Page 1

Oil Burner Controls

LOA3...

ISO 9001

Mechanical design

Ordering

for single- or two-stage pressure-jet burners

with intermittent operation

1)

118

7

LOA2...

LOA2...

Burner controls for automatic startup, control and supervision of pressure-jet oil

burners with an oil throughput of up to 30 kg / h.

The burner controls are tested to EN 230 and CE-certified in compliance with the

directives for electromagnetic compatibility.

The LOA2... / LOA3... and this data sheet are intended for use by OEMs that

integrate the burner controls in their products!

The burner controls are of plug-in design. The casing is made of impact-proof and heatresistant plastic and accommodates the

– thermal-electric sequence switch which acts on a multiple snap-action switching

system

– flame signal amplifier with the flame relay

– lockout reset button with integrated fault indication lamp

Burner control refer to table overleaf

Flame detectors

– Photo-resistive detectors QRB1... refer to data sheet 7714

– Blue-flame detectors QRC1... refer to data sheet 7716

Plug-in base, without cable gland holder or without cable holder

– With screw terminals AGK11

Plug-in base, for clip connection

– Clipses (single pieces in lots of 100)

– Clipses (10,000 pieces on strap)

– Mounting tool

– Removal tool

Cable gland holder for 5 x Pg11, for insertion in plug-in base AGK65

Cable holder, for insertion in plug-in base and introduction of cable AGK66

Spacer (empty casing), to increase the overall height of LOA...- AGK21

types to LAB / LAI height

Adapter, for replacing LAB1 / LAI... by LOA... KF8819

(rewiring of plug-in base not required)

Service adapter, with signal lamps for making a functional check KF8833

and with jacks for making detector current measurements

Remote reset module for use with LOA26... / LOA36... ARK21A27

(printed circuit board)

2)

2)

2)

2)

2)

LOA3...

AGK12

AGK 4 408 5625 0

AGK 4 408 5626 0

KF8883

KF8884

Landis & Staefa CC1N7118E December 10, 1997 1/13

1)

For safety reasons (self-test of flame supervision circuit, etc.), at least one controlled shutdown

must take place every 24 hours

2)

On request only

Page 2

The type references given in the table apply to burner controls without base and without

Standard

Standard

With remote

For flash-steam

For incinerator

Type summary

flame detector.

Version Voltage

(VAC)

Type reference Under-

voltage

CE

detection

Without bridging contact for the release contact of the oil pre-heater

3))

3)

3)

1)

– – 13 13 10 15 – 15

– – 13 13 10 15 – 15

– – 13 13 10 20 2 20

x – 13 13 10 2 – 15

version

220

110

220

220

LOA21.171B27

LOA21.171B17

LOA21.173A27

LOA28.173A27

With bridging contact (fr**) for the release contact of the oil pre-heater

3)

3)

2)

2)

– – 13 13 10 15 – 15

– – 13 13 10 15 – 15

x x 13 13 10 15 – 15

x x 13 13 10 15 – 15 –

x x 13 13 10 20 2 20

x x 13 13 10 35 2 35 –

2)

x x 13 13 10 15 – 15 –

x x 13 13 10 15 – 15 –

x x 6 6 10 20 – 20

version

reset facility

220

110

220

110

220

220

220

220

220

LOA22.171B27

LOA22.171B17

LOA24.171B27

LOA24.171B17

LOA24.173A27

LOA24.174A27

LOA26.171B27

LOA36.171A27

LOA24.571C27

generators

1)

1)

x – 13 13 10 2 – 15

x – 13 13 10 2 – 15

plants or

220

110

LOA25.173C27

LOA25.173C17

similar

t1

(s)t3(s)

t2 max.

(s)

t3n

(s)

t3n’

(s)

t4

(s)

Replacement for:

LAB1,

LAI1, LAI2

LAI2.2, LAI4

–

LAI2.3

LAI2.3

LAI2.3

LAI2.3

LAI5

LAB2

LAB2

Legend

Times

Functions and components

1)

LOA25... and LOA28... can only be used with photo-resistive detectors QRB1...

