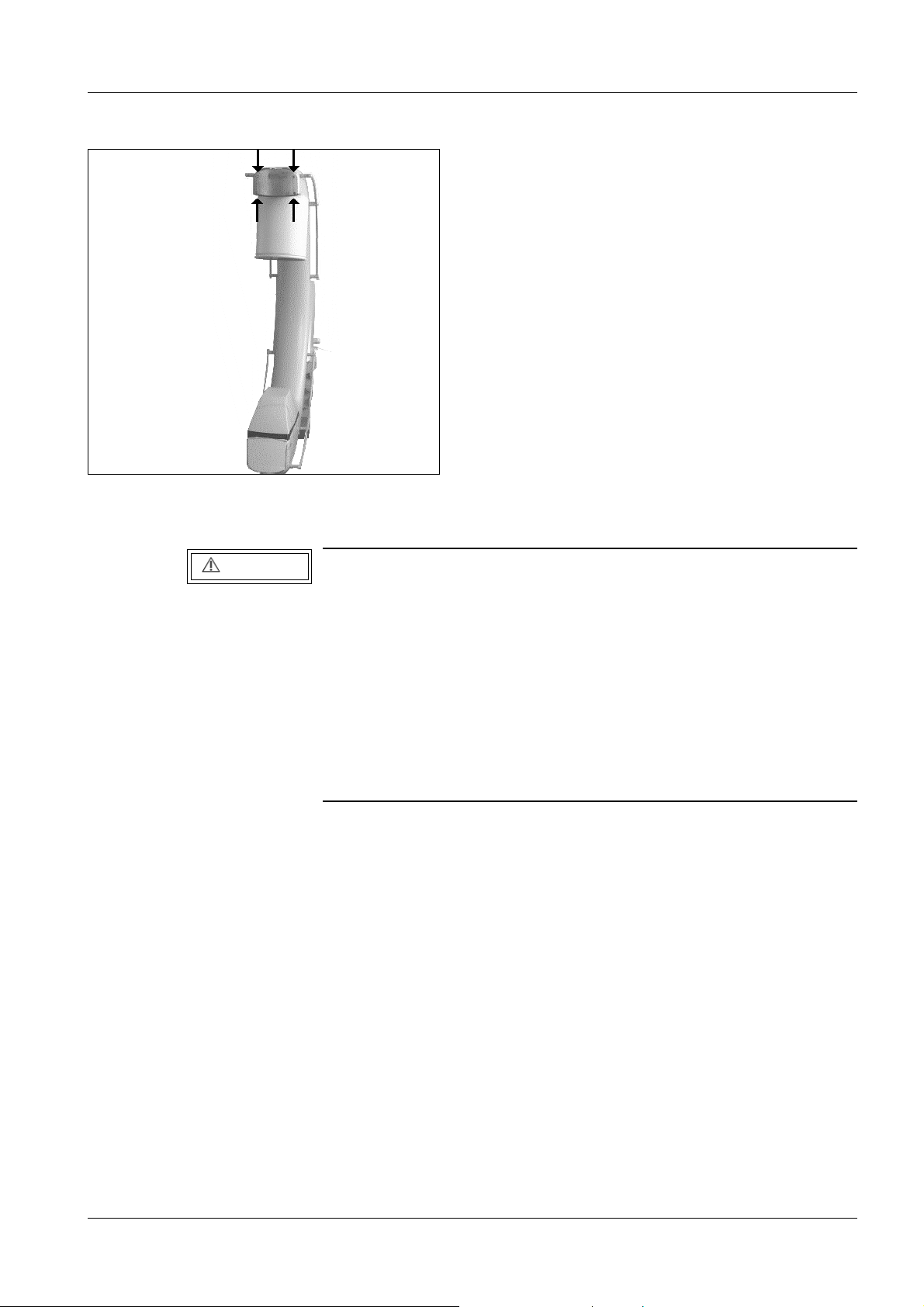

Fig. 9 Monitor support system cover 1-2

• Remove the screw fastening of the cover halves on the upper joint of the cover,

see arrow Fig. 9.

• Loosen the remaining cover screws and remove the two cover halves to the side.

• After taking the necessary action install the covers again in the reverse order.

ARCOSKOP SPR2-250.840.01 Seite 12 von 16 Siemens AG

System Manual Rev. 01 09.05 CS PS 24 Medical Solutions

Page 19

Prerequisites 1 - 13

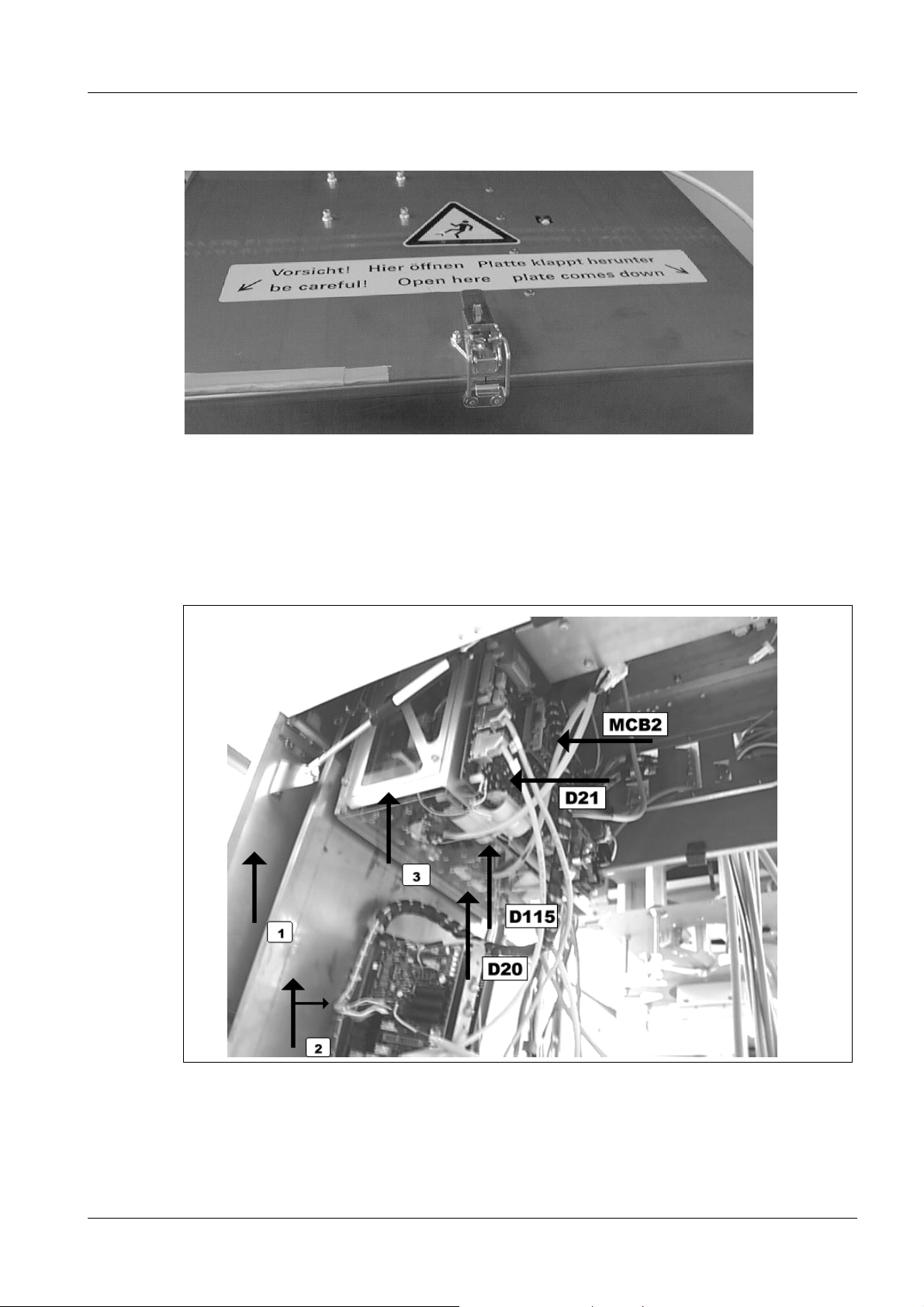

Service position for the board access of the electronics box 1

Fig. 10

• The cover latch must be closed before loosening the screws (see Fig. 10).

• Remove the screws from the sides of the cover (see Fig. 10).

• Be aware of the weight added by the components attached to the rear side when opening

the latch and the service cover (see 2/Fig. 11).

Fig. 11

• You can now lower the generator unit. Use an extension to loosen the two screws on the

upper sides (see 3/Fig. 11).

