Page 1

Instruction Manual November 2005

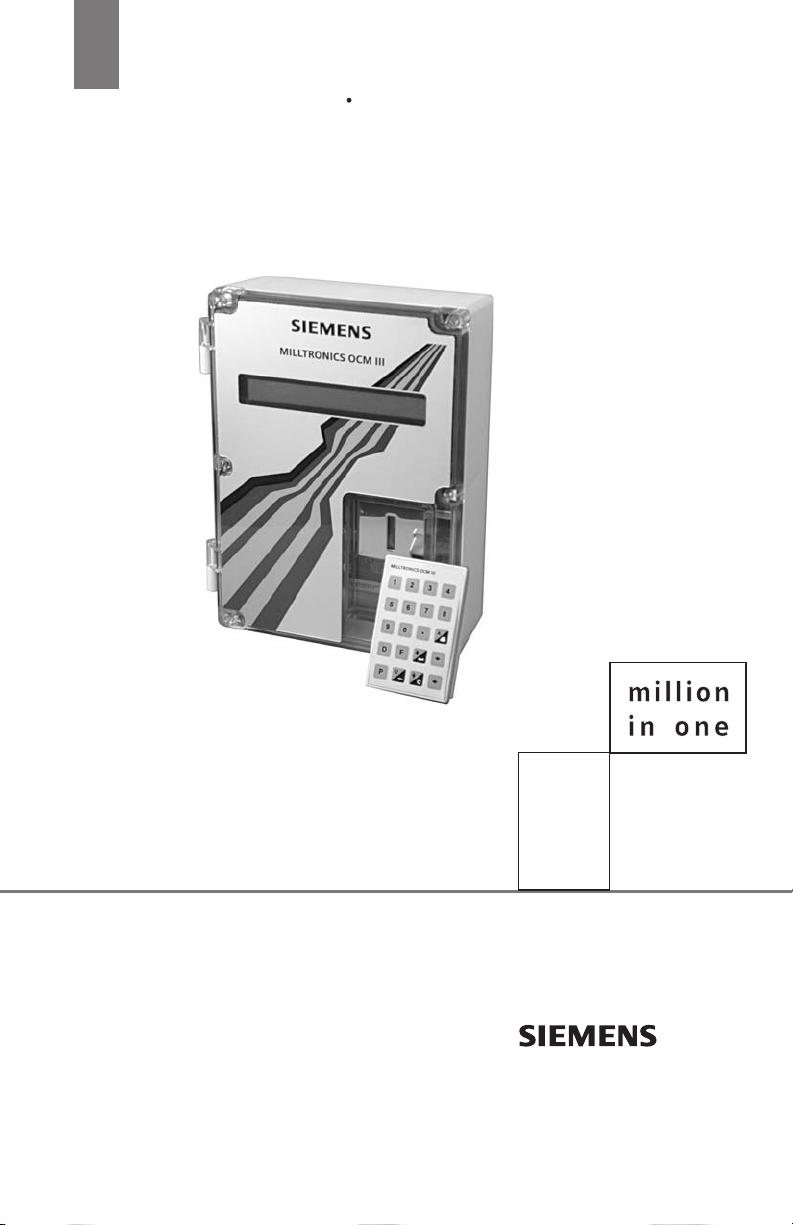

open channel

OCM III

Page 2

Safety Guidelines: Warning notices must be observed to ensure personal safety as well as that of

others, and to protect the product and the connected equipment. These warning notices are

accompanied by a clarification of the level of caution to be observed.

Qualified Personnel: This device/system may only be set up and operated in conjunction with this

manual. Qualified personnel are only authorized to install and operate this equipment in accordance with

established safety practices and standards.

Unit Repair and Excluded Liability:

• The user is responsible for all changes and repairs made to the device by the user or the user’s

agent.

• All new components are to be provided by Siemens Milltronics Process Instruments Inc.

• Restrict repair to faulty components only.

• Do not reuse faulty components.

Warning: This product can only function properly and safely if it is correctly transported, stored,

installed, set up, operated, and maintained.

Note: Always use product in accordance with specifications.

Copyright Siemens Milltronics Process

Disclaimer of Liability

Instruments Inc. 2005. All Rights Reserved

This document is available in bound version and in

electronic version. We encourage users to purchase

authorized bound manuals, or to view electronic versions

as designed and authored by Siemens Milltronics Process

Instruments Inc. Siemens Milltronics Process Instruments

Inc. will not be responsible for the contents of partial or

whole reproductions of either bound or electronic

versions.

While we have verified the contents of this

manual for agreement with the

instrumentation described, variations

remain possible. Thus we cannot

guarantee full agreement. The contents of

this manual are regularly reviewed and

corrections are included in subsequent

editions. We welcome all suggestions for

improvement.

Technical data subject to change.

MILLTRONICS®is a registered trademark of Siemens Milltronics Process Instruments Inc.

Contact SMPI Technical Publications at the following address:

Technical Publications

Siemens Milltronics Process Instruments Inc.

1954 Technology Drive, P.O. Box 4225

Peterborough, Ontario, Canada, K9J 7B1

Email: techpubs.smpi@siemens.com

• For a selection of Siemens Milltronics level measurement manuals, go to:

www. siemens.com/processautomation. Under Process Instrumentation, select

Measurement

• For a selection of Siemens Milltronics weighing manuals, go to:

www. siemens.com/processautomation. Under Weighing Technology, select

Weighing Systems

and then go to the manual archive listed under the product family.

and then go to the manual archive listed under the product family.

Level

Continuous

© Siemens Milltronics Process Instruments Inc. 2005

Page 3

TABLE OF CONTENTS

TITLE PAGE

ABOUT THIS ...

About This Ma nual 7

About the OC M-3 7

SPECIFICATIONS 9

Programmer 10

Transducer 11

Temperature Sensor 11

Cabling 11

Communication Softwa re 11

INSTALLATI ON

Installing the OCM-3 13

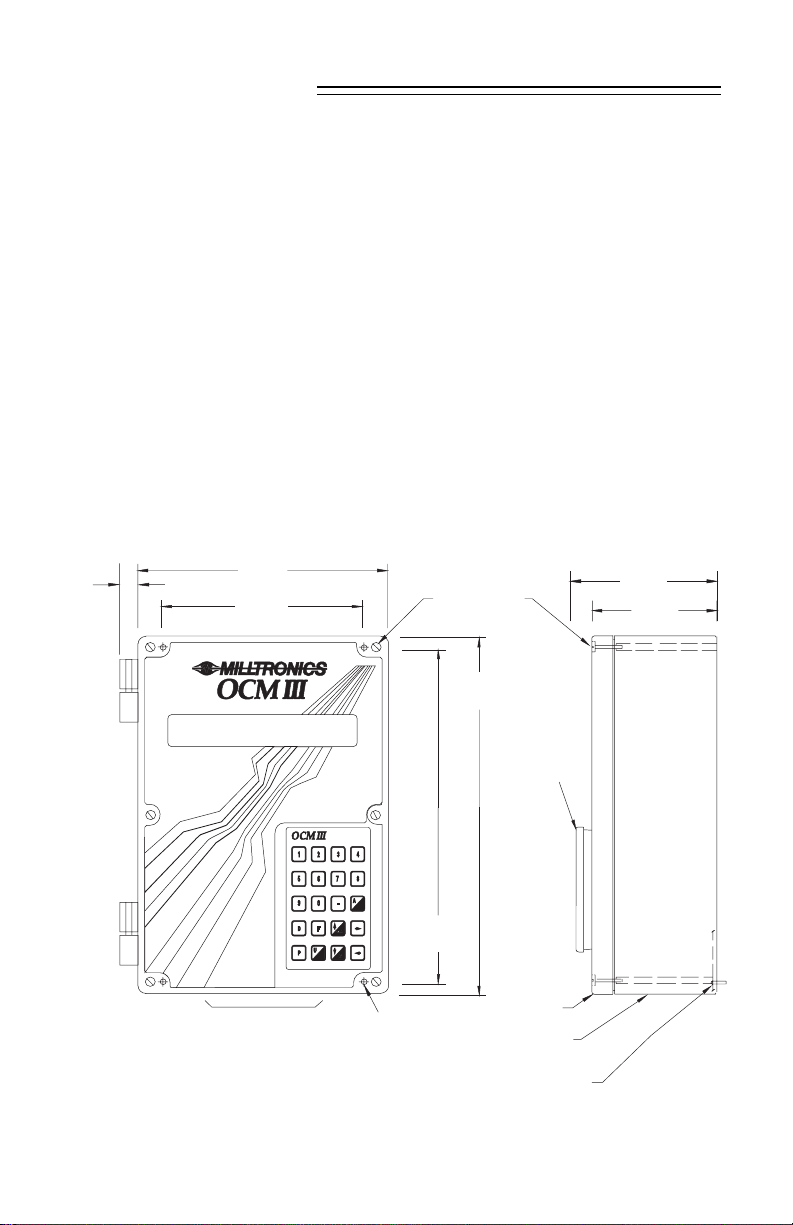

Outline and Mounting 13

OCM- 3 Layout 14

System Diagram 15

Installing the Transducer 16

Installing the Temperature Sensor 16

mA Output 17

Relays 17

Synchronization 18

Power Conne ctions 19

Installing the Memory Back-up Ba ttery 20

Communicating Via Compute r 20

Installing the Programmer 20

7ML19985AB01 OCM III 3

Page 4

START UP

General 21

Keypad 21

Legend 22

Initial Start Up 22

Fundamenta l Checks 25

OPERATION

Memory 27

Security 27

Units 27

Flow Calculation 28

Display 28

Damping 29

Relays 30

mA Output 30

Fail-Safe 31

Flow rate a nd Totaliz ing 31

Logging 3 2

Blanking 34

Temperature 34

Time and Date 34

Emulation Mode 35

Reset 35

Flow Velocity I nput 36

Auxiliary Head Input 36

DC Output 37

Diagnostic Aids 37

7ML19985AB01 OCM III 4

Page 5

‘D’ PARAMETER LISTING 39

‘F’ P ARAME TER LIST ING 41

‘P’ PARAMETER LISTING 43

‘U’ PARAMETERS FOR P3 PRIMARY ELEMENT 51

Simple Exponential Device s, P3 = 0 53

BS-3680 Rectangular Flume, P3 = 1 58

BS-3680 Round Nose Horizonta l Crest Weir, P3 = 2 60

BS-3680 Trapezoidal Flume, P3 = 3 62

BS-3680 U - Flume, P3 = 4 64

BS-3680 Finite Crest Weir, P3 = 5 66

BS-3680 Thin Plate Rectangular Weir, P 3 = 6 68

BS-3680 Thin Plate V-Notch Weir, P3 = 7 70

Rectangula r Weir (Contra cted), P3 = 8 72

Round Pipe, P3 = 9 74

Palmer-Bowlus Flume, P3 = 10 76

H - Flume, P3 = 11 78

Universal Head vs. Flow, P3 =12 80

Rectangula r Area x Velocity, P3 = 13 82

Trapezoidal Area x Velocity, P3 =14 84

Modified Trapezoidal Area x Velocity, P3 = 15 86

U Channel Area x Velocity, P3 = 16 88

Circular Area x Velocity, P3 = 17 90

Gull-Wing Area x Velocity, P3 = 18 92

Egg-Shaped Area x Velocity, P3 =19 94

Universal Area x Velocity, P3 = 20 96

APPENDICES

Maintenance 99

Error Codes 100

Communications 101

7ML19985AB01 OCM III 5

Page 6

7ML19985AB01 OCM III 6

Page 7

ABOUT THIS ...

ABOUT THIS MANUAL

Although the OCM-3 is very ‘approacha ble’ due its dialogue capa bilities and intuitive

operation, the user should be familiar with this manua l. This manual provide s the user

with the ne cessary information require d to install, sta rt up and operate the OCM-3.

As the OCM -3 prompts the user with spe cific message s in a step-by-ste p fashion

during programming, the Start Up section serves essentially to complime nt the

OCM- 3. Start Up provides the use r with instructions on the use of the programme r

and a n overview of the programming requirements.

The ‘D’, ‘F’, ‘P’ and ‘U’ para meters listed in the Paramete rs section provide a quick

refe rence of the available programming and display parame ters and the ir options. The

‘U’ parameter listing also provides mathema tical and graphical details as a reference

to assist the user in programming the OCM-3 to the primary element being used. The

user is urge d to rely on the ma nufacturer’s specification for obta ining and identifying

the primary element to which the OCM-3 is being applied.

In short,

If you want to know about

the product About This . . .

getting started Installa tion

how it works Opera tion

Read

Spe cifications

Start Up

Parame ters

Appendices

ABOUT THE OCM-3

The OCM-3 is to be used only in the manner

outlined in this instruction manual.

The Milltronics OCM-3 , Open Channel Meter, is an electronic instrument designed to

measure flow in open channels. I t is housed in a polycarbonate e nclosure and comes

with a removable programmer. As a system, it is used in conjunction with a re mote

ultrasonic transducer (or auxiliary head measurement device) and a temperature

sensor.

The OCM-3 transmits a pulse signal to the transducer which is then emitted as

ultrasonic pulses. The pulses echo off the water surface and are then sensed by the

transducer. The time for a pulse to echo back from the water surface is temperature

compensated and converted into a measurement of head.

7ML19985AB01 OCM III 7

Page 8

The OCM-3 converts the head measurement into flow rate, but also provides a

velocity sensor input for applications whe re a flow ve locity measurement is re quired to

perform the flow calculation. The flow rate is totalized and stored in a comprehensive

data log to provide deta iled flow analysis.

Programming of the OCM- 3 allows the opera tor to se lect the flow ca lculation specific

to the prima ry measuring device ( flume, we ir or pipe). Spe cial e mphasis has be en

placed on providing the most accurate flow calculations possible. To this end, specific

routines have been writte n to comply with the British Standards Institute’s

Specifications BS-3680. These routines calculate correction factors taking into

account se cond order effe cts such as approa ch velocity and bounda ry layer. In the

event that flow measurement is not covered by one of the flow calculations provided,

the O CM-3 ca n be programme d for flow measure ment using one of the universal

flow calculations.

The OCM-3 provides serial communication for re mote programming, data log re trieval

and print out for devices such as computers, PLC s and printers. Milltronics provides a

standa rd utilities softwa re package for OCM -3 programming, re mote display and data

retrieval. Howeve r, the use r is not limited to the software provided. T he user ca n

develop his own softwa re program to pe rform ta sks suited to his specific nee ds.