Since LOA25... and LOA28... do not feature extraneous light lockout, they do not conform to EN 230

2)

It is also possible to use an infrared flicker detector IRD1010 (refer to data sheet 7120)

3)

Since LOA21... and LOA22... do not feature undervoltage detection, they do not conform to EN 230

tw Heating up time of «OH» until contact «OW»

delivers a signal

t2 Safety time t3 Pre-ignition time

t3n Long post-ignition time t3n’ Short post-ignition time

t4 Interval from establishment of flame to release

of the 2nd fuel valve

Burner control output signals

Required input signals

A’ Beginning of startup sequence with burners

using an oil pre-heater «OH»

A Beginning of startup sequence with burners

using no oil pre-heater

B Time of flame establishment OH Oil pre-heater

C Running position OW Release contact of «OH»

D Controlled shutdown by «R» QRB Photo-resistive detector

AL Alarm device

BV Fuel valve R Control thermostat or pressurestat

EK1 Lockout reset button SA Actuator with automatic setback

EK2 Remote lockout reset button Si External pre-fuse

FR Flame relay TZ Thermal-electric sequence switch

fr** Bridging contact for release contact of «OH» tz... Contacts of «TZ»

FS Flame signal V Flame signal amplifier

LED1 Indication of flame strength (green) W Limit thermostat or pressure monitor

L1 Indication of faults (red) Z Ignition transformer

L2 Indication of operation (orange)

