Page 1

Operating and

installation instructions

LB 23…

LB 54…

LB 75…

Page 2

Operation Instructions

Operating modes

Exhaust-air mode:

❑ The extractor-hood fan extracts the kit-

chen vapours and conveys them

through the grease filter into the atmosphere.

❑ The grease filter absorbs the solid

particles in the kitchen vapours.

❑ The kitchen is kept almost free of grease

and odours.

Circulating-air mode

❑ An activated carbon filter must be fitted

for this operating mode (see Filters and

maintenance).

Activated carbon filters can be

purchased from specialist outlets

(see Optional accessories on the last

page).

❑

The ventilator fan draws the vapours

produced during cooking into the

extractor hood, where they pass

through the grease filter and the activated carbon filter before the clean air is

discharged back into the kitchen.

❑

The grease filter absorbs the grease

contained in the vapours produced

during cooking.

❑

The activated carbon filter absorbs any

odorous substances.

When the extractor hood is operated

D

in exhaust-air mode simultaneously

with a different burner which also

makes use of the same chimney

(such as gas, oil or coal-fired heaters,

continuous-flow heaters, hot-water boilers) care must be taken to ensure that

there is an adequate supply of fresh

air which will be needed by the burner

for combustion.

Safe operation is possible provided that the

underpressure in the room where the

burner is installed does not exceed 4 Pa

(0.04 mbar).

This can be achieved if combustion air can

flow through non-lockable openings, e.g. in

doors, windows and via the airintake/exhaust-air wall box or by other

technical measures, such as reciprocal

interlocking, etc.

If the air intake is inadequate, there is a

risk of poisoning from combustion gases

which are drawn back into the room.

An air-intake/exhaust-air wall box by itself

is no guarantee that the limiting value will

not be exceeded.

Note: When assessing the overall

requirement, the combined ventilation

system for the entire household must be

taken into consideration. This rule does not

apply to the use of cooking appliances,

such as hobs and ovens.

Unrestricted operation is possible if the

extractor hood is used in recirculating

mode – with activated carbon filter.

If no activated carbon filter is installed,

it is not possible to bind the odorous

substances in the cooking vapours.

2

Page 3

Before using the first time

Important notes:

❑ The Instructions for Use apply to several

versions of this appliance. Accordingly,

you may find descriptions of individual

features that do not apply to your

specific appliance.

❑ This extractor hood complies with all

relevant safety regulations.

Repairs should be carried out by

qualified technicians only.

Improper repairs may put the user at

considerable risk.

Do not use the appliance if damaged.

The appliance may be connected to

the mains by a qualified technician only.

The appliance is not intended for use

by young children or infirmed persons

without supervision.

Young children should be supervised to

ensure they do not play with the appliance.

If the connecting cable for this

appliance is damaged, the cable must be

replaced by the manufacturer or his customer service or a similarly qualified person in

order to prevent serious injury to the user.

Dispose of packaging materials

properly (see Installation instructions).

This extractor hood is designed for

domestic use only.

Light bulbs must always be fitted

when the extractor hood is in use.

Defective bulbs should be replaced

immediately to prevent the remaining bulbs

from overloading.

Never operate the extractor hood

without a grease filter.

Overheated fat or oil can easily catch

fire.

If you are cooking with fat or oil, e.g. chips,

etc., never leave the cooker unattended.

Do not flambé food directly under the

extractor hood.

Risk of grease filter catching fire due

! to flames.

❑ Before using your appliance for the first

time, please read these Instructions for

Use carefully. They contain important

information concerning your personal

safety as well as on use and care of the

appliance.

❑ Please retain the operating and

installation instructions for a subsequent

owner.

The hotplates must always be covered

with a utensil.

Restrictions apply to the use of the

extractor hood over a solid-fuel burner

(coal, wood, etc.). (See Installation

instructions).

