Page 1

MULTIMOBIL 10

Troubleshooting Guide

SP

© Siemens AG 2003

The reproduction, transmission or

use of this document or its contents

is not permitted without express

written authority. Offenders will be

liable for damages. All rights,

including rights created by patent

grant or registration of a utility

model _or_ design,_are_ reserved.

English

Print No.: SPR8-X01.840.10.02.02 Doc. Gen. Date: 10.05

Replaces: SPR8-X01.840.10.01.02

Page 2

Multimobil 10

Service Manual

Service Instructions

Med

Service Instructions

Version: 4.0

The reproduction, transmission or use

of this document or its contents is not

permitted without express written

authority. Offenders will be liable for

damages.

Siemens Ltd. Med Division India Version 4.0

Page 1 of 48

Page 3

Service Manual

Service Instructions

INDEX

1 SERVICE................................................................................................................................................... 4

1.1 SAFETY PRECAUTIONS : .......................................................................................................................... 4

1.2 TROUBLESHOOTING : .............................................................................................................................. 4

1.2.1 Tools and measuring instruments required....................................................................................... 4

1.3 MEASURING WITH OSCILLOSCOPE : ......................................................................................................... 4

1.4 HANDLING PRECAUTIONS........................................................................................................................ 4

1.5 CONTROL VOLTAGES .............................................................................................................................. 5

1.6 SIGNALS & LINE VOLTAGE DISPLAY: ...................................................................................................... 5

1.7 HT CHECK : ............................................................................................................................................ 6

1.8 EXPOSURE :............................................................................................................................................. 6

1.9 TIMING :.................................................................................................................................................. 6

1.10 KVP,KVN &KV MEASUREMENT :.......................................................................................................... 6

1.10.1 kVp-meter :................................................................................................................................... 6

1.10.2 Electrical :.................................................................................................................................... 7

1.11 MA/MAS MEASUREMENT :...................................................................................................................... 7

1.11.1 mAs-meter : .................................................................................................................................. 7

1.11.2 Electrical :.................................................................................................................................... 7

1.12 CALIBRATION :........................................................................................................................................ 7

1.13 FORMING :............................................................................................................................................... 8

1.14 SAFETY NOTES AND PROTECTIVE MEASURES .......................................................................................... 8

1.15 REPLACING DAMAGED OR MISSING SCREWS ............................................................................................ 8

1.16 CLEANING............................................................................................................................................... 8

1.17 CLEANING THE UNIT............................................................................................................................... 8

1.18 DISINFECTING ......................................................................................................................................... 9

1.19 MAINTENANCE........................................................................................................................................ 9

1.20 PRODUCT DISPOSAL................................................................................................................................9

1.21 SAFETY CHECKS ................................................................................................................................... 10

1.21.1 Daily checks................................................................................................................................ 10

1.21.2 Monthly checks ........................................................................................................................... 10

1.21.3 Performance Check (Every Six months) ..................................................................................... 10

1.22 PROGRAM MODES FOR SERVICING........................................................................................................ 11

1.22.1 Program 1 : To display the DC voltage on the capacitor........................................................... 11

1.22.2 Program 2 : To check the total number of exposures taken . .................................................... 11

1.22.3 Program 3 : To check the type of codes that occurred in the unit maximum 20 ....................... 11

1.22.4 Program 4 : To Erase the errors that have occurred on the unit. .............................................. 12

1.22.5 Program 5 : To set the display value at switch ON to Default Kv mAs combination or last

selected Kv mAs combination. ....................................................................................................................... 12

1.22.6 Program 6 : To set the maximum kV and mAs value for the unit. .............................................. 12

1.22.7 Program 7 : To set the max.inverter firing frequency(REG)...................................................... 12

2 CODES..................................................................................................................................................... 14

3

TROUBLESHOOTING ......................................................................................................................... 16

3.1 REMOVING THE TOP PANEL, FRONT COVER AND X-RAY SOURCE ASSEMBLY ......................................... 16

3.1.1 Removing the top panel ................................................................................................................... 16

3.1.2 Removing the Front cover. .............................................................................................................. 17

3.1.3 Removing the X-ray source assembly..............................................................................................17

3.2 CHECKING THE LINE VOLTAGE, FUSES AND LEDS................................................................................. 18

Siemens Ltd. Med Division India Version 4.0

Page 2 of 48

Page 4

Service Manual

3.2.1 Checking the line voltage ................................................................................................................ 18

3.2.2 Checking the fuses........................................................................................................................... 19

3.2.3 Checking the LEDs on D801 ........................................................................................................... 19

3.3 CHECKING THE CONTROL VOLTAGES ................................................................................................... 19

3.4 CHECKING THE INTERMEDIATE CIRCUIT VOLTAGE................................................................................ 20

3.5 CHECKING THE MAXIMUM MAIN INVERTER FREQUENCY ...................................................................... 20

3.6 FILAMENT CURRENT MEASUREMENT .................................................................................................... 20

3.7 CHECKING THE HIGH VOLTAGE KVSOLL AND KVIST............................................................................. 20

3.8 SETTING THE MAXIMUM FILAMENT FREQUENCY .................................................................................. 21

3.9 CHECKING THE TUBE CURRENT ............................................................................................................. 21

3.10 CHECKING THE KV AND TUBE CURRENT (JR)........................................................................................ 21

3.11 CHECKING THE MAS VALUES ................................................................................................................ 21

3.12 ADJUSTING THE MAS ............................................................................................................................ 22

3.13 SWITCHING THE COLLIMATOR LIGHT ON............................................................................................. 22

3.14 ALIGNING THE LIGHT FIELD TO THE RADIATION FIELD .......................................................................... 22

3.14.1 Operating sequence .................................................................................................................... 22

3.14.2 Evaluation: ................................................................................................................................. 22

3.15 CHECKING AND READJUSTING THE COUNTERWEIGHT ........................................................................... 23

3.16 ADJUSTMENT INSTRUCTIONS : .............................................................................................................. 23

3.17 REPLACING THE SINGLE TANK............................................................................................................... 23

3.18 REPLACING THE COLLIMATOR............................................................................................................... 24

3.19 REPLACING THE COLLIMATOR LAMP .................................................................................................... 24

Service Instructions

4 SPECIFIC CODE HANDLING ............................................................................................................ 25

4.1 UNIT NOT SWITCHING ON ..................................................................................................................... 25

4.2 NO RADIOGRAPHY ................................................................................................................................27

4.3 NO STANDBY ........................................................................................................................................ 29

4.4 INITIALISATION CODES.......................................................................................................................... 30

4.4.1 Code 90 (EPROM CHECKSUM FAILURE)................................................................................... 30

4.4.2 Code 96 (KV SOLL FAILURE) ......................................................................................................30

4.4.3 Code 97 ( mA FAILURE) ................................................................................................................ 30

4.5 STANDBY CODES .................................................................................................................................. 31

4.5.1 Code 02 : +15 V Supply Code......................................................................................................... 31

4.5.2 Code 03 & 04 : Iheiz < Istby & Iheiz > Istby.................................................................................. 32

4.5.3 Code 05 : kVist <> 0....................................................................................................................... 33

4.5.4 Code 06 : JR <> 0........................................................................................................................... 34

4.5.5 Code 33 : Main Inverter Short Circuit............................................................................................ 35

4.6 EXPOSURE CODES ...........................................................................................................................36

4.6.1 Code 11 : Main Inverter Short Circuit............................................................................................ 36

4.6.2 Code 12 : kVist > kVmax................................................................................................................. 37

4.6.3 Code 13 : Iheiz > Imax OR JR > Jrmax......................................................................................... 38

4.6.4 Code 14 : kVist < kVsoll.................................................................................................................. 39

4.6.5 Code 15 : JR < JRS......................................................................................................................... 40

4.6.6 Code 17 : Exposure terminated by Backup Timer........................................................................... 41

4.6.7 Code 18 : Premature termination of Exposure................................................................................ 42

4.6.8 Code 21 : Iheiz > Iheiz maximum.................................................................................................... 43

4.6.9 Code 22 : Maximum Preparation Time........................................................................................... 44

4.6.10 Code 10 : Rotating Anode not OK.............................................................................................. 45

4.6.11 Code 31 : No charging ............................................................................................................... 46

4.6.12 Code 01 : Err signal on D950A active ....................................................................................... 48

Siemens Ltd. Med Division India Version 4.0

Page 3 of 48

Page 5

Service Manual

Service Instructions

1 Service

1.1 Safety Precautions :

Before working on the unit ensure that the Mains is switched OFF.

For completely safe working remove mains plug.

The unit must be OFF before removing or putting back the assemblies.

The protective earthing of subassemblies must not be removed in any case.

1.2 Troubleshooting :

1.2.1 Tools and measuring instruments required

• Usual service tools

• Digital Multimeter:

• 2 channel storage oscilloscope with 2 probes and one current probe.

• mAs meter

• Protective ground wire and leakage current tester: Bender safety tester

• Radiation detector

During Oscilloscope operation the protective ground wire connection

in the power cable must not be interrupted under any circumstances.

For measurements where ground loops that may be present could impair the

measuring result, use the Tek amplifier and the trigger attachment.

1.3 Measuring with oscilloscope :

For normal working, the protective earthing of mains must not be removed.

In case system noise is getting coupled to the scope, use the scope in differential

mode.

To measure high voltage, use DIFFERENTIAL probe isolated from ground.

1.4 Handling precautions

Strictly observe ESD precautions while handling PCBs and ESD sensitive

devices.

After the unit is switched ON, the capacitors C1~C12 on D970A and D971

charge to 355V DC. After switching the unit OFF, it takes about 08 minutes for

capacitors to discharge. The presence of DC voltage is indicated by Green

LED V24 on D950A and also V1 ~ V12 LED’s on D970A / D971.

Siemens Ltd. Med Division India Version 4.0

Page 4 of 48

Page 6

Service Manual

Service Instructions

1.5 Control Voltages

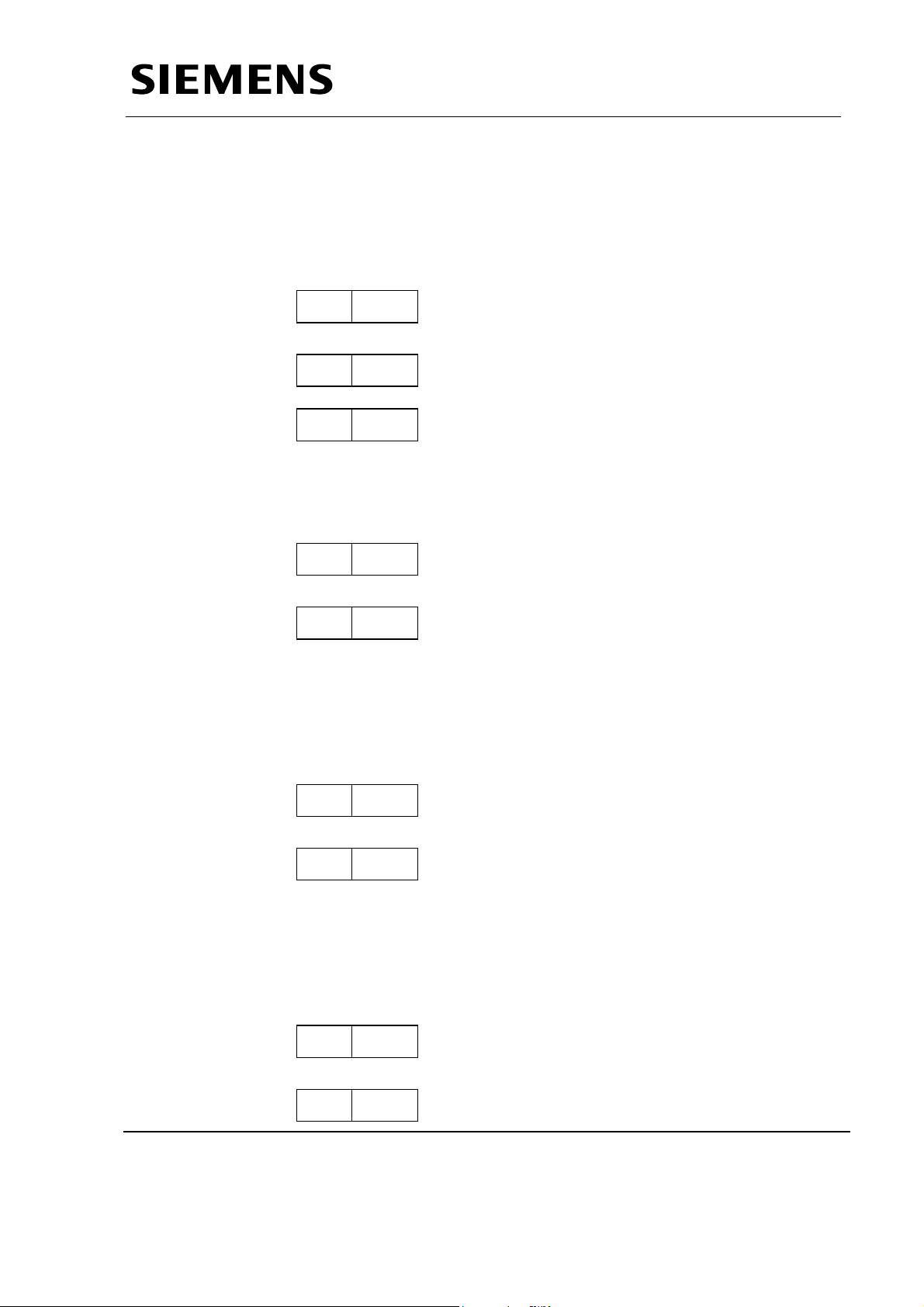

Voltage Measuring Point Range

+5 V D915. X15.4 4.8v to 5.2v

+15 V D915. X15.5 13.5v to 16.5v

-15 V D915. X15.7 -13.5v to -16.5v

Collimator Supply D801 . X6 12V ac to 16V ac

1.6 Signals & Line voltage display:

Signal Measuring Point Range Adjustment

kVsoll D915.TP.KVS

2.0 ± 0.1 V for 60kV

D915.P7

during Exposure

mAsoll D915.TP.JRS

3.2 V ± 0.1 V for 160mA

D915.P6

during Exposure

D915.TP. IH during

1.5V± 0.1V

Standby

IH

REG: Max

Main Inv. req.

CAL :Max

Fil.Inv. Freq

D915.TP. IH during

Preparation

D915.TP.REG point

during exposure

D915 TP CAL during

start up

2V ±0.3V (for critically

damped mA)

15 kHz ± 0.5 kHz

15KHz ± 0.5 kHz

D915.P5

D915.P4

D915 .P3

The actual mains Line voltage, at 110 and 230 V supply, is being monitored for

display on the 7 segment display during first step of hand release switch for

radiography. Ensure that display value mathes with actual line voltage with allowed

tolerance ± 5 %. Using P1 potetiometer on D801 PCB, set the voltage accordingly.

This is applicalbe while replacing D915 and D801 PCB also.

If the Line voltage is less than 205 volts on on 230 V line, microcontroller switches

“ON“ the ’LN’ contactor which will support extra voltage through auto transformer

for rotating anode to run at higher speed. In preperation and exposure mode

contactor retains its position. After 5 second of each termination of radiography Line

voltage is being monitored once again.

When unit is connected to 110 V line LN contactor does not function even though

there is a variation in the supply voltage.

Siemens Ltd. Med Division India Version 4.0

Page 5 of 48

Page 7

Service Manual

Service Instructions

1.7 HT Check :

Presence of High Tension

Observe Safety Precautions.

Use radiation protection

1.8 Exposure :

Switch the generator ON.

Set exposure parameters as 60Kv, 16 mAs.

Pull the recoilable exposure release switch and release an exposure.

The yellow LED on top panel lights up for a short duration equal to exposure time.

Audible indication by a Buzzer from the control and muffled sound from inverter

confirms the working of the inverter.

The LED’s on D915 light in the following sequence:

S27 - STEP 1(half press) : V22

Exposure state : V23

In case of code : V24

Code corresponding to the code is displayed on the seven-segment display.

Sharps knocking sound from inverter indicates inverter short circuit, resulting in

code display on the top panel.

1.9 Timing :

Set 60 kV 16mAs

Release an exposure. The radiation indication LED will light for 100msec ± 5msec.

