Siemens OP7,OP17 Equipment Manual

RGB ELEKTRONIKA AGACIAK CIACIEK

SPÓŁKA JAWNA

Jana Dlugosza 2-6 Street

51-162 Wrocław

Poland

biuro@rgbelektronika.pl

+48 71 325 15 05

www.rgbautomatyka.pl

www.rgbelektronika.pl

DATASHEET

www.rgbautomatyka.pl

www.rgbelektronika.pl

OTHER SYMBOLS:

6AV3617-1JC20-0AX1 COVER

SIEMENS

YOUR

PARTNER IN

MAINTENANCE

At our premises in Wrocław, we have a fully equipped servicing facility. Here we perform all the repair

works and test each later sold unit. Our trained employees, equipped with a wide variety of tools and

having several testing stands at their disposal, are a guarantee of the highest quality service.

OUR SERVICES

ENCODERS

SERVO

DRIVERS

LINEAR

ENCODERS

SERVO AMPLIFIERS

CNC

MACHINES

MOTORS

POWER

SUPPLIERS

OPERATOR

PANELS

CNC

CONTROLS

INDUSTRIAL

COMPUTERS

PLC

SYSTEMS

Repair this product with RGB ELEKTRONIKA

ORDER A DIAGNOSIS

∠

Buy this product at RGB AUTOMATYKA

BUY

∠

SIMATIC HMI

Preface, Contents

1

Part I Introduction

2

3

Part II Basic Functions

OP7, OP17

Operator Panel

Equipment Manual

10

11

Part III Expanded, Configurable

Functions

13

14

Part IV Commissioning and

Description of Devices

16

A

Part V Appendix

F

Glossary, Index

6AV3991–1AE05–1AB0

Release 04/99

Safety

Guidelines

!

!

This manual contains notices which you should observe to ensure your own personal safety, as

well as to protect the product and connected equipment. These notices are highlighted in the

manual by a warning triangle and are marked as follows according to the level of danger:

Warning

indicates that death, severe personal injury or substantial property damage can result if proper

precautions are not taken.

Caution

indicates

that minor personal injury or property damage can result if proper precautions are not

taken.

Note

draws

your attention to particularly important information on the product, handling the product, or

to a particular part of the documentation.

Qualified Personnel

Correct Usage

!

Trademarks

Equipment

may be commissioned and operated only by

qualified

personnel

. Qualified personnel

within the meaning of the safety notices in this manual are persons who are authorized to commis

sion, ground and identify equipment, systems and circuits in accordance with safety engineering

standards.

Note the following:

Warning

The equipment may be used only for the applications stipulated in the catalog and in the techni-

cal description and only in conjunction with other equipment and components recommended or

approved by Siemens.

must not take place until it is established that the machine, which is to accommodate this

Startup

component, is in conformity with the guideline 89/392/EEC.

Faultless and safe operation of the product presupposes proper transportation, proper storage,

erection and installation as well as careful operation and maintenance.

SIMATIC is a registered trademark of Siemens AG.

Some of the other designations used in these documents are also registered trademarks; the

owner’s rights may be violated if they are used be third parties for their own purposes.

-

Impressum

Copyright

The reproduction, transmission or use of this document or its

contents is not permitted without express written authority.

Offenders will be liable for damages. All rights, including rights

created

reserved.

Siemens

Automation & Drives

SIMA

TIC Human Machine Interface

Postfach 4848,

Siemens Aktiengesellschaft

Siemens

by patent grant

AG,

D-90327 Nuernberg

AG 1996 All rights reserved

or registration of a utility model or design, are

Editor and Publisher: A&D PT1

Disclaimer of Liability

We

have checked the contents of this manual for agreement with

hardware

cluded

data

rections

ment

T

Order No. 6A

Equipment

and software described. Since deviations cannot be pre

entirely

in this manual

are welcomed.

echnical data subject to change.

Siemens

, we cannot guarantee full agreement. However

are reviewed regularly and any necessary cor

included in subsequent editions. Suggestions for improve

AG 1996

V3991–1AE05–1AB0

Manual OP7, OP17

the

-

, the

-

-

Preface

Guide through the

manual

The

“OP7, OP17 Operator Panel” equipment manual is divided into five

parts:

Part Chapter Contents

Conventions

1

Appendix

The following conventions are used in this manual:

Motor off Text

Variable

Screens

1 – 2

3 – 10 Step-by-step instructions on how you control the

1 – 13

14 – 16

A – F

Overview of the OPs and their range of func

tions.

OPs with the standard screens.

Expanded functions of the OPs (online changes

to system settings, PLC jobs and the scheduler).

–

Mechanical and electrical installation

– Commissioning

–

Detailed information about the OPs and their

maintenance

Contains general tables and a list of the techni

cal terms used in this manual.

on the display of the OP is shown in

“typewriter” style.

Symbolic names representing variable values on the

display are shown in italic ”typewriter” style.

Functions which you can choose are shown in

normal italics.

-

-

Equipment

Release 04/99

Manual OP7, OP17

Scr

eens →Print

ESC

Steps that are performed in succession are linked by

an arrow

The names of keys are shown in a dif

.

ferent typeface.