t1 Pre-purge time

M Burner motor

Catch of flame relay for locking contact

K

«tz1» in the case of premature flame

signals or for locking this contact when

flame signal is correct

QRC Blue-flame detector

bl = blue br = brown sw = black

2/13 CC1N7118E December 10, 1997 Landis & Staefa

Page 3

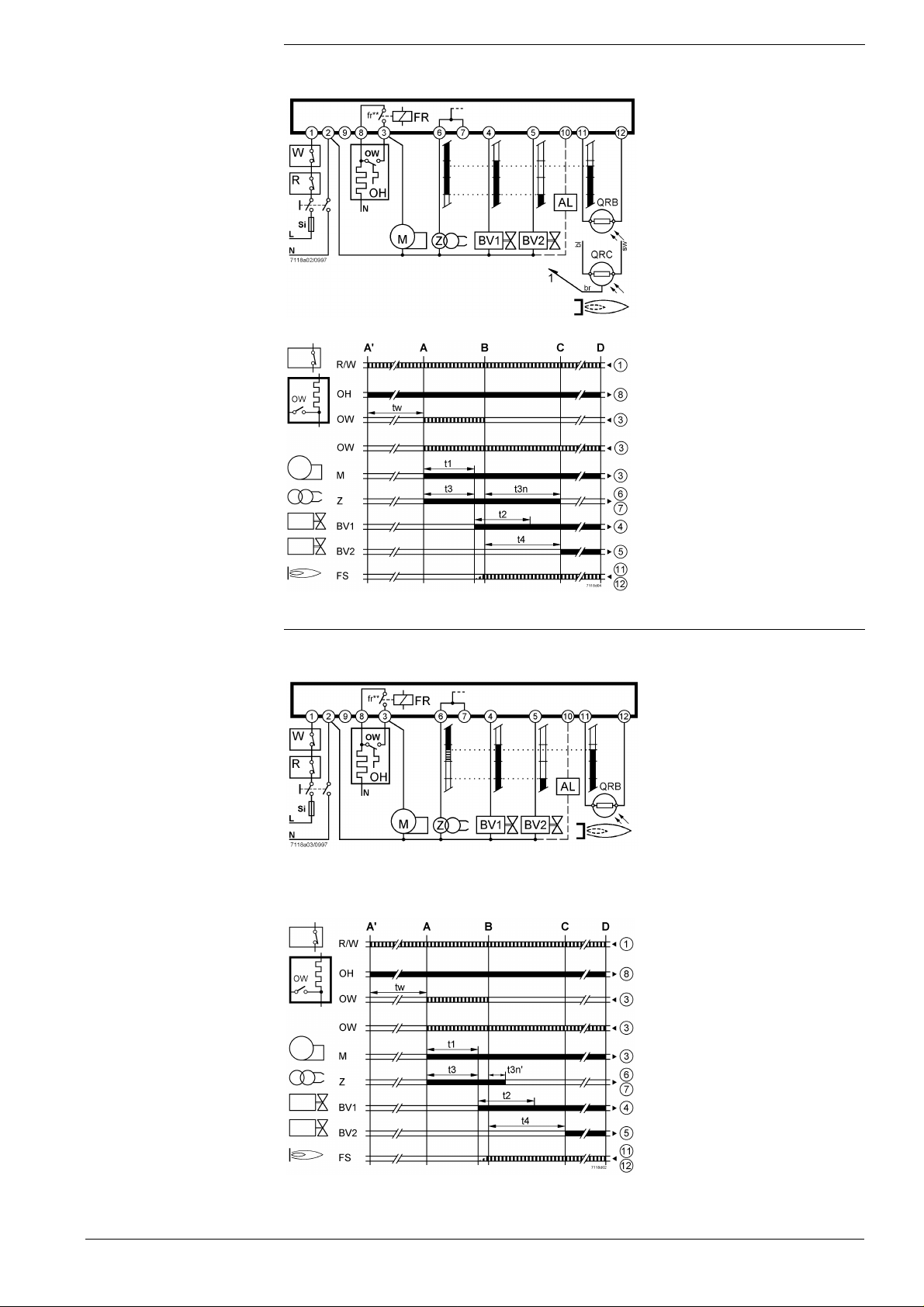

Connection diagram,

control sequence

LOA21.171B27

LOA21.171B17

LOA22.171B27

LOA22.171B17

LOA24.171B27

LOA24.171B17

LOA24.571C27

fr** Not provided with the LOA21...

LOA22.171B27 / LOA22.171B17 / LOA24.171B27

LOA24.171B17 / LOA24.571C27

LOA21.171B27 / LOA21.171B17

LOA25.173C27

LOA25.173C17

LOA28.173A27

These types of LOA… may not be used with blue-flame detectors QRC...

