Siemens OOH740, OOHC740 Technical Manual

OOH740, OOHC740

Bui

lding Technologies

Automatic fire detectors

Technica l Manual

A6V10305793_m_en_-2016-02-15 Control Products and Systems

Legal notice

Building Technologies

A6V10305793_m_en_

--

Fire Safety

Legal notice

Technical specifications and availability s ubject to change without notice.

Transmitt al, reproduction, diss emination and/or editing of this document as well as

utilization of its contents and communication thereof to others wit hout express

authorization are prohibited. Off enders will be held liable for payment of damages.

All rights creat ed by patent grant or registration of a utilit y model or design patent

are reserved.

Issued by:

Siemens Switzerland Ltd.

Building Technologies Div ision

International Headquarters

Gubelstrasse 22

CH-6301 Zug

Tel. +41 41 724-2424

www.siemens.com/buildingtechnologies

Edition: 2016-02-15

Document ID: A6V10305793_m_en_--

© Siemens Switzerland Lt d, 2010

2 | 108

2016-02-15

Building Technologies

A6V10305793_m_en_

--

Table of contents

1 Ab ou t thi s doc um e nt ............................................................................. 7

1.1 Applicable documents ................................................................................. 9

1.2 Download center ......................................................................................... 9

1.3 Technical terms .........................................................................................10

1.4 History of changes .....................................................................................10

2 Sa fet y ............................................................................................... 1 3

2.1 Safety instructions .....................................................................................13

2.2 Safety regulations for the method of operation ...........................................15

2.3 Standards and directives complied with......................................................17

2.4 Release Notes ...........................................................................................17

3 Str u ct ur e an d fun c ti o n ......................................................................... 18

3.1 Overview ...................................................................................................18

3.1.1 Multi-s enso r smoke dete c tor, ASA O OH7 40 ................................19

3.1.2 Neura l fire d e te ctor OOHC7 4 0 ....................................................20

3.1.3 Feature s of fire de tectio n functio nality .........................................21

3.1.4 Feature s of the 'Te chnica l CO Alarm' ..........................................22

3.1.5 Features of the 'Technical Ambient Supervision Message' ...........24

3.1.6 Detail s for orderi ng ......................................................................24

3.1.7 Product vers i on ES .....................................................................25

3.2 Setup .........................................................................................................26

3.2.1 Structure of OOH74 0 ..................................................................26

3.2.2 Structure of OOHC740 ................................................................27

3.3 Function ....................................................................................................30

3.3.1 Parame ter sets ...........................................................................30

3.3.1.1 Parameter sets for fire detection ...................................31

3.3.1.2 Parameter sets for 'Technical CO Alarm' ......................34

3.3.2 Dange r le ve l s and wa rn i n g le vels ................................................35

3.3.2.1 Danger levels for fire detection .....................................35

3.3.2.2 Warning levels for CO ..................................................36

3.3.2.3 Danger levels for 'Technical Ambient Supervision

Message'36

3.3.3 Diagn osis levels ..........................................................................37

3.3.4 Line separator .............................................................................38

3.3.5 Internal alarm indicator in the case of ES <20 (OOH740 and

OOHC740 ) ................................................................................................38

3.3.6 External alarm indicator in the case of ES <20 (OOH740 and

OOHC740 ) ................................................................................................39

3.3.7 Advanced flashing behavior of the alarm indicators in the case of

ES ≥20 (OOH 740 and O OHC740 ) .............................................................40

3.3.8 Conne ctio n for external alarm indi cato rs ......................................42

3.3.9 Renova tion mode ........................................................................42

Fire Safety

3 | 108

2016-02-15

Building Technologies

A6V10305793_m_en_

--

Fire Safety

3.3.10 Test mode .................................................................................. 42

3.3.11 Behavior in degraded mode ........................................................ 43

3.3.12 Line tester ................................................................................... 44

3.4 Mechanical setup ....................................................................................... 44

3.5 Accessories ............................................................................................... 45

3.5.1 Detecto r base with loop contac t DB721 ....................................... 45

3.5.2 Detecto r base DB722 .................................................................. 4 5

3.5.3 Detecto r base DB721D ............................................................... 4 6

3.5.4 Detecto r base (collecti ve) DB110 ................................................ 4 6

3.5.5 Sound er base DBS720 ............................................................... 4 7

3.5.6 Desig nation plate FDBZ291 ........................................................ 47

3.5.7 Detecto r base seal RS720 .......................................................... 47

3.5.8 Base attachmen t BA720 ............................................................. 48

3.5.9 Base attachment wet BA721 ....................................................... 48

3.5.10 Designation plate DBZ1193A ...................................................... 48

3.5.11 Detector heating unit FDBH291 ................................................... 49

3.5.12 Protective cage DBZ1194 ........................................................... 49

3.5.13 Detector locking device LP720 .................................................... 49

3.5.14 Micro terminal DBZ1190-AA ........................................................ 50

3.5.15 Connection terminal DBZ1190-AB............................................... 50

3.5.16 Parameter set resistor 33 kΩ PSR720-1 ...................................... 50

3.5.17 Parameter set resistance 68 kΩ PSR720-2 ................................. 50

4 Planning ............................................................................................51

4.1 Compatibility .............................................................................................. 51

4.2 Fire detection ............................................................................................. 51

4.2.1 Ambient features ......................................................................... 51

4.2.2 Parame ter sets: Sen sor mode 0 'Neura l fire dete ctor' .................. 53

4.2.2.1 Description ................................................................... 53

4.2.2.2 Use .............................................................................. 55

4.2.2.3 Specification ................................................................ 56

4.2.3 Parame ter sets: Sensor mode 1 'Heat detector' ........................... 57

4.2.4 Parame ter sets: Sen so r mode 2 'Smoke dete c tor' ....................... 58

4.2.4.1 Description ................................................................... 58

4.2.4.2 Use .............................................................................. 59

4.2.4.3 Specification ................................................................ 59

4.2.5 Parame ter sets for collecti ve operation ........................................ 60

4.2.5.1 Description ................................................................... 60

4.2.5.2 Use .............................................................................. 60

4.2.5.3 Specification ................................................................ 61

4.2.6 Defaul t setting s for opera ting on the C-N ET ................................ 61

4.2.7 Setting the para me ter se t in col le cti ve ope rati o n.......................... 62

4.2.8 Sample appli catio ns for OOH740 ................................................ 62

4.2.9 Sample applica tions for OOHC74 0 .............................................. 63

4 | 108

2016-02-15

Building Technologies

A6V10305793_m_en_

--

4.3 Technical CO alarm ...................................................................................64

4.3.1 Parame ter sets for the 'Technical CO Alarm' ...............................64

4.3.1.1 Description ...................................................................64

4.3.1.2 Use ..............................................................................65

4.3.1.3 Specification.................................................................66

4.3.1.4 Default settings ............................................................67

4.3.1.5 Application examples ...................................................67

4.3.2 Ambien t feature s .........................................................................68

4.4 Technical Ambient Supervision Message ...................................................69

4.4.1 Ambien t feature s .........................................................................69

4.4.1.1 Temperature monitoring ...............................................71

4.4.1.2 CO monitoring ..............................................................71

4.4.2 Config urati on ..............................................................................72

4.4.3 Defaul t settings ...........................................................................72

5 Mo u nt i ng / In s ta l l a ti o n ......................................................................... 73

5.1 Required space .........................................................................................73

5.2 Detector base DB72x and detector base (collective) DB110 .......................74

5.3 Sounder base DBS720 ..............................................................................76

5.4 Detector base seal RS720 .........................................................................77

5.5 Base attachment BA720 ............................................................................78

5.6 Base attachment wet BA721 ......................................................................79

5.7 Detector locking device LP720 ...................................................................82

5.8 Designation plate FDBZ291 .......................................................................83

5.9 Cable entry ................................................................................................84

5.9.1 Auxili ary terminals DBZ1190-AA/ -AB ...........................................85

5.10 Detector lines ............................................................................................85

5.10.1 Connection diagram, addressed ..................................................85

5.10.2 Connection diagram, collective ....................................................87

5.11 Detector dust cap ......................................................................................89

5.12 Detector heating unit FDBH291 .................................................................90

5.12.1 Installation of the detector heating unit ........................................90

5.12.2 Connection of the detector heating unit .......................................91

5.13 Migrat ion from collective detector line to addressed detector line . .... ..... .... .92

5.13.1 Removing the diode unit..............................................................93

Fire Safety

6 Co mm i ss i on i ng .................................................................................. 9 4

6.1 Commissioning on the C-NET ....................................................................94

6.2 Commissioning on a collective detector line ...............................................94

7 Ma in te na nc e / Repa i r .......................................................................... 9 5

7.1 Performance check ....................................................................................95

5 | 108

2016-02-15

Building Technologies

A6V10305793_m_en_

--

Fire Safety

7.2 Testing the point detector .......................................................................... 95

7.2.1 Test mode on the contro l panel ................................................... 96

7.2.2 Testing the fire detectio n function ali ty.......................................... 9 7

7.2.3 Testing the CO fun ctio na li ty (only for OOH C7 40 ) ........................ 97

7.2.4 Testing the functionality of the 'Technical Ambient

Superv ision Message' ................................................................. 98

7.2.4.1 'Technical Ambient Supervision Message'

performa nce check ....................................................... 98

8 Sp eci fi cat io ns .....................................................................................9 9

8.1 Technical data for OOH740 ....................................................................... 99

8.2 Technical data for OOHC740 ................................................................... 102

8.3 Dimensions ............................................................................................. 104

8.4 Environmental compatibility ..................................................................... 104

Ind ex ....................................................................................................... 105

6 | 108

2016-02-15

About this document

Applicable documents

108

A6V10305793_m_en_

--

Fire Safety

1 About this document

Goal and purpose

This document contains all the inform ation you'll need on automatic fire detectors

● OOH740

● OOHC740

Following the instruc tions consistently will ensure that the product can be used

safely and without any problems.

Intended use

The automatic fire detectors OOH740 and OOHC740 may only be used on a C-

NET detector line in a FS720 fire detection system.

The automatic fire detector OOH740 may also be used on a collective detector line

or a conventional detector line.