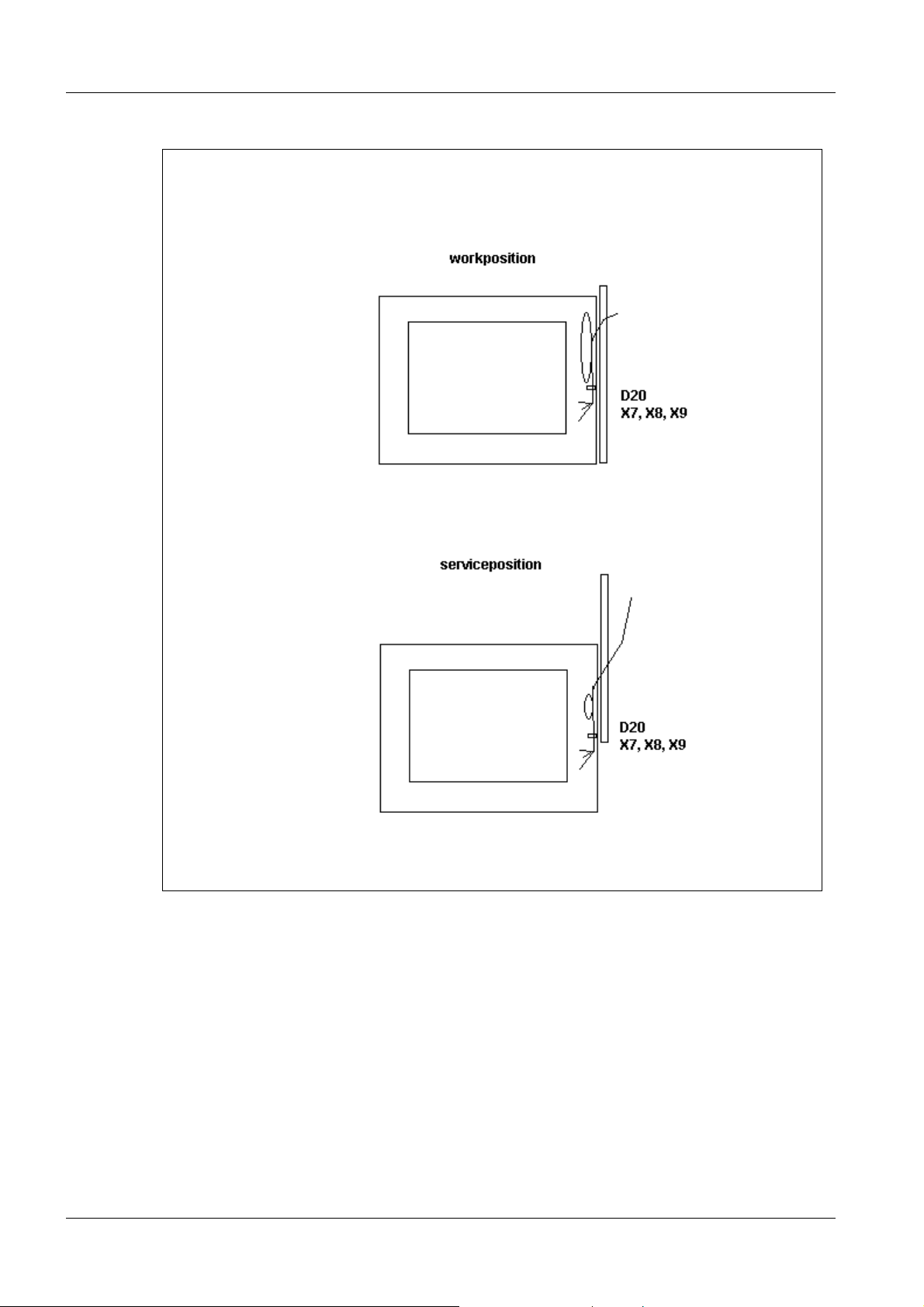

Siemens AG SPR2-250.840.01 Seite 13 von 16 ARCOSKOP

Medical Solutions Rev. 01 09.05 CS PS 24 System Manual

Page 20

1 - 14 Prerequisites

Fig. 12

• Cables D20, X7, X8, and X9 should be fastened to the cable clamps with a torque of

4.8 Nm. Loop the cables and attach the shield as shown in Fig. 12. Ensure that the

cables do not become crimped or torn when moving the generator.

• When routing cables in the E-box, ensure that the cover can be opened and closed

without crimping or stretching the cables or loosening the plug connection.

ARCOSKOP SPR2-250.840.01 Seite 14 von 16 Siemens AG

System Manual Rev. 01 09.05 CS PS 24 Medical Solutions

Page 21

Prerequisites 1 - 15

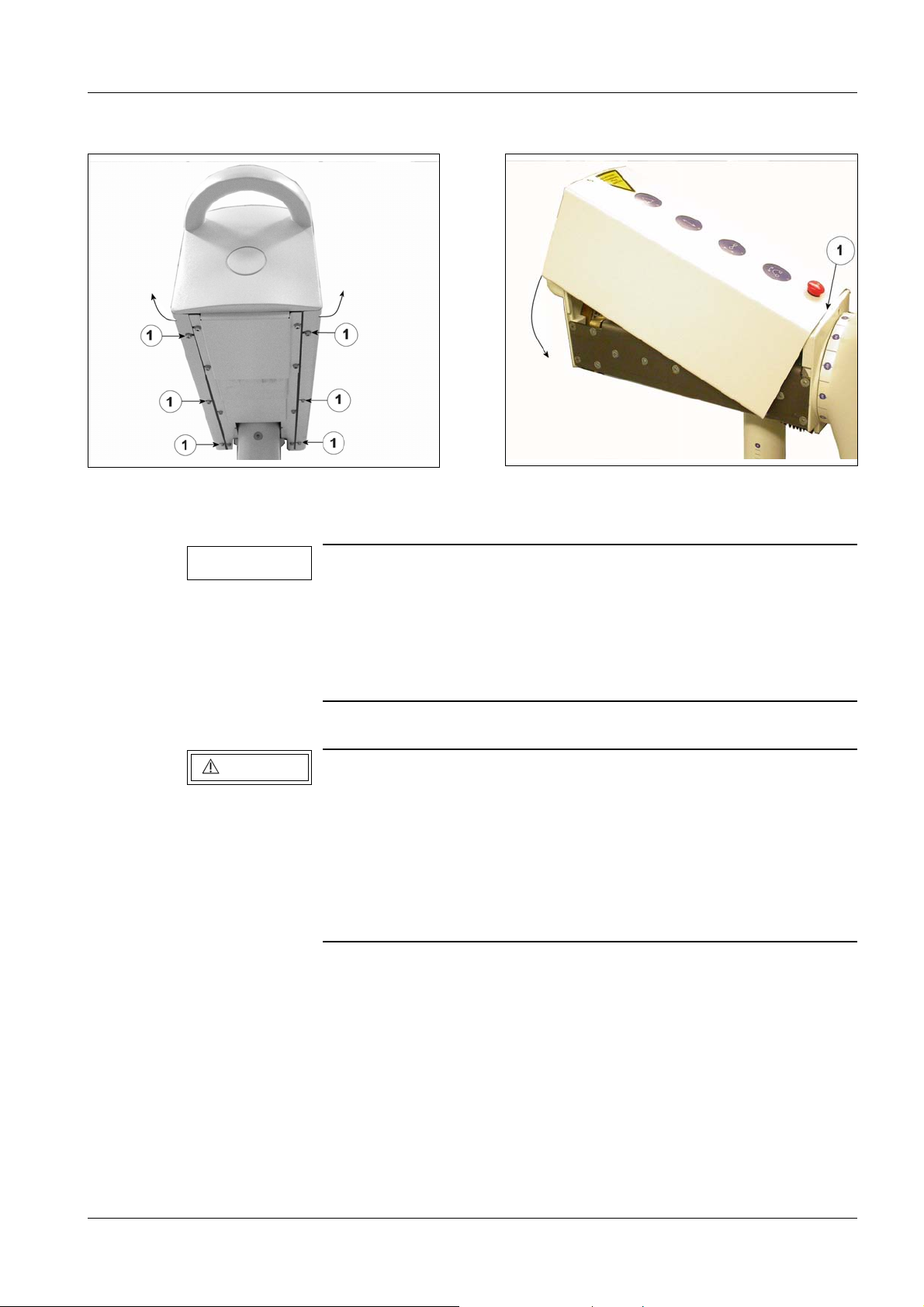

Fig. 13 Fig. 14

Fig. 15

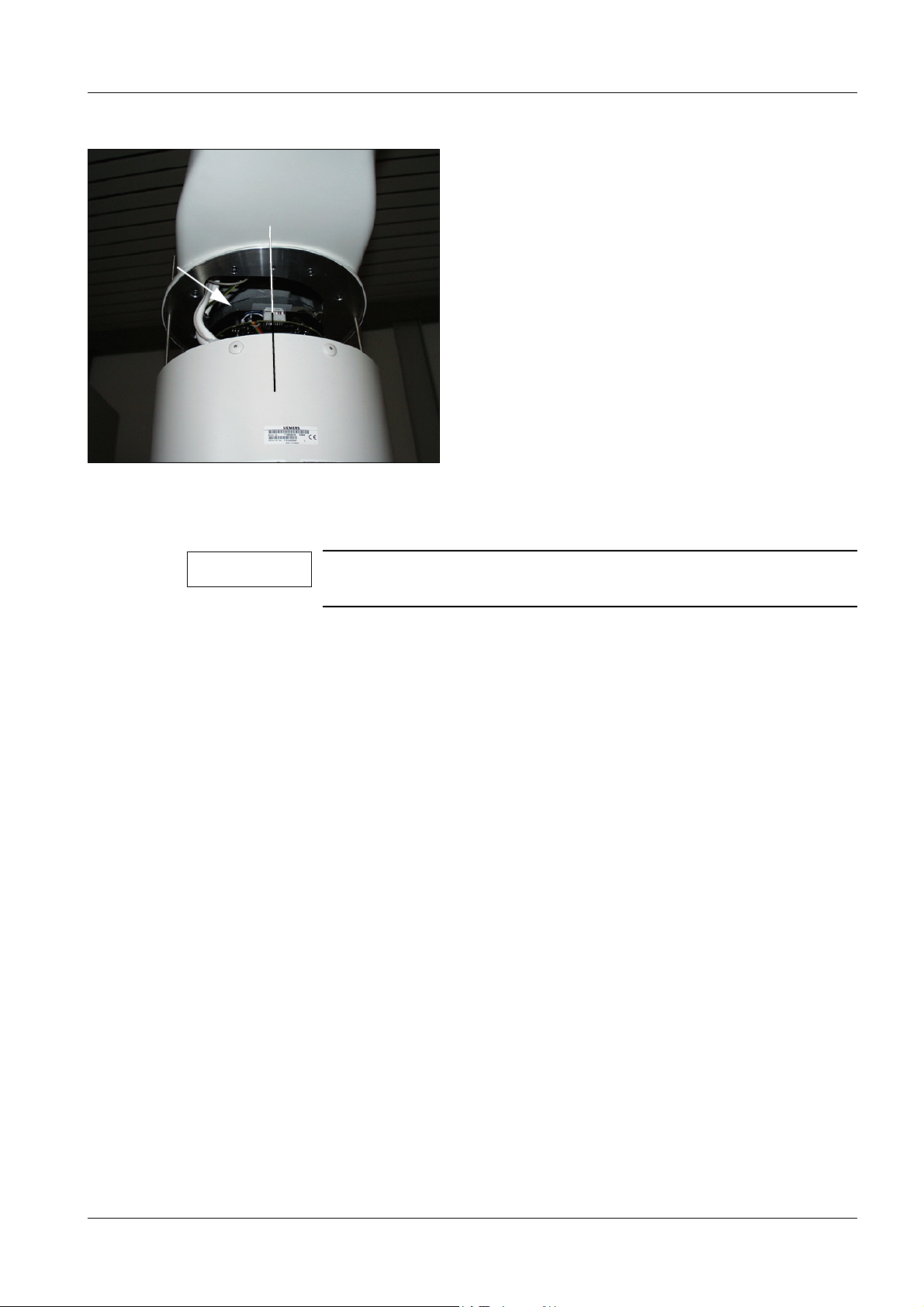

I.I. service position 1

Moving the I.I. into the service position 1

• Take the threaded rods, spacers and nuts out of the accessory pack ("Service Pack I.I./

Camera" part no. 71 43 519 / Fig. 15).