Gas hobs / Gas cookers

Do not use all the gas hotplates

simultaneously for a prolonged period

(max. 15 minutes) at maximum thermal

load, otherwise there is a risk of burns if

the housing surfaces are touched or a risk

of damage to the extractor hood. If the

extractor hood is situated over a gas hob,

operate the hood at maximum setting if

three or more gas hotplates are operated

simultaneously.

If you encounter a problem

If you have any questions or if a fault

occurs, please call Customer Service.

(See list of Customer Service

representatives).

When you call, please quote the following:

E-Nr. FD

Enter the relevant numbers into the box

above. The E-Nr. (product no.) and FD

(production date) are shown on the

nameplate which can be seen inside the

extractor hood after the filter frame has

been detached.

3

Page 4

1

P

0

2

3

P

1

2

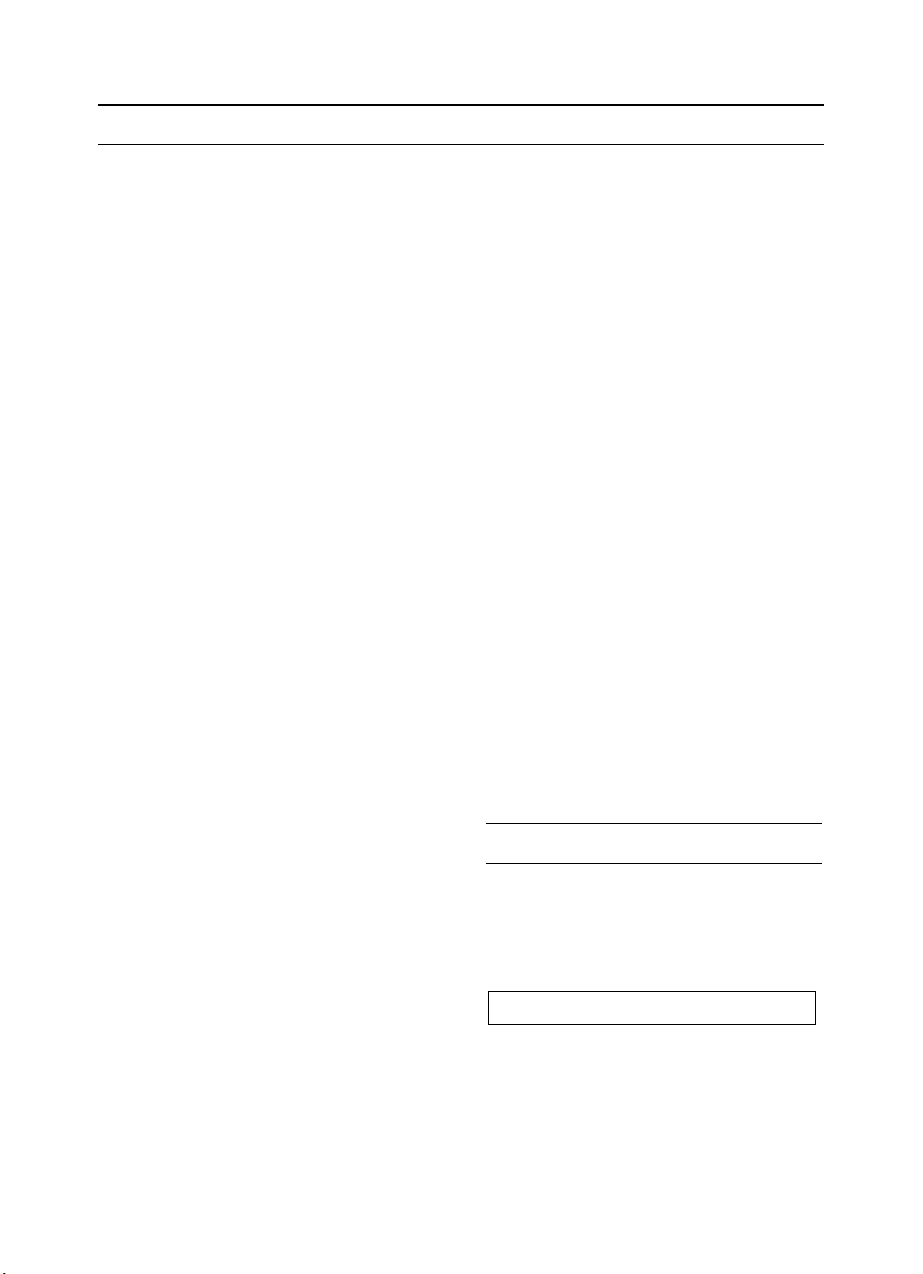

How to operate the extractor hood

The most effective method of remo-

ving vapours produced during cooking is

to:

❑

Switch the ventilator ON

as soon as you begin cooking.

