Siemens OpenAir G..B181.1E/KN Series, OpenAir GDB181.1E/KN, OpenAir GLB181.1E/KN Technical Basics

s

OpenAir

T

M

VAV compact controller KNX/PL-Link G..B181.1E/KN

Technical Basics

CE1P3547en

2017-03-23 Building Technologies

2 / 44

Siemens VAV compact controller KNX/PL-Link G..B181.1E/KN CE1P3547en

Building Technologies 2017-03-23

Issued by

Siemens Switzerland Ltd

Building Technologies Division

International Headquarters

Gubelstrasse 22

6301 Zug

Switzerland

Tel. +41 41-724 24 24

www.siemens.com/buildingt echnologies

© Siemens Switzerland Ltd, 2017

Technical specifications and availability subject to change without notice.

3/44

Siemens VAV compact controller KNX/PL-Link G..B181.1E/KN CE1P3547en

Building Technologies 2017-03-23

Table of contents

1 Introduction.......................................................................................... 5

1.1 Revision history ..................................................................................... 5

1.2 Before you start ..................................................................................... 5

1.2.1 Trademarks ........................................................................................... 5

1.2.2 Copyright ............................................................................................... 5

1.2.3 Quality assurance .................................................................................. 5

1.2.4 Document use / request to the reader .................................................... 5

1.3 Objectives of this basic documentation................................................... 6

1.4 Abbreviations and naming conventions .................................................. 6

1.4.1 Abbreviations ......................................................................................... 6

1.4.2 Naming conventions .............................................................................. 6

1.5 References ............................................................................................ 7

2 Device ................................................................................................... 8

2.1 Type summary ....................................................................................... 8

2.1.1 Device variants, tools and accessories ................................................... 8

2.1.2 Selection guide for all types ................................................................. 10

2.1.3 Version summary ................................................................................. 11

2.2 Design and device parts....................................................................... 12

2.3 Dimensions .......................................................................................... 12

2.4 Human-machine interface .................................................................... 13

2.5 Internal diagrams ................................................................................. 14

2.6 Measuring principle .............................................................................. 15

3 Functionality / application ................................................................. 16

3.1 Fields of application ............................................................................. 16

3.2 Equipment combinations ...................................................................... 16

3.3 Application examples ........................................................................... 17

3.3.1 Application example 1: Supply air control ............................................. 17

3.3.2 Application example 2: Supply and extract air control ........................... 17

3.3.3 Application example 3: AHU optimization ............................................. 18

3.4 Further application examples ............................................................... 19

3.4.1 Application examples for Synco 700 (Series C or newer)...................... 19

3.4.2 Application examples for Desigo Total Room Automation ..................... 19

4 Electrical and mechanical installation .............................................. 20

4.1 Mechanical installation / mounting ........................................................ 20

4.2 Electrical installation / cabling .............................................................. 21

4.2.1 Power supply cabling ........................................................................... 21

4.2.2 Bus cabling .......................................................................................... 22

5.3 Setting examples ................................................................................. 26

5.3.1 Symbols and parameters ..................................................................... 26

5.3.2 Min/max control by the supervisory controller ....................................... 26

5.3.3 Min/max control by the VAV compact controller .................................... 28

5.3.4 Master/Slave operating mode .............................................................. 30

6 Engineering and commissioning ...................................................... 32

6.1 Fundamentals ...................................................................................... 32

6.1.1 System environments .......................................................................... 32

4/44

Siemens VAV compact controller KNX/PL-Link G..B181.1E/KN CE1P3547en

Building Technologies 2017-03-23

6.1.2 Documentation of engineering and commissioning ............................... 32

6.1.3 Address labels ..................................................................................... 32

6.2 Engineering ......................................................................................... 33

6.2.1 KNX S-mode engineering .................................................................... 33

6.2.2 KNX LTE-mode / Synco 700 engineering ............................................. 33

6.2.3 Desigo PL-Link / Desigo PXC3.. engineering ....................................... 34

6.3 Commissioning .................................................................................... 35

6.3.1 Preconditions ....................................................................................... 35

6.3.2 KNX S-mode commissioning................................................................ 36

6.3.3 KNX LTE-mode commissioning ............................................................ 36

6.3.4 PL-Link commissioning ........................................................................ 36

7 Safety and EMC optimization ............................................................ 37

7.1 Safety notes ........................................................................................ 37

7.2 Device-specific regulations .................................................................. 38

7.3 Notes on EMC optimization .................................................................. 39

8 Technical data .................................................................................... 40

9 Parameters and datapoints ............................................................... 41

9.1 Parameter description .......................................................................... 41

9.2 Device parameters (ACS931 / ACS941 / AST20) ................................. 42

9.3 Parameters for engineering tools ......................................................... 42

9.4 S-mode datapoints............................................................................... 43

10 Environmental compatibility and disposal ....................................... 44

5/44

Siemens VAV compact controller KNX/PL-Link G..B181.1E/KN CE1P3547en

Building Technologies 2017-03-23

1 Introduction

1.1 Revision history

1.2 Before you start

1.2.1 Trademarks

Trademarks used in this document are listed together with their legal owners below.

Use of these trademarks is subject to international and national statutory provisions.

Trademarks

Legal owner

KNX® KNX Association, B - 1831 Brussels-Diegem Belgium

http://www.knx.org/

All the product names listed are trademarks (™) or registered trademarks (®) of

their respective owners, as listed in the table. Further to the notes in this section,

and to facilitate the reading of the text, these trademarks will not be indicated

elsewhere in the text (e.g. by use of symbols such as ® or ™).

1.2.2 Copyright

This document may be duplicated and distributed only with the express permission

of Siemens, and may be passed only to authorized persons or companies with the

required technical knowledge.