• Move the C-arm into the vertical position, with the I.I. below and the POWERPHOS

above.

• Remove both attachment screws for the I.I. and replace them with the threaded rods

from the service pack.

• Insert the threaded rods from the service pack at least 5 turns into the threaded holes of

the I.I.

• Then mount the spacers and nuts (see Fig. 14).

• Tighten the nuts to fasten the I.I. again.

Siemens AG SPR2-250.840.01 Seite 15 von 16 ARCOSKOP

Medical Solutions Rev. 01 09.05 CS PS 24 System Manual

Page 22

1 - 16 Prerequisites

• Turn the C-arm so that the I.I. is above and the POWERPHOS is below (angulation).

• Lower the I.I. by gradually loosening the nuts alternately. Be careful not to damage the

cables. Fig. 13 shows the I.I. in the service position.

Installing the I.I. 1

• Lift the I. I. a little alternately on each side and retighten the nuts.

Repeat this until the I.I. is fastened again. Be careful not to damage the cable.

• Tighten the nuts to fasten the I.I. again.

• Move the C-arm so that the POWERPHOS is above and the I.I. is below (angulation).

• Remove the two threaded rods (service pack) again from the threaded holes of the I.I.

and reinstall the I.I. with the two attachment screws.

ARCOSKOP SPR2-250.840.01 Seite 16 von 16 Siemens AG

System Manual Rev. 01 09.05 CS PS 24 Medical Solutions

Page 23

Power supply adaptation 2

2 - 1

WAR NING

Electrical voltage!

See Chapter 1, Safety Information.

Disconnect the ARCOSKOP power plug.

• Open the back cover of the monitor trolley.

• Measure the on-site line voltage and line frequency.

• Adjust transformer T1 to the required line voltage and line frequency. Refer to the label

on the switch-on assembly.

• Adjust transformer T2 to the required line voltage and line frequency. Refer to the label

on the switch-on assembly.

• Check fuses F1 and F2 to see as to whether they correspond with the values on the label

of the switch-on assembly and replace them, if necessary.

• Mark the correct line voltage and line frequency on the line voltage label at the back of

the monitor trolley.

Checking the line voltages on the monitor trolley 2

• Plug X10 for the basic unit must be disconnected.

• The monitor, memory device and other devices, if present, such as multiformat camera,

video printer or video recorder must be disconnected from the line voltage supply.

• Check the secondary voltages for line voltage transformer T1 according to table 1.

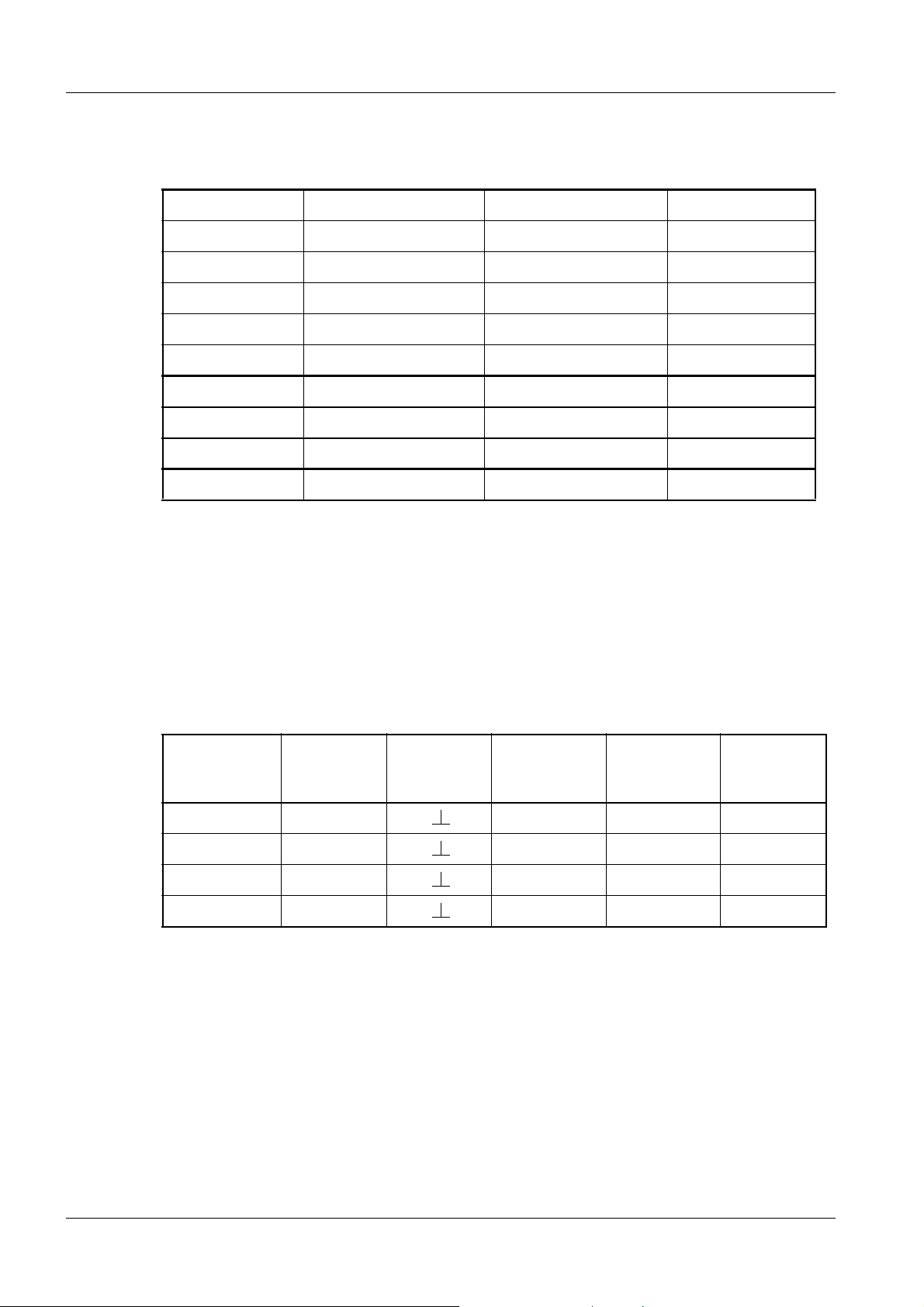

From test point to test point Voltage Comment

Transformer T1.31 Transformer T1.32 190 V ~ to

205 V ~

Transformer T1.31 Transformer T1.33 230 V ~ to

246 V ~

Power cable

Memoskop, N

Power cable

Monitor 1, N

Option: Power cable

Monitor 2, N

Option: Power cable

Multispot, N

Option: Power cable

Video printer, N

Option: Power cable

Video recorder, N

Option

Power cable optical

video separation, N

Power cable

Memoskop, L

Power cable

Monitor 1, L

Power cable

Monitor 2, L

Power cable

Multispot, L

Power cable

Video printer, L

Power cable

Video recorder, L

Power cable optical

video separation, L

230 V ~ to

246 V ~

230 V ~ to

246 V ~

230 V ~ to

246 V ~

230 V ~ to

246 V ~

230 V ~ to

246 V ~

230 V ~ to

246 V ~

230 V ~ to

246 V ~

if Video printer present, not

not adjustable

not adjustable

not adjustable

not adjustable

not adjustable

if Multispot present, not

adjustable

adjustable

if Video recorder present,

not adjustable

if optical video separation

present, not adjustable

Tab. 1

Siemens AG SPR2-250.840.01 Seite 1 von 2 ARCOSKOP

Medical Solutions Rev. 01 09.05 CS PS 24 System Manual

Page 24

2 - 2 Power supply adaptation

Diese Seite wurde bewusst leer gelassen.