1.10 KVp,KVn &KV Measurement :

The kVp, KVn & KV measurement can be carried out either by kVp-meter or by

electrical measurement.

1.10.1 kVp-meter :

Switch the unit ON.

Insert the kV sensor into collimator channel and connect the cable to the meter.

Open collimator flaps such that the sensor is well covered by the field.

Set the kVp meter at 12pulse and 55-85kV ranges.

Set exposure parameters as 60kV 20mAs.

Release an exposure. The radiation LED will light up during exposure.

The meter will read 57-63kV.

Repeat with meter setting 77-150kV and exposure parameter setting, as 90kV

20mAs.The meter will read 85.5-94.5 kV.

Siemens Ltd. Med Division India Version 4.0

Page 6 of 48

Page 8

Service Manual

Service Instructions

1.10.2 Electrical :

Connect oscilloscope at D915.TP.kV.

Set the exposure parameters as 60kV 16mAs.

Release an exposure.

The recorded waveform will read 2.9V - 3.1V.

Repeat with 100kV 10mAs.

The recorded waveform will read 5V +/-0.25V.

Lower kV indicates code in kVsoll / kV sensing / kV-regulator OR high mA.

Higher kV indicates code in kVsoll / kV sensing / kV regulator.

1.11 mA/mAs Measurement :

mAs measurement could be carried out either by mAs-meter or by electrical

measurement.

1.11.1 mAs-meter :

Remove mAs link on D800 PCB on the Single tank.

Insert mAs-meter leads in the banana sockets mA+ and mA- on D800.

Set meter at, 200mAs and in the mAs mode.

Set exposure parameters as 60kV 32mAs.

Release an exposure.

The meter will read 31 – 33 mAs.

Repeat for exposure parameters 100kV 40mAs.

The meter will read 39 to 41mAs.

1.11.2 Electrical :

Connect oscilloscope at D915.TP.JR.

Set exposure parameters 60kV 16mAs.

Release an exposure.

The recorded waveform will read 3 – 3. 2V.

The exposure time will be 95 - 105mS.

Lower mA indicates code in mAsoll / mA sensing / mA regulator circuit.

Higher mA indicates code in mAsoll / mA sensing / mA regulator or Low kV.

Incorrect mAs indicate code in timer circuitry.

1.12 Calibration :

It is advisable to re-calibrate the unit in case of undershoot or overshoot observed in

the mA wave shape.

Recalibration is required when the single tank is replaced.

Siemens Ltd. Med Division India Version 4.0

Page 7 of 48

Page 9

Service Manual

Service Instructions

1.13 Forming :

If the unit is being installed after six months from the date of despatch, the

capacitors C1~C12 on D970A/D971 need forming. Refer Installation

instructions for forming procedure.

1.14 Safety notes and protective measures

Refer to the General safety note in Chapter on Installation.

Before working on the open MULTIMOBIL 10, switch off the unit with the power

switch at the control panel, the MCB in off position and remove the Mains cable

from socket.

Before inserting or removing PC boards, switch off the generator and observe the

ESD regulations.

1.15 Replacing damaged or missing screws

Damaged or missing screws should only be replaced by steel screws having the

specified tensile strength with Nickel Plating (6492) specified in the Surface Finish

Documents.

1.16 Cleaning

The unit must always be switched OFF or disconnected before cleaning.

Use only water or a Luke warm mixture of a household cleaner diluted with water to

clean the unit.

Do not use an abrasive or organic solvents or cleaning agents containing solvents

such as gasoline used for cleaning purposes, alcohol or stain remover. Do not spray

water on the unit.

1.17 Cleaning the Unit

Switch OFF the system prior to cleaning, disinfecting or sterilizing.

Clean the stand with a damp cloth or cotton pad.

Dampen the cloth or pad with water or lukewarm, diluted commercially available

liquid cleaning solution.

Note:

Do not use scouring powder; organic solvents (may damage materials) or

solvent based cleaning fluids (benzene, alcohol, spot remove).

Siemens Ltd. Med Division India Version 4.0

Page 8 of 48

Page 10

Service Manual

Service Instructions

Do not spray any fluid on the unit. The cleaning fluid must not seep into the

generator.

1.18 Disinfecting

As is commonly known, the ingredients in disinfectants are hazardous to your

health. Ensure that the room is well ventilated when using any disinfectant. Follow

manufacturer’s instructions for the use of the product.

To disinfect surfaces, we recommend common liquid solutions of aldehyde-based or

ampholytic surfactant -based disinfectant.

Substituted phenol based or chlorine-releasing disinfectant can weaken

materials and are not recommended. The same restrictions apply to undiluted solutions

with a high alcohol content (e.g. for disinfecting hands). Disinfectant sprays should

generally not be used, the spray can seep into the system, and safety features can no

longer be guaranteed (possible damage to electrical components, formation off

flammable mixtures of air and the solution vapor.

1.19 Maintenance

All parts, modules of this product must be tested, inspected, for performance and

safety aspects every 12 months to ensure that the product functions properly and is

safe for patients, operating personnel and other persons.

Every 12 months, trained technical personnel should inspect and if necessary

replace system components of the generator, which may produce hazardous,

conditions due to excessive wear and tear. These instructions should be included in

the annual maintenance performed by Siemens Customer Service.

If more frequent inspections and maintenance are required by federal or local

regulations, ensure compliance with them.

1.20 Product Disposal

Legal regulations may contain special prescriptions concerning the disposal of this

product. In order to avoid environmental damage and/or personal injury, please

inform SIEMENS Customer Service if you want to put the unit out of operation and

dispose it.

Radioprotection Material

Lead in X-ray tube assembly and in Collimator 3 kg.

Siemens Ltd. Med Division India Version 4.0

Page 9 of 48

Page 11

Service Manual

Service Instructions

Transformer Oil

Oil in X-ray tube assembly, approx. 7 kg.

Plastics

Epoxy resin on PC boards, PVC of cables approx. 10 kg.

Electrolytic Capacitors

These capacitors must be emptied. Please inform the Siemens Customer Service.

Capacitors approx. 15 kg

Remaining Electrolytic Capacitors approx. 0.5 kg.

1.21 Safety Checks

The user shall follow the following safety checks:

1.21.1 Daily checks

Check the power cord. Do not use the unit if the power cord is damaged.

Check the exposure indicator and audible signal during exposure.

Check that the Single tank assembly and the arm system remain in the desired

position.

1.21.2 Monthly checks

Check the lifting and lowering movements of the support arm.

Check function of locking lever and cap screw on the X-ray tube

Check the legibility of the labels according to those in section Location of Labels.

If any labels require to be replaced, please notify Siemens customer service.

1.21.3 Performance Check (Every Six months)

Check counterbalancing of the support arm at each position.

Check the locking mechanism for the support arm.

Check brake for proper functioning .

Take a sample exposure at 60 kV, 16 mAs.

Check for Radiation indication LED and the Audio indication in form of Buzzer.

Siemens Ltd. Med Division India Version 4.0

Page 10 of 48

Page 12

Service Manual

Service Instructions

Note : Annual Maintenance must be performed as per the guidelines described in

the Maintenance section.

Notify Siemens Customer Service if you do not have a maintenance contract.

1.22 Program Modes for servicing.

To put the unit into service mode, Short the ST link on the D915 and put ON the

unit.Use the Kv+ and Kv- switches to select the required program from 1 to 7.

To check the parameters in the program,press the DL-serv switch once.

1.22.1 Program 1 : To display the DC voltage on the capacitor.

Select the program one in service mode and the display will read as below

Pr 1

Press the switch DL-serv on the D936 once.

The display will read as below

Cap XXX

XXX corresponds to the DC voltage on the capacitors.

1.22.2 Program 2 : To check the total number of exposures taken .

Select the program two in service mode and the display will read as below

Pr 2

Press the DL-serv switch and enter into the program.The display will be

XXX XXX

XXX corresponds to the total number of exposures taken on the unit.

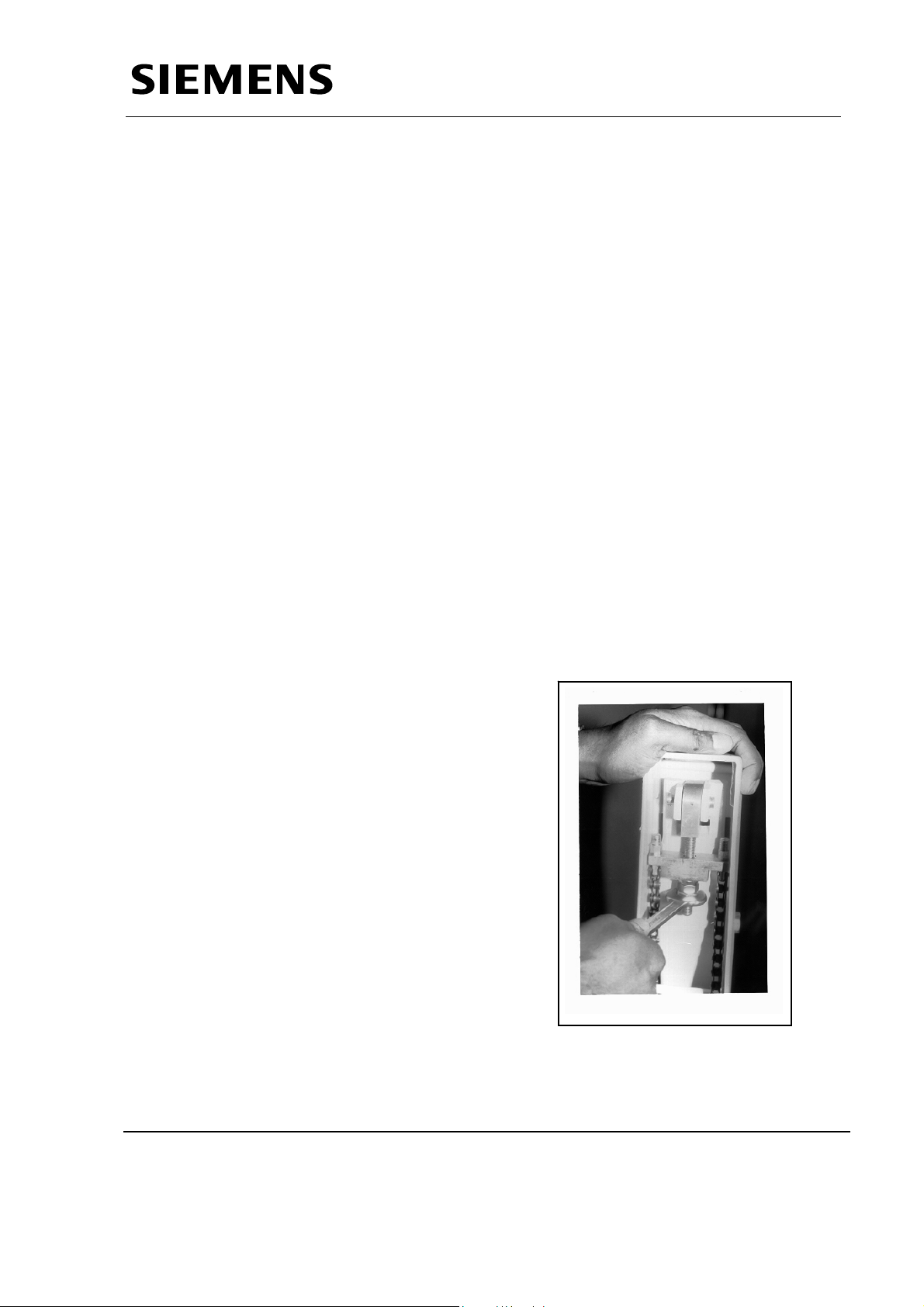

1.22.3 Program 3 : To check the type of codes that occurred in the unit

maximum 20 .

Select the program three in service mode and the display will read as below

Pr 3

Press the switch DL-serv on the D936 once.The display will read as below.

AA XX

AA displays the serial no of the errors occurred in chronological order.

XX corresponds to the type of code.

Siemens Ltd. Med Division India Version 4.0

Page 11 of 48

Page 13

Service Manual

Service Instructions

Press the kV+ switch to check all the codes stored. Maximum 20 codes can be

stored.

1.22.4 Program 4 : To Erase the errors that have occurred on the unit.

Select the program four in service mode and the display will read as below

Pr 4

Press the switch DL-serv on the D936 once.The display will read as below.

Era Err

To erase the errors keep the mAs + switch pressed till the display reads

0 Err

1.22.5 Program 5 : To set the display value at switch ON to Default Kv mAs

combination or last selected Kv mAs combination.

Select the program five in service mode and the display will read as below

Pr 5

Press the switch DL-serv on the D936 once.The display will read as below.

las Val

The default value can be set by selecting the desired kV, mAs combination.

Last selected combination can be stored by pressing the DL-serv switch twice.

1.22.6 Program 6 : To set the maximum kV and mAs value for the unit.

Select the program six in service mode and the display will read as below

Pr 6

Press the switch DL-serv on the D936 once.The display will read as below.

125 100

Set the required limit for kV and mAs using the kV /mAs increment and decrement

switches.

1.22.7 Program 7 : To set the max.inverter firing frequency(REG).

Select the program seven in service mode and the display will read as below

Pr 7

On activation of this program by pressing the DL-serv switch , the display indicates

Adj F

Siemens Ltd. Med Division India Version 4.0

Page 12 of 48

Page 14

Service Manual

Service Instructions

Press the Radiographic exposure switch and monitor REG on Digital storage

Oscilloscope.

The display indicates

F On

Adjust REG for 15 kHz ±0.5kHz by using P4 on D915 card.

Siemens Ltd. Med Division India Version 4.0

Page 13 of 48

Page 15

Service Instructions

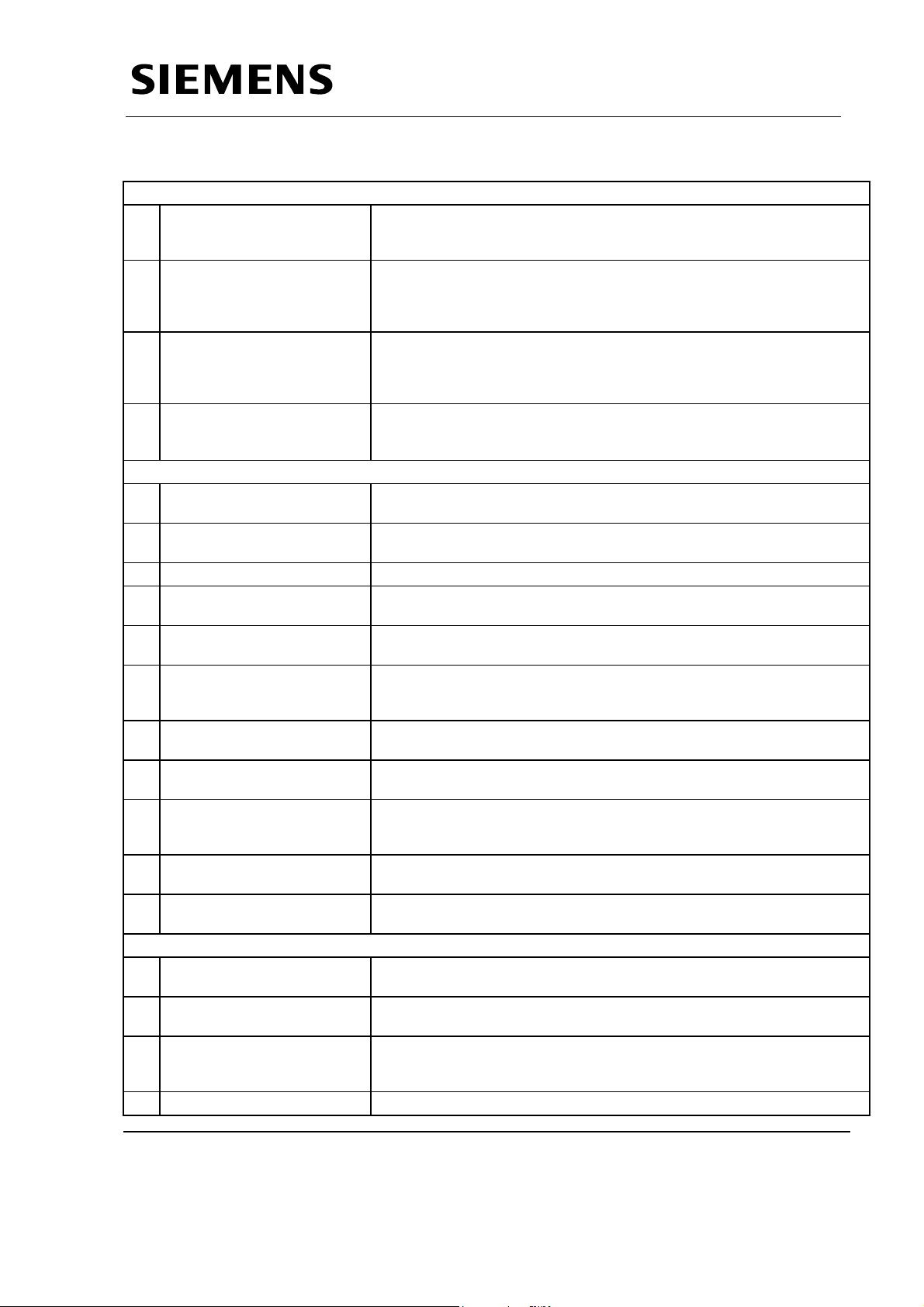

2 Codes

Initialisation Codes

90

EPROM Checksum Failure

96

KVsoll Failure

97

JRS Failure

99 Last Reset by Watchdog

Timer

02

+15V Supply Code

03

Iheiz < Istby

04

Iheiz > Istby The maximum value of Standby current permitted is 3.3 A.