1.2.3 Quality assurance

These documents were prepared with great care.

∂ The contents of all documents are checked at regular intervals.

∂ Any corrections necessary are included in subsequent versions.

∂ Documents are automatically amended as a consequence of modifications and

corrections to the products described.

Please make sure that you are aware of the latest document revision date.

If you find lack of clarity while using this document, or if you have any criticisms or

suggestions, please contact your local point of contact in your nearest branch

office. The addresses of the Siemens regional companies are available at

www.siemens.com/sbt.

1.2.4 Document use / request to the reader

Before using our products, it is important that you read the documents supplied

with or ordered at the same time as the products (equipment, applications, tools

etc.) carefully and in full.

We assume that persons using our products and documents are authorized and

trained appropriately and have the technical knowledge required to use our

products as intended.

More information on the products and applications is available:

Version

Date

Changes

Section

Pages

2.0 23.03.2017 Update for Series G

1.0 26.02.2016 EU and RCM Conformity,

European Directive 2012/19/EU

8 Technical data,

10 Environmental

compatibility and disposal

38

42

6/44

Siemens VAV compact controller KNX/PL-Link G..B181.1E/KN CE1P3547en

Building Technologies 2017-03-23

∂ On the intranet (Siemens employees only) at

https://workspace.sbt.siemens.com/content/00001123/default.aspx

∂ From the Siemens branch office near you www.siemens.com/sbt or from your

system supplier

∂ From the support team at headquarters fieldsupport-zug.ch.sbt@siemens.com

if there is no local point of contact

Siemens assumes no liability to the extent allowed under the law for any losses

resulting from a failure to comply with the aforementioned points or for the

improper compliance of the same.

1.3 Objectives of this basic documentation

This basic documentation covers the networked VAV compact controllers

GDB181.1E/KN and GLB181.1E/KN. These devices are designed for controlling

variable or constant air volume flows.

This document is structured along the according workflow. Following a description

of the devices and their application, mounting, engineering, and commissioning are

covered. A references section lists technical data, parameters, and data points.

1.4 Abbreviations and naming conventions

1.4.1 Abbreviations

Abbreviation

Description

Desigo TRA Total Room Automation (Part of Desigo V5)

ABT Automation Building Tool – part of Desigo XWP

SSA Setup and Service Assistant

LTE Logical Tag Extended (KNX Mode)

USS Universal Serial Interface Protocol (industry automation protocol)

VSD Variable Speed Drive

1.4.2 Naming conventions

Throughout this documentation the term “VAV compact controller(s)” refers to the

GDB181.1E/KN as well as to the GLB181.1E/KN.

7/44

Siemens VAV compact controller KNX/PL-Link G..B181.1E/KN CE1P3547en

Building Technologies 2017-03-23

1.5 References

[1] G..B181.1E/KN – Datasheet for VAV compact controller (N3547)

[2] G..B181.1E/KN – Mounting instruction for VAV compact controller (M3547)

[3] AST20 – Handheld tool for VAV compact controller (A6V10631836)

[4] AST11 – Interface converter (N5852)

[5] ACS931 – PC-Software for OEM (N5853)

[6] ACS941 – PC-Software for Service (N5854)

[7] Scan-to-HIT App for iOS devices (link)

[8] Scan-to-HIT App for Android devices (link)

[9] Desigo V5 Basic manual, chapter 21 “Room automation”

[10] Desigo XWP (ABT Online help)

[11] Desigo TRA Setup and Service Assistant (SSA) (CM111050en)

[12] Desigo TRA mounting and installation manual (CM111043en)

[13] Synco Communication over KNX Bus – Basic documentation (P3127)

[14] Synco 700 Universal controller RMU710B, RMU720B, RMU730B (P3150)

[15] Synco planning and commissioning protocol V2.6 (C3127)

[16] Synco KNX S-Mode datapoints (Y3110)

