Page 1

s

MULTIGAS and MULTIGAS+ Modules

Service Manual

Service Manual

Service ManualService Manual

E341.E536U.061.01.02.02

Replaces/Ersetzt:

ASK-T876-02-7600

EM Guidelines, 1997-04-02

Product Drawing

E341.E536U.061.01.01.02

Page 2

ADVISORY

Siemens is liable for the safety of its equipment only if maintenance, repair, and modifications are performed by

authorized personnel, and if components affecting the equipment's safety are replaced with Siemens spare parts.

Any modification or repair not done by Siemens personnel must be documented. Such documentation must:

• be signed and dated

• contain the name of the company performing the work

• describe the changes made

• describe any equipment performance changes.

It is the responsibility of the user to contact Siemens to determine warranty status and/or liabilities if other than

an authorized Siemens Service Representative repairs or makes modifications to medical devices.

Page 3

Table of Contents

Chapter 1: Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 1-1 MultiGas and MultiGas+ Modules - Rear Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Hardware Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3 Service Strategy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

4 Preventative Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

5 Recommended Tools & Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chapter 2: Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2-1 Functional MGM Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Overall Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Method of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2-2 Anesthetic Gas Subsystem Functional Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 Subassemblies, Modules and Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5 Anesthetic Gas Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

6 Main System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

7 Agent Measurement Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 2-3 Agent Measurement Analyzer Functional Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

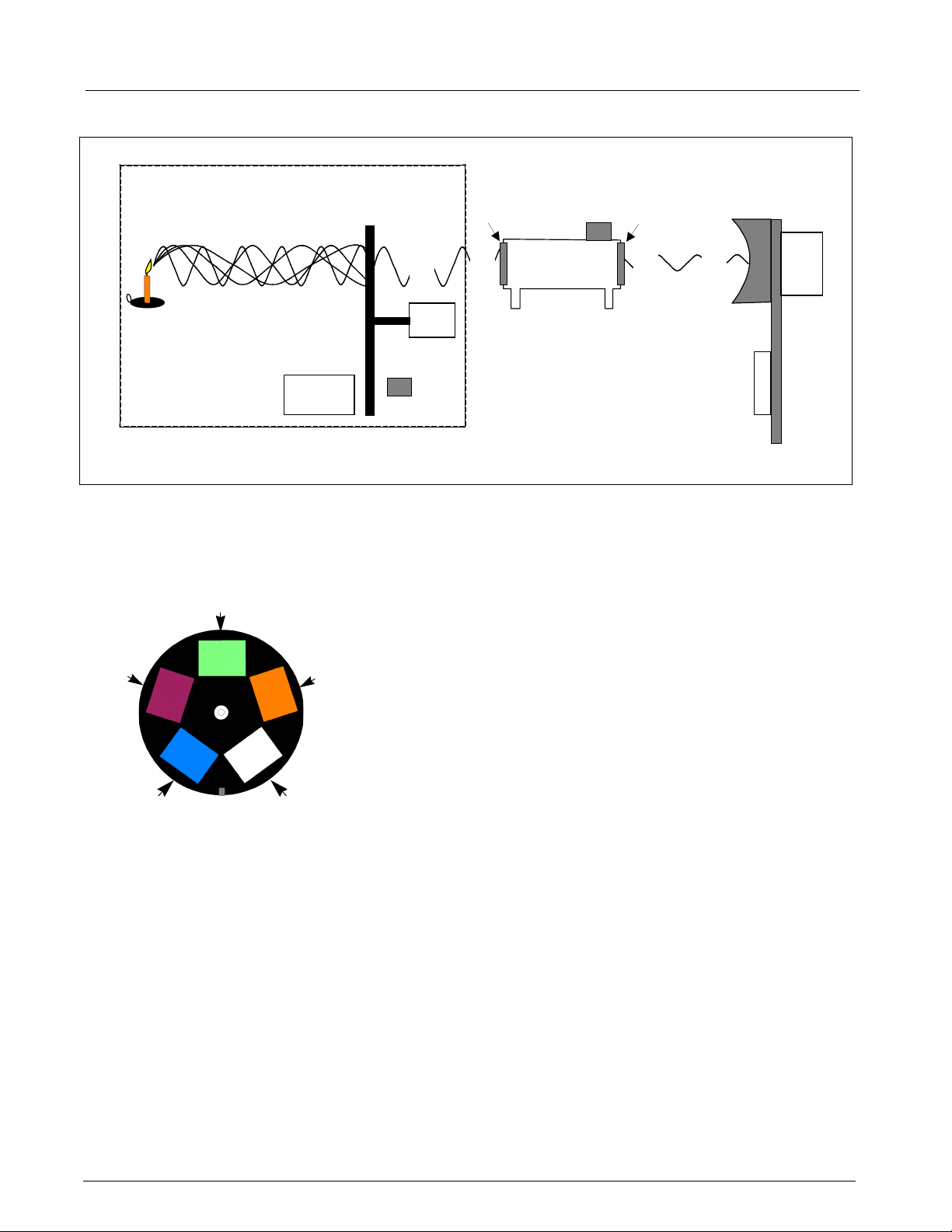

Figure 2-4 Agent Identification Analyzer (AIDA) Functional Block Diagram . . . . . . . . . . . . . . . . . . . . . . 9

8 Agent Identification Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

9 Oxygen Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

9.1 Paramagnetic O2 Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

9.2 Electrochemical O2 Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

10Pneumatic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 2-5 Pneumatics Block Diagram (excerpt from Figure 2-2.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 2-1 Pump Flow Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

11Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

12Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

12.1Factory Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

12.2Field Span Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

12.3Zero Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

12.4Storage of Calibration Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

12.5Calibration of Agent Measurement Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

12.5.1 Factory Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

12.5.2 Field Span Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

12.5.3 Zero Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

ASK-T876-02-7600 Siemens Medical Systems, EM-PCS Danvers i

mgm2.sm.fm/11-00/kaupp

Page 4

MGM and MGM+ Modules Service Manual

12.6Agent Identification Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

12.6.1 Factory Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

12.6.2 Field Span Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

12.6.3 Zero Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

12.7Paramagnetic O2 Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

12.7.1 Factory Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

12.7.2 Field Span Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

12.7.3 Field Zero Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

12.8Fuel Cell Type O2 Analyzer Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

12.8.1 Factory Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

12.8.2 Field Span and Zero Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

12.8.3 Field Zero Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

12.9Pneumatic System Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

12.9.1 Factory Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

12.9.2 Field Flow Rate Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

13Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

13.1AMA Data Acquisition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 2-6 Software Functional Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

13.2AMA Signal Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

13.3AMA Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

13.4Patient Data Derivation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

13.5Host System Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

13.6Anesthetic Gas Subsystem / Host System Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