05

KVist <> 0

06

JR <> 0

33

Main Inverter Short Circuit

34

Filament Inverter Short Circuit

07

Rot ≠ 0

08

Braking Failure

01

Err signal on D950A active

31

No Charging

10

No Rotation of Rotating Anode

11

Main Inverter Short Circuit

12

KVist > kVmax

13

Iheiz > Imax OR JR > JRmax

The EPROM Checksum is stored at 7FFEh and 7FFFh as a 16 bit word.

During self Diagnostics the software calculates the checksum of the EPROM

and compares with the stored checksum.

During Self Diagnostics the software outputs 7Fh to the D/A converter (B).

The 2.5V at the output of the D/A converter is Read by the µC through Analog

Port 4. The value read should be greater than 7Ah and less than 86h. (I.e.

between 2.39V and 2.62V)

During Self Diagnostics the software outputs 7Fh to the D/A converter (A).

The 2.5V at the output of the D/A converter is Read by the µC through Analog

Port 3. The value read should be greater than 7Ah and less than 86h. (I.e.

between 2.39V and 2.62V)

The built-in Watchdog timer (WDT) is reset by the software every 25 mSec. If

due to some failure the software doesn’t reset the WDT, the WDT in turn will

reset the µC after 65 mSec

Standby Codes

The +15V supply from SMPS is polled by the µC through Analog port 0. The

+15V supply should be between +12V to +18V.

The Filament Standby current is 3A. Iheiz read by the µC through Analog port

2 should be greater than 2.75A. i.e. 1.35V (Iheiz ratio : 1V = 2A)

kVist is read by the µC through Analog port 7. During Standby the value of

kVist read should be Zero. (kVist ratio : 1 V = 20kV)

JR is read by the µC through Analog port 1. During Standby the value of JR

read should be Zero. (JR ratio : 1 V = 50mA)

If the Main Inverter Driver (Cable) is disconnected this Code gets activated.

Also if IGBT Drivers on D960 Card detects Short Circuit of IGBT’s this Code

gets activated.

This Code gets activated if IGBT Drivers on D801 Card detects Short Circuit

of Filament Inverter IGBT’s

The current flowing through both the windings of motor is monitored

separately. During standby Rotor should be off.RT1, RT2=0.

After exposure is terminated the Unit returns to Standby state and braking of

Rotor is started by allowing a DC current to flow through the KI2.During this

state which is for 8 sec after exp, RT1=0 and RT2=1.

Temperature on the heat sink of D950A exceeds it’s limit or Voltage exceeds

365v across capacitors C1~C12 or IGBT V24 on D950A is short circuit.

Voltage on capacitors C1~ C12 does not increase within 3.5sec of CS picking

up or it is less than 335 V DC

Exposure Codes

Anode Rotation in the Single Tank is not taking place. This Code is displayed

if any one of the RT1and Rt2 signal goes low during preparation.

This Code is displayed, when the drivers of the Main Inverter detect short

circuit.

The PkV and NKV is monitored for Max.68kV separately. If the actual value of

kV is greater than this i.e. if the voltages at J12.8 and J12.10 on D915 cross

4.5V, Code is displayed.

Maximum value of Iheiz above which Code will be displayed is 7 A (3.5V).

Service Manual

Siemens Ltd. Med Division India Version 4.0

Page 14 of 48

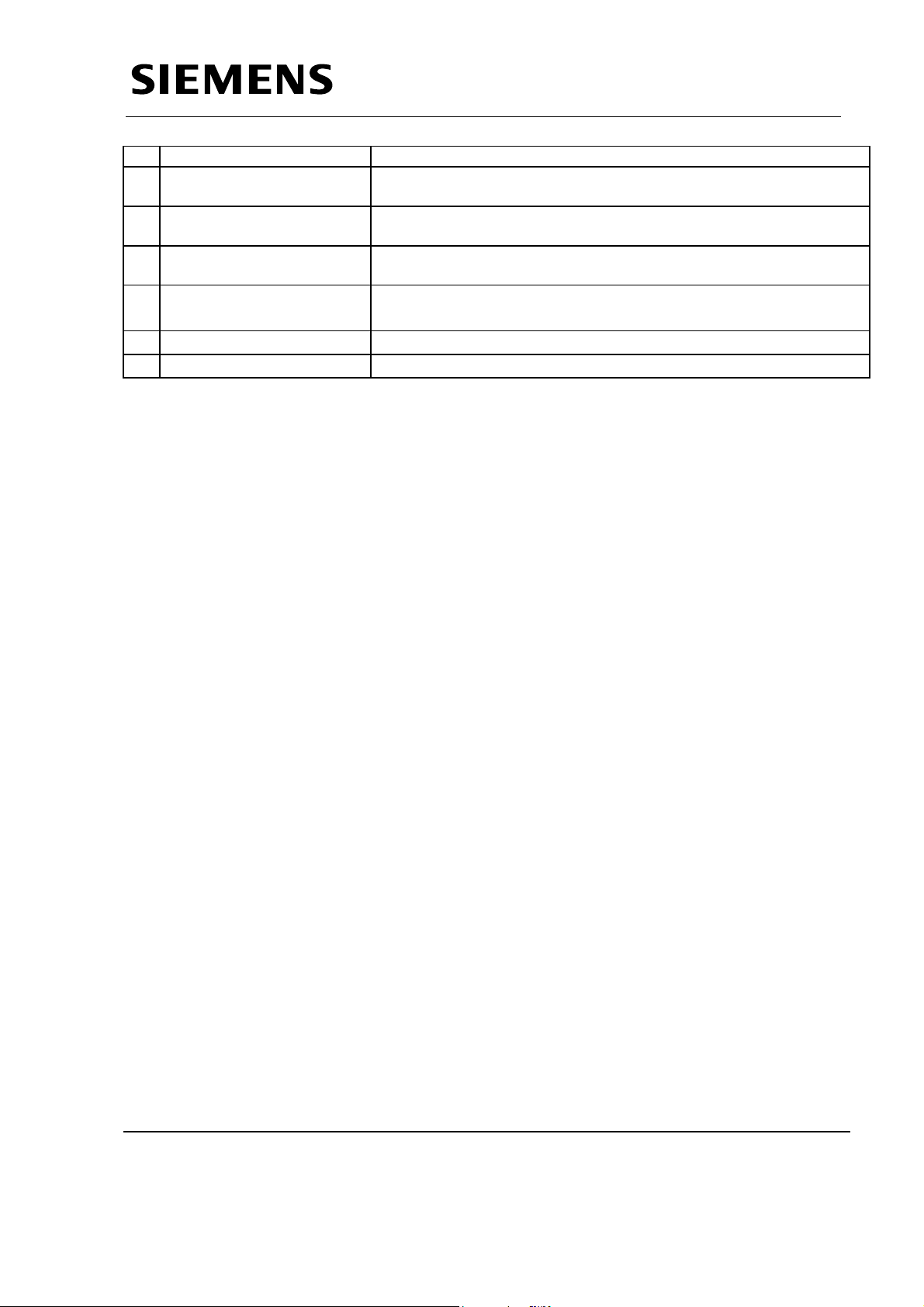

Page 16

Service Manual

Maximum value of mAist above which Code is displayed is 180mA.

14

KVist < kVsoll

15

JR < JRS

17

Backup Timer

18

Premature Exposure

Termination

21

I > Iheiz Same as Code 04, but during Exposure.

22

Maximum Preparation Time This Code is displayed if First step is pressed for more than 15 sec.

kVist is continuously polled during exposure. The value of kVist should be

greater than 85% of kVsoll

JR is continuously polled during exposure. The value of JR should be greater

than 50% of JRS.

If regular means of terminating exposure fails and exposure gets terminated

by the backup timer.

Exposure Release Switch is released before the exposure is terminated by

the mAs Integrator.

Service Instructions

Siemens Ltd. Med Division India Version 4.0

Page 15 of 48

Page 17

Service Manual

Service Instructions

3 Troubleshooting

In case of Code, perform the following checks.

3.1 Removing the top panel, front cover and X-ray source assembly

3.1.1 Removing the top panel

Turn off the Multimobil 10,disconnect the mains chord and wind the cord around the

cable holder.

Lower the X-ray source assembly to transport position. Lock the Multimobil 10 by

applying the brake.

Unscrew the two ornamental screws (see location in figure) with 2.5 mm allen key.

Grasp the top panel and lift it (as shown in figure).

Siemens Ltd. Med Division India Version 4.0

Page 16 of 48

Page 18

3.1.2 Removing the Front cover.

Service Manual

Service Instructions

Turn off the Multimobil 10,disconnect the

mains chord and wind the cord around the

cable holder.

Lower the X-ray source assembly to

transport position. Lock the Multimobil 10

by applying the brake.

Arrange some kind of soft bedding to place

the front cover on .

Unscrew the four ornamental screws with

2.5mm allen key.

Grasp the cassette box and slowly pull it

outside.

Place the front cover on a soft bedding.

3.1.3 Removing the X-ray source assembly.

Turn off the Multimobil 10,disconnect the mains chord and wind the cord around the

cable holder.

Lower the X-ray source assembly to transport position. Lock the Multimobil 10 by

applying the brake.

Make sure that the X-ray source assembly is properly secured with the transport

safety lock. It should not be possible to move the X-ray source assembly

upwards.This is very important for safety reasons.

Siemens Ltd. Med Division India Version 4.0

Page 17 of 48

Page 19

Service Manual

Service Instructions

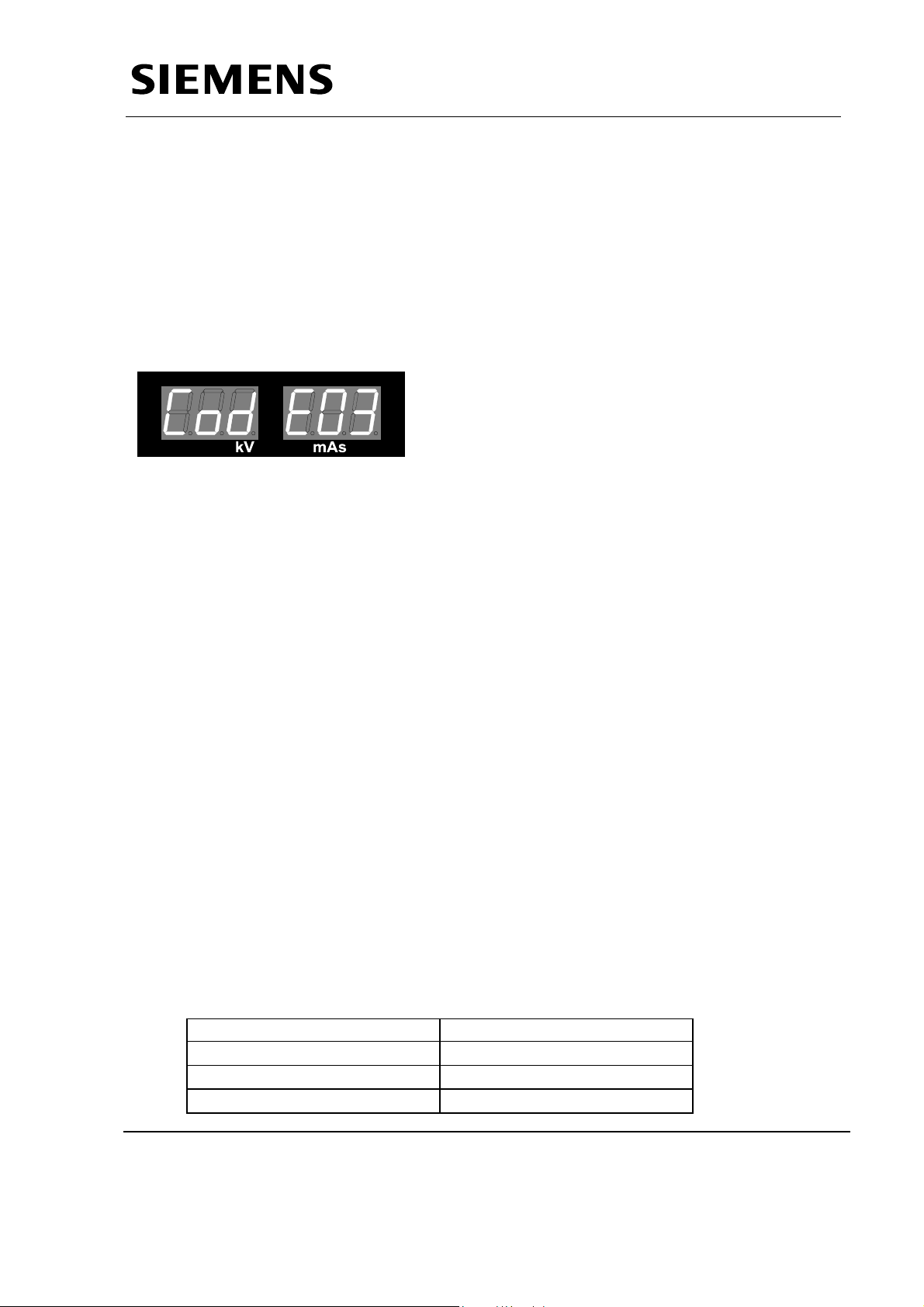

Tighten the clamping knob.

Rotate the X-ray source aassembly so that the collimator points towards the floor.

Loosen the two Socket head Screws with a 8mm allen key three to four turns for

each screw.

Loosen the other four Socket head Screws with a 5mm allen key as shown in the

above figure.

Grab the handles and remove the X-ray source assembly. Place it on a soft bedding

with collimator facing upwards.

Do not attach anything other than the X-ray source

assembly to the arm system.

Other objects will disengage the transport safety

WARNING

lock, causing the arm system to move

unanticipated which can cause both personal injury

and damage to the equipment.

3.2 Checking the line voltage, fuses and LEDs

3.2.1 Checking the line voltage

Measure the supply voltage at site using the digital Multimeter.

Ensure that the supply conditions

• Voltage

• Frequency

are within limits as specified in the Technical Specifications for the Unit.

Switch the Unit ON

Note : If the Unit cannot be switched ON

Check Supply at Mains socket.

Check Continuity of mains cable with the Plug pins.

Check Over Current Protective devices U1 & U2.

Switch the Unit OFF.

Siemens Ltd. Med Division India Version 4.0

Page 18 of 48

Page 20

Service Manual

Service Instructions

3.2.2 Checking the fuses

Open the front cover of the control unit.

Loosen the Fuse carrier, which are mounted on the transformer bracket of the

control unit and check the continuity of fuse link. If fuse link has responded for

overcurrent replace the Fuse Link.

3.2.3 Checking the LEDs on D801

F1 6AT Filament Inverter supply.

F2 1AT SMPS supply

F3 2.5AT Rotating Anode supply .

F4 2.5AT 24V Ac supply for Control ckt.

F5 10AT Collimator supply

F6 0.8 AT DC-DC Conv. ckt.

F7 1.6AT 220V AC supply for contactors.