8 / 44

Siemens VAV compact controller KNX/PL-Link G..B181.1E/KN CE1P3547en

Building Technologies 2017-03-23

2 Device

2.1 Type summary

2.1.1 Device variants, tools and accessories

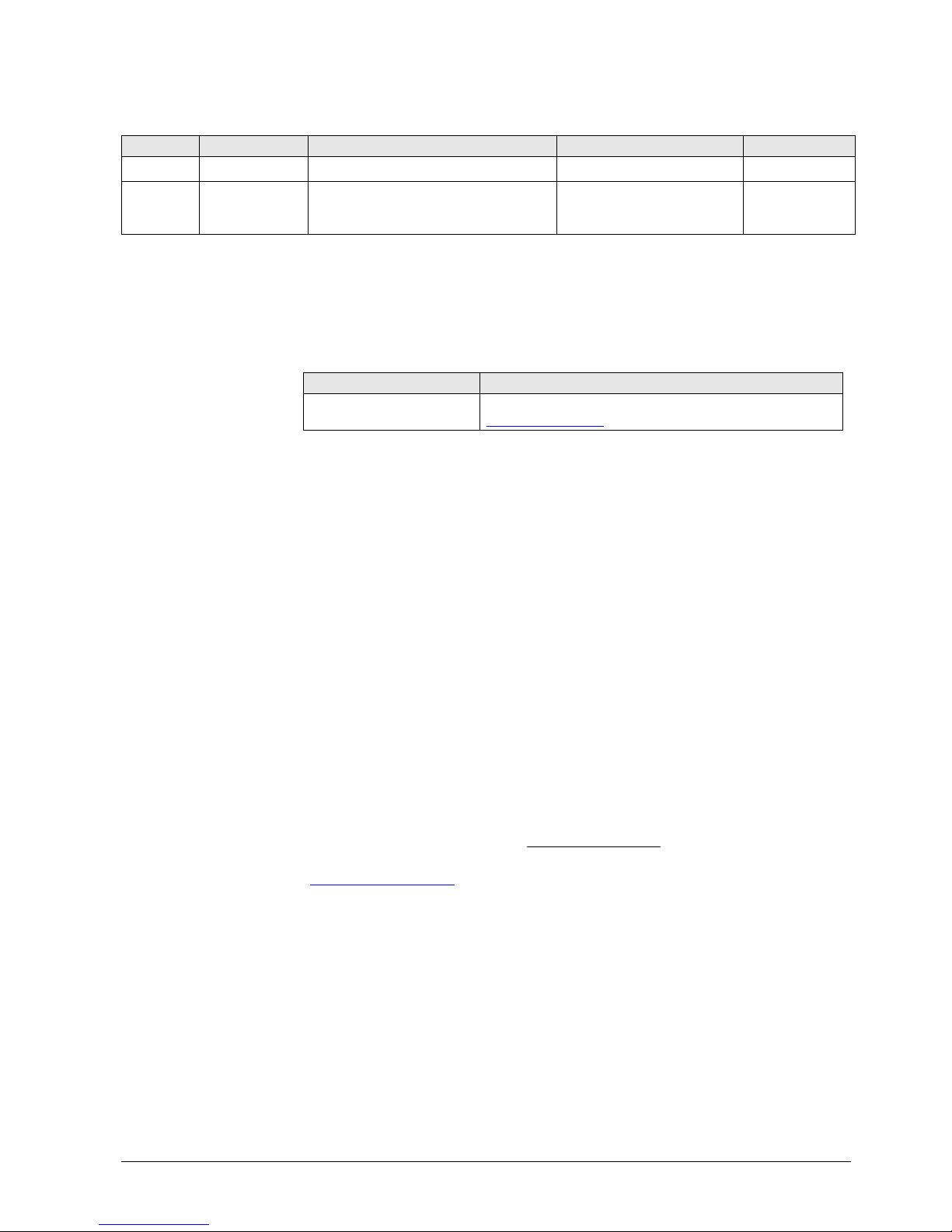

GDB181.1E/KN (5 Nm) GLB181.1E/KN (10 Nm)

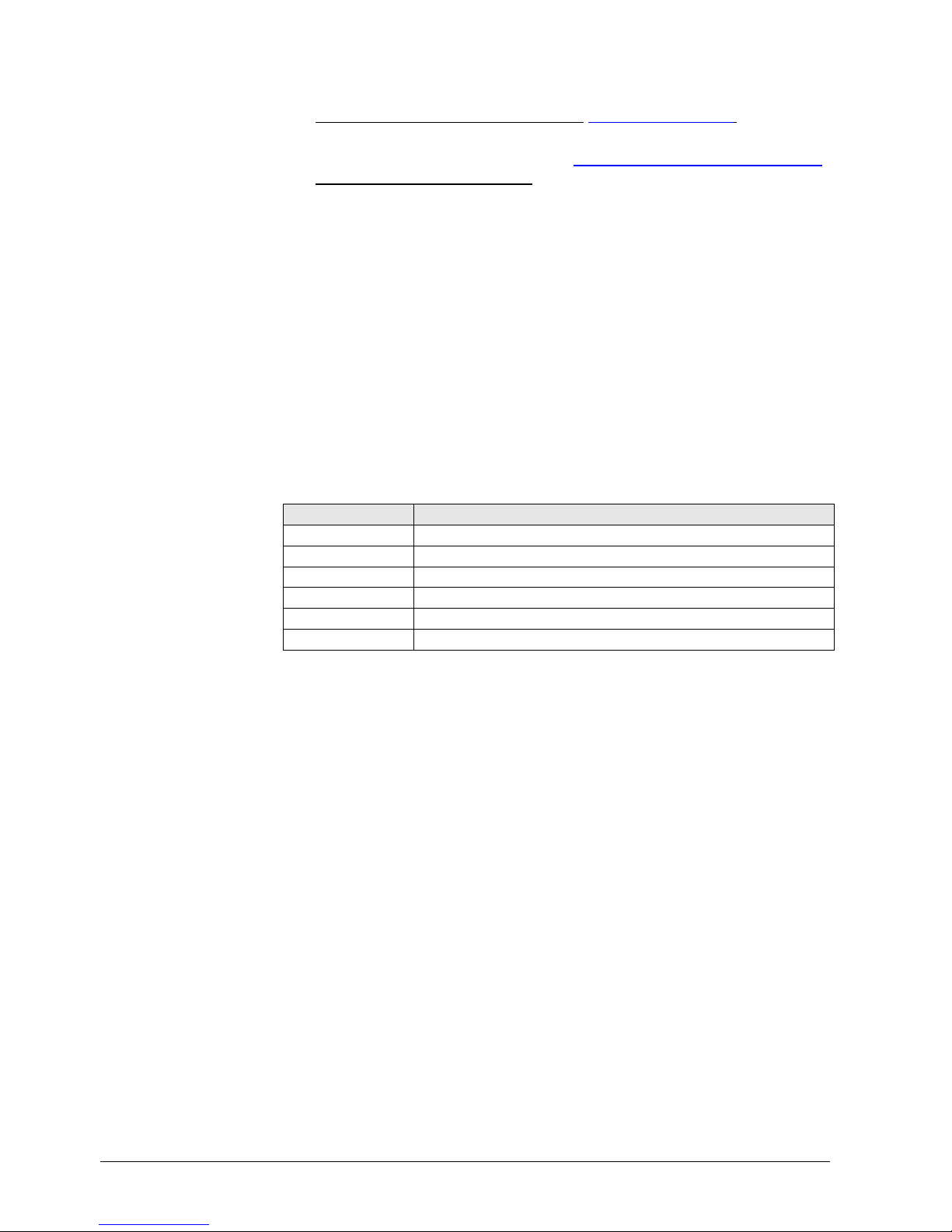

AST10

The handheld tool AST20 can be

used to set the VAV and actuator

parameters and supports access

levels for service technicians and

OEMs.

