Siemens MXG461B Series, MXG461B15-0.6, MXG461B15-3, MXG461B15-1.5, MXG461B25-8 Technical Instructions

...Page 1

Siemens Industry, Inc.

MXG461B Series

Technical Instructions

Document No. 125-4461

October 23, 2018

Modulating Control Valves with

Magnetic Actuators, Positioning

Control and Position Feedback for

Domestic Water

Description

Control valves with magnetic actuators, for modulating control of domestic water, cold

water and hot water systems.

Features

• Fast positioning time (< 2 seconds)

• Selectable valve characteristic: Equal percentage or linear

• Selectable standard interface: 0/2 to 10 Vdc or 0/4 to 20 mA

• High resolution (>1:1000)

• High rangeability

• Wear-free inductive stroke measurement

• Spring return A → AB closed when de-energized

• Positioning control and position feedback signal

• Low-friction, heavy-duty and maintenance-free

• Accepts 0 to 20 Vdc phase-cut control signal input

Product Numbers

See Table 1.

Warning/Caution

Notations

WARNING:

Personal injury or loss of life may occur if you do not

follow the procedures as specified.

CAUTION:

Equipment damage or loss of data may occur if you

do not follow the procedures as specified.

Page 2

Technical Instructions MXG461B Series Modulating Control Valve

Document Number 125-4461 with Magnetic Actuator

October 23, 2018

Page 2 Siemens Industry, Inc.

Application

The MX4G61B Series valves are through-port or mixing valves with magnetic

actuators. The actuator is equipped with an electronics module for positioning control

and position feedback. If the power is off, the valve control path A → AB is closed.

The short positioning time, high resolution and high rangeability make these valves

ideal for modulating control of domestic, hot and cold-water systems.