❑

Switch the ventilator OFF

a few minutes after you have finished

cooking.

Operating controls on different

models

on

off

Light

Intensive setting

Fan settings

Light

Intensive setting

Fan settings

Filters and maintenance

Various types of grease filter can be

used to absorb the grease contained in

the vapours produced during cooking.

Fleece grease filter

The filter mat is made from material that is

itself virtually non-inflammable.

Caution:

As it becomes more and more saturated

with grease however, the filter becomes

increasingly inflammable. The efficiency of

the extractor hood can also be adversely

affected.

Important:

Renewing the fleece filter at appropriate

intervals prevents the possibility of it

catching fire as a result of a build-up of

heat, such as occurs when deep-fat frying

or roasting is taking place.

Renewing the fleece filter:

❑

Under normal operating conditions

(1 to 2 hours per day), the fleece filter

will require replacing after 8 to 10

weeks. Printed fleece filters must be

renewed no later than when the coloured printing has started to fade.

❑

Use only original replacement filters.

In so doing you will ensure that safety

regulations are upheld and the extractor

hood performs as effectively as possible.

Disposing of the old fleece grease filter:

Fleece grease filters do not contain any

pollutants. They can be composted and

disposed of as biodegradable waste.

Note: The light can be switched on at any

time, including when the vapour extractor

tray has been pushed back into the hood.

4

Page 5

Filters and maintenance

Metal grease filter

The filter mat is made of non-combustible

metal.

Caution:

As it becomes more and more saturated

with grease, the filter also becomes

increasingly inflammable. The efficiency of

the extractor hood can also be adversely

affected.

Important:

Clean the metal grease filter at regular

intervals.

Cleaning the metal filter:

Under normal operating conditions (1 to 2

hours per day), the metal grease filter will

require cleaning after 8 to 10 weeks.

❑

The filter can be cleaned in a

dishwasher.

This can however cause slight

discoloration.

Important:

Metal filters that are heavily saturated with

grease should not be cleaned at the same

time as any crockery, etc.

❑

If the filter mat is going to be cleaned by

hand, soak it first of all in a hot detergent solution for several hours.

Clean the filter with a brush, rinse it off

thoroughly and allow it to drip dry.

❑

Use only original replacement filters.

In so doing you will be ensuring that the

extractor hood performs as effectively

as possible.

