Page 1

Preface, Table of Contents

Introduction

COROS

Operator Panel

OP25, OP35, OP45

Equipment Manual

Functions od the Operator Panel

Commissioning and Operation

Device Description,

Installation and Maintenance

Appendices

Glossary, Index

6AV3991–1AD02–0AB0

Release 04/96

Page 2

Safety Guidelines

!

!

This manual contains notices which you should observe to ensure your own personal safety, as

well as to protect the product and connected equipment. These notices are highlighted in the

manual by a warning triangle and are marked as follows according to the level of danger:

Danger

indicates that death, severe personal injury or substantial property damage can result if proper

precautions are not taken.

Caution

indicates that minor personal injury or property damage can result if proper precautions are not taken.

Note

draws your attention to particularly important information on the product, handling the product, or

to a particular part of the documentation.

Qualified Personnel

Correct Usage

!

Trademarks

Impressum

Equipment may be commissioned and operated only by qualified personnel. Qualified personnel

within the meaning of the safety notices in this manual are persons who are authorized to commission, ground and identify equipment, systems and circuits in accordance with safety engineering

standards.

Note the following:

Warning

The equipment may be used only for the applications stipulated in the catalog and in the technical description and only in conjunction with other equipment and components recommended or

approved by Siemens.

Faultless and safe operation of the product presupposes proper transportation, proper storage,

erection and installation as well as careful operation and maintenance.

Startup must not take place until it is established that the machine, which is to accommodate this

component, is in conformity with the guideline 89/392/EEC.

SIMATIC and SINEC are registered trademarks of SIEMENS AG. Some of the other designations used in these documents are also registered trademarks; the owner’s rights may be violated

if they are used be third parties for their own purposes.

Published by AUT 91

Copyright Siemens AG 1996 All rights reserved

The reproduction, transmission or use of this document or its

contents is not permitted without express written authority.

Offenders will be liable for damages. All rights, including rights

created by patent grant or registration of a utility model or design,

are reserved.

Siemens AG

Automation Group

Industrial Automation Systems

P.O. Box 4848, D-90327 Nürnberg

Siemens Aktiengesellschaft Order No. 6AV3991–1AD02–0AB0

Equipment Manuel OP25, OP35, OP45

We have checked the contents of this manual for agreement with

the hardware and software described. Since deviations cannot be

precluded entirely , we cannot guarantee full agreement. However ,

the data in this manual are reviewed regularly and any necessary

corrections included in subsequent editions. Suggestions for

improvement are welcomed.

Technical data subject to change.

Siemens AG 1995, 1996

Page 3

Preface

Purpose

Audience

Applicability

This equipment manual contains precise information about the functionality

and technical design of operator panels OP25, OP35, and OP45.

The present equipment manual is written for operators, fitters, configurers, and

system support engineers.

The operator of an operator panel will find all the information he requires for

handling the device in Part II.

For the fitter, Part IV contains all the information he requires to install and

commission the operator panel.

The different versions of the equipment manual refer to the following OP firmware and ProT ool versions:

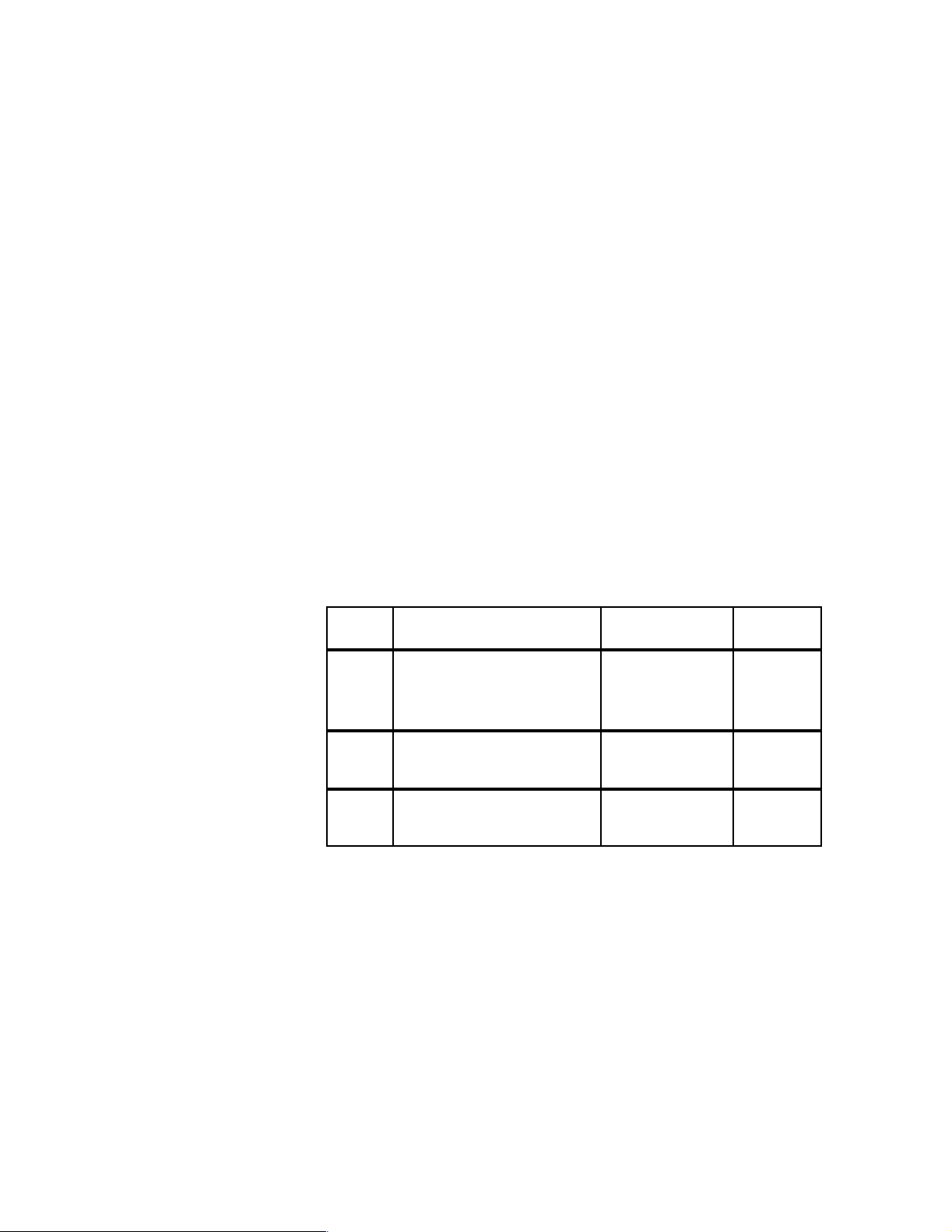

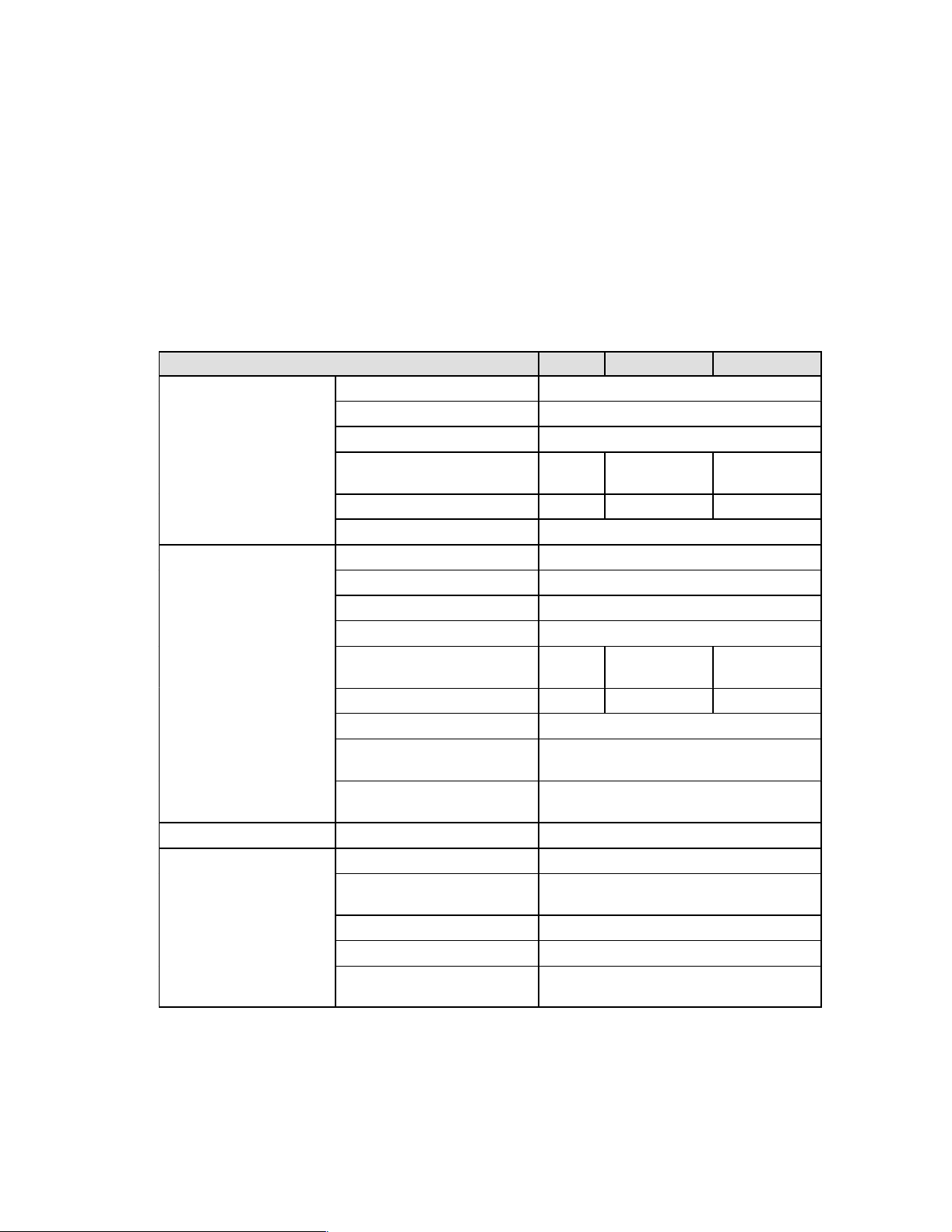

Release Remarks OP Firmware ProTool

Version

04/95 Initial release of Equipment

Manual

Summary of OP25, OP35 Equip-

ment Manual, and OP45 added

10/95 Extensions for Release 2 OP25: from V. 1.31

04/96 SINEC L2-DP for OP45 and MPI

for SIMATIC S7 added

1)

As well as an upgrade floppy disk

OP25: from V. 1.31

OP35: from V. 1.31

OP45: from V. 1.31

OP35: from V. 1.31

OP45: from V. 1.31

OP25: from V. 2.0

OP35: from V. 2.0

OP45: from V. 1.40

Up to V. 1.31

Up to V. 1.31

Up to V. 1.31

Up to V 2.0

Up to V 2.0

Up to V. 2.0

Up to V 2.0

Up to V 2.0

V. 2.0

1

Further support

Should you have any queries regarding technical matters, please get into touch

with your point of contact at the Siemens agency or branch responsible. You

will find the addresses in Appendix F of this manual, in catalogs, and in Compuserve (go autforum) ..., for instance. In addition, you can call our hotline by

dialing +49(911) 895-7000 (fax 7001).

Conventions

The following conventions are used in this manual:

Trans Mode T ext on the display of the OP appears in the manual in

Login: Field name on screens

( section 7.2) Cross-reference, reference to additional information

Equipment Manuel OP25, OP35, OP45

Release 04/96

Courier

i

Page 4

Preface

How the manual is

organized

The OP25/35/45 Equipment Manual is organized as follows:

Chapters 1 to 2 provide an overview of the operator panels and their

functions in tabular form.

Chapters 3 to 9 describe in step-by-step instructions how to operate oper-

ator panels – for example, how to

– create new screens (in addition to the standard

screens)

– output messages or alarms

– enter recipe data records

– print messages or screens.

Chapters 10 to 13 contain information on

– how you commission operator panels

– which system settings you can perform, and

– how you can back up and restore data.

Chapters 14 to 18 contain detailed information about the different devices,

as well as their mechanical and electrical installation and

maintenance.