ARCOSKOP SPR2-250.840.01 Seite 2 von 2 Siemens AG

System Manual Rev. 01 09.05 CS PS 24 Medical Solutions

Page 25

Checking the operating voltages 3

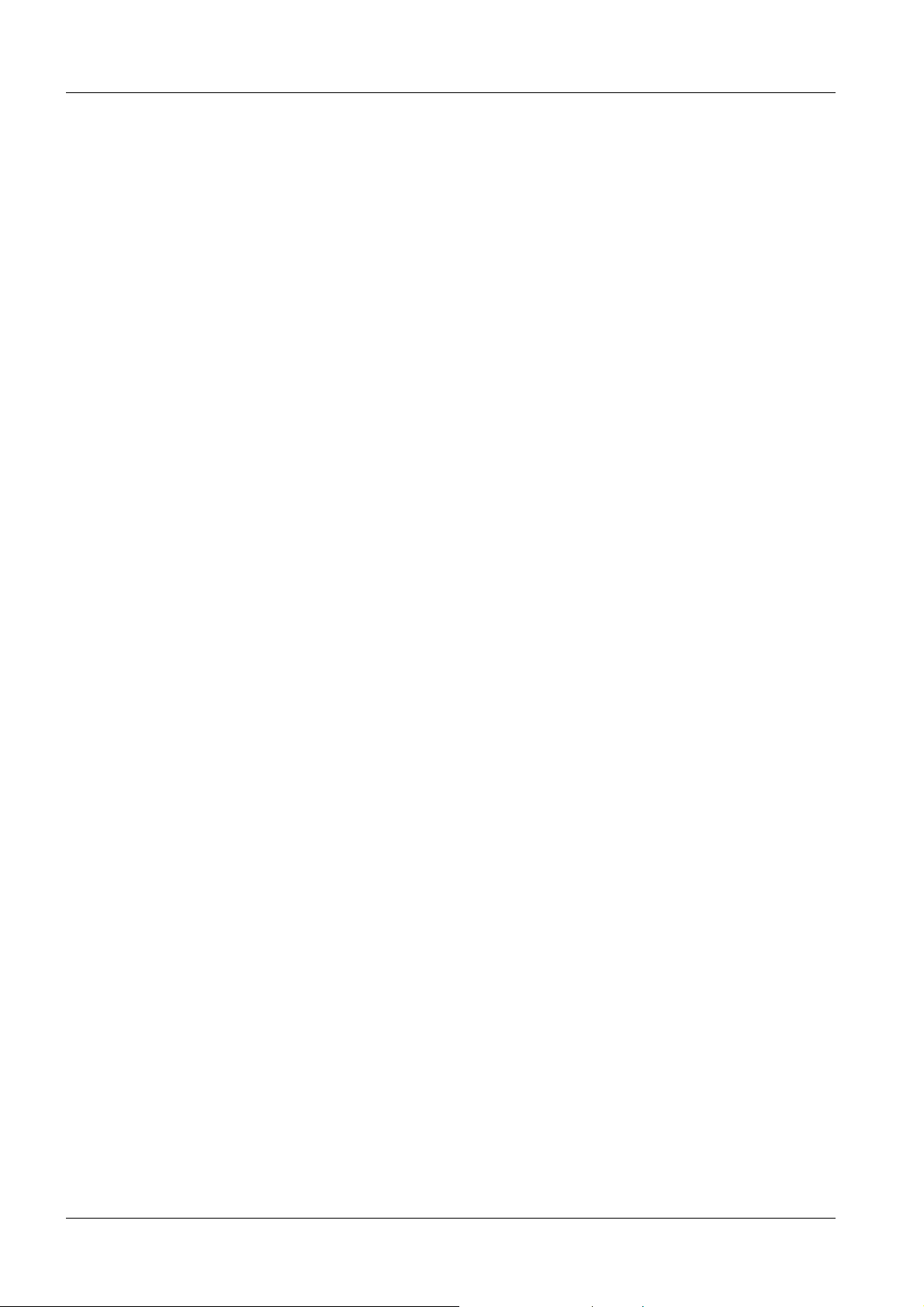

Fig. 1 Fig. 2

3 - 1

Fig. 3 Fig. 4

Siemens AG SPR2-250.840.01 Seite 1 von 4 ARCOSKOP

Medical Solutions Rev. 01 09.05 CS PS 24 System Manual

Page 26

3 - 2 Checking the operating voltages

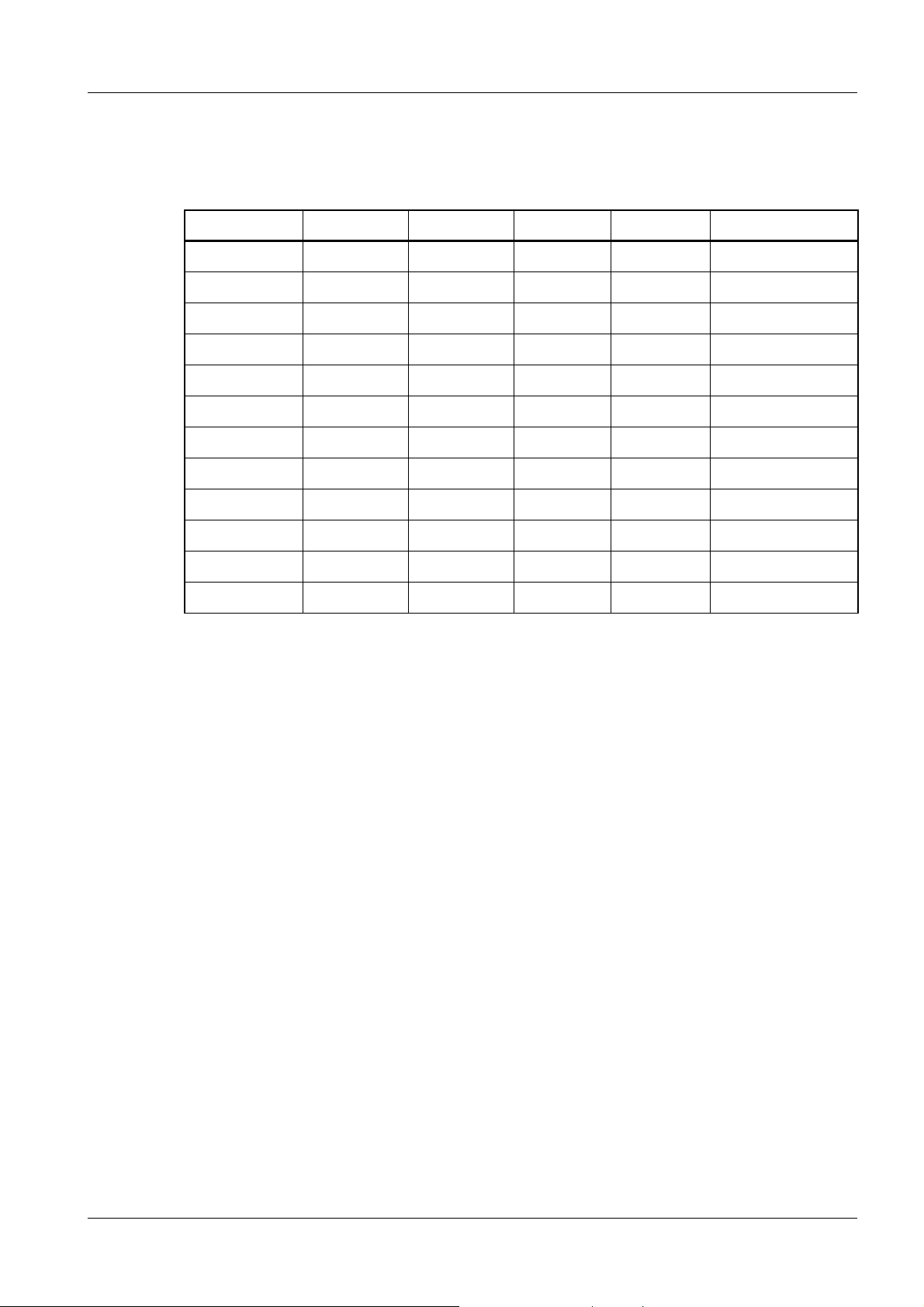

Low voltages 3

• Check the operating voltages of the ARCOSKOP according to tables 1 and 2 (Fig.1 - 4).

From test point To test point Voltage Adjuster

D1.X37 (0V) D1.X30 (+5 V) +5.1 V to 5.2 V M14. +5 V/Adj.

D1.X39 (0V) D1.X32 (+15 V) +4.9 V to 15.1 V M14. +15 V/Adj.

D1.X39 (0V) D1.X33 (-15 V) - 4.8 V to -15.2 V M14. -15 V/Adj.

D30.X1.8 (0V) D30.X1.9 (+24 V) +24.0 V to 29.6 V not adjustable

D30.X21.1 (0V) D30.X21.10 (+24 V) +22.8 V to +29.5 V not adjustable

D30.X20.1 (0V) D30.X20.3 (+27 V) +27.3 V to +27.8 V D30 R115

D42.MP1 (0V) D42.MP2 (+5 V) + 5,0 V bis +5,2 V D40.P1

D40.D17.A (0V) TP (+5 V) +5,0 V to +5,2 V D40.P1 *1

M13.S- (0V) M13.S+ (+13 V) +13.1 V to 13.3 V M13.TR1

Ta b . 1

*1

With existing "operation free" option, i.e. the control console is detachable, you must measure and check on board D40 that the voltage does not exceed 5.2 V. Should the voltage

on D40 be too high, the voltage on D42 can be reduced to 5.0 V.

Image intensifier voltages 3

• Take the voltages E1 / E2 / E3 and A from the test protocol of the image intensifier and

check or adjust them at the test points of the control unit listed in Table 2.

Voltage Test point Ground

point (0V)

E1 UE1 P10 P11 1:1

E2 UE2 P6 P7 1:1

E3 UI 15 P2 P3 1:10000

30 kV, anode UI 30 P1 P1 1:10000

Ta b . 2

Potentiome-

ter for

full format

Potentiome-

ter for

zoom format

Volt ag e d ivi -

der ratios

ARCOSKOP SPR2-250.840.01 Seite 2 von 4 Siemens AG

System Manual Rev. 01 09.05 CS PS 24 Medical Solutions

Page 27

Checking the operating voltages 3 - 3

D41/D42 Programming 3

• Make sure that the jumpers on boards D41 and D42 are installed as follows:

Board Jumper Pins on off Components

D41 21 1 - 2 X E-Box

D41 22 1 - 2 X E-Box

D41 23 2 - 3 X E-Box

D41 24 X E-Box

D41 25 X E-Box

D41 26 X E-Box

D42 21 2 - 3 X Panel

D42 22 2 - 3 X Panel

D42 23 1 - 2 X Panel

D42 24 X Panel

D42 25 X Panel

D42 26 X Panel

Tab. 3

• Board D41 for the E-box and board D42 for the control panel have to be clearly identified

with an X in the respective field.