fr** Not provided with the LOA28.173A27

LOA25.173C27 / LOA25.173C17

LOA28.173A27

Landis & Staefa CC1N7118E December 10, 1997 3/13

Page 4

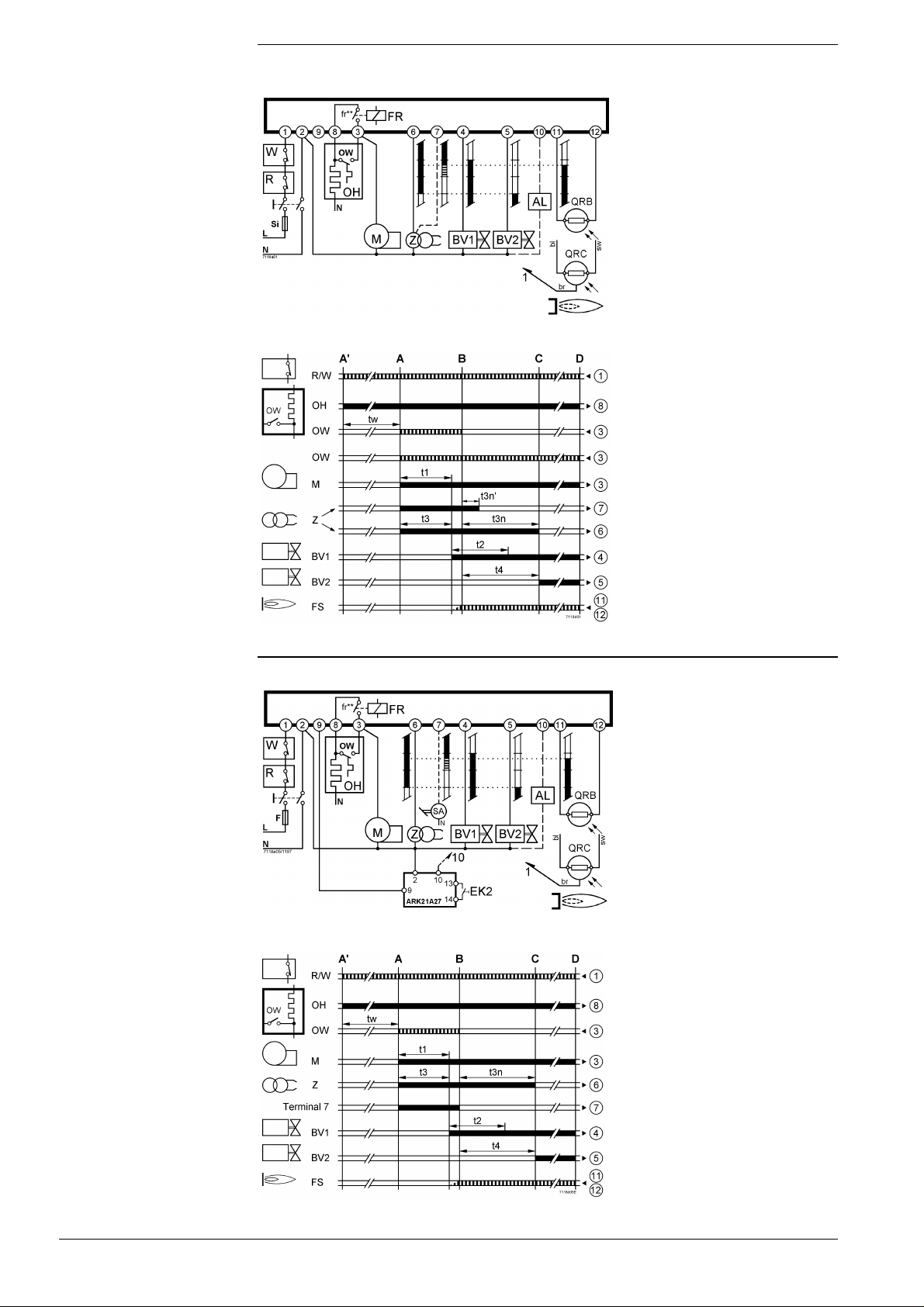

Connection diagram,

control sequence

LOA21.173A27

LOA24.173A27

LOA24.174A27

fr** Not provided with the LOA21...

LOA24.173A27 / LOA24.174A27

LOA21.173A27

With remote reset

module ARK21:

LOA26.171B27

LOA36.171A27

4/13 CC1N7118E December 10, 1997 Landis & Staefa

Page 5

Internal diagram

LOA21.171B27

LOA21.171B17

LOA22.171B27

LOA22.171B17

LOA24.171B27

LOA24.171B17

LOA24.571C27

LOA25.173C27

LOA25.173C17

LOA28.173A27

fr** Not provided with the LOA21...

LOA21.173A27

LOA24.173A27

LOA24.174A27

fr** Not provided with the LOA28...

fr** Not provided with the LOA21...

Landis & Staefa CC1N7118E December 10, 1997 5/13

Page 6

Internal diagram

LOA26.171B27

LOA36.171A27

6/13 CC1N7118E December 10, 1997 Landis & Staefa

Page 7

Whenever a fault occurs, the supply of fuel is immediately interrupted.

Control sequence in

the event of faults

Indications

With every lockout, the control outputs will be de-energized in less than one second,

while terminal 10 (AL) for the remote indication of lockout receives voltage.

The LOA… can be reset no earlier than 50 seconds after lockout.

Extraneous light /

premature flame signal

Non-appearance of

flame

During the pre-purge time, no flame signal may be present.

If, however, a signal is delivered during this period of time, the LOA… locks out on expiry

of the pre-purge and safety time. Under these circumstances, the oil valve does not

open.

An erroneous flame signal can be caused, for instance, by

– premature establishment of flame due to a leaking oil valve

– extraneous light

– a short-circuit in the detector or its wiring

– faults in the flame signal amplifier, or similar

Exception: with the LOA25… and LOA28…, there will be no lockout, but burner startup

will be prevented until the premature flame signal is no longer present.

This means that LOA25… and LOA28… may be used only where the requirements of

EN 230 need not be met.

If, at the end of the safety time, there is no flame signal, the LOA… will immediately

lock out.

If, with the LOA25… and LOA28…, there are flame signal failures of short duration

during the safety time «t2» and the interval «t4», the ignition transformer will immediately

be switched on again.