13.7AIDA Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

13.8MGM/AMA Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

13.9AIDA Data Acquisition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

13.10AIDA Signal Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

13.11AIDA Agent Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

13.12AIDA Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Chapter 3: Removing / Installing Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.1 Opening Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 3-1 Pump and Pneumatic Subassemblies in MGM+ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2 MGM+ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.1 Pneumatic Tubing Subassemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.1.1 Removing Pneumatic Subassemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.1.2 Installing Pneumatic Subassemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 3-2 Pump and Pneumatic Subassemblies in MGM (Slo-O2) . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

ii Siemens Medical Systems, EM-PCS, Danvers ASK-T876-02-7600

mgm2.sm.fm/11-00/kaupp

Page 5

Service Manual MGM and MGM+ Modules

3 MGM (Slo-O2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.1 Replacing Pneumatic Subassemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.1.1 Removing Pneumatic Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.1.2 Installing Pneumatic Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4 Replacing Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.1 Removing Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.2 Installing Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5 Pump Filter Removal/Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.1 Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.2 Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6 Nafion® or other Tubing Removal/Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.1 Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.2 Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7 Room Air Filter Removal/Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

7.1 Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.2 Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8 AMA Analyzer Head Removal/Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.1 Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.2 Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

9 AMA Sample Cell Removal/Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

9.1 Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 3-3 System PC Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

9.2 Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

10Agent ID Analyzer Removal/Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

10.1Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

10.2Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

11MGM System Board Removal/Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

11.1Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

11.2Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

12Fast O2 Sensor Assembly Removal/Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

12.1Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 3-4 MGM Module Rear View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 3-5 Pneumatic Tubing Disconnection Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 3-6 Rear Panel Subassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

12.2Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

13CAN PC Board Removal/Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

13.1Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

13.2Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

ASK-T876-02-7600 Siemens Medical Systems, EM-PCS Danvers iii

mgm2.sm.fm/11-00/kaupp

Page 6

MGM and MGM+ Modules Service Manual

14Power Supply Removal/Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

14.1Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

14.2Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

15Solenoid #1 & #3 Removal/Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

15.1Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

15.2Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

16Solenoid #2 Removal/Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

16.1Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

16.2Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

17NVRAM Transfer Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

17.1Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

17.2Equipment required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

17.3NVRAM Transfer procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Chapter 4: Adjustment / Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

1 Recommended Tools & Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2 Leakage Check Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3 Pump Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4 O2 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5 Pump Flow Rate Adjustment Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6 Agent Detection and Analysis Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 4-1 Gas Calibration / Test Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Chapter 5: Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

1 Agent Measurement Analyzer Head) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 5-1 AMA Analyzer Head Problems 37

2 Agent Measurement Analyzer Optical Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 5-2 AMA Optical Path Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3 Agent Identification Analyzer Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 5-3 AIDA Analyzer Head Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 5-4 Power Supply Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

5 O2 Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 5-5 O2 Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6 Sample Delivery Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 5-6 Sample Delivery Subsystem Problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7 Gas Flow Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 5-7 Gas Flow Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

iv Siemens Medical Systems, EM-PCS, Danvers ASK-T876-02-7600

mgm2.sm.fm/11-00/kaupp

Page 7

Service Manual MGM and MGM+ Modules

8 Bad MGM System Board suspected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 5-8 MGM System Board Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

9 MGM System Board Test Points, Jumpers, & Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 5-9 MGM System Board Test Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 5-10Connector Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Table 5-11Jumpers, Functions, and Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 5-12O2 Jumper Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Chapter 6: Functional Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

1 Pneumatics Leakage Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

2 Pump Flow Rate Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3 Gas Identification Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4 Safety Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.1 Resistance Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.2 Chassis Leakage Current Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 4-2 Leakage Current Tests Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Appendix A: Spare / Exchange Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure A-1 MultiGas Module (Fuel Cell Type Sensor) Pneumatics . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure A-2 MultiGas+ Module (Paramagnetic Sensor) Pneumatics . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure A-3 MultilGas Module (Fuel Cell Type Sensor) Cable Interconnections . . . . . . . . . . . . . . . . . 50

Figure A-4 MultilGas+ Module (Paramagnetic Sensor) Cable Interconnections . . . . . . . . . . . . . . . . 51

Figure A-5 MGM / MGM+ Selected Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure A-6 MGM / MGM+ Cover and Mounting Feet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure A-7 MultiGas / MultiGas+ Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Appendix B: Exploded-View Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure B-1 MultiGas Module - Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure B-2 MultiGas+ Module - Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure B-3 MultiGas Module Rear Panel Subassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure B-4 MultiGas+ Module Rear Panel Subassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure B-5 Agent Measurement Analyzer / Agent Identification Analyzer Subassembly . . . . . . . . . 58

Figure B-6 MGM Top Cover and Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure B-7 MGM System Board Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Appendix C: Functional Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Appendix D: Disease Prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

1 Siemens Disease Prevention Policy Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

ASK-T876-02-7600 Siemens Medical Systems, EM-PCS Danvers v

mgm2.sm.fm/11-00/kaupp

Page 8

MGM and MGM+ Modules Service Manual

2 Know the Facts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

2.1 Types of Viruses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

2.2 Facts About ARC, AIDS, Hepatitis B, and TB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

3 Environmental Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

4 Protocol for Servicing the MGM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4.1 Preparation for Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4.2 Precautions During Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4.3 After Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4.4 Disposing of Pneumatic System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5 Accidental Skin Puncture Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6 Disease Prevention Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Appendix E: Supplemental Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

2 Hardware Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

vi Siemens Medical Systems, EM-PCS, Danvers ASK-T876-02-7600

mgm2.sm.fm/11-00/kaupp

Page 9

Chapter 1 Introduction

1Overview

Fan Filter

(covered)

ULTIGAS

M

perform sidestream measurements of respiratory and anesthetic gases.

The modules automatically identify and measure five common anesthetic

agents (Isoflurane, Halothane, Enflurane, Sevoflurane, Desflurane), and

report the agent detected and its measurement data to the host device

(such as an SC 9000, SC 7000, SC9000XL, or SC 8000 Patient Monitor, or

KION). The modules also monitor respiratory gases CO

report measurements to the host as waveforms (except N

parameters.

M

ULTIGAS

measure O

cell, and calculates average inspiratory values for O

ULTIGAS

M

provides both inspired and expired O

outward appearance of the modules differs only in the rear view. The O

galvanic cell is visible on the rear panel of the M

paramagnetic cell is internal in the M

this service manual, the term M

ULTIGAS

M

Exhaust Port Grounding Stud

™ and M

and M

2

ULTIGAS

ULTIGAS

. The basic M

+™ Modules (MGM) are free-standing units that

, N2O, and O2, and

2

O) and

2

+ Modules differ only in the way that they

ULTIGAS

Module measures O2 using a galvanic

(labeled iO2). The

2

+ Module Incorporates a faster-acting paramagnetic sensor that

measurements (iO2 and etO2). The

2

2

ULTIGAS

ULTIGAS

ULTIGAS

Module. The

+ Module. See Figure 1-1. In

is used synonymously with

+ unless specifically stated otherwise.

