Siemens OP5, OP15 Equipment Manual

SIMATIC HMI

Preface, Contents

1

Teil I: Introduction

2

3

Teil II: Basic Functions

OP5, OP15

Operator Panel

Equipment Manual

10

11

Teil III: Expanded, Configurable

Functions

13

14

Teil IV: Commissioning and

Description of Devices

20

A

Teil V: Appendix

F

Glossary, Index

6AV3991–1 AB20–0AB0

Release 01/96

Safety Guidelines

!

!

This manual contains notices which you should observe to ensure your own personal safety, as

well as to protect the product and connected equipment. These notices are highlighted in the

manual by a warning triangle and are marked as follows according to the level of danger:

Warning

indicates that death, severe personal injury or substantial property damage can result if proper

precautions are not taken.

Caution

indicates that minor personal injury or property damage can result if proper precautions are not taken.

Note

draws your attention to particularly important information on the product, handling the product, or

to a particular part of the documentation.

Qualified Personnel

Correct Usage

!

Trademarks

Equipment may be commissioned and operated only by qualified personnel. Qualified personnel

within the meaning of the safety notices in this manual are persons who are authorized to commission, ground and identify equipment, systems and circuits in accordance with safety engineering

standards.

Note the following:

Warning

The equipment may be used only for the applications stipulated in the catalog and in the technical description and only in conjunction with other equipment and components recommended or

approved by Siemens.

Startup must not take place until it is established that the machine, which is to accommodate this

component, is in conformity with the guideline 89/392/EEC.

Faultless and safe operation of the product presupposes proper transportation, proper storage,

erection and installation as well as careful operation and maintenance.

SIMATIC is a registered trademark of Siemens AG.

Some of the other designations used in these documents are also registered trademarks; the

owner’s rights may be violated if they are used be third parties for their own purposes.

Impressum

Copyright Siemens AG 1996 All rights reserved

The reproduction, transmission or use of this document or its contents is not permitted

without express written authority. Offenders will be liable for damages. All rights,

including rights created by patent grant or registration of a utility model or design, are

reserved.

Siemens AG,

Bereich Automatisierungstechnik,

Bedienen und Beobachten

Postfach 4848, D-90327 Nuernberg

Siemens Aktiengesellschaft Order No. 6AV3991–1AE05–0AB0

Editor and Publisher: AUT 91

Disclaimer of Liability

We have checked the contents of this manual for agreement with the hardware and

software described. Since deviations cannot be precluded entirely, we cannot guarantee

full agreement. However, the data in this manual are reviewed regularly and any necessary corrections included in subsequent editions. Suggestions for improvement are

welcomed.

Technical data subject to change.

Siemens AG 1996

Gerätehandbuch OP7, OP17

Preface

Purpose

Complete

documentation

This equipment manual is a part of the documentation for the OP5 and OP15

Operator Panels which have been configured with ProTool configuration

software. It provides operators, fitters, configurers and system support engineers with information on functionality and the technical design of the OP5

and OP15 Operator Panels.

The following manuals/media make up the complete set of documentation for

the OP5 and OP15 Operator Panels.

PC

Configuration

COROS

ProTool/Lite

User’s Guide

Online

help

OP

Installation

Operator control

COROS

Operator Panel

OP5, 15

Equipment Manual

Manual OP5, OP15

( ) J31069-D0840-U001-A2-7618

PLC

Coupling

COROS

Communication

User Manual

Other PLCs

i

Preface

How the Manual is

Organized

Part I

Part II

Part III

Part IV

Part V

This manual is divided into five parts:

Chapters 1 and 2 contain information of a general nature. They describe the

general design of Operator Panels OP5 and OP15 and provide an overview of

the functions of the different device versions.

Chapters 3 and 4 describe how you operate the devices. You should study

these chapters before using the different functions.

Chapters 5 to 10 provide a detailed description of how you use different functions – for instance, screens, messages, password protection and recipes.

Chapters 11 to 13 describe the expanded functions of the OP such as online

modification of system settings, controller jobs and schedulers.

Chapters 14 to 20 inform you about installation, connecting, commissioning,

testing and maintenance of the Operator Panels. This part is aimed primarily

at installation and commissioning personnel.

Appendices A to F contain miscellaneous tables, ESD guidelines and a glossary of the terms used in this manual.

Conventions

The following conventions are used in this manual:

Motor off T ext on the display of the OP is shown in “type-

writer”style

Variable

Symbolic names representing variable values on the

display are shown in italic ”typewriter” style.

Screens Functions which you can choose are shown in nor-

mal italics.

Screens →Print Steps that are performed in succession are linked by

an arrow.

ESC The names of keys are shown in a different typeface.

ii

( ) J31069-D0840-U001-A2-7618

Manual OP5, OP15

Preface

History

Other support

Abbreviations

The different editions of the equipment manual refer to the following ProT ool/Lite versions or OP firmware versions.

Edition Remarks ProTool/Lite-

Version

06/95 First edition of the manual Up to V 1.01 OP5: From V 1.20

01/96 Expansion of the manual

to include recipe and

scheduler functions

From V 2.0 OP5: From V 1.30

OP-Firmware

OP15: From V 2.20

OP15: From V 2.30

For technical questions, get in touch with your local Siemens representative.

You will find the addresses in appendix F of this manual, in our catalogs and

under Compuserve (go autforum) to mention a few examples. In addition,

our hotline is ready to help you (telephone +49 (911) 895–7000,

fax +49 (911) 895–7001).

AS511 Protocol of the PU interface to the SIMATIC S5

ASIC Application-specific integrated circuit

CPU Central processing unit

EM Equipment manual (German abbreviation: GHB)

EPROM (with UV light) erasable programmable read-only memory

EV Event messages

FB Function block

IF Interface designation

LCD Liquid-crystal display

LED Light-emitting diode

MPI Multitpoint Interface

OD Output double word (on the PLC)

OP Operator Panel

PLC Programmable Logic Controller

PPI Point to Point Interface

PU Programming Unit (German abbreviation: PG)

RAM Random access memory (working memory)

SRAM Static RAM (buffered)

VF Vacuum fluorescence

Manual OP5, OP15

( ) J31069-D0840-U001-A2-7618

iii

Preface

iv

( ) J31069-D0840-U001-A2-7618

Manual OP5, OP15

Contents

Preface

Part I Introduction

1 Product Description 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Configuration and process control phases 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Functions of an Operator Panel 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