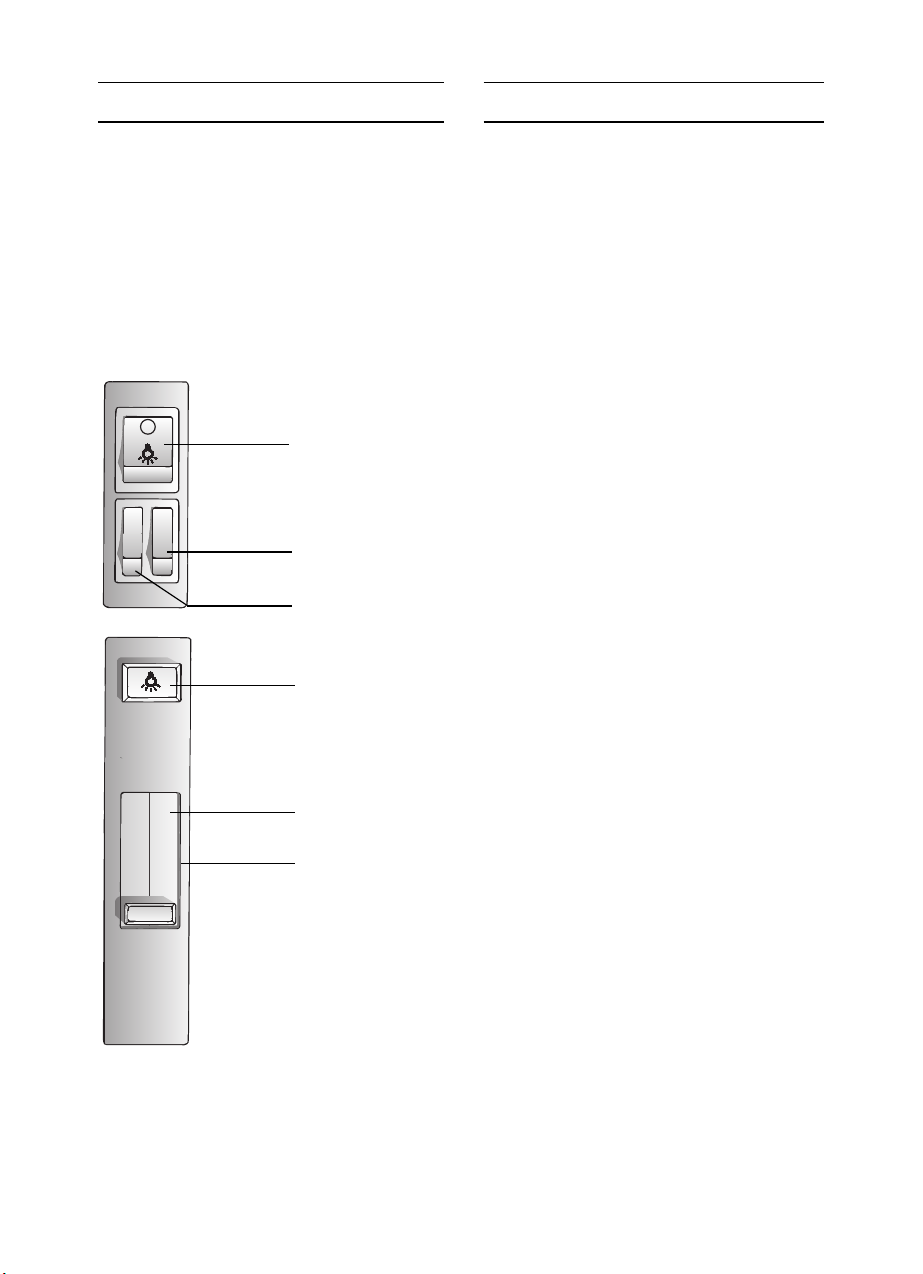

Removing and installing the grease

filter

Extractor hoods with a filter mat:

1. Rotate the handles on the left and right

of the filter grille.

2. Press the retaining spring and remove

the filter frame.

3. Remove the wire grille and replace the

filter mat.

4.Install the filter frame in reverse sequence.

Re-attach the retaining spring.

The left and right sides of the filter

frame must lock into position!

5

Page 6

Filters and maintenance

Extractor hoods with two filter cartridges:

Warning: The halogen bulbs must be swit-

ched off and cool.

1. Depress the detent on the grease filters

in the direction of the arrow and fold

down the grease filter slightly. Detach

the grease filter by pulling it towards

yourself.

Activated carbon filter

Removing and installing the activated carbon filter

Extractor hoods with a filter mat:

1. Remove the filter; see grease filter.

❑ The wire grille is no longer required

when an activated carbon filter is

installed.

2. Place the activated carbon filter on the

filter mat and clamp it in.

2. Clean the grease filters.

3. Re-insert the clean grease filters.

6

3. Install the filter frame.

❑ See grease filter.