i

Preface

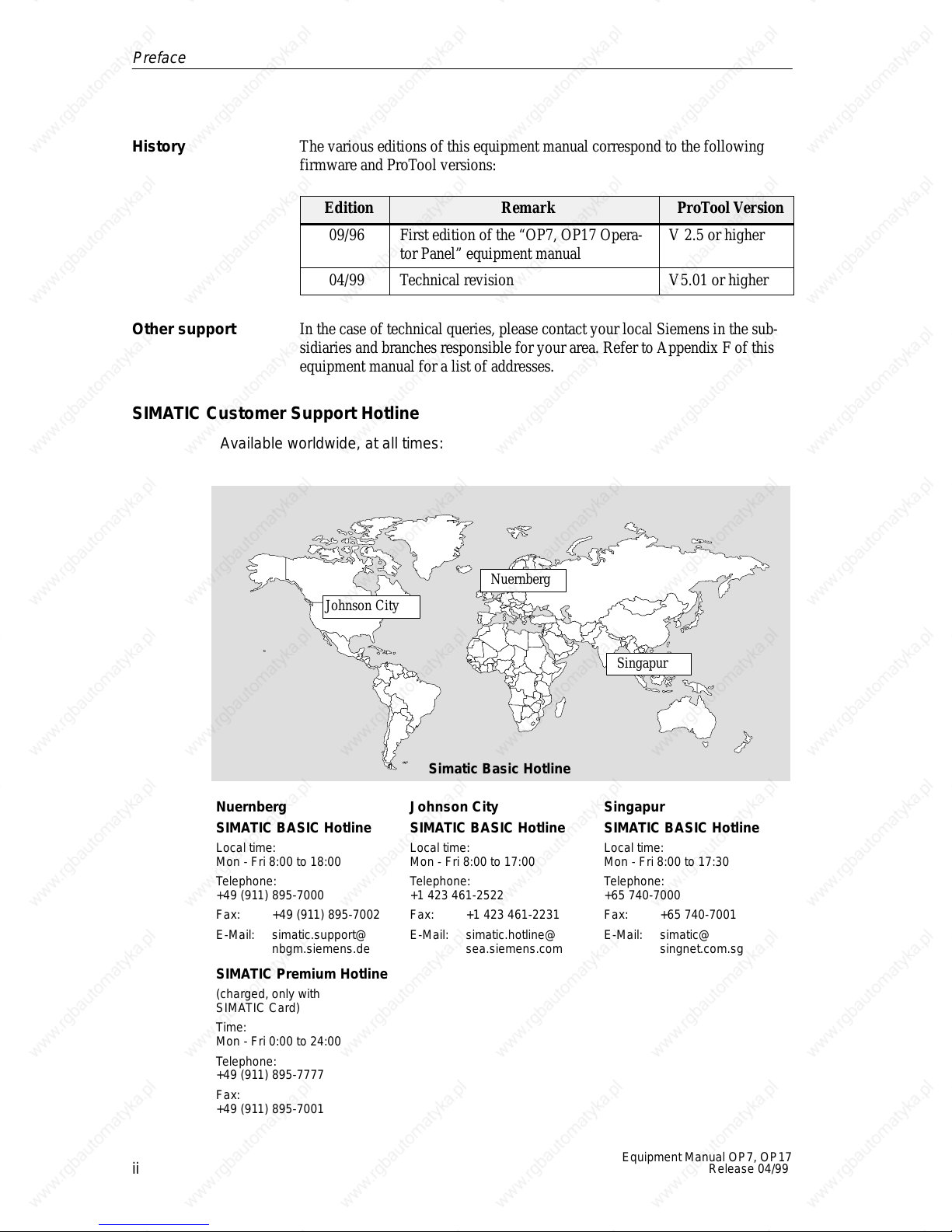

History

The

various editions of this equipment manual correspond to the following

firmware and ProT

ool versions:

Edition Remark ProT

09/96

First edition of the “OP7, OP17 Opera

tor Panel” equipment manual

04/99 T

Other support

In the case of technical queries, please contact your local Siemens in the sub

sidiaries and branches responsible for your area. Refer to Appendix F of this

equipment manual for a list of addresses.

SIMATIC Customer Support Hotline

Available

worldwide, at all times:

Johnson City

echnical revision

Nuernberg

-

V 2.5 or higher

V5.01 or higher

ool V

ersion

-

Nuernberg

SIMATIC BASIC Hotline

Local

time:

Mon - Fri 8:00 to 18:00

T

elephone:

+49 (911) 895-7000

Fax:

E-Mail: simatic.support@

SIMATIC

(charged,

SIMA

T

ime:

Mon - Fri 0:00 to 24:00

T

elephone:

+49 (911) 895-7777

Fax:

+49 (911) 895-7001

+49 (911) 895-7002

nbgm.siemens.de

Premium Hotline

only with

TIC Card)

Simatic

Basic Hotline

Johnson City

SIMATIC BASIC Hotline

Local time:

Mon - Fri 8:00 to 17:00

T

elephone:

+1 423 461-2522

Fax:

E-Mail: simatic.hotline@

+1 423 461-2231

sea.siemens.com

Singapur

Singapur

SIMATIC BASIC Hotline

Local time:

Mon - Fri 8:00 to 17:30

T

elephone:

+65 740-7000

Fax:

E-Mail: simatic@

+65 740-7001

singnet.com.sg

ii

Equipment

Manual OP7, OP17

Release 04/99

SIMATIC Customer Online Services

Preface

SIMATIC

concerning SIMA

Up–to–date

Abbreviations

Customer Support of

fers comprehensive additional information

TIC products through its Online services as follows:

general information is provided

–

in

–

Internet

via

Fax-Polling

under

http://www.ad.siemens.de/simatic

under 08765-93 02 77 95 00

Up–to–date product information and downloads for practical use can be found:

–

in

Internet

unter

http://www.ad.siemens.de/support/

html–00/

–

via the

Bulletin Board System

mer Support Mailbox)

In

order to contact the mailbox, please use a modem with up to 28.8

kBaud (V

.34) capacity

under

. Set the parameters as follows: 8, N, 1, ANSI,

(BBS) in Nürnber

g (

SIMA

+49 (911) 895–7100

TIC Custo

or dial for connection via ISDN (x.75, 64 kBit).

The abbreviations used in this equipment manual have the following mea

nings:

AM

AS 51

ASCII

1

Alarm message

Protocol of the PU interface to the SIMA

TIC S5

American Standard Code für Information Interchange

-

-

CPU

EEPROM

EM

FB

HMI

IF

LCD

LED

MPI

OP

PLC

PPI

PU

RAM

TD T

TP T

Central Processing Unit

Electrically erasable programmable read-only memory

Event message

Function block

Human Machine Interface

Interface designation

Liquid-crystal display

Light-emitting diode

Multitpoint Interface

Operator Panel

Programmable Logic Controller

Point to Point Interface

Programming Unit (German abbreviation: PG)

Random access memory (working memory)

ext Display

ouch Panel

Equipment

Release 04/99

Manual OP7, OP17

iii

Preface

iv

Equipment

Manual OP7, OP17

Release 04/99

Contents

Part I Introduction

1 Product

1.1 Configuration

1.2 Visualizing

1.3 Design

1.4 Design

2 Functionality 2-1

Description

of Operator Panel OP7

of Operator Panel OP17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

and process control phases

and controlling processes

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1.

1-1.

1-3.

1-6.

1-8.

Part II Basic Functions

3 General

3.1 Integrated

3.1.1 System

3.2 Entering Values 3-6.

3.2.1 Entering

3.2.2 Entering

3.2.3 Entering

3.2.4 Entering T

3.3 Help Text 3-14.

4 Using the OP with Its Standard Functions 4-1.

Operation

Keys

Numerical V

Alphanumeric V

Symbolic V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

keyboard

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

imer V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

alues 3-7.

alues 3-11.

alues 3-12.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

alues 3-8.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1.

3-1.

3-2.

4.1 Operating

4.2 Standard

4.3 Branching

5 Screens 5-1

5.1 Screen

5.2 Selecting

5.3 Editing

5.4 Printing

6 Password

6.1 Password

6.2 Logging-in

6.3 Password

Equipment Manual OP7, OP17

Release 04/99

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Protection

Levels

Screens

in Standard Screens

Entries

Screens

Screens

Screens

Levels and Access

and logging-out on the OP (LOGIN/LOGOUT)

Management

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . .

4-1.

4-3.

4-5.

5-2.

5-3.

5-4.

5-4.

6-1.

6-1.

6-3.

6-4.

v

7 Messages 7-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Message

7.1.1 Event

7.1.2 Alarm

7.1.3 System

7.2 Displaying

7.2.1 Display

7.2.2 Scrolling

7.2.3 Viewing

7.3 Message

7.4 Deleting

7.4.1 Deleting

7.4.2

Deleting alarm and event messages via standard screens

7.4.3 Automatically

7.5

Printing Messages

7.5.1 Direct

7.5.2 Printing

8 Recipes 8-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Creating

8.2 Copying

8.3 Transferring

types

and alarm messages

messages

messages

Messages

Sequences

through W

Event and Alarm Message T

Buf

Messages

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

aiting Messages at Message Level

ext 7-9.

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

fers 7-10.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

alarm message and event message buf

Deleting the System Message Buf

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message Logging

the Message Buf

and Editing Data Records

Data Records

Data Records

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

fer 7-15.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

fers upon buffer overflow

. . . . . . . . . . . .

fer upon Buf

fer Overflow

7-2.

7-2.

7-4.

7-6.

7-7.

7-8.

7-8.

7-12.

7-12

7-13.

7-13

7-14.

7-14.

8-4.

8-6.

8-7.

8.4 Deleting

Data Records

9 STATUS/FORCE VAR with the OP

9.1 FORCE VAR 9-2.

10 System Settings 10-1.

10.1 Selecting

10.2 Modifying

10.3 Adjusting

10.4 Setting

OP Modes

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

a Language

Parameters in Online Mode

Contrast

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-10.

9-1.

10-1.

10-2.

10-4.

10-5.

vi

Equipment Manual OP7, OP17

Release 04/99

Part III Expanded, Configurable Functions

11 Process-Dependent

11.1 Branching

11.2 Self-Defined

12 Schedulers

13 Controlling

(OP17 only)

the OP from the PLC

Operator Guidance

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

by Means of Soft Keys and Function Keys

Screen Hierarchy

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

11-1.

11-1.

11-3.

12-1.

13-1.

Part IV Commissioning and Description of Devices

14 Installation 14-1.

14.1 Mechanical

14.2 Electrical

14.2.1 Connecting

14.2.2 Connecting

14.2.3 Connections

14.2.4 Loop-Through

14.2.5 Connecting

15 Commissioning 15-1

15.1 Initial

15.2 Recommissioning 15-4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation

Installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the Power Supply

a Configuration Computer

to PLC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mode (OP17 only)

a Printer

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14-2.

14-3.

14-4.

14-5.

14-6.

14-8.

14-9.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

commissioning

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15-3.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.3 Start-up

15.4 Testing

15.5 Testing

15.6 Testing

16 Device

Description

16.1 OP7 16-1

16.2 OP17 16-3

16.3 Labeling

16.4 Optional

16.5 Maintenance 16-9

Behavior

the Configuration in OFFLINE Mode

the Configuration in Conjunction with the PLC

Communication via the PROFIBUS-DP

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

of the Function Keys

Backup Battery for the OP17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15-5.

15-6.

15-7.

15-8.

16-1.

16-5.

16-8.

Equipment Manual OP7, OP17

Release 04/99

vii

Part V Appendix

A Brief

B System

C Technical

D Interface

E SIMATIC

Description of Standard Screens

Messages

Data

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assignment

HMI Documentation

F Siemens Worldwide F-1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A-1.

B-1.

C-1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D-1.

E-1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii

Equipment Manual OP7, OP17

Release 04/99

Part

I

Introduction

Product Description

Functionality

1

2

2-2

Equipment

Manual OP7, OP17

Release 04/99

Product Description

1

Applications of

OP7 and OP17

Operator

and malfunctions of a connected PLC to be visualized. In addition, inputs can

be made on the OP which can be written directly to the PLC. Some functions

relating to machine diagnostics can also be executed on the Operator Panel.

The Operator Panels feature a number of standard functions. The displays

and operation of the devices can be optimized by the configurer to meet the

requirements of the process.

The Operator Panels are suitable for fitting into switching cabinets and con

trol desks. A printer can be attached to the OP for logging processes during

automation operation.

1.1 Configuration

Creating data

areas

Before

visualizing data from the PLC, i.e. it has to be configured. As far as the PLC

is concerned, data areas used by the OP to communicate with the PLC have

to be created in the memory

Panels OP7 and OP17 allow operating states, current process values

-

and process control phases

an OP can go into service, it has to be prepared for its job of

.

Configuration with

ProTool

Equipment Manual OP7, OP17

Release 04/99

The configuration for the OP is created on a computer (PC/PU) using

ProT

ool configuration software under Microsoft W

configuration is ready, it is transferred to the OP

however

transfer of the configuration, the OP has to be connected to the PLC.

The OP now communicates with the PLC and reacts to program flows on the

PLC on the basis of the configured requirements.