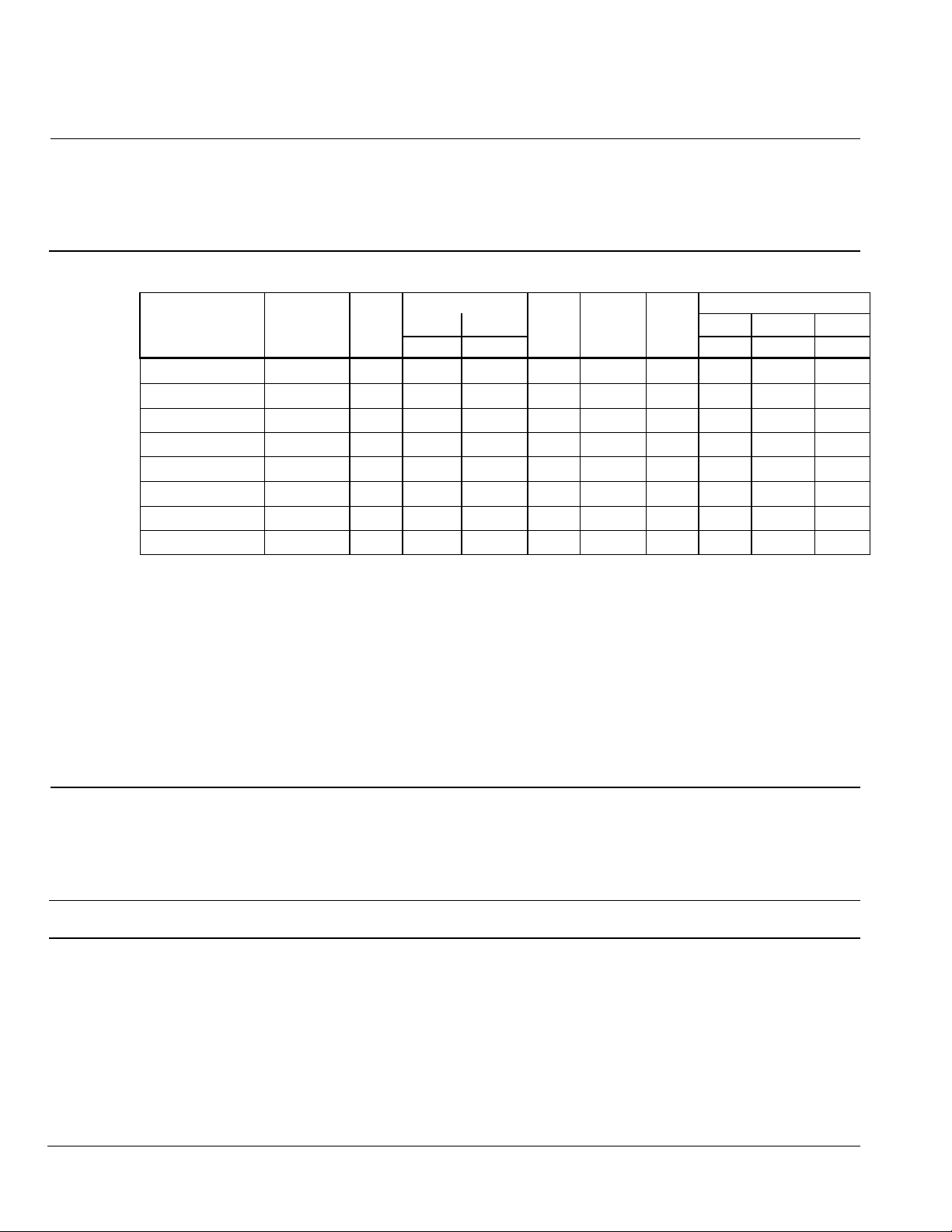

Table 1. Product Numbers.

Product

Number

Wire Gauge (AWG)

Line Size

Cv

ps

p

max

SNA

Pmed

IN

16

14

12

(in)

(psi)

(psi)

(VA)

(W)

Fuse

L (ft)

MXG461B15-0.6

1/2

0.7

145

70

33

15

3.15

130

215

360

MXG461B15-1.5

1/2

1.8

145

70

33

15

3.15

130

215

360

MXG461B15-3

1/2

3.5

145

70

33

15

3.15

130

215

360

MXG461B20-5

3/4

5.8

116

70

33

15

3.15

130

215

360

MXG461B25-8

1

9.3

102

40

33

15

3.15

130

215

360

MXG461B32-12

1-1/4

14

87

40

43

20

4

100

165

260

MXG461B40-20

1-1/2

23

87

40

43

20

4

100

165

260

MXG461B50-30

2

35

87

40

65

22

6.3

65

100

185

Key:

p

max

= Maximum permissible differential pressure across the valve's control path,

valid for the entire actuating range of the motorized valve (maximum

recommended operating differential pressure).

ps = Maximum permissible differential pressure at which the motorized valve will

close securely against the pressure (close-off pressure).

SNA = Nominal apparent power for selecting the transformer.

Pmed = Average true power.

IN = Slow fuse (mandatory).

Cv = Nominal flow rate of cold water [41°F to 86°F (5°C to 30°C)].

L = Maximum cable length. With four-wire connections the maximum

permissible length of the separate 14 AWG Cu signal cable is 656 feet

(200 m).

Ordering

• The valve body and magnetic actuator assemblies cannot be separated.

• The brass/bronze fittings are included.

• When placing an order, specify the quantity, product number and description.