In the appendices you will such items as technical data, interface assign-

ments, test functions, and system messages.

Related

documents

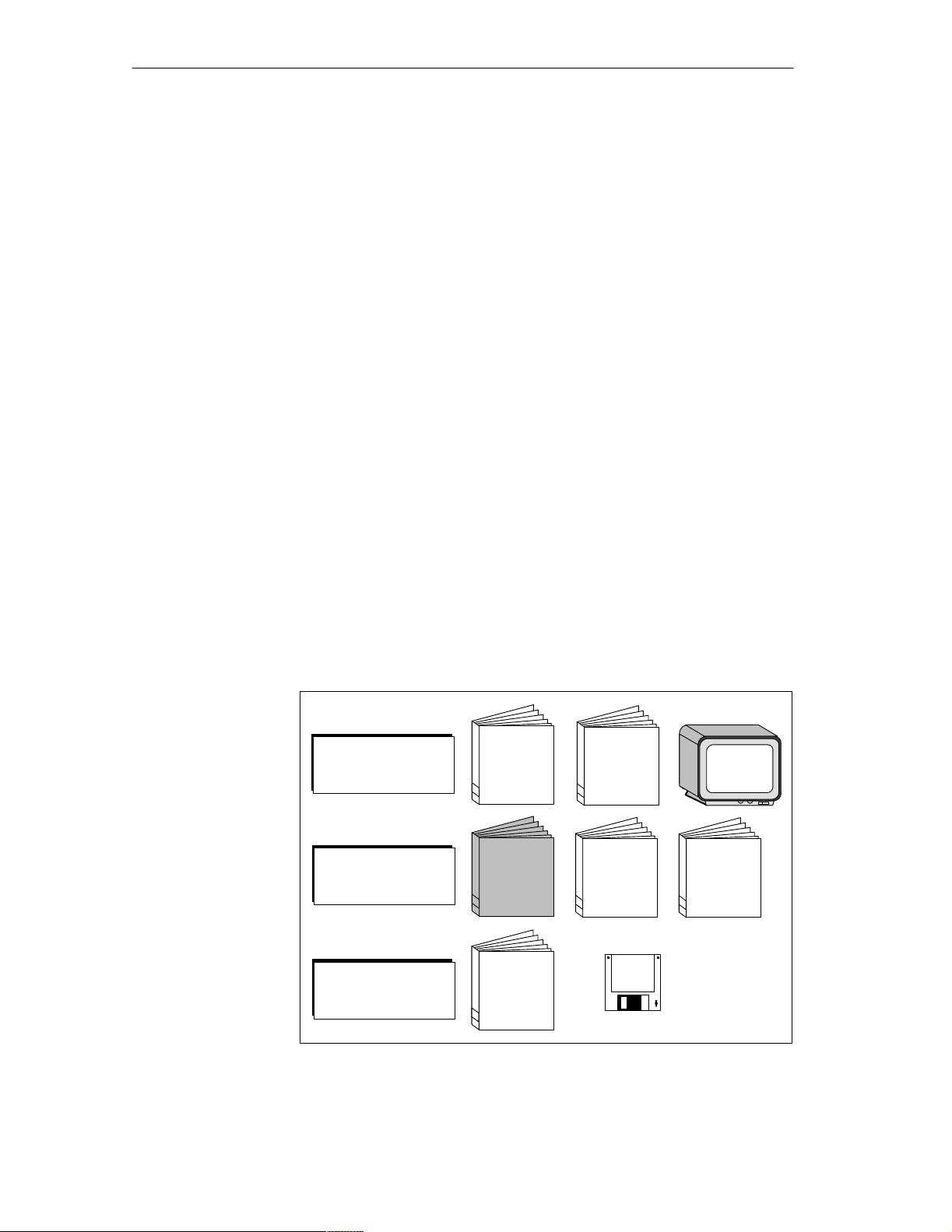

The illustration shown below provides an overview of how the complete range

of documents covering manuals and online help is organized. The present

manual is shaded.

PC

Configuration

"

!

"

OP

Installation

Operation

"!

" "

"!

"!

"

PLC

"#

Connection

!

"

!

ii

Equipment Manuel OP25, OP35, OP45

Release 04/96

Page 5

Table of Contents

Part I: Introduction

1 Product Description 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 The Operator Panel at a Glance 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Process V isualization and Manipulation 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Functionality 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part II: Functions of the Operator Panel

3 Using the OP 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Keyboard 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Input/Output Fields 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Numeric Fields 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2 String Fields 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.3 Symbolic Fields 3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Using the Windows of OP25/OP35 3-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Screens 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 The Operator Panel in Action 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Screen Elements 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Selecting a Screen 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Standard Screens 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Messages 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Event and Alarm Messages 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.1 General Features 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.2 Current Messages 5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.3 Stored Messages 5-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.4 Standard Screen: Message Processing 5-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 System Messages 5-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Recipes 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Processing and Transferring the Data Records 6-4. . . . . . . . . . . . . . . . . . . . . . .

6.1.1 Standard Screens: Data Record Processing and

Data Record Transferring 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.2 Setting Up and Editing Data Records 6-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Manuel OP25, OP35, OP45

Release 04/96

iii

Page 6

Table of Contents

6.2 Parameter Records 6-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Print Functions 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Hardcopy 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Message Logging 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Forced Logging 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 Printing Screen List (OP25, OP35 Only) 7-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Password Protection 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Logging In on the OP 8-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Logging Out on the OP (Logout) 8-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Password Management 8-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Status/Force Variable with the OP 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 Status Variable 9-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 Force Variable 9-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part III: Commissioning and Operation

10 Commissioning 10-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 Initial Commissioning of the OP25/OP35 10-2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 Initial Commissioning of the OP45 10-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3 Recommissioning 10-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4 MPI Transfer (OP25/35 only) 10-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.5 Startup Sequence 10-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.6 Error Diagnosis 10-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.7 Notes on Data Security 10-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11 System Settings 11-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1 Standard Screen: System Settings 11-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.2 Standard Screen: Printer Settings 11-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3 Blanking Circuit (OP25/35 Only) 11-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4 Contrast and Brightness Adjustment on the OP25/35 11-6. . . . . . . . . . . . . . . . .

11.5 System-Related Key Assignments (OP45 Only) 11-7. . . . . . . . . . . . . . . . . . . . . .

11.6 User-Specific Key Assignment (OP45 Only) 11-8. . . . . . . . . . . . . . . . . . . . . . . . .

12 Operating Modes 12-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1 Normal Operation, Loop-Through Operation and Transfer Mode 12-2. . . . . . .

12.2 Setting/Changing the Operation Mode 12-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.3 DOS Operation with the OP45 12-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv

Equipment Manuel OP25, OP35, OP45

Release 04/96

Page 7

Table of Contents

13 Storing and Loading Data 13-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1 Storage Principle and Storage Media (Data Media) 13-2. . . . . . . . . . . . . . . . . . .

13.2 Backup and Restore with the OP25/35 13-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part IV: Device Description, Installation, and Maintenance

14 Device Description 14-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.1 Device Description: OP25 14-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.1.1 Operating and Indicating Elements of the OP25 14-2. . . . . . . . . . . . . . . . . . . . . .

14.1.2 Connections of the OP25 14-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.1.3 Dimensions of the OP25 14-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.2 Device Description: OP35 14-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.2.1 Operating and Indicating Elements of the OP35 14-5. . . . . . . . . . . . . . . . . . . . . .

14.2.2 Connections/Interfaces of the OP35 14-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.2.3 Dimensions of the OP35 14-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.3 Device Description: OP45 14-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.3.1 Operating and Indicating Elements of the OP45 14-8. . . . . . . . . . . . . . . . . . . . . .

14.3.2 Connections of the OP45 14-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.3.3 Dimensions of the OP45 14-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.4 Options 14-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.4.1 Direct Key Module for the OP25 14-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.4.2 Direct Key Module for the OP35 14-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15 Labelling the Function Keys 15-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.1 Labelling the Keys for OP25 15-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.2 Labelling the Keys for OP35 15-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.3 Labelling the Keys for OP45 15-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16 Mechanical Installation 16-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.1 Installing the OP25 16-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.2 Installing the OP35 16-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.2.1 Installation in 19” Cabinets/Racks 16-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.2.2 Installation in Switching Cabinets/Consoles 16-6. . . . . . . . . . . . . . . . . . . . . . . . . .

16.3 Installing the OP45 16-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.3.1 Installation in 19” Cabinets/Racks 16-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.3.2 Installation in Switching Cabinets/Consoles 16-1 1. . . . . . . . . . . . . . . . . . . . . . . . . .

17 Electrical Installation 17-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.1 Electrical Installation of the OP25/OP35 17-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.1.1 Connecting the Voltage Supply and Relay Contacts 17-3. . . . . . . . . . . . . . . . . .

17.1.2 Connecting the Configuration Computer 17-4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.1.3 Link to the Controller 17-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.1.4 Connecting the Printer 17-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.1.5 Loop-Through Operation 17-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.2 Electrical Installation of the OP45 17-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.2.1 Connection to the Power Supply 17-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Manuel OP25, OP35, OP45

Release 04/96

v

Page 8

Table of Contents

17.2.2 Connecting the Configuration Computer 17-10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.2.3 Link to the Controller 17-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.2.4 Connecting the Printer 17-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.2.5 Connecting an MF2 Keyboard 17-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18 Maintenance 18-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.1 Backup Battery 18-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.2 Display 18-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.2.1 Replacing the Display for the OP25 18-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.2.2 Replacing the Display for the OP35 18-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.2.3 Replacing the Display for the OP45 18-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part V: Appendices

A Technical Data A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B Interface Assignment B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1 Interface Assignment for OP25 and OP35 B-1. . . . . . . . . . . . . . . . . . . . . . . . . . .

B.2 Interface Assignment for OP45 B-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C Test Functions C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.1 Hardware Test for OP25 C-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.1.1 General Operating C-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.1.2 Individual Tests C-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.1.3 Test Adapters C-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D System Messages D-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E ESD Guidelines E-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F Siemens Worldwide F-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

Equipment Manuel OP25, OP35, OP45

Release 04/96

Page 9

INTRODUCTION

1 Product Description

2 Functionality

Part I

Equipment Manuel OP25, OP35, OP45

Release 04/96

i-i

Page 10

i-ii

Equipment Manuel OP25, OP35, OP45

Release 04/96

Page 11

Product Description

1

Overview

Application of

operating panels

Electronically controlled machines are usually supervised and controlled ”on

the spot”. Depending on the size and complexity of the machine or system,

the requirements for operator interface systems differ greatly.

Operator panels OP25/35/45 allow a realistic graphical display of the machine or system under supervision and are designed for easy machine control.

With operator panels OP25/35/45 you can

Control and supervise the process by means of menus – for example, you

can control setpoints or signal control elements by means of inputs, soft

keys, and function and system keys.

Visualize processes, machines and systems as pixel or character graphics

images.

Display event and alarm messages as well as process variables as an out-

put field, a bar graph, trends or a status display, for instance.

Intervene in the process flow using the integrated keyboard.