Fan Filter

(covered)

Exhaust Port

Grounding Stud

Power ConnectorO

O2 Cell

Figure 1-1 M

Cell

2

Connector

ULTIGAS

ULTIGAS

M

and M

Module M

ULTIGAS

2 Hardware Installation

X12

X12

CPS Connectors

IDS Connectors

SC 8000 ADV COM Option

CAN

Hardware Version

Label

RS232 Connector

Software Version

Label

Power Connector

ULTIGAS

+ Module

Hardware Version

Label

RS232 Connector

Software Version

Label

+ Modules - Rear Views

MGM connects to the host (monitor) via an I

Power Supply (CPS) or I

NFINITY

Docking Station (IDS) or SC 8000 Patient

NFINITY

Device Communication

Monitor. A cable connects the RS232 port on the rear of the MGM to the

SC 8000 or to X12 on the CPS/IDS. (The IDS must have a MIB Option

installed; SC 8000 requires installed Adv Com Option.) See illustrations at

left. The host displays parameter and setup information, only while the

module is actually connected. When the module is disconnected, all

parameters, waveforms, and setup menus remain on the display until the

host is powered off. If host is powered on again without MGM connected,

gas parameters and waveforms do not reappear.

Refer to the User Guide for the software version installed in the monitor,

for applicable Technical Data, and for procedures to access the MGM

menu structure in the monitor.

ASK-T876-02-7600 Siemens Medical Systems, EM-PCS Danvers 1

mgm2.sm.fm/11-00/kaupp

Page 10

MGM and MGM+ Modules Service Manual

3Service Strategy

In light of the state-of-the-art technology used in the manufacture of

Siemens' equipment, proprietary nature of the software, and specialized

equipment required for replacement of most individual parts, Siemens’

policy is for the MGM to be serviced only to the field-replaceable

subassembly level, after expiration of the warranty period. While in the

warranty period, an MGM found to be malfunctioning should be returned

to the factory for repair or replacement. After expiration of the warranty

period, replacement of components other than those listed in Spare /

Exchange Parts should be performed only at Siemens service depots.

4 Preventative Maintenance

Siemens recommends that the following preventative maintenance

procedures be performed annually.

Warning

All parts of a MultiGas/+ module that come in contact with the

patient’s airway (such as all internal and external tubing, water

trap and water trap manifold, and filters) may be contaminated.

Handle according to the hospital’s procedures and guidelines for

handling infectious substances. Also, see Disease Prevention.

Before initiating preventative maintenance procedures, do the following:

• With MGM running with host, verify that the reported revision of the

software and hardware is up to date in accordance with the Software

Compatibility Chart for the I

software in the host if the host is operating in standalone mode). If

not, the unit can be updated later in this procedure.

• Verify status that no errors are flagged. If any errors are flagged,

troubleshoot and repair the MGM before completing the following

procedure.

1. Turn off power to MGM.

2. Unscrew top cover, and gently remove cover.

3. Inspect and replace the following, if necessary (expected replacement

rate of these parts is once per year):

• Internal Nafion® Tubing Assy (qty=2)

•Room air filter

• Pump filter

• Internal Bacterial filter (qty=2)

• Water trap seals (qty=2)

•Fan filter

NFININTY NETWORK

(or with the installed

• Water trap

4. Clean and remove any excess dust, etc.

5. If necessary, update software and/or hardware.

6. Power up MGM.

2 Siemens Medical Systems, EM-PCS, Danvers ASK-T876-02-7600

mgm2.sm.fm/11-00/kaupp

Page 11

Service Manual MGM and MGM+ Modules

7. Perform Leakage Check Procedure.

8. Perform Pump Flow Rate Verification Procedure.

9. Perform Span Verification Procedure.

10. Turn unit off and replace top cover.

11. Power up unit and verify status is okay.

5 Recommended Tools & Test Equipment

• SC 9000, SC 7000 / SC 9000XL Patient Monitor with CPS or IDS (with

installed MIB Option + CAN), or SC 8000 (with installed Adv Com

Option), or KION

• Appropriate communication cables (from host to MGM).

• Siemens Calibration Kit - SVC TOOL MGM/MGM+ CAL KIT, Art. No.

52 07 415 E536U, containing the following:

Calibration gas - contains 3.00% Isoflurane, 5.00% CO

, 40.00% N2O,

2

52% Oxygen (with a 1% gas concentration accuracy), Siemens Art.

No. 57 36 322 E536U.

Gas Regulator

Tubing w/ Luer-lock fittings

T-Piece w/ Luer-lock fittings

Two-way valve w/ Luer-lock fittings

Gas collection bag

• Flow meter with a range of minimum 0 - 350 ml/min, accuracy ±5%

or better, (Sierra Flow Control Model 822-13-OV1-PV1-V1 calibrated

for “standard - l/min” is recommended

• Pressure Gauge

Recommended: Setra Digital Pressure Gauge, Model 370 or equiv.

Note: Pressure gauge required only if verifying and/or calibrating the

pressure channel. The hospital and/or a local weather station or

airport may be able to provide a reading.

• Exhaust system (for exhausting calibration gas).

• Digital Voltmeter w/ 3½ digit resolution (minimum)

• Oscilloscope (optional)

• Hand tools:

— Medium sized Phillips screwdriver

— Medium sized flat head screw driver

— Wire cutters

— Non - serrated needle nose pliers

• Loctite adhesive or equivalent

ASK-T876-02-7600 Siemens Medical Systems, EM-PCS Danvers 3

mgm2.sm.fm/11-00/kaupp

Page 12

MGM and MGM+ Modules Service Manual

This page intentionally left blank

4 Siemens Medical Systems, EM-PCS, Danvers ASK-T876-02-7600

mgm2.sm.fm/11-00/kaupp

Page 13

Chapter 2 Functional Description

1Introduction

Breathing

Circuit

Airway

Adapter

THE MULTIGAS

Both

infrared measurement of respiratory and anesthetic gases. The O

analyzer subsystem of the M

cell, and the M

are designed to work with the host monitor through a serial digital

interface. The MGM is intended for measuring airway gases of ventilated

patients, within the anesthesia workplace, during the induction and

maintenance of, and emergence from, general anesthesia.