Target groups

The information in this document is int ended for the following target groups :

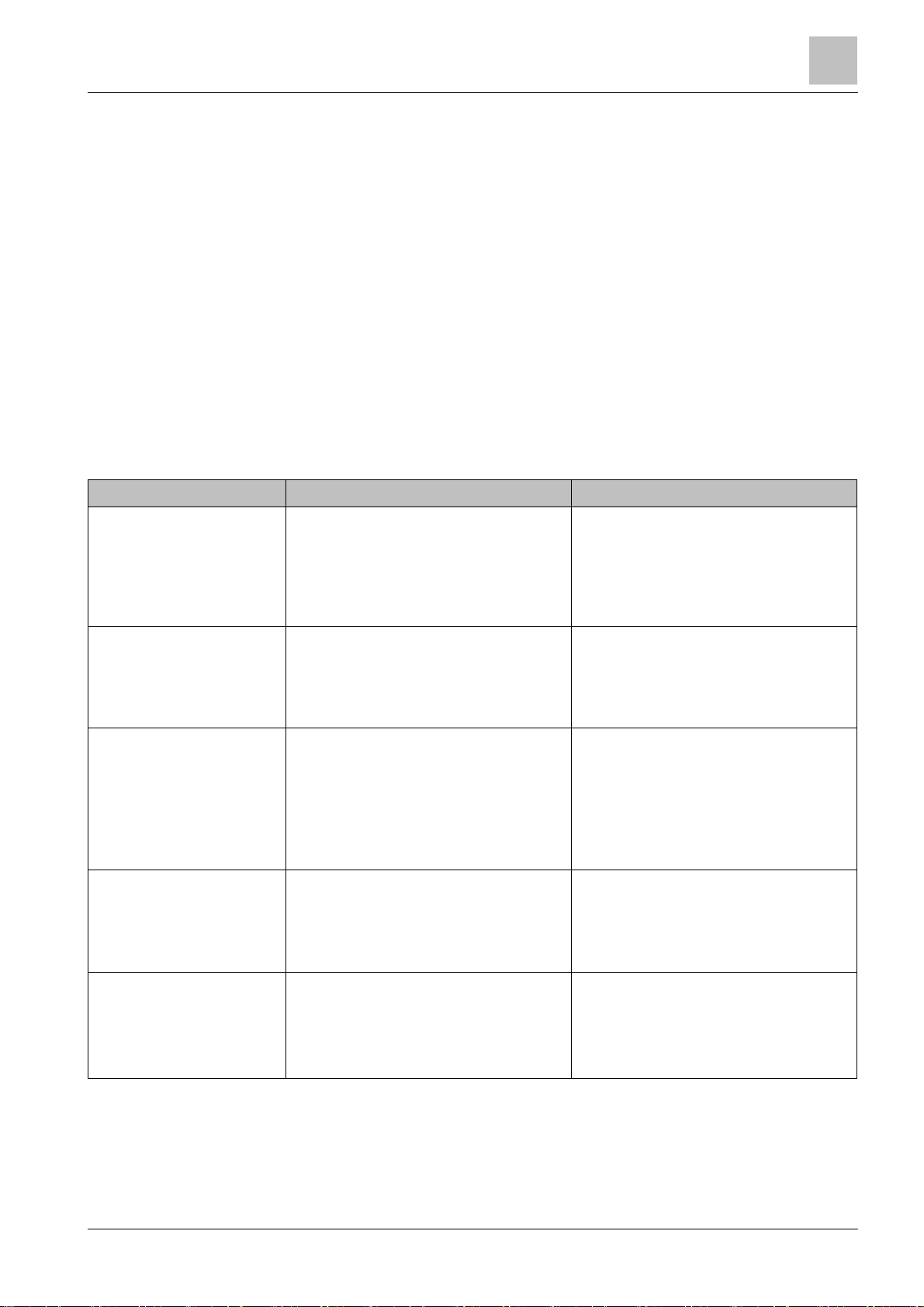

Target group Activity Qualificatio n

1

Product Manager

Project Manager

Project engineer

Installation pers onnel

● Is responsible for information

passing between the manuf acturer

and regional company.

● Coordinates the flow of information

between the individual groups of

people involved in a project.

● Coordinates the deployment of all

persons and resources involved in

the project according to schedule.

● Provides the information required to

run the project.

● Sets parameters for product

depending on specific national

and/or customer requirements.

● Checks operability and approves

the product for commissioning at the

place of installation.

● Is responsible for troubleshooting.

● Assembles and installs the product

components at the place of

installation.

● Carries out a performance check

following installation.

● Has obtained suitable specialist

training for the function and for the

products.

● Has attended the training courses

for Product Managers.

● Has obtained suitable specialist

training for the function and for the

products.

● Has attended the training courses

for Project Managers.

● Has obtained suitable specialist

training for the function and for the

products.

● Has attended the training courses

for Product Engineer.

● Has received specialist training in

the area of building installation

technology or electrical installations.

Maintenance personnel ● Carries out all maint enance work.

Building Technologies

● Has obtained suitable specialist

● Checks that the products are in

perfect working order.

● Searches for and corrects

malfunctions.

training for the function and for the

products.

Source language and reference document

● The source/original language of this document is German (de).

● The reference version of this document is the international version in E nglish.

The international ver sion is not localized.

7 |

2016-02-15

About this document

Applicable doc

uments

1

Building Technologies

A6V10305793_m_en_

--

Fire Safety

The 'i' symbol identifies supplementary information and t

ips for an easier way of

Document identification

The document ID is structured as follows:

ID code Examples

ID_Modificat ionIndex_Language_COUN

TRY

-- = multilingual or international

A6V10215123_a_de_DE

A6V10215123_a_en_-A6V10315123_a_--_--

Date format

The date format in the document corresponds to the recommendation of

international standard ISO 8601 (format YYYY-MM-DD).

Conventions for text marking

Markups

Special markups are shown in this document as follows :

⊳ Requirement for a behavior instruction

1.

2.

– Version, option, or detailed information for a behavior instruction

⇨ Intermediate result of a behavior instruction

⇨ End result of a behavior instruction

●

Behavior instruction with at least two operation sequences

Numbered lists and behavior instructions with an operation

sequence

[➙ X] Reference to a page number

'Text' Quotation, repr oduced identically

<Key> Identificat ion of keys

>

Relation sign and for ident ification between st eps in a sequence,

e.g., 'Menu bar' > ' Help' > 'Help topics'

↑ Te xt Identification of a glossary entry

Supplementary information and tips

working.

8 | 108

2016-02-15

About this document

Applicable documents

108

A6V10305793_m_en_

--

Fire Safety

1.1 Applicable documents

You will also find inform ation about search variants and links to mobil

e

Document ID Name

008250 Technical Manual Line tester FDUL221

1

009122

Technical manual Input/output module ( transponder)

FDCIO223

A6V10200373

Installation Det ector base with loop contact DB721,

DB722, detector base DB720, sounder base DBS720,

detector base seal RS 720, detector locking device

LP720, base attachment BA720

A6V10201731

Installation Det ector exchanger DX791, adapt er for

detector exchanger FDUD491

A6V10210416

FS720 Fire detection system - Commissioning,

Maintenance, Troubleshooting

A6V10210424 FS720 Fire detection system - Configuration

A6V10229261 List of compatibility (for 'Cerberus™ PRO' pr oduct line)

A6V10254740

Operating instructions Solo461 heat detector tester kit

RE7T

A6V10284161

Data sheet Automatic fire detectors OOH740,

OOHC740

A6V10316300

Installation Det ector base (collective) DB110, DB110D,

DB110R, DB110RD, detector base seal RS720,

detector locking device LP720, base attachment BA720

A6V10323905

Installation Det ector base DB721D, detector base seal

RS720, detector locking device LP720

A6V10406006

Please also observe the documentation for your fire detection system.

1.2 Download center

You can download various types of documents, such as data sheets, installat ion

instructions, and license texts via the following Internet address:

http://siemens.com/bt/download

l Enter t he document ID in the 'Find by keyword' input box.

applications (apps) for various sy stems on the home page.

Installation Bas e attachment wet BA721, Detector

designation plate DBZ1193A, Protective cage

DBZ1194, EMC-protective cage FDBZ294

Building Technologies

9 |

2016-02-15

About this document

Technical terms

1

Building Technologies

A6V10305793_m_en_

--

Fire Safety

The first edition of a language version or a country variant may , for example, be

1.3 Technical terms

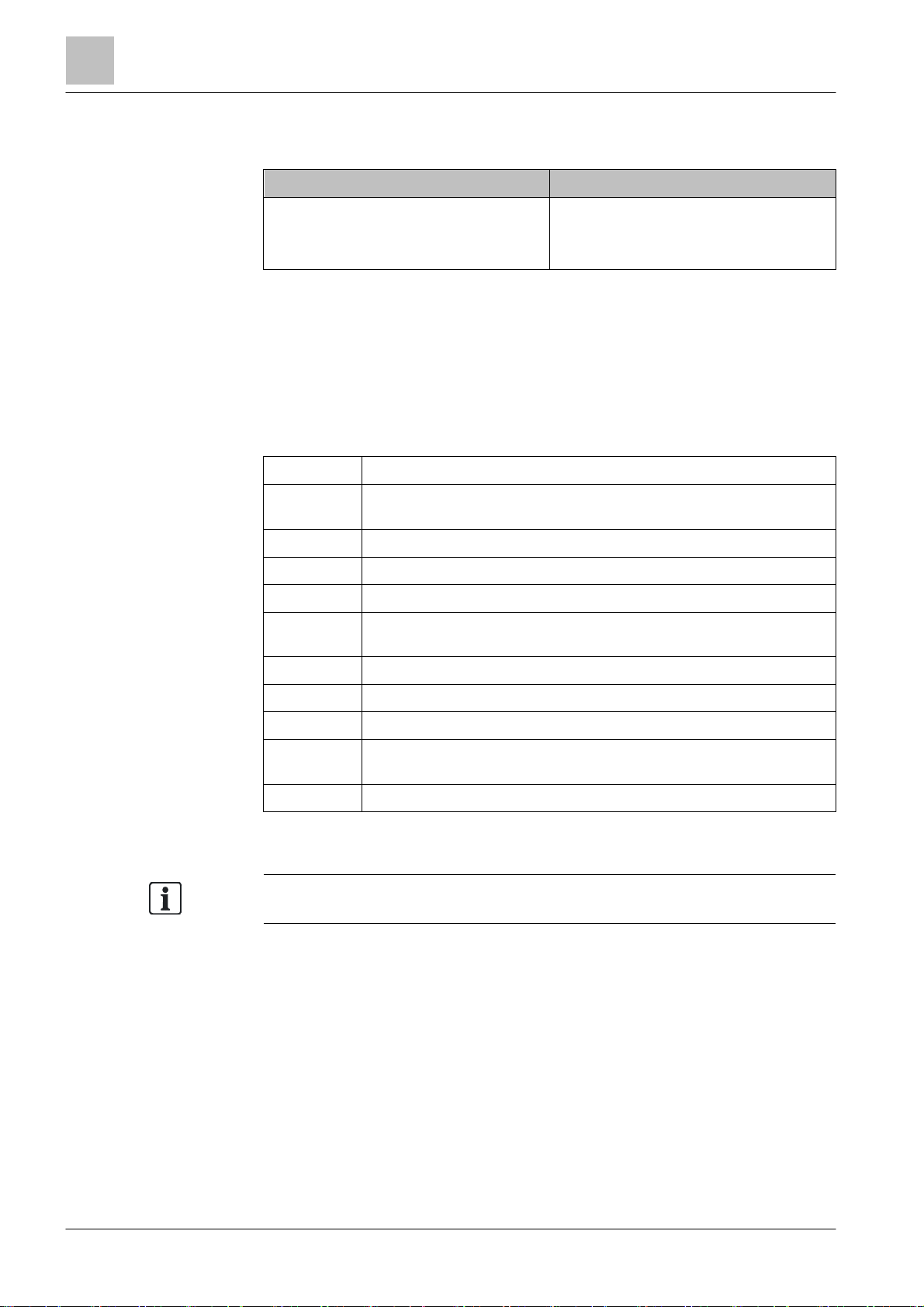

Term Explanation

AI Alarm indicator

ASA (ASA

technology

CO Carbon monoxide

EAI External alarm indic ator

EOL End-of-line

ES Product version

C-NET Addressed detect or line

IAI Internal alarm indicator

LED Light-emitting diode

TM

) Advanced Signal Analysis

MAK value

Maximum concentration at the workplace: maxim um

permissible concent ration of a toxic substance in the air

at the workplace

1.4 History of changes

The reference docum ent's version applies to all languages into which the reference

document is trans lated.

version 'd' inst ead of 'a' if the reference document is already this version.