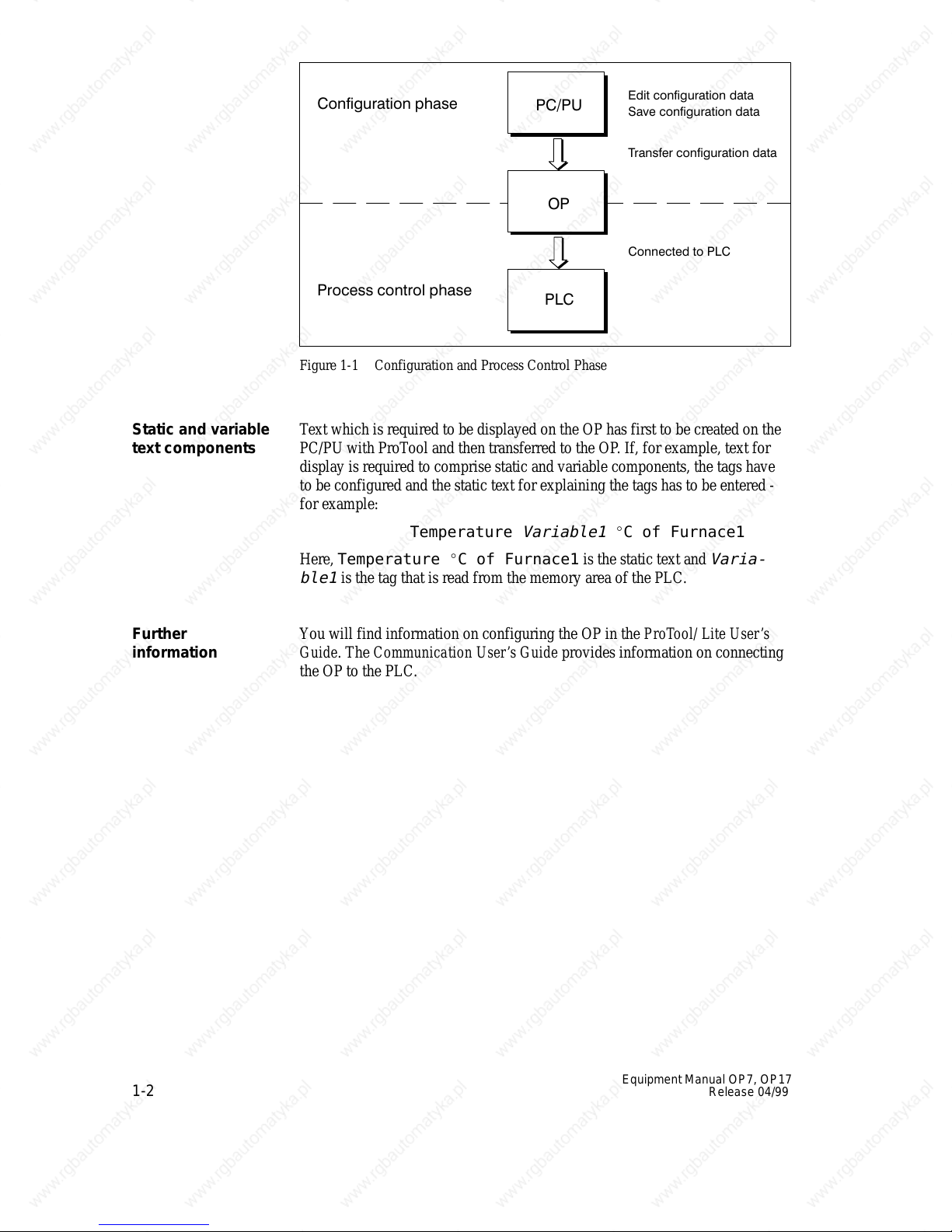

figure 1-1 depicts the configuration and process control phases described

above:

, the computer has to be connected to the Operator Panel. Following

indowsTM. When the

. Before this can be done,

1-1

Static

and variable

text components

Further

information

Figure 1-1 Configuration and Process Control Phase

Text

which is required to be displayed on the OP has first to be created on the

PC/PU with ProT

ool and then transferred to the OP

. If, for example, text for

display is required to comprise static and variable components, the tags have

to be configured and the static text for explaining the tags has to be entered -

for example:

Temperature

Here,

Temperature C of Furnace1

ble1

is the tag that is read from the memory area of the PLC.

Y

ou will find information on configuring the OP in the

Guide

. The

Communication User’s Guide

Variable1

C of Furnace1

is the static text and

ProT

ool/ Lite User

provides information on connecting

Varia-

’s

the OP to the PLC.

1-2

Equipment

Manual OP7, OP17

Release 04/99

1.2 Visualizing and controlling processes

The

Display and

control functions

basic functions of an OP consist in displaying process states and in con

trolling the process. The following display and control functions can be con

figured on Operator Panels OP7 and OP17:

screens

event messages

alarm messages

recipes

help text

logging

languages

schedulers for the OP17

-

-

Screens

Event messages

Data supplied by the PLC may be displayed together on a screen and modi

fied individually

since, for example, more related data are required for describing a machine

state than can normally be displayed in the window of a screen. Therefore

data on operating temperature, fill level, speed and running time can illus

trate the current machine state.

The OP7 and OP17 are Operator Panels with text based displays. Accordin

gly

, a screen on the display comprises text items which may include static

text and current state values.

Screens may be combined on the OP in a directory

to display

Event messages are information and operating notes on current machine and

process states during regular production operations. Event messages may

contain process values. Process values are displayed either numerically - for

example,

Motor running at 3000 revs

or

symbolically - for example,

Motor running normally,

where

a specific control value is assigned to

, if required. A screen consists of several screen entries

. Y

ou can use the directory

, print and edit screens.

normally.

-

-

-

The classification of a message as an event message is done at the configura

tion stage.

Equipment

Release 04/99

Manual OP7, OP17

-

1-3

Alarm

messages

Alarm

messages show

dur ing production operations. Due to their ur

, in contrast to event messages, critical machine states

gency

, they have to be acknowl

edged before any other action is possible.

Alarm messages may contain process values. Process values are displayed

either numerically - for example

Motor speed 4500

or

symbolically - for example

Motor speed too high,

where

a specific control value is assigned to

This

type of message has a higher display priority than an event message. If

too high.

an alarm message is issued, any event message or screen that is being dis

played is replaced with a flashing alarm on the display

.

-

-

Recipes

Help text

The classification of a message as an alarm message is made at the configu

-

ration stage.

When a product is made up of various ingredients in certain ratios, this infor

mation is stored in a so-called recipe.

T

ake orange juice for example. Its production and bottling requires that

orange concentrate and water be mixed in a certain ratio. These values are

stored as tags in a recipe.

Each recipe can be made up of several data records containing dif

ferent va

-

lues for the recipe.

The data can be edited in the OP

, transferred to the PLC and read out from

the PLC.

In the OP

, the recipes are combined by recipe number and title in a recipe

directory.

Help text consists of configurable additional information and operator in

structions relating to event messages, alarm messages and screens. If for ex

-

-

ample an alarm message arises, this enables additional information on how to

eliminate faults to be displayed.

Help text can also be displayed by pressing a key

HELP

LED is on.

, if required, when the

-

Logging

Messages can be printed in online mode by means of the printer connected to

the OP

messages that have accumulated in the buf

1-4

. Furthermore, there is a possibility of printing all the event and alarm

fer concerned.

Equipment

Manual OP7, OP17

Release 04/99

Multilinguality

Message

several languages. Up to three of the languages listed below can be loaded

simultaneously on the same OP and presented to the operator for selection on

line:

text, screens, help text and system messages may be displayed in

German

English

French

Italian

Spanish

Russian (Cyrillic characters).

Schedulers

A scheduler is a regularly recurring point in time (i.e., hourly

annually) at which a certain function is to be executed. When a scheduler

time is reached, the configured bit is set in the interface area of the PLC and

the configured function is executed.