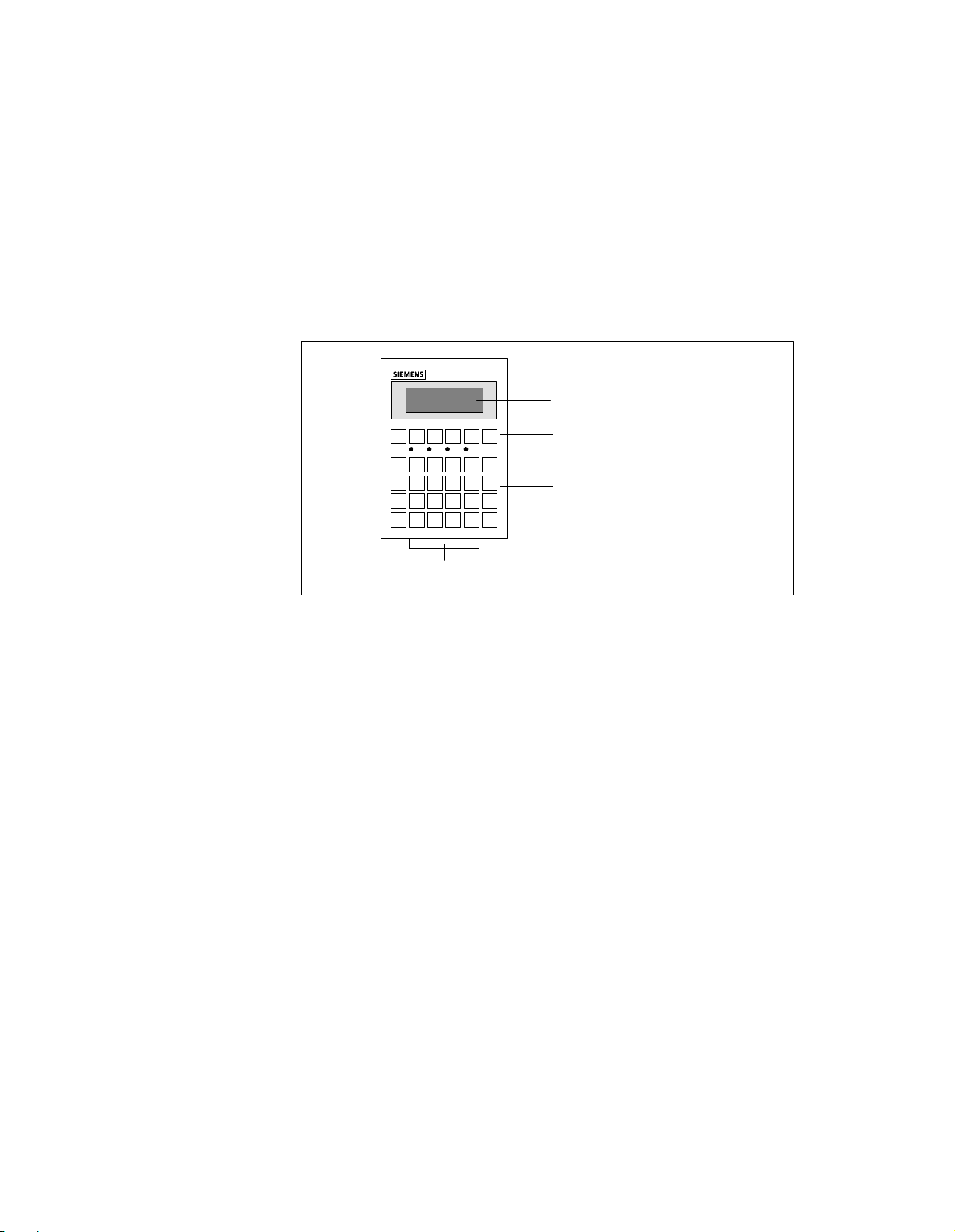

1.3 Design of Operator Panel OP5 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

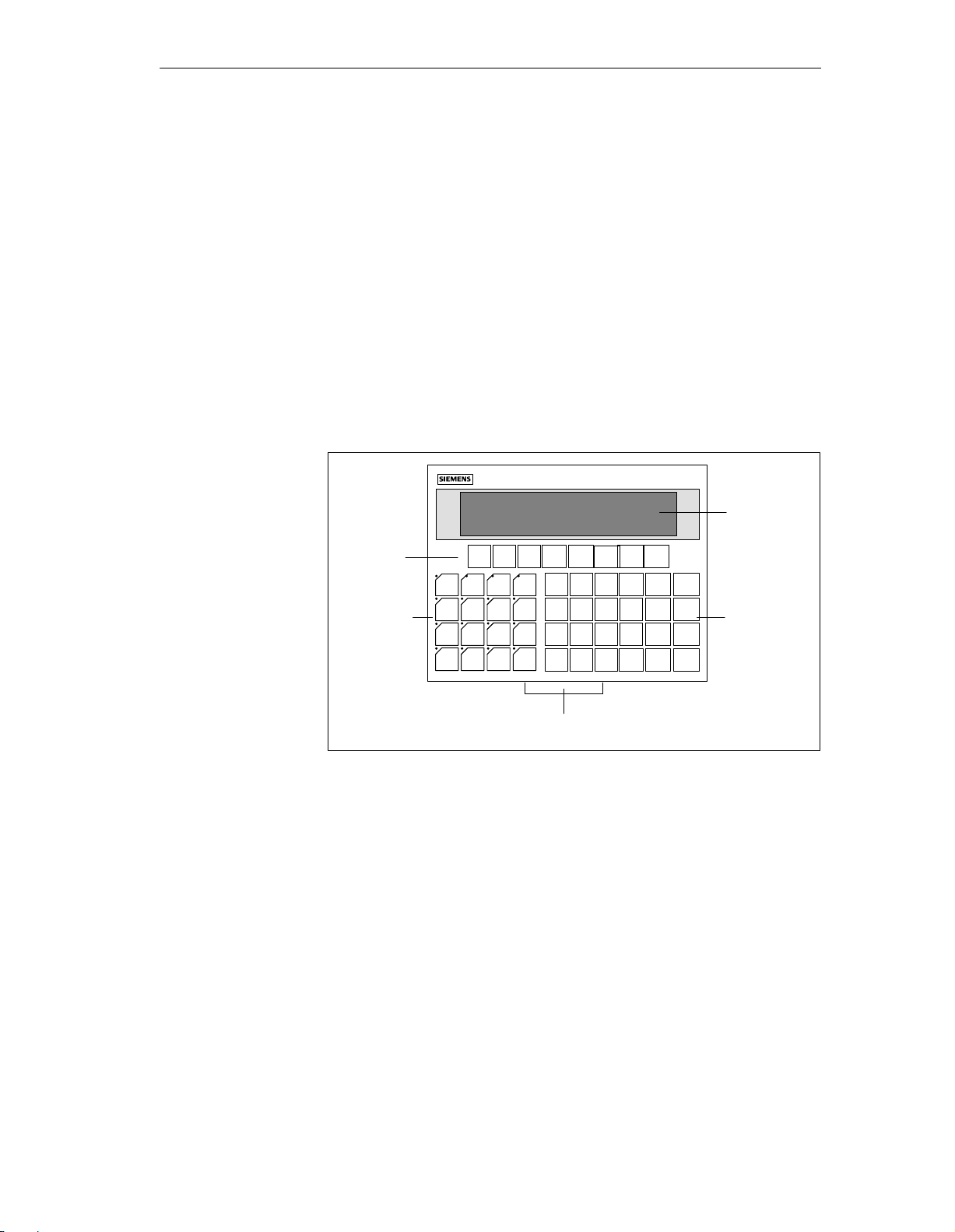

1.4 Design of Operator Panel OP15 1-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Functionality 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part II Basic functions