The table below shows this document's revision history:

10 | 108

2016-02-15

About this document

History of changes

108

A6V10305793_m_en_

--

Fire Safety

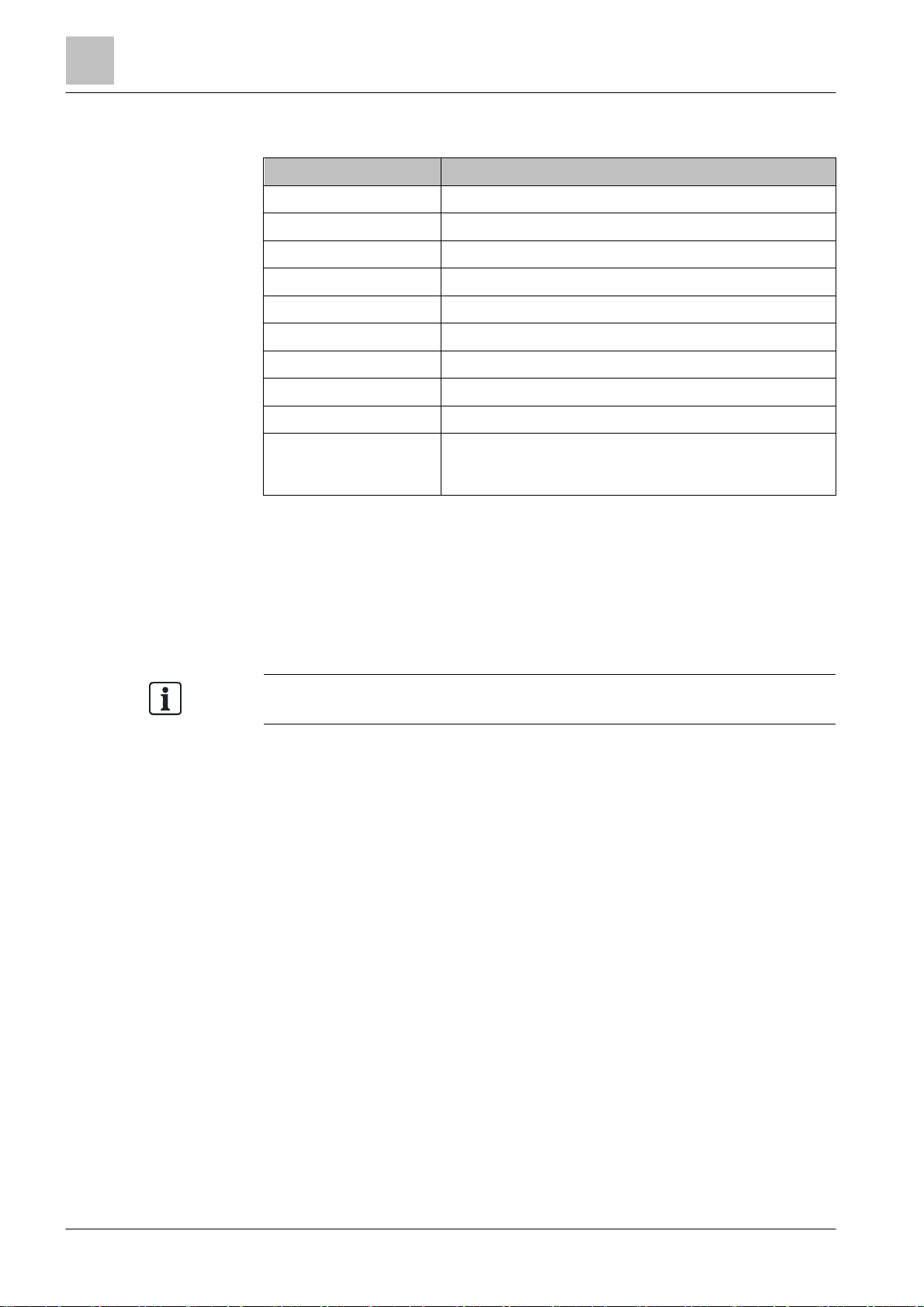

Modificatio n in dex Editio n da te Brief description

m

l 2014-05-08

k 2013-04-04

j 2013-01-25

2016-02-15

● Intende d us e ad de d

● Extended flash ing behav ior of th e alarm i ndicators added

● Additions to the 'Detector base DB72x and detector bas e ( collective) DB110'

chapter

● EMC-protective cage FD BZ294 remove d as accessory part

● Temperature ranges for 'Technical Ambient Supervision Message' corrected

● Editorial changes

● Changes in the following chapters :

– 'Multi-sensor smoke detector, ASA OOH740'

– 'Neura l fire detector OOHC740'

– 'Structure of OOHC740'

– 'Parameter sets for fire detection'

– 'Behavi or in degrad ed m od e op eration'

– 'Line separators'

– 'External alarm indicator in the case of ES <20 (OOH740 and OOHC740)'

– 'Extend ed flashi ng behavior of the alarm indicators in the case of ES ≥20

(OOH740 and OOHC740)'

– 'Detector base DB722'

– 'Compatibility'

– 'Fire detection' > 'Spec ification'

– 'Parameter sets: Sensor m ode 0 'Neural fire detector' ' > 'Des cription'

– 'Parameter sets: Sensor m ode 0 'Ne ural fire detector' ' > 'Application'

– 'Parameter sets: Sensor mode 2 smoke detector > 'Description'

– 'Parameter sets: Sensor mode 2 smoke detector > 'Application'

– 'Parameter sets for collective operation' > 'Specification'

– 'Default settings for operating on the C-NET'

– 'Sam ple applications for OOH740'

– 'Sample applications for OOHC740'

– 'Parameter sets for the 'Technical CO Alarm' ' > 'Description'

– 'Parameter sets for the 'Technical CO Alarm' ' > 'Specification'

– 'Parameter sets for the 'Technical CO Alarm' ' > 'Sample a pplications'

– 'Technical 'Ambient Supervision' Mes s age' > 'A mb ient features'

– 'Detector base DB72x and detector base (collective) DB110'

– 'Base attachment BA720'

– 'Connec tio n diagra m, ad dressed'

– 'Connection di agram, collective'

– 'Migration from collective detector line to addressed detector line'

– 'Testing the fire detection functionality'

– 'Testing the CO functionality'

– ' 'Technical Ambient Supervis ion Message' function check'

– 'Technical data'

● 'Danger levels for 'T echnical Ambient Supervision Mes sage' ' chapter corrected

Data she et in 'Applicable documents' c hapter added; new parameter sets add ed;

'Technical Ambient S upervis ion Message' made available in point detector OOH740;

various changes in the 'Specifications' chapter; editorial changes; base attachment

wet BA721, designation plate DBZ1193A, protective cage DBZ1194, EMC-protec tive

cage FDBZ294, and detector heating unit FDBH291 added, 'Download center'

chapter added; addition parameter sets for OOH740 added; changes made to

'Compatibility' chapter

Technical data adapted

LPCB appr ov als ad ded

1

Building Technologies

11 |

2016-02-15

About this document

History of changes

1

Building Technologies

A6V10305793_m_en_

--

Fire Safety

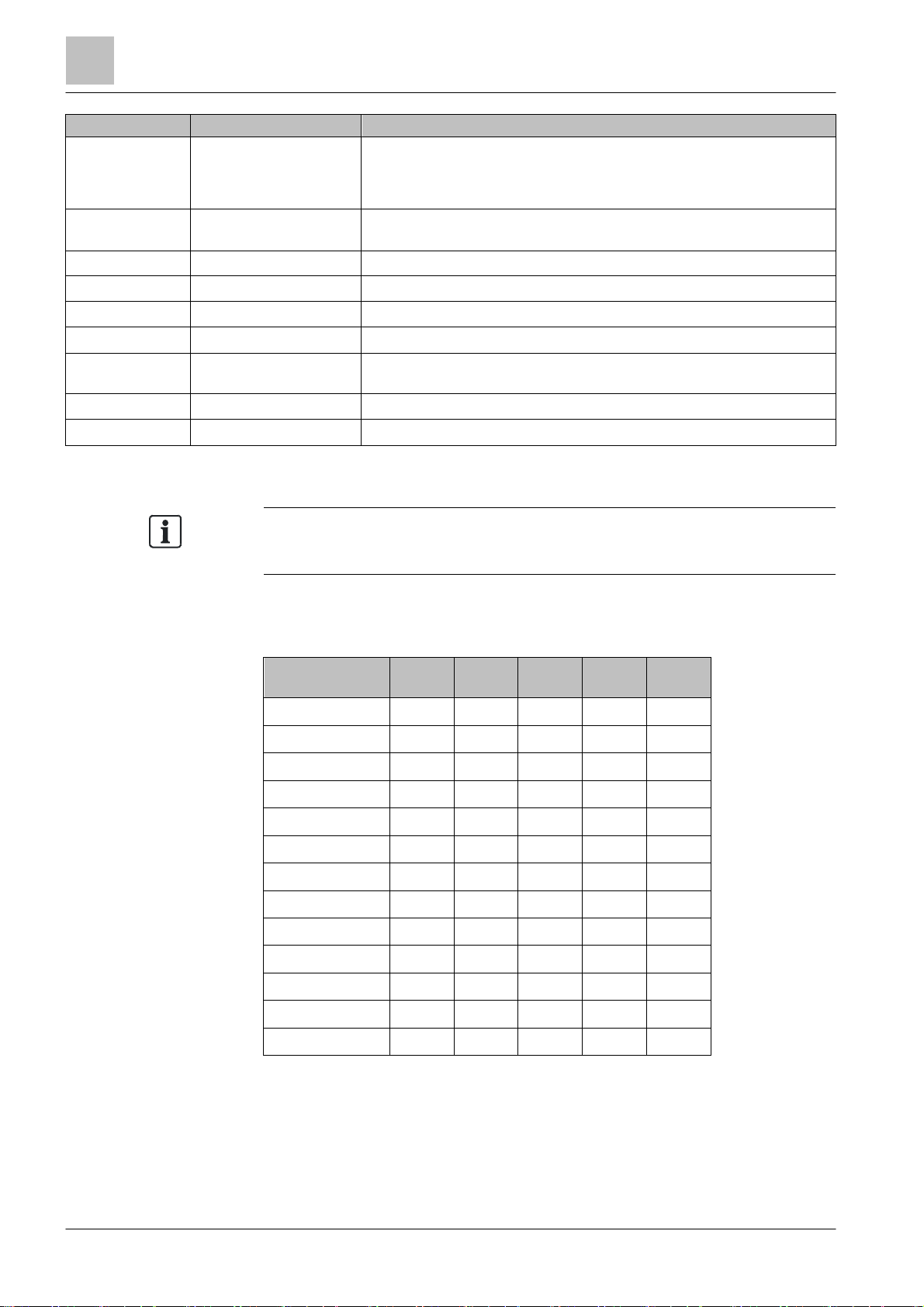

The language versions and country variants produced by a local company have

Modificatio n

en_--de_--fr_--it_--es_

--

Modificatio n in dex Editio n da te Brief description

i 2012-08-16

h 02.2012

g 11.2011

f 09.2011

e 06.2011

d 05.2011

c 02.2011

b 12.2010

a 07.2010

Details concerning product version corrected in 'Planning' chapter; notice added:

Parameter sets 'Balanced CO' and 'Suppression CO' do not have LPC B approval;

date format changed in accordance with specifications of ISO 8601 (format: yyy ymm-dd)

Detector base DB722 and base attachment BA7 20 added , marine approva l for

OOH740 added

OOH740: VdS approval and CPD n umber added

IP protec tion categories adapted

Chapter 'Removing the diode unit' adde d

Detector base DB110 a dded

Removing the d iode unit on the detector base DB721D changed; detector

designations changed

Editori al revision; detector base DB721D added

First editi on

the same modification index as the corresponding reference document. They are

not however included in the t able below.

