Siemens OP121, OH121 Installation Instructions Manual

Installation Instructions

Models OP121/OH121

Photoelectri c Smoke Detector and Photo

Smoke/Thermal Detector

Figure 1 OP121 Photoelectric Figure 2 OH121 Photo Smoke

Smoke Detector Thermal Detector

These instructions are written in accordance with the

installation guidelines of NFPA No. 72, Nati onal Fire Alarm

Code, and CAN/ULC-S524, The Installation of Fire Alarm

Systems.

DETECTO R PLACEMENT

For a clear air, 0 to 4000 ft/min velocity application, use 30

foot center spacing (900 sq ft) from NFPA Standard 72

initiating devices chapter and CAN/ULC-S524 as a starting

point for a detector installation layout. This spacing, however,

is based on ideal conditions – smooth ceiling, no air

movement, and no physical obstructions. In some

applications, considerably less area is protected adequately

by each smoke detector. In all installations, place the

detector on the ceiling, a minimum of 6 inches from a side

wall, or on a wall, 6 inches from the ceiling.

Follow the drawings provided or approved by Siemens

Industry, Inc. or by its authorized distributors. See NFPA 72,

National Fire Alarm Code, initi ating devices chapter for

additional guidance on special issues such as beamed

construction and high stockpiling.

TO AVOID NUISANCE ALARMS:

DO NOT locate the OP121/OH121 detector where

excessive smoke concentrations exist under normal

conditions, or in areas of prolonged high relative humidity

where condensation occurs.

DO NOT locate the OP121/OH121 detector next to an oil

burner, kitchen, or garage where exhaust fumes can trigger

an alarm. Other causes of false alarms are dust

accumulation, heavy concentrations of st eam, heavy pipe

or cigar smoke, and certain aerosol sprays.

AIR CURRENTS

Before a detector can sense a fire, the products of combustion or smoke must travel from the fire to th e detector.

Since their travel is especially influenced by air currents,

consider the movement of air in the design of the system.

While combustion products tend to rise, drafts from hallways,

air diffusers, fans, etc., may help or hinder the travel of

combustion products to the detector. W hen positioning a

detector at a particular location, give consideration to

windows and doors, both open and closed, and to influencing

air m ovement. Never install a detector in the air stream of a

room air supply diffuser. It is better to position a detector

closer to an air return.

A6V10281367_b_en--

SPECIFICATIONS

Environmental

Operating Temperature (Model OP121): 320F (00C) to 1200F

(490C)

Operating Temperature (Model OH121): 320F (00C) to 1000F

(380C)

Humidity: Up to 95% RH, non condensing

Air Pr essure: No effec t

Air Vel ocit y: 0 to 4000 ft/min. For op en area prot ection and direc t

air duct application.

Thermal Alarm Temp. (Model OH121): 1350F (570C)

UL listed with STI Mechanical Protection Guard Model: STI-9604

(see www.STI-USA.com for det ails)

Electrical

Voltage: 16-27 VDC

Ripple: 3V peak-to-peak

Supervisory Current: 100μA max

Alarm Current: 30-50mA

Start-up Time: 30 seconds max

DETECTO R WIRING

The OP121/OH121 shoul d be connected as shown in Figure 3 using

the separate moun ting base, Model DB-11. F ollow the control panel

wiring connection dr awing installed on the inside face of each

contr ol panel c over . See D B-11 instruction, P/N 315-094193, for

base mounting. Duplicate wiring information is als o in the

Installati on, Oper ation, and M aint enance Manual provid ed with

every control panel. Note any limitations on the number of

detectors and restrictions on the use of remote devices

permitted for each circuit.

END OF

LINE

DEVICE

(NOTE

POLARITY

WHEN

APPLICABLE)

1a

1b

1b

1b

5

5

6

6

5

+

DB-1

1/DB-1

1E

[WITH REMOTE DEVICE(S)]

+

-

TO INIT IATING

CIRCUITOF

SIEMENS

INDUSTRY, INC.