3 Using the OP with Its Standard Functions 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Operating Levels 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Standard Screens 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Branching in Standard Screens 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 General Operation 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 System Keyboard 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.1 ESCAPE Functions 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.2 Information Text 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Entering Values 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1 Entering Numerical Values 4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.2 Entering Alphanumeric Values 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.3 Entering Symbolic Values 4-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Screens 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Screen Entries 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Choosing Screens 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Editing Screens 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Printing Screens 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual OP5, OP15

( ) J31069-D0840-U001-A2-7618

v

Contents

6 Password Protection 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Password Levels and Access 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Login/Logout on OP (LOGIN/LOGOUT) 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Password Management 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Message Handling 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Event Messages and Alarm Messages 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.1 Acknowledging Alarm Messages 7-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2 Inhibiting Alarm Messages 7-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 System Messages 7-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Displaying Messages 7-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.1 Display Sequences 7-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.2 Scrolling through Waiting Messages at Message Level 7-8. . . . . . . . . . . . . . . .

7.3.3 Viewing Event and Alarm Message Text 7-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 Viewing Message Buffers 7-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5 Deleting Messages 7-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5.1 Deleting Event and Alarm Messages Using Standard Screens 7-12. . . . . . . . .

7.5.2 Automatically Deleting the Alarm Buffer upon Buffer Overflow 7-12. . . . . . . . . .

7.5.3 Automatically Deleting the Event Buffer upon Buffer Overflow 7-13. . . . . . . . . .

7.5.4 Automatically Deleting the System Message Buffer upon Buffer Overflow 7-13

7.6 Printing Messages 7-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6.1 Direct Message Logging 7-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6.2 Printing the Message Buffer 7-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Recipes 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Setting Up and Editing Data Records 8-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Copying Data Records 8-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Transferring Data Records 8-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 Deleting Data Records 8-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 STATUS VAR and FORCE VAR Functions with the OPs (S7/S5 Only) 9-1. . . . . . . .

10 System Settings on Standard Screens 10-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 Selecting a Language 10-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 Modifying Parameters in Online Mode 10-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3 Adjusting Contrast 10-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4 Modes 10-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

( ) J31069-D0840-U001-A2-7618

Manual OP5, OP15

Contents

Part III Expanded, Configurable Functions

11 Process-Dependent Operator Guidance 11-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1 Branching by Means of Soft Keys and Function Keys 11-1. . . . . . . . . . . . . . . . .

11.2 Self-Defined Screen Hierarchy 11-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12 Schedulers 12-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13 Controlling the OP from the PLC 13-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part IV Commissioning and Description of Devices

14 Mechanical Installation 14-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15 Electrical Installation 15-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.1 Setup Guidelines for Interference-Proof Installation 15-2. . . . . . . . . . . . . . . . . . .

15.2 Assigning the Terminal Block 15-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.3 Connecting a Configuration Computer 15-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.4 Connections to PLC 15-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.5 Loop-Through Mode (OP15 only) 15-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16 Commissioning 16-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.1 Commissioning Guide 16-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.2 Start-up Behavior 16-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.3 Testing the Configuration in OFFLINE Mode 16-5. . . . . . . . . . . . . . . . . . . . . . . . .

16.4 Testing the Configuration in Conjunction with the PLC 16-6. . . . . . . . . . . . . . . .

17 Device Description 17-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.1 OP5 17-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.2 OP15 17-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.3 Labeling strips 17-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.4 External Floppy Disk Station (Option for OP15) 17-6. . . . . . . . . . . . . . . . . . . . . .

18 Connecting a Printer 18-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19 Test and Monitoring Functions 19-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20 Maintenance 20-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual OP5, OP15

( ) J31069-D0840-U001-A2-7618

vii

Contents

Part V Appendices

A Brief Description of Standard Screens A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B System Messages B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C Technical Data C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D Interface Assignment D-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.1 Interface Configuration D-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.2 Pin Assignment D-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E ESD Guidelines E-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E.1 What Does ESD Mean? E-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E.2 Important Precautions against Electrostatic Discharge E-2. . . . . . . . . . . . . . . .

E.3 Handling ESD Assemblies E-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E.4 Measuring and Modifying ESD Assemblies E-2. . . . . . . . . . . . . . . . . . . . . . . . . .

E.5 Shipping ESD Assemblies E-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F Siemens Worldwide F-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary

Index

viii

( ) J31069-D0840-U001-A2-7618

Manual OP5, OP15

Part I Introduction

Product Description

Functionality

1

2

-2

( ) J31069-D0840-U001-A2-7618

Manual OP5, OP15

Product Description

1

Applications of

OP5 and OP15

Operator Panels OP5 and OP15 allow operating states, current process values

and malfunctions of a connected PLC to be visualized. In addition, inputs can

be made on the OP which can be written directly to the PLC. Some functions

relating to machine diagnostics can also be executed on the Operator Panel.

The Operator Panels are suitable for fitting into switching cabinets and control desks. A printer can be attached to the OP for logging processes during

automation operation.

The Operator Panels feature a number of standard functions. The displays

and operation of the devices can be optimized by the configurer to meet the

requirements of the process.

1.1 Configuration and process control phases

Creating data

areas

Configuration with

ProTool/Lite

Before an OP can go into service, it has to be prepared for its job of visualizing data from the PLC, i.e. it has to be configured. As far as the PLC is concerned, data areas used by the OP to communicate with the PLC have to be

created in the memory.

The configuration for the OP is created on a computer (PC/PU) using ProT ool/Lite configuration software under Microsoft Windows

configuration is ready, it is transferred to the OP. Before this can be done,

however, the computer has to be connected to the Operator Panel. Following

transfer of the configuration, the OP has to be connected to the PLC.

TM

. When the

The OP now communicates with the PLC and reacts to program flows on the

PLC on the basis of the configured requirements.