Main System &

Subsystem Hardware

Pneumatic System

Agent Analyzer

Oxygen Analyzer

Agent Identification

and M

ULTIGAS

Central

Processing

(Firmware)

Communications

Data Processing

Flow Control

ULTIGAS

+ Modules provide a non-dispersive

ULTIGAS

module uses an electrochemical fuel

2

+ module uses a paramagnetic cell. Both modules

Host Unit

Sample Gas

Exhaust

Figure 2-1 Functional MGM Block Diagram

2 Overall Functionality

3 Method of Operation

The MGM pulls the sample gas off the endotracheal tube of a ventilated

patient and leads the sample gas through three analyzer subsystems: the

Agent Measurement Analyzer (AMA), the Oxygen (O

) Analyzer, and the

2

Agent Identification Analyzer (AIDA). The computational processing unit in

the MGM derives waveform data for CO

Halothane, Enflurane, Isoflurane, Sevoflurane, and Desflurane), and O

, anesthetic agents (one out of

2

,

2

together with airway respiration rate and inspired and end-tidal values for

the gases, and also including N

O. The derived data is transmitted to the

2

host system which derives alarms from the received data, displays all the

alarms and data, and communicates them to other functional modules in

the monitoring system.

The airway gases measurement technique used in the AMA subsystem

and the AIDA subsystem are based on the non-dispersive infrared

absorption of light by molecular gases.

The airway gases measurement technique used in the oxygen analyzer

subsystem of the Anesthetic Gas Subsystem is dependent on the type of

O

transducer used.

2

ASK-T876-02-7600 Siemens Medical Systems, EM-PCS Danvers 5

mgm2.sm.fm/11-00/kaupp

Page 14

MGM and MGM+ Modules Service Manual

Figure 2-2 Anesthetic Gas Subsystem Functional Block Diagram

4 Subassemblies, Modules and Components

This document describes the subassemblies, modules, and components

of the MGM, how they are controlled by the central processing unit, how

the CPU processes the data received from the analyzer subsystems, and

how communication between the MGM and the host system (SC 9000,

SC 7000, SC 9000XL, or SC 8000 Patient Monitor) works.

5 Anesthetic Gas Subsystem

Figure 2-2 shows a functional block diagram of the Anesthetic Gas

Subsystem, which houses the system board and the following major

components:

• Agent Measurement Analyzer (AMA)

• Agent Identification Analyzer (AIDA)

• Oxygen (O

• Pneumatic System

• Power Supply

These components are typically built into a metal box whose dimensions,

weight, and additional features meet the unique requirements of the

SC9000, SC 7000, SC 9000XL, SC 8000 or similar host. Typically it includes

a power switch, a power connector, an RS-232 connector, a gas inlet, and

an exhaust tube.

) Analyzer

2

6 Main System

The Pneumatic System (consisting of the pump, tubing system, solenoid

valves, and flow control components) pulls the gas from the gas inlet

through the analyzer subsystems at a well-defined flow rate. The second

solenoid valve is used when both the Oxygen (O

Identification Analyzer are installed.

6 Siemens Medical Systems, EM-PCS, Danvers ASK-T876-02-7600

) Analyzer and the Agent

2

mgm2.sm.fm/11-00/kaupp

Page 15

Service Manual MGM and MGM+ Modules

The Agent Measurement Analyzer determines the concentration of CO

N

O and one anesthetic agent in the gas sample. The AMA is plumbed

2

“first in line,” so that CO

data is not distorted and capnographic

2

2

waveforms can accurately be displayed by the host monitoring system.

The O

Analyzer determines the oxygen concentration in the gas sample.

2

The Pressure Transducer measures the differential pressure of the gas

contained in the pneumatic system. During a Zero calibration this equals

the ambient environmental pressure. This pressure transducer is

physically housed in the AMA, but plumbed after the O

Analyzer.

2

The Agent Identification Analyzer determines which anesthetic agents, if

any, are contained in the gas sample.

The Power Supply provides the Anesthetic Gas Subsystem and all of its

components with the power necessary to keep the system working. It

operates at an input voltage range of 100 - 240 V

, and is certified to be in

ac

compliance with the applicable requirements of UL544 (Patient Care

Equipment), CSA 22.2 No. 234 (Level 3), IEC 601-1 (1988), EN60601, and

VDE 0750/5.82.

The Electronics Subsystem, with memory (ROM and RAM), multiplexers,

A-D converter, and power line supervision, is responsible for the following

functions:

• Acquisition and processing of data from, and control of, the AMA

• Acquisition and processing of data from the Oxygen Analyzer

,

• Controlling the Pneumatic System

• Controlling the communications between the Anesthetic Gas

Subsystem and the host monitoring system

• Controlling the communications between the Anesthetic Gas

Subsystem and the Agent Identification Subsystem.

The MGM/AMA Electronics Subsystem has two communications

channels -- one connected to an external RS-232 port and the other

connected to the AIDA Electronics Subsystem.

The AIDA Electronics Subsystem, with memory (ROM and RAM),

multiplexers, A-D converter, and power line supervision, acquires and

processes data from agent identification and controls the AIDA. The only

communications channel in the AIDA Electronics Subsystem is the one

connected to the MGM/AMA Electronics Subsystem.

Full functionality of the Anesthetic Gas Subsystem is controlled by its

firmware.

7 Agent Measurement Analyzer

The proven, known, and widely used technology of non-dispersive infrared

gas analysis is used by the AMA in the Anesthetic Gas Subsystem.Figure

2-3 on page 8 is a functional block diagram of this analyzer subsystem.

The infrared light source is constructed of tungsten powder metal which is

embedded in an Al

operating temperature of 600°C. Infrared emission from this source is

distributed as a blackbody radiator.

ceramic. This source is electrically heated to an

2O3

ASK-T876-02-7600 Siemens Medical Systems, EM-PCS Danvers 7

mgm2.sm.fm/11-00/kaupp

Page 16

MGM and MGM+ Modules Service Manual

Metal Cavity

Infrared

Detector

With TE

Cooler

NVRAM

Memory

AMA Preamp

Board Assembly

Preamp

Circuits

Infrared

Light

Source

Wideband

Light Beam

Containing

Infrared

Filter Wheel

Cavity Heater

Filter Wheel

With IR Optical

Bandpass Filters

Thermistor

Mot or

Sample Cell

Window

Gas

Input

Gas

Sample

Cel l

Thermistor

Gas

Output

Sample Cell

Window

Figure 2-3 Agent Measurement Analyzer Functional Block Diagram

The sample cell is constructed of a stainless steel tube with a reflective

inside surface which serves as a light pipe. The sample cell length has been

designed to provide an adequate absorption length to obtain the desired

signal-to-noise ratio for the weakest anticipated absorption. Sapphire serves

N2O

as the sample cell window material for the two ends of the sample cell.