Equipment Manuel OP25, OP35, OP45

Release 04/96

1-1

Page 12

Product Description

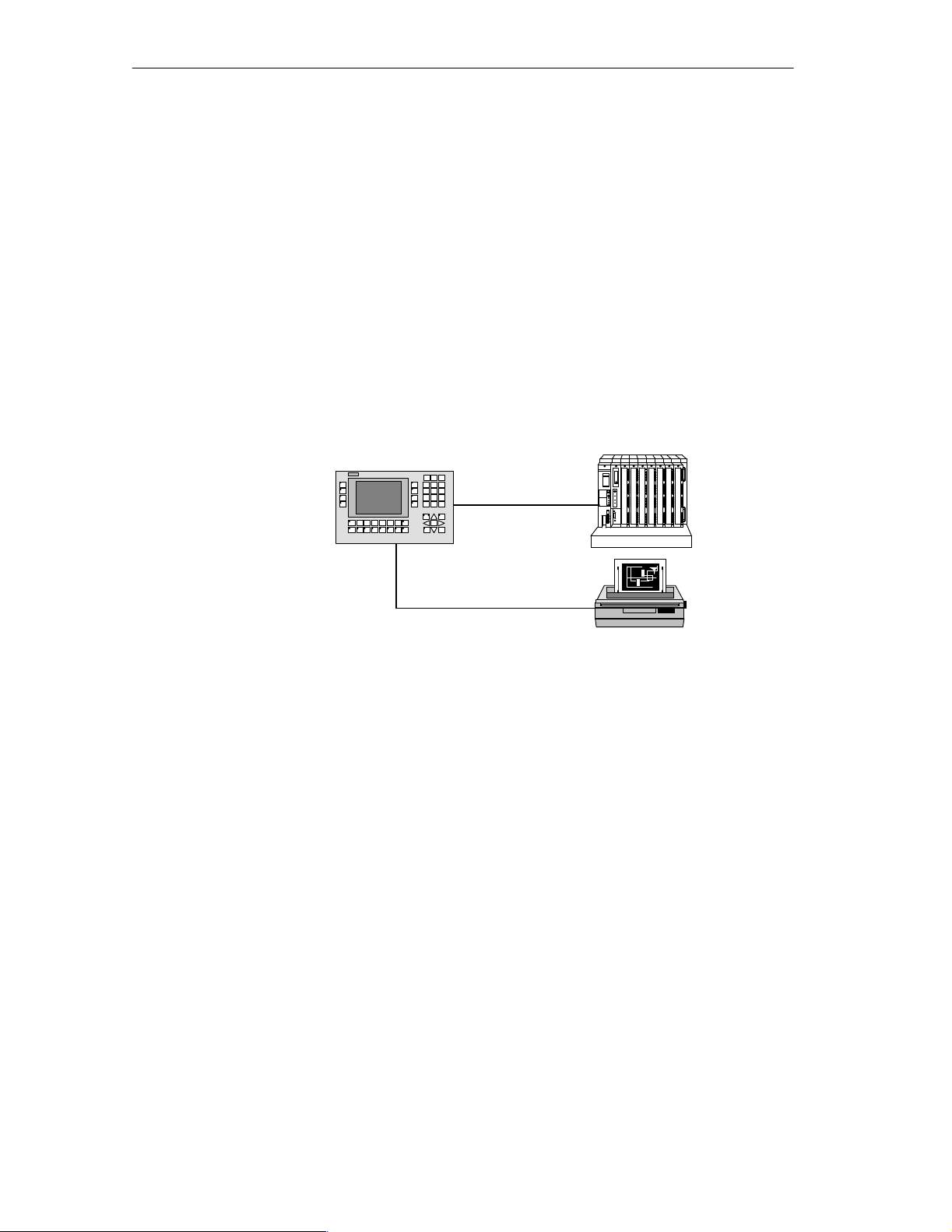

Installation

options

System

configuration

Operator panels OP25, OP35 and OP45 are panel mounting devices for use

locally on the machine.

Due to the high degree of protection (IP65 at the front panel), the OP is also

suitable for hostile industrial environments.

Possible installation locations for the OPs are:

Cabinets or panels

19” cabinets or racks (OP35 and OP45 only)

The OP’s integrated interfaces permit it to be connected directly to controllers.

A printer can also be added for hardcopies and listings.

Controller

OP25, OP35, OP45

Planning

Printer

A PC or programmer is used to configure the OP with ProT ool (a configuring

program which runs under Windows).

1-2

Equipment Manuel OP25, OP35, OP45

Release 04/96

Page 13

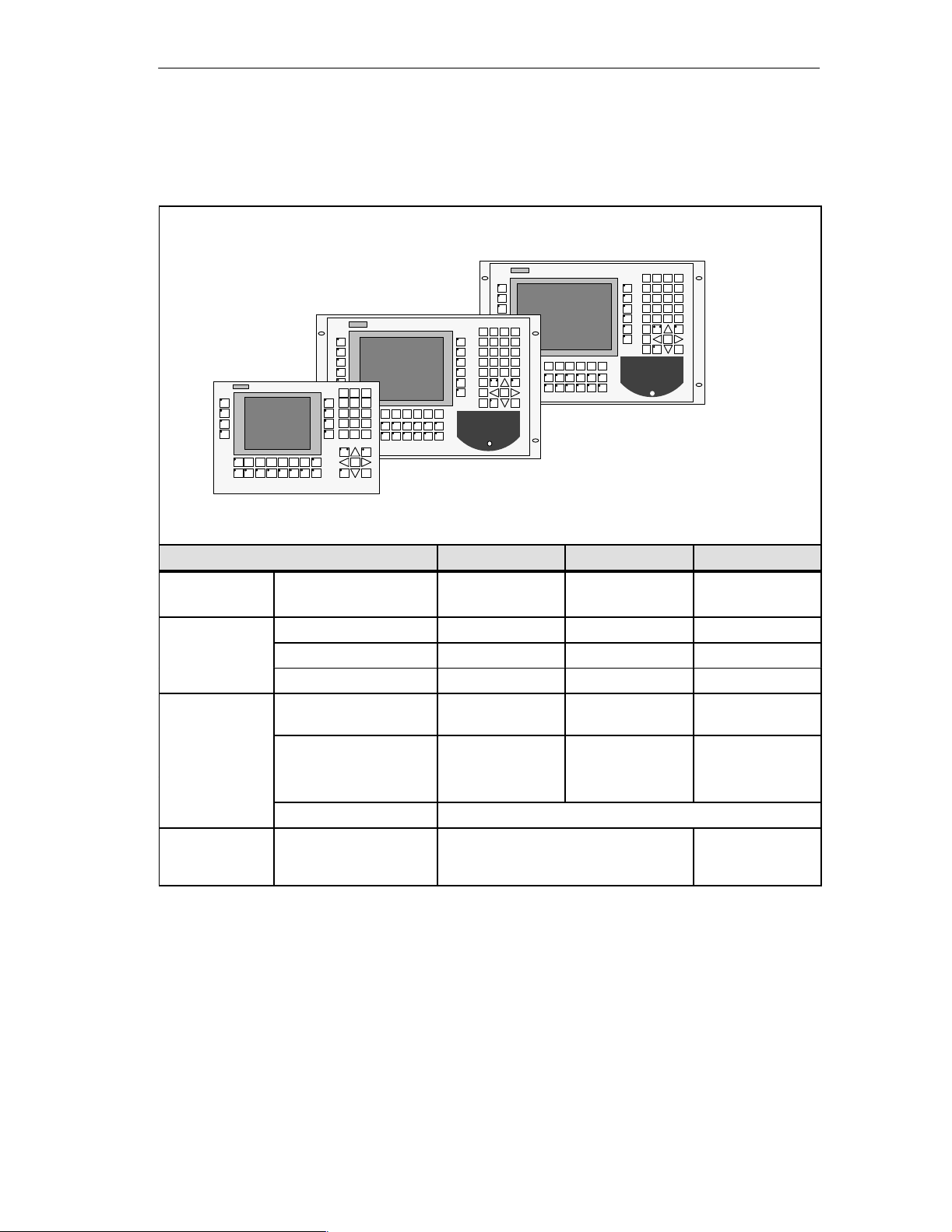

1.1 The Operator Panel at a Glance

OP45

OP35

OP25

Product Description

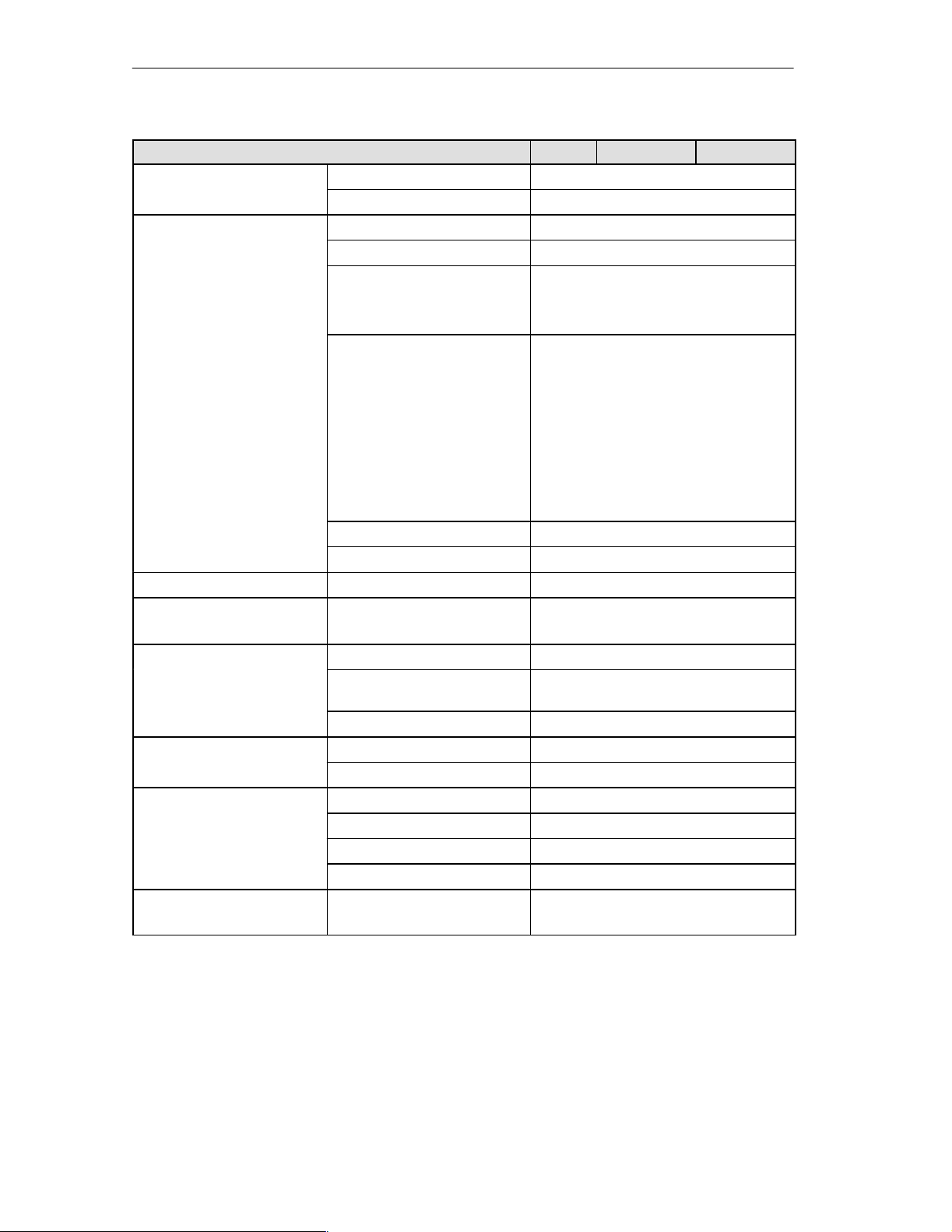

Basic Models OP25 OP35 OP45

Models Black and white display

Color display

Display

Sealed keyboard

Interfaces Serial interfaces for con-

Type STN-LCD STN-LCD TFT-LCD

Resolution (in pixels) 320 x 240 640 x 480 640 x 480

Background illumination Yes Yes Yes

System keys with fixed

functions

Function keys with confi-

gurable functions

Softkeys thereof 14 20 20

Function key labels Customized labelling with label strips

nection of controller,

PC/PG, printer

Yes

–

24

(4 with LED)

24

(18 with LED)

2 x V.24/TTY

1 x RS 422/RS 485

1 x TTY/RS 422/RS 485

Yes

Yes

32

(4 with LED)

36

(28 with LED)

–

Yes

32

(4 with LED)

36

(28 with LED)

