Siemens OOH740-A9-Ex Technical Manual

Building Technologies

OOH740-A9-Ex

Automatic fire detector

Technica l Manual

A6V10367521_h_en_-2015-02-02 Control Products and Systems

Legal notice

Legal notice

Technical specifications and availability subject to change without notice.

© Siemens Switzerland Lt d, 2012

Transmitt al, reproduction, dissemination and/or editing of this doc ument as well as

utilization of its contents and communication thereof to others without expr ess

authorization are prohibited. Offenders will be held liable for payment of damages.

All rights creat ed by patent grant or registration of a utility model or design patent

are reserved.

Issued by:

Siemens Switzerland Ltd.

Building Technologies Div ision

International Headquarters

Gubelstrasse 22

CH-6301 Zug

Tel. +41 41 724-2424

www.siemens.com/buildingtechnologies

Edition: 2015-02-02

Document ID: A6V10367521_h_en_--

2

Building Technologies A6V10367521_h_en_--

Fire Safety 2015-02-02

Table of contents

1 About this document ......................................................................................7

1.1 Applicable documents ..................................................................................... 11

1.2 Downloa d center............................................................................................. 11

1.3 Technica l terms, abbreviation s, and formu la sy mbols ...................................... 12

1.4 Revision history .............................................................................................. 1 3

2 Safety ............................................................................................................ 14

2.1 Safety instruction s .......................................................................................... 14

2.2 Safety regu lat ions for the meth od of operat ion ................................................ 15

2.3 Standa rds an d directives co mp lied with .......................................................... 18

2.4 Releas e Notes ................................................................................................ 18

3 Structur e and function ................................................................................. 19

3.1 Setup.............................................................................................................. 19

3.1.1 Point detecto r OOH740 -A9-E x with ASAtechno log y ......................... 19

3.1.2 Feature s of fire detect ion function ality .............................................. 21

3.1.3 Feature s of the 'Tech nica l Ambient Super vis ion Mes s age '................ 22

3.1.4 Details for ordering ........................................................................... 23

3.1.5 Reference to technical manual ......................................................... 23

3.1.6 Product version ES .......................................................................... 23

3.2 Function ......................................................................................................... 24

3.2.1 Parame ter sets ................................................................................ 24

3.2.2 Danger levels ................................................................................... 25

3.2.3 Diagnosis levels ............................................................................... 25

3.2.4 Automat ic recognit ion of the detecto r line proto col ............................ 25

3.2.5 Interna l alarm indicator ..................................................................... 26

3.2.6 Conne ction for external alar m indicators ........................................... 26

3.2.7 Renovation mode ............................................................................. 26

3.2.8 Test mode ....................................................................................... 27

3.2.9 Beha vior in degrade d mode ............................................................. 27

3.2.10 Line tester ........................................................................................ 27

Building Technologies A6V10367521_h_en_-Fire Safety 2015-02-02

3

3.3 Accessories .................................................................................................... 28

3.3.1 Address able detector base FDB221 ................................................. 28

3.3.2 Collecti ve detector base FDB201 ..................................................... 28

3.3.3 Flat, addres s ab le detecto r bas e FDB22 2 ......................................... 28

3.3.4 Flat, collect ive detector bas e FDB222 .............................................. 29

3.3.5 Base attachment FDB291 ................................................................ 29

3.3.6 Base attachment wet FDB295 .......................................................... 29

3.3.7 Sealing element FDBZ295 ............................................................... 30

3.3.8 Design ation plate FDBZ29 1 ............................................................. 30

3.3.9 Design ation plate DBZ119 3A ........................................................... 30

3.3.10 Detecto r locking device FDBZ293 .................................................... 30

3.3.11 Dummy detecto r FDX291 ................................................................. 31

3.3.12 Detecto r dust cap FDZ291 ............................................................... 31

3.3.13 Conne ction termina l DBZ1190 -AB ................................................... 31

3.3.14 M20 x 1.5 metal cable gland ............................................................ 31

3.3.15 Line adapter (Ex) FDCL221-E x ........................................................ 32

4 Planning ........................................................................................................ 33

4.1 Compatibility ................................................................................................... 33

4.2 Ambient features ............................................................................................ 3 3

4.3 Parame ter sets for addre s sed ope ration ......................................................... 35

4.3.1 Sens or mode 0 – Multis en s o r fire detec tor ....................................... 35

4.3.1.1 Descr iption ...................................................................................... 35

4.3.1.2 Use .................................................................................................. 36

4.3.1.3 Specification .................................................................................... 37

4.3.2 Sens or mode 1 – Heat detecto r ........................................................ 38

4.3.2.1 Descr iption ...................................................................................... 38

4.3.2.2 Specification .................................................................................... 39

4.3.3 Sens or mode 2 – Smoke detecto r .................................................... 40

4.3.3.1 Descr iption ...................................................................................... 40

4.3.3.2 Specification .................................................................................... 40

4.4 Parame ter sets for collec ti ve operation ........................................................... 41

4.4.1 Replacing exis ting AlgoRex point detectors ...................................... 41

4.5 Default settings ............................................................................................... 42

4.6 Technica l Ambien t Super vision Message ........................................................ 42

4.6.1 Ambient condition s .......................................................................... 43

4.6.1.1 Temperature monitoring ................................................................... 44

4.6.2 Configuration ................................................................................... 44

4.6.3 Default settings for the 'Technical Ambient Supervision

Message' ......................................................................................... 44

4

Building Technologies A6V10367521_h_en_--

Fire Safety 2015-02-02

5 Mounting/Installation .................................................................................... 45

5.1 Required space .............................................................................................. 4 6

5.2 Collective and addre s sab le detecto r bas e FDB20 1/2 21 .................................. 47

5.3 Flat detector bas e FDB202/22 2 ...................................................................... 48

5.4 Base attachment FDB291 ............................................................................... 4 9

5.5 Sealing element FDBZ295 .............................................................................. 5 0

5.6 Detecto r locking device FDBZ293 ................................................................... 51

5.7 Design ation plate FDBZ291 ............................................................................ 52

5.8 Design ation plate DBZ1 193A .......................................................................... 5 2

5.9 Detecto r dust cap FDZ29 1 .............................................................................. 53

5.10 Conne cting the detector base ......................................................................... 54

5.10.1 Conne ction terminal DBZ1190-A B.................................................... 55

5.10.2 Conne ction diagram (C-NET -Ex) ...................................................... 56

5.10.3 Conne ction diagram (collecti ve) ....................................................... 57

6 Commissioning ............................................................................................. 59

7 Mainte nance / Repair .................................................................................... 6 0

7.1 Performance check ......................................................................................... 60

7.1.1 'Technical Ambient Supervision Message' performance check ......... 60

7.2 Testing detecto rs ............................................................................................ 61

8 Specifications ............................................................................................... 62

8.1 Technica l data for OOH740-A9-E x .................................................................. 62

8.1.1 Genera l (irrespecti ve of the detecto r line) ......................................... 62

8.1.2 Detector lines ................................................................................... 63

8.2 Dimens ions .................................................................................................... 6 6

8.3 Environ mental compatib ility and dispo sal ........................................................ 66

9 Annex ............................................................................................................ 67

Glossary....................................................................................................................... 68

Index ....................................................................................................................... 69

Building Technologies A6V10367521_h_en_-Fire Safety 2015-02-02

5

6

Building Technologies A6V10367521_h_en_--

Fire Safety 2015-02-02

About this document

Applicable documents

Missing information

be accessed by target groups .

The use of peripheral devices on collective detector lines in potentially explosive

Document A6V10324 618 is an integral part of this document.

You must observe

1 About this document

Retention and availability

NOTICE

Damage due to misuse

● This document must be available in a usable format throughout the entire life

cycle of the product. Keep the document for reference and ensure that it can

Should you require another copy of this document, please contact the Customer

Support Center, phone +49 89 9221-8000.

Goal and purpose

This document contains all the information relating to the automatic fire detector

OOH740-A9-Ex. Following the instructions consistently will ensure that the product

can be used safely and without any problems.

This document is aimed at users who are planning, installing, com missioning,

operating, and maintaining a fire detection inst allation FS720 or SIGMASYS with a

line card (FDnet/C-NET) with addressed detector lines within the scope of Directive

94/9/EC (ATEX directive) or IECEx.