Standby mode

On D801 the following LED’s are illuminated

V30 Supply for SMPS

V31 Supply for Filament Inverter.

V32 Supply for Rotating Anode ckt

V35 12V AC Supply for Collimator

V36 +VP supply

V50 24V DC on D801

V23&V24 DC supply for filament inverter

3.3 Checking the Control Voltages

In the standby state of the Unit,measure the voltages DC at X15 connector of D915

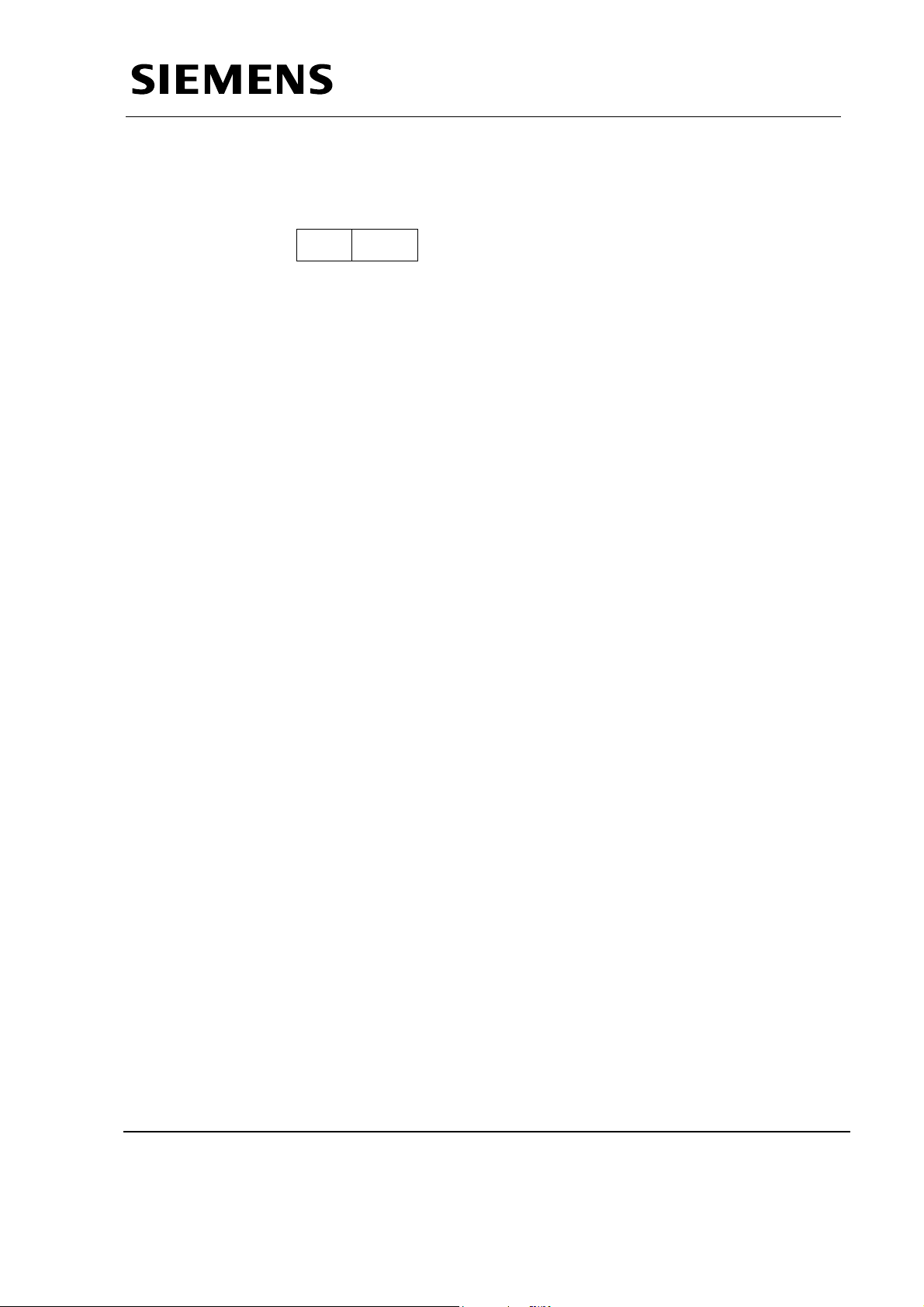

PCB.

Pin

No.

Signal Name Input/Output max. permissible

voltage/current

1 Dgnd Input 0V

2 -nc- -nc- 3 Dgnd Input 0V

4 DC supply Input + 5V

5 DC supply Input +15V

6 Agnd Input 0V

7 DC supply Input -15V

- nc - = No Connection

Siemens Ltd. Med Division India Version 4.0

Page 19 of 48

Page 21

Service Manual

Service Instructions

3.4 Checking the Intermediate circuit voltage

Measure the voltage on the D970A or D971 PCB across the capacitor using the

digital Multimeter. It should be 355 V dc (+ 10 V / - 5 V dc).

3.5 Checking the maximum main inverter frequency

Turn the Unit OFF.

Place the ST Link on D915 so as to short the two terminals.

Connect oscilloscope on D915.TP.REG and D915.TP.GND.

Turn Unit ON. The unit is now in the Service mode.

In the Service Mode of the unit, select the Prog 7.

On activation of this mode by pressing the DL Service Switch on D936, the

radiographic display indicates

AdJ F

Press the Radiographic Exposure switch and monitor REG on the oscilloscope.

The display indicates

F On

No Radiation.

F max= 15 ± 0.5 kHz.

Adjust the maximum main inverter frequency with potentiometer P4 on D915

Turn the Unit OFF. Remove ST link.

3.6 Filament current measurement

Turn the Unit OFF.

Connect oscilloscope to D915.TP.IH

Turn the Unit ON.

After approx. 3 seconds the Stand-by filament current starts & equal to 1.5V ± 0.2V

Trigger exposure with default values for kV and mAs.

Observe the change in voltage level from 1.5 V ± 0.2V to Preheat value approx.2.0V

Note: Preheat value is parameter (kV & mAs) specific. Just observe the change in

level on preheating step.

3.7 Checking the high voltage kVsoll and kVist

Connect oscilloscope to D915.TP.KVS & D915.TP.KV

Turn the unit ON.

Trigger an exposure with the default values.

Siemens Ltd. Med Division India Version 4.0

Page 20 of 48

Page 22

Service Manual

Service Instructions

Observe the voltage on C.R.O with the scale corresponding to 1V= 30kVfor KVS

and 1V=20KV for KV.

3.8 Setting the Maximum filament frequency

Turn the Unit OFF.

Remove the cable Connector X11 ON D915.

Connect oscilloscope to D915.TP.CAL

Turn the unit ON

The display indicates

Using P3, set the maximum filament frequency on D915 (15 kHz ± 0.5kHz)

Note: Duty Cycle of the waveform is varying as the ON time is fixed.

Connect X11 on D915.

3.9 Checking the tube current

Connect oscilloscope to D915.TP.JRS & D915.TP.JR

Turn the unit ON.

Trigger an exposure with the default values.

Observe the voltage on CRO (1V = 50mA) & confirm value for selected kV & mAs.

3.10 Checking the kV and tube current (JR)

Connect oscilloscope to D915.TP.KV & D915.TP.JR

Turn the unit ON.

Trigger an exposure with the default values.

Observe the voltage on CRO (1V = 50mA & 1V=20kV) for selected kV & mAs .

3.11 Checking the mAs values

Turn the Unit OFF.

Connect mAs meter to “mAs +/ mAs-” on D800 PCB.

Turn the Unit ON.

Trigger the following exposures:

Setting at control panel Valid mAs values

60kV,16mAs

60kV,100mAs

100kV,50mAs

15.5−16.5 mAs

96−104 mAs

48−52 mAs

Siemens Ltd. Med Division India Version 4.0

Page 21 of 48

Page 23

Service Manual

Service Instructions

Turn the Unit OFF.

Remove the mAs meter and reinsert the Link on the D800 PCB.

3.12 Adjusting the mAs

Turn the Unit OFF.

Remove the Shorting Link “mAs +/-” on D800 PCB banana sockets.

Connect mAs meter to “mAs +/ mAs-” on D800 PCB.

Turn the unit ON.

Trigger the exposures for default kV & mAs settings.

Observe the mAs meter reading and if it is not within the tolerance (i.e. 10% for mAs

<20 mAs and 5% for mAs > 20mAs) of set value adjust the potentiometer P1 on

D915 card

3.13 Switching the Collimator Light ON

Switch ON Collimator Lamp. The Halogen lamp will light up and field of light will

appear on the target. The lamp will be switched OFF automatically after 30

seconds.

If the collimator lamp is switched ON and OFF several times within a short

period, overload protection will automatically switch the light OFF. Cool-down

periods are recommended.

3.14 Aligning the light field to the radiation field

3.14.1 Operating sequence

Load a 24 Cm x 30 cm or 10” x12 “ cassette with film and place it on a table or a

similar base. Using a tape measure, set a vertical SID of 100cm or 40” to the upper

edge of the cassette. Using slide flaps set a format of 18 cm x 24 cm or 8”x 10”.

Switch on the Collimator Lamp and align the cassette. Attach radio-opaque

markings to the cassette. Attach a washer as lateral marking. Trigger an exposure

and develop the film .

Using a waterproof felt pen, write the following data on the developed film.

- Set SID, Film size, Radiation field size.

3.14.2 Evaluation:

Measure the deviations between light field edges and radiation field edges on all

four sides (X1, X2, Y1, Y2) as shown.

Determine the total deviations in the X and Y direction (ignore the +/- signs).

Both, length deviation (ΣY) and width deviation (ΣX) must be less than 1.6 cm.

Siemens Ltd. Med Division India Version 4.0

Page 22 of 48

Page 24

Service Manual

Service Instructions

If the deviation is higher, loosen the 4 screws slightly and move the collimator

accordingly. Then, tighten the screws at the collimator again.

Repeat the check and, if necessary, adjust the collimator again until the deviation

between the light field and the radiation field is within the tolerance (< 2 cm).

The adjustment can also be achieved with the help of a fluorescent screen.

3.15 Checking and readjusting the counterweight

Unlock the support arm and release the turning knob. Without any accessories

attached, the support arm should be easy to move across the entire movement

range and stop in any position. If the arm is not counterbalancing itself adjustments

in the spring tension are required.

Movements:

Check arm counterbalancing at all positions.

It should be easy to lift the arm UP or pull it down.

When the single tank does not remain at the required position, the spring tension

should be adjusted for complete balancing. If the Single tank moves DOWN from

the required position, the spring tension is to be increased. If it moves UP, then the

spring tension is to be reduced.

3.16 Adjustment Instructions :

Carry out the change in the pre-tension of

the spring tension as explained below.

Remove the cover from the stand.

Fully release the supplementary brake on

the support arm.

Move the support arm into the horizontal

position.

Firmly tighten the screw using a 17mm

open-ended spanner. Set the spring tension

so that the state of equilibrium is obtained

when the support arm is in the horizontal

position, i.e. that the raising and lowering

forces of the tube assembly are the same.

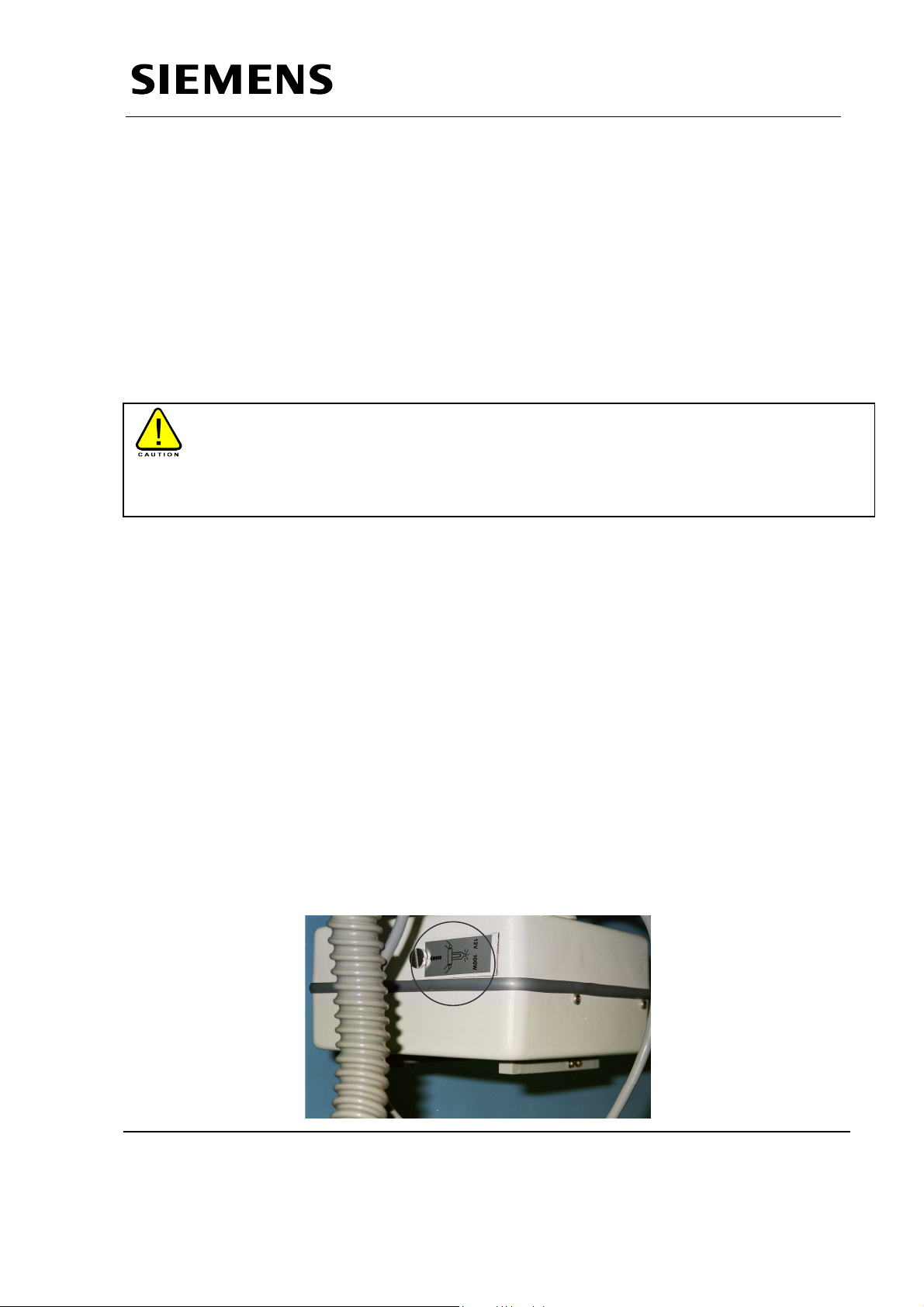

3.17 Replacing the single tank

To replace the single tank, remove it from the mobile stand as follows:

Move the arm system in the lowest (parking) position and check if the safety

locking has engaged.

The arm cannot be moved upwards any longer.

Siemens Ltd. Med Division India Version 4.0

Page 23 of 48

Page 25

Service Manual

Service Instructions

Tighten the supplementary lock turning the knob.

Detach the collimator from single tank. Also remove the allied connector connected

to the single tank bottom cover.

Remove the handle, single tank bottom cover and the single tank top cover.

Disconnect the Single Tank connections from Control by removing snap-on

connections and the M5 hex nuts of U, V and Gnd.

Remove the 4 nos. socket head screws M6 X 18 using 5mm Allen key. Loosen the

two socket head screws M10 X 35 using the 8mm Allen key.

Lift the single tank off vertically and place it on a soft base.

Install the new single tank in the reverse order.

Check alignment of light field to radiation field and adjust if necessary.

The parameter adjustments and the calibration of the Unit is Specific to the Single

Tank. In case if the Single Tank is replaced it is necessary to recalibrate the

equipment.

3.18 Replacing the collimator

In case of any damage to collimator housing, the collimator has to be replaced

completely.

Proceed as described in the following

Loosen the allied connector on the collimator cable and disconnect it from the single

tank bottom cover.

Remove the collimator after loosening the four screws.

Attach the new collimator, fasten it with the four screws Connect the allied back.

Follow the light field to radiation field alignment procedure as mentioned above.

3.19 Replacing the Collimator lamp

Loosen the screw of the clamp, which has marked for light indication on the

collimator. Take out the defective lamp and replace it by a new lamp.