Example: 1 MXG461B15-0.6 valve and 1 ASE12 Replacement Circuit Board

Accessory

ASE12 Replacement Circuit Board

Technical/

Mechanical Design

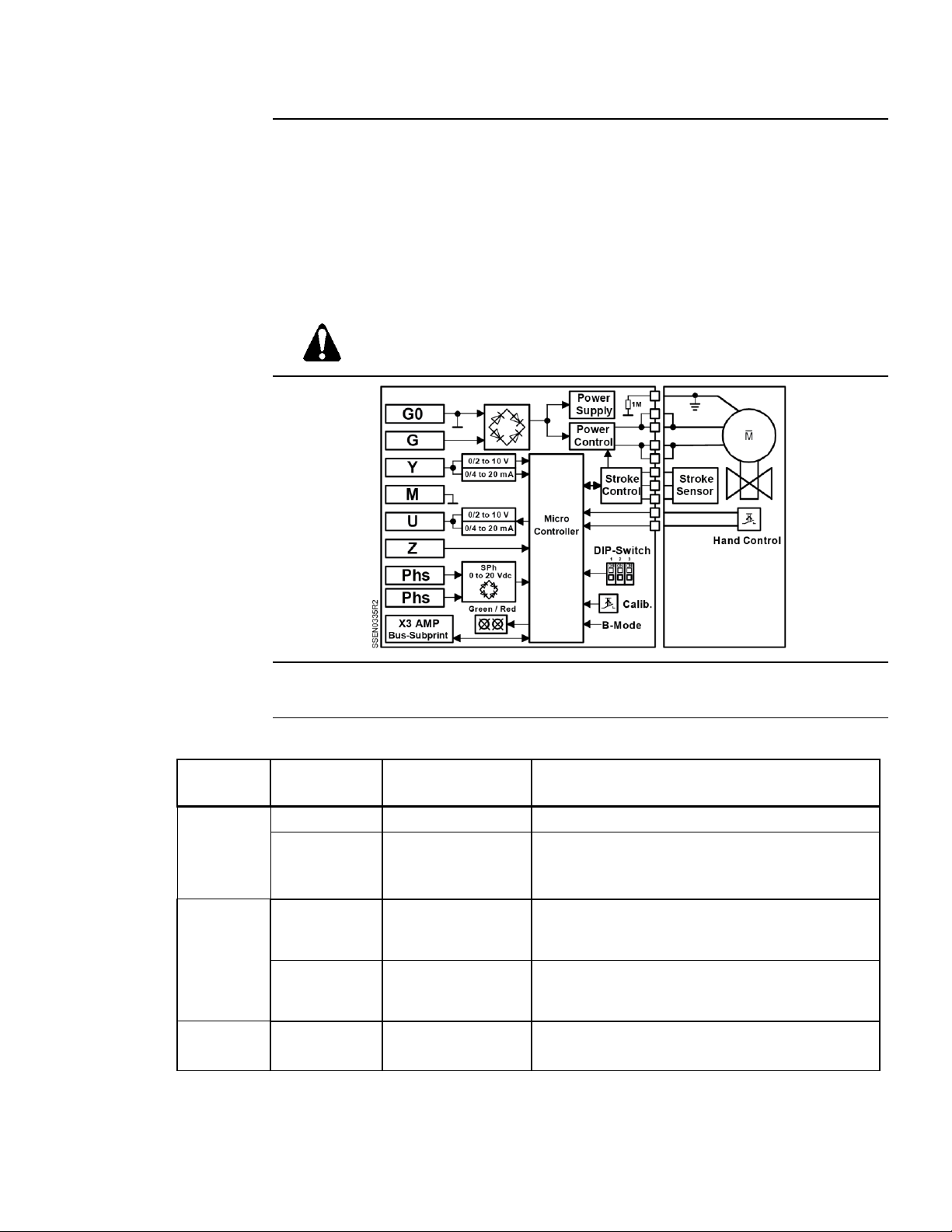

Operation Control

The electronics module converts the positioning signal to a phase-cut power signal,

which generates a magnetic field in the coil. This causes the armature to change its

position according to the interacting forces (magnetic field, counterspring, hydraulics,

etc.). The armature responds rapidly to any change in signal, transferring the

corresponding movement directly to the valve plug. This enables fast changes in load to

be corrected quickly and accurately.

The valve’s position is measured continuously. Any disturbance in the system is rapidly

corrected by the internal positioning controller, which ensures that the positioning signal

and the valve stroke are exactly proportional, and also delivers the position feedback

signal.

Page 3

MXG461B Series Modulating Control Valve Technical Instructions

with Magnetic Actuator Document Number 125-4461

October 23, 2018

Siemens Industry, Inc. Page 3

Control

The magnetic actuator can be driven by any controller with a 0/2 to 10 Vdc or 0/4 to

20 mA output signal.

To achieve optimum control performance, it is recommended to use a 4-wire connection

for the valve.

NOTE: When using a dc power supply a 4-wire connection is mandatory.

The controller’s signal ground terminal M must be connected to the valve’s terminal M.

Terminals M and G0 have the same potential and are internally interconnected in the

valve’s electronics.

CAUTION:

You must use a four-wire connection with Vdc power supply.

Basic Diagram

Spring Return Action

If the power or positioning signal is switched off or fails, the valve control path

(port A → AB) is automatically closed by the force of the spring.

Table 2. Indication of Operating State.

LED

Indication

Operating State,

Function

Remarks, Troubleshooting

Green

Lit

Control mode

Normal operation; everything OK.

Flashing

Calibration

In manual control

Wait until calibration is finished

(green or red LED will be lit).