Page 7

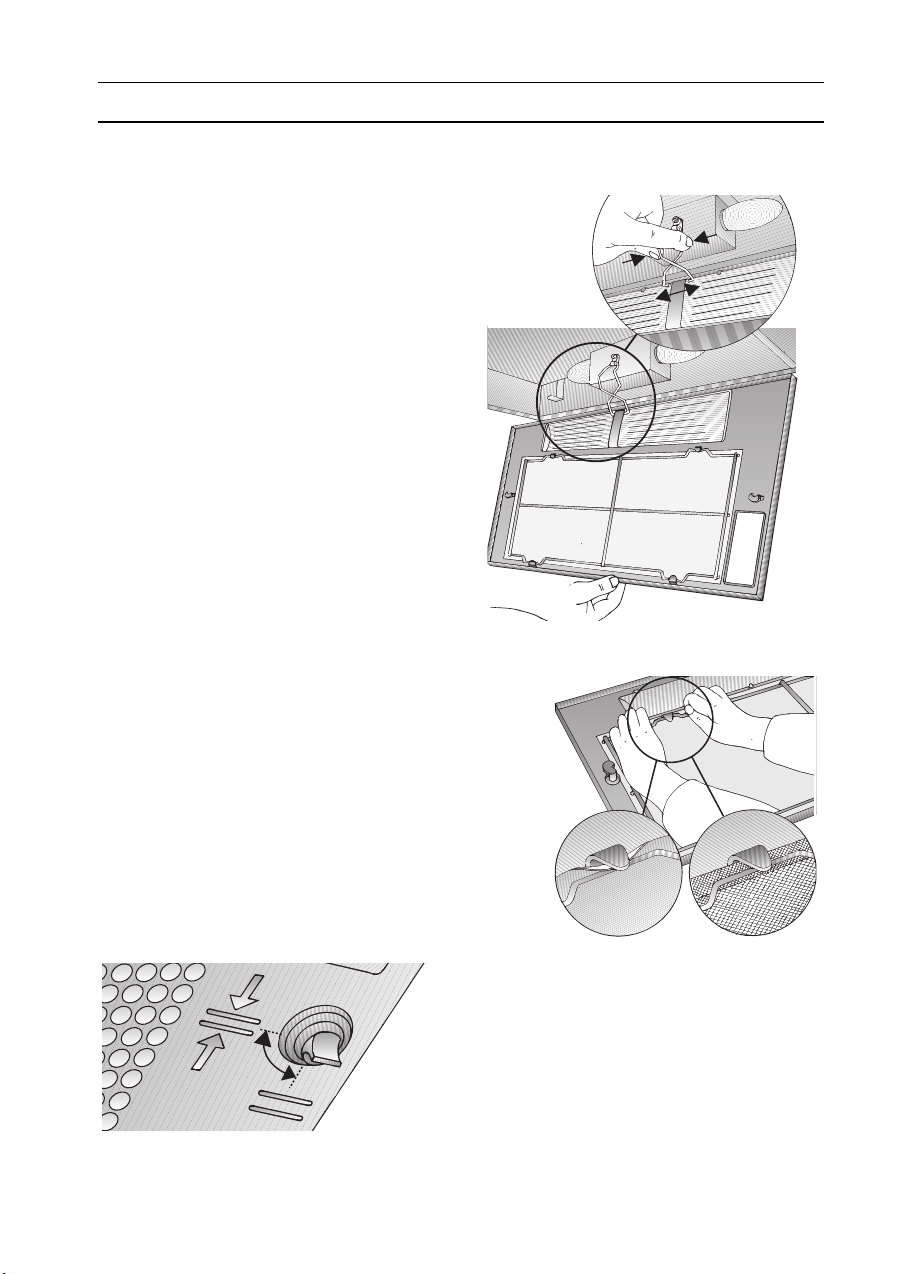

Activated carbon filter

Extractor hoods with two filter cartridges:

1. Remove the filter cartridge.

❑ See grease filter.

2. Insert the screw through the wing nut

and the sleeve and screw in the middle

screw in the false bottom (required only

during the initial installation). Screw,

sleeve and wing nut are enclosed with

the activated carbon filter.