CONTROL PANEL

(SEE CAUTION 1)

MULTIPLE REM OTE DEVICES

SEE REMOTE DEVI CE INSTRUCTIONS

FOR WIRI NG DETAILS:

each detecto r/base may have up t o 2 remote devices

with the follo wing configurati ons and restriction s only:

If remote device s are supported by the initiatin g circuit,

DEVICE

RR-11

RLC- 11, RLW-11

RSAC-11, RSAW-11

ADB- 11

Device 1

Remote

RR -11

RR -11

RLC -11, RLW- 11

RLC -11, RLW- 11

Devic e 2

Remote

RLC-11, RLW-11

RSAC-11, RSAW-11

RSAC-11, RSAW-11

RLC-11, RLW-11

Restrictions

See Caution 2

See Caution 2

Wire from base to

RSAC-11/RSAW-11

to RL-11

INSTRUCTIONS

INSTALLATION

P/N 315-094924

P/N 315-094925

P/N 315-094926

P/N 315-096162

DB-1

1/DB-1

1E

[NO REMOTE DEVICE]

-

Figure 3 Installations and W iring D iagram for OP1 21/OH121

Conventional Detectors

Siemens, Industry, Inc.

Building Technologies Division

WAR NING : CONNECT DETECTOR ONLY TO CIRCUITS SPECIFIED IN DETECTOR

AND PANEL

LITERATURE OR SYSTEM MAY NOT OPERATE.

CAUTION:

1. Do not use loope d wire under base

terminal 5. Brea k wire run to provide

supervision of connection.

2. When a remote relay is used to

control a critical system function, the

relay and its associated detector and

optional module(s ) must be the ONLY

devices on the initiating circuit.