Hand wheel in Man or Off position.

Red

Lit

Calibration error

Internal error

Recalibrate (bridge contacts behind the

calibration slot).

Replace electronics module.

Flashing

Mains fault

DC Supply -/+

Check electric main network (outside the

frequency or voltage range);

Vdc supply +/- connection polarity.

Both

Dark

No power supply

Electronics faulty

Check electric main network, check wiring.

Replace electronics module.

Page 4

Technical Instructions MXG461B Series Modulating Control Valve

Document Number 125-4461 with Magnetic Actuator

October 23, 2018

Page 4 Siemens Industry, Inc.

Manual Adjustment

Press (a) and turn the hand wheel (b):

• clockwise (CW). Control path A → AB can be

mechanically opened to between 80% and 90%,

or

• counterclockwise (CCW). The actuator will be

switched off and the valve closed.

As soon as the hand wheel is pressed and turned,

neither the forced control signal Z, the input signal

Y, nor the phase-cut signal acts on the actuator.

The green LED will flash.

For automatic control, the hand wheel must be set

to the Auto position. The green LED will be lit.

Figure 1.

Calibration

If the electronics module is replaced or the actuator turned

through 180°, the valve’s electronics must be recalibrated. To

recalibrate, the hand wheel must be set to Auto.

The printed circuit board has a slot (see Figure 2). Calibrate by

bridging the contacts located behind the slot on the printed

circuit board, using a screwdriver. The valve will then travel

across the full stroke to store the end positions.

While calibration is in progress, the green LED will flash for

about 10 seconds (see Indication of Operating State).

Figure 2.

DIP Switches

Figure 3. Configuration DIP Switches.

DIP

Function

OFF (Default)

ON

Remarks

1

ON

OFF

Voltage or current

input

[ V ]

[ mA ]

Assignment of

terminal Y:

Voltage or current

2

ON

OFF

Correcting span

Terminals Y and U

0 to 10 Vdc,

0 to 20 mA

2 to 10 Vdc,

4 to 20 mA

Offset settings of input

and output

3

ON

OFF

Characteristic

V

log

(equal

percentage)

V

lin

(linear)

–

Page 5

MXG461B Series Modulating Control Valve Technical Instructions

with Magnetic Actuator Document Number 125-4461

October 23, 2018

Siemens Industry, Inc. Page 5

DIP Switches, Continued

Figure 4. Assignment of Positioning

Signal Y: Voltage or Current.

.

Figure 5. Selection of Valve

Characteristic: Equal-Percentage or

Linear.

Figure 6. Assignment of Correcting

Span Y and U: 0 to 10 Vdc/0 to 20 mA or

2 to 10 Vdc/4 to 20 mA.

Output signal U (position feedback signal)

is dependent on the load resistance.

Above 500 ohm, it is automatically a

voltage signal; below 500 ohm a current

signal.

Forced Control Input

Transfer

Connections

Figure 7.

If terminal Z for the forced control input is:

− not connected, the valve will follow the Y-signal or the phase-cut signal.

− connected to G, the valve will fully open via control path A → AB.

− connected to G0, the valve will close via control path A → AB.

Signal Priority

1. Hand wheel position Man or Off

2. Forced control signal Z

3. Phase-cut signal

4. Signal input Y

Page 6

Technical Instructions MXG461B Series Modulating Control Valve

Document Number 125-4461 with Magnetic Actuator

October 23, 2018

Page 6 Siemens Industry, Inc.

Valve Sizing

Characteristic

Figure 8. Equal Percentage.

Figure 9. Linear.

Installation Notes

• Installation instructions for the valve and terminal housing are enclosed with the

valve.

• Valves are supplied complete with brass/bronze fittings.

• The screwed valves are flat-faced to facilitate sealing with the gaskets supplied.

The use of sealing compounds, tape or hemp thread is not recommended.

• For electrical installation, see Wiring Diagrams.

CAUTION:

• Always disconnect the power before fitting or removing the terminal

housing. The terminal housing is calibrated and matched to the

actuator and should be replaced only by qualified personnel.

• Use the valve only as a mixing or straight-through valve, not as a

diverting valve. Note the flow direction.

• Do not allow the surface temperature of the actuator to fall below the

dew point temperature of the surrounding air (causing condensation).