The OCM-3 features:

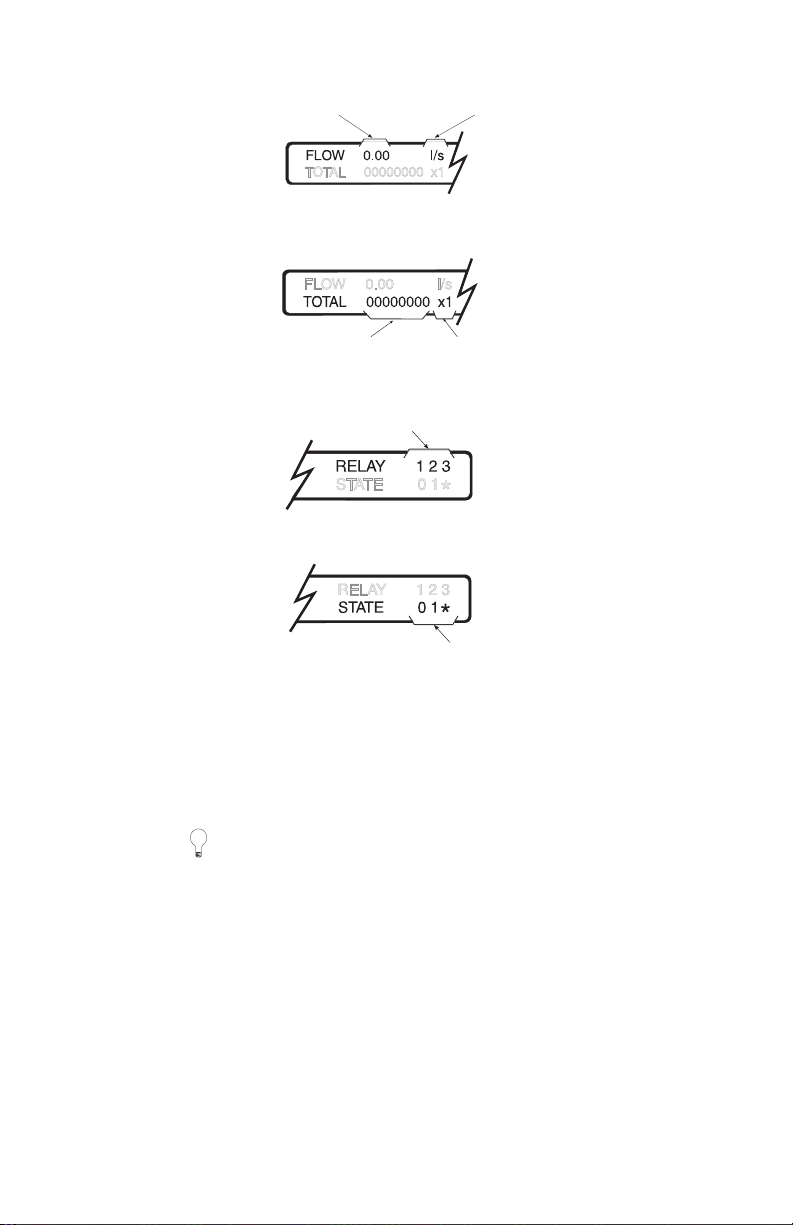

✓ multi field illuminated LC D, for ‘Flow and Tota l’ and ‘Relay Status’ display

✓ 0 or 4 to 20 mA output

✓ three multipurpose rela ys, including remote totaliza tion

✓ 1 to 2 4 months data log, subject to logging ra te

✓ extensive se rial communication, including RS-2 32

✓ removable infra-red programme r

✓ AC and D C (bi-current) opera tion.

7ML19985AB01 OCM III 8

Page 9

SPECIFICATIONS

Power: » dc supply: » 9 to 30 V D C, 8 W max

» ac supply: » 100/115/200/230 V ac ± 15%, 50/60 Hz,

20 VA max

Environmental: » location » indoor /outdoor

» altitude: » 2000 m max

» ambient temperature » – 20 to 50 °C (–5 to 122 °F)

» relative humidity » suitable for outdoor (Type 4X/Nema 4X

» installation category » II

» pollution degree » 4

Memory

back-up: » 3 V lithium battery (NEDA 5003LC or equivalent)

» operating life 1 year

» ‘SuperC ap’ capacitor for back-up

during battery replace ment

Range: » 0.3 m min to 1.2 m max ( 1 to 4 ft)

0.6 m min to 3 m max (2 to 10 ft)

Resolution: » 0.2 mm (0.007")

and / or

IP65 enclosure)

Accuracy: » ±1 mm/m, calculated error less than 0.02%

Temperature

Compensation: » external sensor to compensate over

Programming: » via supplied progra mmer and

Inputs: » velocity sensor and

Outputs: » transducer drive: » 44 Khz, 400 Vpp pulses of 0.1 msec typical

7ML19985AB01 OCM III 9

the ope rating range

communication link

auxiliary head » range: » 0 to 10 V dc

» resolution: » 2.7 mV

duration at a 100 msec typical repetition rate.

» instrumentation: » range: 0-20 or 4-20 mA

» resolution: 5 uA

» maximum loading: 1 KΩ

Page 10

» isolation: 300 V ac continuous

» relays: » 3 alarm/control relays

» 1 form ’C’ SPDT contact per relay, ra ted at

5 A at 250 V ac non-inductive or 3 0 V dc

» dc output: » +24 V dc

» 20 mA average to 200 mA at 1/10 duty

cycle max

Communication: » RS-232 or ± 20 mA bipolar current loop,300,

600, 1200, 2400, 4800, 9600 or 19200 baud

Data Logs: » va riable rate on 1 , 5, 15, 30 or 6 0 min or 24 hr

» 31 days minimum/2 years maximum

Display: » illuminated liquid crystal 5 x 7 dot matrix

display with 2 lines of 40 characters each

Enclosure: »Type 4X / NEMA 4X / IP65

» 209 mm W x 285 mm H x 92 mm D

(8.2" W x 11.2" H x 3.6" D)

» polycarbonate

Weight: » 2.3 Kg (5.1 lb)

Approvals: » CE *, F M, C SA

NRTL/C

» MCERT S C lass 1 open channel flow device with environment

operation limits at 35 °C (95 °F) at 93% relative humidity

SIRA MC 050058/01

PROGRAMMER

Enclosure: » genera l purpose

» 67 mm W x 100 mm H x 25 mm D

(2.6 " W x 4" H x 1" D)

» ABS plastic

Operating Temperature: » –20 to 50 °C (–5 to 122 °F)

7ML19985AB01 OCM III 10

Page 11

Battery: » 9 V (ANSI / NEDA 1604, PP3 or equivalent) or

3V lithium battery

TRANSDUCER

Model: » XRS-5*

Refer to associated Transducer manual.

TEMPERATURE SENSOR

Model: » TS-2 , LTS-1 or LTS-1C

Refer to associated Temperature Sensor manual.

CABLING

Transducer: » RG-62U coaxial

» maximum separation 183 m (600 ft)

» must be run in grounded meta l conduit

mA Output: » Belden 8760 or equivalent

Synchronisation: » Belden 8760

Temperature Sensor: » Belden 8760, 1 pair shielded/twisted,

Communication: » RS-232: » Belden 8770, 3 wire shielded, 24 AWG

» Bipolar Current: » Belden 9552, 2 pair shielded/twisted,

*Note: The XRS-5 must be used with the TS-2 external temperature sensor when

operating with the OC M- 3.

Velocity Input: » Belden 8760 or equivalent

7ML19985AB01 OCM III 11

18 AWG or equivalent

» maximum separation 183 m (600 ft)

» can be run in conduit with transduce r cable

or equivalent

» maximum separation 15 m (50 ft)

18 AWG or equivalent

» maximum separation 1,500 m (5,000 ft)

Page 12

Auxiliary Input: » Belde n 8760 or equivalent

24 V Output: » Belden 8760

COMMUNICATION SOFTWARE

Milltronics Utilities Software on standard P C floppy disk for DO S 3 .1 a nd up.

7ML19985AB01 OCM III 12

Page 13

INSTALLATION

Installation shall only be performed by qualified personnel

and in accordance with local governing regulations.

INSTALLING THE OCM-3

The OC M-3 should be mounted in a clean, dry are a that is: within the ambient

temperature range a nd suitable for the specified enclosure. The front cover should be

accessible for programming and viewing.

It is advisable to keep the OCM-3 away from high voltage or current runs, contactors

and SCR control drives.

Do not mount the OCM-3 in direct sunlight without the use of a sun shield.

This product is susceptible to electrostatic shock.

Follow proper grounding procedures.

OUTLINE AND MOUNTING

209 mm

16 mm

(0.6")

Milltronics reccomends using a punch for making

holes in enclosure. Use suita ble cable glands to

maintain ingre ss rating.

(8.2")

172 mm

(6.8")

suitable loca tion for

conduit entrances

lid screws

(6 places)

267 mm

(10.5")

mounting holes

(acce ssed under

lid 4.3 mm (0.17")

dia.,4 place s

285 mm

(11.2")

progra mmer

enclosure

customer mounting

screw

lid

106 mm

(4.2")

91 mm

Non metallic enclosure does not provide grounding between connections.

Use grounding type bushings and jumpers.

(3.6")

13 OCM III 7ML19985AB01

Page 14

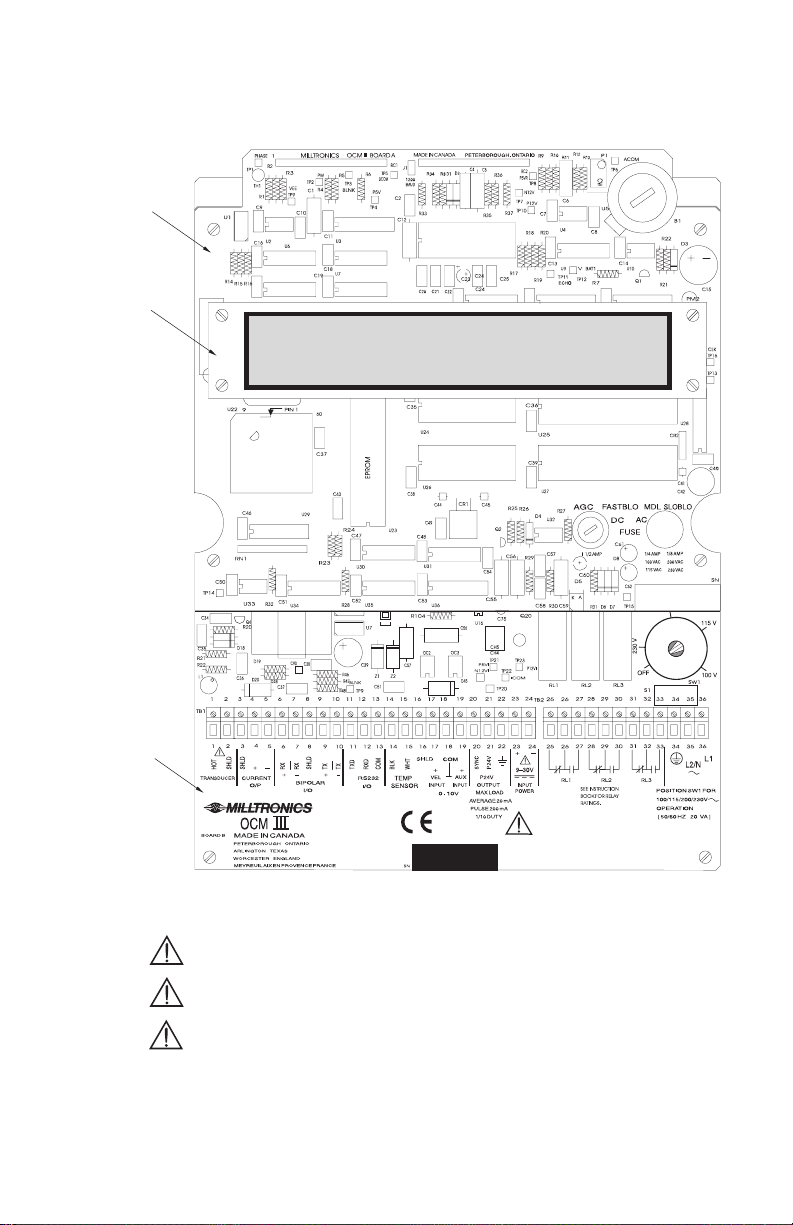

OCM-3 LAYOUT

board A

display

board

board B

All field wiring must have insulation suitable for at least 250 V.

Hazardous voltage present on transducer terminals during operation.

dc terminals shall be supplied from SELV source in accordance

with IEC 1010-1 Annex H.

Relay contact terminals are for use with equipment having no accessible

live parts and wiring having insulation suitable for at least 250 V.

The maximum allowable working voltage between

adjacent relay contacts shall be 250 V.

14 OCM III 7ML19985AB01

Page 15

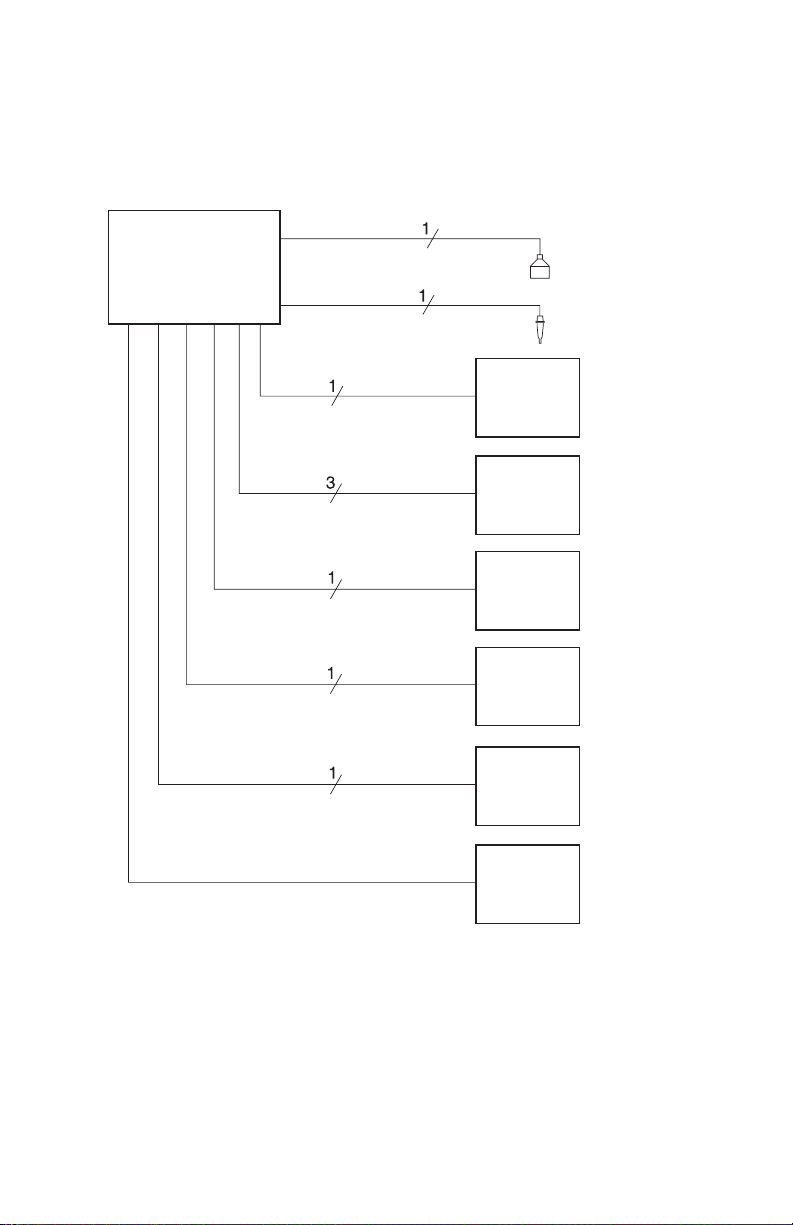

SYSTEM DIAGRAM

OCM-3

mA output

relay output

auxiliary input

velocity input

RS-232

Milltronics transducer,

see Specifications

Milltronics TS-2 ,

temperature sensor

customer device

customer alarm,

pump or control

device

customer device

customer device

customer device

bi-polar curre nt

(Milltronics communication)

Maximum system capa bility. Not a ll components or their maximum qua ntity

may be required.