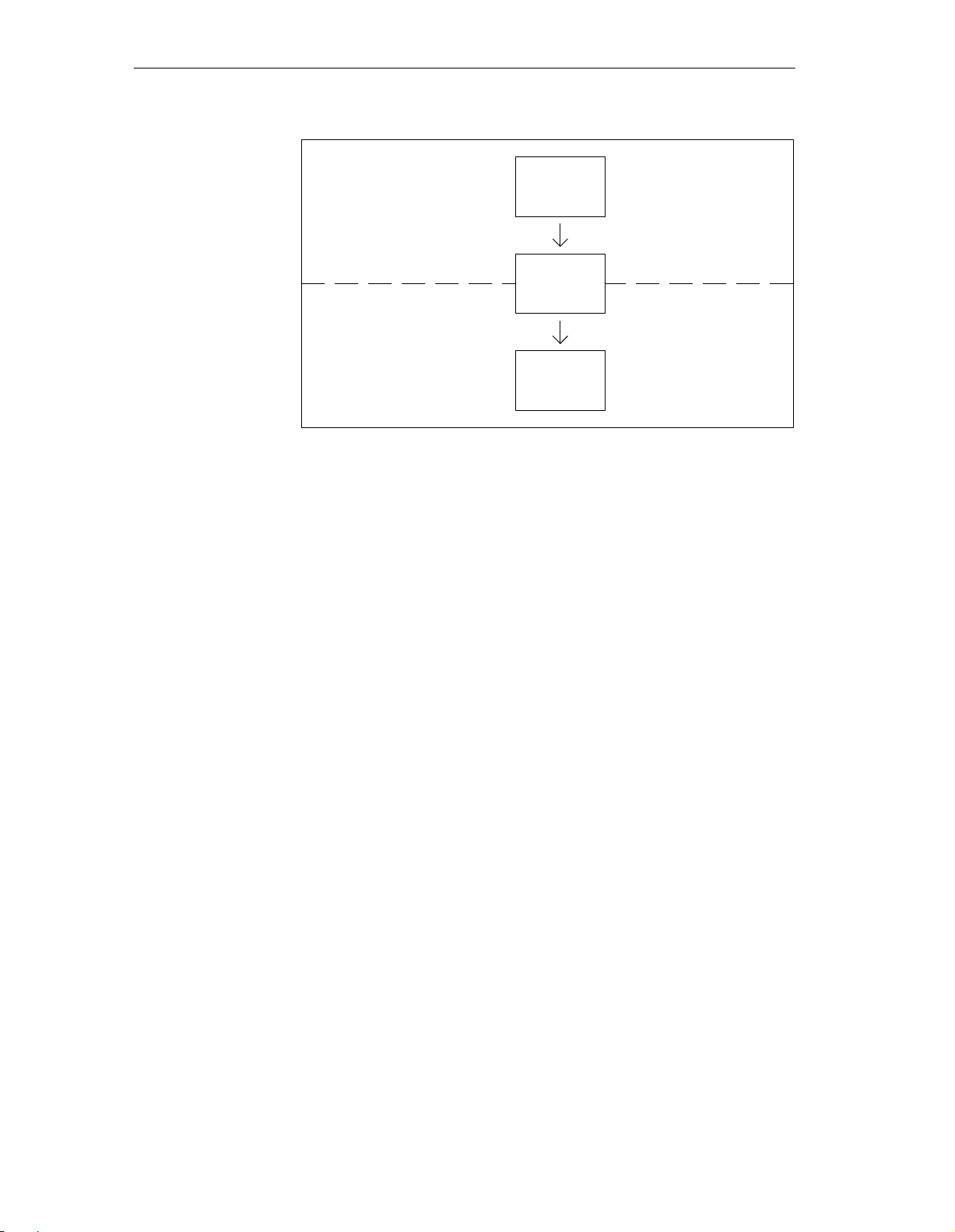

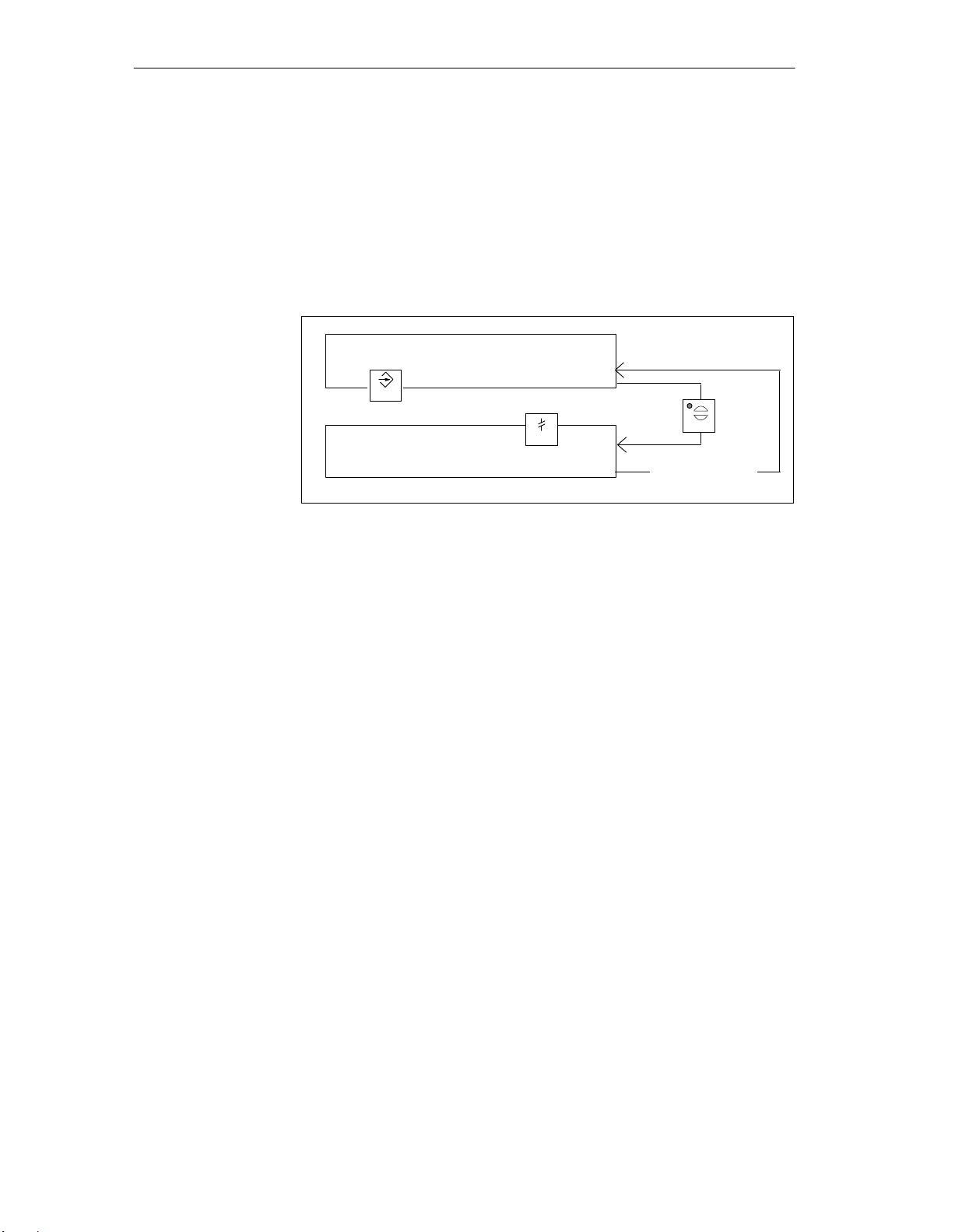

The following illustration depicts the configuration and process control

phases de scribed above:

Manual OP5, OP15

( ) J31069-D0840-U001-A2-7618

1-1

Product Description

Static and variable

text components

Figure 1-1 Configuration and Process Control Phase

T ext which is required to be displayed on the OP has first to be created on the

PC/PU with ProT ool/Lite and then transferred to the OP. If, for example, text

for display is required to comprise static and variable components, the variables have to be configured and the static text for explaining the variables has

to be entered – for example:

Temperature

Variable_xx

C of Furnace 1

Further

information

Here, Temperature C of Furnace 1 is the static text and

able_xx

is the variable that is read from the memory area of the PLC.

Vari-

You will find information on configuring the OP in the ProTool/ Lite User’ s

Guide. The Communications User’ s Guide provides information on connect-

ing the OP to the PLC.

1-2

( ) J31069-D0840-U001-A2-7618

Manual OP5, OP15

1.2 Functions of an Operator Panel

Product Description

Display and

control functions

Screens

The basic functions of an OP consist in displaying process states and in control ling the process. The following display and control functions can be configured on Operator Panels OP5 and OP15:

screens

event messages

alarm messages

recipes

information text

logging

languages.

Data supplied by the PLC may be displayed together on a screen and modified individually , if required. A screen consists of several screen entries

since, for example, more related data are required for describing a machine

state than can normally be displayed in the window of a screen. Therefore

data on operating temperature, fill level, speed and running time can illustrate the current machine state.

The OP5 and OP15 are line displays. Accordingly, a screen on the display

comprises text items which may include static text and current state values.

Event messages

Alarm messages

Screens may be combined on the OP in a directory. You can use the directory

to display, print and edit screens.

Event messages are information and operating notes on current machine and

process states during regular production operations. Event messages may

contain process values. Process values are displayed either numerically – for

example,

Motor running at 3000 revs

or symbolically – for example,

Motor running normally,

where a specific control value is assigned to normally.

The classification of a message as an event message is done at the configura-

tion stage.

Alarm messages show, in contrast to event messages, critical machine states

dur ing production operations. Due to their urgency, they have to be acknowledged before any other action is possible.

Manual OP5, OP15

( ) J31069-D0840-U001-A2-7618

1-3

Product Description

Alarm messages may contain process values. Process values are displayed

either numerically – for example

Motor speed 4500

or symbolically – for example

Motor speed too high,

where a specific control value is assigned to too high.

This type of message has a higher display priority than an event message. If

an alarm message is issued, any event message or screen that is being displayed is replaced with a flashing alarm on the display.

The classification of a message as an alarm message is made at the configuration stage.