The table below shows the published language versions with the corresponding

modification index:

index

m X X X X X

l X X X X X

k X X X X X

j X X X X X

i X X X X X

h X X X X X

g X X X X X

f X X X X X

e X X X X X

d X X X X X

c – X – – –

b X X – – –

a – X – – –

X = published

– = no publication with this modification index

12 | 108

2016-02-15

Safety

Safety instructions

108

A6V10305793_m_en_

--

Fire Safety

2 Safety

2.1 Safety instructions

The safety notices mus t be observed in order to protect people and property.

The safety notices in this document contain the following elements:

● Symbol for danger

● Signal word

● Nature and origin of the danger

● Consequences if the danger oc curs

● Measures or prohibitions for danger avoidance

Symbol for danger

This is the symbol for danger. It warns of risks of injury.

Follow all measures ident ified by this symbol to avoid injury or death.

Additional dan ger symbols

These symbols indic ate general dangers, the type of danger or possible

consequences, measures and prohibitions, examples of which are shown in the

following table:

2

General danger Explosive atmosphere

Voltage/electric shock Laser light

Battery Heat

Signal word

The signal word classifies the danger as defined in the following table:

Signal word Danger level

DANGER

WARNING

CAUTION

NOTICE

DANGER identifies a dangerous situation, which will result directly in death or

serious injury if you do not avoid this situation.

WARNING identifies a dangerous situation, which may result in death or s erious

injury if you do not avoid this situation.

CAUTION identif ies a dangerous situat ion, which could result in slight to

moderately serious injury if you do not avoid this situation.

NOTICE

observance.

identifies possible damage to property that may result from non-

Building Technologies

13 |

2016-02-15

Safety

Safety instructions

2

Building Technologies

A6V10305793_m_en_

--

Fire S

afety

Nature and origin of the danger

●

Measures / prohibit ions for danger avoidance

Nature and origin of the danger

How risk of injury is presented

Information about the risk of injury is shown as follows:

WARNING

Consequences if the danger oc curs

How possible damage to property is presented

Information about possible damage to proper ty is shown as follows:

NOTICE

Consequences if the danger oc curs

● Measures / prohibit ions for danger avoidance

14 | 108

2016-02-15

Safety

Safety

regulations for the method of operation

108

A6V10305793_m_en_

--

Fire Safety

2.2 Safety regulations for t he method of operation

Electrical volt age

regulations.

National standards, regulations and legislation

Siemens products ar e developed and produced in compliance wit h the relevant

European and international safety standards. Should additional national or local

safety standards or legislation concerning the planning, mounting, installation,

operation or disposal of the product apply at the place of operation, then these

must also be taken into account together with the safety regulations in the product

documentation.

Electrical installations

WARNING

Electric shock

● Work on electric al installations may only be carried out by qualified

electricians or by instructed persons working under the guidance and

supervision of a qualified electrician, in acc ordance with the elect rotechnical

2

● Wherever possible disconnect products from the power supply when carrying

out commissioning, maintenance or repair work on them.

● Lock volt-free areas to prevent them being switched back on again by mistake.

● Label the connection terminals with external external voltage using a

'DANGER External voltage' sign.

● Route mains connect ions to products separately and fuse them with their own,

clearly marked fuse.

● Fit an easily accessible disconnecting devic e in accordance with IEC 60950-1

outside the installation.

● Produce earthing as stated in local safety regulations.

Mounting, installation, commissioning and maintenance

● If you require tools such as a ladder, these must be safe and must be intended

for the work in hand.

● When starting the fire control panel ensure that unstable conditions c annot

arise.

● Ensure that all point s listed in the 'Testing the product operability' section below

are observed.

● You may only set controls to normal function when the product operability has

been completely tested and the system has been handed over to the customer.

Building Technologies

15 |

2016-02-15

Safety

Safety regulations for the method of operation

2

Building Technologies

A6V10305793_m_en_

--

Fire S

afety

Testing the product operability

● Prevent the remote transmission from triggering erroneously.

● If testing building installations or activating devices from third-party companies,

you must collaborate with the people appointed.

● The activation of fire control installations for test purposes must not cause

injury to anyone or damage to the building installations. The following

instructions m ust be observed:

– Use the correct potential for activation; this is generally the potential of the

building installation.

– Only check controls up to the interface (relay with blocking option).

– Make sure that only the controls to be tested are activated.

● Inform people before testing the alarm devic es and allow for possible panic

responses.

● Inform people about any noise or mist which may be produced.

● Before testing t he remote transmission, inform the corresponding alarm and

fault signal receiving stations.

Modifications to the system design and the products

Modifications to the system and to individual product s may lead to faults,

malfunctioning and safety risks. Written confirmation must be obtained from

Siemens and the corresponding safety bodies f or modifications or additions.

Modules and spare parts

● Components and spare part s must comply with the technical specifications

defined by Siemens. Only use products specified or recommended by

Siemens.

● Only use fuses wit h the specified fuse characteristics.

● Wrong battery ty pes and impr oper battery changing lead t o a risk of explosion.

Only use the same battery type or an equivalent battery type recommended by

Siemens.

● Batteries must be disposed of in an environmentally friendly manner. Observe

national guidelines and regulations.

Disregard of the safety regulations

Before they ar e delivered, Siemens product s are tested to ensure they function

correctly when used properly. Siemens disclaims all liability for dam age or injuries

caused by the incorrec t application of the inst ructions or the disregard of danger

warnings contained in the documentation. This applies in particular to the following

damage:

● Personal injuries or damage to property caused by improper use and incorrect

application

● Personal injuries or damage to property caused by disregarding safety

instructions in the documentation or on the product

● Personal injury or damage to property caused by poor maintenance or lack of

maintenance

16 | 108

2016-02-15

Safety

Standards and directives complied with

108

A6V10305793_m_en_

--

Fire Safety

2.3 Standards and directives compl ied with

Limited or non

-

existent fire detection

detection installation.

Incorrect planning and/or configuration

detection installation.

A list of the standards and directives com plied with is available from your Siemens

contact.

2.4 Release Notes

Limitations t o the configuration or use of devices in a fire detection installation with

a particular firmware version are possible.

WARNING

Personal injury and damage to property in t he event of a fire.

● Read the 'Release Notes' before you plan and/or configure a fire detection

installation.

● Read the 'Release Notes' before you carry out a firmware update to a fire

2

NOTICE

Important st andards and specifications are not satisfied.

Fire detection installation is not accept ed for commissioning.

Additional expense result ing from necessary new planning and/or configuration.

● Read the 'Release Notes' before you plan and/or configure a fire detection

installation.

● Read the 'Release Notes' before you carry out a firmware update to a fire

Building Technologies

17 |

2016-02-15

Structure and function

Overview

3

Building Technologies

A6V10305793_m_en_

--

Fire Safety

Multi-

sensor smoke detector, ASA

Neural fire det ector

3 Structure and functio n

3.1 Overview

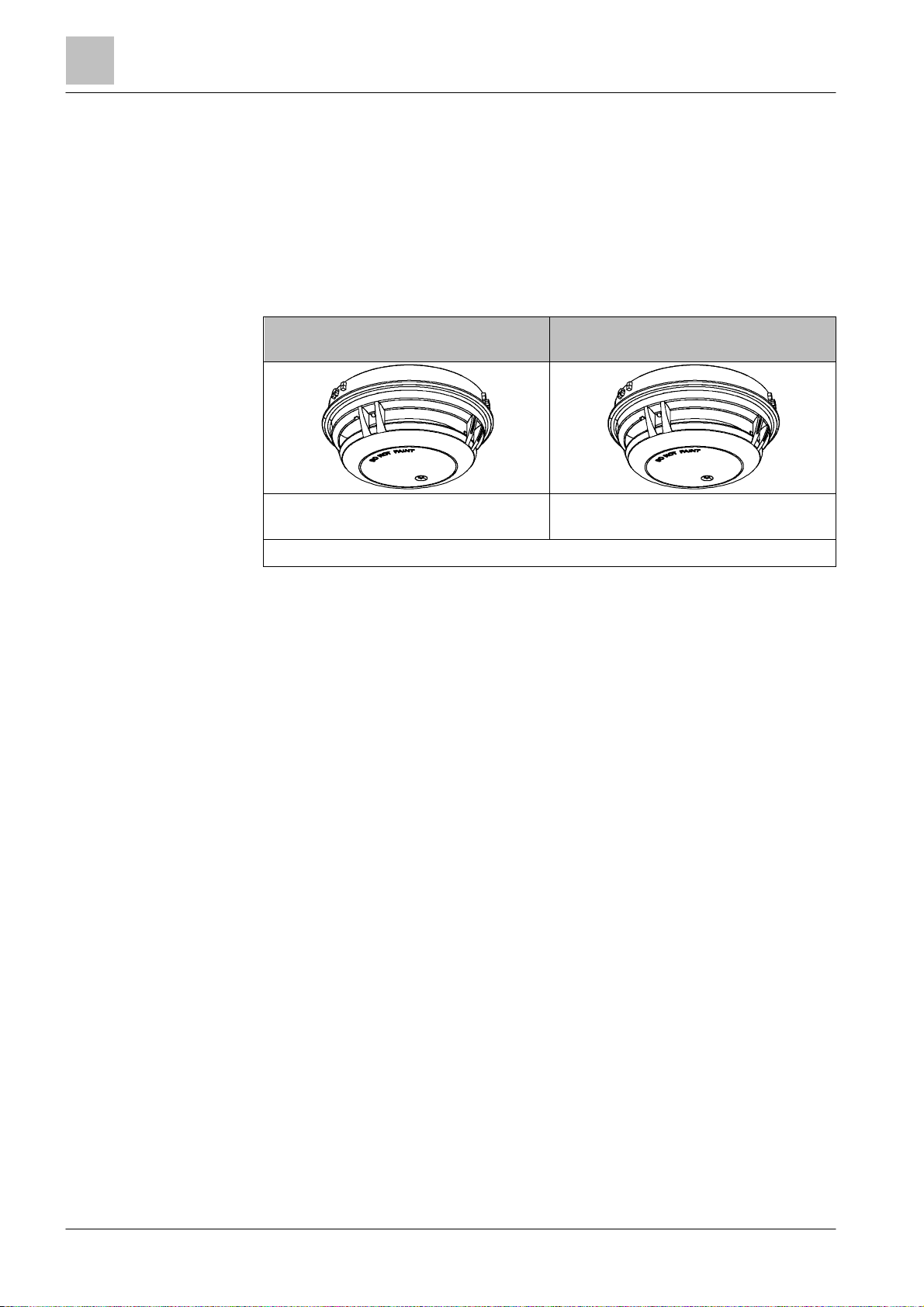

In this document t he following point detectors are referred to collectively using the

term 'Automatic fire detectors':