15 OCM III 7ML19985AB01

Milltronics CVCC

98/03/05

Page 16

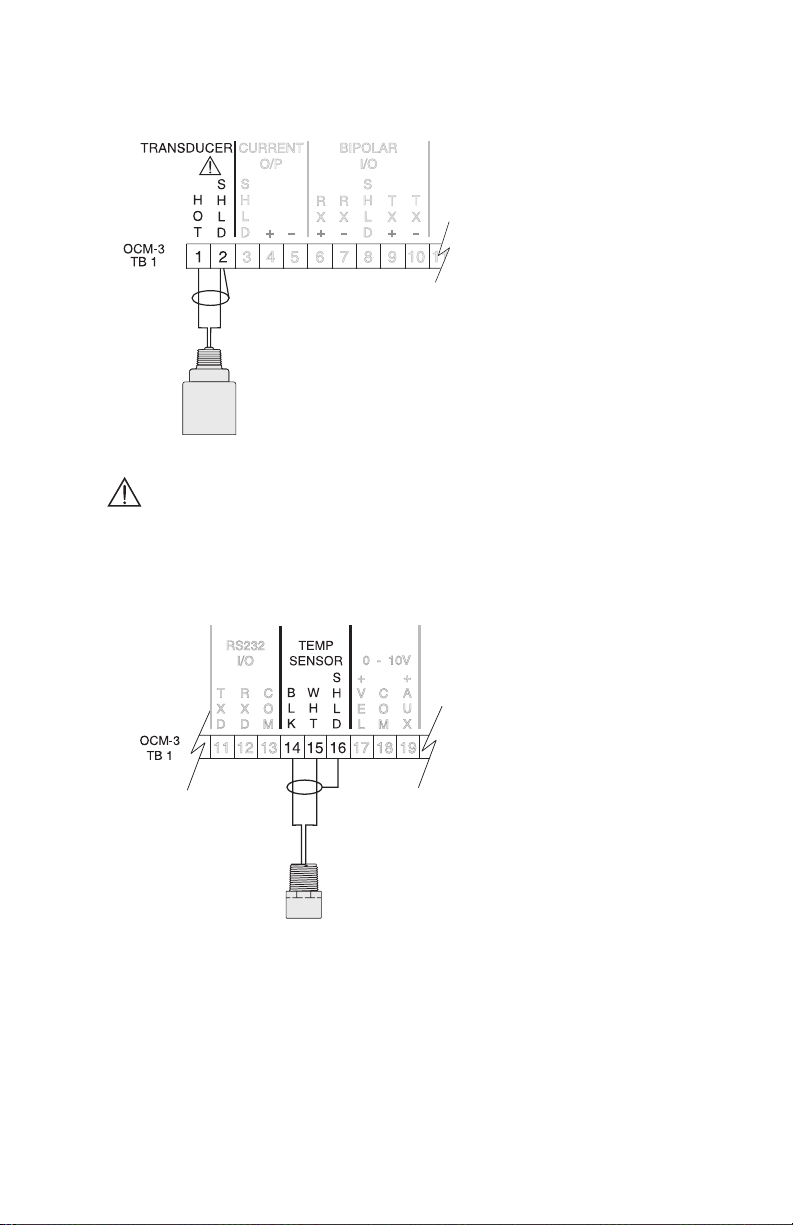

INSTALLING THE TRANSDUCER

Max cable run 183 m (600 ft) of

RG-62U or equiva lent. Cable must

be run in a grounded metal conduit

with no other cabling (except

Temp. Sensor ca ble).

Ground shield at O CM-3 only.

Insulate shie ld at junctions to

prevent inadvertent grounding.

Basic Wiring – T ransducer

Hazardous voltage present on transducer terminals during operation.

Note: When using the XRS-5 transducer with the OCM-3, use the TS-2 external

temperature sensor. The internal temperature sensor in the XRS-5 cannot be used.

INSTALLING THE TEMPERATURE SENSOR

In order to compensa te for uniform

temperature change in the air

between the transducer and the flow

surface, the temperature sensor

must be connected to the OC M-3.

Maximum cable run 183 m (600 ft) of

Beldon 8760, 1 pair shielded/twisted,

18 AWG or equivalent.

Tempera ture sensor cable ca n be

run with the transducer cable in a

grounded metal conduit.

Ground shield at OCM-3 only.

Basic Wiring – Temperature Sensor

16 OCM III 7ML19985AB01

Page 17

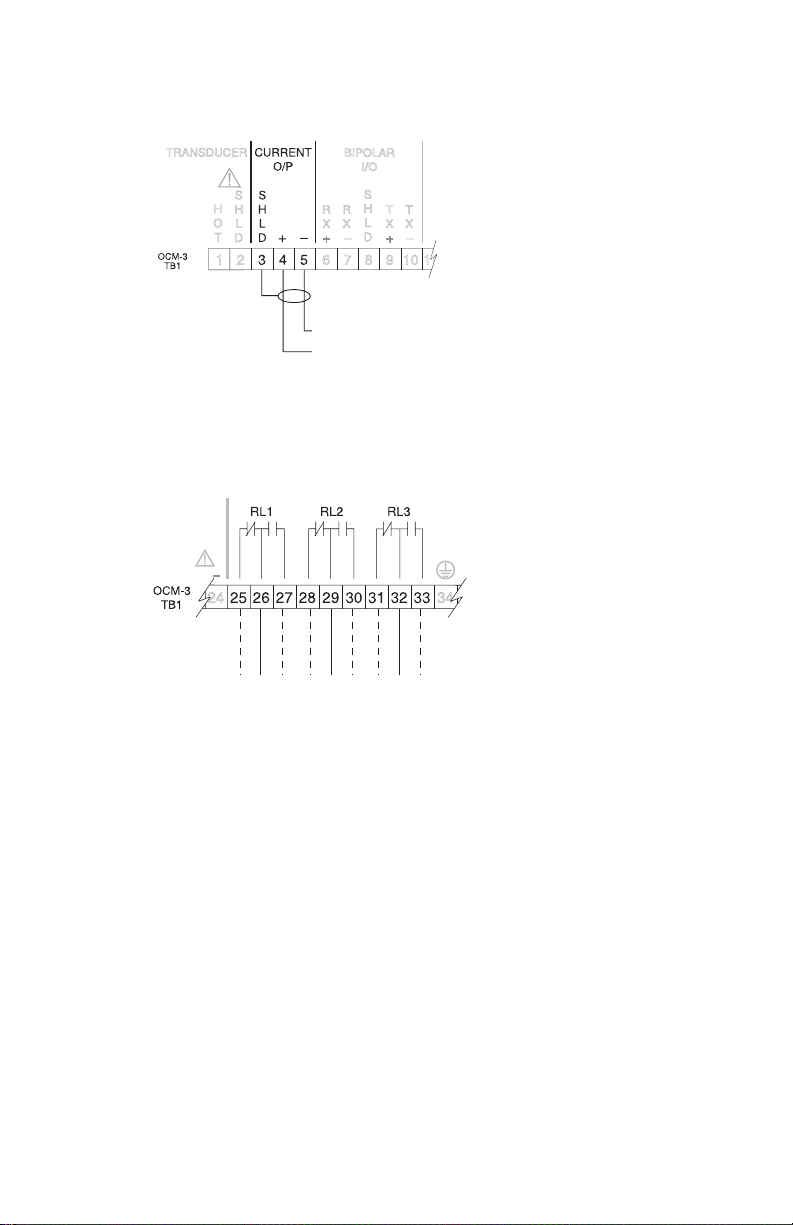

mA OUTPUT

RELAYS

isolated 0 or 4 to 20 mA output (P26) into 1 KΩ load maximum.

Wiring should conform to standard instrumentation practice s.

Ground shield at OCM-3 only.

relays shown in de- energized state ,

contacts rated at 5 A at 250 V

non-ind uctive.

n.c. com n.o. n.c. com n.o. n.c. com n.o.

All relays are certifie d for use in equipment whe re the short circuit capacity of the

circuits in which they are connected is limited by fuses ha ving ratings not exce eding

the rating of the re lays.

17 OCM III 7ML19985AB01

Page 18

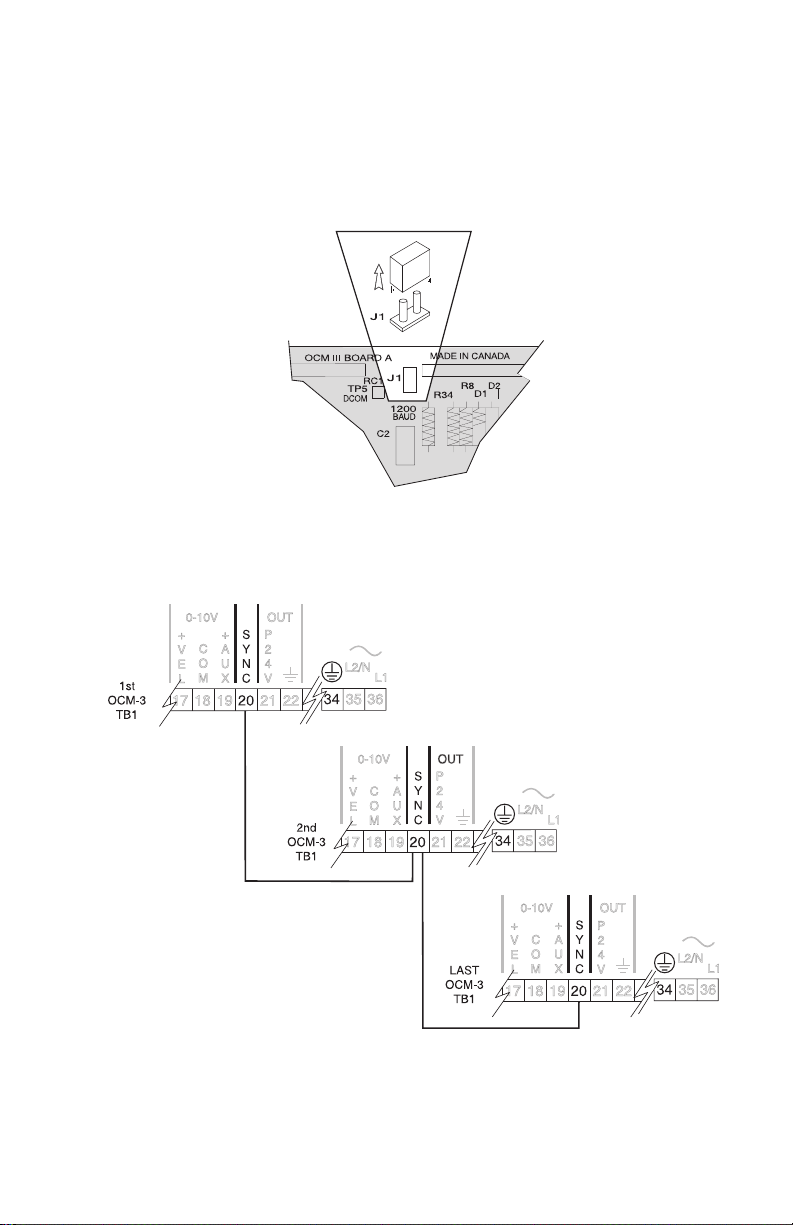

SYNCHRONIZATION

Where two to a maximum of twelve transducers will be sharing a common conduit the

OCM- 3s should be synchronize d. In order to synchronize OCM-3s:

» remove jumpe r J1 on board A on all but one OCM-3

» interconnect the SYNC terminal (T B1-20) of all OC M-3s. I nsure that

all O CM-3s sha re a common ground ( TB1-34 ).

18 OCM III 7ML19985AB01

Page 19

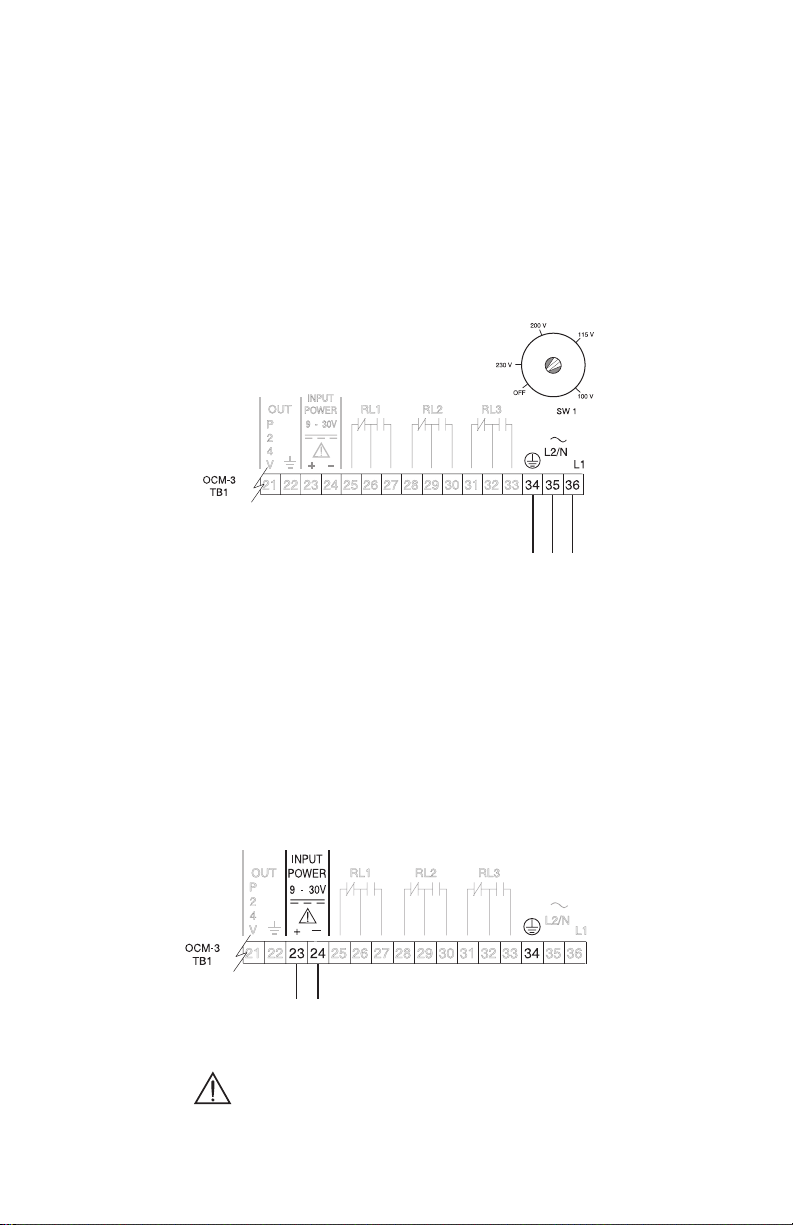

POWER CONNECTIONS

The OCM-3 power supply accepts 100, 115, 200 or 230 V ac per switch SW1

(board B) se lection and 9 to 30 V dc.