General knowledge about the structure and function of fire detection installations

FS720 is required in or der to understand the inform ation.

1

atmospheres is described in document 001204.

See chapter 'Applicable documents'.

WARNING

the information in both this document and docum ent A6V103 24618!

Before installing the device, you must make yourself familiar with the content of

document A6V10324618 'Planning, Mounting/Inst allation, Commissioning,

Maintenance of fire detection installations wit h addressed detector lines in

potentially explosive atmospheres'. You c an download the current version of the

document from the Internet, at the address http://siemens.com/bt/download

.

Building Technologies A6V10367521_h_en_-Fire Safety 2015-02-02

7

About this document

Applicable documents

Please note the documents listed in the chapter 'Applicable docum

ents'.

1

Device labeling

Device type OOH740-A9-Ex

Manufacturer

Siemens Switzerland Ltd.

Infrastructure & Cities Sector

Building Technologies Div ision

International Headquarters

Gubelstrasse 22

CH-6301 Zug

Tel. +41 41 724-2424

www.siemens.com/buildingtechnologies

Year of construct ion 2014 or later

IECEx scheme Ex ia IIC T4 Ga, Ta = -35…70 °C

Directive 94/9/ EC

II 1 G Ex ia IIC T4 Ga, Ta = -35…70 °C

(ATEX Directive)

When used in atmospheres at ris k of gas explos ion:

The automatic fire detector OOH740-A9-Ex must be protected against electros tatic

charging, along with all its accessory parts.

Intended use

The automatic fire detector OOH740-A9-Ex may only be used as follows:

l On an C-NET-Ex detector line in a fire detection installation FS720 or in

collective mode.

l On the detector line the automatic fire detector OOH740-A9-Ex must be

installed downstream of a line adapter (Ex) approved in accordanc e with

national and international regulations or a safety barrier.

– For the C-NET-Ex detector line, this is line adapter (Ex) FDCL221-Ex.

– For a collective detector line, these are safety barriers SB2 or SB3.

8

Building Technologies A6V10367521_h_en_--

Fire Safety 2015-02-02

Applicable documents

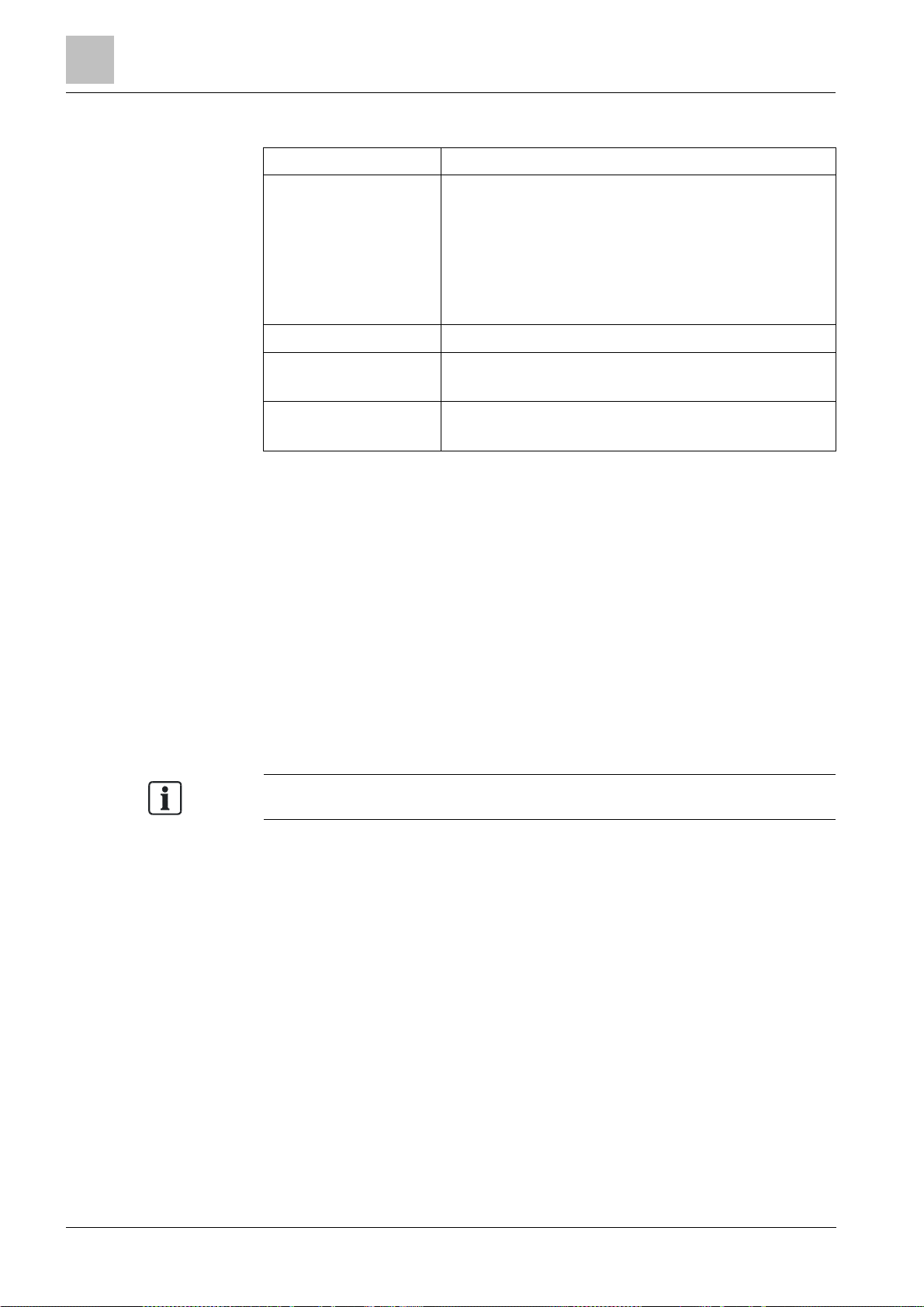

Target groups

The information in this document is intended f or the following target groups:

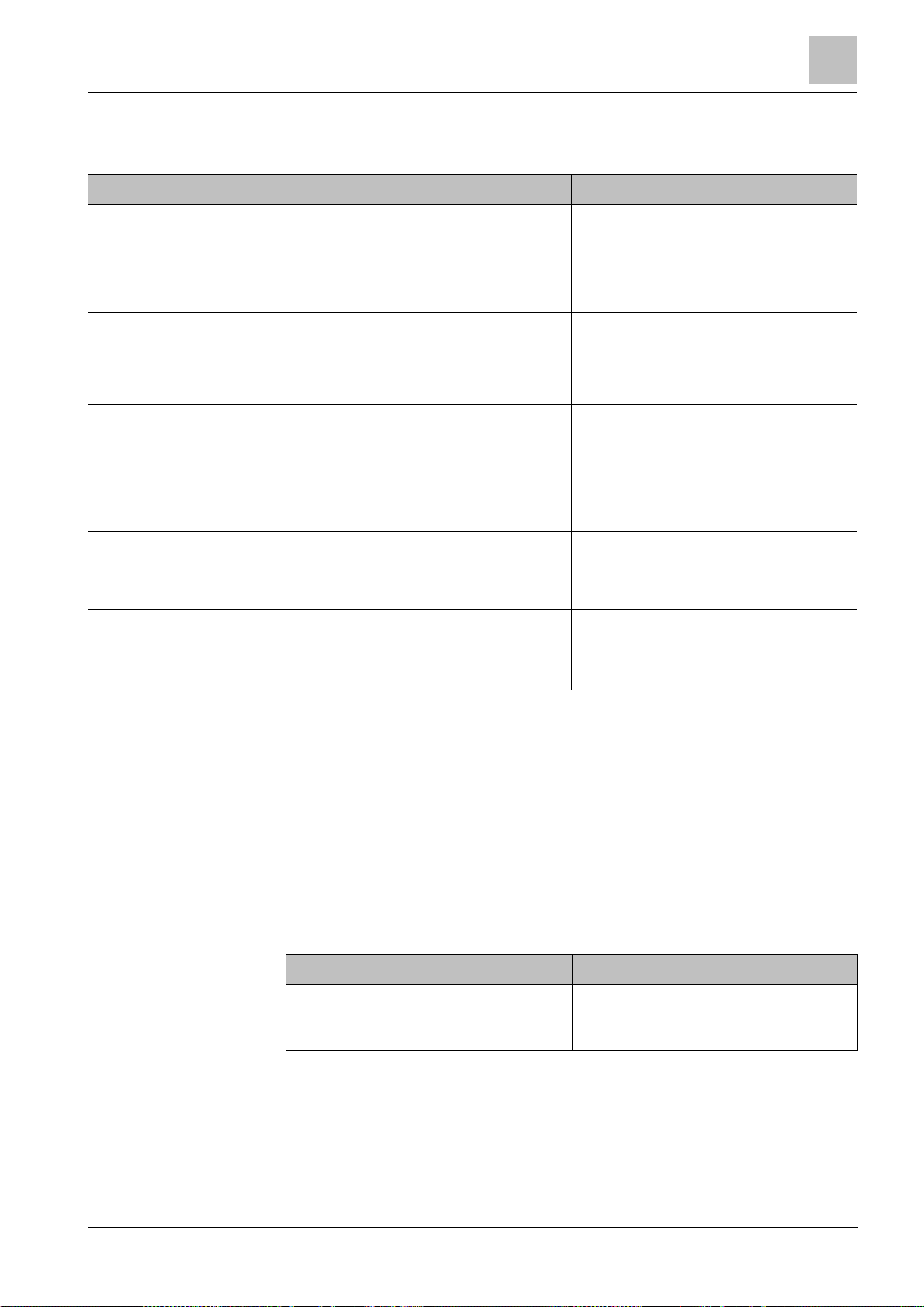

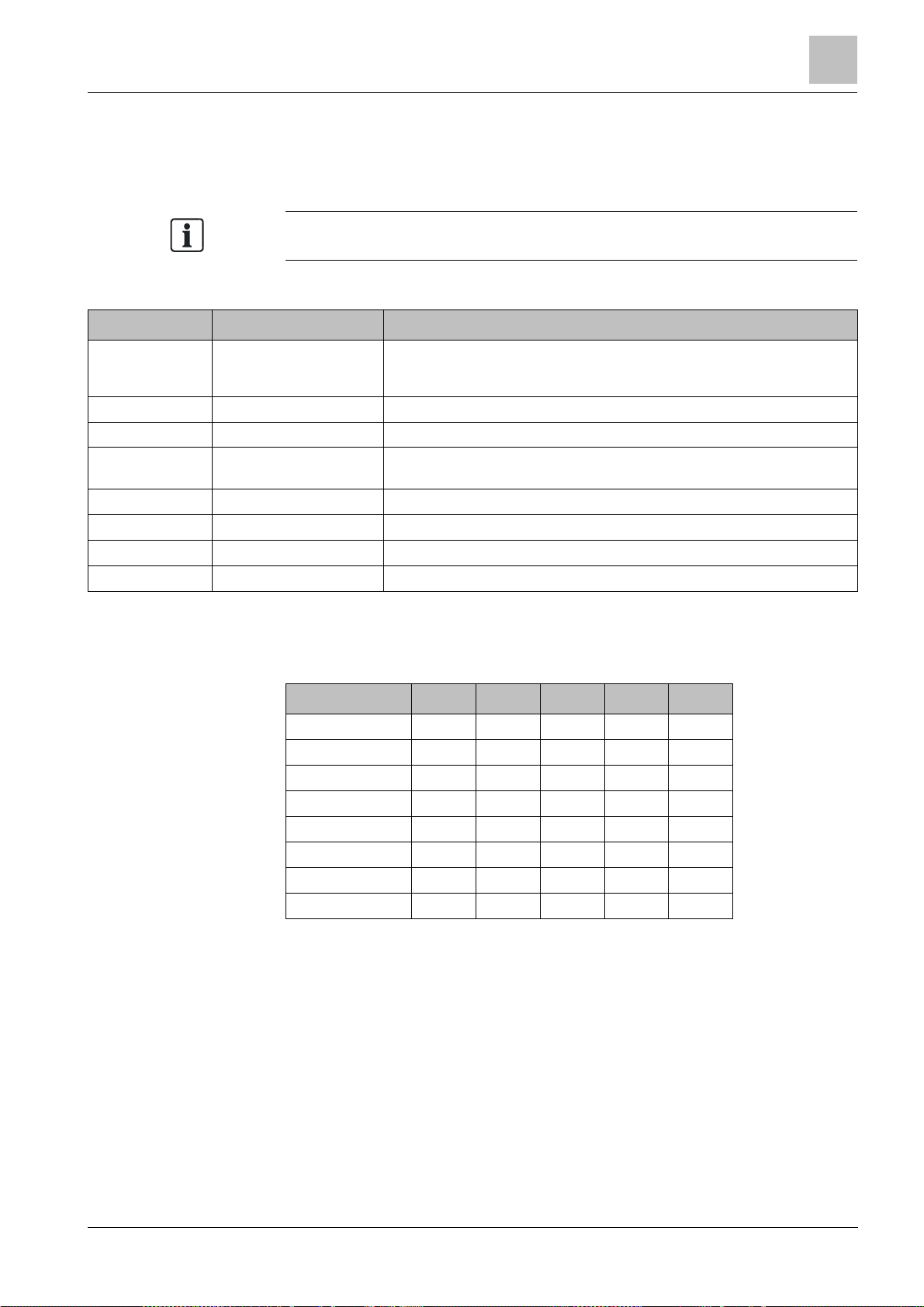

Target group Activity Qualificat ion

About this document

1

Product Manager

Project Manager

Project engineer

Installation personnel

Maintenance personnel l Carries out all maintenance work.

l Is responsible for information passing

between the manufacturer and regional

company.

l Coordinates the flow of information

between the individual groups of people

involved in a project.

l Coordinates the deployment of all

persons and resources involved in the

project according to schedule .

l Provides the information required to run

the project.

l Sets parameters for product depending

on specific national and/or customer

requirements.

l Checks operability and approves the

product for commissioning at the place

of installation.

l Is responsible for trouble-shooting.

l Assembles and installs the product

components at the place of installation.

l Carries out a performance check

following installation.

l Checks that the products are in perfect

working order.

l Searches for and corrects malfunctions.

l Has obtained suitable specialist training

for the function and for the products.

l Has attended the training courses for

Product Managers.

l Has obtained suitable specialist training

for the function and for the products.

l Has attended the training courses for

Project Managers.

l Has obtained suitable specialist training

for the function and for the products.

l Has attended the training courses for

Product Engineer.

l Has received specialist training in the

area of building installation technology

or electrical installations.

l Has obtained suitable specialist training

for the function and for the products.

There are various tasks that may only be performed by qualified persons in

accordance with the national implementation of Directive 2009/104/EC (e.g. in

Germany: Section 2 (7) of the Ordinance on Industrial Safety and Health

(BetrSichV)).

Source language and reference document

l The source/original language of this document is G erman (de).

l T he reference version of this document is the international version in English.

The international ver sion is not localized.

Document identification

The document ID is structured as follows:

ID code Examples

ID_ModificationIndex_Language_COUNTRY

-- = multilingual or international

A6V10215123_a_de_DE

A6V10215123_a_en_-A6V10315123_a_--_--

Date format

The date format in the document corresponds to the recomm endation of

international standard ISO 8601 (format YYYY-MM-DD).

Building Technologies A6V10367521_h_en_-Fire Safety 2015-02-02

9

About this document

Applicable documents

The 'i' sy

mbol identifies supplementary informat ion and tips for an easier way of

1

Conventions for text marking

Markups

Special markups are shown in this document as follows:

⊳ Requirement for a behavior instruction

1.

Behavior instruction with at least two operation sequences

2.

– Version, option, or detailed information for a behavior instruction

⇨ Intermediate result of a behavior instruction

⇨ End result of a behavior instruction

l

Numbered lists and behavior instructions with an operation

sequence

[➙ X] Reference to a page number

'Text' Quotation, reproduced identically

<Key> Identificat ion of keys

Supplementary information and tips

working.