Datasheet: A6V10631836

ACS941 / AST11

The PC software for service

ACS941 can be used for setting

and reading a certain set of device

parameters (values set by OEM

and current configuration, and

actual values), cf. section 9.2.

For connecting to a PC with

RS232 interface, an interface

converter AST11 is required.

Datasheet: N5852

VAV compact controller

KNX/PL-Link

Tools for

commissioning and

service

9 / 44

Siemens VAV compact controller KNX/PL-Link G..B181.1E/KN CE1P3547en

Building Technologies 2017-03-23

Scan

-to-

HIT App

The Scan-to-Hit App can be used to

retrieve technical information about

the actuator by scanning the DMC

(data matrix code) in the top right

corner of the actuator.

The app can be obtained free of charge at [7] resp. [8]

For information regarding accessories and spare parts for VAV compact controllers,

please refer to datasheet N4698.

Accessories

10 / 44

Siemens VAV compact controller KNX/PL-Link G..B181.1E/KN CE1P3547en

Building Technologies 2017-03-23

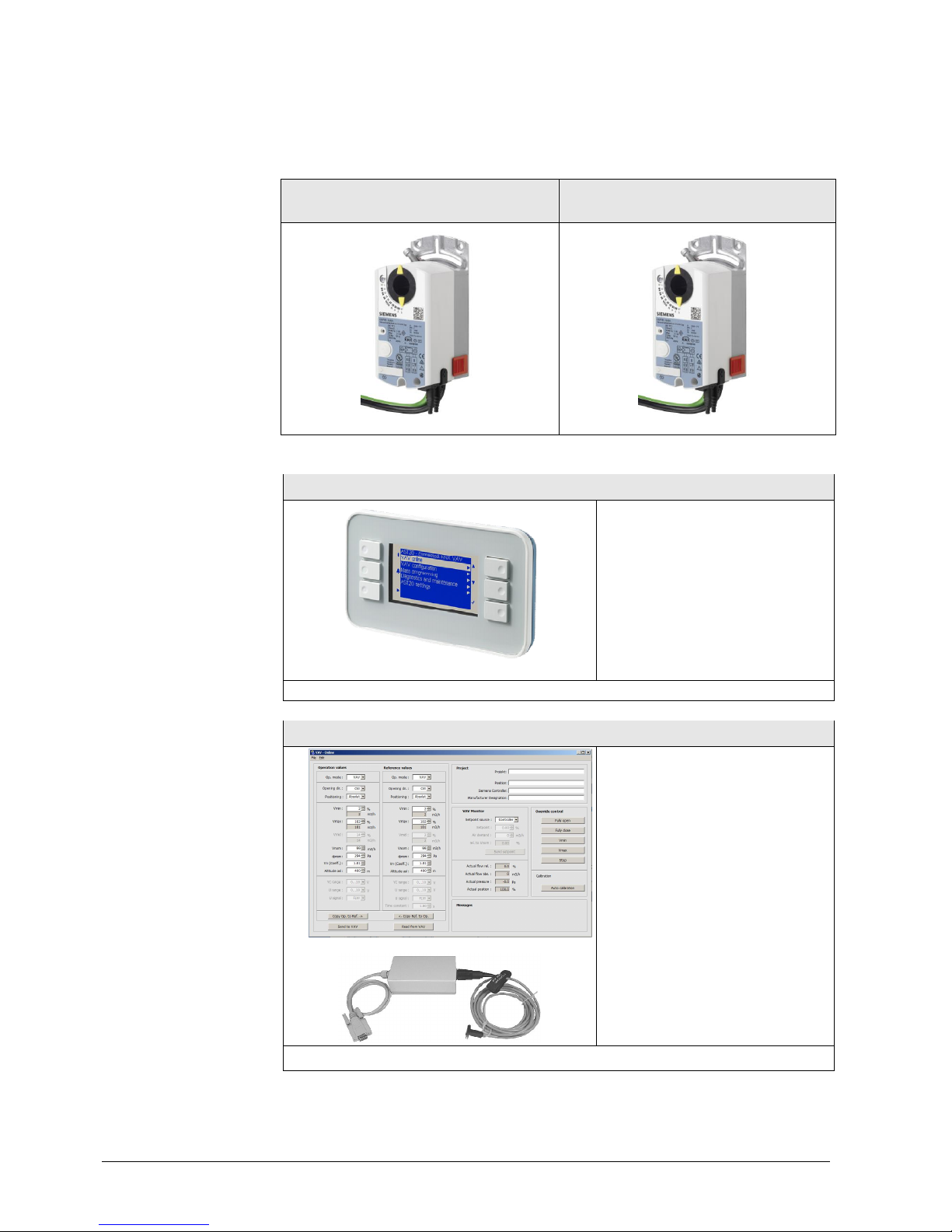

2.1.2 Selection guide for all types

Spring return

function?