The OC M- 3 operates e ither under ac or dc power, or both ac and dc live

simultaneously. If both ac and dc power are live, the OC M-3 normally draws power

from the ac supply. In the e vent tha t the ac supply fails, the OCM- 3 then draws power

from the dc supply.

AC POWER

*

* switch shown in

‘OFF ’ position,

select appropriate

voltage.

100/115/200/230 V ac, 50/60 Hz,

select volta ge via switch on board B

The equipment must be protected by a 15 A fuse or

circuit breaker in the building installation.

A circuit breaker or switch in the building installation, marked

as the disconnect switch, shall be in close proximity to

the equipment and within easy reach of the operator.

DC POWER

nega tive dc input ( TB1- 24 ) is

9 to 30 Volt

dc input

dc terminals shall be supplied from SELV source in accordance

with IEC 1010-1 Annex H.

19 OCM III 7ML19985AB01

tied to ground (TB1-3 4)

Page 20

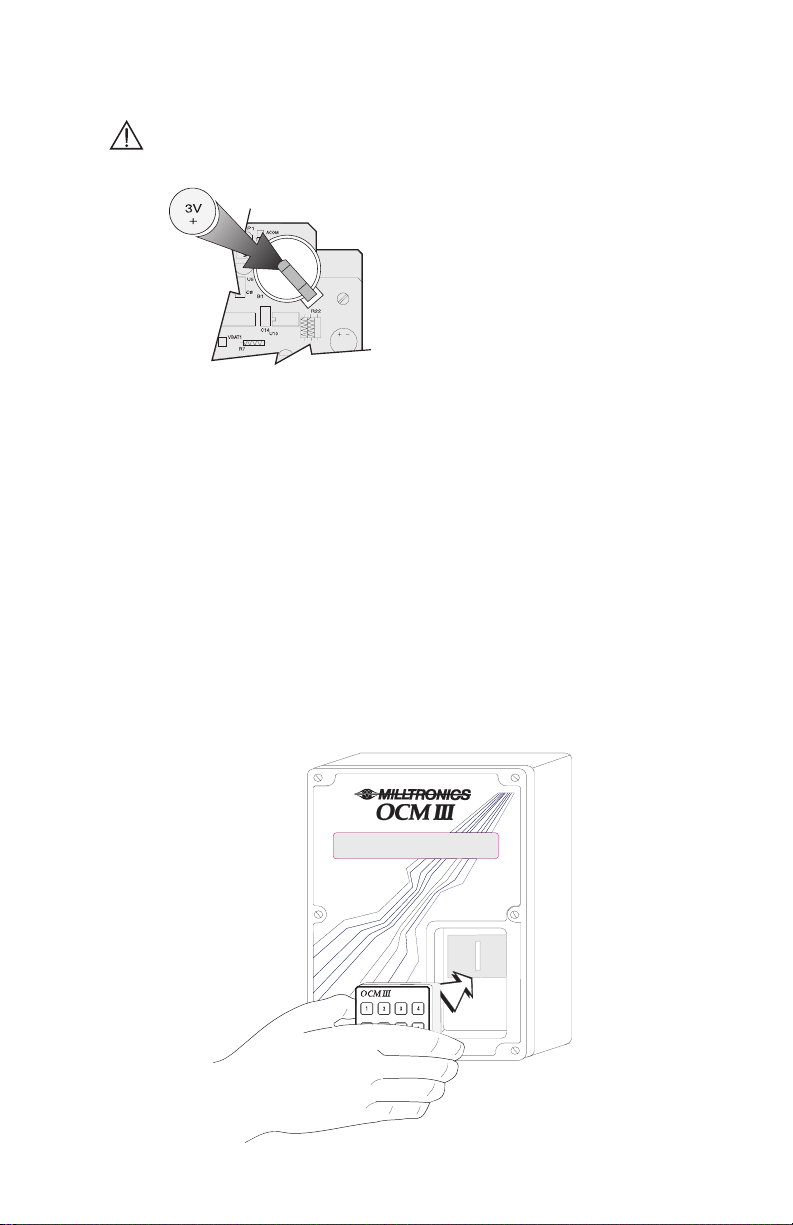

INSTALLING THE MEMORY BACK-UP BATTERY

Disconnect power before installing or replacing the ba ttery.

Do not install the memory back- up

battery until the OCM -3 is to be used.

The unit is supplied with one battery

package. Remove the battery from

the pa ckage and insert it into the

batte ry socket.

Refer to Operation \ M emory.

The memory battery, B1 (see Specifications) should be replaced yea rly to insure

memory back up during lengthy power outages. An on board capacitor provides

one hour of memory retention in order to preserve the me mory while the battery

is being changed.

COMMUNICATING VIA COMPUTER

Refer to Communication.

INSTALLING THE PROGRAMMER

To program the OCM-3 via the Programmer, it must be placed into the front cover

recess of the OCM -3. The back of the Programmer has a magne tic plate which will

hold the progra mmer in place. I t ca n be removed when programming is completed.

20 OCM III 7ML19985AB01

Page 21

START UP

GENERAL

For the initial start up, it is advisable to use the programmer for programming the

OCM-3. The programmer transmits a coded infrared signal each time a key is pressed.

The OCM- 3 is designed to a utomatically scroll through the ‘A’, ‘D’, ‘F’, ‘P’ and ‘U’

paramete rs in a structured sequence. The scrolling is interactive in that, depe nding on

the option chosen for a given para meter, subseque nt parameters may be skipped or

modified. The user is thus prompted to satisfy only the pa rameters which are availa ble

to him for the application he ha s chosen.

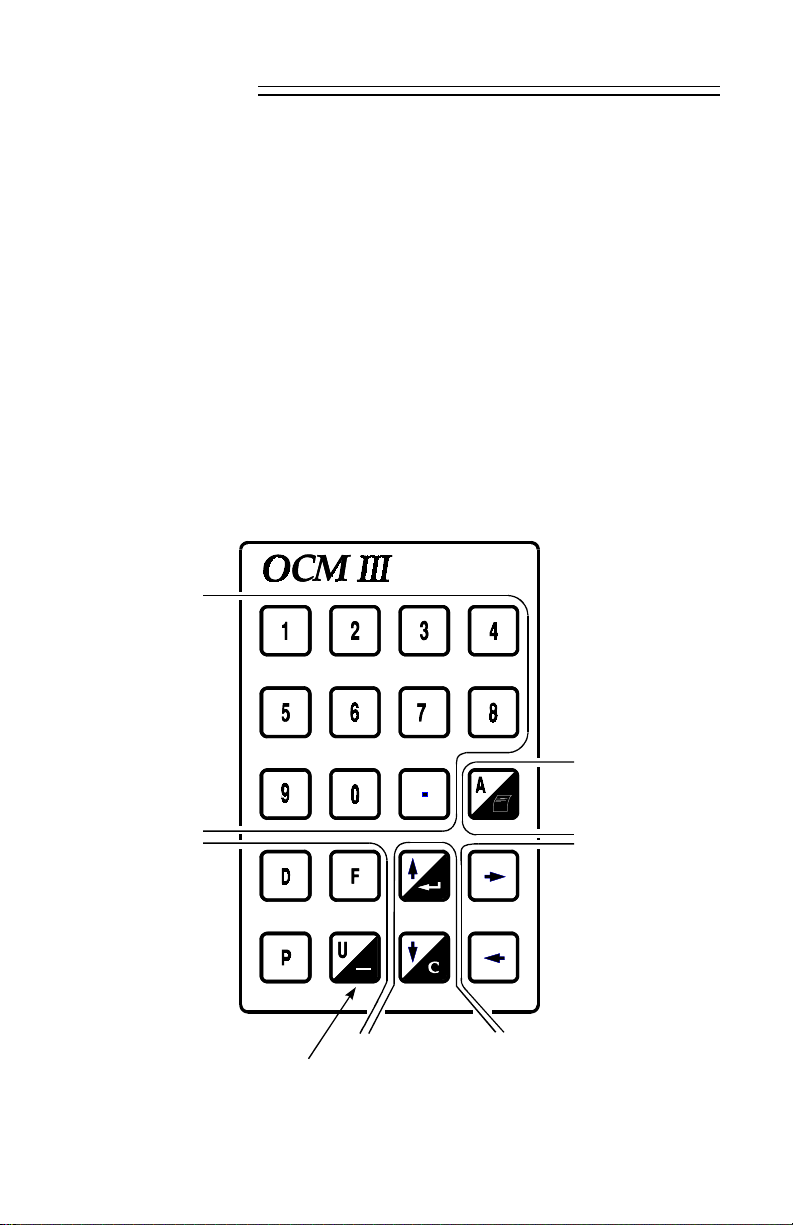

KEYPAD

numeric

entries with

decimal point

access to ‘A’ parame ters

/ initiate s a printout while

viewing ‘Flow and Total’

access to ‘D’, ‘F ’,

‘P’ and ‘U’

paramete rs

negative

scrolls

Forward

Backward

through

through the

the parame ters / ente rs

content of entry field

scrolls

parameters / clears content of entry field

scrolls through selecte d

parameter options

7ML19985AB01 OCM III 21

Page 22

LEGEND

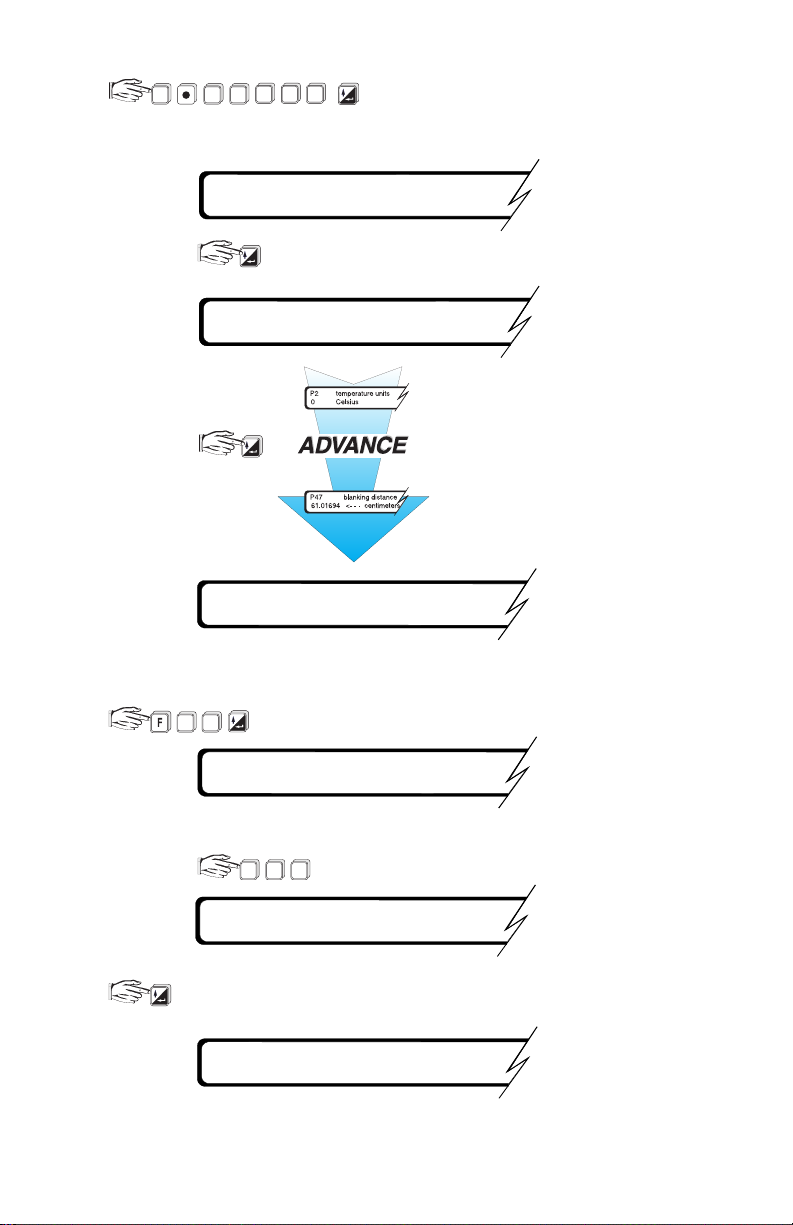

Press the a ssociated progra mmer key:

Display shown on OCM- 3:

Programmer key:

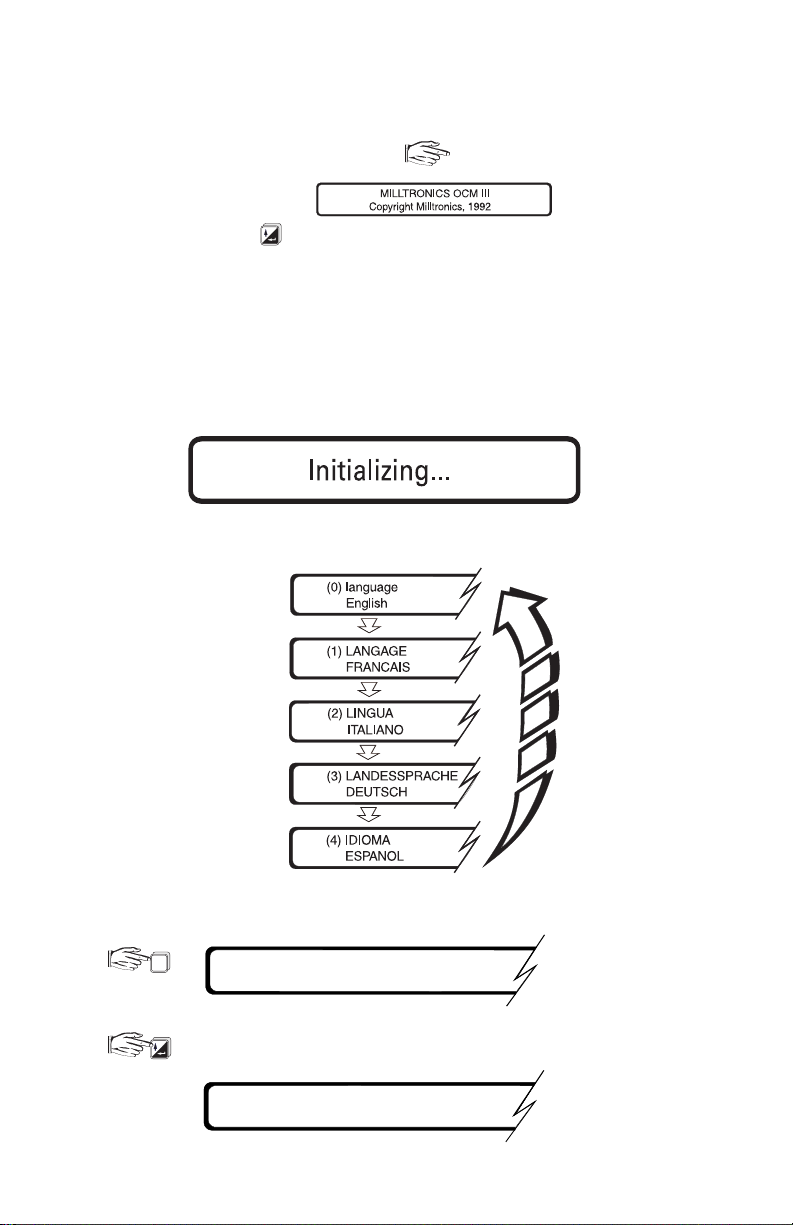

INITIAL START UP

After installation procedures ha ve been completed, the OC M- 3 may be powered up.