1 x V.24/TTY

1 x V.24

1 x RS 485

Equipment Manuel OP25, OP35, OP45

Release 04/96

1-3

Page 14

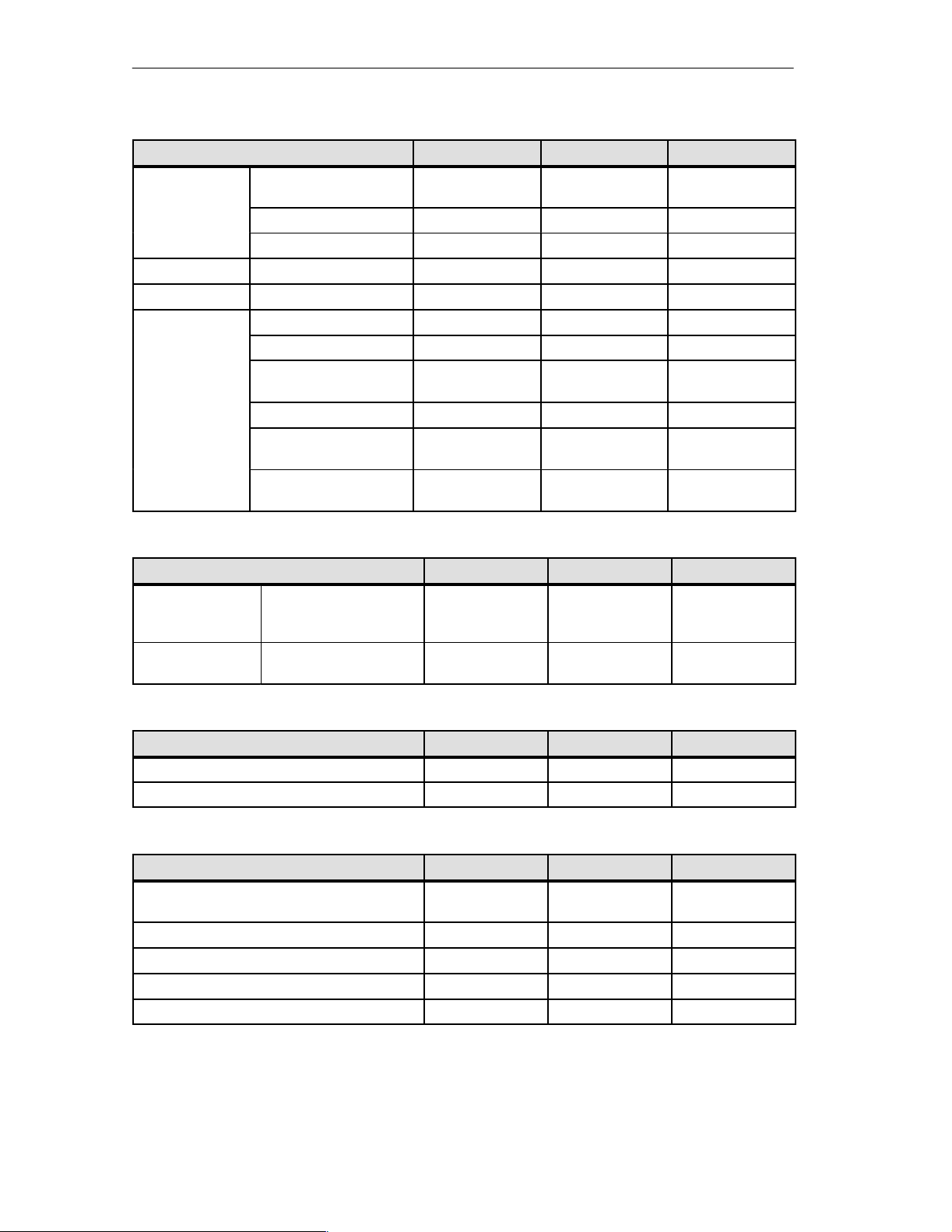

Product Description

Basic Model OP25 OP35 OP45

Memory

Floppy disk drive – Optional Yes

Hard disk – – 425 Mbytes

Special features

Flash EPROM for firmware and user data

Working storage (DRAM) 2 Mbytes 4 Mbytes 8 Mbytes

Memory for configuration 1 Mbyte 3 Mbytes 5.5 Mbytes

Hardware clock (buffered) Yes Yes Yes

Relay output Yes Yes –

Operation of an external

MF2 keyboard

DOS operation – – Yes

Operation of an external

monitor

Module slot for PCMCIA/

JEIDA cards

1 Mbyte 2 Mbytes –

– – Yes

– – Yes

Yes Yes –

Options OP25 OP35 OP45

Direct key module Digital outputs, address-

able via either keys or configurable ports

Floppy disk drive – 3 ” drive (Included in stan-

Installation Possible in OP25 OP35 OP45

Switching cabinets/consoles Yes Yes Yes

19” cabinets/racks – Yes Yes

Controllers That Can Be Used OP25 OP35 OP45

SIMATIC S5 programmable controllers Yes Yes Yes

SIMATIC S7 automation system Yes Yes –

SIMATIC 500/505 Yes Yes –

PC/AT-compatible computers Yes Yes –

Controllers of other manufacturers Yes Yes –

8 16 16

dard model)

(AS 511 only)

1-4

Equipment Manuel OP25, OP35, OP45

Release 04/96

Page 15

1.2 Process Visualization and Manipulation

“One picture is worth a thousand words” goes the familiar saying.

This is particularly true of machine and system monitoring where it is impor-

tant to provide the operator with clear and easy-to-understand information

about the state of the process.

Product Description

Screens

Full graphic plant

screens

Bars, curves

Symbolic graphics

Process manipulation

Process values and process sequences are shown by screens which can contain graphics, texts and values. Process values in a system are often related

in some way. Screens show this relationship and thus represent an image of

the process.

The OP permits you to represent machines and plants as full graphic

screens. This improves operator orientation.

You can show current process values (e.g., filling level and speed) as numeric

values, or symbolically as text or bars.

Curves are a particularly good way to show changeable process values (e.g.,

changes in temperature) over a period of time.

Symbolic graphics are another way to indicate process values. Symbolic

graphics are graphic elements (i.e., bit maps) which are indicated alternately

to show different process states (e.g., valve open or closed).

The operator can use the OP’s integrated keyboard to intervene in the process

sequence.

For example, you can control actuators (e.g., valves) by specifying process

values (i.e., setpoints).

Features important to operator control include ease of handling, short training

periods, and a high degree of reliability.

You can configure the structure of the OP operating environment as desired

(i.e., you can tailor operator control to your particular application).

A few features:

Free configurable function keys

Softkeys

Pop-up windows for symbolic entries

Equipment Manuel OP25, OP35, OP45

Release 04/96

1-5

Page 16

Product Description

Messages

Information texts

Recipes

Password protection

Process or machine states (e.g., the current operating mode) are displayed by

the OP as plain-text event messages.

Alarm messages provide information on critical machine states.

Current measured values (e.g., temperatures, speeds, etc.) can also be in-

cluded in the text of event or alarm messages.

Event and alarm messages are stored with date and time in a message buffer.

At the same time, all event and alarm occurrences can be printed (if message

logging is switched on and a printer is connected).

Information texts can be configured. You can use them to give the operator

additional information which will help him/her to correct a malfunction.

Complete blocks of machine data can be stored as recipes on the OP.

The structure of a recipe is specified during the configuring phase. It makes

no difference whether the recipes are “real recipes” or only piece number

specifications, traversing paths or temperature progressions.

You can change or redefine recipe data directly on the OP.

The OP offers password protection. Each operator can be assigned a different password. A password level can then be used to enable or disable each

operator’s access to special operating functions. This prevents incorrect entries and improves system security.

Multiple languages

PG functions

All messages and texts for screens can be stored in the OP in up to three different languages.

This permits international use even when operating personnel speak different

languages.

The “STATUS/FORCE VARIABLE” PG functions are available for testing

and trouble-shooting. They can be used on the OP to specify and change

address areas in the controller. This makes on-site troubleshooting fast even

without a programmer.

1-6

Equipment Manuel OP25, OP35, OP45

Release 04/96

Page 17

Functionality

The functions of the operating panels are listed below. The numerical values

contained in the tables are the maximum values that can be managed by an

OP and are limited possibly only by the size of the user memory.

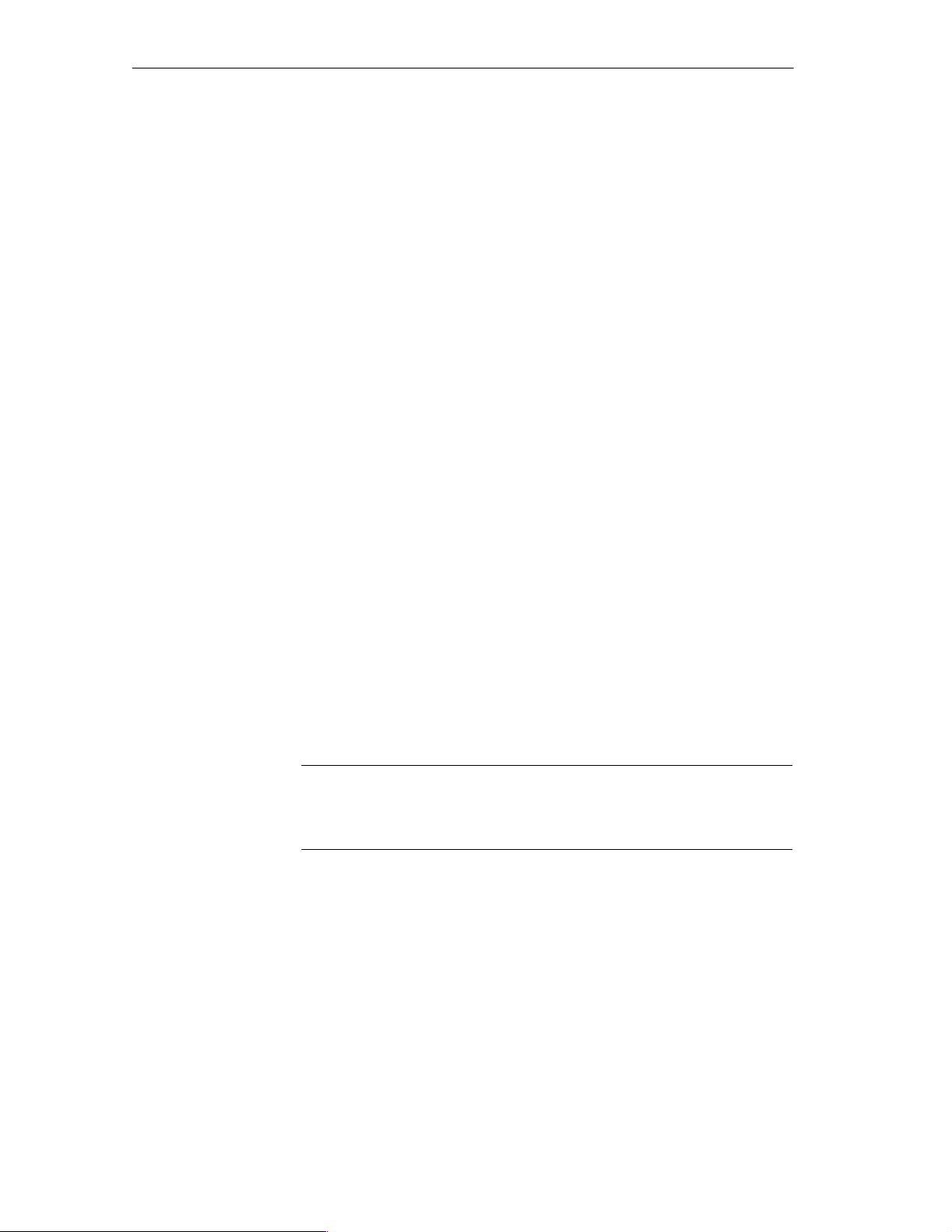

Functions OP25 OP35 OP45

Event messages Number 2000

Indication In message line/message window

View all queued events On message page

Length of message text (in char-

acters)

Lines per message 2 1 1

Process values in message text 8

Alarm messages Number 2000

Indication In message line/message window

Indication type 1st value/last value (can be selected)

View all queued alarms On message page

Length of message text (in char-

acters)

Lines per message 2 1 1

Process values in message text 8

Acknowledge single alarm mes-

sages

Acknowledge several alarm mes-

sages simultaneously

Message logging Logged on a printer Yes

Message buffer Capacity 512 message occurrences

Look at buffered event messages/

alarm messages

Delete Yes

Buffer overflow warning Yes

Forced printout for buffer over-

flow

2 x 35 70 70

2 x 35 70 70

Yes

Yes, 16 acknowledgement groups

On puffer page

Yes

2

Equipment Manuel OP25, OP35, OP45

Release 04/96

2-1

Page 18

Functionality

Functions OP25 OP35 OP45

Message acquisition Time of occurrence Date/time

Message status Arriving, departing, acknowledged

Screens Indicate Yes

Print (hardcopy) Yes

Static screen elements Static full graphics

Fixed text

Semigraphic characters

Input/output elements Input fields

Output fields

Combined input/output fields

Symbolic input

(pop-up window)