Actuator >10 Nm

Actuator >5 Nm

Auxiliary switch

GLB181.1E /3

10 Nm

GDB181.1E/3

5 Nm

GDB181.1E/MO

5 Nm

ASV181.1E/3

with 3P actua tor

GMA131.1E (7 Nm )

GCA131.1E (18 Nm)

ASV181.1E/3

with 3P actuator

GMA136.1E (7 Nm )

GCA136.1E (18 Nm)

ASV181.1E/3

with 3P actuator

GEB136.1E ( 15 Nm)

GBB136.1E ( 25 Nm)

GLB136.1E (35 Nm)

ASV181.1E/3

with 3P actuator

GEB131.1E ( 15 Nm)

GBB131.1E ( 25 Nm)

GLB131.1E (35 Nm)

Bus conn ection

Actuator <=10 Nm

and >5 Nm

Actuator <=5 Nm

Yes

No

No

No

Yes

Yes

No

No

Yes

Yes Auxiliary switch

No

Yes

Modbus

No

GDB181.1E/BA

5 Nm

BACnet

GDB181.1E/KN

5 Nm

KNX

GLB181.1E/MO

10 Nm

Modbus

GLB181 .1E/BA

10 Nm

BACnet

GLB181 .1E/KN

10 Nm

KNX

11 / 44

Siemens VAV compact controller KNX/PL-Link G..B181.1E/KN CE1P3547en

Building Technologies 2017-03-23

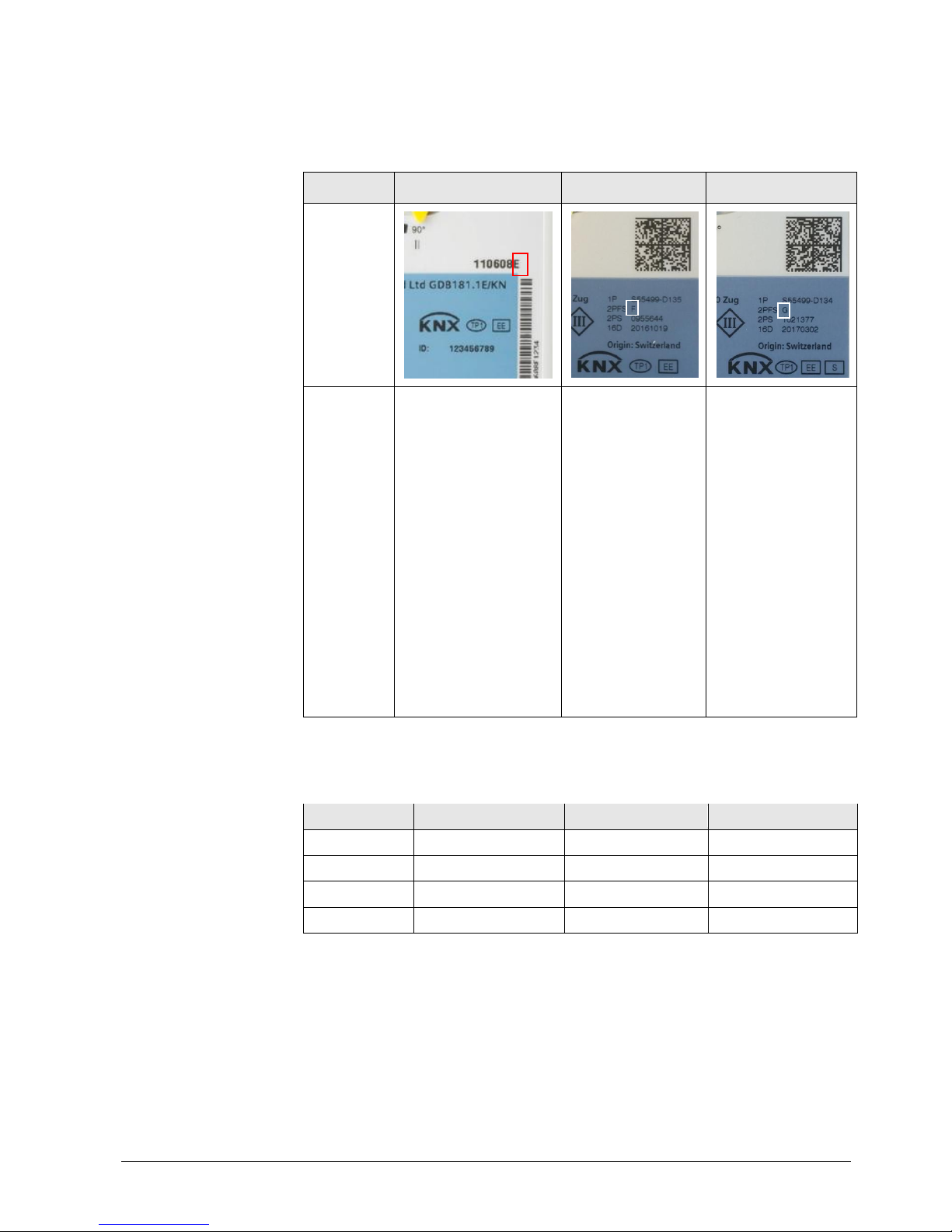

2.1.3 Version summary

Series identification and actuator data can be found in the top right corner of the

product label. As of Series F, the device data is also stored in a DMC (data matrix

code) in the top right corner. It can be read out with any QR Code / DMC scanner

or the Scan-to-HIT app available at ([7] resp. [8]).

VAV Compact Controllers series G are designed for using ETS device profile v2.x,

however ETS device profile v1.x is supported for backward compatibility reasons.

Version

Series E

Series F

Series G

Production period 10/2011 – 03/2014 03/2014 – 01/2017 01/2017

FW version 4.16 4.18 4.24

ETS profile v1.x supported supported supported

ETS profile v2.x not supported not supported supported

Version identification

Version Series E Series F Series G

Identification

Features

∂ Communication over

Desigo PL-Link or

KNX (LTE- and Smode).