Siemens AG SPR2-250.840.01 Seite 3 von 4 ARCOSKOP

Medical Solutions Rev. 01 09.05 CS PS 24 System Manual

Page 28

3 - 4 Checking the operating voltages

Diese Seite wurde bewusst leer gelassen.

ARCOSKOP SPR2-250.840.01 Seite 4 von 4 Siemens AG

System Manual Rev. 01 09.05 CS PS 24 Medical Solutions

Page 29

Operating software 4

Loading the operating software 4

• Connect the service PC to the serial service interface on ARCOSKOP.

• Insert the "Parameter" disk in drive A.

• Start the service program.

• Select the Download menu, select the relevant file (Host, Gen....) and start Download.

• After successfully downloading, wait for the system to boot (1 minute).

• The ARCOSKOP is operational.

4 - 1

NOTE

If you cannot run Download (e.g. power failure during Download):

- Switch the ARCOSKOP off and back on

- Restart Download

Backing up the system parameters 4

NOTE

Prerequisite:

The service PC is already connected, the service program is already started.

• Select the "Data" menu.

• Select the "Backup" submenu.

• Click the "Parameter" check box.

• If required select the back-up of further data by selecting the corresponding check box.

After changing settings / parameters, back these up on the parameter disk.

Note that the data are stored correctly only after ending the service program

Therefore always exit the service program with "Logoff" and

"Quit".

• Click the "Backup" button. Wait until the data are backed up temporarily on disk.

• Then back to the main menu.

• Select the "System" menu.

• Select the "Logoff" submenu. Wait until the data are stored on disk.

• You can now exit the service program by selecting the "System" and "Quit" menus.

Siemens AG SPR2-250.840.01 Seite 1 von 4 ARCOSKOP

Medical Solutions Rev. 01 09.05 CS PS 24 System Manual

Page 30

4 - 2 Operating software

Reading and storing the load counter data 4

NOTE

The procedure is divided in 4 steps:

Before the replacement of the POWERPHOS, all load counter

values have to be stored on disk. After storing the load counter

values, the load counter has to be reset. All values are set to 0.

After the replacement and all adjustments, send back the disk

with the defective POWERPHOS for repair.

• Store the actual load counter values on disk.

• Release the resetting of the load counters.

• Reset the load counter values to 0.

• Return the defective POWERPHOS, including the load counter data disk.

Storing the actual load counter values 4

• Connect the service PC to the serial interface of the unit.

• Start the service program.

• Select the "Diagnostics / Monitoring" menu.

• Select "LOAD COUNTERS" in the "Group 1:" combo box.

• Click on "Update Start" and wait until the actual values are displayed.

• Click on "Update Stop".

• Click on the "Save" button.

• Change the data disk of the service program in drive A against a formatted empty one.

• Select the drive A for storage.

• For the file name, enter the current date, the part no. and the serial no. of the

POWERPHOS.

Example:

The current date is:

Use the date format DD-MM-YY:

The POWERPHOS part no. is:

The POWERPHOS serial no. is:

Enter the file name:

08-22-1999

22-08-99

55 73 501

01234

22-08-99_5573501_01234.his

• Store the file on disk.

• After storage, change the disk in drive A against the previously used data disk of the

service program.

• Close the Monitoring window by clicking on the "Cancel" button.

ARCOSKOP SPR2-250.840.01 Seite 2 von 4 Siemens AG

System Manual Rev. 01 09.05 CS PS 24 Medical Solutions

Page 31

Operating software 4 - 3

Releasing the resetting of the load counter values 4

• Select the "Adjustment / Parameters..." menu.

• Select "SETTINGS FOR SERVICE PC" in the "Parameter Groups:" combo box.

• Click on the "Get from Unit" button.

• Select the parameter "ENABLE RESET TUBE VALUES".

• In the "Value / Actual" field, select "YES".

• Click on the "Set Value" button.

• Click on the "Put to Unit" button.

• Answer the query with "YES" and wait until the unit has rebooted.

• Close the Parameters window by clicking on the "Cancel" button.

Resetting the load counters 4

• Select the "Adjustment / Calibrations..." menu.

• Answer the query with "YES".

• Select "RESET TUBE VALUES" in the "Function Groups:" combo box.

• Select "LOAD COUNTER" and click on "Execute".

• The load counters are set to 0.

• Close the Status window by clicking on the "OK" button.

• Answer the query "Do you want to reset the Unit" with "Yes".

Returning the defective POWERPHOS incl. load counter data disk 4

• Mark the load counter data disk label with:

the current date

the system part no (ARCOSKOP)

the system serial number

the POWERPHOS part number and

the POWERPHOS serial number.

• Add the disk to the defective POWERPHOS and send it all back for repair together with

the completed tube questionnaire.

Siemens AG SPR2-250.840.01 Seite 3 von 4 ARCOSKOP

Medical Solutions Rev. 01 09.05 CS PS 24 System Manual

Page 32

4 - 4 Operating software

Storing the error log in ASCII format 4

• When storing the error log using the backup function of the service program, it will be

stored as a binary file which cannot be read by a text editor.

• For easier evaluation of the error log, it can be stored in ASCII format as well.

• For easier service support from the USC or HSC, please send the error log as an ASCII

file.

NOTE

The parameter disk must be in drive A before starting the service

program and during service work. Otherwise, the text "no error

text available" will display behind the error codes instead of the

actual error messages.

Prerequisites 4

• The service PC is connected and the service program is started.

• Select the "Diagnostics..." menu.

• Select the "Error log" menu.

• Click the "Get from unit" button. Wait until the error log is transferred to the service PC.

• Click the "Export to file" button.

• Save the file to your hard drive.

• For the file name, please enter the current date, the part number and the serial number of

the unit as described in the example.

Example:

The current date is (DD-MM-YY): 29-03-01

The unit part no. is: 4774019

The unit serial no. is: 01234

Enter this file name: 22-03-01_4774019_01234.txt

• Save the file to the hard drive of your service PC under a path of your choice.

• Exit the service program.

• Copy the previous stored file to an emty, formatted floppy disk.

ARCOSKOP SPR2-250.840.01 Seite 4 von 4 Siemens AG

System Manual Rev. 01 09.05 CS PS 24 Medical Solutions

Page 33

Adjustments / Programming 5

Generator adjustment 5

5 - 1

NOTE

The mAs counter adjustment must be performed immediately

after the generator adjustment.

• Cover the radiation exit window with a lead cover or a folded lead apron.

WAR NING

X-ray radiation!

See Chapter 1, Safety Information.

Use radiation protection.

Wear a lead apron when making adjustments! Maintain a safe

distance!

• Select the DIAGNOSTICS - MONITORING menu.

• Select "GENERATOR ADJUSTMENT" in the "Group 1" combo box.

• Click on "Update Start".

➪ The collimator closes automatically.

• After about 5 seconds, press the radiation release button on the hand control or the

ARCOSKOP fluoroscopy foot switch.

NOTE

When the generator adjustment begins, continue pressing the

radiation release button until the "Stop monitoring" message

appears in the "ACTIONS" line. If the radiation release button is

released too soon, the entire generator adjustment will have to be

repeated.

Exception: Briefly releasing the radiation release button (less

than 30 seconds) is permitted during the warm-up phase of the

POWERPHOS (the message "Warm-up" appears in the "Status"

line on the service PC). The generator adjustment will continue if

the radiation release button is pressed again within 30 seconds.

➪ After approximately 8 minutes, the message "Learning pushfactor" appears.

➪ A maximum of 15 exposures is automatically released.

➪ When the generator adjustment has been successfully completed, the message

"Learning done" appears in the status display.

➪ The message "Stop monitoring" then appears in the status line.

• Click on "Update Stop".

Concluding tasks

• Perform the mAs counter adjustment.

• Switch the ARCOSKOP off and then on again.

Siemens AG SPR2-250.840.01 Seite 1 von 42 ARCOSKOP

Medical Solutions Rev. 01 09.05 CS PS 24 System Manual

Page 34

5 - 2 Adjustments / Programming

mAs counter adjustment 5

NOTE

The mAs counter adjustment must also be performed after the

generator adjustment.

• Cover the radiation exit window with a lead cover or a folded lead apron.

WAR NING

X-ray radiation!

See Chapter 1, Safety Information.

Use radiation protection.

Wear a lead apron when making adjustments! Maintain a safe

distance!

• Select the DIAGNOSTICS - MONITORING menu.

• Select "MAS COUNTER ADJUSTMENT" in the "Group 1" combo box.

• Click on "Update Start".

➪ The collimator closes automatically.

• After about 5 seconds, press the radiation release button on the hand control or the

ARCOSKOP fluoroscopy foot switch.

NOTE

When the mAs-counter adjustment begins, continue pressing the

radiation release button until the message "Stop monitoring"

appears in the "ACTIONS" line. If the radiation release button is

released too soon, the mAs-counter adjustment will have to be

repeated.

➪ A maximum of 9 exposures is automatically released.

➪ When the mAs-counter adjustment has been successfully completed, the mes-

sage "Stop monitoring" appears in the status line.

• Click on "Update Stop".

Concluding tasks

• If no other adjustments or settings need to be made, save the learned data to a disk

(Data menu - Backup on the Service PC).

• Perform the checking of the generator adjustment, see next page.

ARCOSKOP SPR2-250.840.01 Seite 2 von 42 Siemens AG

System Manual Rev. 01 09.05 CS PS 24 Medical Solutions

Page 35

Adjustments / Programming 5 - 3

Checking the generator adjustment 5

• Select the DR operating mode.

• Temporarily set K-factor to K = 1 (= EB).

• Select the HC 2 or HC 3 characteristic curve.

• Select the ->0<- key on the basic unit control console.

• Select kV Stop.

• Set 75 kV ± 1 kV with the kV+ / kV- keys.

• These default settings give a 200 mA pulsed current.

• Connect a storage oscilloscope to the test points for "kV_Ist" (D21.X118. kV_IST) and

"mA_IST" (D21.X118. I_T_IST). Ground: D21.X118.ANA_GND.