If necessary, insulate the valve. Do not insulate the actuator.

Use in Straight-through

Applications

Only three-way valves are supplied. These may

be used as straight-through valves by closing off

port B with the accessories supplied (nut, cover

and gasket).

Figure 10. Straight-through

Application.

Mounting Position

Vertical to horizontal mounting:

Do not mount the valve below the horizontal.

Figure 11. Acceptable Mounting

Positions.

Page 7

MXG461B Series Modulating Control Valve Technical Instructions

with Magnetic Actuator Document Number 125-4461

October 23, 2018

Siemens Industry, Inc. Page 7

Specification s

Electrical

Low-voltage use only Class 2 (SELV, PELV)

24 Vac

Operating voltage 24 Vac ± 20%

Frequency 45 to 65 Hz

Typical power consumption See Table 1 P

med

Standby <1 W (valve fully closed)

Nominal apparent power See Table 1, SNA

Suitable fuse Slow, see Table 1, IN

24 Vdc

Operating voltage 20 to 30 Vdc

Current draw 0.5A/4A (maximum)

Functional data, actuator

Input

Positioning signal Y 0/2 to 10 Vdc or 0/4 to 20 mA, or

0 to 20 Vdc Phs phase cut

Impedance 0/2 to 10Vdc 100K ohm//5nF (load < 0.1mA)

0/4 to 20 mA 240 ohm//5nF

Forced control

Impedance 22K ohm

Closing the valve (Z connected to G0) <1 Vac; <0.8 Vdc

Opening the valve (Z connected to G0) >6 Vac; >5 Vdc

No function (Z not wired) Phase-cut or positioning signal Y

active

Output

Position feedback signal U voltage 0/2 to 10 Vdc; load resistance > 500Ω

current 0/4 to 20 mA; load resistance < 500Ω

Stroke measurement Inductive

Nonlinearity +3% of end value

Functional data, valve

Nominal pressure ANSI 125 (PN 16)

Operating pressure p

e

max

1)

232 psi (16 bar)

Pressure differential p

v

max See Table 1

Leakage at A→ AB max. 0.05% Cv

p = 14.5 psi (1 bar) B→ AB < 0.2% Cv depending on

operating conditions

Permissible media Drinking water, cooling, cold and hot

water, water with anti-freeze

Water temperature –4°F to 266°F (–20°C to 130°C)

Valve characteristic 2) Equal percentage or linear, optimized

near the closing point

Resolution H/H100 1 : 1000 (H = Stroke)

Type of operation Modulating

Position when de-energized A → AB closed

Orientation: Upright to horizontal

Positioning time <2 seconds

Materials

Valve body Red bronze (CC499K)

Cover flange Red bronze (CC499K)

Seat/Inner valve Stainless Steel

Valve stem seal EPDM (O-ring)

1. Tested at 1.5 × PN (24 bar), similar to DIN 3230-3

2. Can be selected via DIP switch.

Page 8

Technical Instructions MXG461B Series Modulating Control Valve

Document Number 125-4461 with Magnetic Actuator

October 23, 2018

Page 8 Siemens Industry, Inc.

Specifications,

Continued

Pipe connections

Screwed fittings Bronze/brass

Electrical connections

Cable entries 2 × Ø 20.5 mm (for M20)

Connection terminals Screw terminals for up to 12 AWG wires

Min. cross-sectional area 1) 0.75 mm2

Max. cable length See Table 1, 9 (AWG)

Ambient conditions

Temperature

Operation and storage 23°F to 113°F (-5°C to 45°C)

Transport -13°F to 158°F (-25°C to 70°C)

Humidity 5 to 95% rh (non-condensing)

Agency approvals

Degree of protection IP31 to EN60529

Conforms to CE requirements CA2T4461.1

UL 873

Certified to Canadian standard C22.2 No. 24

C-Tick N-474

PED 2014/68/EU

DVGW-Reg.-Nr. DW-6340BR0230

(EU potable water standard)

Miscellaneous

Weight See Figure 15

Dimensions See Figure 15

Connection

Terminals

WARNING:

If the controller and the valve receive their power supply from separate

sources, the valve transformer must not be grounded on the secondary

side.

A four-wire connection is mandatory with DC power supply.