The following functions are available:

Print alarm message buf

Print event message buf

Select screen

Print screen

Print data record

fer

fer

, daily

, weekly

,

Equipment

Release 04/99

Manual OP7, OP17

1-5

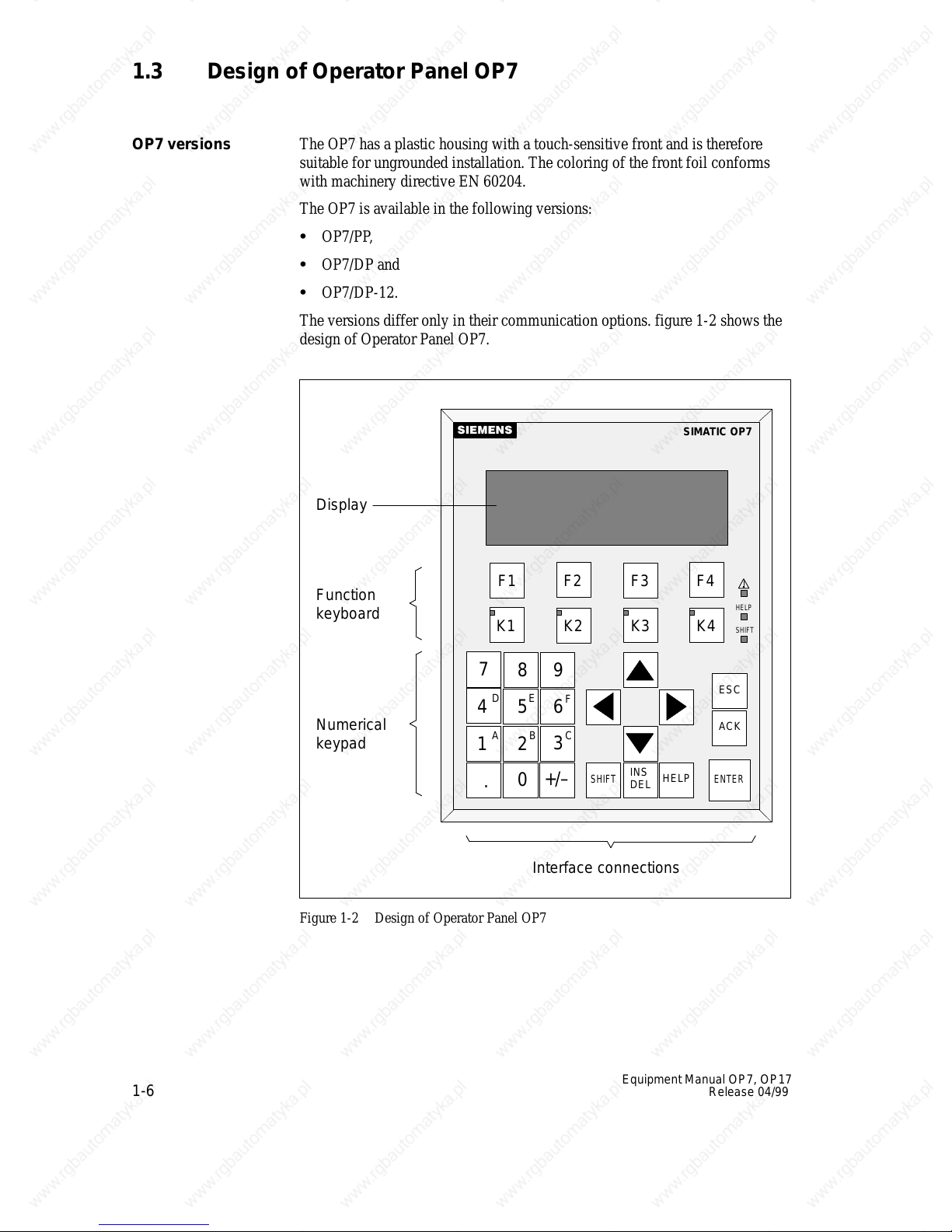

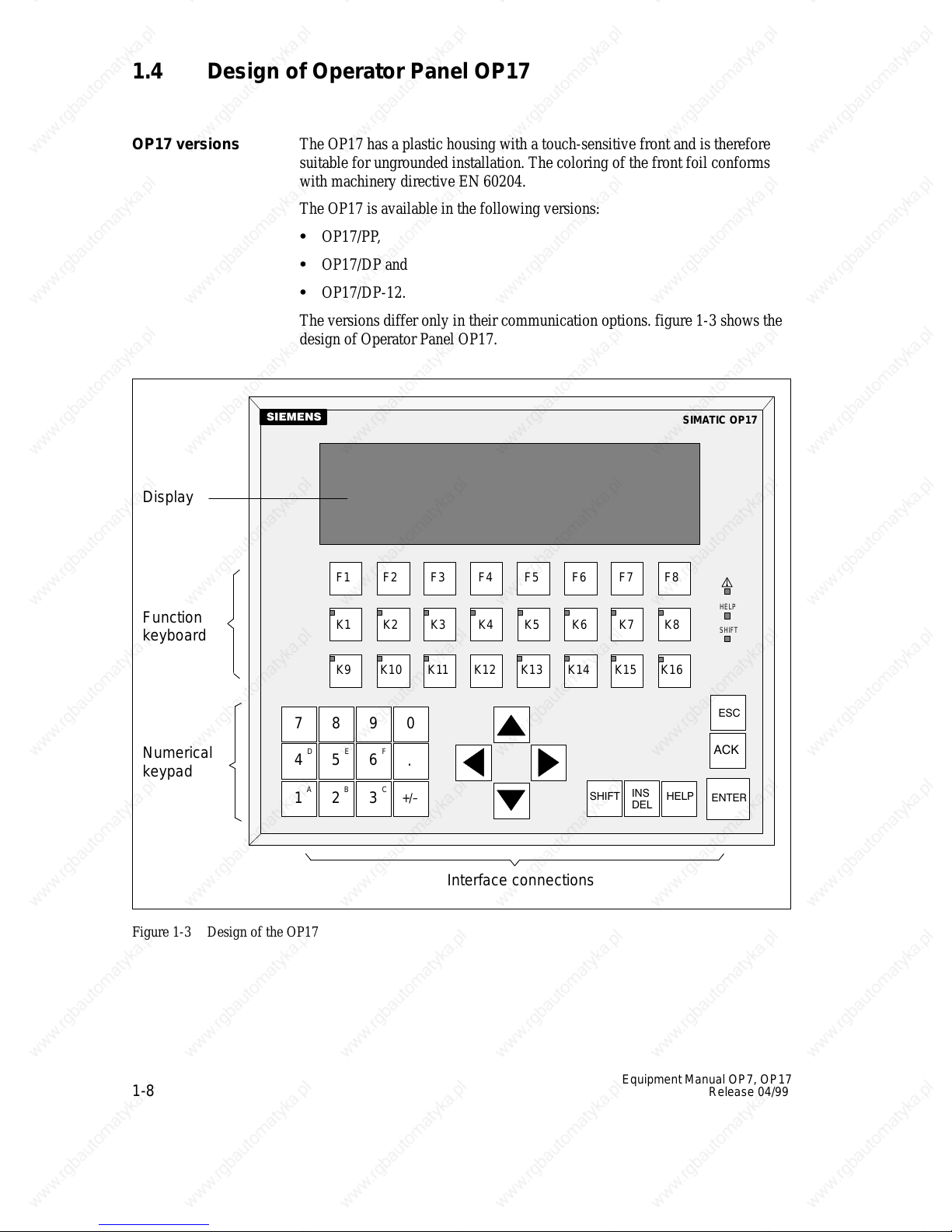

1.3 Design of Operator Panel OP7

The

OP7

versions

OP7 has a plastic housing with a touch-sensitive front and is therefore

suitable for ungrounded installation. The coloring of the front foil conforms

with machinery directive EN 60204.