• Store and evaluate the oscillogram:

Tolerances for the mA curve

- 5 ms after pulse start to 5 ms before pulse

end:

- during the last 5 ms before pulse end:

± 20 %

± 10 %

• If the tube current exceeds the specified tolerances, the generator setup and the mAs

counter adjustment must be repeated.

Siemens AG SPR2-250.840.01 Seite 3 von 42 ARCOSKOP

Medical Solutions Rev. 01 09.05 CS PS 24 System Manual

Page 36

5 - 4 Adjustments / Programming

Dose rate adjustment 5

NOTE

There are 2 methods to set the dose rates.

• Automatic dose rate adjustment: with this method the dose rate

needs only to be set for the DR operating mode and dose rate

level HIGH in the full format. All other dose rate levels and the

necessary TV iris diaphragm values are automatically calculated

and stored.

After the automatic dose rate adjustment, perform

"Calibrating the TV iris diaphragm for automatic iris diaphragm

regulation (AIR)", Chapter 5.

Then all dose rate values must be checked according to

"Checking the set dose or dose rate", Chapter 5. If the dose or

dose rate values deviate from the nominal values by more than

the permissible tolerance, the dose rate adjustment must be

repeated according to "Manual dose rate adjustment" of

Chapter 5.

• Manual dose rate adjustment: with this method about 40 dose

rate values must be set for the different operating modes.

Use this method only if automatic dose rate adjustment is not

successful.

Automatic dose rate adjustment 5

Preparing the service PC 5

• Switch the system on.

• Connect the service PC to the serial interface of the system.

• Start the service program, the parameter disk must be inserted in drive A.

• Select the "Diagnostics..." menu.

• Select the "Monitoring..." menu.

• Select the "DOSERATE ADJUSTMENT" menu in the combo box "Group 1".

• Select "Update Start".

ARCOSKOP SPR2-250.840.01 Seite 4 von 42 Siemens AG

System Manual Rev. 01 09.05 CS PS 24 Medical Solutions

Page 37

Adjustments / Programming 5 - 5

The following messages are displayed on the service PC:

AUTO REGULATION displays the current status during the adjustment.

(active / not active / not ready / done)

ADJUSTMENT displays the regulation operating mode.

(Generator / Camera iris / Stop)

ACTUAL MODE displays the operating mode currently selected.

(FL/ PFL/DR/EB/SUB)

II. ZOOM STATUS displays the current I.I. format.

(Full format / Zoom format)

DOSE ADJ. NOMINAL VAL displays the nominal values for the dose rate.

(see Menu Adjustments... - Parameter - DOSE ADJ.

(respective operating mode) - NOMINAL VALUES )

DOSE LEVEL displays the dose rate level selected.

(Low / Mid / High)

TV IRIS ACTUAL POSITION displays the current position of the TV iris.

NOTE

After clicking on "Update Start" on the service PC, the primary

up-to-date operating statuses (see above) will be displayed

during the dose rate adjustment.

Siemens AG SPR2-250.840.01 Seite 5 von 42 ARCOSKOP

Medical Solutions Rev. 01 09.05 CS PS 24 System Manual

Page 38

5 - 6 Adjustments / Programming

Key assignment on the control console during dose rate adjustment

During the dose rate adjustment, certain keys are assigned special functions.

Fig. 1

11 1413

12

17

1234567

11A

9

10

8

1615

1 Selects FL operating mode (Fluoroscopy)

2 Selects PFL operating mode (Pulsed Fluoroscopy)

3 Selects DR operating mode (Digital Radiography)

4 Selects DCM operating mode (Digital Cine Mode)

5 Selects DSA operating mode (Subtraction)

6 Selects EB operating mode (EB = Single Image Mode)

7 I.I. full format (LED off) / Zoom (LED on)

8 kV Stop (LED on), 75 kV curve

9 mA coarse adjustment

10 mA fine adjustment

11 TV Iris adjustment

11A Opens TV Iris

12 TV Iris adjustment fine (LED on, adjust with key 11)

or coarse (LED off, adjust with key 11)

13 Displays actual brightness - nominal brightness deviation

14 Saves TV Iris position

15 Selects the dose rate level LOW MID and HIGH (see also 16).

16 LED display for dose rate levels (1 LED = LOW; 2 LEDs = MID;

3 LEDs = HIGH)

17 Starts and saves the automatic dose rate adjustment.

ARCOSKOP SPR2-250.840.01 Seite 6 von 42 Siemens AG

System Manual Rev. 01 09.05 CS PS 24 Medical Solutions

Page 39

Adjustments / Programming 5 - 7

Dose rate value to be set for the automatic dose rate adjustment 5

NOTE

NOTE

NOTE

The dose rate value to be set is not the same as the dose rate

value or dose values / pulse at normal operation. Please refer to

Table 4 "Checking the dose or dose rate" in this chapter for this

value.

The dose rate value given in Table 1 must be set.

For all other dose rate values the associated TV iris diaphragm

values are automatically calculated and stored.

If a dose measuring device with a solid-state detector is used,

take care that the solid-state detector lies outside the dominant of

the dose rate control.

The dominant has a diameter of approx. 6 cm in relation to the

monitor screen.

The dose measuring chamber correction factor is not to be taken

into account in this case. The dose rates then result from:

[Dose rate at I.I. input (nGy/s)] * [Grid correction factor].

23 cm I.I. 5

Operating

mode

DR Full format HIGH 740 1176

Tab. 1

Tolerance for dose rate: + 5%.

Correction factors:

DALI and NOMEX dose measuring device, large measuring chamber: 1.06

23 cm (9") I.I.: Grid correction factor: 1.5

WAR NING

I.I. format Dose rate

level

X-ray radiation!

See Chapter 1, Safety Information!

Use radiation protection. Wear a lead apron when making the

adjustments! Keep the fluoro time as short as possible!

Maintain a safe distance!

Dose rate at

the I.I. input

(nGy/s)

Dose rate at the I.I. input

* Grid correction factor

* Dose measuring

chamber correction

factor (nGy/s)

Siemens AG SPR2-250.840.01 Seite 7 von 42 ARCOSKOP

Medical Solutions Rev. 01 09.05 CS PS 24 System Manual

Page 40

5 - 8 Adjustments / Programming

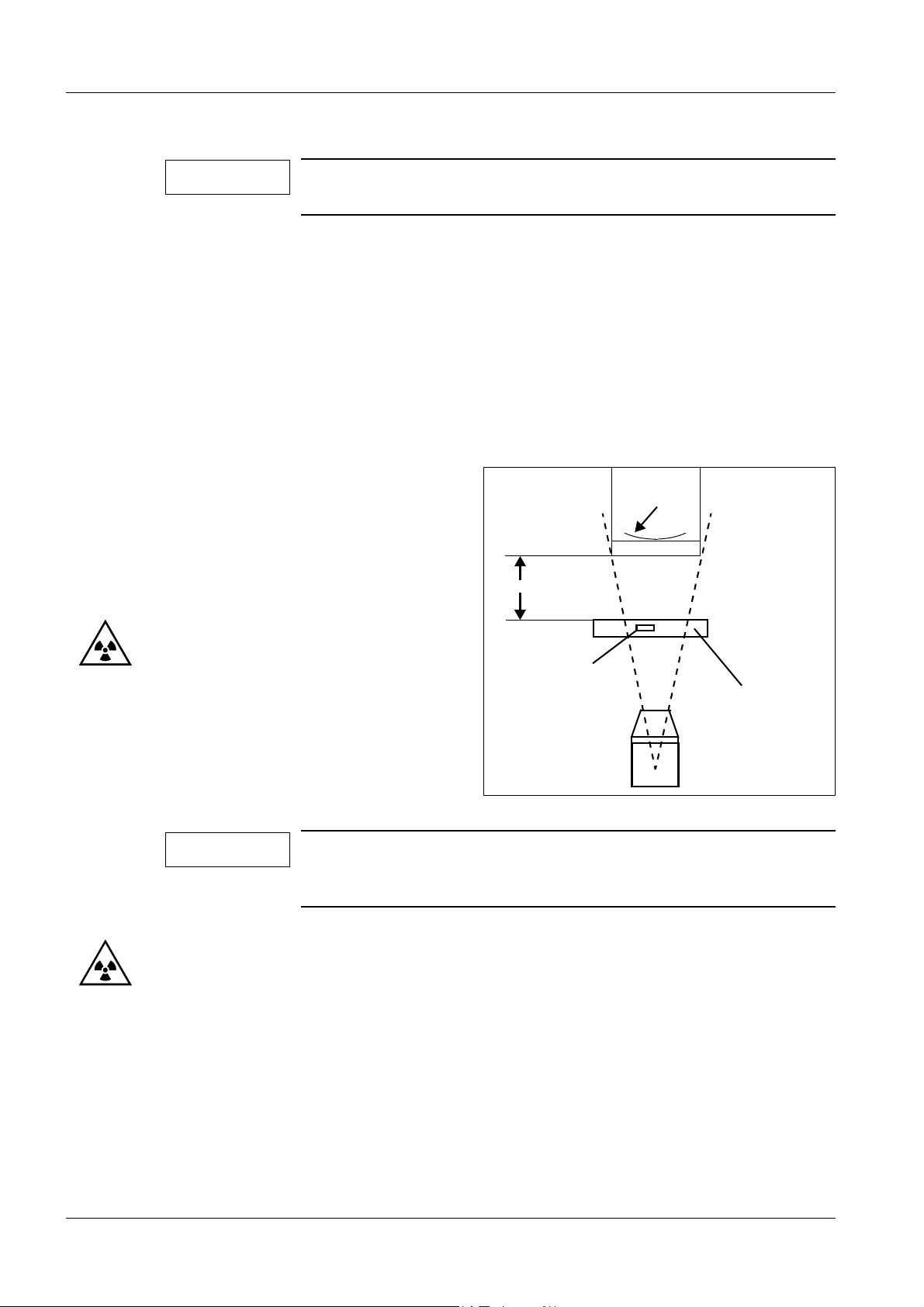

Measuring setup

• The grid should be attached to the I.I.