Symbolic output

(graphics/text)

Bars

Curves

Operator prompting Icons for softkey functions

Fixed window Yes

Limit value monitoring For inputs/outputs Yes

Conversion functions For inputs/outputs Linear

Square

Fonts Loadable fonts per language 3

Fonts not dependent on language

(with semigraphic characters)

Character sizes in pixels 8 x 8 to 64 x 64

Text attributes Display Flashing, inverse, underlined

Printer Bold, italics, underlined

Information texts Lines/characters 7/35

For messages Yes

For input fields Yes

For screens Yes

Password protection Number of passwords

Password levels

1

50

9

2-2

Equipment Manuel OP25, OP35, OP45

Release 04/96

Page 19

Functionality

Functions OP25 OP35 OP45

Recipes Number 255

Data records per recipe 500

Entries per data record 500

Save data records (set up) Controller/OP storage medium

Load data records Storage medium OP/controller

Delete data records In storage medium

Change data records (edit) In storage medium

Transfer current values Controller OP

OP controller

Transfer data records Data medium OP

OP data medium

Parameter records Yes

Print functions Hardcopy of the contents of the

display

Character mode (ASCII)

Graphic mode

Direct message logging Yes

Screen printout in character mode

(ASCII)

Data backup Backup/restore function for

PCMCIA/JEIDA cards

Online language switchover Number of languages 3

PG functions For SIMATIC S5 Yes Yes Yes

(Status/force variable)

For SIMATIC S7 Yes Yes Yes

Loop–through operation For PG or additional TD/OP

(only with SIMATIC S5 and

AS 511 protocol)

Display Setting for display brightness/

contrast

Blanking circuit Yes Yes –

Connection to PLC SIMATIC S5-AS511

SIMATIC S5-FAP

SIMATIC S5-L2-DP

SIMATIC S7-MPI

SIMATIC S7-PPI

SIMATIC 500/505

Free Serial

Allen Bradley

Mitsubishi

Telemecanique

Yes

Yes

Yes Yes –

Yes Yes –

Yes Yes No

Yes Yes –

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

3

3

3

Yes

Yes

Yes

3

3

3

Yes

–

No

–

–

–

–

–

–

–

2

2) The immunity to interference cannot be guaranteed on account of the hardware characteristics of the OP45

3) Driver available as an option

Equipment Manuel OP25, OP35, OP45

Release 04/96

2-3

Page 20

Functionality

2-4

Equipment Manuel OP25, OP35, OP45

Release 04/96

Page 21

FUNCTIONS OF THE

OPERATOR

3 Using the OP

4 Screens

5 Messages

6 Recipes

7 Print Functions

8 Password Protection

9 Status/Force Variable with the OP

PANEL

Part II

Equipment Manuel OP25, OP35, OP45

Release 04/96

ii-i

Page 22

ii-ii

Equipment Manuel OP25, OP35, OP45

Release 04/96

Page 23

Using the OP

3

Overview

Screen section

Fixed window

Processes (e.g., a machine tool, mixing station or similar) are displayed on the

OP with screens. The processes can also be manipulated.

One screen takes up the entire display. An example of a possible layout is

shown below.

Fixed window

Main screen area

Icons for softkey

functions

Figure 3-1 Screen layout for the OP25

The fixed window provides the operator with a continuous stream of important

process variables regardless of which screen is open at the moment.

Main screen area

Icons

Equipment Manuel OP25, OP35, OP45

Release 04/96

The main screen area contains the actual contents of the currently opened

screen.

Additional windows (e.g., message windows, help windows and pop-up windows) are faded in over the main screen area and the fixed window.

Icons symbolize softkey functions related to specific screens.

3-1

Page 24

Using the OP

3.1 Keyboard

Overview

Function keys/

softkeys

The keyboard of the OP is equipped with two blocks of keys:

The function keys/softkeys

The system keys

A function key always triggers the same action in the OP or controller (i.e.,

global significance for the OP) regardless of which screen is currently open.

A few possible actions are listed below.

Open a screen

Indicate the current alarm messages

Start a hardcopy of a screen

Indicate the time window

The term softkey means that function keys can have a meaning related to the

currently open screen (i.e., local).

The function of a softkey can vary from screen to screen. When a screen is

open, a softkey’s function is shown by an icon in the margin of the monitor

screen.

The following keys can have softkey functionality:

For OP25: F1 to F14

Repeat function

(for OP45 only)

For OP35/OP45: F1 to F20

The repeat function activates when a key is repeatedly pressed.

Note

Do not press several keys on the OP45 at the same time. This can cause incorrect entries.

3-2

Equipment Manuel OP25, OP35, OP45

Release 04/96

Page 25

Using the OP

System keys

The system keys are used to make entries on the OP.

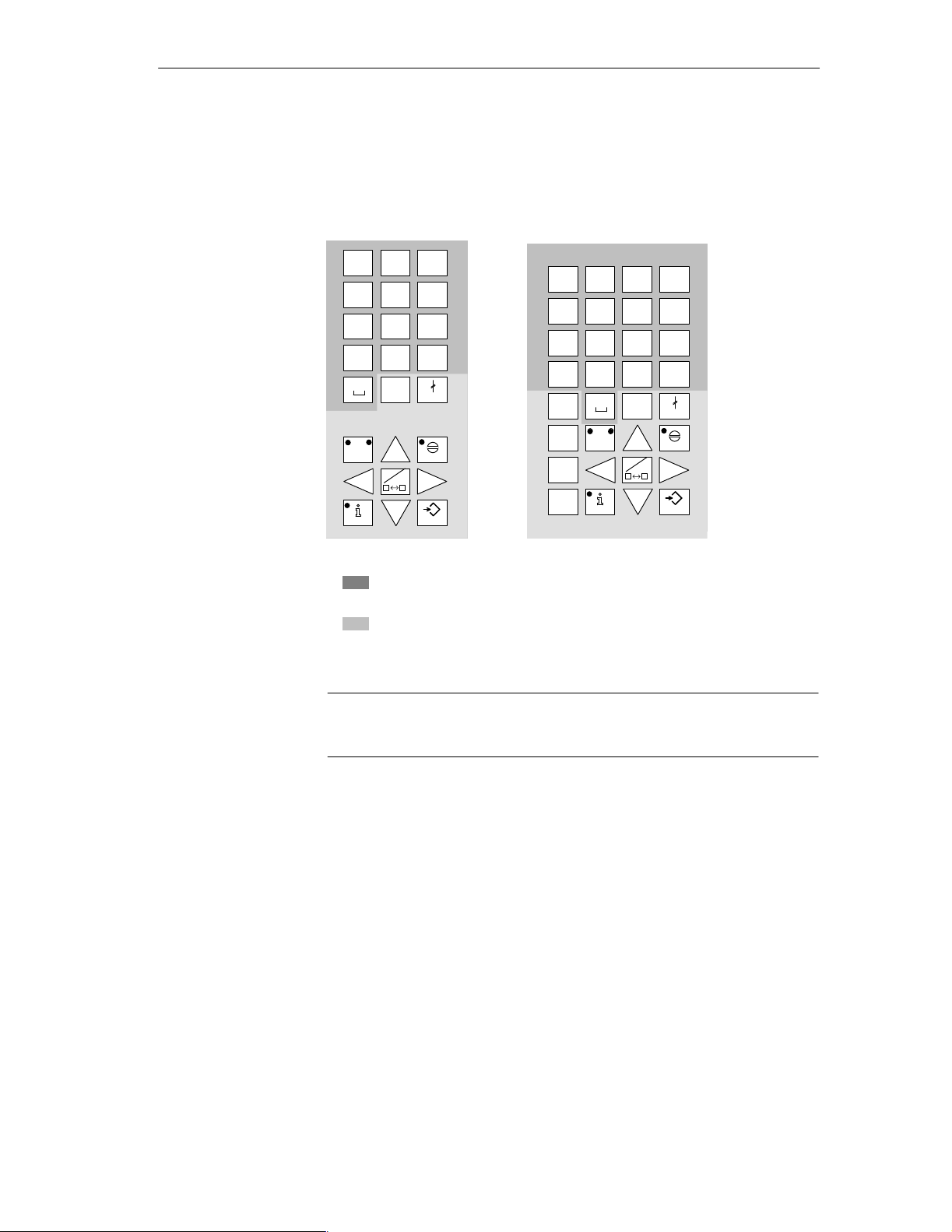

Figure 3-2 shows the system keyboard for the OP25 and OP35/OP45.

OP25

AB8CD9EF

7

GH5IJ6KL

4

MN2OP3QR

1

ST0UV

.

YZ

A–Z

HELP

A–Z

INS

DEL

WX

+/–

ESC

ACK

ENTER

= Input keys for numeric and alphanumeric characters

OP35/OP45

AB7CD8EF9GH

/

IJ4KL5MN6OP

*

QR1ST2UV3WX

–

YZ.:\0=,

+

TAB

ALT

A–Z

A–Z

CTRL

SHIFT

HELP

A–Z

INS

DEL

()

+/–

ESC

ACK

ENTER

= Control keys

Figure 3-2 Assignment of the system keys

Note

The TAB, ALT, CTRL and SHIFT keys of the OP35 have no function.

Equipment Manuel OP25, OP35, OP45

Release 04/96

3-3

Page 26

Using the OP

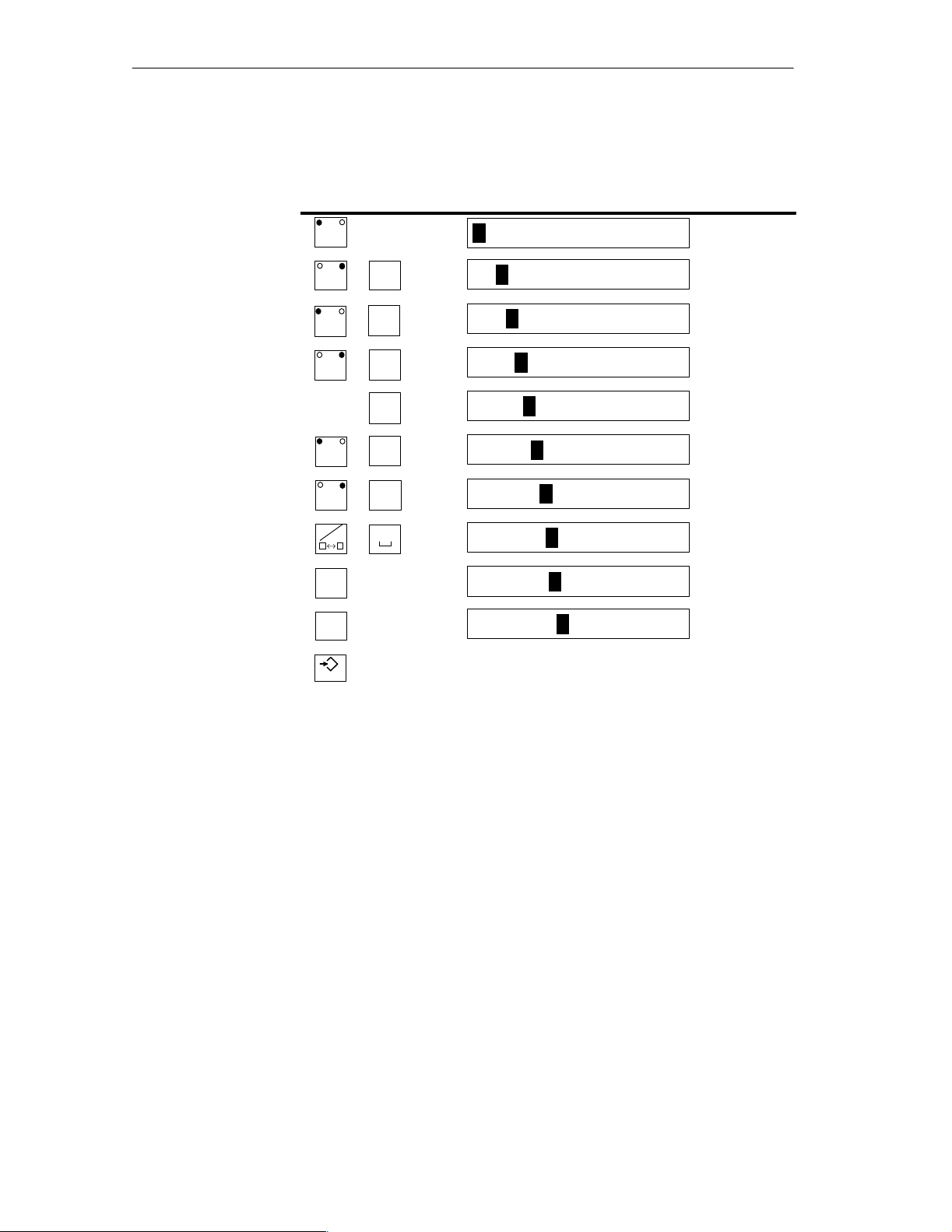

Key functions

The control keys of the OP have the following functions:

Key Description

A–Z

Shift key

This key is used to shift the input keys from numeric to

alphanumeric.