Recipes

Information text

Logging

When a product is made up of various ingredients in certain ratios, this information is stored in a so–called recipe.

T ake orange juice for example. Its production and bottling requires that

orange concentrate and water be mixed in a certain ratio. These values are

stored as variables in a recipe.

Each recipe can be made up of several data records containing different values for the recipe.

The data can be edited in the OP, transferred to the PLC and read out from

the PLC.

In the OP, the recipes are combined by recipe number and title in a recipe

directory .

Information text is additional information and hints for operators referring to

the current display on the screen (event messages, alarm messages and

screens). This means that additional troubleshooting information can be displayed when, for instance, an alarm message is issued.

Information text can also be displayed by pressing a key, if required, when

the LED of the HELP key is on.

Messages can be printed in online mode by means of the printer connected to

the OP. Furthermore, there is a possibility of printing all the event and alarm

messages that have accumulated in the buffer concerned.

1-4

( ) J31069-D0840-U001-A2-7618

Manual OP5, OP15

Product Description

Languages

Message text, screens, information text and system messages may be displayed in several languages. Up to three of the languages listed below can be

loaded simultaneously on the same OP and presented to the operator for

selection on line:

German

English

French

Italian

Spanish.

For the OP15/C, displays can be configured in Russian, i.e. in Cyrillic characters.

Manual OP5, OP15

( ) J31069-D0840-U001-A2-7618

1-5

Product Description

1.3 Design of Operator Panel OP5

OP5 versions

The OP5 is available in the following two versions:

OP5/A1 and

OP5/A2.

The two versions differ only in their communication options.

Figure 1-2 Design of Operator Panel OP5

LCD

Function keyboard

Soft keys

System keyboard

Interfaces

Display of up to 4 lines each having a maximum length of 20 characters; the

height of the characters is 5 mm.

6 keys (F1 to F6) for calling freely programmable, generally valid standard

functions.

4 keys (F2 to F5) may alternatively be configured as soft keys. Each of these

keys can be configured with different functions for the various screens.

24 keys with permanently assigned function calls.

The OP5/A1 has an interface for connecting the PLC/computer and printer.

The OP5/A2 has two interfaces for this purpose.

1-6

( ) J31069-D0840-U001-A2-7618

Manual OP5, OP15

1.4 Design of Operator Panel OP15

Product Description

OP15 versions

The OP15 is available in the following versions:

OP15/A1,

OP15/A2,

OP15/A1-VF,

OP15/A2-VF,

OP15/C1 and

OP15/C2.

The versions listed above differ in their display and communication options.

Figure 1-3 Design of Operator Panel OP15

Manual OP5, OP15

( ) J31069-D0840-U001-A2-7618

1-7

Product Description

LCD

Vacuumfluorescence

display

Function keyboard

Soft keys

OP15/A:

Display of 2 lines each containing up to 40 characters; the height of the characters is 5 mm.

OP15/C:

Display of up to 4 lines each having a maximum length of 20 characters; the

height of the characters is 8 mm;

or

display of up to 8 lines each having a maximum length of 40 characters; the

height of the characters is 4 mm.