The gas sample to be analyzed enters the sample cell through the gas inlet and

leaves it through the gas outlet. While in the cell, the gas sample is penetrated

Agent CO

by light from the infrared light (IR) source. This light is filtered by coated optical

2

bandpass filters mounted on the filter wheel (see illustration at left). The

attached brushless DC motor spins the filter wheel so that the appropriate filter

for each gas type (CO

, N2O, agent) comes into place one after the other. The

2

filter wheel cavity heater maintains the metal cavity at 65°C under control of a

thermistor. The wavelengths used are --

Reference Blank

Filter Wheel

•4.3µ for CO

•3.6µ for N2O

• 3.3µ for anesthetic agents

2

The thermistor attached to the sample cell wall provides a measure for the

sample cell temperature. Knowledge of sample pressure and sample

temperature is vital to accurately determine gas concentrations in the gas

sample. Sample pressure is provided by a pressure transducer housed in

the AMA but actually plumbed behind the O

Analyzer. It is therefore its

2

own gas connection.

The photoresistive lead selenide (PbSe) infrared detector, mounted on the

preamplifier board assembly, converts the IR radiation not absorbed by the

gas sample to an electrical signal. The transmittance of IR radiation is a

measure of the total number of molecules of a given gas in the sample cell.

The detector’s output signals are preamplified and consist of a pulse

stream, one pulse for each IR filter, corresponding to the fraction of this gas

type in the sample. The IR detector temperature is kept at 2°C by a thermoelectric cooler to enhance signal-to-noise ratio.

A calibration mechanism guarantees long-term stable measurements and

eliminates filter variations.

8 Siemens Medical Systems, EM-PCS, Danvers ASK-T876-02-7600

mgm2.sm.fm/11-00/kaupp

Page 17

Service Manual MGM and MGM+ Modules

Chopped

Infrared

Light

Source

Wideband

Light Beam

Containing

Infrared

Light

Chopper

Motor

Wideband

Infrared

Light

Sample Cell

Window

Gas

Input

Gas

Sample

Cell

Figure 2-4 Agent Identification Analyzer (AIDA) Functional Block Diagram

8 Agent Identification Analyzer

Gas

Output

Sample Cell

Window

Specific

IR Wavelengths

IR Optical

Bandpass

Filters

(4 of 7 illustrated)

Thermopile

Infrared

Detectors

(4 of 7 illustrated)

AIDA Preamp

Board Assembly

Thermistor

Preamp

Circuits

NVRAM

Memory

The agent identification function identifies which of the following

anesthetic agents is being used:

• one agent out of Isoflurane, Halothane, Enflurane, or

• one agent out of Isoflurane, Halothane, Sevoflurane, or

• one agent out of Isoflurane, Halothane, Desflurane.

Like the AMA, the AIDA in the Anesthetic Gas Subsystem uses the

technology of non-dispersive infrared gas analysis. Figure 2-4 shows a

functional block diagram of this analyzer subsystem.

Infrared light from the IR light source (which is identical to the AMA IR light

source) is modulated using a rotating chopper wheel driven by a stepping

motor which is speed controlled by the Electronics Subsystem.

Narrow band filtering and demodulation techniques greatly enhance the

quality of the signal generated in the infrared absorption process.

The sample cell is made of thermoplastic, and has a conical shape and nonreflective walls. The cell window material is silicon.

Seven thermopile IR detectors which do not require cooling, each output

an analog signal whose magnitude is inversely proportional to the infrared

light absorption at the corresponding frequency. These frequencies are

determined by the bandpass filters (4 of 7 illustrated in Figure 2-4)

operating in the wavelength region from 10µ to 13µ. The thermistor output

is used to compensate for the effect of IR filter temperature changes. The

analog signals are directly related to the anesthetic agent gas

concentrations in the sample cell.

The IR detector outputs are measured during both chopper wheel phases.

Measurements taken when the IR light beam is interrupted provide the

dark level reference needed by the signal processing software.

ASK-T876-02-7600 Siemens Medical Systems, EM-PCS Danvers 9

mgm2.sm.fm/11-00/kaupp

Page 18

MGM and MGM+ Modules Service Manual

These signals are amplified, filtered, and digitized by the pre-amplifier on

the pre-amplifier board assembly. The digitized waveform is then

demodulated by the electronics subsystem to obtain a transmission value

for each detector.

The following transmission data is used to obtain the gas concentration

values used by the agent identification routine.

• The seven preamplified IR detector outputs

• The thermistor output

• The Zero calibration constants

• Factory characterization constants

• Gas concentration algorithms

• Primary agent ID thresholds

• Secondary agent ID thresholds

• Primary to secondary agent ID crosstalk factors

A calibration mechanism guarantees long-term stable measurements and

eliminates filter variations.

9 Oxygen Analyzer

9.1 Paramagnetic O2

Measurement

9.2 Electrochemical O2

Measurement

10Pneumatic System

In the M

“fast” O

type sensor provides O

ULTIGAS

2

+ Module, the Paramagnetic Oxygen Transducer provides

measurement. In the M

measurement with a slower response time. Both

2

ULTIGAS

Module, the electrochemical

the paramagnetic sensor and the electrochemical cell deliver an analog

signal linearly proportional to the oxygen concentration in the sample gas.

O2 is paramagnetic, which means that a magnetic field induced in O2 will

be in the same direction as, and in greater strength than, the magnetizing

field. In the paramagnetic oxygen transducer, O

is placed in two sealed

2

spheres of a dumb-bell assembly, which is suspended on a spring device

in a symmetrical non-uniform magnetic field. The assembly assumes a

position away from the most intense part of the field.

Sample gas surrounds the dumb-bell assembly, and when the surrounding

gas contains O

by the relatively stronger paramagnetic O

, the dumb-bell spheres are pushed further out of the field

2

. The strength of the torque

2

acting on the dumb-bell is proportional to the paramagnetism of the

surrounding gas, and is converted into an analog voltage which is likewise

proportional to the oxygen concentration.

The electrochemical O2 analyzer operates like a battery. O2 in the gas

sample, in contact with an electrolyte, generates a voltage proportional to

the concentration of O

.

2

The Anesthetic Gas Subsystem includes a gas sampling system which

accurately controls the flow rate of gas through the analyzer system.

Nafion® tubing, a hygroscopic material made from Teflon and polypropylenesulfonic acid copolymer, is added to the sampling line inside the

Anesthetic Gas Subsystem to eliminate residual water. Anesthetic agents,

N

O, and CO2 are impermeable to the tubing.