● Multi-sensor smoke detector, ASA OOH740

● Neural fire detector OOHC740

OOH740

Can be used addressed in the C-NET

and in collective mode

Detection behavior can be selected

OOHC740

Can be used addressed on the C-NET

18 | 108

2016-02-15

Structure and function

Overview

108

A6V10305793_m

_en_

--

Fire Safety

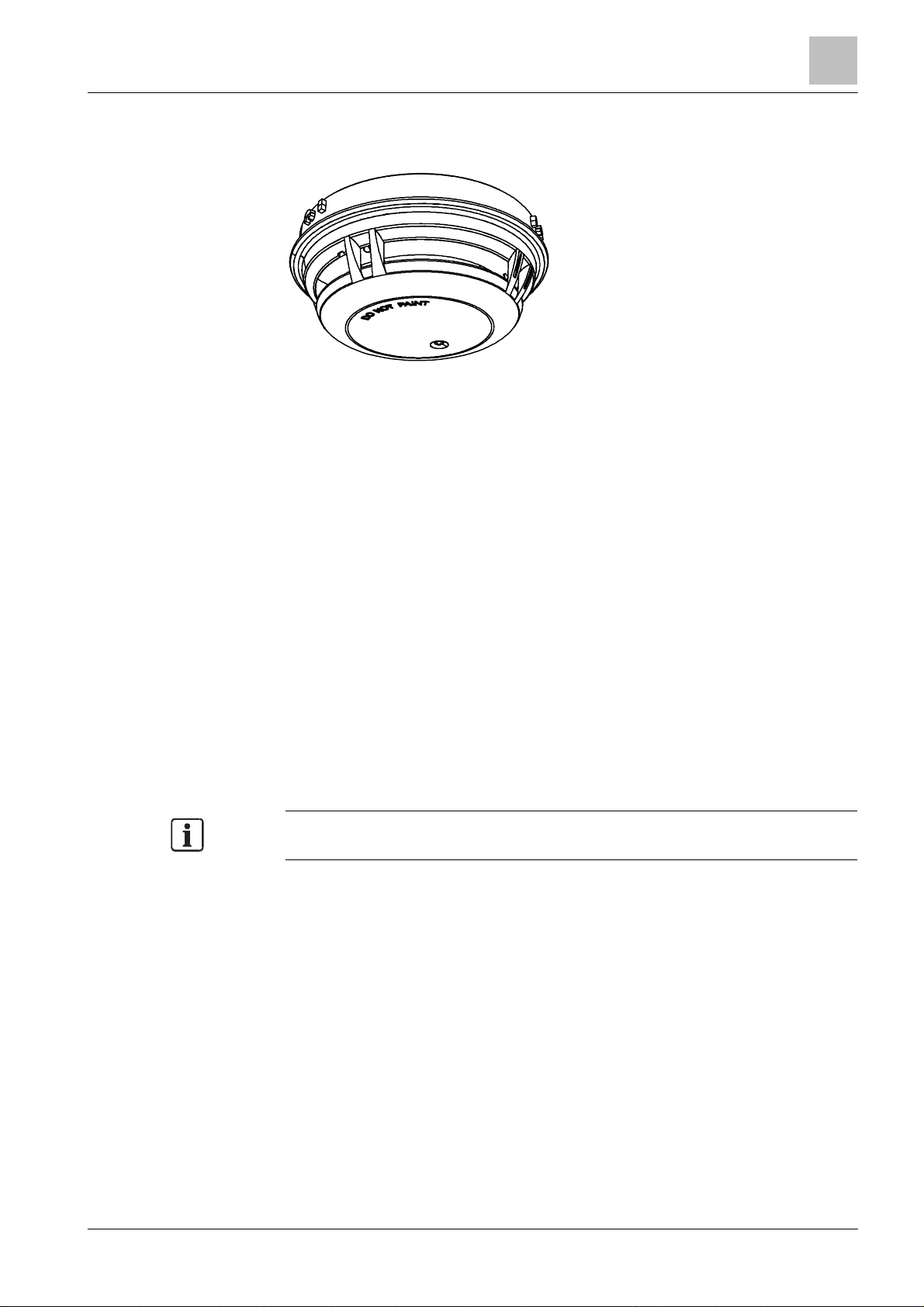

3.1.1 Multi-sensor smoke detector, ASA OOH740

Check the version of your

FS720

control panel. Some features ar e only available

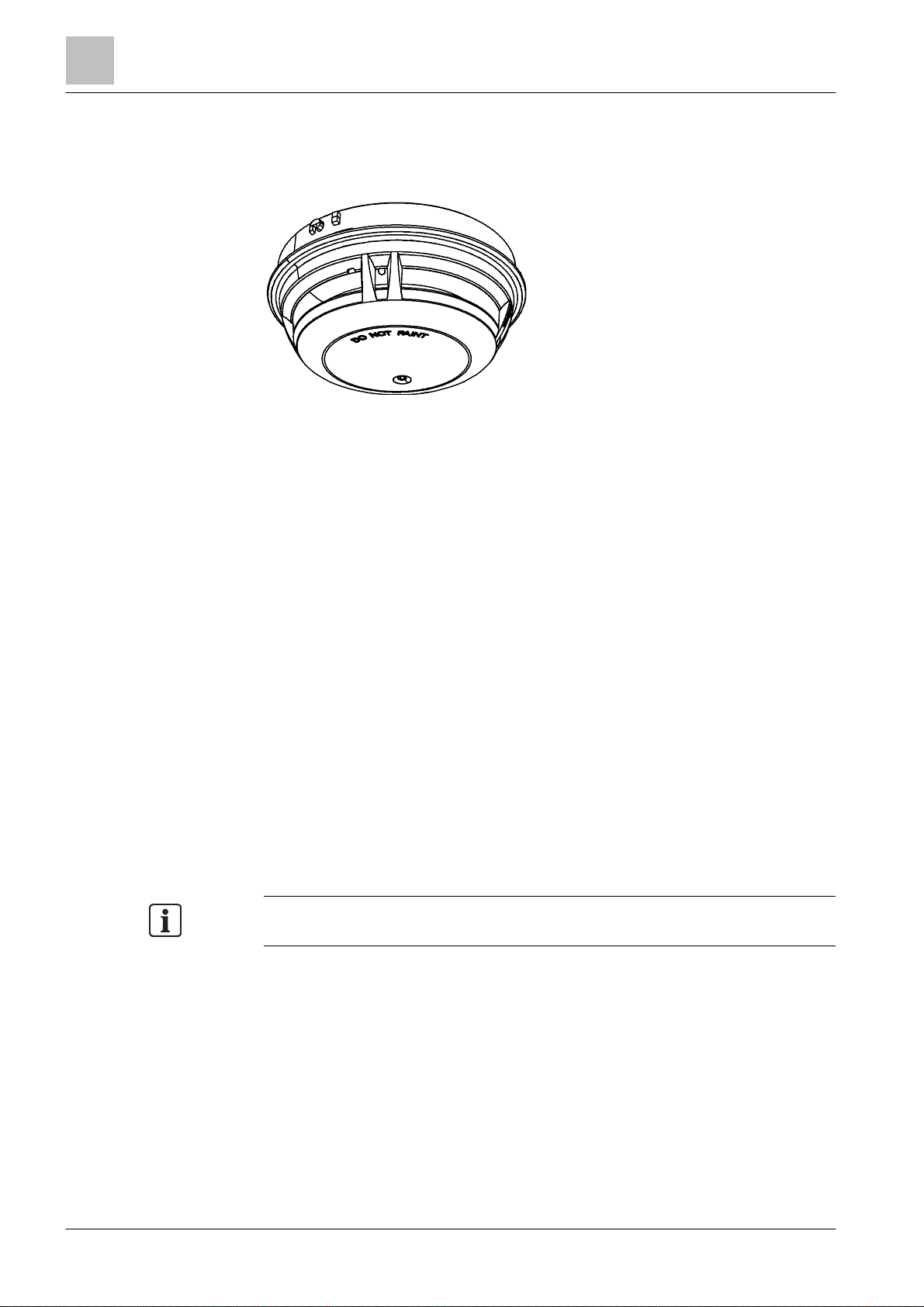

Figure 1: Multi-sensor smoke detector, ASA OOH740

Properties

● Communication via C-NET (addressed detector line)

● Address automat ically issued during commissioning

● Can also be used on collective detector lines in conjunction with the detector

bases DB721D and DB110

● Built-in line separator

● Signal processing with ASA

(application-specific ASA parameter sets)

● Software can be us ed to set as:

– Neural fire detector

– Wide-spectrum smoke detector

– Heat detector

● Red LED as alarm indicator

● The following funct ions are also included from point detector product version

[➙ 25] ES ≥20:

– 'Technical Ambient Supervision Message' mode can be selected

– Extended flashing behavior of the internal alarm indicator

– Additional 'Super Sensitive' and 'Ultra Sensitive' parameter sets

technology

and optional detection behavior

3

Building Technologies

as of certain versions. You will find details in the 'List of compatibility'.

19 |

2016-02-15

Structure and function

Overview

3

Building Technologies

A6V10305793_m_en_

--

Fire Safety

Check the version of your

FS720

control panel. Some features ar e only available

3.1.2 Neural fire detector OOHC740

Figure 2: Neural fire detector OOHC740

Properties

● Communication via C-NET (addressed detector line)

● Address automat ically issued during commissioning

● Built-in line separator

● Signal processing with ASA

(application-specific ASA parameter sets)

● Software can be us ed to set as:

– Neural fire detector

– Neural CO-supported fire detector

– Wide-spectrum smoke detector

– Heat detector

● Detection behavior of the 'Technical CO Alarm' can be set regardless of the

ASA parameter sets fo r fire detection. Can be set using software.

● 'Technical CO Alarm': Detection of carbon monoxide (CO) at concent rations of

5 ppm CO or more (MAK value=30 ppm CO)

● 'Technical Ambient Supervision Mes sage': Adjustable hysteresis-induced

ambient monitoring of temperature or carbon m onoxide. Can be set using

software.

● From point detector product version [➙ 25] ES ≥20: Extended flashing behavior

of the internal alarm indicator

● Red LED as alarm indicator

technology

and optional detection behavior

as of certain versions. You will find details in the 'List of compatibility'.

20 | 108

See also

2 Applicable documents [➙ 9]

2016-02-15

Structure and function

Overview

108

A6V10305793_m

_en_

--

Fire Safety

3.1.3 Features of fire detection functionality

Properties

● Dynamic influence on the param eter sets

● Pattern recognition

● Real time interpr etation of the situation

● Process- and time-controlled switchover of the parameter sets

Signal processing of t he point detectors is based on ASA

Advanced Signal Analysis). ASA

generation algorithms". Signal processing with ASA

adaptation of detector behavior to the corresponding ambient conditions.

Point detectors withASA

technology

reliability and very high resist ance to deceptive phenomena.