Upon initial powering up, the unit momentarily displays:

and the n scrolls through the ava ilable languages:

The OC M- 3 is asking which langua ge you prefer to communicate in!

0

(0) la nguage

English

English language

selecte d

advance to ‘F0’

F0 enter security code

< - - -

7ML19985AB01 OCM III 22

Page 23

8 2 8

1

72

factory set security code

2.71828 must be entered

P0 language

0 English

if the wrong language

was selected, it may

be changed here

P1 dimensional units

0centimeters

continue programming by

entering the desired options

and advancing until the

scroll returns to ‘P0’. It is

then assumed that the

user has entered all the

required paramete rs.

P0 language

0 English

For optimum calibration accuracy, an ‘F13’ should be performed prior to acce ssing

‘F2’, the normal operating mode.

3

1

F13 auto zero calibration

enter the current head. The

OCM-3 calculates ‘P46’ and

automatically ente rs the va lue.

e.g. 1 6 0

01 6

F13 auto zero calibration

160

F13 auto zero calibration

0 completed

7ML19985AB01 OCM III 23

Page 24

If data logging is desired, the time and date must be set.

4

F4 24-hr. time

e.g. 1141

4

1

1

1

F4 24-hr. time

1141

11: 41 a.m.

seconds are always

assumed to be 00

,

F4 24-hr. time

11:41:00 enter new time

time is displa yed in

hh:mm:ss

F5 (ddmmyyyy) date

e.g. 12101492 October 12, 1492

0 1

4

9 211 2

F5 (ddmmyyyy) date

12/10/1492 enter new date

The start up procedure is now complete. Enter ‘F2’ to place the OCM-3 in the normal

operating mode.

2

Note: To save parameter values, return to RUN mode (F2) after programming.

The OC M-3 now displays the flow ra te and total. Refer to Ope ration \ Display

7ML19985AB01 OCM III 24

Page 25

FUNDAMENTAL CHECKS

For accurate determination of flowrate, accurate head measurement is essential.

Check the following and correct if necessary.

» check D5 for correct temperature at transducer location.

» check D9 for corre ct distance from transducer to he ad.

» check D0 for accurate head measurement.

7ML19985AB01 OCM III 25

Page 26

7ML19985AB01 OCM III 26

Page 27

OPERATION

Upon powe r up, the transducer is fired pe riodically as se t by P36. A long interval

betwe en measureme nts may be de sirable in order to conserve power* whe n

operating the OCM- 3 from a D C source of limite d capacity.

The echo is processed to determine the head (D0). The flow rate (D1) is calculated by

the OCM-3 as a mathematical function (P3 and P4) of head or a function of head and

velocity (P42). The flow rate is then integrated to yield the totalized flow (D2). The

‘Flow’ and ‘Total’ fields which a re displayed during the norma l running mode (F2) are

also continuously updated.

Viewing or changing the content of a paramete r (except F1, e mulation) is done

without disturbing the acquisition, processing or logging of flow da ta (see \ Security).

*

restricted usage of display lighting (P14), relays (P15, 18 & 21), mA

output and communications will also conserve power.

MEMORY

During a power interruption, the memory back up will hold the programming, the log

and the totaliz er values, and run the clock. The memory battery (B1) provides up to

one ye ar of memory re tention (se e Appendices \ M aintena nce).

Note: To save parameter values, return to RUN mode (F2) after programming.

SECURITY

The content of all ‘A’, ‘D’, ‘F’, ‘P’ and ‘U’ parameters ca n be viewed without having to

satisfy the security parameter, F0. However if it is desired to change the content of

any of these pa ramete rs, the se curity para meter must be satisfied (exce pt for

resetting the running min/max displays, parameters D3/D 4 and D 6/D7).

Once security ha s been satisfied, access continue s for 5 minutes after the last key is

pressed or until F2 is re -entered.

The security code may be changed from its factory set value, 2.71828, by entering a

new value into F10. It is imperative that the new value be recorded, as the code can

not be vie wed. I f the code is lost, consult Milltronics.

UNITS

Programming of the OCM-3 involves setting the units of measure:

» P1 linear and velocity

» P2 temperature

» P5 flow rate and volume

If the units are change d during the course of opera tion, the change will be effected

through all a ssociated parameters and displa ys and will rescale flow and tota l data

stored in the logs.

7ML19985AB01 OCM III 27

Page 28

FLOW CALCULATION

Absolute vs. ratiometric

The OC M-3 can be progra mmed to use e ither of two methods (P4) for calculating flow

from the head measurement: absolute or ratiometric. The result is the same

regardless of the method use d. The principal difference is the information that must

be e ntered in orde r for the OC M-3 to carry out the calculation. T he user’s choice of

method may ultimately be based upon the information which is at hand. Re fer to U

parameters for the primary element selected for a listing of the information required.

For the ratiometric me thod, it is usually sufficient that the user know the flow rate

) which occurs at maximum he ad (h

(Q

cal

On the other hand, absolute calculations require that the user enter information such

as: the physical dimensions of the primary ele ment and the constant rela ting to units

of mea sure for both linear dimensions and flow ra tes.

).

cal

e.g.

the genera l formula for flow through a single exponent primary element is:

x

Q = KH

the specific formula for flow through a 45° V-notch we ir is:

cfs = 1.03H

2.5

thus: Q = flow in cubic feet pe r second

K = constant of 1.03

H = head in feet

The absolute method is not applicable to the following:

Palmer Bowlus flume

H flume

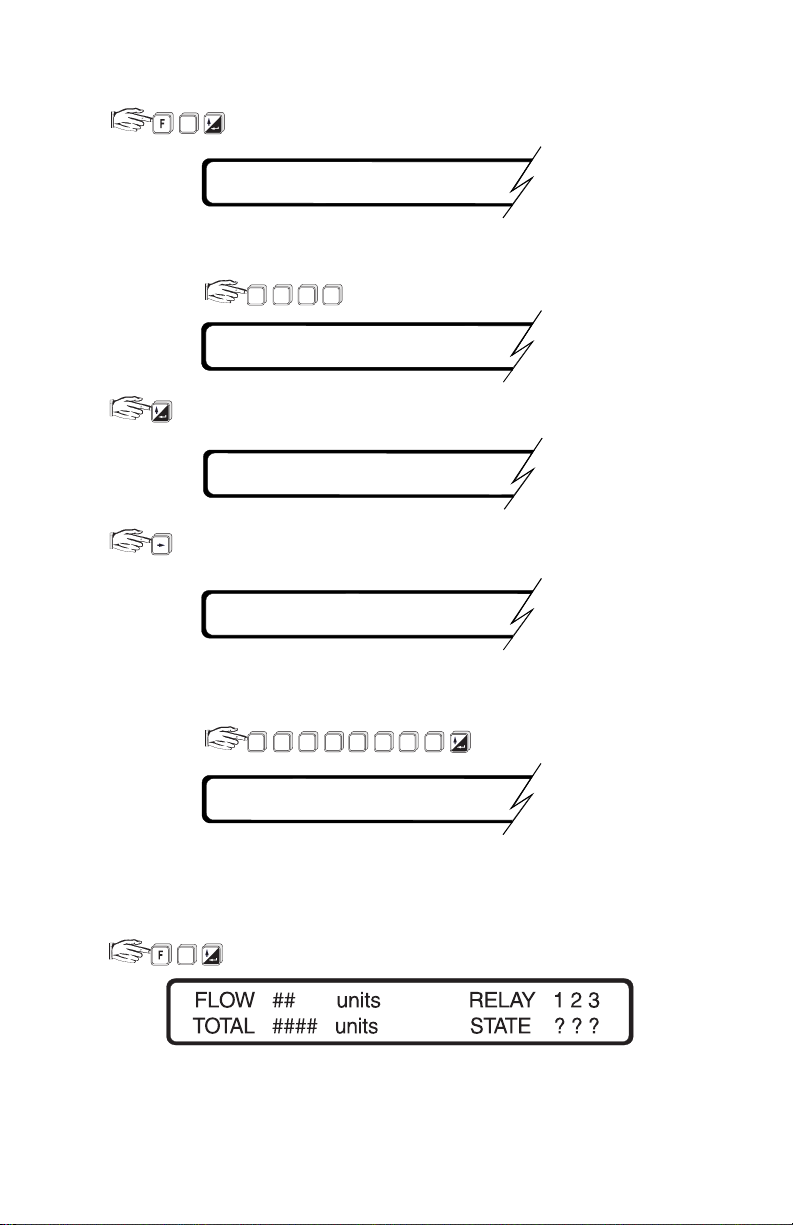

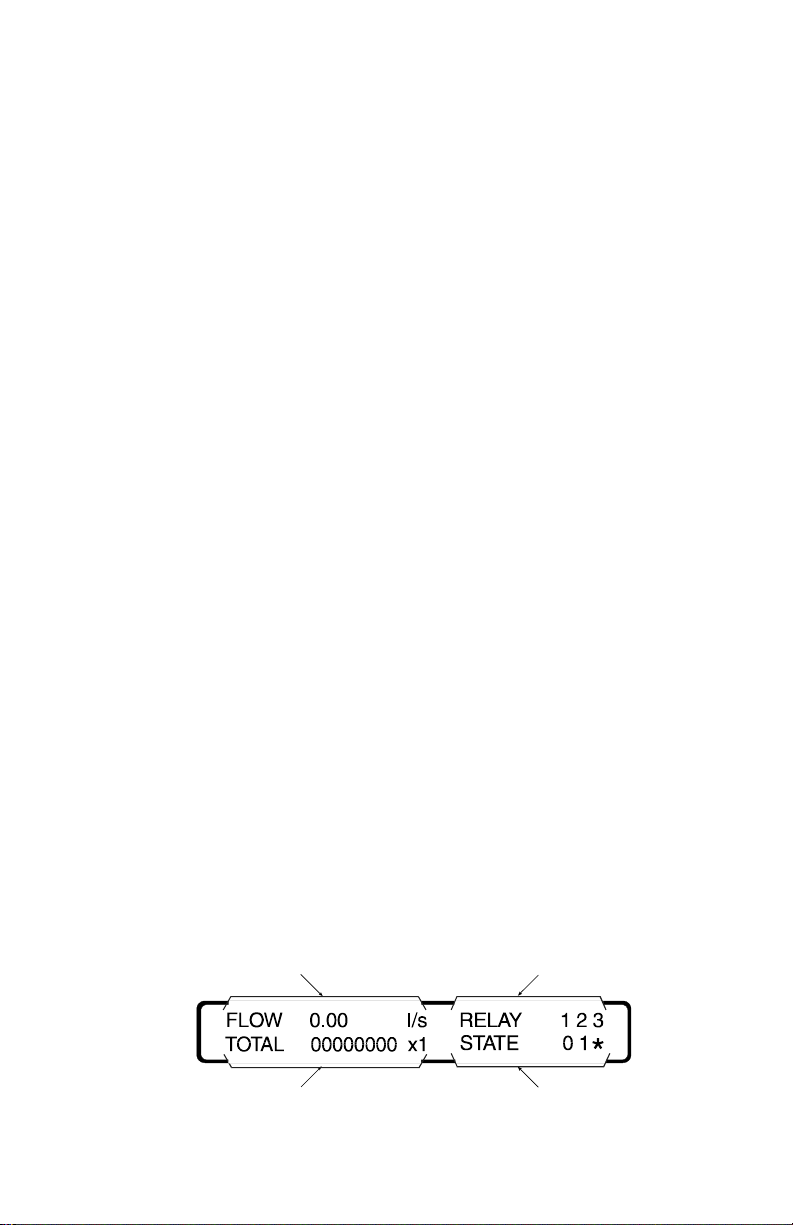

DISPLAY

The normal display during operation is the Flow and Total Display (F2).

flow rate fie ld

relay / "no echo" field

totalizer field

status field

7ML19985AB01 OCM III 28

Page 29

Flow Rate Field

Totalizer Field

flow rate

units, P5

total

multiplier, P3 2

Relay / No Echo Field

relay identification

under loss of echo

condition, "NO

ECHO" will

alternately flash

Status Field

relay sta tus : 0 = re lay de -e nergized

1 = relay energized

* = alarm state (indicated when

flashing)

The OCM- 3 provides illumination for the LCD for ea sier viewing of the display.

Illumination can be set (P 14) to be normally on or off, or a utomatic. When automatic is

selected, the lighting will automatica lly go on when ke ypad activity is sense d and the n

extinguish after 1 5 seconds of inactivity.

For battery operation, set display lighting to off or auto.

DAMPING

The OC M- 3 provides two separate da mping functions: rea ding and mA output. Ze ro

or no damping allows fastest re sponse while high or 100% provides the slowest

response. The damping is usually set to provide a re liable response without

sacrificing stability.

The rea ding damping, P13 , dampe ns only the flow rate reading of the ‘Flow and T otal’

display F2. The damping selections are: off, low, medium and high. Rela y functions

associated with flow rate respond to the dampened re ading values.

mA output damping, P27, da mpens the cha nge in the mA output. The parame ter entry

is in seconds for spanning the 0 to 100% of the mA range selected (P26). Displays

and relay functions a ssociated with the mA output respond to its

dampened value.