• Center the dose measuring chamber on the I.I. input screen and attach it.

• Attach 0.9 mm CU to the radiation exit window of POWERPHOS.

NOTE

NOTE

If the dose rate value to be set cannot be attained, adjust the prefiltration accordingly.

To prevent inaccuracies, the measuring chamber of the dose rate

measuring device must be fully irradiated during setting.

Setting the dose rate 5

• "Dose rate adjustment" must be started.

• "Update Start" must be selected.

• Select the DR operating mode. (LED in the key (3/Fig. 1) lights up).

• Select full format. (LED in the key (7/Fig. 1) is off).

• Press one of the keys (10/Fig. 1). The 75 kV curve is selected. 75 kV are shown in the

display.

• Select kV stop. (LED in the key (8/Fig. 1) lights up).

• Select dose rate level HIGH (all three LEDs in the display (16/Fig. 1) light up).

• Turn the radiation on (fluoroscopy hand switch or fluoroscopy foot switch).

• Set the dose rate with the kV+ and kV- keys according to the table (coarse adjustment).

• The value can be adjusted with the mA+ and mA- keys in 1/16 exposure points.

• Then set the Brightness Nom. - Brightness Act. deviation with the camera rotation keys

(11/Fig. 1), shown in the display (13/Fig. 1) to 0 +

3.

• When the key (12/Fig. 1) is selected (LED in the key lights up), the TV iris will move more

slowly (fine adjustment).

• Press the key (14/Fig. 1). An acoustic signal sounds. The current TV iris diaphragm

position will be stored.

• Then press the key (17/Fig. 1). An acoustic signal sounds (Multiple "beep"). All TV iris

diaphragm values will automatically be calculated and stored.

• Do not exit the dose rate setting window yet! First calibrate the TV iris diaphragm for

automatic iris diaphragm regulation!

• Then perform "Checking the set dose or dose rate", Chapter 5.

• If one or several dose or dose rate values show deviations, the setting must be repeated

according to "Manual dose rate adjustment".

ARCOSKOP SPR2-250.840.01 Seite 8 von 42 Siemens AG

System Manual Rev. 01 09.05 CS PS 24 Medical Solutions

Page 41

Adjustments / Programming 5 - 9

Manual dose rate adjustment 5

Preparation of the service PC 5

• Switch the ARCOSKOP on.

• Connect the service PC to the serial interface of the ARCOSKOP.

• Start the service program. The parameter disk must be inserted into disk drive A.

• Select the "Diagnostics..." menu.

• Select the "Monitoring..." menu.

• Select the "DOSERATE ADJUSTMENT" menu in the "Group 1" combo box.

• Select "Update Start".

The following messages are displayed on the service PC:

AUTO REGULATION displays the current status during the adjustment.

(active / not active / not ready / done)

ADJUSTMENT displays the regulation operating mode.

(Generator / Camera iris / Stop)

ACTUAL MODE displays the operating mode currently selected.

(FL/ PFL/DR/EB/SUB)

II. ZOOM STATUS displays the current I.I. format.

(Full format / Zoom format)

DOSE ADJ. NOMINAL VAL displays the nominal values for the dose rate.

(see Menu Adjustments... - Parameter - DOSE ADJ.

(respective operating mode) - NOMINAL VALUES )

DOSE LEVEL displays the dose rate level selected.

(Low / Mid / High)

TV IRIS ACTUAL POSITION displays the current position of the TV iris.

NOTE

Siemens AG SPR2-250.840.01 Seite 9 von 42 ARCOSKOP

Medical Solutions Rev. 01 09.05 CS PS 24 System Manual

After clicking on "Update Start" on the service PC, the primary

up-to-date operating statuses (see above) will be displayed

during the dose rate adjustment.

Page 42

5 - 10 Adjustments / Programming

Key assignment on the control console during dose rate adjustment

During the dose rate adjustment, certain keys are assigned special functions.

Fig. 2

1 Selects FL operating mode (Fluoroscopy)

2 Selects PFL operating mode (Pulsed Fluoroscopy)

3 Selects DR operating mode (Digital Radiography)

4 Selects DCM operating mode (Digital Cine Mode)

5 Selects DSA operating mode (Subtraction)

6 Selects EB operating mode (EB = Single Image Mode)

7 I.I. full format (LED off) / Zoom (LED on)

8 kV Stop (LED on), 75 kV curve

9 mA coarse adjustment

10 mA fine adjustment

11 TV iris adjustment

11A Opens TV iris

12 TV iris adjustment fine (LED on, adjust with key 11)

or coarse (LED off, adjust with key 11)

13 Displays actual brightness - nominal brightness deviation

14 Saves TV iris position

15 Selects the dose rate level LOW MID and HIGH (see also 16).

16 LED display for dose rate levels (1 LED = LOW; 2 LEDs = MID;

3 LEDs = HIGH)

ARCOSKOP SPR2-250.840.01 Seite 10 von 42 Siemens AG

System Manual Rev. 01 09.05 CS PS 24 Medical Solutions

Page 43

Adjustments / Programming 5 - 11

Dose rate values to be set for the manual dose rate adjustment

NOTE

NOTE

NOTE

The dose rate values to be set for pulsed operating modes are not

the same as the dose rate values or dose values/pulse output by

these modes. Please refer to the Operating Instructions for these

values.

Table 2 shows the dose rate values to be set in the order of the

operating modes.

Table 3 shows a useful arrangement for setting the dose rate

values (from low to high values).

The dose rate values printed in bold in Table 3 must be set.

All other identical dose rate values will automatically be transferred.

This means that the same dose rate value only needs to be set

once for different operating modes.

During the dose rate setting, write down the generated TV iris

position values.

If the setting from low dose rate values to high dose rate values is

performed (sequence as per Table 3), ensure that the current TV

iris diaphragm value is not higher than or equal to the previously

set TV iris diaphragm value.

Otherwise the setting must be repeated.

The error message 7500/7501 will be displayed in the event of an

incorrect setting after next boot up of the unit.

If only individual new dose rate values are set, the new TV-iris

positions have to be checked for plausibility.

To ensure this, check the parameters (Menu "Adjustments..." /

Parameters..." / "DOSE ADJ. II. FULL FORMAT" and "DOSE ADJ.

II. ZOOM FORMAT") after setting the TV iris diaphragm value.

For every next higher dose rate level, the corresponding TV iris

diaphragm value must decrease.

Siemens AG SPR2-250.840.01 Seite 11 von 42 ARCOSKOP

Medical Solutions Rev. 01 09.05 CS PS 24 System Manual

Page 44

5 - 12 Adjustments / Programming

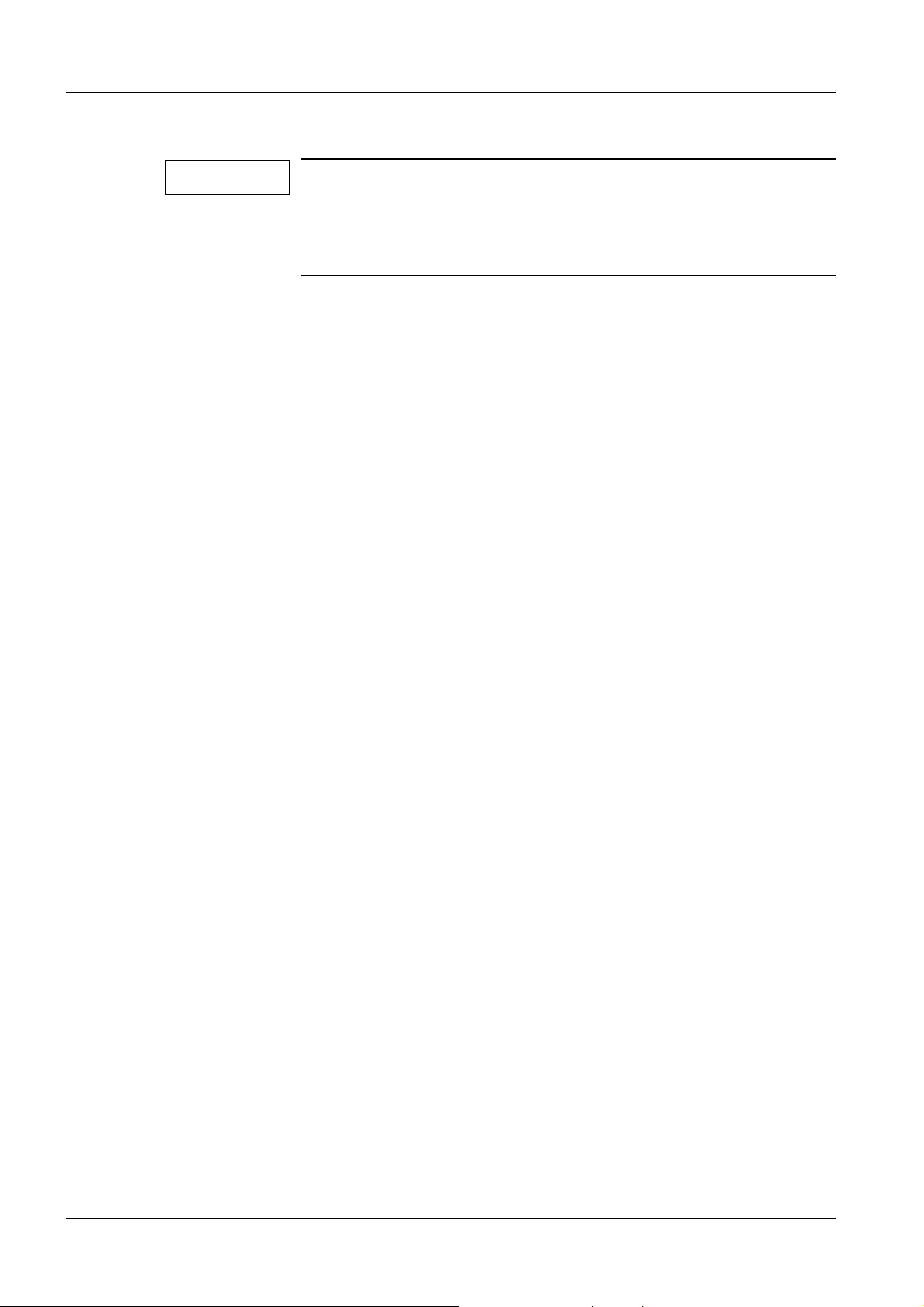

23 cm I.I., in the order of the operating modes 5

Operating

mode

FL Full format LOW 110 175

FL Full format MID 185 295

FL Full format HIGH 370 588

PFL Full format LOW 220 350

PFL Full format MID 370 588

PFL Full format HIGH 740 1176

DR Full format MID 370 588

DR Full format HIGH 740 1176

EB Full format MID 1480 2353

EB Full format HIGH 2960 4706

DCM Full format LOW 770 1224

DCM Full format MID 1295 2059

I.I. format Dose rate

level

Dose rate at

the I.I. input

(nGy/s)