The total duration of the repeated ignition attempts equals the safety time «t2»

(10 seconds).

Flame failure during

operation

Undervoltage detection

Fault position

Flame strength

Operation

On flame failure during operation, the LOA… will immediately shut down the fuel

supply and automatically recycle (restart attempts).

If flame failure occurs on completion of «t4», almost the complete startup sequence

will be restarted.

With burner controls featuring undervoltage detection, an additional electronic circuit

ensures that in the event of mains voltages below about 165 V, burner startup will be

prevented, or - without opening the oil valve - the burner control locks out.

The fault position is indicated by the lamp integrated in the reset button.

Only with the LOA36...

The green LED for indication of the flame strength is used for checking the flame signal.

To ensure reliable burner operation, this LED must be lit.

If, during burner operation, the green LED flickers or extinguishes, the light conditions at

the burner are inadequate, caused by dirt, for instance.

Only with the LOA36...

Landis & Staefa CC1N7118E December 10, 1997 7/13

If the contact of the control thermostat «R» is closed, the orange LED is lit, thus indicating

the start of the oil pre-heater's heating up phase (if fitted).

Page 8

Technical data

Burner control

LOA21.171B27

LOA21.171B17

LOA22.171B27

LOA22.171B17

LOA24.171B27

LOA24.171B17

LOA24.571C27

LOA25.173C27

LOA25.173C17

LOA28.173A27

LOA21.173A27

LOA24.173A27

LOA24.174A27

Mains voltage AC 220 V -15 %...240 V +10 %

AC 100 V -15 %...110 V +10 %

Mains frequency 50 Hz -6 %...60 Hz +6 %

External pre-fuse (Si) 10 A, fast

Input current to

- terminal 1 5 A (short-term 15 A during 0.5 s)

- terminal 3 5 A (excl. burner motor and oil pre-

heater)

Permissible loading of terminals

- Terminal 4 1 A

- Terminal 5 1 A

- Terminal 6 2 A

- Terminal 7 2 A

- Terminal 8 5 A

- Terminal 10 1 A

- Terminal 4 1 A

- Terminal 5 1 A

- Terminal 6 2 A

- Terminal 7 1.5 A

- Terminal 8 5 A

- Terminal 10 1 A

LOA26.171B27

LOA36.171A27

- Terminal 4 1 A

- Terminal 5 1 A

- Terminal 6 2 A

- Terminal 7 0.1 A

- Terminal 8 5 A

- Terminal 10 1 A

Environmental conditions

Condensation, formation of ice and ingress of water are not permitted.

• Transport IEC 721-3-2

– Climatic conditions class 2K2

- Temperature range -50...+60 °C

- Humidity < 95 % r.h.

- Mechanical conditions class 2M2

• Operation IEC 721-3-3

– Climatic conditions class 3K5

- Temperature range -20...+60 °C

- Humidity < 95 % r.h.

Power consumption approx. 3 VA

Degree of protection of housing IP40

Mounting position optional

Weight

- Burner control 180 g

- Base 80 g

- Cable gland holder 12 g

Indication of flame strength (only with LOA36...)

- Min. detector current LED lit with QRB... 60 µA ±15 %

- Min. detector current LED lit with QRC... 40 µA ±15 %

CE conformity to the directives of the EC

89 / 336 EEC incl. 92 / 31 EEC

and 73 / 23 EEC

8/13 CC1N7118E December 10, 1997 Landis & Staefa

Page 9

Flame detectors

For measurement circuits and lengths of detector cables, refer to data sheets 7714 (QRB…)

and 7716 (QRC…).

At AC 230 V or AC 110 V mains voltage

QRB...