The OP7 is available in the following versions:

OP7/PP,

OP7/DP and

OP7/DP-12.

The versions dif

fer only in their communication options. figure 1-2 shows the

design of Operator Panel OP7.

Display

Function

keyboard

456

Numerical

keypad

1

F1

F2 F3 F4

K1 K2 K3 K4

7

D

A

.

9

8

E

BC

3

2

+/–

0

F

SHIFT

INS

DEL

HELP

SIMA

TIC OP7

HELP

SHIFT

ESC

ACK

ENTER

Figure 1-2 Design of Operator Panel OP7

1-6

Interface

connections

Equipment

Manual OP7, OP17

Release 04/99

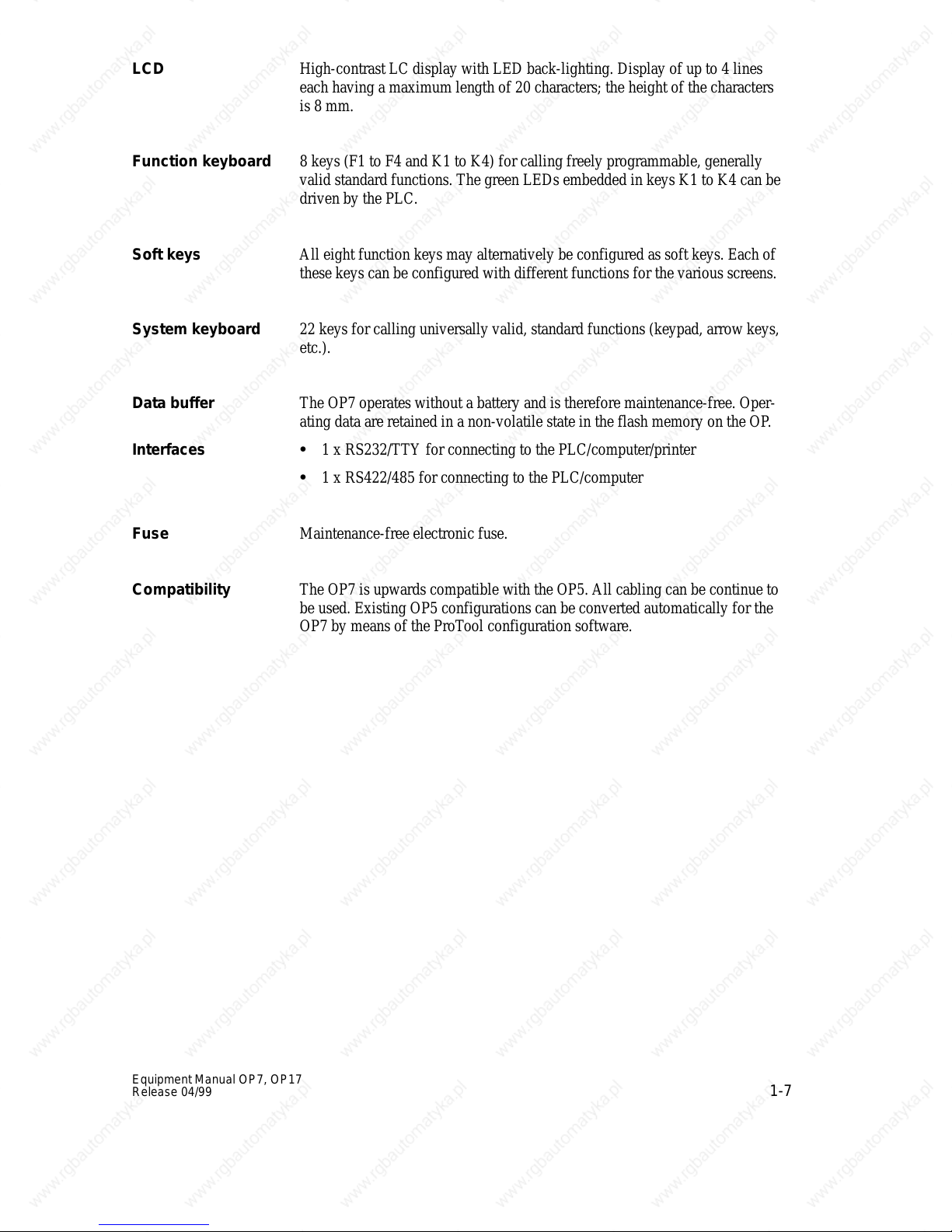

LCD

High-contrast

LC display with LED back-lighting. Display of up to 4 lines

each having a maximum length of 20 characters; the height of the characters

is 8 mm.

Function

keyboard

Soft keys

System keyboard

Data buffer

Interfaces

Fuse

Compatibility

8 keys (F1 to F4 and K1 to K4) for calling freely programmable, generally

valid standard functions. The green LEDs embedded in keys K1 to K4 can be

driven by the PLC.

All eight function keys may alternatively be configured as soft keys. Each of

these keys can be configured with dif

ferent functions for the various screens.

22 keys for calling universally valid, standard functions (keypad, arrow keys,

etc.).

The OP7 operates without a battery and is therefore maintenance-free. Oper

ating data are retained in a non-volatile state in the flash memory on the OP

1 x RS232/TTY for connecting to the PLC/computer/printer

1 x RS422/485 for connecting to the PLC/computer

.

Maintenance-free electronic fuse.

The OP7 is upwards compatible with the OP5. All cabling can be continue to

be used. Existing OP5 configurations can be converted automatically for the

OP7 by means of the ProTool configuration software.

-

Equipment

Release 04/99

Manual OP7, OP17

1-7

1.4 Design of Operator Panel OP17

The

OP17

versions

OP17 has a plastic housing with a touch-sensitive front and is therefore

suitable for ungrounded installation. The coloring of the front foil conforms

with machinery directive EN 60204.

The OP17 is available in the following versions:

OP17/PP,

OP17/DP and

OP17/DP-12.