∂ New differential

pressure sensor.

∂ Simultaneous

feedback of actual

values of damper

position and air

volume flow.

∂ Optional adaptive

opening range

measurement

(adaptive positioning).

∂ HMI with push button

and LED.

∂ Stability

Improvements

∂ Support for DMC

(data matrix code)

based workflows

∂ Improved ETS and

Desigo ABT

interfaces

Compatibility

12 / 44

Siemens VAV compact controller KNX/PL-Link G..B181.1E/KN CE1P3547en

Building Technologies 2017-03-23

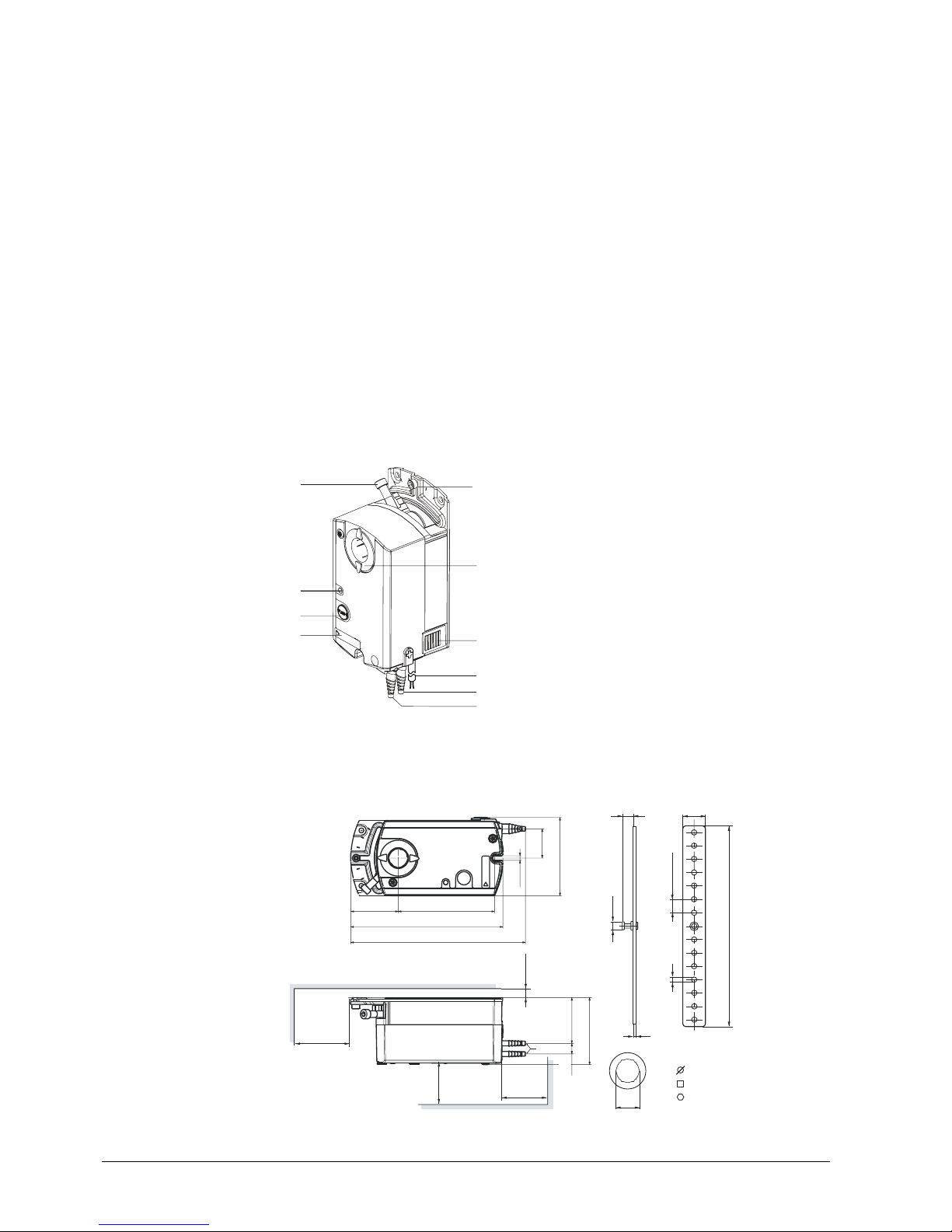

2.2 Design and device parts

The VAV compact controllers consist of a differential pressure sensor, actuator and

digitally configurable control electronics. They are intended for mounting on

damper shafts of a minimum length of 30 mm. They consist of base and 2-sectional

housing.

Components contained in the base:

∂ Steel base plate with damper drive shaft fixing for different drive shaft

diameters / cross-sectional areas (cf. section 2.3) and angular rotation limiter,

∂ maintenance-free, low-noise gear train,

∂ magnetic hysteresis clutch with practically contact-free force transmission; this

means that the actuator is locking- and overload-proof, also in continuous

operation.

Components contained in the housing (Note: the housing cover must not be

removed):

∂ Controller electronics,

∂ differential pressure sensor,

∂ synchronous motor for the damper actuator.

1 Shaft attachment screw

2 LED

3 Push button

4 Configuration and maintenance interface (below c over)

5 Connection nozz le f or m

easuring differential pressure in

the VAV box

6

Connection nozzle for measuri ng differential pressure in

the VAV box ("+": Side with higher pressure)

7 Two connecting cables (power and communications),

2-c ore each

8 Dis engagement of gear train

9 Rotation angle display

10 Rotation angle check screw

Manual control of the air dampers is possible by gear train disengagement (8)

when the VAV compact controller is disconnected from the power supply.