See also

2 Applicable documents [➙ 11]

10

Building Technologies A6V10367521_h_en_--

Fire Safety 2015-02-02

Applicable documents

1.1 Applicable documents

You will also find inform ation about search variants and links t

o mobile

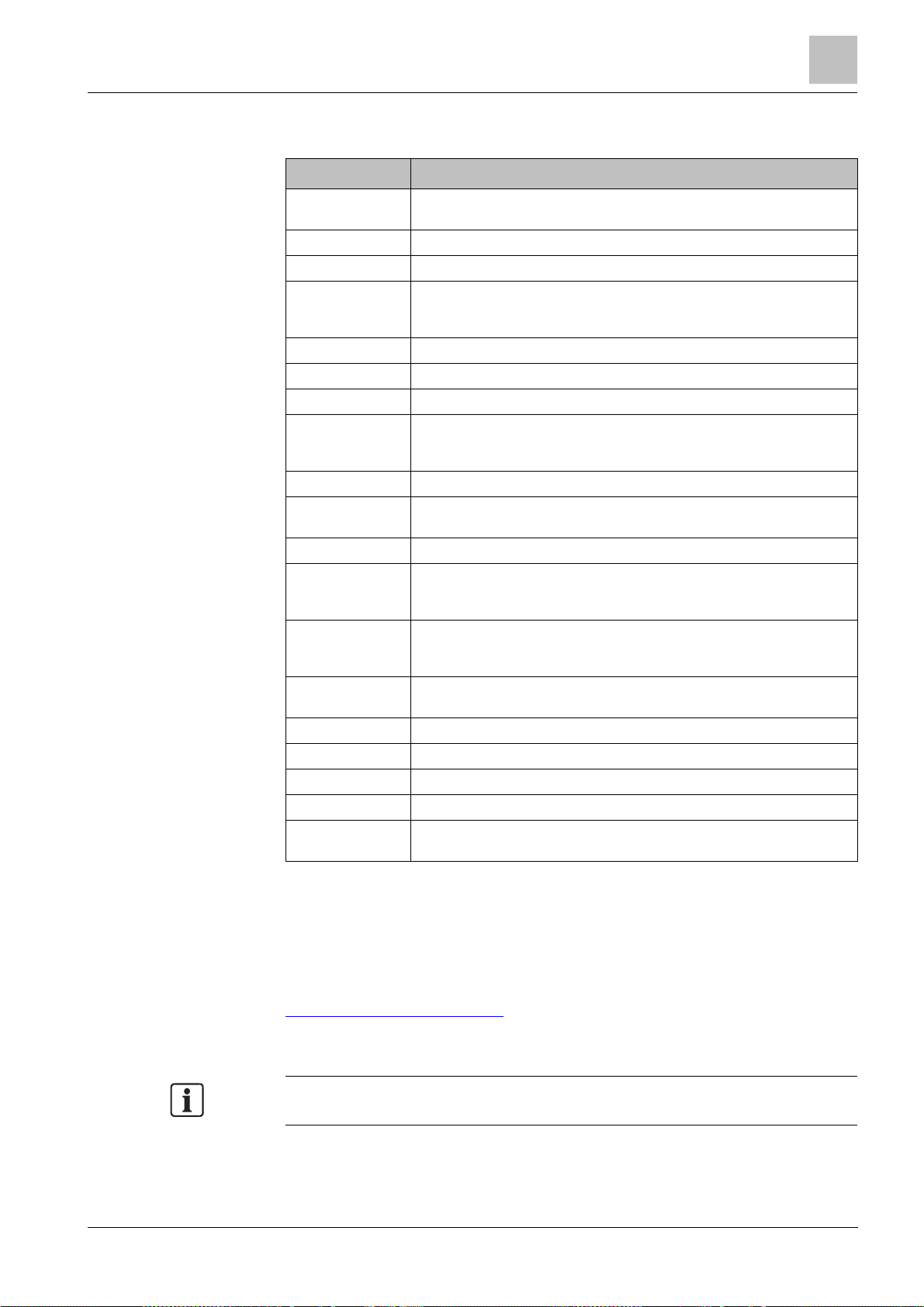

Document ID Title

About this document

1

001204

001227 Installation instructions Shunt Zener Diode SB2, SB3

001519 Installation instructions Input / output module DC1192

007228

008250 Technical Manual Line tester FDUL221

009122 Technical manual Input/output module (transponder) FDCIO223

A6V10208532 Installation Sealing element FDBZ295

A6V10208546

A6V10208552 Installation Detector locking device FDBZ293

A6V10210416

A6V10210424 FS720 Fire detection system - Configuration

A6V10260486

A6V10324618

A6V10331076

A6V10333771 Technical Manual Line adapter (Ex) FDCL221-Ex

A6V10367523 Installation Automatic fire detector OOH740-A9-Ex

A6V10371417 Data sheet Automatic fire detector OOH740-A9-Ex

A6V10414910 Technical manual Zone module, external powered FDCI723

A6V10443621

Principles, applications, installation, maintenance Fire alarm signal in

areas at risk of explosion

Data Sheet Test equipment and accessories FDUD291, FDUD292,

FDUD293, RE6, RE7T, RE8ST, RE8STCO, RE10, FDUM291,

FDUM292, FDUL221, Sinteso-Test, FDUD29x-E

Installation Detector base FDB20x/FDB201-AA, FDB22x/FDB221-AA,

Base attachment FDB291, Detector designation plate FDBZ291,

Dummy detector FDX291

FS720 Fire detection system - Commissioning, Maintenance,

Troubleshooting

Installation Alarm indicators, adapter frame, surface-mounted housing,

indicator housing, incl. washer FDAI92EX, FDAI93EX, AI330,

DCA1191, DJZ1193

Planning, Mounting/Installation, Commissioning, Maintenance of fire

detection installations with addressed detector lines in potentially

explosive atmospheres

Installation Base attachment wet FDB295, Detector designation plate

DBZ1193A, Protective cage DBZ1194, EMC-protective cage FDBZ294

Modernizing fire detection installations with multiple protocol detectors

in potentially explosive atmospheres

Please also observe the documentation for your fire detection system.

1.2 Download center

You can download various types of documents, such as data sheets, installation

instructions, and license texts v ia the following Internet address:

http://siemens.com/bt/download

l Ent er the document ID in the 'Find by keyword' input box.

applications (apps) for various systems on the home page.

Building Technologies A6V10367521_h_en_-Fire Safety 2015-02-02

11

About this document

Technical terms, abbreviations, and formula symbols

The symbols

used correspond to t he EN

60079

-

11 standard.