The key is equipped with two LEDs which indicate the

current status.

No LED is on.

Numeric assignment of the input keys is active.

Alphanumeric assignment of the input keys becomes

active when this key is pressed once.

One of the two LEDs (i.e., left or right) is on.

Left or right alphanumeric assignment of the input

keys is active.

Input key assignment alternates between the left and

right alphanumeric assignment each time this key is

pressed.

A–Z

A–Z

Switches the active window (OP25/OP35 only)

Switch from alphanumeric assignment of the input

keys back to numeric assignment

INS

DEL

ESC

Cancel key

Activates edit mode (OP25/OP35 only)

Deletes/inserts single characters

This key cancels already started actions. Some examples

are listed below.

Delete an already entered character for a value input

Delete a queued system message

Acknow-

ACK

ledgement

key

Info key

HELP

Apply key

ENTER

Cursor keys Move the cursor to the individual input fields in a

This key acknowledges the currently indicated alarm

message or all messages of an acknowledgement group.

The LED remains on as long as an unacknowledged

alarm message is queued.

This key is used to open a window containing a help text

for the selected object (e.g., message, input field).

The LED goes on when a help text is available for the

selected object.

The help window is closed by pressing any key.

Accept and exit an entry

Open the pop-up window for a symbolic entry

screen

Move the cursor within an input field

Select an entry from the message buffer

Select a value from the pop-up window

3-4

Equipment Manuel OP25, OP35, OP45

Release 04/96

Page 27

3.2 Input/Output Fields

Using the OP

Overview

Procedure

Correcting/canceling entries

The screens on the OP contain different types of input/output fields.

Numeric fields (digital or analog)

String fields

Symbolic fields

Values can be entered on the OP in these input fields which are then transferred

to the controller.

The basic procedure for entering values on the OP is described below.

1. Using the cursor keys, position the cursor on the desired input field.

2. Enter the value. The method of entry varies depending on the type of field.

See the following subsections for information on handling the individual

fields.

3. Confirm the entry with with ENTER key.

The following methods of correction are available before the entry is applied.

Using the INS/DEL key, insert/delete single characters where the cursor is

positioned. Then use the ENTER key to confirm the correct value.

Cancel the entry with the ESC key.

Edit mode

(OP25/35 only)

The original value is then automatically rewritten in the field. Enter the

correct value, and confirm with the ENTER key.

An edit function is available on the OP25/35. This edit function can be used to

edit entries which have already been applied.

1. Position the cursor on the desired input field.

2. Activate edit mode by pressing the INS/DEL key.

In contrast to input mode, the indicated value is retained.

3. Move the cursor to the appropriate position of the input field.

4. Using the INS/DEL key, insert/delete characters where the cursor is positioned.

5. Confirm the entry with the ENTRY key.

The entry can be canceled with the ESC key. The old value is indicated

again.

Equipment Manuel OP25, OP35, OP45

Release 04/96

3-5

Page 28

90

Using the OP

3.2.1 Numeric Fields

The shape of the cursor changes in input mode. Input starts at the right-hand

edge of the input field. Digits are shifted to the left similar to a pocket calculator.

Entry

T o make entries in a numeric field, proceed as follows:

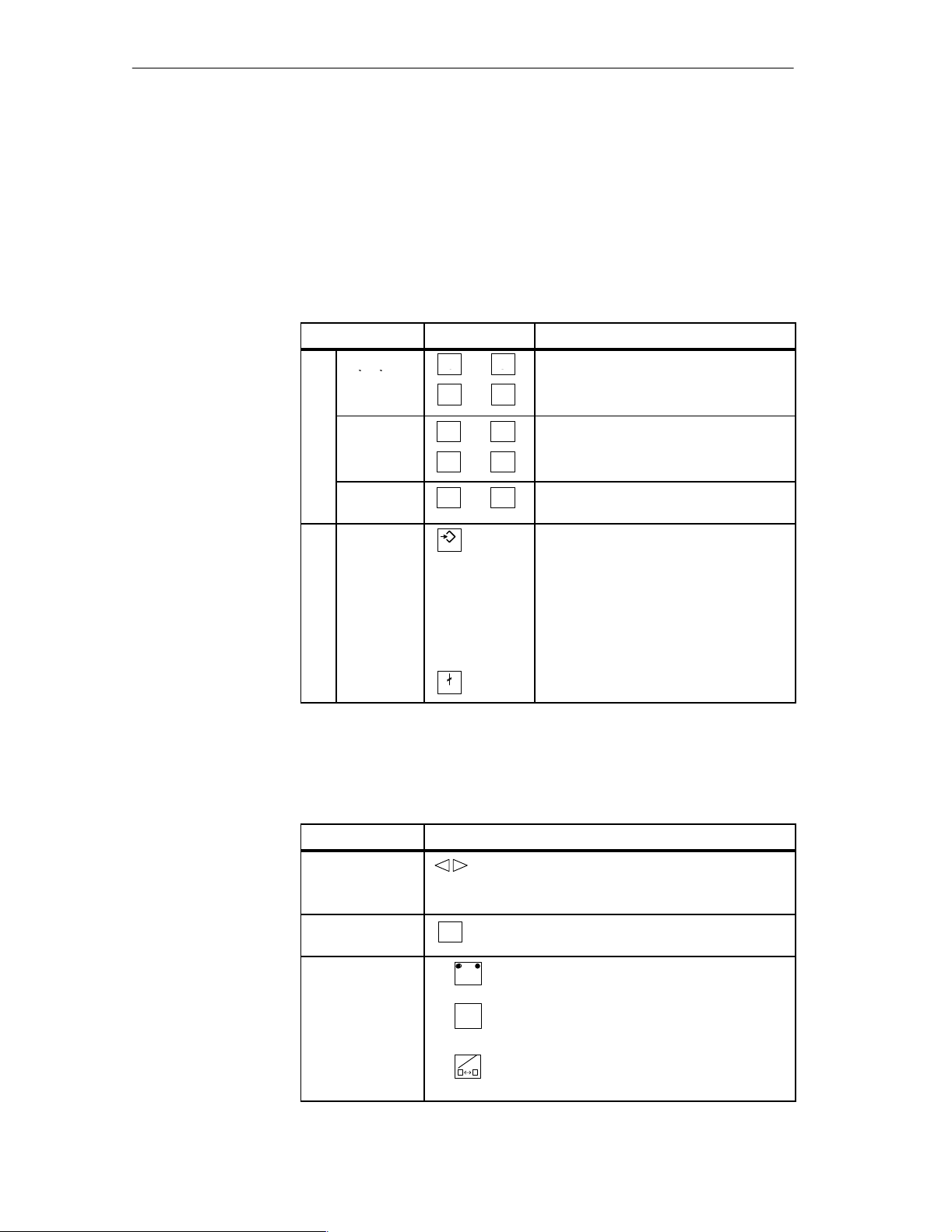

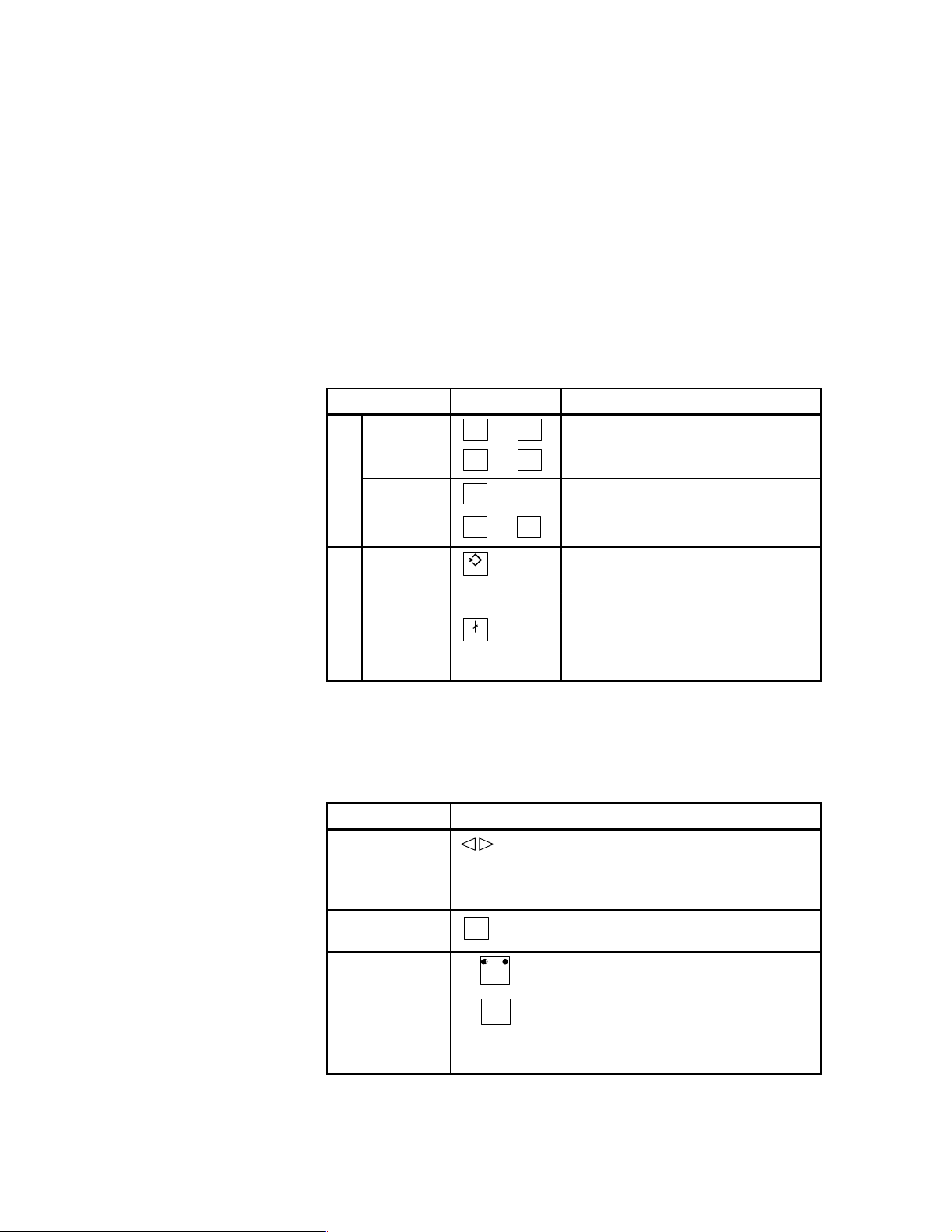

Step Key Description

1 Enter deci-

mal value

Enter

hexadecimal

value

Enter digital

value

2Apply entry

Or

Cancel entry

+/–

ST

AB EF

S

01

ENTER

ESC

90

to

.

,

to

90

to

,

The characters A to F must be entered in

alpha mode.

The entered value becomes valid.

The entry becomes invalid if the en-

tered value violates a configured limit

value or an incorrect entry is made.

The “old” value is retained.

The “old” value becomes valid again.

Correction

If you have made a mistake and have not yet applied the entry, proceed as follows:

IF ... THEN ...

Position the cursor on the digit and over-

Wrong digit

One digit too

many

1. Switch to alpha mode.

One digit too few

2. Inserts a blank where the cursor is positioned and

3. Shift back to numeric assignment of the input keys.

4. Overwrite blank.

3-6

write.

(The cursor remains on this position.)

INS

Deletes the digit at the cursor position and

DEL

consolidates the input from the left.

A–Z

INS

DEL

shifts the entry to the left starting at the cursor

position.