2

10 Siemens Medical Systems, EM-PCS, Danvers ASK-T876-02-7600

mgm2.sm.fm/11-00/kaupp

Page 19

Service Manual MGM and MGM+ Modules

Figure 2-5 Pneumatics Block Diagram (excerpt from Figure 2-2.)

As illustrated in Figure 2-5, pneumatic solenoid valves are incorporated in

the gas stream to switch between the patient gas stream (normal

operation) and room air (during Zero calibration). The selected gas (patient

or room air) is directed to the Agent Measurement Analyzer, O

analyzer,

2

and Agent Identification Analyzer.

A servo controlled pump is attached to the exhaust of the analyzer. The

pump generates the flow through the system and pulls the gas from the

airway adapter through the analyzers to the exhaust outlet. It also delivers

the Zero calibration gas to the sample cells of the analyzer subsystems for

the periodic zero procedures, and exhausts the patient’s sample gas, zero

calibration and field calibration gases. The pump can be operated at four

different flow rates, which are hardware-adjusted during factory calibration

of the MGM. See Table 2-1.

Table 2-1 Pump Flow Rates

Flow

Type

Flow

Rate

Idle No Flow Pump switched off

Low 120

ml/min

With Paramagnetic O

analyzer

Used for analysis of

patient gas samples

High 200

ml/min

With Paramagnetic O

analyzer

Used for purging

Agent Measurement

and paramagnetic O

analyzers before and

after zero calibration

Purge 350 ml/

min

With Paramagnetic O

analyzer

Used for purging the

Agent Identification

Analyzer before and

after Zero calibration

Description

With Electrochemical O

2

analyzer

Optionally used for

analysis of patient gas

samples.

With Electrochemical O

2

analyzer

Used for normal analysis

of patient gas samples

2

With Electrochemical O2

2

analyzer

Used for purging the

Agent Measurement and

Agent Identification

Analyzers before and

after Zero calibration

2

2

ASK-T876-02-7600 Siemens Medical Systems, EM-PCS Danvers 11

mgm2.sm.fm/11-00/kaupp

Page 20

MGM and MGM+ Modules Service Manual

A flow sensor, consisting of a differential pressure transducer, a dampener,

and a flow restrictor, is used to determine, stabilize and limit the flow rate

of the sampled gas. The output from the pressure transducer is used in a

servo system to control the drive power to the pump. The dampener (a

15cc container) isolates the sample cells of the analyzer subsystems from

pulsations, enabling a smooth flow through the system. The flow rate

control logic works as hard as necessary to maintain the selected flow rate.

A partial occlusion, or an inefficient pump, result in the pump being driven

harder. A serious occlusion results in the pump being driven at or near its

maximum drive. A sense circuit is then triggered to report an occlusion.

11Self-Test

A power-up self-test is performed to validate the contents of firmware

memory (ROM), read/write memory (RAM) and non-volatile memory

(NVRAM), and to verify errorless access to these storage devices for read

and write operations.

12Calibration

In order to guarantee long-time stable measurement performance the

MGM must be enabled to cope with three types of conditions that can lead

to measurement errors:

12.1 Factory Calibration

12.2 Field Span

Calibration

• Small differences among the components of a subsystem (e.g.,

caused by limitations in manufacturing precision)

• Changes of the physical properties of some components over time

(e.g., caused by aging or pollution)

• Limitations in the compensation for certain effects (e.g., changes in

cell temperature/pressure or cross-gas interference)

Each of these conditions can be handled by an appropriate calibration

process performed either during original manufacture, as part of normal

preventive maintenance, or during normal use.

During factory calibration, the individual performance of each subsystem

unit is measured. Polynomial coefficients are then calculated from these

individual response curves and stored in the unit itself. These coefficients

are later used to compensate for possible unit-to-unit component

differences.

During field Span calibration, accurately known concentrations of each gas

of interest are introduced into the AMA and O

measured. Differences between the known and the measured values are

used to calculate the appropriate coefficients for compensation of these

differences.

Field Span calibration of the anesthetic agent, CO

typically part of preventive maintenance.

The paramagnetic O

When an electrochemical O

periodically be Span calibrated.

analyzer typically does not require Span calibration.

2

sensor is in use, the O2 channel must

2

Analyzer sample cells and

2

and N2O channels is

2

12.3 Zero Calibration

12 Siemens Medical Systems, EM-PCS, Danvers ASK-T876-02-7600

During Zero calibration, the analyzer subsystems are purged with room air

or nitrogen to eliminate any gas of interest (concentration of these gases is

“zero”). Oxygen or nitrogen are convenient “Zero calibration gases” since

they do not absorb infrared radiation in the wavelengths used by the AMA

and AIDA. Since atmospheric air is composed primarily of oxygen and

mgm2.sm.fm/11-00/kaupp

Page 21

Service Manual MGM and MGM+ Modules

nitrogen, with small amounts of water and CO2, normal room air is used

for zeroing the MGM system. Optionally, the MGM can be Zero calibrated

with 100% dry nitrogen.

Since changes of physical properties of subsystem components have the

same effect on room air measurement performance, this is used as a

reference and therefore to calculate new coefficients which help

compensate for such changes. Zero calibration of the MGM analyzer

subsystem is requested by the MGM as follows:

• after certain time intervals

• after certain changes in operation

• after certain operational failures have been detected.

The Zero calibration process measures the infrared signal strength

(transmittance) when no IR absorbing gases are in the sample cell. AMA

and AIDA field calibration software compensates for the small absorption

12.4 Storage of

Calibration Data

from atmospheric CO

With one exception, all Zero calibration data is stored in and used from

volatile RAM memory. The Zero calibration data calculated by the first

successful Zero calibration after is stored in non-volatile NVRAM memory

for use after subsequent resets.

.

2

All Span calibration data is stored in non-volatile NVRAM memory. Critical

data is replicated into a second location in both RAM memory (for

immediate use) and NVRAM memory.

Block checksums are used to confirm continued validity of NVRAM and

RAM data. Power cycling does not affect this data

Both the AMA and AIDA subsystems have their own NVRAM memory for

storing their own calibration data, enabling interchangeability of these

subsystems with system boards.

Calibration data for the oxygen analyzer is stored in AMA NVRAM memory.

12.5 Calibration of Agent

Measurement

Analyzer

12.5.1 Factory Calibration Factory calibration compensates for small differences among the following

components: pressure transducer, infrared (IR) light source, sample cell

thermistor, filter heater element, filter cavity thermistor, each of the IR

bandpass filters, IR detector, and thermo-electric cooler. Near the end of

the manufacturing process, binary gases are used to characterize each

AMA. The characterization process also analyzes individual cross-gas

interference. The last function performed during characterization is to

verify performance by sampling cocktail gases. Each unit ends up with is

own unique set of response curves, and the ability to accurately report gas

concentrations based on its individual parts and characteristics.