Caution : Do not touch the glass envelope with your bare fingers.

Check functioning of the lamp.

Siemens Ltd. Med Division India Version 4.0

Page 24 of 48

Page 26

Service Manual

Service Instructions

4 Specific Code Handling

Note :Please Ensure that the Calibration of the unit is done properly before

starting with the code Handling.

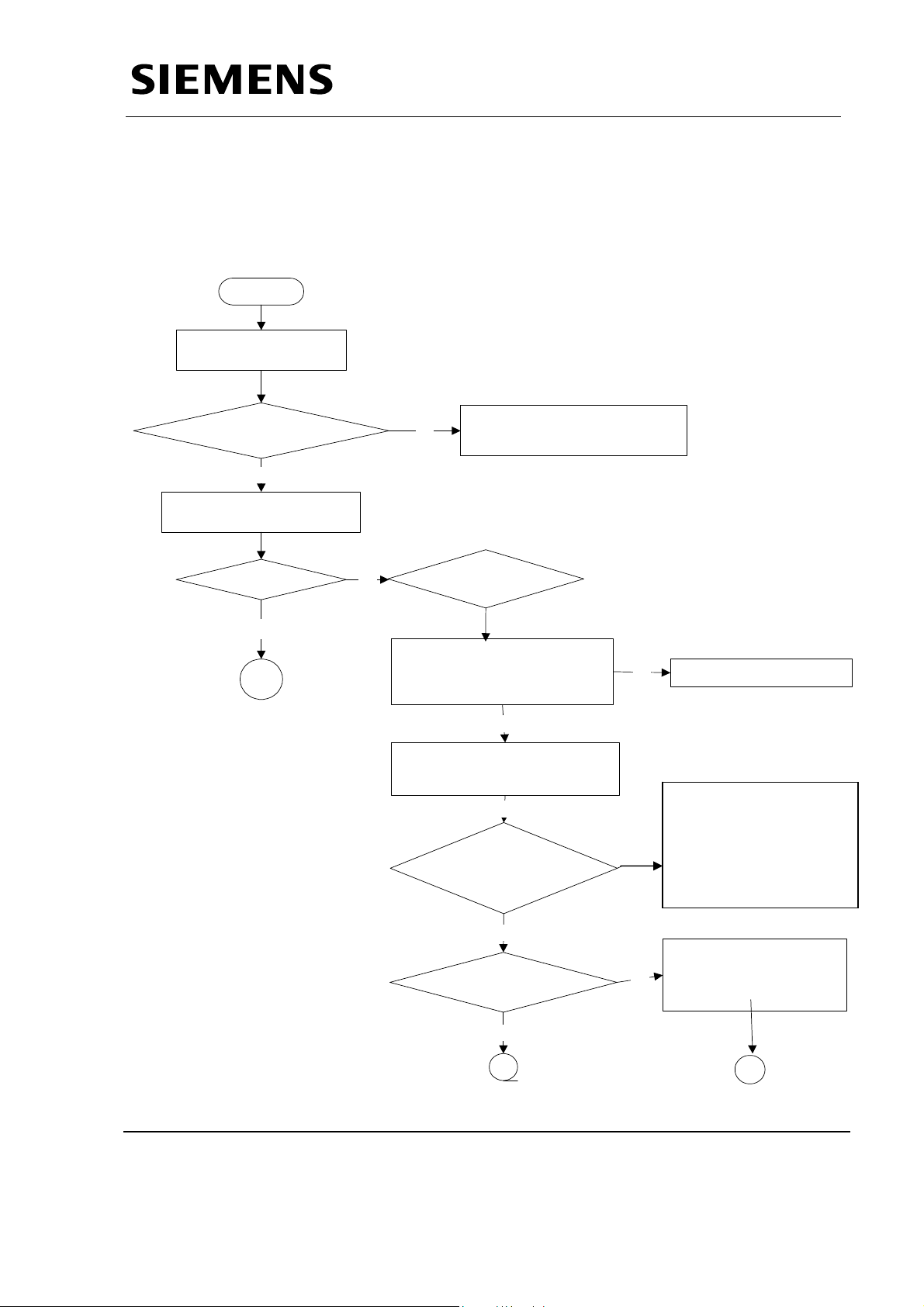

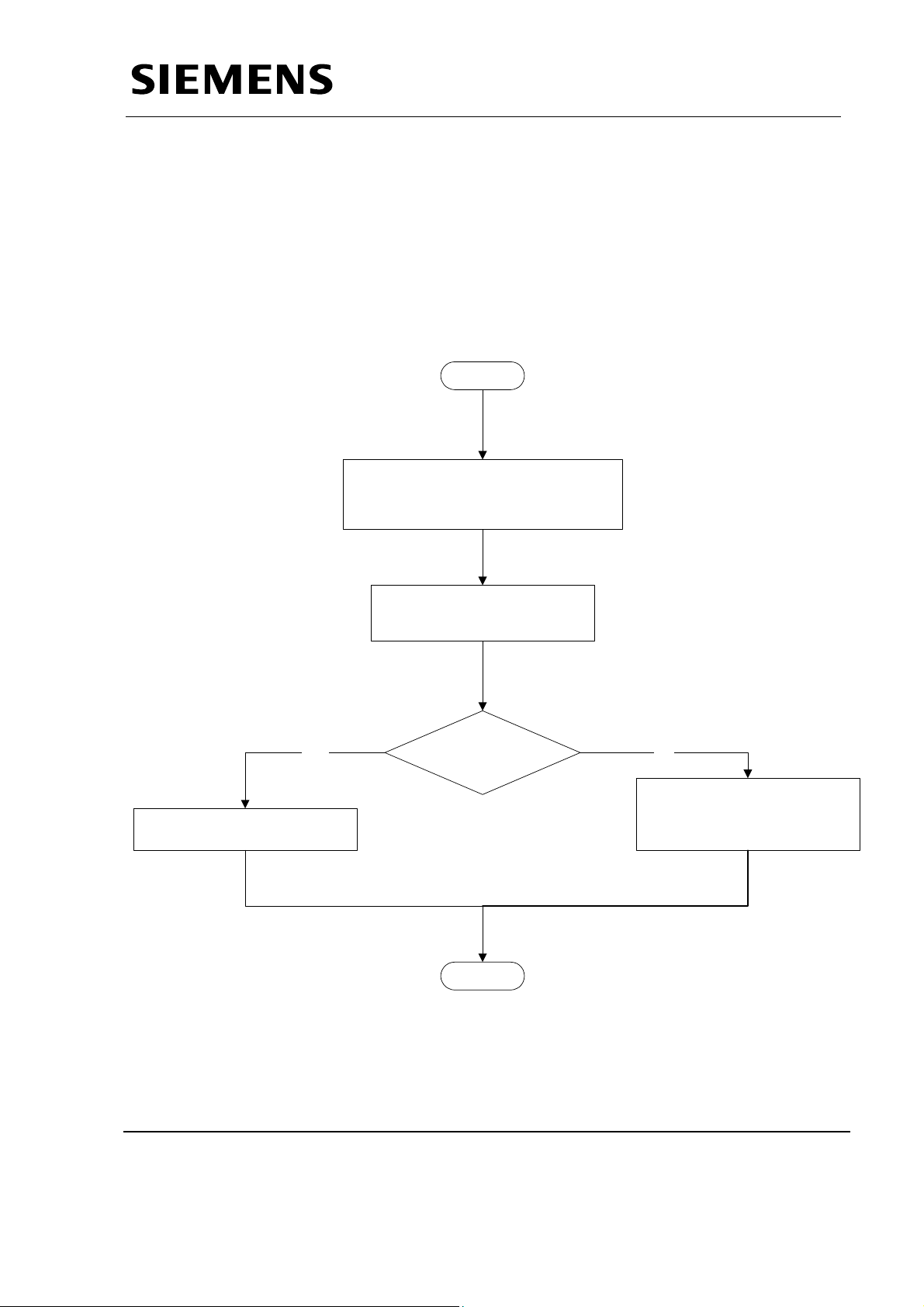

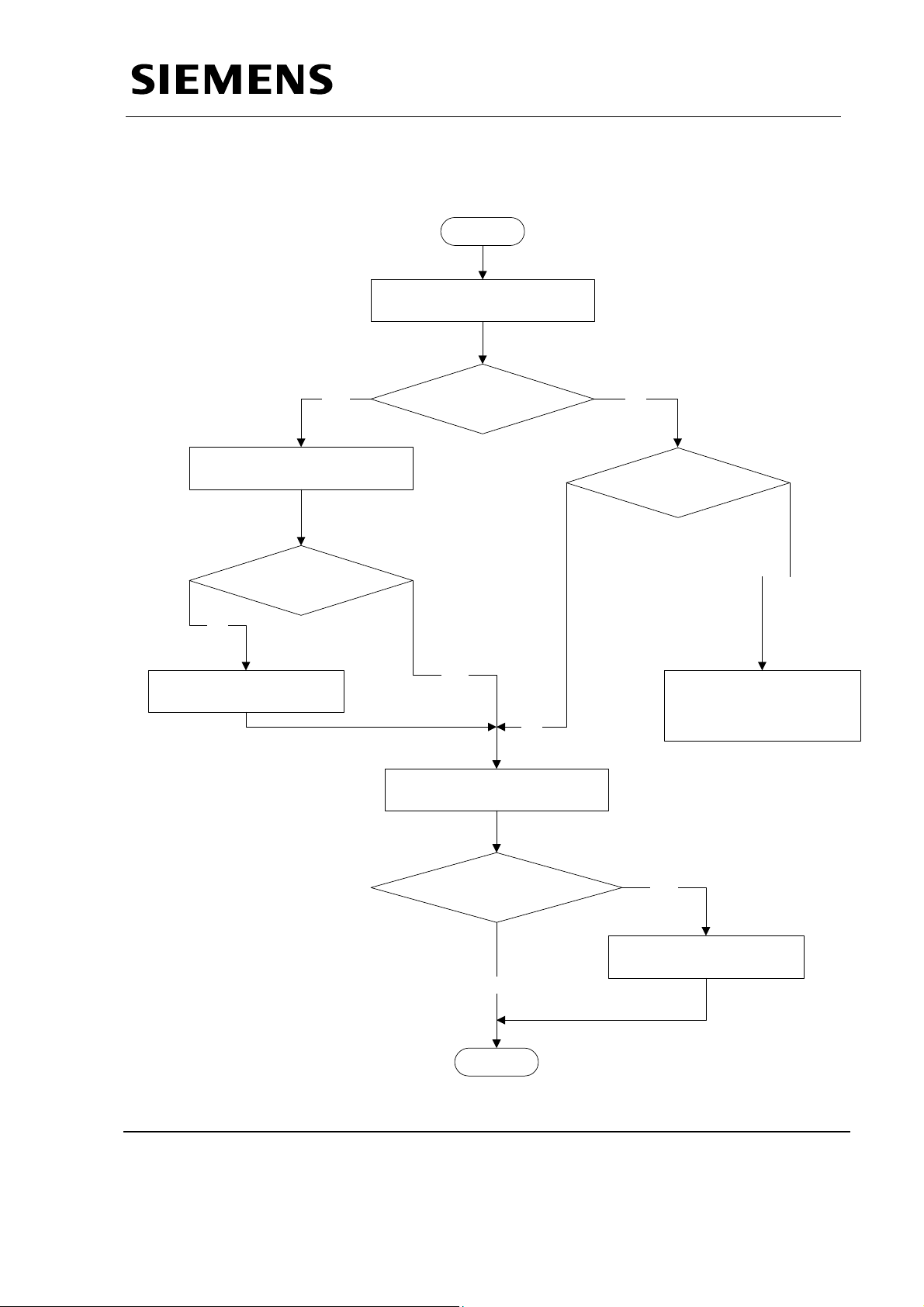

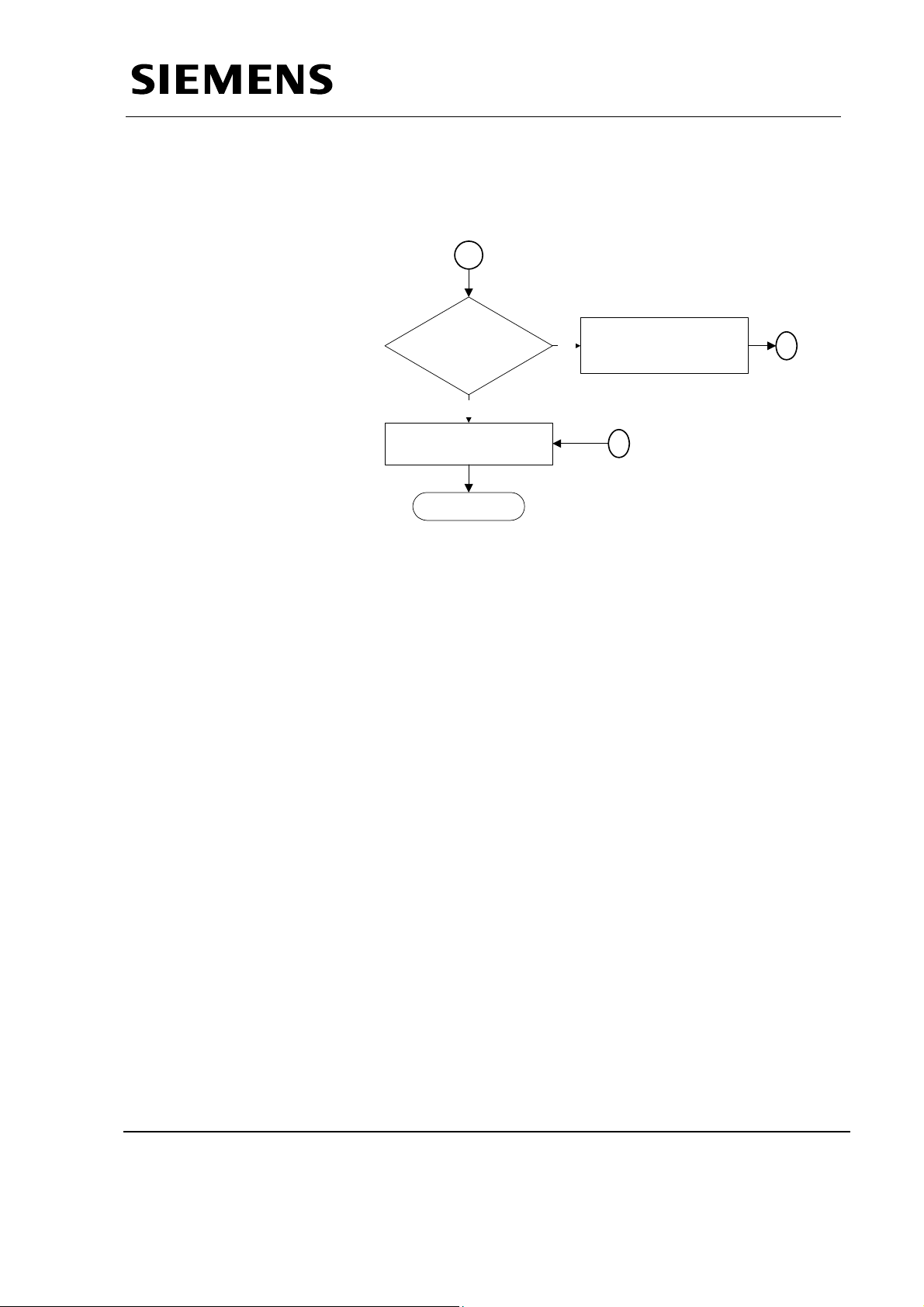

4.1 Unit not switching ON

START

MAKE MAINS

SWITCH ON

LED V50 ON on D801

Yes

PRESS SWITCH I ON

THE TOP PANEL

UNIT ON ?

yes

B

No

No

Are Transformer O/P?

Check Voltages on D801

between terminals X1.6-X1.7

Press the On Switch on the

Relay K5 and then K4 on

CHECK MAINS SUPPLY

should be 24V~.

Yes

Top Panel

Yes

D801 ON

No

No

Replace Transformer

(ON/OFF SWITCH IS

IF (ON/OFF SWITCH IS

Found faulty)

found faulty) THEN

THEN REPLACE D936

REPLACE D936 ELSE

ELSE

REPLACE D801.