OP15/A-VF:

Display of 2 lines each containing up to 40 characters; the height of the characters is 5 mm.

16 keys (K1 to K16), each having an LED for freely programmable functions. The LEDs can be driven from the PLC.

8 keys (F1 to F8) beneath the display, which can be configured with screenspecific functions.

System keyboard

Interfaces

24 keys with permanently assigned function calls.

3 interfaces for connecting the PLC and a printer or a computer.

1-8

( ) J31069-D0840-U001-A2-7618

Manual OP5, OP15

Functionality

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

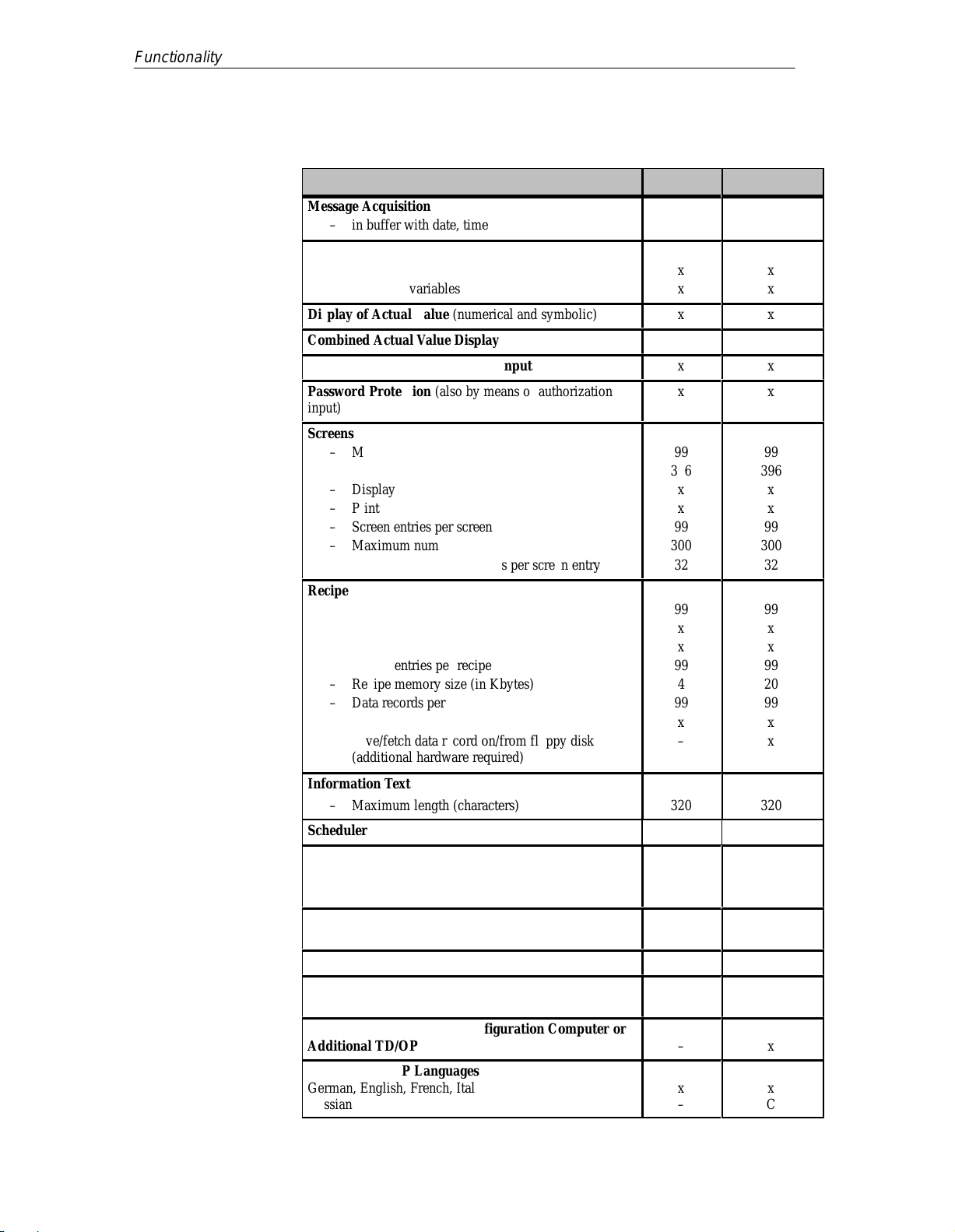

2

Functions of OP5

and OP15 versions

Manual OP5, OP15

( ) J31069-D0840-U001-A2-7618

The table below provides an overview of the functions of Operator Panels

OP5 and OP15 with their different versions.

Table 2-1 Functionality of OP5 and OP15

Display

– Technology

БББББББББББББ

БББББББББББББ

БББББББББББББ

БББББББББББББ

– Lines x characters per line/character height (mm)

БББББББББББББ

БББББББББББББ

БББББББББББББ

БББББББББББББ

– Contrast control

Event Messages

БББББББББББББ

– Maximum number

– Maximum length (characters)

БББББББББББББ

– Display

БББББББББББББ

– Print

БББББББББББББ

– View event message text

БББББББББББББ

– Maximum number of entries in the event buffer

БББББББББББББ

– View event buffer

БББББББББББББ

– Print event buffer

БББББББББББББ

– Delete event buffer

Alarm Messages

БББББББББББББ

– Maximum number

БББББББББББББ

– Maximum length (characters)

– Display

БББББББББББББ

– Print

БББББББББББББ

– View alarm message text

БББББББББББББ

– Maximum number of entries in alarm buffer

БББББББББББББ

– View alarm buffer

БББББББББББББ

– Print alarm buffer

БББББББББББББ

– Delete alarm buffer

OP5 OP15

LCD

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

4x20/5

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

x

ÁÁÁ

499

80x

ÁÁÁ

x

ÁÁÁ

x

ÁÁÁ

x

ÁÁÁ

256

ÁÁÁ

x

ÁÁÁ

x

ÁÁÁ

x

ÁÁÁ

499

ÁÁÁ

80

x

ÁÁÁ

x

ÁÁÁ

x

ÁÁÁ

256

ÁÁÁ

x

ÁÁÁ

x

ÁÁÁ

x

A, C:

ÁÁÁ

LCD

ÁÁÁ

A-VF:

ÁÁÁ

VF

ÁÁÁ

A, A-VF :

2x40/5

ÁÁÁ

C:

ÁÁÁ

4x20/8 or

ÁÁÁ

8x40/4

ÁÁÁ

A, C

ÁÁÁ

999

80

ÁÁÁ

x

ÁÁÁ

x

ÁÁÁ

x

ÁÁÁ

256

ÁÁÁ

x

ÁÁÁ

x

ÁÁÁ

x

ÁÁÁ

999

ÁÁÁ

80

x

ÁÁÁ

x

ÁÁÁ

x

ÁÁÁ

256

ÁÁÁ

x

ÁÁÁ

x

ÁÁÁ

x

2-1

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Functionality

2-2

Table 2-1 Functionality of OP5 and OP15

OP15OP5

Message Acquisition

– in buffer with date, time, state

БББББББББББББ

Variable Input

БББББББББББББ

– Numbers or letters

БББББББББББББ

– Symbolic variables

Display of Actual Value (numerical and symbolic)

Combined Actual Value Display and Variable Input

Limit Value Check of Operator Input

Password Protection (also by means of authorization

БББББББББББББ

input)

Screens

БББББББББББББ

– Maximum number

– Maximum number of lines per screen

БББББББББББББ

– Display

БББББББББББББ

– Print

БББББББББББББ

– Screen entries per screen

БББББББББББББ

– Maximum number of fields per screen

– Maximum number of fields per screen entry

БББББББББББББ

Recipes

– Maximum number

БББББББББББББ

– View

БББББББББББББ

– Print

БББББББББББББ

– Recipe entries per recipe

– Recipe memory size (in Kbytes)

БББББББББББББ

– Data records per recipe (maximum)

БББББББББББББ

– Save/fetch data record in/from the OP

БББББББББББББ

– Save/fetch data record on/from floppy disk

(additional hardware required)

БББББББББББББ

Information Text

– Maximum length (characters)

БББББББББББББ

Scheduler times - 48

Function Keys

– Number

БББББББББББББ

– Integrated LEDs

БББББББББББББ

Soft Keys (number)

БББББББББББББ

Logs

Diagnostic Function

БББББББББББББ

(STATUS/FORCE VAR) S7/S5 only

Loop-Through Mode for Configuration Computer or

Additional TD/OP

БББББББББББББ

Configurable OP Languages

German, English, French, Italian, Spanish

БББББББББББББ

Russian

( ) J31069-D0840-U001-A2-7618

x

ÁÁÁ

ÁÁÁ

x

ÁÁÁ

x

x

x

x

x

ÁÁÁ

ÁÁÁ

99

396

ÁÁÁ

x

ÁÁÁ

x

ÁÁÁ

99

ÁÁÁ

300

32

ÁÁÁ

99

ÁÁÁ

x

ÁÁÁ

x

ÁÁÁ

99

4

ÁÁÁ

99

ÁÁÁ

x

ÁÁÁ

–

ÁÁÁ

320

ÁÁÁ

6

ÁÁÁ

–

ÁÁÁ

4 (of funct.

ÁÁÁ

keys)

x

x

ÁÁÁ

–

ÁÁÁ

x

ÁÁÁ

–

Manual OP5, OP15

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

8 (extra)

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

x

x

x

x

x

x

x

99

396

x

x

99

300

32

99

x

x

99

20

99

x

x

320

16

x

x

x

x

x

C

Table 2-1 Functionality of OP5 and OP15

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Changing Languages in Online Mode

Communication by means of

SIMATIC S5

БББББББББББББ

– AS511

БББББББББББББ

–FAP

БББББББББББББ

– SINEC L2-DP

БББББББББББББ

БББББББББББББ

SIMATIC S7

БББББББББББББ

– PPI

– MPI

БББББББББББББ

БББББББББББББ

Other PLCs

БББББББББББББ

– SIMATIC 500/505

БББББББББББББ

– Free serial

БББББББББББББ

– Allen Bradley

БББББББББББББ

– Mitsubishi

3

ÁÁÁ

A1

ÁÁÁ

A1

ÁÁÁ

A2

ÁÁÁ

ÁÁÁ

ÁÁÁ

A2

A2

ÁÁÁ

ÁÁÁ

ÁÁÁ

x

ÁÁÁ

x

ÁÁÁ

1)

1)

ÁÁÁ

Functionality

OP15OP5

3

ÁÁÁ

A1, A1-VF, C1

ÁÁÁ

A1, A1-VF, C1

ÁÁÁ

A2, A2-VF, C2

ÁÁÁ

ÁÁÁ

ÁÁÁ

A2, A2-VF, C2

A2, A2-VF, C2

ÁÁÁ

ÁÁÁ

ÁÁÁ

x

ÁÁÁ

x

ÁÁÁ

1)

1)

ÁÁÁ

Manual OP5, OP15

( ) J31069-D0840-U001-A2-7618

1) Driver optional

2-3

Functionality

2-4

( ) J31069-D0840-U001-A2-7618

Manual OP5, OP15

Part II Basic functions

Using the OP with Its Standard

Functions

General Operation

3

4

Screens

Password Protection

Message Handling

Recipes

STATUS VAR and FORCE VAR

Functions with the OPs

System Settings on Standard

Screens

5

6

7

8

9

10

-2

( ) J31069-D0840-U001-A2-7618

Manual OP5, OP15

Using the OP with Its Standard Functions

3

Loading a

configuration

Using standard

screens

Once the operating voltage has been connected, you have to load a configuration into the OP so that you can operate it. The OP is in Transfer mode until a

configuration is loaded.

The configuration software supplied to you, ProT ool/Lite, includes a configuration which contains standard screens. You can choose all the functions required for operating the OPs by using these standard screens. The different

functions are described in this manual with reference to the standard screens.

3.1 Operating Levels

Message level and

screen level

In OP operation, you have to distinguish between two distinct operating levels, between which you can switch:

Message level

At the message level, current messages are displayed.

Screen level

At the screen level, functions are chosen, serviced and executed.

The message level is the highest level on the OP. At message level, waiting

event messages, alarm messages and system messages are displayed. After

the OP starts up, it changes to message level and displays the ”standby message”.

The screen level is reached by pressing the ENTER key. The first screen to

be called is the ”start” screen. From the start screen you branch, depending

on the configuration, to other screens. On the screens, you view current process values, can enter values and initiate functions by means of soft keys.

Screen hierarchy

Manual OP5, OP15

( ) J31069-D0840-U001-A2-7618

The linking of individual screens is referred to as a ”screen hierarchy”. If you

go to the bottom of the screen hierarchy, you go back one stage by pressing

key ESC, right back to the start screen should you wish. From here you can

return to the message level by pressing the ESC key. You can also return directly to the message level from a screen, depending on the configuration.

3-1

Using the OP with Its Standard Functions

Changing operating levels

Forced change to

message level

You change the operating level

from message level to screen level by pressing the ENTER key,

from screen level to message level by pressing the ESCAPE key.

Figure 3-1 illustrates how you can change from one operating level to another.