2.3 Dimensions

min. 100

min.

200

min. 80

min. 6

8

20

ø7

2

5

180

X

8 - 16 mm

12.8 mm

15 mm

3547M01

14 x 12

X =

4.15

71

26.5

87

158

137

Ø 3.. .8

43

41.3

61

9.6

Measures in mm

2

3

4

5

8910

3547J01

617

Main device parts

Gear train

disengagement

13 / 44

Siemens VAV compact controller KNX/PL-Link G..B181.1E/KN CE1P3547en

Building Technologies 2017-03-23

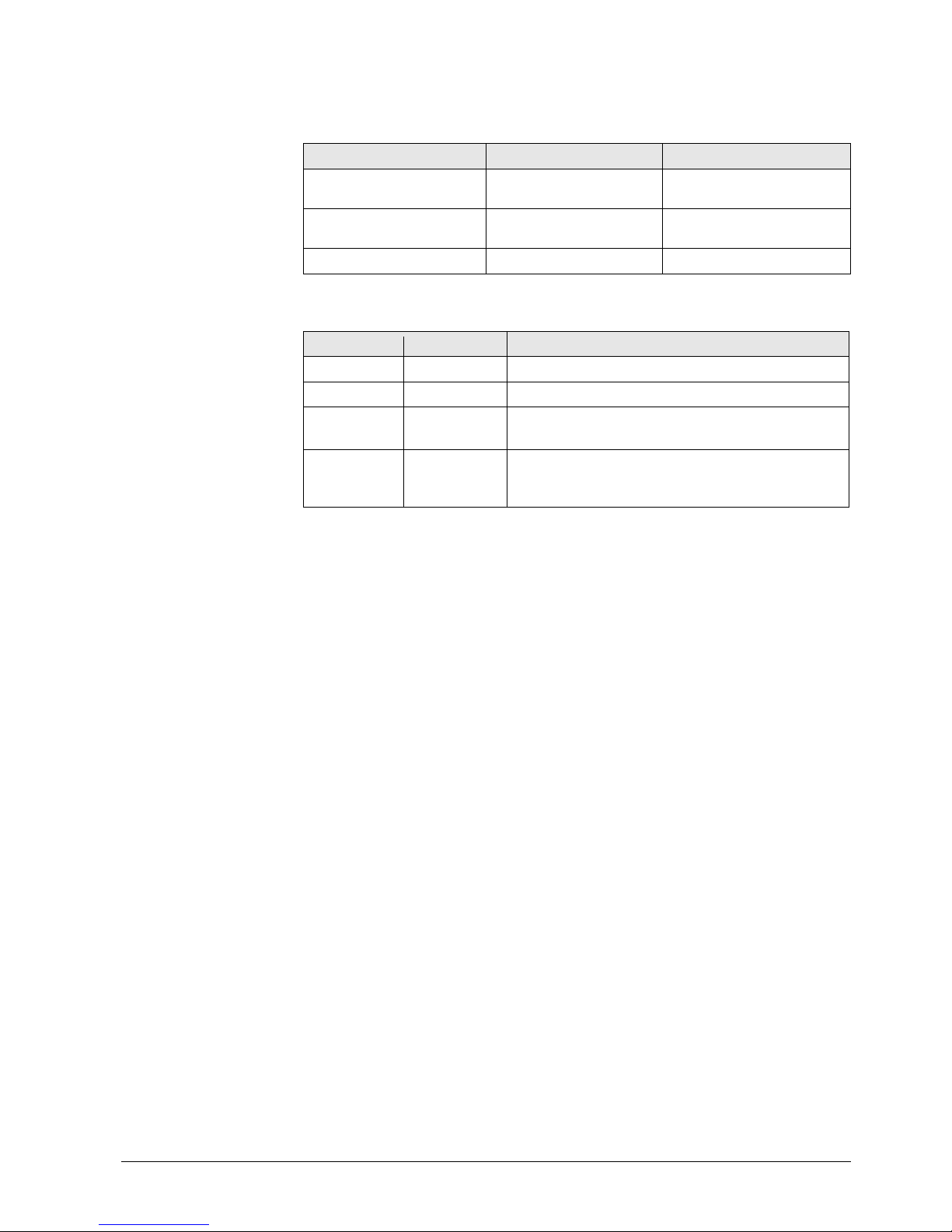

2.4 Human-machine interface

User interaction with the VAV compact controllers’ human-machine interface (HMI)

(multicolor LED and push-button) is described below, cf. also section 6.3.1.

Activity Push-but ton operation Confirmation

Enter / leave addressing

mode

Press button < 1s LED turns red or gets off

Reset to factory settings Press button > 20s LED flashes orange until

device restarts

PL-Link connection test1) Press key >2s and < 20s LED flashes 1x orange

Color

Pattern

Off --- Fault free operation or device not powered

Green steady Connection test successful

1)

Orange flashing a) Factory reset in progress

b) When a connection test was triggered: wait

1)

Red steady c) Device is in programming/addressing mode

d) When a connection test was triggered: Connection

test failed

2)

1)

Function or part of the function available in PL-Link operation only

The VAV compact controllers can be set into addressing/programming mode by

push-button:

ƒ Press push button (>0.1s and <1s)

ƒ KNX bus wiring OK ⇓ LED turns red until addressing/programming is finished

ƒ KNX bus wiring not OK ⇓ LED stays dark

The VAV compact controllers can be reset by push-button:

ƒ Press push button > 20s

ƒ LED flashes orange

ƒ Device restarts

All parameters which can be set by the OEM are reset to the OEM default values.