REPLACE D801

IF

Yes

Check 220V on

Contactors NS,CS

operates?

Yes

B

No

D801X50.1-X50.3

Ensure relays K4,CS1

are operating.

A

Siemens Ltd. Med Division India Version 4.0

Page 25 of 48

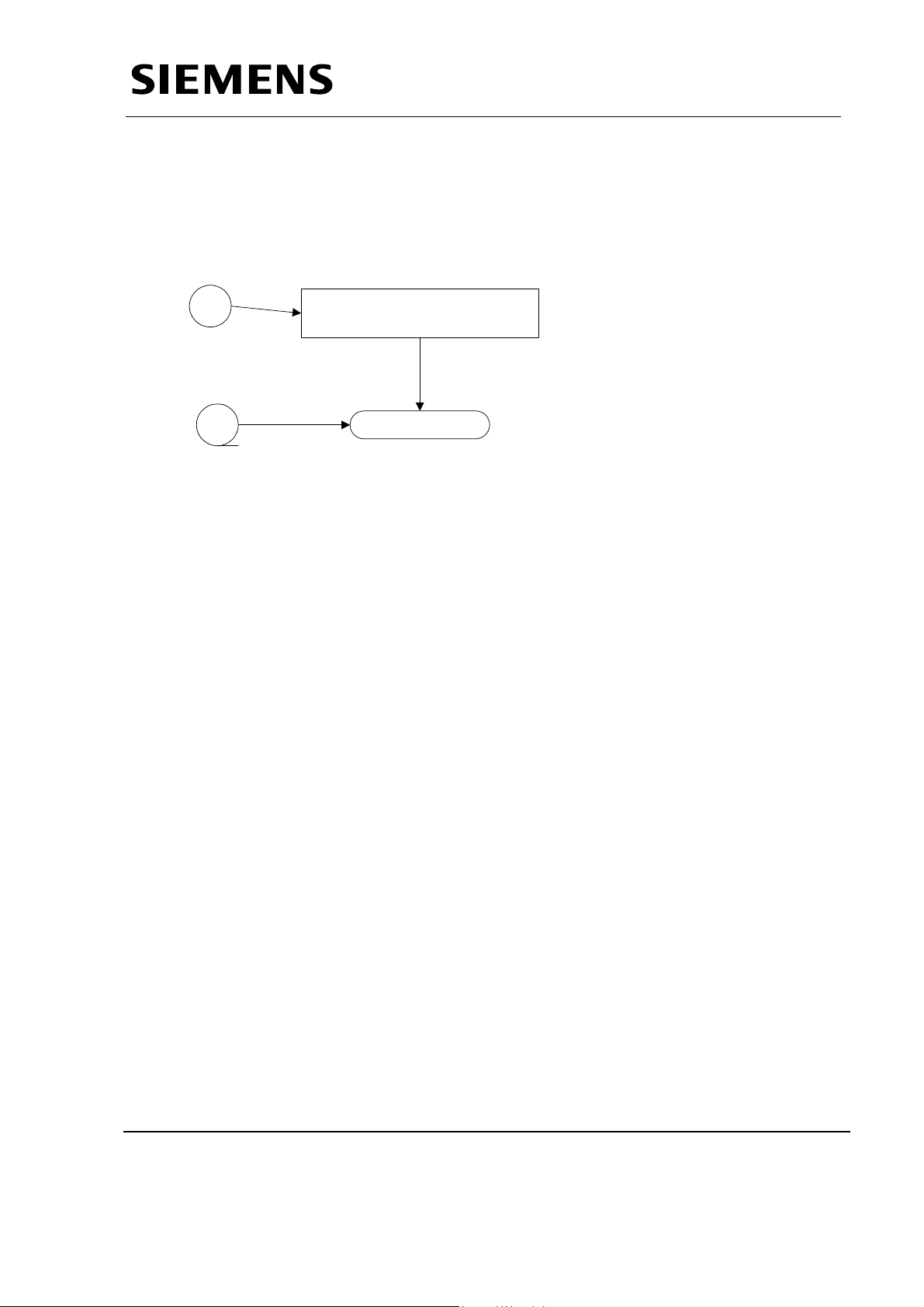

Page 27

Service Manual

Service Instructions

A

Measure voltages at X1.1 and

X1.4 of D801 should be 230v~

StopB

Siemens Ltd. Med Division India Version 4.0

Page 26 of 48

Page 28

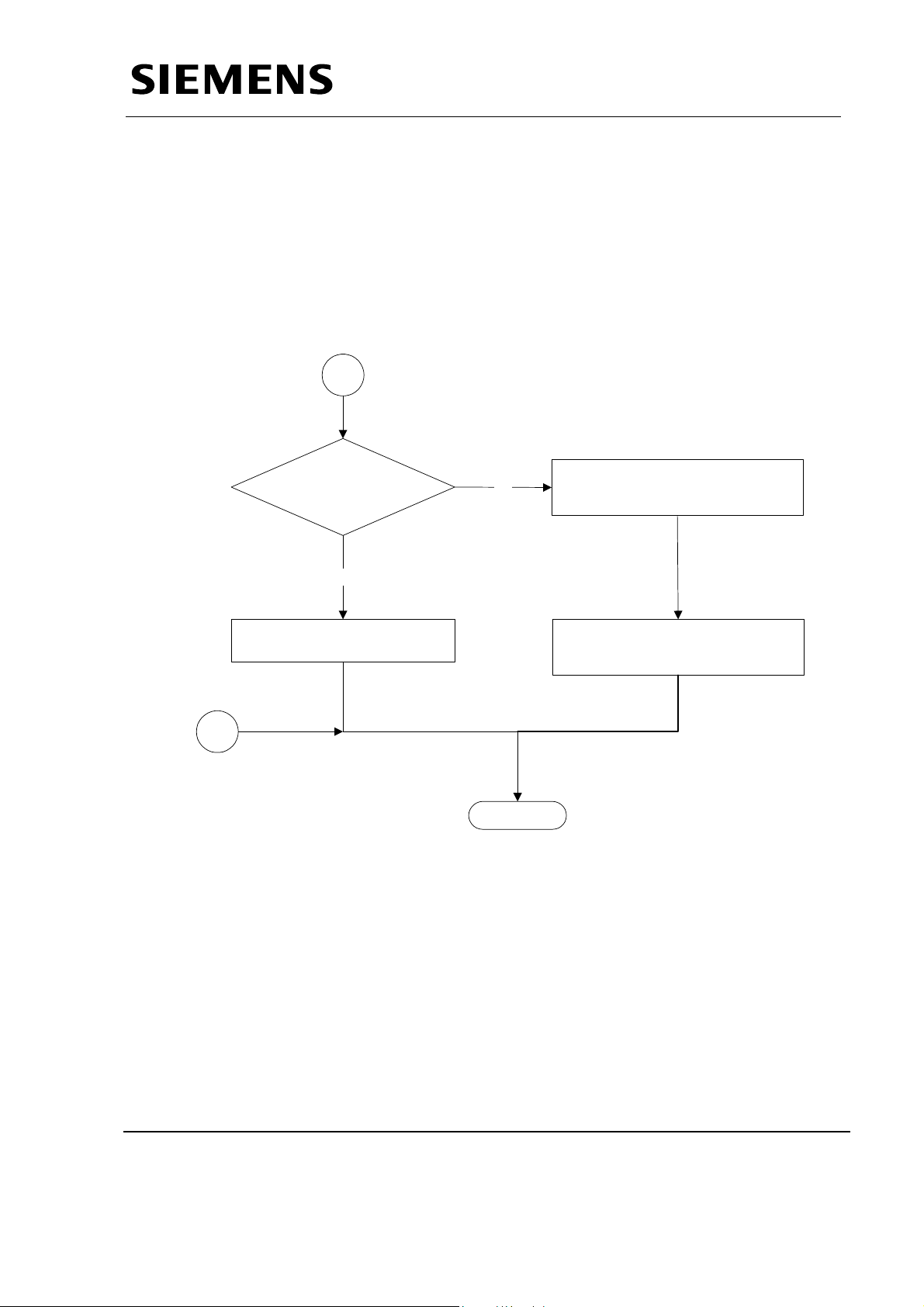

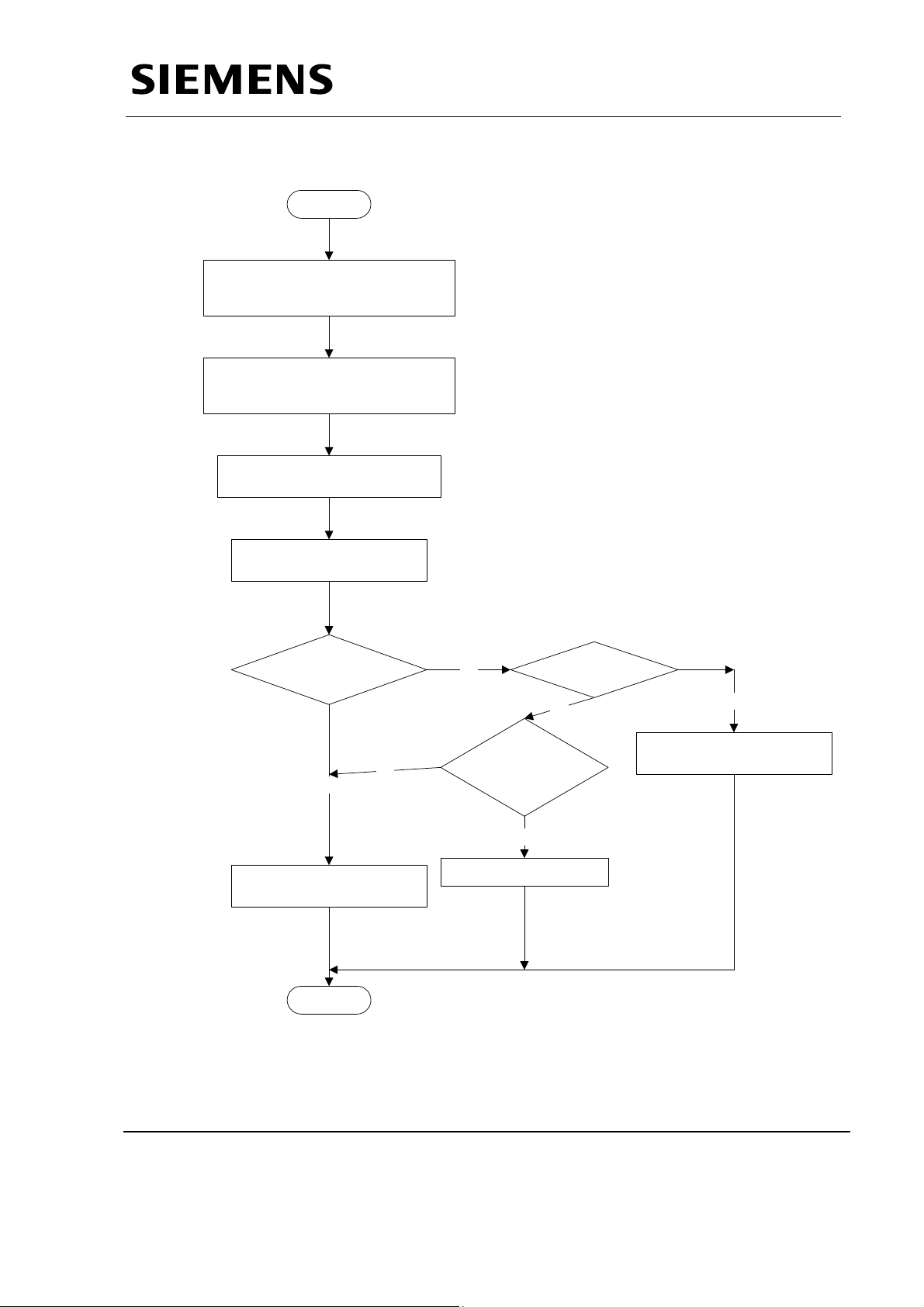

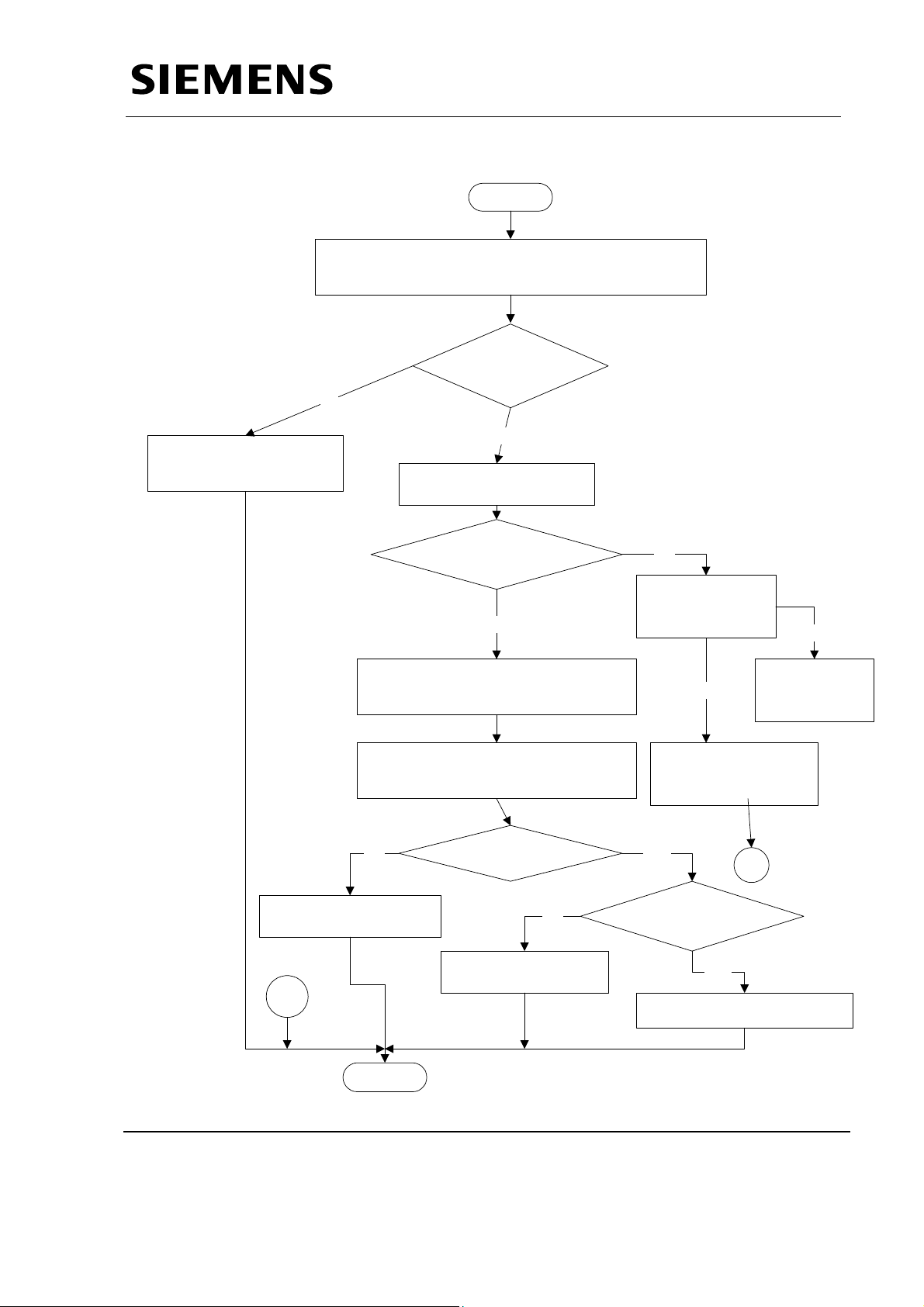

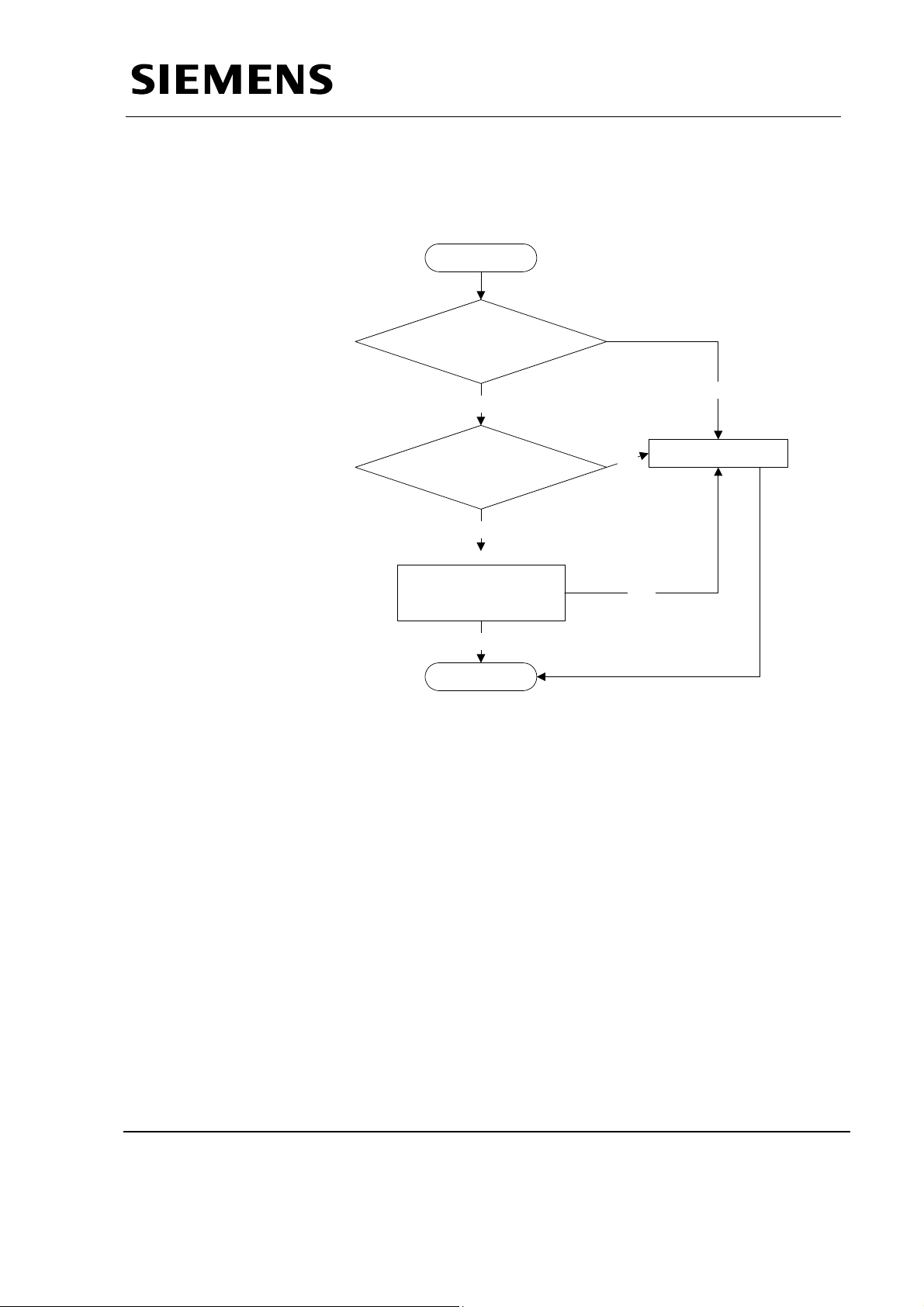

4.2 No Radiography

Service Manual

Service Instructions

START

UNIT IN STANDBY

STATE ?

Yes

PRESS RADIOGRAPHIC FIRST STEP.

FILAMENT BOOSTING ?

Yes

PRESS RADIOGRAPHIC SECOND

STEP.

No

GO TO INITIALISATION

GO TO INITIALISATION

ERRORS

ERRORS PAGE 25

NO

RADIAGRAPHIC

EXPOSURE INITIATED

No

B

?

Yes

EXPOSURE ERROR ?

Yes

GO TO EXPOSURE

GO TO EXPOSURE ERRORS

ERRORS

PAGE 31

NO

A

Siemens Ltd. Med Division India Version 4.0

Page 27 of 48

Page 29

Contd….

B

Service Manual

Service Instructions

HK

SIGNAL ON J36.15 ON

D915 OK ?

Yes

REPLACE D915 PCB

No