Display

Function

keyboard

Numerical

keypad

The versions dif

fer only in their communication options. figure 1-3 shows the

design of Operator Panel OP17.

F1 F2 F3 F4 F5 F6 F7 F8

K1 K2 K3 K4 K5 K6 K7 K8

K9 K10 K11 K12 K13 K14 K15 K16

7 0

8

9

D

E

4

5

A

2

1

F

6

.

B

C

+/–

3

SIMA

TIC OP17

HELP

SHIFT

Figure 1-3 Design of the OP17

1-8

Interface

connections

Equipment

Manual OP7, OP17

Release 04/99

LCD

High-contrast

LC display with LED back-lighting. The following displays

can be configured:

4 lines each of 20 characters; height of characters is 1

8 lines each of 40 characters; height of characters is 6 mm.

1 mm

Function

keyboard

Softkeys

System keyboard

Data buffer

Interfaces

24 keys (F1 to F8 and K1 to K16) for calling freely configurable functions.

The two-color LEDs (red/green) embedded in keys K1 to K16 can be driven

by the PLC.

16 function keys (F1 to F8 and K1 to K8) can be used as function keys too.

Soft keys can be configured with functions which vary from screen to screen.

22 keys for calling universally valid, standard functions (keypad, arrow keys,

etc.).

The OP7 operates without a battery and is therefore maintenance-free. Oper

ating data are retained in a non-volatile state in the flash memory on the OP

The message buf

turned of

f.

fer is backed up for several hours after the power supply is

.

The internal hardware clock has reserve power for several days after the

power supply is turned of

f.

The OP17 can be optionally upgraded with a lithium battery. The battery is

not supplied with OP as a standard component.

1 x RS232/TTY active, for connecting to the PLC/computer/printer

1 x RS232/TTY passive, for connecting to the PLC/computer/printer

-

Fuse

Compatibility

Equipment

Release 04/99

Manual OP7, OP17

1 x RS422/485 for connecting to the PLC/computer

Maintenance-free electronic fuse.

The OP17 is upwards compatible with the OP15/C. All cabling can be con

tinue to be used. Existing OP15/C configurations can be converted automati

cally for the OP17 by means of the ProTool configuration software.

-

-

1-9

1-10

Equipment

Manual OP7, OP17

Release 04/99

Functionality

g

g

gq

gp

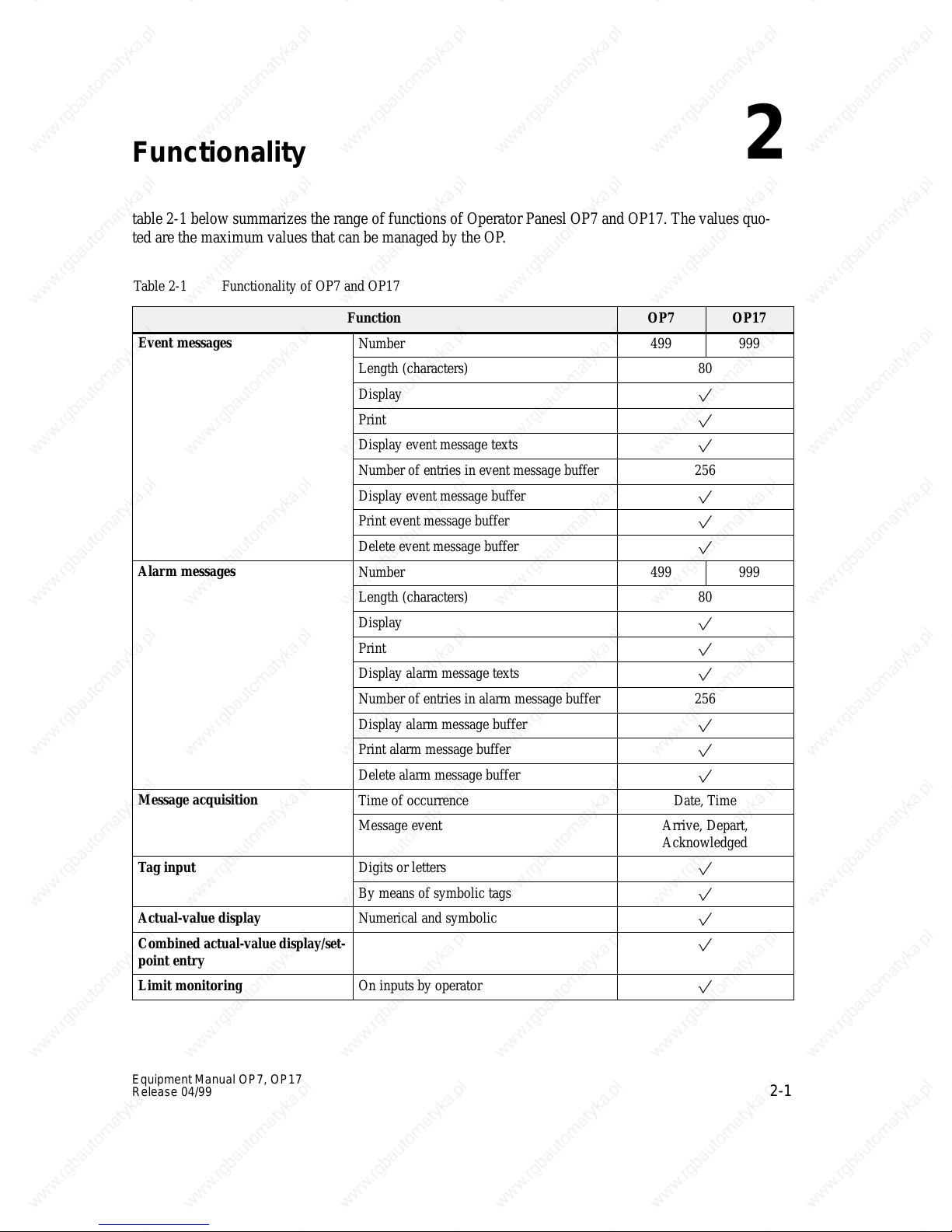

table

2-1 below summarizes the range of functions of Operator Panesl OP7 and OP17. The values quo

ted are the maximum values that can be managed by the OP

Table 2-1 Functionality of OP7 and OP17

Function OP7 OP17

Event messages

Alarm messages

Message acquisition

Tag input

Actual-value display Numerical and symbolic

Combined

point entry

Limit monitoring On inputs by operator

actual-value display/set

Number 499 999

Length (characters) 80

Display

Print

Display event message texts

Number of entries in event message buffer 256

Display event message buffer

Print event message buffer

Delete event message buffer

Number 499 999

Length (characters) 80

Display

Print

Display alarm message texts

Number of entries in alarm message buffer 256

Display alarm message buffer

Print alarm message buffer

Delete alarm message buffer

Time of occurrence Date, Time

Message event Arrive, Depart,

Digits or letters

By means of symbolic tags

-

.