A–Z

A–Z

Equipment Manuel OP25, OP35, OP45

Release 04/96

Page 29

3.2.2 String Fields

Both numeric characters (i.e., digits) and alphanumeric characters (i.e., letters

of the alphabet) can be entered in a string field. Strings may also contain

blanks.

The cursor changes shape in input mode. The entry starts at the left edge of the

input field. The cursor jumps one position to the right each time a character is

entered.

Using the OP

Entry

Correction

T o make entries in a string field, proceed as follows:

Step Key Description

1

Enter digits

Enter letters

2 Apply entry

to

+/–

,

A–Z

ST

AB Y

to

ENTER

If necessary, switch back from alpha mode.

90

.

Switch to alpha mode.

Z

The entered string becomes valid.

Switch back from alpha mode

4

Or

Cancel entry

ESC

The input cursor is deleted.

Switch back from alpha mode

1

The “old” string becomes valid again.

If you have made a mistake and have not yet accepted the entry, proceed as

follows:

Wrong character

One character too

many

One character too

few

4) Not applicable to OP45

Equipment Manuel OP25, OP35, OP45

Release 04/96

IF ... THEN ...

Position the cursor on the character and

overwrite.

(The cursor jumps one position to the right

after the overwrite.)

INS

Deletes the character at the cursor position

DEL

and consolidates the input from the right.

1. Switch to alpha mode.

A–Z

INS

2. Inserts a blank where the cursor is

DEL

positioned and shifts the entry to the

right starting at the cursor position.

3. Overwrite blank.

3-7

Page 30

Using the OP

Example of a

string entry

You want to enter “valve 05”. Proceed as follows:

Key Display

A–Z

A–Z

A–Z

A–Z

A–Z

A–Z

A–Z

UV

,

EF

,

MN

,

ST

IJ

,

KL

,

,

0

V

VA

VAL

VALV

VALVE

VALVE

VALVE

VALVE 0

5

ENTER

VALVE 05

Apply entry .

3-8

Equipment Manuel OP25, OP35, OP45

Release 04/96

Page 31

3.2.3 Symbolic Fields

1

Open pop-up

indo

ENTER

Entries in symbolic fields are made with a pop-up window indicating the entries available for this field.

Using the OP

Entry

Example

T o make an entry in a symbolic field, proceed as follows:

Step Key Description

1 O

en o-u

w

w

2 Select entry

3 Apply entry

ENTER

ENTER

The value belonging to the selected

entry becomes valid.

The pop-up window is closed.

Or

Cancel entry

ESC

You want to use a symbolic entry to turn on mixer 3.

The pop-up window appears.

ENTER

The “old” value becomes valid again.

The pop-up window is closed.

ENTER

Equipment Manuel OP25, OP35, OP45

Release 04/96

Mixer 3 is marked “off”.

–

Off

On

You select mixer 3 “on”.

–

Off

On

The entry you selected is applied (i.e., accepted).

3-9

Page 32

Using the OP

3.3 Using the Windows of OP25/OP35

Several windows can be displayed at the same time on the OP.

T o use them, you can switch between the individual windows.

Switches between the following windows are possible.

Main screen

Fixed screen

Message line and message window

Selecting a window

Restrictions/

special features

Information key

Use the middle cursor key to select the window in which you want to work or

make entries.

Key Description

A–Z

A–Z

Each time you press this key the cursor jumps from one

window to the next.

The window in which the cursor is located is the active window (i.e., you can

make entries or perform other operations in this window).

You cannot switch to windows which do not contain input fields.

Exceptions: Message line, message window and message page

For these exceptions, the cursor is positioned on the first message. You can

then select the information text pertaining to the message.

How to use the information key

The first time the key is pressed

The information text pertaining to the selected field or message is displayed.

3-10

The second time the key is pressed

The information text pertaining to the main screen is displayed.

Equipment Manuel OP25, OP35, OP45

Release 04/96

Page 33

Using the OP

Static and dynamic

windows

The position of the displayed window is static on the OP25.

When an alarm message window or a pop-up window is displayed, for exam-

ple, an entry field hidden by the window cannot be used.

Generally , entries on the OP25 cannot be made unless all windows are closed.

The OP35 can be configured with dynamic window positioning.

When a window is to be displayed, it jumps automatically to a position which

does not cover up the input field or the cursor.

This means that entries can always be made regardless of the contents of the

display .

Equipment Manuel OP25, OP35, OP45

Release 04/96

3-11

Page 34

Using the OP

3-12

Equipment Manuel OP25, OP35, OP45

Release 04/96

Page 35

Screens

4

Overview

Logically related process values are combined into screens. Graphic elements

illustrate the relationships between these values. The individual screens provide a quick overview of a process or a system. In addition to showing what is

happening in the process, screens can also be used to control the process by

entering new process values.

Equipment Manuel OP25, OP35, OP45

Release 04/96

4-1

Page 36

Screens

4.1 The Operator Panel in Action

The OP is to control and monitor a plant which mixes and bottles various fruit

juices. Plant functions are divided roughly into the mixing and bottling stations.

Mixing station

Bottling station

The ingredients for the juices are stored in three tanks. The ingredients are

mixed in certain proportions depending on which fruit juice is to be produced.

After the juice is mixed, a valve is opened, and the finished fruit juice flows

into a filling tank and is then bottled. The bottles are transported on a conveyor belt. Before being filled, they are checked for glass breakage. After

being filled, the bottles are sealed, labelled and palletized.

TANK1 TANK2 TANK3

To the bottling station

MIXER

M

4-2

Equipment Manuel OP25, OP35, OP45

Release 04/96

Page 37

From

the mixer

Screens

Bottling station

Labelling

Figure 4-1 Mixing and bottling stations

Palletization

Equipment Manuel OP25, OP35, OP45

Release 04/96

4-3

Page 38

Screens

4.2 Screen Elements

Screens on the OP are made up of various screen elements. Some examples

are listed below.

Fixed texts

Semigraphic characters

Input fields for process values

Output fields for process values

Bars

Curves

Symbolic graphics

We will use the mixing station of the fruit juice plant to show you the various

screen elements.

Screen elements of

the sample screen

The screen might look something like this.

Mixing Station

1

3

6

Tank 1 Tank 2 Tank 3

Amount in

the mixer

(in l)

44

Valve 4

open

1

Fixed text

2

Semi-graphic (corresponding to tank)

3

Bar shows filling level of the tank graphically.

4

Symbolic input field to open and close the valve

5

Symbolic graphic shows the status of the valve (i.e., open or closed)

6

Numeric output field

7

Icons for the softkey functions

Valve 4

closed

Ingredients (in l)

Mixer mo-

Mixer

motor

on

tor

off

Selection

bottling station

2

4

5

Valve 4

7

Selection

main screen

4-4

Figure 4-2 Sample screen for a mixing station

Equipment Manuel OP25, OP35, OP45

Release 04/96

Page 39

4.3 Selecting a Screen

You can select a screen in the following ways.

Via function key (softkey)

Via an appropriately configured input field

Via job from the controller

Screens

Via function key

Via input field

Via job from the

controller

You can open a certain screen by pressing a function key (or a softkey).

A screen is opened after an entry has been executed in an input field configured for the selection of this screen.

When the state of the process/plant requires, the controller causes a screen to

be selected on the OP.

Equipment Manuel OP25, OP35, OP45

Release 04/96

4-5

Page 40

Screens

4.4 Standard Screens

The OP comes already equipped with standard screens. You can use these

standard screens for your configuration, or adapt them to fit your application.

Main screen

The standard screens are called from a main screen via softkey.

Main screen

Softkeys for

selecting

the standard

1

2 3 4 5 6

Figure 4-3 Main screen (example)

1

Password processing

2

Printer settings

3

Status Variable

4

System settings

screens

4-6

5

Message processing

6

Mixing station (our example)

For detailed information on function and use of the standard screens, see the

applicable sections in this manual.

Equipment Manuel OP25, OP35, OP45

Release 04/96

Page 41

Messages

5

Messages inform the operator of certain occurrences by displaying a text.

There are three types of messages.

Event messages indicate process states during normal operation of the sys-

tem.

Alarm messages indicate malfunctions/interruptions in the process.

System messages

In contrast to event and alarm messages which contain process-related information, system messages provide information on internal operating

states/errors of the OP.

Equipment Manuel OP25, OP35, OP45

Release 04/96

5-1

Page 42

Messages

5.1 Event and Alarm Messages

Event and alarm messages provide information on normal or critical process

states by indicating message texts. The message texts may also contain current

measured values.

Below are two examples showing the differences between event and alarm

messages.

Event messages

Alarm messages

The fruit juice plant has finished a mixing procedure. An event message informs the operator of this. The event message might look something like this:

Mixing procedure finished

Juice in the mixer: 5000 l

The operator would now like to start the bottling procedure but has forgotten to

open the filling valve. The controller automatically stops the bottling procedure and outputs an alarm message. The alarm message might look something

like this:

Bottling procedure terminated

Filling valve is closed !

Because of their urgency, alarm messages must be acknowledged to ensure that

the operator has noticed the message.

Acknowledgement can also be performed by the controller.

5-2

Equipment Manuel OP25, OP35, OP45

Release 04/96

Page 43

5.1.1 General Features

Messages

Available methods

of indication

Message line,

message window

The OP offers the following ways to indicate event and alarm messages.

You can indicate a current event or alarm message in a message line or in a

message window.

You can configure one of the following combinations:

Indicate an event or alarm

message in the message line

Indicate an event message in

the message line and an

alarm message in the message window

Message line

Event or alarm message

Message line

Event message

Alarm message window

Alarm message

Indicate an event/alarm mes-

sage in the appropriate message window

Event message window

Alarm message window

Event message

page, alarm

The operator can look at all still queued event messages or alarm messages on

the appropriate message page.

message page

The OP stores all messages in a battery-buffered memory. The operator can

Message buffer

look at these stored messages.

Indication priorities

Each message is given a priority during configuration. This priority determines the importance of the message.

When several messages are queued, the message with the highest priority is

indicated first.

When several, unacknowledged alarm messages are queued, either the first

(i.e., the oldest) or the last (i.e., the latest) message is indicated.

The operator can change the configured type of indication (first/last).

When several event messages with the same priority are queued, the latest

is indicated.

Equipment Manuel OP25, OP35, OP45

Release 04/96

5-3

Page 44

Messages

Message states

Message indicator

Acknowledging

alarm messages

Message occurrences may assume the following states:

Arriving Marks the occurrence of the message

Departed Cause of the message no longer exists.

Acknowledged Only for alarm messages.

The operator or the controller has recognized the message

and confirmed it.

The OP acquires these message states with the precise time and outputs them

when a message page or the message buffer is indicated.

At least one alarm message is still queued when this symbol appears on the

OP’s display.

Alarm messages must be acknowledged by either the operator or the controller.

Acknowledgement

groups

Key Description

Acknowledge indicated alarm message

ACK

After acknowledgement, the next unacknowledged message (if one exists) is

then faded in.

You can combine messages into acknowledgement groups.

When the indicated message belongs to an acknowledgement group, its ac-

knowledgement automatically acknowledges all other alarm messages of this

acknowledgement group.

5-4

Equipment Manuel OP25, OP35, OP45

Release 04/96

Page 45

5.1.2 Current Messages

Messages

Message line

Flashing alarm

messages

Priorities of indication

The message line is always present regardless of which screen is selected.

Depending on your configuration, event messages and/or alarm messages are

displayed in the message line.

Example of an event message:

Mixing procedure finished

Juice in mixer: 5000 l

Process value at the time of arrival

Alarm messages flash to distinguish them from event messages.

Alarm messages

Event messages

Alarm messages always take precedence

over event messages.

Event messages are not indicated unless no

more alarm messages are queued and all

have been acknowledged.

Message window

Standby

message

A standby message is indicated when no

event messages are queued.

In addition to the message text, messages in a message window contain other

information (e.g., message number and date/time of the arrival of a message).

Example of an alarm message window:

Message number Date

Time

Acknowledge–

ment group

Number of unacknowledged messages

0048 11:34:02 11.11.93 QGR.01 2

Tank 25: Temperature 156 degrees

Call shift supervisor: Tel: 9465

Process value at time of arrival

Equipment Manuel OP25, OP35, OP45

Release 04/96

5-5

Page 46

Messages

Event message

window

Alarm message

page,

event message

page

The event message window is not automatically faded in. It must be selected

by the operator or the controller and then deselected again later.