1

1.3 Technical terms, abbreviations, and formula symbols

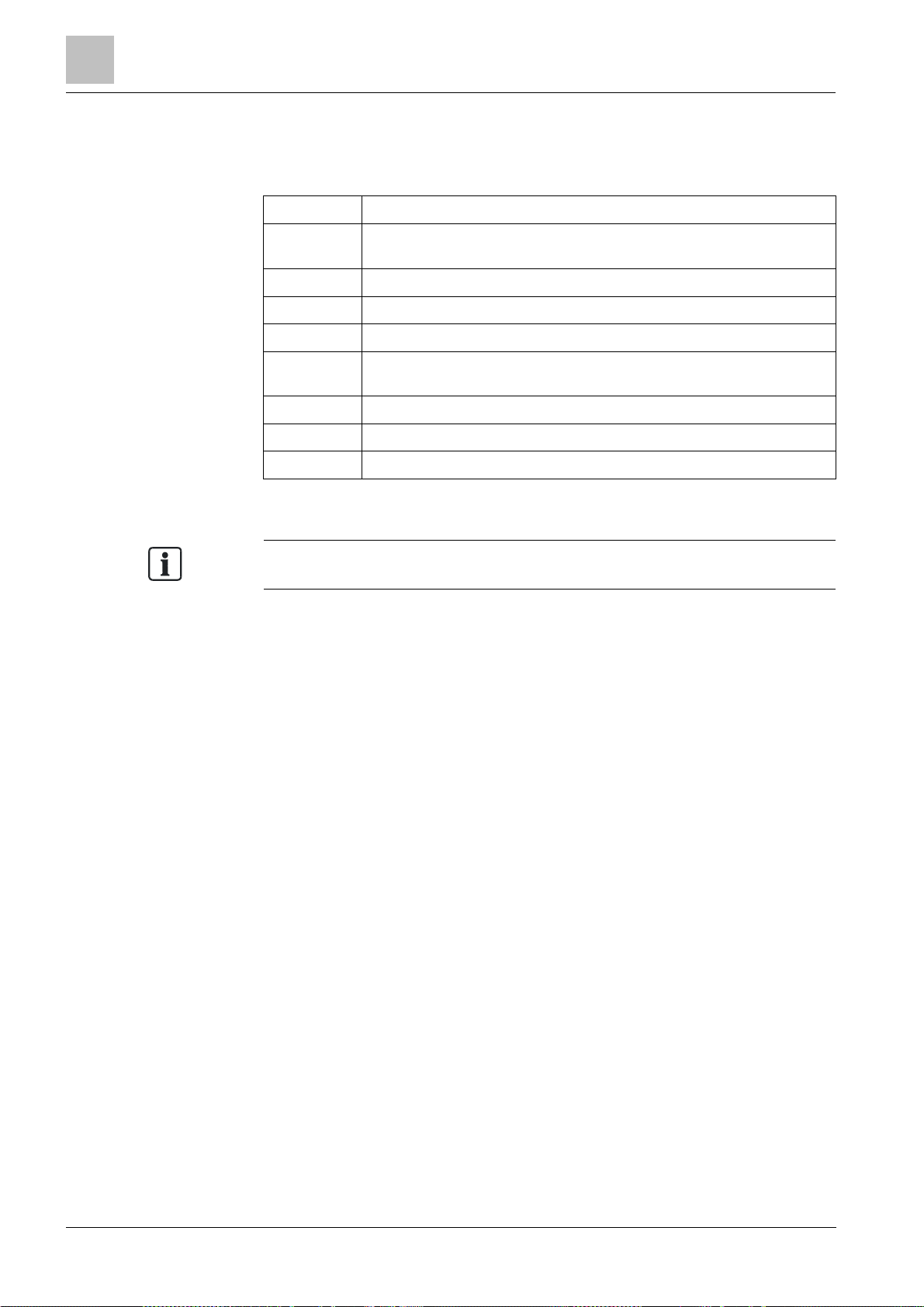

Term Explanation

AI Alarm indicator

ASA Advanced Signal Analysis

ES Product version

C-NET Addressed detector line

C-NET-Ex

K-MK Maximum current connection factor on a collective detector line

LED Light-emitting diode

Symbol Meaning

Addressed detector line in a potentially explosive atmosphere

downstream of a line adapter (Ex) FDCL221-Ex

C

0

C

C

C

i

I

0

I

i

L

0

L

C

L

i

P

0

P

i

R

C

T

a

U

i

U

m

Maximum external capa city

Maximum permissible cable capacitance

Maximum internal capacity

Maximum output current

Maximum input current

Maximum external inductivity

Maximum permissible cable inductance

Maximum internal inductivity

Maximum output power

Maximum input power

Resistance of the connection cable

Ambient temperature in a potentially explosive atmosphere

Maximum input voltage

Maximum r.m.s. value of the alternating voltage.

Maximum permissible voltage of an associated item of electrical

equipment without canceling the energy limitation.

U

0

Maximum output voltage

You will find more technical terms in the glossary at the end of this document.

12

Building Technologies A6V10367521_h_en_--

Fire Safety 2015-02-02

Revision history

1.4 Revision history

The first edition of a language version or a country variant may, for example, b

e

The reference docum ent's version applies to all languages into which the reference

document is trans lated.

version 'd' inst ead of 'a' if the reference document is already this version.

The table below shows this document's revision history:

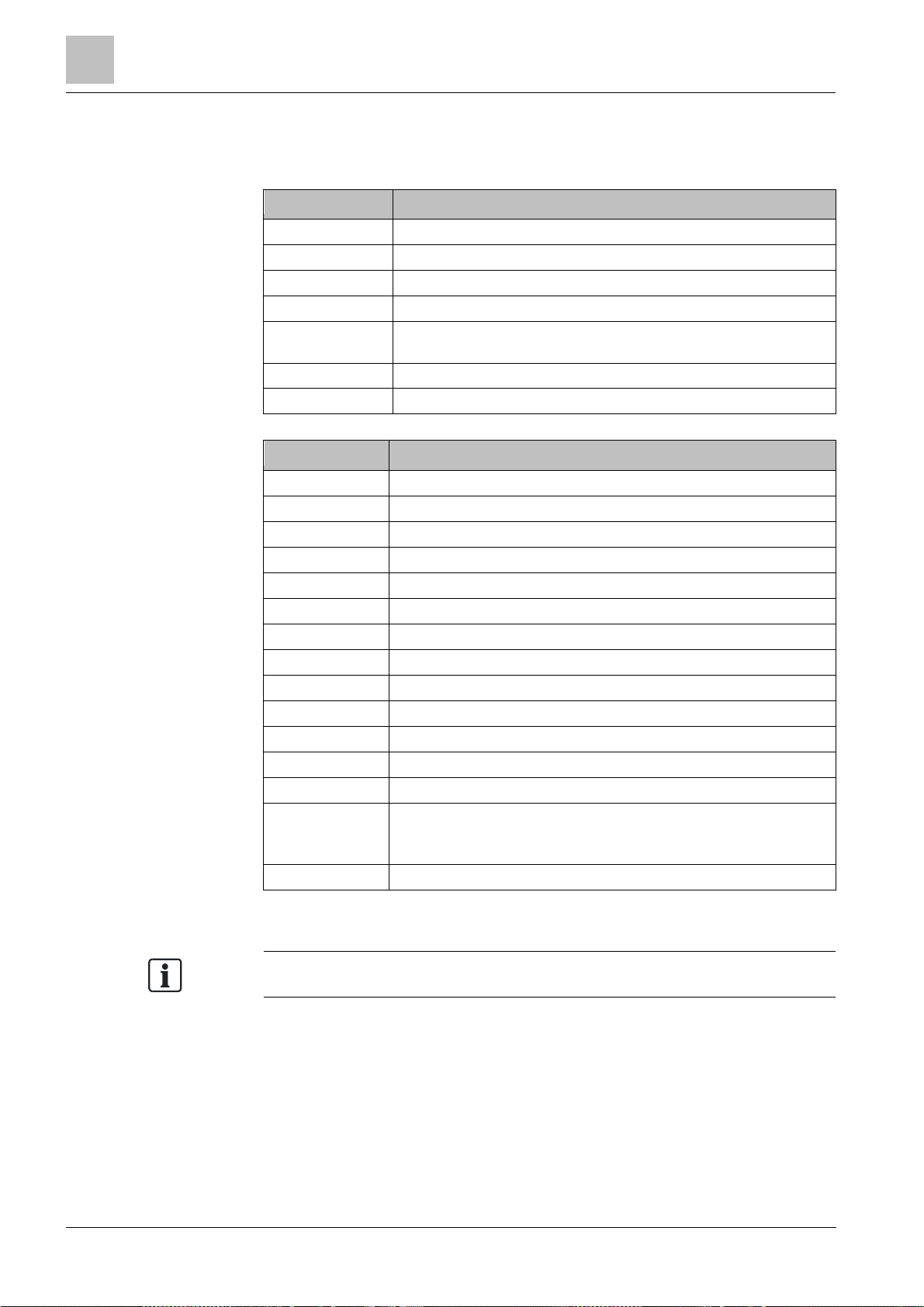

Modification index Edition date Brief description

About this document

1

h 2015-02-02

g 2014-07-22 Editorial changes

f 2014-05-08 Editorial changes

e 2014-02-04

d 2013-04-30 'Technical Ambient Supervision Alarm' added; editorial changes

c 2012-08-17 Labels adapted; Annex added

b 2012-06-15 Editorial changes

a 2012-05-11 First edition

Table listing published language versions corrected; base attachment wet

FDB295 added as optional accessory; sealing element FDBZ295 added; IP

protection category amended in 'Technical data' chapter; editorial changes

Changes in chapter: parameter sets for addressed operation; editorial

changes

The table below shows the published language versions with the corresponding

modification index:

Modification index en_-- de_- - fr_-- it_-- es_--

h X X X X X

g X X X X X

f – X – – –

e – X – – –

d X X – – –

c – X – – –

b – X – – –

a – X – – –

X = published

– = no publication with this modification index

Building Technologies A6V10367521_h_en_-Fire Safety 2015-02-02

13

2

Safety instructions

Contradictory safety instructions

protection.