QRB… detector current (typical)

Burner control

LOA21.171B27

LOA21.171B17

LOA22.171B27

LOA22.171B17

LOA24.171B27

LOA24.171B17 70 µµA 5.5 µµA 210 µµA

LOA24.571C27

LOA25.173C27

LOA25.173C17

LOA26.171B27

LOA28.173A27

LOA21.173A27

LOA24.173A27 45 µµA 5.5 µµA 45 µµA

LOA24.174A27

Minimum required

(with flame

present)

Maximum

permitted

(without flame)

Maximum possible

(with flame

present)

QRC1A...C27

LOA36.171A27 70 µµA 5.5 µµA 900 µµA

QRC… detector current (typical)

Burner control

LOA21.171B27

LOA21.171B17

LOA22.171B27

LOA22.171B17 70 µµA 5.5 µµA 110 µµA

LOA24.171B27 90 µµA at AC 110 V

LOA24.171B17

LOA24.571C27

LOA26.171B27

LOA25.173C27

LOA25.173C17 — — —

LOA28.173A27

LOA21.173A27

LOA24.173A27 45 µµA 5.5 µµA 45 µµA

LOA24.174A27

Minimum required

(with flame

present)

Maximum

permitted

(without flame)

Maximum possible

(with flame

present)

LOA36.171A27 70 µµA 5.5 µµA 110 µµA

Landis & Staefa CC1N7118E December 10, 1997 9/13

Page 10

10/13 CC1N7118E December 10, 1997 Landis & Staefa

Page 11

Safety notes

Non-observance of the following safety notes may lead to

unforeseen detrimental consequences, such as electric shock,

explosion, environmental damage, etc.

• In the geographical areas where DIN standards are in use, the

installation must be in compliance with VDE requirements, particularly

with the standards DIN / VDE 0100 and 0722!

In all other areas in compliance with the national and local standards

and regulations.

• All regulations and standards applicable to the particular application

must be observed!

• Installation and commissioning work must always be carried out by

qualified personnel!

• Ignition cables must always be laid separately, maintaining the greatest

possible distance to the unit and other cables!

• Observe the notes on the laying of detector cables (refer to «Flame

detectors»)!

Accessories

• Check wiring carefully before putting the burner control into operation!

• LOA... are safety devices. It is therefore not permitted to open, interfere

with or modify the units!

• The LOA... must be completely isolated from the mains before

performing any work on it!

• Check all safety functions when putting the burner control into

operation or after performing service work!

• Ensure protection against electric shock on the unit itself and on all

electrical connections through appropriate mounting!

• Electromagnetic emissions must be checked from an application point

of view!

• Always press reset button manually without using any tools or sharp-

edged objects!

Adapters

KF8833 KF8819

For description of adapters, refer to «Ordering».

Landis & Staefa CC1N7118E December 10, 1997 11/13

Page 12

12/13 CC1N7118E December 10, 1997 Landis & Staefa

Page 13

Dimensions

Burner controls

©

Plug-in bases

Dimensions in mm

Remote reset module

ARK21A27

AGK11 AGK12

Plug-in base with screw terminals. Hatched: position of Plug-in base for clip connections. Hatched: position of

insertable cable gland holder or cable holder insertable cable gland holder or cable holder

«B»: holes for cable entry «B»: holes for cable entry from below

«31», «32»: auxiliary terminals. «N»: neutral terminals, Connection choices:

connected to neutral input (terminal 2) 1, 3 and 4 each max. 4 clips Earthing: total of 6 clips,

Bottom: 4 earth terminals, joining a lug 2 max. 8 clips connected to lug «C»

for earthing the burner 5 through 10 eachmax. 3 clips for earthing the burner

11, 12 each max. 4 clips

31, 32 each max. 2 clips

The two narrow sides of the base are provided with catches which engage in the casing when the

latter is plugged in. To disengage the catches, a screwdriver must be slightly tilted in the appropriate

guiding slots.

Mandatory ( AGK11 and AGK12 ): connection of earthing lug «C» and of fixing screws in «A»

to the ground of the burner (using a metric screw with lockwasher or similar).

ARK21A27

Remote reset module for use with LOA26... / LOA36...

(printed circuit board with no housing).

Degree of protection IP00, that is, protection against

electric shock hazard must be ensured through

mounting.

Do not place any metal objects in the hatched area.

The module must be fitted with the help of spacers

made of plastic. Do not use spacers made of metal!

Landis & Staefa CC1N7118E December 10, 1997 13/13

1997 Landis & Staefa Produktion (Deutschland) GmbH

Loading...

Loading...