technology

can also be characterized as "second

are characterized by their unique detect ion

technology

technology

3

(ASA =

allows for optimum

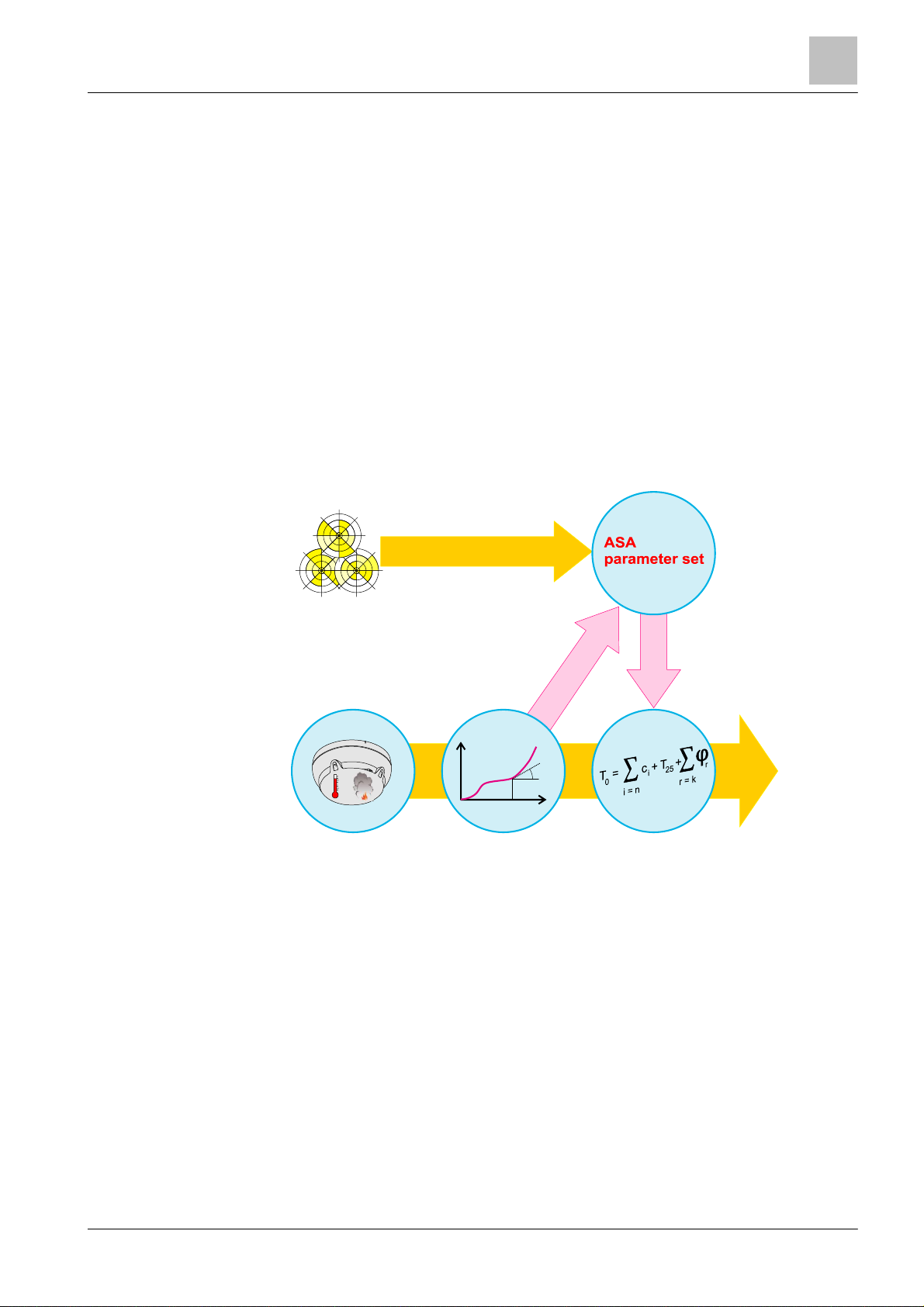

Operating mode: Signal processing with ASA

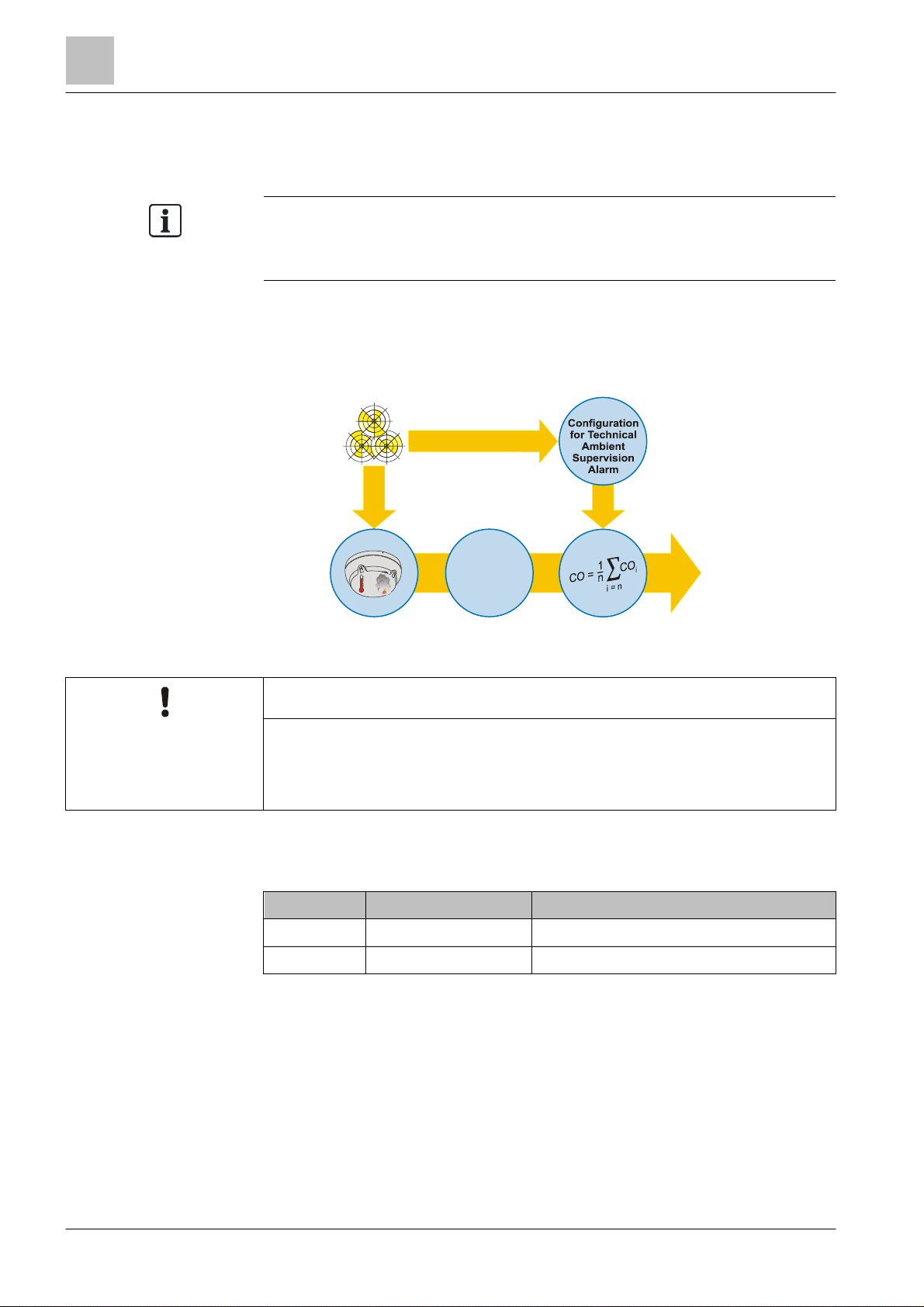

technology

The figure below shows signal processing on point detectors with ASA

in the form of a diagram:

Environment

Evaluation of the

situation

C

Signal analysisSensory

Algorithms

Dynamic influence

of parameter

technology

Danger

level

Result

Building Technologies

Figure 3: Signal processing with ASA

technology

Sensory

The signals captured by the sensory are transmitted to the algorithm. The

algorithms are set by selec t ing the parameter set.

Algorithms

The individual parameters in the selected parameter set can be adapted with

ASA

technology

. A real time interpretation of the situat ion leads t o a dynamic

influence on the algorithm. This results in the parameter set's and therefore the

point detector's application range broadening. The detector reacts more sensitively

in the event of fire, and more robustly in the event of deceptive phenom ena.

21 |

2016-02-15

Structure and function

Overview

3

Building Technologies

A6V10305793_m_en_

--

Fire Safety

The 'Technical CO Alar m' mode can only be selected on the point detector

Warning lev el

Technical CO alarm

Result

Signal analysis

Sensory

Algorithms

Switching over the parameter set

In addition to selec ting the parameter set, the point detectors wit h ASA

enable time- or process-controlled swit ching over of the parameter sets

(Manned/Unmanned swit chover). Thanks to this function, the detector can be used

in places where the situation changes regularly and f requently (e.g. kitchens,

production halls).

Downloadable parameter s ets

Point detectors withASA

technology

have several permanently progr ammed

parameter sets. For special applications new, additional parameter sets can be

downloaded in the field (depending on the control pane l).

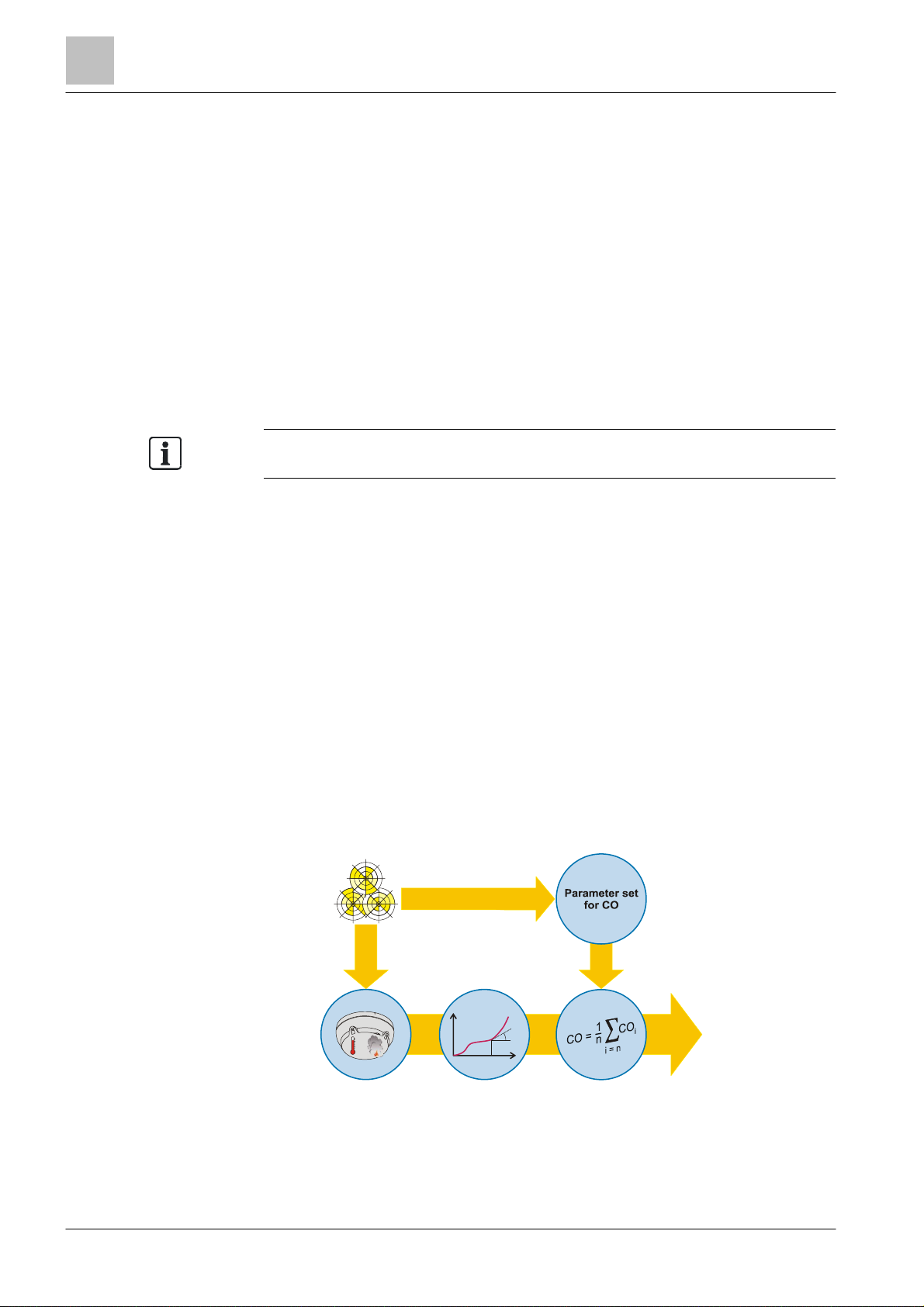

3.1.4 Features of the 'Technical CO Alarm'

OOHC740.

Alongside its fire detection functionality, the point detector also has a CO detection

functionality with the following features:

● Static or dynamic alarm profiles

● Real time interpr etation of the situation

● Process- and t ime-controlled switchov er of the parameter sets for CO

Signal processing by the 'Technical CO Alarm' is undert aken regardless of CO

signal processing for the fire detection f unctionality with the 'S uppression CO' and

'Balanced CO' parameter sets.