3. Using a screwdriver, press in the two

lugs on the false bottom. If a spacer rail

has been installed, it must be removed.

4. Tape over the activated carbon filter with

the enclosed sealing strip.

5. Insert the activated carbon filter at the

rear, fold up and lock in the middle with

the wing nut. If the spacer rail has been

removed, it must be re-installed.

6. Re-insert the two filter cartridges.

Removing the activated carbon filter:

❑ The activated carbon filter is removed in

reverse sequence.

Changing the activated carbon filter:

If used normally (1 to 2 hours daily), the

activated carbon filter should be changed

approx. once a year.

Activated carbon filters can be purchased

from SPECIALIST OUTLETS (see optional

accessories on the last page).

Use original filters only. This will ensure

optimum performance.

Disposing of the old activated carbon

filter:

Activated carbon filters do not contain any

pollutants. They can be disposed of e.g. as

residual waste.

7

Page 8

Cleaning and care

Switch off the extractor hood and isolate by pulling out the mains plug or switching off the disconnector on the installation side.

❑

At the same time as you renew the

grease filter (see Filters and

maintenance), clean off any grease from

all accessible parts of the housing.

This significantly reduces the fire hazard

and ensures that the extractor hood

performs as effectively as possible.

❑ Clean the extractor hood with a hot

detergent solution or a mild window

cleaning agent.

❑

If the hood is extremely dirty (older

stains), use a liquid window cleaner.

❑ Do not scratch off dried-on dirt, but

wipe off with a damp cloth.

❑ Do not use scouring agents.

Warning: Clean the control buttons with a

mild detergent solution and a soft, damp

cloth only.

Painted, aluminium and plastic surfaces:

❑ Do not use scouring agents or abrasive

sponges.

❑ Do not use dry cloths.

❑ Do not use corrosive, acidic or alkaline

cleaning agents.

❑

Note: Do not use alcohol (spirit) on

plastic parts, otherwise the surface may

become matt in appearance.

❑

Caution! Ensure that the kitchen is ade-

quately ventilated. Avoid naked flames.

Changing the bulbs

Candle bulbs:

1. Switch off the extractor hood and isolate

by pulling out the mains plug or switching off the disconnector on the installation side.

2. Remove the filter frame.

❑ See grease filter.

3. Replace the bulb

(standard filament bulbs, max. 40 watt,

E 14 bulb holder).

4. Attach the filter frame.

❑ See grease filter.

8

Page 9

Cleaning and care

Halogen bulbs:

1. Switch off the extractor hood and isolate

by pulling out the mains plug or switching off the disconnector on the installation side.

When switched on, the halogen

bulbs become very hot. Even for some

time after the bulbs have been switched

off there is still a risk of burns.

2. Remove the bulb ring with a screwdriver

or similar tool.

3. Replace the halogen light bulb

(conventional halogen bulb, 12 Volt,

max. 20 Watt, G4 cap).

Caution: Refer to for plug-in

lampholder.

Take hold of the bulb with a clean cloth.

4. Re-insert the bulb ring.

5. Plug the appliance into the mains or

switch it on at the fuse box.

Note: If the light does not function, check

that the bulbs have been inserted correctly.

9

Page 10

min 650

Installation Instructions: Important information

Old appliances are not worthless

rubbish. Valuable raw materials can be

reclaimed by recycling old appliances.

Before disposing of your old appliance,

render it unusable.

You received your new appliance in a

protective shipping carton. All packaging

materials are environmentally friendly and

recyclable. Please contribute to a better

environment by disposing of packaging

materials in an environmentally-friendly

manner.

Please ask your dealer or inquire at your

local authority about current means of

disposal.

The extractor hood can be used in

exhaust air or circulating air mode.

Always mount the extractor hood over

the centre of the hob.

Minimum distance between electric hob

and bottom edge of extractor hood:

650 mm.

The extractor hood must not be

installed over a solid fuel cooker – a

potential fire hazard (e.g. flying sparks) –

unless the cooker features a closed,

non-removable cover and all national

regulations are observed.