+15V SUPPLY TO

RADIOGRAPHIC SWITCH

REPLACE RADIOGRAPHIC

RELEASE SWITCH

A

STOP

Siemens Ltd. Med Division India Version 4.0

Page 28 of 48

Page 30

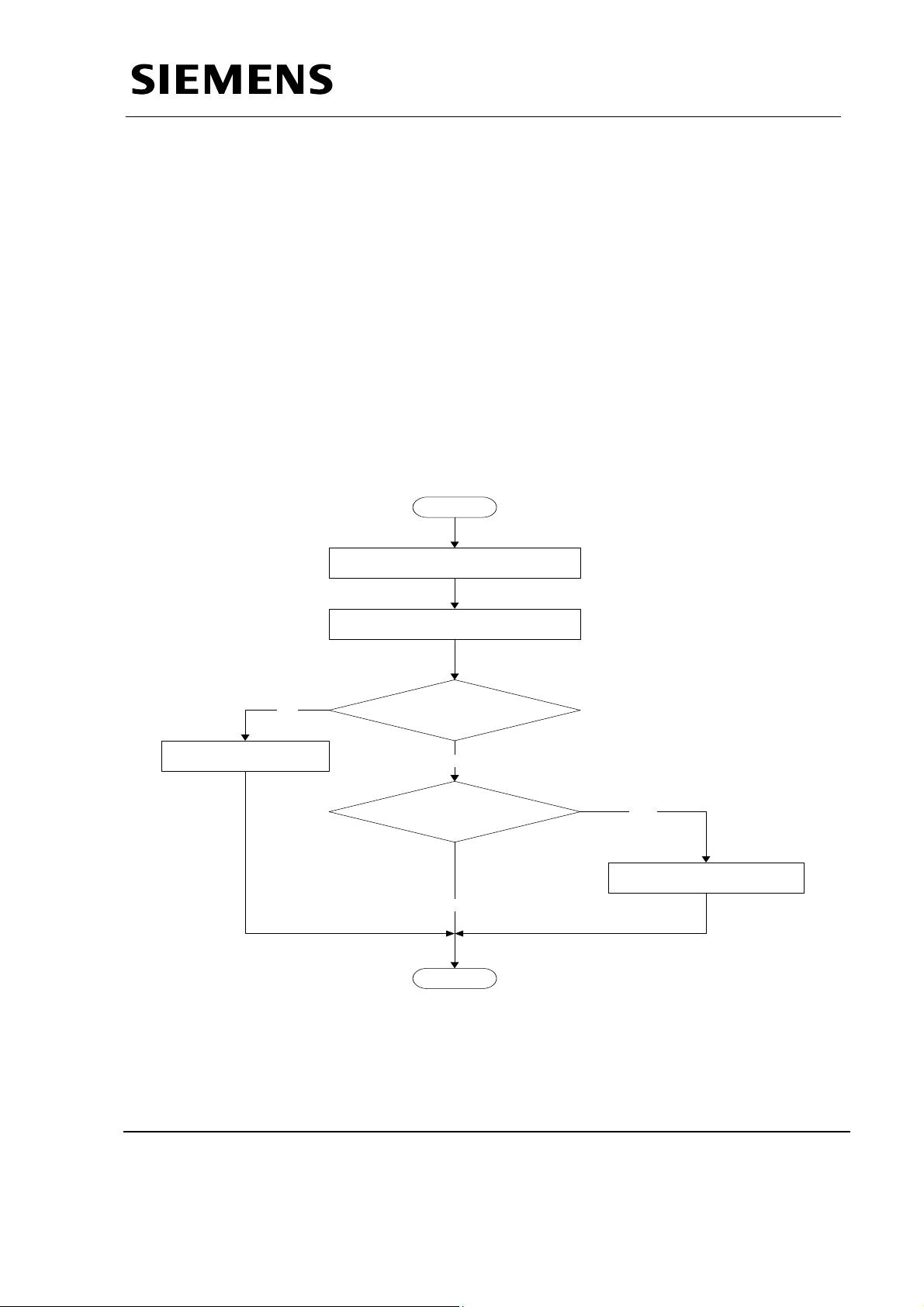

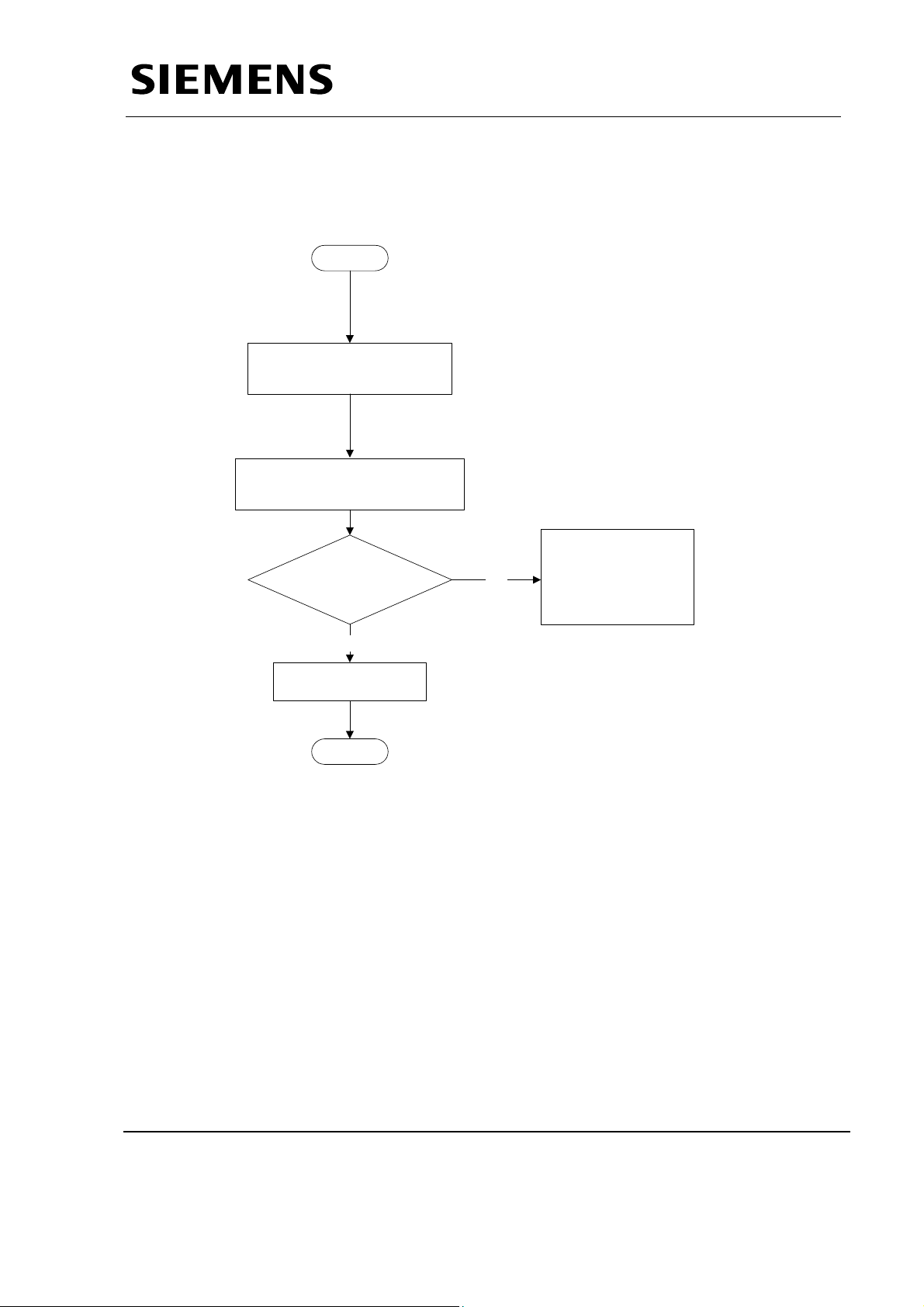

4.3 No Standby

START

MAKE THE MAINS SUPPLY

ON

PRESS the ON SWITCH ON

THE TOP PANEL

UNIT ON

?

Service Manual

GO TO “UNIT NOT

No

GO TO UNIT NOT

SWITCHING ON”

SWITCHING ON PAGE 20.

Service Instructions

Yes

WAIT FOR 3 SEC.

CS contactor

picks up?

Yes

DISPLAYS STABLE

KV,mAS ?

Yes

No

ANY ERROR

?

No

REPLACE D915 AND

CALIBRATE THE UINT

No

GO TO STANDBY ERRORS

GO TO STANDBY ERRORS

PAGE 26

Yes

GO TO INITIALISATION

GO TO “INITIALISATION

ERRORS PAGE 25

ERRORS”

CONFIRM STANDBY

PARAMETERS

STOP

Siemens Ltd. Med Division India Version 4.0

Page 29 of 48

Page 31

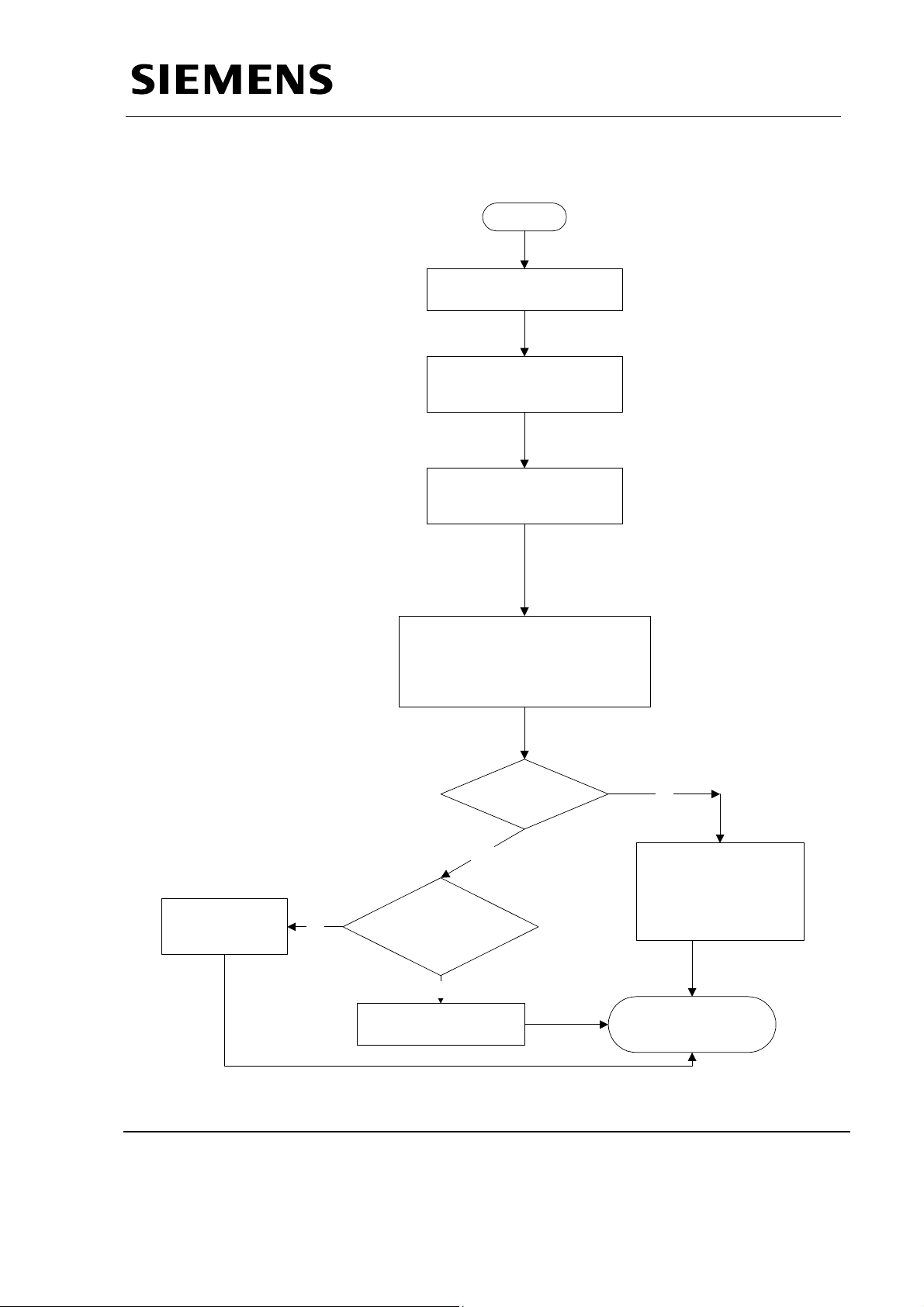

4.4 Initialisation codes

4.4.1 Code 90 (EPROM CHECKSUM FAILURE)

REPLACE J32 FIRMWARE

4.4.2 Code 96 (KV SOLL FAILURE)

ADJUST PRESET P7 ON D915

4.4.3 Code 97 ( mA FAILURE)

ADJUST PRESET P6 ON D915

START

Service Manual

Service Instructions

CONFIRM 230v SUPPLY

SWITCH ON THE UNIT

IS

SUPPLY OK ?