Dose rate at the I.I.input

* Grid correction factor

* Dose measuring

chamber correction

factor (nGy/s)

DCM Full format HIGH 2590 4118

DSA Full format MID 370 588

DSA Full format HIGH 740 1176

FL Zoom format LOW 160 254

FL Zoom format MID 260 413

FL Zoom format HIGH 520 827

PFL Zoom format LOW 310 493

PFL Zoom format MID 520 827

PFL Zoom format HIGH 1050 1669

DR Zoom format MID 520 827

DR Zoom format HIGH 1050 1669

EB Zoom format MID 2100 3339

EB Zoom format HIGH 4200 6678

DCM Zoom format LOW 1100 1749

DCM Zoom format MID 1850 2941

ARCOSKOP SPR2-250.840.01 Seite 12 von 42 Siemens AG

System Manual Rev. 01 09.05 CS PS 24 Medical Solutions

Page 45

Adjustments / Programming 5 - 13

Operating

mode

DCM Zoom format HIGH 3650 5803

DSA Zoom format MID 520 827

DSA Zoom format HIGH 1050 1669

Tab l e 2

Setting values:

Tolerances during the dose rate setting: +

The positive tolerance range should be utilized preferably for the setting.

I.I. format Dose rate

level

5%.

Dose rate at

the I.I. input

(nGy/s)

Dose rate at the I.I.input

* Grid correction factor

* Dose measuring

chamber correction

factor (nGy/s)

Siemens AG SPR2-250.840.01 Seite 13 von 42 ARCOSKOP

Medical Solutions Rev. 01 09.05 CS PS 24 System Manual

Page 46

5 - 14 Adjustments / Programming

23 cm I.I., in the order of the dose rate 5

Operating

mode

FL Full format LOW 110 175

FL Full format MID 185 295

PFL Full format LOW 220 350

DR Full format MID 370 588

DSA Full format MID 370 588

FL Full format HIGH 370 588

PFL Full format MID 370 588

DR Full format HIGH 740 1176

DSA Full format HIGH 740 1176

PFL Full format HIGH 740 1176

DCM Full format LOW 770 1224

DCM Full format MID 1295 2059

I.I. format Dose rate

level

Dose rate at

the I.I. input

(nGy/s)

Dose rate at the I.I.input

* Grid correction factor

* Dose measuring

chamber correction

factor (nGy/s)

EB Full format MID 1480 2353

DCM Full format HIGH 2590 4118

EB Full format HIGH 2960 4706

FL Zoom format LOW 1) 160 1) 254

FL Zoom format MID 260 413

PFL Zoom format LOW 310 493

DR Zoom format MID 520 827

DSA Zoom format MID 520 827

FL Zoom format HIGH 520 827

PFL Zoom format MID 520 827

DR Zoom format HIGH 1050 1669

DSA Zoom format HIGH 1050 1669

PFL Zoom format HIGH 1050 1669

DCM Zoom format LOW 1100 1749

DCM Zoom format MID 1850 2941

EB Zoom format MID 2100 3339

ARCOSKOP SPR2-250.840.01 Seite 14 von 42 Siemens AG

System Manual Rev. 01 09.05 CS PS 24 Medical Solutions

Page 47

Adjustments / Programming 5 - 15

Operating

mode

DCM Zoom format HIGH 3650 5803

EB Zoom format HIGH 4200 6678

Tab l e 3

Setting values:

Tolerances during the dose rate setting: +

The positive tolerance range should be utilized preferably for the setting.

1) Note on the FL / Zoom format / Low dose rate level

For setting in this operating mode, the BRIGHTNESS DEVIATION may be greater than

± 3.

Therefore, when measuring the dose rate for FL / Zoom format / Low in normal operation,

the dose rate can be a maximum of twice that for FL / Full format / Low.

If the BRIGHTNESS DEVIATION is greater than +

tion values of the TV iris diaphragm for the FL operating mode and LOW dose rate level in

Full format and Zoom format must be read and evaluated.

I.I. format Dose rate

level

5%.

Dose rate at

the I.I. input

(nGy/s)

3 after the dose rate setting, the posi-

Dose rate at the I.I.input

* Grid correction factor

* Dose measuring

chamber correction

factor (nGy/s)

(Service PC, menu "Adjustments... / Parameters... , Parameter "DOSE ADJ. II. FULL

FORMAT / FL LOW - FULL POS" and Parameter "Dose ADJ. II. ZOOM FORMAT / FL

LOW ZOOM POS".)

• If, after setting, the error message 6231 is displayed, the parameter "DOSE ADJ. II.

FULL FORMAT / FL LOW FULL POS" must be read and the parameter "DOSE ADJ. II.

ZOOM FORMAT / FL LOW - ZOOM POS" must be programmed to the read value +1.

- Permissible parameter values are:

FL LOW - ZOOM POS > FL LOW FULL POS

Inadmissible parameter values are:

FL LOW ZOOM POS <= FL LOW FULL POS.

• If, after setting, the error message 7501 is displayed, the parameter "DOSE ADJ. II.

FULL FORMAT / FL LOW - ZOOM POS" must be read and the parameter "DOSE ADJ.

ALL MODES / TV-IRIS MAX POS" must be programmed to the read value +1.

- Permissible parameter values are:

TV-IRIS MAX POS > FL LOW ZOOM POS

Inadmissible parameter values are:

TV-IRIS MAX POS <= FL LOW ZOOM POS

Siemens AG SPR2-250.840.01 Seite 15 von 42 ARCOSKOP

Medical Solutions Rev. 01 09.05 CS PS 24 System Manual

Page 48

5 - 16 Adjustments / Programming

Correction factors:

DALI and NOMEX dose measuring device, large measuring chamber: 1.06

23 cm (9") I.I.: Grid correction factor: 1.5

WAR NING

X-ray radiation!

See Chapter 1, Safety Information.

Use radiation protection. Wear a lead apron when making the

adjustments! Keep the fluoro time as short as possible!

Maintain a safe distance!

Measuring setup 5

• The grid should be attached to the I.I.

• Center the dose measuring chamber on the I.I. input screen and attach it.

NOTE

If a dose measuring device with a solid-state detector is used,

take care that the solid-state detector lies outside the dominant of

the dose rate control.

The dominant has a diameter of approx. 6 cm in relation to the

monitor screen.

The dose measuring chamber correction factor is not to be taken

into account in this case. The dose rates then result from:

[Dose rate at I.I. input (nGy/s)] * [Grid correction factor].

• Attach 20 mm AL + 1.2 mm (4 x 0.3 mm) CU to the POWERPHOS radiation exit window.

NOTE

NOTE

NOTE

If the setting sequence described in Table 3 is followed, it is useful to adjust the prefiltration of these types of operations before

setting the dose rate so that a tube current of approximately

0.3 mA to 0.6 mA is displayed on the console:

• FL, full format, LOW

• DR, full format, HIGH

• FL, zoom format, LOW

• DR, zoom format, HIGH.

The dose rate values that fall in between can then be set without

having to change the prefiltration.

If the dose rate value to be set cannot be attained, adjust the prefiltration accordingly.

To prevent inaccuracies, the measuring chamber of the dose rate

measuring device must be fully irradiated during setting.

For dose rate settings in Zoom format, the X-Iris is opened automatically, so that the entire area of the dose measuring chamber

is irradiated.

ARCOSKOP SPR2-250.840.01 Seite 16 von 42 Siemens AG

System Manual Rev. 01 09.05 CS PS 24 Medical Solutions

Page 49

Adjustments / Programming 5 - 17

Setting the dose rate 5

• "Dose rate adjustment" must be selected.

• "Update Start" must be selected.

• Begin in the FL operating mode with a LOW dose rate level.

• Select fluoroscopy. The LED in the key (1/Fig. 2) lights up.

• Select I.I. full format. The LED in the key (7/Fig. 2) is off.

• Select kV Stop. The LED in the key (8/Fig. 2) lights up.

• With pressing the kV+ or kV- key, 75 kV are displayed.

• Select dose rate level LOW. One LED in the display (15/Fig. 2) lights up.

1. Switch radiation on (fluoroscopy hand switch or fluoroscopy foot switch).

2. Set the dose rate with the kV+ and kV- keys according to the table (coarse

adjustment).

3. The value can be adjusted with the mA+ and mA- keys in 1/16 exposure points

(fine adjustment).

4. Then set the Brightness Nom - Brightness Act deviation with the camera rotation

keys (11/Fig. 2), shown in the display (13/Fig. 2) to 0 ± 3.

5. When the key (12/Fig. 2) is selected (LED in the key lights up), the TV Iris will

move more slowly (fine adjustment).

6. Then press the key (14/Fig. 2). The current TV iris diaphragm position will be

stored.

7. Switch radiation off.