A standby message is displayed when no current event message is queued.

Message number Date

Time

i

Number of not departed

messages

0050 11:42:17 11.11.93 12

Tank 25: Temperature within tol.

again 94 degrees

Process value at time of arrival

The message pages give the operator an overview of the still queued (i.e., not

yet departed) alarm or event messages.

The event message page or the alarm message page can be selected on the OP

or via the controller.

The individual message occurrences are sorted by indication priority and, if

alarm messages, listed by first/last setting.

Example of an alarm message page:

Alarm Message Page

0049 K 11:32:00 11.18.93 QGR:01

Tank press. too high: 12.7 bar

0049 KQ 11:33:20 11.18.93 QGR:01

Tank press. too high: 10.3 bar

0010 K 11:34:36 11.18.93 QGR:02

Oil feed stopped!

0010 KQ 11:35:18 11.18.93 QGR:02

Oil feed stopped!

Message status:

K = arrived,

Q = acknowledged

Message number

Time and date of arrival

Process value

at time of arrival

Acknowledgement

group

If all messages do not fit on the display at the same time, you can scroll the

contents of the message page up/down with the

, cursor keys.

5-6

Equipment Manuel OP25, OP35, OP45

Release 04/96

Page 47

Messages

The message page contains the following information for each message occurrence.

Message number

Message status with date and time

The OP updates the message status display (e.g., K for arriving, Q for

acknowledged).

Acknowledgement group to which an alarm message belongs

Message text, with process values if applicable

When a message contains process values, the OP indicates these values as

they were when the state occurred or stopped occurring (i.e., time of arrival

or time of departure).

The OP does not acquire current process values after the message has been

acknowledged.

To message buffer

and back

Message logging

You can switch back and forth between indication of the message page and the

message buffer by repeatedly pressing the function key which you used to call

the alarm message page/event message page.

All message occurrences are logged directly on a printer (if message logging is

switched on and a printer is connected).

Equipment Manuel OP25, OP35, OP45

Release 04/96

5-7

Page 48

Messages

5.1.3 Stored Messages

The OP stores all message occurrences in a battery-buffered memory.

This allows you to indicate the messages at a later time.

Alarm message

buffer, event

message buffer

The stored message occurrences are indicated in the alarm message buffer or

the event message buffer depending on what type of message they are.

A buffer page can be selected on the OP or via the controller.

All messages are indicated in the order of when they occurred. The latest

message is shown at the top of the display.

Example of indicating the alarm message buffer:

Alarm Message Buffer

0010 KGQ11:38:04 11.18.93 QGR:02

Oil feed stopped!

0010 KQ 11:35:18 11.18.93 QGR:02

Oil feed stopped!

0049 KGQ11:34:09 11.18.93 QGR:01

Tank press. too high: 9.3 bar

0049 KQ 11:33:20 11.18.93 QGR:01

Tank press. too high: 10.3 bar

0049 K 11:32:00 11.18.93 QGR:01

Tank press. too high: 12.7 bar

Message status:

K = arrived,

G = departed,

Q = acknowledged

Message number

Time and date of arrival

Process

value

Acknowledgement

group

Deleting the buffer

5-8

If a message text contains process values, the OP indicates these values as they

were when the message occurrence arrived and departed.

Otherwise, the information is identical to that of the event message page or

alarm message page.

The event message buffer/alarm message buffer can be deleted by operator

input on the OP or via the controller.

Exceptions:

Queued messages

Not yet acknowledged alarm messages

Equipment Manuel OP25, OP35, OP45

Release 04/96

Page 49

Messages

Buffer overflow

The OP stores message occurrences in a common memory area for event and

alarm messages (i.e., the so-called message buffer).

If there is only a certain amount of memory space left in the message buffer

(i.e., remaining buffer space), the OP can fade in a system message to that effect.

If there is no space left in the message buffer and new messages arrive, the OP

continues deleting message occurrences from the message buffer until a certain

remaining buffer space is available again.

The oldest message occurrences are deleted in the following order.

1. Event messages which have already departed

2. Alarm messages which have departed and have been acknowledged

3. Event messages which are queued

4. Alarm messages which are queued

A forced printout of the deleted messages is made (if overflow was configured

as on, and a printer is connected).

Equipment Manuel OP25, OP35, OP45

Release 04/96

5-9

Page 50

Messages

5.1.4 Standard Screen: Message Processing

Layout

Uses

Event and alarm messages can be processed with the standard screen Message

Processing.

Message Processing

ESC

1 2 3

Softkeys

Return to main

screen

Figure 5-1 Standard screen: Message Processing

The softkeys have the following meaning:

1

Open event message window

2

Delete event message buffer

3

Delete alarm message buffer

In addition, the following functions can be selected via function keys.

Open event message page, alternate between indicating the event

K1

message page and the event message buffer

Open alarm message page, alternate between indicating the alarm

K2

message page and the alarm message buffer

5-10

Equipment Manuel OP25, OP35, OP45

Release 04/96

Page 51

5.2 System Messages

System messages inform you of certain internal operating states of the OP.

The messages include everything from informational notes to serious and fatal

error messages.

System messages can be caused by the following:

Operator errors

(e.g., illegal entries)

System errors

(e.g., disturbed communication between OP and controller)

Messages

System message

window

Deselecting

As soon as a certain operating state/error occurs, the OP automatically fades in

a window containing a system message.

Example of a system message window:

Message number

i

210 Buffer overflow warning

A system message consists of a message number and a message text. The message text can also contain internal system variables which help to localize the

cause of the error message.

Some system messages expect a confirmation from or a decision by the operator. For example:

“Format data medium? 0 Yes/ 1 No”

The entry of 0 (yes) or 1 (no) then determines what happens next.

The system message window can be closed by pressing the cancel key or by

selecting another screen.

Error causes,

remedies

The appendix of this manual contains a list of system messages including additional information on the cause of the message and any system variables indicated. In some cases, possible remedies are also shown.

Equipment Manuel OP25, OP35, OP45

Release 04/96

5-11

Page 52

Messages

5-12

Equipment Manuel OP25, OP35, OP45

Release 04/96

Page 53

Recipes

6

Our fruit juice plant was introduced in section 4 of this manual. The finished

product of our fruit juice plant is a bottle of fruit juice.

The finished product (i.e., a bottle of fruit juice) is determined by the various

variables of the system.

You can combine the variables for one type of juice into a set of “processing

instructions”. This set of “instructions” is called a recipe. The individual variables are called recipe entries. Recipes are configured and cannot be changed

on the OP.

Equipment Manuel OP25, OP35, OP45

Release 04/96

6-1

Page 54

Recipes

Example of

a recipe

Data records

We will call our recipe “ORANGE”.

Tank 1

Tank 2

Mixing time

Bottle size

Label

Bottles per case

One type of juice can be mixed in different concentrations to make orange

“drink”, orange “nectar” or “pure” orange juice, for example. The juice can

then be bottled in different-sized containers. All this is performed with the

same recipe but using different values for the individual entries. Related values for the entries (e.g., for the orange drink) are combined into a data record.

The data records for a recipe are put together on the OP. An example of how

they could appear is shown below.

Data Records For

“ORANGE” Recipe

Drink Nectar Juice

Tank 1

Tank 2

Mixing time

Bottle size

Label

Bottles per case

90

10

5

1

4

6

70

30

10

0.7

2

12

0

100

0

1

1

6

6-2

Equipment Manuel OP25, OP35, OP45

Release 04/96

Page 55

Recipes

Analogy of a file

cabinet

A file cabinet is a good way to illustrate how recipes function.

The file cabinet is the plant or the process to be controlled. Each of the indi-

vidual drawers represents the fixed structure of one recipe. Index cards in the

drawer contain the data records for that recipe.

Fruit Juice Plant

GRAPEFRUIT

LEMON

.......

Juice

Nectar

Drink

ORANGE

The operator uses the operator panel to “handle the index cards”.

We will now show you how to do this in the following subsections.

Equipment Manuel OP25, OP35, OP45

Release 04/96

6-3

Page 56

Recipes

6.1 Processing and Transferring the Data Records

Up to now, you have learned that the recipe and its entries are configured and

that you cannot change the recipes with the OP later on.

Thus, handling of the recipes with the operator panel is limited to the following

operations on the data records.

Store (set up)

Load

Delete

Edit

6-4

Equipment Manuel OP25, OP35, OP45

Release 04/96

Page 57

Recipes

6.1.1 Standard Screens: Data Record Processing and Data Record Transferring

The standard screen Data Record Pr ocessing is available for processing data

records. A second standard screen called Data Record Transmission provides

you with special transmission functions.

Data record

processing screen

Layout of the “Data Record Processing” Standard Screen

Data Record Processing

Recipe:

Data record name:

Comments:

Storage medium:

ORANGE

Drink

(T ext)

Int. Flash

Format

ESC

Symbolic input

String input

Symbolic input

Softkeys

Figure 6-1 Standard Screen: Data record processing

The icons in the softkey bar have the following meaning:

Softkey Description

A-Z

SAVE

Copy the current values from the PLC to the OP and store

them as a data record on the required storage medium

( Chap. 13):

OP25/35: internal flash memory or Jeida / PCMCIA-

module

OP35/45: floppy disk

OP45: hard disk

A-Z

A-Z

A-Z

A-Z

LOAD

DELETE

EDIT

SELECT

Load the selected data record from the selected storage

medium in the OP and transfer to the controller

Delete the selected data record from the selected storage

medium

Note:

If you want to delete all data records, it is easier to just

reformat the FLASH memory or floppy disk.

Edit (change) the selected data record on the selected

storage medium

Select a data record from the selected recipe

Equipment Manuel OP25, OP35, OP45

Release 04/96

6-5

Page 58

Recipes

Data record transmission screen

You can transfer the current values back and forth between the OP and the controller without storing the values on a data medium. This makes process startups easier, for example.

Transmission between OP and data medium is also possible.

The Data Record Transmission screen is available for these transmissions.

Data Record Transmission

Recipe:

Data record name:

Comment:

Data medium:

ORANGE

Drink

(Text)

Int. Flash

ESC

Symbolic entry

String entry

Symbolic entry

Softkeys

Figure 6-2 Example of a data record transmission screen

The icons in the softkey bar have the following meaning:

Softkey Description

SPS OP

OP SPS

Dat OP

OP Dat

SELECT

Transfer the current values from the controller to

the OP (update values in the OP)

Transfer the current values from the OP to the controller (transfer values to the controller)

Transfer a data record from the data medium to the

OP

Transfer a data record from the OP to the data medium

Select a data record name

6-6

Equipment Manuel OP25, OP35, OP45

Release 04/96

Page 59

Recipes

General use

Step Key/

1 Select recipe

name

2

Entering data

record names

or

Select data

record name

The following table shows you how to use the standard screens “Data Record

Processing” and “Data Record Transmission”.

Description

Softkey

Adhere to the following conventions when assigning data record names.

Names may not contain more than 11 characters.

After the eighth character is entered, a period is inserted automatically.

After the period, up to three characters can still be entered.

Special characters, blanks and commas may not be used.

A-Z

Activating the softkey causes a window to appear indicating all

data records of the selected recipe.

ORANGE

Drinks 05.10 11:34 Commentary

Nectar 05.12 20:17 Commentary

Juice 05.13 08:56 Commentary

Recipe

Data record

name

Time and date of the last storage/

change

Using the data record selection window:

3 Select data me-

dium

1. Select the desired data record with the cursor

2. Accept selected data record, and close window.

Data records can be stored/archived on the following data mediums to the ex-

tent that the OP is equipped with these:

keys.

ENTER

,

Internal FLASH, floppy disk, hard disk and PCMCIA/JEIDA card

4 With the softkey, select the function to be executed (e.g., load, save, and edit).

Equipment Manuel OP25, OP35, OP45

Release 04/96

6-7

Page 60

Recipes

6.1.2 Setting Up and Editing Data Records

Only the recipe structure is specified during configuration of the OP. No data

records exist yet. These are generated/set up on the OP.

Setting up/editing

data records

The standard screen called Data Record Pr ocessing contains an edit function.

You can use this function to accomplish the following.

Set up new data records on a selected data medium

Change the contents of data records stored on a data medium

T o set up/edit data records, proceed as follows.

1. Select recipe.

2. Enter data record names.