You cannot branch backward from the message level by pressing ESCAPE. The

key is designed to terminate the display of a system message at this level.

ENTER

⇓

Figure 3-1 Changing between Message Level and Screen Level

You exit from the screen level automatically whenever a system message or

an alarm message is waiting to be displayed. The OP then changes to message level to display the message. You cannot exit from the message level

while a system message or unacknowledged alarm message is being displayed. The display of an unacknowledged alarm message is indicated on the

OP by the

⇑

3-2

– alarm message flashing and

– lit ACK LED.

You acknowledge an alarm message by pressing the ACK key. You hide a

system message by pressing the ESCAPE key.

Once the alarm message has been acknowledged or the system message

cleared, the OP returns to the point from which it changed to the message

level.

( ) J31069-D0840-U001-A2-7618

Manual OP5, OP15

3.2 Standard Screens

Using the OP with Its Standard Functions

Basic operations

with standard

screens

Functions on

standard screens

The standard screens contain functions that are fundamental to OP operation.

They include, for instance, calling and printing message buffers, editing passwords and modifying parameters in online mode. Process-specific implementations, such as event messages or screens for the process, are not included.

Standard screens are called from a basic screen by means of a soft key. From

the basic screen, a jump is made to the following screens:

Alarm messages

At this point the alarm buffer is called, printed or deleted.

Event messages

At this point the event buffer is called, printed or deleted.

Screens

At this point the screen directory is called to edit or print screens. All the

screens which were given the ”directory” attribute are listed here. If you

still have not created any screens of your own, the directory will be

empty .

Data records

At this point you can set up and edit data records. You can also transfer

data records from the OP to the PLC and back.

System settings

At this point you can modify settings in online mode. This includes, for

example, printer parameters, interface parameters, mode, and language

changing.

Status variable

Force variable

Edit password

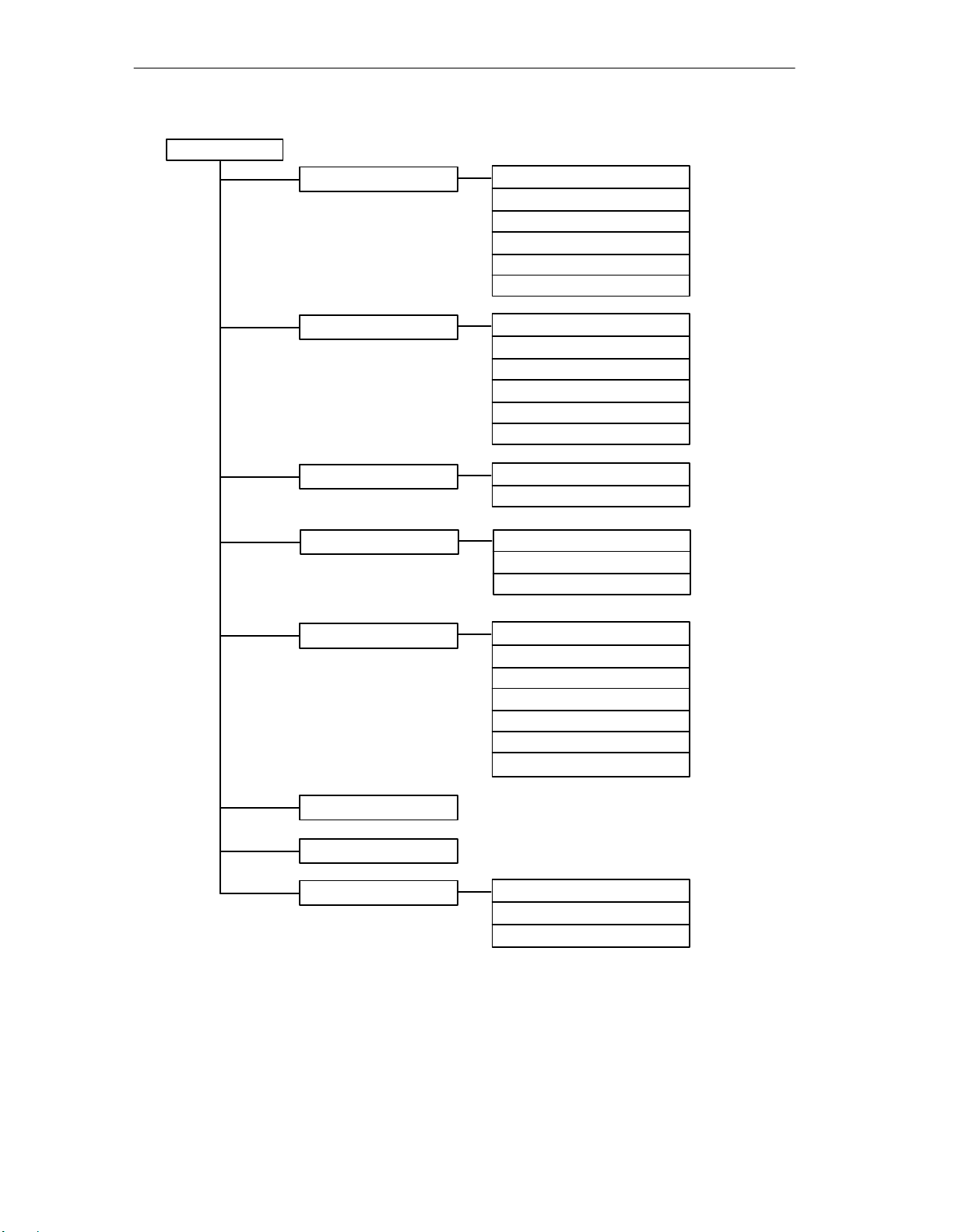

Figure 3-2 shows an overview of the screen hierarchy of standard screens.

You will find detailed information on functions and handling standard screens

in the relevant chapters of this manual.

Manual OP5, OP15

( ) J31069-D0840-U001-A2-7618

At this point the PU function STATUS VAR is called; you can use it to

display PLC operands.

At this point the PU function FORCE VAR is called; you can use it to

display and modify PLC operands.

At this point the superuser assigns passwords for the different password

levels. Furthermore, login and logout are included here.

3-3

Using the OP with Its Standard Functions

Basic Screen

Event Messages

Alarm Messages

Screens

Data Records

View

Print

Number

Delete

Overflow

Text

View

Print

Number

Delete

Overflow

Text

Edit

Print

Edit

Change

Print

System Settings

Status Variable

Force Variable

Edit Password

Figure 3-2 The Standard Screens

Operating mode

Display message

System messages

Change language

Date/Time

Printer parameters

IF1/IF2 ( )

Login

Logout

Edit

3-4

( ) J31069-D0840-U001-A2-7618

Manual OP5, OP15

Loading...

Loading...