7ML19985AB01 OCM III 29

Page 30

RELAYS

Three on board multipurpose relays are provided by the OCM-3. P15, 18 and 21 set

the respective functions for relays 1, 2 and 3. D epending on the function selected,

these para meters de termine the need and configuration of the subsequent re lay

control parameters, P16, 17 (relay 1); P19, 20 (relay 2) and P22, 23 (relay 3).

If the relay is to function as a driver for a remote totalizer or as a flow sampler contact,

the totalizer multiplier (P32) will be factored by the setpoint . Note that paramete rs

P16, P19, and P22 will default to zero. When a relay is set to totalizer (P32), you must

have the applicable parameter (P16 for relay 1, P19 for relay 2, or P22 for relay 3) set

to something othe r than zero (normally 1).

Example: For relay 1

Re lay totalize r fa ctor =

The status of e ach relay is shown in the display. Re fer to \ Flow and Total Display.

totalizer factor (P32)

relay 1 setpoint (P16)

100 (P32=5)

=

2 (P16)

= 50 units/pulse

For battery opera tion, have relays energiz ing on alarm.

mA OUTPUT

The OC M-3 provides a mA output ( TB1 -4/5) which can be a ssigned (P24 ) to

represent the measurement of flow, head, velocity or temperature. The associated

scaling, P2 5, is fa ctory set to a value of ‘0’. This provides normal scaling with respect

to the assigned measurement.

Normal scaling for representation of flow, head or ve locity is:

» 0 or 4 mA = 0

*

» 20 mA = maximum measurement value for: » P6

at maximum head

» P7: maximum head

: flow rate

» P10: velocity

at maximum head

Normal scaling for representation of te mperature is:

» 0 or 4 mA = – 40 °C

» 20 mA = 60 °C

If custom scaling is required, the 20 mA corresponding va lue ( other than 0) can be

entered into P25. The range (0 to 20 or 4 to 20 mA) and damping (see Damping) are

set via P26 and P27 respectively.

7ML19985AB01 OCM III 30

Page 31

The mA function can be ove rridden for test purposes by se tting the desire d mA value

into F3. When the value is entered, the mA output will go to that value. When F3 is

exited, the mA output will revert to normal operation. Also, see \ Emulation Mode.

P6 is calculated by the OCM-3.

*In the case of absolute calculations (P4=0),

FAIL-SAFE

In the event of an echo loss, the fail- safe timer will begin counting. I f the echo loss

duration surpasses that of the time set (P29), a ‘

Status field (see \ D isplay) . The mA output will respond (P 30) by either holding the last

value or immedia tely going to a pre determine d value (P31) . The head and derive d flow

will hold their last value a nd totalization and logging will continue, based on that value.

Upon resumption of a valid echo, the mA output will re turn to a value corresponding to

the present value of the measurement assigned, at the mA damping rate (P27).

No Echo

’ alert will be displa yed in the

FLOW RATE AND TOTALIZING

Flow rate

Calculation of the flow rate is ongoing. It is normally viewed under the Flow and Total

display (F2 ) with the de cimal point set pe r P33. I t can also be viewed under D1 a s the

raw flow calculation. Da ta on the running minimum and ma ximum flows that ha ve

occurred since the last reset can be vie wed in two ways:

» F7 gives the running min/ma x flows and the ir time a nd date of occurrence since

the la st reset. F7 is reset by F8 but only a fter satisfying the security pa ramete r F0.

» D3/D 4 give the respective running min/max flow data, only, that have occurre d

since they were last reset. D3/D4 are reset simultaneously by entering 0 into

either D3 or D4. D3 and D4 will then adopt the current flow rate and track the

running min/max values from that point on. The security parame ter (F0) does

not need to be satisfied in order to reset D3 /D 4.

Flow data spe cific to a particular time and date ca n be viewed unde r the data log F14

(see \ Logging).

Totalizing

Totalizing of the calculate d flow is ongoing. It is norma lly viewed under the Flow and

Tota l display (F 2).

An auxiliary totalizer (D2 ) is provided for operator usage and is intende d for short term

totalizing to a maximum count of 999999. It can be reset or preset independently of

the F 2 totalizer after satisfying the security pa ramete r (F0 ).

In order to adjust the ra te of filling of the tota lize r, the totalize r multiplier (P32) can be

set to an appropriate value. The totalizer can be reset via F11. Totalizing that is

specific to the time and da te can be viewe d under the da ta log F1 4.

The OC M-3 can be programmed to operate a remote totalizer by a ssigning any of the

relays (P15, 18 or 21) to act as a totalizer contact*. Under this function, the maximum

rate of contact closure is 2/sec with a closure duration of 200 msec**.

The totalizer count is set by the relay setpoint parameter (P16, 19 or 22 respectively).

*

**

Typically the totalizer should be set for 300 to 3000 counts per day at maximum flow.

7ML19985AB01 OCM III 31

Page 32

Under low flow conditions, a cut- off head ( P45) can be ente red to avoid totalizing

flows occurring at or below the flow corresponding to the cut-off head.

LOGGING

The OC M- 3 provides an extensive logging feature which can be viewed on the local

display or retrieved via the serial communication link. T he logging rate (P 39) can be

fixed or va riable. The latter being useful in conserving logging space. The condition for

variable logging is determined when selecting the logging rate.

Variable logging rate conditions are ca tagorized as : rate of change of flow, percent of

maximum flow or percent of maximum head. Logging occurs at the normal (slower)

rate while the condition is less than the setpoint (P 40 ). If the condition excee ds the log

rapid setpoint, the ra pid rate of logging ta kes effe ct until the condition falls below the

log normal setpoint (P41).

The associa ted se tpoint units are : % cha nge of maximum flowrate per minute, % of

maximum flowrate a nd % of maximum hea d, respectively. The setpoints represent the

absolute value of the rate of change; that is, for either increasing or decreasing

flowrate . The OCM- 3 does not recognize negative e ntries into P-40 and P-4 1.

Flow data is logged in 1/2 % increments from 0 to 110 % of maximum flow. Flows

above 110 % are logged as 110 %. Truncation of flows to 110 % does not apply to

daily totalization.

Log Capacity vs Rates

rate capacity

1 min 31 days

5 3 months

15 9 months

30 1 year

60 1.5 years

24 hr 2 years

e.g. 15 / 5 9 months max / 3 months min

Once the log is filled, the old da ta will be successively written over with the new

data being logge d.

The log can be examined via F1 4. Viewing of the log is done by task a nd by method.

The viewing ta sks are: daily flow totals, flow rates and min-ma x flow data for flow or

temperature. The viewing me thods are : by first entry, by last entry and by specified

date . The scrolling keys are used to mane uver through the tasks, methods and

time of da y.

7ML19985AB01 OCM III 32

Page 33

Viewing the data log

The day totalizer (F14) does not use the master totalizer multiplier (P32). It is possible

that the da ily total overflows. I n such a case the display will show ++ +. ++.

7ML19985AB01 OCM III 33

Page 34

BLANKING

Blanking is used to ignore the zone in front of the transducer where ringing or other

false echo is at a level that interferes with the processing of the true echo. The

minimum blanking is factory set, but can be overridden by ente ring the de sired

distance into P47.

Ringing is the inherent na ture of the transducer mass to continue vibrating after the

transduce r has bee n fired. Ringing decays to a cceptable levels in the order of

milliseconds. Excessive cold or over tighte ning of the transduce r mounting may

increa se the ring time such that it appea rs as an e cho during the receive cycle. This is

usually indicated by an incorrect high head re ading. Excessive ring time may be

overcome by increasing the blanking.

TEMPERATURE

The temperature a s currently registe red by the temperature sensor is viewe d under

D5. D ata on the running minimum and maximum temperatures that ha ve occurred

since the last reset can be viewe d in severa l ways:

F7 gives the running min/max temperature s and their time and date of occurrence

since the last reset. F7 is re set by F8 but only a fter satisfying the se curity

parameter F0.

D6/D7 give the respective running min/max te mperature data, only, that ha ve

occurred since they we re last reset. D6 is reset by entering a value lower than D 5,

and D 7 is reset by entering a value larger tha n D5. D6 and D7 will then adopt the

current te mperature value and track the min/max va lues from that point on. The

security parameter F0 does not need to be satisfied in order to reset D6 or D7.

Tempera ture data specific to the time and date can be viewed unde r the data log F14

(see \ Logging).

D14 indica tes the resistance of the temperature sensor corre sponding to the

temperature shown in D5.

TIME AND DATE

If the data logging fea tures of the OC M-3 are to be used, the time (F4 ) and date (F5)

must be set. The day starts at 00:00:00 and ends at 23:59:59.

Adjusting the Time

If the clock time is advance d beyond the next anticipated logging time, the entry for

each missed logging time is filled with a code which indica tes that the system was not

able to make entries at those times.

The daily total will be reduced proportional to the amount of time the day

was shortened.

If the clock time is set back beyond the pre ceding logging time, the previously logged

date will be written ove r with new data as the logging proceeds.

7ML19985AB01 OCM III 34

Page 35

The daily total will be increased proportional to the amount of time the day was

lengthened.

Adjusting the Date

If the calenda r is reset, the OCM-3 will adjust the log date s accordingly, ta king into

account le ap years and days per month.

EMULATION MODE

The flow calculation (P3/P 4) can be checked for accura cy by using the e mulation

paramete r F1 . The head is entered a nd the corresponding flow is displayed. This

function is useful whe n troubleshooting discrepancies be tween the OCM-3 calculation

and the expected flow.

Relays a ssigned to functions associa ted with the emulation para meter re spond to the

emulated flows.

The mA output does not track the emulated flows whe n P2 8 (mA output emulation) =

0. Howe ver, if it is required to do so, then the e mulator pa rameter should be set to 1.

RESET

The following rese ts can only be executed after satisfying the se curity access, F0 .

Cold Start

If it is de sired to rese t all para meters, logs and totalizers to their fa ctory setting, this is

done by forcing a cold start, F12.

Master Totalizer

If it is de sired to rese t the maste r totalize r (F2), this is done by para meter F 11.

Data Log

If it is de sired to rese t the data log (F14) , this is done by pa rameter F15.

Min/Max Log

If it is de sired to rese t the min/ma x log (F7 ), this is done by parameter F8.

7ML19985AB01 OCM III 35

Page 36

FLOW VELOCITY INPUT

In some applications, the flow calculation for the chosen primary element requires a

velocity input. In this type of application, the transducer measureme nt is used to

calculate the cross sectional area of the flow. By multiplying the area with the distance

per time units of velocity, the volume per time units of flow are calculated. The

calculated velocity ca n be viewed via D8 .

The 0% and 100% limits of the velocity input must be scaled using parameters

P8 and P9.

» se lect P8

» enter the voltage corresponding to z ero velocity

» se lect P9

» enter the velocity corresponding to 5 V

e. g. If the velocity sensor output is 1 V per m/ sec and the output is

scaled for 7 V at 100% velocity (7 m/sec), then enter 5 m/sec. If the

output is scaled for 4 V at 100% velocity (4 m/sec), enter 5 m/sec.

P8 and P9 can only be accesse d if P3 has been set for an option that requires the use

of a velocity input. The input voltage level can be viewed via D12.

Voltage Input

typical 1 - 5 V signal from

velocity sensor.

Signal must be positive with respect to ground.

Velocity Input

typical 4 - 20 mA signal from velocity sensor.

Add termina ting resistor.

e.g. 250 Ω for 1 - 5 V over 4 - 20 mA.

(additional to Basic Wiring)

Current Input

AUXILIARY HEAD INPUT

In some applications, the transducer input (T B1- 1/2 ) is not used to provide a signal for

head measureme nt. A typical exa mple of this is an application which is beyond the 3

m (10 ft) range of the OCM-3. In such a case, the he ad could be derive d from anothe r

Milltronics level monitor or other compa tible device.

The method of hea d determination is set by P42. The OCM -3 simply substitutes the

signal from the auxiliary device for the ultrasonic me asurement provided by the

transduce r. T he programming and consequent flow calculation are performed

as normal.

7ML19985AB01 OCM III 36

Page 37

The 0% and 100% limits of the auxiliary input must be scaled using parameters P4 3

and P44.

» se lect P4 3

» enter the voltage corresponding to zero he ad

» se lect P4 4

» enter the head corresponding to 5 V.

e. g. if the he ad output is 1 V per m and the output is sca led for 7 V at

100% head (7 m), then enter 5 m. If the output is scaled for 4 V at

100% head (4 m), enter 5 m.

P43 and P44 can only be a ccessed if P42 has bee n set for head de termination by an

auxiliary device. The input voltage level can be viewed via D1 3.

Voltage Input

typical 1 - 5 V signal from

auxiliary de vice.

Signal must be positive with respect to ground.

Auxiliary Input

typical 4 - 20 mA signal from a uxiliary device .

Add termina ting resistor.

e.g. 250 Ω for 1 - 5 V over 4 - 20 mA.

(additional to Basic Wiring)

Current Input

DC OUTPUT

The OCM-3 provides a 24 V DC output that ca n be used to supply powe r to a remote

customer device. The output is not isolate d from the DC rails that supply the OCM -3

electronics and no overload protection is provide d. As such, the output must not

operate beyond its specified ca pacity.

DIAGNOSTIC AIDS

D15 through D 18 are diagnostic aids to Milltronics service personnel when

troubleshooting system problems.

D18 also serves a s a performa nce indicator by displaying the number of valid echos

received a s a perce ntage of the number of pulses be ing fired by the transducer. A low

value indicates that a large proportion of the pulses fired are not producing valid

echos. In such insta nces, the transducer should be checked for prope r mounting and

aiming or the transducer wiring checked for excessive noise. If the va lue is zero,

shorted or ope ned transduce r wiring may be suspe ct.

7ML19985AB01 OCM III 37

Page 38

‘D’ PARAMETER LISTING

Refer to ‘Operation’ for details.

D0 head

D1 flow rate

D2 short total *

D3 maximum flow rate

D4 minimum flow rate

D5 temperature

D6 maximum tempe rature

D7 minimum tempera ture

D8 velocity

D9 nominal target range

D10 analog milliamps

D11 internal DC volts

D12 velocity volts

✧

✧

D13 auxiliary input volts

D14 tempe rature sensor ohms

D15 self- test checksum

D16 restarts

D17 exceptions

D18 valid echos per 100

*

security access required

✧

applicable to flow calculations requiring velocity sensor

7ML19985AB01 OCM III 39

Page 39

7ML19985AB01 OCM III 40

Page 40

‘F’ PARAMETER LISTING

Refer to ‘Operation’ for details.