Controllers with:

0 to 10 Vdc

2 to 10 Vdc

0 to 20 mA

4 to 20 mA

Figure 12.

1. In case of strong vibrations, use high-flex stranded wires.

Page 9

MXG461B Series Modulating Control Valve Technical Instructions

with Magnetic Actuator Document Number 125-4461

October 23, 2018

Siemens Industry, Inc. Page 9

Connection

Terminals,

Continued

Controllers with phase-cut

0 to 20 Vdc

Figure 13.

Application

Examples

This example shows only a schematic diagram, without installation-specific details.

CAUTION:

1. Use the valve only as a mixing or straight-through valve, not a

diverting valve. Note the direction of flow.

2. Ensure that adequate air venting is provided for the entire hydronic

system.

3. Select a non-return valve with minimum pressure loss for the

circulating pipes.

Key :

A Mixing circuit

B Mixing circuit with bypass

(underfloor heating system)

C Injection circuit

D Diverting circuit

E Injection circuit with throughport valve

Figure 14.

Service

In case of strong vibrations, use high-flex stranded wires.

CAUTION:

Do not disassemble the valve and actuator combination. This assembly is

factory-calibrated and should only be replaced by qualified personnel.

• The low-friction and robust, maintenance-free design makes regular servicing

unnecessary and ensures a long service life.

• The valve stem is sealed from external influences by a maintenance-free gland.

• If the red LED is lit, the electronics must be recalibrated or replaced.

• If required, the circuit board can be replaced. Order part number ASE12.

Page 10

Technical Instructions MXG461B Series Modulating Control Valve

Document Number 125-4461 with Magnetic Actuator

October 23, 2018

Information in this publication is based on current specifications. The company reserves the right to make changes in specifications and models as

design improvements are introduced. Product or company names mentioned herein may be the trademarks of their respective owners.

© 2018 Siemens Industry, Inc.

Siemens Industry, Inc.

Building Technologies Division

1000 Deerfield Parkway

Buffalo Grove, IL 60089-4513

USA

+1-847-215-1000

Your feedback is important to us. If you have

comments about this document, please send them to

SBT_technical.editor.us.sbt@siemens.com

Document No. 125-4461

Printed in the USA

Page 10

Dimensions

Figure 15. Dimensions in Inches (Millimeters).

NOTE: The screwed fittings and gaskets are supplied with these valves.

Product Number

DN

G

(in)

L1

L2

L3 H E

F W lb

(kg)

(mm)

(in)

MXG461B15-0.6

15

Rp ½

G1B

3.15

(80)

1.67

(42.5)

1.97

(50)

13.4

(340)

3.15

(80)

4.53

(115)

15.65

(7.1)

MXG461B15-1.5

15

Rp ½

G1B

3.15

(80)

1.67

(42.5)

1.97

(50)

13.4

(340)

3.15

(80)

4.53

(115)

16.09

(7.3)

MXG461B15-3

15

Rp ½

G1B

3.15

(80)

1.67

(42.5)

1.97

(50)

13.4

(340)

3.15

(80)

4.53

(115)

16.09

(7.3)

MXG461B20-5

20

Rp ¾

G1¼B

3.74

(95)

2.07

(52.5)

2.36

(60)

13.3

(339)

3.15

(80)

4.53

(115)

16.97

(7.7)

MXG461B25-8

25

Rp 1

G1½B

4.33

(110)

2.22

(56.5)

2.52

(64)

13.6

(346)

3.15

(80)

4.53

(115)

18.73

(8.5)

MXG461B32-12

32

Rp 1¼

G2B

4.92

(125)

2.66

(67.5)

2.95

(75)

15.12

(384)

3.94

(100)

4.92

(125)

28.22

(12.8)

MXG461B40-20

40

Rp 1½

G2¼B

5.51

(140)

3.17

(80.5)

3.66

(93)

15.79

(401)

3.94

(100)

4.92

(125)

32.19

(14.6)

MXG461B50-30

50

Rp 2

G2¾B

6.69

(170)

3.68

(93.5)

4.2

(108)

402

(15.83)

3.94

(100)

4.92

(125)

41.00

(18.6)

G: External thread G…B to ISO228/1

DN: Internal thread Rp to ISO7/1

Fittings to ISO 49/DIN 2950 (supplied complete with flange gaskets)

Loading...

Loading...