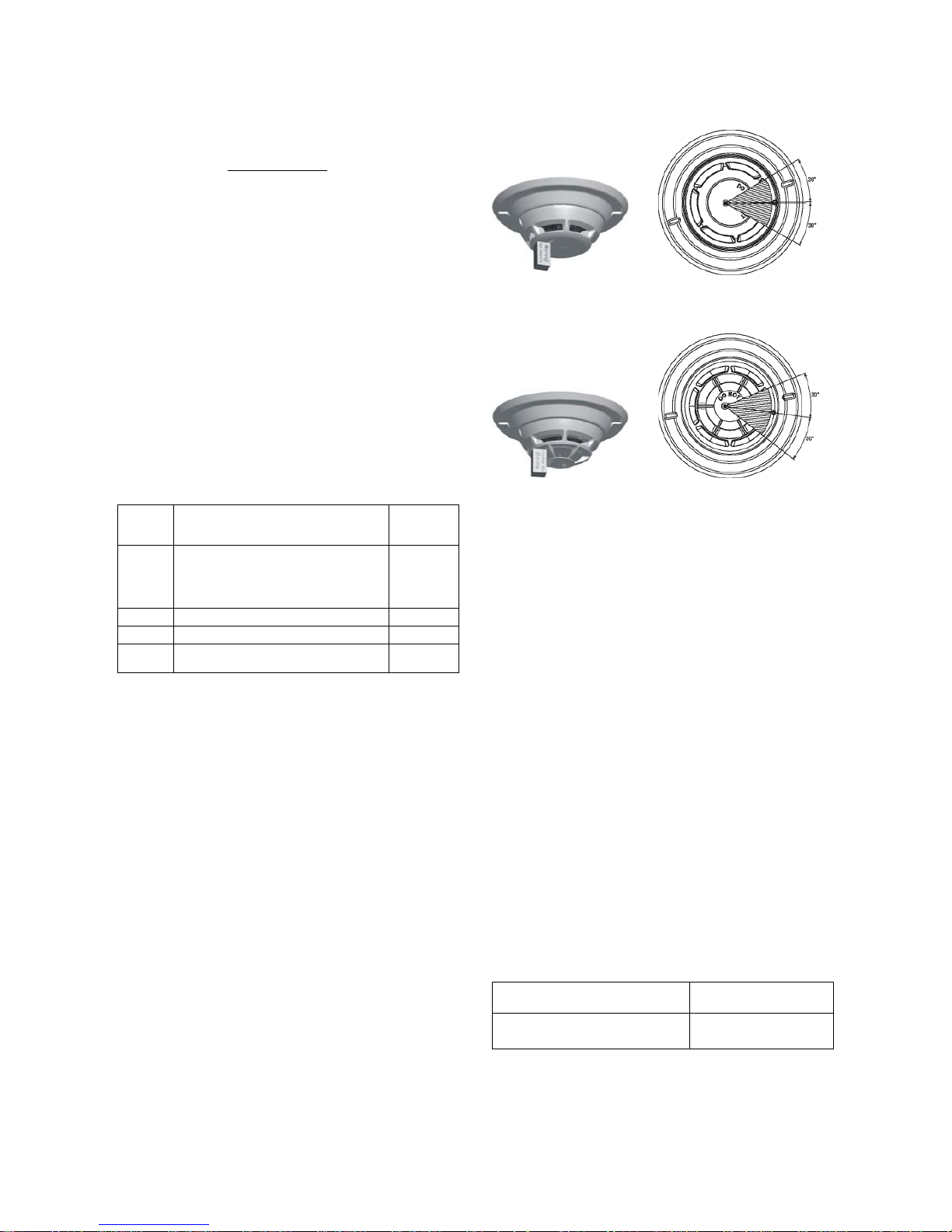

Figure 4 OP121 with T M121 Figure 5 TM121 Test Magnet

Test Magnet Placement on OP121

Figure 6 O H121 with TM121 Figure 5 TM121 Test Mag net

Test Magnet Placement on O H121

(after 3 mi nutes) when the green LED is a single blink every 10

seconds. The test mode provides a reduced test time period

and utilizes less concentration of test gas or aerosol.

Detector and control panel functionality can also be tested

using the TM121 test magnet as shown in Figure 4 for the

OP121 detector and Figure 6 for the OH121 detector. Place the

magnet in the specific area at the bottom of the detector that is

shown in Figure 5 for the OP121 detector and Fi gure 7 for t he

OH121 detector for at least 5 seconds with the colored side

towards the centered LED. The detector will send an alarm to

the panel.

WARNING: Testing with the magnet only tests the circuit; it

does not test the detector’s sensing ability.

WARNING: The TM 121 test magnet is a strong magnet that

can be harmful to pacemaker wearers and to those with

medical implants. Keep the magnet away from magnetic

media such as credit cards and memory disks/chips.

CAUTION: UNDER NO CIRCUMSTANCES IS THE

DETECTOR HEAD TO BE DISASSEMBLED. NO REPAIRS

OR CLEANING SHOULD BE ATTEMPTED.

DO NOT PAINT

The detector/base plastic is marked DO NOT PAINT. This is

intended to prohibit painting during routine maintenance of

the occupancy which can affect proper operation of the

det ector.

COMPATIBLE CONTROL EQUIPMENT

Equipment

Compatibility Identifier

Installation/Wiring

Instructions

SXL-EX

SZM (FS-250C)

P/N 315-095997-8

P/N 315-034850C-4

The detector model number is the compatib ility identifier .

A6V10281367_b_en--

INSTALLATION / REMOVAL OF DETECTOR

TO INSTALL:

· Rotate detector counterclockwise while gently pressing

on it until the detector drops fully into base.

· Then rotate the detector clockwise until it stops

and locks

in place. Insert optional locking screw (

Order Model

LK-11).

TO REMOVE:

· Loosen locking screw, if installed. Then rotate the

detector counter clockwise until stop is reached.

· Pull detector out of base.

LED INDICATOR OPERATION

The OP121/OH121 contains an LED indicator capable of

flashing either one

of three distinct colors: green, yellow, or

red. The microprocessor based detector monitors the

following:

· Smoke in its sensing chamber

· Smoke sensitivity is within the range indicated on the

nameplate label (sensitivity verification)

· Internal sensors and electronics

Based on the results of these checks, the LED indicator

flashes as follows:

Flash

Color

Condition

Flash

Interval

(Seconds)

Green

Normal supervisory operation. Smo ke

sensitivity is within rated limits. Double

blinking fir s t 3 min after power up or reset.

Si ng le blinki ng after the first 3 min.

10

Yellow Detector is in trouble and needs replacement. 5

Red Alarm

2½

No

Flashes

Detector is not powered or repl acement is

needed.

TESTING AND MAINTENANCE

To assure proper operation of the detector and control panel,

it

is required that both the Sensitivity test and the Functional

test

be conducted using the procedures outlined below.

SENSITIVI TY TEST

The OP121/OH121 monitors its smoke sensitivity

automatically and requires no test equipment. A green fl ash

of

the detector LED about every 10 seconds indicates that the

smoke sensitivity is within its listed limits.

FUNCTIONAL TEST

To test the detector and control panel for functional operation,

use SIEMENS Test Gas, P/N 500-649750. Follow t

he

instructions on the gas canister label.

Smoke entry test mode: To test the detector for smoke entry,

place the detector into a test mode. The test mode condition

is

automatically started after the initial power up and after

every

reset for a period of 3 minutes. It is recommended that

a

control panel reset be performed after every smoke entry

test

is conducted to restart the 3 minute test period. The test

mode

is indicated when the green LED is doubl e blinking every 10

seconds. A normal operational mode is indicated

Siemens Industry, Inc. Siemens Canada Limited

Building Technologies Division Building Technologies Division

Florham Park, NJ 2 Kenview Boulevard

Brampton, Ontario L6T 5E4 Canada

Loading...

Loading...