Acknowledged

2

-

Equipment

Release 04/99

Manual OP7, OP17

2-1

Table 2-1 Functionality of OP7 and OP17, continued

p

p

y

OP17OP7Function

Password protection

Number of passwords 50

Password levels 9 (1..9)

Screens

Number 99

Display

Print

Screen entries per screen 99

Number of fields per screen 300

Number of fields per screen entry 32

Recipes

Number 99

Display

Print

Recipe entries per recipe 99

Recipe memory size (kbytes) 4 20

Data records per recipe 99

Store/retrieve data record in/from OP

Help text Length (characters) 320

Schedule times – 48

Function keys

Number 8 24

Of which can be configured as soft keys 8 16

Integrated LEDs 4 16

Reports

Diagnostics function STATUS/FORCE VAR

Loop-through operation for con-

figuration computer

Configurable OP languages German, English,

French, Italian,

Spanish, Russian

(Cyrillic characters)

Online language change Number of languages 3

2-2

Equipment

Manual OP7, OP17

Release 04/99

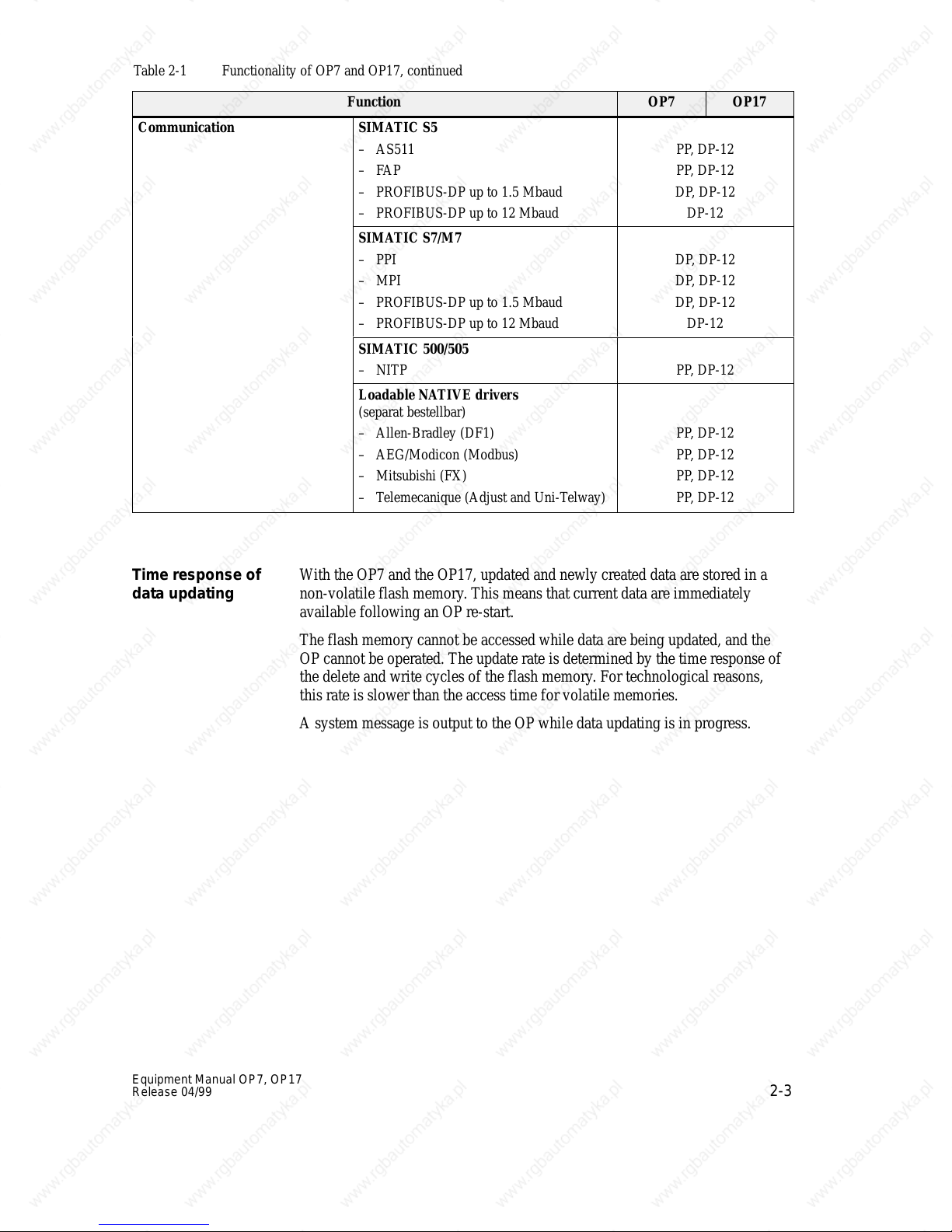

Table 2-1 Functionality of OP7 and OP17, continued

Communication

SIMATIC S5

– AS511

–FAP

– PROFIBUS-DP up to 1.5 Mbaud

– PROFIBUS-DP up to 12 Mbaud

SIMATIC S7/M7

– PPI

– MPI

– PROFIBUS-DP up to 1.5 Mbaud

– PROFIBUS-DP up to 12 Mbaud

SIMATIC 500/505

– NITP

Loadable NATIVE drivers

(separat bestellbar)

– Allen-Bradley (DF1)

– AEG/Modicon (Modbus)

– Mitsubishi (FX)

– Telemecanique (Adjust and Uni-Telway)

OP17OP7Function

PP, DP-12

PP, DP-12

DP, DP-12

DP-12

DP, DP-12

DP, DP-12

DP, DP-12

DP-12

PP, DP-12

PP, DP-12

PP, DP-12

PP, DP-12

PP, DP-12

Time response of

data updating

With

the OP7 and the OP17, updated and newly created data are stored in a

non-volatile flash memory

. This means that current data are immediately

available following an OP re-start.

The flash memory cannot be accessed while data are being updated, and the

OP cannot be operated. The update rate is determined by the time response of

the delete and write cycles of the flash memory

. For technological reasons,

this rate is slower than the access time for volatile memories.

A system message is output to the OP while data updating is in progress.

Equipment Manual OP7, OP17

Release 04/99

2-3

2-4

Equipment

Manual OP7, OP17

Release 04/99

Part

II

Basic Functions

General Operation

Using the OP with Its

Standard Functions

3

4

Screens

Password Protection

Messages

Recipes

STATUS/FORCE VAR

with the OP

System Settings

5

6

7

8

9

10

2-6

Equipment

Manual OP7, OP17

Release 04/99

Loading...

Loading...