Safety

2 Safety

WARNING

Risk of explosion caused by disregarding safety instr uctions

● Should safety instructions relating to explosion protection contradict other

safety instructions, please observe the safety instructions relat ing to explosion

2.1 Safety instructions

The safety notices mus t be observed in order to protect people and property.

The safety notices in this document contain the following elements:

l Symbol for danger

l Signal word

l Nature and origin of the danger

l Consequences if the danger occurs

l Measures or prohibit ions for danger avoidance

Symbol for danger

This is the symbol for danger. It warns of risks of injury.

Follow all measures ident ified by this symbol to avoid injury or deat h.

Additional dan ger symbols

These symbols indic ate general dangers, the type of danger or poss ible

consequences, measures and prohibitions, examples of which are shown in the

following table:

General danger Explosive atmosphere

Voltage/electric shock Laser light

Battery Heat

14

Building Technologies A6V10367521_h_en_--

Fire Safety 2015-02-02

Safety regulations for the method of operation

Signal word

Nature and origin of the danger

●

Measures / prohibit ions for danger avoidance

Nature and origin of the danger

●

Measures / prohibit ions for danger avoidance

The signal word classifies the danger as defined in the following table:

Signal word Danger level

Safety

2

DANGER

WARNING

CAUTION

NOTICE

DANGER identifies a dangerous situation, which will result directly in deat h or

serious injury if you do not avoid this situation.

WARNING identifies a dangerous situation, which may result in death or serious

injury if you do not avoid this situation.

CAUTION identifies a dangerous situation, which could result in slight to

moderately serious injury if you do not avoid this situation.

NOTICE

observance.

identifies possible damage to property that may result from non-

How risk of injury is presented

Information about the risk of injury is shown as follows:

WARNING

Consequences if the danger oc curs

How possible damage to property is presented

Information about possible damage to property is s hown as follows:

NOTICE

Consequences if the danger oc curs

2.2 Safety regulations for the method of operation

National standards, regulations and legislation

Siemens products ar e developed and produced in compliance with the relevant

European and international safety standards . Should additional national or local

safety standards or legislation concerning the planning, mounting, inst allation,

operation or disposal of the product apply at the place of operation, then these

must also be taken into account together with the safety regulations in the product

documentation.

Building Technologies A6V10367521_h_en_-Fire Safety 2015-02-02

15

2

Safety regulations for the method of operation

Electrical volt age

regulations.

Work carried out by pers onnel who are not qualified

and international direct ives and regulations.

Safety

Electrical installations

WARNING

Electric shock

● W ork on electrical installations may only be carried out by qualified

electricians or by instructed persons work ing under the guidance and

supervision of a qualified electrician, in accordanc e with the electrotechnical

l W herever possible disconnect products from the power supply when carrying

out commissioning, maintenance or repair work on them.

l Lock volt-free areas to prevent them being switched back on again by mistake.

l Label the connection terminals with external external voltage using a

'DANGER External voltage' sign.

l Rout e mains connections to products separately and fuse them with their own,

clearly marked fuse.

l F it an easily accessible disconnecting device in acc ordance with IEC 60950-1

outside the installation.

l Produce earthing as stated in local safety regulations.

Mounting, installation, commissioning and maintenance

l If you require tools such as a ladder, these must be safe and must be intended

for the work in hand.

l W hen starting the fire control panel ensure that unstable conditions cannot

arise.

l Ensure that all points listed in the 'Testing the product operability' section below

are observed.

l You may only set controls to normal function when the product operability has

been completely tested and the system has been handed over to the customer.

WARNING

Risk of explosion

● W ork in potentially explosive areas may only be carried out by qualified

specialists or by specially instructed persons, in accordance with the national

l You must only mount, install, and test the devices if the atmosphere in the area

is not at risk of explosion.

16

Building Technologies A6V10367521_h_en_--

Fire Safety 2015-02-02

Safety

Safety regulations for the method of operation

2

Testing the product operability

l Prevent the remot e transmis sion from trigger ing err oneously.

l I f testing building installations or activating devices from third-party companies,

you must collaborate with the people appointed.

l T he activation of fire control installations for test purposes must not cause

injury to anyone or damage to the building installations. The following

instructions m ust be observed:

l Use the correct potential for activation; this is generally the potential of the

building installation.

l O nly check controls up to t he interface (relay with blocking option).

l Mak e sure that only the controls to be tested are activated.

l I nform people before testing the alarm devices and allow for possible panic

responses.

l I nform people about any noise or mist which may be produced.

l Bef ore testing the remote transmission, inform the corresponding alarm and

fault signal receiving stations.

Modifications to the system design and the products

Modifications to the system and to individual products m ay lead to faults,

malfunctioning and safety risks. Written confirmation must be obtained from

Siemens and the corresponding safety bodies for m odifications or additions.

No changes may be made to devices with EC-type examination certificates.

Modules and spare parts

l Components and spare parts must comply with the technical specifications

defined by Siemens. Only use products specified or recommended by

Siemens.

l Only use fuses with t he specified fuse characteristics.

l Wrong battery types and improper battery changing lead to a risk of explosion.

Only use the same battery type or an equivalent battery t ype recommended by

Siemens.

l Bat teries must be disposed of in an environmentally friendly manner. Observe

national guidelines and regulations.

Disregard of the safety regulations

Before they ar e delivered, Siemens products ar e tested to ensure they function

correctly when used properly. Siemens disclaims all liability for damage or injuries

caused by the incorrec t application of the instructions or the disregard of danger

warnings contained in the documentation. This applies in particular to the following

damage:

l Per sonal injuries or damage to property caused by improper use and incorrect

application

l Per sonal injuries or damage to property caused by disregarding safety

instructions in the documentation or on the product

l Personal injury or damage to property caused by poor maintenance or lack of

maintenance

Building Technologies A6V10367521_h_en_-Fire Safety 2015-02-02

17

2

Standards and directiv

es complied with

We are grateful for any suggestions for improvement.

Limited or non

-

existent fire detect

ion

detection installation.

Incorrect planning and/or configurat ion

detection installation.

Safety

Disclaimer

We have checked that the content of this document matches the hardware and

software described. Despite this, we cannot rule out deviations and cannot

therefore assume liability for them matching completely. The details in this

document are checked regularly and any corrections needed included in

subsequent editions.

2.3 Standards and directives complied with

A list of the standards and directives complied wit h is available from your Siemens

contact.

2.4 Release Notes

Limitations t o the configuration or use of devices in a fire detection installation with

a particular firmware version are possible.

WARNING

Personal injury and damage to property in the event of a fire.

● Read the 'Release Notes' before you plan and/or configure a fire detection

installation.

● Read the 'Release Notes' before you carry out a firmware update to a fire

NOTICE

Important st andards and specifications are not satisfied.

Fire detection installation is not accepted f or commissioning.

Additional expense result ing from necessary new planning and/ or configuration.

● Read the 'Release Notes' before you plan and/or configure a fire detection

installation.