F0 e nter security code

F1 e mulation mode

F2 run mode

F3 ke ypad to mA output

F4 show time

set time

F5 show da te

set da te

F6 software identification number

F7 vie w min/max da ta

F8 re set min/max data

F9 se lf check

F10 change security code

F11 reset master totalizer

F12 force a cold sta rt

F13 auto zero calibration

*

*

*

*

*

*

*

*

*

*

F14 examine da ta log:

task: vie w daily totals

view flow rates

view min/ma x data

method:

first day

last day

specified day

F15 clear data log

*

*

security access required

7ML19985AB01 OCM III 41

Page 41

7ML19985AB01 OCM III 42

Page 42

‘P’ PARAMETER LISTING

Refer to ‘Operation’ for details.

P0 langua ge

0 = english

1 = french

2 = italian

3 = german

4 = spanish

P1 dimensiona l units

linear velocity

0 = centimetres centimetres per second

1 = inches inches per second

2 = feet feet per second

3 = metres metres per second

P2 temperature units

0 = Celcius

1 = Fa hrenheit

P3 primary element

0 = expone ntial device

1 = BS-3680 Rectangular Flume

2 = BS-3680 Round Nose Horizontal Crest Weir

3 = BS-3680 Trapezoidal Flume

4 = BS-3680 U-throated Flume

5 = BS-3680 Finite Crest Weir

6 = BS-3680 Thin Plate Rectangula r Weir

7 = BS-3680 Thin Plate V-notch Weir

8 = Re ctangular Weir ( contracted)

9 = Round Pipe

10 = Palmer Bowlus Flume

11 = H Flume

12 = Universal Head vs. Flow

7ML19985AB01 OCM III 43

Page 43

13 = R ectangular Area x Velocity

14 = Trapezoidal Area

15 = Modified Trapezoidal Area

16 = U-channel Area

17 = Circular Area

18 = Gull-wing Area

19 = Egg-shaped Area

20 = Universal Area

P4 method of calculation

0 = absolute

1 = ratiometric

P5 flow rate units

x

Velocity

x

Velocity

x

Velocity

x

x

Velocity

x

Velocity

Velocity

Velocity

x

flowrate

0 = litres per second litres

1 = cubic feet pe r second cubic feet

2 = imperial gallons pe r minute imperial gallons

3 = U. S. gallons per minute U.S. gallons

4 = imperial million gallons per day imperial million gallons

5 = U. S. million gallons per da y U.S. million gallons

6 = cubic metres per hour cubic metre s

7 = cubic metres per day cubic metre s

P6 flow at maximum head

P7 height of maximum he ad

P8 volts in at zero ve locity

P9 velocity at 5 volts in

volume

P10 velocity at maximum flow

7ML19985AB01 OCM III 44

Page 44

P13 display damping

0 = off

1 = low

2 = med

3 = high

P14 display lighting

0 = on

1 = auto off

2 = off

P15 / P18 / P21 relay 1 / 2 / 3 assignment

0 = not in service

1 = de- energize on loss of echo

2 = ene rgize on loss of echo

3 = de- energize on high flow ra te

4 = ene rgize on high flow ra te

5 = de- energize on low flow rate

6 = ene rgize on low flow ra te

7 = de- energize on high he ad

8 = ene rgize on high head

9 = de- energize on low he ad

10 = energize on low head

11 = de -energize on high velocity

12 = e nergize on high velocity

13 = de -energize on low velocity

14 = energize on low velocity

15 = de -energize on high analog

16 = e nergize on high ana log

17 = de-energize on low analog

18 = energize on low analog

19 = de-energize on low D11 volts

20 = energize on low D11 volts

21 = de -energize on high D11 volts

22 = e nergize on high D1 1 volts

23 = de -energize on low Aux. volts

7ML19985AB01 OCM III 45

Page 45

24 = energize on low Aux. volts

25 = de -energize on high Aux. volts

26 = e nergize on high Aux. volts

27 = de -energize up control on head

28 = e nergize up control on head

29 = de -energize down control on head

30 = e nergize down control on head

31 = de -energize up control on analog

32 = e nergize up control on analog

33 = de -energize down control on analog

34 = e nergize down control on analog

35 = ( pulse ) flow totaliz er

36 = ( pulse ) sample r by volume

37 = ( pulse ) sampler by time

38 = ( pulse ) by time of day

P16 / P19 / P22 relay 1 / 2 / 3 high setpoint

P17 / P20 / P23 relay 1 / 2 / 3 low setpoint

P24 mA a ssignment

0 = flow rate

1 = head

2 = velocity

3 = temperature

P25 If custom mA, 20 mA = ?

0 = normal

0 = custom

P26 mA span

0 = 4-20 mA

1 = 0-20 mA

7ML19985AB01 OCM III 46

Page 46

P27 mA damping (secs)

P28 mA options ( emulator tra cking)

0 = don’t track emulator

1 = track emulator

P29 fail-safe time (secs)

P30 fail-safe analog mode

0 = hold last value

1 = assume value in P3 1

P31 fail-safe analog mA (default value)

P32 totalizer multiplier

0 = x 1/1000 (0.001)

1 = x 1/100 (0.01)

2 = x 1/ 10 (0.1)

3 = x 1

4 = x 10

5 = x 100

6 = x 1000

P33 flow ra te display (decima l point)

0 = no decimal places

1 = 1

2 = 2

3 = 3

4 = 4

7ML19985AB01 OCM III 47

Page 47

P34 printe r mode

0 = neve r print

1 = interval to be in minutes

2 = interva l to be in hours

3 = print once each day

P35 printe r timing

P36 measurement interval

0 = 1 sec

1 = 15 sec

2 = 30 sec

3 = 1 min

4 = 5 min

P37 serial data rate

0 = 300 baud

1 = 600

2 = 1200

3 = 2400

4 = 4800

5 = 9600

6 = 19200

P38 site number

7ML19985AB01 OCM III 48

Page 48

P39 da ta logging rate

fixed

0 = 1 min 3 = 30

1 = 5 4 = 60

2 = 15 5 = 24 hr

6 = 15/1 min (

% flow / min

(

condition

) 19 = 60 / 1 (

)

flow

varia ble

7 = 15 / 5 " 20 = 60 / 5 "

8 = 30 / 1 " 21 = 24 hr / 1 min "

9 = 30 / 5 " 22 = 24 hr / 5 min "

10 = 60 / 1 " 23 = 24 hr / 15 min "

11 = 60 / 5 " 24 = 15 / 1 min (

head

12 = 24 hr / 1 min " 25 = 15 / 5 "

13 = 24 hr / 5 min " 26 = 30 / 1 "

14 = 24 hr / 15 min " 27 = 30 / 5 "

) 28 = 60 / 1 "

15 = 15 / 1 min (

flow

16 = 15 / 5 " 29 = 60 / 5 "

17 = 30 / 1 " 30 = 24 hr / 1 min "

18 = 30 / 5 " 31 = 24 hr / 5 min "

32 = 24 hr / 15 min "

)

)

P40 log rapid setpoint

P39 va riable logging condition units

% flow / min % change of maximum flow per minute

flow % of ma ximum flow

head % of maximum head

P41 log normal setpoint

P39 va riable logging condition units

% flow / min % change of maximum flow per minute

flow % of ma ximum flow

head % of maximum head

7ML19985AB01 OCM III 49

Page 49

P42 head determination

0 = by OCM-3

1 = by auxiliary de vice

P43 volts in for zero head

P44 head at 5 volts in

P45 low flow cut-off head

P46 range at zero head

P47 blanking distance

7ML19985AB01 OCM III 50

Page 50

‘U’ PARAMETERS FOR P3 PRIMARY ELEMENT

The number of ‘U’ parame ters required varie s according to the primary element

chosen (P3 ) and the method of calculation (P4). The OC M-3 prompts the use r by

displaying the next required parameter, insuring the programming is complete.

The following is a list of the specific primary elements to which the OCM-3 can

be applied.

Refer to the pa ge covering your pa rticular application; the re st may be disregarded.

P3 primary element

0 exponential device (e .g. proportional, V-notch, Pa rshall e tc)

1 BS-3680 Rectangular Flume (ISO 4359)

2 BS-3680 Round Nose Horizontal Cre st Weir (IS O 4374)

3 BS-3680 Trapezoidal Flume (ISO 4359)

4 BS-3680 U-throated Flume (ISO 4359)

5 BS-3680 Finite Crest Weir (ISO 3846)

6 BS-3680 Thin Plate Rectangular Weir (ISO 1438/1)

7 BS-3680 Thin Plate V Notch Weir (ISO 1438/1)

8 Rectangular W eir (contracted)

9 Round Pipe

10 Palmer-Bowlus Flume

11 H Flume

12 Universal Head vs. Flow

13 Rectangula r Area

14 Trapezoidal Area

15 Modified Trapezoidal Area

16 U-channel Area

Velocity

x

Velocity

x

Velocity

x

Velocity

x

7ML19985AB01 OCM III 51

Page 51

17 Circular Area

x Velocity

18 Gull Wing Area

19 Egg-shaped Area

20 Universal Area

x Velocity

x Velocity

x Velocity

The primary element must be installed in accordance with the manufacturers

recommendations and in accorda nce with all governing regulations.

7ML19985AB01 OCM III 52

Page 52

SIMPLE EXPONENTIAL DEVICES, P3 = 0

‘U’ parameters required *

U0 = exponent

U1 = k factor (P4 = 0 only)

Typical Exponential D evices:

» Sutro (proportiona l) we ir

» head measurement only

» Recta ngular ( suppresse d) or Trapezoidal (Cipolletti) weir

» Kahfagi venturi

» Parshall flume

» Leopold Lagco

» Triangular (V -notch) weir

*

obtain from manufacture r’s specifications.

Reference

ABSOLUTE CALCULATION, P4 = 0¤

For flows tha t can be calculated by the equation:

x

q = k h

where q = flowra te x = exponent (U0)

k = consta nt factor (U 1) h = hea d

RATIOMETRIC CALCULATION, P4 = 1¤

For flows tha t can be calculated by the equation:

x

(h/h

q = q

cal

where q = flowrate q

)

cal

h = head h

= flowrate at maximum head

cal

= maximum head

cal

x = exponent (U0)

Refer to manufacturers spe cifications for the e xponent value.

¤

Refer to Operation \ Flow Calculation.

7ML19985AB01 OCM III 53

Page 53

SIMPLE EXPONENTIAL DEVICES, P3 = 0

TYPICAL SHARP-CRESTED WEIRS

transducer *

minimum

3 x h

max

Typical Weir Profiles

V - notch or Triangular

U 0 = 2.5

Tra pez oidal (Cipolletti)

U 0 = 1.5

Rectangular - suppressed

U 0 = 1.5

Sutro (Proportional)

U 0 = 1

(symmetrical or asymmetrical)

For rated flows under fre e flow conditions, the head is measured upstre am of the we ir

plate at a minimum distance of 3 times the maximum head (i.e. where the liquid

surface is not affecte d by drawdown).

* The transducer must be above the maximum head by at least the

blanking value, P47.

7ML19985AB01 OCM III 54

Page 54

SIMPLE EXPONENTIAL DEVICES, P3 = 0

KHAFAGI VENTURI

15 cm (6")

plan

transducer *

0

head

front

side

For rated flows under free flow conditions, the head is measured 15 cm (6 ") upstream

from the be ginning of the converging se ction.

* The transducer must be above the maximum head by at least the

blanking value, P47.

7ML19985AB01 OCM III 55

Page 55

SIMPLE EXPONENTIAL DEVICES, P3 = 0

TYPICAL PARSHALL FLUME

C

2/3 C

plan

0

head

transducer *

front

side

For rated flows under free flow conditions, the hea d is mea sured at 2/3 the length of

the conve rging section upstream of the beginning of the throat section.

* The transducer must be above the maximum head by at least the

blanking value, P47.

7ML19985AB01 OCM III 56

Page 56

SIMPLE EXPONENTIAL DEVICES, P3 = 0

TYPICAL LEOPOLD LAGCO

throat

Q

converging

point of measurement

plan

side

diverging

transducer *

0

head

front

For rated flows under fre e flow conditions, the head is measured a t a point upstrea m

refe renced to the beginning of the conve rging section. Refer to the following table.

Flume Size Point of Measurement

(pipe dia. in inches) mm inches

4 - 12 25 1.0

15 32 1.3

18 38 1.5

21 44 1.8

24 51 2.1

30 64 2.5

36 76 3.0

42 89 3.5

48 102 4.0

54 114 4.5

60 127 5.0

66 140 5.5

72 152 6.0

* The transducer must be above the maximum head by at least the

blanking value, P47.

7ML19985AB01 OCM III 57

Page 57

BS-3680 Rectangular Flume, P3 = 1

‘U’ parameters required * ‘U’ parameters calculated **

U0 = approach width B U4 = Cv

U1 = throat width b U5 = Cd

U2 = hump height p U6 = A

U3 = throat length L

*obtain from manufacturer’s specifications.

**

calculated by OCM -3. Ma y be viewed by accessing ‘U’ para meter.

Reference

ABSOLUTE CALCULATION, P4 = 0¤

For flows tha t can be calculated by the equation:

1.5

q = (2/3)

0.5

x g

x Cv x C s x Cd x B x h

where : q = flow rate Cv = velocity coefficie nt

b = throat width Cs = shape coefficient

g = gravitationa l acce leration Cd = discharge coefficient

h = head

1.5

RATIOMETRIC CALCULATION, P4 = 1¤

For flows tha t can be calculated by the equation:

q = q

x Cd/Cd

cal

x Cv/Cv

cal

cal

x (h/h

1.5

)

cal

where : q = flow rate

q

= flow rate at maximum head

cal

h = head

h

= maximum head

cal

Cv = velocity coefficient

Cv

= velocity coefficient for ma ximum head

cal

Cd = discharge coefficient for head

Cd

= discharge coe fficient for maximum head

cal

¤

Refer to Operation \ Flow Calculation.

7ML19985AB01 OCM III 58

Page 58

BS-3680 RECTANGULAR FLUME

3 to 4 x h

max

L

transducer *

0

head

h

p

* The transducer must be above the maximum head by at least the

blanking value, P47.

7ML19985AB01 OCM III 59

Page 59

BS-3680 Round Nose Horizontal Crest Weir, P3 = 2

‘U’ parameters required * ‘U’ parameters calculated **

U0 = crest width b U3 = Cv

U1 = crest height p U4 = Cd

U2 = crest length L U5 = A

*

obtain from manufacture r’s specifications.

**

calculated by OCM -3. Ma y be viewed by accessing ‘U’ para meter.