The signal processing f eature of the 'Technical CO Alarm' enables optimum

calculation of t he CO concentration. The electro-chemical cell allows the best

possible level of accuracy to be obtained depending on the ambient conditions.

The point detector's CO detection is characterized by the ability f or parameters to

be set and a relatively low cross-sensitivity to other gases, e.g. ethanol or

hydrogen (H2).

technology

22 | 108

Function of the Technical CO Alarm's signal processing

The figure below shows CO signal pr ocessing in the form of a diagram:

Environment:

CO and other

gases

CO

CO

°C

Figure 4: Signal processing by the 'Technical CO Alarm'

t

2016-02-15

Structure and function

Overview

3

108

A6V10305793_m

_en_

--

Fire Safety

Functionality of the 'Technical CO Alarm'

control panel.

The system is not controlled as laid d

own in EN

54-2

equipment in accordance with EN

54-2.

Sensory

The signals captured by the CO sensor are corrected with regard to CO exposure,

sensor sensitivity, temperature, and aging and supplied to the algorithm. The

algorithms are set by selec t ing the parameter set.

Algorithms

The parameter set can be used to select static and dynamic algorit hms. A real time

interpretation of the ambient conditions r esults in improved measurement

accuracy.

The alarm limits correspond to the specified or proposed limits in the respective

standards.

Switching over of parameter set for the 'Technical CO Alarm'

The point detector allows for the time-or process-controlled independent changing

over of the parameter set for CO (Manned / Unmanned changeover). This function

allows the detect or to be used in places where the situation changes significantly

on a regular basis.

Configurable parameter sets for the 'Technical CO Alarm'

The point detect or has several permanently programmed 'Technical CO Alar m'

parameter sets.

NOTICE

There is a risk of undetected CO exposure if the 'Technical CO Alarm' is not

configured on the cont rol panel

● Use the documentation provided for the fire control panel to ensure that the

parameters you want to set for the 'Technical CO Alarm' are support ed by the

NOTICE

Infringement of the EN 54-2 standard

● The signals for CO detection alone must not be used to control f ire detection

Building Technologies

23 |

2016-02-15

Structure and function

Overview

3

Building Technologies

A6V10305793_m_en_

--

Fire Safety

'Technical Ambient Super

vision Message' mode can only be selected for point

The system is not controlled as laid down in EN

54-2

control fire detection equipment in acc ordance with EN

54-2.

Warning l evel for

T echnical Ambi ent

Result

Signal analysis

Sensory

Algorithms

3.1.5 Features of the 'Technical Ambient Supervision Message'

detector OOH740 from product version ES ≥20.

The evaluation of t he CO conc entration in 'Technical Ambient S upervision

Message' mode can only be selected for point detector OOHC740.

In 'Technical Ambient Supervision Message' mode, the point detector can detect

an increase in temperat ure or CO concentration above a specified trigger threshold

caused by hysteresis.

The control panel is used to configure the paramet ers.

Environment:

CO or

temperature

CO

°C

Figure 5: Signal proces sing by t he 'Technical Ambient Supervision Mess age'

NOTICE

Infringement of the EN 54-2 standard

● The signals for CO detection or temperature recording m ust not be used to

3.1.6 Details f or ordering

Type Order no. Designation

OOH740 S54320-F7-A3 Multi-sensor smoke detector, ASA

OOHC740 S54320-F8-A3 Neural fire det ector

Supervision Alarm

24 | 108

2016-02-15

Structure and function

Overview

108

A6V10305793_m

_en_

--

Fire Safety

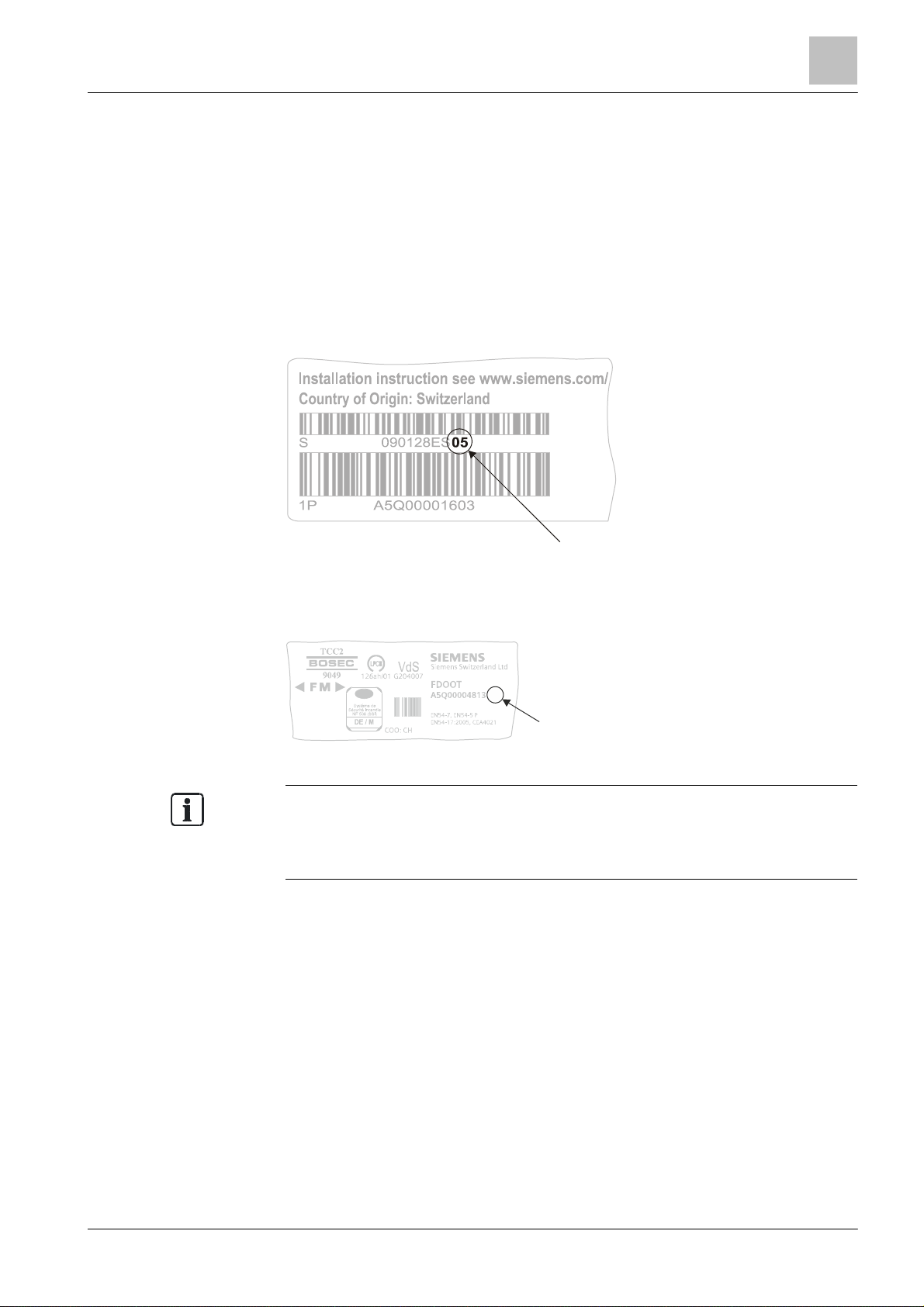

3.1.7 Product versio n ES

Depending on the product and various approvals, the product labels may dif fer in

ES

The product version ES provides the technical st atus of a device in terms of

software and hardware. The product version is provided as a two-digit number.

You will find the det ails of your device's product version:

● On the packaging label

● On the product label or the type plate

Product version on the packaging label

Details of the product version can be found direct ly on the packaging label in the

barcode:

3

Figure 6: Example of a p ackaging label with det ails of the produc t version

Product version on the product label and t he type plate

Details of the product version can be found af ter the device order number:

04

ES

Figure 7: Example of a product label with details of the product version

terms of the informat ion type and layout.

Look for your device' s order number on the product label.

You will find the produc t version after the order number.

Building Technologies

25 |

2016-02-15

Structure and function

Setup

3

Building Technologies

A6V10305793_m_en_

--

Fire Safety

3.2 Set up

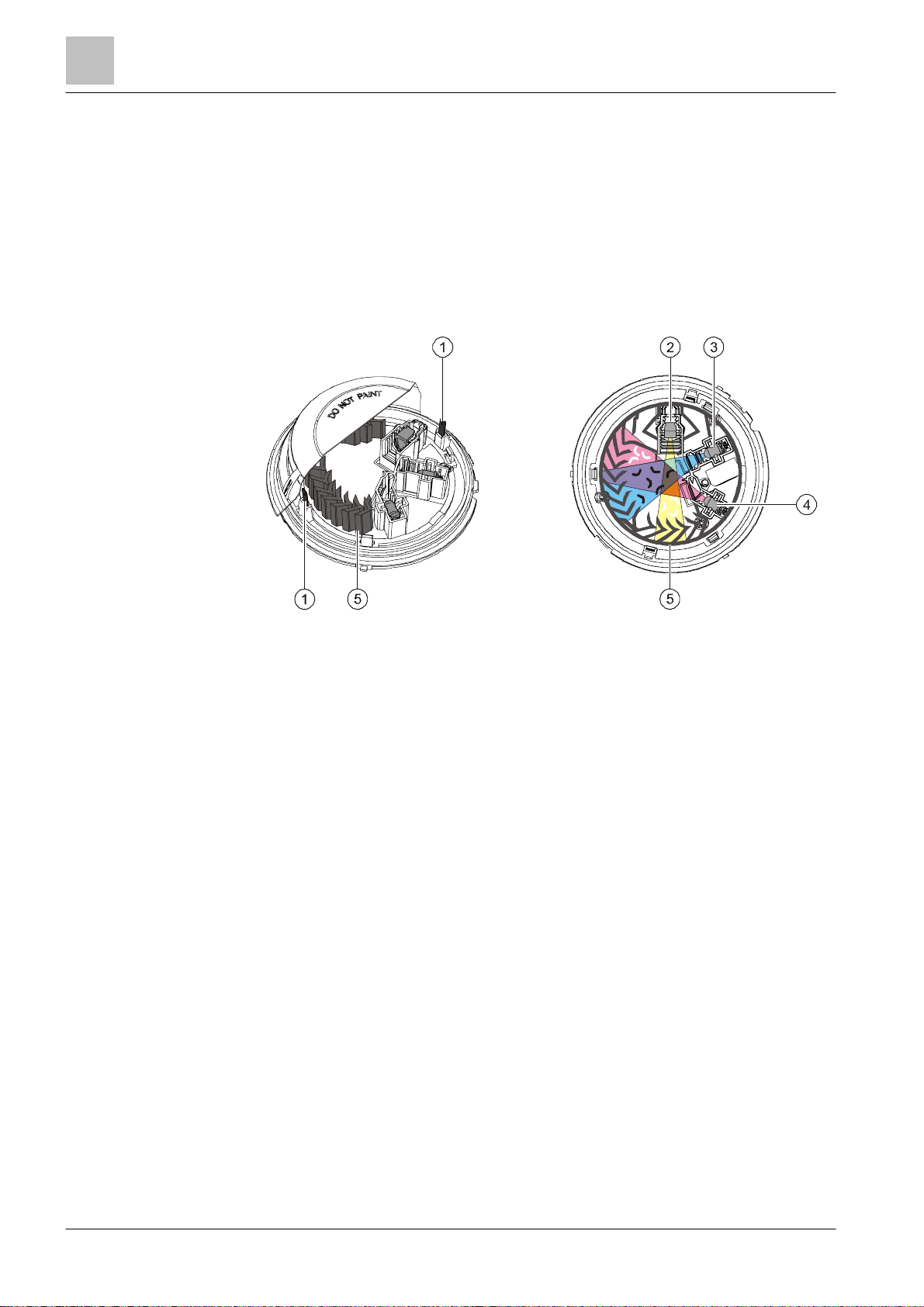

3.2.1 Structure of OOH740

The multi-sensor smoke detector ASA OOH740 is a multi-criteria fire det ector and

has two optical and two thermal sensors.