12.5.2 Field Span Calibration The AMA should be calibrated by trained service personnel once every 12

months using precision calibration gases. The resulting Span calibration data

is stored in NVRAM memory. The host system can replace field calibration

data with the original factory calibration data via software command.

12.5.3 Zero Calibration To maintain the highest gas concentration measurement accuracy

possible, the MGM requests that the host command Zero calibration at the

following time intervals The Zero calibration is performed automatically,

requiring no user intervention.

ASK-T876-02-7600 Siemens Medical Systems, EM-PCS Danvers 13

mgm2.sm.fm/11-00/kaupp

Page 22

MGM and MGM+ Modules Service Manual

:

Zero Calibration Time Interval

1st 8 minutes after power-up or reset

2nd 15 minutes after power-up or reset

3rd 30 minutes after power-up or reset

4th 45 minutes after power-up or reset

5th 90 minutes after power-up or reset

next 8 hours after previous calibration

12.6 Agent Identification

Analyzer

12.6.1 Factory Calibration Factory calibration compensates for small differences among the following

components: infrared (IR) light source, detector thermistor, each of the

seven IR bandpass filters, and each of the seven IR detectors. Near the end

of the manufacturing process, binary gases are used to characterize each

AIDA. The last function performed during characterization is to verify performance by sampling cocktail gases. Each Analyzer ends up with its own

unique set of response curves, and the ability to accurately measure and

identify anesthetic agents based on its individual parts and characteristics.

12.6.2 Field Span Calibration The function of the AIDA is to measure accurately very low gas

concentrations, most critically in the range of 0.0% to 0.5% where

identification thresholds are set. Since field Span calibration would not

influence the performance of the Analyzer in this very narrow range, none

is required.

12.6.3 Zero Calibration As with the AMA, regular Zero calibration is required. The Zero calibration

process is exactly the same as for the AMA, but the time intervals are

slightly different. The first Zero calibration is performed automatically

(without host involvement) 2 minutes after power-up. Other Zero calibrations are requested of the host system as described in Section 12.5.3.

12.7 Paramagnetic O2

Analyzer

12.7.1 Factory Calibration The paramagnetic O2 analyzer is calibrated with potentiometers at the 0%

and 100% point of its measurement range.

12.7.2 Field Span Calibration The paramagnetic O

calibration commands using appropriate precision calibration gases.

The resulting Span calibration data is stored in NVRAM memory. The host

can replace field calibration data with the original factory calibration data via

software command.

12.7.3 Field Zero Calibration Zero calibration of the paramagnetic O

air. This is done every time the AMA is Zero calibrated.

analyzer may be Span calibrated in the field via Span

2

analyzer is performed with room

2

12.8 Fuel Cell Type O2

Analyzer Calibration

12.8.1 Factory Calibration The fuel cell type O2 analyzer does not require “characterization” or factory

calibration. In the case where a fuel cell type O

to original equipment shipment, field Span and Zero calibration are

performed.

14 Siemens Medical Systems, EM-PCS, Danvers ASK-T876-02-7600

analyzer is installed prior

2

mgm2.sm.fm/11-00/kaupp

Page 23

Service Manual MGM and MGM+ Modules

12.8.2 Field Span and Zero

Calibration

The fuel cell type O

output is continually degrading during use. Fuel cell type O

analyzer must be periodically Span calibrated since its

2

analyzer Span

2

and Zero calibration is performed using the MGM 2-point Span calibration

command as discussed in Section 12.7.2. The resulting O

calibration data

2

is stored in NVRAM memory.

12.8.3 Field Zero Calibration Separate Zero calibration of the fuel cell type O

analyzer is not required.

2

12.9 Pneumatic System

Calibration

12.9.1 Factory Calibration The pneumatic system of the Agent Analyzer Subsystem is factory-

calibrated by performing range adjustments. A flow meter is used to adjust

the four possible flow rates in which the pump can operate. These values

are set by appropriately adjusting three potentiometers.

The specific flow rates listed below are representative of one MGM

configuration. Other configurations may use slightly different flow rates.

Flow Type Flow Rate

Idle No flow

Low 120 ml/min

High 200 ml/min.

Purge 350 ml/min.

12.9.2 Field Flow Rate Calibration Trained service personnel may perform a field calibration of the pneumatic

system. A field calibration consists of the same range adjustments done

during the factory calibration.

13Software

Figure 2-6 on page 16 shows a functional block diagram of MGM software.

Each bubble indicates a submodule of that software and represents a

functional task that is described in more detail below. Each box indicates a

hardware part controlled by the firmware. Figure 2-6 also shows that the

AIDA Control and Data Processing submodules run on its own AIDA

Electronics Subsystem while all remaining submodules are executed by

the MGM/AMA Electronics Subsystem, both shown in Figure 2-6.

13.1 AMA Data

Acquisition

The AMA Data Acquisition submodule, physically located on the AMA,

acquires IR detector output signal pulses, sample cell pressure, sample

cell temperature, filter wheel cavity temperature, and IR detector

temperature data from the AMA. Additional data acquired by the

submodule includes ambient temperature, pump flow rate, four MGM

system board voltage measurements and the output of the O

analyzer.

2

These analog signals are digitized by an A-D converter in the MGM/AMA

Electronics Subassembly. The submodule stores this raw data in shared

RAM memory so that the AMA Signal Processing and the Control

submodules can access and further process them.

ASK-T876-02-7600 Siemens Medical Systems, EM-PCS Danvers 15

mgm2.sm.fm/11-00/kaupp

Page 24

MGM and MGM+ Modules Service Manual

Figure 2-6 Software Functional Block Diagram

13.2 AMA Signal

Processing

The AMA Data Acquisition and Control submodules send control signals to

the AMA to control its IR source, TE cooler temperature, filter wheel motor

speed, and filter wheel heater temperature.

Additional data acquired by the submodule includes ambient temperature,

pump flow rate, four MGM system board voltage measurements and the

output of the O

These analog signals are digitized by an A-D converter in the MGM/AMA

Electronics Subassembly. The submodule stores this raw data in shared

RAM memory so that the AMA Signal Processing and the Control

submodules can access and further process them.

The AMA Data Acquisition and Control submodules send control signals to

the AMA to control its IR source, TE cooler temperature, filter wheel motor

speed, and filter wheel heater temperature.