The smaller the gap between the

extractor hood and hotplates, the greater

the likelihood that droplets will form on the

underside of the extractor hood.

Additional information concerning gas

cookers:

When installing gas hotplates, comply

with the relevant national statutory

regulations (e.g. in Germany: Technische

Regeln Gasinstallation TRGI).

Always comply with the currently valid

regulations and installation instructions supplied by the gas appliance

manufacturer.

Only one side of the extractor hood may

be installed next to a high-sided unit or high

wall. Gap at least 50 mm.

Minimum distance on gas hotplates

between the upper edge of the trivet

and lower edge of the extractor

hood: 650 mm.

10

Page 11

Prior to installation

Exhaust-air mode

The exhaust air is discharged upwards

through a ventilation shaft or directly

through the outside wall into the open.

Exhaust air should neither be directed

D

into a smoke or exhaust flue that is

currently used for other purposes, nor into a

shaft that is used for ventilating rooms in

which stoves or fireplaces are also located.

Exhaust air may be discharged in

accordance with official and statutory

regulations only (e.g. national building

regulations).

Local authority regulations must be

observed when discharging air into smoke

or exhaust flues that are not otherwise in

use.

When the extractor hood is operated

D

in exhaust-air mode simultaneously with

a different burner which also makes use

of the same chimney (such as gas, oil or

coal-fired heaters, continuous-flow heaters,

hot-water boilers) care must be taken to

ensure that there is an adequate supply

of fresh air which will be needed by the

burner for combustion.

Safe operation is possible provided that the

underpressure in the room where the

burner is installed does not exceed 4 Pa

(0.04 mbar).

This can be achieved if the combustion air

can be replenished by being able to flow

through non-closeable openings such as in

doors, windows, wall ventilation boxes, or by

alternative technical measures such as reciprocally shutting the other device off, etc.

If the air intake is inadequate, there is a

risk of poisoning from combustion gases

which are drawn back into the room.

An air-intake/exhaust-air wall box by itself is

no guarantee that the limiting value will not

be exceeded.

Note: When assessing the overall

requirement, the combined ventilation

system for the entire household must be

taken into consideration. This rule does not

apply to the use of cooking appliances,

such as hobs and ovens.

All legal requirements concerning the

discharge of exhaust air must be observed.

Unrestricted operation is possible if the

extractor hood is used in recirculating mode

– with activated carbon filter.

The extractor hood should be fitted with a

one-way flap for exhaust-air mode if there is

not already one installed in the exhaust-air

pipe or wall box. If a one-way flap is not

enclosed with the appliance, purchase one

from a specialist outlet (see optional accessories on the last page).

Attaching the one-way flap

❑ Insert the two lugs on the one-way flap

into the holes on the air-pipe connector

or air outlet and lock into position.

Before installing the one-way flap, ensu-

re that the lettering or stamp is on the outside.

11

Page 12

Prior to installation

Optimum performance of the extractor

hood:

❑

Short, smooth extraction pipe.

❑

As few pipe bends as possible.

❑

Largest possible pipe diameter (preferably 150 mm ø) and large pipe bends.

❑

Round pipes:

We recommend

for single-motor model,

inner diameter of at least 120 mm

for double-motor model.

inner diameter of at least 150 mm

❑

Flat ducts must have an inner crosssection equivalent to round pipes

which have an inner diameter of

120/150 mm.

120 mm l approx. 113 cm

150 mm l approx. 177 cm

❑

If pipe diameters differ: use sealing

strip.

❑

Ensure an adequate air supply for

exhaust-air mode.

2

2

Pipe connection

Extractor hoods with 120 mm Ø air

outlet:

100 mm Ø extraction pipe

❑ Insert the reducing connector (see optio-

nal accessories on the last page) into the

air-pipe connector and then attach the

exhaust-air pipe.

120 mm Ø extraction pipe

❑ Attach the exhaust-air pipe directly to

the air-pipe connector.

Extractor hoods with 150 mm Ø air

outlet:

150 mm l extraction pipe

❑ Screw the reducing connector (see

optional accessories on the last page)

onto the air outlet.