Yes

YES

?

REPLACE D915 PCB

No

STOP

REPLACE D980

NO

X15 CONNECTOR

ERROR CONTINUES

Siemens Ltd. Med Division India Version 4.0

Page 30 of 48

Page 32

4.5 Standby Codes

4.5.1 Code 02 : +15 V Supply Code

REMOVE CONNECOR X15 ON D915

& SWITCH ON THE UNIT

Service Manual

Service Instructions

START

YES

REPLACE D915 PCB

MEASURE +15 V ON X15

CONNECTOR

VOLTAGE=

13.5 TO 16.5 V ?

STOP

NO

ADJUST BY PRESET ON

D980. ELSE

REPLACE D980 PCB

Siemens Ltd. Med Division India Version 4.0

Page 31 of 48

Page 33

4.5.2 Code 03 & 04 : Iheiz < Istby & Iheiz > Istby

START

REMOVE X11 CONNECTOR ON

D915 & SWITCH ON THE UNIT

MONITOR

OBSERVE CAL FOR = 15KHz. &

SWITCH OFF THE UNIT

CAL

FREQUENCY.

TUNE BY P3

Service Manual

Service Instructions

MONITOR I RMS ON D915

I RMS = 0.6V +/- 0.1

No

Yes

REPLACE D915 PCB

STOP

No

Is Filament ON ?

No

Fil pulses at

J22.15 & J22.16 of

D915?

Yes

Replace D801

Yes

ADJUST BY PRESET P5

Siemens Ltd. Med Division India Version 4.0

Page 32 of 48

Page 34

4.5.3 Code 05 : kVist <> 0

START

Service Manual

Service Instructions

KVIST = 0 ?

(NO SPIKES)

Yes

REPLACE D915

No

X8 & X1

(ON D915 & D800) ARE

CONNECTED

PROPERLY ?

SWITCH OFF THE UNIT

R=20 Kohms AT

X8.1,X8.2 & X8.3

YES

Yes

MAKE THEIR

No

NO

REPLACE D800 PCB

ON THE SINGLE

TANK.

PROPER

CONNECTION

STOP

Siemens Ltd. Med Division India Version 4.0

Page 33 of 48

Page 35

4.5.4 Code 06 : JR <> 0

Service Manual

Service Instructions

START

ENSURE ALL CONNECTORS ARE

CONNECTED.

MONITOR JR & SWITCH ON

THE UNIT

REPLACE D915

REPLACE D915

YES

IS

JR = 0 & NO

SPIKES ?

Yes

Yes

STOP

CHECK X8

No

CONNECTOR ON D915.

SWITCH OFF THE UNIT

R=20 OHM AT X8.5 &

X8.6

No

REPLACE D800.

IF THE ERROR CONTINUES,

REPLACE SINGLE TANK AND

CALIBRATE THE UNIT.

Siemens Ltd. Med Division India Version 4.0

Page 34 of 48

Page 36

4.5.5 Code 33 : Main Inverter Short Circuit

START

ENSURE CONNECTIONS OF

X20 CONNECTORS ON

D960 AND D915.

MONITOR VP=15V ON D801.

AND REPLACE D801 IF FOUND

FAULTY.

Service Manual

Service Instructions

ERR/ SIGNAL

OBTAINED FROM D960

IN STBY MODE

No

REPLACE D915

STOP

Yes

CHECK IGBTs AND

REPLACE IF FOUND

SHORTED.

ELSE REPLACE IGBT

MODULE.

Siemens Ltd. Med Division India Version 4.0

Page 35 of 48

Page 37

4.6 EXPOSURE CODES

4.6.1 Code 11 : Main Inverter Short Circuit

START

MONITOR SCM SIGNAL AND

SWITCH ON THE UNIT

ENSURE J34 IC ON

D915 IS WORKING

Service Manual

Service Instructions

IC FAULT ?

No

SWITCH OFF & WAIT

FOR 5 SEC

IGBTS

SHORTED?

Yes

REPLACE IGBTs

ELSE REPLACE IGBT

MODULE

YES

No

REPLACE D915

STOP

Siemens Ltd. Med Division India Version 4.0

Page 36 of 48

Page 38

4.6.2 Code 12 : kVist > kVmax

START

MONITOR KVM & REG SIGNAL AND

TAKE AN EXPOSURE

Service Manual

Service Instructions

KVM PULSE

Yes

IS REG>15KHz ?

Yes

SWITCH OFF THE UNIT AND SHORT

THE

ST

LINK ON D915 PCB

SWITCH ON THE UNIT & SELECT THE

Pr.7 BY PRESSING KV+

PRESS DL_SERV KEY AND THEN

EXPOSURE RELEASE SWITCH

No

YES

ERROR CONTINUES

NO

SWITCH OFF THE UNIT

X8.1,X8.2 W.R.T. X8.3 ON

Yes

REPLACE D915

?

20K AT PIN

IS

D915

PCB ?

NO

A

No

REPLACE D800 PCB

ON SINGLE TANK

MONITOR REG AND SET THE

FREQUENCY TO 15KHz. BY VARYING

POT P4

A

ERROR CONTINUES

?

No

Yes

REPLACE SINGLE

TANK

STOP

Siemens Ltd. Med Division India Version 4.0

Page 37 of 48

Page 39

4.6.3 Code 13 : Iheiz > Imax OR JR > Jrmax

START

MONITOR IH AND JR ON

D915 PCB

IS

YES NO

DECREASE BY VARYING

POT P5 AND P6

IH MAX ERROR

?

Service Manual

Service Instructions

IS JR>JRmax ?

MONITOR I FOR

PULSES

NO

REPLACE D801 PCB

YES

NO

TAKE AN EXPOSURE

ERROR CONTINUES ?

No

YES

REDUCE OVERSHOOTS

IN JR BY PRESET P5

ELSE REPLACE D915

YES

REPLACE D915 PCB

STOP

Siemens Ltd. Med Division India Version 4.0

Page 38 of 48

Page 40

4.6.4 Code 14 : kVist < kVsoll

Service Manual

Service Instructions

START

No

REPLACE D800 PCB ON

SINGLE TANK

SWITCH

COME OUT IN INVERTER MODULE

MONITOR KVIST & KVSOLL AND

OFF

THE UNIT CONFIRM NO WIRE HAS

CONFIRM REG=15+/- 0.2 KHZ

IS

20K AT X8.1,X8.2

w.r.t. X8.3

?

Yes

SWITCH ON THE UNIT

CAP. BANK ON D970A IS

CHARGED ?

Yes

TAKE AN EXPOSURE

NO

CHECK THE O/P

DC VOLTAGE OF

D950A .

Yes

no

REPLACE THE

D950A PCB

MONITOR DISP1 & DISP2

PULSES,TAKE AN EXPOSURE

NO

REPLACE D915 PCB

PULSES ?

NO

U/V CURRENT W/F.

REPLACE THE

CHARGER MODULE

YES

A

OK?

REPLACE IGBT

MODULE

A

YES

REPLACE SINGLE TANK

STOP

Siemens Ltd. Med Division India Version 4.0

Page 39 of 48

Page 41

4.6.5 Code 15 : JR < JRS

Service Manual

Service Instructions

START

SWITCH OFF THE UNIT

CONFIRM mAS LINK ON

D800 PCB

CHECK 'I' FOR 0.6V

+/ -0.1V AC RMS

Check and

replace D800 if

found fauly.

No

Check for 22+/- 3 Ohms between

X8.5 and X8.6 and replace D800 if

found faulty.

KV build up OK?

Yes

Voltage betw. X8.5

and X8.6 is OK?

Yes

Check and replace

D915 if found faulty

No

Check Inverter ckt/

Inverter pulses/

Resonance cap. C5.

STOP

Siemens Ltd. Med Division India Version 4.0

Page 40 of 48

Page 42

4.6.6 Code 17 : Exposure terminated by Backup Timer

START

MONITOR JR ON D915 &

mAS ON D800 PCBS

Service Manual

Service Instructions

YES

MULTIPLY JR & PULSE

DURATION OF J1.9

IS

IT EQUAL TO mAS

?

Yes

ARE PULSES ?

NO

No

ADJUST FREQUENCY AT J1.9 BY

VARYING P1

NO

TAKE AN EXPOSURE AND

NOTE THE TIME

TIME EXCEEDS

EXPOSURE TIME ?

Yes

ERROR CONTINUES

Yes

?

REPLACE D915 PCB

NO

STOP

Siemens Ltd. Med Division India Version 4.0

Page 41 of 48

Page 43

4.6.7 Code 18 : Premature termination of Exposure

START

PRESS KV mAs KEY.

ERROR IS REMOVED.

Service Manual

Service Instructions

PRESS AND HOLD EXPOSURE RELEASE

SWITCH TILL EXPOSURE GETS

TERMINATED.

STOP

Siemens Ltd. Med Division India Version 4.0

Page 42 of 48

Page 44

4.6.8 Code 21 : Iheiz > Iheiz maximum

START

MONITOR IH ON D915 PCB

DECREASE BY VARYING

POT P5 AND P6

Service Manual

Service Instructions

YES

REPLACE D801

IS THERE ANY SPIKE ?

NO

TAKE AN EXPOSURE

ERROR CONTINUES ?

No

YES

REPLACE D915 PCB

STOP

Siemens Ltd. Med Division India Version 4.0

Page 43 of 48

Page 45

4.6.9 Code 22 : Maximum Preparation Time

START

ALLOW 2 TO 10 SEC TIME IN BETWEEN

FIRST & SECOND STEP OF RADIOGRAPHY

TAKE AN EXPOSURE

Service Manual

Service Instructions

ERROR CONTINUES

?

Yes

NO

REPLACE D915 PCB

STOP

Siemens Ltd. Med Division India Version 4.0

Page 44 of 48

Page 46

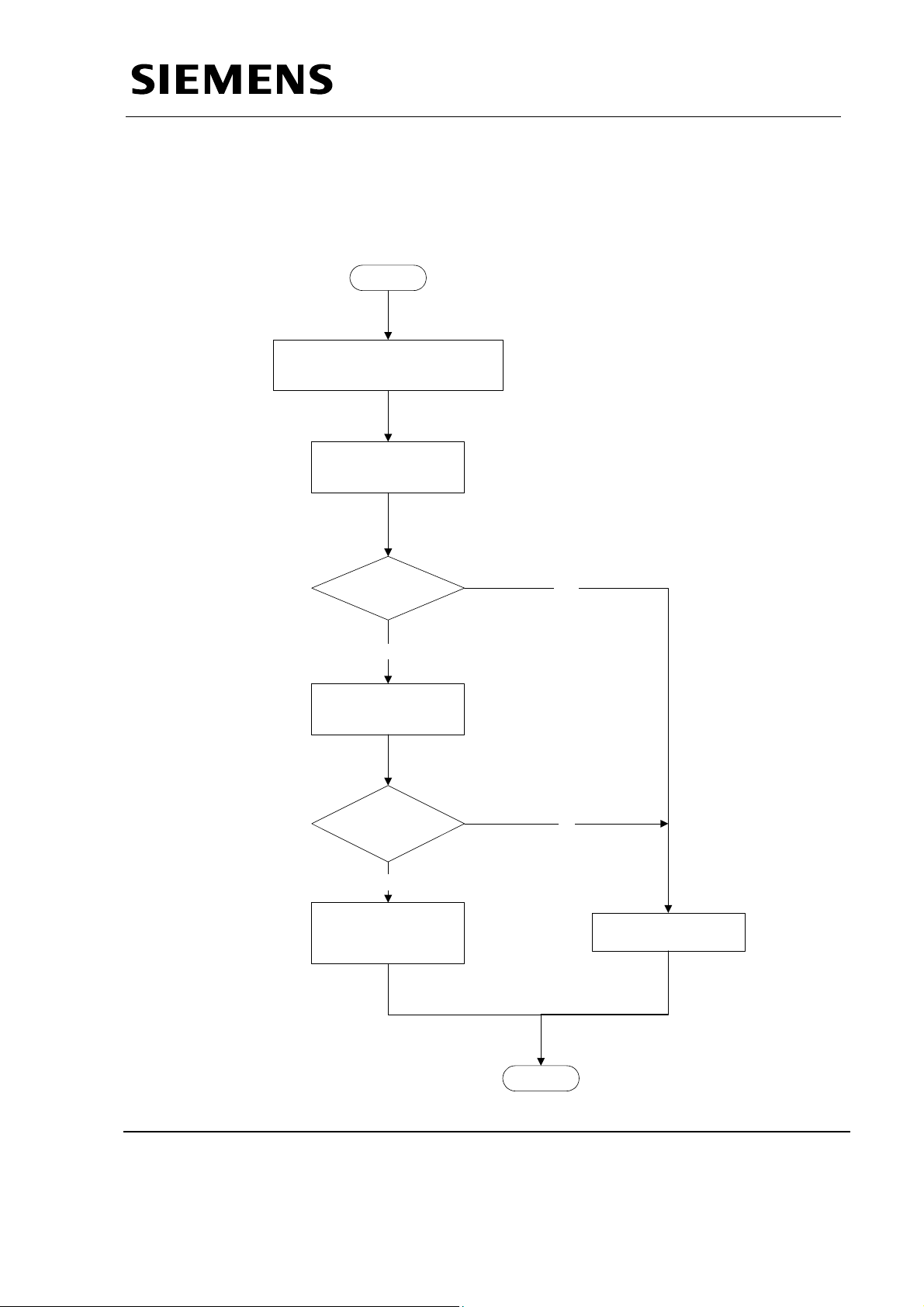

4.6.10 Code 10 : Rotating Anode not OK

ALLOW 2 TO 10 SEC TIME IN BETWEEN

FIRST & SECOND STEP OF RADIOGRAPHY

SingleTank rotating ?

No

Is ARR signal

obtained on D915?

Yes

220V AC supply to

Rot. Anode ckt OK?

Service Manual

Service Instructions

START

Is anode in the

Yes

Check feedback

voltages on test points

I1 and I2.

Yes

No

Replace D915

Check fuse F3 on D801

and replace if found

If relay K2 on D801

doesn't operate,replace

No

Replace D801

faulty.

K2

stop

Siemens Ltd. Med Division India Version 4.0

Page 45 of 48

Page 47

4.6.11 Code 31 : No charging

Service Manual

Service Instructions

Start

Check fuseF1 on

D950A is blown?

No

Check for 230v

across x3.2 and

x3.6 on D950A?

Yes

Check V24 on

D950A glows?

Yes

Check Vc test point on

D950A? Should be 3.3 Vdc.

Yes

Replace

fuse

1.Check for the

continuity of the wires.

If found faulty. Replace

No

with OK wires.

2.If found OK. Confirm

if CS operates. If not

Replace CS contactor

NO

NO

S

S

Yes

Replace D950A

Check Fr1 test point on

D950A? Should be 25 KHz

NO

frequency.

Yes

A

Siemens Ltd. Med Division India Version 4.0

Page 46 of 48

Page 48

Contd…….

Service Manual

Service Instructions

A

Check Vc on

D915? Should be

3.3V.

Yes

Replace D915.

Stop

Check if X20 cable is

No

OK.If found faulty

replace the cable.

S

S

Siemens Ltd. Med Division India Version 4.0

Page 47 of 48

Page 49

4.6.12 Code 01 : Err signal on D950A active

Start

Is tp test point on D950A

low?

Service Manual

Service Instructions

Yes

Is Vc>3.35v (A test point on

D950A?)

Yes

Whether IGBT V3 is

Short circuited.

NO

Stop

Replace D950A.

NO

YES

NO

Siemens Ltd. Med Division India Version 4.0

Page 48 of 48

Loading...

Loading...