The Data Acquisition submodule checks the digitized data against A-D

converter boundary conditions and issues an A-D limit error to the MGM/

AMA Control submodule if necessary.

The AMA Signal Processing submodule reads the AMA IR detector output

data from RAM memory, takes an average of four samples and normalizes

this average by multiplying the zero constant offset determined during the

last Zero calibration of the AMA. This zero constant is read from the AMA

RAM memory. The normalized data is stored in RAM memory from where

it is read and further processed by the AMA Gas Concentration Algorithms

submodule.

analyzer.

2

16 Siemens Medical Systems, EM-PCS, Danvers ASK-T876-02-7600

mgm2.sm.fm/11-00/kaupp

Page 25

Service Manual MGM and MGM+ Modules

The AMA Signal Processing submodule then checks the normalized data

against an allowable input range stored in NVRAM during factory

calibration. In case the normalized data is out of that range, an overrange or

underrange error is flagged to the MGM/AMA Control submodule.

During Zero calibration of the AMA, the AMA Signal processing submodule

is triggered by the MGM/AMA Control submodule to compute a new zero

constant based on the current average. This average is interpreted as “zero

gas concentration.” The AMA Signal Processing then stores that new zero

constant offset into AMA NVRAM and into AMA RAM memory.

13.3 AMA Compensation

The AMA Gas Concentration Algorithms submodule reads the normalized

sample data from RAM memory and corrects for sample cell pressure and

sample cell temperature.

Since the spectra of the various measured gases partly overlap, the AMA

Gas Concentration Algorithms submodule performs necessary corrections

to compensate for the effects of this overlapping (called “cross-channel.

This compensation is based on the characteristics of each gas spectrum as

they were stored into NVRAM memory during factory calibration.

The submodule then applies the field calibration factor. The field calibration

factor is read from AMA NVRAM. The resulting gas concentration data is

stored in RAM memory for further processing.

The submodule checks the compensated data for mathematical errors (as

recognized by the floating point part of the CPU, e.g., a number going to

infinity or out of the floating point range), against the allowable absorption

data range (as stored in NVRAM during factory calibration), and against the

minimum and maximum reporting range limits (stored in ROM memory). In

case of wrong or out-of-range data, errors are issued to the MGM/AMA

Control submodule.

During field Span calibration of the AMA, the AMA Gas Concentration

Algorithms submodule is triggered by the MGM/AMA Control submodule

to compute new field Span calibration factors based on current gas concentration data. The AMA Gas Concentration Algorithms submodule then

stores the new field Span calibration factors in AMA NVRAM memory.

13.4 Patient Data

Derivation

13.5 Host System

Communications

ASK-T876-02-7600 Siemens Medical Systems, EM-PCS Danvers 17

mgm2.sm.fm/11-00/kaupp

The Patient Data Algorithms submodule reads the compensated sample

data (wave samples) from RAM memory and derives the following

numerical values from them:

•Breath Rate

• Inspired values for CO

O

2

• Expired end-tidal values for CO2, N2O, and anesthetic agent; Expired

end-tidal value for O

Breath rate is calculated based on the time between two breaths. The

inspired and expired end-tidal values are calculated from the wave samples

which were valid at the beginning and end of a breathing cycle. Patient data

is stored in RAM memory from where it can be read and transmitted to the

host system. If the Patient Data Algorithms submodule cannot derive

numerics from the wave sample data, e.g., if the patient stops breathing,

it issues a status message to the MGM/AMA Control submodule.

The Host System Communications submodule reads the wave samples,

patient data numerics and status/error information from RAM memory and

transmits them to the host.

, N2O, and anesthetic agent; Inspired value for

2

2

Page 26

MGM and MGM+ Modules Service Manual

The submodule receives commands from the host (e.g., requests to Zero

calibrate, requests to field Span calibrate, requests to format data in certain

units) and executes them either by itself or by passing them on the MGM/

AMA Control submodule or, via AMA-AIDA interprocessor communications to the AIDA Control submodule. Thus, the Host System

Communications submodule is the only one that communicates directly

with the host system.

13.6 Anesthetic Gas

Subsystem /

Host System

Communications

13.7 AIDA

Communication

Communications between the Anesthetic Gas Subsystem and the host

system consists of communications between the Host System

Communication submodule and the host’s communications software over

the external RS-232 interface of the MGM. All messages from and to the

MGM include a checksum to assure the detection of communication

interferences. Moreover, a message length is defined for the commands

sent to the MGM and their corresponding responses to enable a check on

the format of the received message.

The AMA-AIDA Interprocessor Communications submodule in the MGM/

AMA Electronics subsystem serves as the communication link between

the MGM/AMA Electronics Subsystem and the AIDA electronics

subsystem. lt communicates directly with its counterpart, the AIDA-AMA

Interprocessor Communications submodule in the AIDA Electronics

Subsystem, using the same communications protocol that the Host

System Communications submodule uses to communicate with the host.

It is controlled by the MGM/AMA Control submodule (e.g., to synchronize

Zero calibration of both the AMA and the AIDA). It exchanges status

information with the MGM/AMA Control submodule and the Host System

Communications submodule.

The AIDA-AMA Interprocessor Communications submodule serves as the

communication link between the AIDA electronics subsystem and the

MGM/AMA electronics subsystem. It communicates directly with its

counterpart, the AMA-AIDA Interprocessor Communications submodule,

using the same communications protocol that the Host System

Communications submodule uses to communicate with the host.

It exchanges status/control information with the AIDA Control submodule

and receives data from the AIDA Agent Identification submodule via RAM

memory and passes them on to the AMA-AIDA Interprocessor

Communications submodule for further transmission to the Host System

Communications submodule.

13.8 MGM/AMA Control

18 Siemens Medical Systems, EM-PCS, Danvers ASK-T876-02-7600

The MGM/AMA Control submodule performs a variety of control tasks:

It receives commands, e.g., requests to Zero or field Span calibrate, from

the Host System Communications submodule and triggers the AMA Data

Acquisition, AMA Signal Processing, AMA Gas Concentration Algorithms,

and Patient Data Algorithms submodules accordingly.

It receives error messages from the AMA Data Acquisition, AMA Signal

Processing, AMA Gas Concentration Algorithms, and Patient Data

Algorithms submodules, and passes them on with other status information

to the Host System Communications submodule.

The MGM/AMA Control submodule is also involved in controlling the

pump: The pump control hardware reads the current gas flow rate from the

flow sensor and controls the pump to guarantee a stable gas flow through

the system. The flow rate is monitored by the MGM/AMA Control

mgm2.sm.fm/11-00/kaupp

Page 27

Service Manual MGM and MGM+ Modules