● Read the 'Release Notes' before you carry out a firmware update to a fire

18

Building Technologies A6V10367521_h_en_--

Fire Safety 2015-02-02

Structure and function

Setup

C-NET-Ex

C-NET

3 Structure and functio n

3.1 Setup

3.1.1 Point detector OOH740-A9-Ex with ASAtechnology

3

View of point detector OOH740-A9-Ex

Properties

l Signal processing with ASA

l Can be used either addressed to the C-NET-Ex detector line or to collective Ex

detector lines

l Can be set as neural fire detector, wide-spectrum smoke detector or heat

detector on the software side

l Selectable detection behavior thanks to application-specific ASA parameter

sets

l Adjustable monitoring of ambient temperature based on hysteresis. The

configuration is set with the 'Cerberus-Engineering-Tool' software.

l Indication of the condition (alarm, localization or test) by means of a red LED

l Mount ing on the C-NET-Ex downstream of a line adapter (Ex) FDCL221-Ex

l W ith collective detector lines, mounting downstream of an input/output module

DC1192 or FDCIO223 or a zone module FDCI723 and a safety barrier SB2 or

SB3

Area not at risk Ex area

technology

FDCL221-Ex

FC72x

Use of several point detectors OOH740-A9-Ex on the C-NET-Ex downstream of a line

adapter (Ex) FDCL221-Ex

19

Building Technologies A6V10367521_h_en_-Fire Safety 2015-02-02

Structure and function

Setup

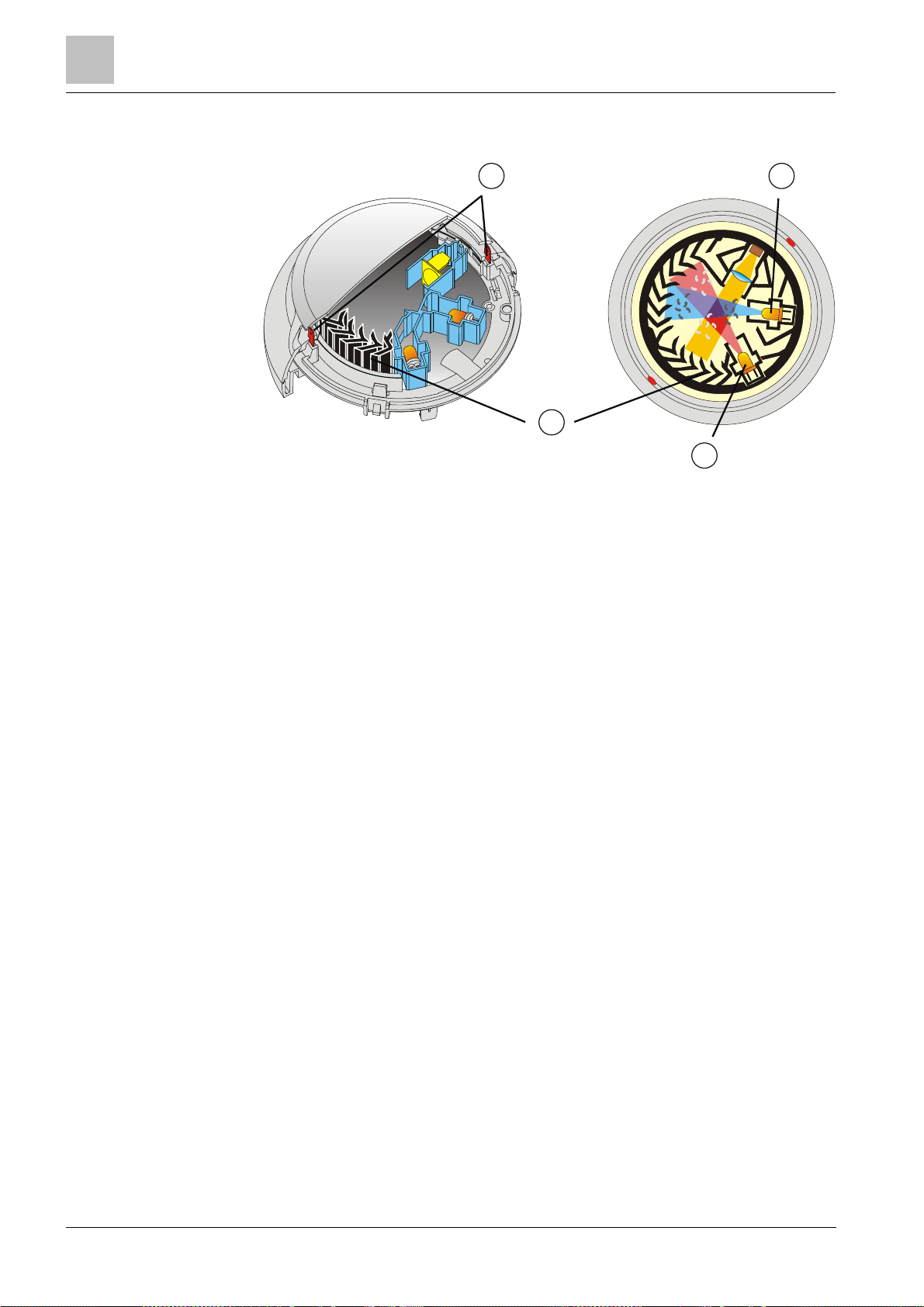

2

3

4

1

Heat sensors

3

Forward scatterer

2

Backward scatterer

4

Labyrinth

3

Setup of the point detector

The point detector OOH740-A9-Ex has two optical and two thermal sensors.

1

The detector has a sophisticated opto-electronic measuring chamber with two

optical transmitters, an optical receiv er, and two thermal sensors.

The transmitt ers illuminate the smoke par ticles from different angles. One sensor

acts as forward scatterer, the other as backward scatterer. The scattered light then

hits the receiver (photodiode) and generates a measurable elect ric signal.

The combination of a forward and backward scatt erer facilitates an optimum

detection and the dif ferentiation of light and dark par ticles, which leads to a

homogenous response behavior and optimizes the differentiation of wanted signals

and deceptive phenomena.

In addition, the heat sensors make it possible to detect fires without smoke

generation.

The combination of optical and thermal sensor signals optim izes detection

reliability. This has the following advantages:

l Early detection of all types of fire, whether they generate light or dark smoke, or

no smoke at all.

l The multisensor fire detector can be operated at a lower sensitivity level and

thus achieves a higher immunity against false alarms, which can be caused by

cold aerosols (e.g., by smoking). In the case of an open fire, the smoke

sensitivity is heightened by the temperature increase, which means that a

detection reliabilit y level that is compar able to that of the wide-spectrum sm oke

detector can be achiev ed.

The detector can also be used pur ely as an optical smoke detector or purely as a

heat detector. T his is determined by selecting one of the following sensor modes:

l Sensor mode 0: Applic ation as neural fire detector

l Sensor mode 1: Application as heat detector

l Sensor mode 2: Application as smoke detector

20

Building Technologies A6V10367521_h_en_--

Fire Safety 2015-02-02

See also

2 Applicable documents [➙ 11]

Setup

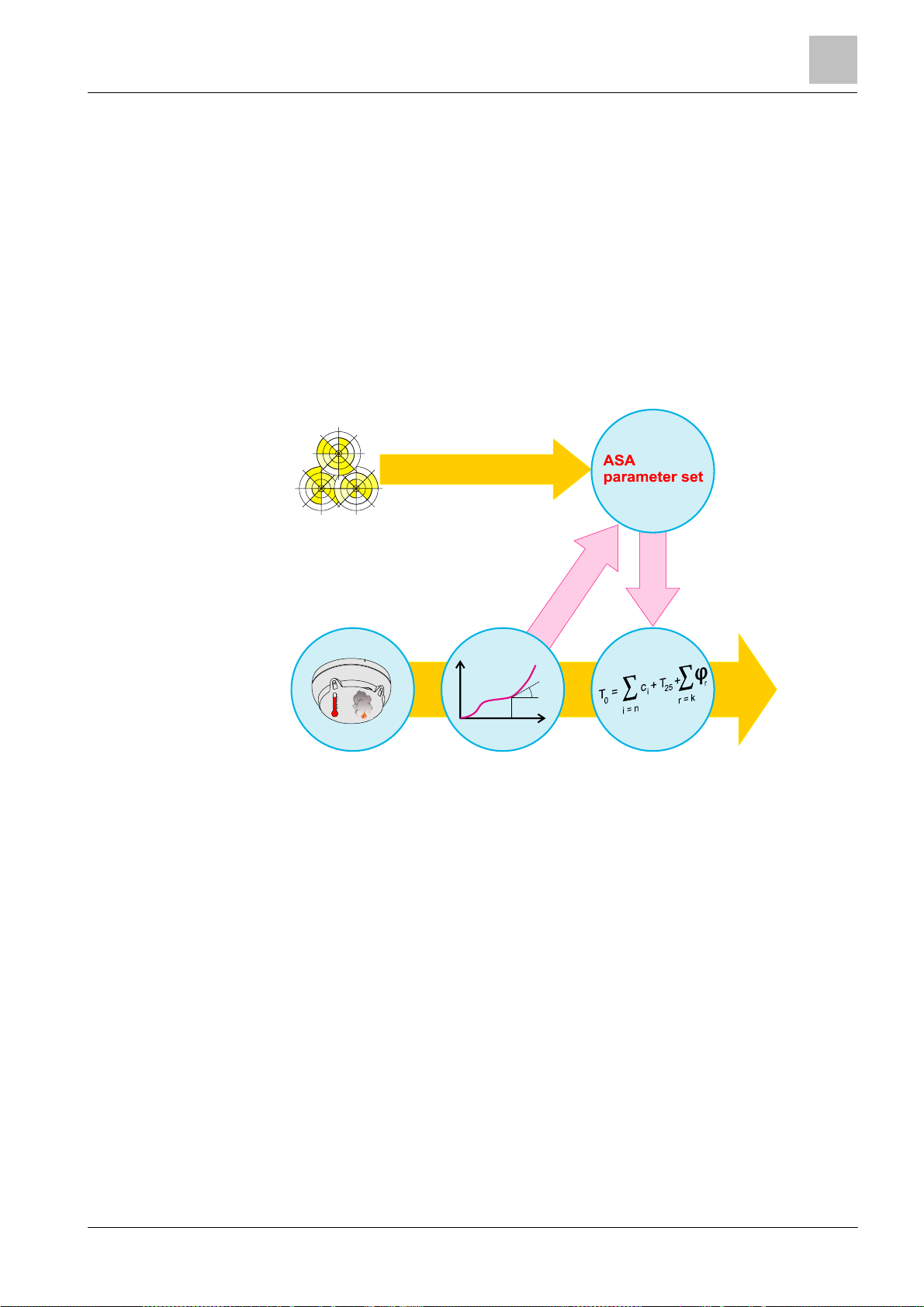

3.1.2 Features of fire detection functionality

The point detector OOH740-A9-Ex has the following features in terms of its fire

detection functions:

l Dynamic influence on the parameter sets

l Pattern recognition

l Real time int erpretation of the situation

l Process- and time-controlled switchover of the parameter sets

Signal processing is based on ASAtechnology (ASA = Advanced Signal Analysis).

ASAtechnology can als o be characterized as second generation algorithms. Signal

processing with ASAtechnology allows for opt imum adaptation of detector behavior

to the corresponding ambient conditions.

Operating mode: Signal processing with ASAtechnology

The figure below shows signal processing in the form of a diagram:

Structure and function

3

Environment

Evaluation of the

situation

Dynamic influence

of parameter

Danger

level

C

Signal analysisSensory

Signal processing with ASAtechnology

Sensory

The signals captured by the sensory are transmitted to the algorithm. The

algorithms are set by selec t ing the parameter set.

Algorithms

In comparison t o the det ection algorithms (DA), the individual parameters of the

selected parameter set can be adapted with ASAtechnology. A r eal time

interpretation of the situation leads to a dynamic influence on the algorithm. T he

real time interpr etation results in a broadening of the application range of the

parameter set and thus of the detector. The detector reacts more sensitively in the

event of fire, and more robustly in the event of deceptive phenomena.

Algorithms

Result

21

Building Technologies A6V10367521_h_en_-Fire Safety 2015-02-02

Structure and function

Setup

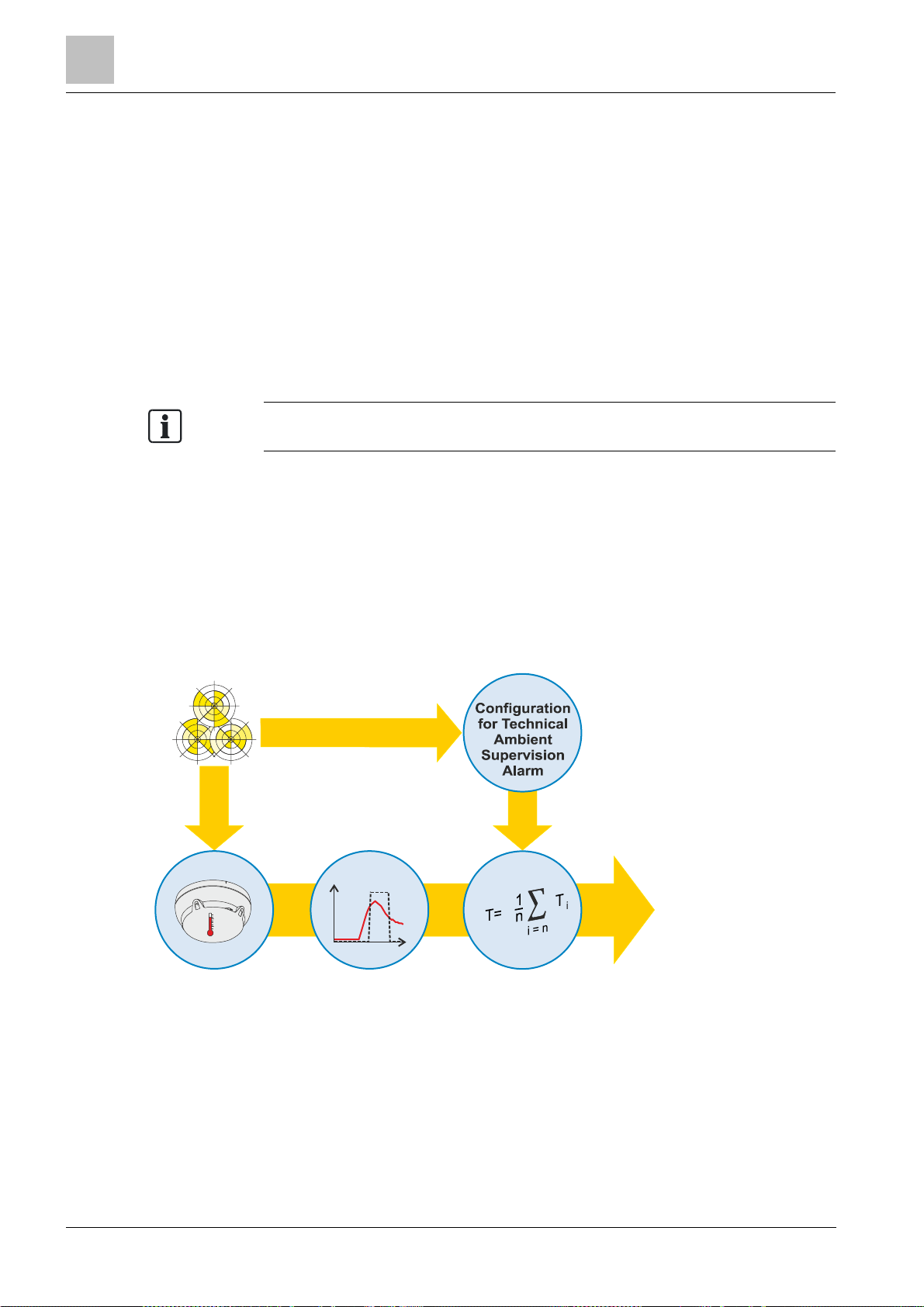

The 'Technical Ambient Supervision Message' c annot be configured on all fire

Warning level for

T echnical Am bient

Result

Sensory

3

Switching over the parameter set

In addition to selecting the parameter set, the point detectors with ASAtechnology

enable time- or process-controlled switching ov er of the parameter sets

(Manned/Unmanned swit chover). The time- or process-controlled switching over of

parameter sets allows the detector to be used in places where the situation

changes significant ly on a regular basis (e.g. kitchens, production halls).

Parameter sets which can be loaded

The detectors have several permanently programmed parameter sets. For special

applications new, addit ional parameter sets can be downloaded in the field

(depending on the control panel) .

3.1.3 Features of the 'Technical Ambient Supervision Message'

control panels. Observe the information in the 'List of compatibility'.

'Technical Ambient Supervision Message' mode det ects an increase in

temperature c aused by hysteresis above a specified threshold.

Temperature monitoring compares the current measured temperature with a preset

threshold value.

You can configure t he following parameters for the point detector:

l Threshold value for temperature

l Alar ming when the temperature threshold value is exceeded or undershot

l Hysteresis range

Parameter conf iguration is carried out using the soft ware 'Cerberus-EngineeringTool'.

Environment:

Temperature

T [°C]

°C

Signal analysis

Signal processing by the 'Technical Ambient Supervision Message'

t

Supervision Alarm

Algorithms

22

Building Technologies A6V10367521_h_en_--

Fire Safety 2015-02-02

Loading...

Loading...