Reference

ABSOLUTE CALCULATION, P4 = 0¤

For flows tha t can be calculated by the equation:

1.5

q = (2/3)

0.5

x g

x Cv x Cs x Cd x b x h

where : q = flow ra te Cv = ve locity coefficient

g = gravitational acceleration Cs = shape coefficient

b = throa t width Cd = discharge coe fficient

h = head

1.5

RATIOMETRIC CALCULATION, P4 = 1¤

For flows tha t can be calculated by the equation:

q = q

x Cd/Cd

cal

x Cv/Cv

cal

cal

x (h/h

1.5

)

cal

where : q = flow rate

q

= flow rate at maximum head

cal

h = head

h

= maximum head

cal

Cv = velocity coefficient

Cv

= velocity coefficient for ma ximum head

cal

Cd = discharge coefficient for head

Cd

= discharge coe fficient for maximum head

cal

¤

Refer to Operation \ Flow Calculation.

7ML19985AB01 OCM III 60

Page 60

BS-3680 ROUND NOSE HORIZONTAL CREST WEIR

transducer *

3 to 4 x h

max

* The transducer must be above the maximum head by at least the

blanking value, P47.

7ML19985AB01 OCM III 61

Page 61

BS-3680 TRAPEZOIDAL FLUME, P3 = 3

‘U’ parameters required * ‘U’ parameters calculated **

U0 = approach width B U5 = Cv

U1 = throat width b U6 = Cd

U2 = hump height p U7 = Cs

U3 = throat length L U8 = A

U4 = slope m

*obtain from manufacturer’s specifications.

**

calculated by OCM -3. Ma y be viewed by accessing ‘U’ para meter.

Reference

ABSOLUTE CALCULATION, P4 = 0¤

For flows tha t can be calculated by the equation:

1.5

q = (2/3)

0.5

x g

x Cv x Cs x Cd x b x h

where : q = flow rate Cv = velocity coefficie nt

g = gravitational acceleration Cs = shape coefficient

b = throa t width Cd = discharge coe fficient

h = head

1.5

RATIOMETRIC CALCULATION, P4 = 1¤

For flows tha t can be calculated by the equation:

q = q

x Cs/Cs

cal

x Cd/Cdal x Cv/Cv

cal

x (h/h

cal

1.5

)

cal

where :

q = flow ra te Cs

q

= flow rate at maximum hea d Cv = velocity coefficient

cal

h = head Cv

h

= maximum head Cd = discharge coefficient for head

cal

Cs = shape coefficient for head Cd

¤

Refer to Operation \ Flow Calculation.

= shape coefficient for maximum head

cal

= velocity coefficient for ma ximum head

cal

= discharge coe fficient for maximum head

cal

7ML19985AB01 OCM III 62

Page 62

BS-3680 TRAPEZOIDAL FLUME

p

transducer *

b

end

B

plan

3 to 4 x h

h

max

p

L

side

* The transducer must be above the maximum head by at least the

blanking value, P47.

7ML19985AB01 OCM III 63

Page 63

BS-3680 U-Flume, P3 = 4

‘U’ parameters required * ‘U’ parameters calculated **

U0 = approach diameter Da U4 = Cv

U1 = throat diameter D U5 = Cd

U2 = hump height p U6 = Cu

U3 = throat length L U7 = A

*

obtain from manufacture r’s specifications.

**

calculated by OCM -3. Ma y be viewed by accessing ‘U’ para meter.

Reference

ABSOLUTE CALCULATION, P4 = 0¤

For flows tha t can be calculated by the equation:

1.5

q = (2/3)

0.5

x g

x Cv x Cu x Cd x D x h

where : q = flow rate Cv = velocity coefficie nt

g = gravitational acceleration Cu = shape coefficient

b = throa t width Cd = discharge coe fficient

h = head

1.5

RATIOMETRIC CALCULATION, P4 = 1¤

For flows tha t can be calculated by the equation:

q = q

x Cu/Cu

cal

x Cd/Cd

cal

x Cv/Cv

cal

cal

x (h/h

1.5

)

cal

where : q = flow rate

q

= flow rate at maximum head

cal

h = head

h

= maximum head

cal

Cu = shape coefficient for head

Cu

= shape coefficient for maximum head

cal

Cv = velocity coefficient

Cv

= velocity coefficient for ma ximum head

cal

Cd = discharge coefficient for head

Cd

= discharge coe fficient for maximum head

cal

¤

Refer to Operation \ Flow Calculation.

7ML19985AB01 OCM III 64

Page 64

BS-3680 U-FLUME

3 to 4 x h

max

L

D

Da

transducer *

0

head

h

p

* The transducer must be above the maximum head by at least the

blanking value, P47.

7ML19985AB01 OCM III 65

Page 65

BS-3680 FINITE CREST WEIR, P3 = 5

‘U’ parameters required * ‘U’ parameters calculated **

U0 = crest width b U3 = C

U1 = crest height p U4 = Cp

U2 = crest length L

*

obtain from manufacture r’s specifications.

**

calculated by OCM -3. Ma y be viewed by accessing ‘U’ para meter.

Reference

ABSOLUTE CALCULATION, P4 = 0¤

For flows tha t can be calculated by the equation:

1.5

q = (2/3)

0.5

x g

x C x Cp x b x h

1.5

where : q = flow rate C = a function of h and L

g = gravitational acce leration

b = crest width Cp = a correction factor a s a function

h = head of h and p applied to C

RATIOMETRIC CALCULATION, P4 = 1¤

For flows tha t can be calculated by the equation:

q = q

cal

x C/C

x Cp/Cp

cal

x (h/h

cal

1.5

)

cal

where : q = flow rate

q

= flow rate at maximum head

cal

h = head

h

= maximum head

cal

C = discharge coefficient for head

C

= discharge coe fficient for maximum head

cal

Cp = correction factor for C

Cp

= correction factor for C

cal

¤

Refer to Operation \ Flow Calculation.

cal

7ML19985AB01 OCM III 66

Page 66

BS-3680 FINITE CREST WEIR

transducer *

3 to 4 x h

max

* The transducer must be above the maximum head by at least the

blanking value, P47.

7ML19985AB01 OCM III 67

Page 67

BS-3680 THIN PLATE RECTANGULAR WEIR, P3 = 6

‘U’ parameters required * ‘U’ parameters calculated **

U0 = approach width B U3 = Ce

U1 = crest width b U4 = K

b

U2 = crest height p

*obtain from manufacturer’s specifications.

**

calculated by OCM -3. Ma y be viewed by accessing ‘U’ para meter.

Reference

ABSOLUTE CALCULATION, P4 = 0¤

For flows tha t can be calculated by the equation:

= Ce x

2

√⎯⎯⎯2g x be x (

⁄

3

q

where : q = flow rate Ce = a function of h, p, b and B

g = gravitationa l acce leration be = effective crest width ( b + K

b = crest width h

h = head K

RATIOMETRIC CALCULATION, P4 = 1¤

For flows tha t can be calculated by the equation:

q = q

x Ce/Ce

cal

cal

x (h/h

1.5

h

)

e

= effective head (h + Kh)

e

= 1 mm

h

1.5

)

cal

)

b

where : q = flow rate

q

= flow rate at maximum head

cal

h = head

h

= maximum head

cal

Ce = discharge coefficient for head

Cv

= discharge coe fficient for maximum head

cal

¤

Refer to Operation \ Flow Calculation.

7ML19985AB01 OCM III 68

Page 68

BS-3680 THIN PLATE RECTANGULAR WEIR

transducer *

4 to 5 x h

max

* The transducer must be above the maximum head by at least the

blanking value, P47.

7ML19985AB01 OCM III 69

Page 69

BS-3680 THIN PLATE V-NOTCH WEIR, P3 = 7

‘U’ parameters required * ‘U’ parameters calculated **

U0 = notch angle alpha U1 = Ce

*

obtain from manufacture r’s specifications.

**

calculated by OCM -3. Ma y be viewed by accessing ‘U’ para meter.

Reference

ABSOLUTE CALCULATION, P4 = 0¤

For flows tha t can be calculated by the equation:

0.5

q = Ce x 8/15 x tan(

/2) x (2g)

α

where : q = flow rate h = head

g = gravitational acce leration C e = function of h and

= notch a ngle alpha

α

◊

angle is restricted to 90°, 53.133° or 28.066°. Otherwise use ratiometric calculation.

x h

◊

2.5

α

RATIOMETRIC CALCULATION, P4 = 1¤

For flows tha t can be calculated by the equation:

q = q

x Ce/Ce

cal

cal

x (h/h

2.5

)

cal

where : q = flow rate

q

= flow rate at maximum head

cal

h = head

h

= maximum head

cal

Ce = discharge coefficient for head

Ce

= discharge coe fficient for maximum head

cal

¤

Refer to Operation \ Flow Calculation.

7ML19985AB01 OCM III 70

Page 70

BS-3680 THIN PLATE V-NOTCH WEIR

transducer *

4 to 5 x h

max

* The transducer must be above the maximum head by at least the

blanking value, P47.

7ML19985AB01 OCM III 71

Page 71

RECTANGULAR WEIR (CONTRACTED), P3 = 8

‘U’ parameters required *

U0 = crest width b

*

obtain from manufacture r’s specifications.

**

calculated by OCM -3. Ma y be viewed by accessing ‘U’ para meter.

Reference

ABSOLUTE CALCULATION, P4 = 0¤

For flows tha t can be calculated by the equation:

q = K x (b - 0.2h) x h

where : q = flow rate

h = head

K = consta nt

RATIOMETRIC CALCULATION, P4 = 1¤

For flows tha t can be calculated by the equation:

q = q

x (b - 0.2h)/(b - 0.2h

cal

1.5

) x (h/h

cal

2.5

)

cal

where : q = flow rate

q

= flow rate at maximum head

cal

h = head

h

= maximum head

cal

¤

Refer to Operation \ Flow Calculation.

7ML19985AB01 OCM III 72

Page 72

RECTANGULAR WEIR - CONTRACTED

transducer *

4 to 5 x h

max

* The transducer must be above the maximum head by at least the

blanking value, P47.

7ML19985AB01 OCM III 73

Page 73

ROUND PIPE, P3 = 9

(based on the Manning Formula)

‘U’ parameters required *

U0 = pipe inside diameter D

U1 = slope (fall/run) s

U2 = roughness coefficient n

*obtain from manufacturer’s specifications.

Reference

ABSOLUTE CALCULATION, P4 = 0¤

For flows tha t can be calculated by the equation:

q = K/n x f(h) x s

where : q = flow rate

0.5

h = head

K = consta nt

f(h) = A x R

0.66

A = cross se ctional are a

R = hydraulic ra dius

s = slope of hydraulic gradient

n = roughness coefficient

RATIOMETRIC CALCULATION, P4 = 1¤

For flows tha t can be calculated by the equation:

q = q

x f(h)/f( h

cal

)

cal

where : q = flow rate h = head

q

= flow rate at maximum head h

cal

¤

Refer to Operation \ Flow Calculation.

= maximum head

cal

7ML19985AB01 OCM III 74

Page 74

ROUND PIPE

transducer

*

**

h

* This dimension should be at least 15 cm ( 6") shorter tha n

the blanking value, P47.

** The transducer must be above the maximum head by at least the

blanking value, P47.

7ML19985AB01 OCM III 75

Page 75

PALMER-BOWLUS FLUME *, P3 = 10

‘U’ parameters required **

U0 = maximum flume width, h

*

typically those manufactured by Warminste r or Pla sti-Fab.

**

obtain from manufacture r’s specifications.

max

Reference

RATIOMETRIC CALCULATION, P4 = 1¤

For flows tha t can be calculated by the equation:

q = q

x f(h/h

cal

max)

/ f(h

cal/hmax

)

where : q = flow rate

q

= flow rate at maximum head

cal

h = head

h

= maximum head

cal

f(h/ h

) is determine d by polynomial synthesis

max

¤

Refer to Operation \ Flow Calculation.

7ML19985AB01 OCM III 76

Page 76

PALMER-BOWLUS FLUME

D / 2, point of mea sureme nt *

0

head

D = pipe or sewer dia mete r

* for ra ted flows under free flow conditions

** The transducer must be above the maximum head by at least the

blanking value, P47.

transducer **

7ML19985AB01 OCM III 77

Page 77

H-FLUME *, P3 = 11

‘U’ parameters required *

U0 = maximum listed head, h

*

as developed by the U.S. Departme nt of Agriculture, Soil Conserva tion Se rvice.

**

obtain from manufacture r’s specifications.

max

Reference

RATIOMETRIC CALCULATION, P4 = 1¤

For flows tha t can be calculated by the equation:

q = q

x f(h/h

cal

max

)/f(h

cal/hmax

)

where : q = flow rate

q

= flow rate at maximum head

cal

f(h/ h

) and f(h

max

¤

Refer to Operation \ Flow Calculation.

) a re determined by polynomia l synthesis

cal/hmax

7ML19985AB01 OCM III 78

Page 78

H-FLUME

transducer *

point of measurement

plan

front

side

For rated flows under free flow conditions, the head is me asured at a point downstream

from the flume entrance. Refer to the following table.

Flume Size Point of Measurement

D (feet) cm inches

0.5 4.7 1.88

0.75 6.7 2.69

1.0 9.1 3.63

1.5 13.5 5.38

2.0 17.9 7.19

2.5 22.5 9.00

3.0 27.2 10.88

4.5 40.5 16.19

* The transducer must be above the maximum head by at least the

blanking value, P47.

7ML19985AB01 OCM III 79

Page 79

UNIVERSAL HEAD vs FLOW, P3 = 12

The flow curve is characterized by entering the head (A

) and flow (A

even

odd

)

ordinates for the number of data points (n, 4 to 16) over the flow range. The first

point (A0,A1) ge nera lly being a t 0 he ad and the last point (A

2n-2,A2n-1

) genera lly being

at maximum head .

‘U’ parameters required *

U0 = number of data points

= head

A

even

A

= flow rate

odd

*

obtain from manufacture r’s specifications.

Reference

RATIOMETRIC CALCULATION, P4 = 1¤

For flows tha t can be calculated by the equation:

q = q

x f(h)/f( h

cal

where : f(h) and f(h

)

cal

) are polynomials based on interpolation of data points

cal

(n, 4 to 16)

¤

Refer to Operation \ Flow Calculation.

7ML19985AB01 OCM III 80

Page 80

UNIVERSAL HEAD vs FLOW

e. g. typica l compound weir

Parame ters

U0 = 11

A0 = 0 head, point 1 A12 = 1.05 head, point 7

A1 = 0 flow, point 1 A13 = 2. 65 flow, point 7

A2 = 0.3 head, point 2 A14 = 1.2 head, point 8

A3 = 0. 1 flow, point 2 A15 = 3.4 flow, point 8

A4 = 0.6 head, point 3 A16 = 1.4 head, point 9

A5 = 0. 7 flow, point 3 A17 = 5.0 flow, point 9

A6 = 0.8 head, point 4 A18 = 1.7 head, point 10

A7 = 1. 5 flow, point 4 A19 = 8.0 flow, point 10

A8 = 0.95 head, point 5 A20 = 2 head, point 11

A9 = 2. 25 flow, point 5 A21 = 11 .8 flow, point 11

A10 = 1 head, point 6