Push button

LED state display

Addressing and bus

test with push button

Reset with push button

14 / 44

Siemens VAV compact controller KNX/PL-Link G..B181.1E/KN CE1P3547en

Building Technologies 2017-03-23

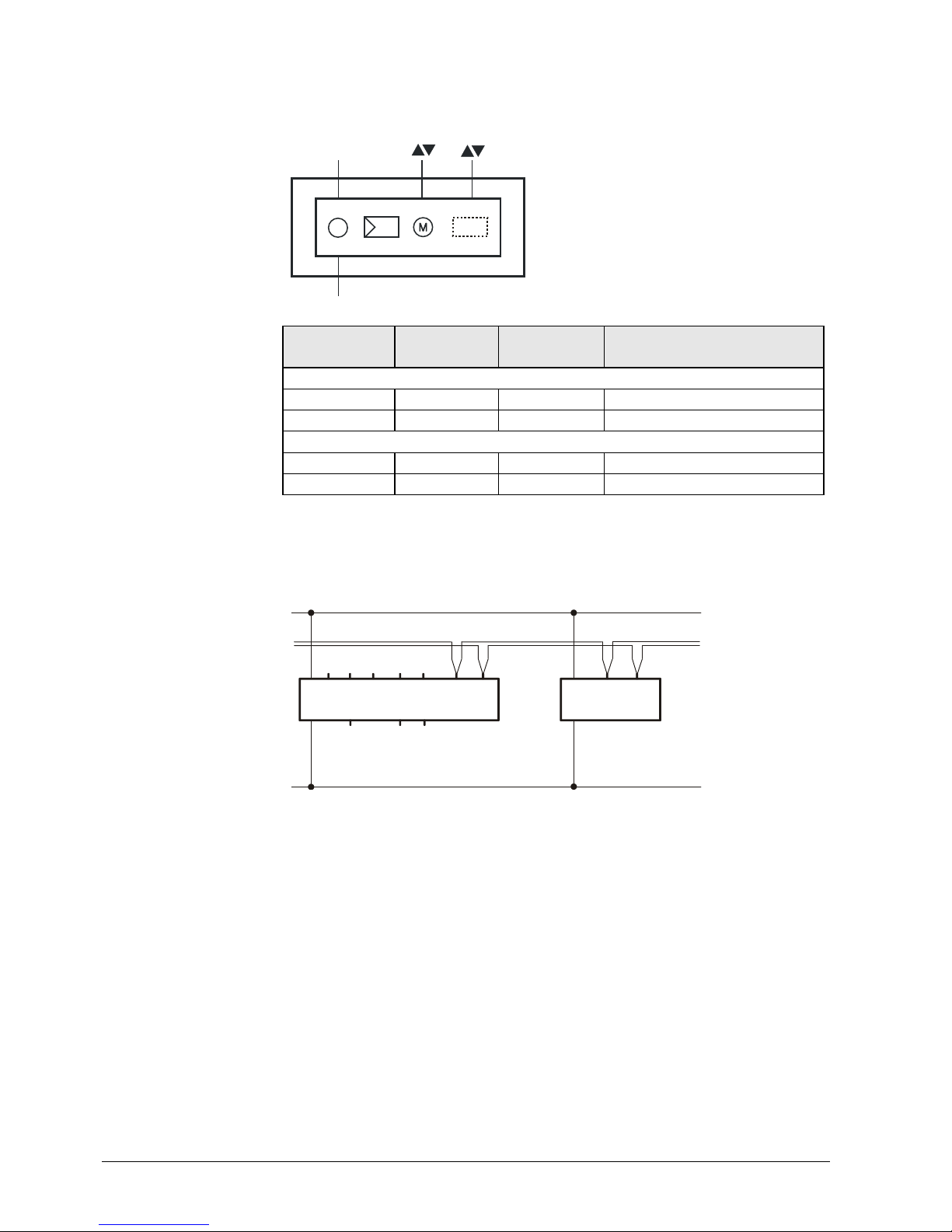

2.5 Internal diagrams

The VAV compact controllers are supplied with two prewired connecting and

communication cables.

Χp

(G) (CE+) (CE-)

1 1 2

(G0)

2

3547G01

Tool

Tool = Configuration and maintenance interf ace

(Series E and newer: 7-pin)

Core

designation

Core color

Terminal

code

Description

Cable 1: Power / black sheathing

1 red (RD) G System voltage AC 24 V

2 black (BK) G0 System neutral AC 24 V

Cable 2: Bus / green sheathing

1 red (RD) CE+ Bus (KNX / PL-Link)

2 black (BK) CE- Bus (KNX / PL-Link)

The VAV compact controllers are connected to the bus as KNX devices according

to the KNX-TP1 standard. KNX-specific limitations regarding cable length, power

supply, number of attachable devices, and distances apply. For more details please

refer to [13] and [16] or to the KNX standard.

N1 G..B181.1E/KN

N2 RDG400KN (Example for a VAV enabled room unit)

Terminal layout may differ for each device. Devices with twin-terminals or internally

connected terminals may be encountered as well as bus connection in junction

boxes. Please refer to the technical basic documentation for product specific

information.

∂ The operating voltage at terminals G and G0 must comply with the

requirements under SELV or PELV.

∂ Safety transformers with twofold insulation as per EN 61558 required; they

must be designed to be on 100 % of the time.

G

CE+

CE-

G0

N1

3547A01

G

CE+

CE-

G0

X1M U1 D1 GND

Y10 Y1 Y2

N2

Internal diagram

(Applies to all types)

Power supply and bus

cable (color coded and

labeled)

Wiring diagram VAV

Connection to the KNX

TP1-Bus

Note

Loading...

Loading...