❑ Attach the extraction pipe to the redu-

cing connector.

150 mm l extraction pipe

❑ Attach the exhaust-air pipe directly to

the air outlet..

If a one-way flap has been fitted, con-

duct a performance test.

Extractor hoods with rectangular air

outlet:

❑ Screw the enclosed

air-pipe connector

over the air outlet.

Recirculated

air mode

12

❑

The air cleaned by an additional activated carbon filter is conveyed back into

the room.

❑

In recirculated air mode the exhaust opening must be protected by a grille (see

optional accessories on the last page) in

order to prevent a mechanical or electrical hazard.

Page 13

160

47

75

120

248

248

75

100

280

530

12

256

min 10

min 15

500

-3

260

-3

16

Electrical connection Installation

The extractor hood must be connected to

a correctly installed earthed socket only.

Attach the earthed socket as close to the

appliance as possible and in an accessible

position. If the earthed socket is no longer

accessible following installation of the

extractor hood, a disconnector must be

provided on the installation side. Disconnectors are switches with a contact

opening of more than 3 mm and all-pole

disconnection. LS switches and contactors

are regarded as disconnectors.

The appliance must be isolated before

repairs are carried out.

Repairs may be carried out by authorised

technicians only.

If the connection cable of this appliance

is damaged, it must be replaced by the

manufacturer, his customer service or a

similarly qualified person in order to prevent

a hazardous situation.

Improper repairs may put the user at

considerable risk.

Length of connection cable: 1.20 m.

Electrical specifications:

The electrical specifications can be found

on the rating plate inside the appliance

when the filter frame has been removed.

The extractor hood is particularly suitable

for installation in a flue or chimney.

To ensure optimum extraction performance

(especially important for kitchen island solutions):

❑

Install the extractor hood as high as

possible within the structure

❑

The structure must cover the entire

cooking area.

The following cutouts must be made for

the installation depending on the model:

Extractor hood with rocker switch, 53 cm

wide, 1-motor:

Do not place hand in the air outlet.

This appliance complies with the EC radio

interference suppression regulations.

13

Page 14

9

346

380

530

160

55

95

150

120

248

248

100

35

225

min 15

min 15

500

-3

16

35

2

-3

9

346

160

55

95

150

120

348

348

100

35

225

380

730

min 15

min 15

16

35

2

-3

700

-3

Installation

310

160

150

120

95

80

60

496

9

230

250

380

530

346

310

160

150

120

95

80

60

696

9

230

250

380

730

346

Extractor hood with slide control, 53 cm

wide, 1 and 2-motor:

Extractor hood with slide control, 73 cm

wide, 1 and 2-motor

14

Page 15

Installation

1. Remove the filter grille (see operating

instructions).

2. Connect the power.

3. Press the extractor hood up into the

installation opening until the installation

aid locks into position at the front and

rear.

4. Screw in the extractor

hood.

Removal

1. Loosen the screws.

2. Hold the underside of the extractor

hood, Hold the underside of the extrac-

tor hood.

Installation spring

3. Lower the extractor hood and remove.

5. Insert and secure the filter grille (see

operating instructions).

Weight in kg:

Model

1-motor

Rocker switch

1-motor

Slide control

1-motor

Slide control

2-motor

Slide control

2-motor

Slide control

Design changes with respect to technical development

shall remain withheld

Width

53 cm

53 cm

73 cm

53 cm

73 cm

Exhaust

5,0 6,3

9,5

10,3 11,6

8,3

8,7

Recircu

air

lated air

10,7

9,5

9,9

15

Page 16

280

280

280

380

380

280

LZ 23000

530

LZ 72040

530

LZ 73040

530

380

530/730

530/730

380

530/730

530/730

530

LZ 73050

461423

Siemens Elektrogeräte GmbH

380

380

530/730

530/730

280

530

380

530/730

380

530/730

481051

095660

9000 018538

Printed in Germany 0904 Hi.

Loading...

Loading...