Structure and function

Figure 8: Sensors of the OOH740

1 Heat sensors 4 Forwar d scatterer

2 Receiver 5 Labyrinth

3 Backward scatterer

The point detect or's high-quality opto-electronic measuring chamber houses the

following components:

● Two optical trans mitters

● One optical receiver

● Two thermal sensors

The transmitt ers illuminate the smoke particles from different angles. One sensor

acts as forward scatterer, the other as backward scatterer. The scatter ed light then

hits the receiver (photodiode) and generates a m easurable electric signal.

The combination of a forward and backward scatterer facilitates an optimum

detection and the dif ferentiation of light and dar k particles, which leads t o a

homogenous response behavior and optimizes the differentiation of wanted signals

and deceptive phenomena.

In addition, the heat sensors make it possible to detect fires without smoke

generation.

26 | 108

2016-02-15

Structure and function

Setup

3

108

A6V10305793_m

_en_

--

Fire Safety

The combination of optical and thermal sensor signals optimizes detection

reliability. This has the following advantages:

● Early detection of all types of fire, whether t hey generate light or dark smok e, or

no smoke at all.

● The neural fire detector can be operated at a lower sensitivity level and thus

achieves a higher immunit y against false alarms which can be caused by cold

aerosols (e.g. by smoking, elect rical welding, etc.). In the case of an open fire,

the smoke sensitivity is heightened by the temperature increas e, which means

that a detection reliabi lity level that is comparable to that of the wide-spectrum

smoke detector can be achieved.

Technical Ambient Supervision Message

'Technical Ambient Supervision Message' mode detects an increase in

temperature above a specified trigger thres hold caused by hysteres is.

You can set the following parameters:

● Temperature t hreshold value

● Messaging when the temperature threshold value is exceeded or undershot

● Hysteresis range

The 'Technical Ambient Supervision Message' is configured using the 'CerberusEngineering-Tool' sof tware.

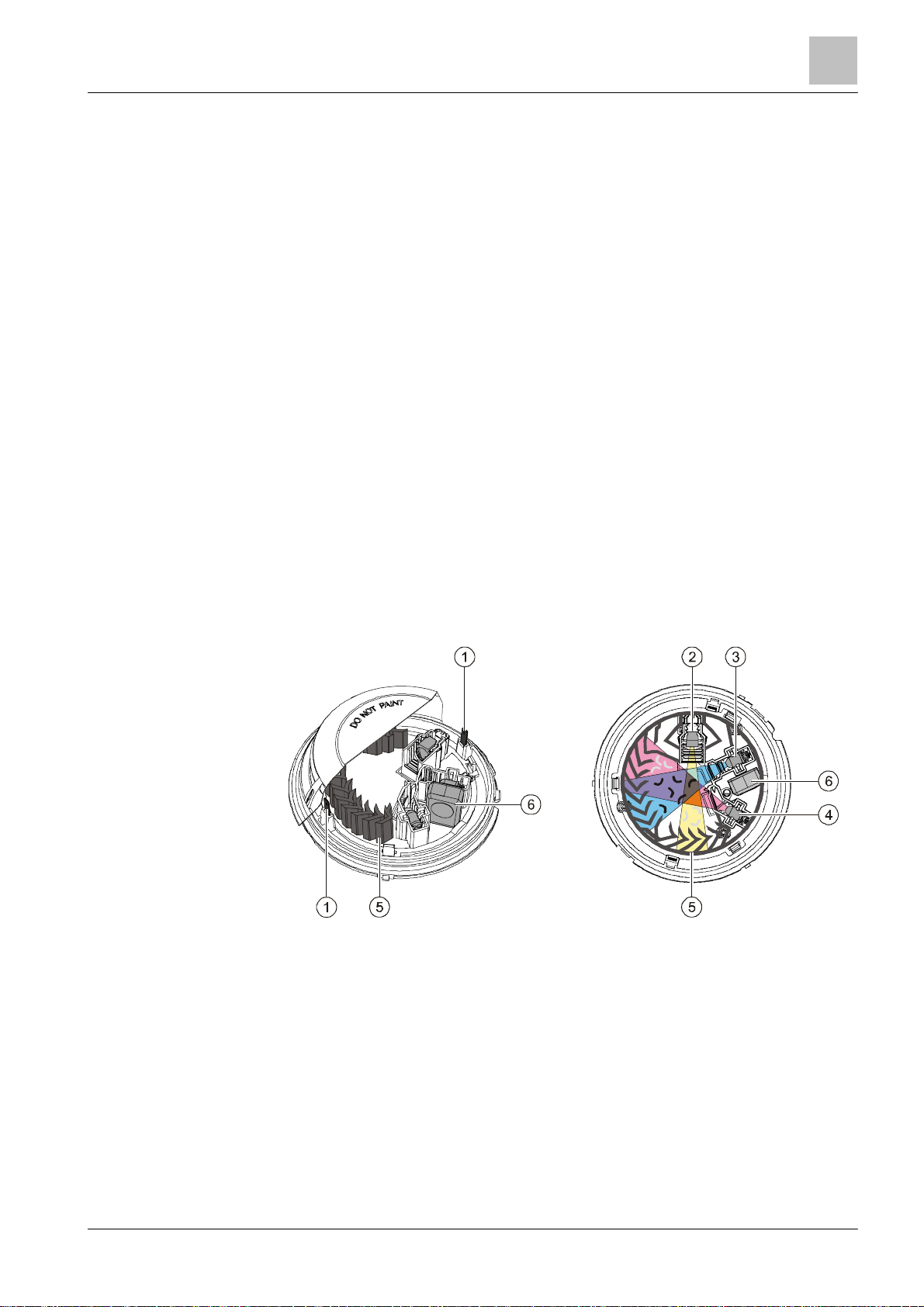

3.2.2 Structure of OOHC 740

The neural fire detector OOHC740 is a multi-c riteria fire detector and has two

optical sensors, two thermal sensors, and one CO sensor.

Structure and function

Figure 9: Sensors of the OOHC740

1 Heat sensors 4 Forward scatterer

2 Receiver 5 Labyrint h

Building Technologies

3 Backward scatterer 6 CO sensor

27 |

2016-02-15

Struc

ture and function

Setup

3

Building Technologies

A6V10305793_m_en_

--

Fire Safety

Functionality of sensor modes

used in such environments.

Fire detection

The point detect or's high-quality opto-electronic measuring chamber houses the

following components:

● Two optical trans mitters

● One optical receiver

● Two thermal sensors

● One CO sensor

The transmitt ers illuminate the smoke particles from different angles. One sensor

acts as forward scatterer, the other as backward scatterer. The scatter ed light then

hits the receiver (photodiode) and generates a m easurable electric signal.

The combination of forward scatterers and backward scatterers allows for optimum

detection of and distinction between light and dark particles and particle sizes. The

distinction between light and dark particles firstly results in a homogeneous

response behavior and secondly enables better differentiation bet ween wanted

signals and deceptive phenomena.

In addition, the heat sensors make it possible to detect fires without smoke

generation.

The CO sensor enables faster detection of fires with incomplete combustion and

fires with the development of a lot of CO.

The combination of optical, thermal and CO sensor signals optimizes detect ion

reliability for all types of fir e, regardless of whether they generate dark or light

smoke, or none at all.

You can set the following response behaviors on the neural f ire detector

OOHC740:

● Combined optical and therm al

● Combined optical, thermal and CO

● Optical smoke detector alone

● Heat detector alone

The response behavior is determined by selecting one of the following sensor

modes:

● Sensor mode 0: Applicat ion as neural fire det ector

● Sensor mode 1: Applicat ion as heat detector

● Sensor mode 2: Applicat ion as smoke detector

The sensor mode is configured with the 'Cerberus-Engineering-Tool' soft ware.

NOTICE

Danger of alarm activation as a result of deceptive phenomena

● Depending on the configuration software used for the fire cont rol panel,

sensor modes 1 and 2 may not be available.

If the deceptive phenom ena occurring (e.g. if the operator suspect s that both

CO and smoke-like deceptive phenomena are present at the same time)

mean that only one heat detector can be operated, the OOHC740 may not be

28 | 108

Combined optical-thermal or optical-t hermal CO mode is select ed by choosing the

parameter set in sensor mode 0!

The parameter sets of t he heat detector or optical detector can be selected in

sensor mode 1 or 2.

2016-02-15

Structure and function

Setup

3

108

A6V10305793_m

_en_

--

Fire Safety

Technical CO alarm

The point detector has a high-quality CO sensor which is based on the

measurement principle of the electro- chemical cell.

Instances of the s pecified CO concentration being exceeded can be detected by

the CO sensor. The limi t values vary depending on t he parameters set.

You can set the following CO response behaviors on the neural fire det ector

OOHC740:

● Static CO alarm thresholds

● Dynamic CO alarm thresholds

The response behavior is configured with the 'Cerberus-Engineering-Tool'

software.

Technical Ambient Supervision Message

'Technical Ambient Supervision Message' mode detects an increase in

temperature or CO conc entration above a specified t rigger threshold caused by

hysteresis.

Temperature monitoring compares the current measured temperature with a preset

threshold value.

CO monitoring compares the current measured CO c oncentration with a preset

threshold value.

You can set the following parameters on the neural fire detector OOHC740:

● CO concentration or temperature threshold value

● Messaging when the temperature threshold value is exceeded or undershot

● Messaging when the CO conc entration threshold value is exceeded

● Hysteresis range

– Fixed hysteresis range

– Average CO value over a period of 15 minutes

The 'Technical Ambient Supervision Message' is configured using the 'CerberusEngineering-Tool' sof tware.

See also

2 Parameter s ets [➙ 30]

Building Technologies

29 |

2016-02-15

Structure and function

Function

3

Building Technologies

A6V10305793_m_en_

--

Fire Safety

On a

C-NET

detector line, the parameter set must always be set explicit ly.

Please note the chapt er 'Applicable documents'.

3.3 Functi on

3.3.1 Parameter sets

The detection behavior of the point detectors is influenced by the parameter sets

so that it can be specifically adjust ed to the fire phenomena and environmental

conditions to be expected in the environment to be monitored.

All parameter sets are programmed in the point detectors. During commissioning,

the optimum parameter set must be selected for the conditions at t he place of

installation.

You can select and set the parameter sets as follows:

● Using the 'Cerberus-E ngineering-Tool' software

● Directly on your fire detection system (only within the same sensor mode)

You will find a description of the exact proc edure for selecting and setting the

parameters in the relevant documentation.

Parameter sets for fire detection in collective mode

The point detect or OOH740 can also be operated in collective mode.

There are several parameter sets for fire detection available in collective mode.

The parameter s ets ar e selected in collective mode using resistors inst alled in the

detector base.

See also

2 Parameter s et resistor 33 kΩ PSR720-1 [➙ 50]

2 Parameter set resistance 68 kΩ PSR720-2 [➙ 50]

2 Connection diagram, collective [➙ 87]

2 Applicable documents [➙ 9]

30 | 108

2016-02-15

Loading...

Loading...